Batch machining device and technology for reinforcing-steel-bar straight threads

A technology of batch processing and processing equipment, applied in metal processing equipment, other manufacturing equipment/tools, metal processing and other directions, can solve the problems of easy collision of steel bars in workshops, scattered processing sites, high noise, etc., to achieve convenient processing, production and installation, Reasonable structure design and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

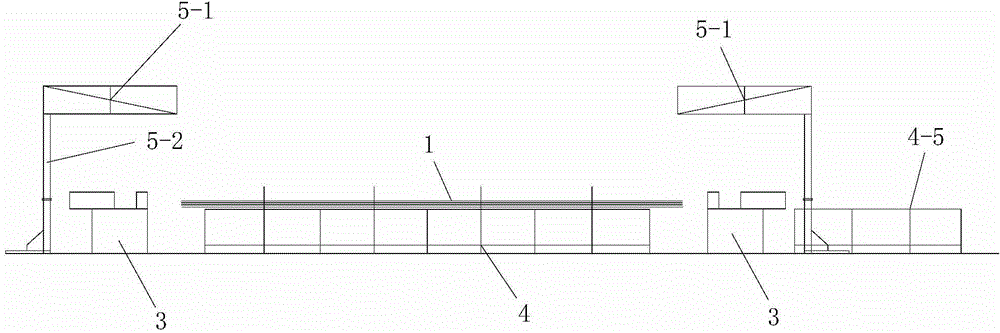

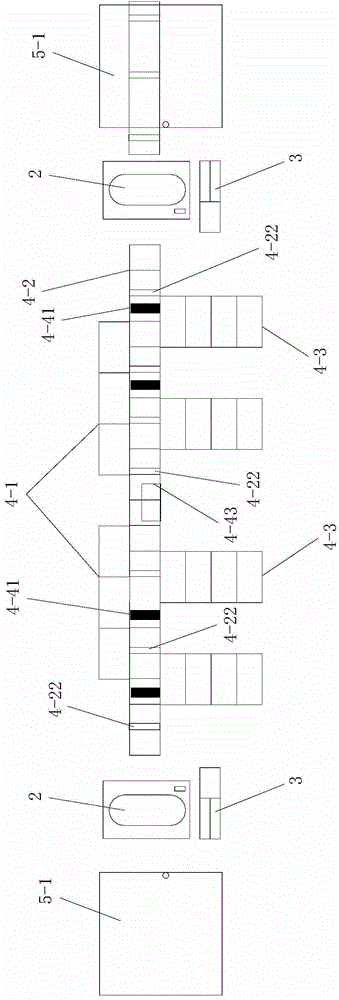

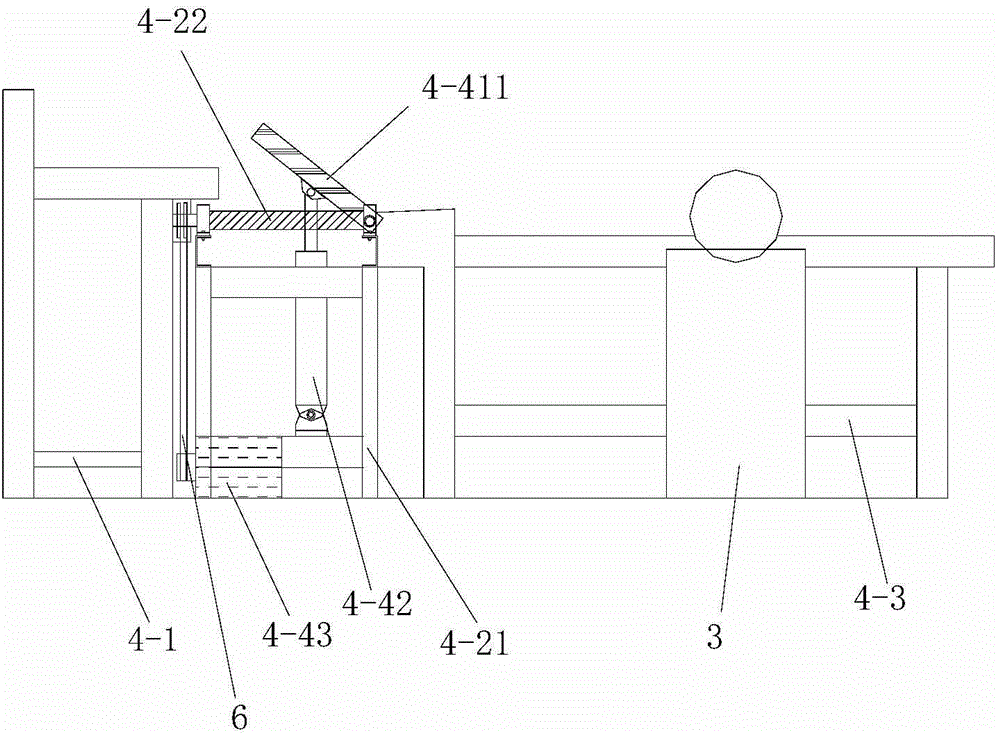

[0061] like figure 1 , figure 2 The shown batch processing equipment for steel bar straight thread includes two left and right steel bar straight thread processing equipments for processing the two ends of the steel bar 1 to be processed respectively, and two left and right steel bar straight thread processing equipments which are respectively housed above the two said steel bar straight thread processing equipments. The protective shed and the automatic transmission platform 4 for conveying the steel bar 1 to be processed, the automatic transmission platform 4 is located between the two steel bar straight thread processing equipment, and the two steel bar straight thread processing equipment are arranged symmetrically. The steel bar straight thread processing equipment includes a steel bar cutting device 2 for cutting the steel bar 1 to be processed and a straight thread threading machine 3 for threading the steel bar 1 to be processed, and the straight thread threading mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com