Patents

Literature

50results about How to "High precision assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

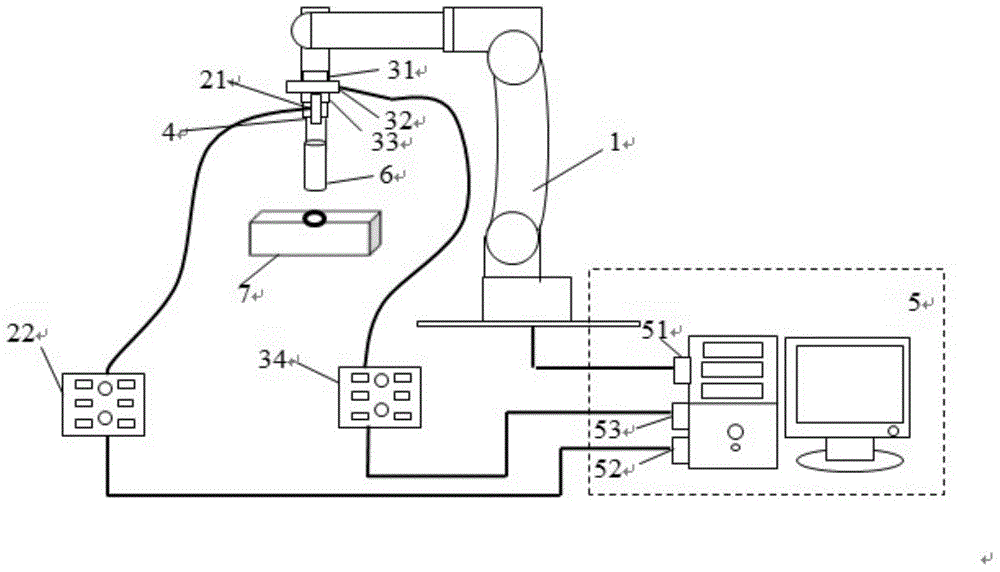

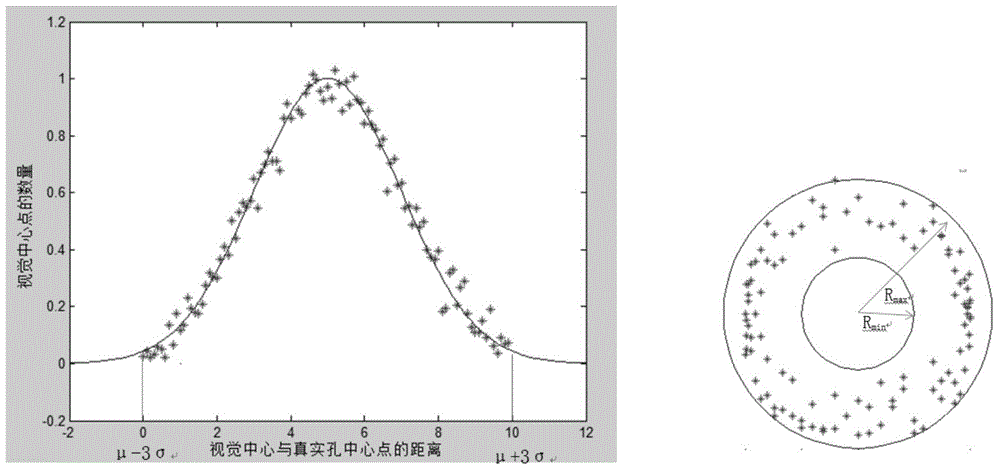

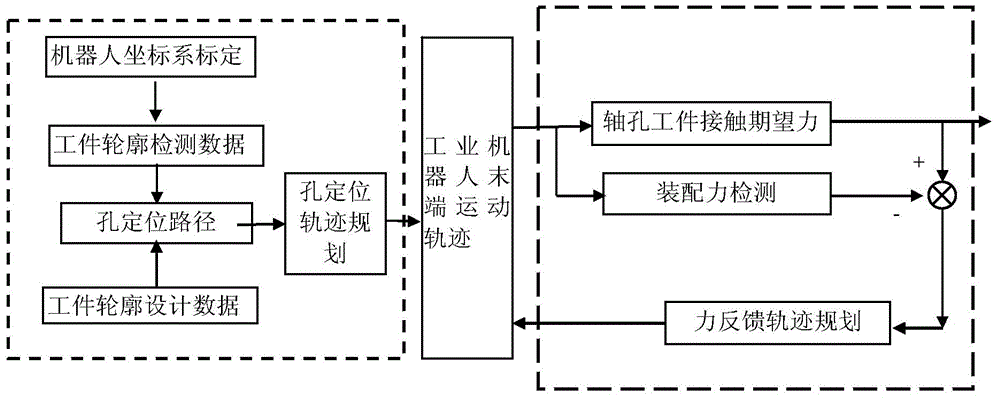

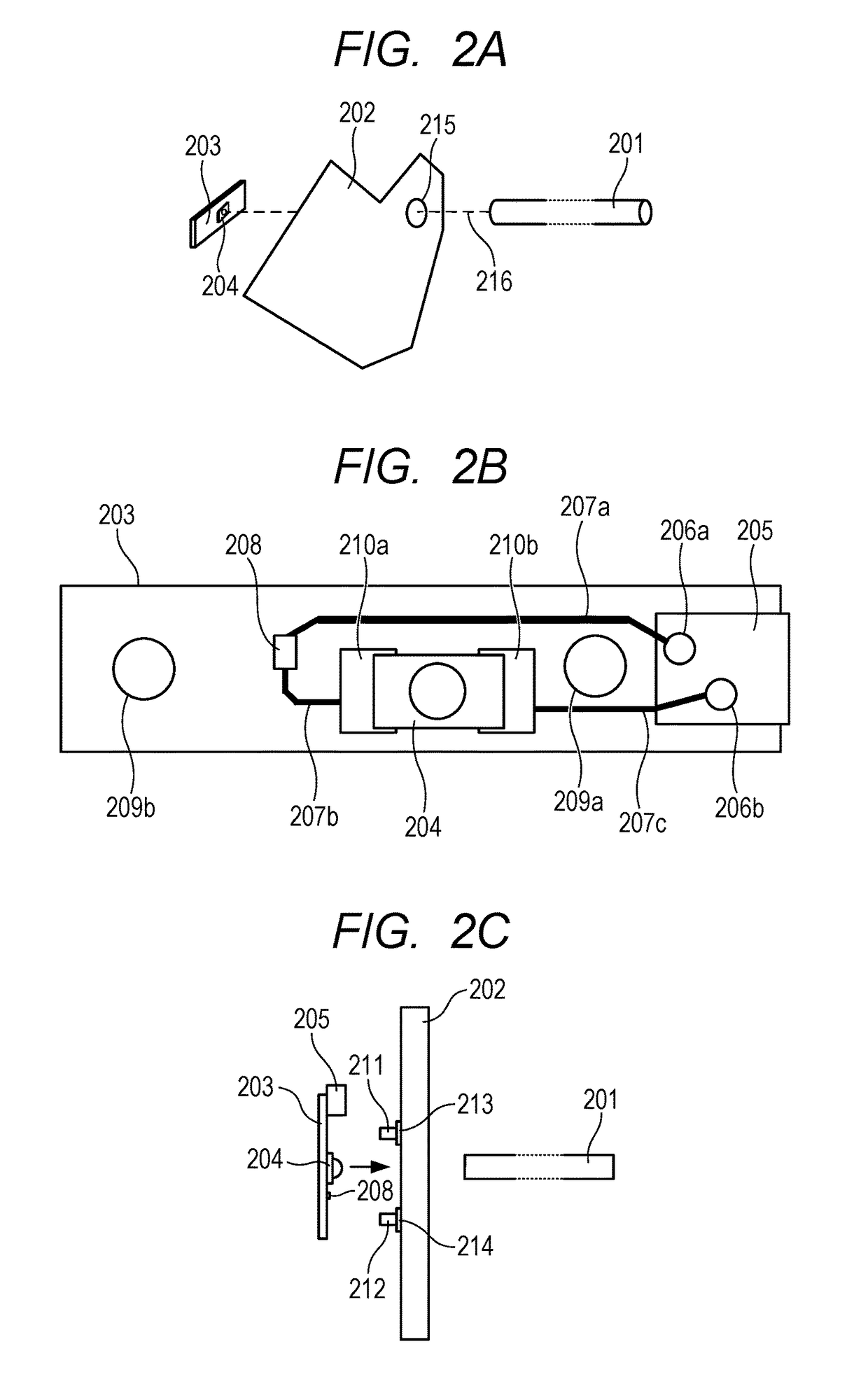

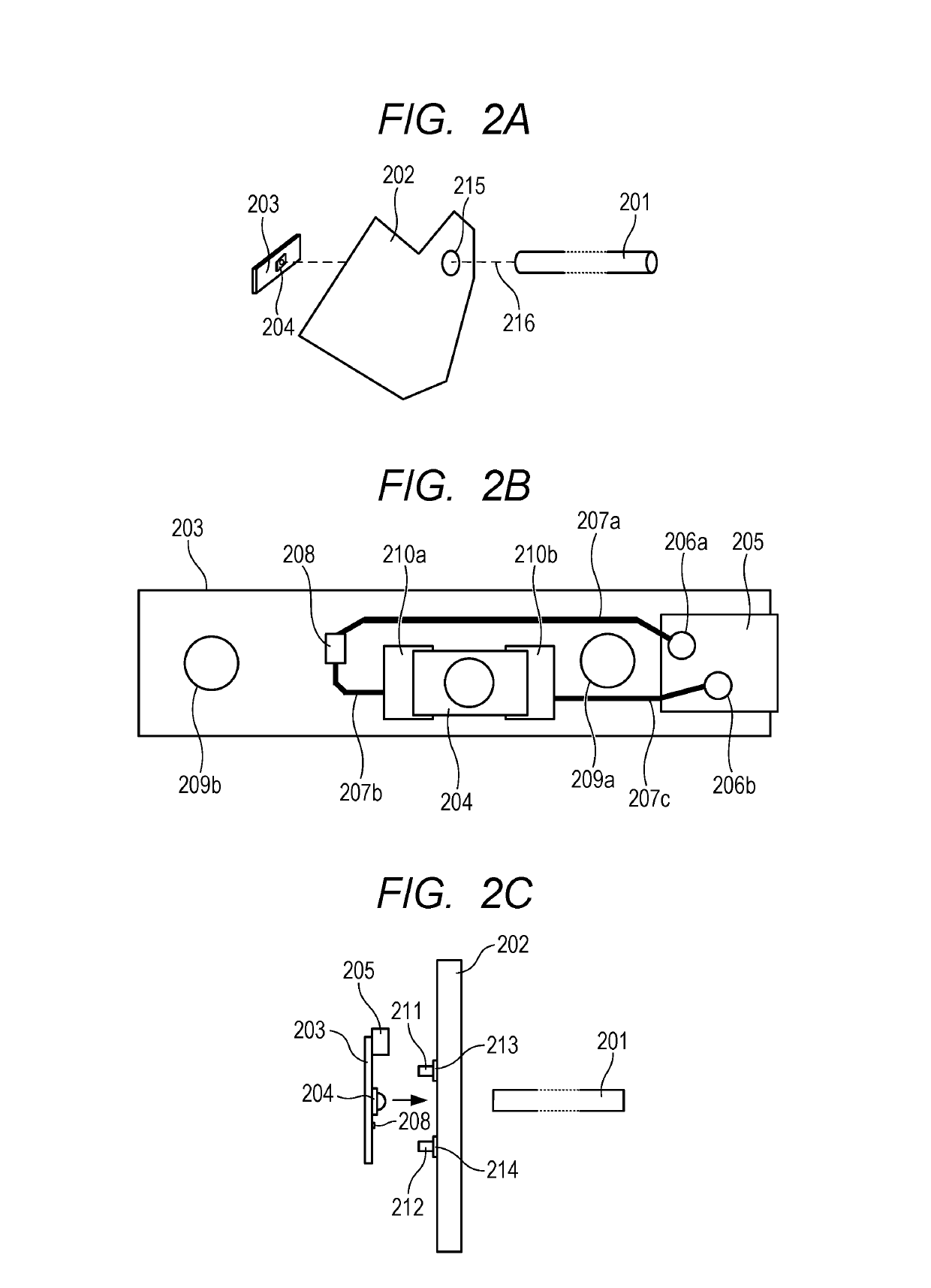

Method and system for assembling robot based on visual sense and force feedback control

ActiveCN104057290AQuick assemblyEffective positioningProgramme-controlled manipulatorMetal working apparatusSimulationVision based

The invention discloses a system for assembling a robot based on visual sense and force feedback control. The system comprises an industrial robot, a workpiece contour detection unit, an assembling force detection unit, a clamping unit and a system control host machine, wherein the industrial robot is used for driving the tail end to move according to a control command of the system control host machine; the assembling force detection unit is used for acquiring the contact force between a shaft workpiece and a hole during the assembling process; the clamping unit is used for clamping the shaft workpiece; the workpiece contour detection unit is used for acquiring the measured data of workpiece contour; the system control host machine is used for receiving the position and the force data and positioning the assembled workpiece according to received data so as to generate the control command to be sent to the industrial robot. The invention further discloses a method for assembling the robot based on visual sense and force feedback control. Rapid hole positioning is carried out and the optimal path of assembling is planned according to the three-dimensional data of hole contour and the force feedback data when the axle hole is assembled, and thus high-precision self-assembling of the axle hole is realized.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

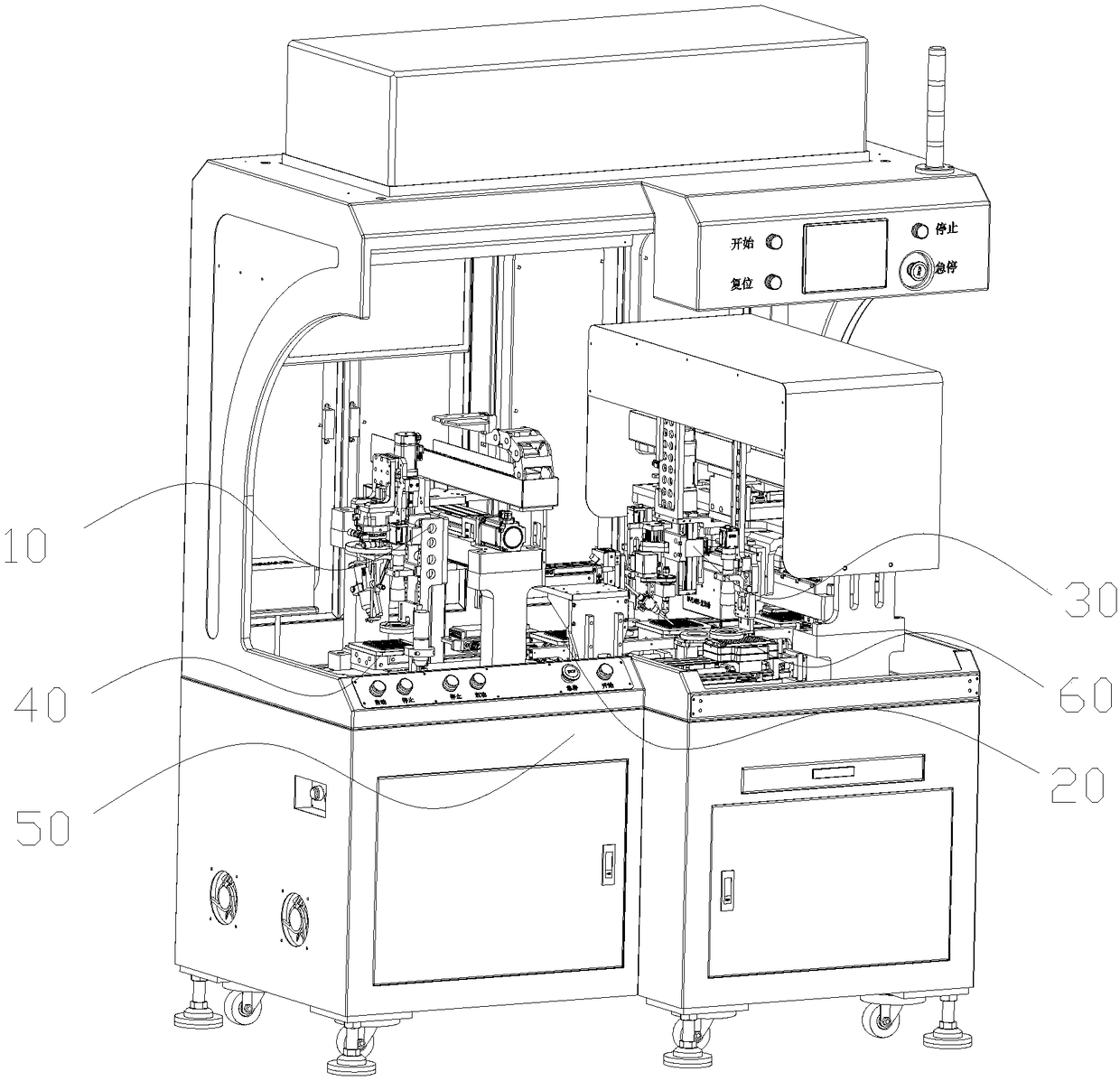

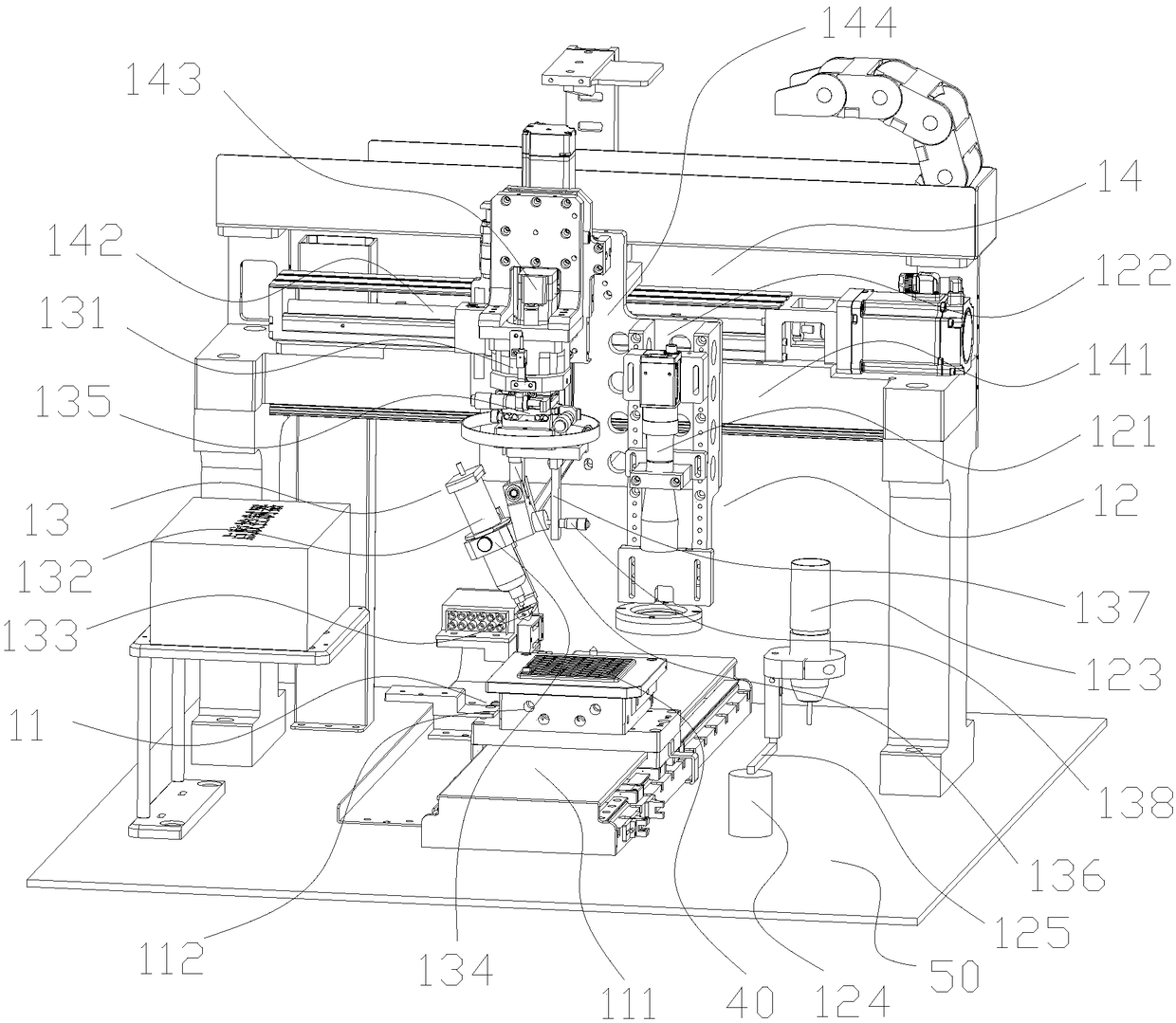

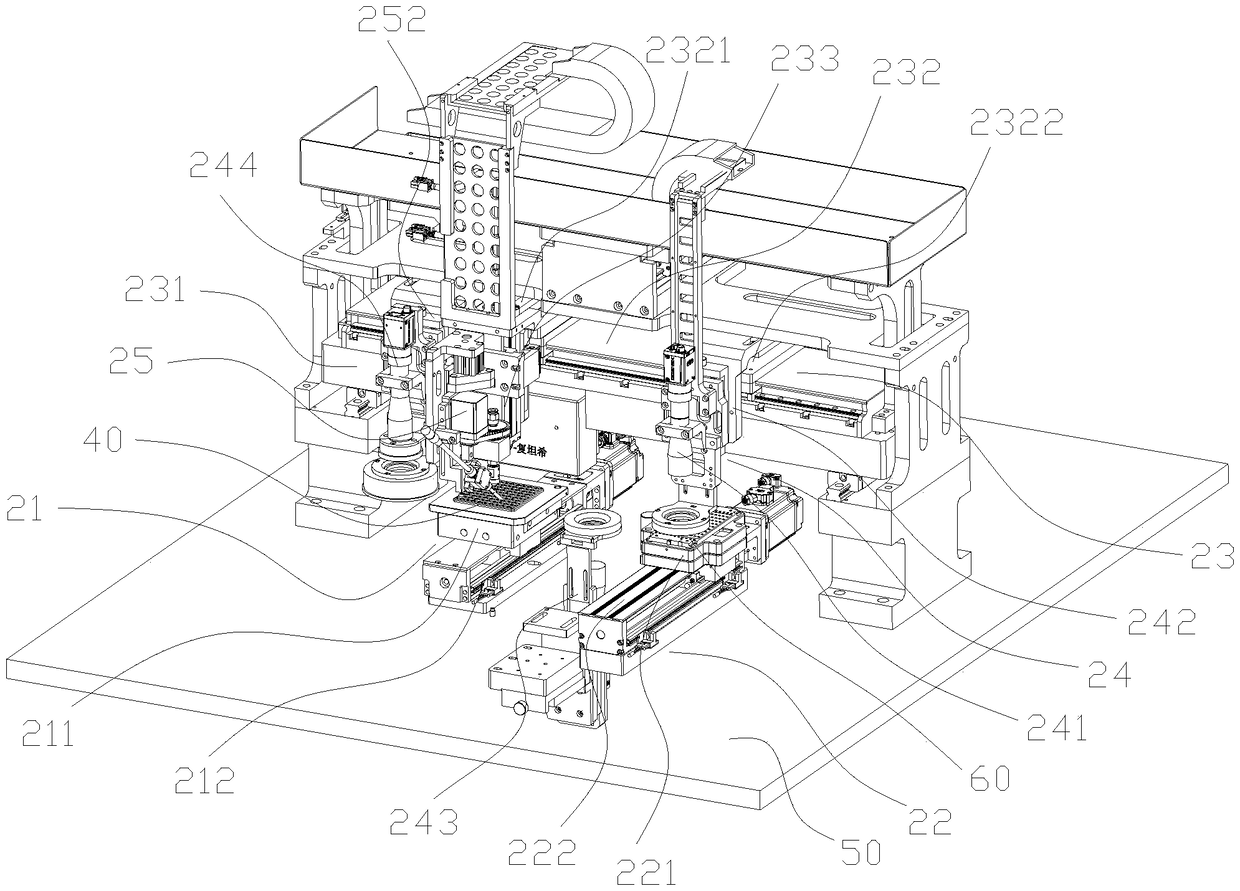

Integrated mobile phone camera assembling equipment

PendingCN109351560AImprove automated productionHigh precision assemblyLiquid surface applicatorsMaterial gluingEngineeringTransfer mechanism

The invention discloses integrated mobile phone camera assembling equipment. A glue dispensing mechanism comprises a glue dispensing station, a first positioning module, a glue dispensing module and afist moving module. The glue dispensing station is arranged on the table surface of an equipment table. The first positioning module, the glue dispensing module and the first moving module are supported above the glue dispensing station. An attaching mechanism comprises a lens barrel module, a lens module, a second moving module, an attaching module and a second positioning module. The lens barrel module and the lens module are arranged on the equipment table in parallel. The second moving module, the attaching module and the second positioning module are supported above the lens barrel module and the lens module. A transfer mechanism comprises a conveying module and a lifting module. The glue dispensing station and the lens barrel module are arranged at the two ends of the conveying module correspondingly. The lifting module pushes the conveying module to move up and down, product transfer and conveying are automatically completed, high-precision assembling is achieved, and the automation degree is increased.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

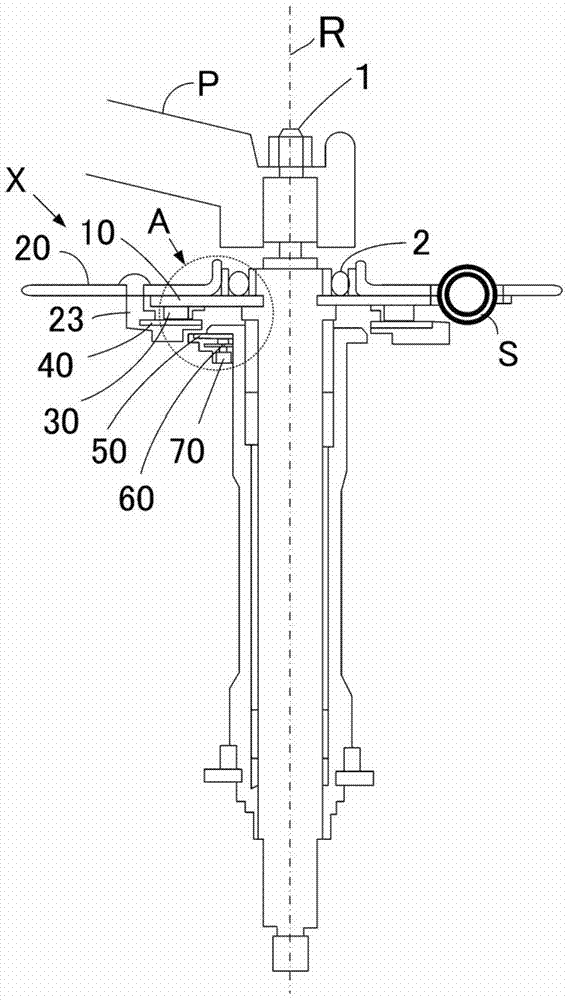

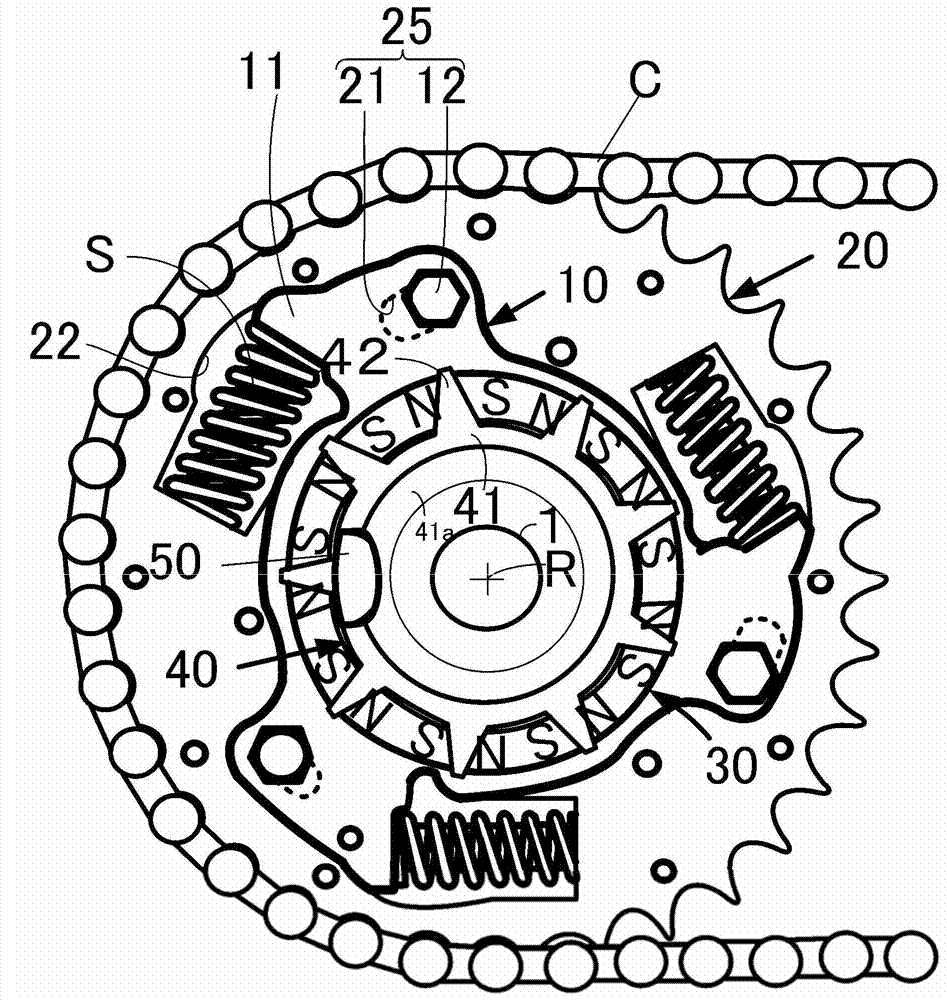

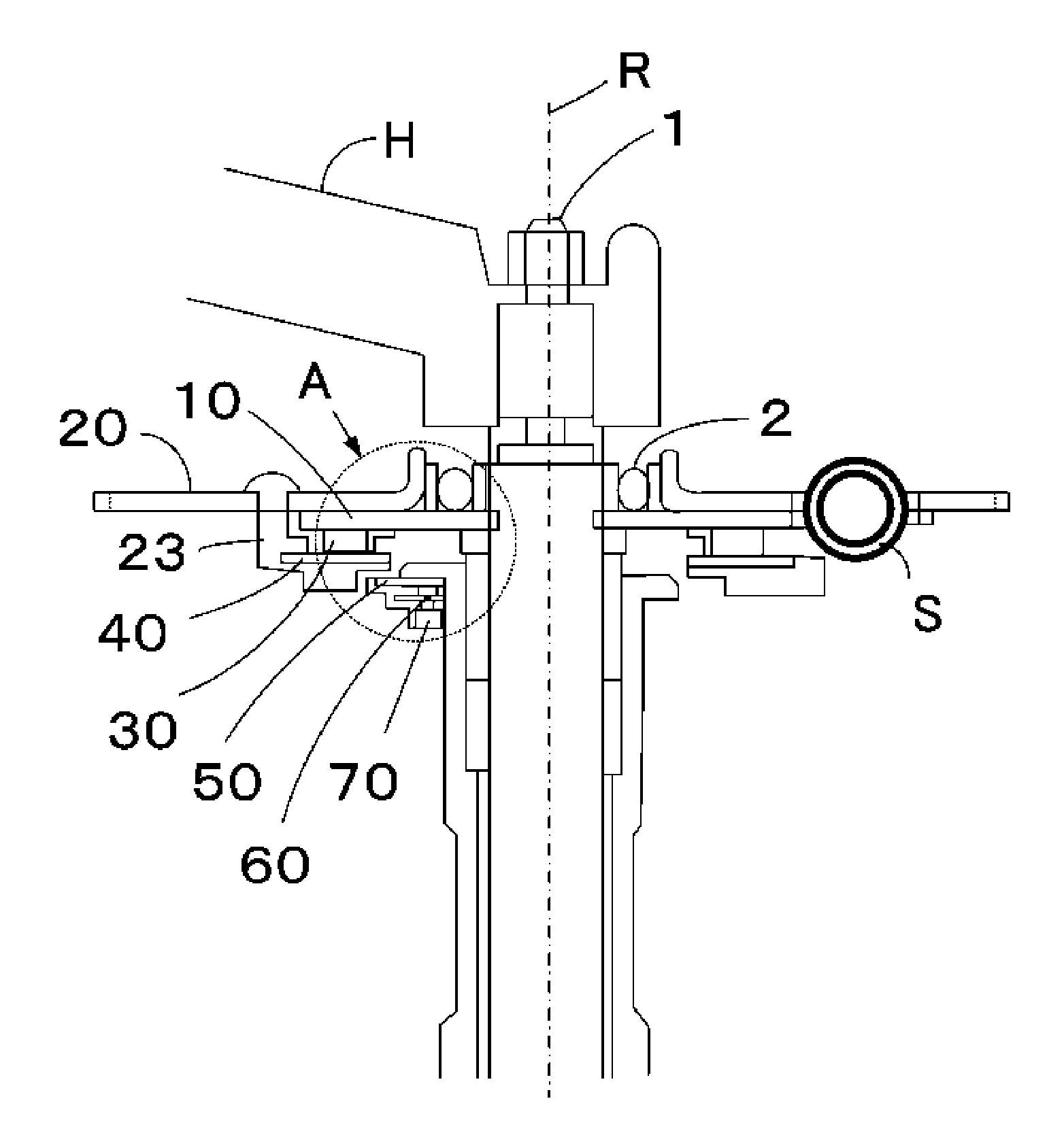

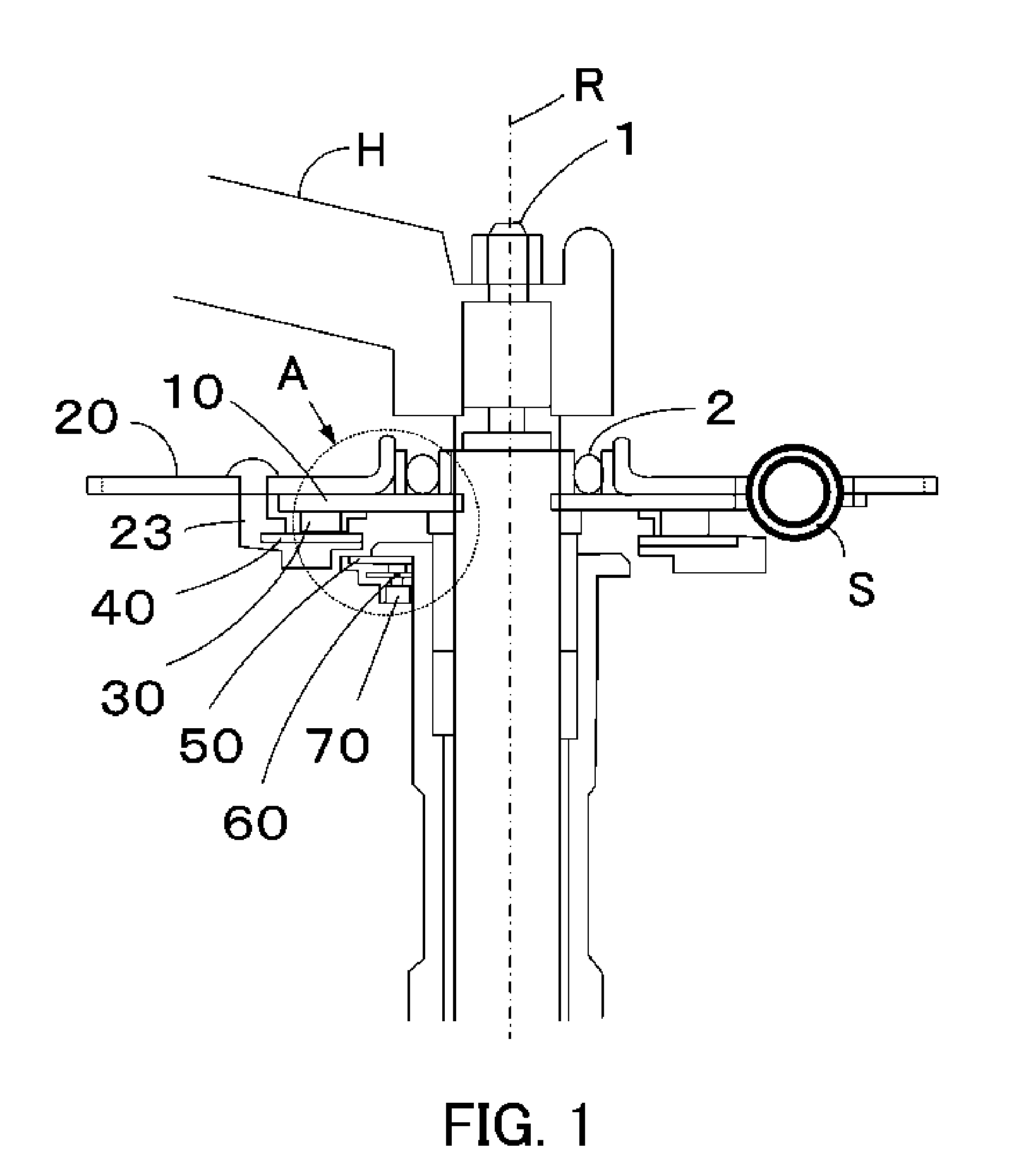

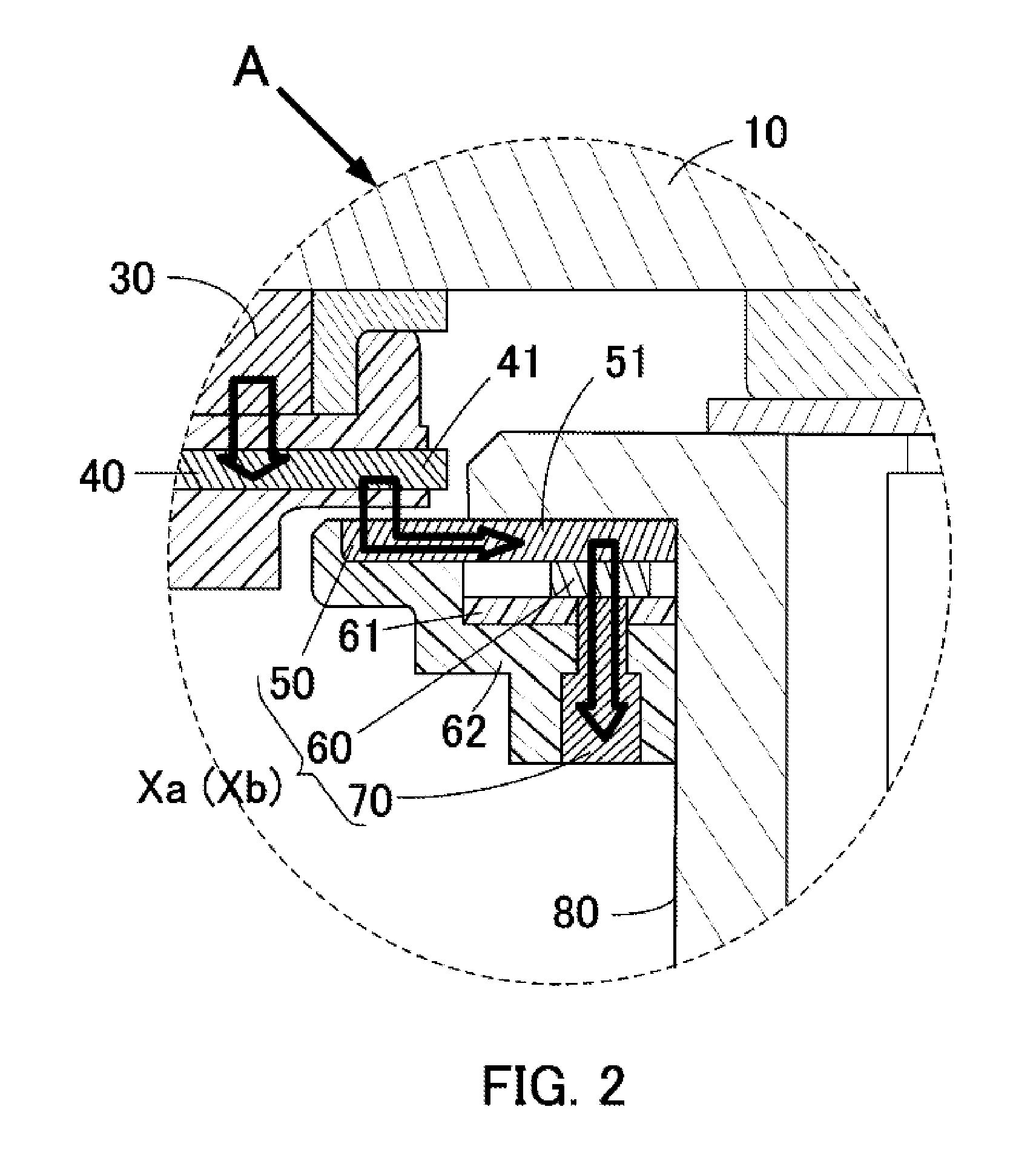

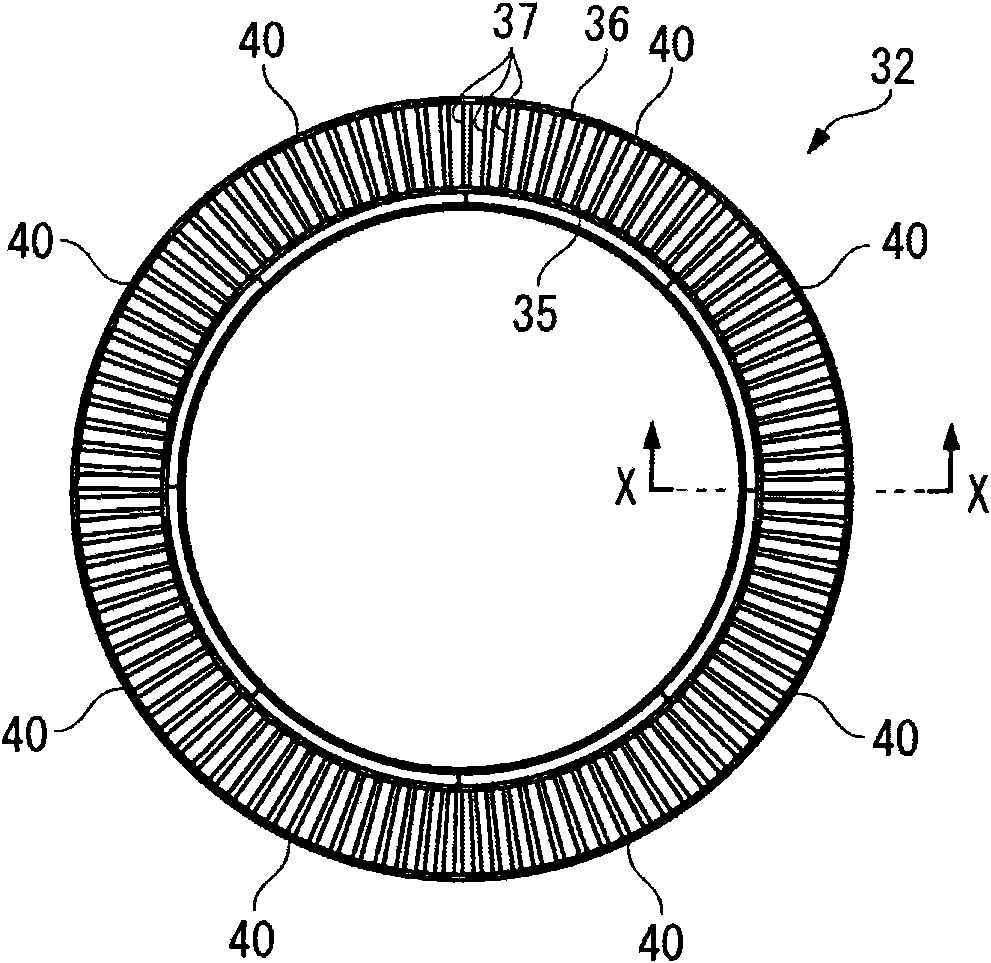

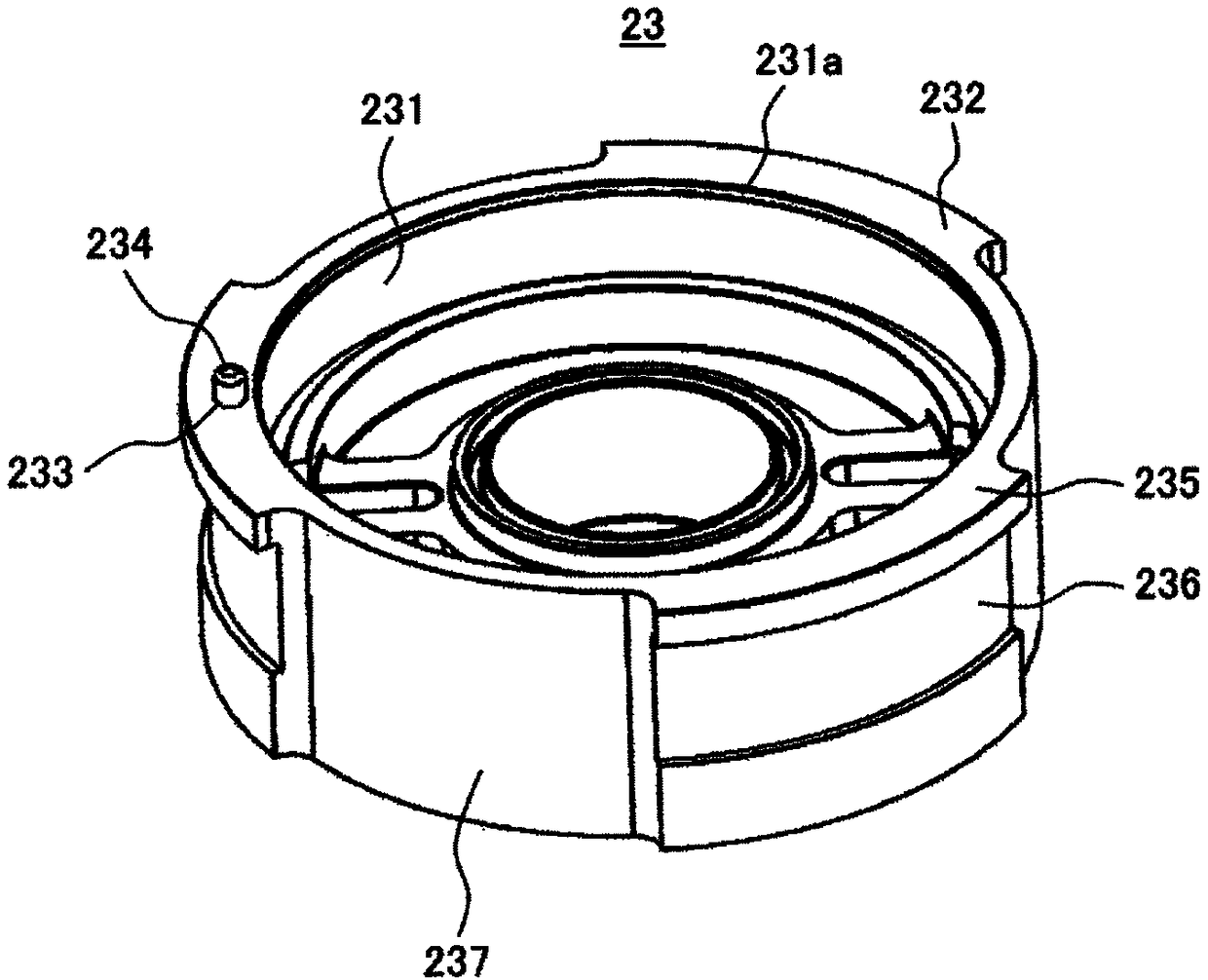

Relative rotational angular displacement detection device, torque detection device, torque control device, and vehicle

InactiveCN103673868AHigh precision manufacturingHigh precision assemblyCycle equipmentsWork measurementMagnetic polesEngineering

The present invention provides a relative rotational angular displacement detection device, a torque detection device, a torque control device, and a vehicle. A relative rotational angular displacement detection device includes a pair of rotatable members relatively rotatable in a circumferential direction. A permanent magnet is attached to one of the rotatable members and includes magnetic poles magnetized in an axial direction of the axis of rotation and arranged to alternate in polarity in the circumferential direction. A magnetic flux inducing ring includes an annular ring body attached to the other of the rotatable members and is arranged coaxially with the axis of rotation, and a plurality of protrusions having a circumferential width smaller than a circumferential width of a magnetic pole. A magnetic detection portion is configured to detect a magnetic flux of the ring body of the magnetic flux inducing ring. The flux inducing ring is magnetized depending on a relative positions the protrusions and positions of the magnetic poles.

Owner:YAMAHA MOTOR CO LTD

Relative rotational angular displacement detection device, torque detection device, torque control device, and vehicle

InactiveUS20140076656A1High precisionHigh precision assemblyElectronic commutation motor controlWork measurementElectrical polarityMagnetic poles

A permanent magnet includes magnetic poles that are arranged so as to alternate in polarity in the circumferential direction of the axis of rotation. The magnet is attached to one of a pair of rotatable members. The rotatable members are relatively rotatable about an axis of rotation. A magnetic flux inducing ring, including an annular ring body and a plurality of protrusions protruding from the ring body, is attached to the other rotatable member. A plurality of magnetic sensors is arranged adjacent to the ring body. A first facing portion and a second facing portion, each for inducing a part of a magnetic flux of the ring body, are provided and do not rotate with the permanent magnet and the magnetic flux inducing ring.

Owner:YAMAHA MOTOR CO LTD

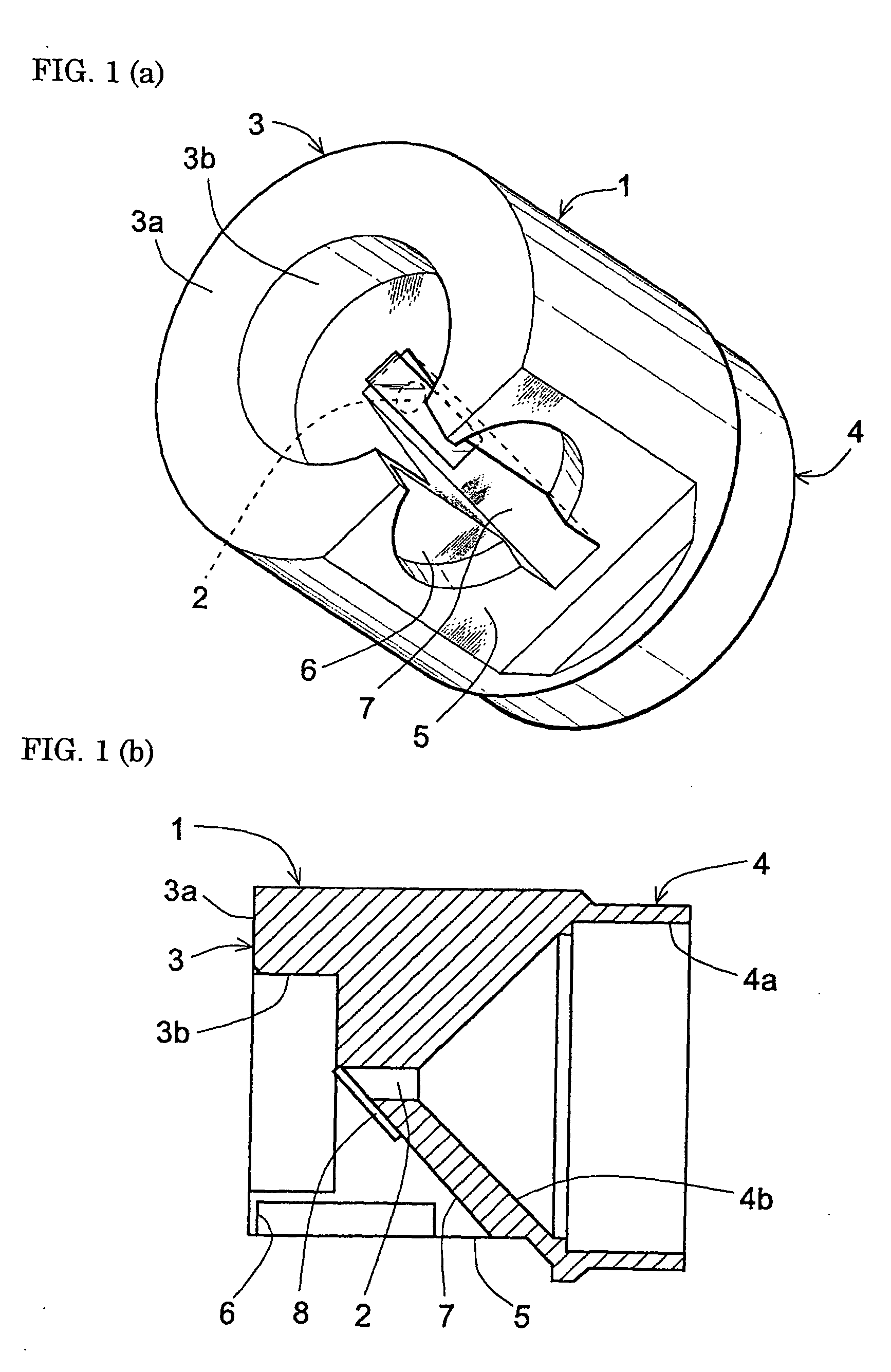

Object lens and optical pickup device

ActiveCN103443857AHigh precision assemblyEfficient determinationRecord information storageCondensersOptical pickupOptical axis

Provided is a high NA object lens which, in spite of being a high NA object lens, permits excellent measurement of inclination when the object lens is attached to an optical pickup device and which permits high precision assembly with the optical pickup device, and also provided is the optical pickup device comprising the high NA object lens. The object lens comprises: a first optical face that is formed on the light source side; a second optical face that faces the first optical face and is formed having a radius of curvature greater than that of the first optical face; and a planar end face that is positioned outside the second optical face as seen from the optical axis direction and is substantially orthogonal to the optical axis. The object lens satisfies the expression 0.12=A / B= 0.5 (1), where the image-side aperture number (NA) is 0.7 to 0.9, and, as seen from the optical axis direction, the distance of a straight line, which passes through the optical axis and the end face, within the area of the end face is A (mm), and the distance of a straight line from the optical axis to the outermost circumferential section of the end face is B (mm).

Owner:KONICA MINOLTA INC

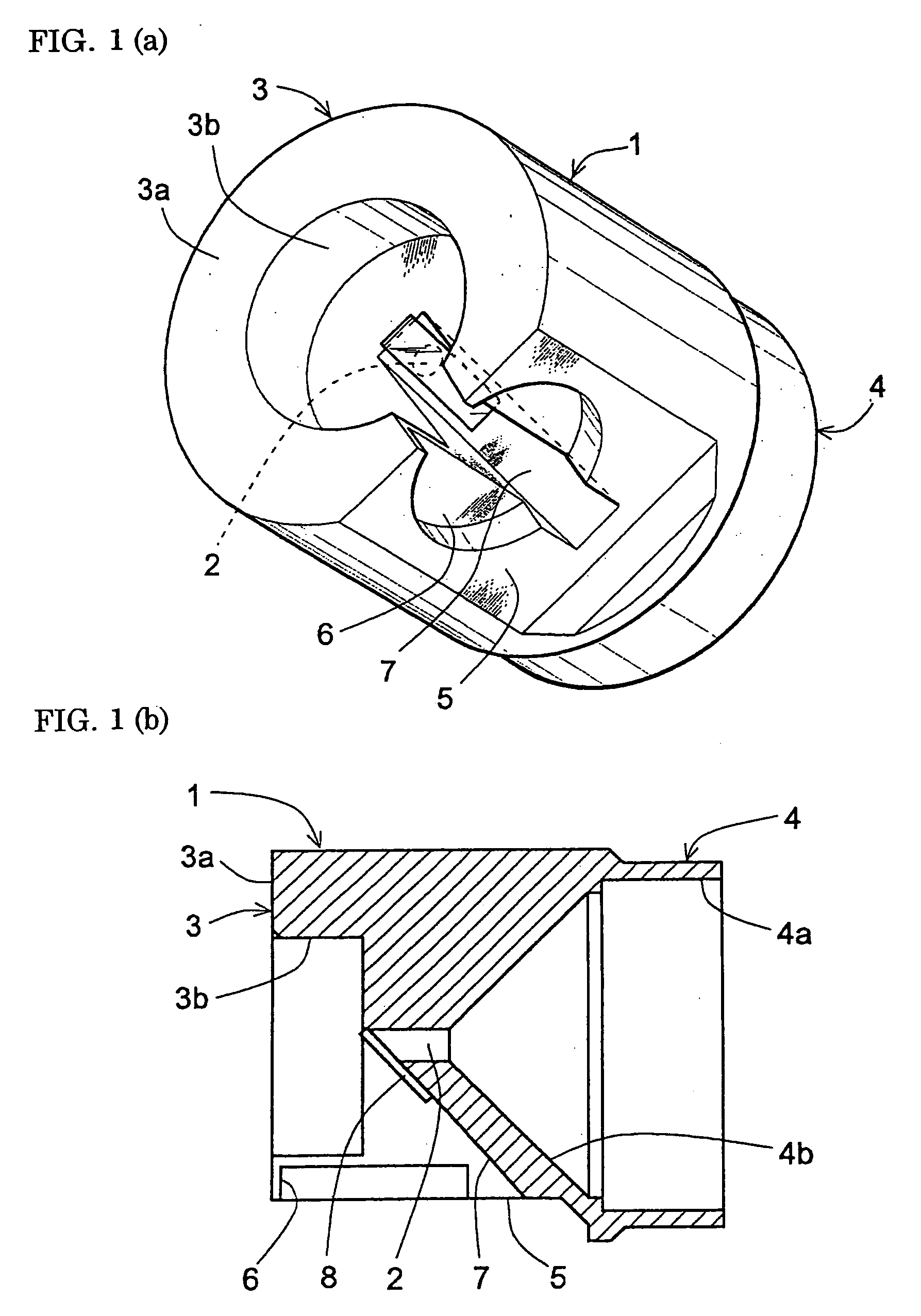

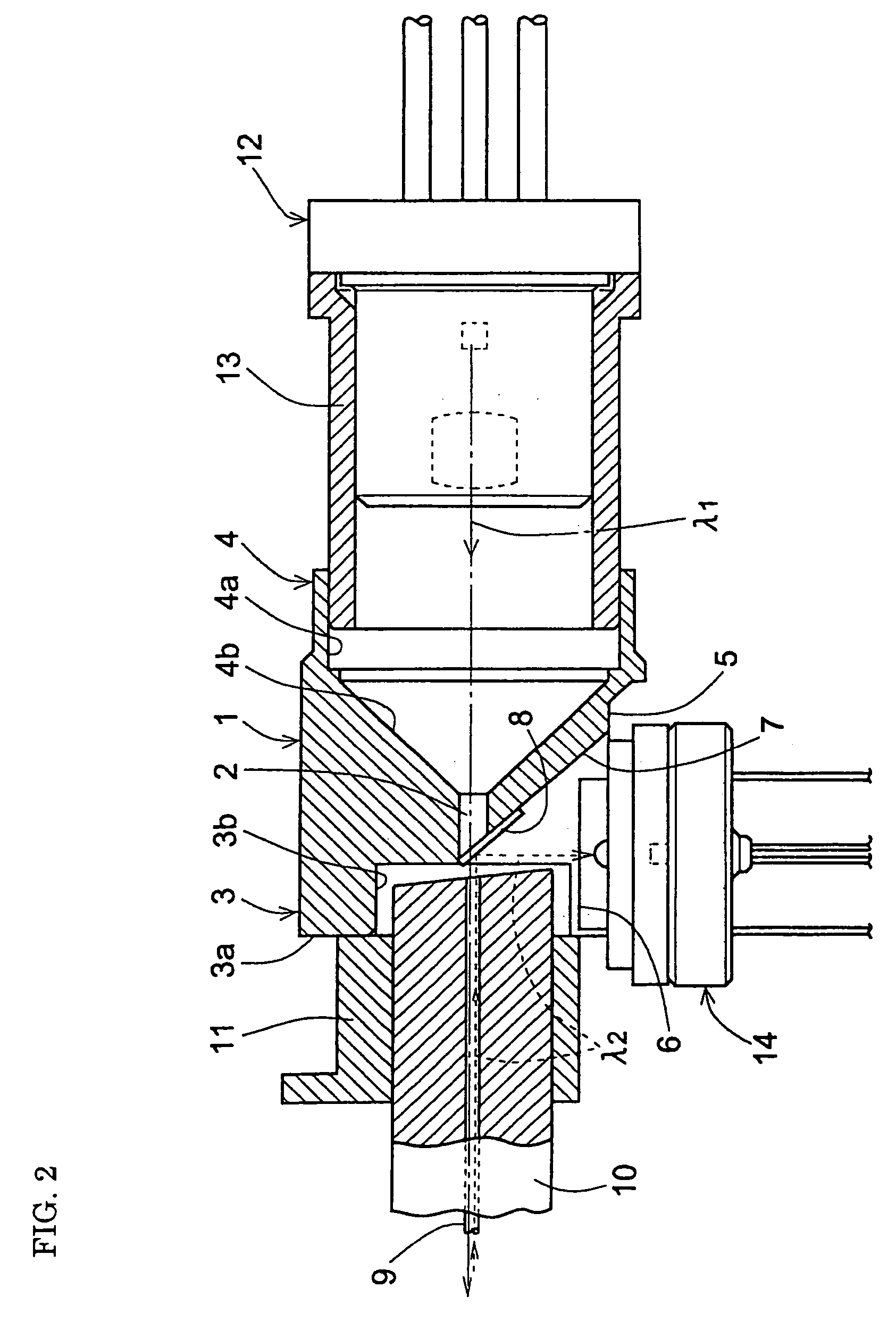

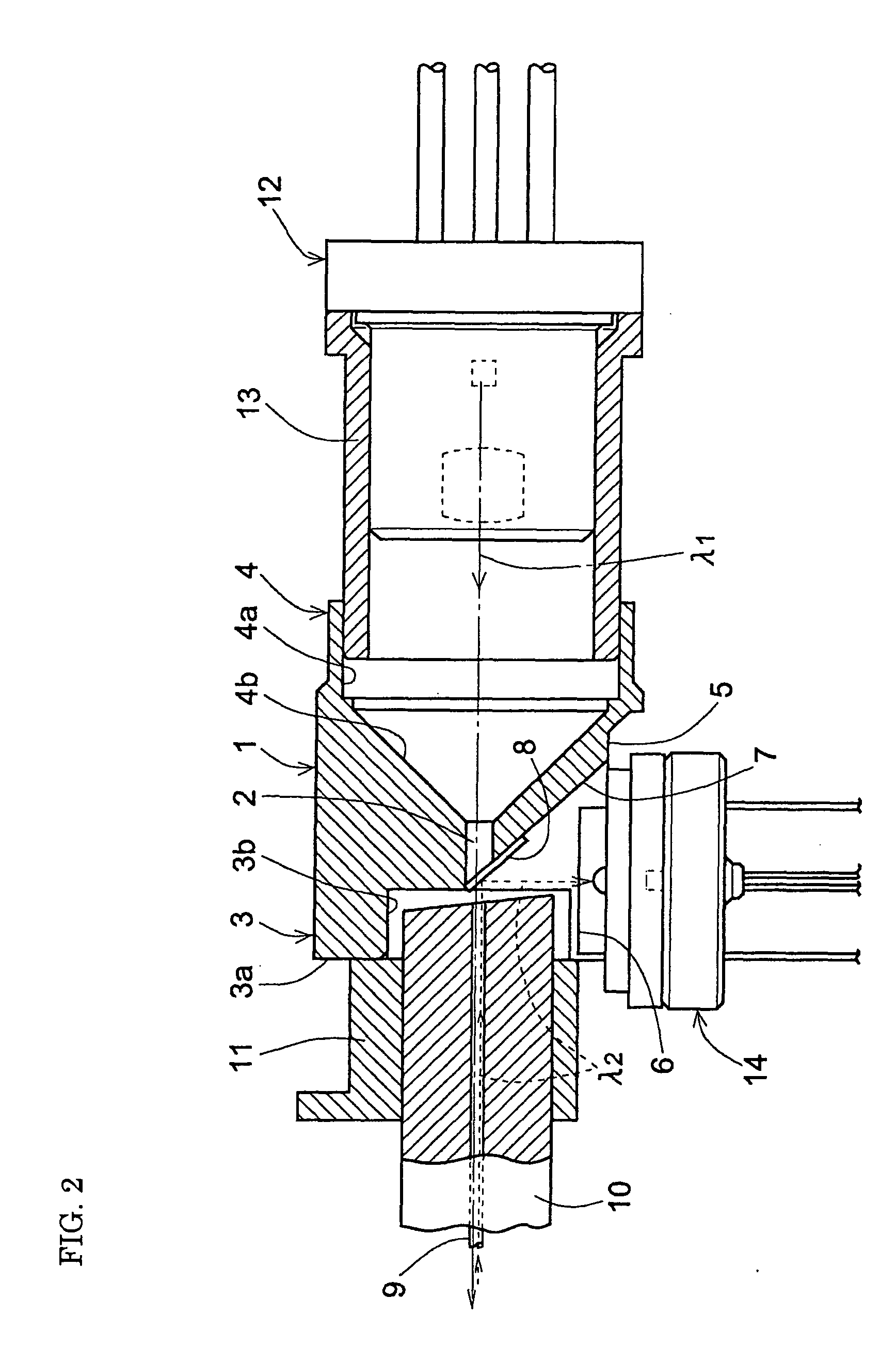

Jointing holder for optical module for single-fiber bidirectional communication and optical module incorporating the jointing holder

InactiveUS20060039657A1Reduces dimensional deviationReduce in quantityCoupling light guidesElectromagnetic transceiversOptical ModuleSingle fiber

A jointing holder for an optical module for single-fiber bidirectional communication comprises a unitarily structured cylindrical body that has the following portions: (a) an optical fiber-fixing portion for securely holding an optical fiber for transmitting multiwavelength light bidirectionally, (b) a semiconductor laser-fixing portion for securely holding a semiconductor laser for emitting outgoing light λ1, (c) a photodiode-fixing portion for securely holding a photodiode for receiving incoming light λ2, (d) an optical path-forming space for optically coupling the optical fiber, the semiconductor laser, and the photodiode, and (e) in the optical path-forming space, an optical filter-fixing face for securely holding an optical filter for separating multiplexed wavelengths. The jointing holder enables the optical module to reduce the number of components, to be miniaturized, and to reduce the dimensional deviation at the time of the assembly, enabling high-precision assembly. An optical module for single-fiber bidirectional communication incorporates the jointing holder.

Owner:SUMITOMO ELECTRIC IND LTD

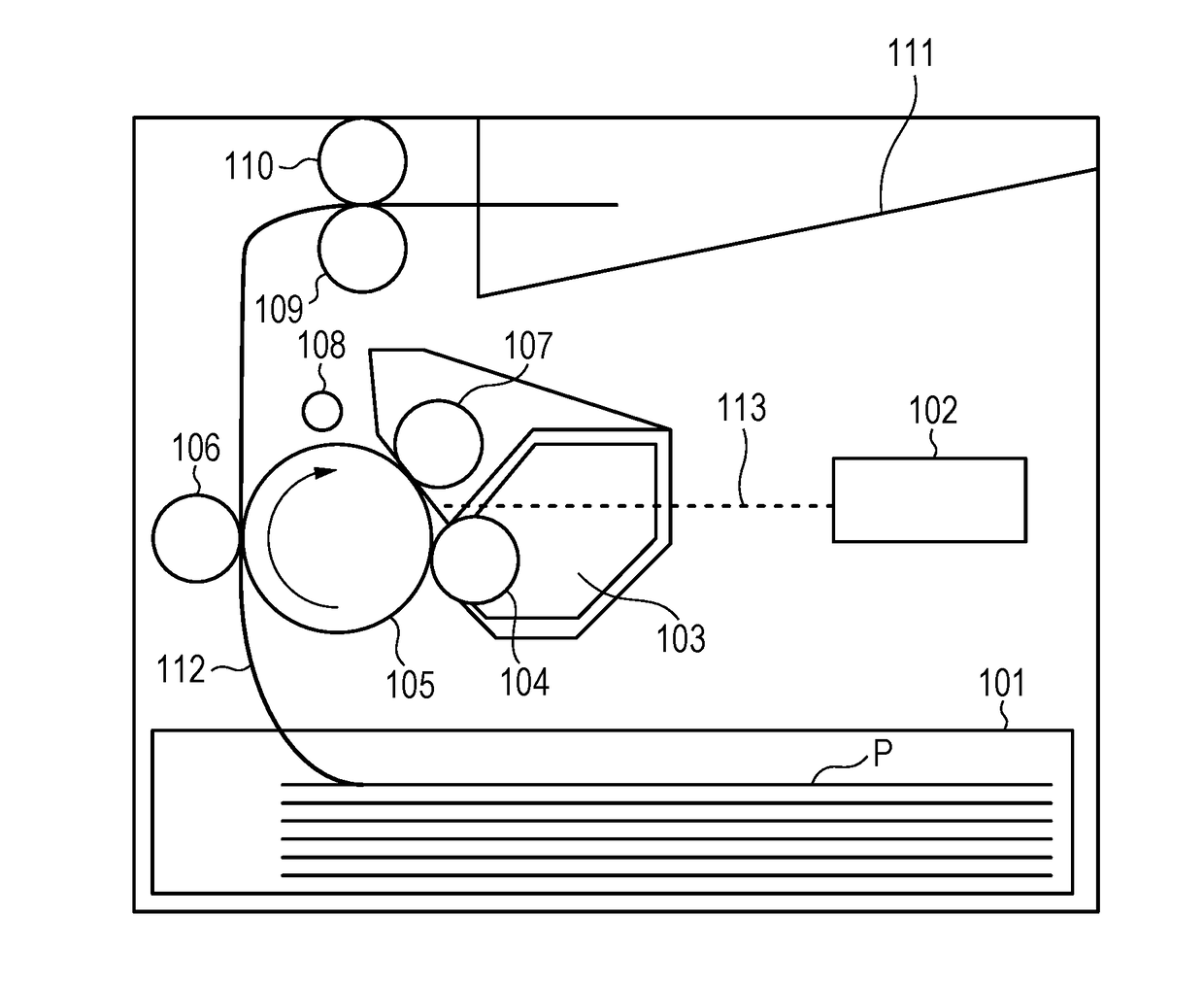

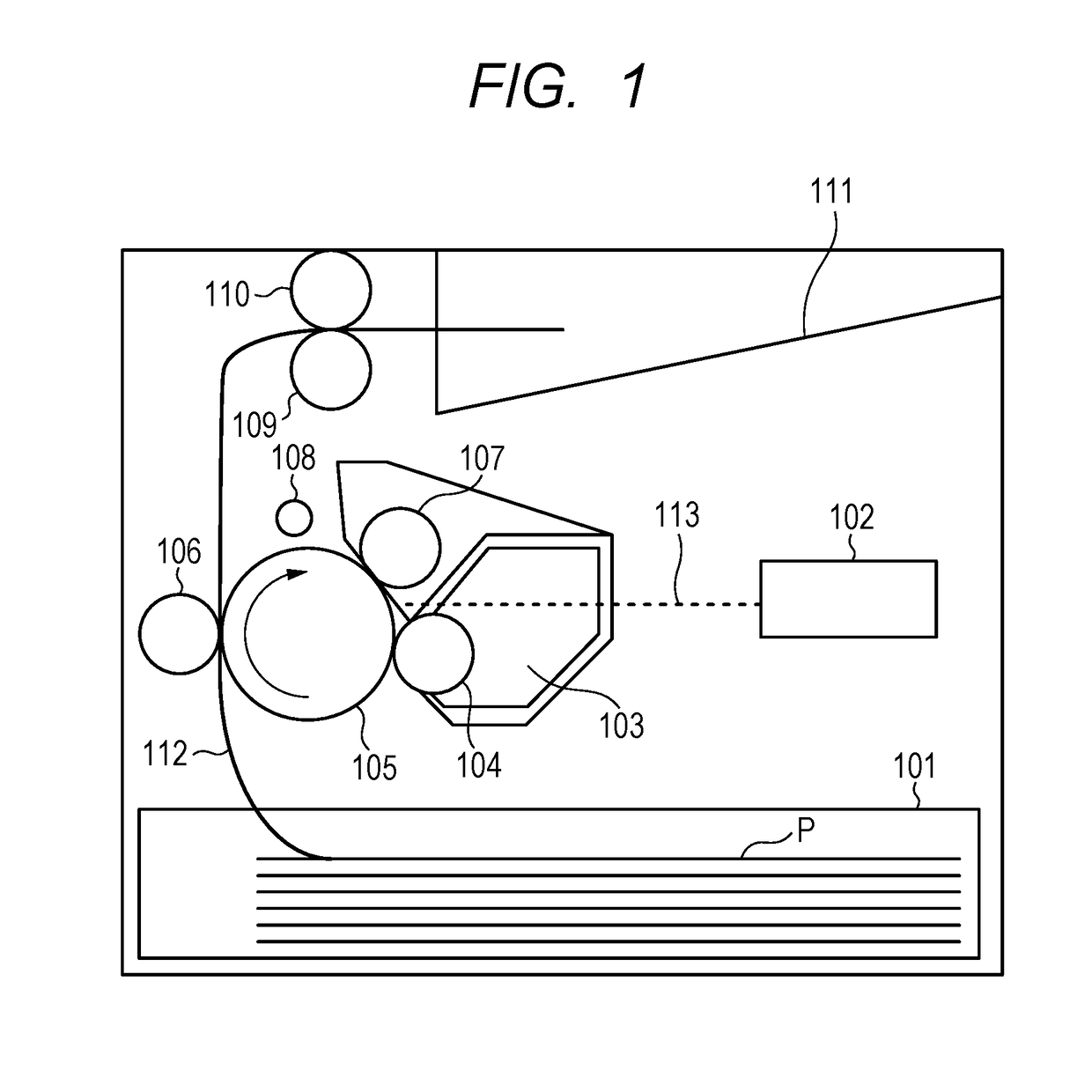

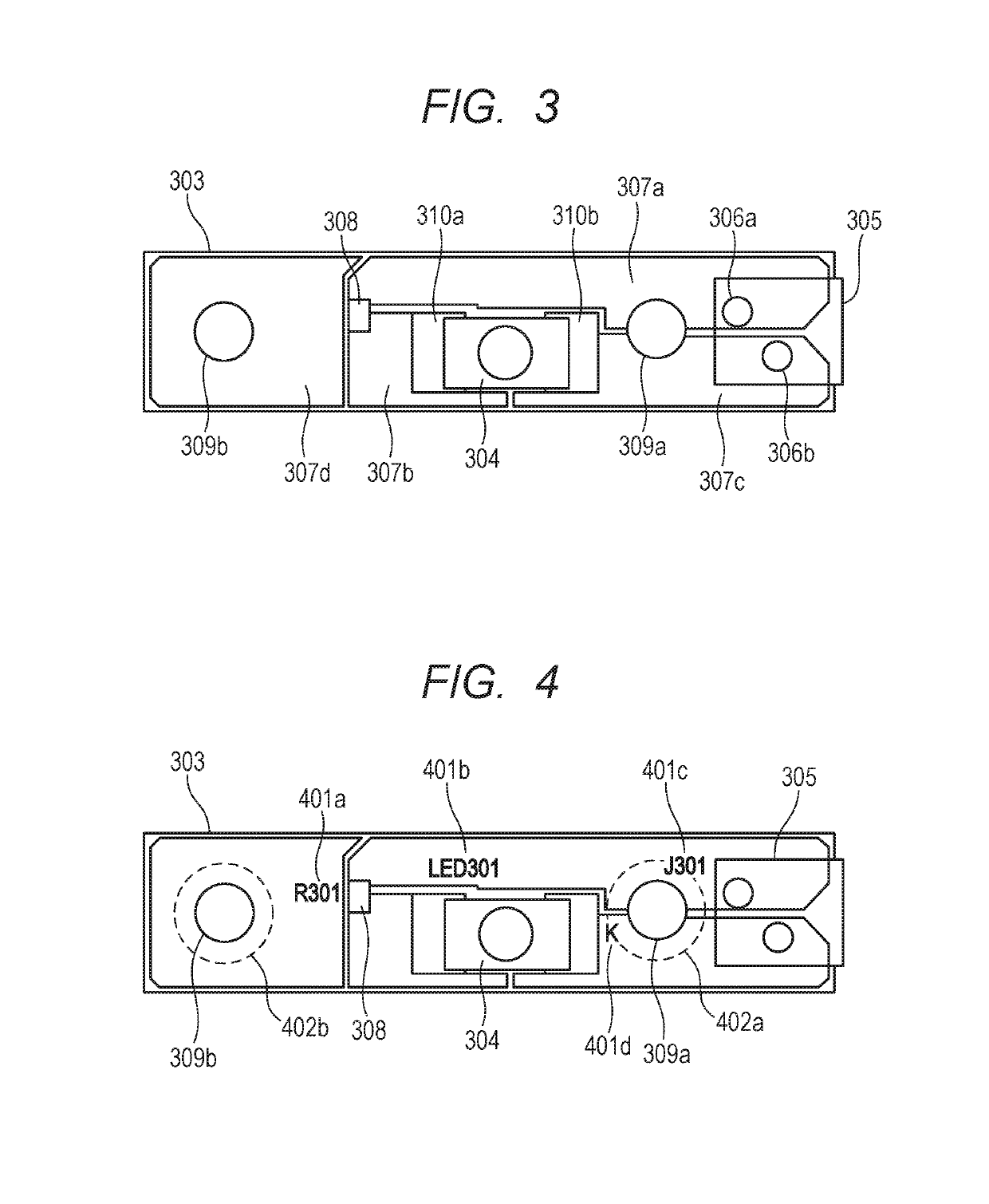

Circuit board and image forming apparatus

ActiveUS20180010739A1High precision assemblyHigh light reflectivityCircuit optical detailsPrinted circuit aspectsCopper foilReflectivity

The circuit board has a surface mount LED with a lens on the circuit board. A conductive portion and remaining space in the periphery of the LED are covered with solid copper foil so that reflectance of light and a heat dissipation effect are enhanced. In addition, layer structures between the circuit board and an assembled component are the same between contact portions with the assembled component so that tilt in mounting the board is suppressed. As a result, the circuit board having mounted thereon the surface mount LED having high directivity can be accurately mounted on the assembled component, tilt of an optical axis can be suppressed, the reflectance of light from the LED can be increased, and the heat dissipation effect can be enhanced.

Owner:CANON KK

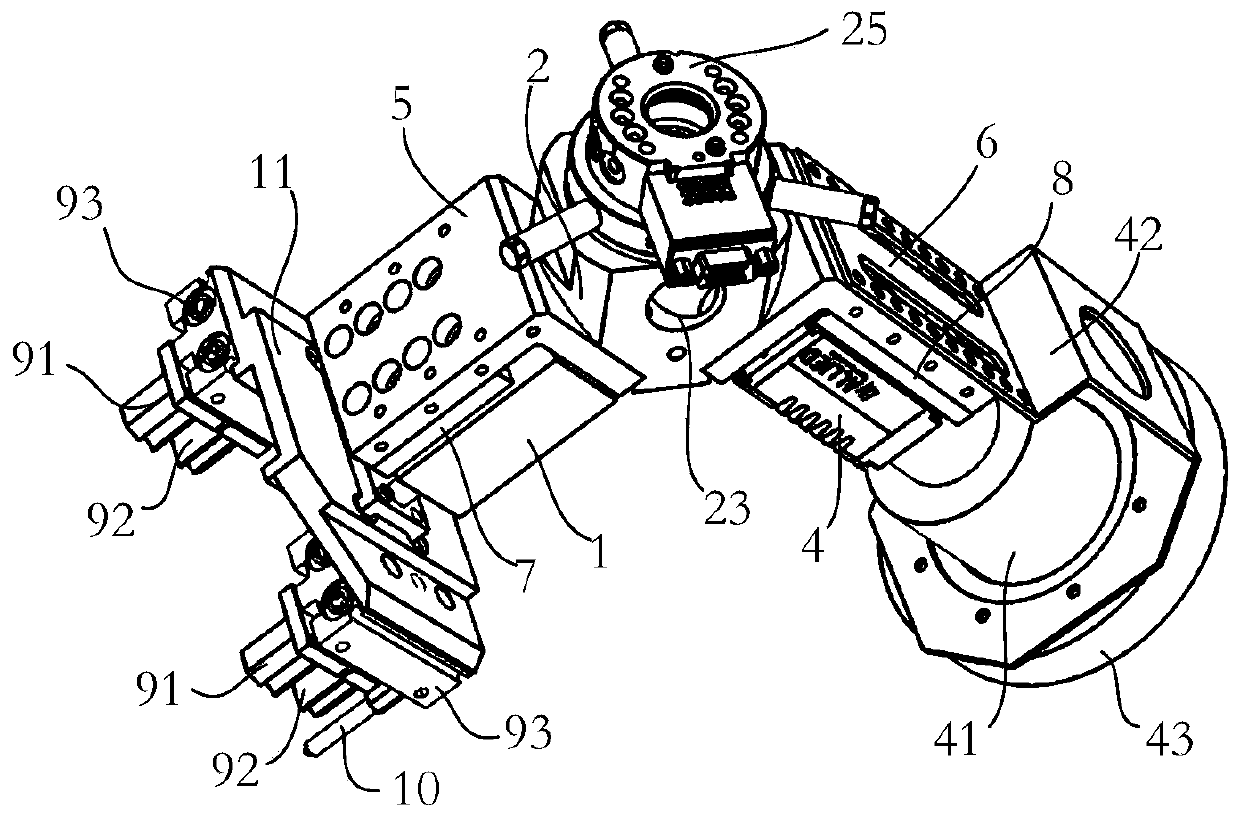

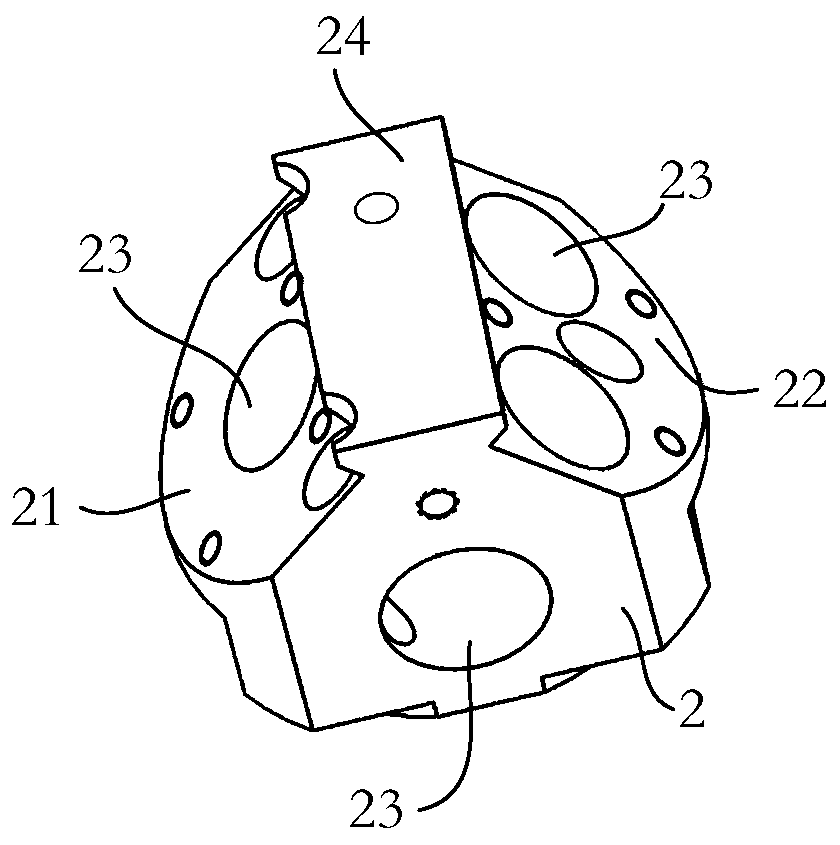

Antenna unit assembly assembling device and collecting, assembling and measuring integrated control system and method thereof

ActiveCN110328528APrecise positioningHigh precision assemblyWave based measurement systemsAssembly machinesControl systemOptical axis

The invention relates to an antenna unit assembly assembling device and a collecting, assembling and measuring integrated control system and method thereof. The assembling device comprises a mountingand dismounting air cylinder, a mounting support, an outer supporting assembly for picking or dismounting an antenna unit assembly and a camera. A first mounting face and a second mounting face whichare perpendicular are arranged on the mounting support, the mounting and dismounting air cylinder is arranged on the first mounting face, the camera is arranged on the second mounting face, the optical axis of the camera is perpendicular to the second mounting face, the driving end of the mounting and dismounting air cylinder is away from the first mounting face, and is connected with the outer supporting assembly to drive the outer supporting assembly to do reciprocated moving in the direction perpendicular to the first mounting face, the camera is used for carrying out image collecting and parameter extracting on the characteristics of the assembling position of the antenna array face, and the mounting and dismounting air cylinder can rotate to the assembling position and drive the outersupporting assembly to move to finish mounting or dismounting of the antenna unit assembly on the antenna array face. Mechanical and electrical mounting and switching of the antenna unit assembly assembling device and an industrial robot or execution mechanism can be achieved, and assembling precision needs are ensured.

Owner:BEIJING INST OF RADIO MEASUREMENT

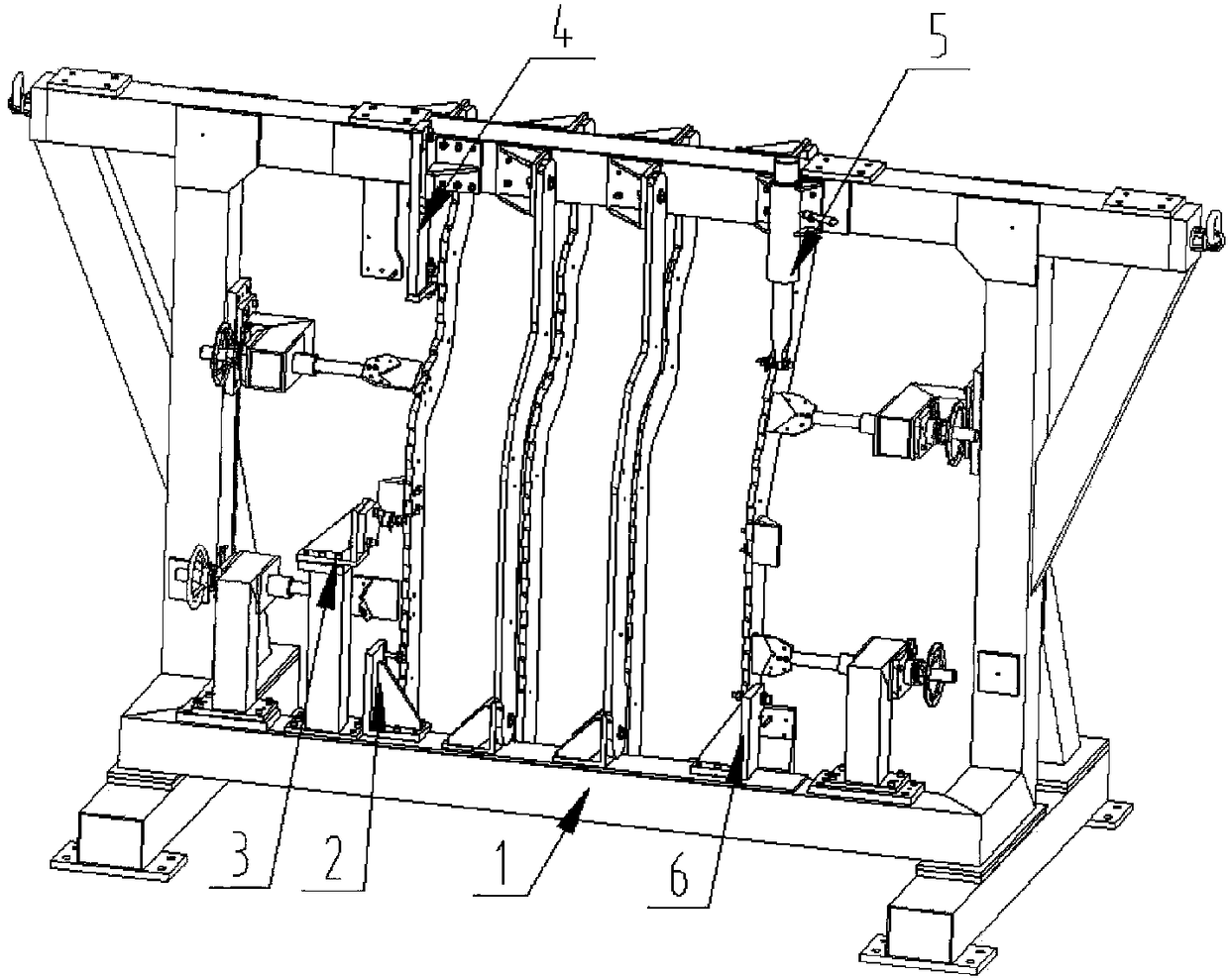

Assembling clamp for carbon fiber composite aircraft cabin door

PendingCN108382605AHigh precision assemblyAvoid relative position deviationWork holdersAircraft assemblyAirplaneCarbon fiber composite

The invention provides an assembling clamp for a carbon fiber composite aircraft cabin door. The assemble assembling clamp has the function of assembling five metal joints on the composite cabin doorthrough a riveting bonding mode, and the outline precision of the tooth-shaped edge relative to five joint holes, and the relative position degree and the coaxial degree among the joint holes are ensured. Through the assembling clamp, high precision assembling of the carbon fiber composite cabin door and the metal joints can be achieved, relative position deviation caused by the unreasonable positioning and clamping mode or the rebound and super poor precision of a manufactured piece caused by large state deviation between the state of the manufactured workpiece and the state after the manufactured workpiece is removed from a frame during assembling is avoided, meanwhile, the mode of a frame-type structure combined positioning assembly has the enough openness, the operation space can be ensured, the structure can be simplified as far as possible, and the manufacturing cost is reduced.

Owner:HENGSHEN

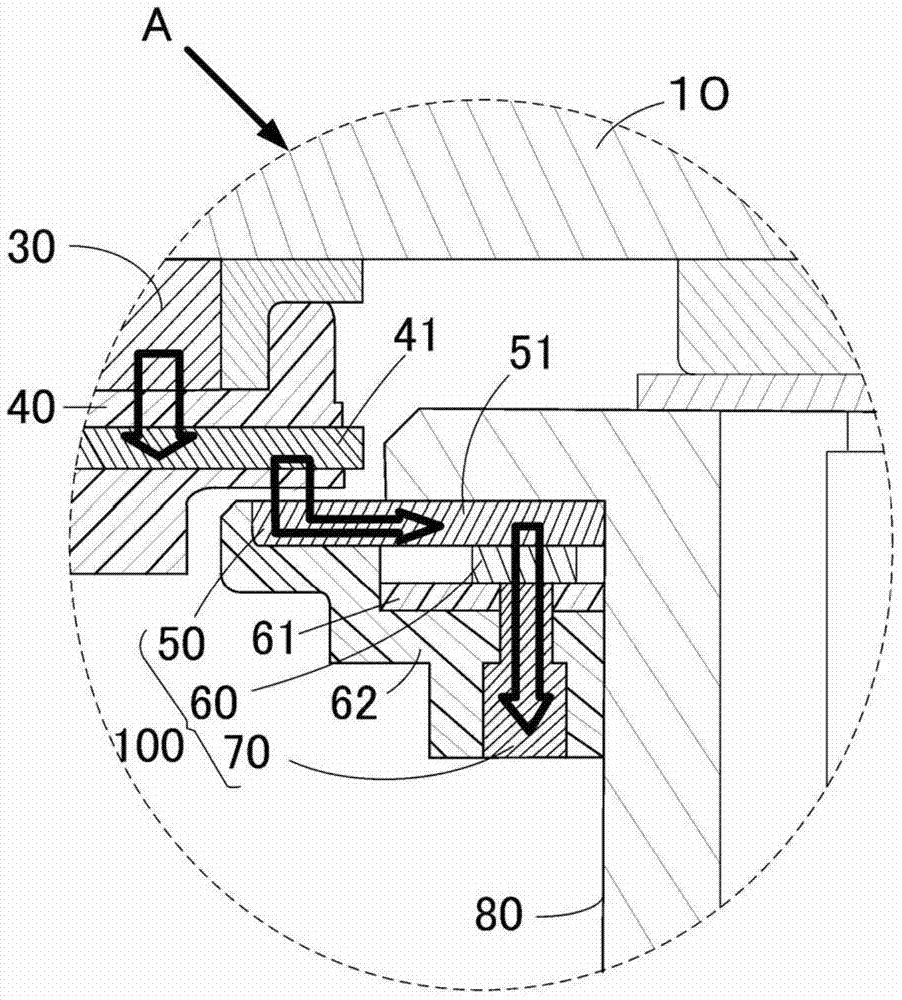

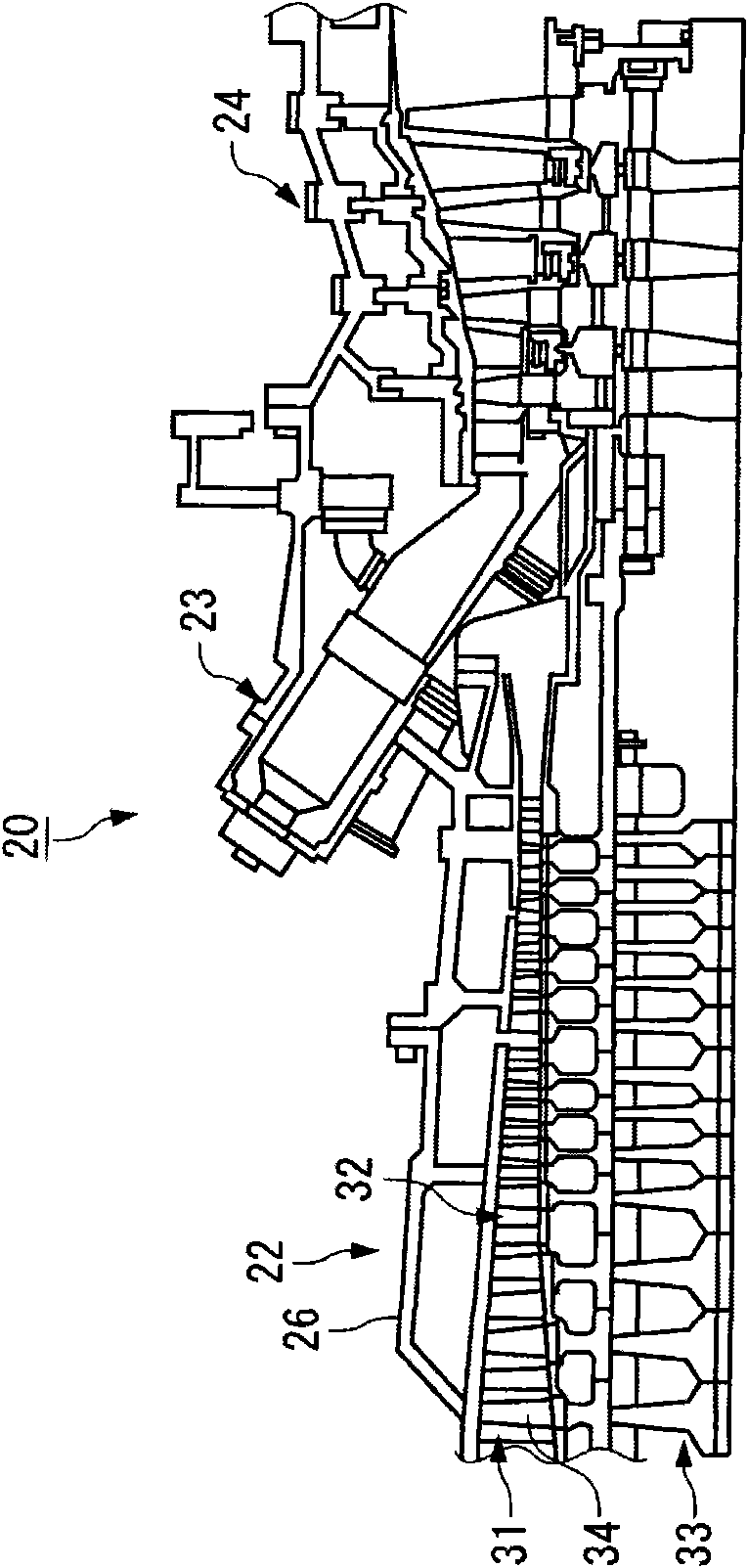

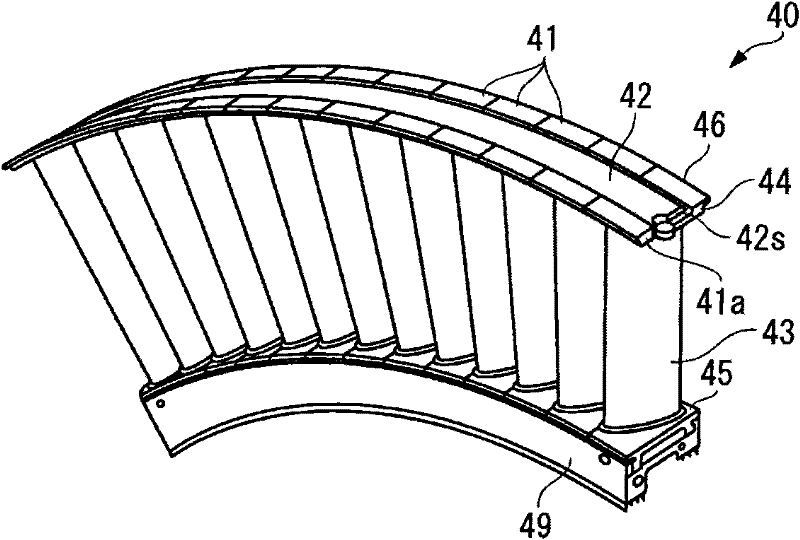

Assembling method of stator blade ring segment, stator blade ring segment, coupling member, welding method

ActiveCN101617129AInhibit accessAvoid deformationPump componentsStatorsThermal deformationEngineering

An assembling method of a stator blade ring segment which can suppress the risks of thermal deformation and deterioration of strength, secure a degree of freedom of profile, and enhance the compression performance of a compressor. Furthermore, welding is provided in which a welding object can be prevented from floating from a groove or a recess at the time of welding, and welding can be carried out well. Sidewall portions (50b) on the opposite sides are formed to incline against the bottom (50a) so that the width of a groove (50) formed in each segment split body (41) decreases gradually from the outer circumferential side toward the bottom(50a). A coupling member (42) has such a cross-section that its width becomes largest at a protrusion (42b) located at an intermediate part in the thickness direction. When the coupling member (42) is placed in the groove (50), the protrusions (42b) on the opposite sides abut against or approach the sidewall portion (50b) of the groove (50), a space (100) is formed on the bottom (50a) side of the groove (50) and a groove (200) of substantially V-shaped cross-section is formed on the side away from the bottom (50a) of the groove (50).

Owner:MITSUBISHI POWER LTD

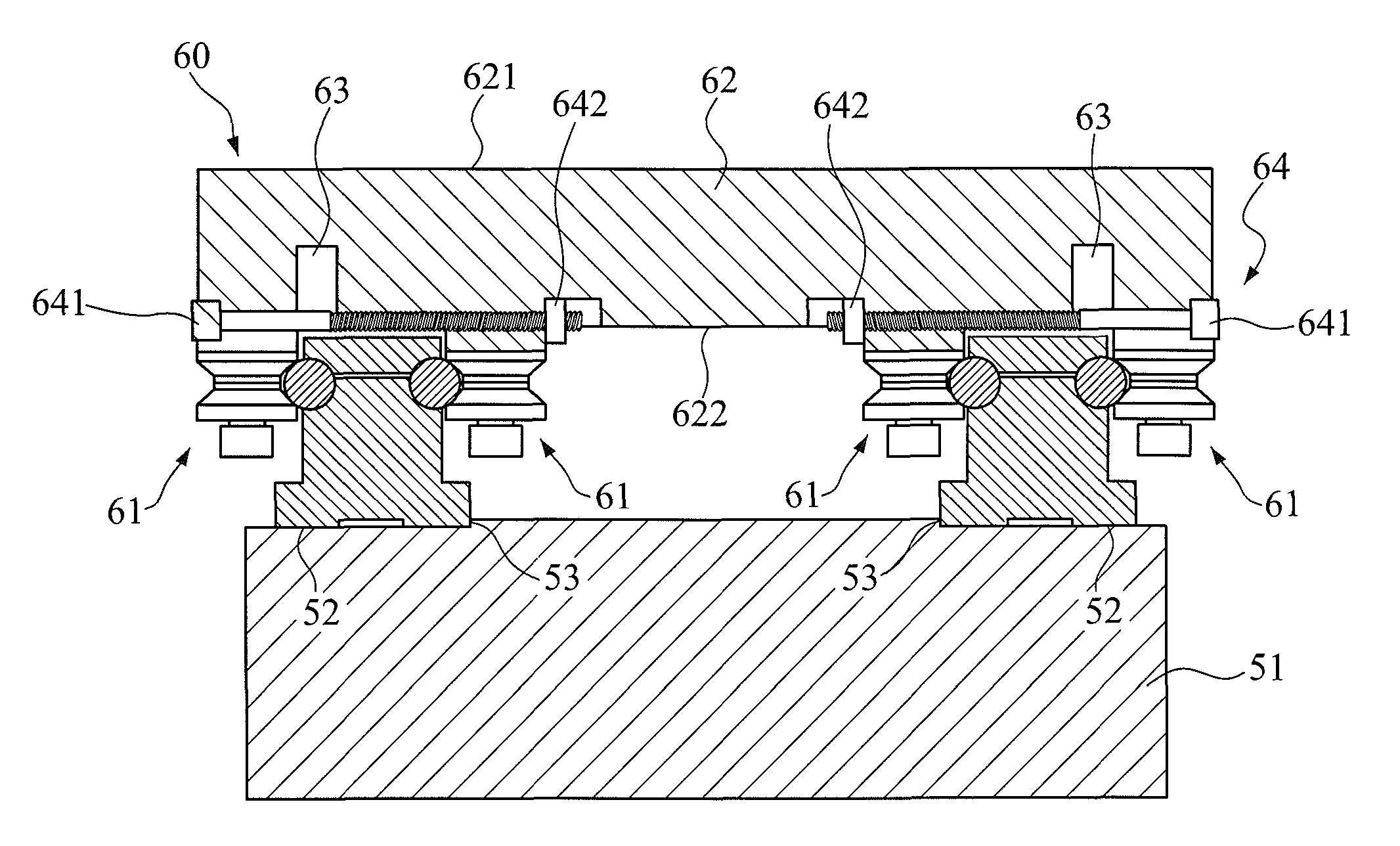

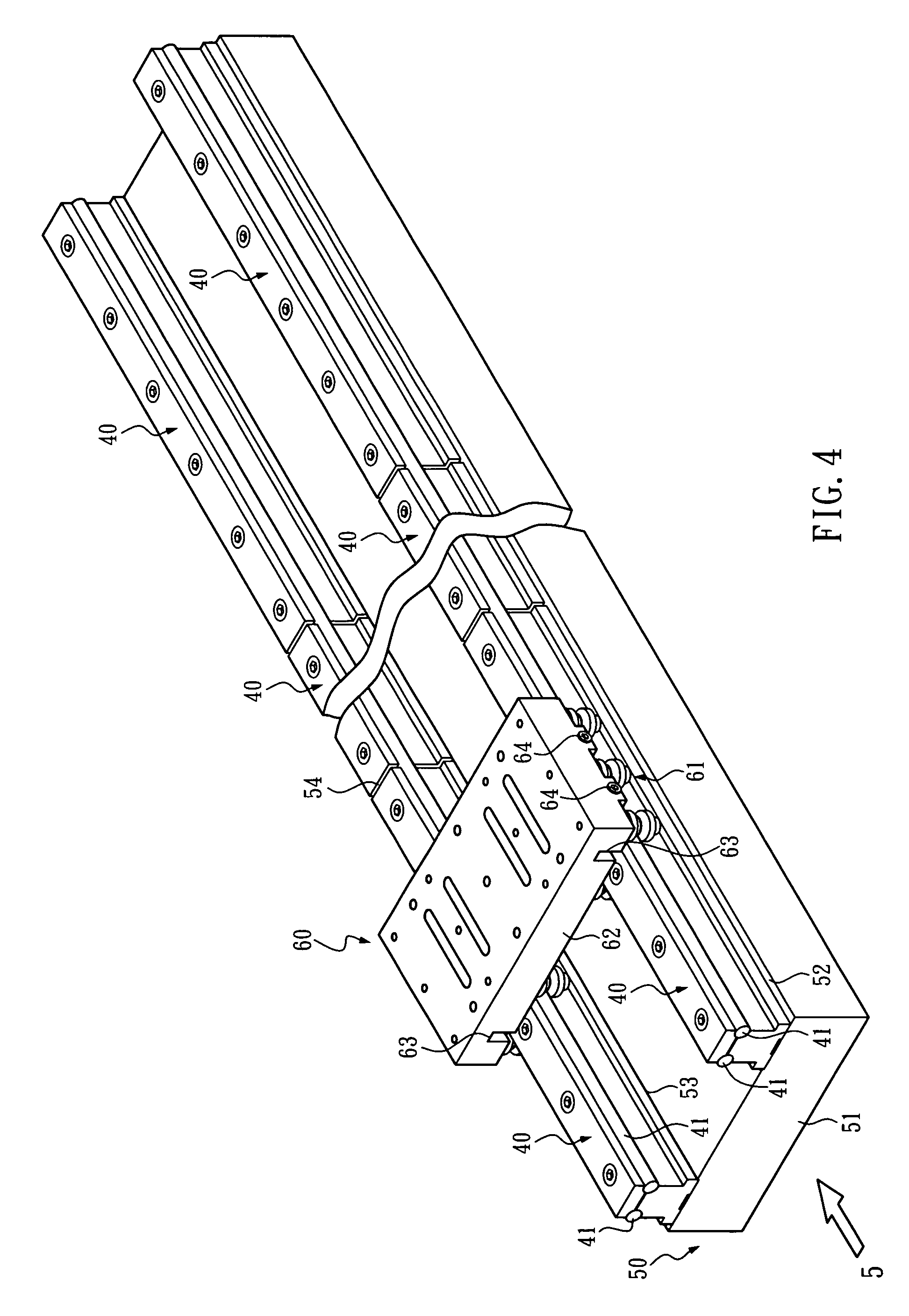

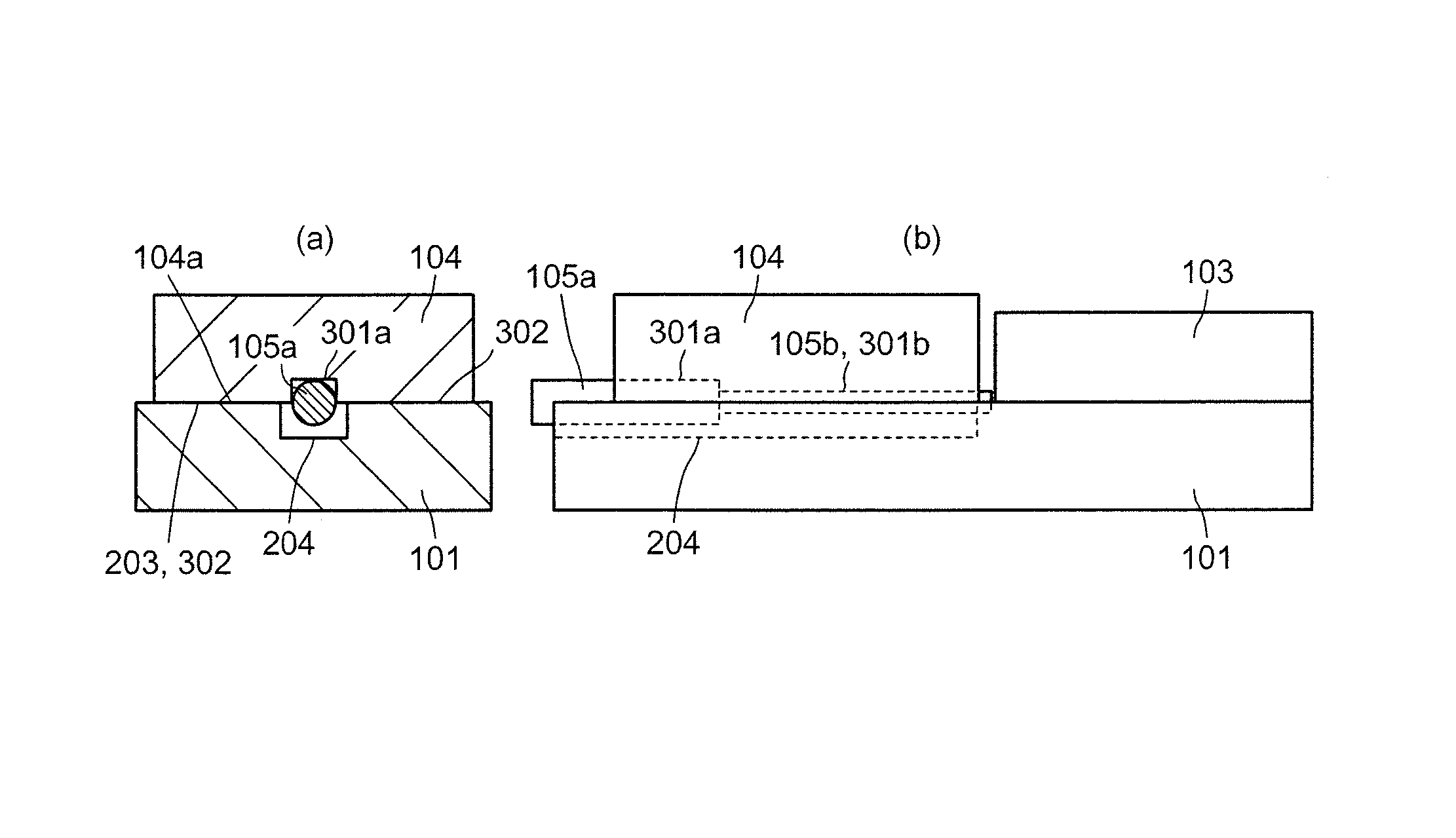

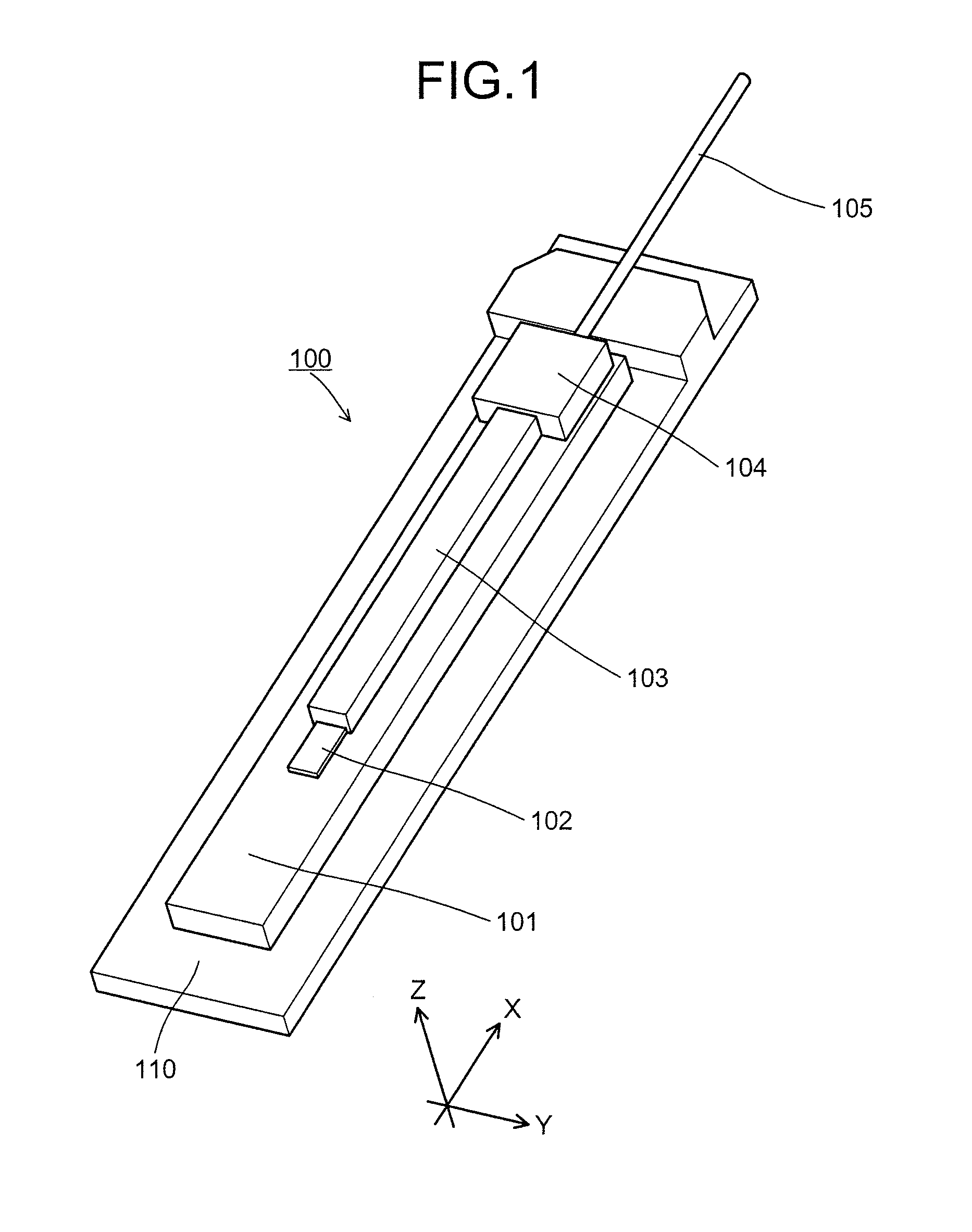

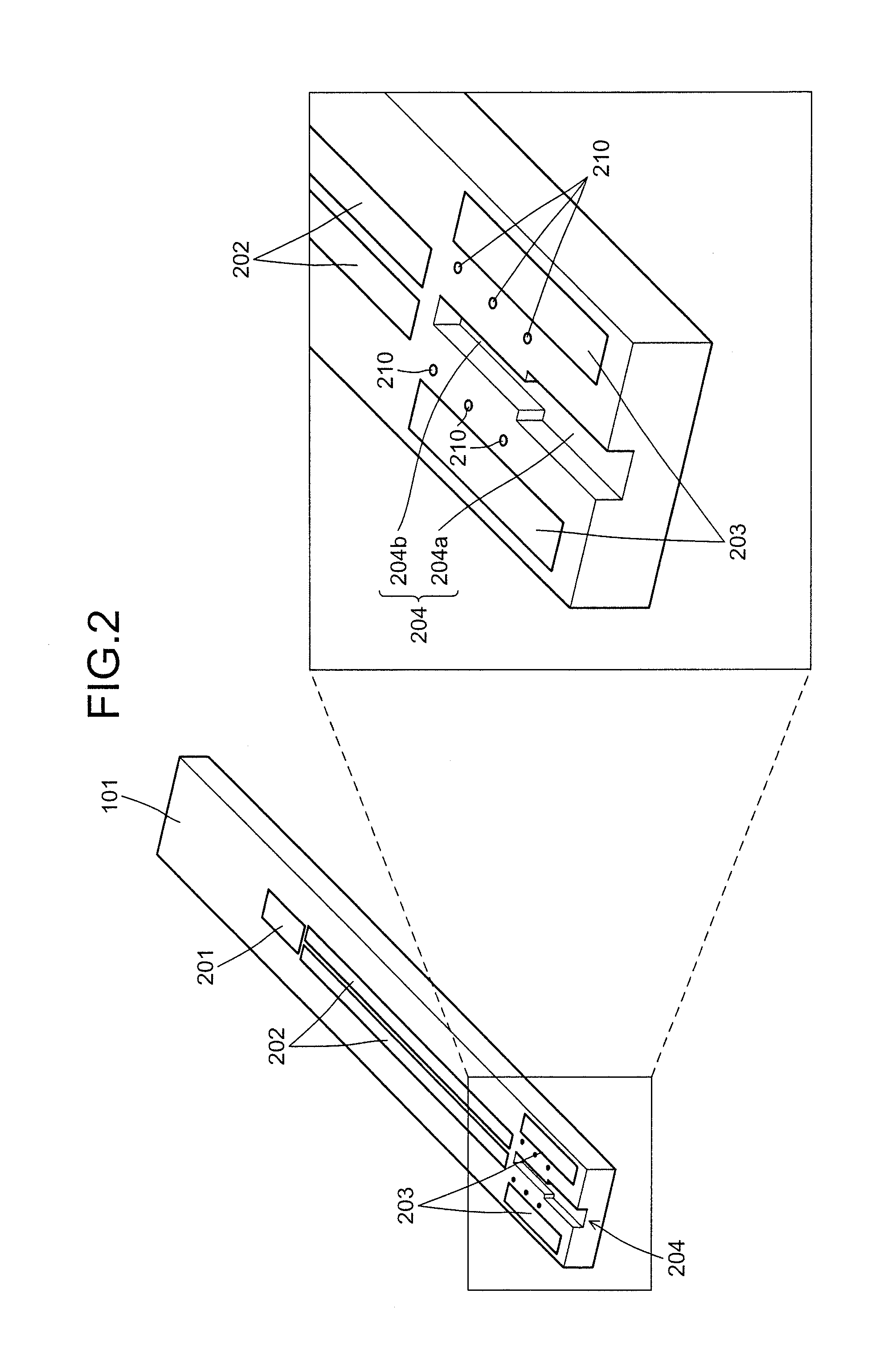

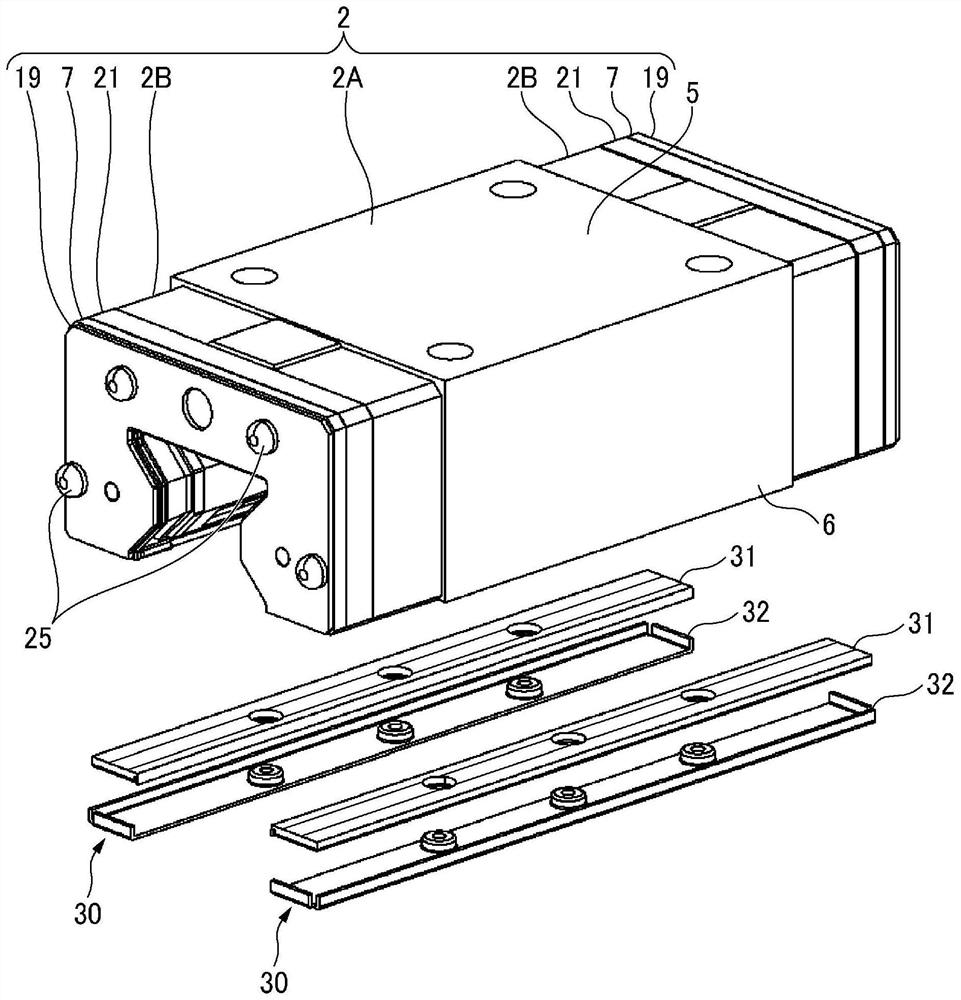

Automatic-positioning linear guide

InactiveUS8152378B2High precision assemblyRolling contact bearingsLinear bearingsLinearityMechanical engineering

An automatic-positioning linear guide has a driven body combined with guiding rails at two sides of a stationary base via a plurality of rollers. Each of the rollers is composed of two bearings combined by an axial shaft and can be assembled with the corresponding guiding rail without an assembly error therebetween.

Owner:TSAI SHU FU

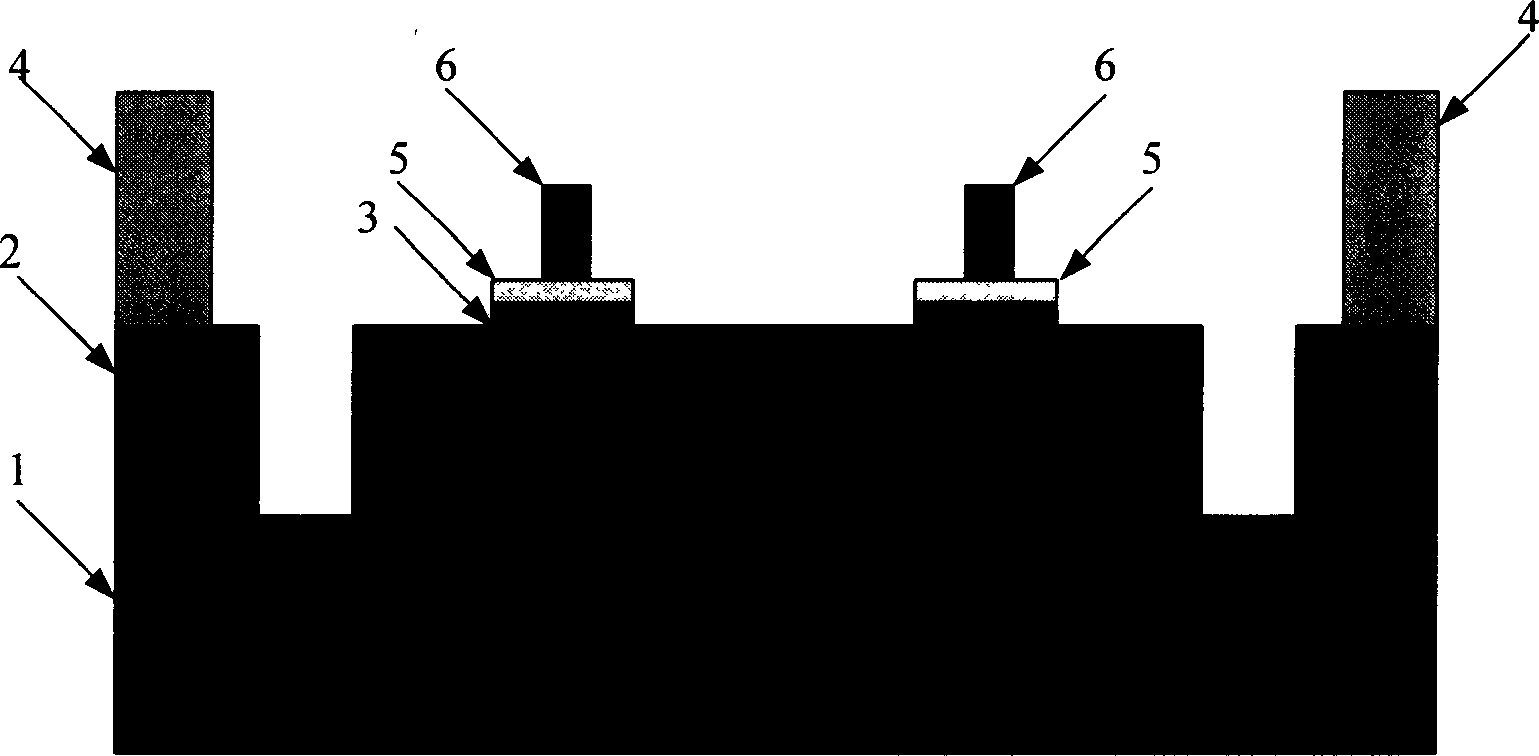

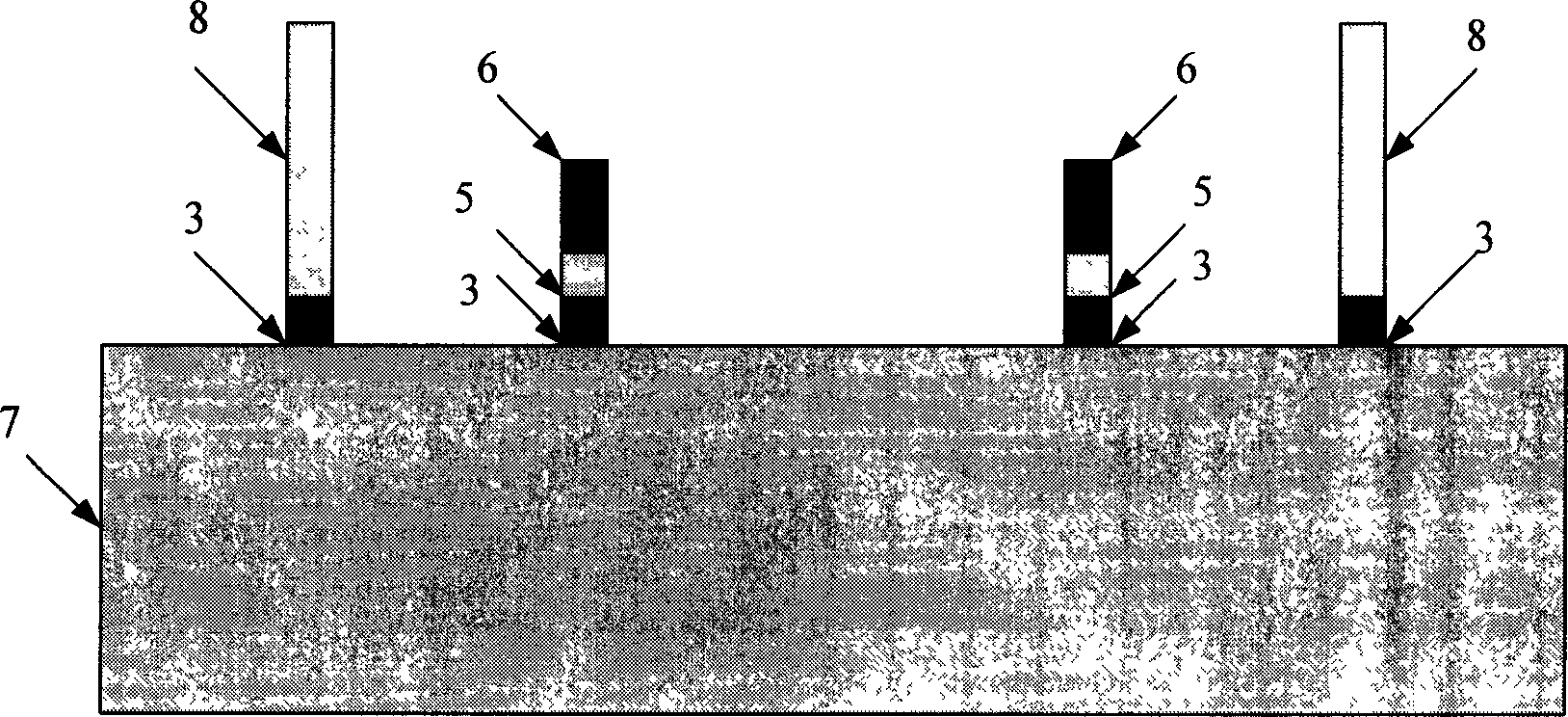

High-precision three-dimensional micro-assembling method and assembly parts based on MEMS

InactiveCN1803577AHigh precision assemblyAchieve high-precision assemblyPrecision positioning equipmentSoldering apparatusEngineeringSurface tension

The invention discloses a high-precision three-dimensional micro-assembly method and combined component based on MEMS, which comprises the following steps: setting a micro-clamp to match the loading chip; setting the alignment part and alignment accessory and welding button on the corresponding substrate and loading chip separately; injecting liquid in the micro-clamp; putting the chip in the micro-clamp back-off; locating the chip on the substrate through alignment part and alignment accessory and welding fusion reflux.

Owner:PEKING UNIV

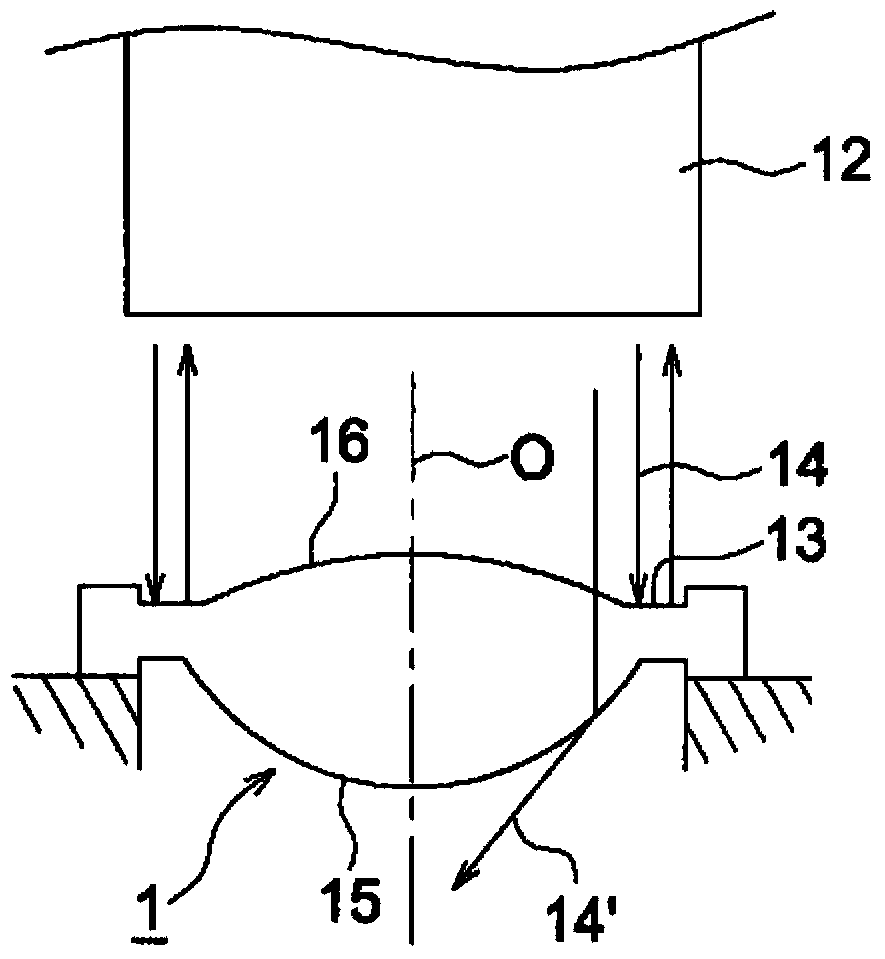

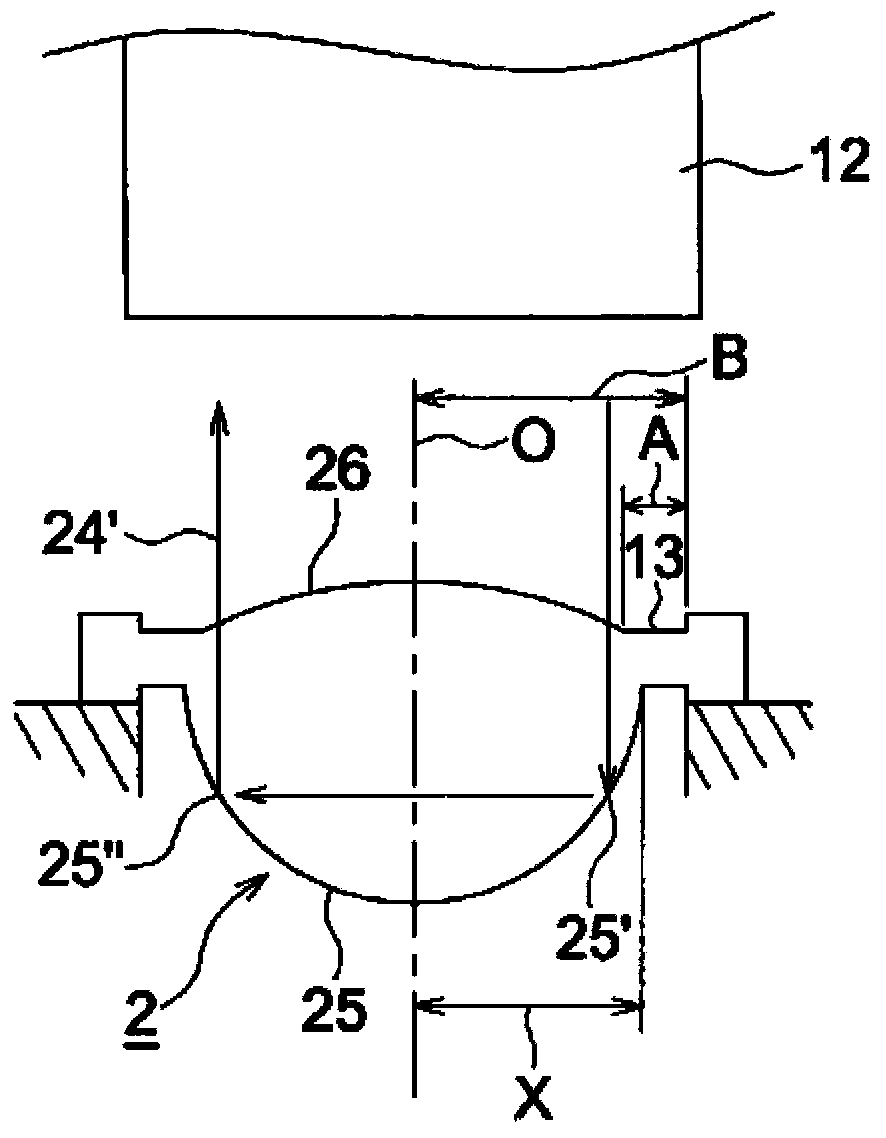

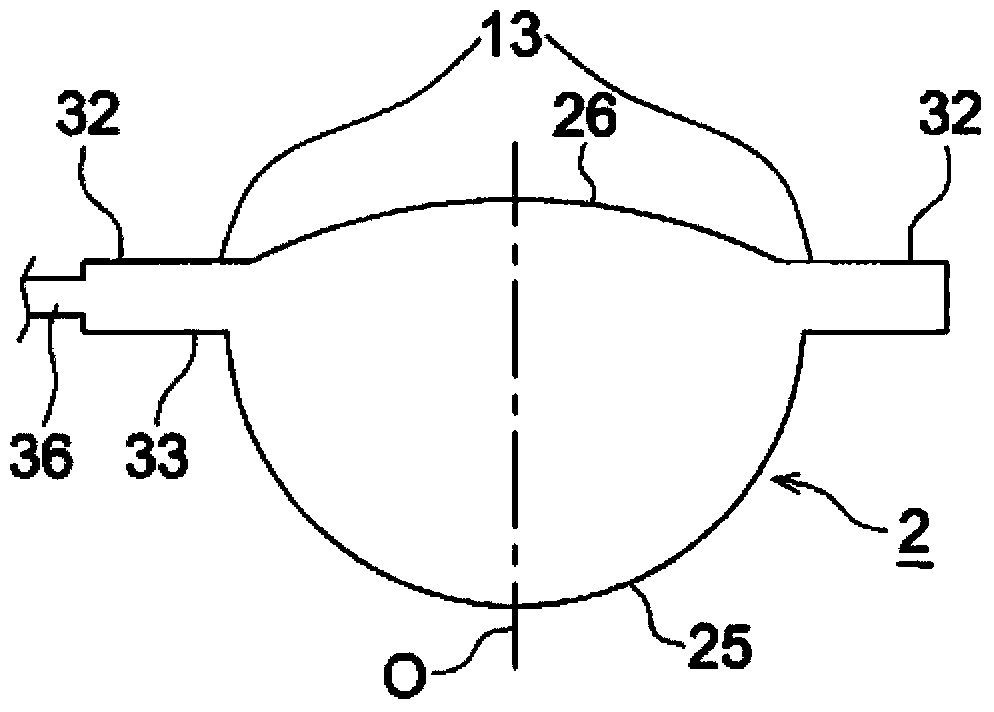

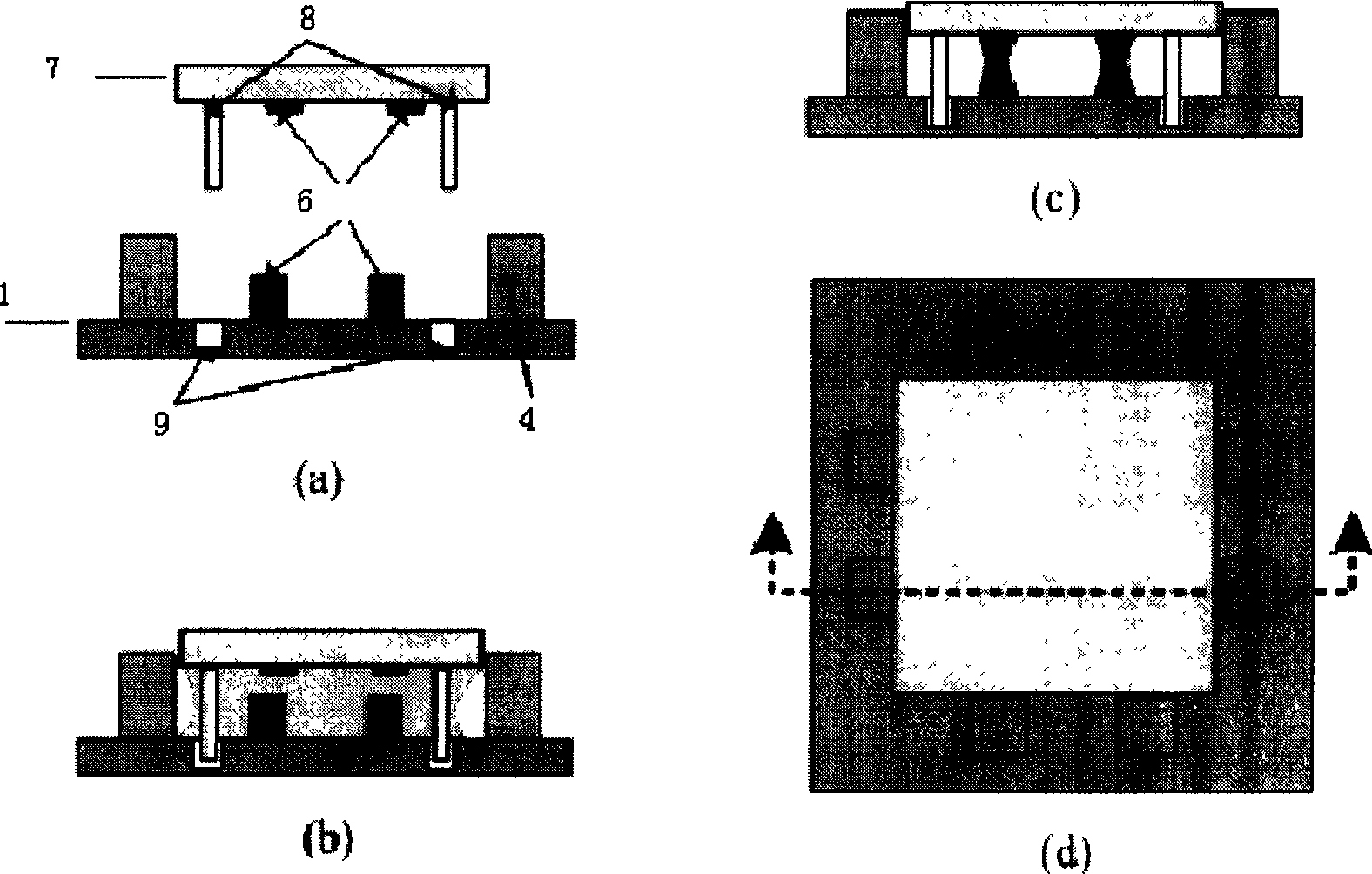

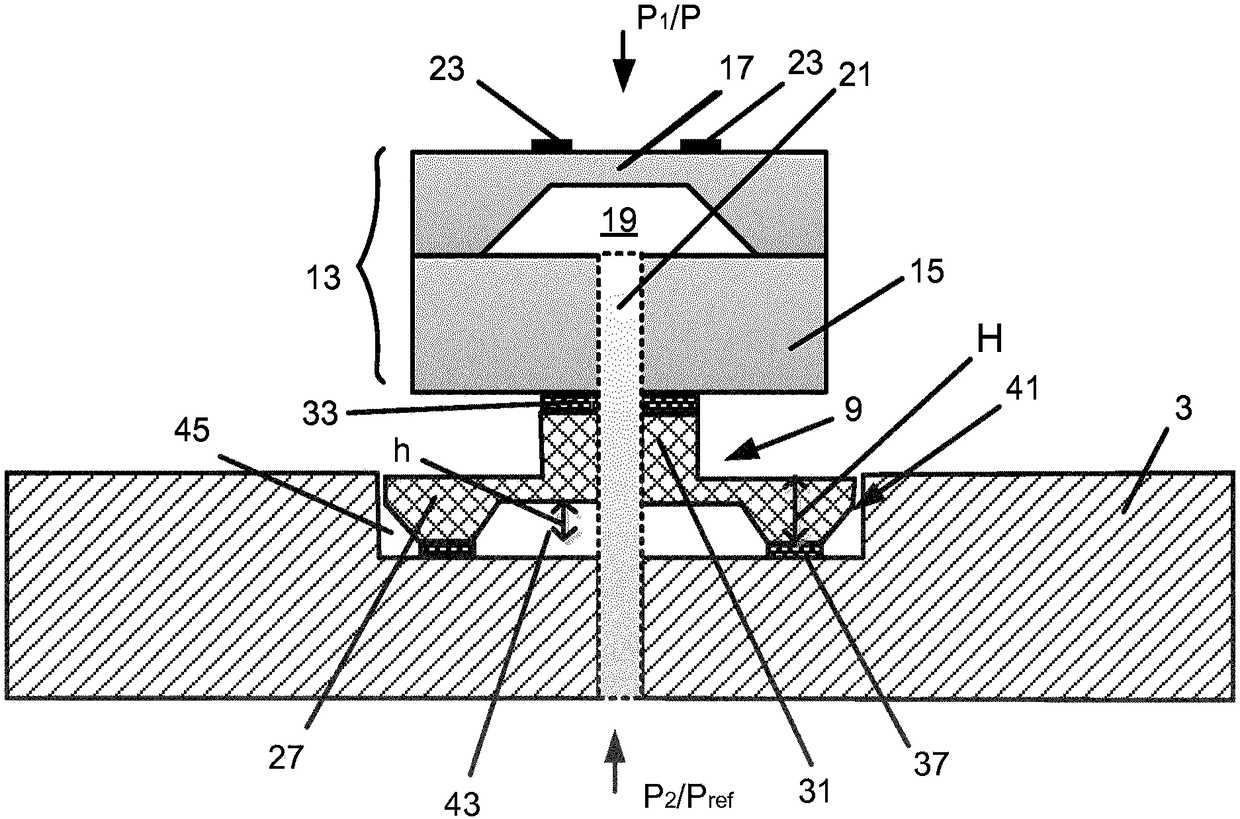

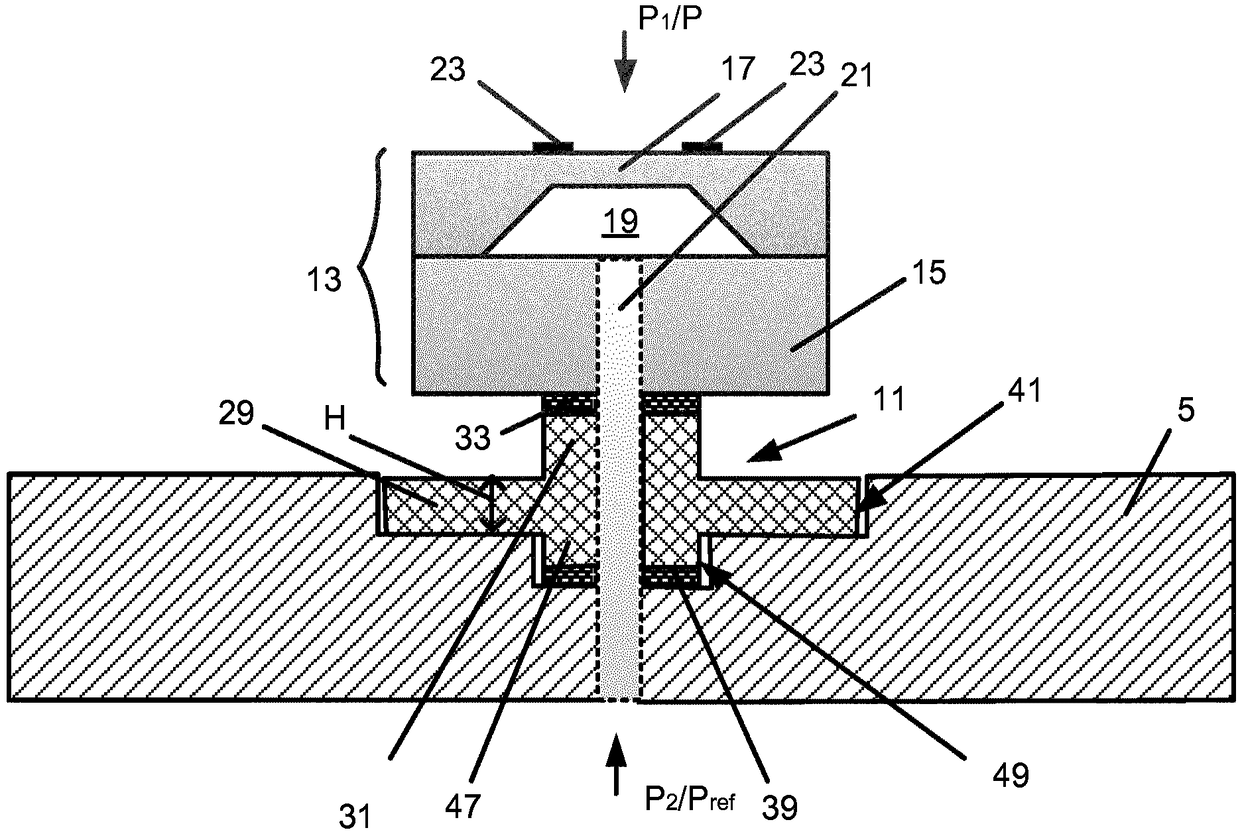

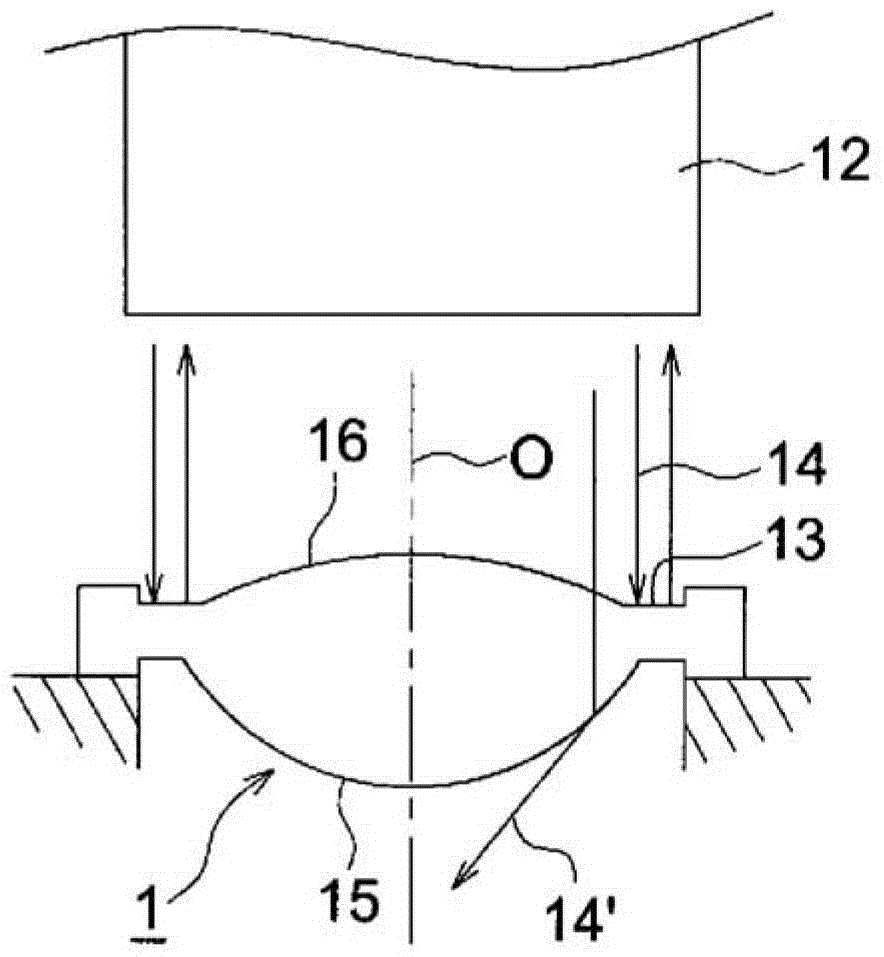

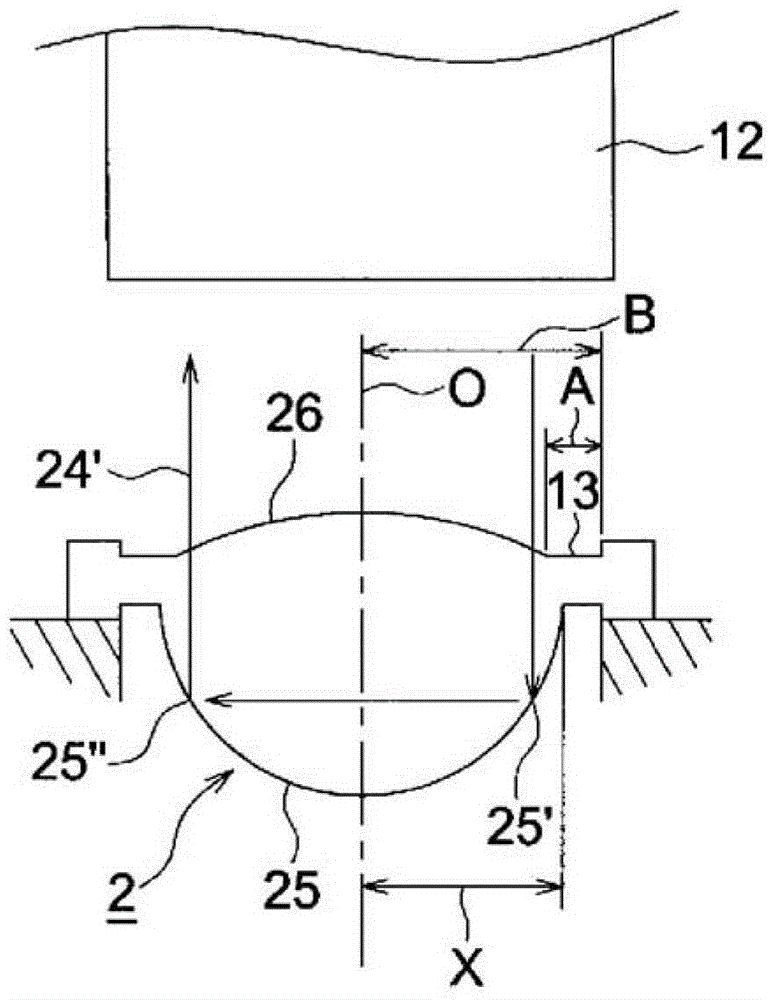

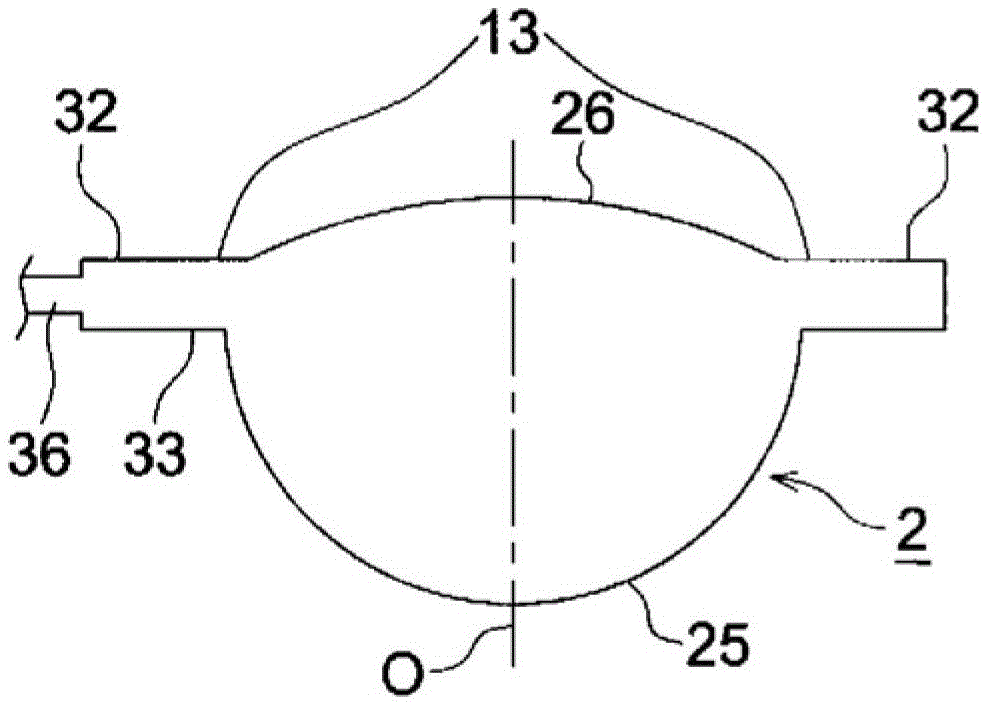

Pressure measuring device

ActiveCN108369149AHigh precision assemblyLarge footprintFluid pressure measurementEngineeringPressure measurement

The invention describes a pressure measuring device which can be produced in a simple manner and has a carrier (1, 3, 5), in particular a metal carrier (1, 3, 5), in particular a stainless steel carrier, a pedestal (7, 9, 11) connected to the carrier (1, 3, 5) and a pressure sensor (13) mounted on a free-standing end of the pedestal (7, 9, 11), the pressure sensor (13) of which is protected against thermomechanical stresses and is distinguished by the fact that the pedestal (7, 9, 11) comprises a base (25, 27, 29) arranged on the carrier (1, 3, 5), the pedestal (7, 9, 11) comprises an extension (31) which extends from the base (25, 27, 29) in the direction of the pressure sensor (13) and comprises the free-standing end of the pedestal (7, 9, 11), the base (25, 27, 29) has an area which isgreater than an area of the extension (31), and the extension (31) has an area which is smaller than an area of the pressure sensor (13) mounted thereon.

Owner:EHNDRESS KHAUZER GMBKH KO KG

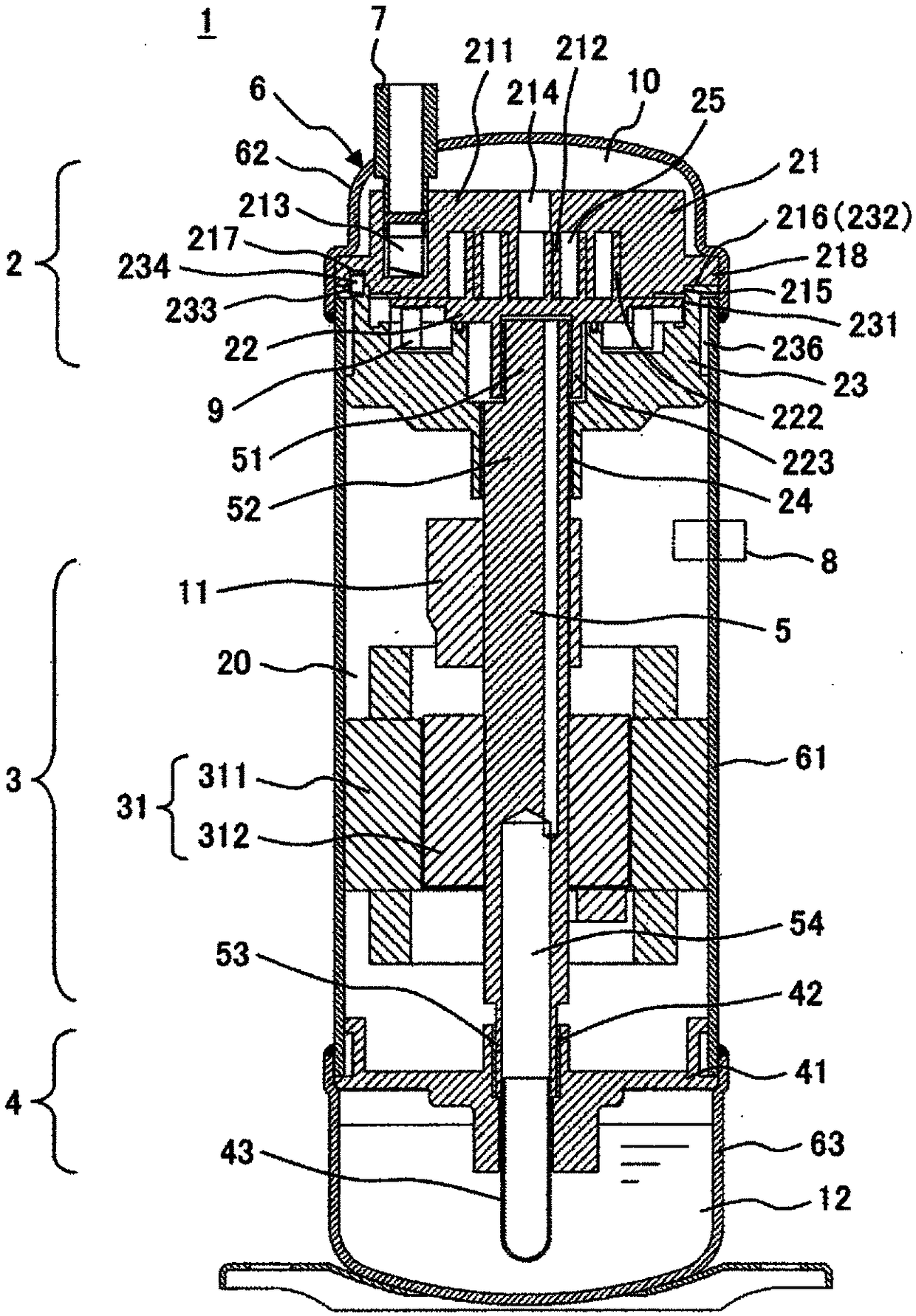

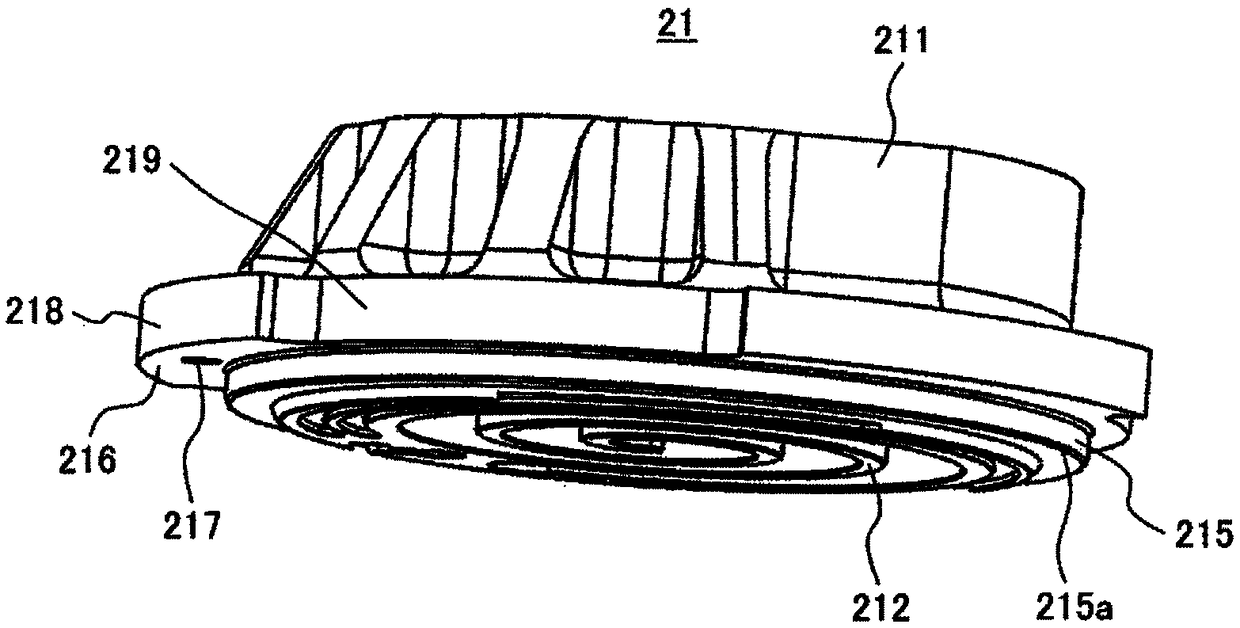

Scroll compressor

ActiveCN108869280AHigh precision assemblyPrecise positioningRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringFlange

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

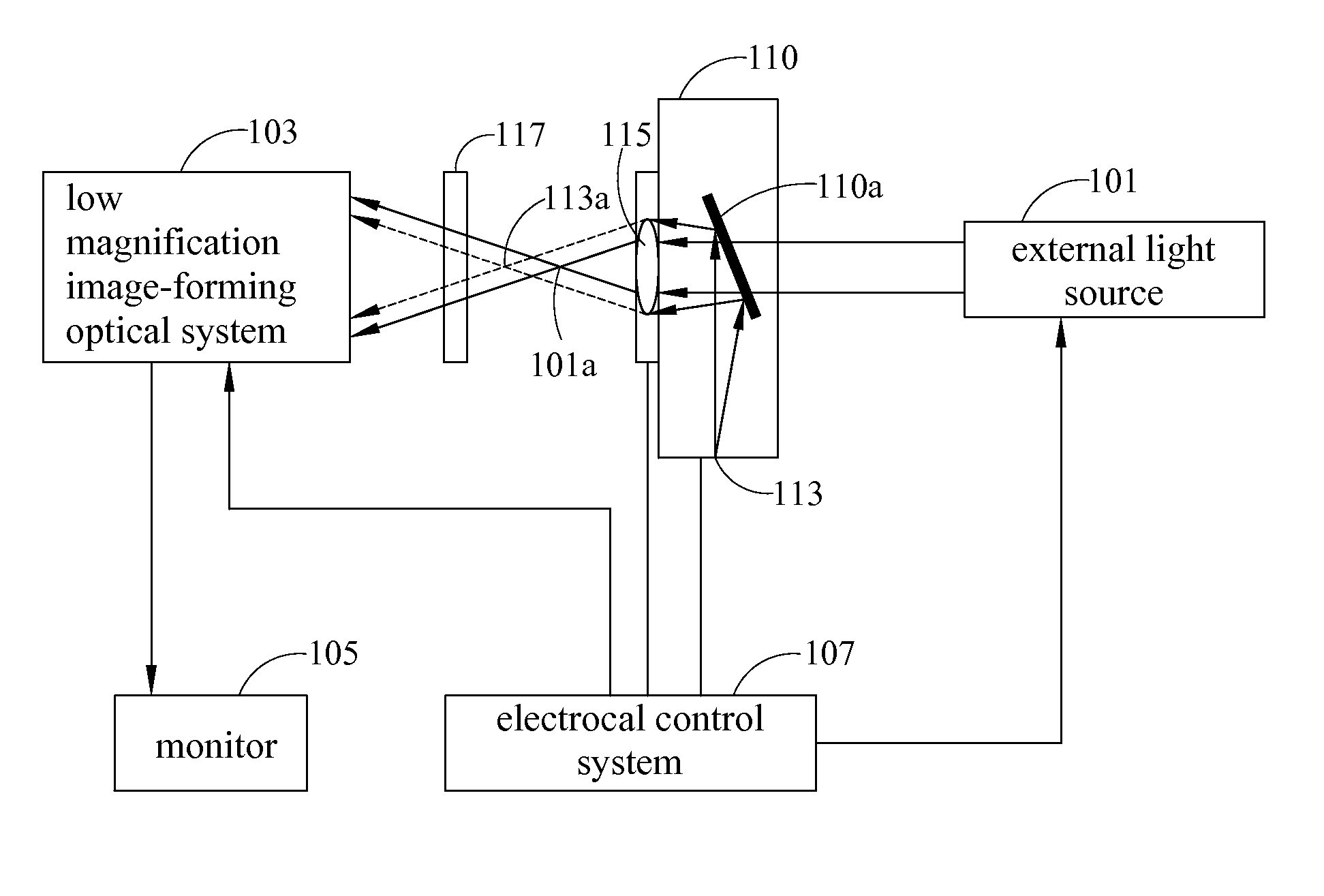

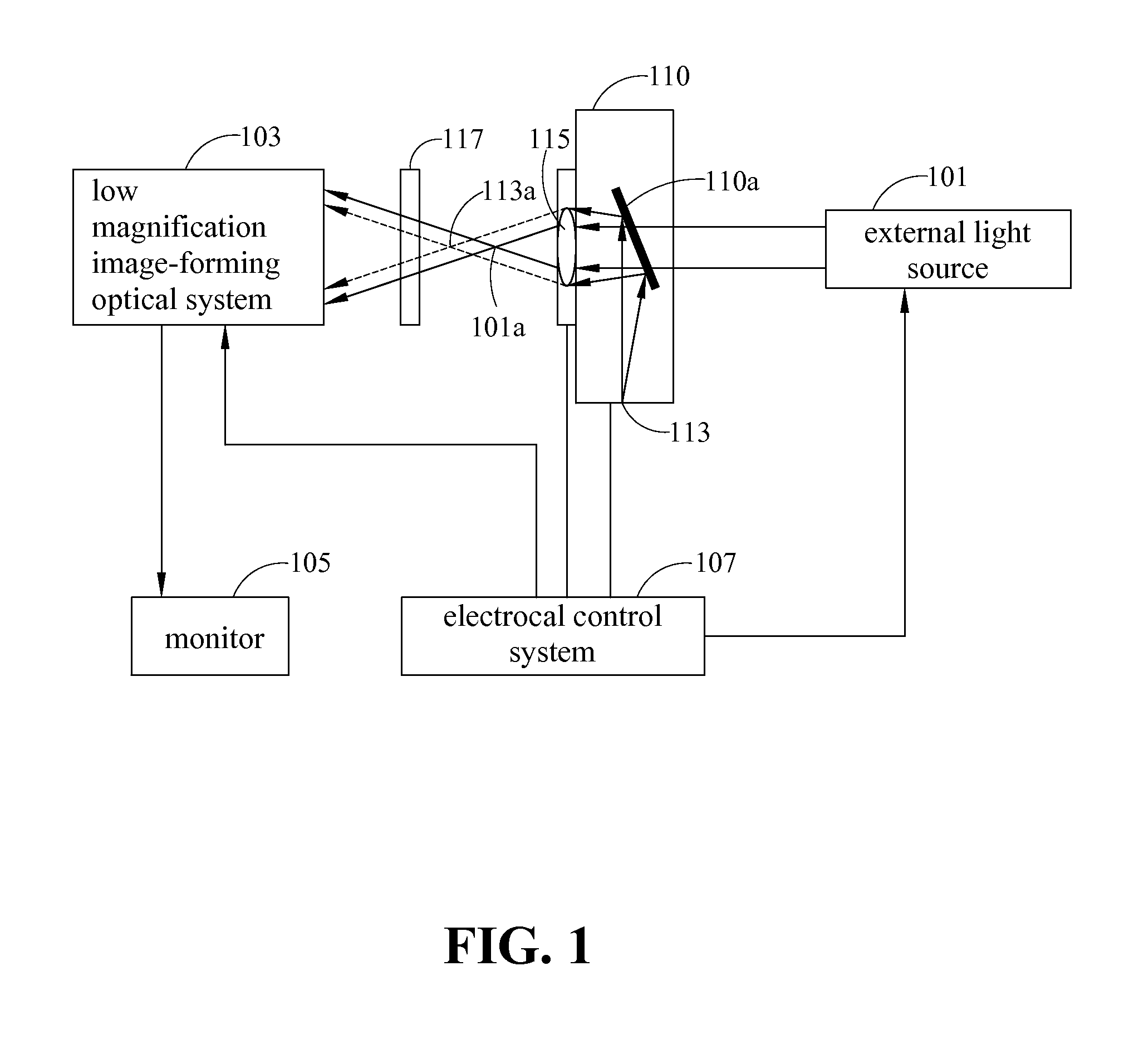

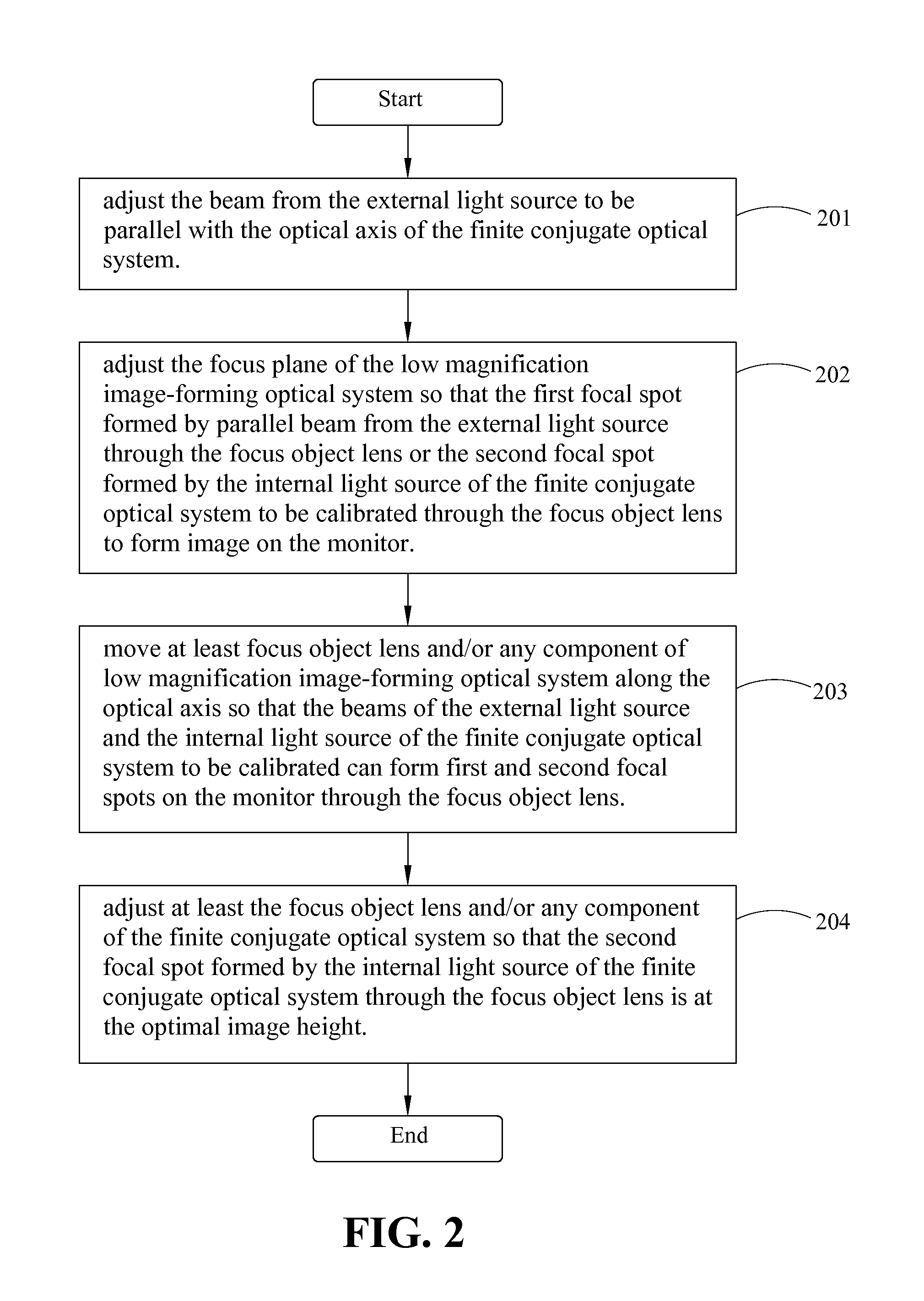

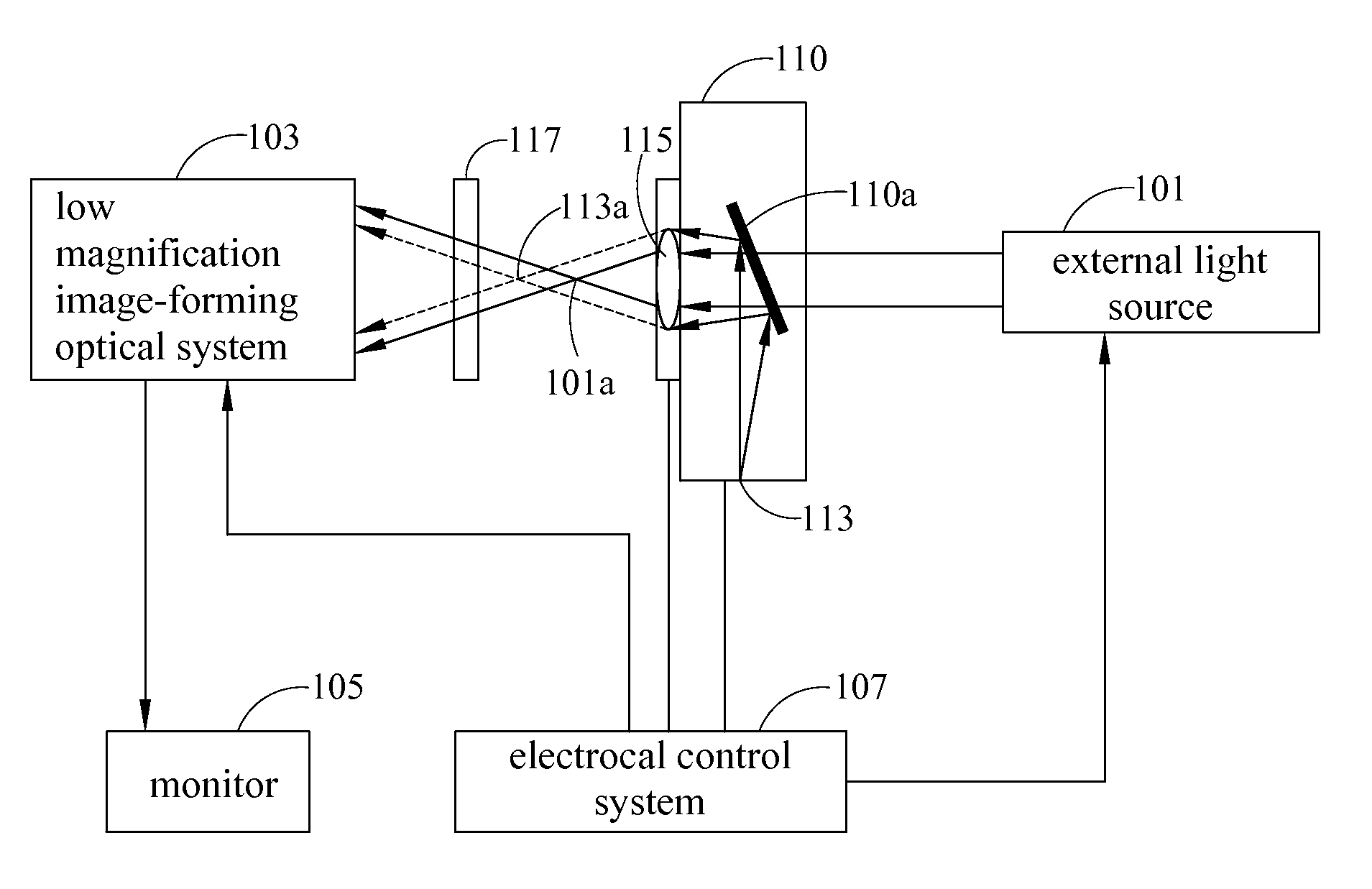

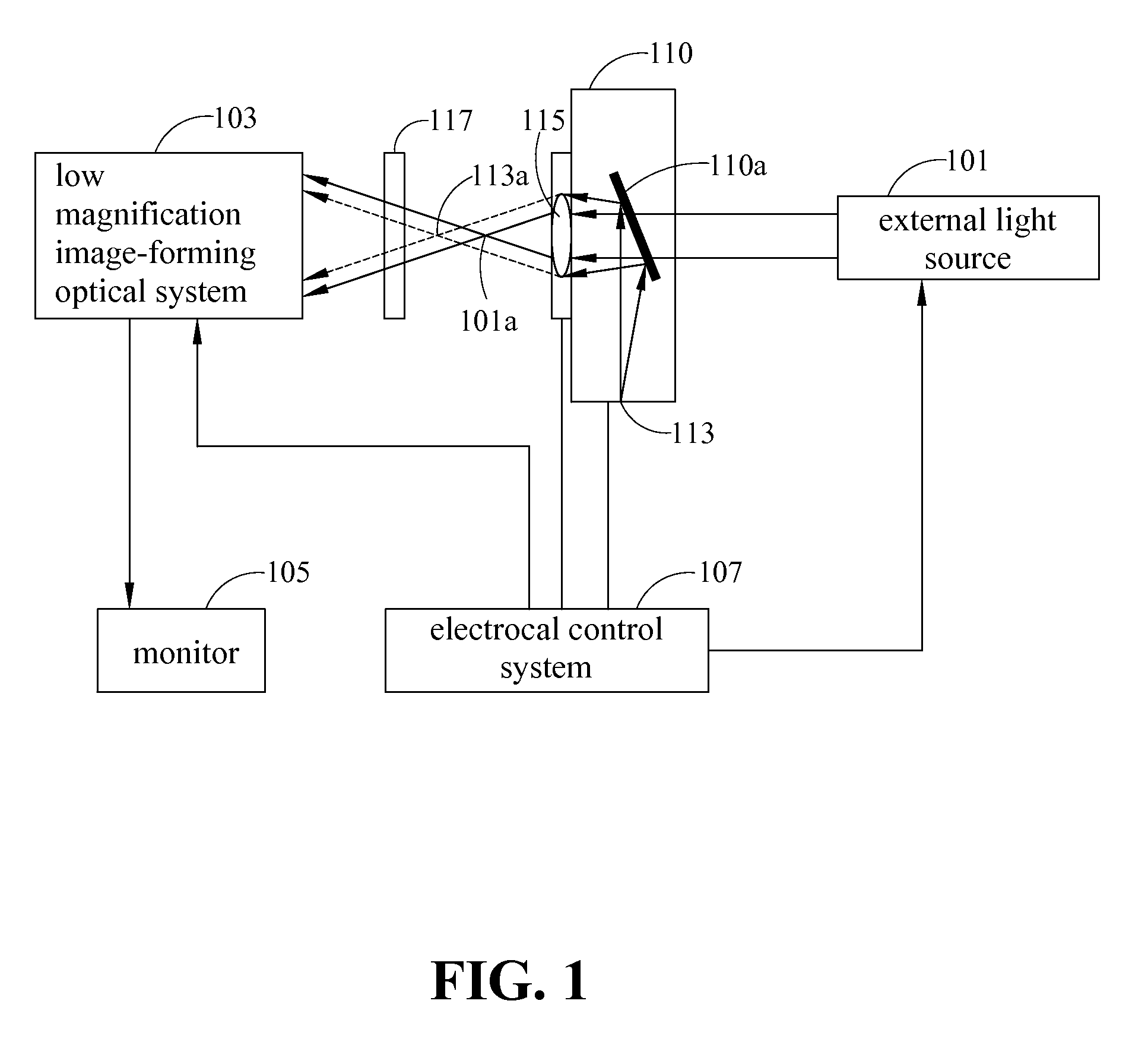

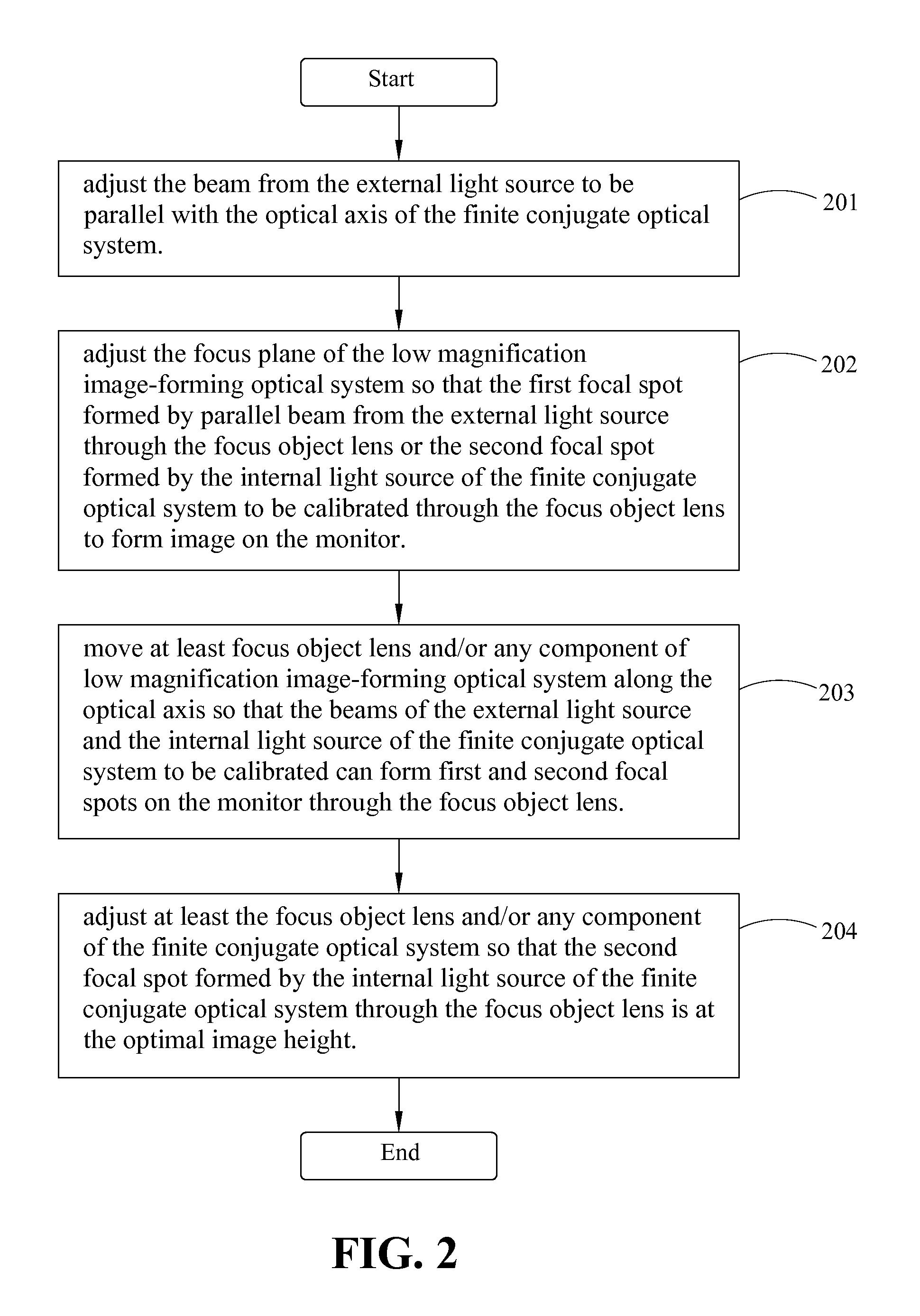

Calibration Apparatus And Method For Optical System Assembly

InactiveUS20100290036A1Great image heightConvenient heightOptical head manufactureUsing optical meansElectricityOptical axis

A calibration apparatus and method for optical system assembly is provided, applicable to a finite conjugate optical system to determine the optimal image-forming positions of the light source and the focus object lens of the finite conjugate optical system. The apparatus includes an external light source, a low magnification image-forming optical system, an electrical control system and a monitor. When the parallel beam generated by the external light source is parallel to the optical axis of the finite conjugate optical system, the low magnification image-forming optical system is used to magnify the two focal spots formed by the external light source and the internal light source of the finite conjugate optical system to be calibrated. Finally, by adjusting the related position of the focus object lens or the internal light source of the finite conjugate optical system, the optimal relative positions between the light source and the focus object lens of the finite conjugate optical system can be found. The calibration apparatus of the present invention has the advantages of simple structure, easy assemble and setup, high precision assembly and low cost, as well as the capability to perform optimal calibration of the relative position of the focus object lens and the light source of each individual finite conjugate optical system.

Owner:TOPRAY MEMS

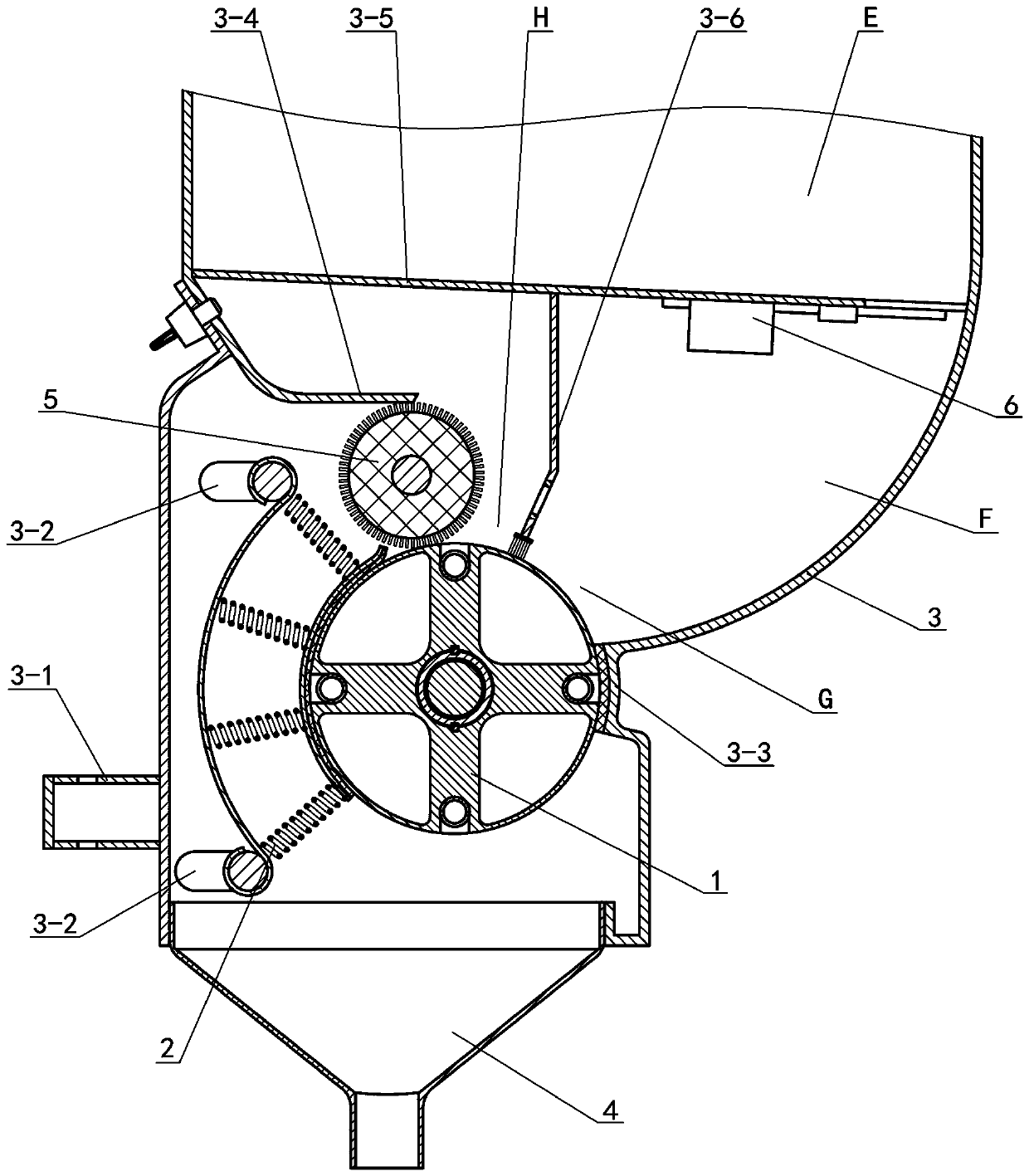

Control method for volume-adjustable non-destructive seeding

ActiveCN111010943AAvoid damageAvoid the problem of repeated positioningSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringControl theory

Owner:HUNAN AGRICULTURAL UNIV

Objective lens and optical pickup device

ActiveCN103443857BHigh precision assemblyEfficient determinationRecord information storageCondensersOptical pickupOptical axis

The present invention provides a high NA objective lens that can satisfactorily measure the inclination when mounted on an optical pickup device and can assemble the optical pickup device with high accuracy, and an optical pickup device provided with the high NA objective lens. The objective lens has a first optical surface formed on the light source side, a second optical surface formed to face the first optical surface and with a radius of curvature larger than the first optical surface, and is located outside the second optical surface when viewed from the optical axis direction and is in contact with the second optical surface. The end surface is a plane that is approximately perpendicular to the optical axis. The image side numerical aperture (NA) is 0.7 or more and 0.9 or less. As a straight line passing through the optical axis and the end surface when viewed from the optical axis direction, let the distance of the straight line within the end surface range be A (mm ), when the distance from the optical axis to the straight line at the outermost peripheral portion of the end face is B (mm), the following equation (1) is satisfied, that is, 0.12<A / B<0.5 (1).

Owner:KONICA MINOLTA INC

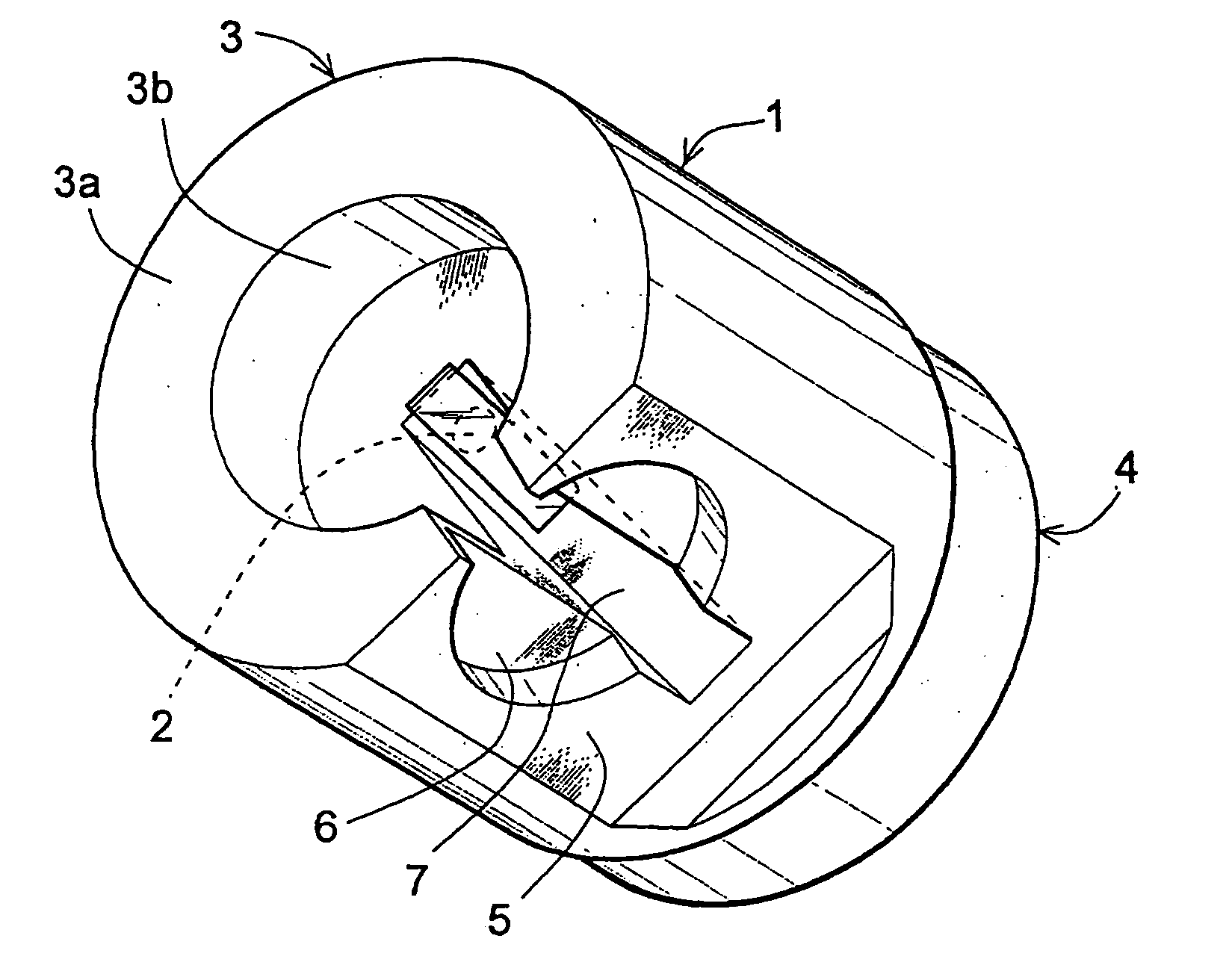

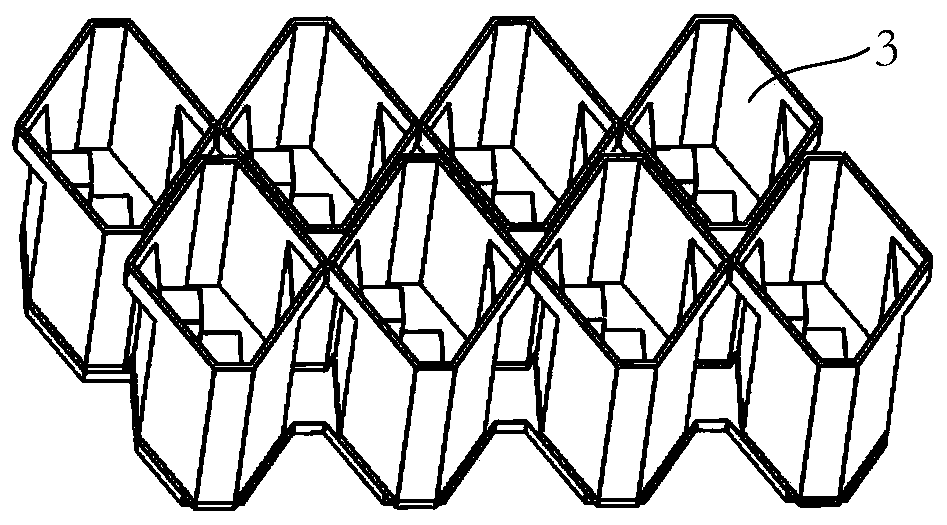

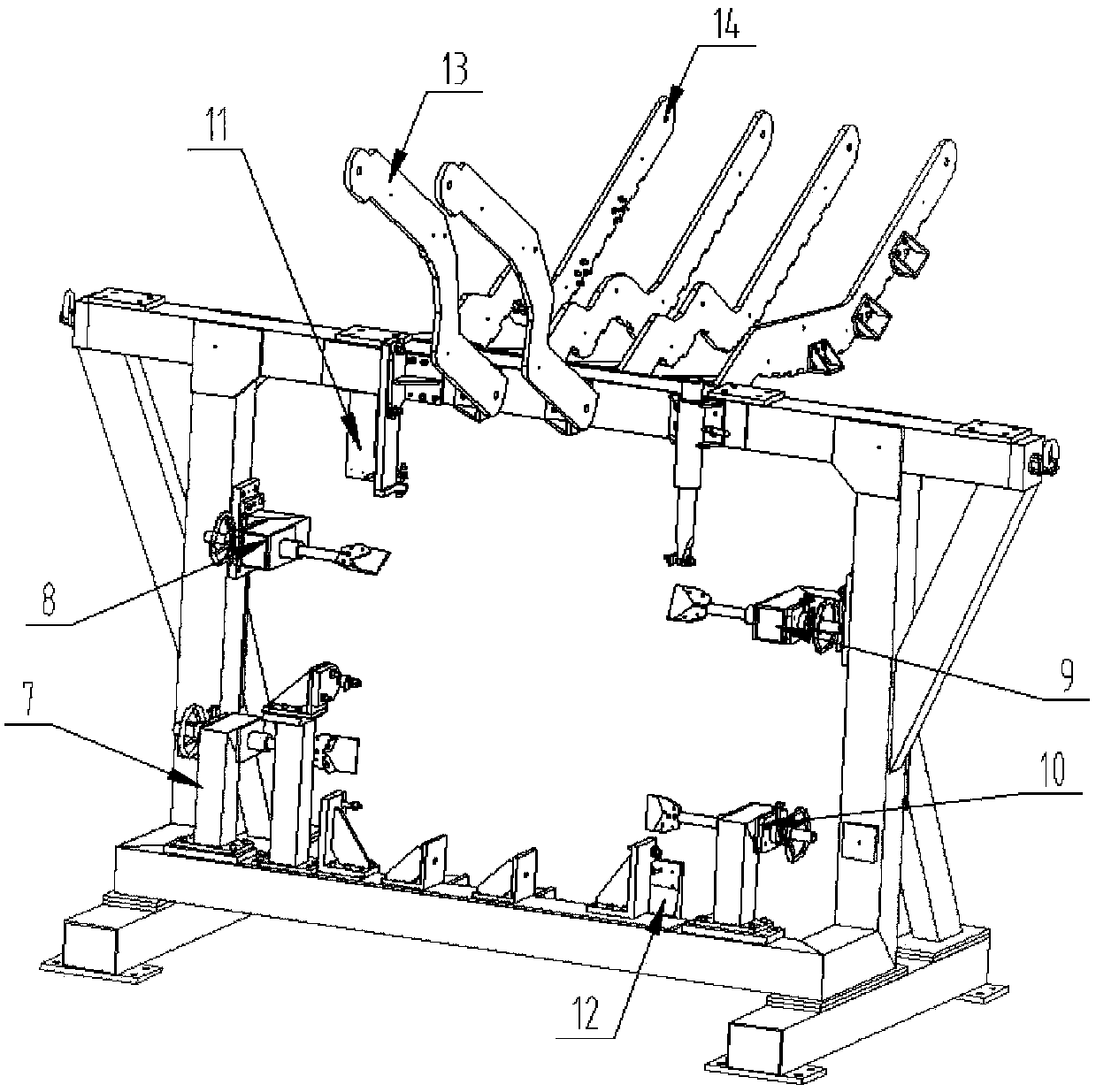

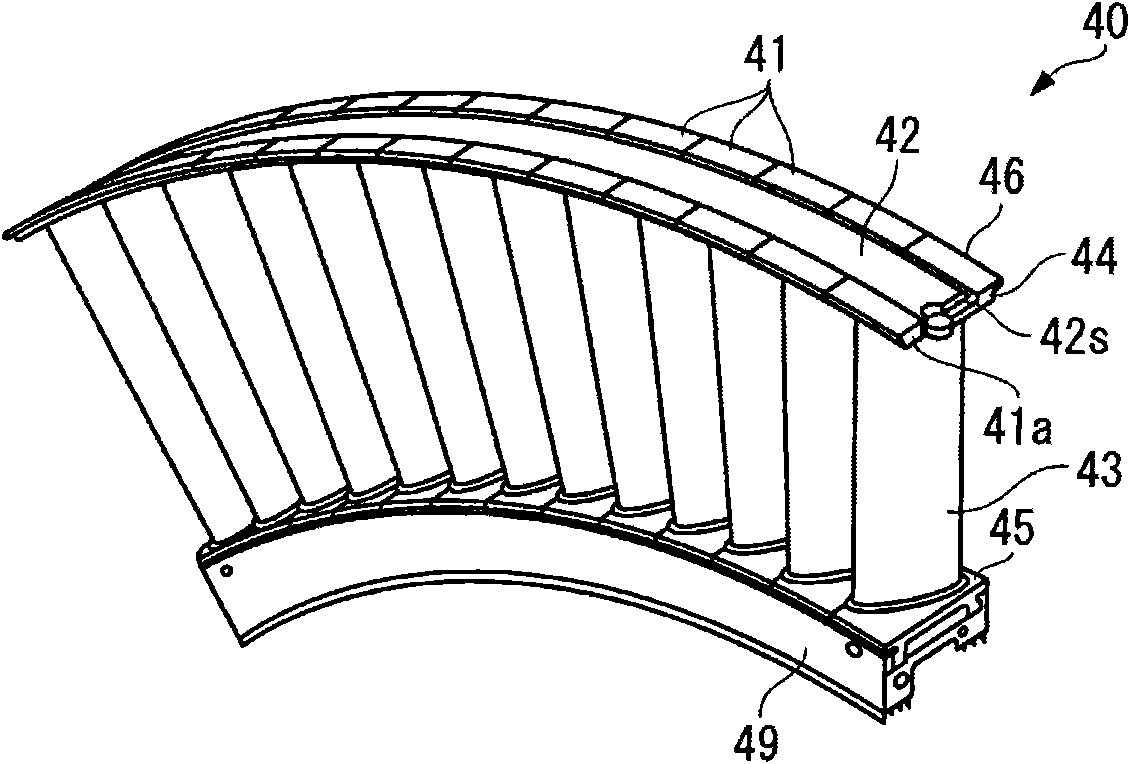

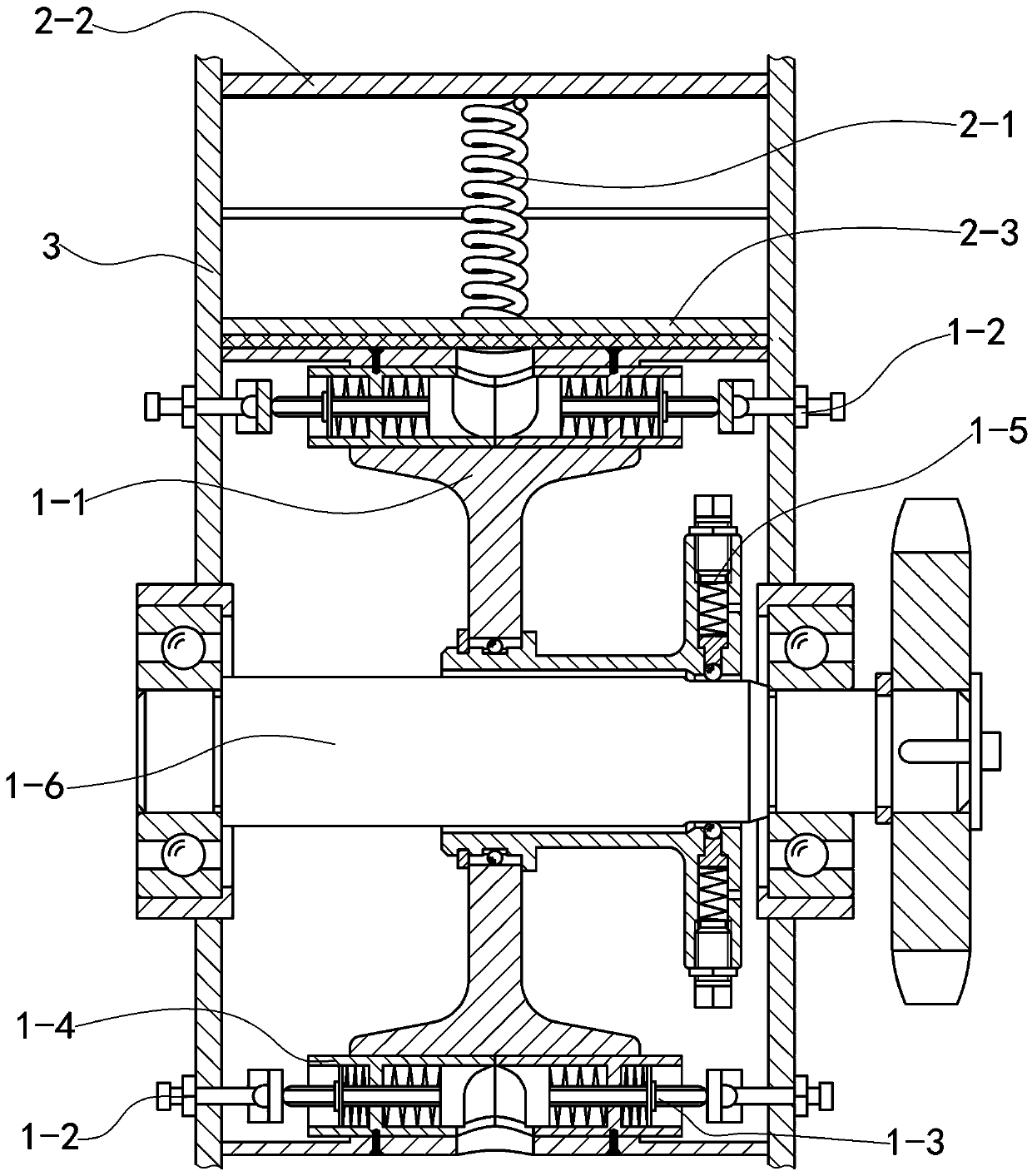

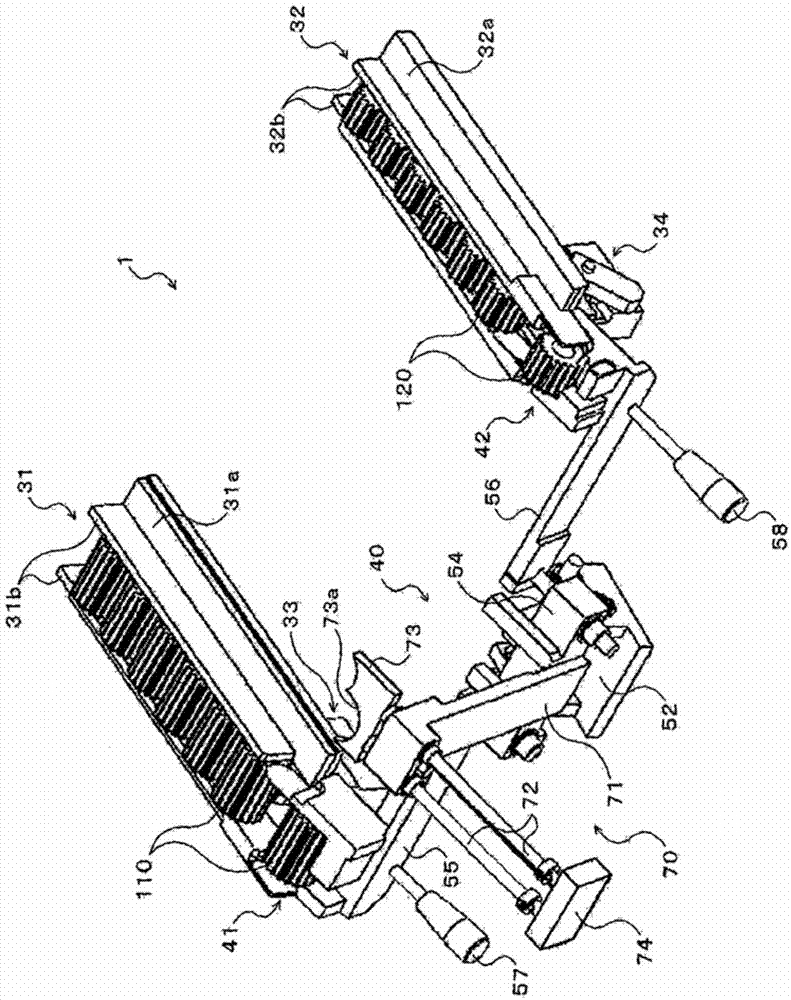

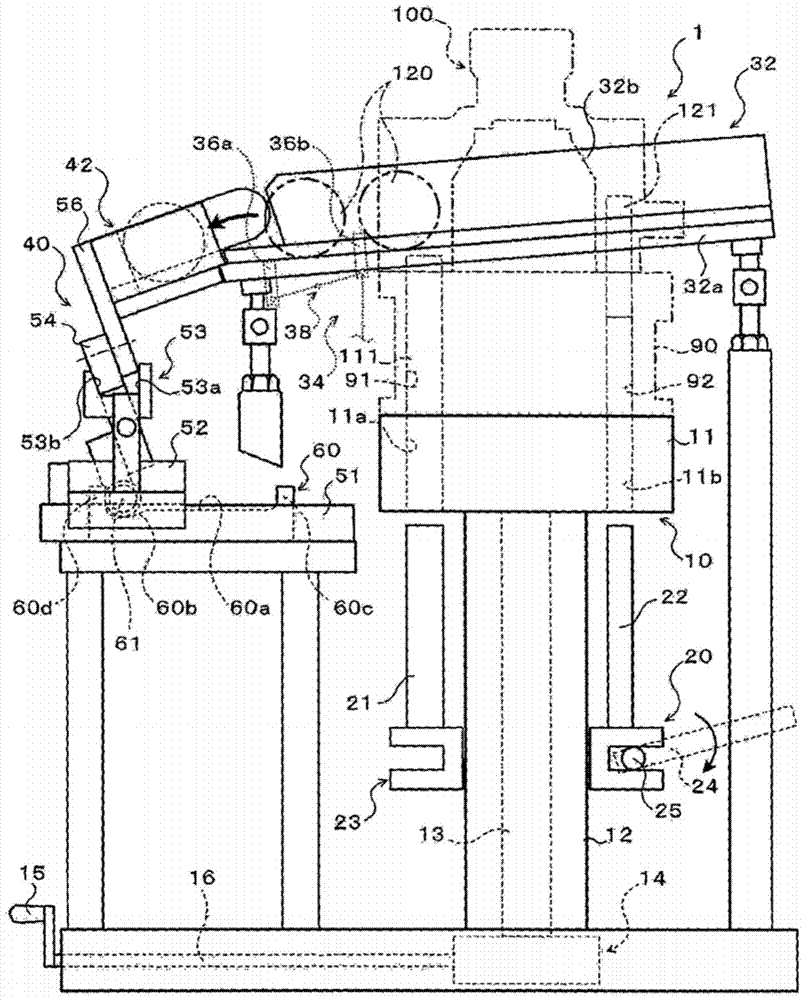

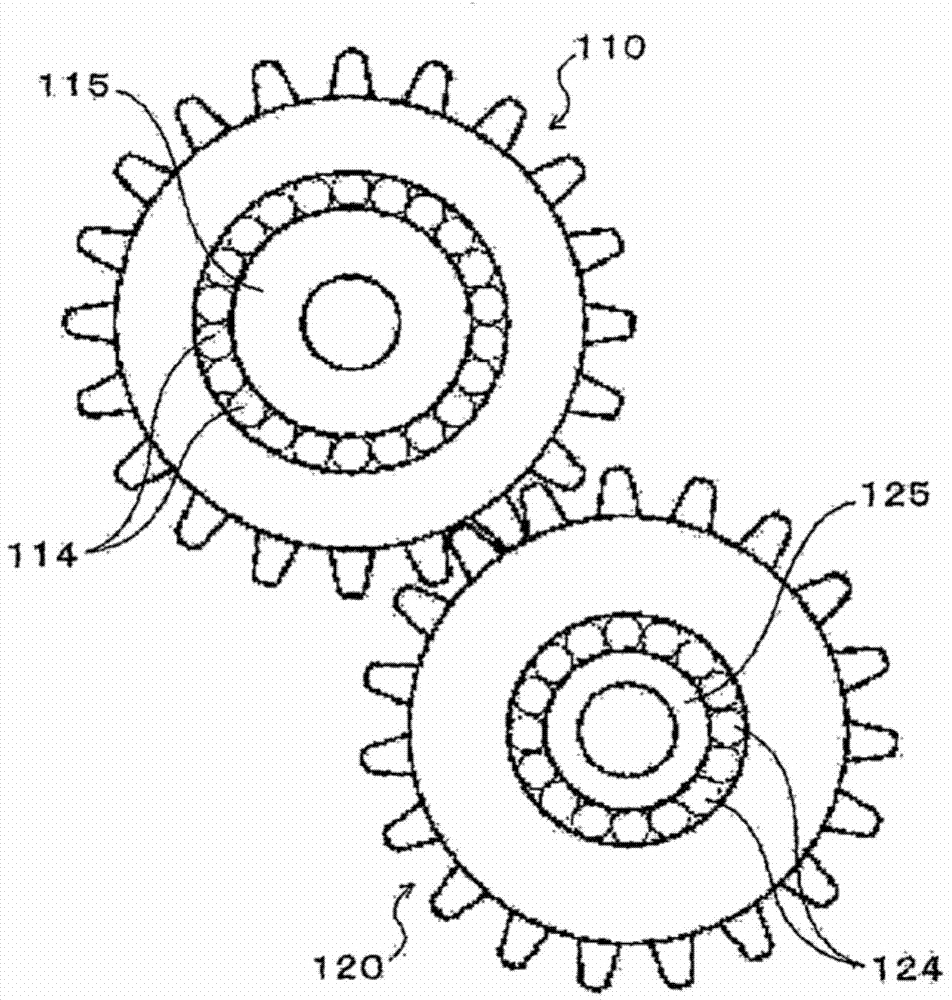

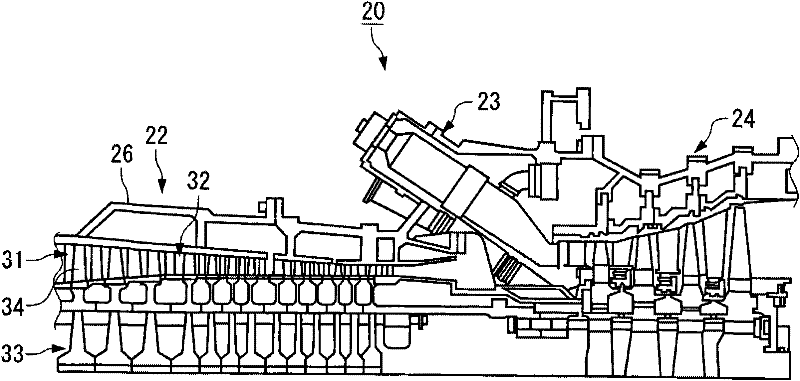

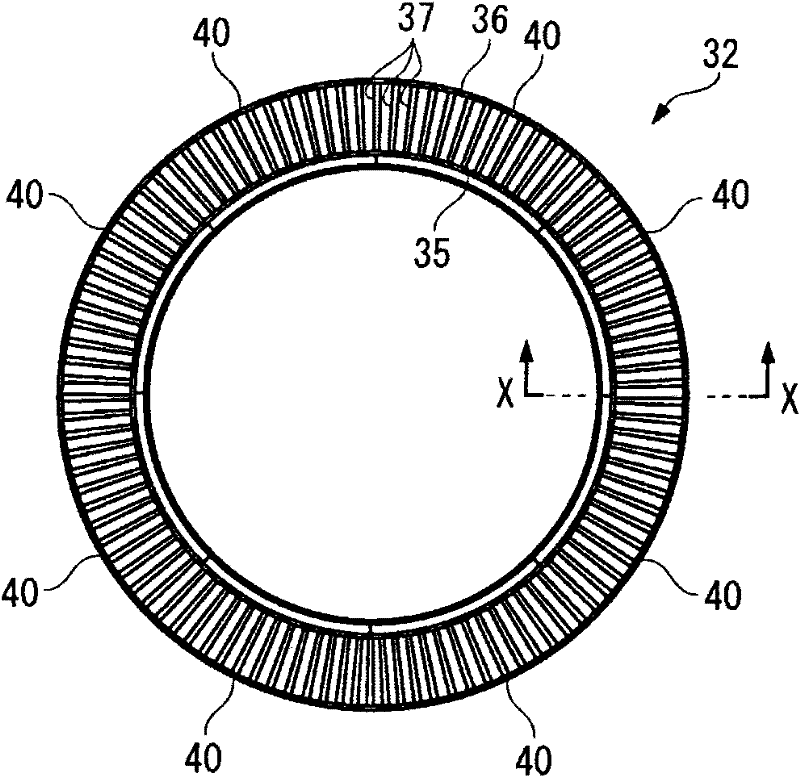

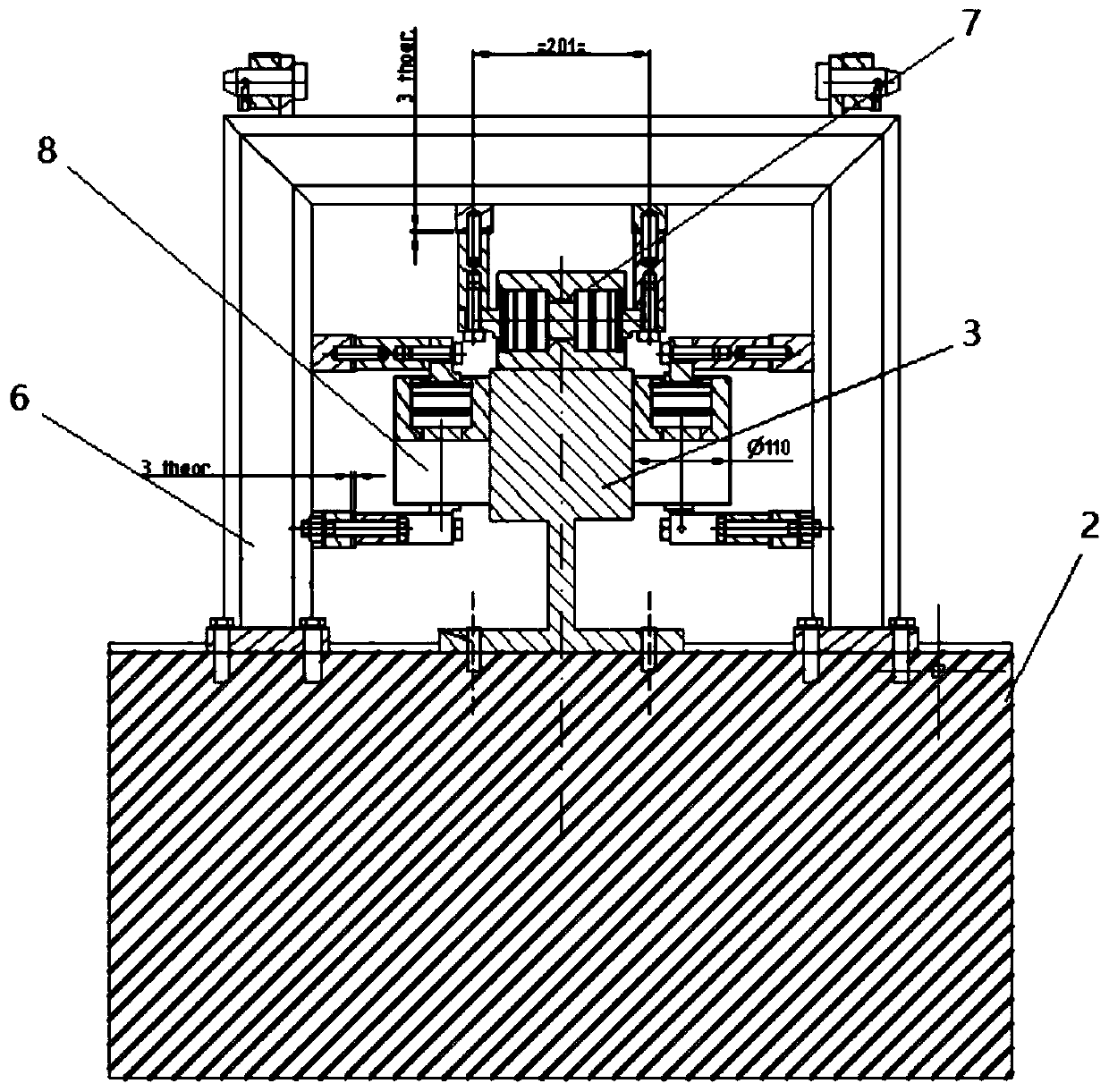

Assembly device of planetary gear and an assembly method thereof

ActiveCN103697116AAvoid damageHigh precision assemblyToothed gearingsGearing detailsEngineeringMechanical engineering

The invention provides an assembly device of planetary gear and an assembly method thereof, which can restrains the damage of addendum and mesh the first small gear and the second small gear with high precision to assembling a planet carrier. The small gear assembly system (40) of planetary gear assembly device (1) is formed by such steps: making a first small gear (41) and a second small gear (42) approaching one another towards the direction of orthorhombic with axes, making the first small gear (110) mesh the second small gear (120) in the vertical direction of the inclined state.

Owner:AISIN AW CO LTD

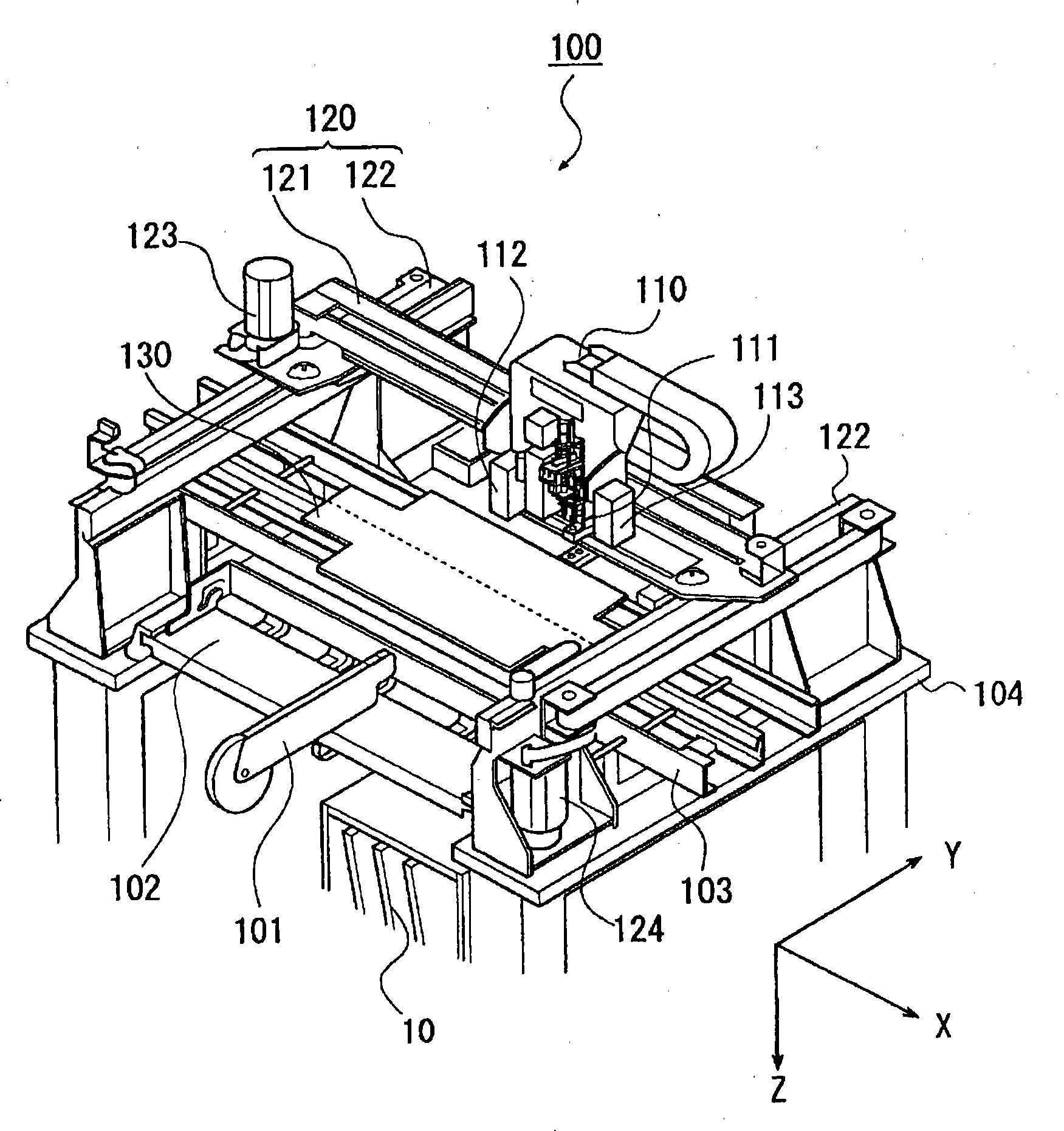

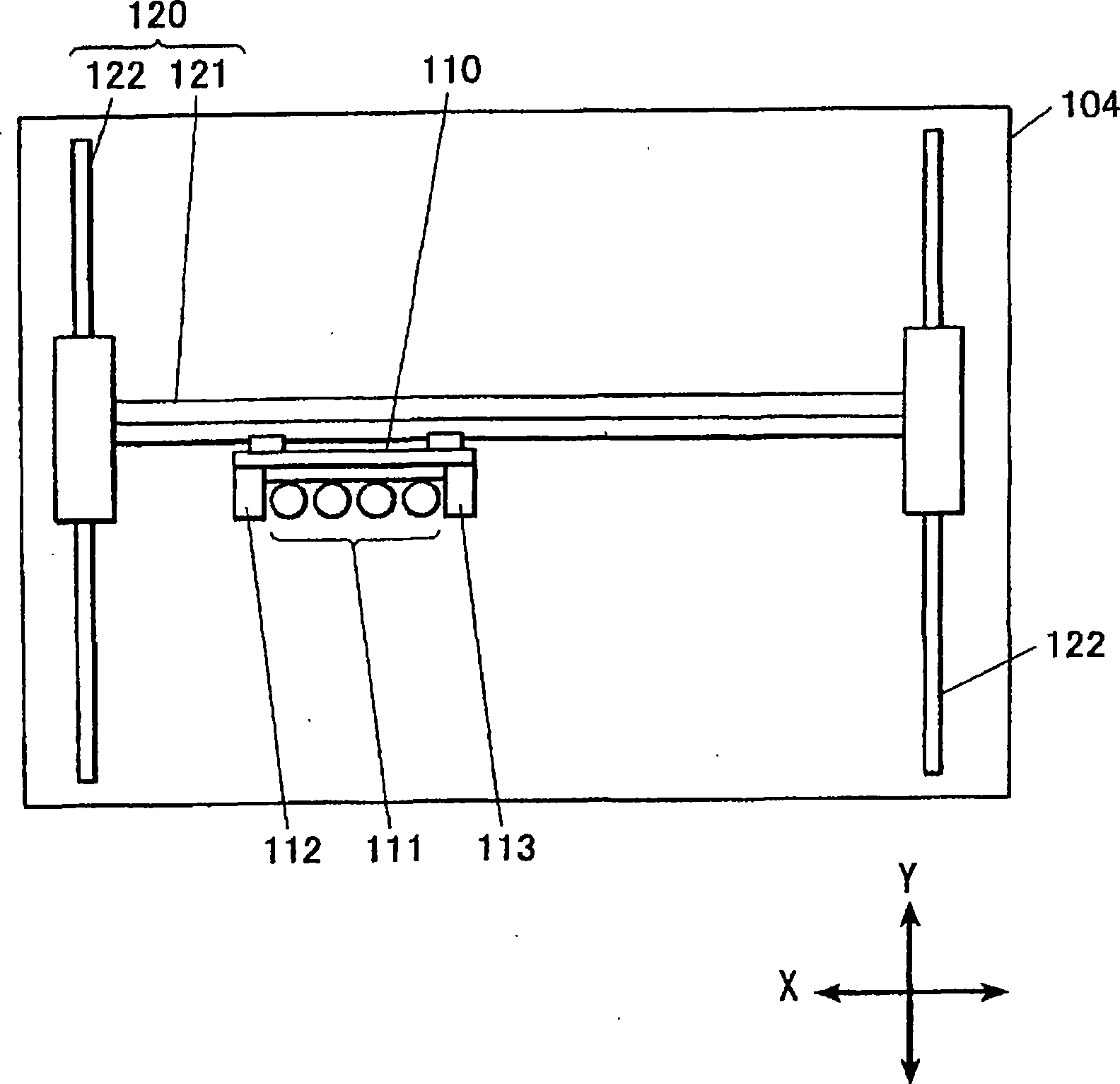

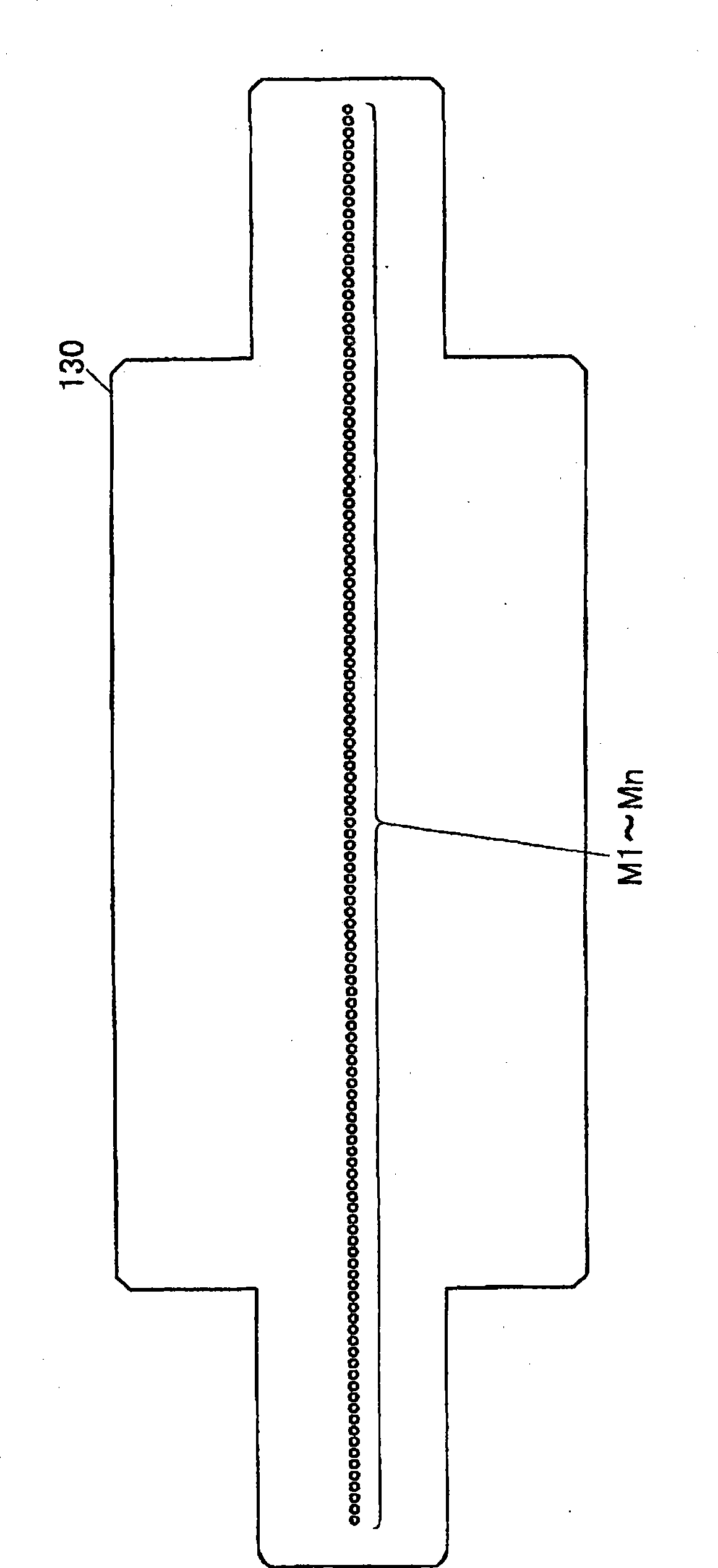

Nozzle position correcting method for electronic device mounting apparatus

InactiveCN100508725CHigh precision assemblyFind position errorUsing optical meansElectrical componentsEngineeringElectronic component

A nozzle position correction method of an electronic device assembly device can position the nozzle with higher precision. The electronic device assembly device has: a base; an assembly head with an adsorption nozzle; an X-axis guide rail guiding the assembly head along the X-axis direction; a Y-axis guide rail guiding the X-axis guide rail along the Y-axis direction; displaying a plurality of identification marks M1-Mn Marker display section; first and second cameras provided on the assembly head. This nozzle position correction method includes: a photographing process of photographing each identification mark with two cameras; a deviation amount acquisition process of obtaining the photographed position deviation amount for each camera; A Y-axis deviation determination process to calculate the deviation in the Y-axis direction from the imaging position deviation in the axial direction and the relative positional relationship between each camera and the nozzle; a positioning process to position the nozzle by correcting the calculated deviation.

Owner:JUKI CORP

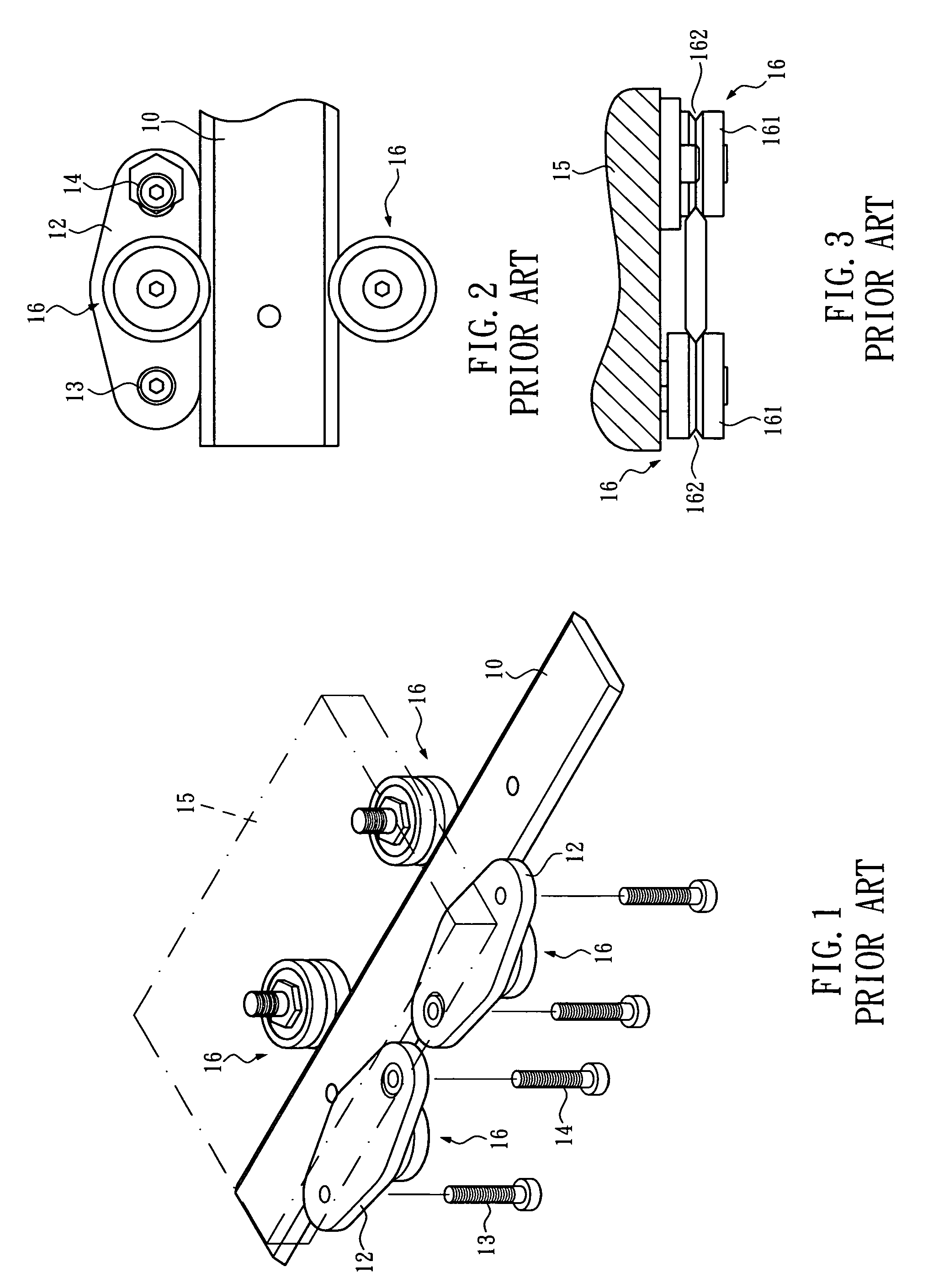

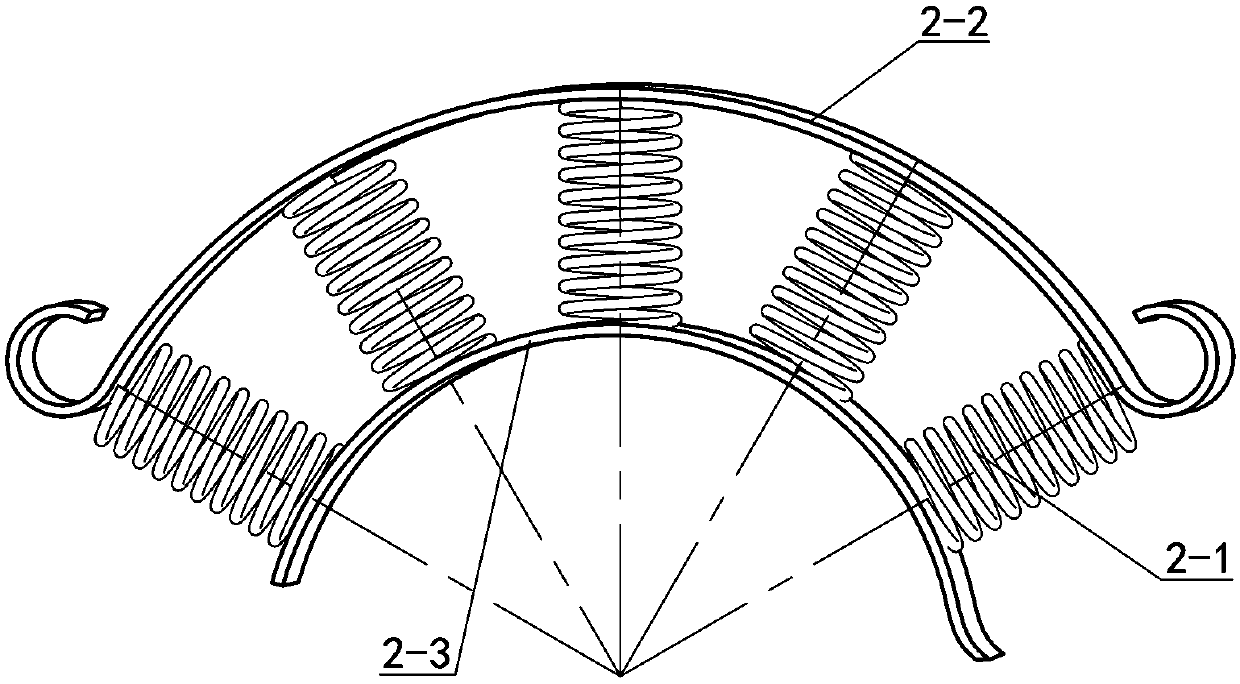

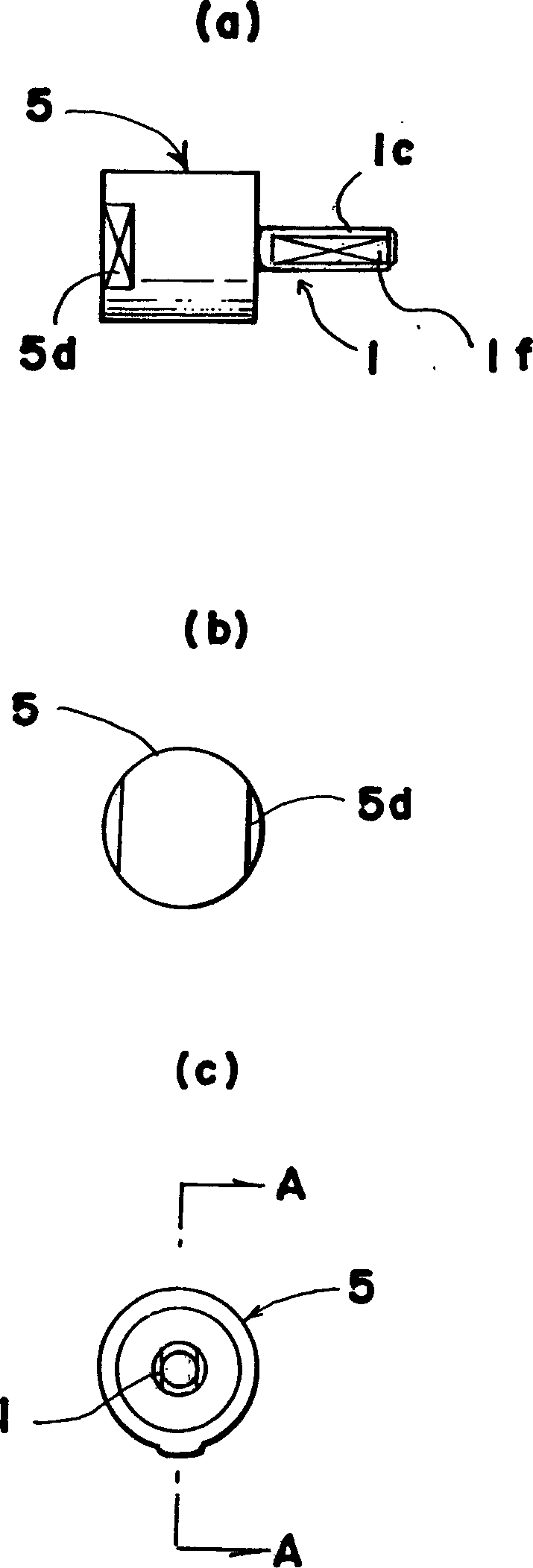

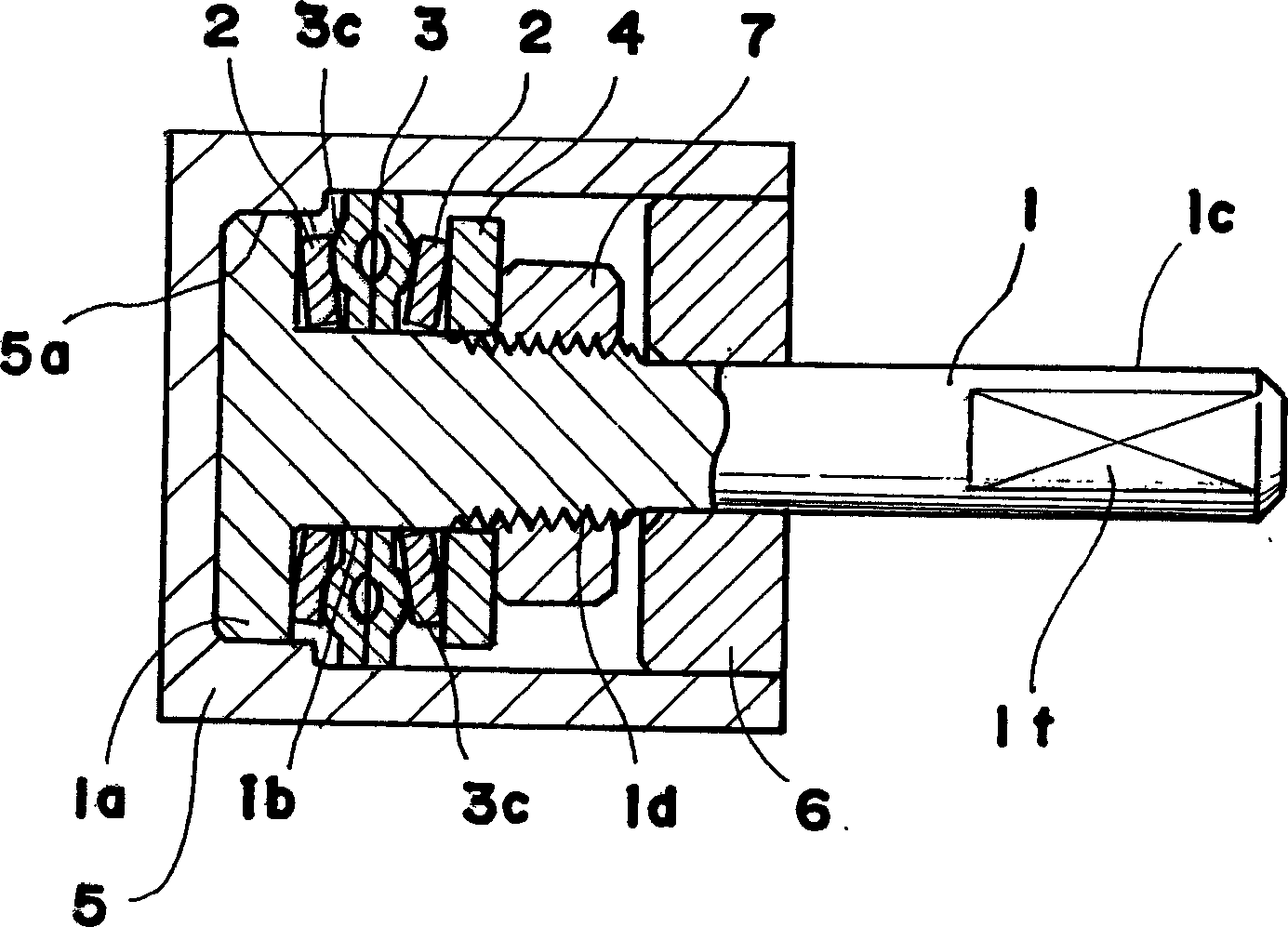

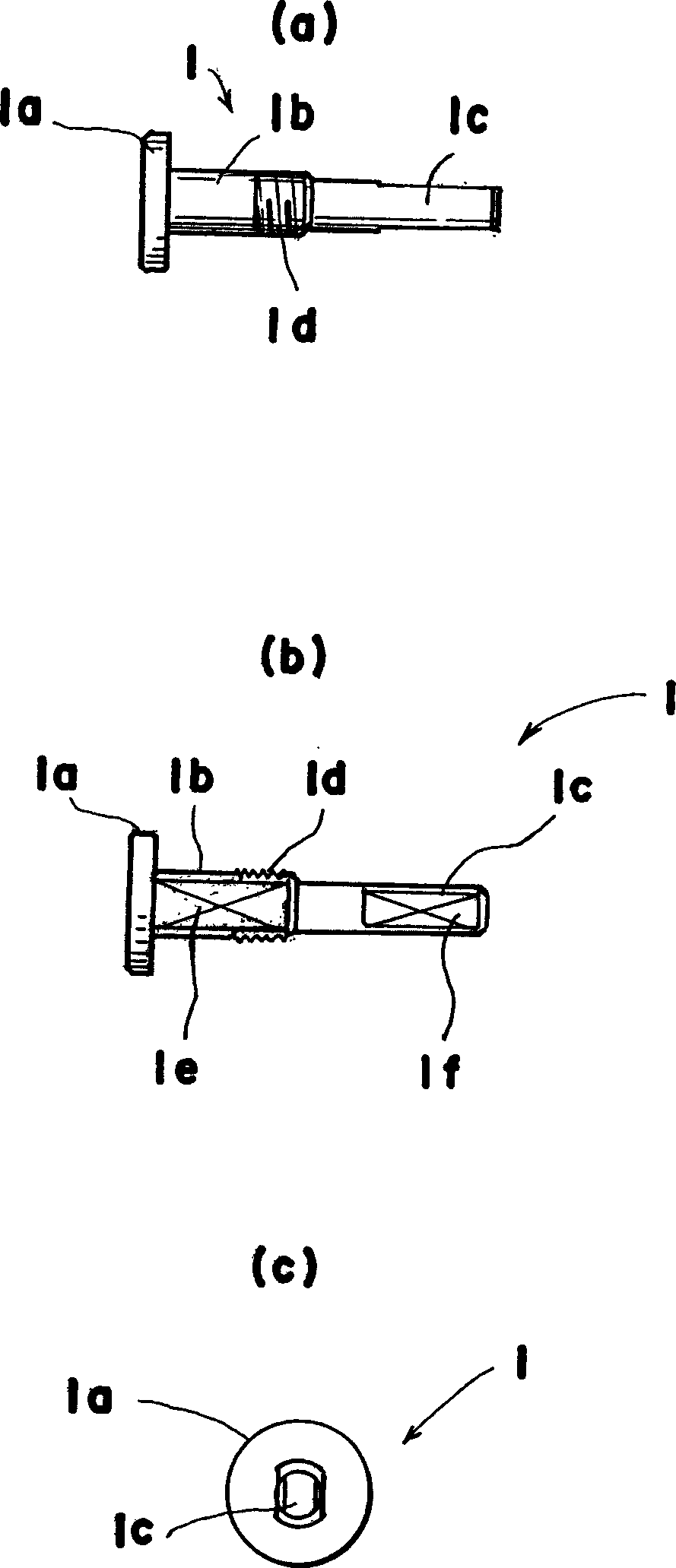

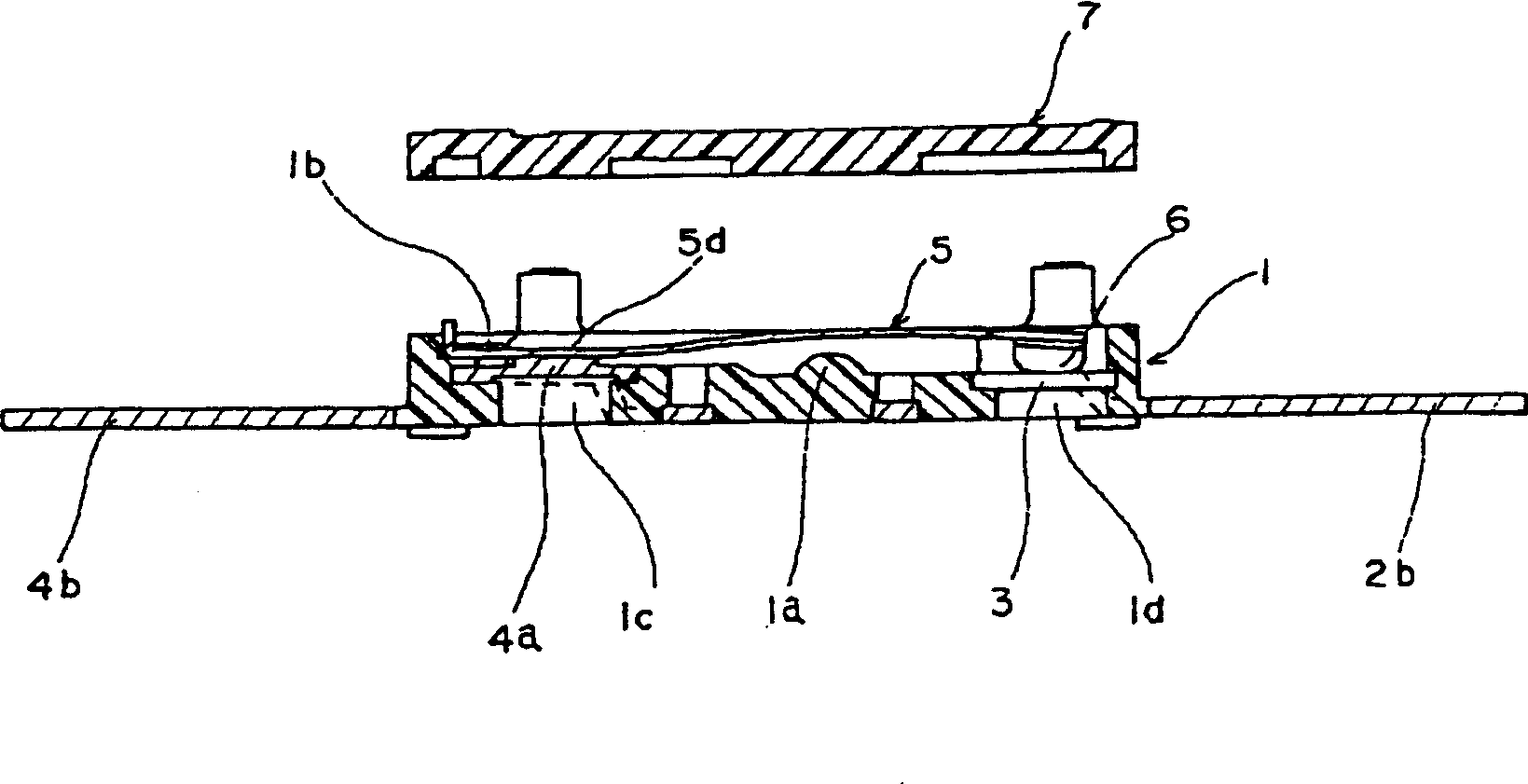

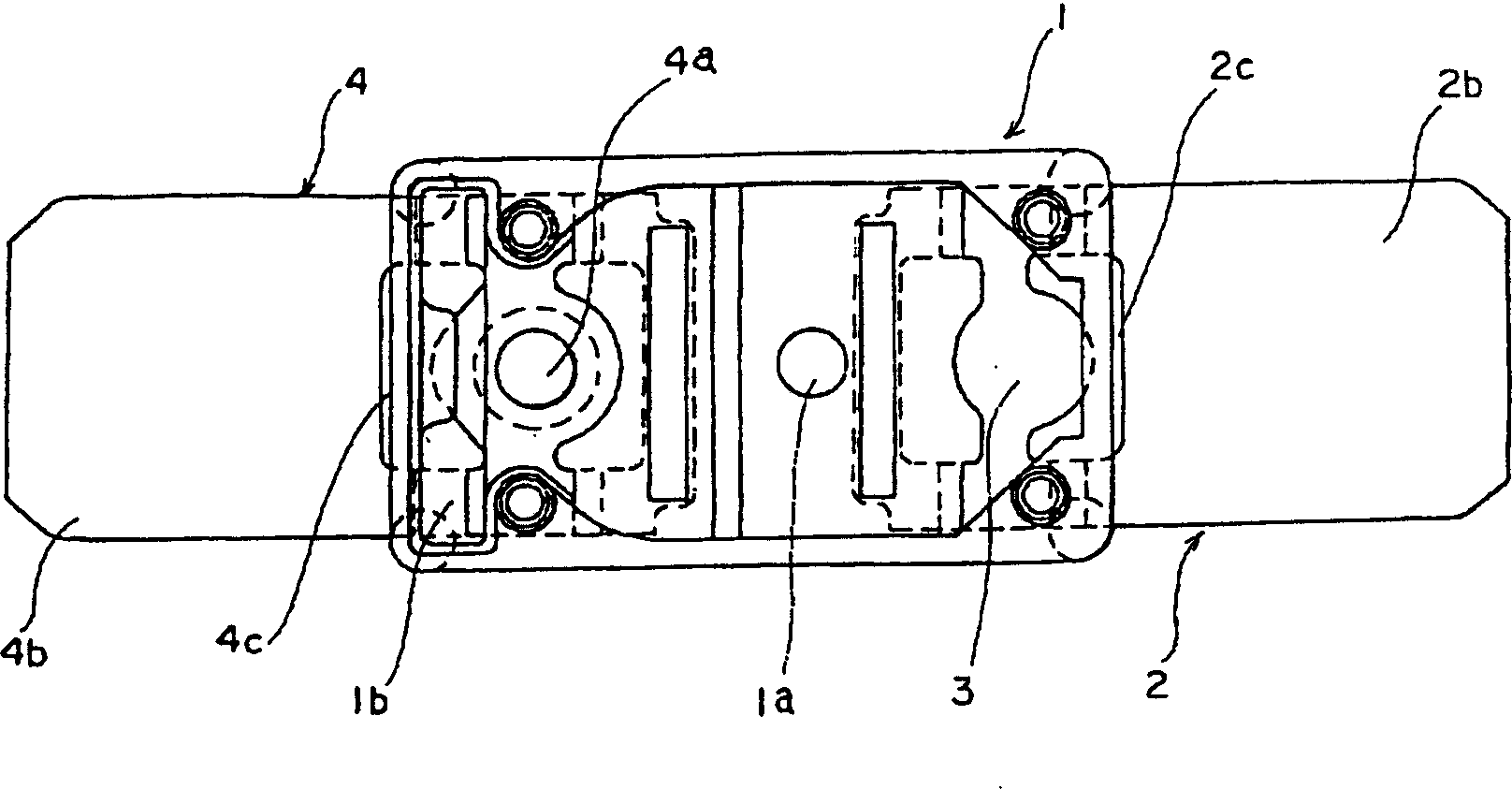

Hinge device

InactiveCN1701184AReduce in quantitySimple structureBelleville-type springsLeaf springsEngineeringLeaf spring

Disclosed is a hinge device for openably and closably connecting one member and the other member, including: a base member fixed to the one member; a movable shaft that is rotatably supported by the base member and to which the other member is fixed; a leaf spring member having a curved portion and non-rotatably but axially movably inserted onto the movable shaft; and a fixing plate inserted onto the movable shaft such that the fixing plate does not rotate when the movable shaft rotates but is axially movable, the fixing plate having at least two protrusions provided on its surface in contact with the leaf spring member. The leaf spring member and the fixing plate are pressed into contact with each other for relative rotation therebetween.

Owner:NHK SPRING CO LTD

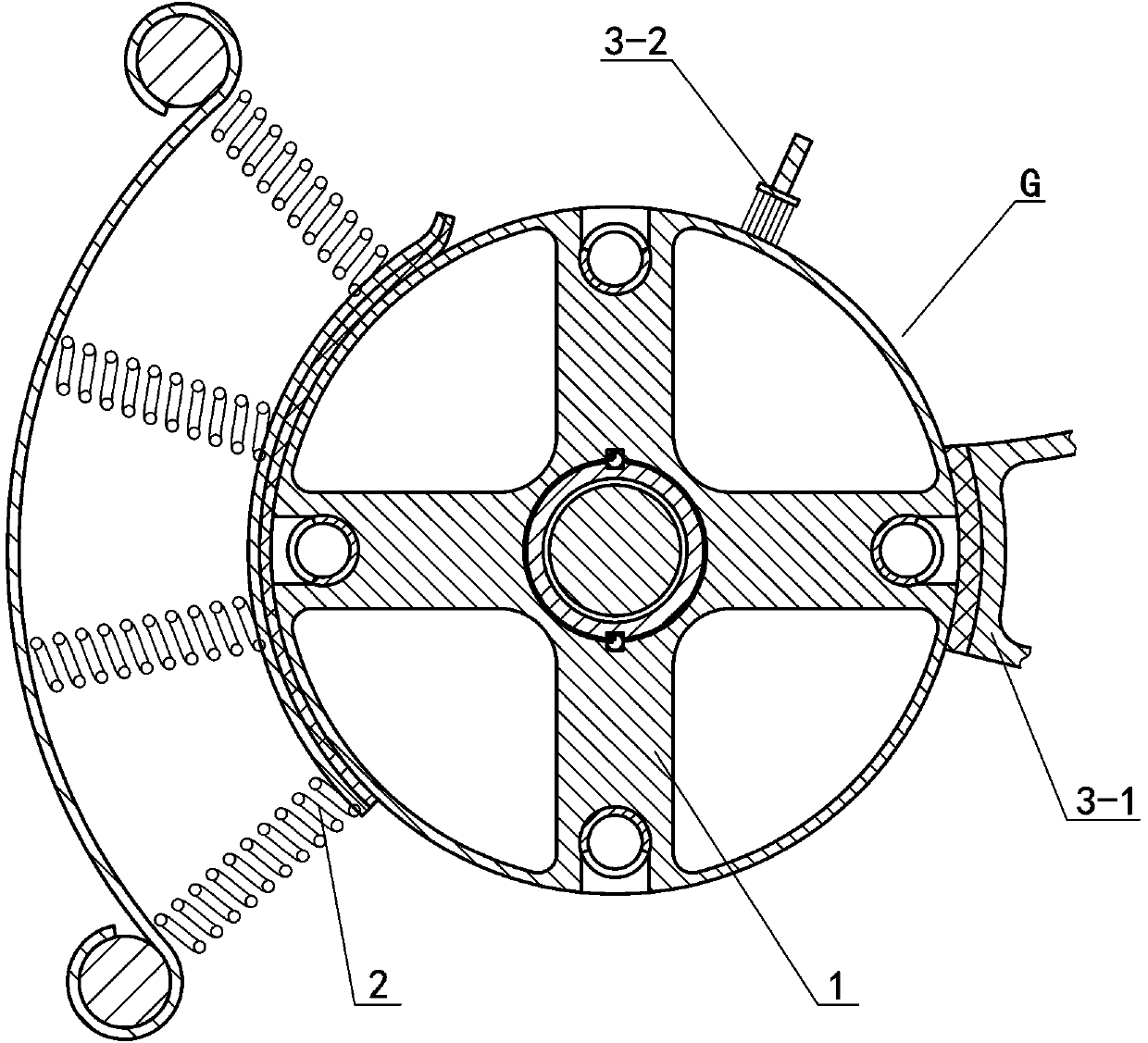

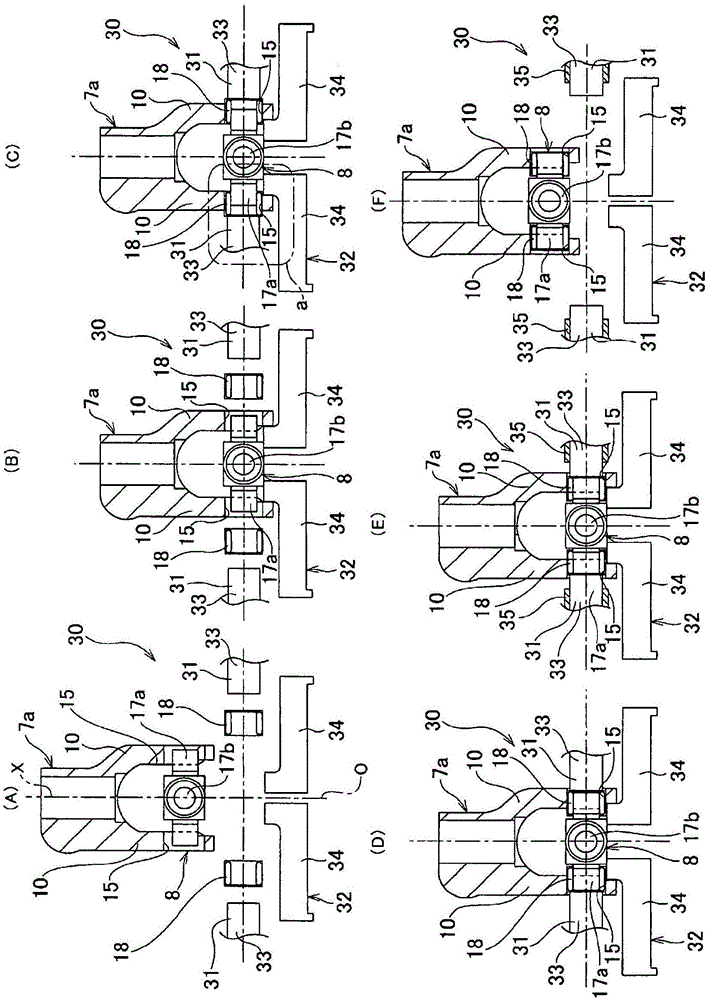

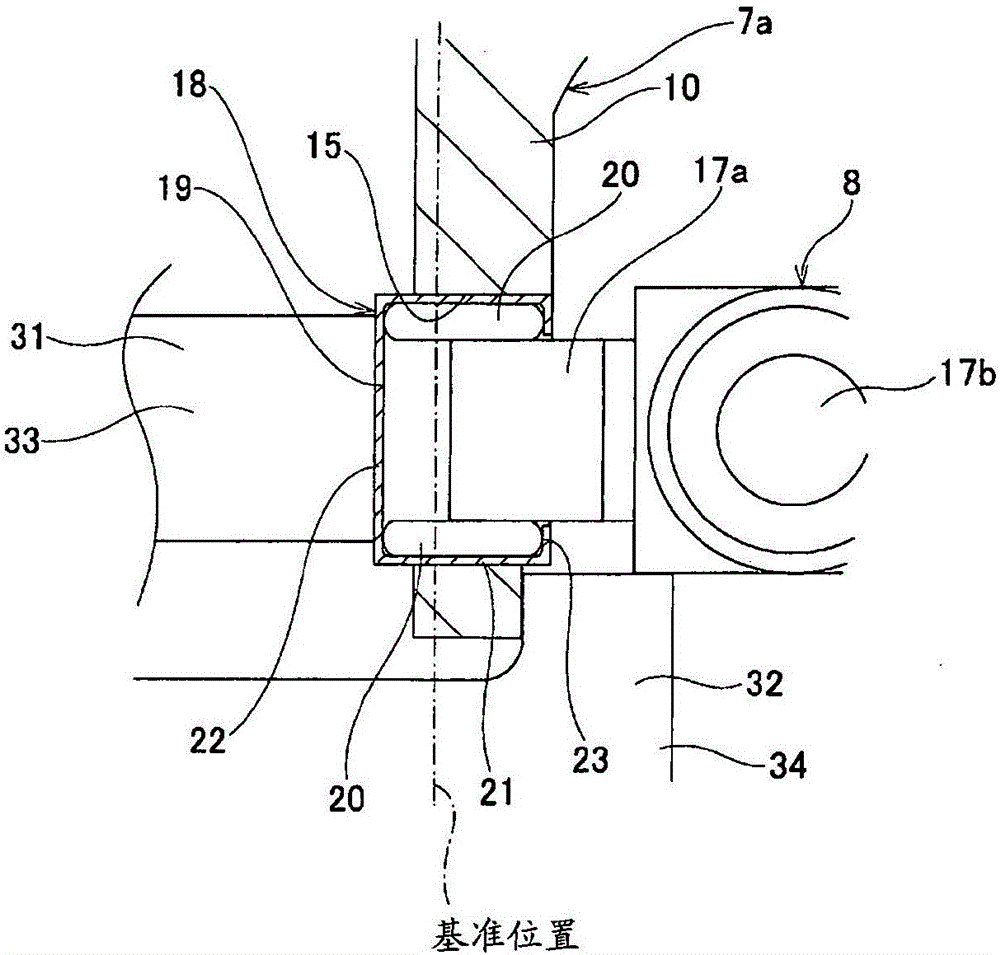

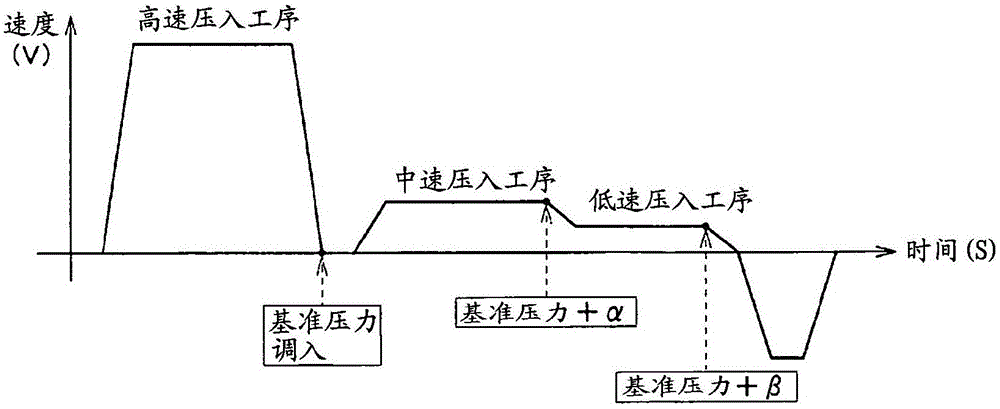

Assembly method for cross shaft type universal joint

ActiveCN106662161AHigh precision assemblyClutchesRotary combination bearingsUniversal jointEngineering

In order to be able to precisely install a cup bearing (18) at a section that is between the tip of a shaft part (17a) of a cross shaft (8) and a circular hole (15) that is formed in a joining arm part (10) of a yoke (7a, 7b) of a cross shaft type universal joint (6) regardless of variations in the dimensions of the joining arm part (10), the circular hole (15) in the tip thereof, and the cup bearing (18) and regardless of the elastic deformation of the joining arm part (10) of the yoke (7a) that accompanies the press-fitting of the cup bearing (18), a press-fitting punch (33) is used to press-fit the cup bearing (18) into the circular hole (15) up to a preset reference position, the value of the pressure applied to the press-fitting punch (33) at the reference position is set as a reference pressure, and the cup bearing (18) is determined to have reached a press-fitting completion position when the pressure applied to the press-fitting punch (33) is larger than the reference pressure by a preset designated value.

Owner:NSK LTD

Assembling method of stator blade ring segment, stator blade ring segment, coupling member, welding method

ActiveCN101617129BInhibit accessAvoid deformationPump componentsStatorsThermal deformationDegrees of freedom

Owner:MITSUBISHI POWER LTD

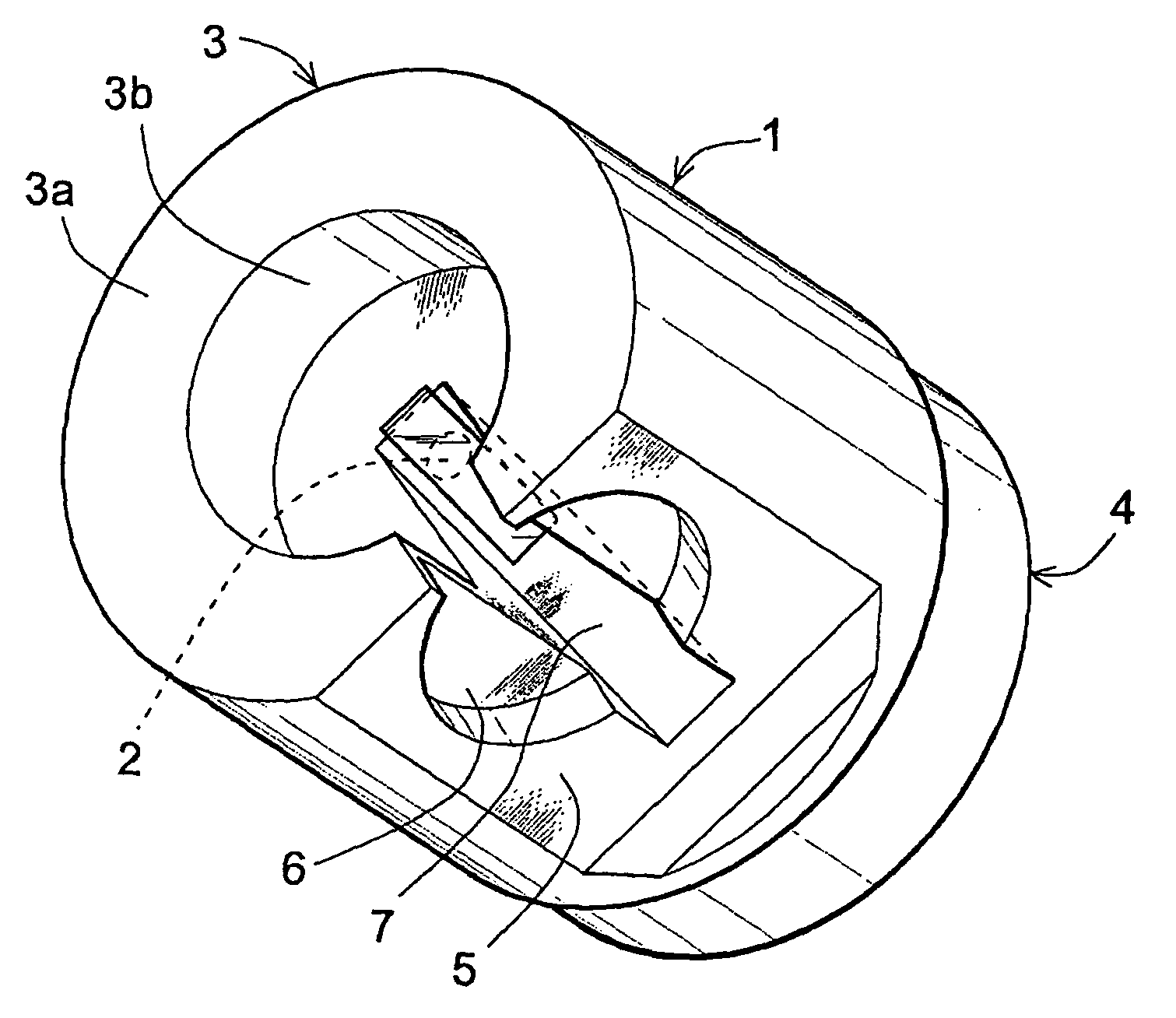

Jointing holder for optical module for single-fiber bidirectional communication and optical module incorporating the jointing holder

ActiveUS20050025497A1Reduces dimensional deviationReduce in quantityCoupling light guidesElectromagnetic transceiversOptical ModuleSingle fiber

A jointing holder for an optical module for single-fiber bidirectional communication comprises a unitarily structured cylindrical body that has the following portions: (a) an optical fiber-fixing portion for securely holding an optical fiber for transmitting multiwavelength light bidirectionally, (b) a semiconductor laser-fixing portion for securely holding a semiconductor laser for emitting outgoing light λ 1, (c) a photodiode-fixing portion for securely holding a photodiode for receiving incoming light λ 2, (d) an optical path-forming space for optically coupling the optical fiber, the semiconductor laser, and the photodiode, and (e) in the optical path-forming space, an optical filter-fixing face for securely holding an optical filter for separating multiplexed wavelengths. The jointing holder enables the optical module to reduce the number of components, to be miniaturized, and to reduce the dimensional deviation at the time of the assembly, enabling high-precision assembly. An optical module for single-fiber bidirectional communication incorporates the jointing holder.

Owner:SUMITOMO ELECTRIC IND LTD

Optical module

InactiveUS8920047B2High precision assemblySimple configurationLaser detailsCoupling light guidesOptical ModuleEngineering

Owner:CITIZEN WATCH CO LTD

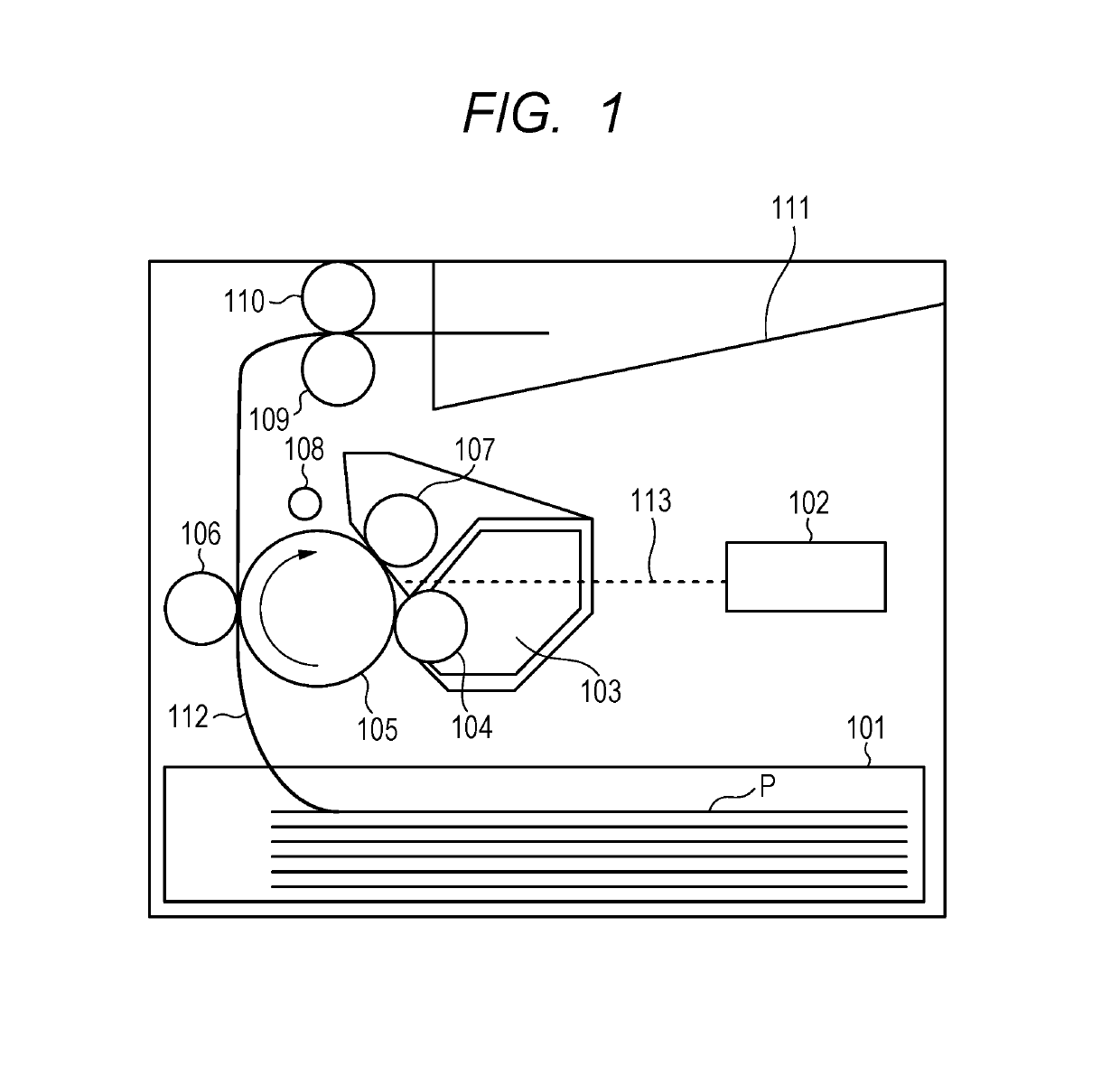

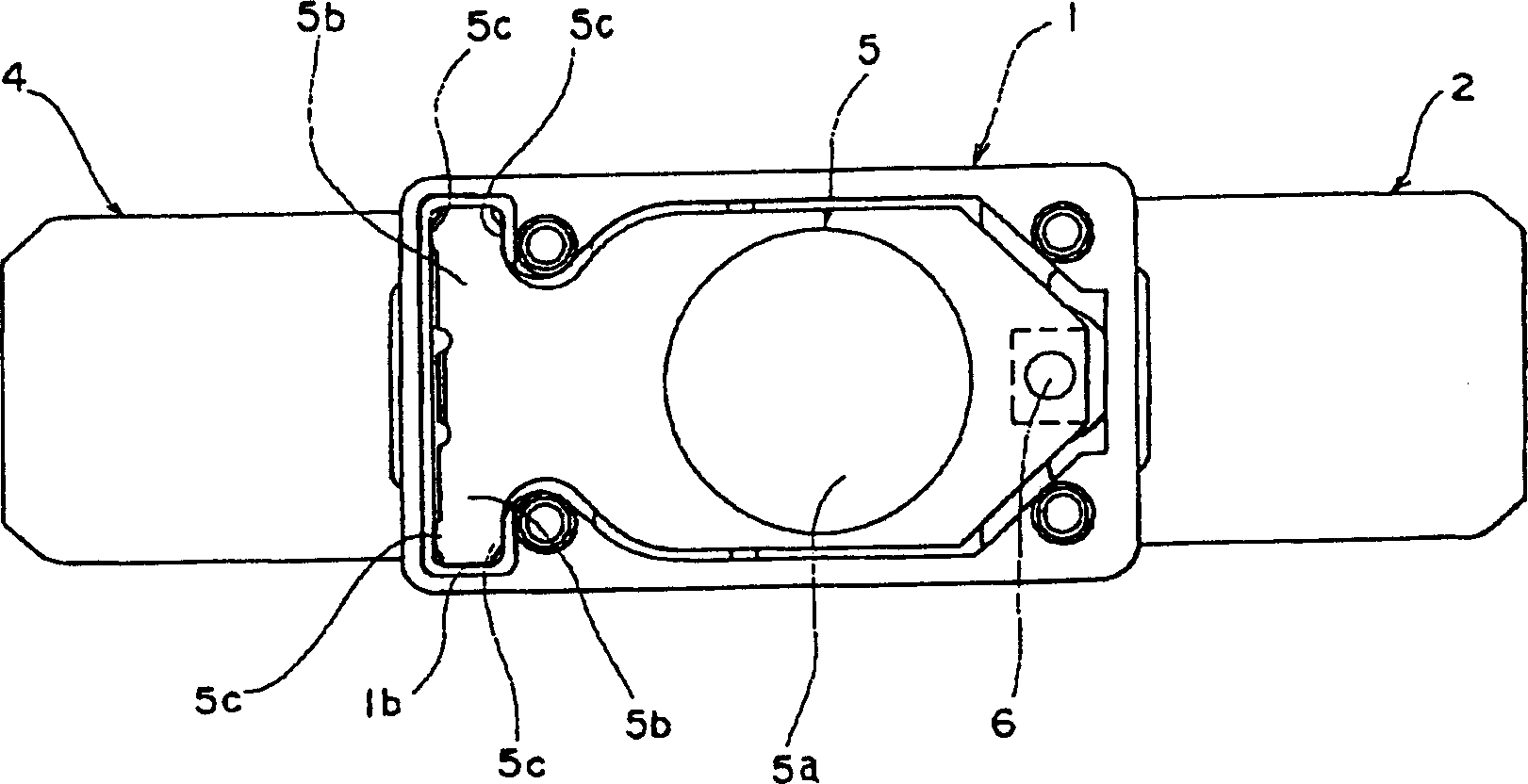

Circuit board and image forming apparatus

ActiveUS10502369B2High precision assemblyHigh light reflectivityCircuit optical detailsPrinted circuit aspectsOptical axisSurface mounting

The circuit board has a surface mount LED with a lens on the circuit board. A conductive portion and remaining space in the periphery of the LED are covered with solid copper foil so that reflectance of light and a heat dissipation effect are enhanced. In addition, layer structures between the circuit board and an assembled component are the same between contact portions with the assembled component so that tilt in mounting the board is suppressed. As a result, the circuit board having mounted thereon the surface mount LED having high directivity can be accurately mounted on the assembled component, tilt of an optical axis can be suppressed, the reflectance of light from the LED can be increased, and the heat dissipation effect can be enhanced.

Owner:CANON KK

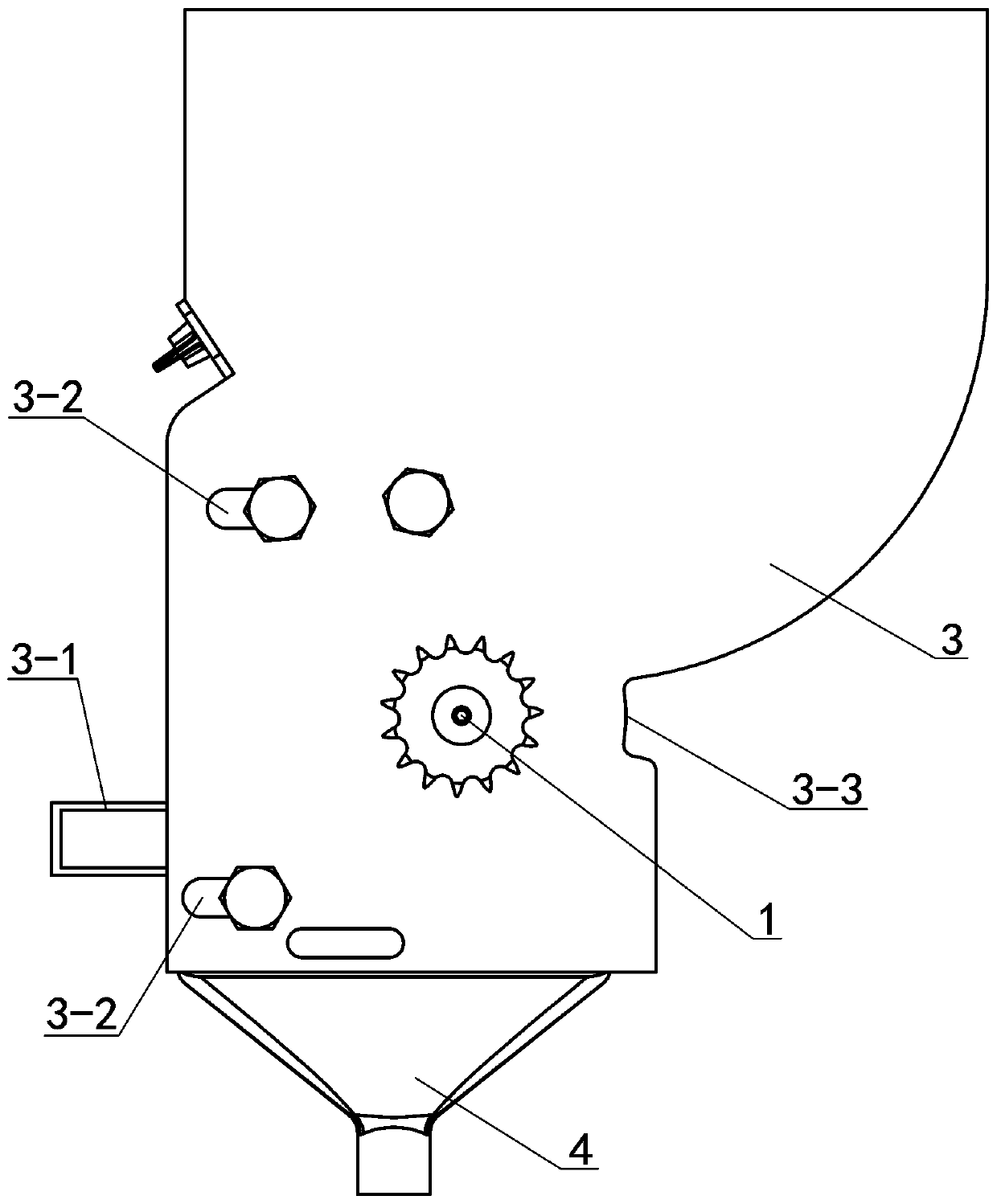

Non-destructive seeding method based on rapid adjustment of seeding amount

ActiveCN111010945AAvoid mechanical damageEnsure accurate outputSeed depositing seeder partsRegular seed deposition machinesHorticultureAgricultural engineering

The invention provides a non-destructive seeding method based on rapid adjustment of a seeding amount. A non-destructive seeding device based on the rapid adjustment of the seeding amount is used to implement seeding, a feeding control mechanism is arranged at the upper part of a box body, a seed brushing mechanism is arranged above a seeding control mechanism, the seeding control mechanism for controlling feeding is installed in the middle part of the box body, a seed protection mechanism is in contact with the seeding control mechanism, and a seed receiving cup is arranged under the box body; and at the same time, a left seed filling channel, a right seed filling channel, a seeding wheel seed filling channel, a seed storage area, a transition area, a seed filling area, a seed brushing area and a seed filling cavity capable of completing rapid adjustment of the seeding amount are formed in the box body through the above structure, and a left cavity cylinder and a right cavity cylinderin a lateral cavity component in the seeding control mechanism can communicate with the seeding wheel seed filling channel after being docked. The volume of the seed filling cavity is adjusted to realize rapid adjustment of the seeding amount, quantified seeds can be received into the seed filling cavity to avoid hard contact with the seed protection mechanism to cause mechanical damage to the seeds, so that the non-destructive operation is realized.

Owner:HUNAN AGRICULTURAL UNIV

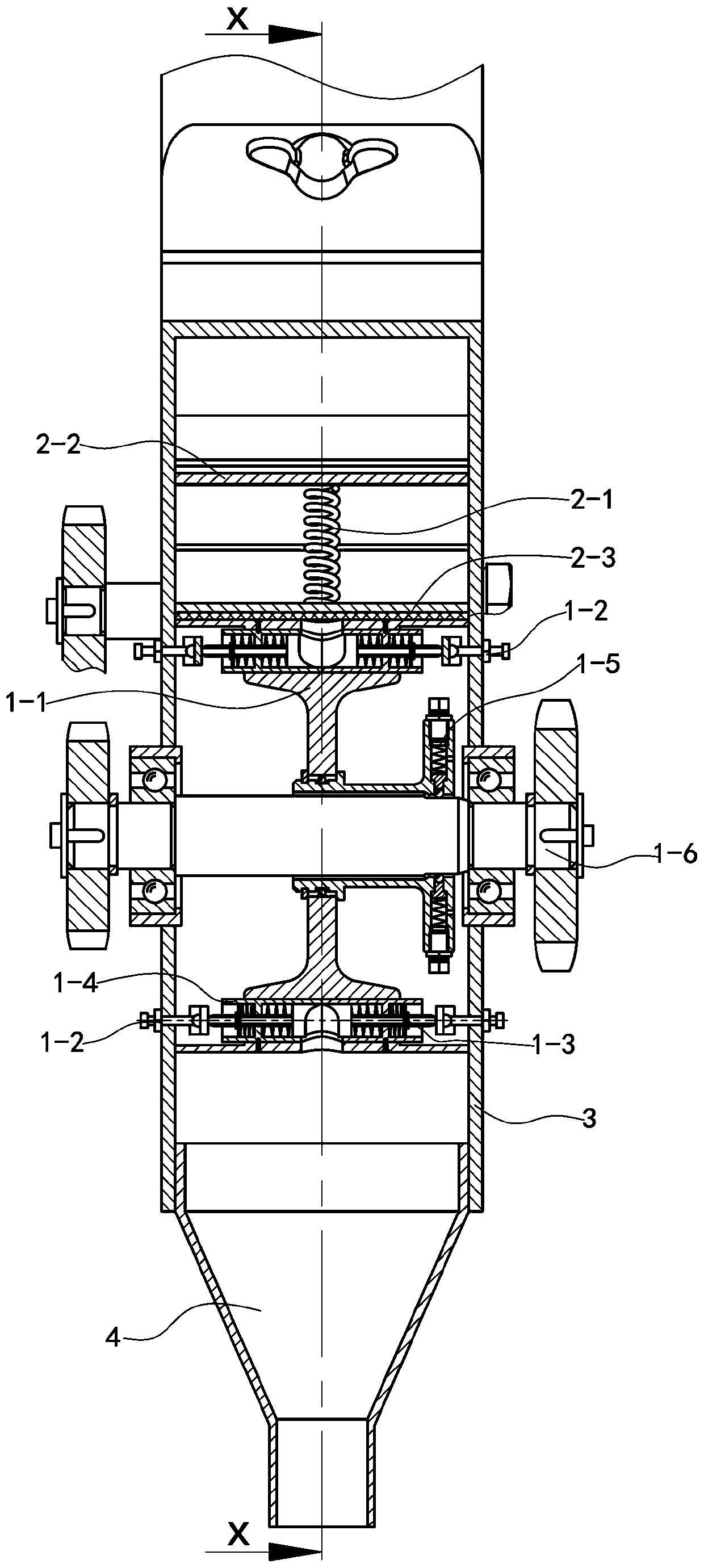

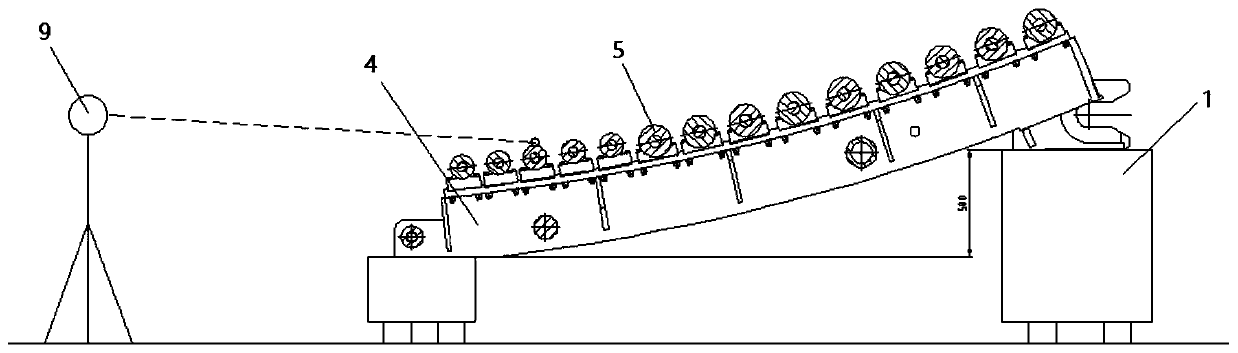

Square billet continuous casting segment assembling method

The invention discloses a square billet continuous casting segment assembling method, and belongs to the technical field. The square billet continuous casting segment assembling method is characterized by comprising the following steps of 1, preparing before assembling, arranging supporting frame square boxes, and arranging a T-shaped auxiliary device; 2, assembling a lower guide roller; and 3, assembling a roller frame. The invention provides the square billet continuous casting segment assembling method. Preassembling and synchronous detection are performed. Quick and high-precision detection and segment assembling can be realized, the production cycle is shortened by one week, the production cost is reduced by 10%-15%, and the product qualification rate is increased to 99.5%.

Owner:一重集团天津重工有限公司

Thermal-response switch

InactiveCN1184658CSimplify the assembly processLow costThermal switch detailsCantileverElectrical and Electronics engineering

The purpose of the present invention is to provide a structure of a thermal-response switch using a bimetal piece, which is capable of preventing the scattering of melted metal when incorporating the bimetal piece into the housing and laser-welding it on a fixed terminal and of incorporating the bimetal piece with high precision. To solve the problem, the thermal switch has a housing with a bottom, a fixed contact arranged on the inner bottom face of the housing and a flip part capable of flipping according to the temperature, and comprises the bimetal piece with a movable contact, which contacts and separates from the fixed contact, fixed at one end thereof, and a fixed terminal arranged on the inner bottom of the housing with the other end of the bimetal piece overlapped and fixed thereon in a cantilever. An opening, through which a laser beam can be emitted from the outer bottom of the housing, is formed on the bottom of the housing to match the overlapped position between the fixed terminal and the bimetal piece.

Owner:ALPS ALPINE CO LTD

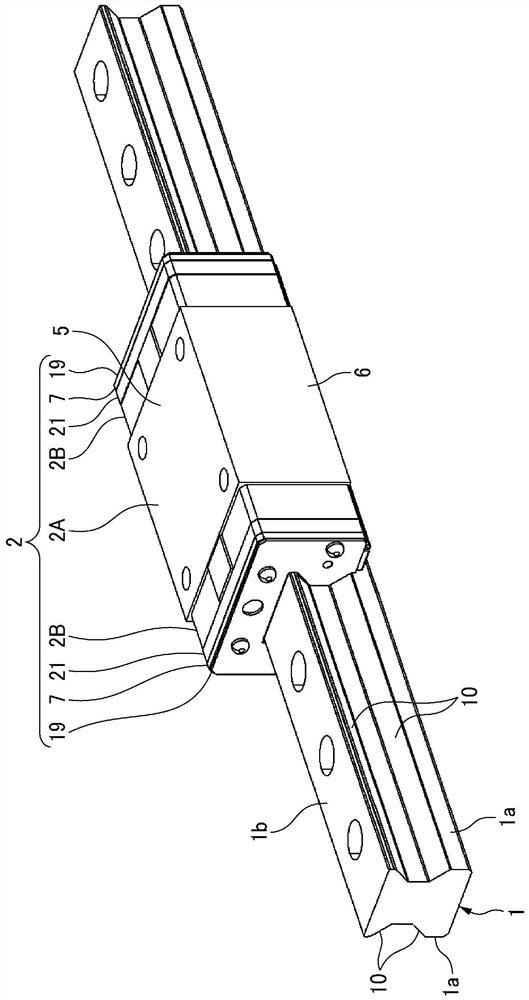

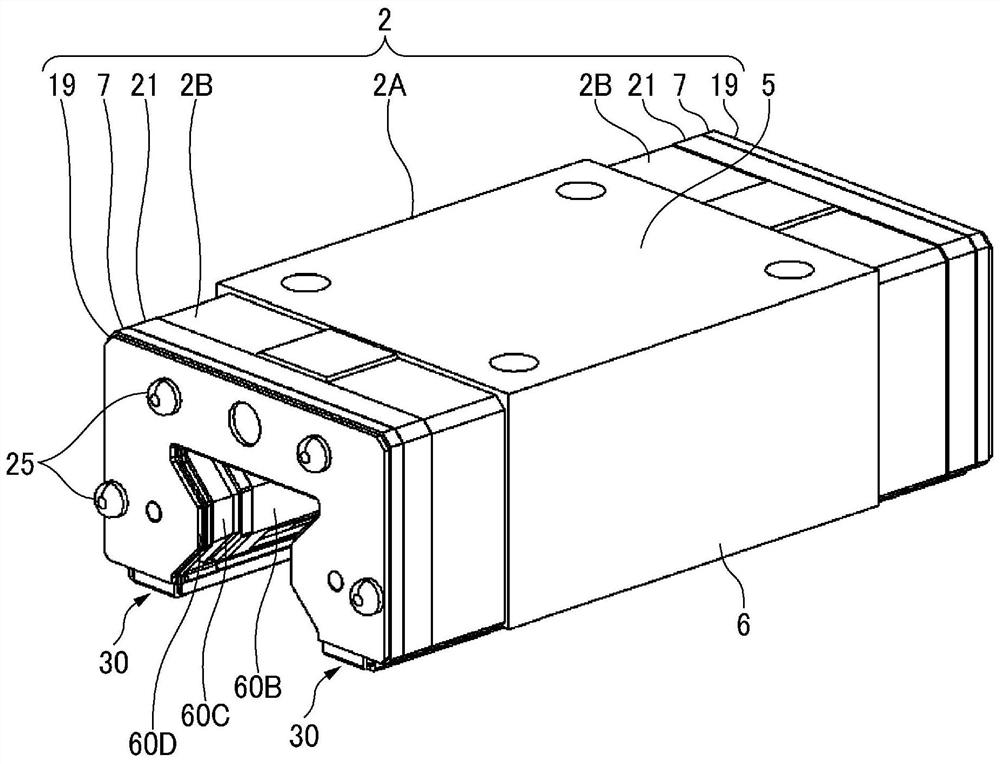

Direct motion guide device and assembly method thereof

ActiveCN111699326BLow costHigh precision assemblyLinear bearingsBearing componentsLinear motionPhysics

The sliding body (2) of the linear motion guide device has: a sliding body main body (2A); a sliding body end face part, which is installed at the moving direction end of the sliding body main body (2A); and a lower seal (30), which closes the guide rail (1) and the gap between the sliding body (2). The lower seal (30) has a seal member (31) having a main lip (31g) in contact with the guide rail (1). The sealing member (31) has a body side lip (31e) protruding toward the lower surface (6c) of the slider body (2A) and extending along the moving direction of the slider (2). The main body side lip (31e) is in contact with both the lower surface (6c) of the slider main body (2A) and the lower surface of the slider end face member. Thereby, high dustproofness and waterproofness can be maintained between the lower surface of the slider main body and the slider end surface member, and the lower seal.

Owner:NSK LTD

Calibration apparatus and method for optical system assembly

InactiveUS7880869B2Convenient heightSimple structureOptical head manufactureUsing optical meansElectricityOptical axis

A calibration apparatus and method for optical system assembly is provided, applicable to a finite conjugate optical system to determine the optimal image-forming positions of the light source and the focus object lens of the finite conjugate optical system. The apparatus includes an external light source, a low magnification image-forming optical system, an electrical control system and a monitor. When the parallel beam generated by the external light source is parallel to the optical axis of the finite conjugate optical system, the low magnification image-forming optical system is used to magnify the two focal spots formed by the external light source and the internal light source of the finite conjugate optical system to be calibrated. Finally, by adjusting the related position of the focus object lens or the internal light source of the finite conjugate optical system, the optimal relative positions between the light source and the focus object lens of the finite conjugate optical system can be found. The calibration apparatus of the present invention has the advantages of simple structure, easy assemble and setup, high precision assembly and low cost, as well as the capability to perform optimal calibration of the relative position of the focus object lens and the light source of each individual finite conjugate optical system.

Owner:TOPRAY MEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com