Antenna unit assembly assembling device and collecting, assembling and measuring integrated control system and method thereof

An antenna unit and assembly device technology, applied in radio wave measurement systems, assembly machines, measurement devices, etc., can solve the problem of low success rate of one-time assembly, poor assembly accuracy and consistency, and the coupling gap between adjacent units is not easy to achieve design. requirements and other issues, to achieve the effect of improving assembly accuracy and consistency, reducing the amount of motion adjustment, and reducing the mutual extrusion of adjacent cavity mouth edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

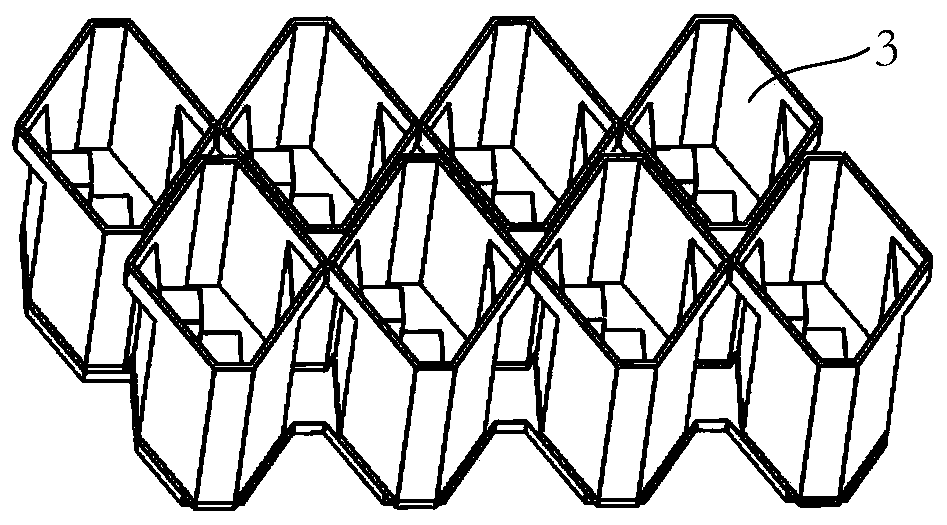

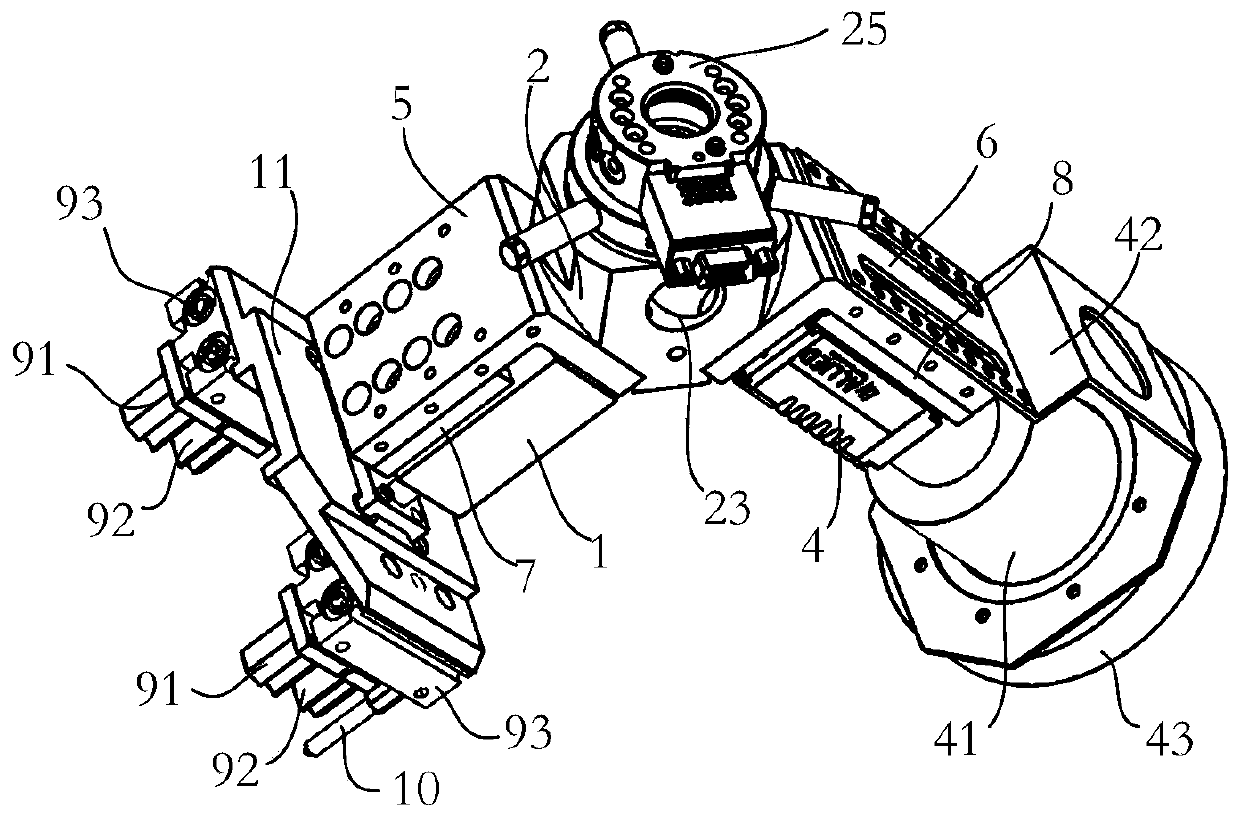

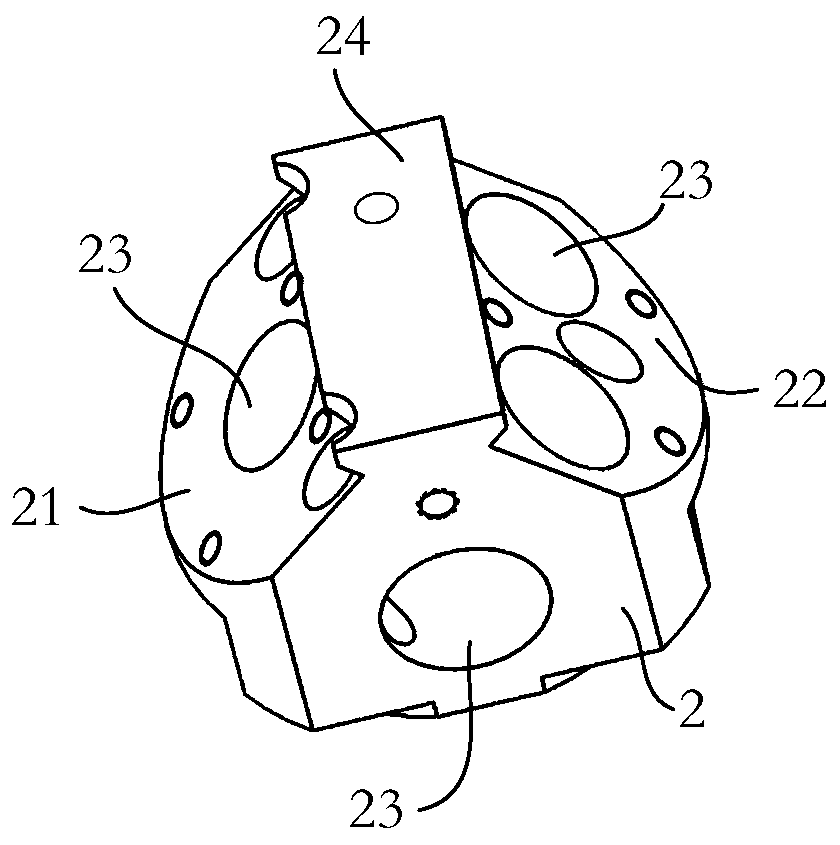

[0053] like Figure 1-Figure 9 As shown, an antenna unit assembly assembly device of this embodiment includes a mounting and dismounting cylinder 1, a mounting bracket 2, an outer support assembly for picking up or dismounting an antenna unit assembly, and a camera 4. The mounting bracket 2 has mutually perpendicular first An installation surface 21 and a second installation surface 22, the assembly and disassembly cylinder 1 is installed on the first installation surface 21, the camera 4 is installed on the second installation surface 22 and its optical axis is the same as the first installation surface 22 The two installation surfaces 22 are vertical, and the driving end of the assembly and disassembly cylinder 1 is arranged away from the first installation surface 21 and connected to the outer support assembly to drive the outer support assembly along a direction perpendicular to the first installation surface 21. direction reciprocating movement; the camera 4 is used for i...

Embodiment 2

[0065] An integrated control system for the assembly of antenna unit components in this embodiment includes the assembly device and the control device, and the camera 4 is used for image acquisition and parameter extraction of the characteristics of the assembly position on the antenna array , to acquire collection information; the control device controls the rotation of the installation bracket 2 according to the collection information so that the assembly and disassembly cylinder 1 rotates to the installation position of the antenna front. In fact, the control device of this embodiment can be an industrial robot or an actuator.

[0066] Wherein, the control system of this embodiment also includes a point-collecting probe 10, which is installed on the outer support assembly and used to collect at least three non-collinear points on the antenna array; the control device Using the point information of the point-collecting probe 10 to determine the pose parameters of the antenna...

Embodiment 3

[0070] A method for assembling an antenna unit assembly using the integrated control system of acquisition, installation and testing in Embodiment 2 above includes the following steps:

[0071] S1, using the point-collecting probe 10 to collect at least three non-collinear points on the antenna array, and using the three-point positioning principle to determine the pose parameters of the antenna array;

[0072] S2. According to the pose parameters of the antenna front, adjust the posture of the camera 4 so that the optical axis of the camera 4 is perpendicular to the antenna front, and then perform image acquisition and parameter extraction on the characteristics of the assembly position of the antenna front to obtain coordinate parameters;

[0073] S3, the control device controls the assembly and disassembly cylinder 1 and the outer support assembly to pick up the antenna unit assembly 3, and transfers the antenna unit assembly 3 to the assembly position of the antenna front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com