Mounting device and mounting method for steel casing of underwater drilling cast-in-place pile

A technology of bored piles and installation devices, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, and can solve the overturning damage of underwater bored pile foundations and their superstructures, and the slippage of underwater bored pile foundations. It can avoid the risks of strength softening and liquefaction catastrophe, save construction costs, and broaden the application prospects of projects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

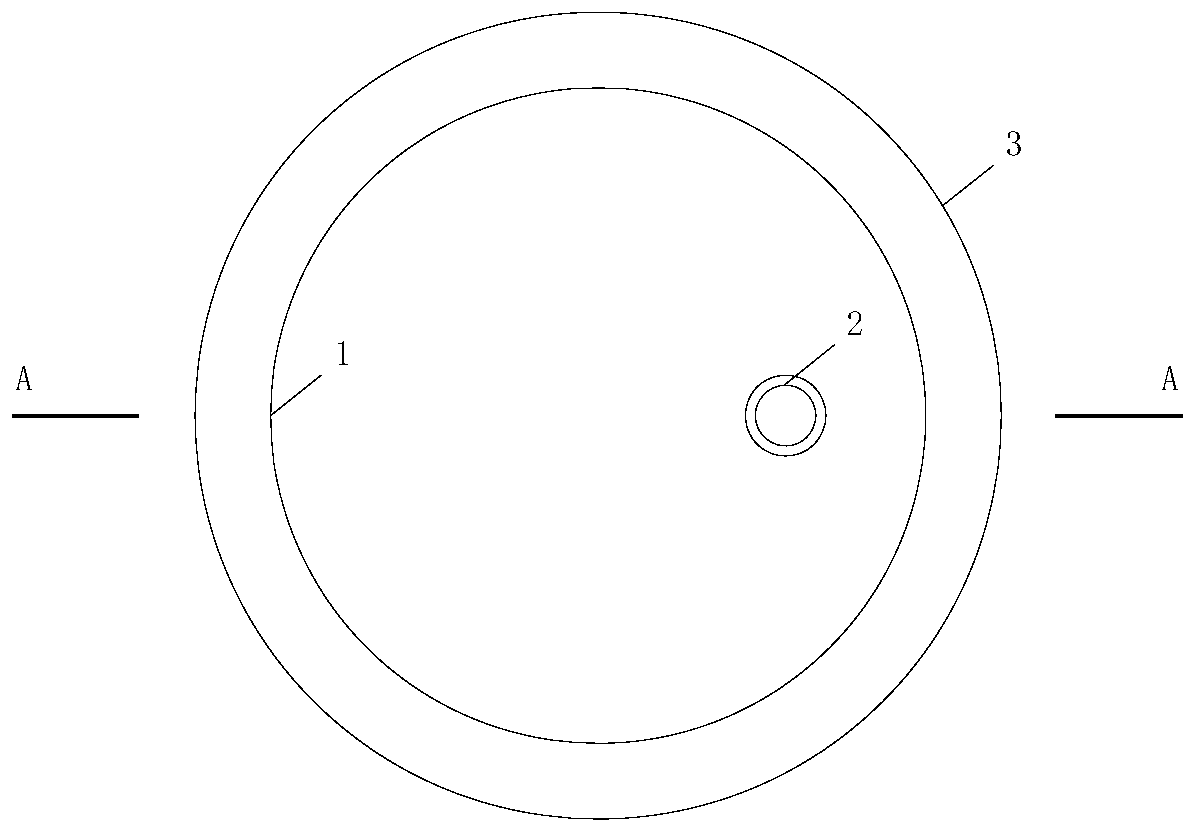

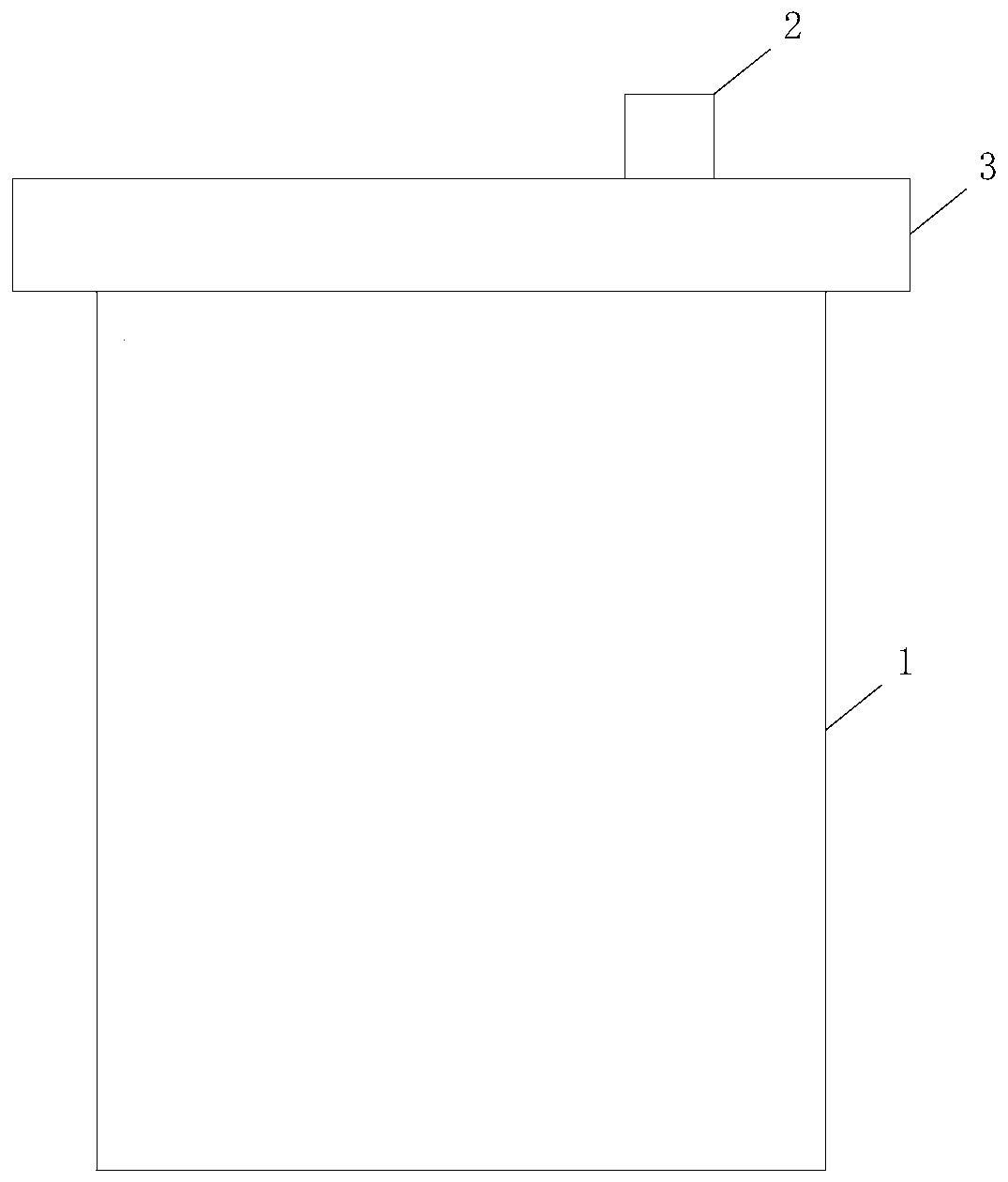

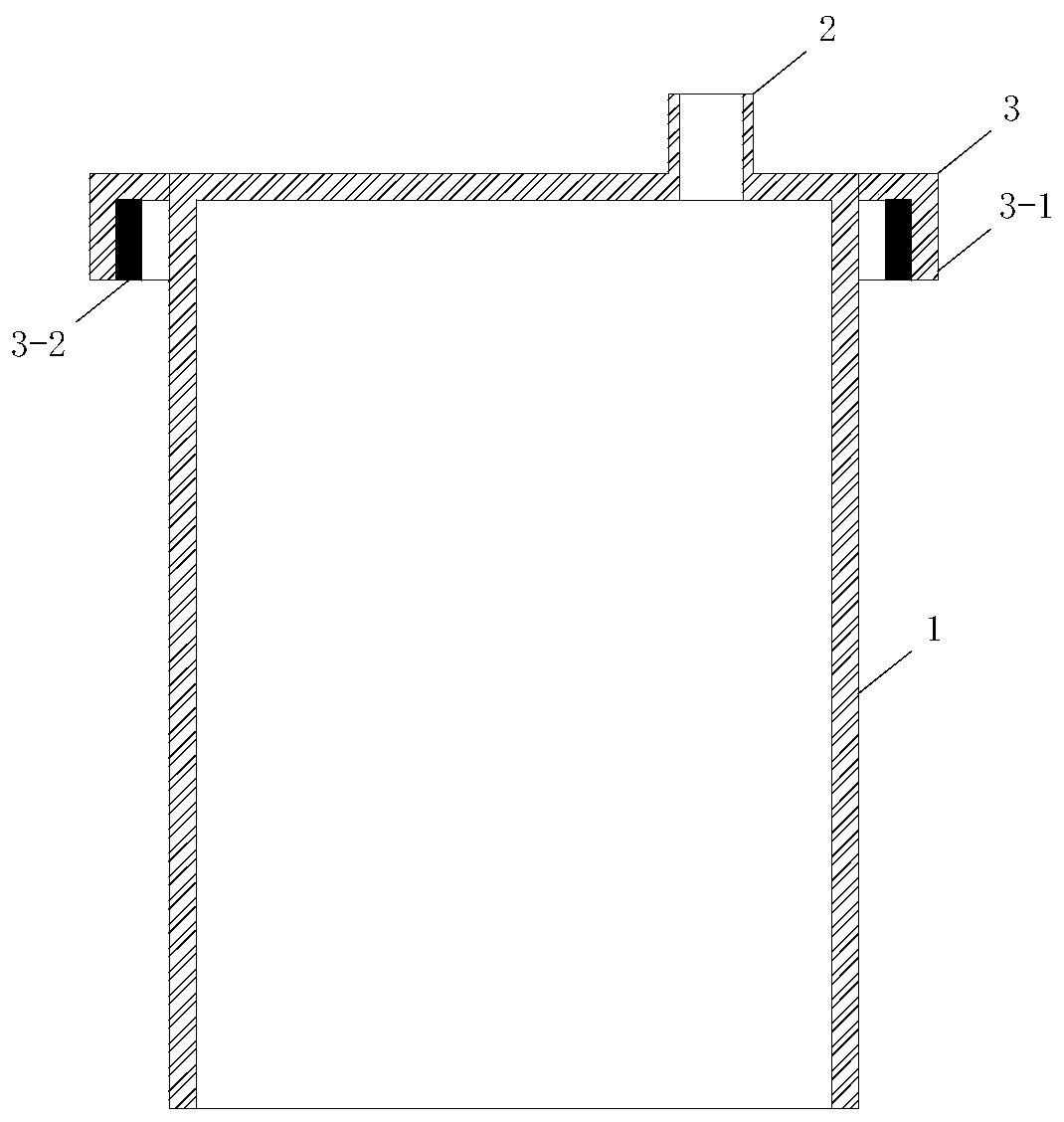

[0041] Such as Figure 1-3 As shown, a steel casing installation device for underwater drilled cast-in-place piles provided by this embodiment includes a suction barrel 1, a water passage / air hole 2 and a magnetic installation top cap 3; the suction barrel 1 is a steel barrel with an open bottom ; The water flow / air hole 2 is located at the top of the suction bucket 1 and communicates with the inside of the suction bucket 1; the magnetic installation top cap 3 is composed of an annular top hat 3-1 and an electromagnet 3-2; the magnetic installation top hat 3 The annular top cap 3-1 is fixedly connected to the top of the suction bucket 1 by circumferential welding; a number of paired and fan-shaped electromagnets 3-2 are installed on the lateral inner wall of the annular top cap 3-1;

[0042] The outer diameter of the suction barrel 1 is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com