An intelligent tower crane system and its working method

A technology of smart towers and hooks, applied in the direction of load hanging components, safety devices, cranes, etc., can solve problems such as low security, hidden safety hazards, fatigue, etc., and achieve the effect of improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

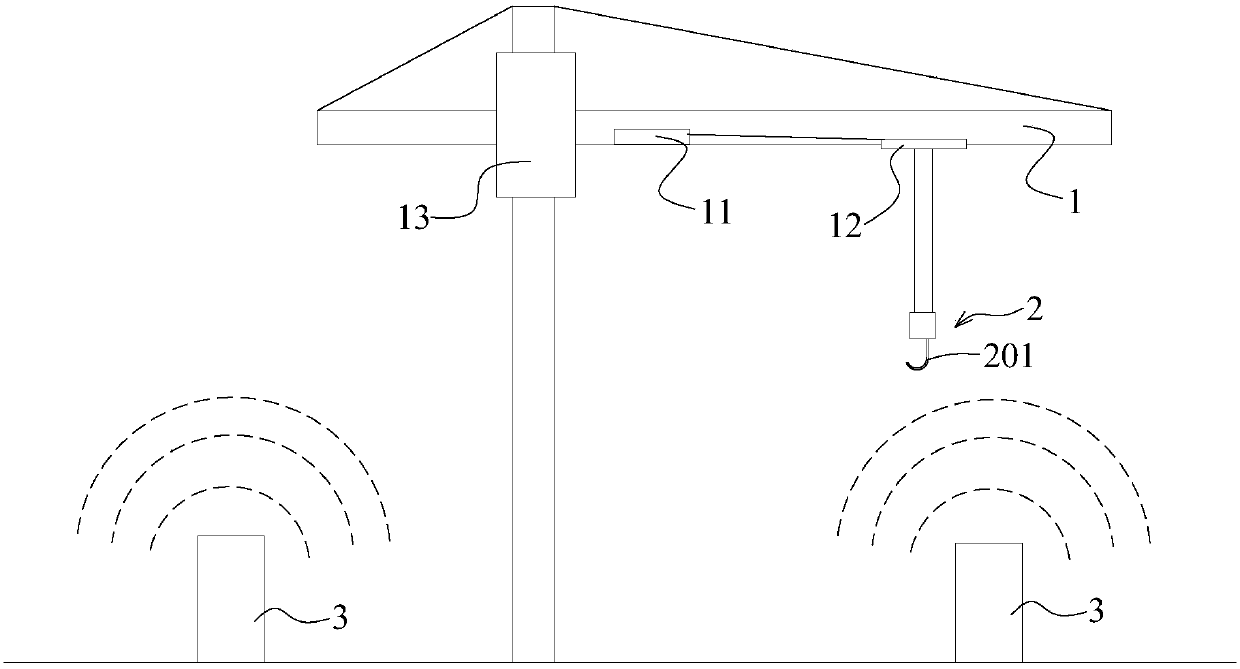

[0022] Such as figure 1 and figure 2 As shown, the present embodiment 1 provides an intelligent tower crane system, including: a boom 1, a control unit, a hook unit 2 and a beacon generator 3 located in the loading and unloading operation area; wherein the control unit is installed in the tower crane operation room 13, and is used to control the boom 1 and the hook unit 2; the hook unit 2 includes: a safety distance detection unit, an audible and visual alarm unit; and the hook unit communicates with the beacon through the safety distance detection unit When the distance is lower than the limit value, the sound and light alarm unit will give an alarm and send the alarm signal to the control unit.

[0023] The limit value includes a safe distance, and is located within the safe distance to set a dangerous range. The controller is also connected to an alarm module, and after the distance enters the safe distance range, the first-level alarm signal is issued by the sound and li...

Embodiment 2

[0036] On the basis of embodiment 1, this embodiment 2 provides a working method of the intelligent tower crane system, wherein the hook unit measures the distance in real time through the safety distance detection unit and the beacon generator, when the distance is lower than the limit value , the sound and light alarm unit will alarm and send the alarm signal to the control unit.

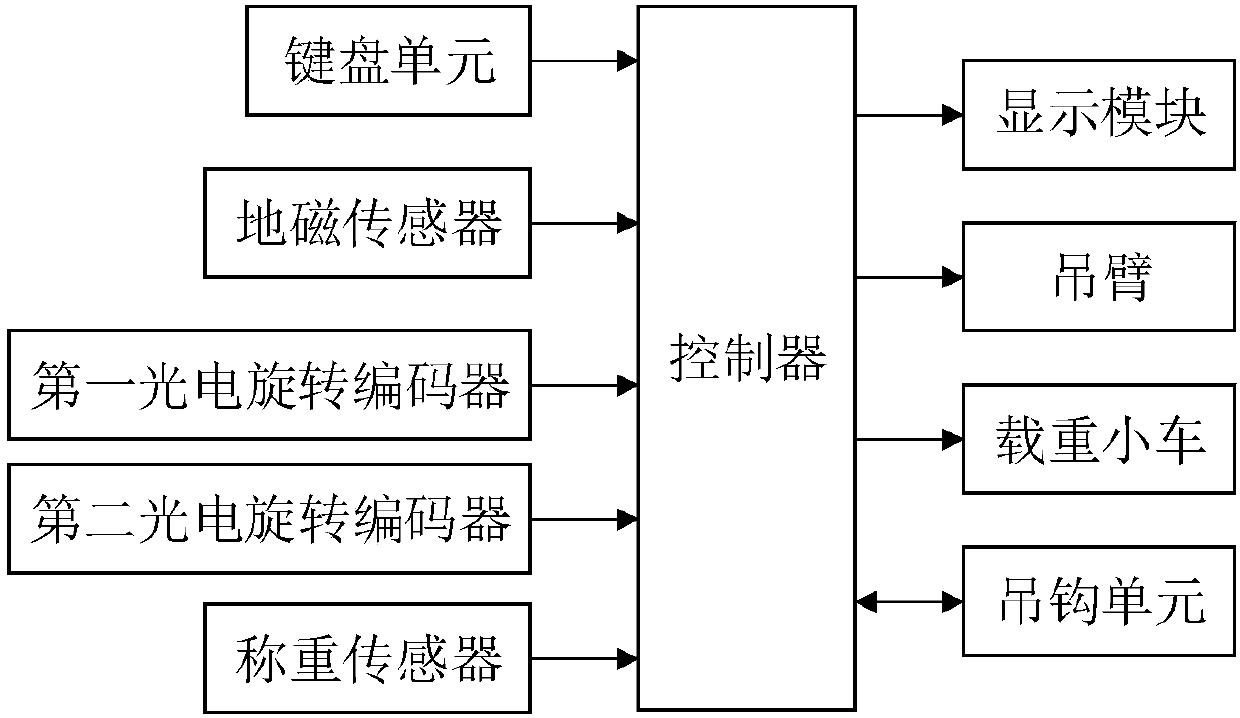

[0037] The control unit includes: a controller, a keyboard unit connected to the controller, and a manipulation action collection unit; wherein the keyboard unit is suitable for inputting lifting instructions; the manipulation movement collection unit is suitable for recording The hoisting trajectory of the main body of the tower crane and the hook unit.

[0038] The control action acquisition unit includes: a geomagnetic sensor used to detect the steering of the boom, a first photoelectric rotary encoder installed in the luffing mechanism, to collect the traveling distance of the trolley correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com