A non-woven fabric production thermosynthesis equipment

A thermal synthesis and non-woven fabric technology, which is applied in the fields of mechanical equipment, non-woven fabrics, textiles and papermaking, etc., can solve the problem of poor quality of forming after flattening treatment, decrease in the appearance quality of bonded non-woven fabrics, and non-woven fabrics. It is prone to problems such as large deformation, so as to achieve the effect of increasing the solidification speed, reducing resistance and avoiding external expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

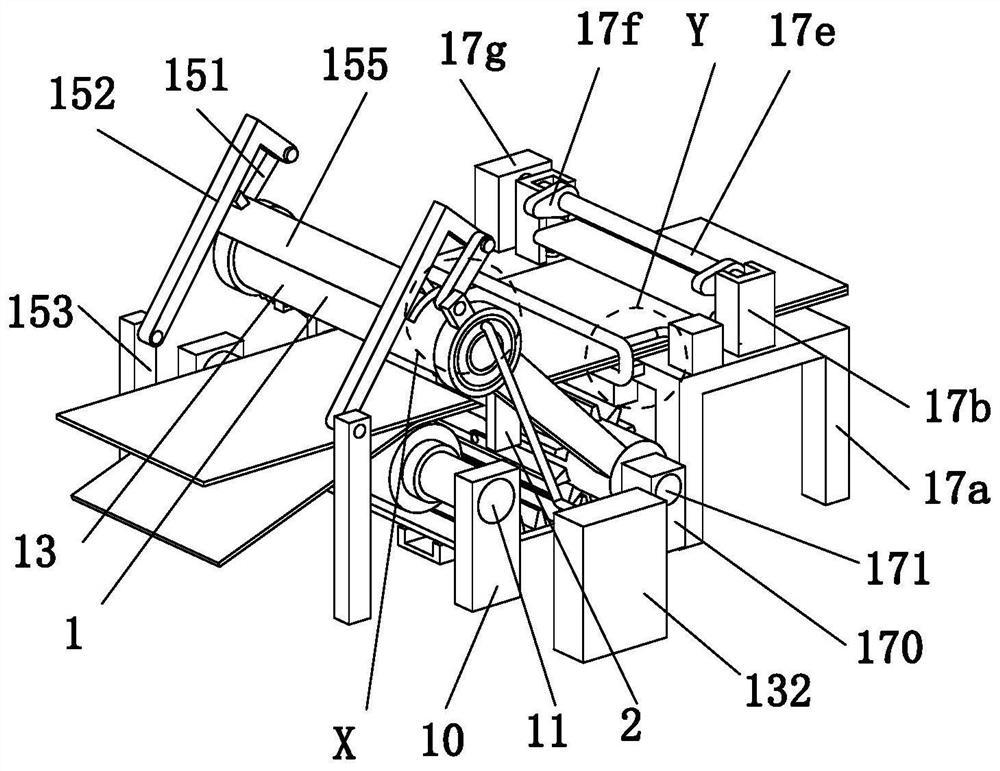

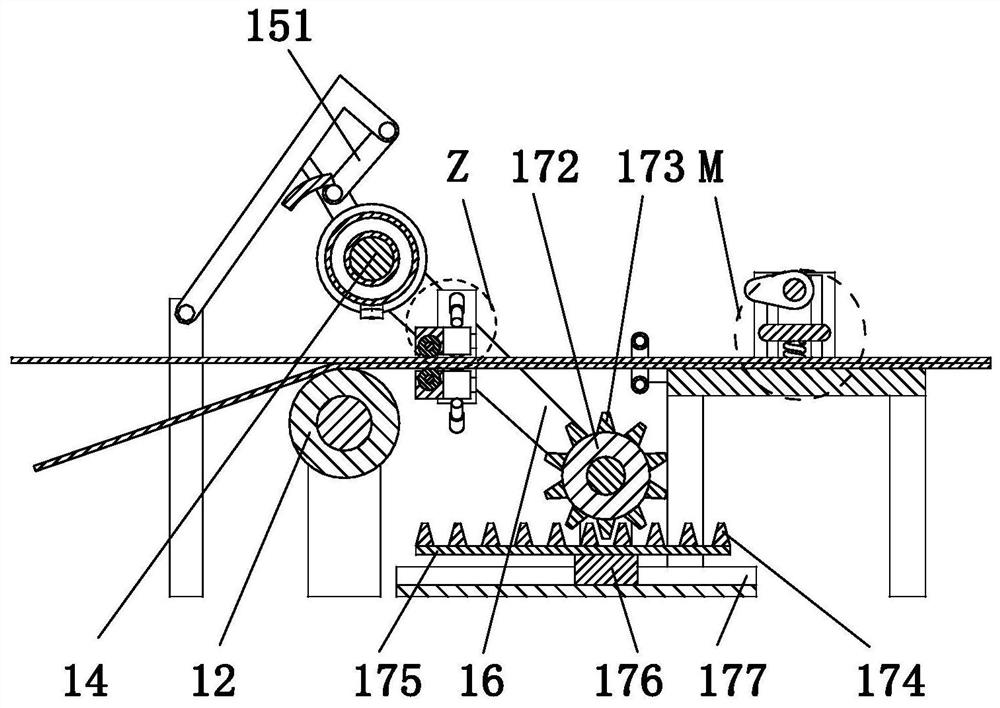

[0033] Such as Figure 1 to Figure 9 As shown, a kind of thermal synthesis type equipment for non-woven fabric production includes a thermal bonding mechanism 1 and an auxiliary pressure mechanism 2. The lower end of the thermal bonding mechanism 1 is installed on the existing working ground, and the upper end of the thermal bonding mechanism 1 is provided with Auxiliary pressure mechanism 2.

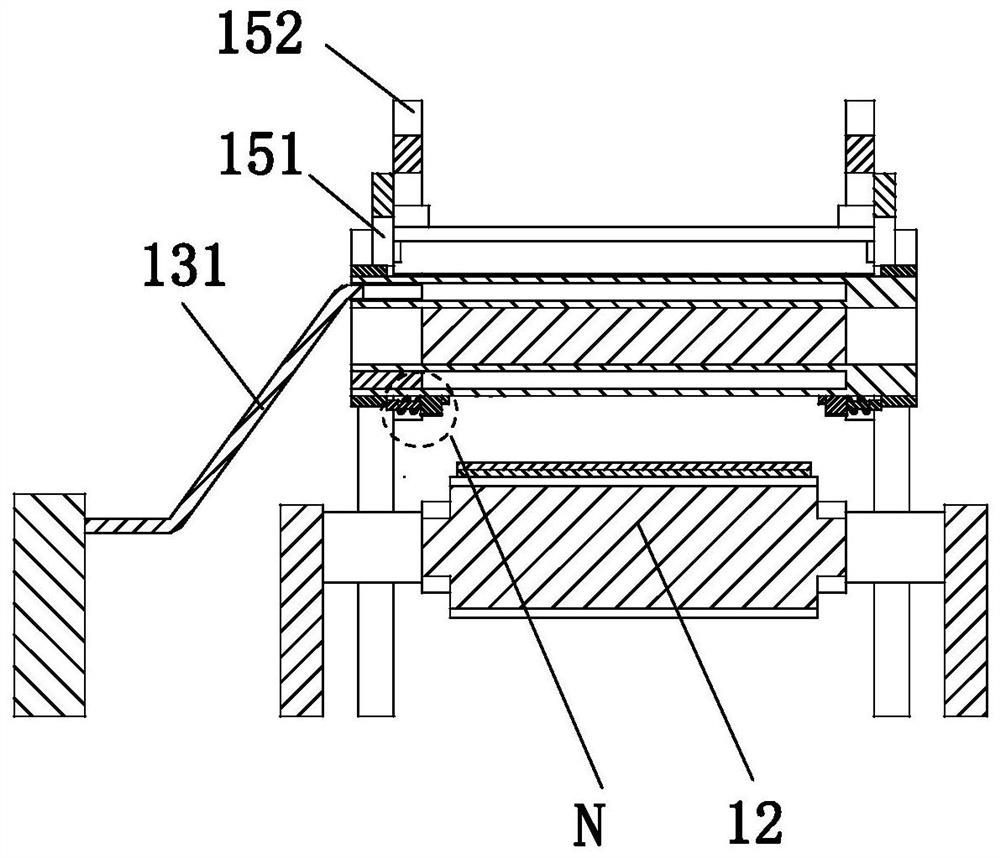

[0034] The thermal bonding mechanism 1 includes a No. 1 vertical plate 10, a connecting shaft 11, a rotating cylinder 12, a steel shaft 13, an electric heating tube 14, a ring sleeve 15, a connecting rod 16 and a transmission group 17. The No. 1 vertical plate 10 is symmetrical front and rear Installed on the existing working ground, a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com