Support system, assembly-type laminated frame column and column bottom module erecting method

A support system and assembled technology, applied in the direction of pillars, columns, pier columns, etc., can solve the problems of affecting the appearance quality of laminated frame columns, high cost, and unreliable node connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

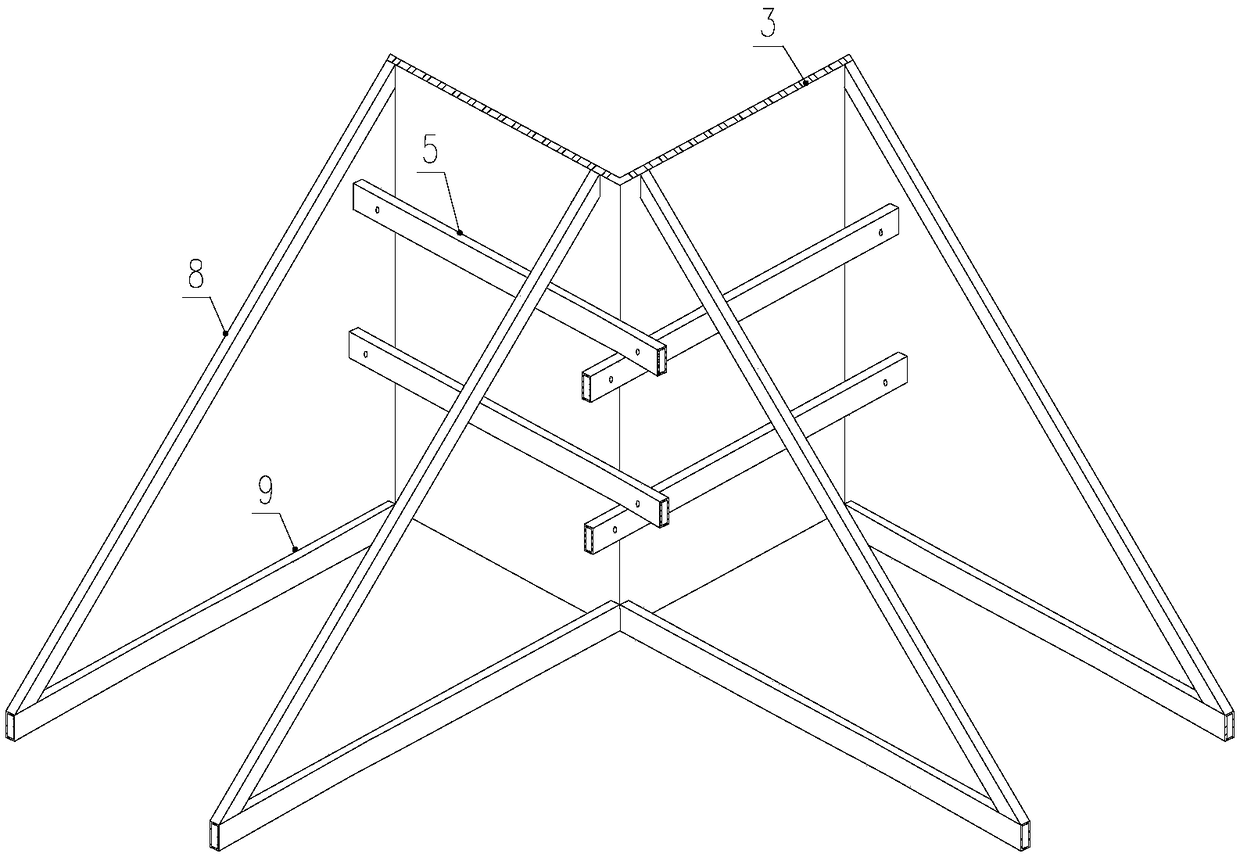

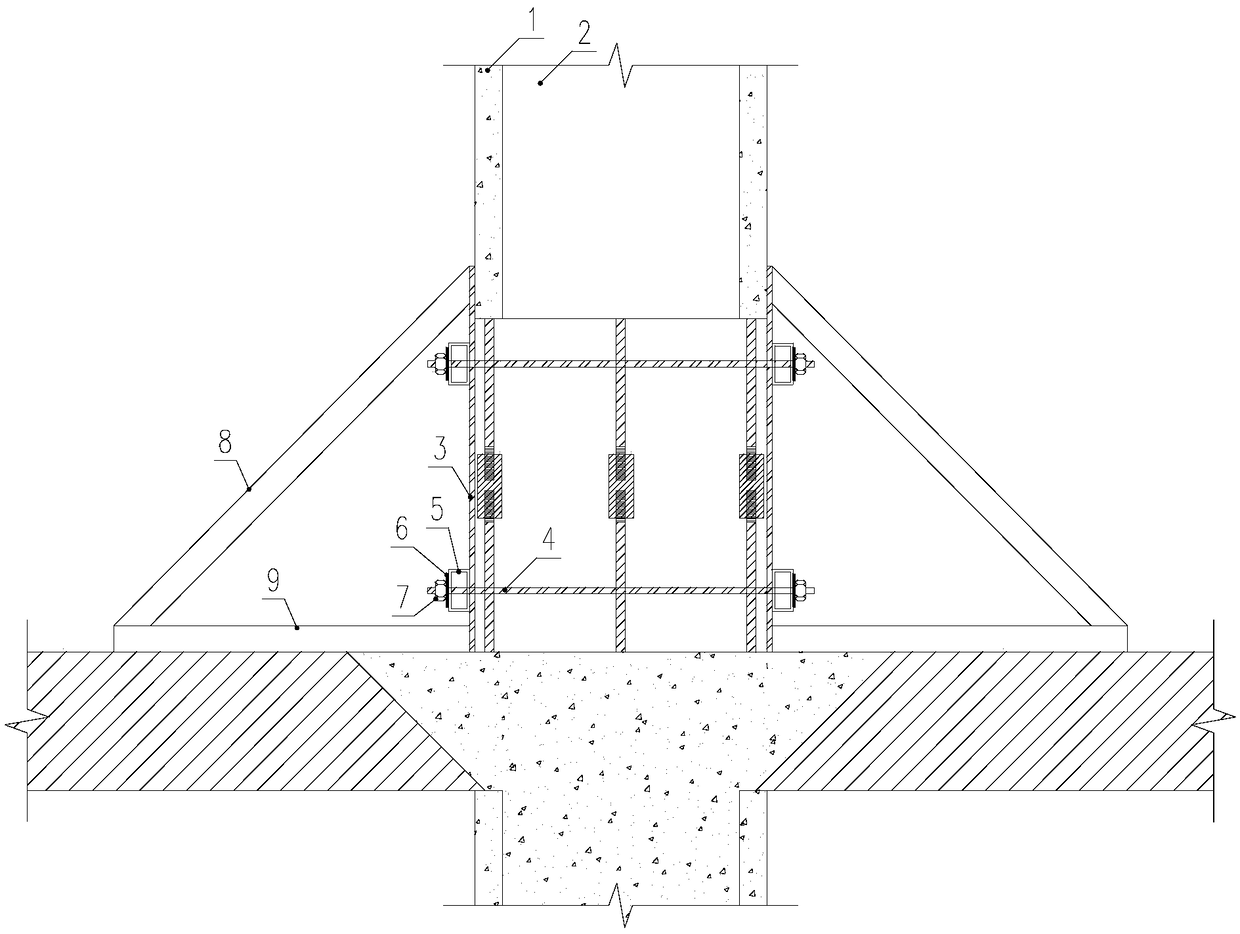

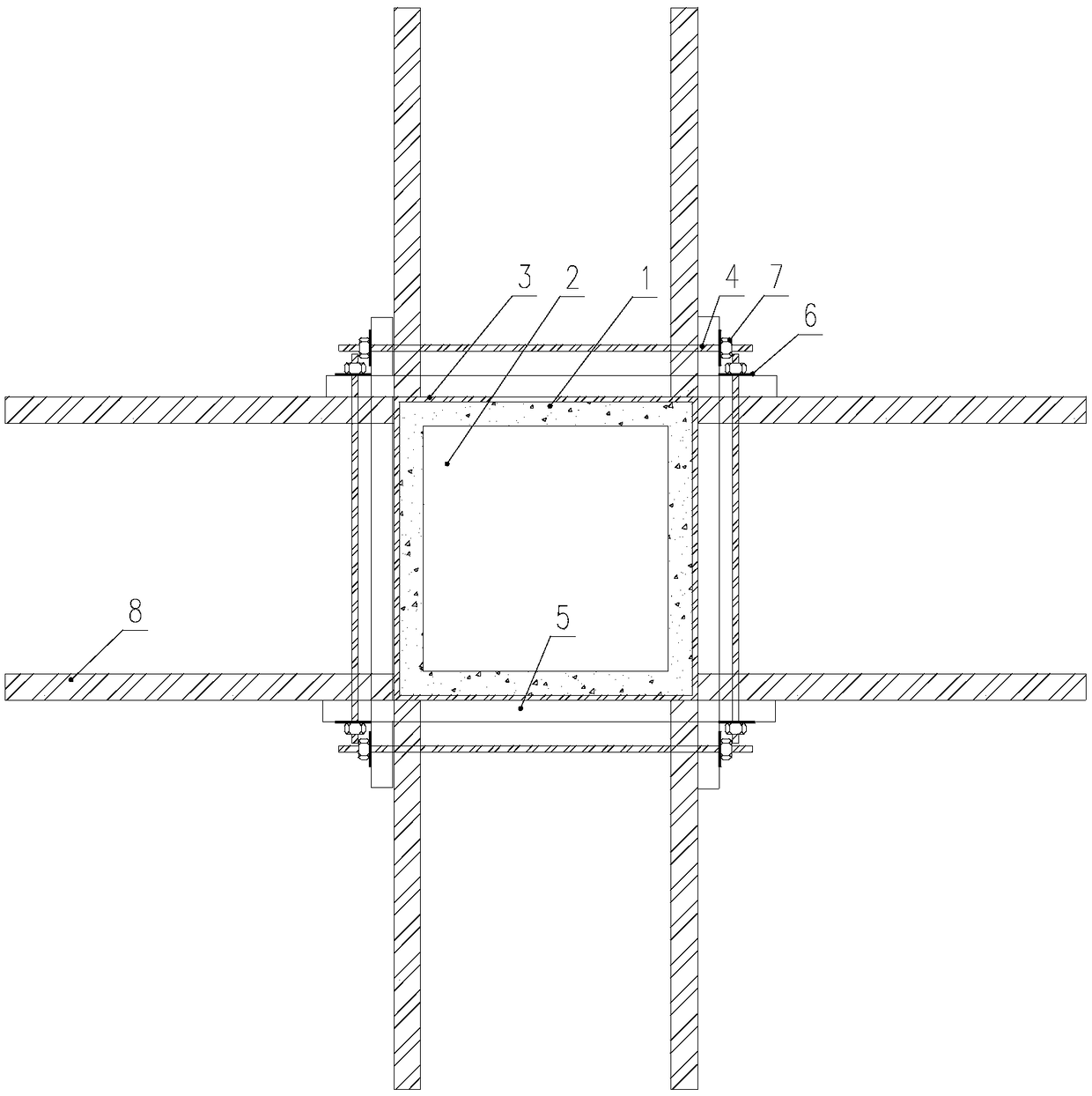

[0042] An embodiment of the present invention provides a support system, the support system includes four support units, and the four support units surround the bottom of the prefabricated laminated column;

[0043] Each of the supporting units includes a steel formwork 3, a square steel pipe horizontal sub-keel 5, and an L-shaped support assembly A; wherein the steel formwork 3 is set in a vertical state; the square steel pipe horizontal sub-keel 5 is arranged along the horizontal Fixedly connected on the surface of the steel formwork 3; the L-shaped support assembly A is in the shape of "∠", the upper end of the right side of the L-shaped support assembly A is connected to the top of the steel formwork 3, and the L-shaped support assembly A The lower end on the right side of the L-shaped support assembly A is correspondingly connected to the bottom of the steel formwork 3, and the bottom edge of the L-shaped support assembly A is connected to the ground.

[0044] Analysis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com