Portable seam beautifying agent filling equipment

A technology for filling equipment and beautifying agent, which is applied in construction, building structure, etc., can solve problems such as injury of staff and inconvenient operation, and achieve the effect of facilitating the filling of beautifying agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

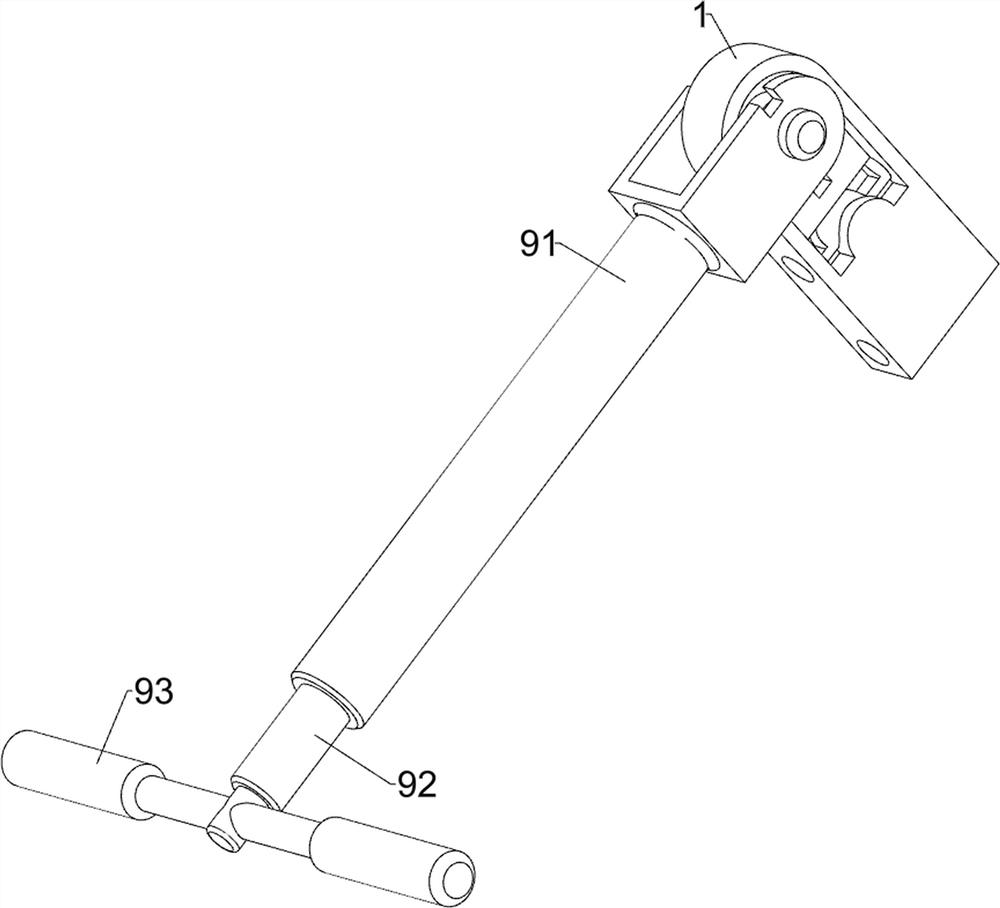

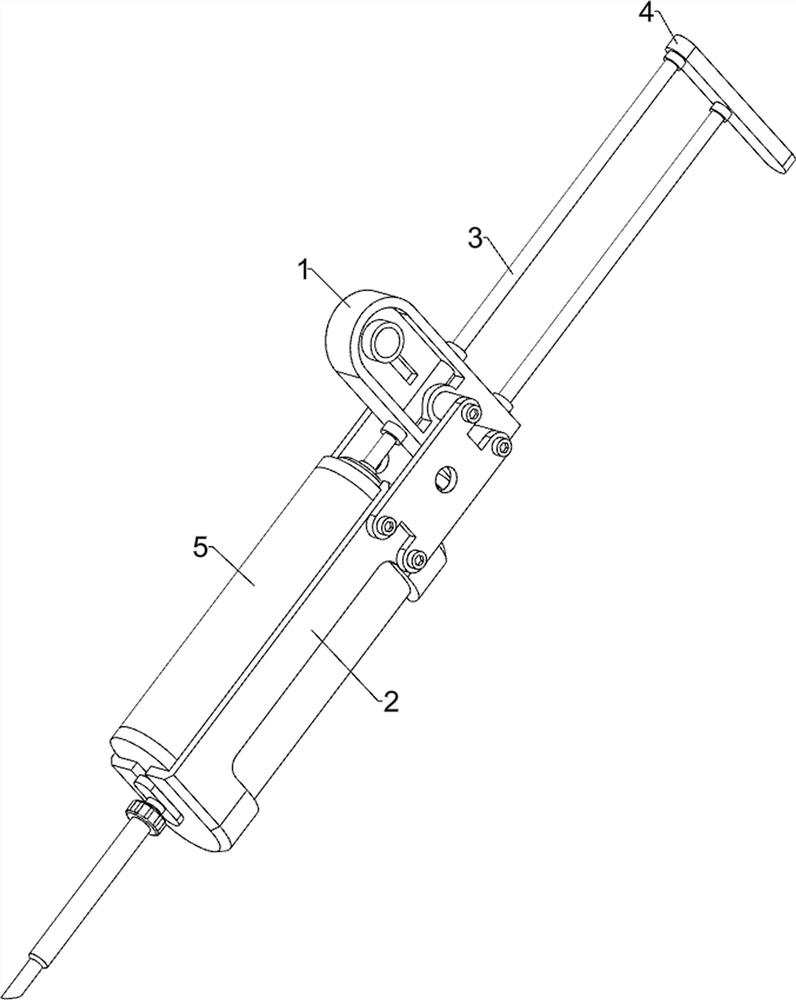

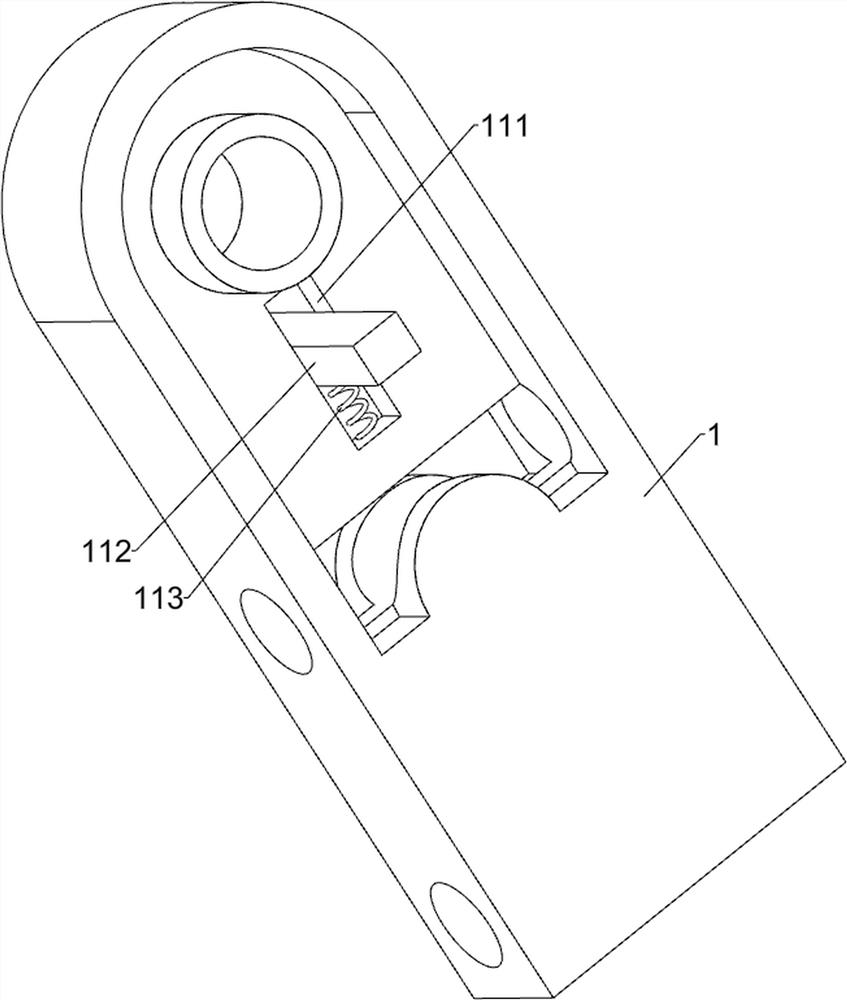

[0031] A convenient filling device for beautifying agent, such as Figure 1-4 As shown, it includes a mounting block 1, a placing frame 2, a push rod 3, a connecting block 4, a sewing agent body 5, a moving assembly 6 and a pulling assembly 7. The lower right part of the mounting block 1 is fixed with a placing frame 2 by bolts. The lower right part of the block 1 is slidably provided with two push rods 3 , the lower left part of the push rod 3 is located in the placing frame 2 , a connecting block 4 is connected between the upper right parts of the two push rods 3 , and the beauty seam agent body is placed in the placing frame 2 5. The lower left part of the push rod 3 extends into the body 5 of the beautifying agent, the placing frame 2 is provided with a moving component 6, and the moving component 6 can drive the body 5 of the beautifying agent to move, and there is a pull between the mounting block 1 and the placing frame 2 Assembly 7, the pulling assembly 7 can drive the...

Embodiment 2

[0038] On the basis of Example 1, as figure 1 and Figure 5 As shown, an inflatable assembly 8 is also included. The inflatable assembly 8 can automatically inflate the first cylinder 71. The inflatable assembly 8 includes a first sliding rod 81, a contact block 82 and a ring 83. The upper left part of the first cylinder 71 The sliding type is provided with a first sliding rod 81, the connecting block 4 moves to the lower left and is in contact with the first sliding rod 81, the upper part of the first sliding rod 81 is welded with a contact block 82, and the contact block 82 is now in contact with the lower left part of the lower push rod 3 Contact, the lower left part of the first cylinder block 71 is slidably provided with a ring 83 , the ring 83 is sleeved on the air inlet, and the ring 83 is connected with the lower left part of the first sliding rod 81 .

[0039] When the device is used, the ring 83 can block the air inlet. When the connecting block 4 moves to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com