Patents

Literature

52results about How to "Avoid Interfering Collisions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

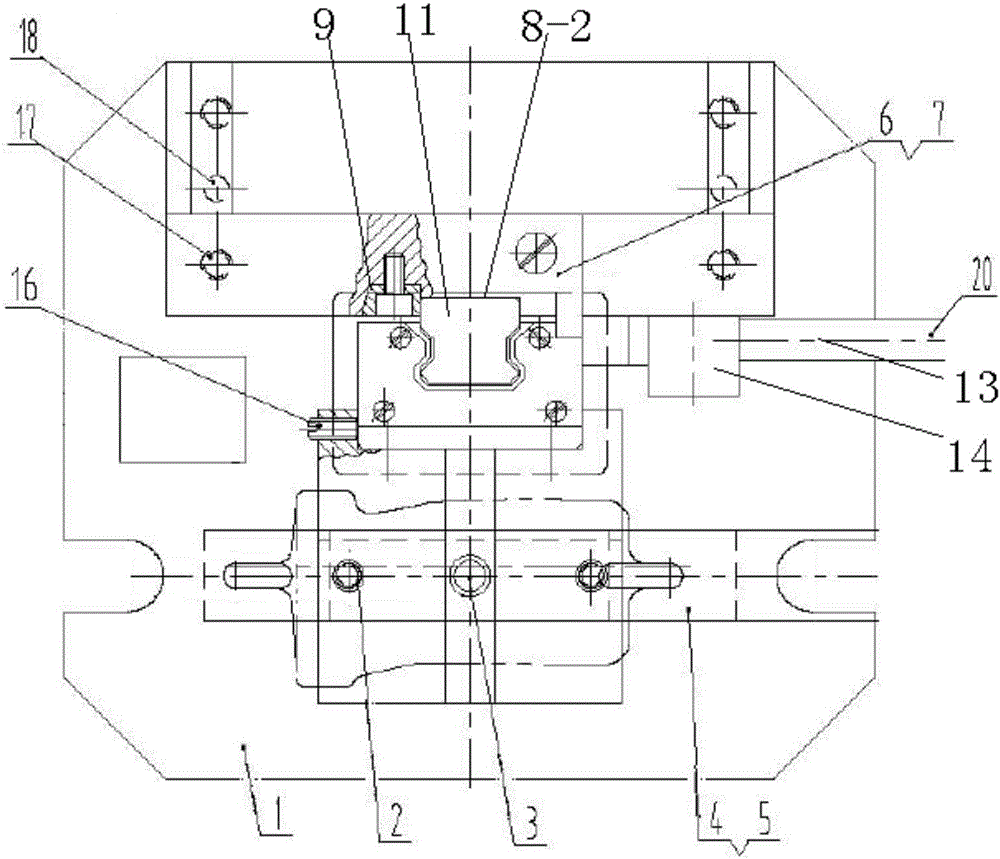

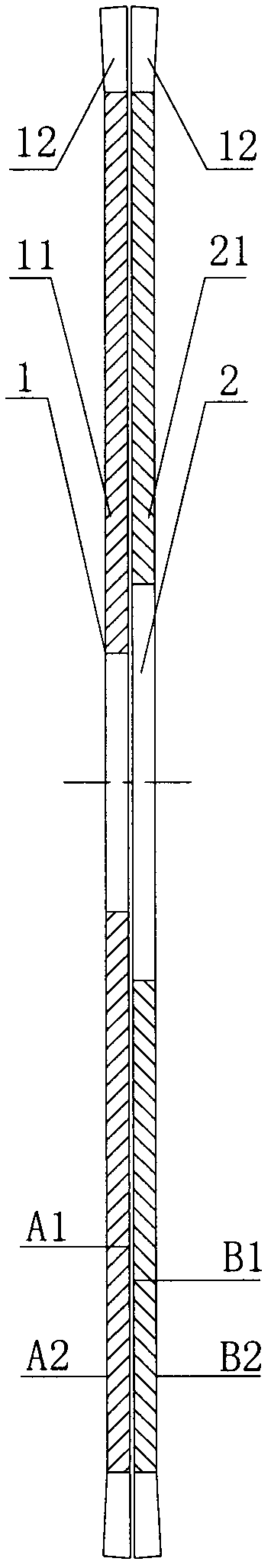

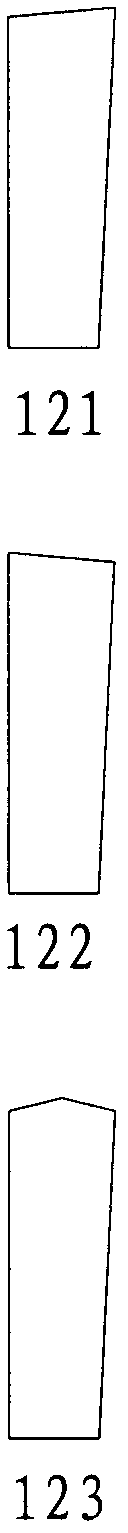

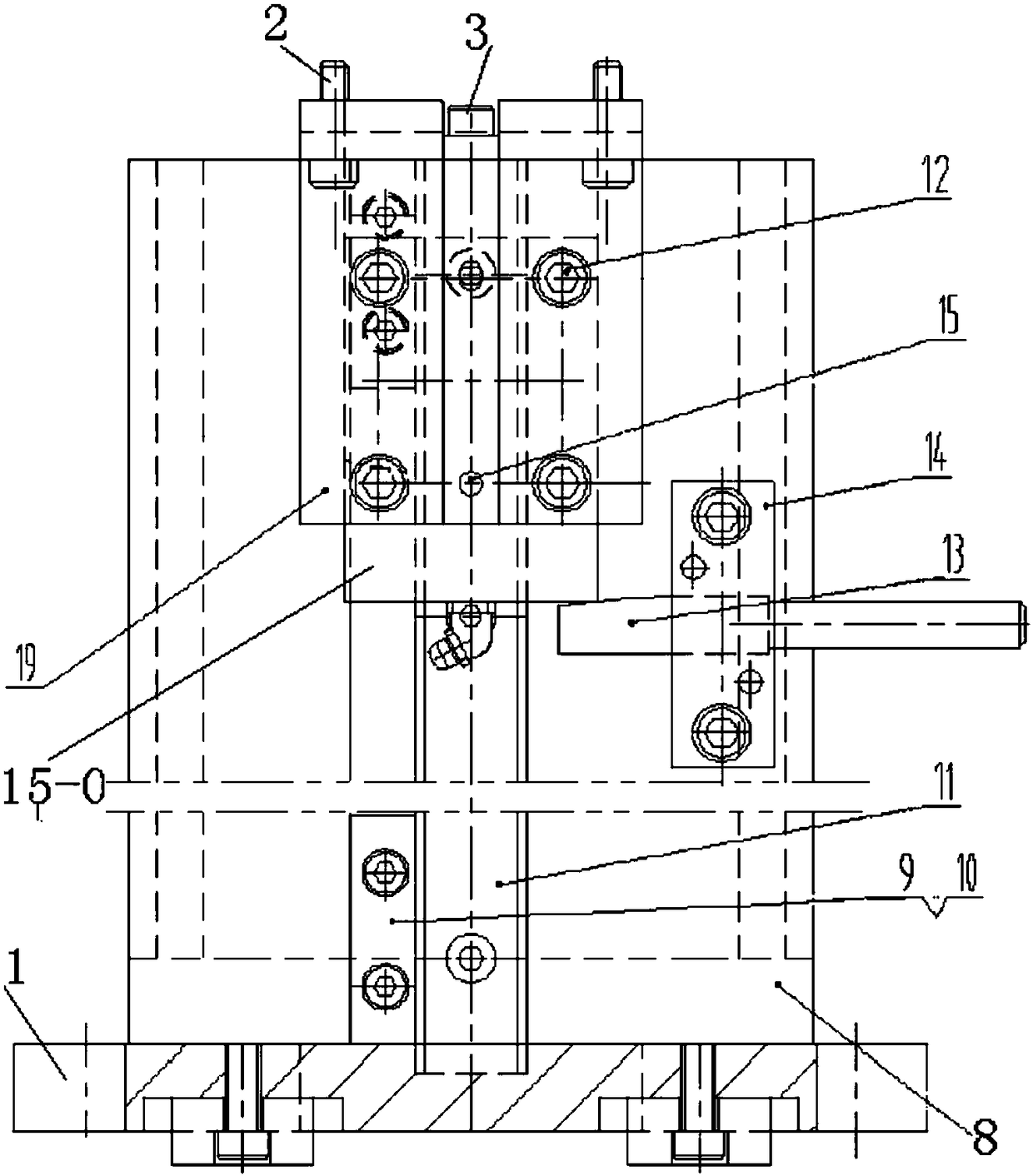

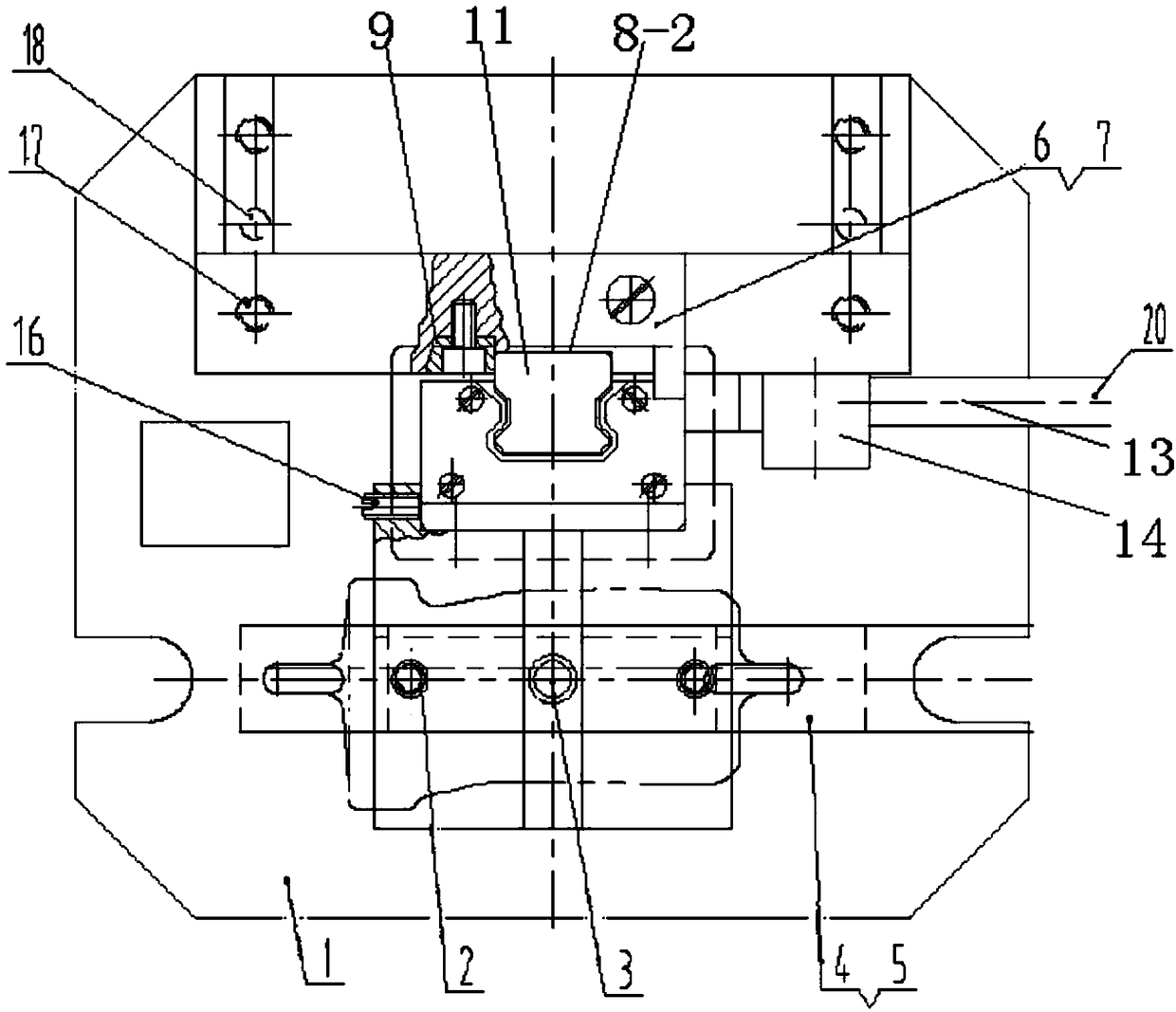

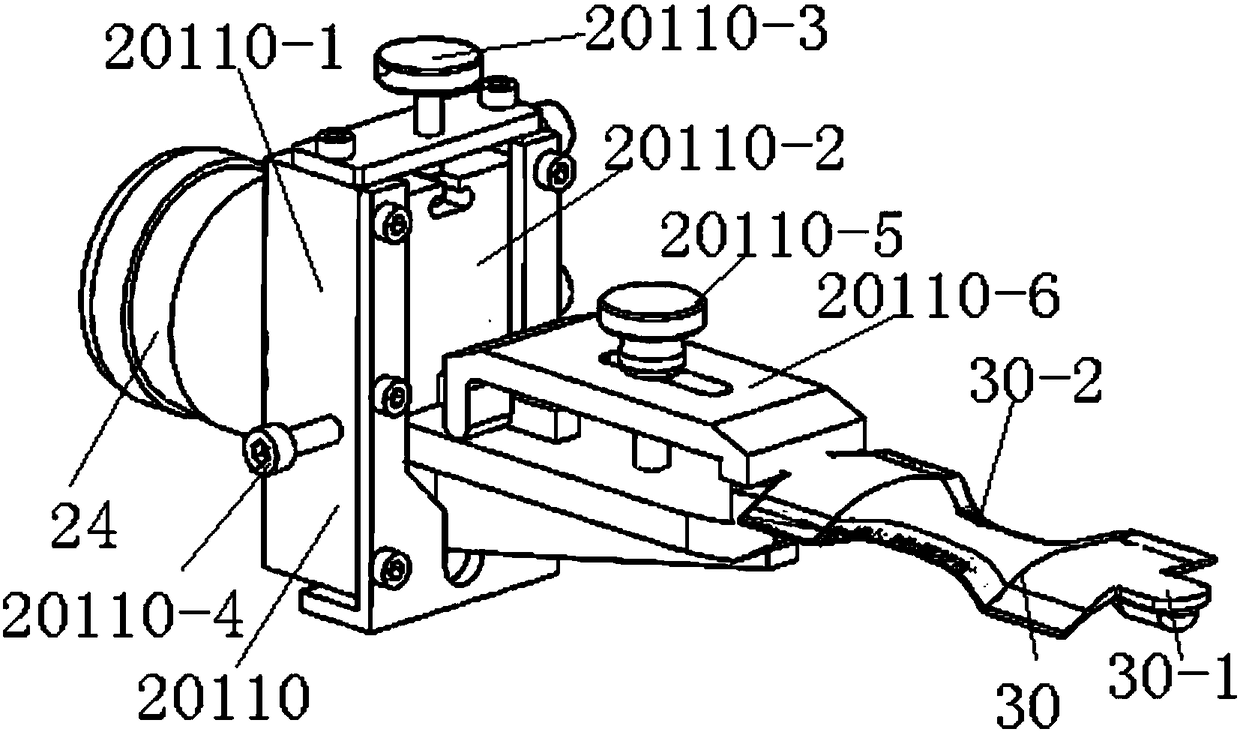

Numerical control abrasive belt grinding tooling for intake and exhaust edges of precise forged stator blade of aircraft engine

ActiveCN106425734AAchieve positioningGuaranteed positioning accuracyEdge grinding machinesBelt grinding machinesNumerical controlBelt grinding

The invention relates to a numerical control abrasive belt grinding tooling for intake and exhaust edges of a precise forged stator blade of an aircraft engine. The numerical control abrasive belt grinding tooling comprises fixtures used for clamping technological bosses at the two ends of the blade, a molded surface locating block used for locating a blade molded surface, and a fixture base, wherein the molded surface locating block is arranged on the fixture base; the fixture base comprises a bottom plate; a bracket is arranged on the bottom plate; a vertical linear guide rail is arranged on the bracket; a movable sliding block which can move up and down along the linear guide rail is arranged on the linear guide rail; a support is fixed to the movable sliding block; the molded surface locating block is fixed to the upper end of the support; a limiting device is further arranged on the bracket; the limiting device is used for fixing the support at a preset height; locating pins are arranged at the upper end of the molded surface locating block; and during locating, second locating pins are in contact with the blade molded surface of the blade, and first locating pins are in contact with the side surfaces of the blade technological bosses of the blade. According to the numerical control abrasive belt grinding tooling, the tooling structure adopts split design, the molded surface and a locating point are separated, and parts are clamped at one time.

Owner:AECC AVIATION POWER CO LTD

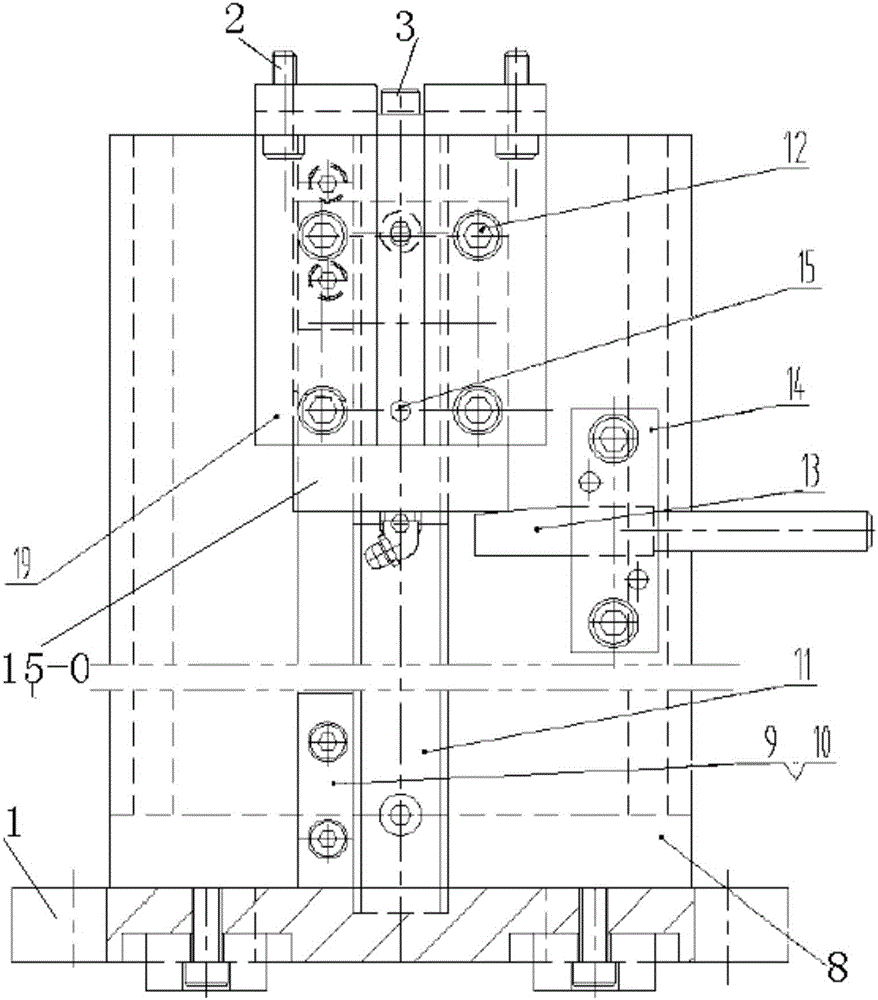

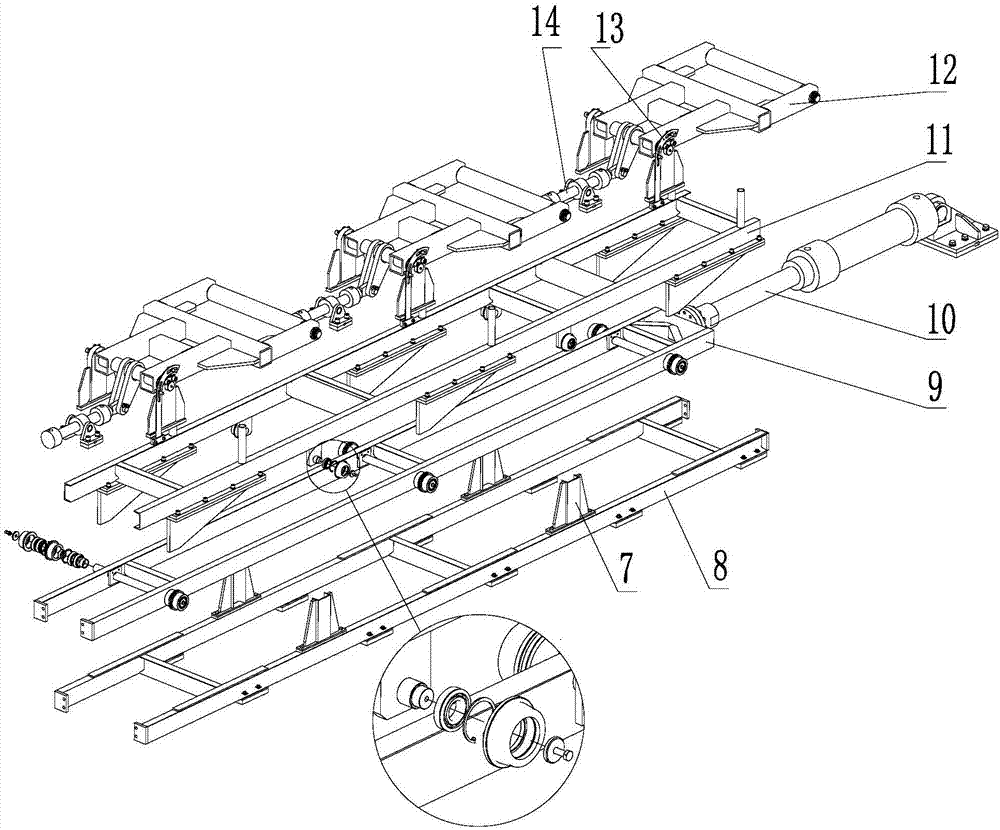

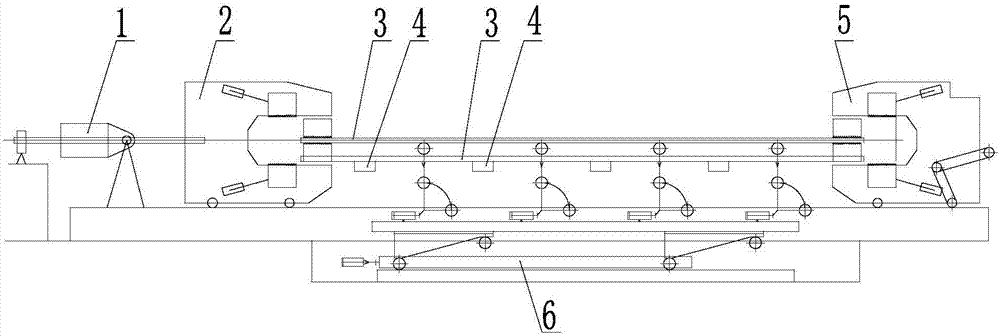

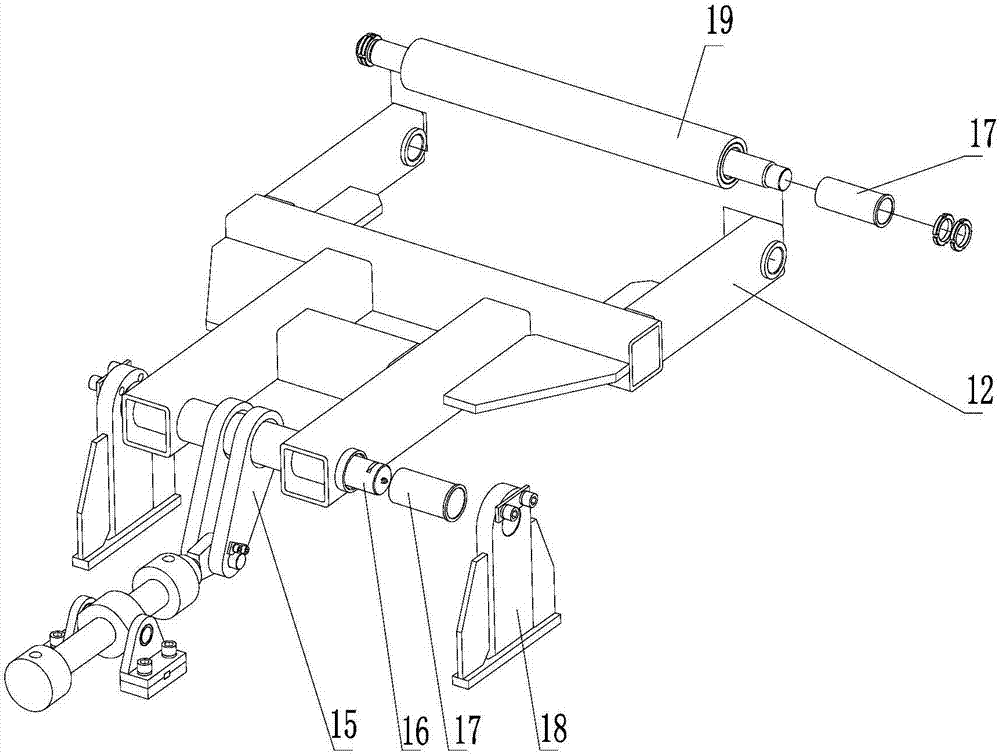

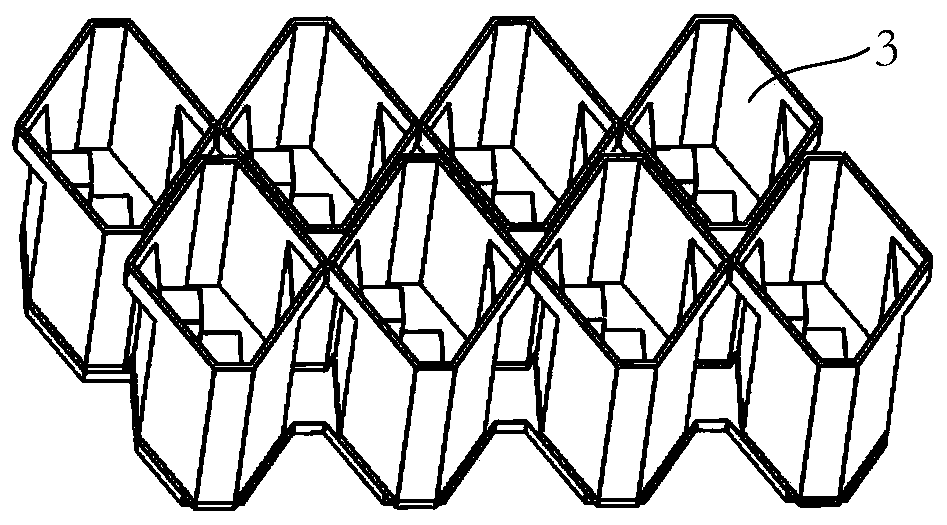

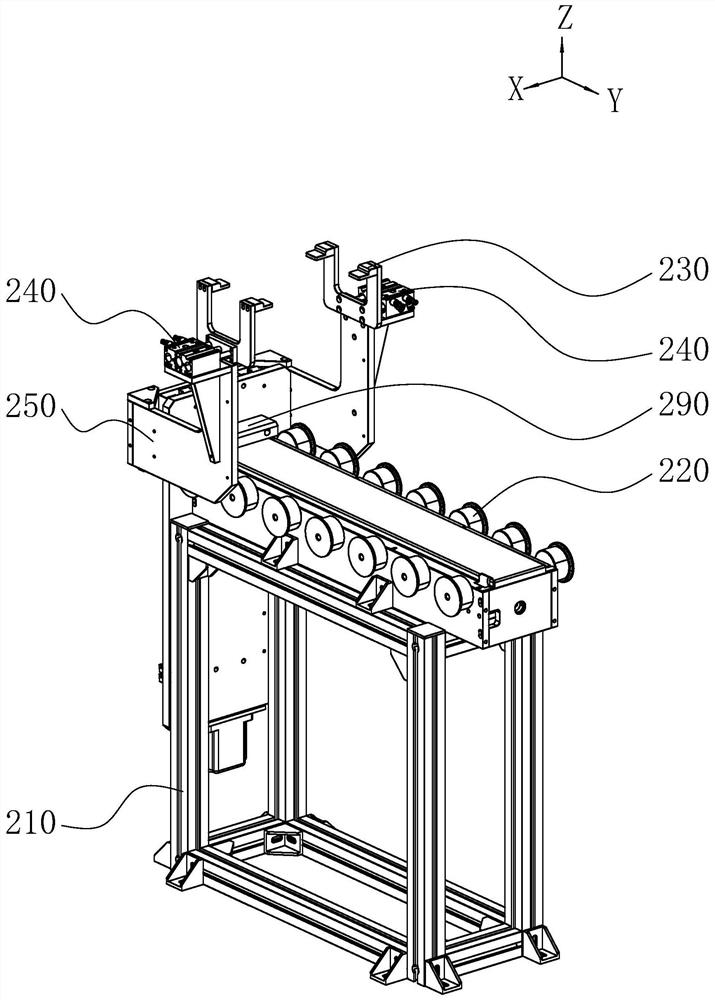

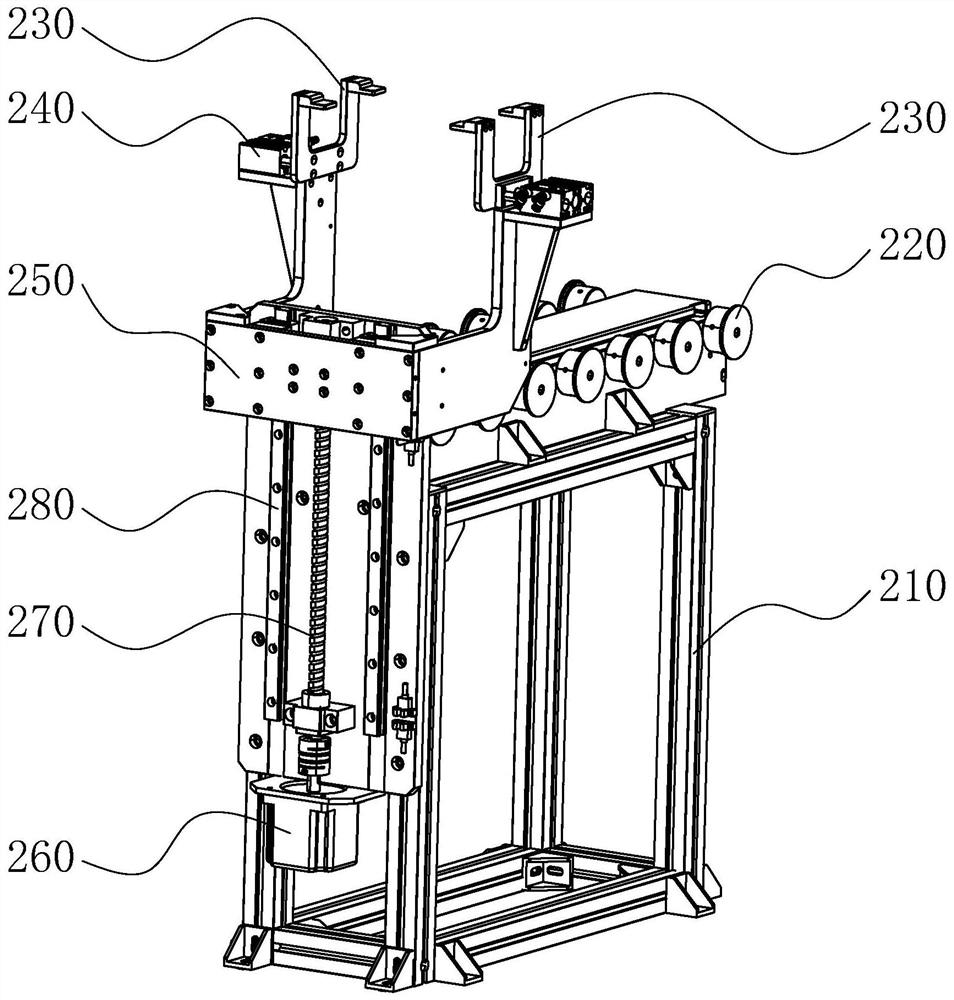

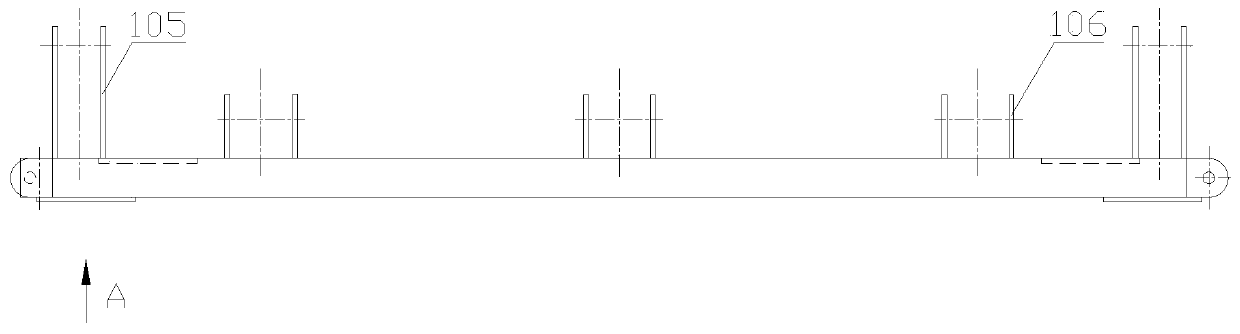

Large aluminum profile straightening machine automatic lifting and feeding mechanism

The invention belongs to the field of metal profile straightening and relates to a large aluminum profile straightening machine automatic lifting and feeding mechanism which sequentially comprises a bottom frame, a middle frame, an upper frame and a swinging mechanism from bottom to top; a plurality of limiting frames with a groove-shaped bracket structure are fixedly installed on the two sides of the bottom frame; a plurality of groups of slanting irons and rolling wheels are fixedly installed at the lower part of the two sides of the upper frame; the rolling wheels are assembled in grooves of the limiting frames respectively; a plurality of rolling wheels with bearings are installed on the middle frame; the slanting surfaces of the slanting irons are in contact to the rolling wheels of the middle frame respectively; a lifting oil cylinder component is connected to the outer side of the middle frame; supporting seats in the swinging mechanism are fixedly installed at the upper part of the upper frame; a rotary shaft with the two ends fixed on the supporting seats respectively is fixedly installed between swinging frames; crank arms are fixedly installed at the middle part of the rotary shaft; and one end, far away from the swing frames, of each crank arm is hinged to a swinging oil cylinder component, so that the problems that feeding by lifting mechanism at a front nip and a back nip enables overlong middle section of a profile to be hung in air and a flexible region to be overlarge in deformation, so that the quality of the profile is lowered; and overlarge deformation can enable the front nip and the back nip not to be liable in clamping, so that the waste head is long are solved.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

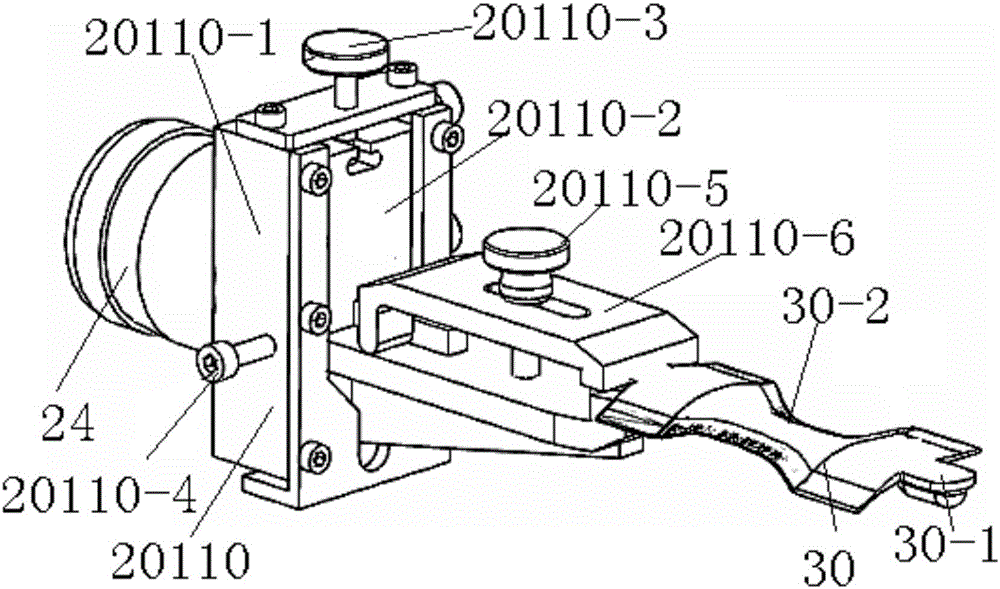

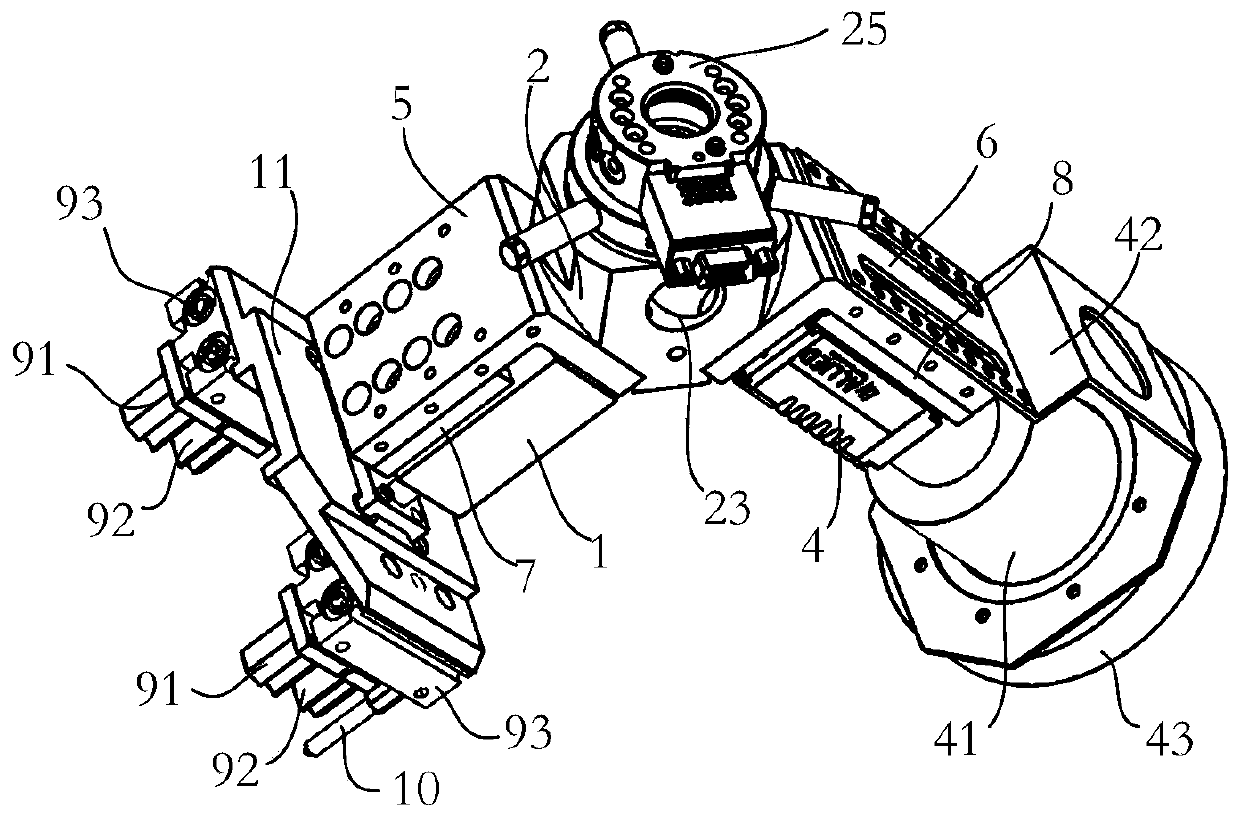

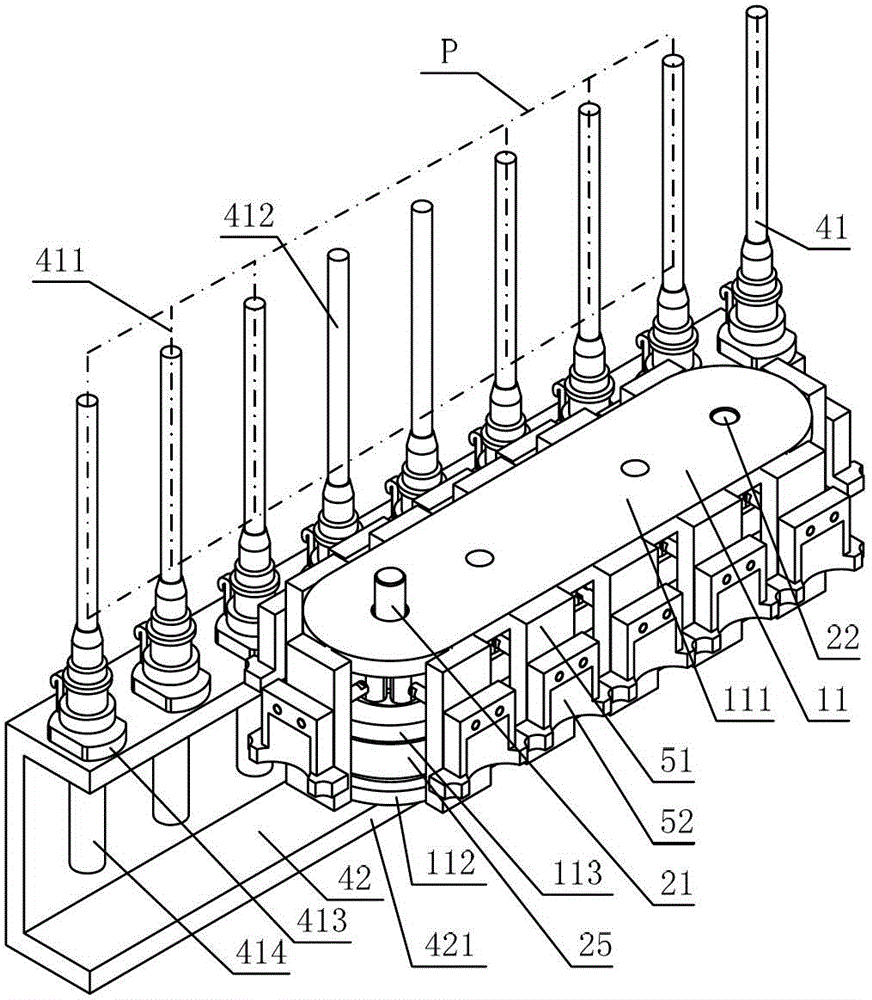

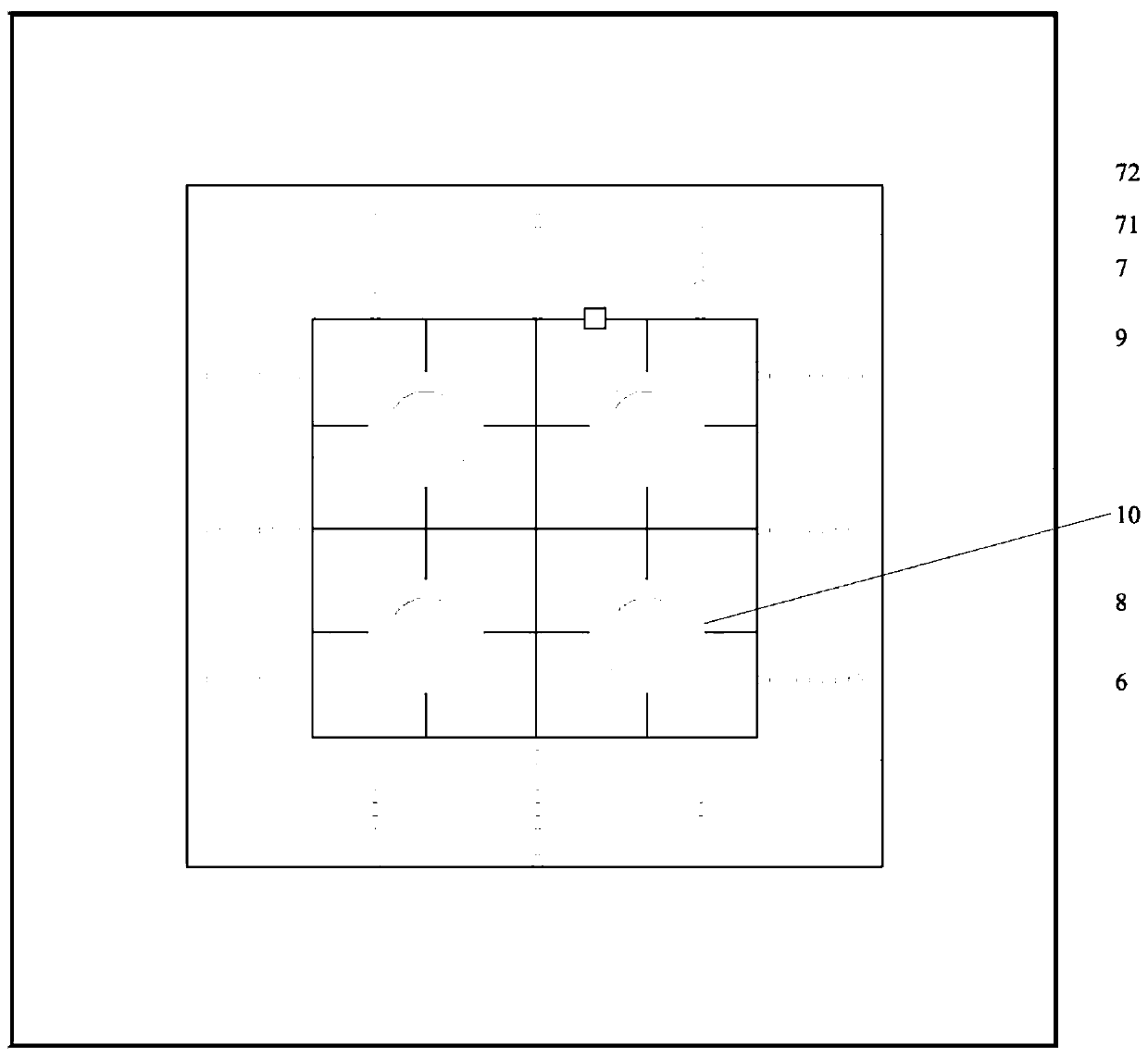

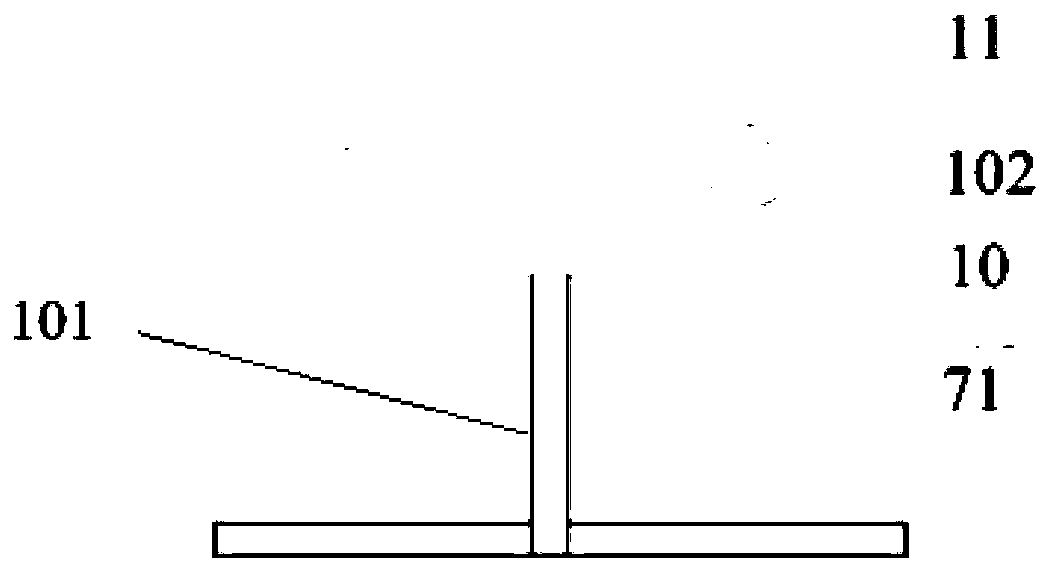

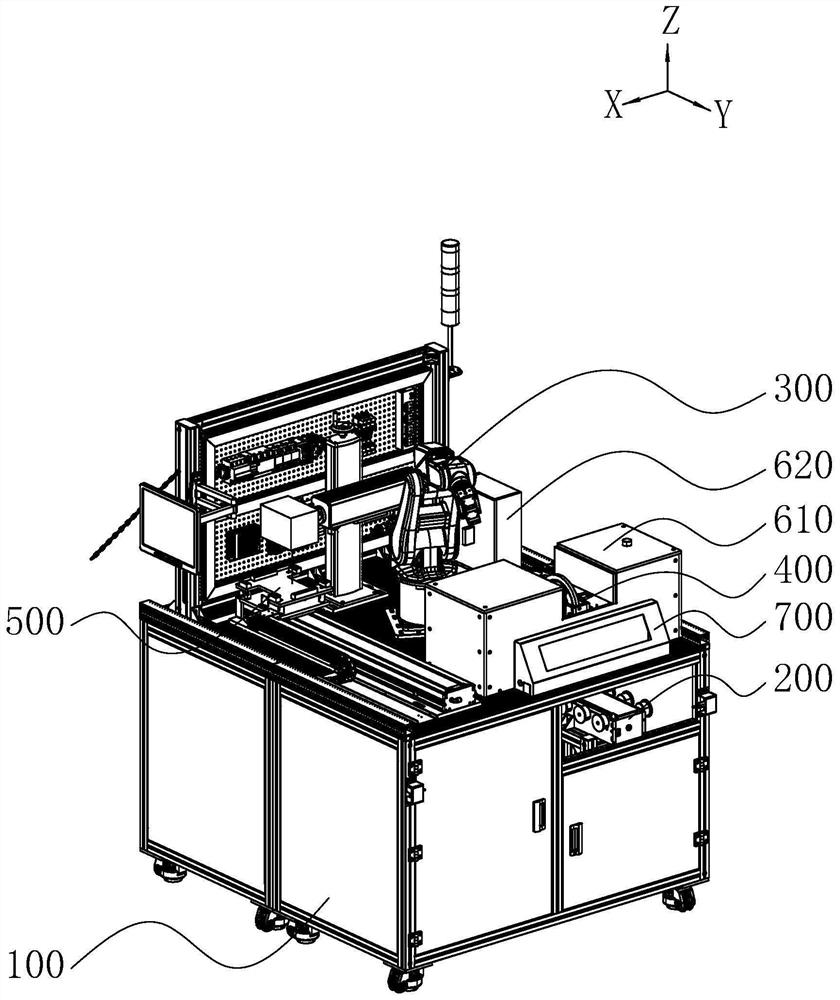

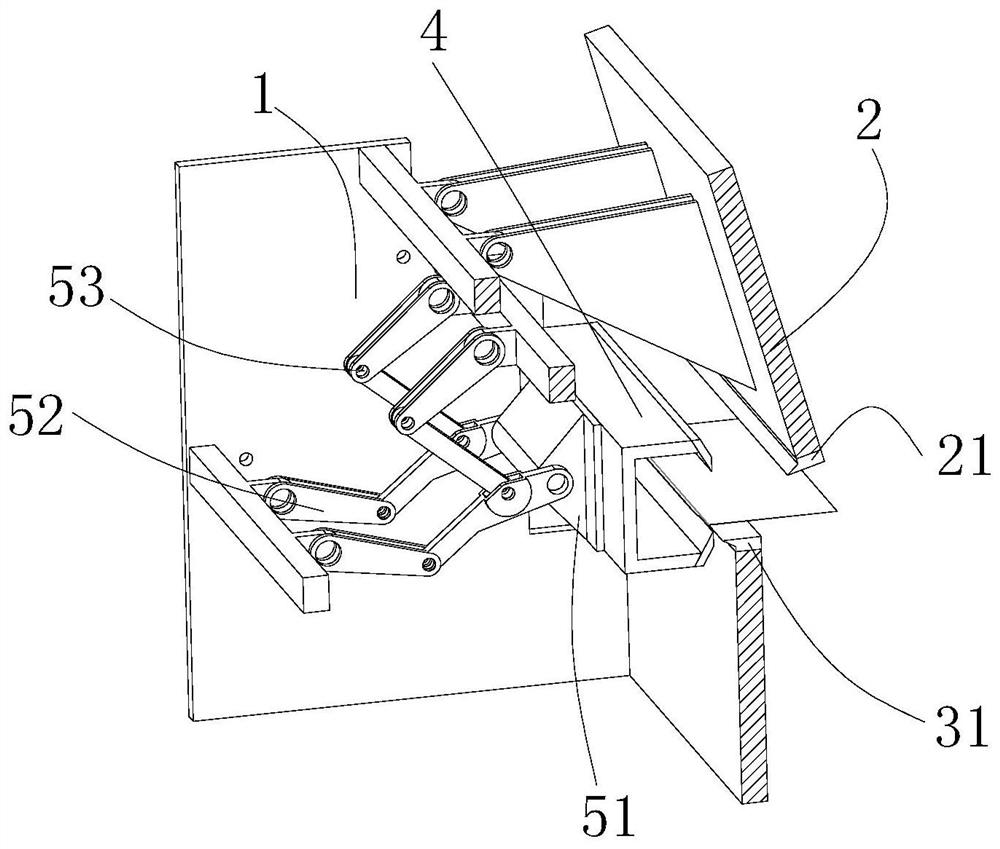

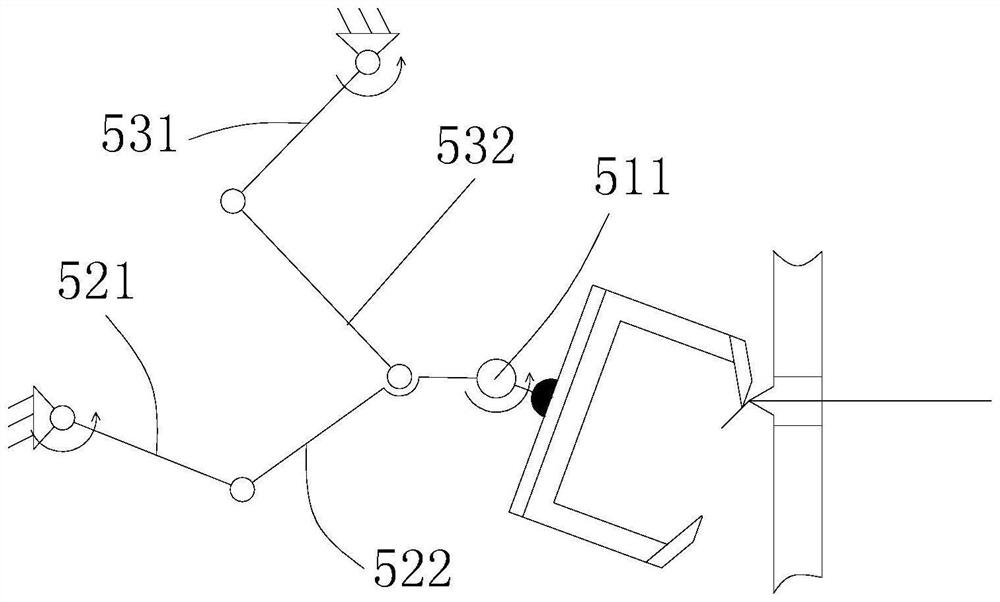

Antenna unit assembly assembling device and collecting, assembling and measuring integrated control system and method thereof

ActiveCN110328528APrecise positioningHigh precision assemblyWave based measurement systemsAssembly machinesControl systemOptical axis

The invention relates to an antenna unit assembly assembling device and a collecting, assembling and measuring integrated control system and method thereof. The assembling device comprises a mountingand dismounting air cylinder, a mounting support, an outer supporting assembly for picking or dismounting an antenna unit assembly and a camera. A first mounting face and a second mounting face whichare perpendicular are arranged on the mounting support, the mounting and dismounting air cylinder is arranged on the first mounting face, the camera is arranged on the second mounting face, the optical axis of the camera is perpendicular to the second mounting face, the driving end of the mounting and dismounting air cylinder is away from the first mounting face, and is connected with the outer supporting assembly to drive the outer supporting assembly to do reciprocated moving in the direction perpendicular to the first mounting face, the camera is used for carrying out image collecting and parameter extracting on the characteristics of the assembling position of the antenna array face, and the mounting and dismounting air cylinder can rotate to the assembling position and drive the outersupporting assembly to move to finish mounting or dismounting of the antenna unit assembly on the antenna array face. Mechanical and electrical mounting and switching of the antenna unit assembly assembling device and an industrial robot or execution mechanism can be achieved, and assembling precision needs are ensured.

Owner:BEIJING INST OF RADIO MEASUREMENT

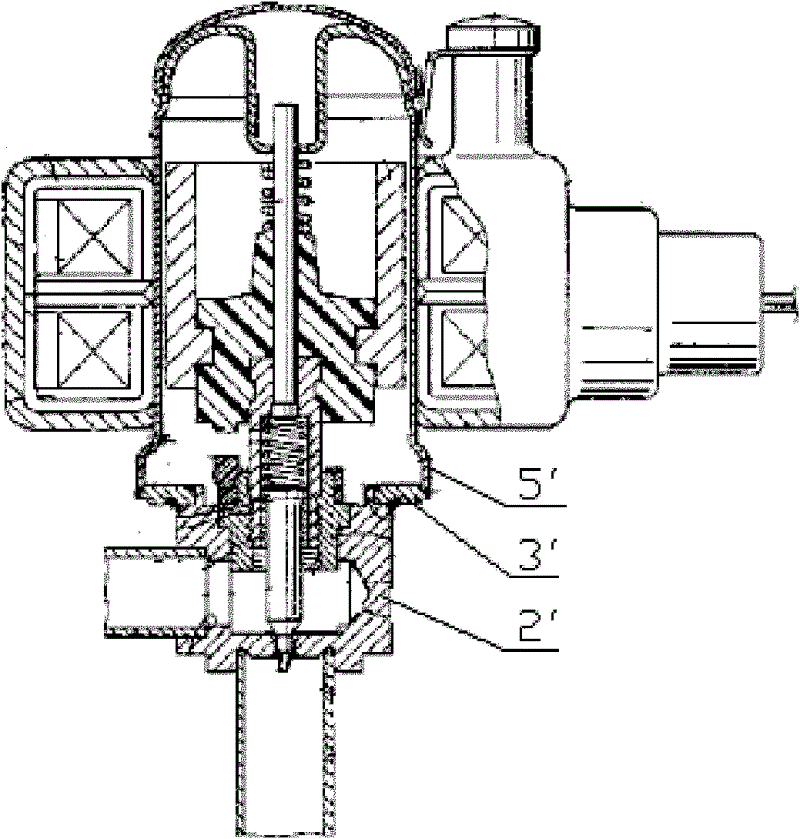

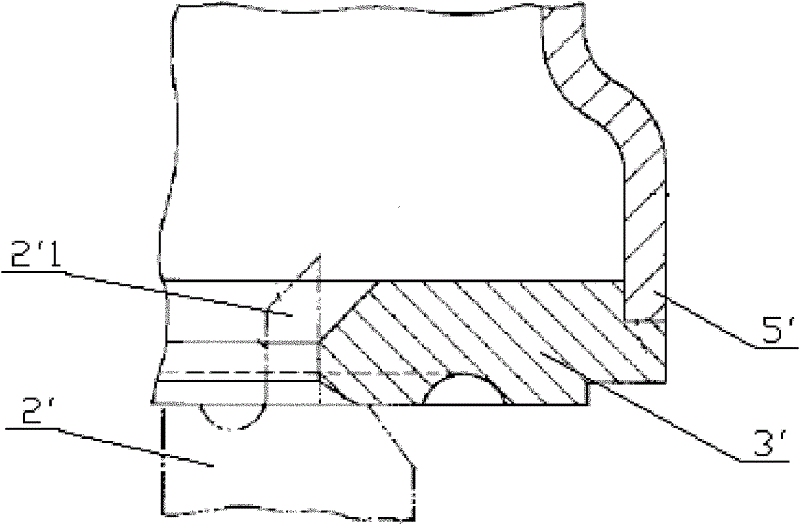

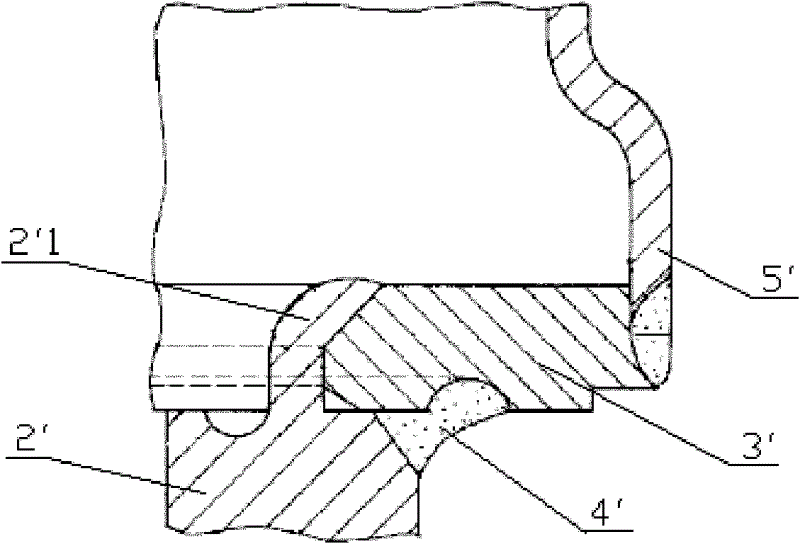

Manufacturing method for valve seat assembly

InactiveCN102620024AImprove coaxialityGuaranteed coaxialityEfficient regulation technologiesFluid circulation arrangementEngineeringSoldering

The invention discloses a manufacturing method for a valve seat assembly, which is used for assembling a valve seat (2) and a cover (3) of an electronic expansion valve together to form a valve seat assembly. The manufacturing method comprises the following steps of: (11) fixedly joining the cover (3) with the valve seat (2) in a braze soldering way; and (12) processing a positioning part on the cover (3) to be assembled with a shell (53) of the electronic expansion valve by adopting the circumferential outer diameter of the valve seat (2) as a positioning benchmark. In specific, following the step (12), the manufacturing method also comprises the following steps of: (13) respectively soldering a first connecting pipe (51) and a second connecting pipe (52) of the electronic expansion valve inside a first connecting hole (25) and a second connecting hole (26) of the valve seat (2), and ensuring the soldering temperature to be lower than the temperature of the braze soldering between the valve seat (2) and the cover (3). According to the manufacturing method, not only are the valve seat (2) and the cover (3) convenient to position, but also the proper alignment between the valve seat (2) and the cover can be ensured.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

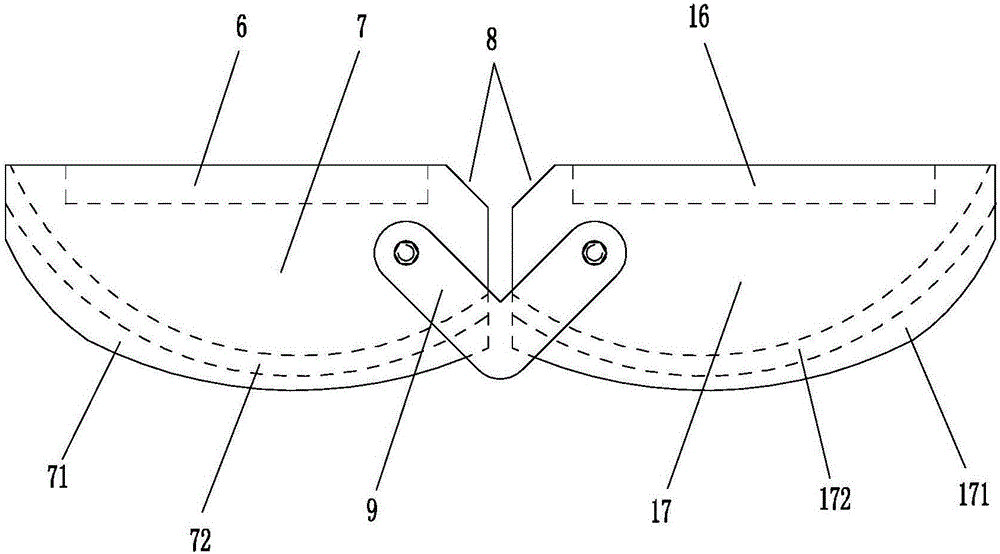

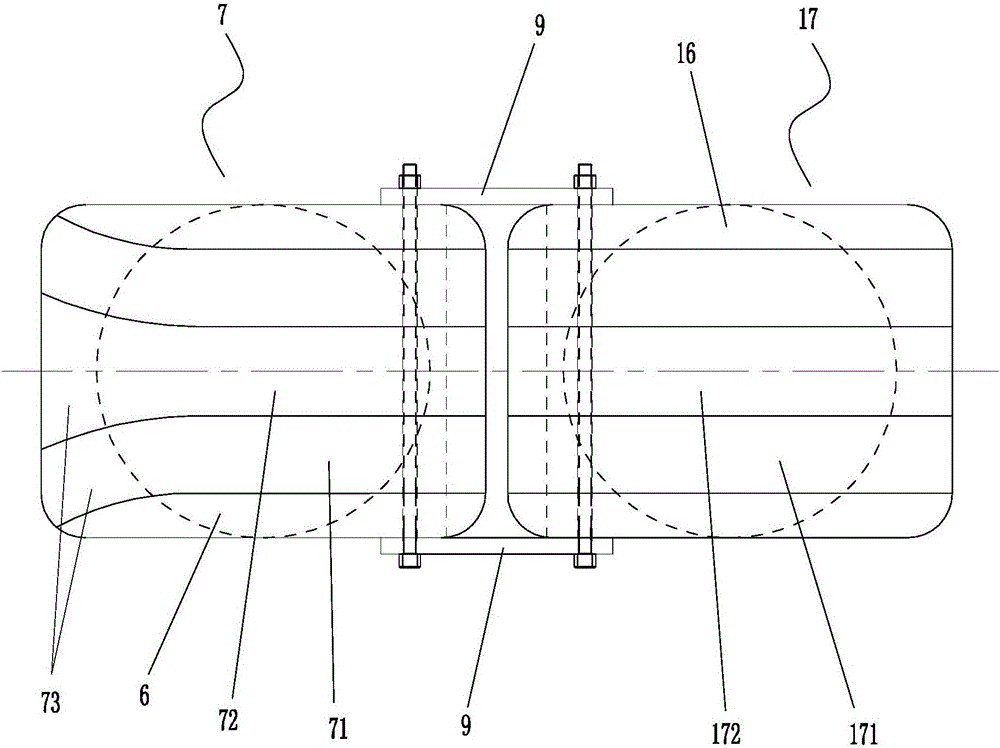

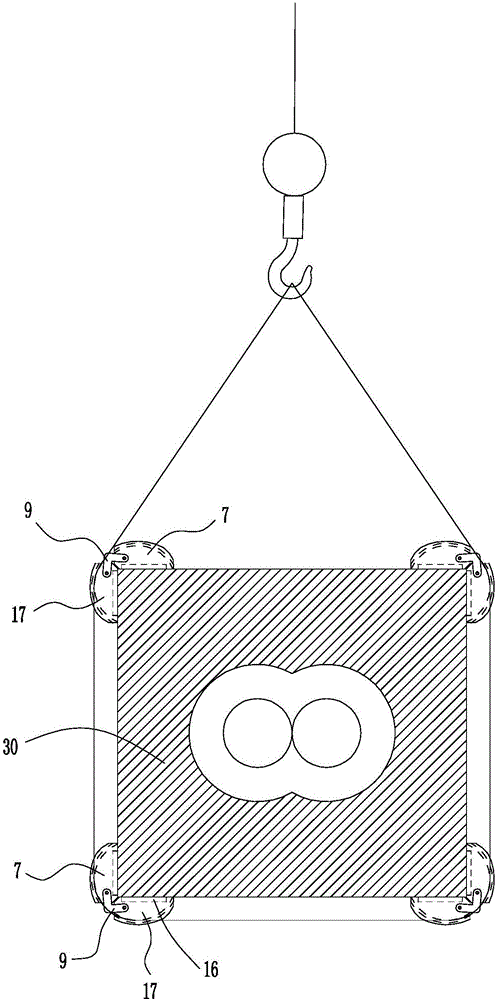

Multi-functional hoisting corner protection device and method for hoisting equipment and steel structure thereof

A multi-functional hoisting corner protection device comprises a left protection block and a right protection block which are connected in a hinged mode, arc-shaped hammock grooves and arc-shaped steel wire rope grooves are formed in the reverse sides of the left protection block and the right protection block, and magnets are installed on the obverse sides of the left protection block and the right protection block. A method for hoisting equipment and a steel structure through the multi-functional hoisting corner protection device comprises the following steps that (1) the left protection block and the right protection block are manufactured, (2) the arc-shaped hammock grooves and the steel wire rope grooves are formed in the reverse sides of the left protection block and the right protection block; (3) the magnets are inlaid into the obverse sides of the left protection block and the right protection block; (4) a chamfer is arranged on the adjacent faces of the left protection block and the right protection block; (5) the left protection block and the right protection block are connected in a hinged mode; and (6) according to the size of a corner angle, the left protection block and the right protection block rotate and are absorbed at the corner angle, hammocks or steel wire ropes are placed into the corresponding grooves, and hoisting is conducted through hoisting machinery. According to the multi-functional hoisting corner protection device and the method for hoisting the equipment and the steel structure through the device, when the equipment and the steel structure are hoisted, the corner angle can be protected and protected against deformation, and the hammocks can be prevented from being damaged, so that the safety risk is lowered, and outcome protection of production and machining of the equipment and the steel structure is facilitated.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

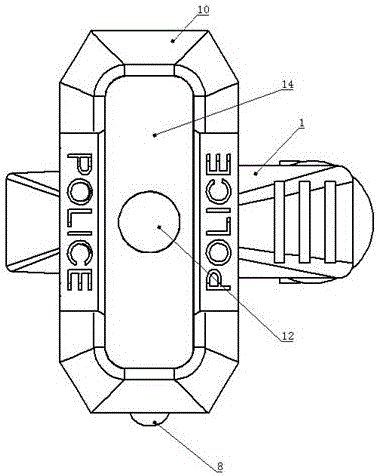

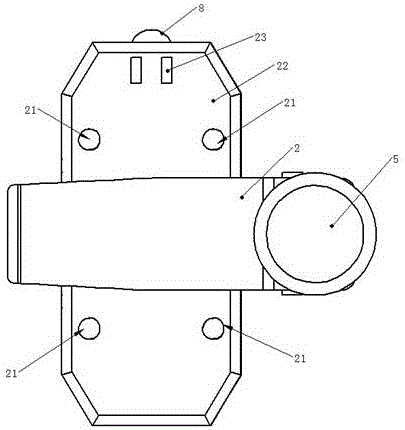

Multifunctional shoulder lamp for policemen

ActiveCN105782736AExpand the radiation rangeEasy to operateElectrical apparatusLighting support devicesHuman bodyGyroscope

The invention relates to a multifunctional shoulder lamp for policemen. The multifunctional shoulder lamp solves the problems that in the prior art, the structure is complex, use is inconvenient, and the application scope is narrow. The multifunctional shoulder lamp is characterized in that a button switch is installed at the top, a magnetic attraction round sheet is installed on the lower surface of the compression end of a shoulder clamp, a top shooting LED lamp is welded to the front face of a circuit board, and flat shooting LED lamps are welded to the periphery of the back face of the circuit board; and an olecranon hook is arranged at the clamping end of an upper clamp, the upper clamp and a lower clamp are provided with arc-shaped opening edges, and the circuit board is further provided with a gyroscope module, a GPS module and a wireless radio frequency receiving and transmitting module. The multifunctional shoulder lamp has the beneficial effects that the radiation scope of LED lamp light is wide, the alarming effect is higher, and the wearing comfort of the human body and the stability of the shoulder lamp are improved. The multifunctional shoulder lamp can be worn on the human body, can be singly attracted to magnetic attraction objects such as a car, a guardrail and an alarming cone, and the alarming effect is achieved; and multiple shoulder lamps can be used in a combined manner, can be combined to be in an arrow shape or a letter shape and the like, and can achieve the alarming effect, and the application scope of the shoulder lamp is accordingly enlarged.

Owner:沈阳广信先锋交通高技术有限公司

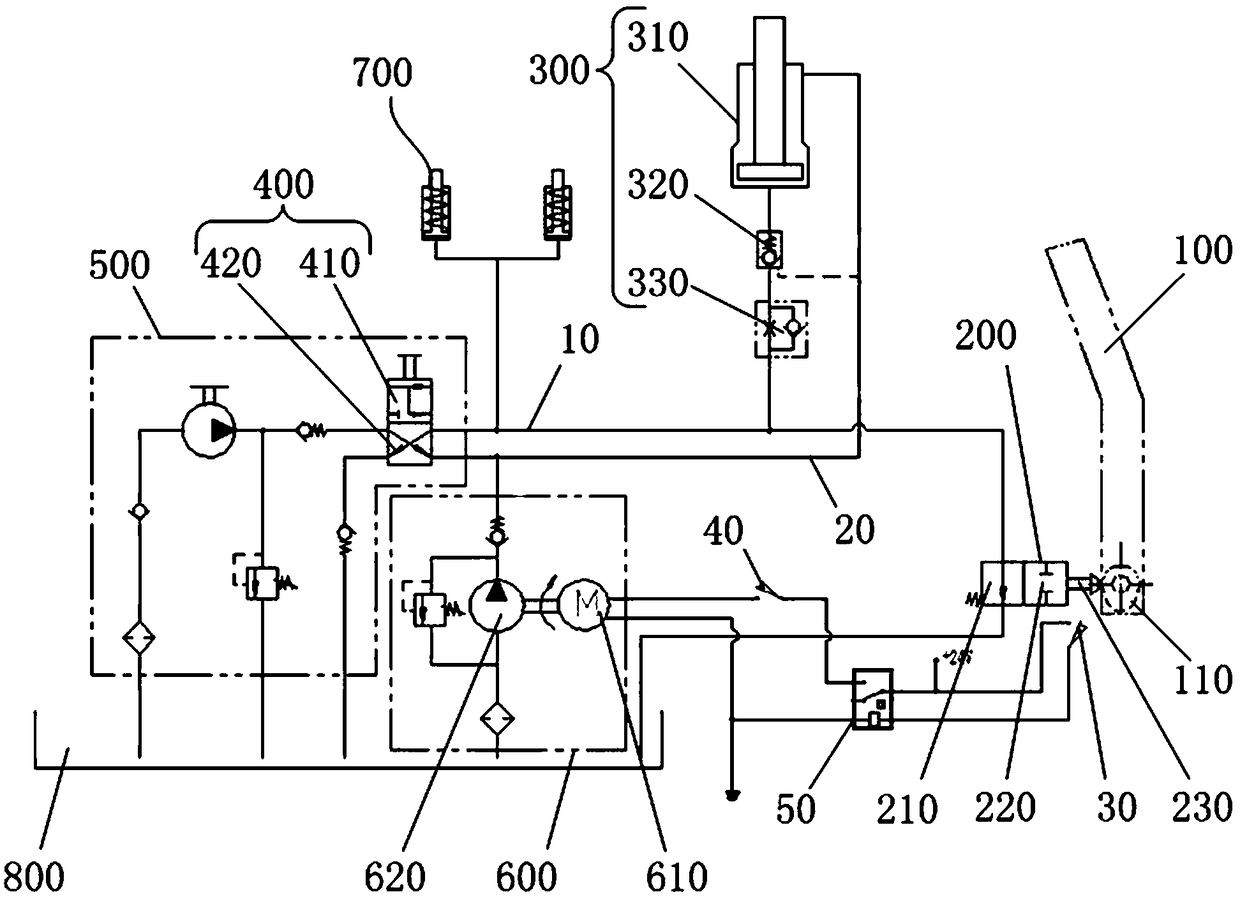

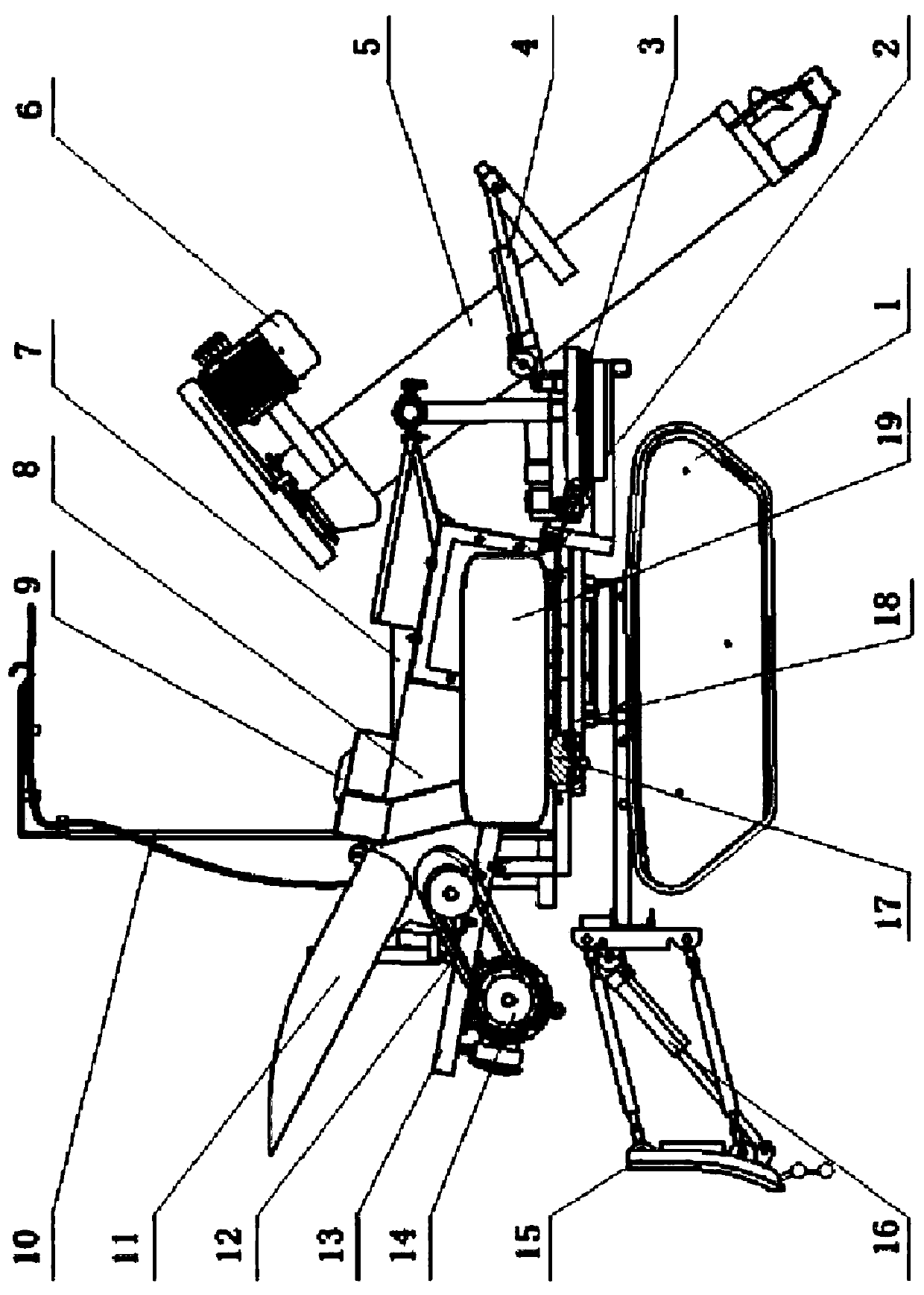

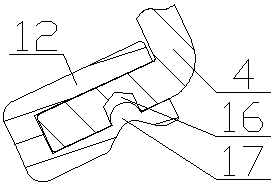

Cab turnover control system and cab

ActiveCN109278878AAvoid Interfering CollisionsPropulsion unit arrangementsLoading-carrying vehicle superstructuresControl systemCam

The invention discloses a cab turnover control system and a cab. The cab turnover control system comprises a liquid control valve, a front protective device, a hydraulic jacking module, an oil supplymodule and a circuit control module, wherein the liquid control valve comprises an access station and an open circuit station, and an ejector rod is arranged on the liquid control valve. A cam is arranged on the front protective device, and the cam is connected with the ejector rod in an abutting mode. The hydraulic jacking module is used for jacking the cab. The oil supply module is used for providing hydraulic oil for the hydraulic jacking module. The circuit control module is used for controlling the oil supply module to start oil supplying or stop oil supplying, the circuit control modulecomprises a first switch, and the first switch is connected with the cam in a contacting mode. According to the cab turnover control system and the cab, through the cooperation of the liquid control valve and the cam, the cab cannot be turned over when the front protective device is not turned over and open, while the cab can be turned over when the front protective device is open, and thus the interference and collision between the cab and the front protective device in the turnover process is avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

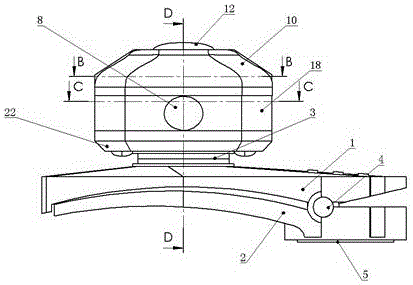

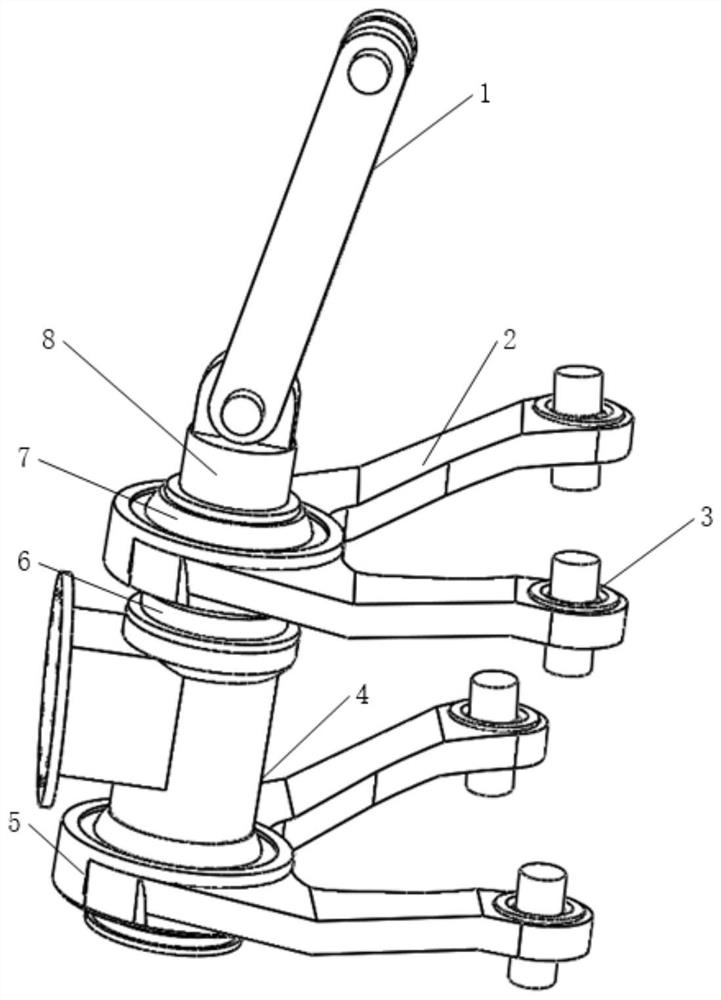

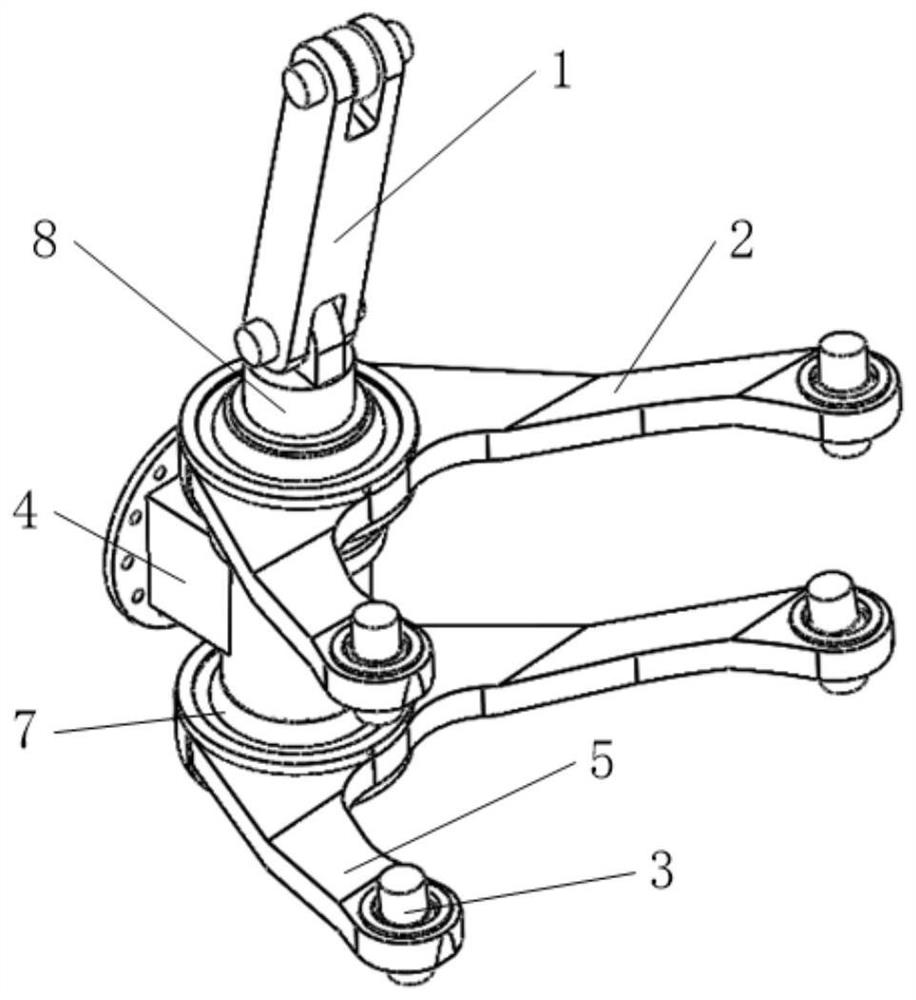

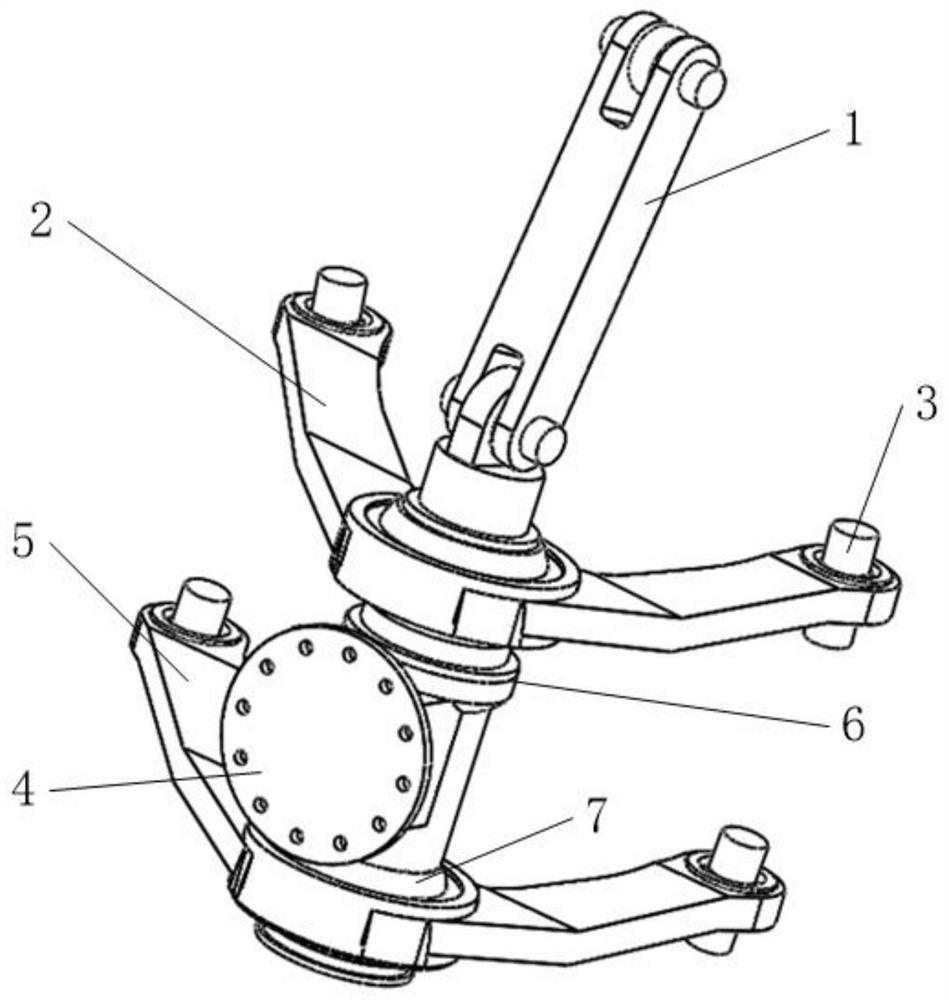

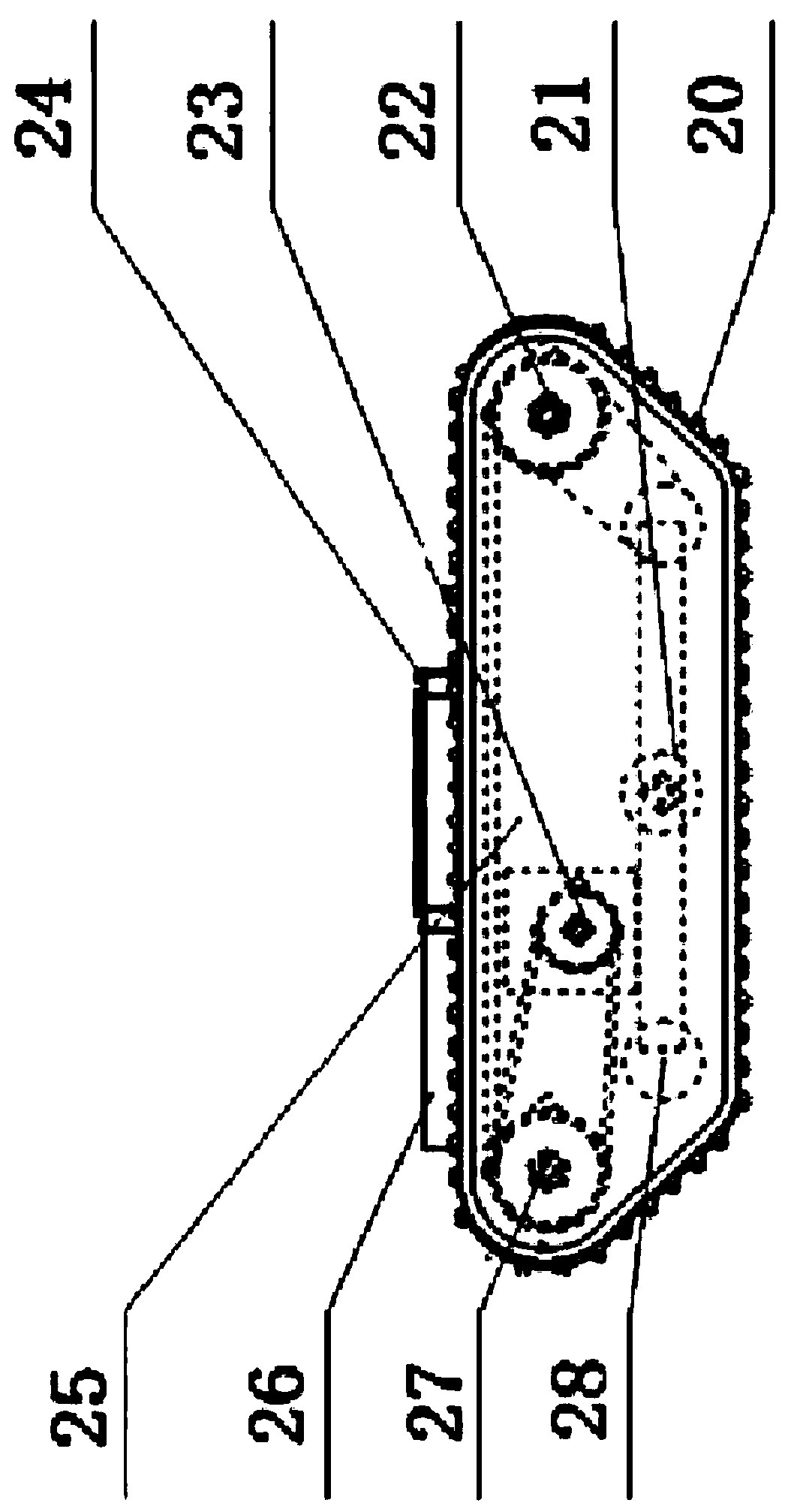

Double-fork-arm type front suspension of off-highway mining dump truck

InactiveCN112172428ASimple structureCompact structureResilient suspensionsPivoted suspension armsVehicle frameAgricultural engineering

The invention provides a double-fork-arm type front suspension of an off-highway mining dump truck, and belongs to the technical field of automobiles. The front suspension comprises an upper pull rod,an upper fork arm, a pin, a hydro-pneumatic suspension cylinder barrel, a lower fork arm, a bearing seat, a knuckle bearing and a hydro-pneumatic suspension piston rod, the hydro-pneumatic suspensioncylinder is connected with a frame, the upper fork arm and the lower fork arm are hinged to the two sides of the hydro-pneumatic suspension cylinder barrel, and the hydro-pneumatic suspension pistonrod is in sliding connection with the hydro-pneumatic suspension cylinder barrel. The upper pull rod is hinged to the hydro-pneumatic suspension piston rod and the frame. The double-fork-arm type front suspension for the heavy-duty car is simple in structure, the system can adopt hydro-pneumatic suspension with small diameter and stroke, the suspension has the functions of a main pin, an elastic element and a damping element at the same time, the lateral stability of the car is enhanced, and the space utilization rate of a front axle and the flexibility of a steering system are improved.

Owner:UNIV OF SCI & TECH BEIJING

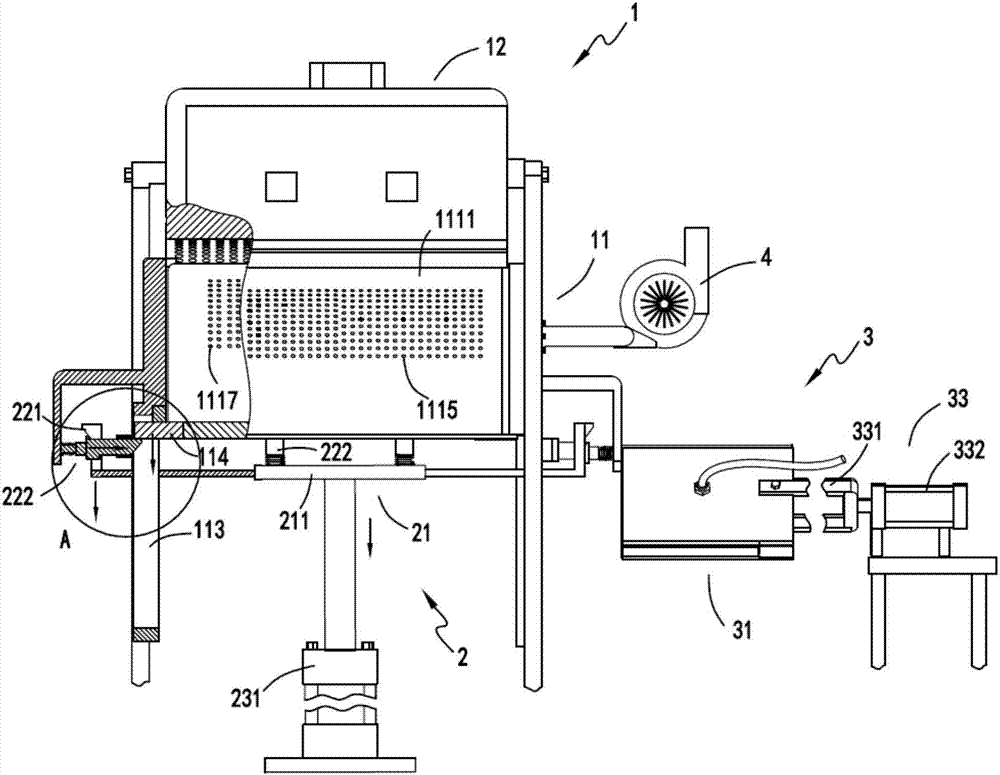

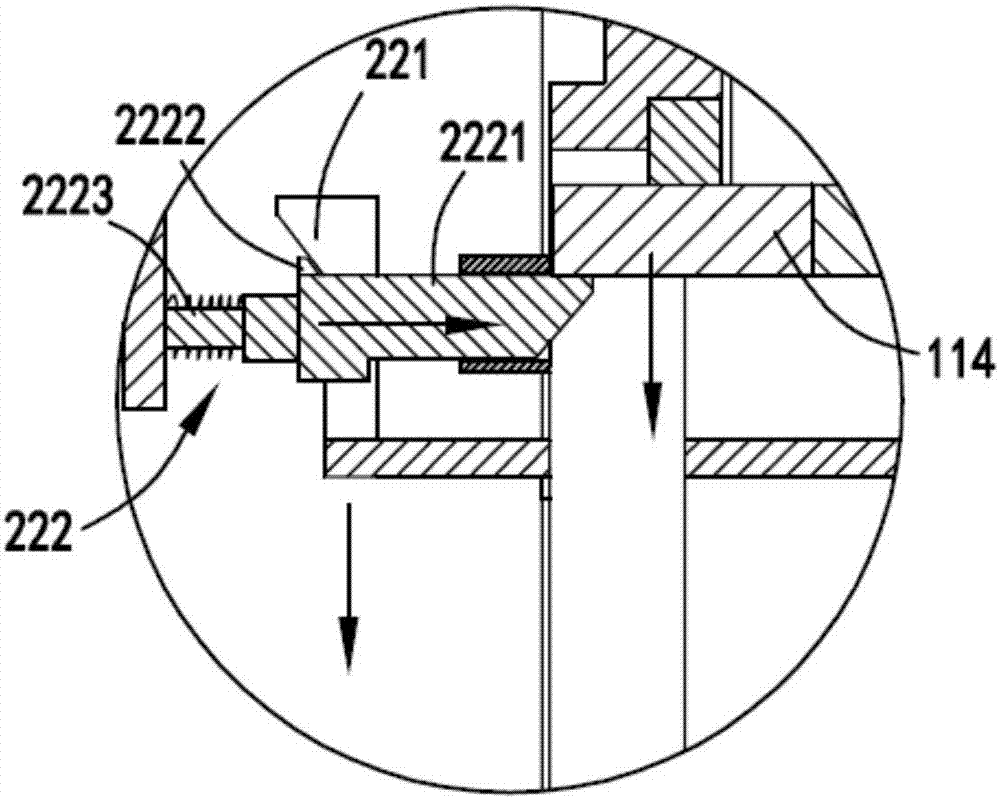

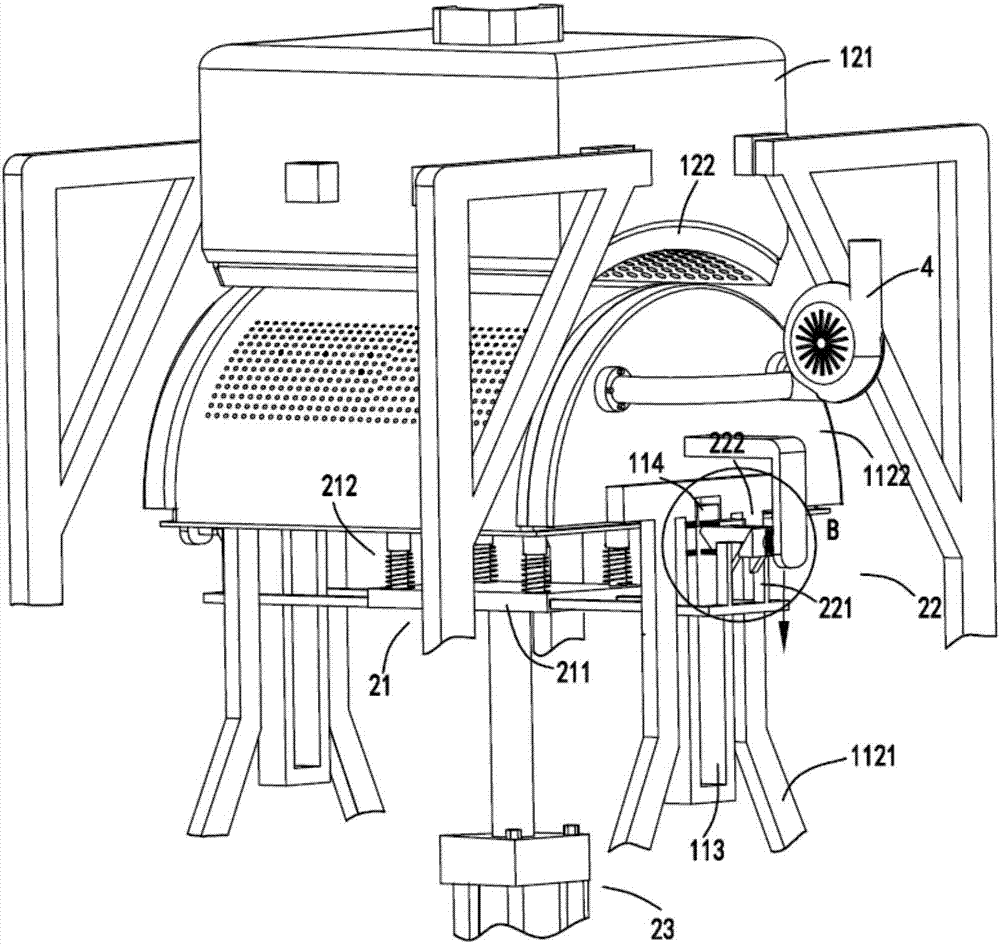

Liftable cleaning type dyeing equipment

InactiveCN106978683AAchieve liftingRealize the cleaning functionTextile treatment cleaning apparatusTextile treatment by spraying/projectingStainingEngineering

The invention relates to liftable cleaning type dyeing equipment. The liftable cleaning type dyeing equipment comprises a dyeing part, a lifting supporting part and a washing part. The dyeing part comprises an auxiliary mechanism and a spray-dyeing device. The auxiliary mechanism comprises a supporting assembly and a seal supporting assembly. The lifting supporting part is arranged bellow the auxiliary mechanism and comprises a bearing assembly, a locking assembly and a power assembly, the bearing assembly is driven by the power assembly to bear the supporting assembly to do lifting motion, and when the supporting assembly ascends to be in butt joint with the seal supporting assembly, the power assembly synchronously drives the locking assembly to lock the supporting assembly. The washing part is arranged on one side of the lifting supporting part and comprises a washing assembly a, a washing assembly b and a push-and-pull assembly. The washing assembly a and the washing assembly b are driven by the push-and-pull assembly to clean the supporting assembly. The problems that dyeing equipment is inconvenient to disassemble, rapid disassembly and rapid positioning and fixing are hard to achieve, and the dyeing quality is poor due to the fact that the dyeing equipment is not cleaned for a long time are solved.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

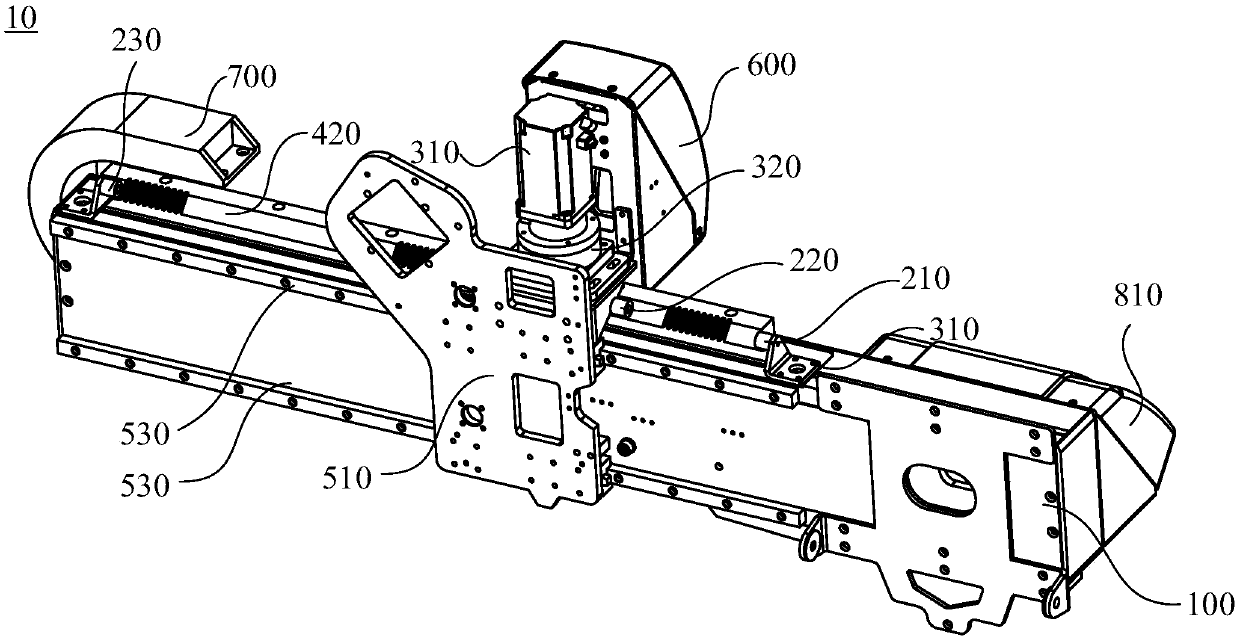

Servo manipulator and mechanical original point resetting method thereof

PendingCN109514562AEnsure consistencyHigh precisionProgramme-controlled manipulatorMotor driveElectric machine

The invention relates to a servo manipulator and a mechanical original point resetting method thereof. The servo manipulator comprises a fixed support, a stop block, an abutting connection block, a servo motor and a controller. The stop block is arranged on the fixed support. The abutting connection block can be in abutting contact with the stop block. The servo motor is used for providing power.The controller is electrically connected with the servo motor, and is used for controlling the servo motor, so that the servo motor drives the abutting connection block to move in the direction closeto the stop block till the abutting connection block abuts against the stop block; a torque value of the servo motor is controlled to increase to a preset torque value, and the torque value of the servo motor is enabled to continue to increase by a preset time period; and the servo motor is controlled to drive the abutting connection block to move by preset distance in the direction away from thestop block, and the position where the abutting connection block after being moved is located serves as the position of a mechanical original point. The servo manipulator and the mechanical original point resetting method thereof can guarantee the consistency of the mechanical original point, the resetting precision of the mechanical original point is high, manual adjusting and correcting are notneeded, and interference colliding between movement mechanisms can be prevented.

Owner:GUANGDONG TOPSTAR TECH

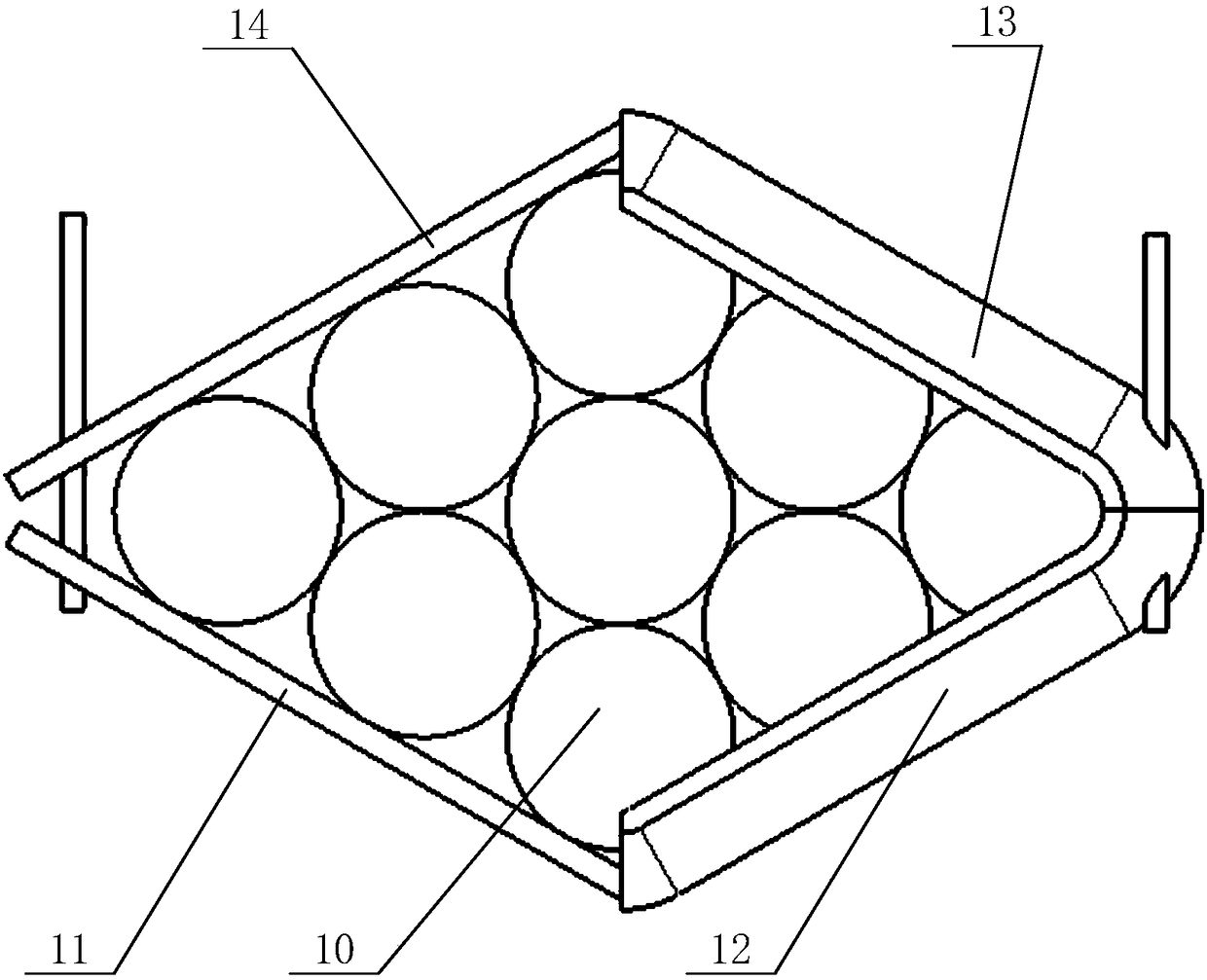

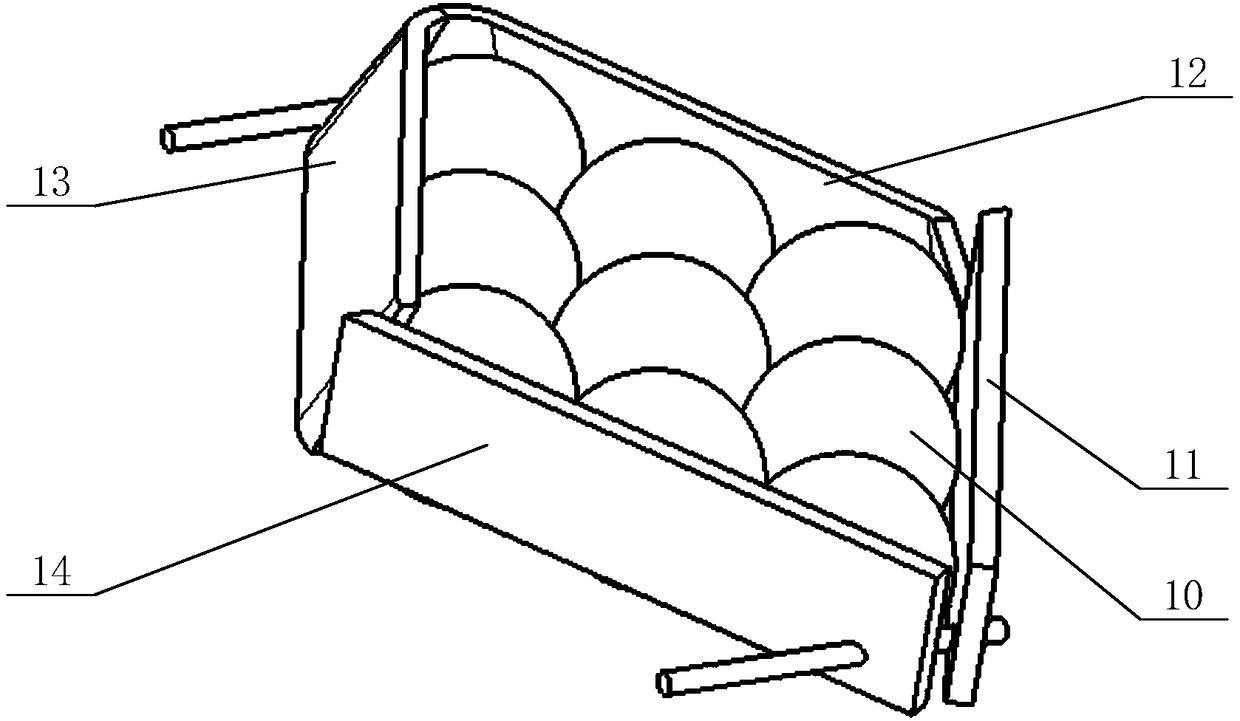

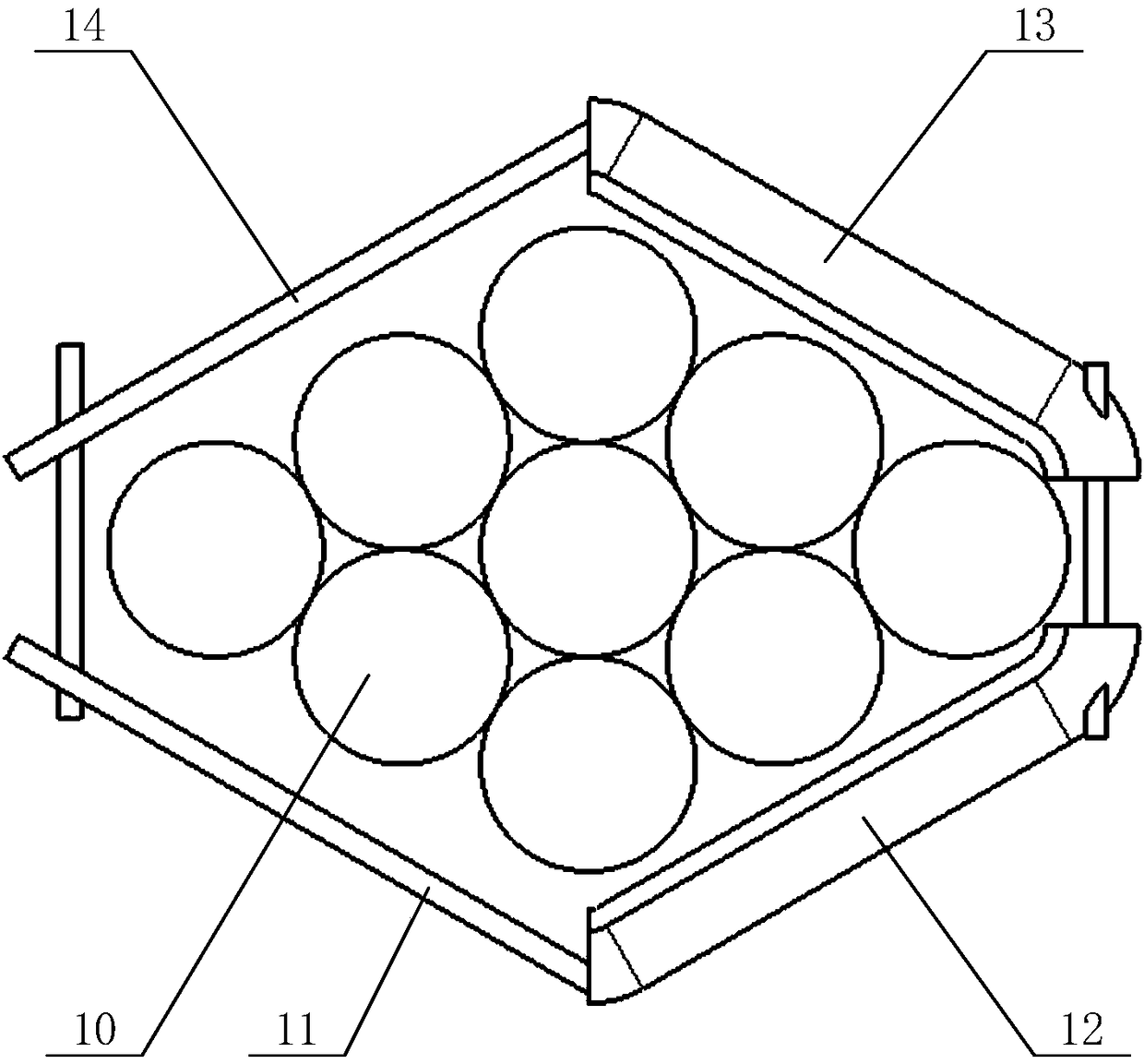

Billiard group positioner

The invention relates to the technical field of billiard placing devices in billiard sport, in particular to a billiard group positioner. The billiard group positioner comprises a polygonal frame forenclosing a billiard group, wherein the polygonal frame comprises a plurality of baffle plates; the plurality of baffle plates include moving baffle plates capable of horizontally moving; through theoutward and inward horizontal movement of the moving baffle plates, a using structure of the polygonal frame is switched; the using structure comprises an unfolding structure for changing the billiardplacing sequence and a gathering structure for positioning and upwardly breaking away from the billiard group; for the unfolding structure, the vertical projection area of the inner edge of the polygonal frame is equal to or larger than the horizontal area occupied by the billiard group, so that each billiard can vertically move; for the gathering structure, the plurality of baffle plates includeupper baffle plates capable of pressing against adjacent billiards and only pressing against upper contact points, and the polygonal frame can limit pressing of the adjacent billiards in the billiardgroup. According to the invention, the billiard group positioner significantly improves the billiard placing convenience and the positioning accuracy.

Owner:屈国栋

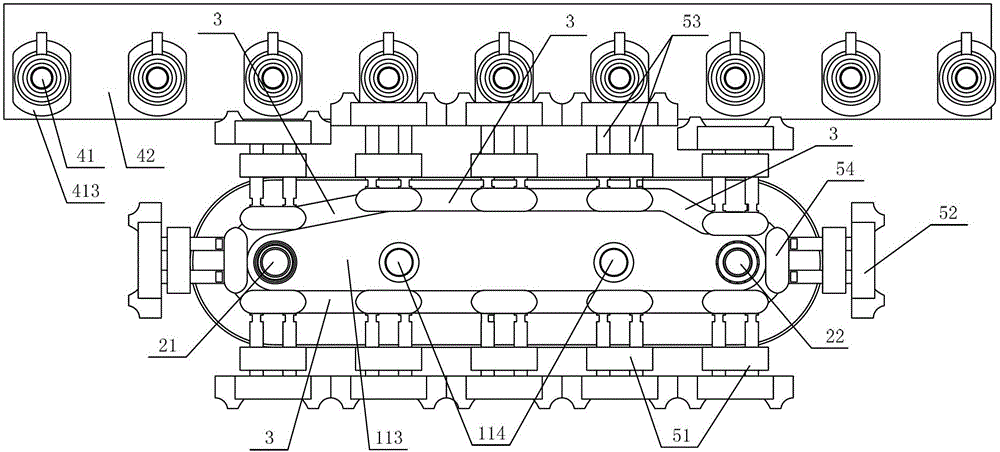

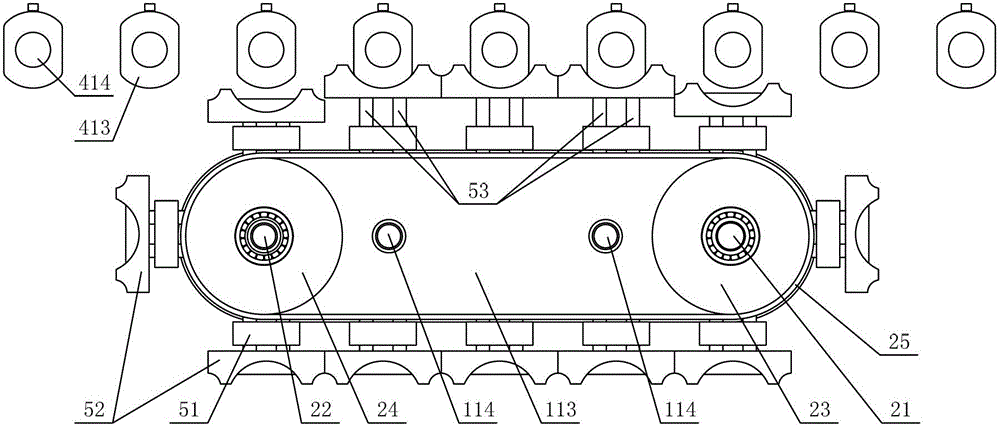

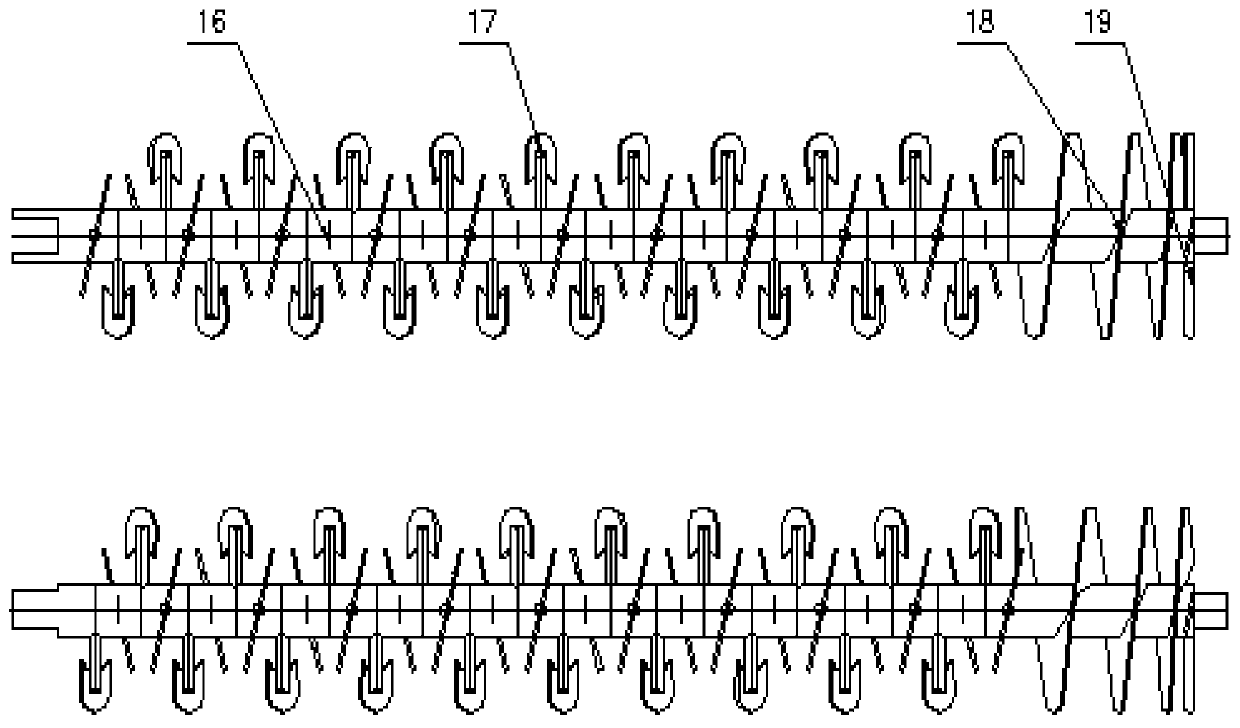

Traveling device of frame spinning automatic doffer

The invention relates to a traveling device of a frame spinning automatic doffer, belonging to the technical field of frame spinning doffing equipment. The traveling device comprises a base, a motor, a driving shaft, a driven shaft, a driving wheel, a driven wheel, a transmission piece, a guide rail and a plurality of stretching units. The device utilizes the motor to drive the stretching units to continuously move through a transmission mechanism, simultaneously utilizes the guide rail to realize sliding bar stretching, and utilizes a dialing block to dial a spindle whorl so as to realize the function of driving the doffer to travel, so that exact positioned traveling of the doffer is realized and slippage phenomenon is avoided. Because the dialing block is stretching, the interference between the dialing block and the spindle whorl in the transmission piece movement process is avoided; and because the center lines of the spindle whorl and spindles are consistent, the traveling accuracy is guaranteed. Due to use of the device, the upper and lower rails of the traditional ring spinner are not needed to be changed; and the device is simple and reliable in structure, and low in manufacture and maintenance cost, and is suitable for intermittent moving type or continuous moving type automatic doffers.

Owner:QINGDAO CHENGYANG HUAXIANG TEXTILE MACHINERY PLANT +1

Transverse flexible supporting structure of top-tensioned vertical pipe

ActiveCN111232142AReduce bending momentReduce relative horizontal displacementWaterborne vesselsFloating buildingsClassical mechanicsStructural engineering

The invention discloses a transverse flexible supporting structure of a top-tensioned vertical pipe. A support assembly includes: a support body, wherein the moon pool is horizontally distributed in amoon pool through which a top tension type vertical pipe on the floating platform penetrates; wherein the supporting main body is flexibly connected with the moon pool, a plurality of openings for the top tension type vertical pipes and seabed equipment to penetrate through are formed in the supporting main body, and the number and the positions of the openings correspond to the number and the positions of the top tension type vertical pipes on the floating platform; and a limiting mechanism is movably arranged on each opening, and the limiting mechanisms limit the horizontal movement of thetop tension type vertical pipes when the floating platform performs in-place operation. According to the transverse flexible supporting structure, the relative horizontal displacement of the verticalpipe and the platform can be reduced, interference and collision between the vertical pipe and the platform structure are avoided, and meanwhile the bending moment of the vertical pipe at the supporting structure can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

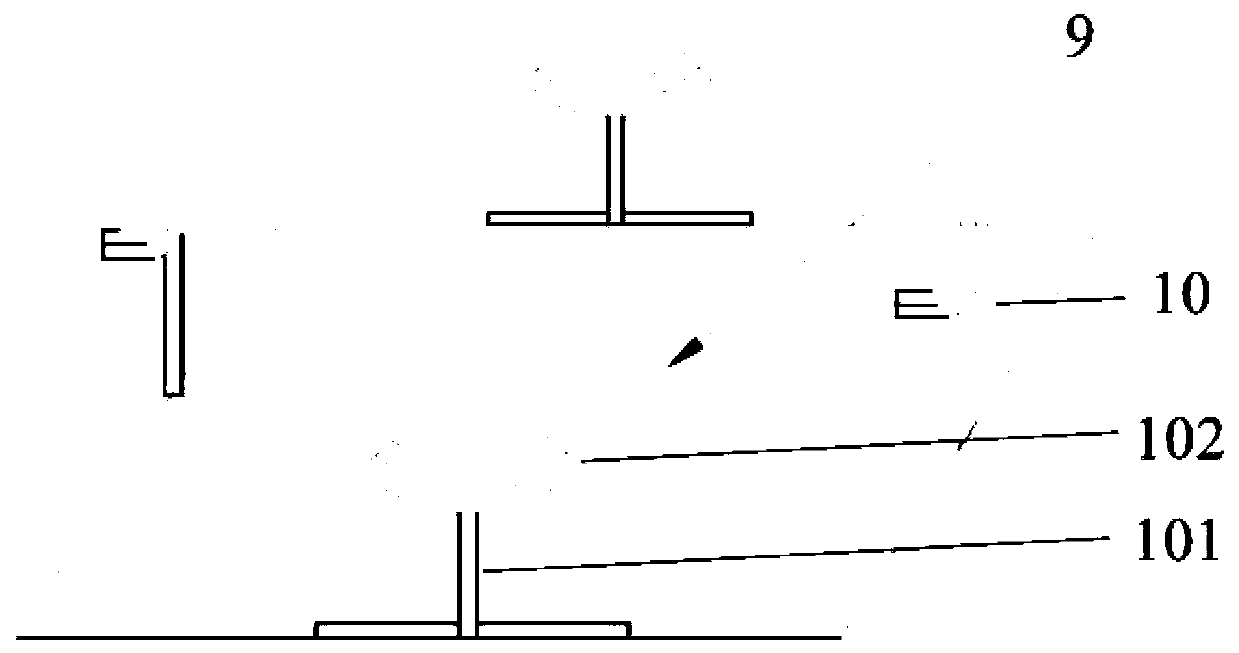

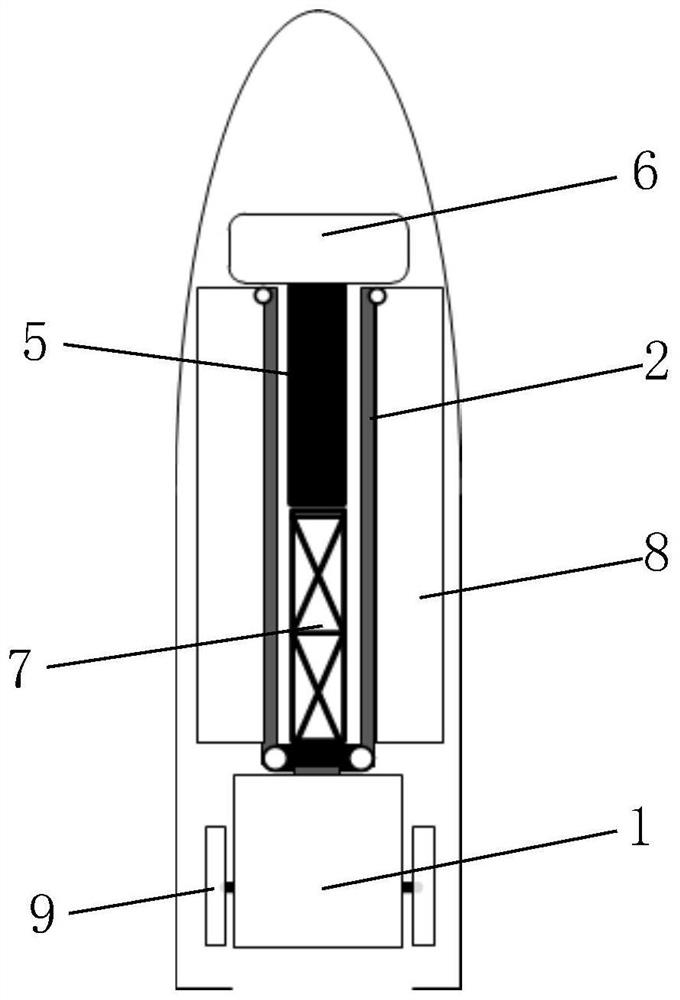

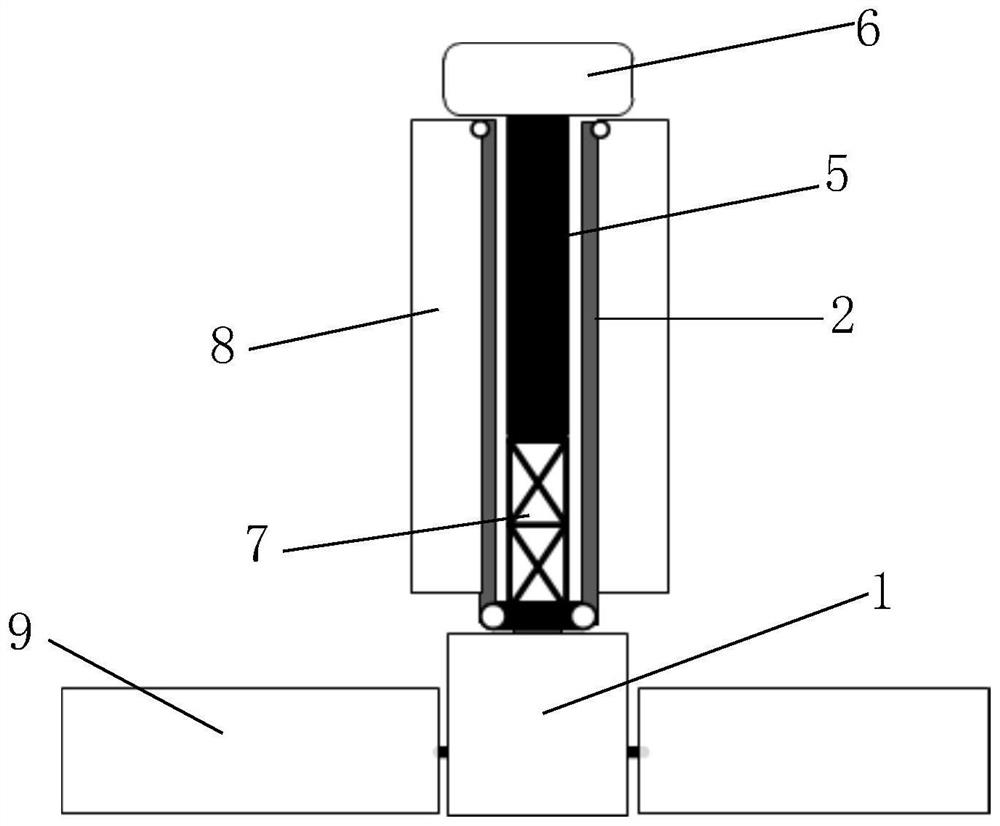

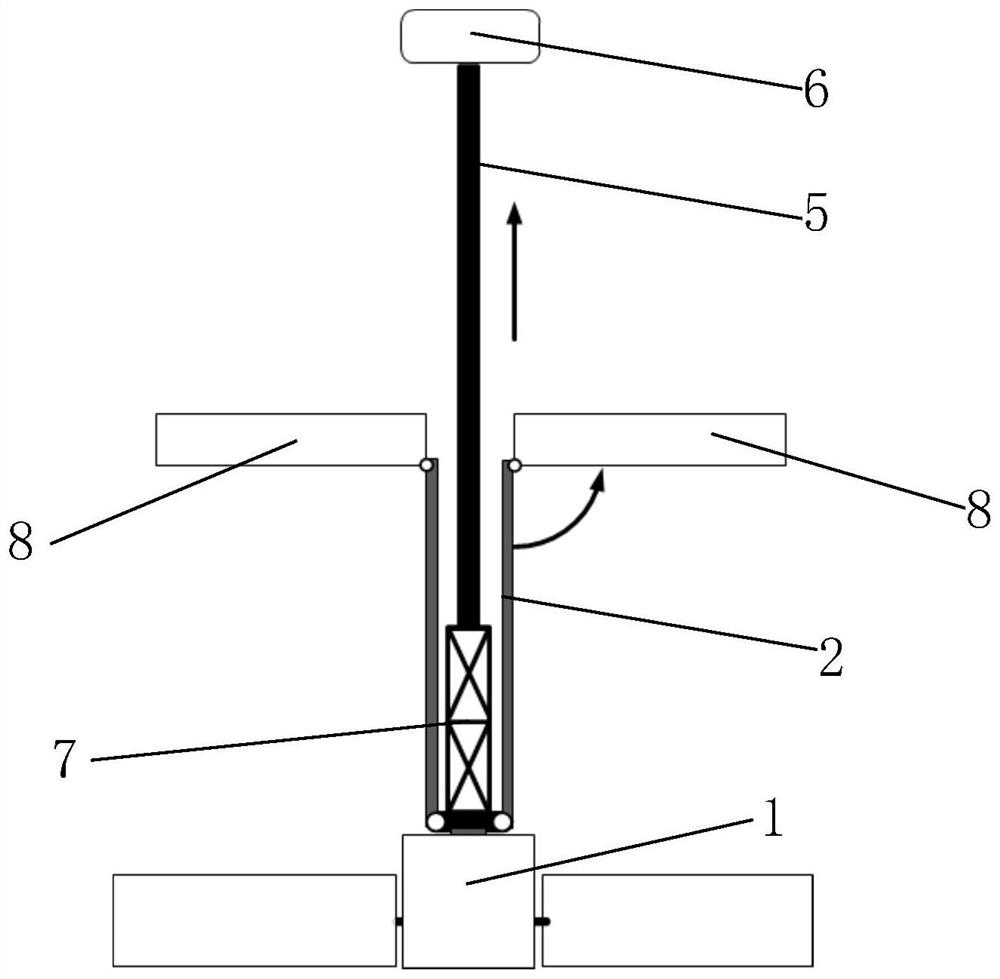

On-orbit ultra-large type deployable space structure system

ActiveCN113258249ASmall structure sizeLarge structure areaPivotable antennasAntenna adaptation in movable bodiesSpatial structureMechanical engineering

The invention discloses an on-orbit ultra-large expandable space structure system. The system comprises a star body; a plurality of rib rods which are circumferentially arranged with the star body as the center, and have first ends hinged to the star body; a plurality of ring beams which are respectively arranged between second ends of the adjacent rib rods, the second ends of the rib rods being connected with the adjacent ends of the adjacent ring beams through hooke joints; a plurality of foldable diagonal bars of which the two ends are hinged to the star body and the second ends of the corresponding rib rods respectively; and a plurality of first unfolding mechanisms through which the rib rods are relatively fixed to the star body, and which can drive the rib rods to rotate away from the star body so as to be unfolded. During folding, the second ends of the rib rods draw close to one another, and the ring beams and the diagonal bars are folded; and during unfolding, the first unfolding mechanisms drive the rib rods to rotate and unfold, and the rib rods drive the ring beams and the diagonal bars to unfold. The system is small in size and large in area after being unfolded.

Owner:SHANGHAI AEROSPACE SYST ENG INST

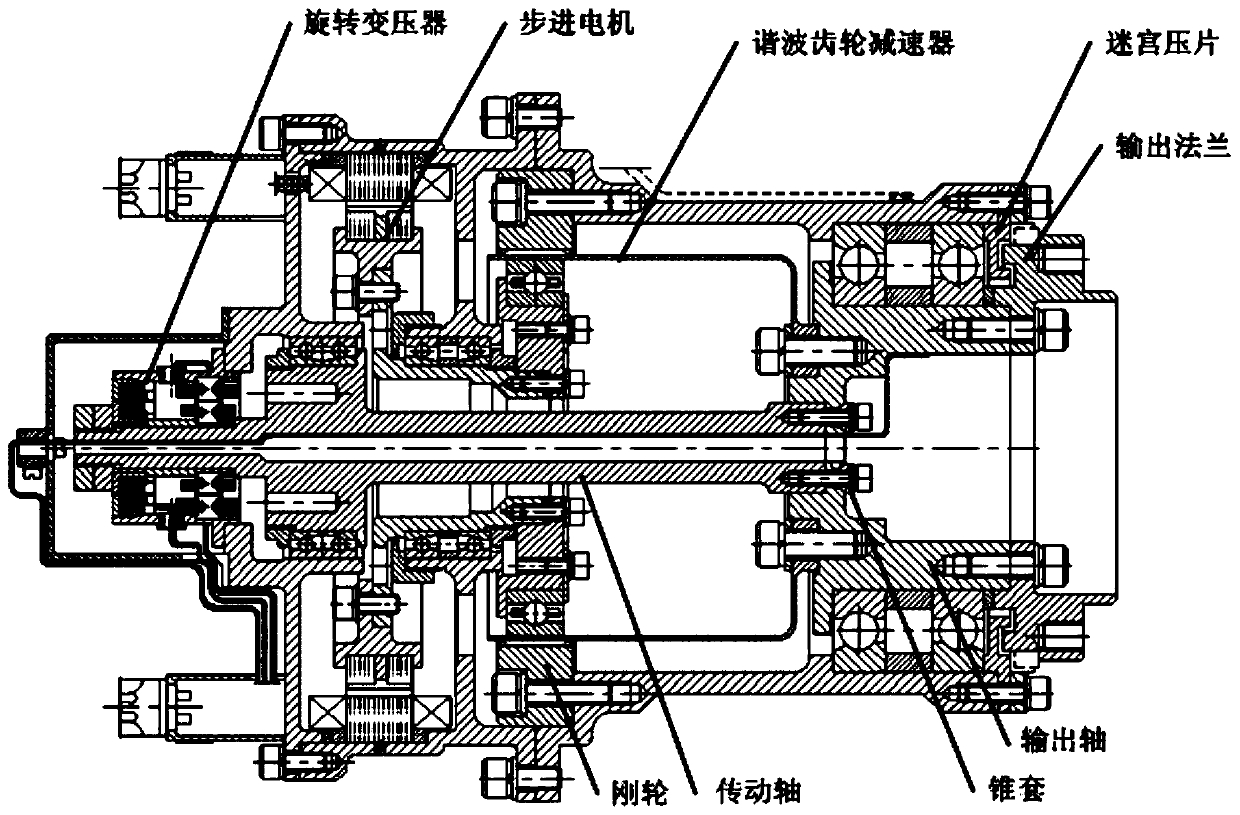

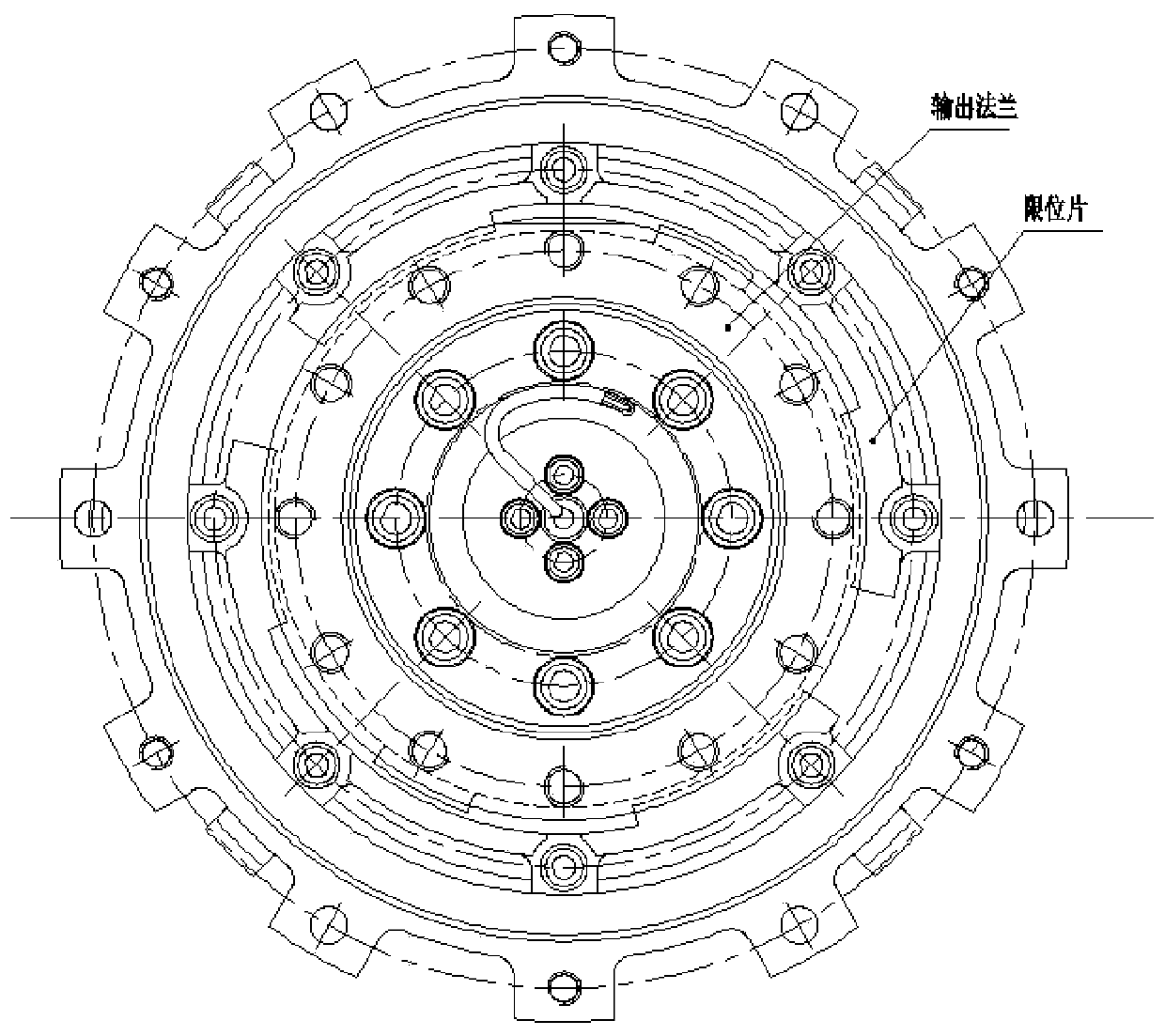

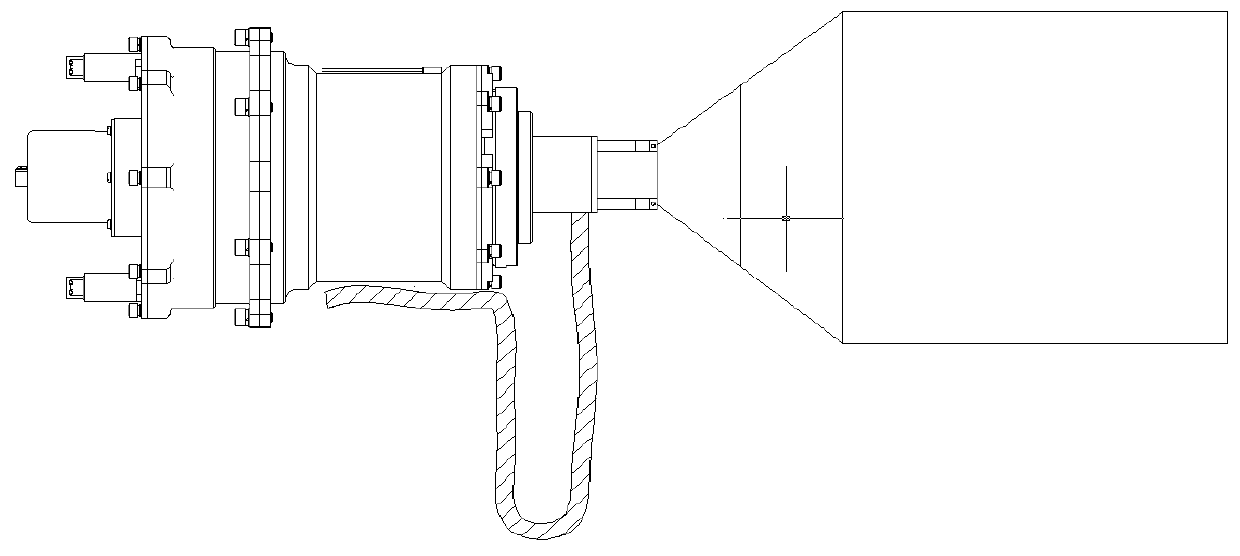

Swing type solar panel driving mechanism

ActiveCN111140636AIncrease stiffnessImprove reliabilityGearingMechanical energy handlingElectric machineGear wheel

The invention relates to a swing type solar panel driving mechanism. The structure of the swing type solar panel driving mechanism comprises a rotary transformer, a stepping motor, a harmonic gear, anoutput shaft, a shell and a torsional pendulum cable; the fixed parts of the stepping motor and the harmonic gear are mounted on the shell; the stepping motor is connected with the harmonic gear, theharmonic gear is used for reducing the rotating speed of the stepping motor and transmitting the torque of a rotating shaft of the stepping motor to the output shaft, and the output shaft is used forbeing connected with an external solar panel and driving the solar panel to swing; the rotary transformer is used for measuring the rotation angle of the output shaft; and one end of the torsional pendulum cable is connected to an external actuating mechanism, and the other end of the torsional pendulum cable is connected to the shell of the drive mechanism. According to the swing type solar panel driving mechanism, a method for realizing electric signal transmission by replacing a slip ring with the torsional pendulum cable is adopted, and low weight, high rigidity, high reliability and longservice life are realized.

Owner:BEIJING INST OF CONTROL ENG

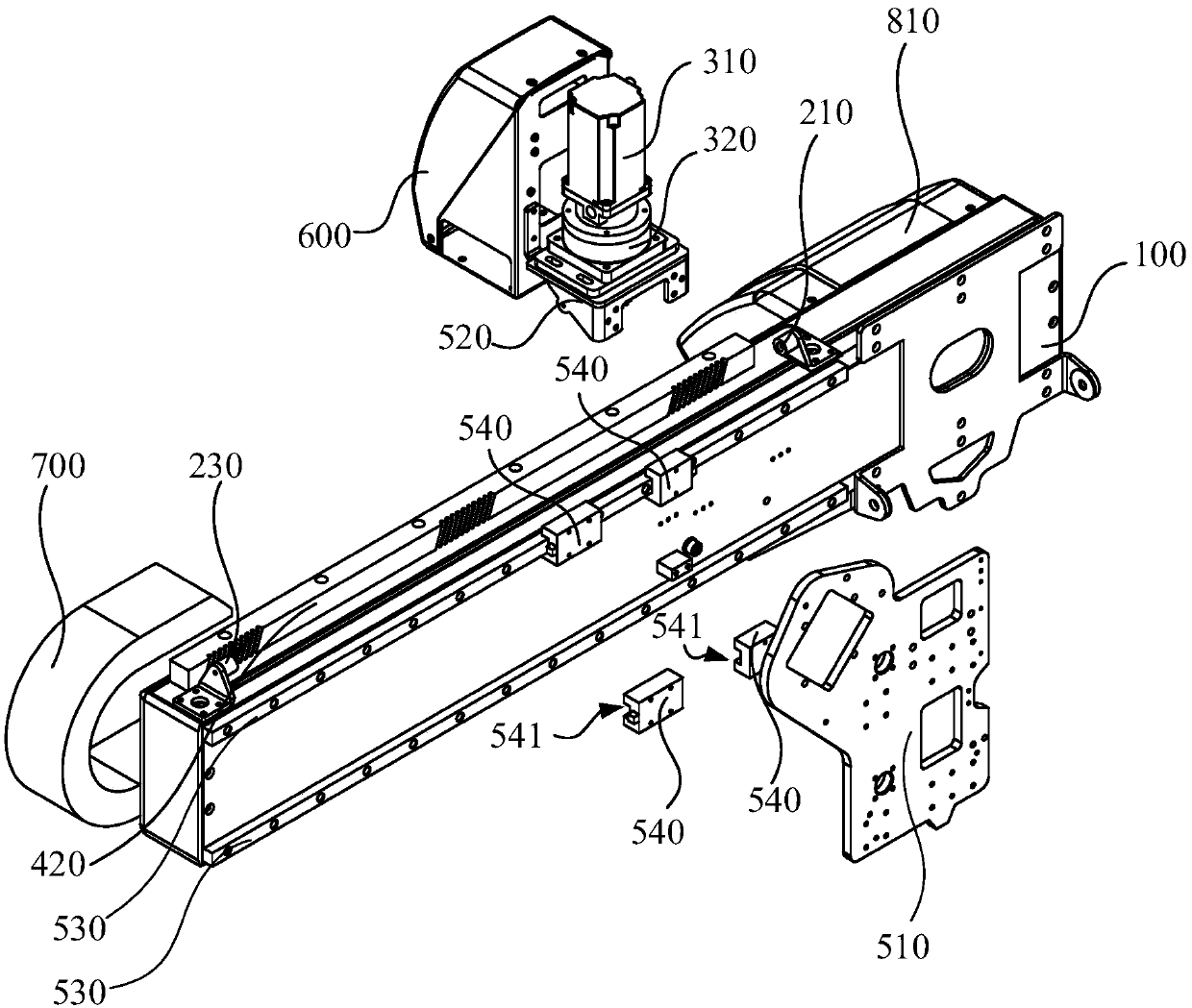

Planetary gear mechanism detecting and marking device

PendingCN114178705ARealize assembly line manufacturingImplement testLaser beam welding apparatusGear wheelDrive by wire

The invention discloses a planetary gear mechanism detecting and marking device, which has the functions of automatic testing and automatic marking, and comprises a conveying mechanism which is used for conveying a planetary gear mechanism and is provided with a discharging station; the clamping manipulator is arranged on one side of the discharging station; the laser marking mechanism is arranged on one side of the clamping manipulator and is provided with a marking station; the detection mechanism is arranged on one side of the clamping manipulator and comprises a base; the number of the supporting seats is two, and the two supporting seats are oppositely arranged and can be close to each other; the detection station is located between the two supporting seats; the motor is arranged on one supporting seat, and an input shaft is arranged at the output end of the motor; the load assembly is arranged on the other supporting seat and is provided with an output shaft, and the input shaft and the output shaft are coaxially arranged; and the first linear drivers are arranged on the base, the number of the first linear drivers is two, and the first linear drivers are respectively connected with the two supporting seats so as to drive the input shaft and the output shaft to be close to the detection station.

Owner:GUANGDONG INST OF SCI & TECH

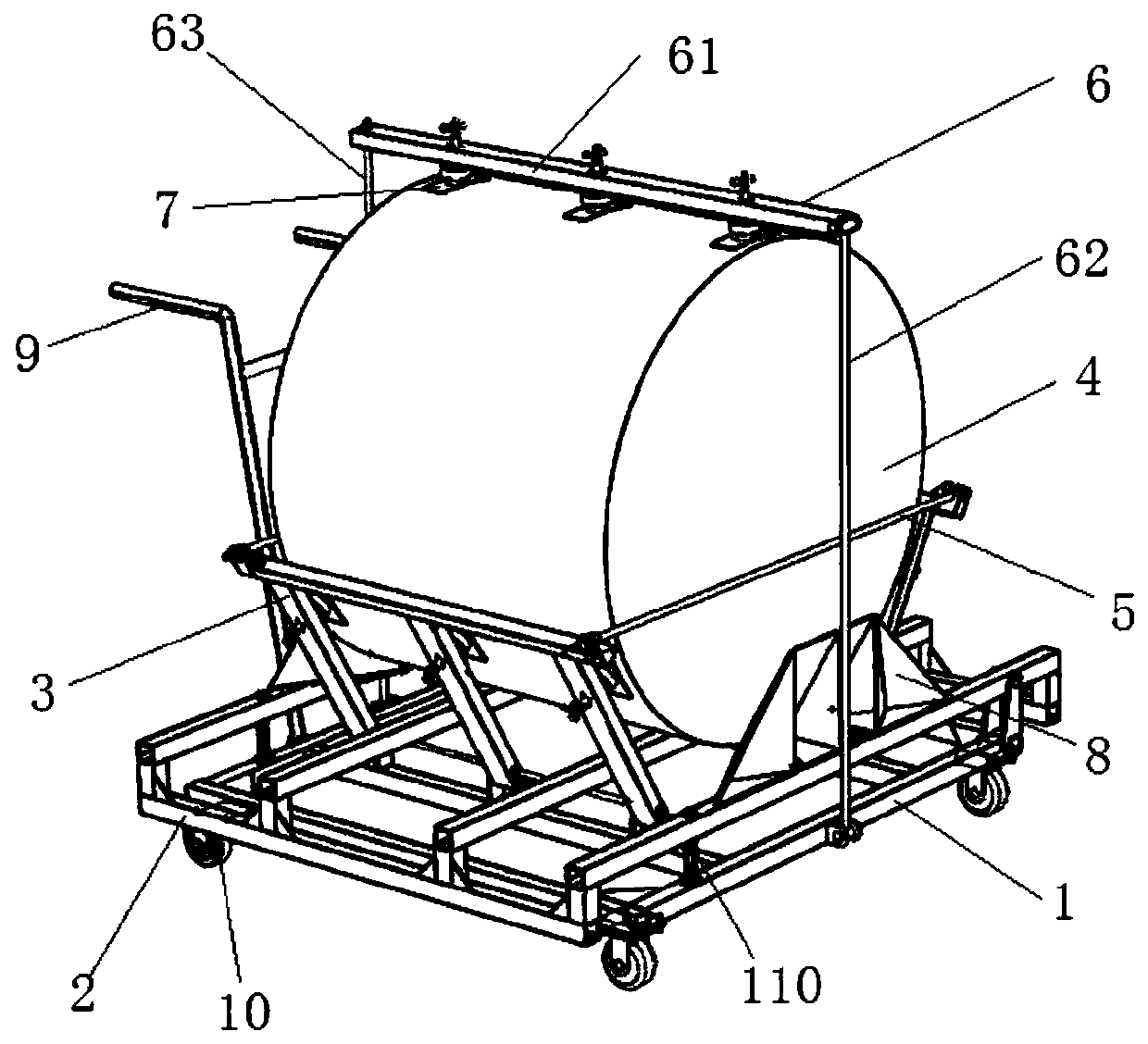

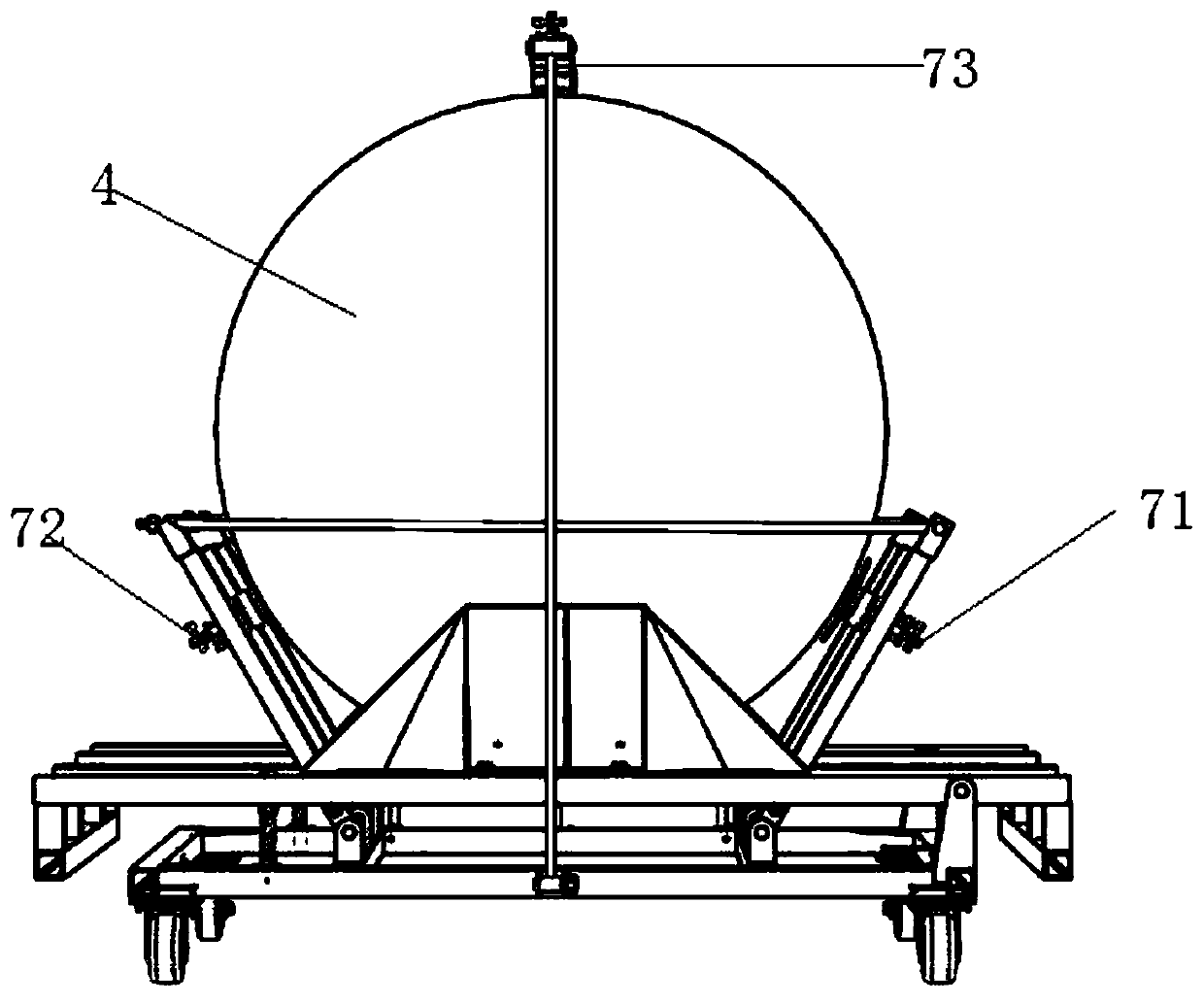

Movable round bale resilience test bench

ActiveCN110307954AFlexible steeringEasy to moveApparatus for force/torque/work measurementElasticity measurementTurning framesEngineering

The invention, which relates to the technical field of mechanization engineering of agriculture and animal husbandry, discloses a movable round bale resilience test bench mainly comprising a bottom frame, a rotating frame, a turning frame, a side bracket, load cells and guiding plates. The rotating frame is installed on the bottom frame in a rotating manner and is used for rolling a round bale onthe ground. The two guiding plates are arranged at the two sides of the rotating frame. The turning frame includes a left turning frame and a right turning frame that are arranged on the bottom frameand are located at the two sides of the round bale; and a first group of load cells and a second group of load cells are respectively disposed at the left turning frame and the right turning frame. The side bracket is arranged on the bottom frame and is provided with a third group of load cells that is arranged above the round bale. According to the invention, the changing relation of the resilience of grass materials with time after rolling can be obtained; and obtained parameters can be used for further optimization of the structure and performance parameters of the round bale machine and the mechanical quality requirements of the bale rope and the wrapping film.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

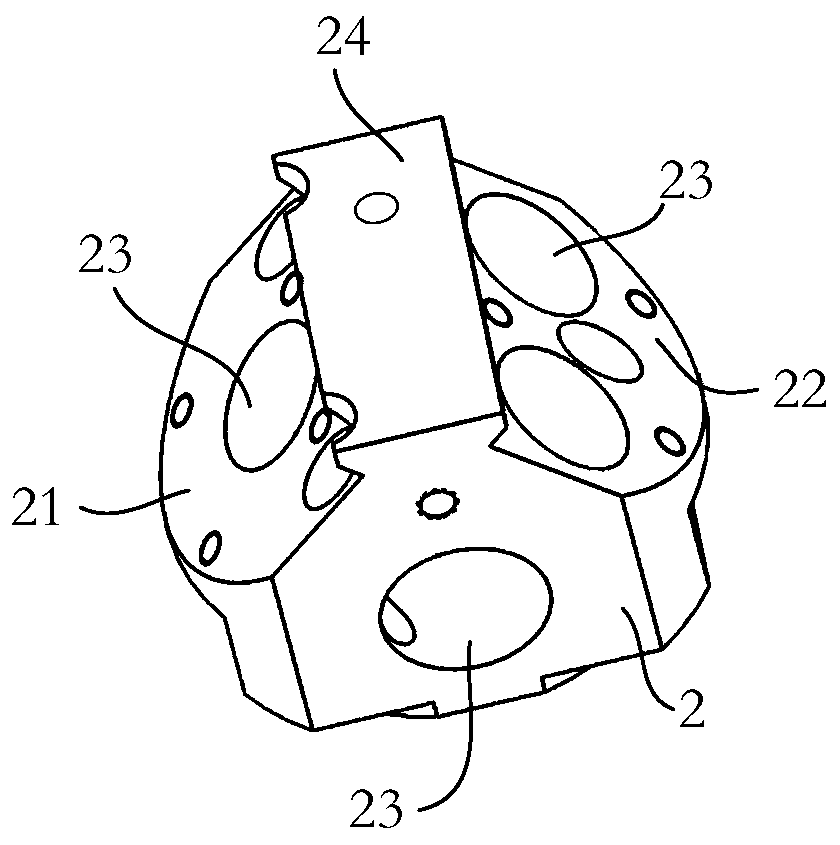

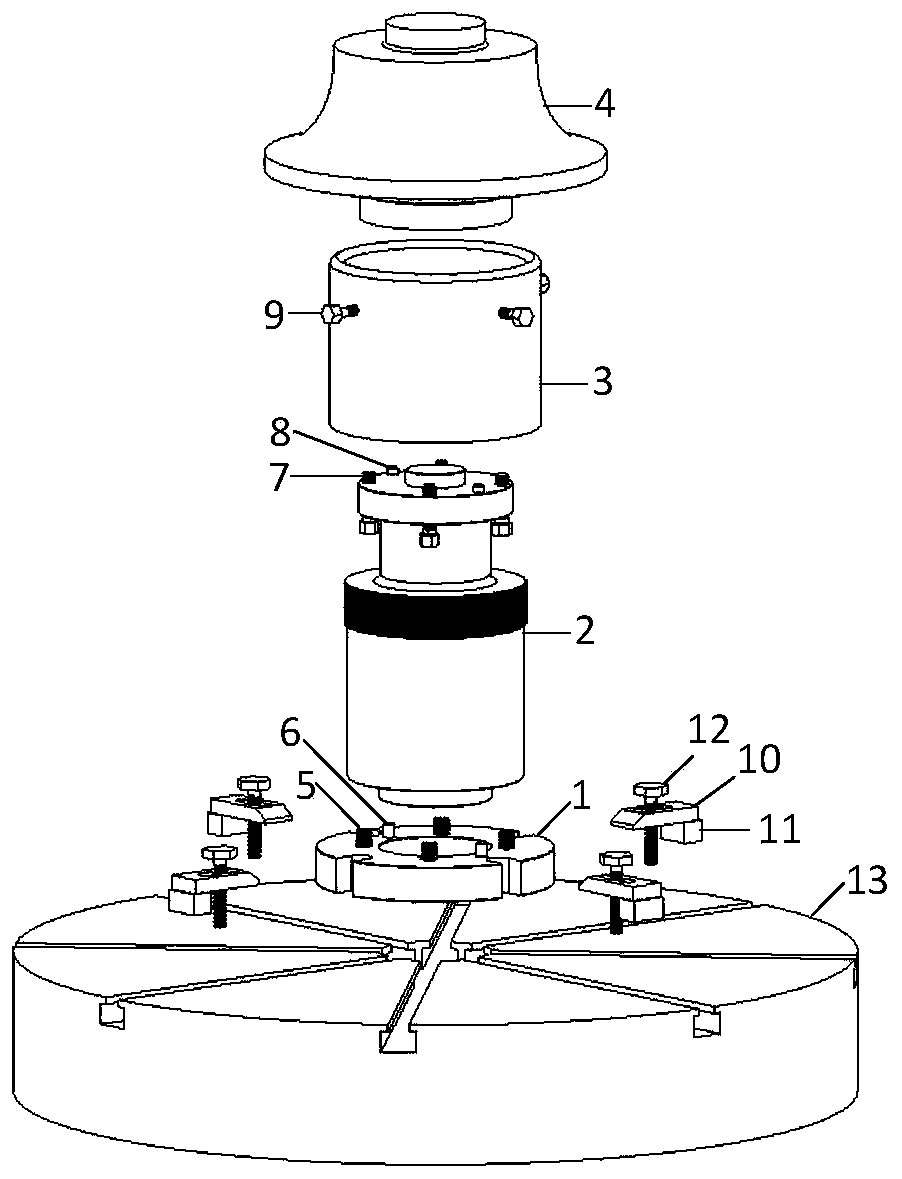

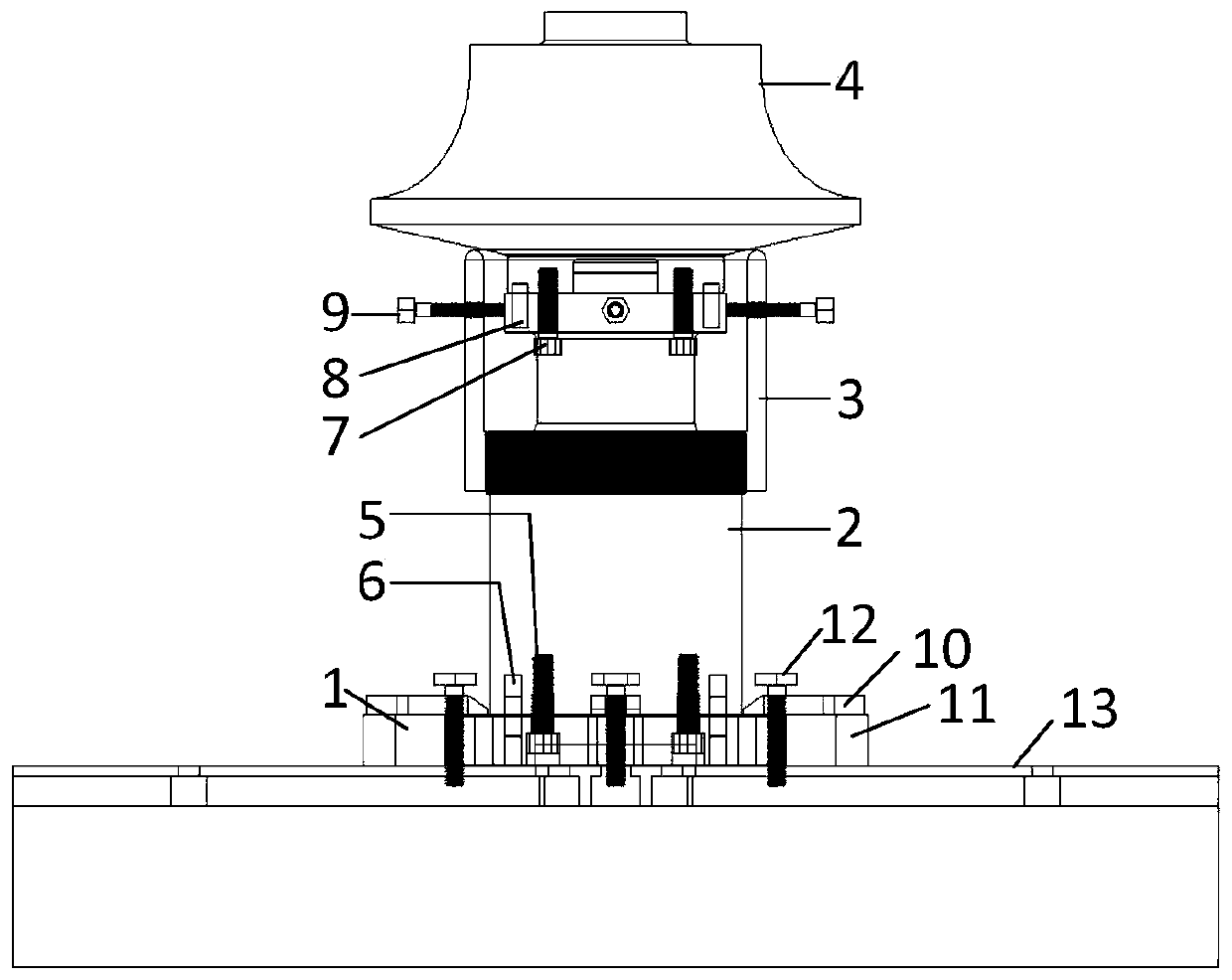

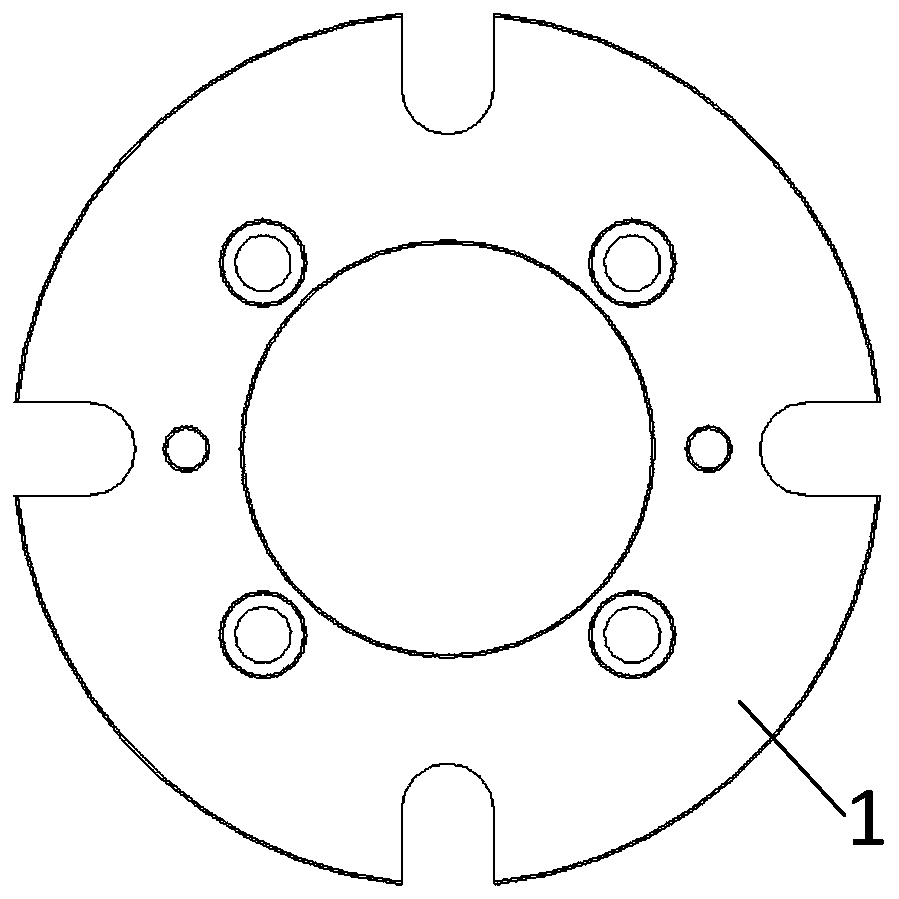

Special fixture for batch numerical control machining of centrifugal impeller with non-through-hole center and mounting method

ActiveCN110000579AAvoid Interfering CollisionsIncrease the support areaWork clamping meansPositioning apparatusNumerical controlImpeller

The invention discloses a special fixture for batch numerical control machining of a centrifugal impeller with a non-through-hole center and a mounting method of the special fixture. The mounting method comprises the following steps that a fixture shaft sleeve sleeves a fixture connecting shaft from the bottom of the fixture connecting shaft, the fixture connecting shaft is connected with a fixture base through base bolts, and the fixture connecting shaft is positioned through base pins; the fixedly-connected fixture base is fixed on a machine tool workbench, and a fixture connecting shaft outer circle is aligned on a machine tool; when each centrifugal impeller is machined, a centrifugal impeller blank is placed on the fixture connecting shaft, connecting shaft bolts are used for connecting the centrifugal impeller blank with the fixture connecting shaft, and meanwhile, connecting shaft pins are used for positioning the centrifugal impeller blank; and the fixture shaft sleeve is screwed from bottom to top until the upper end face of the fixture shaft sleeve abuts against the bottom of the centrifugal impeller blank, and shaft sleeve bolts are tightened to prevent the fixture shaftsleeve from loosening. According to the special fixture for batch numerical control machining of the centrifugal impeller with the non-through-hole center and the mounting method of the special fixture, numerical control machining clamping positioning of the centrifugal impeller can be realized, repeated alignment of a part is avoided, and then the machining precision and the machining consistency of the centrifugal impeller are ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

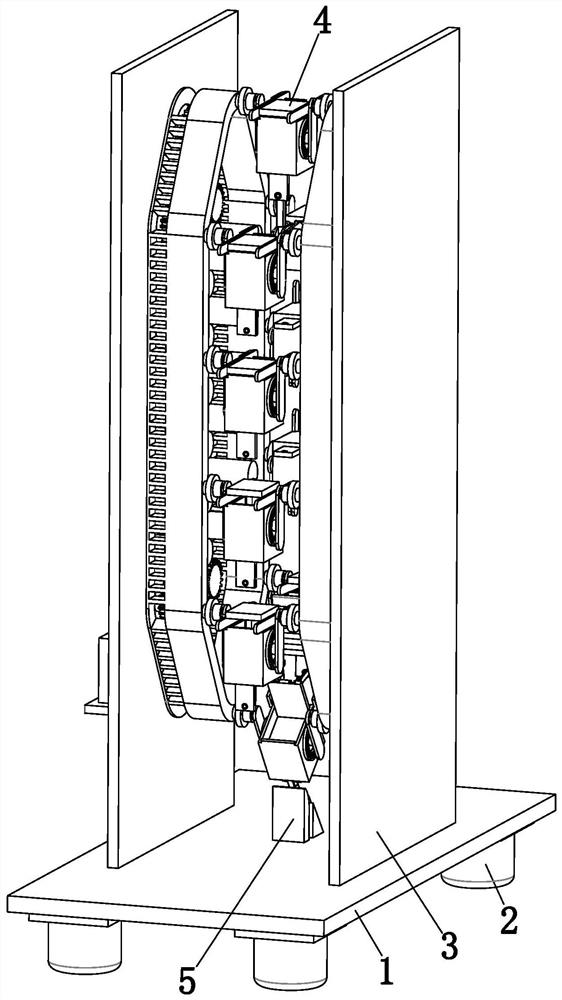

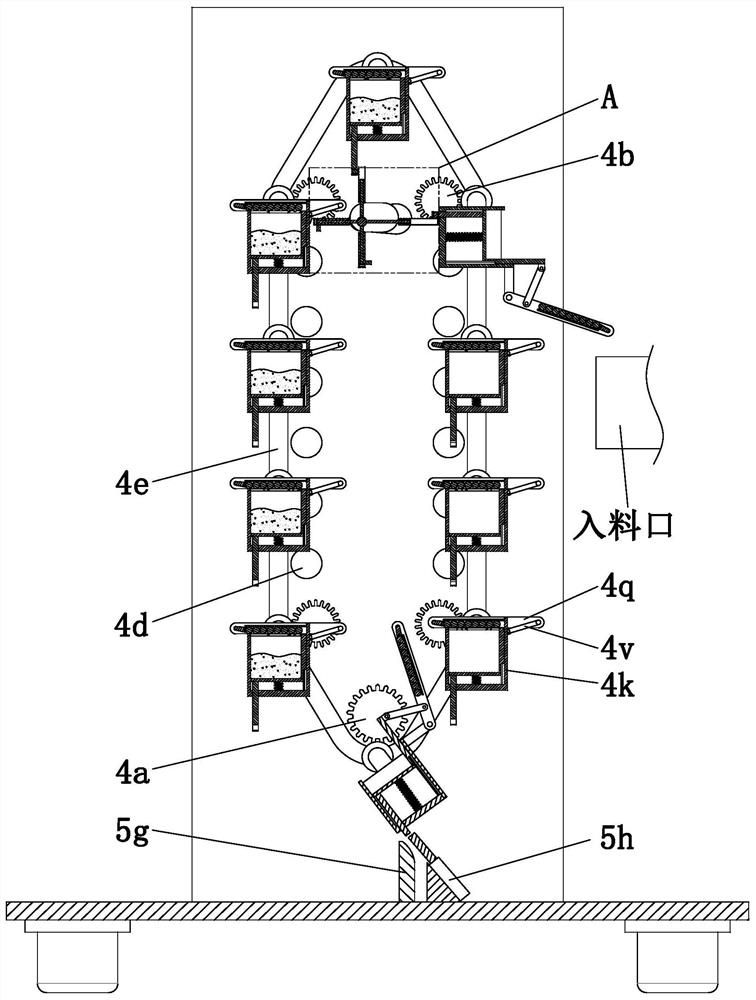

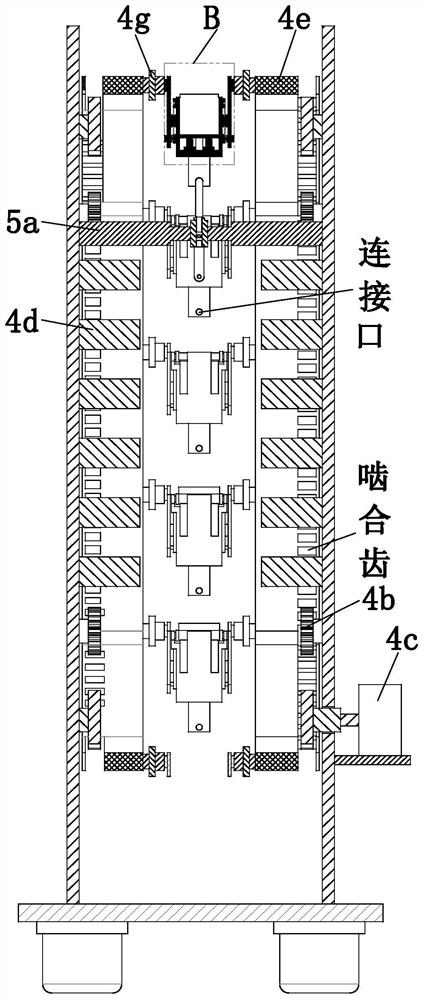

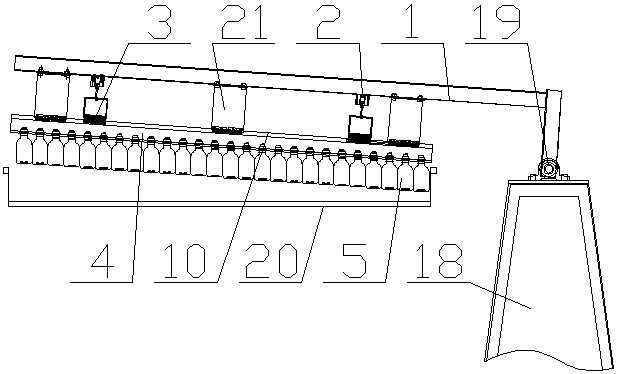

Supply conveying system for activated carbon manufacturing

InactiveCN112320208AAvoid Interfering CollisionsReduce frictionConveyorsConveyor partsActivated carbonProcess engineering

The invention provides supply conveying system for activated carbon manufacturing. The system comprises a mounting bottom plate, supporting legs, a [-shaped frame, a conveying mechanism and a turnovermechanism, and solves the problems that during assembling and fixing work of an electric appliance cabinet, a person needs to use a tool for fill activated carbon materials into a reaction kettle, inthe period, many activated carbon materials needing to be transported exist, due to the operation manner, the labor intensity of workers is increased, the working efficiency of activated carbon transportation operation is reduced, when the activated carbon materials are conveyed through an existing conveying belt, due to the fact that an inlet of the reaction kettle is usually higher, it is difficult to pour all the stored activated carbon materials into an activation furnace manually or through the conveying belt, in the transport process, mechanical vibration easily causes the phenomenon that the activated carbon raw material at a high position fall out of the equipment, so that adverse effects are brought to maintenance of the equipment and body health of workers, and the like.

Owner:宁波锦瑄环保科技有限公司

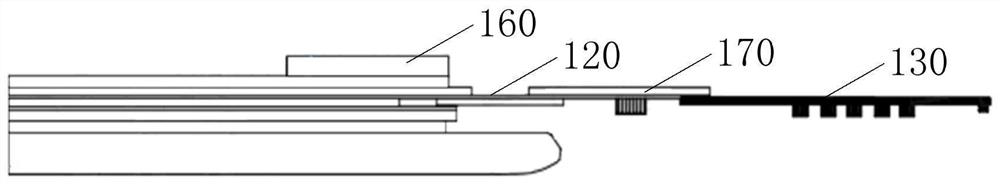

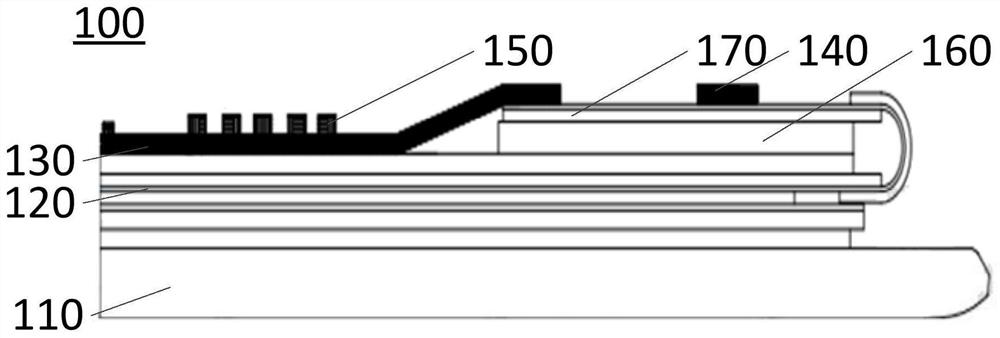

Flexible display module and preparation method thereof

PendingCN114822234AExtended service lifeSmall space ratioPrinted circuit aspectsPrinted circuit manufactureComputer hardwareFlexible circuits

The embodiment of the invention discloses a flexible display module and a preparation method thereof. The flexible display module comprises a flexible display screen, a driving chip and a circuit board, the flexible display screen comprises a display area and a bonding area, and the driving chip and the circuit board are respectively arranged on the bonding area; the circuit board comprises a first flexible circuit board and a first printed circuit board provided with an electronic device, the first printed circuit board is connected with one end of the first flexible circuit board, and the first flexible circuit board is provided with a bonding part in bonding connection with the bonding area of the flexible display screen; the first printed circuit board is bent through the first flexible circuit board, so that the first flexible circuit board, the first printed circuit board and the flexible display screen form a first space, and the electronic device is located in the first space. According to the flexible display module, the space ratio of the circuit board can be effectively reduced, so that the available space of the whole device of the flexible display module is increased, the overall performance of the flexible display device is improved, and the product competitiveness is improved.

Owner:BOE TECH GRP CO LTD +1

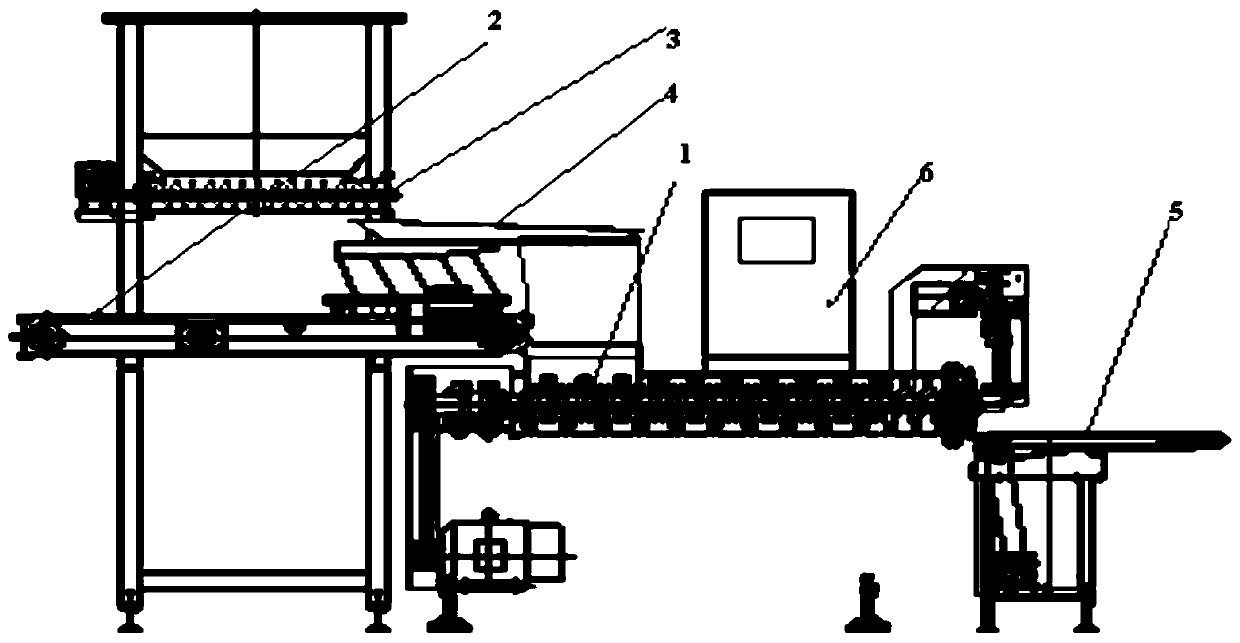

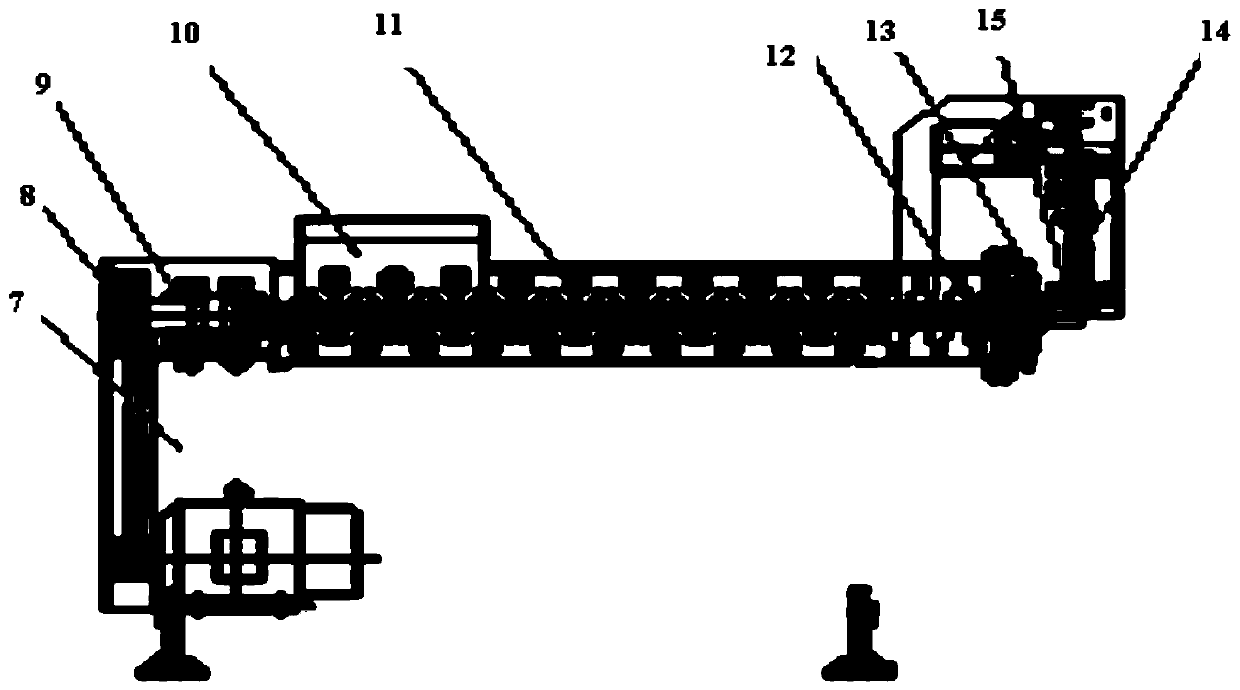

Integrated equipment for paste forming and molding of raw potato products

PendingCN110447860AIncrease stickinessSmooth feedingFood shapingGrain treatmentsEngineeringDistributor

The invention provides integrated equipment for paste forming and molding of raw potato products. The equipment comprises an integrated main unit for paste forming and molding (1), a feeding belt conveyor (2), an auxiliary material conveying device (3), an electromagnetic vibration distributor (4), a discharging belt conveyor (5) and an electric appliance control device (6), wherein the feeding belt conveyor (2) conveys cooked and sliced potatoes into a containing cavity of the integrated main unit for paste forming and molding (1), a material hopper in the auxiliary material conveying device(3) stores to-be-added powdery auxiliary materials and conveys the to-be-added powdery auxiliary materials onto an upper sieve surface of the electromagnetic vibration distributor (4), the powdery auxiliary materials are distributed through vibration and then evenly spread on a sieve plate, then evenly spread in a feeding hopper of the integrated main unit (1) through sieve holes, and mixed and stirred with the cooked material, and paste is formed through impacts, squeezed and molded, conveyed to a discharging pipe port of the integrated main unit for paste forming and molding, and chopped into cakes, falls into a belt of the discharging belt conveyor, and is conveyed by the belt to the next process to complete the functions of mixing, paste forming and molding.

Owner:SINOMACH

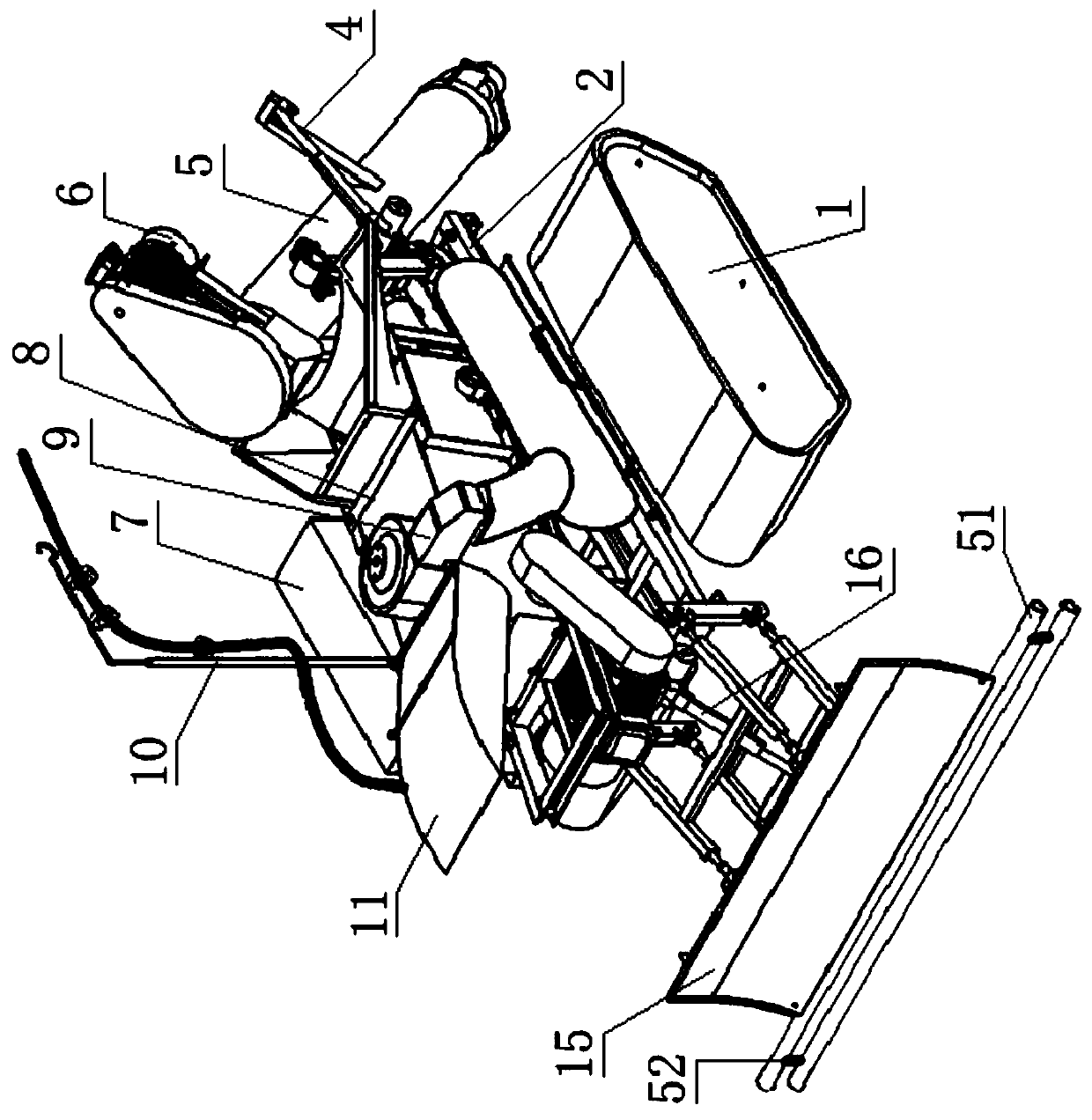

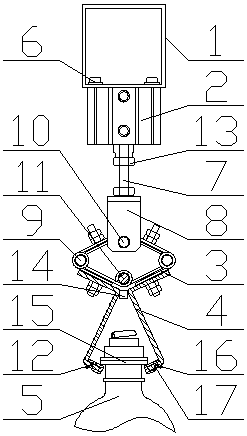

Sucking and throwing separated type steering granary flattening robot

PendingCN110733910AAchieve independent operationPrevent fallingConveyorsLoading/unloadingStructural engineeringControl theory

The invention discloses a sucking and throwing separated type steering granary flattening robot, and belongs to the field of granary flattening robots. The technical problems of how to separate an auger mechanism from a grain throwing mechanism and to give up dependence on staff are solved. The sucking and throwing separated type steering granary flattening robot structurally comprises a bottom bracket, a grain sucking auger device, a grain throwing conveying belt device, a grain flattening device, two traveling devices and a control device, wherein the bottom bracket comprises a head installation frame and a tail installation frame connected with the head installation frame end to end, and both the head installation frame and the tail installation frame are provided with steering devices;the grain sucking auger device is arranged on the tail installation frame through the corresponding steering device; the grain throwing conveying belt device is arranged on the head installation frame through the corresponding steering device; the grain flattening device is arranged on the head side of the head installation frame and located below the grain throwing conveying belt device; the twotraveling devices are both tracked traveling devices and are installed in a spaced mode, arranged on the two sides of the bottom bracket and used for driving the bottom bracket to move; and the control device is connected with the steering device, the grain sucking auger device, the grain throwing conveying belt device, the grain flattening device and the traveling devices.

Owner:SHANDONG INSPUR GENESOFT INFORMATION TECH CO LTD

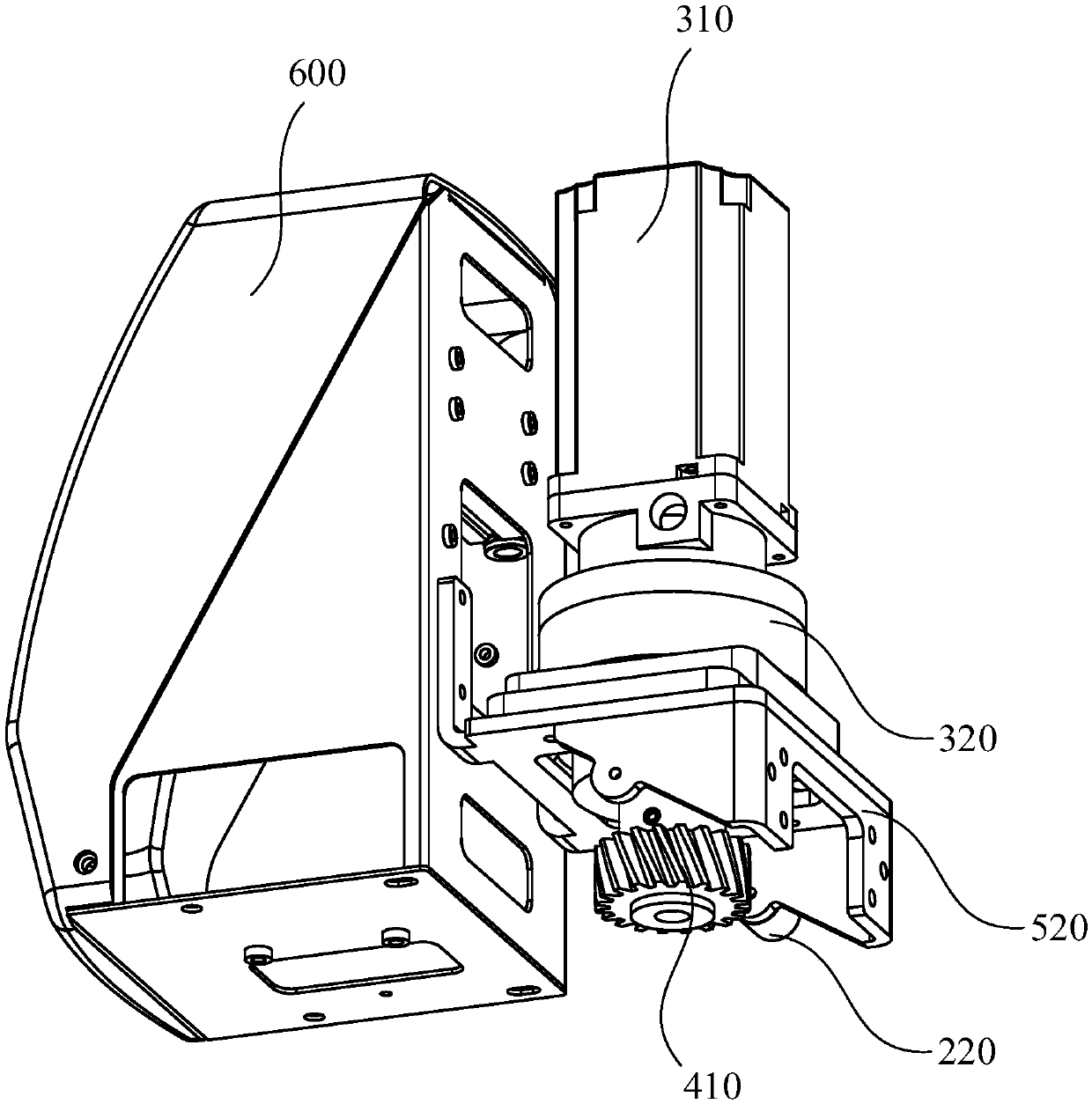

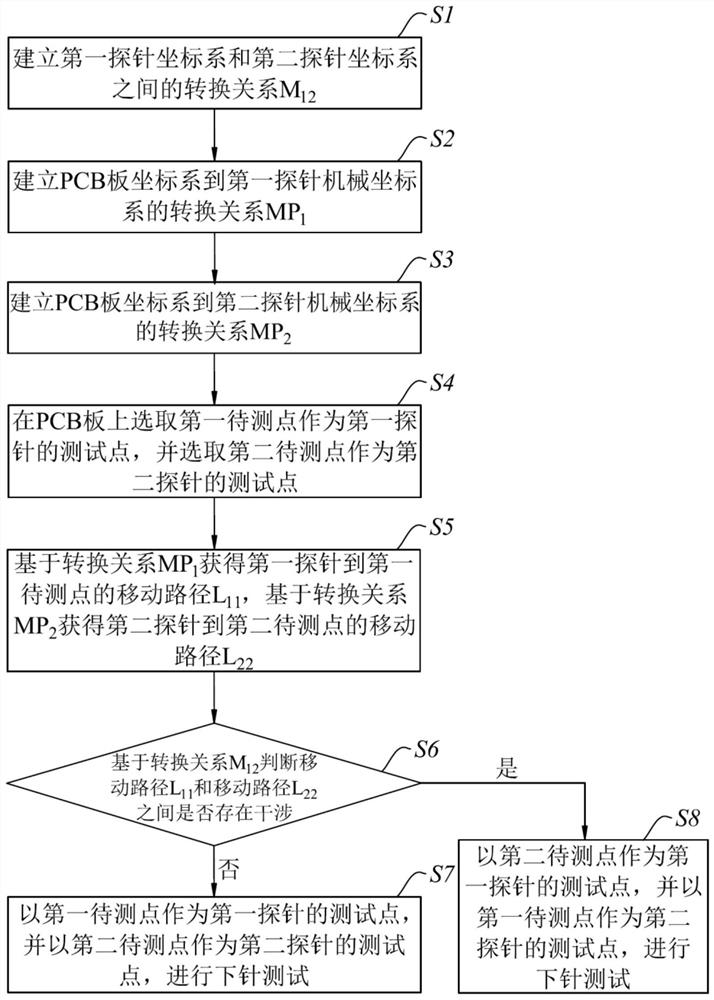

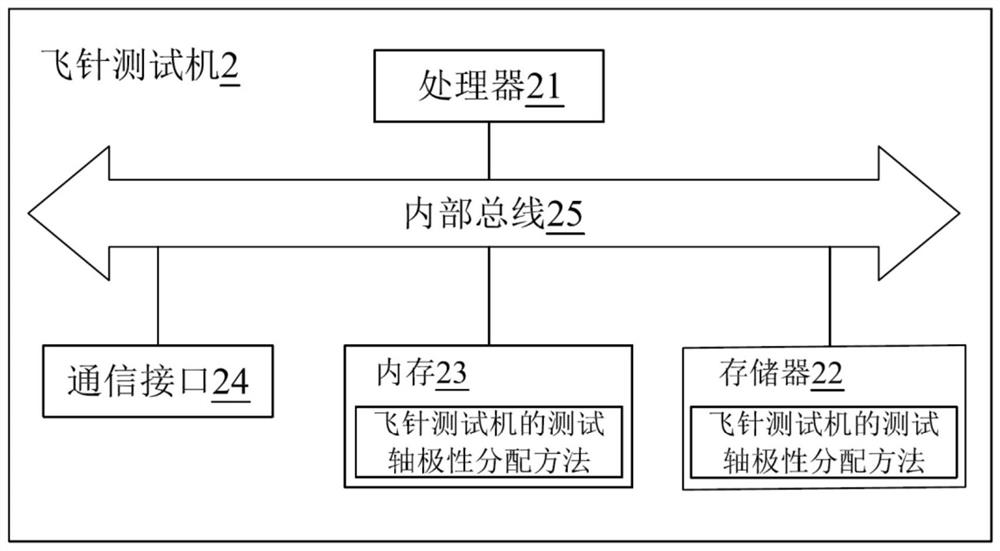

Flying probe testing machine and testing shaft polarity distribution method thereof

ActiveCN114354986AAvoid Interfering CollisionsFlexible and reliable test methodMeasurement instrument housingComputational physicsFlying probe

The invention discloses a flying probe testing machine and a testing shaft polarity distribution method thereof. The method comprises the following steps: establishing a conversion relation M12 between a first probe coordinate system and a second probe coordinate system, a moving path L11 from a first probe to a first to-be-measured point, and a moving path L22 from a second probe to a second to-be-measured point; whether interference exists between the moving path L11 and the moving path L22 or not is judged based on the conversion relation M12; and if interference exists between the moving path L11 and the moving path L22, taking the second to-be-tested point as a test point of the first probe, and taking the first to-be-tested point as a test point of the second probe, and carrying out probe placement test. According to the flying probe testing machine and the testing shaft polarity distribution method thereof, whether interference collision occurs in the testing shaft corresponding to the probe in the testing process can be judged according to the position and the corresponding relation between the testing point on the PCB and the corresponding probe, and the polarity of the testing shaft is distributed according to the judgment result, so that the testing accuracy is improved. Therefore, interference and collision of the test shaft during a lower needle test are avoided.

Owner:苏州格拉尼视觉科技有限公司

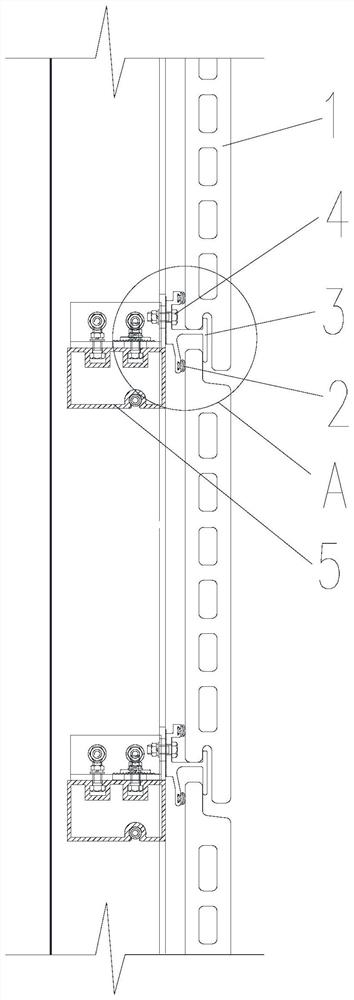

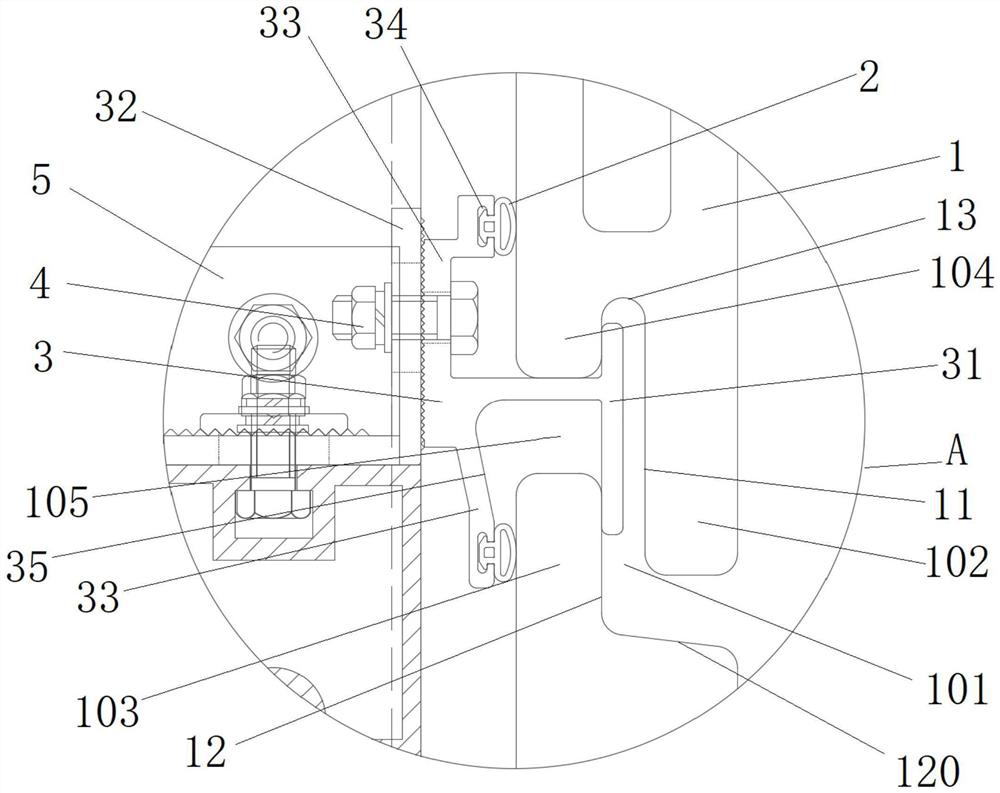

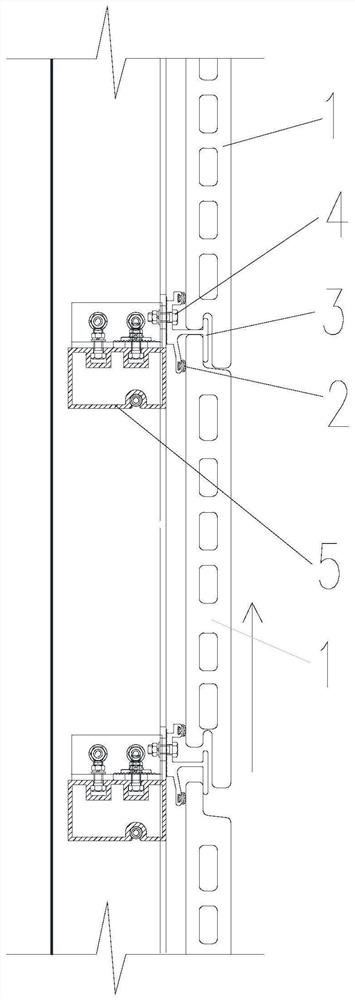

Sliding rail clamp of infusion bottle

PendingCN108327963ARealize loading and unloadingChange the opening and closing distancePackaging bottlesBottle neckEngineering

The invention discloses a sliding rail clamp of an infusion bottle. A driving piston is arranged above Z-shaped sliding rail clamping arms, the driving piston is fixed to an ejector rod, the ejector rod extends in the length direction of the Z-shaped sliding rail clamping arms, and the end portion of a driving piston rod of the driving piston extends downward and is connected with the Z-shaped sliding rail clamping arms in a transmission mode through a rhombic structure frame. The rhombic frame is composed of a plurality of connecting plates which are connected in sequence, and shaft sleeves are separately arranged on both sides of the connecting plates in staggered mode, so that a bottom transverse plate surface of one Z-shaped sliding rail clamping arm faces the other Z-shaped sliding rail clamping arm to clamp a bottle neck of the infusion bottle. The sliding rail clamp further comprises a sterilization plate arranged under the Z-shaped sliding rail clamping arms, and the sterilization plate moves back and forth in the horizontal direction perpendicular to the vertical panel where the infusion bottle in the Z-shaped sliding rail clamping arms is located. According to the structure, the sliding rail clamp of the infusion bottle realizes the simultaneous symmetrical movement of the Z-shaped sliding rail clamping arms, so that the distance between the Z-shaped sliding rail clamping arms can be changed, and the functions of a sliding rail of the infusion bottle and a feeding clamp can be realized.

Owner:JIANGSU HUAIAN DOUBLE CRANE PHARMA CO LTD

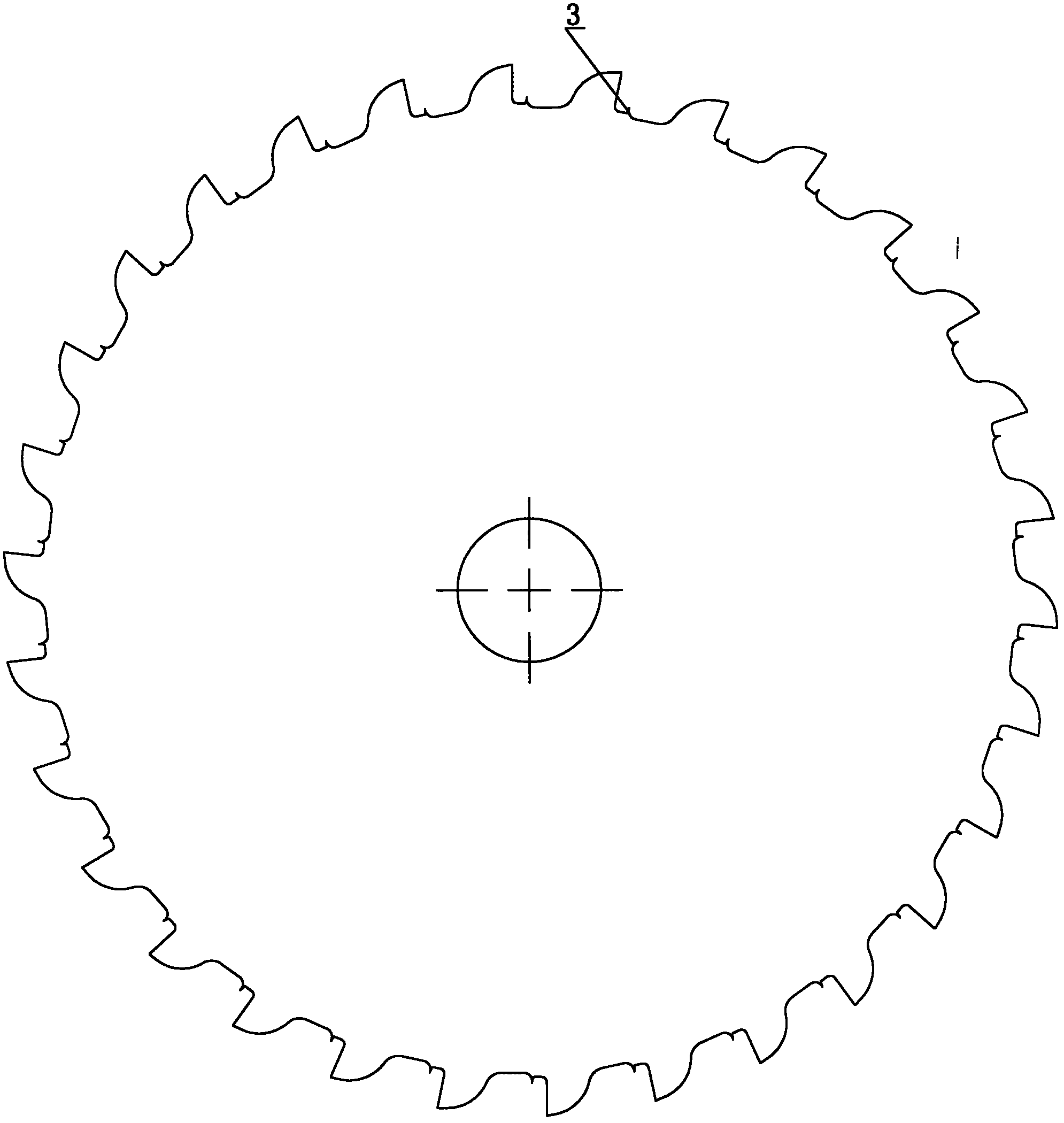

Manufacturing structure of rotary opposite-cutting saw blades

InactiveCN102615351AAvoid stackingOptimal angle designMetal sawing toolsEngineeringMechanical engineering

The invention discloses a manufacturing structure of rotary opposite-cutting saw blades. The manufacturing structure comprises an outer side saw blade and an inner side saw blade. The outer side saw blade consists of an outer side saw blade body and welding cutter teeth; and the inner side saw blade consists of an inner side saw blade body and welding cutter teeth. The manufacturing structure is characterized in that at one side of the working face of the outer side saw blade, the welding cutter teeth are parallel to or lower than the working face and are not allowed to be convex; at one side of the cutting face of the outer side saw blade, the welding cutter teeth are higher than the cutting face to form a secondary cutting blade; at one side of the working face of the inner side saw blade, the welding cutter teeth are parallel to or lower than the working face and are not allowed to be convex; at one side of the cutting face of the inner side saw blade, the welding cutter teeth are higher than the cutting face to form the secondary cutting blade. The manufacturing structure of the rotary opposite-cutting saw blades, provided by the invention, is stable and reliable. The manufacturing structure is applicable to manufacturing a composite saw blade mounted on a cutting machine with double saw blades, and is used for sawing and cutting various materials.

Owner:SUZHOU TINGENS IISAW TECH

Assembly type ceramic-aluminum acoustic panel

PendingCN114016691AEasy to assembleGuaranteed assembly stabilityCovering/liningsFlooringEngineeringAcoustics

The invention discloses an assembly type ceramic-aluminum acoustic panel which comprises an acoustic panel body (1), an air cushion block (2) and a buckle body (3). A first tongue-and-groove (11) is formed in one side of the bottom of each acoustic board body, a second tongue-and-groove (12) is formed in the other side of the top of each acoustic board body, every two adjacent upper and lower acoustic board bodies are assembled in an inserted mode through the corresponding first tongue-and-groove and the corresponding second tongue-and-groove, and a first gap (101) is reserved between the assembling faces of the two acoustic board bodies; a first connecting part (31) is formed on one side of the buckle main body, the first connecting part can be inserted into a first gap between the assembling surfaces of two adjacent upper and lower acoustic board bodies in a matched mode, and the top of the buckle main body abuts against the inner wall of the acoustic board body located on the upper portion through an air cushion block; the bottom of the buckle body abuts against the inner wall of the acoustic panel body located on the lower portion through an air cushion block; and the other side of the buckle main body is fixedly arranged on a building structure (5). The sound absorption board body can be rapidly disassembled and assembled, and operation is easy and convenient.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A metal workpiece edge folding machine with three degrees of freedom

The invention discloses a metal workpiece hemming machine with three degrees of freedom, which comprises a machine frame, a hemming die, a hemming beam and a hemming transmission mechanism; Three degrees of freedom, vertical and rotational; the hemming transmission mechanism includes the hemming beam driving shaft, the first crank linkage mechanism and the second crank linkage mechanism; the hemming beam driving shaft is used to drive the hemming beam Rotation; the other end of the first crank is hinged on the frame and rotates synchronously; the other end of the first connecting rod is hinged on the flange beam drive shaft; the other end of the second crank is hinged on the frame and rotates synchronously; The other ends of the second connecting rods are respectively hinged on the corresponding first connecting rods. The present invention cooperates with each other through the three drive components of the first and second crank-link mechanisms and the flanged beam drive shaft, so as to realize the movement of three degrees of freedom in the horizontal direction, vertical direction and rotation, and during the movement process, There is no swinging attachment, and the folding precision is high.

Owner:南京云上自动化科技有限公司

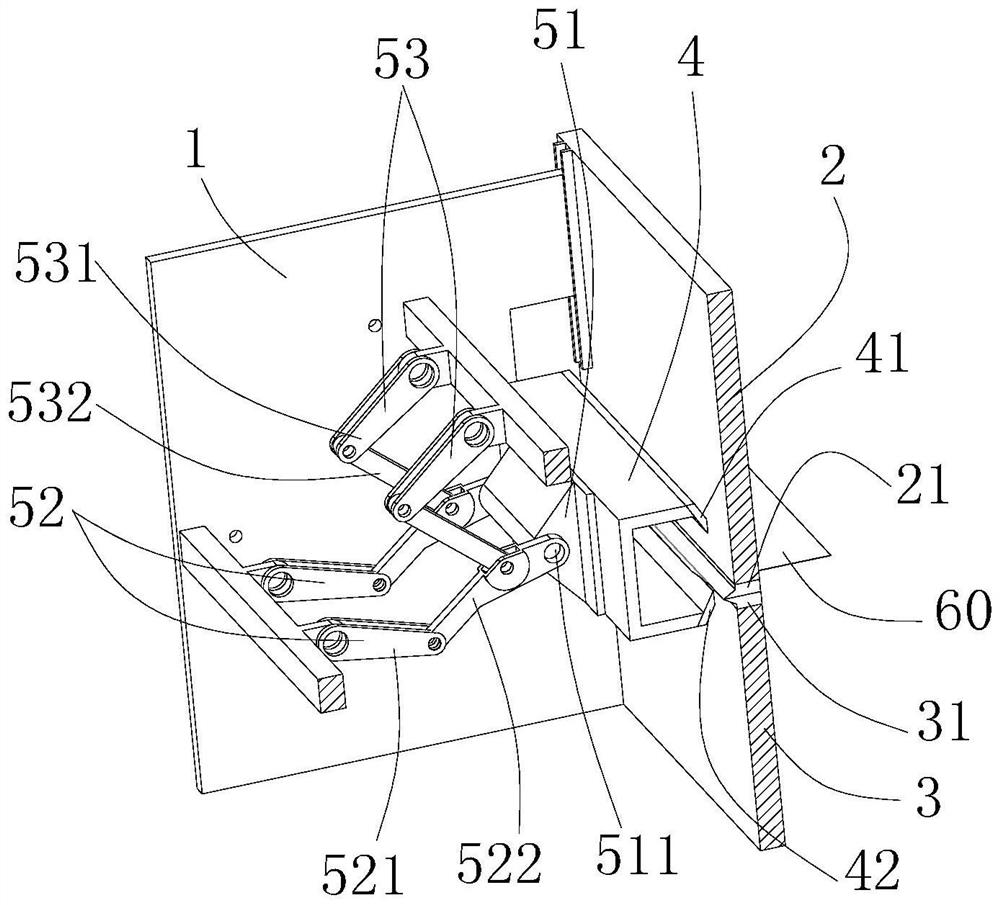

Aeroengine precision forging stator blade intake and exhaust edge CNC abrasive belt grinding tooling

ActiveCN106425734BAchieve positioningGuaranteed positioning accuracyEdge grinding machinesBelt grinding machinesNumerical controlEngineering

The invention relates to a numerical control abrasive belt grinding tooling for intake and exhaust edges of a precise forged stator blade of an aircraft engine. The numerical control abrasive belt grinding tooling comprises fixtures used for clamping technological bosses at the two ends of the blade, a molded surface locating block used for locating a blade molded surface, and a fixture base, wherein the molded surface locating block is arranged on the fixture base; the fixture base comprises a bottom plate; a bracket is arranged on the bottom plate; a vertical linear guide rail is arranged on the bracket; a movable sliding block which can move up and down along the linear guide rail is arranged on the linear guide rail; a support is fixed to the movable sliding block; the molded surface locating block is fixed to the upper end of the support; a limiting device is further arranged on the bracket; the limiting device is used for fixing the support at a preset height; locating pins are arranged at the upper end of the molded surface locating block; and during locating, second locating pins are in contact with the blade molded surface of the blade, and first locating pins are in contact with the side surfaces of the blade technological bosses of the blade. According to the numerical control abrasive belt grinding tooling, the tooling structure adopts split design, the molded surface and a locating point are separated, and parts are clamped at one time.

Owner:AECC AVIATION POWER CO LTD

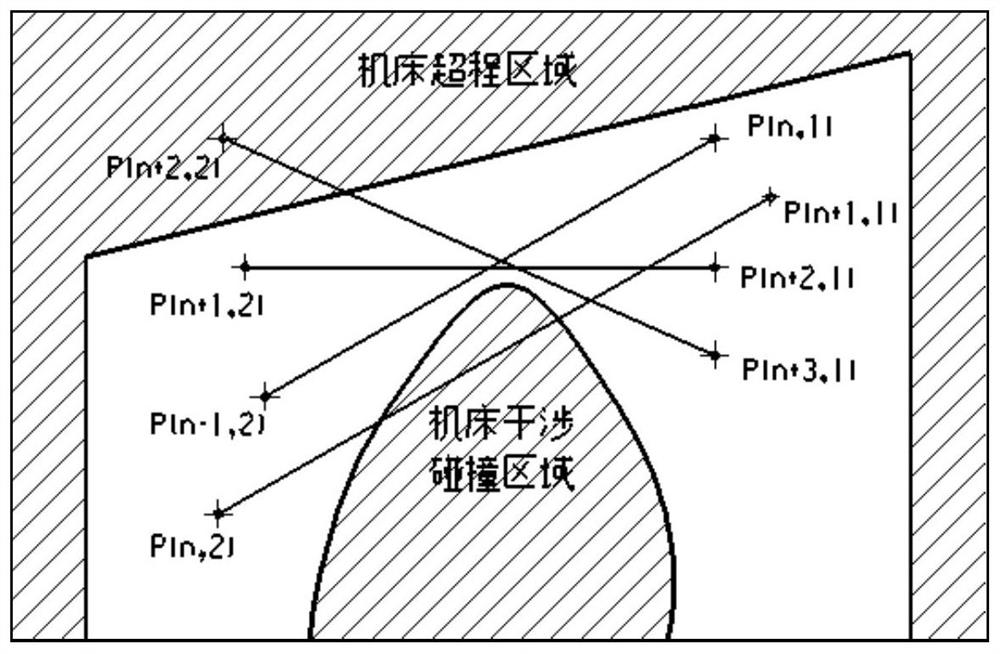

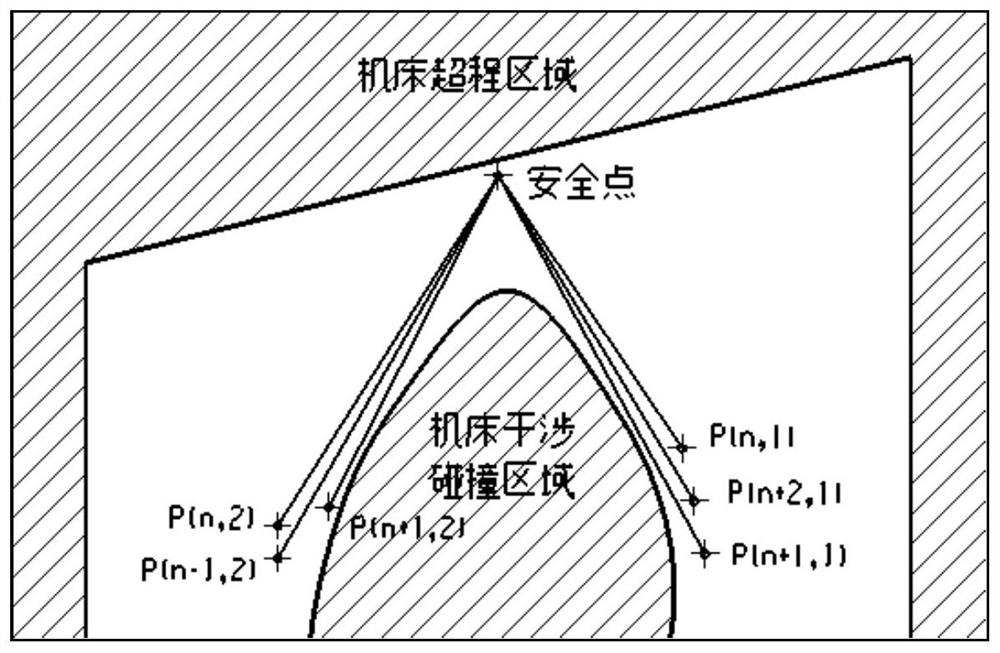

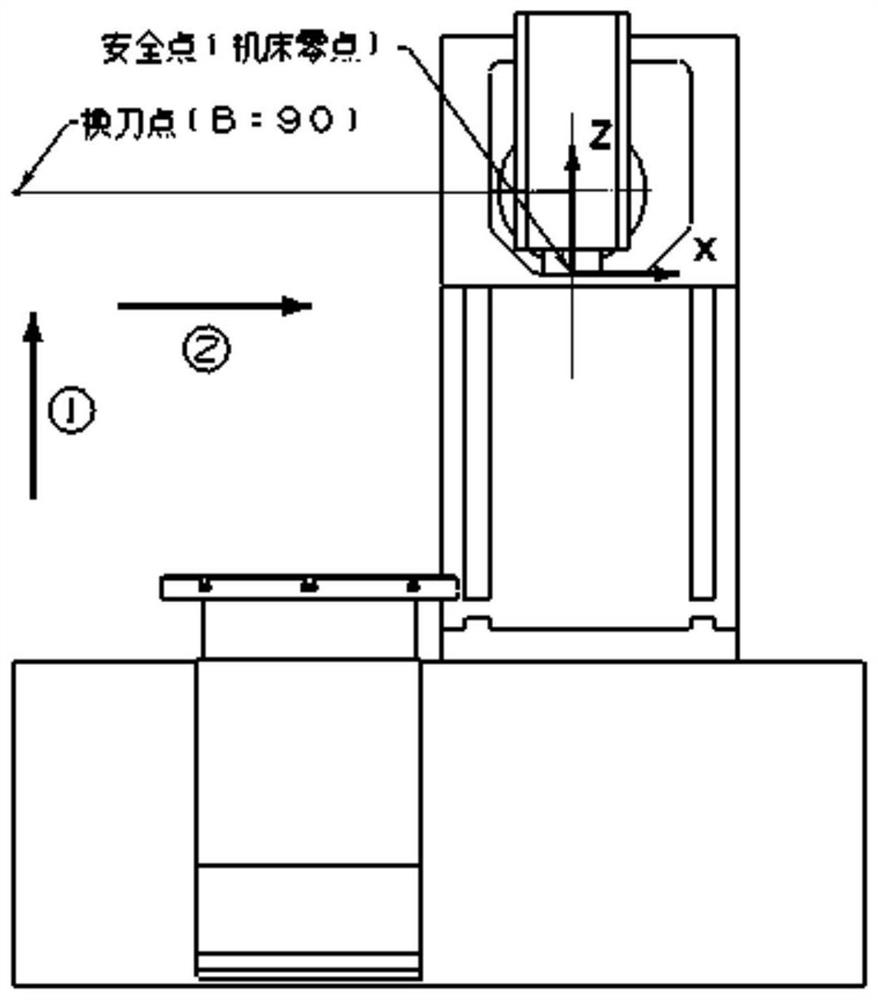

A method to actively prevent interference collisions between alternate tool paths in digital manufacturing operations

ActiveCN108931958BLower setup requirementsLower requirementNumerical controlProgram segmentControl system

The invention belongs to the technical field of mechanical processing and discloses a method for actively preventing a take-over tool path in a digitized manufacturing operation room from interferenceand collision. A machine tool safety point is arranged in such a way that a reciprocating tool path between a CAM programming and machining operation evading point and a machine tool safety point canbe prevented from interference and collision, and the reciprocating tool path is used as the take-over tool path in a machining operation room; according to features of a machine structure and a control system, an NC program segment for the machine tool to move from the machining operation evading point to reach the safety point is designed; at a machining operation take-over position, the NC program between the machining operation evading point and the machine tool safety point can be automatically added in an NC program generated after machining operation post-processing is realized throughdevelopment of a machine tool-specific post-processing program. The method disclosed in the invention is advanced in design principles and convenient and reliable in implementation. Requirements forCAM tool path designers can be lowered. The method is actually verified on a plurality of different machine tools, take-over tool path in the machining operation room in digitized manufacturing can becompletely prevented from interference and collision, and active safety can be realized.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

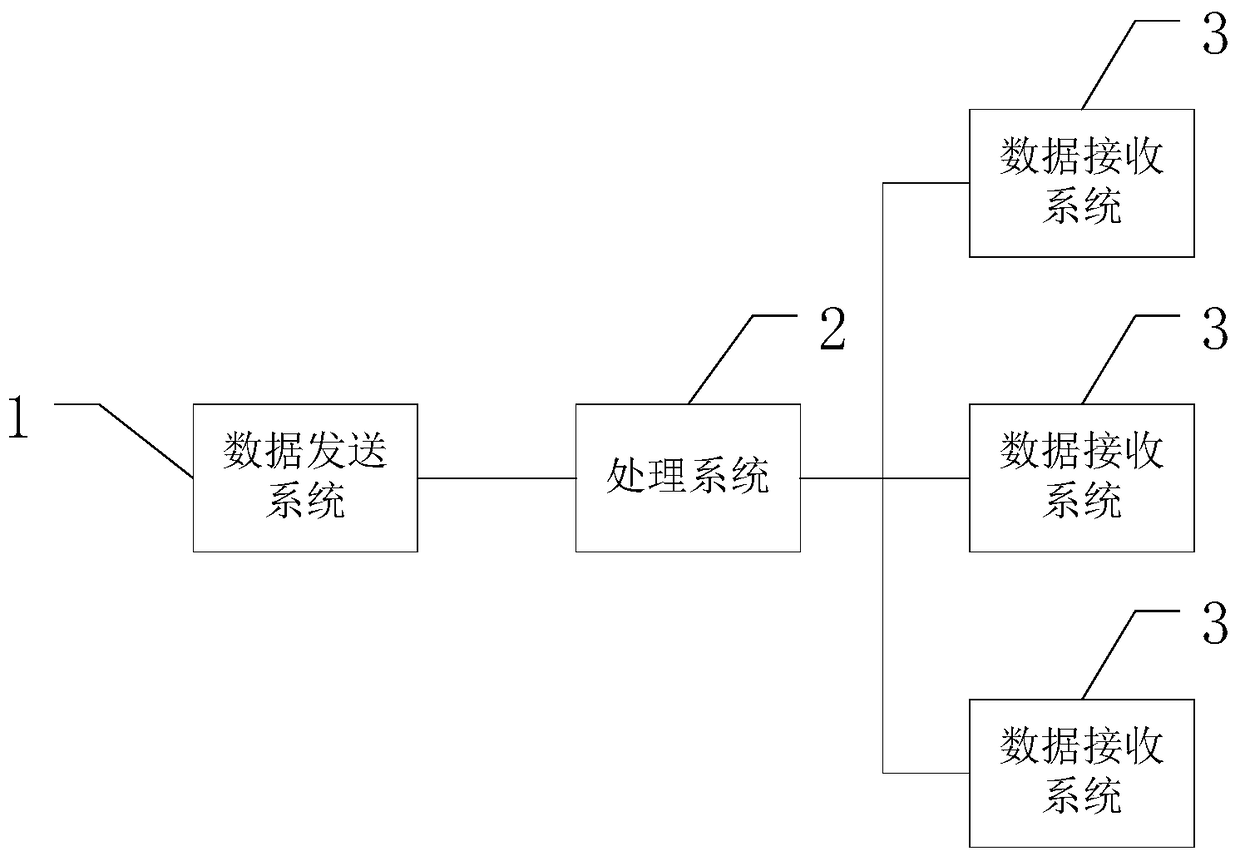

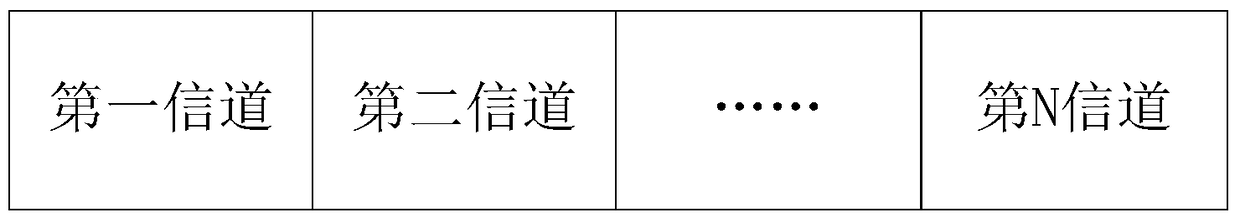

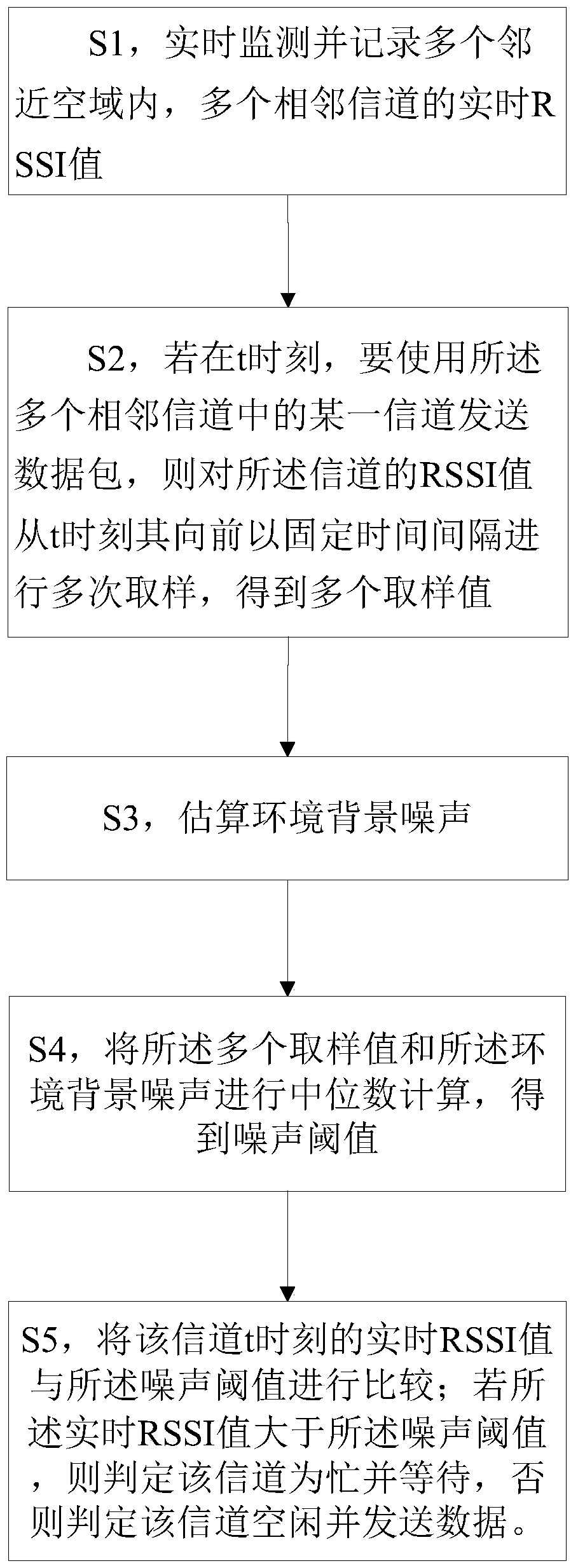

Communication method and device based on multi-channel monitoring and rssi sampling

ActiveCN105142163BEvenly distributedAvoid Interfering CollisionsWireless communicationNetwork packetData transmission

The present invention discloses a communication method and device based on multi-channel monitoring and RSSI sampling, wherein the method includes the following steps: obtaining RSSI values of a plurality of adjacent channels from a plurality of points uniformly distributed in space; At any time, if one of the multiple adjacent channels is to be used to send a data packet, the real-time RSSI values of all channels are obtained, the median calculation is performed on the real-time RSSI values of all channels, and the result is added to the result by one Offset X to obtain a noise threshold; compare the real-time RSSI value of the certain channel at time t with the noise threshold; if the real-time RSSI value is less than the noise threshold, determine that the channel is idle and send data. The communication method and device based on multi-channel monitoring and RSSI sampling provided by the present invention obtains the RSSI value of the channel in real time, and accurately calculates the noise threshold of the channel to ensure normal and reliable data transmission.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com