A lifting mechanism for a lift

A lifting mechanism and lift technology, which is applied in the direction of using feedback control, lifting device, electromechanical device, etc., can solve the problems of unstable use of hydraulic system or cable system, high manufacturing and production costs, and difficulty in popularization and application, so as to avoid lifting accidents. , The effect of reducing manufacturing costs and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

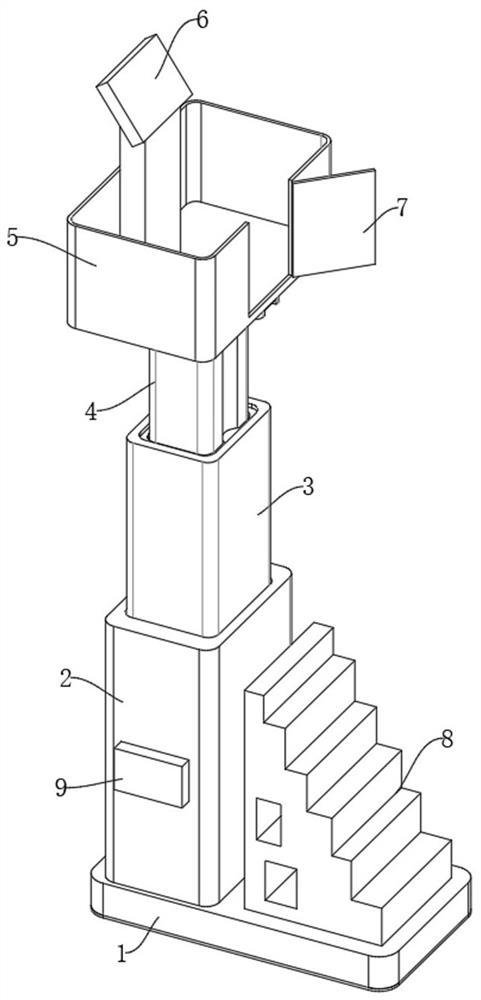

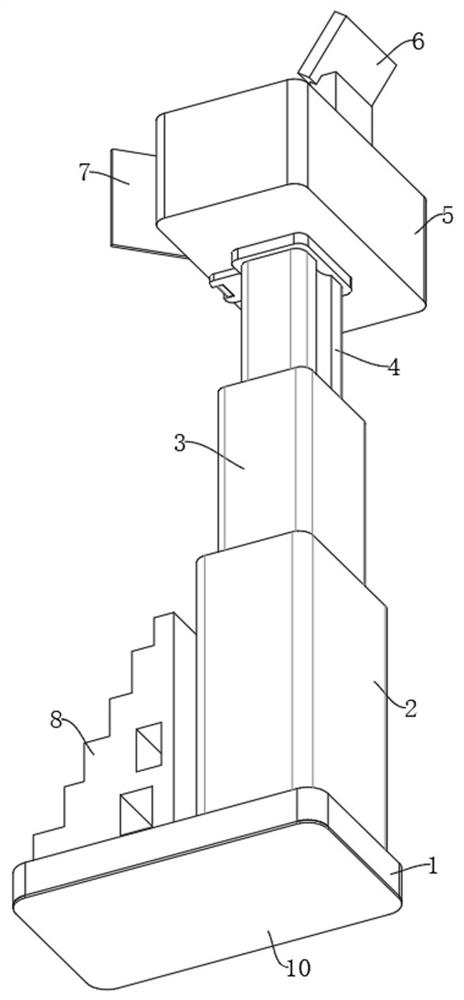

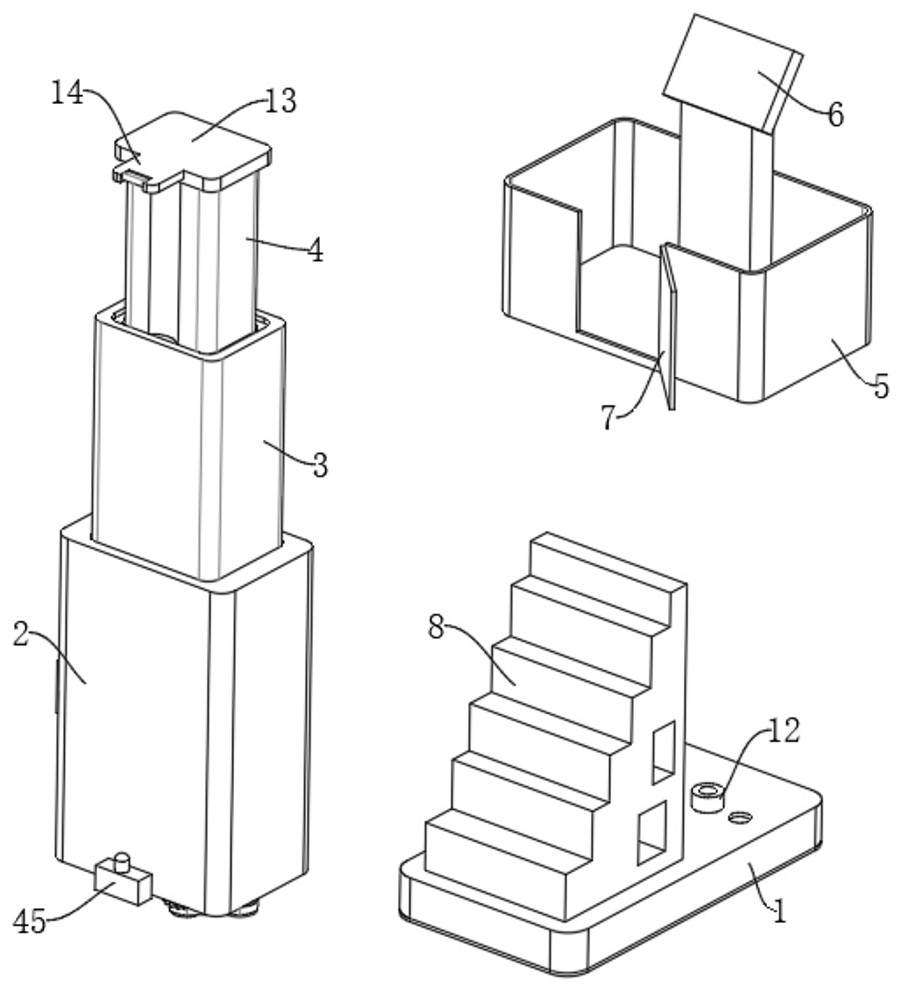

[0039] refer to Figure 1-Figure 10 , a lifting mechanism for a lift, comprising:

[0040] A hollow base 1, the top of the hollow base 1 is fixedly connected with a ladder frame 8, and the bottom of the hollow base 1 is fixedly connected with a sealing plate 10;

[0041] The first telescopic square tube 2, the first telescopic square tube 2 is fixedly connected to the top of the hollow base 1, and the top of the first telescopic square tube 2 is provided with a second socket 35;

[0042] Telescopic table 15, telescopic table 15 is arranged in the first telescopic square tube 2, the top of telescopic table 15 is fixedly connected with the limit sleeve 47, the second jack 35 is inserted with the second telescopic square pipe 3, the second telescopic square pipe The bottom of 3 is connected with the limit sleeve 47, the top of the second telescopic square tube 3 is provided with the first socket 34, the first socket 34 is inserted with the third telescopic square tube 4, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com