Structural separation seam applied to aluminum form and construction process thereof

A technology of aluminum formwork and seam panels, applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

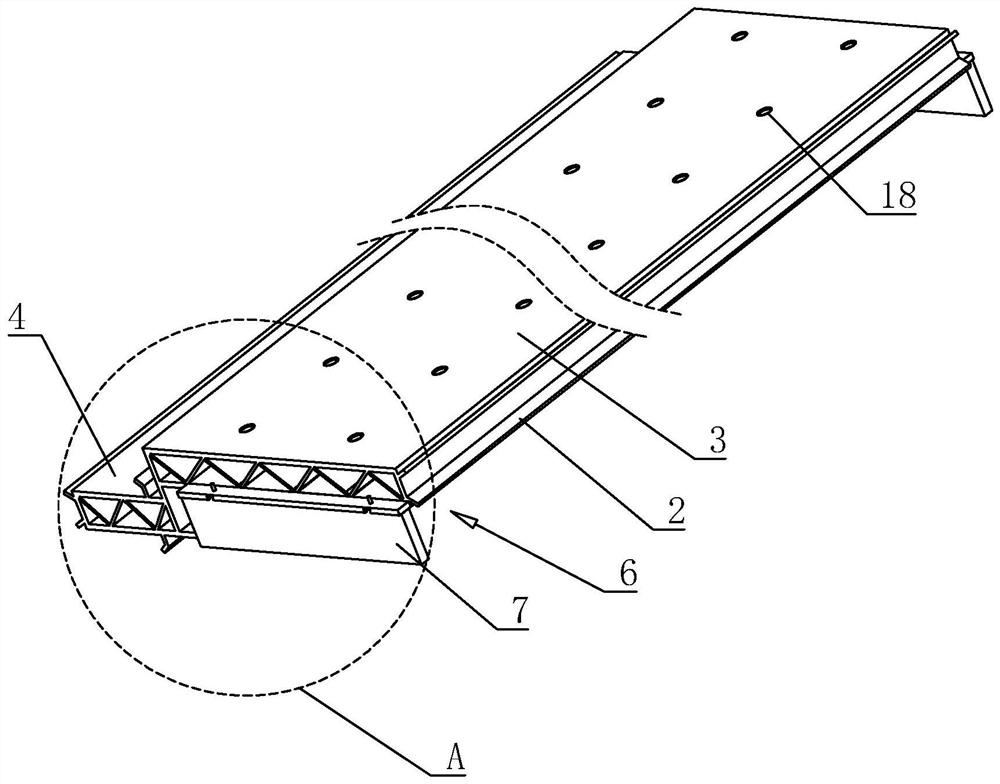

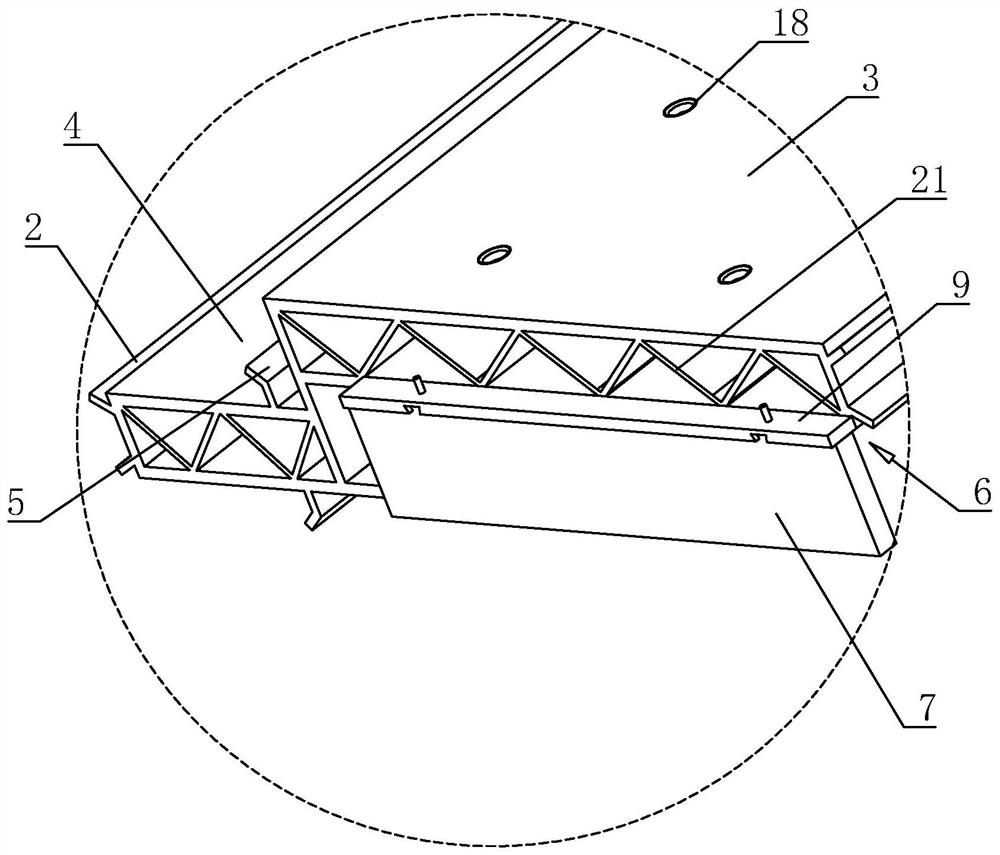

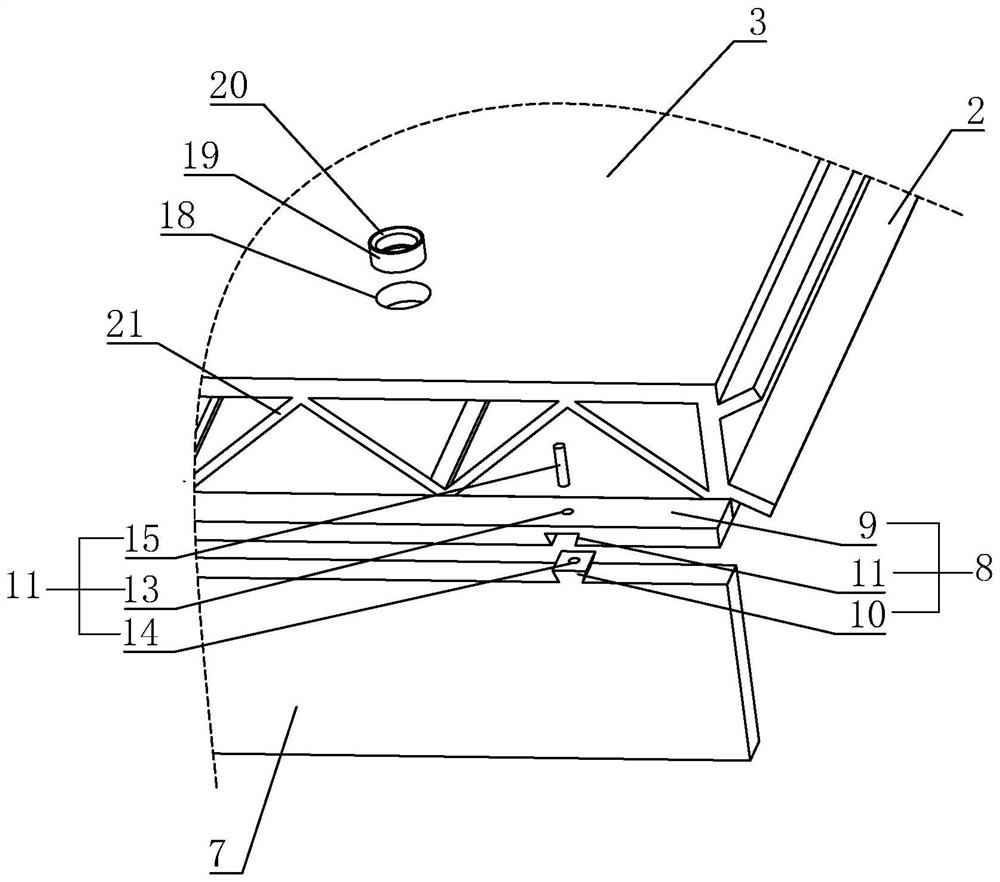

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of this application discloses a structural seam applied to aluminum formwork, refer to figure 1 , including a seamed plate, and the drawn seamed plate is in the shape of a hollow plate, and limit strips 2 are integrally formed on the outer walls of both sides of the drawn seamed plate. In this embodiment, two spacers are integrally formed on the outer walls of both sides of the drawn seamed plate 2, and the two limit bars 2 are arranged obliquely and staggered. When placing the seam plate on the concrete in the initial setting stage, the limit bar 2 can limit the position of the seam plate and reduce the Probability of position shift in concrete.

[0044] refer to figure 1 with figure 2 The higher side and the lower side of the seam plate are respectively set as the first main body 3 and the second main body 4, and the waterproof board 5 is integrally forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com