Patents

Literature

30results about How to "Avoid lifting accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

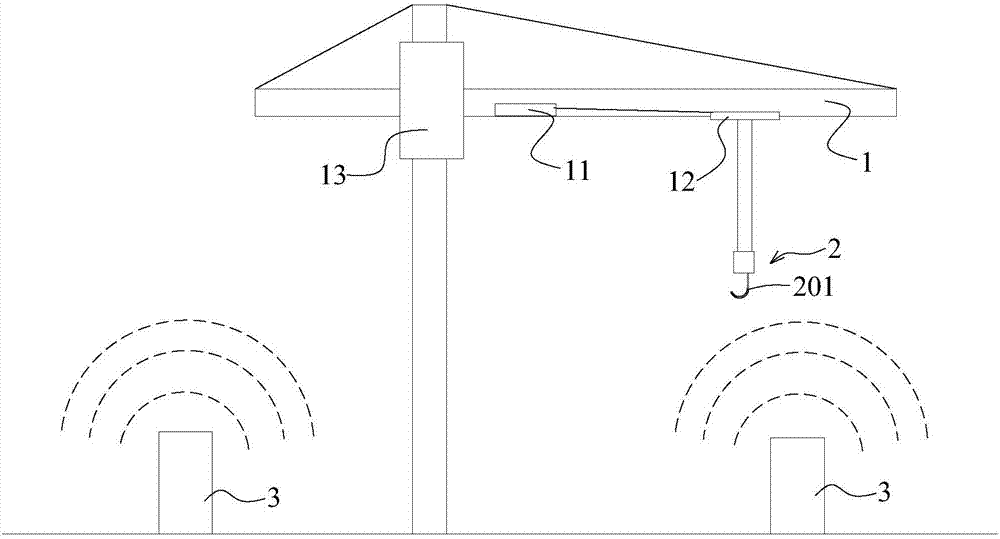

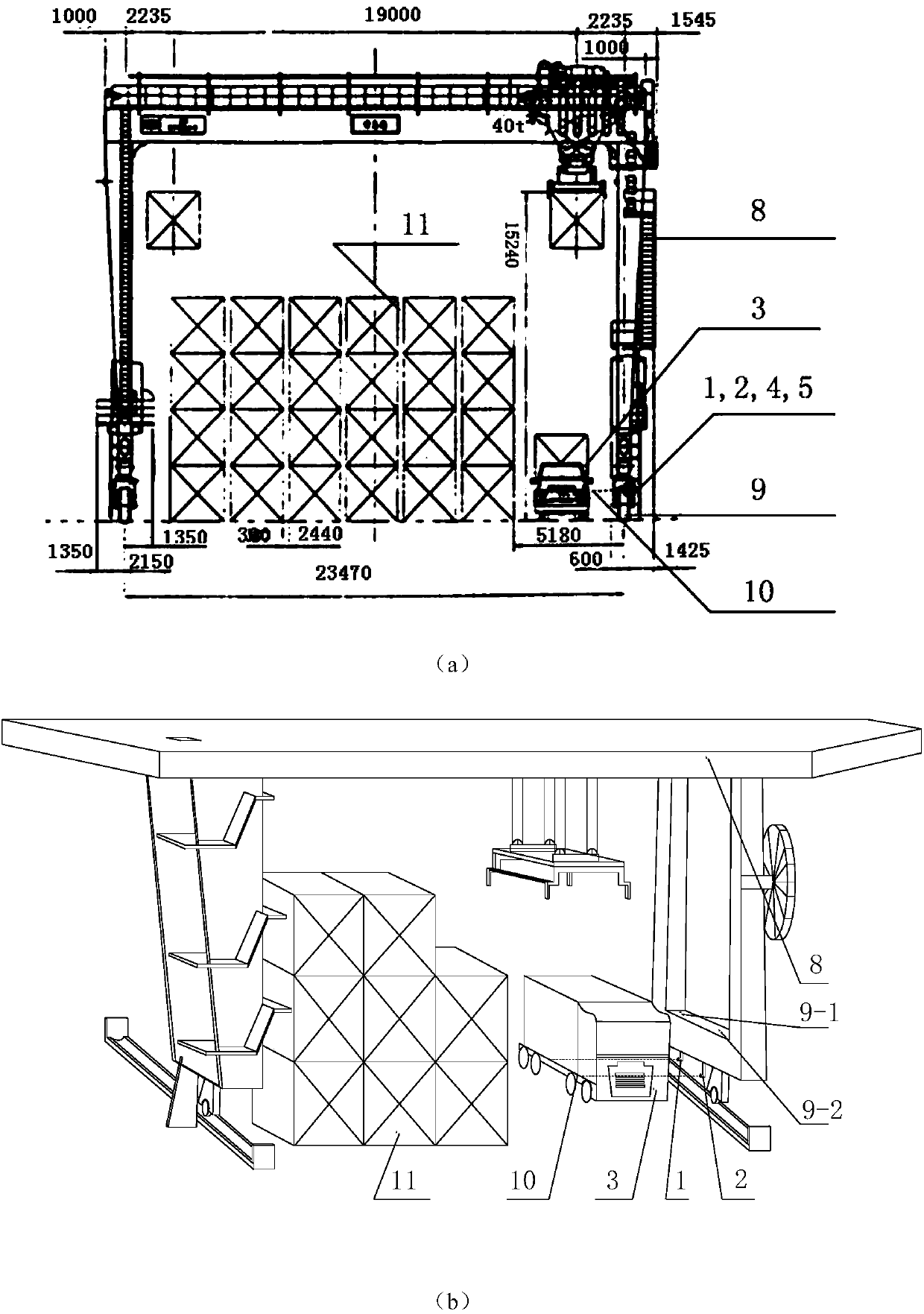

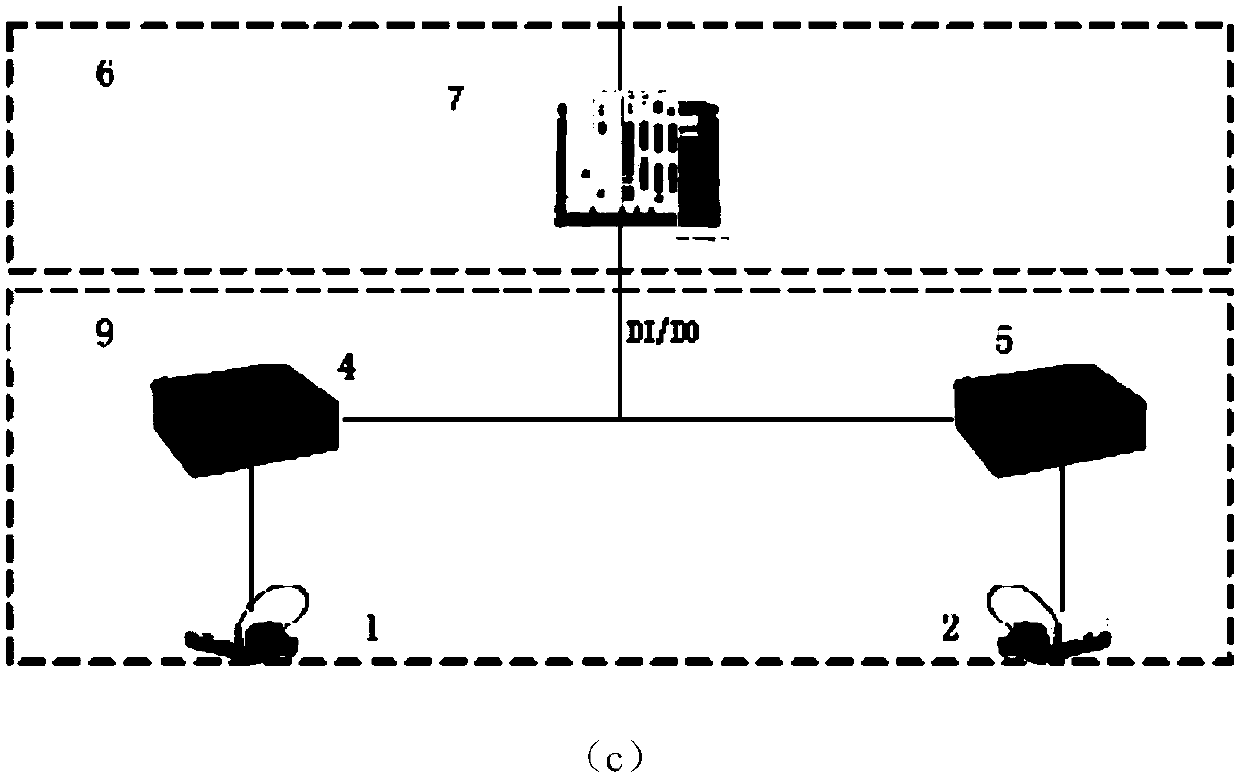

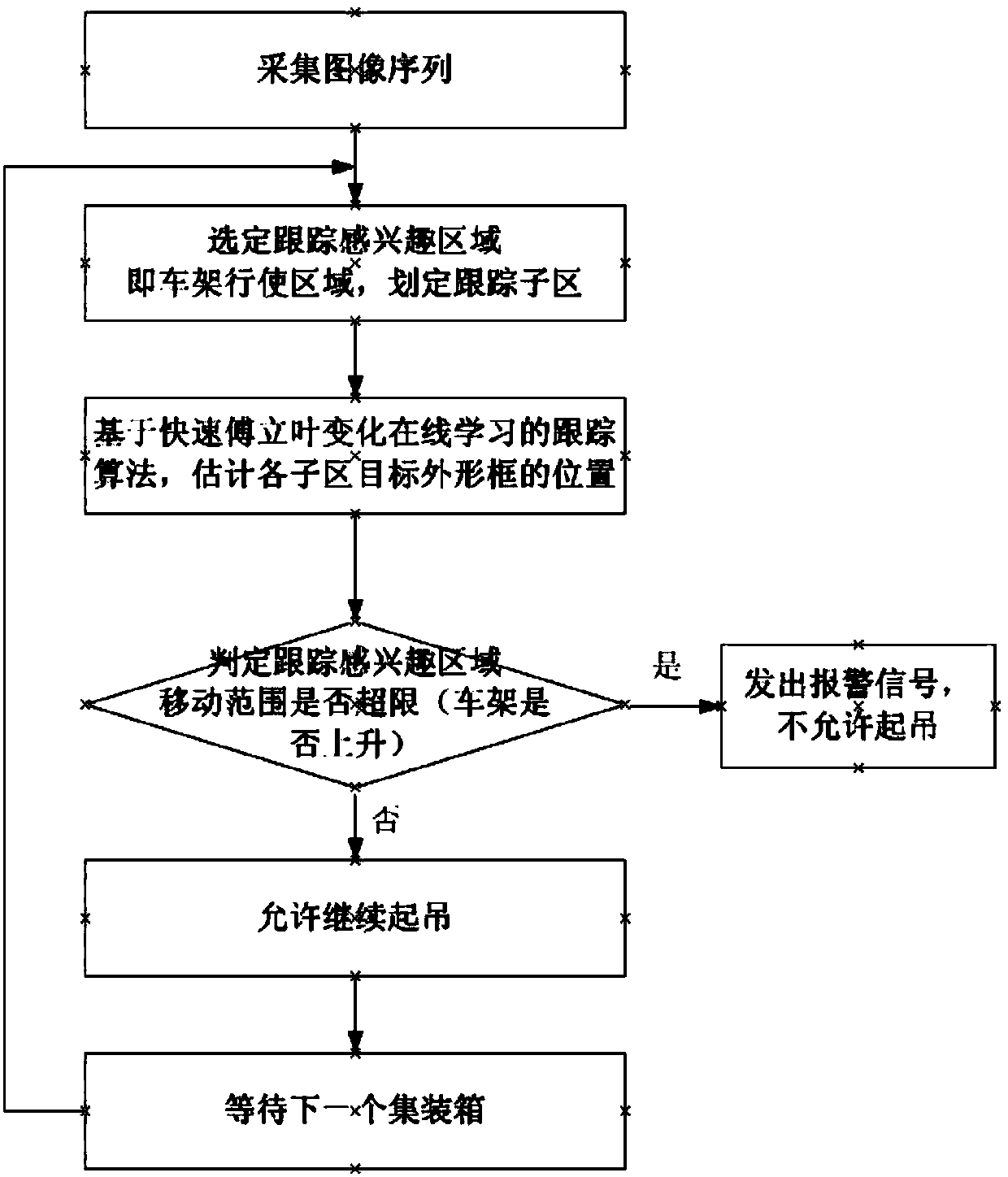

Machine vision tracking based container truck anti-hoisting method and system

ActiveCN106986272AAvoid lifting accidentsGuaranteed accuracyCharacter and pattern recognitionCranesMachine visionControl room

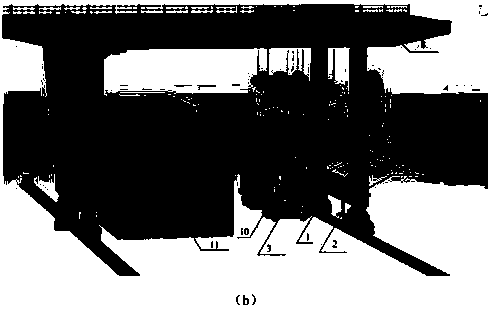

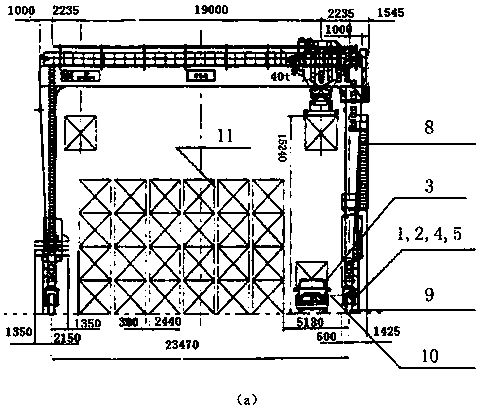

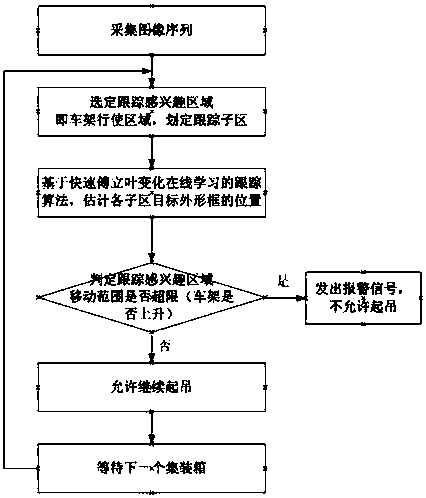

The invention discloses a machine vision tracking based container truck anti-hoisting system. The system comprises a tyre crane, cameras, a container truck, containers, video alarms and central control room control equipment. The cameras are mounted on a bottom support of the tyre crane, the height of the cameras is flushed with a truck frame of the container truck, and the view field of the cameras is perpendicular to the running direction of the container truck. The cameras input video images obtained through tracking to the video alarms, the video alarms process the obtained video images through a fast fourier translation change online learning based tracking algorithm, and when it is judged that the container truck is hoisted, an alarm signal is transmitted to the central control room control equipment. The system can automatically detect whether the containers are separated from the container truck or not, and therefore the situation that the container truck is hoisted by mistake due to manual errors is avoided, and safe precontrol on container area storage yard operation is achieved.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

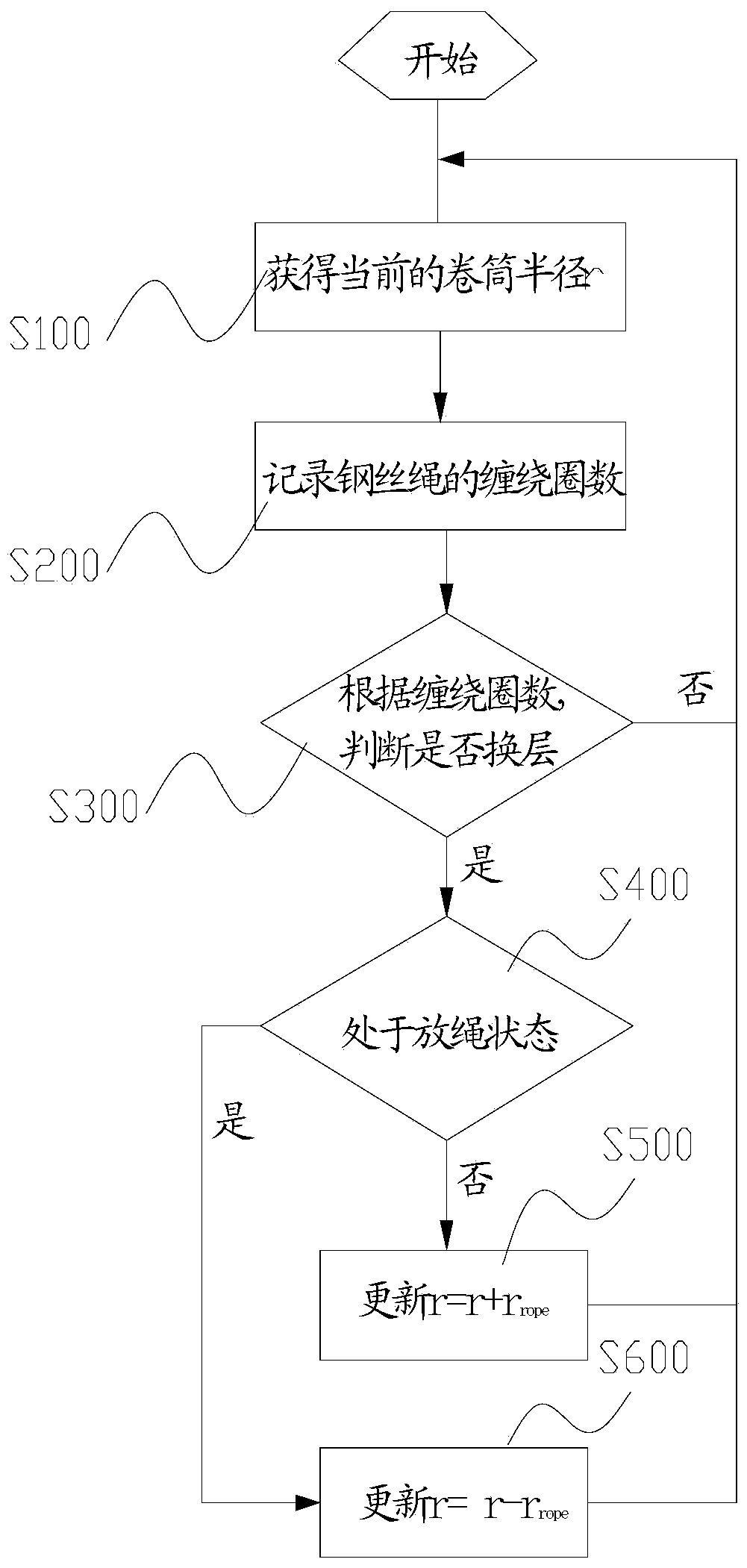

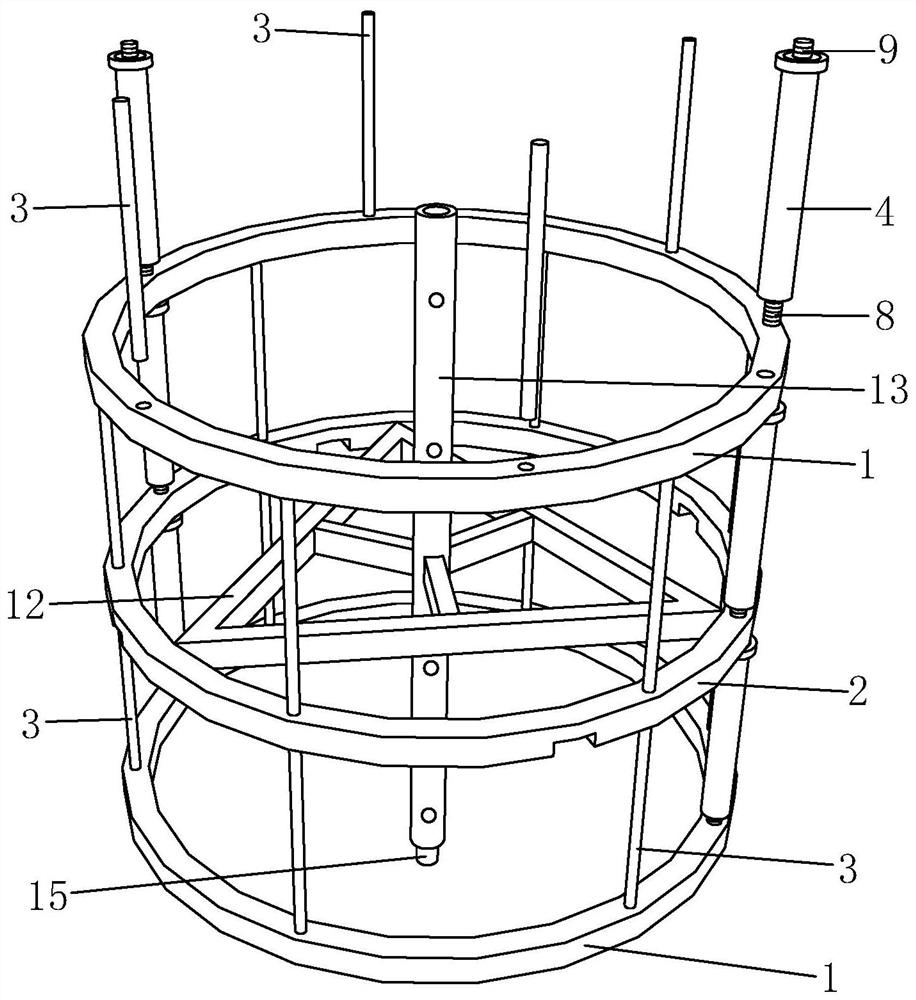

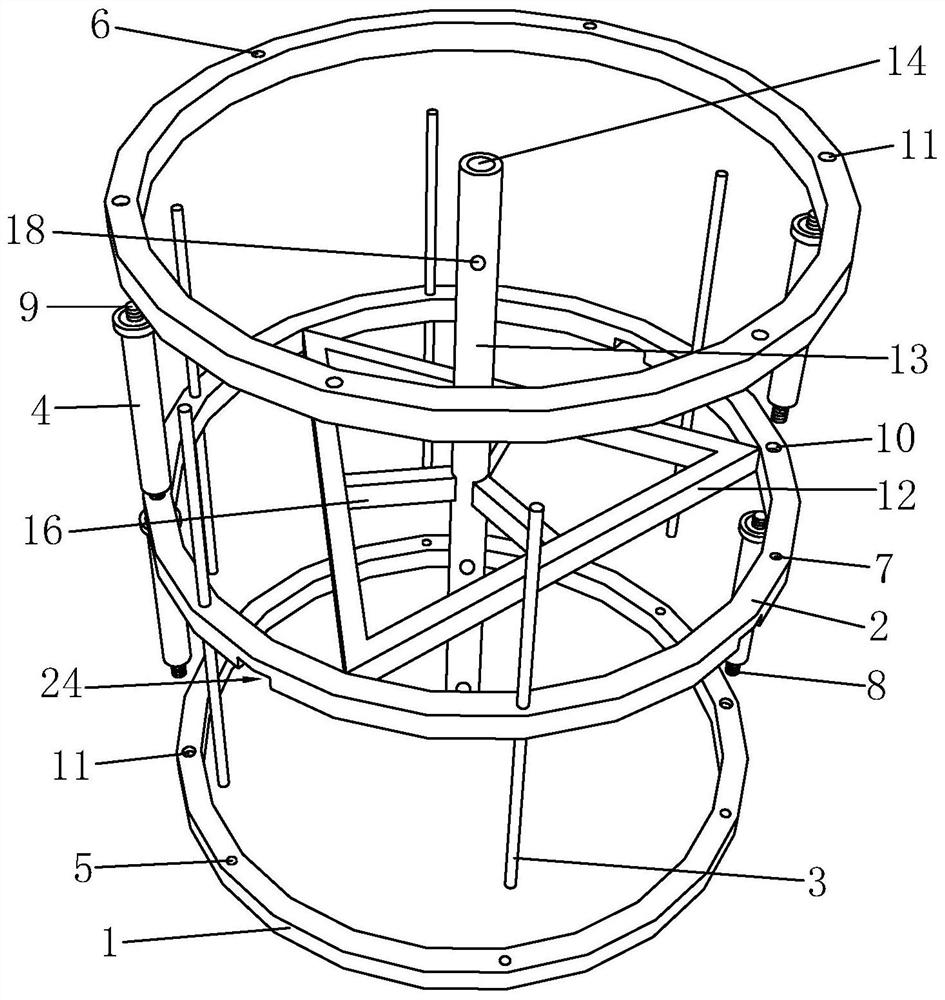

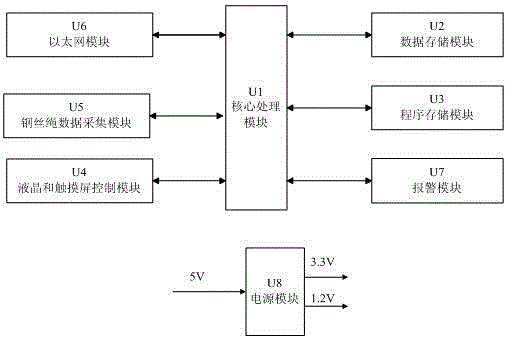

Real-time fault diagnosis and early warning device and method for wire rope of coal mine hoist

InactiveCN102636561ARealize the diagnosis functionRealize the early warning functionTension measurementMaterial magnetic variablesReal-time dataData acquisition

The invention discloses a real-time fault diagnosis and early warning device and a real-time fault diagnosis and early warning method for a wire rope of a coal mine hoist, and belongs to a device and a method for fault diagnosis of the wire rope of the hoist based on on-line monitoring data. A core processing module of the device is simultaneously connected with a data storage module, a program storage module, a liquid crystal and touch screen control module, a data acquisition module, an Ethernet module and an alarm module; and a power module is connected with all the modules to provide power for all the modules. The method comprises the following steps of: calculating loss percentage of the sectional area of the wire rope; transmitting real-time data of the section area of the wire rope into the core processor module through an Ethernet interface; comparing with an initial value of the section area of the wire rope; and outputting in the form of loss percentage of the sectional area of the wire rope. The device and the method have the advantages that safety parameters are set aiming at application places of the wire rope; the application is flexible; the working state of the wire rope can be judged according to the on-line monitoring data; the real-time fault diagnosis and early warning function of the wire rope can be realized; and alarm information is given.

Owner:CHINA UNIV OF MINING & TECH

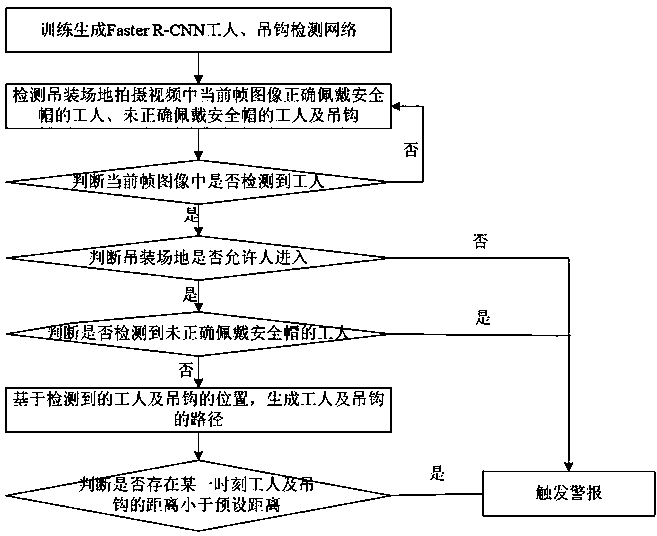

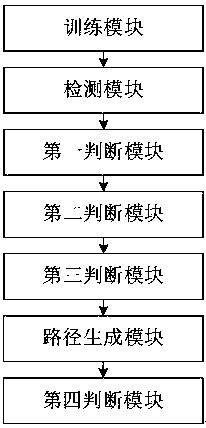

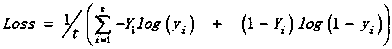

Hoisting process danger identification method and system based on deep learning

PendingCN111062373AVarious identification methodsPracticalForecastingCharacter and pattern recognitionCrash helmetReliability engineering

The invention discloses a hoisting process danger identification method and system based on deep learning, and the method comprises the steps: S1, training to generate a Faster R-CNN worker and lifting hook detection network; S2, detecting a worker who correctly wears the safety helmet, a worker who does not correctly wear the safety helmet and a lifting hook in the current frame image in the video shot by the lifting site by utilizing the detection network; S3, judging whether a worker is detected in the current frame image or not, and if so, executing the step S4; if not, extracting the nextframe of image of the shot video, and continuing to execute the step S2; s4, judging whether a person is allowed to enter the hoisting site or not, and if not, triggering an alarm; if so, executing the step S5; s5, judging whether a worker who does not correctly wear the safety helmet is detected in the current frame image or not, and if so, triggering an alarm; if not, executing the step S6; s6,generating paths of the workers and the lifting hooks based on the detected positions of the workers and the lifting hooks; and S7, judging whether the distance between the worker and the lifting hook is less than a preset distance at a certain moment in the worker and lifting hook prediction path, and if so, triggering an alarm. The danger in the hoisting process is comprehensively and timely recognized, and hoisting accidents can be effectively prevented.

Owner:杭州鲁尔物联科技有限公司

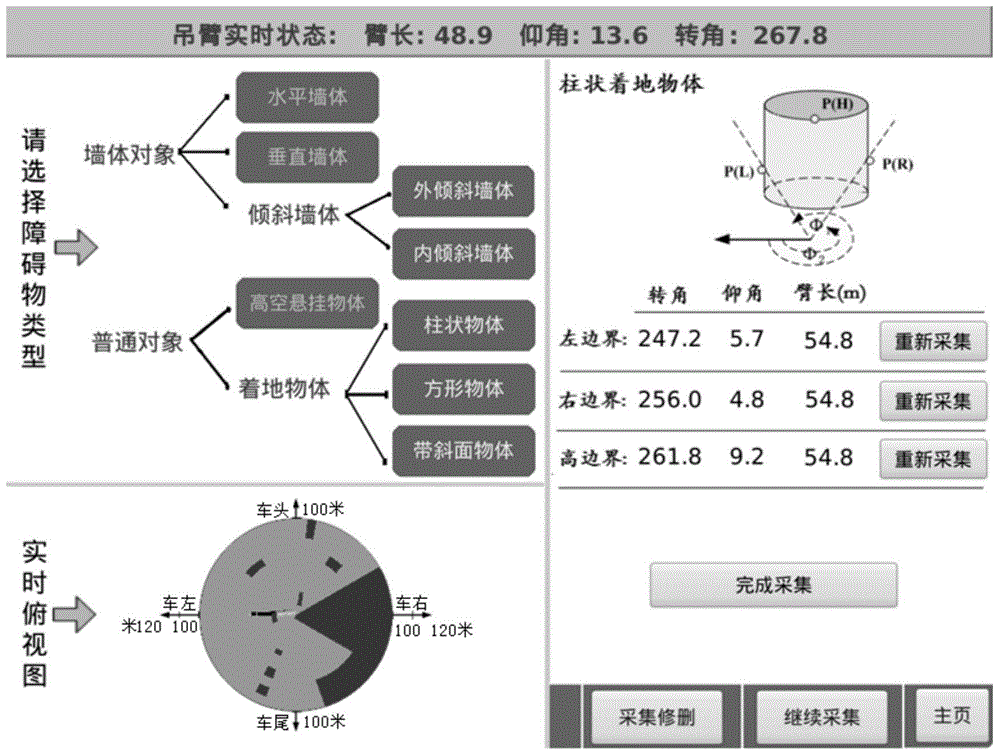

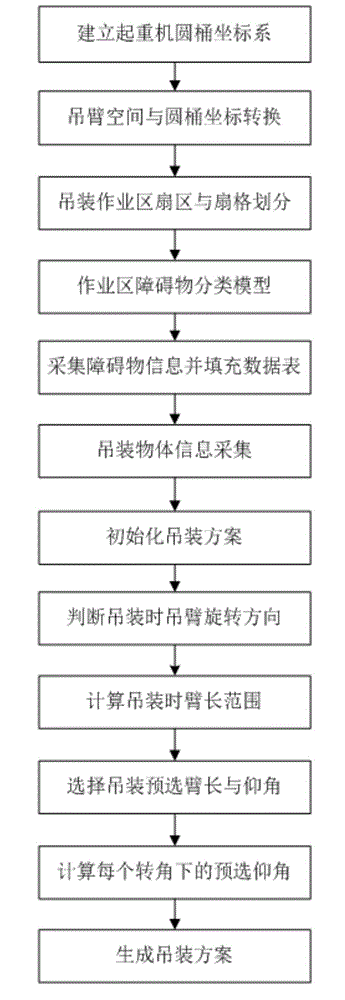

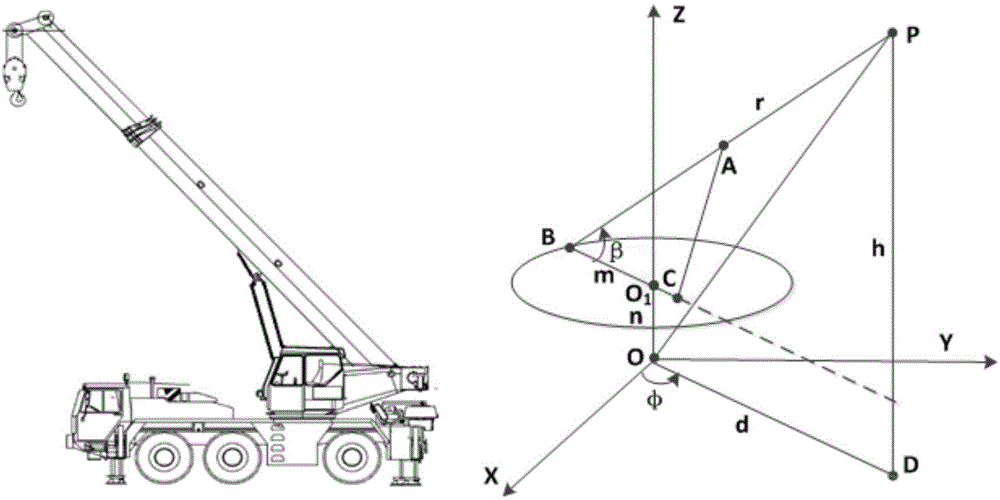

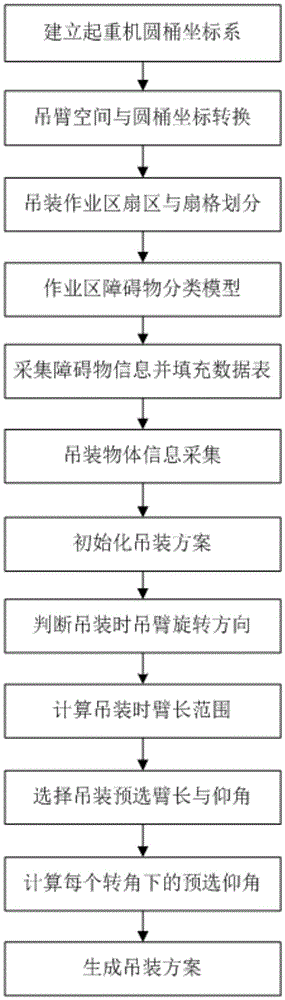

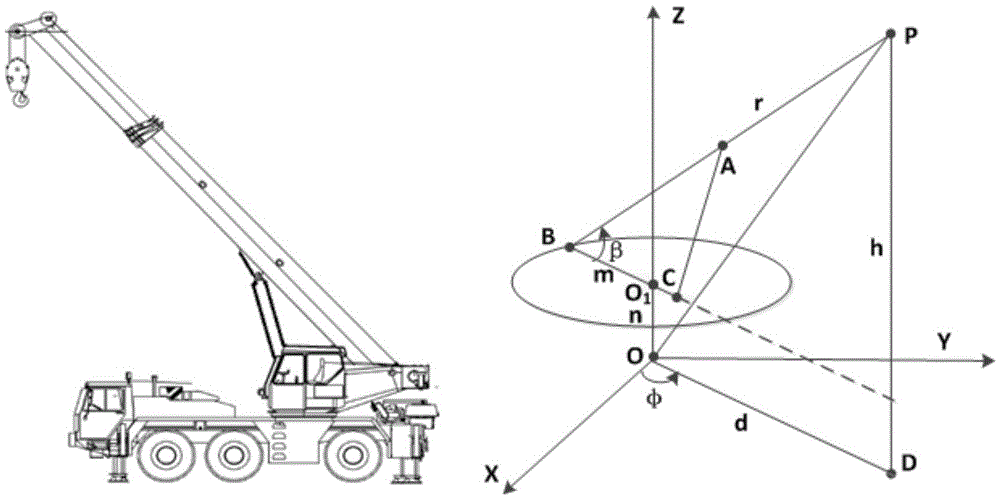

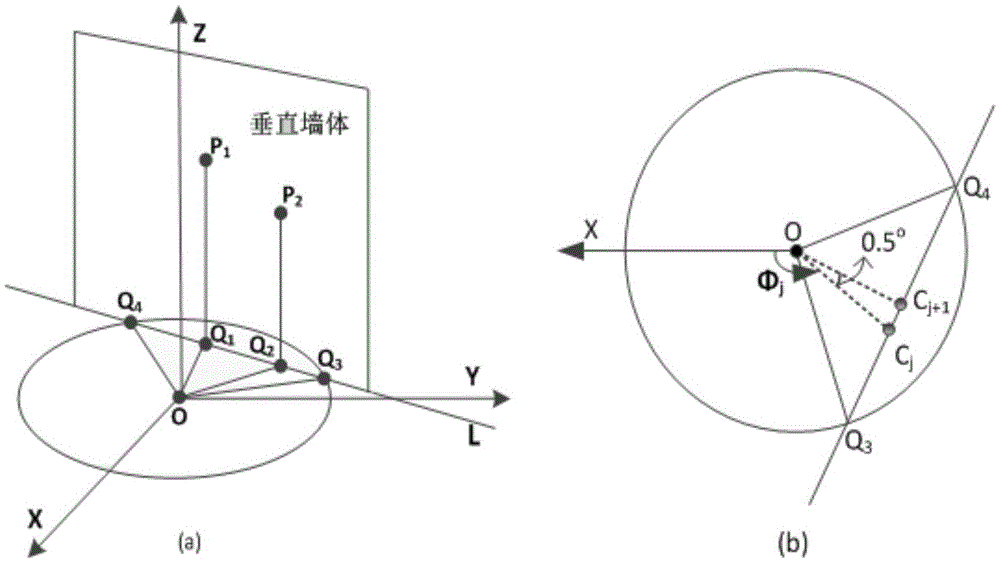

Real-time generation method of hoisting scheme of jib crane in vehicle controller and method thereof

InactiveCN104528540AEasy to collectEasy to integrateLoad-engaging elementsCranesIn vehicleSimulation

The invention discloses a real-time generation method of a hoisting scheme of a jib crane in a vehicle controller and a method thereof, according to the method, an autonomous detection learning by the crane jib is employed, profile and position information of an obstacle in an operation area can be accurately acquired; source position and target position information of an hoisting object which are acquired by the crane jib are employed, according to an environment data table in the hoisting operation area, by combining the a hoisting performance chart of the crane, the hoisting scheme comprising parameters such as crane jib length, rotation direction and a lower elevation angle of each rotation angle enables real-time generation in a vehicle controller, and the generated hoisting scheme is optimized and simulated. The practical hoisting application shows that the system can accurately acquire the environment data in the operation area and can generate the hoisting scheme through optimization.

Owner:CHANGAN UNIV

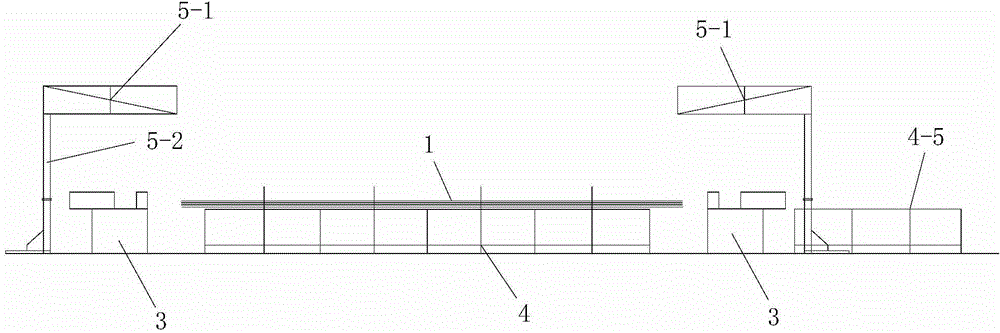

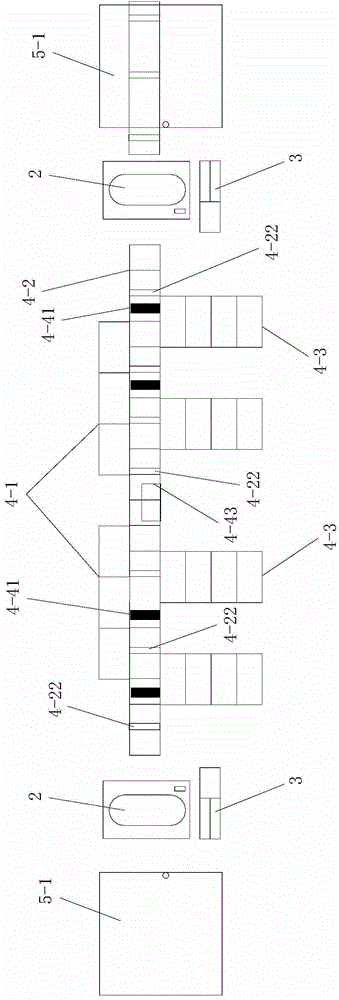

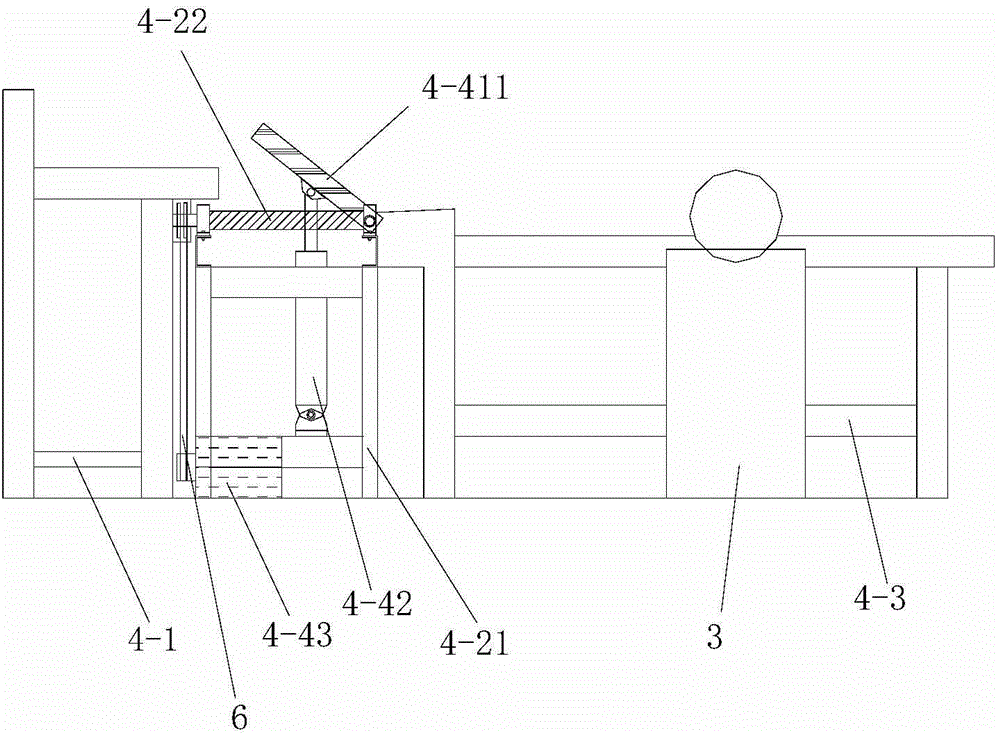

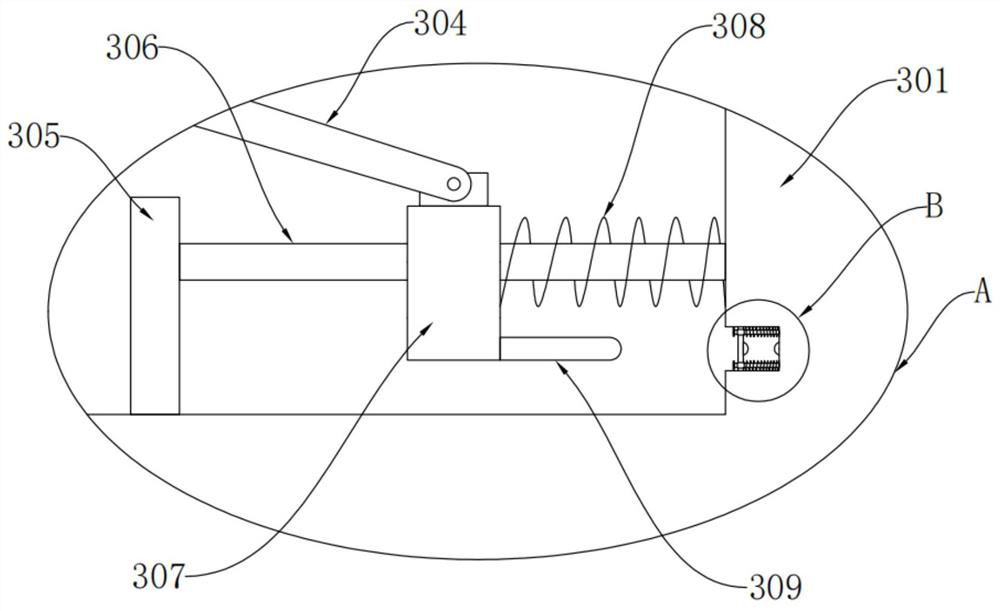

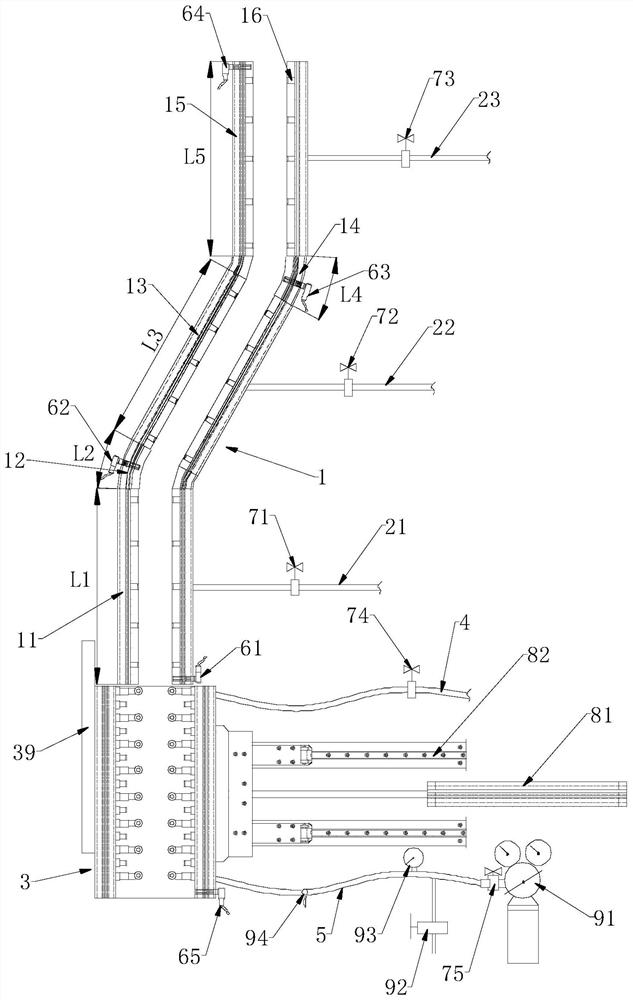

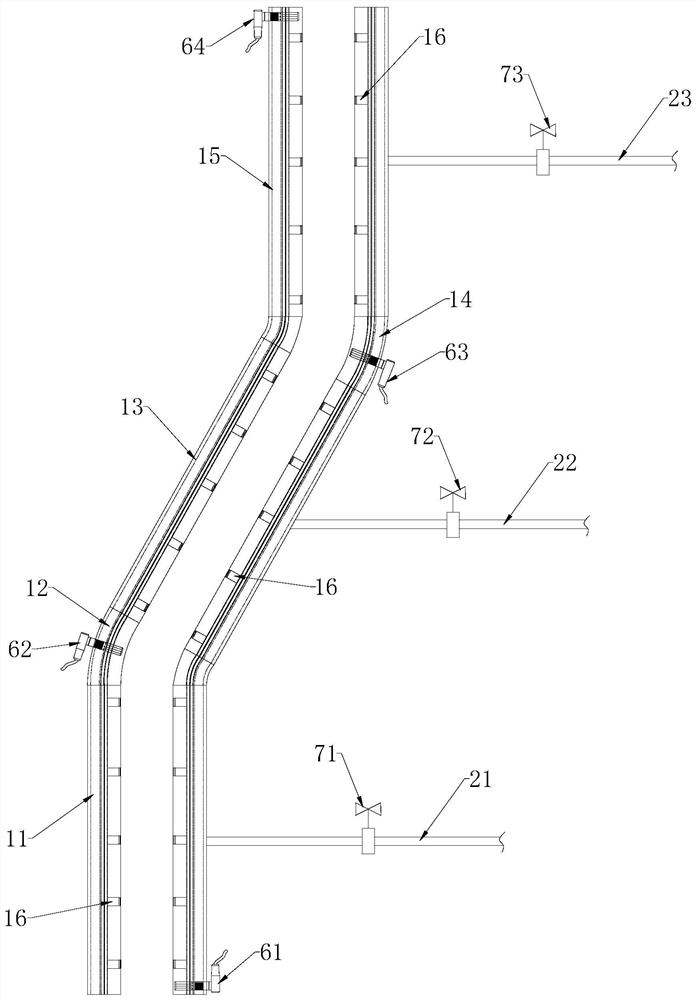

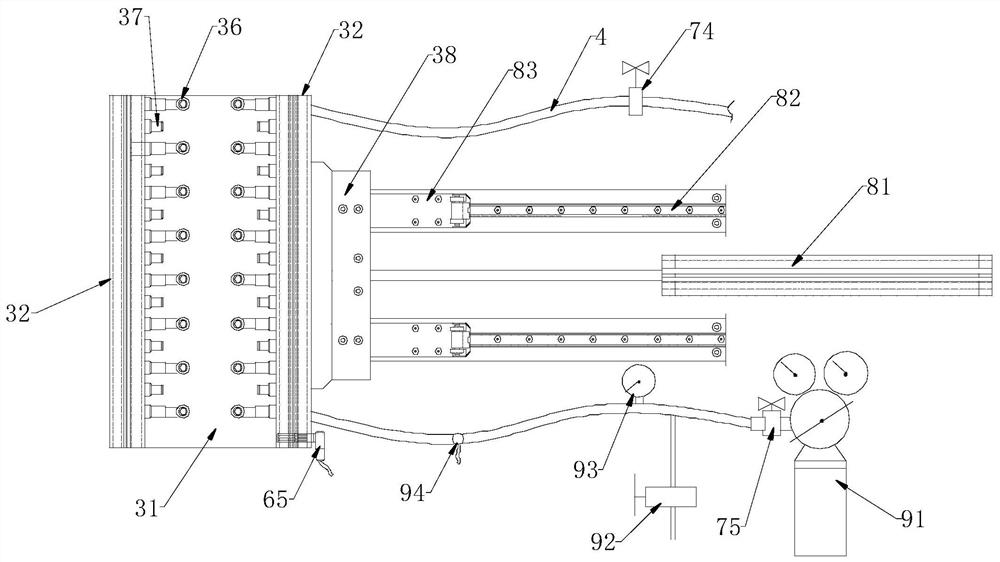

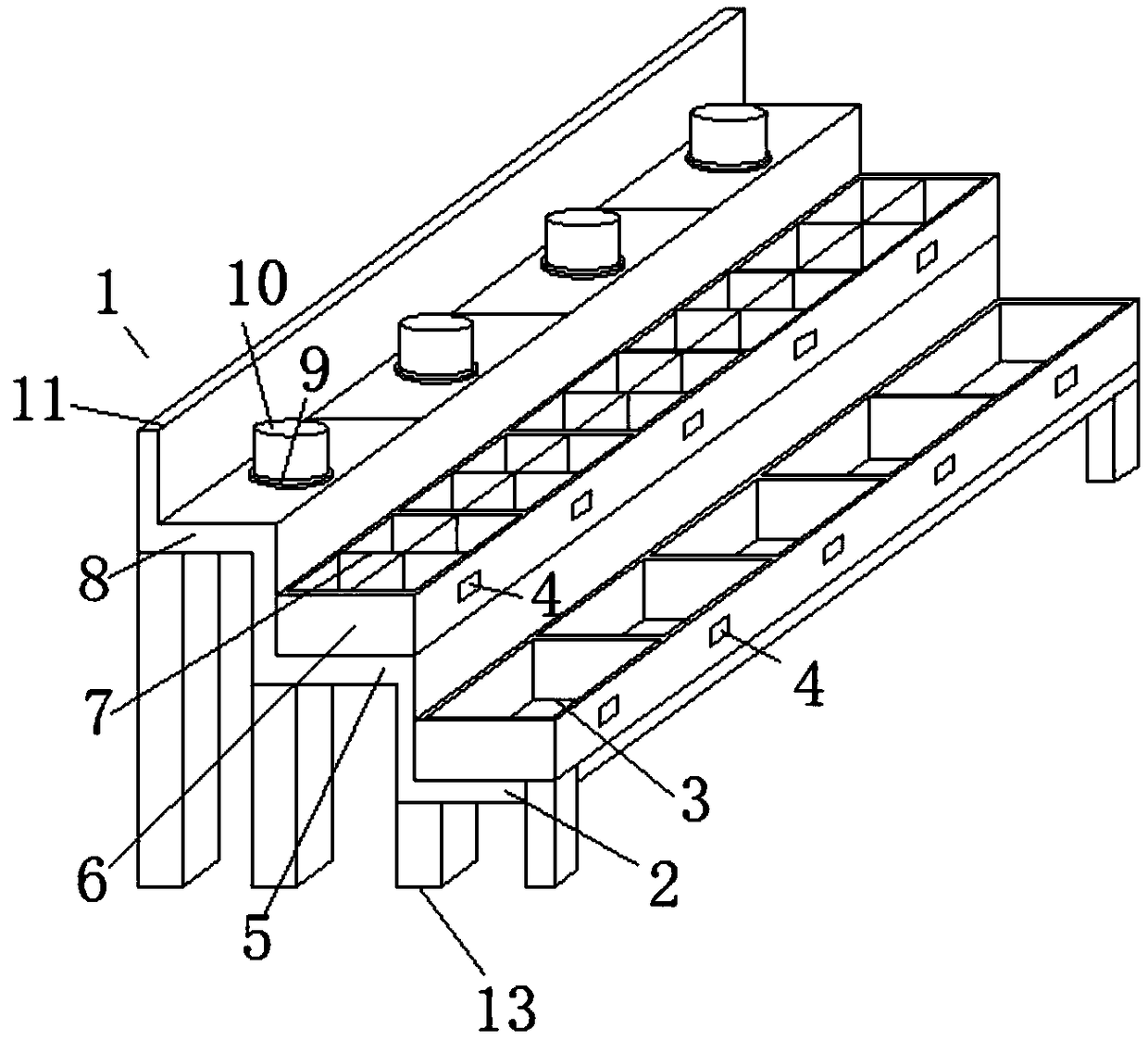

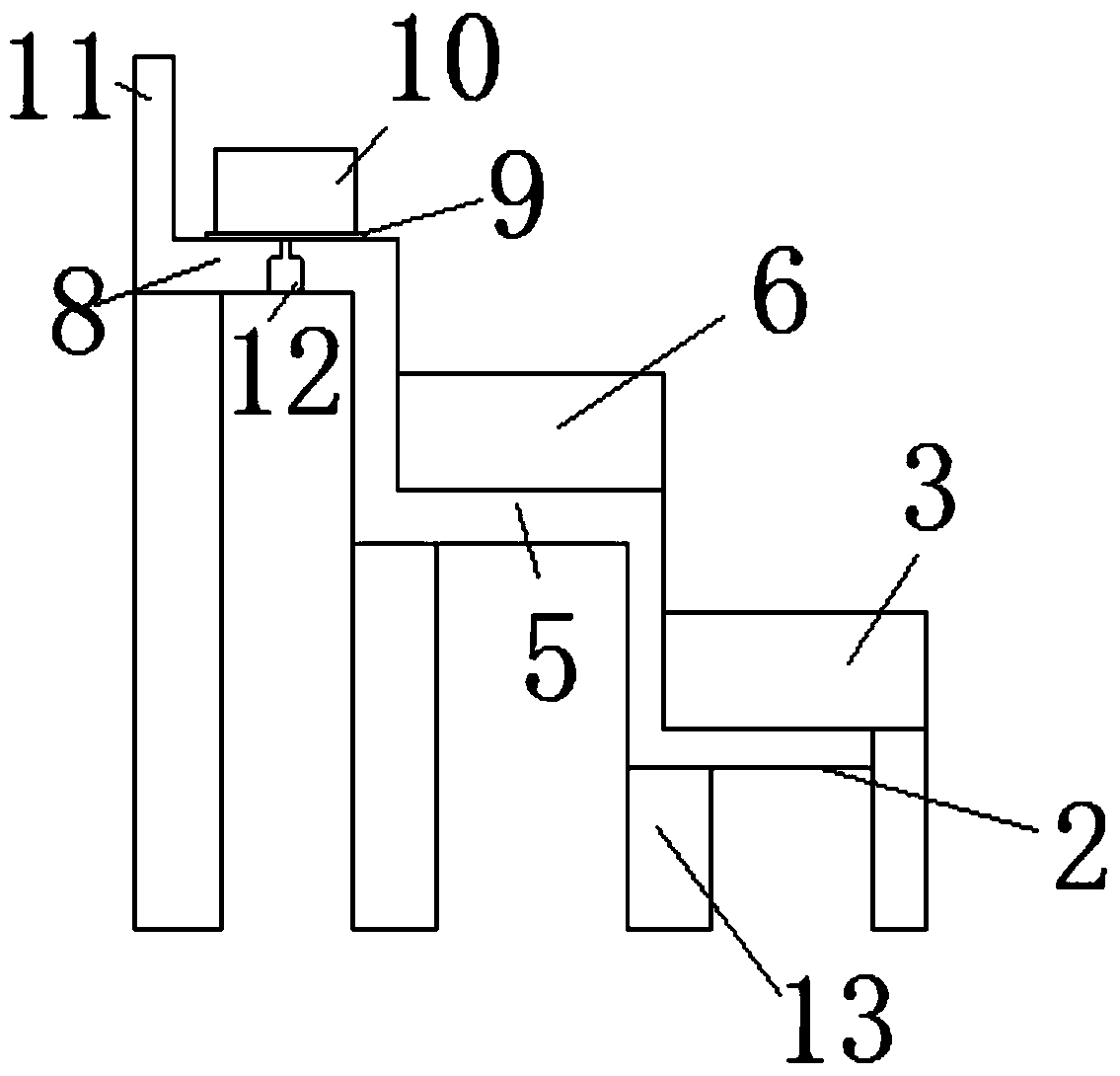

Batch machining device and technology for reinforcing-steel-bar straight threads

ActiveCN104786107ASimple structureReasonable designOther manufacturing equipments/toolsMetal working apparatusRebarScrew thread

The invention discloses a batch machining device and technology for reinforcing-steel-bar straight threads. The machining device comprises a left reinforcing-steel-bar straight thread machining device body, a right reinforcing-steel-bar straight thread machining device body, a left protective shed, a right protective shed and an automatic conveying platform for conveying to-be-machined reinforcing steel bars. The left reinforcing-steel-bar straight thread machining device body and the right reinforcing-steel-bar straight thread machining device body are used for machining the two ends of the to-be-machined reinforcing steel bars respectively. The automatic conveying platform is located between the two reinforcing-steel-bar straight thread machining device bodies. Each reinforcing-steel-bar straight thread machining device body comprises a reinforcing-steel-bar cutting device for cutting the to-be-machined reinforcing steel bars and a straight-thread threading machine for carrying out threading on the to-be-machined reinforcing steel bars. The automatic conveying platform comprises a reinforcing-steel-bar containing frame, a first transverse conveying frame, a threading machining frame and a reinforcing-steel-bar longitudinal movement mechanism. The machining technology includes the steps of 1, reinforcing-steel-bar lifting; 2, reinforcing-steel-bar cutting; 3, reinforcing-steel-bar secondary forward moving; 4, reinforcing-steel-bar threading; 5, reinforcing-steel-bar third-time forward moving. The machining device and technology are reasonable in design, easy and convenient to machine, manufacture, use and operate and good in use effect; the reinforcing-steel-bar straight thread batch machining process can be easily, conveniently and rapidly completed.

Owner:陕西华鑫鼎业建筑物资有限公司

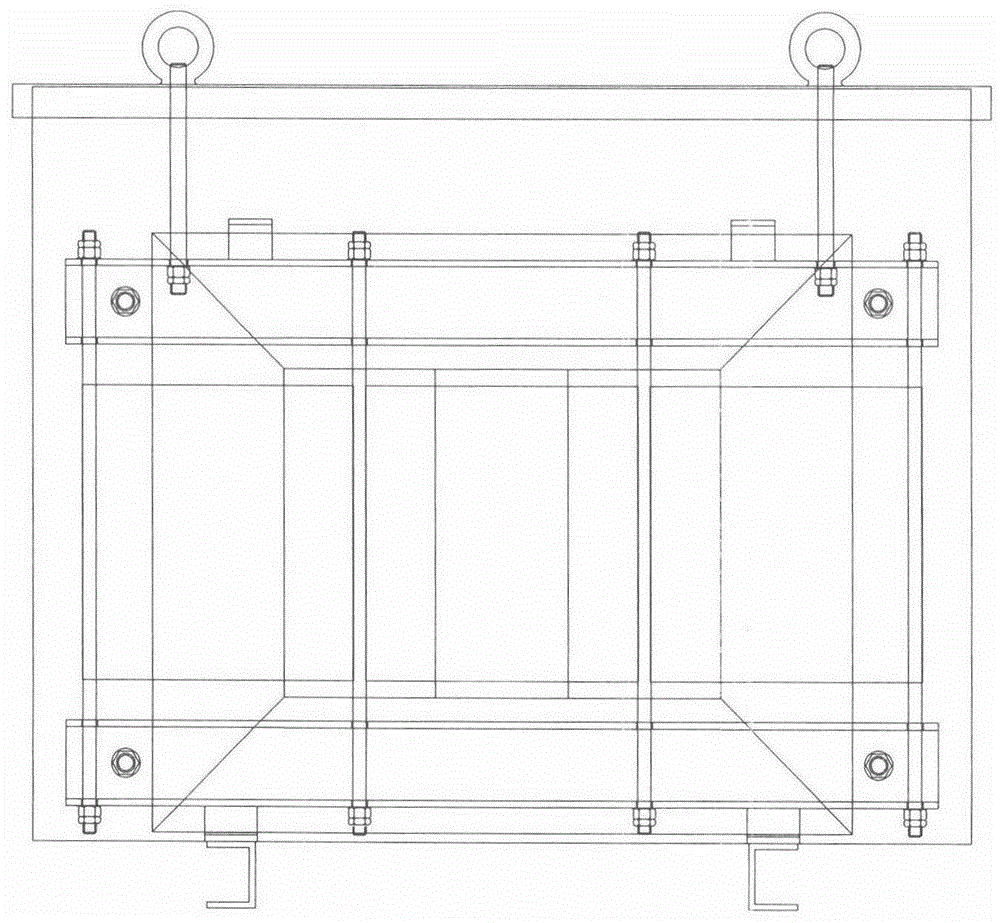

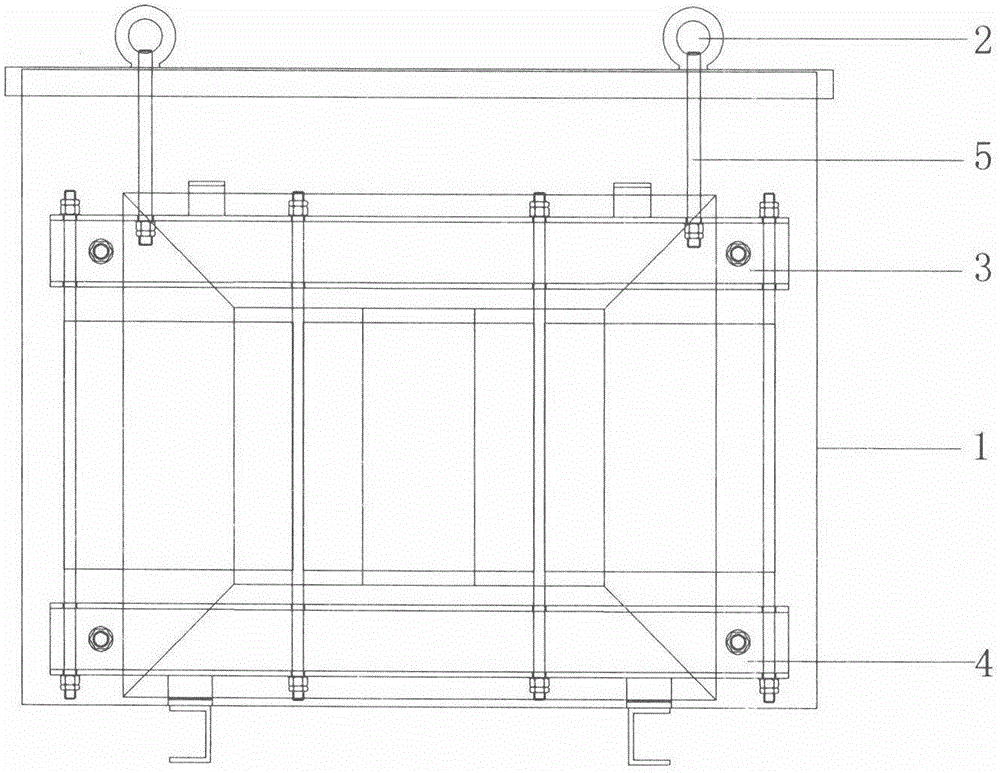

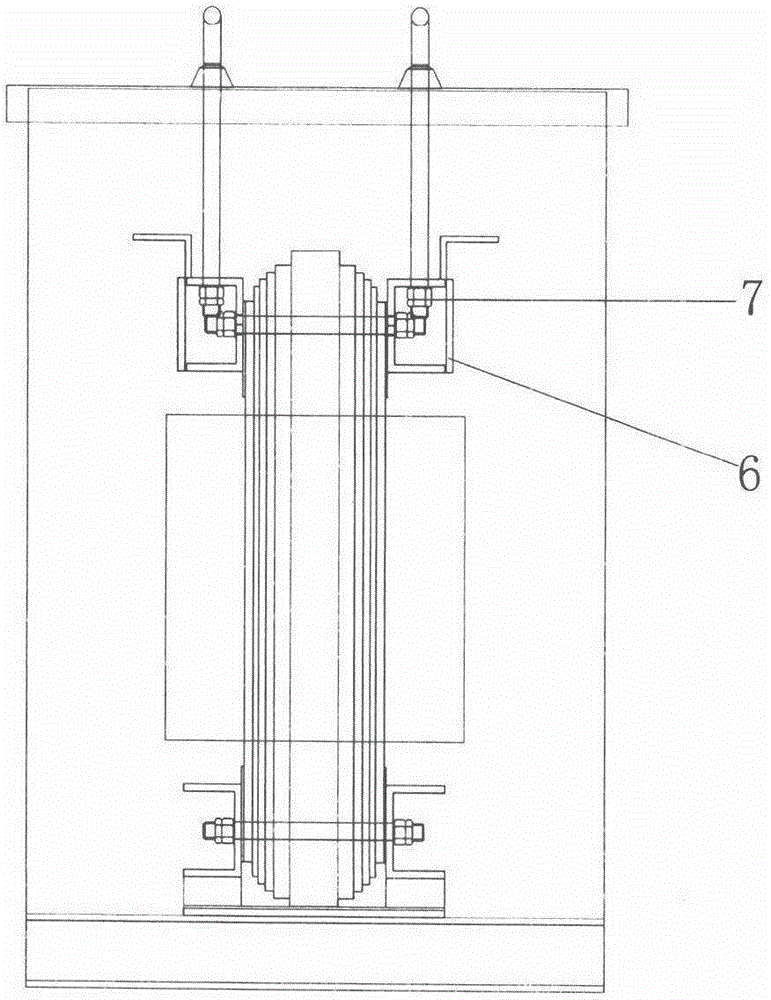

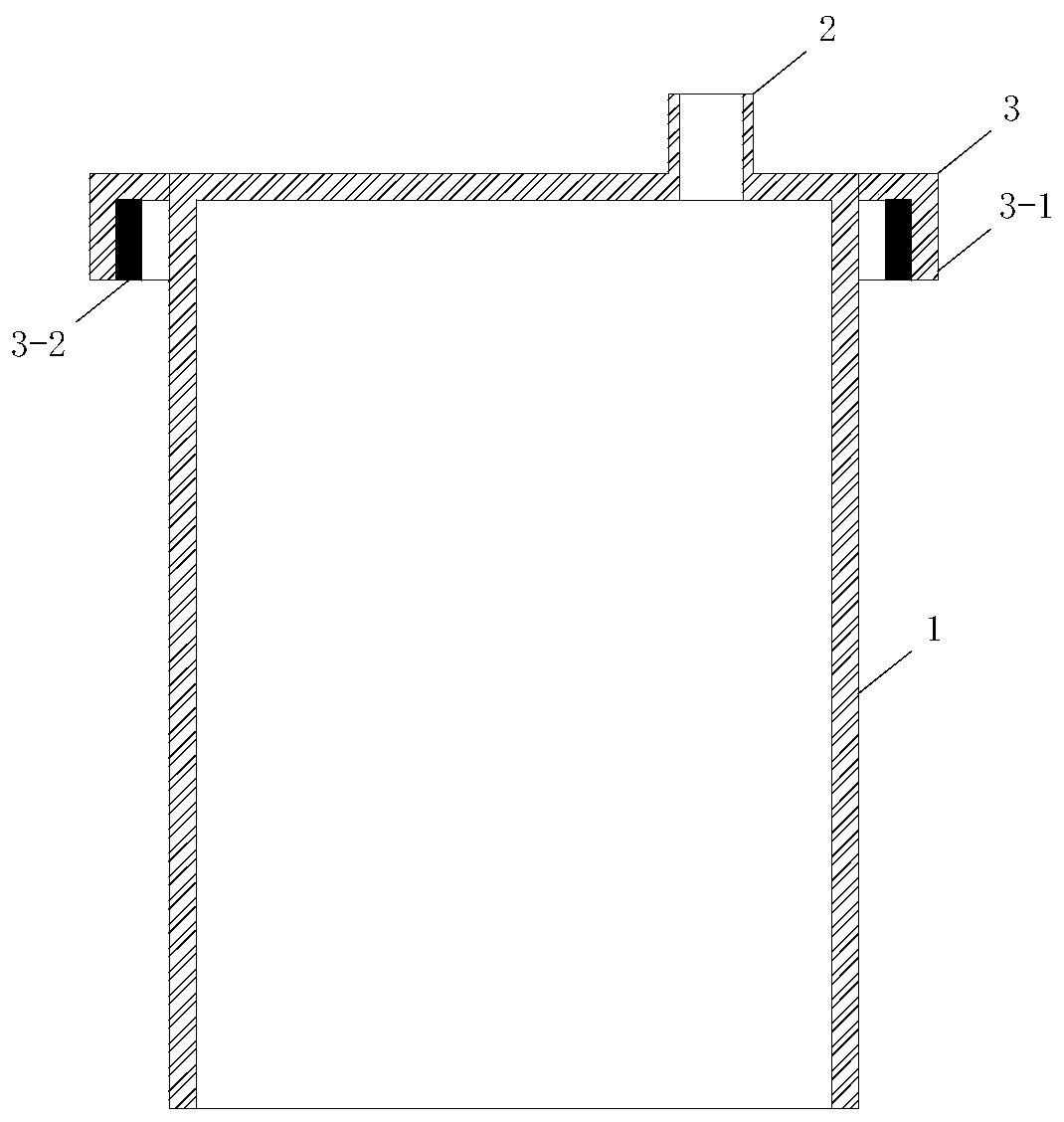

Dry-type transformer lifting structure

InactiveCN105405577ASimple structureAvoid lifting accidentsTransformer transport arrangementsTransformerEngineering

The invention discloses a dry-type transformer lifting structure, comprising a box body, a lifting ring arranged on the box body, an upper clamping element and a lower clamping element for clamping the transformer, and a lifting screw for connecting the upper clamping element and the lifting ring, wherein the upper clamping element and the lower clamping element are made of steel channel, a steel plate is welded on the upper clamping element, and the thickness of the steel plate is consistent with that of the steel channel used by the upper clamping element. The dry-type transformer lifting structure disclosed by the invention has the advantages of being simple in structure, being reliable and durable, and effectively avoiding lifting accidents.

Owner:镇江船舶电器有限责任公司

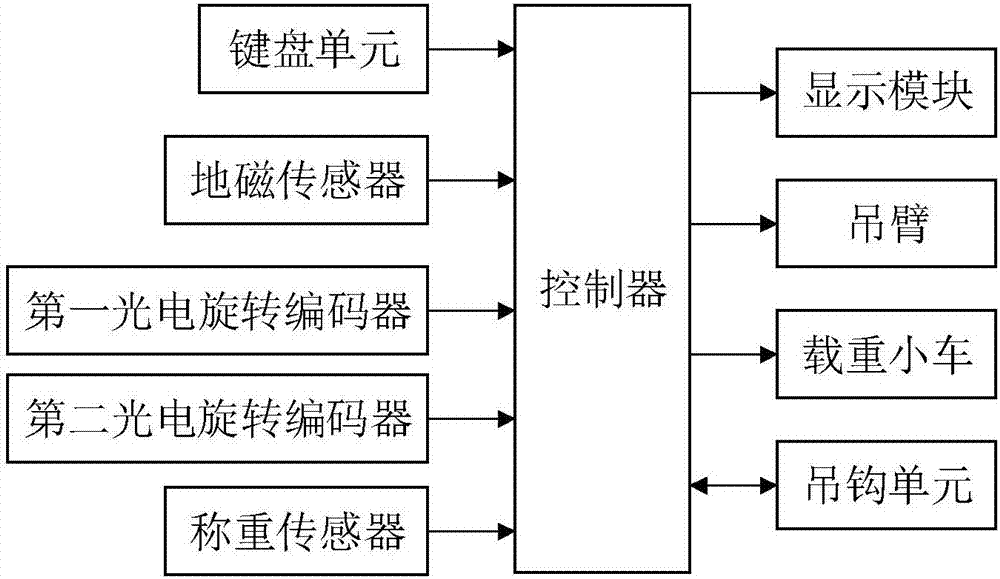

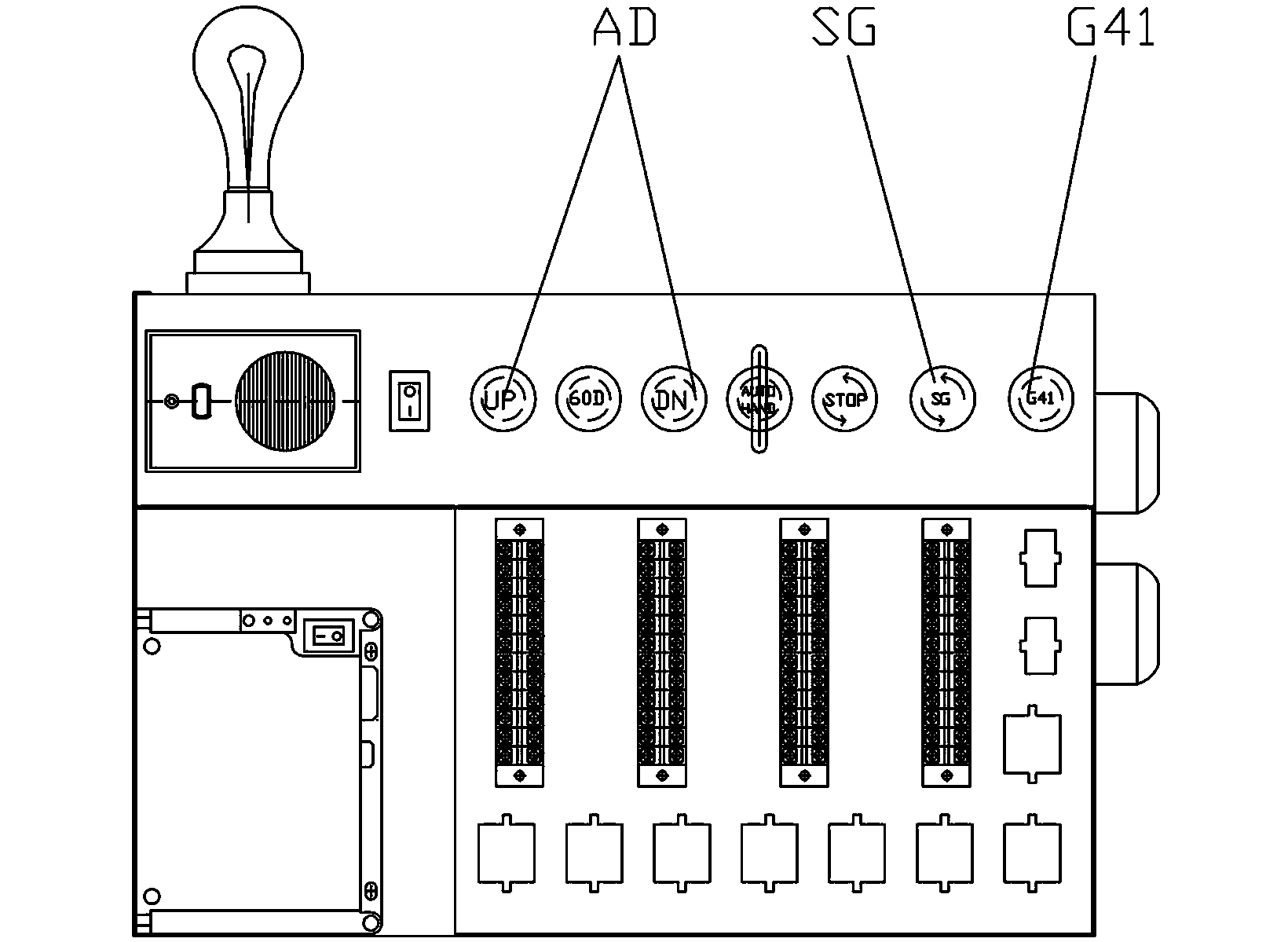

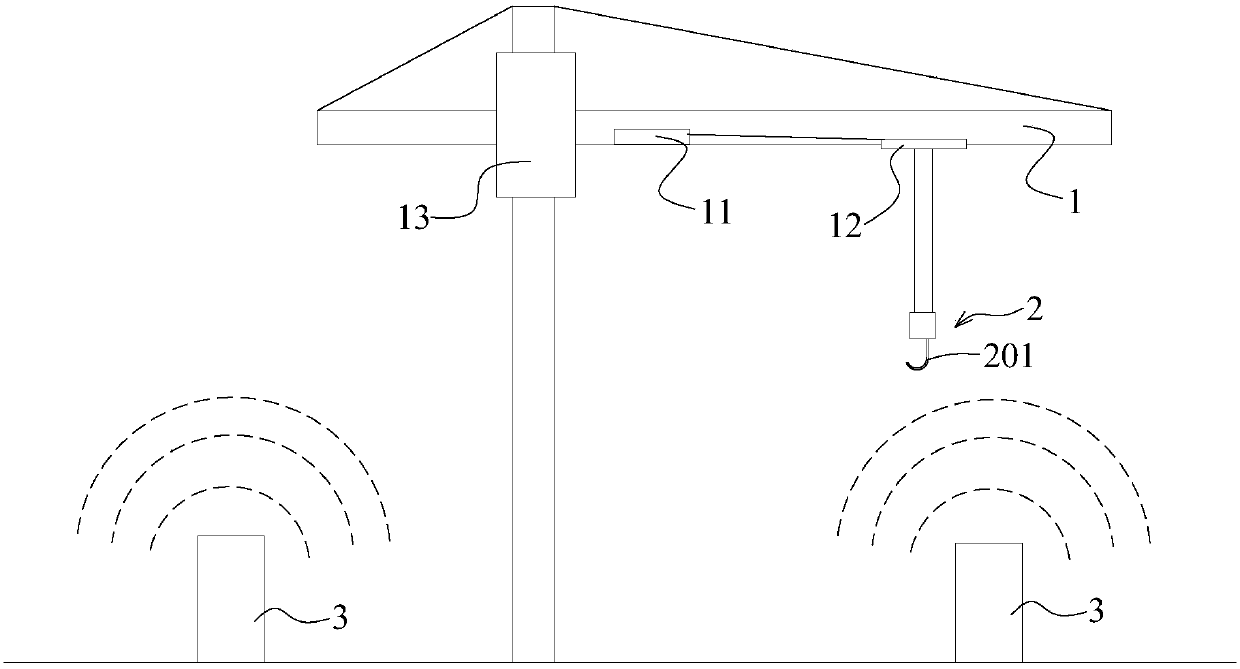

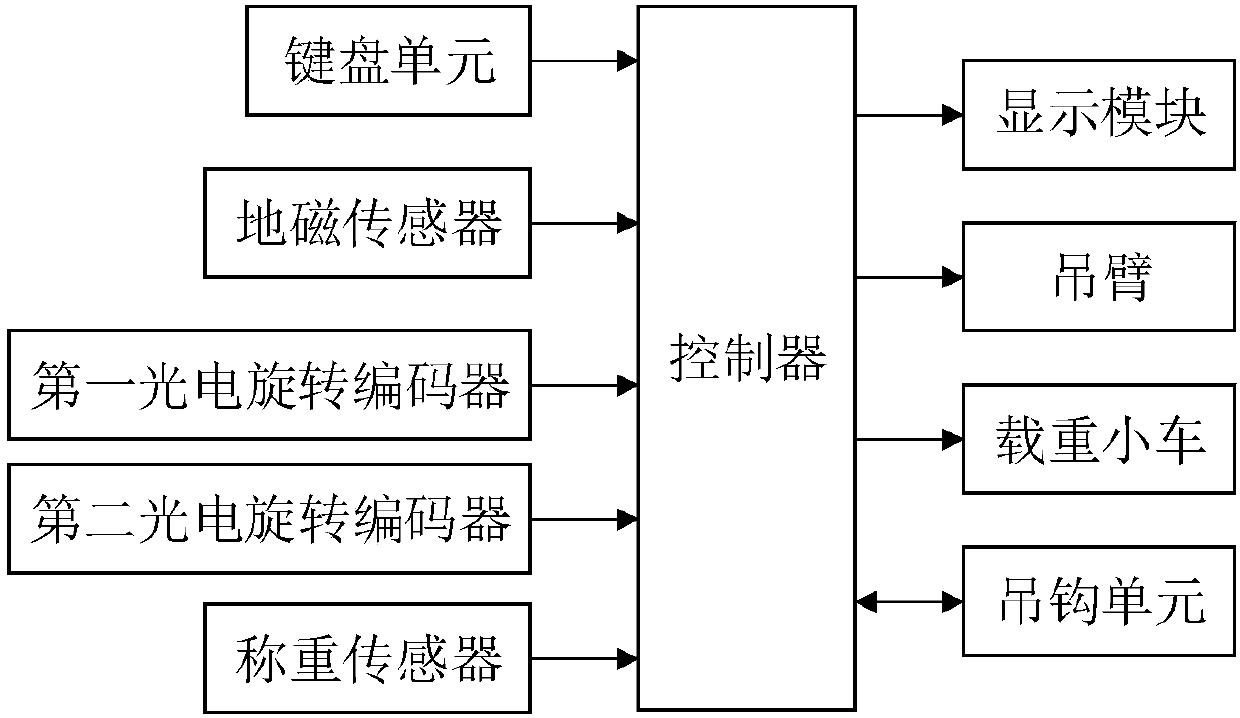

Intelligent tower crane system and operating method thereof

ActiveCN106927368AWith self-learning functionHigh degree of intelligenceCranesSafety gearMaterial typeLimit value

The invention relates to an intelligent tower crane system and an operating method thereof. The intelligent tower crane system comprises a boom, a control unit, a lifting hook unit and a beacon generator, wherein the beacon generator is positioned on a loading and unloading operation area; the control unit is mounted in a tower crane operating room and is used for controlling the boom and a lifting hook unit; the lifting hook unit comprises a safety clearance detection unit and a sound-light alarm unit and measures distance in real time through the safety clearance detection unit and the beacon generator; when the distance is lower than a limit value, the sound-light alarm unit gives an alarm and sends an alarm signal to the control unit. The intelligent tower crane system and the operating method thereof measure the distance in real time through the safety clearance detection unit and the beacon generator; when the distance is lower than the limit value, the alarm is given, and therefore an hoisting accident is avoided. The intelligent tower crane system also has a self-learning function and can identify material types according to weight and record the hoisting track according to the material types so as to realize automatic hoisting, and the intelligent degree of the tower crane is improved.

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

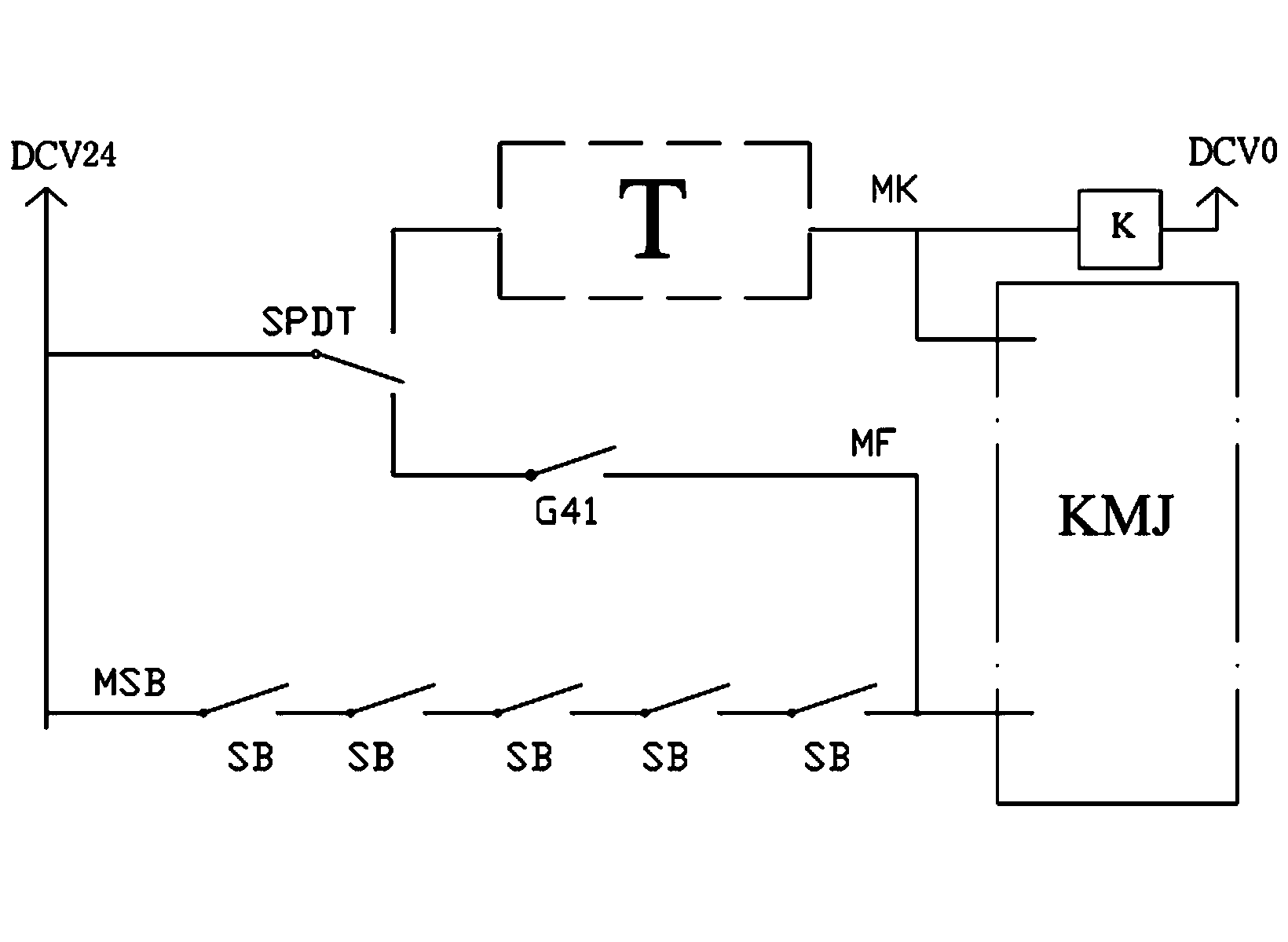

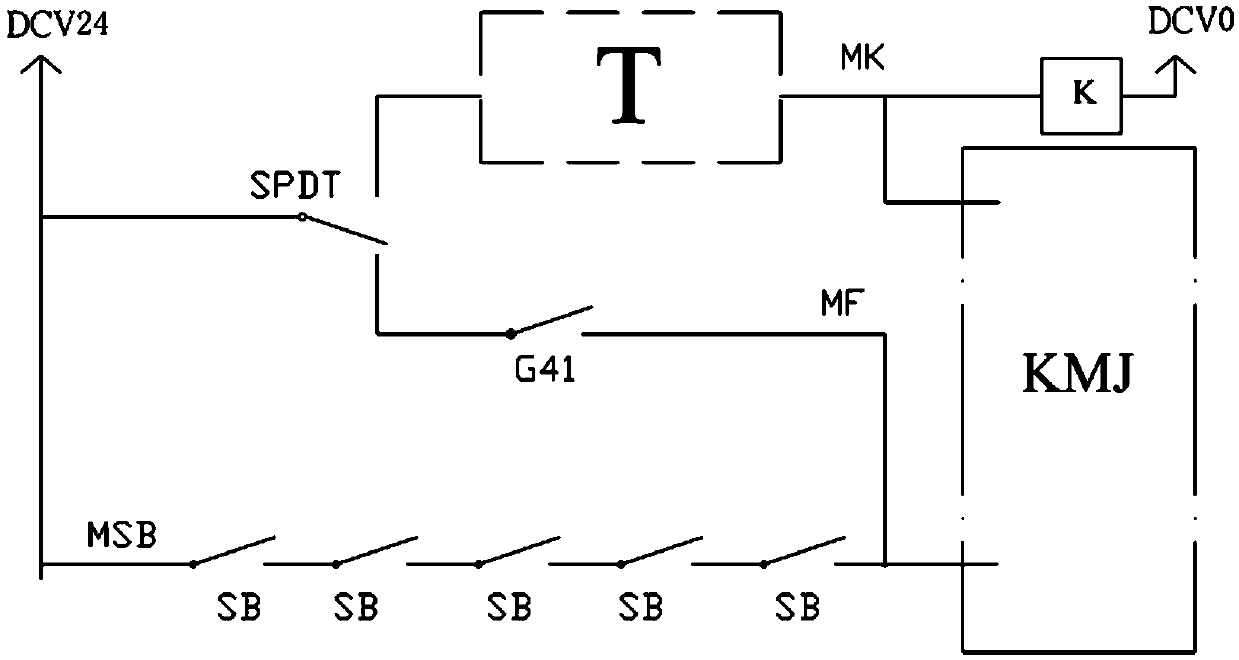

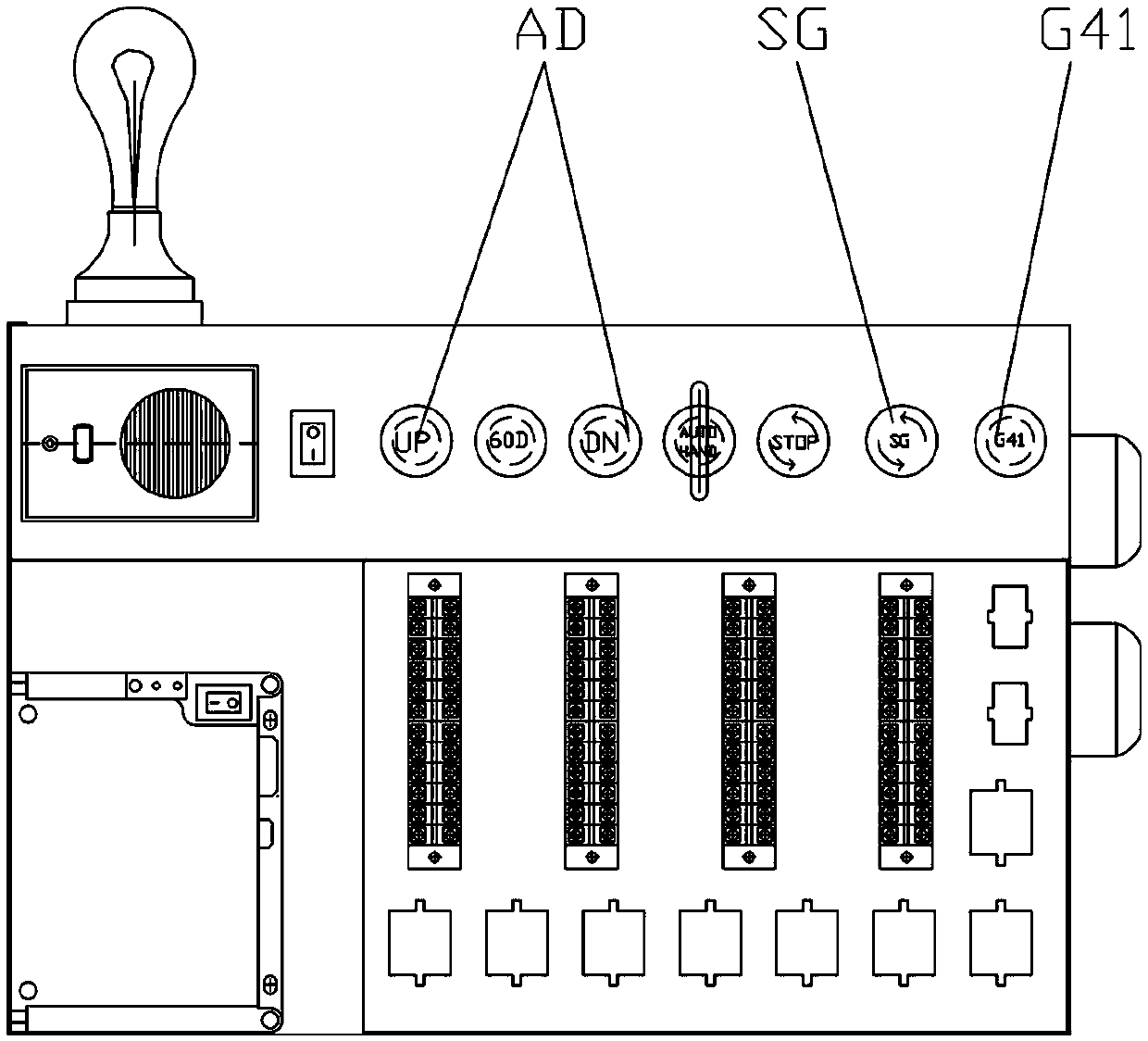

Compensation protection device for door lock during maintenance of elevator

ActiveCN103434905AEasy to installEasy maintenanceElevatorsBuilding liftsElectronic control systemControl system

The invention discloses a compensation protection device for door lock during the maintenance of an elevator. The compensation protection device comprises a maintenance circuit which is sequentially provided with a maintenance control circuit and a maintenance relay; the maintenance circuit is externally connected with a power supply by a power input point and a power output point; a crossover compensating circuit which is connected with the maintenance control circuit in parallel is arranged between the power input point and the maintenance relay; the crossover compensating circuit is provided with an electronic control system. The compensation protection device is convenient and can improve the efficiency in the maintenance work; after the structure is reasonably reformed, the compensation protection device can safely and rapidly remove the fault during the maintenance of the elevator by the series connection of a single-pole double-throw switch and a compensation reset button, and the accident that a lift car goes up and down all the same under the condition that a door is opened due to misoperation can be avoided; the whole structure of the compensation protection device is easy in installation and maintenance, and the compensation protection device is beneficial for technical popularization and application.

Owner:SANYO ELEVATOR ZHUHAI +1

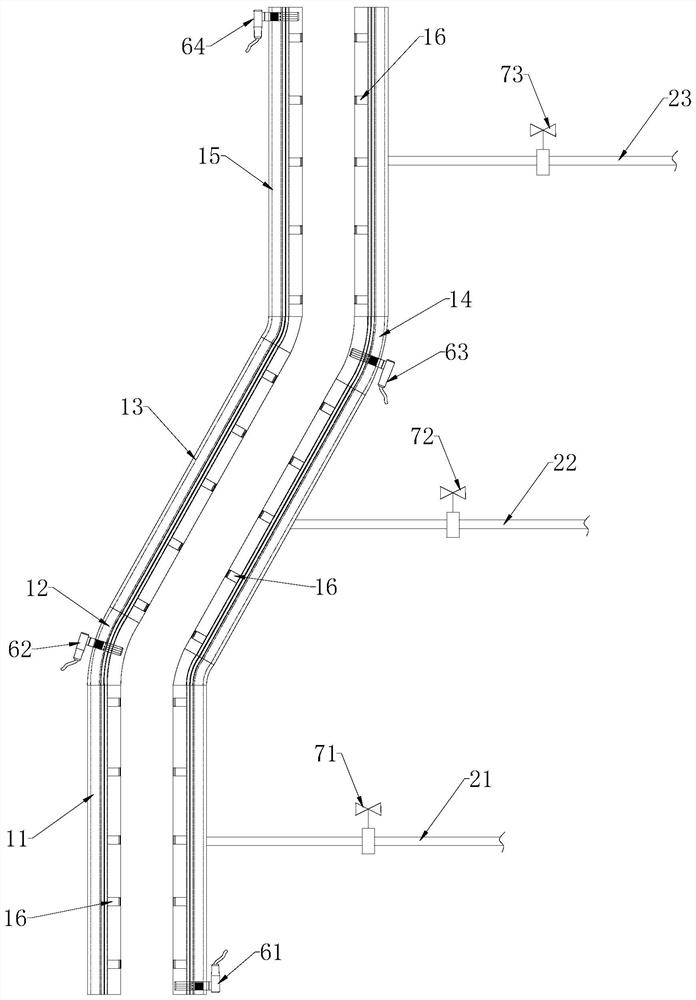

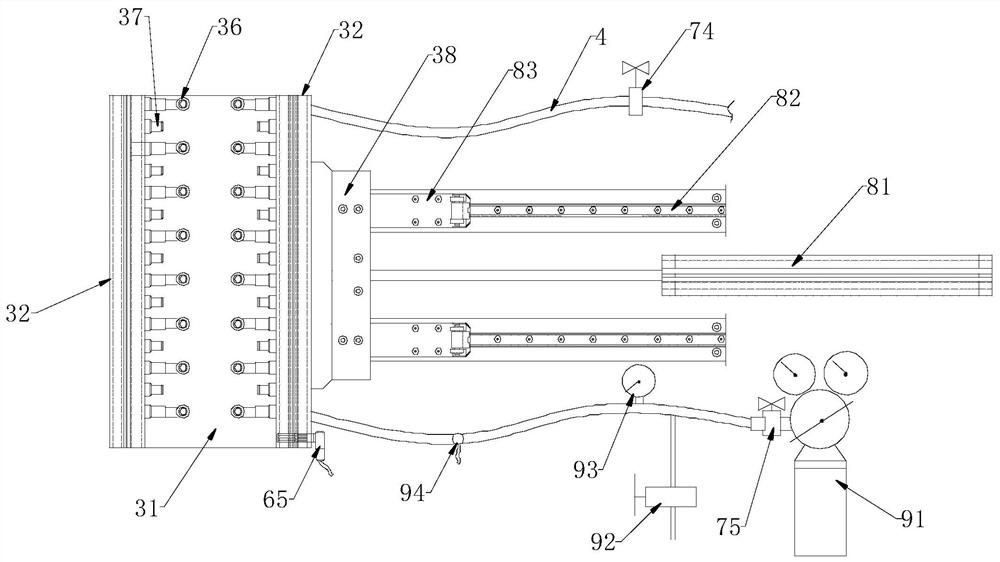

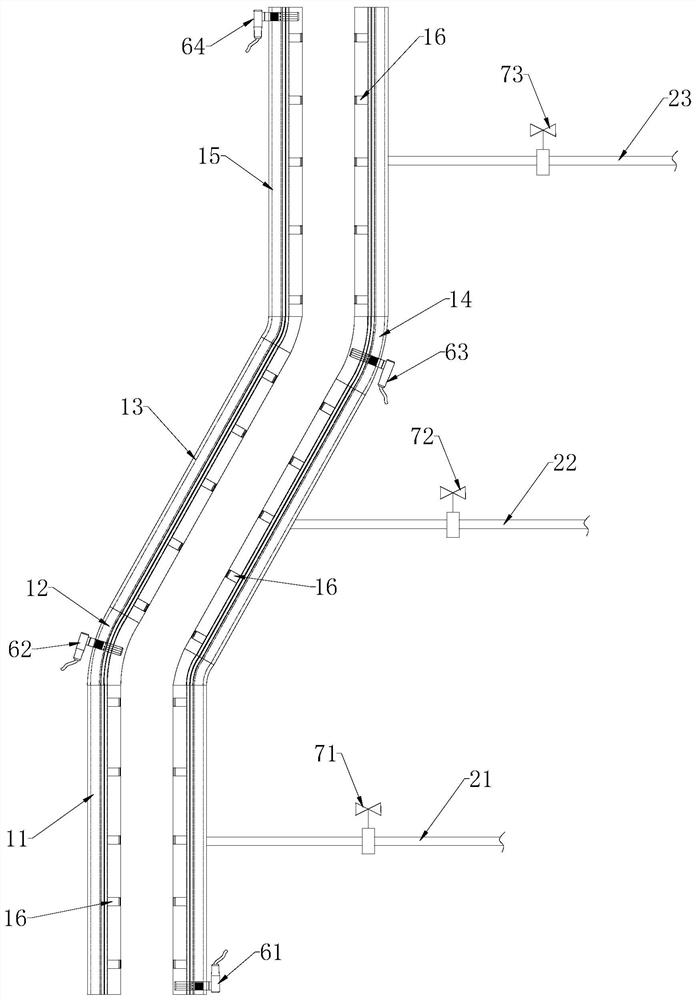

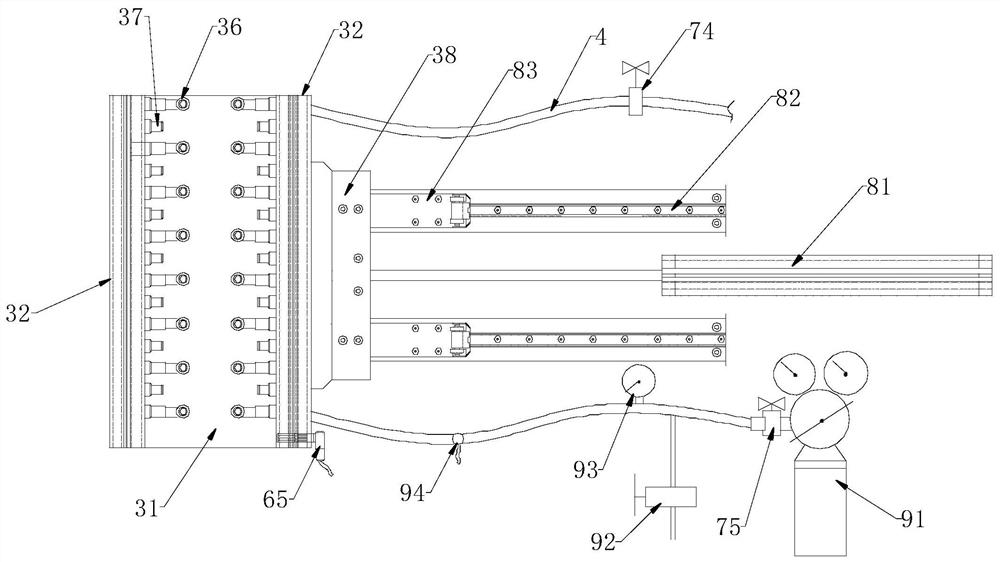

Automatic oiling method for skip bucket unloading curved rail

ActiveCN112225037ALess water consumptionAvoid lifting accidentsElevatorsMine liftsStructural engineeringProcess engineering

The invention provides an automatic oiling method for a skip bucket unloading curved rail, and relates to the technical field of mining equipment. According to the automatic oiling method for the skipbucket unloading curved rail, skip bucket unloading curved rail automatic oiling equipment is applied, and coal slime removing and segmented automatic oiling lubricating operation are sequentially conducted. In the operation process of a skip bucket lifting system, coal slime adhering to an unloading wheel is removed before oiling, the coal slime is completely removed, the water consumption is low, automatic oiling lubrication operation is conducted on the unloading wheel and the curved rail after the coal slime is removed, the oil consumption consumed by oiling lubrication operation is low,and after the unloading wheel operates for a long time, if the posture of the unloading wheel deviates, the lifting system can be controlled to stop in time, and lifting accidents caused by the fact that an unloading wheel with the deviated posture impacts a curved rail are avoided.

Owner:内蒙古上海庙矿业有限责任公司

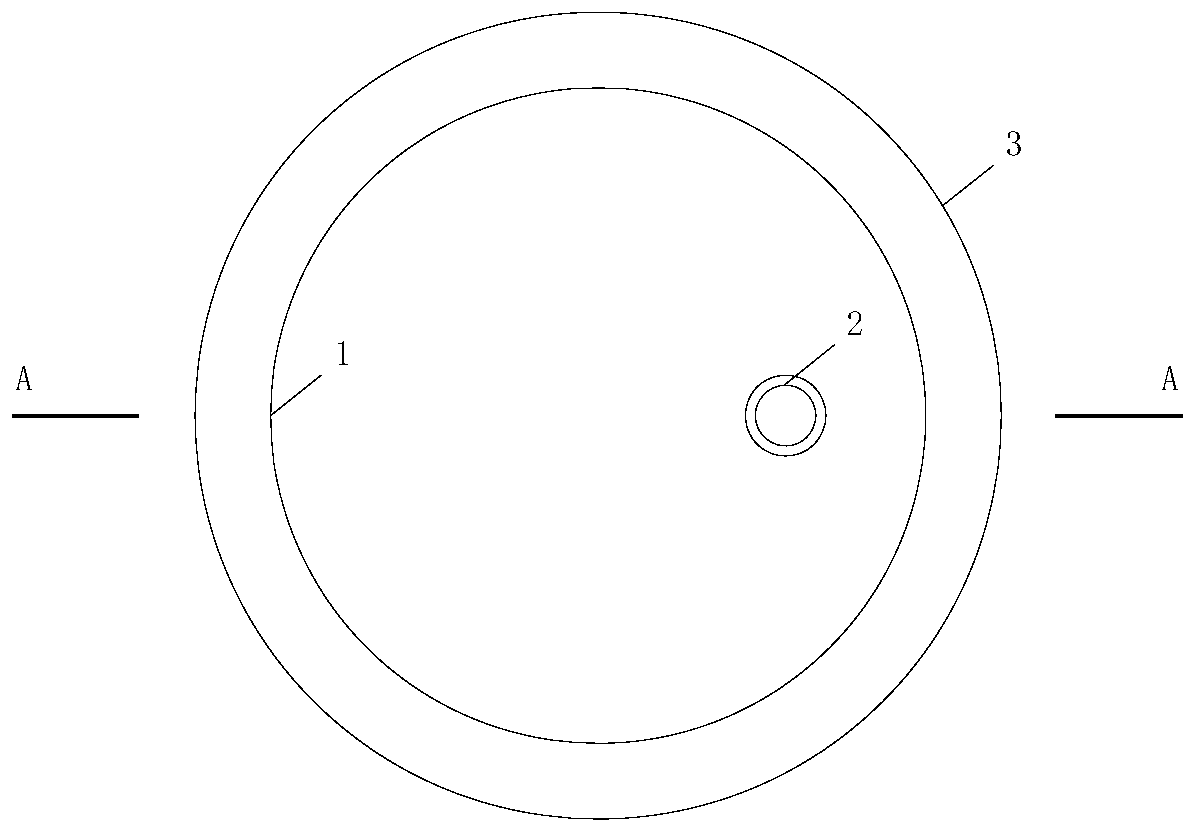

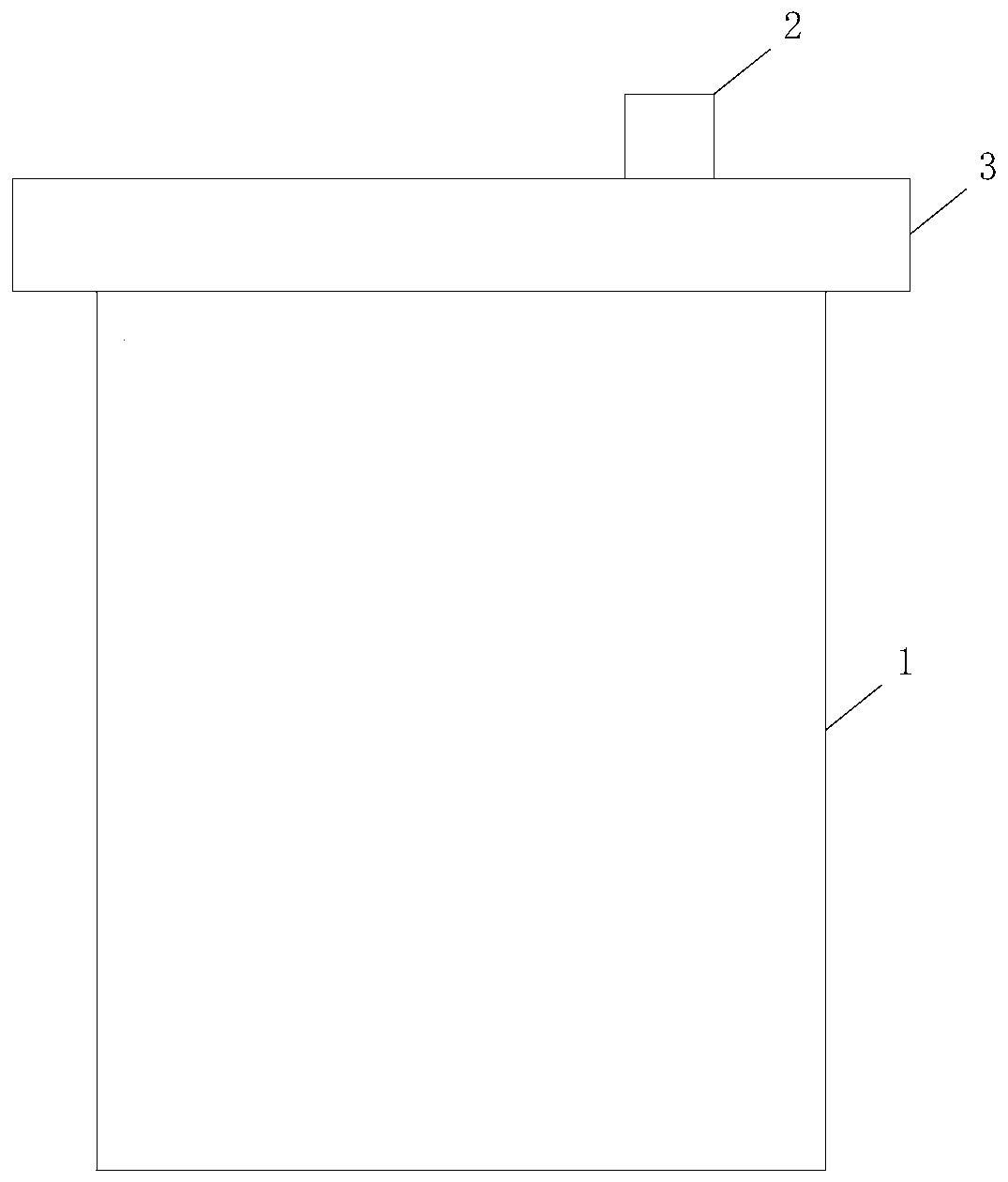

Mounting device and mounting method for steel casing of underwater drilling cast-in-place pile

PendingCN110952540AImprove permeabilityImprove penetration efficiencyBulkheads/pilesSuction forceGas passing

The invention discloses a mounting device and a mounting method for a steel casing of an underwater drilling cast-in-place pile. The mounting device comprises a suction bucket, a water / gas passing hole and a magnetic mounting top cap, wherein the water / gas passing hole is formed in the top of the suction bucket; the magnetic mounting top cap comprises an annular top cap and an electromagnet; the steel casing of the underwater cast-in-place pile is mounted by adopting a suction bucket technology; the steel casing penetrates through soil by vacuumizing the suction bucket of the mounting device,gas is injected in the suction bucket under high pressure and the mounting device is removed by adopting a hoisting method of a crane, the soil to be excavated on the inner side of the steel casing isonly disturbed in the mounting process, the soil at the periphery of the steel casing is not disturbed, and the liquidation risk in the construction period of the soil at the periphery of the underground drilling cast-in-pile foundation is effectively reduced; and the soil in the suction bucket is damaged in the dismantling process of the mounting device, so that the subsequent penetration of thesteel casing is facilitated, the construction period is beneficially shortened, and the construction cost is reduced. The mounting method is safe and reliable, and convenient and quick, and has a wide engineering application prospect.

Owner:ZHEJIANG UNIV CITY COLLEGE

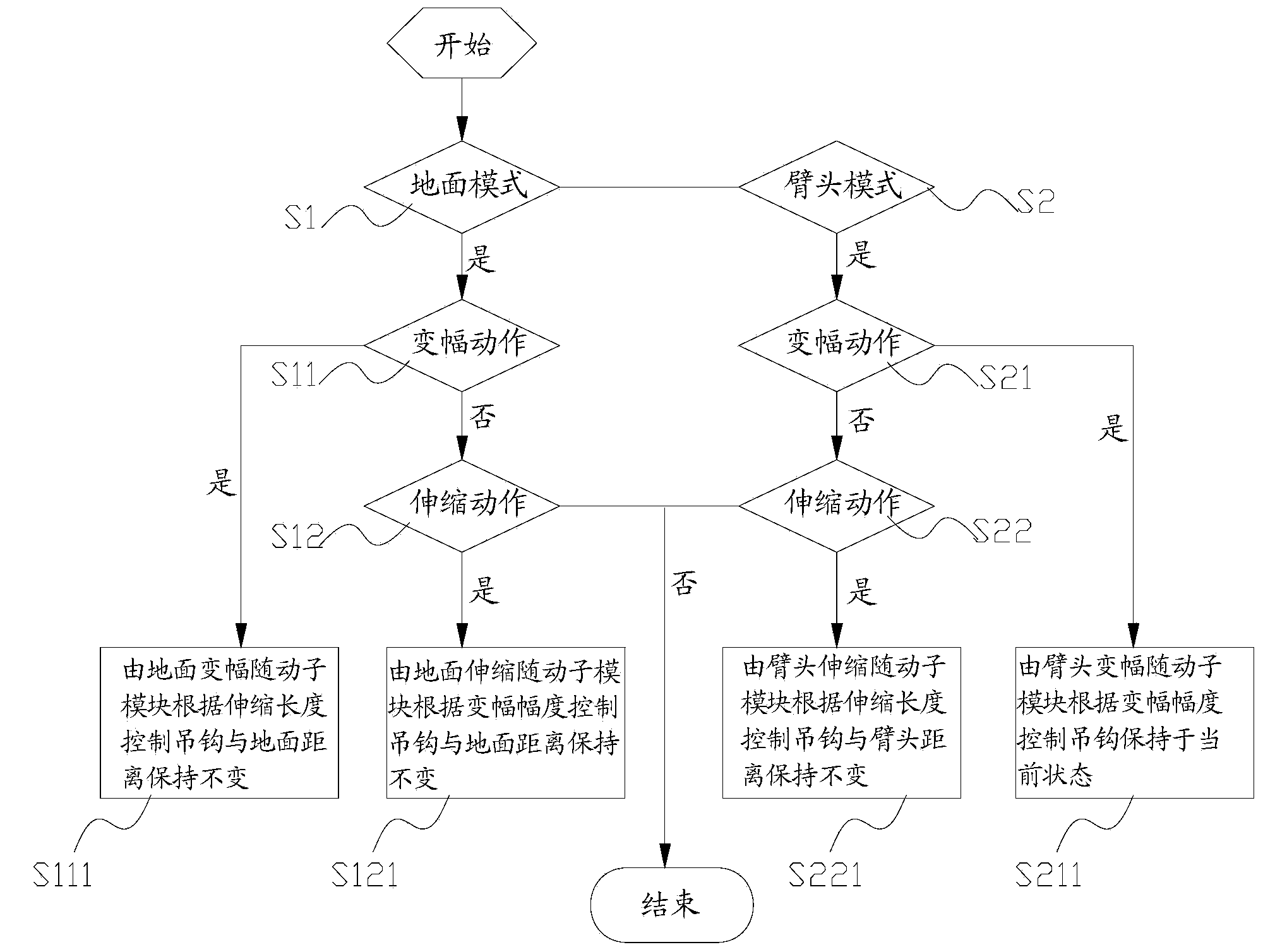

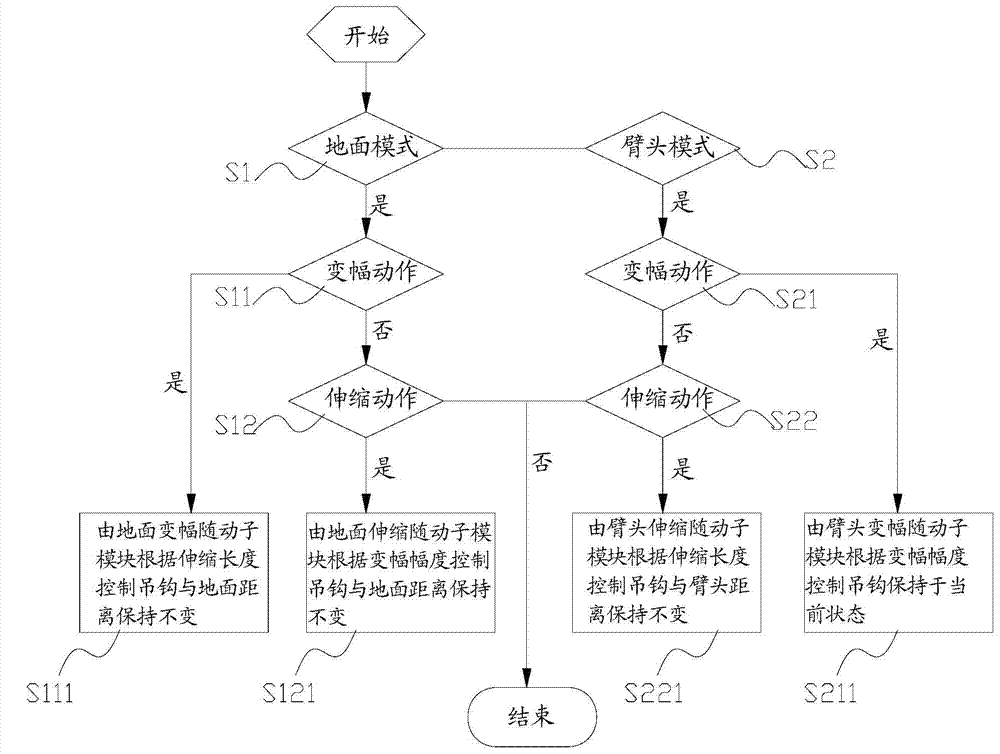

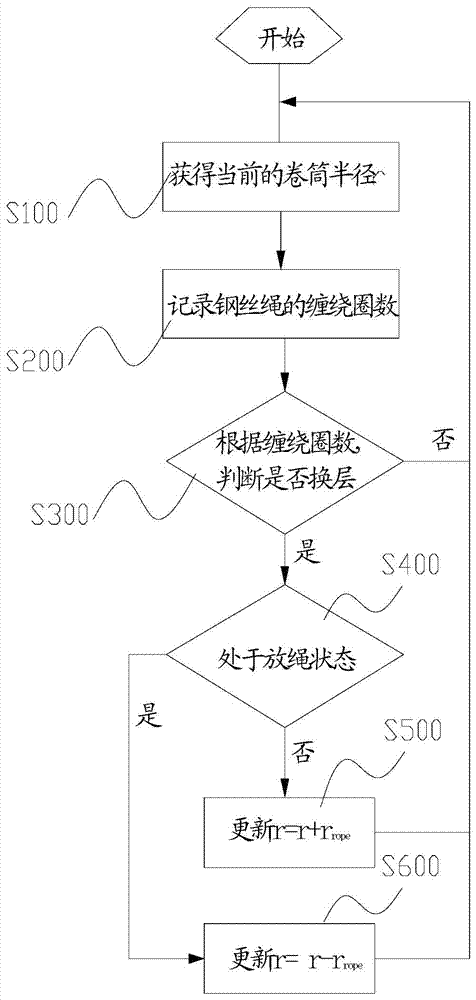

Method and system for controlling winch of crane to move relative to lifting arm

ActiveCN103466453ACrash freeRealize aerial panningLoad-engaging elementsAutomatic controlEngineering

The invention discloses a method and system for controlling a winch of a crane to move relative to a lifting arm. The method includes the following steps of receiving a ground mode command, controlling the distance between a hook and the ground to be unchanged according to the luffing amplitude when the lifting arm carries out luffing motions, controlling the distance between the hook and the ground to be unchanged according to the stretching and retracting lengths when the lifting arm stretches and retracts, and receiving an arm tip mode command, keeping the hook in the current state when the lifting arm carries out the luffing motions, and controlling the distance between the hook to the arm tip to be unchanged according to the stretching and retracting lengths when the lifting arm stretches and retracts. According to the method and system, four work modes are set, in the manipulation process, the distance from the hook to the arm tip or to the ground is automatically kept unchanged, and manual control is needless. Compared with background technologies, on one hand, the method and system achieve automated control and effectively avoid occurrence of hoisting accidents; on the other hand, the distance from the hook to the arm tip or to the ground is controlled to be unchanged so that the method and system are suitable for different working condition requirements, and the control effect is good.

Owner:XUZHOU HEAVY MASCH CO LTD

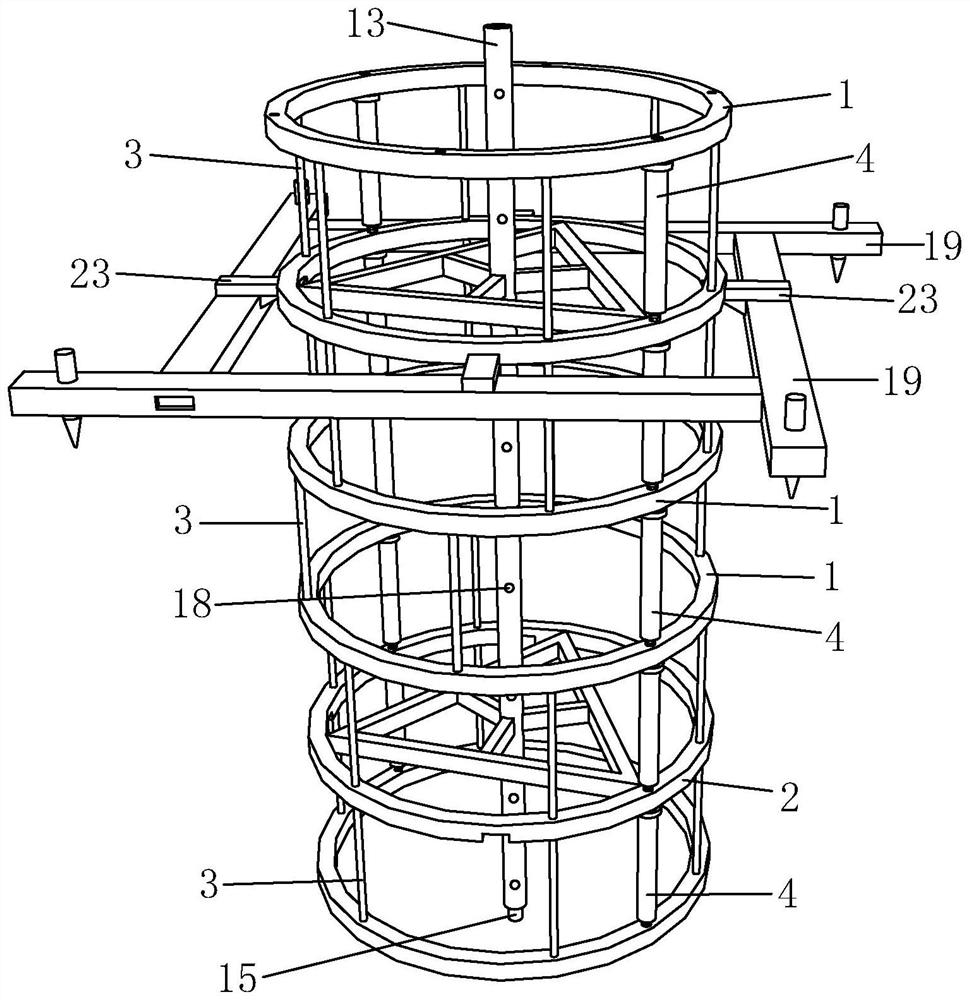

Method for hoisting low-clearance super-long reinforcement cage into hole section by section under high-voltage line

PendingCN113756320AEnough buried depthAvoid lifting accidentsArtificial islandsExcavationsClassical mechanicsHigh tension line

The invention discloses a method for hoisting a low-clearance super-long reinforcement cage into a hole section by section under a high-voltage line. The method comprises the following steps of (a) cleaning a site; (b) assembling a reinforcement cage; (c) butting two sections of reinforcement cages; (d) positioning; and (e) hoisting section by section. The method for hoisting the reinforcement cage into the hole in a segmented mode is adopted, pile holes of different depths can be flexibly adapted, the enough reinforcement cage burying depth is guaranteed, the problem that construction is not allowed within the vertical distance range of 6 m of the high-voltage line is solved, the construction operation of hoisting the long reinforcement cage into the hole at the limited height is achieved, the hoisting weight of the single-section reinforcement cage is more effectively controlled, the accident of hoisting instability of the whole-section reinforcement cage is avoided, and the safety of constructors and equipment is guaranteed.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

A coal mine hoist wire rope real-time fault diagnosis and early warning device and method

InactiveCN102636561BAvoid lifting accidentsFlexible useTension measurementMaterial magnetic variablesReal-time dataData acquisition

The invention discloses a real-time fault diagnosis and early warning device and a real-time fault diagnosis and early warning method for a wire rope of a coal mine hoist, and belongs to a device and a method for fault diagnosis of the wire rope of the hoist based on on-line monitoring data. A core processing module of the device is simultaneously connected with a data storage module, a program storage module, a liquid crystal and touch screen control module, a data acquisition module, an Ethernet module and an alarm module; and a power module is connected with all the modules to provide power for all the modules. The method comprises the following steps of: calculating loss percentage of the sectional area of the wire rope; transmitting real-time data of the section area of the wire rope into the core processor module through an Ethernet interface; comparing with an initial value of the section area of the wire rope; and outputting in the form of loss percentage of the sectional area of the wire rope. The device and the method have the advantages that safety parameters are set aiming at application places of the wire rope; the application is flexible; the working state of the wire rope can be judged according to the on-line monitoring data; the real-time fault diagnosis and early warning function of the wire rope can be realized; and alarm information is given.

Owner:CHINA UNIV OF MINING & TECH

Compensation protection device for elevator inspection door lock

ActiveCN103434905BAvoid Lifting AccidentsAvoid accidentsElevatorsBuilding liftsElectronic control systemControl system

The invention discloses a compensation protection device for door lock during the maintenance of an elevator. The compensation protection device comprises a maintenance circuit which is sequentially provided with a maintenance control circuit and a maintenance relay; the maintenance circuit is externally connected with a power supply by a power input point and a power output point; a crossover compensating circuit which is connected with the maintenance control circuit in parallel is arranged between the power input point and the maintenance relay; the crossover compensating circuit is provided with an electronic control system. The compensation protection device is convenient and can improve the efficiency in the maintenance work; after the structure is reasonably reformed, the compensation protection device can safely and rapidly remove the fault during the maintenance of the elevator by the series connection of a single-pole double-throw switch and a compensation reset button, and the accident that a lift car goes up and down all the same under the condition that a door is opened due to misoperation can be avoided; the whole structure of the compensation protection device is easy in installation and maintenance, and the compensation protection device is beneficial for technical popularization and application.

Owner:SANYO ELEVATOR ZHUHAI +1

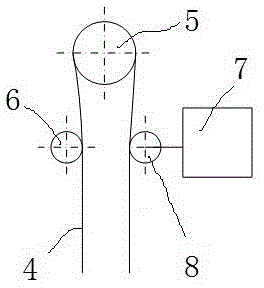

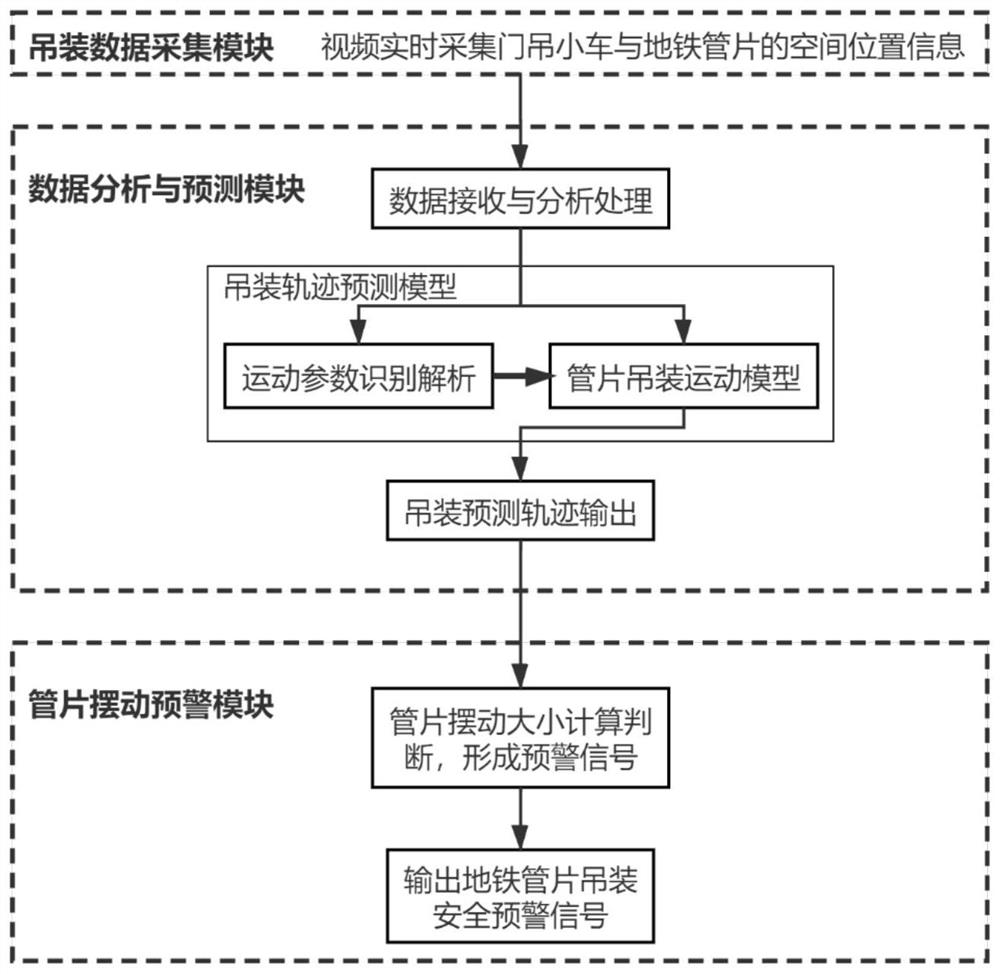

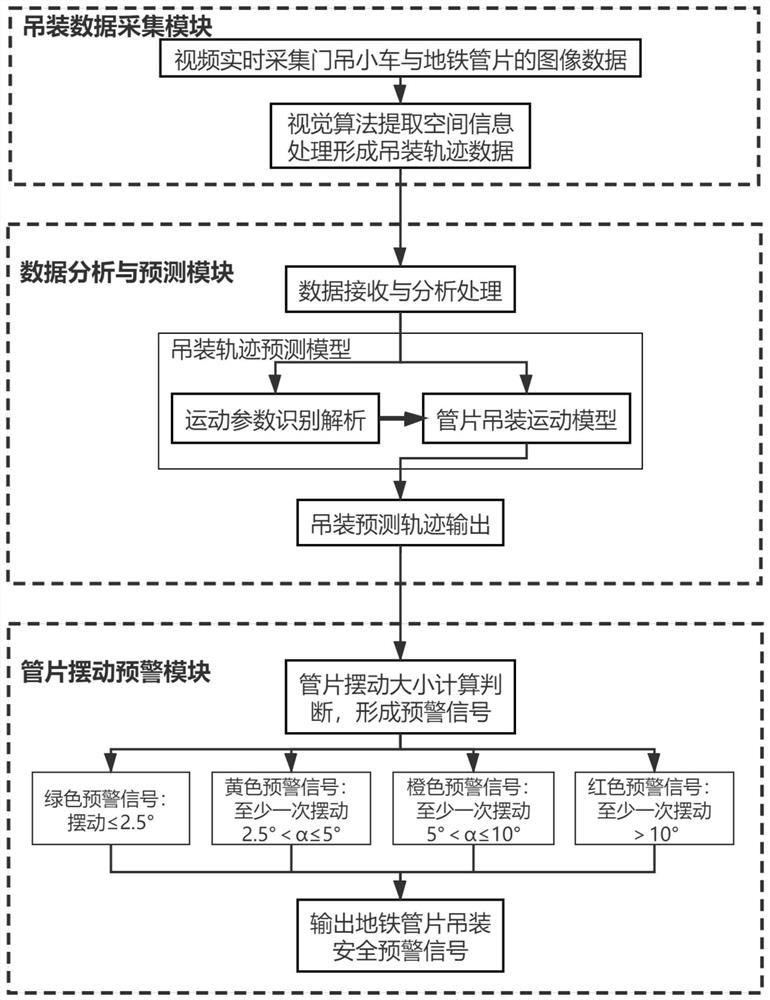

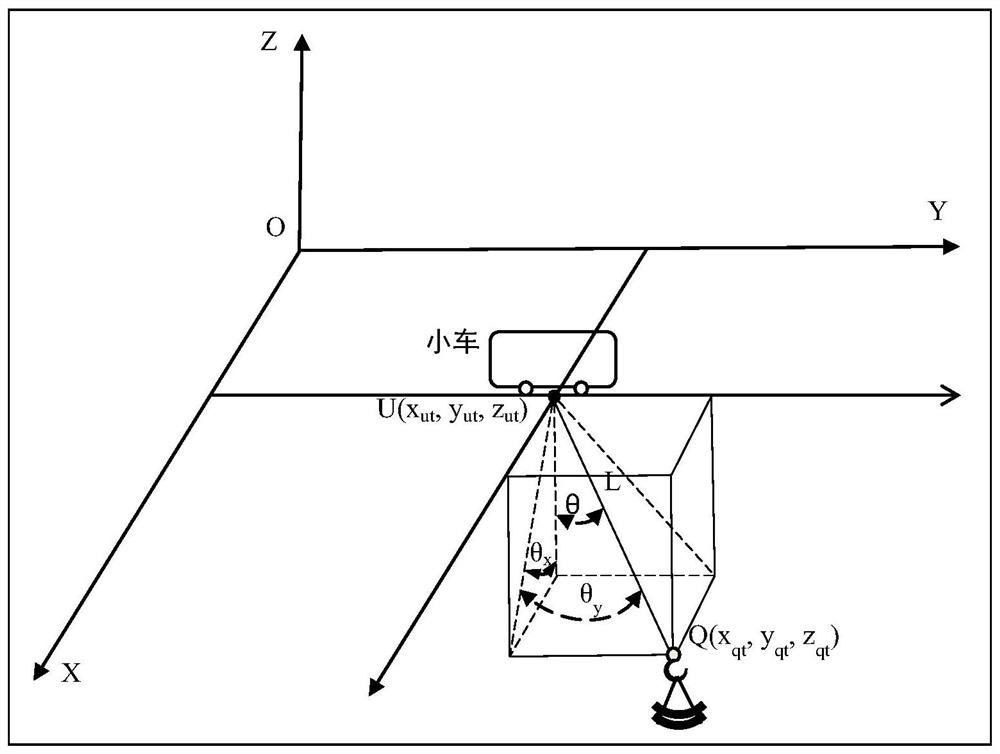

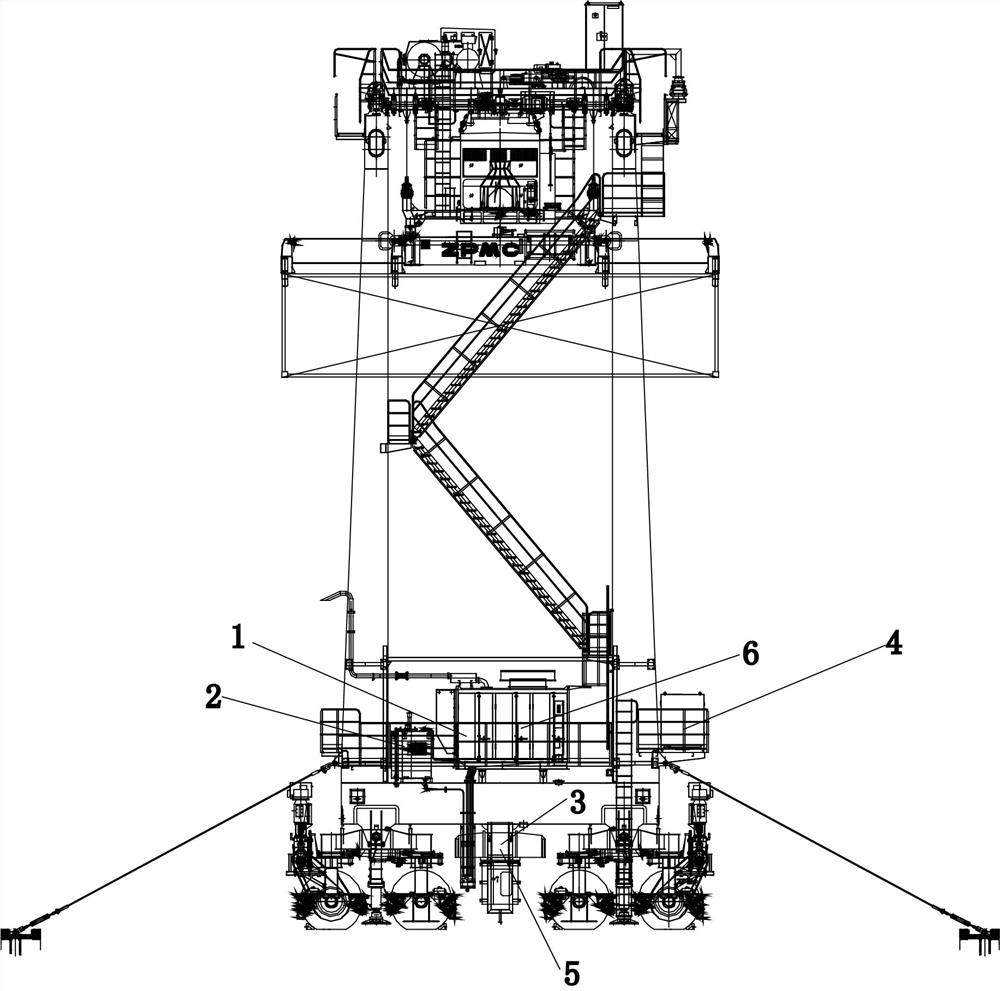

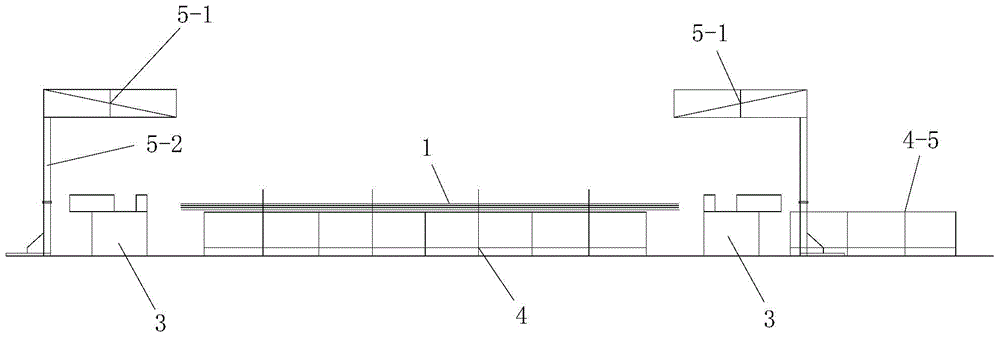

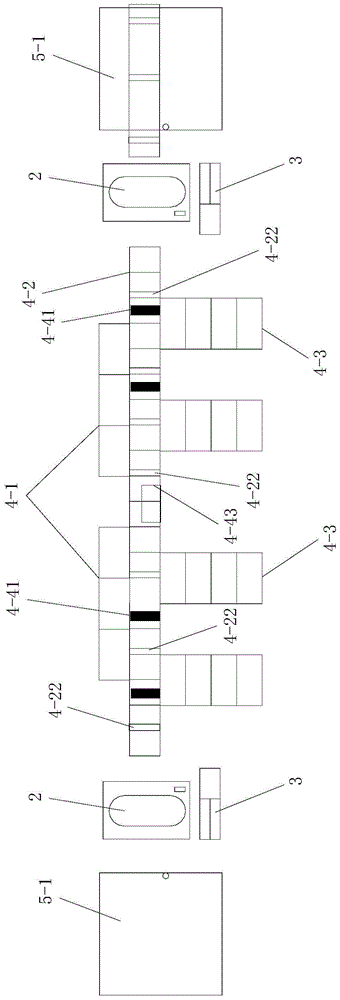

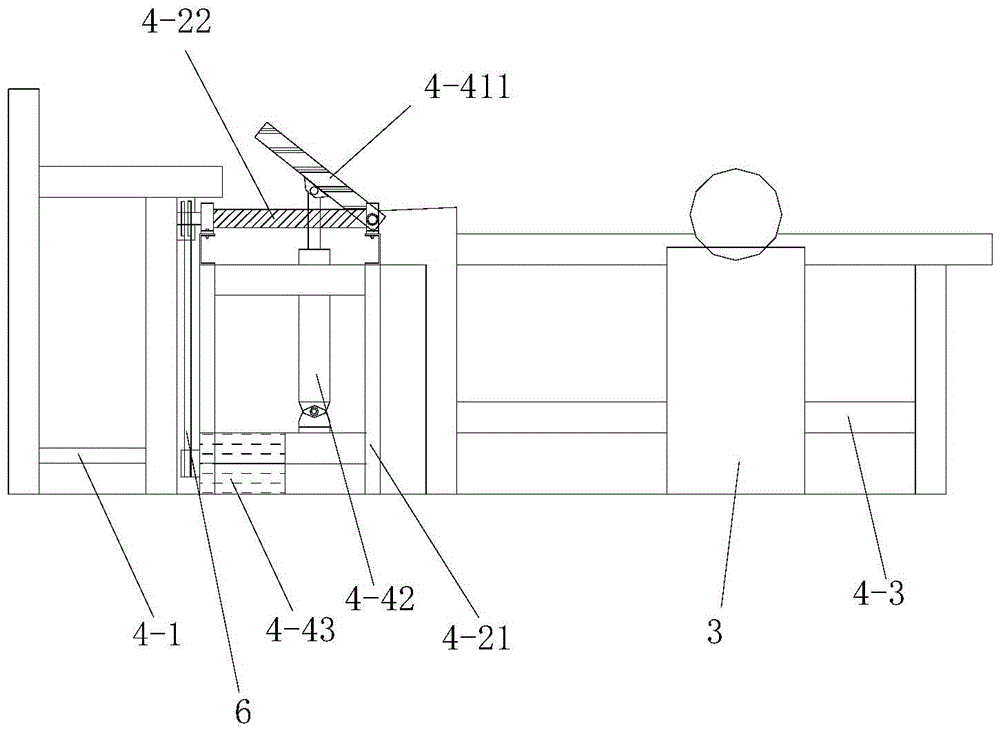

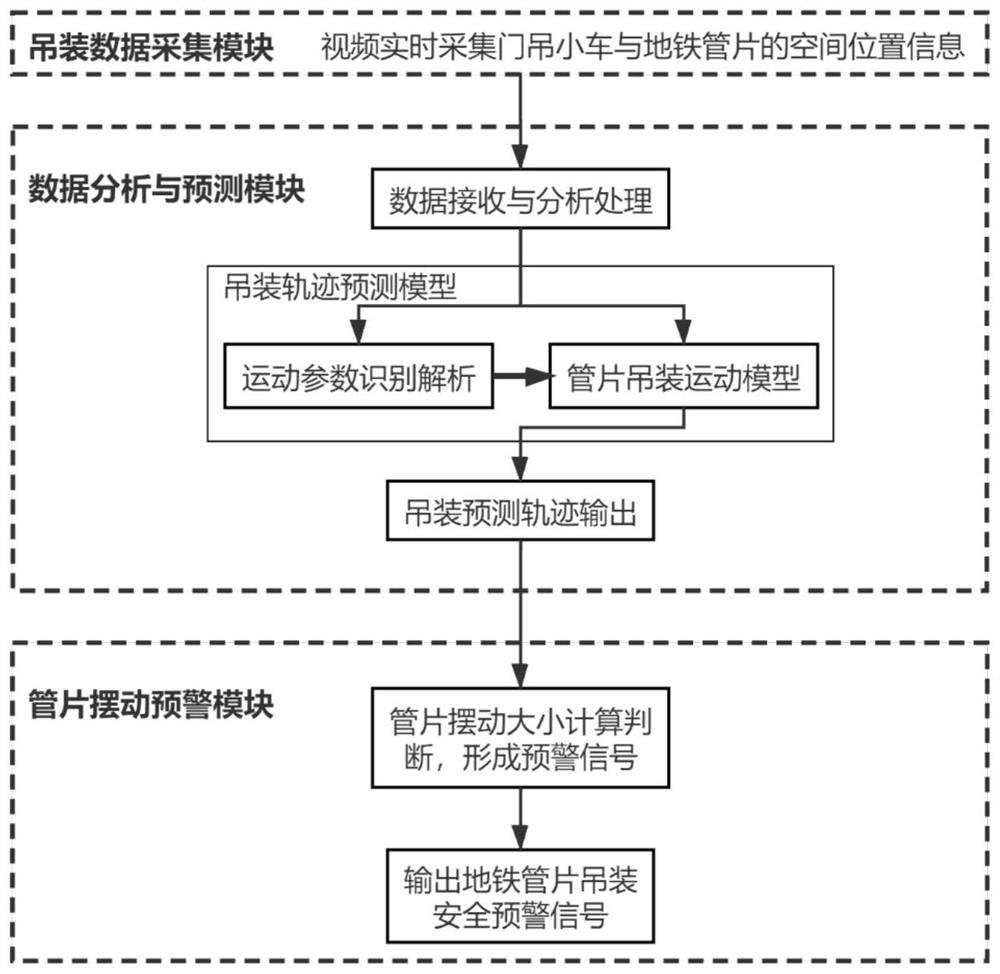

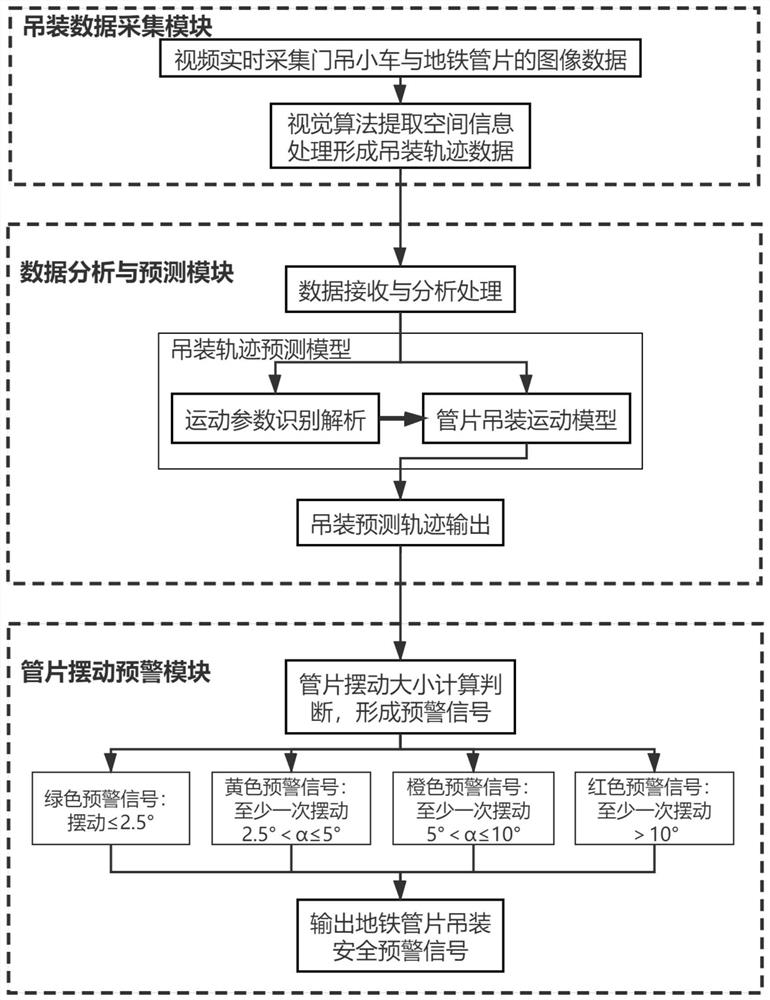

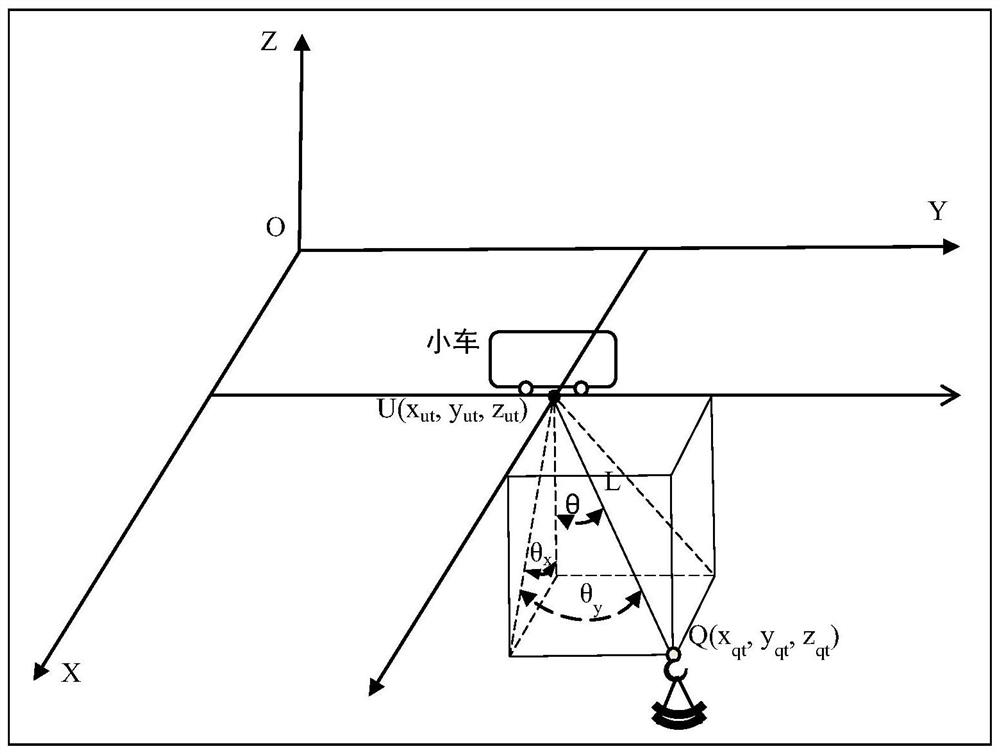

Door crane brake swing warning system and method for segment hoisting of subway shield tunnel

ActiveCN112209251BHigh data accuracyReal-time acquisition and high efficiencySafety gearData acquisitionSafety control

The invention belongs to the field of hoisting operation safety control, and discloses a door crane brake swing early warning system and method for segment hoisting of a subway shield tunnel, wherein the early warning system includes a hoisting data acquisition module, a data analysis and prediction module, and a segment swing early warning module The hoisting data acquisition module is used to collect the spatial information of the subway segment in the hoisting process in the downhole in real time; the data analysis and prediction module reasonably predicts the future hoisting trajectory of the subway segment through the above-mentioned collected data; the segment swing early warning module is based on The hoisting prediction trajectory calculates and judges the possible swing size of the subway segment and outputs the corresponding early warning signal. The invention predicts the hoisting trajectory based on the composite model of data drive and motion analysis, and uses reasonable and accurate predicted trajectory to carry out pre-warning control on the unsafe swing of the subway segment during the deceleration and braking phase of hoisting, and optimizes the safety control of the hoisting process of the subway segment , Actively avoid subway segment hoisting accidents.

Owner:HUAZHONG UNIV OF SCI & TECH

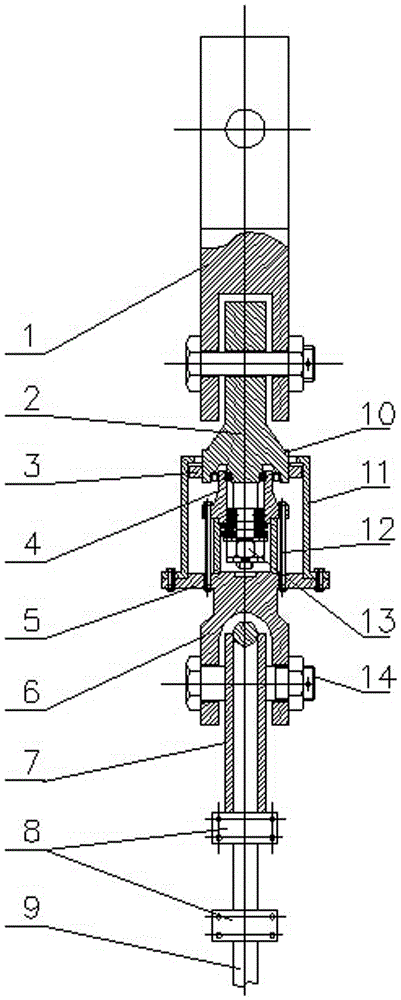

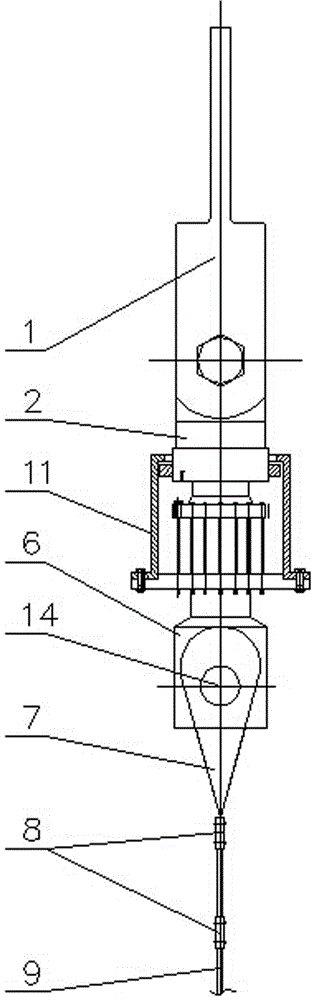

An anti-fall skip tail rope suspension device and tail rope anti-fall method

The invention relates to an anti-drop skip tail rope suspension device and an anti-drop method for a tail rope. An integrated flange is arranged at the bottom of a suspender, a hollow steel barrel sleeves from the top of the suspender, and an outer lug boss at the bottom of the hollow steel barrel is connected with an upper plate of a rotating fork by bolts; the inner diameter of the hollow steel barrel is larger than that of the flange of the suspender, and a 1 to 2 centimeters gap remains between the bottom of an inner lug boss of the top of the hollow steel barrel and the top of the flange; when the gap is reduced to less than 1 centimeter, a proximity switch installed for measuring the gap immediately starts an audible and visual alarm to remind people of performing safety inspection; if the gap is reduced to 0, the inner lug boss at the top of the hollow steel barrel is hung on the flange of the suspender to immediately bear the weight of the tail rope and prevent the tail rope dropping so as to avoid a mine hoisting accident and guarantee the mine safety production.

Owner:JIANGXI HUKENG TUNGSTEN IND CO LTD

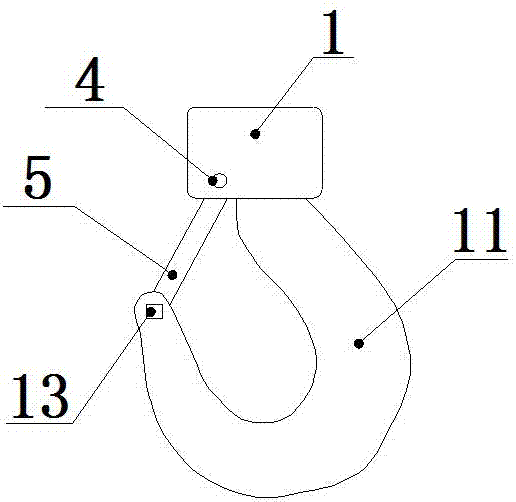

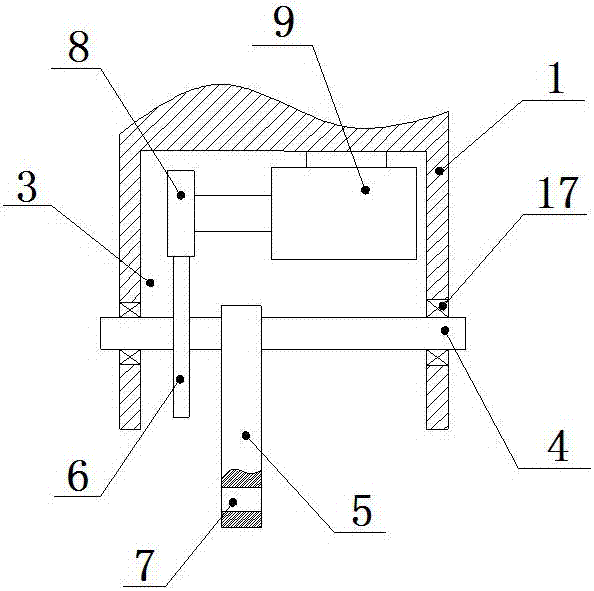

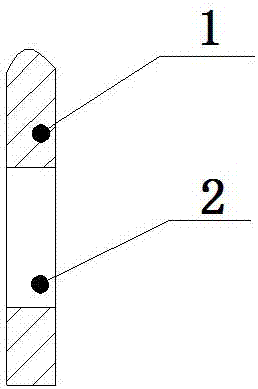

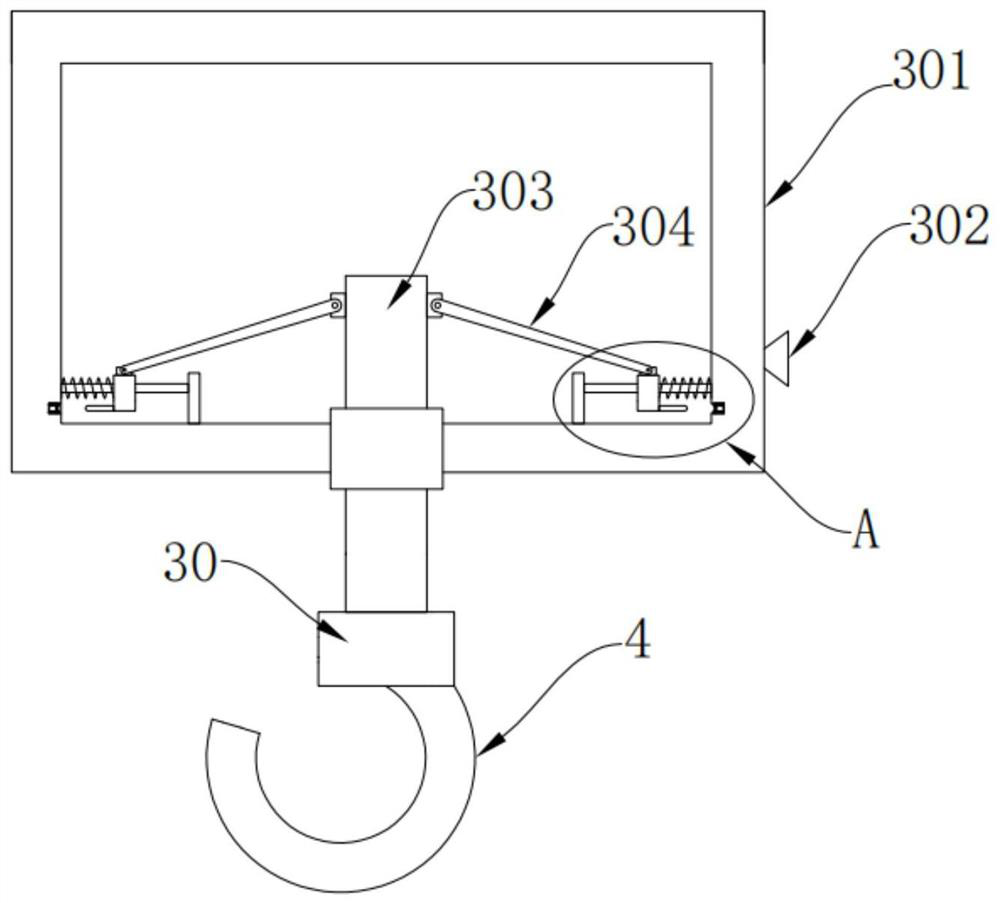

An intelligent self-locking hook

The invention relates to an intelligent self-locking lifting hook which comprises a connecting seat. The lower portion of the connecting seat is provided with a bolt hole and a cavity communicated with the bolt hole. The bolt hole is connected with a bolt through a bearing. A baffle and a driven gear are arranged on the outer wall of the middle of the bolt. A spring bolt hole is formed in the lower portion of the baffle. The driven gear is connected with a drive gear. The drive gear is connected with a motor. The motor is arranged in the cavity and is connected with a controller through a signal line. The lower end of the connecting seat is provided with a lifting hook body, and a pressure sensor is arranged on the upper side face of the arc face of the lifting hook body. The pressure sensor is connected with the controller through a signal line, and an electromagnetic lock is arranged on the outer wall of the upper portion of the lifting hook. The electromagnetic lock is connected with the controller through a signal line. The upper portion of the lifting hook is provided with an opening groove matched with the baffle and a self-locking hole communicated with the opening groove. A contact type sensor is arranged at the bottom of the opening groove. The contact type sensor is connected with the controller through a signal line. The intelligent self-locking lifting hook has the beneficial effects of being simple in structure, convenient to use and low in operation cost.

Owner:HENAN SINOKO CRANES

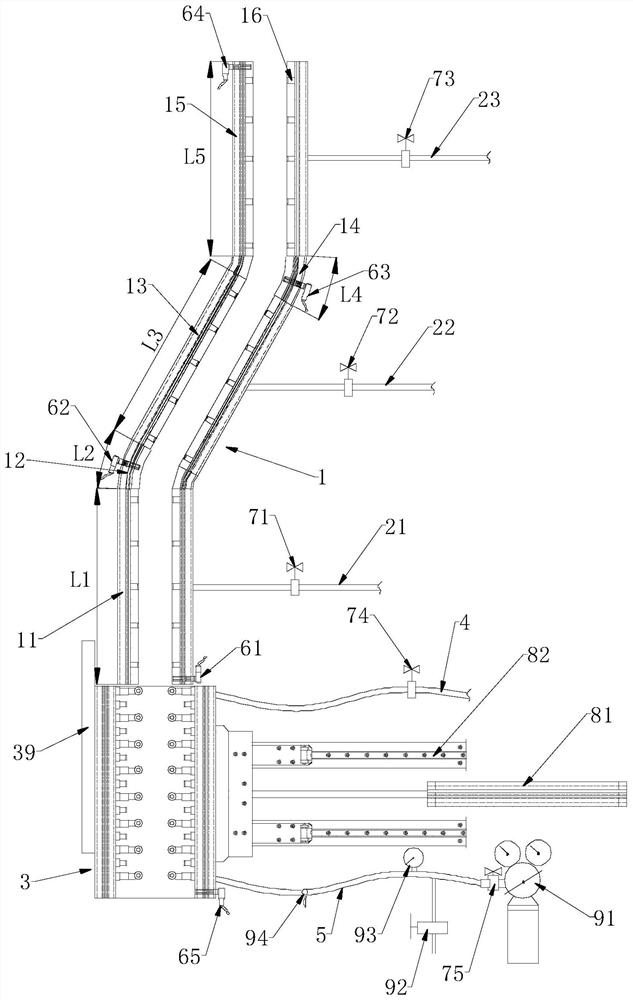

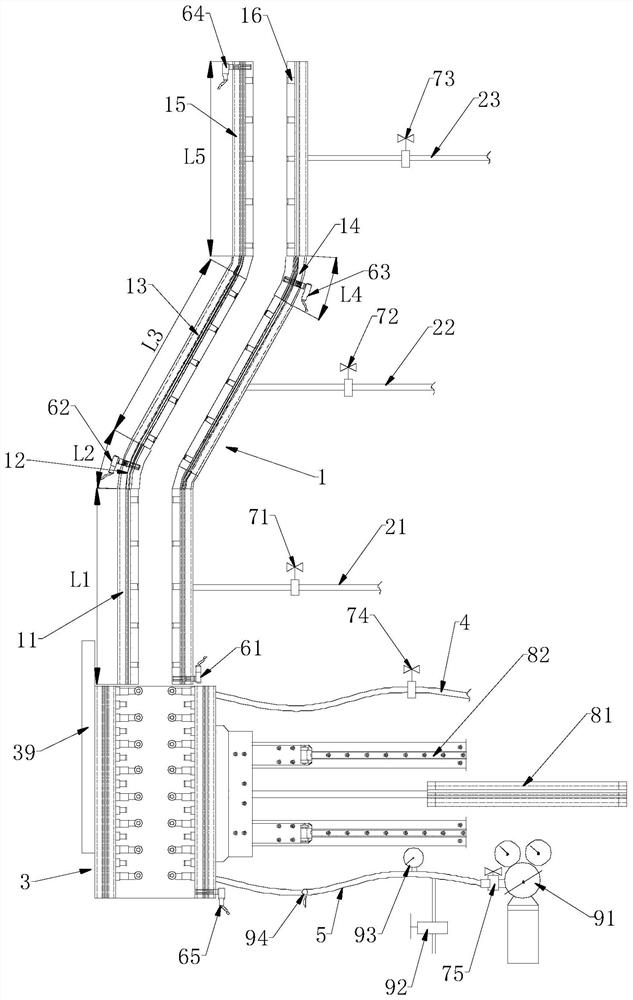

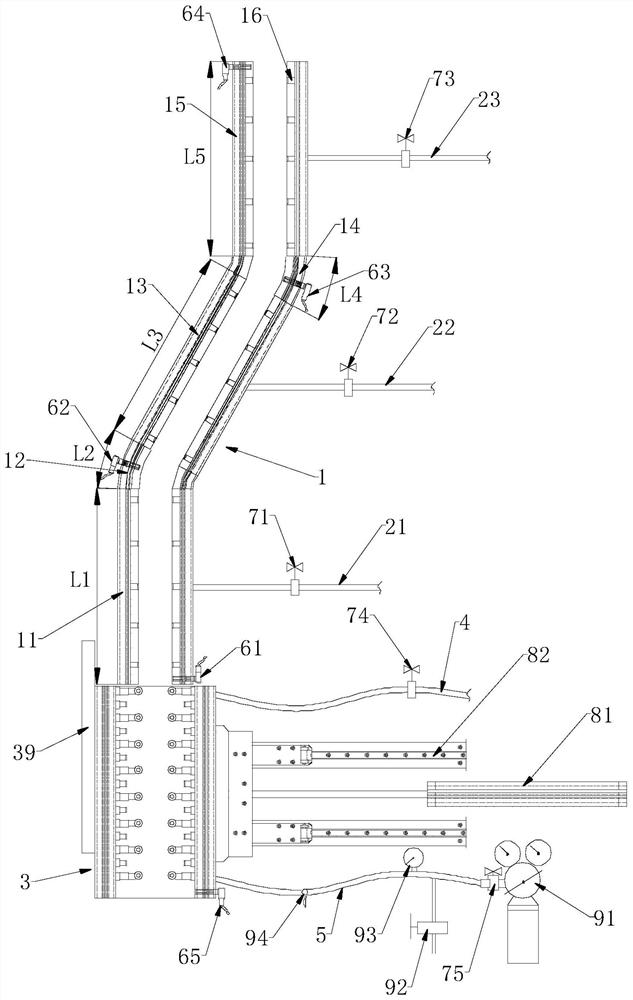

A skip unloading curved track automatic refueling equipment

ActiveCN112225036BLess water consumptionAvoid lifting accidentsElevatorsMine liftsWater sourceMarine engineering

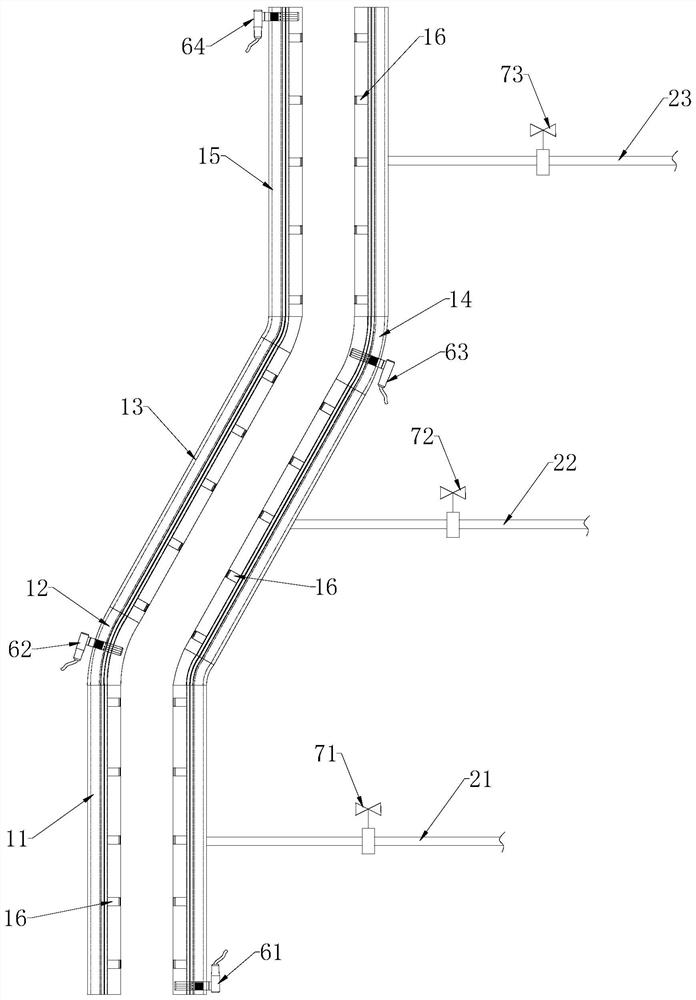

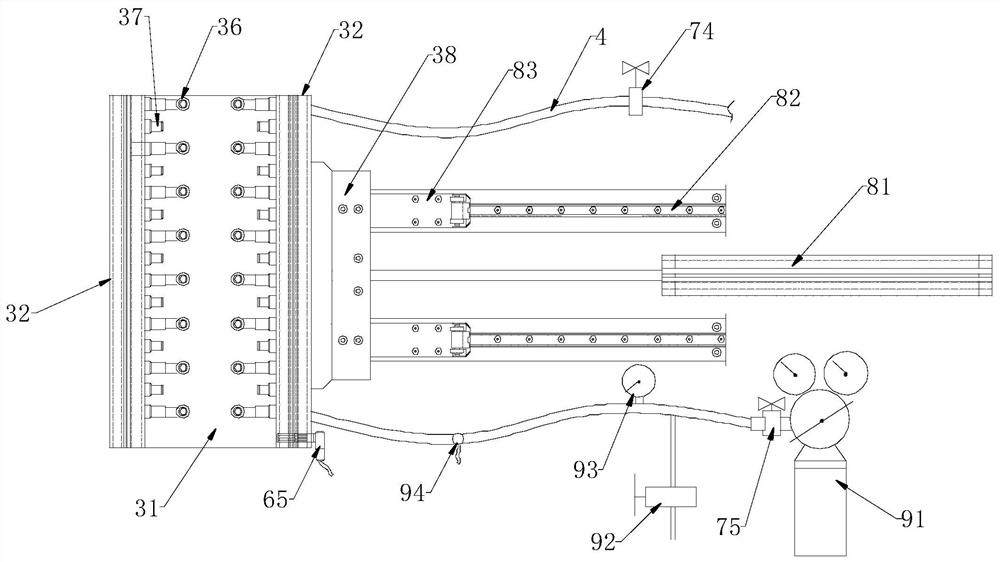

The invention provides a skip unloading curved rail automatic refueling device, which relates to the technical field of mining equipment. The skip unloading curved rail automatic refueling equipment includes curved rails, guide rails, slide rails, telescopic cylinders, the first refueling pipeline, the second refueling pipeline, the third refueling pipeline, oil source, water pipeline, water source, high pressure Gas pipeline, high pressure gas source and control unit. During the operation of the skip lifting system, the present invention removes the coal slime on the unloading wheel before refueling, the coal slime is cleaned and consumes less water. , The oil consumption for refueling and lubrication operations is small. After the unloading wheel has been running for a long time, if the attitude of the unloading wheel deviates, the lifting system can be controlled to stop in time to avoid lifting accidents caused by the unloading wheel with a deviated attitude hitting the curved track.

Owner:内蒙古上海庙矿业有限责任公司

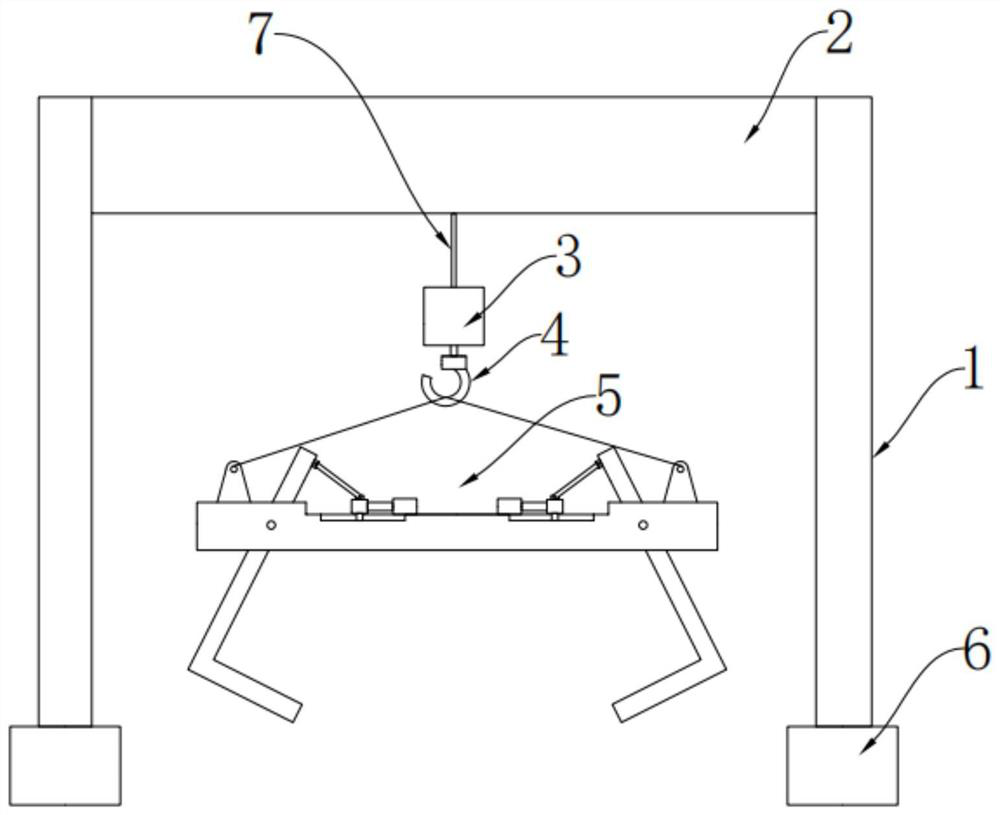

Large box girder hoisting equipment

ActiveCN112723176AAvoid Lifting AccidentsBase supporting structuresBraking devices for hoisting equipmentsStructural engineeringMechanical engineering

The invention relates to the technical field of hoisting equipment, and discloses large box girder hoisting equipment. The large box girder hoisting equipment comprises supporting legs, a supporting frame is fixedly connected to the bottom end of a steel rope, a driving rod is slidably connected to the bottom end of the supporting frame, supporting blocks are fixedly mounted at the positions, on the two sides of the driving rod, of the bottom end of the supporting frame, first sliding rods are fixedly mounted on the inner walls of the supporting blocks and the supporting frame, first moving blocks are slidably connected to the first sliding rods, driving rods are fixedly mounted at the bottom ends of the first moving blocks, second sliding rods are fixedly mounted in first grooves, supporting plates are slidably connected to the second sliding rods, first contacts are fixedly mounted on the supporting plates, second contacts corresponding to the first contacts are fixedly mounted at the bottom ends of the first grooves, and an alarm is fixedly mounted on the outer side wall of the supporting frame. By arranging an alarm mechanism, an operator is reminded, hoisting operation is stopped in time, and therefore, larger hoisting accidents are avoided.

Owner:山东神州钢结构工程有限公司

Method and system for real-time generation of hoisting scheme in on-board controller of jib crane

InactiveCN104528540BEasy to collectEasy to integrateLoad-engaging elementsCranesIn vehicleControl engineering

The invention discloses a real-time generation method of a hoisting scheme of a jib crane in a vehicle controller and a method thereof, according to the method, an autonomous detection learning by the crane jib is employed, profile and position information of an obstacle in an operation area can be accurately acquired; source position and target position information of an hoisting object which are acquired by the crane jib are employed, according to an environment data table in the hoisting operation area, by combining the a hoisting performance chart of the crane, the hoisting scheme comprising parameters such as crane jib length, rotation direction and a lower elevation angle of each rotation angle enables real-time generation in a vehicle controller, and the generated hoisting scheme is optimized and simulated. The practical hoisting application shows that the system can accurately acquire the environment data in the operation area and can generate the hoisting scheme through optimization.

Owner:CHANGAN UNIV

Method and system for controlling crane hoisting relative to boom follow-up

ActiveCN103466453BCrash freeRealize aerial panningLoad-engaging elementsAutomatic controlEngineering

Owner:XUZHOU HEAVY MASCH CO LTD

A container truck anti-lifting method and system based on machine vision tracking

ActiveCN106986272BAvoid lifting accidentsGuaranteed accuracyCharacter and pattern recognitionCranesMachine visionTurning frames

The invention discloses an anti-lifting system for container trucks based on machine vision tracking, which includes a tire crane, a camera, a container truck, a container, a video alarm machine, and control equipment in a central control room. Flush with the frame of the container truck, the field of view of the camera is perpendicular to the direction of travel of the container truck; the camera inputs the video images obtained by tracking to the video alarm machine, and the video alarm machine adopts a tracking algorithm based on fast Fourier transform online learning to obtain The video image is processed, and when it is determined that the container truck is hoisted, an alarm signal is sent to the control equipment in the central control room. The system can automatically detect whether the container is separated from the container truck, so as to avoid human error from lifting the container container truck by mistake, and realize the safety pre-control of the container yard operation.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

A kind of skip unloading curved rail automatic refueling method

ActiveCN112225037BLess water consumptionAvoid lifting accidentsElevatorsMine liftsControl theoryMechanical engineering

The invention provides a skip unloading curved track automatic refueling method, which relates to the technical field of mining equipment. The skip unloading curved rail automatic refueling method uses skip unloading curved rail automatic refueling equipment to sequentially perform coal slime removal and segmented automatic refueling and lubrication operations. During the operation of the skip lifting system, the present invention removes the coal slime on the unloading wheel before refueling. The coal slime is cleaned and consumes less water. The lubricating operation consumes less oil. After the unloading wheel has been running for a long time, if the attitude of the unloading wheel deviates, the lifting system can be controlled to stop in time to avoid lifting accidents caused by the unloading wheel with a deviated attitude hitting the curved track.

Owner:内蒙古上海庙矿业有限责任公司

An intelligent tower crane system and its working method

ActiveCN106927368BWith self-learning functionHigh degree of intelligenceCranesSafety gearMaterial typeWorking set

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

Method for automatically detecting and monitoring vehicle and plate separation during hoisting of container

PendingCN112061993AReduce labor intensityAvoid lifting accidentsSafety gearVideo monitoringSimulation

The invention provides a method for automatically detecting and monitoring vehicle and plate separation during hoisting of a container. The method provided by the invention can be used for monitoring,acquiring and processing video images of a storage yard operation area in real time, monitoring key parts of equipment, implementing real-time identification, analysis and judgment on various features of the image pictures according to various prior conditions of a monitored target and equipment action association, and finally implementing early warning and alarming or feeding back various parameter data in real time so as to eliminate potential safety hazards which can be ignored when a driver operates crane equipment. Different from a traditional detection means, the method provided by theinvention can output a traditional video monitoring picture for a driver to check at any time, has an active detection, recognition and judgment function as well, can effectively alleviate the labor intensity of the driver, provides guarantee for safe operation of the equipment, prevents occurrence of various accidents, and can effectively prevent the accident that a container truck is hoisted dueto manual misoperation.

Owner:NINGBO DAXIE CHINA MERCHANTS INT TERMINAL CO LTD

Skip bucket unloading curved rail automatic oiling equipment

ActiveCN112225036ALess water consumptionAvoid lifting accidentsElevatorsMine liftsMarine engineeringStructural engineering

The invention provides skip bucket unloading curved rail automatic oiling equipment, and relates to the technical field of mining equipment. The skip bucket unloading curved rail automatic oiling equipment comprises a curved rail, a guide rail, sliding rails, a telescopic cylinder, a first oiling pipeline, a second oiling pipeline, a third oiling pipeline, an oil source, a water conveying pipeline, a water source, a high-pressure air pipeline, a high-pressure air source and a control unit. In the operation process of a skip bucket lifting system, coal slime adhering to an unloading wheel is cleared away before oiling, the coal slime is cleared away thoroughly, the water consumption is low, segmented automatic oiling lubrication operation is conducted on the unloading wheel and the curved rail after the coal slime is cleared away, the oil consumption consumed by oiling lubrication operation is low, and after the unloading wheel operates for a long time, if the posture of the unloading wheel deviates, the lifting system can be controlled to stop in time, and lifting accidents caused by the fact that an unloading wheel with deviated postures impacts a curved rail are avoided.

Owner:内蒙古上海庙矿业有限责任公司

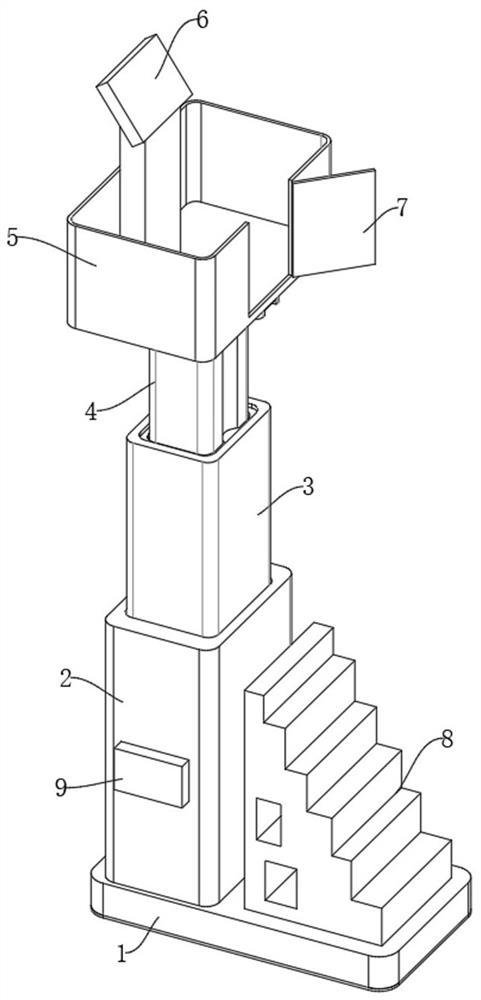

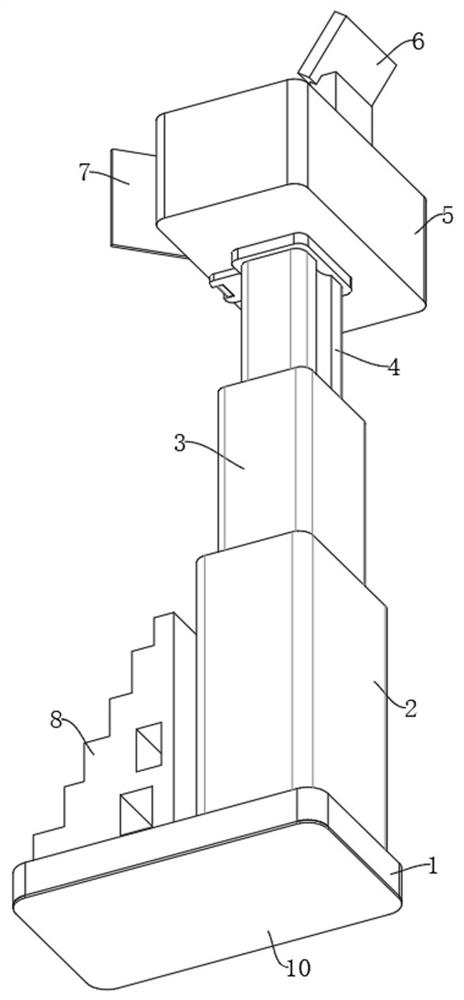

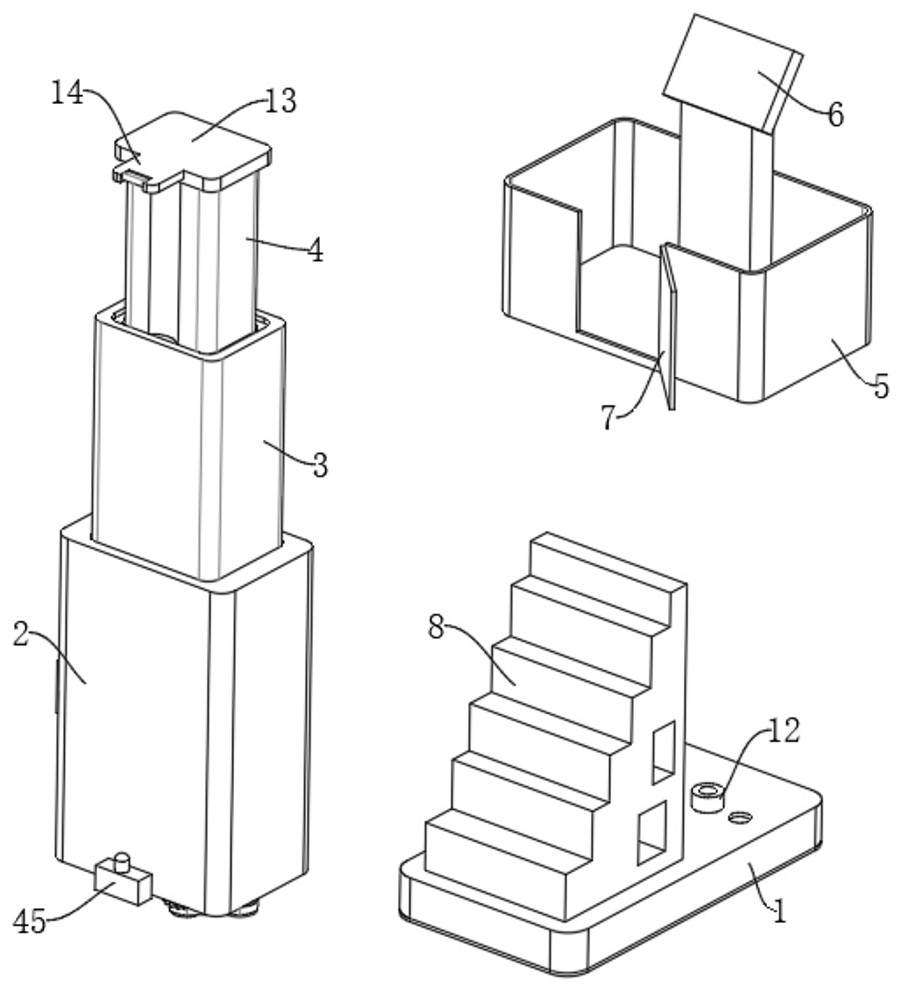

Rigging placing rack for large equipment hoisting

The invention discloses a rigging placing rack for large equipment hoisting. The rigging placing rack for large equipment hoisting comprises a placing rack body. The placing rack body comprises a first step layer, wherein a plurality of storage boxes are connected to the first step layer; a nameplate is connected to the front side of the storage boxes; a second step layer is connected to the upperedge of a back plate of the first step layer; a shackle storage box is connected to the second step layer; a partition plate is arranged in the shackle storage box; a third step layer is connected tothe upper edge of a back plate of the second step layer; a rotary disc is connected to the third step layer; a winding column is connected to the upper side of the rotary disc; and a back baffle plate is connected to the back end of the third step layer. The rigging placing rack for large equipment hoisting disclosed by the invention has the beneficial effects that the rigging placing rack for large equipment hoisting is divided into the first step layer, the second step layer and the third step layer, so that different rigging accessories can be stored in a classified manner; the storage boxes are fixedly connected to the first step layer, and lifting lugs for the rigging can be placed therein; and the storage boxes are connected to the first step layer, so that the different lifting lugs can be finely classified secondarily, and the name plate is connected to the front side of the storage boxes.

Owner:江苏华滋能源工程有限公司

A kind of batch processing equipment and batch processing technology of steel bar straight thread

ActiveCN104786107BSimple structureReasonable designOther manufacturing equipments/toolsMetal working apparatusMachineRebar

The invention discloses a batch machining device and technology for reinforcing-steel-bar straight threads. The machining device comprises a left reinforcing-steel-bar straight thread machining device body, a right reinforcing-steel-bar straight thread machining device body, a left protective shed, a right protective shed and an automatic conveying platform for conveying to-be-machined reinforcing steel bars. The left reinforcing-steel-bar straight thread machining device body and the right reinforcing-steel-bar straight thread machining device body are used for machining the two ends of the to-be-machined reinforcing steel bars respectively. The automatic conveying platform is located between the two reinforcing-steel-bar straight thread machining device bodies. Each reinforcing-steel-bar straight thread machining device body comprises a reinforcing-steel-bar cutting device for cutting the to-be-machined reinforcing steel bars and a straight-thread threading machine for carrying out threading on the to-be-machined reinforcing steel bars. The automatic conveying platform comprises a reinforcing-steel-bar containing frame, a first transverse conveying frame, a threading machining frame and a reinforcing-steel-bar longitudinal movement mechanism. The machining technology includes the steps of 1, reinforcing-steel-bar lifting; 2, reinforcing-steel-bar cutting; 3, reinforcing-steel-bar secondary forward moving; 4, reinforcing-steel-bar threading; 5, reinforcing-steel-bar third-time forward moving. The machining device and technology are reasonable in design, easy and convenient to machine, manufacture, use and operate and good in use effect; the reinforcing-steel-bar straight thread batch machining process can be easily, conveniently and rapidly completed.

Owner:陕西建工华鑫鼎业工程装备有限公司

Gantry crane brake swing early warning system and method for subway shield tunnel segment hoisting

ActiveCN112209251AReal-time hoisting trajectory dataReduce the impactSafety gearSimulationData acquisition

The invention belongs to the field of hoisting operation safety control, and discloses a gantry crane brake swing early warning system and method for subway shield tunnel segment hoisting. The early warning system comprises a hoisting data acquisition module, a data analysis and prediction module and a segment swing early warning module, wherein the hoisting data acquisition module is used for acquiring spatial information of subway segments in the underground hoisting process in real time; the data analysis and prediction module reasonably predicts the future hoisting track of the subway segments through the acquired data; and the segment swing early warning module calculates and judges the possible swing size of the subway segments according to the hoisting prediction track and outputs acorresponding early warning signal. Hoisting track prediction is performed based on the composite model of data driving and motion analysis so that early warning control can be performed on unsafe swing of the subway segments in the hoisting deceleration brake stage through the reasonable and accurate prediction track, safety control of the underground hoisting process of the subway segments canbe optimized and the subway segment hoisting accident can be actively avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

A lifting mechanism for a lift

ActiveCN113845067BImprove stabilityReduce manufacturing production costsGearingLifting devicesElectric machineryMotor power

The invention provides a lifting mechanism for elevators, belonging to the technical field of elevator equipment, which includes a hollow base, a ladder frame is fixedly connected to the top of the hollow base, and a sealing plate is fixedly connected to the bottom of the hollow base; a first telescopic square tube, a first The telescopic square tube is fixedly connected to the top of the hollow base, and the top of the first telescopic square tube is provided with a second jack; the telescopic platform, the telescopic platform is set in the first telescopic square tube, and the top of the telescopic platform is fixedly connected to the limit sleeve, the lifting platform The end face is connected with a safety door through the rotation of the hinge shaft. Both the first telescopic assembly and the second telescopic assembly use a screw as the power assembly during the lifting process. Through the self-locking property of the screw, it replaces the traditional hydraulic pressure or cable, reducing manufacturing production. Expenses, maintenance costs, while improving popularization and application, avoid lifting accidents caused by pressure leakage or motor power failure during the lifting process, and improve the stability of the lift.

Owner:徐州简度智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com