An anti-fall skip tail rope suspension device and tail rope anti-fall method

A suspension device and anti-falling technology, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problems of tail rope falling and connecting parts loose, so as to prevent the tail rope from falling and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

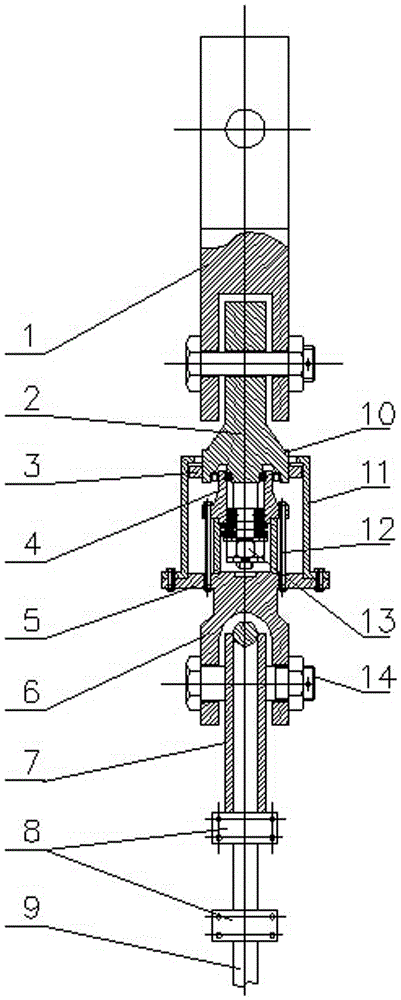

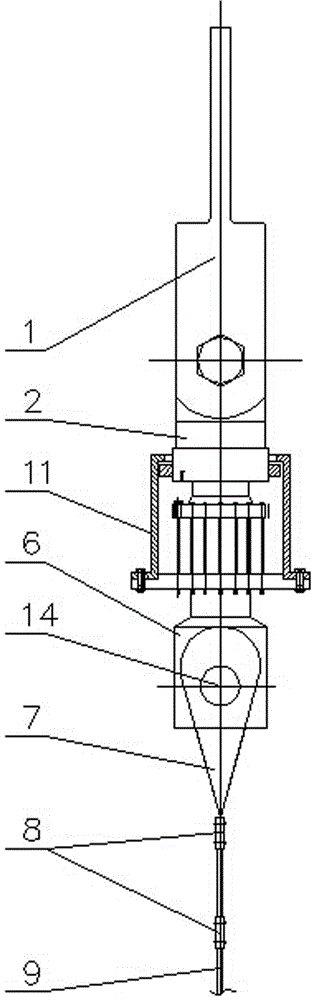

[0016] Example 1 as figure 1 , 2 Shown: a skip tail rope suspension device for anti-falling, including a suspender 2 hinged with a connecting rod 1, the suspender 2 is rotatably connected to a bearing seat 4 through a bearing and a large nut 13, and the bearing seat 4 relies on a longitudinal bolt 12 and The upper plate 5 of the rotary fork 6 is connected, the rotary fork 6 is hinged with the peach ring 7 through the transverse bolt 14, and one end of the steel wire tail rope 9 passes through and circles around the groove of the peach ring 7, and is connected to the peach ring 7. Adopt rope clamp 8 fastening connection with steel wire tail rope 9 below. The bottom of the boom 2 is provided with an integrated flange 3, and the hollow steel cylinder 11 is inserted from the top of the boom 2, and the outer boss at the bottom of the hollow steel cylinder 11 is connected with the upper plate 5 of the rotating fork 6 by bolts; The inner diameter of the steel cylinder 11 is larger ...

Embodiment 2

[0017] Example 2 as figure 1 , 2 Shown: the tail rope anti-falling method of a kind of anti-falling skip tail rope suspension device described in Embodiment 1; including

[0018] ① There is a gap of 1-2 cm between the bottom surface of the inner boss at the top of the hollow steel cylinder 11 and the top surface of the flange 3. Fracture failure, when the rotating fork 6 connected with the hollow steel cylinder 11 falls together, the gap will be reduced;

[0019] ② During hoist-hauled skip hoisting operations, the safety regulations stipulate that: before daily operation, while checking the lifting equipment, the gap between the bottom surface of the inner boss at the top of the hollow steel cylinder 11 and the top surface of the boom flange 3 should also be checked , if the gap drops to less than 1 cm, the proximity switch installed for measuring the gap immediately activates the sound and light alarm, prompting a safety inspection of the skip tail rope suspension device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com