Patents

Literature

31results about How to "Achieve high-precision assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

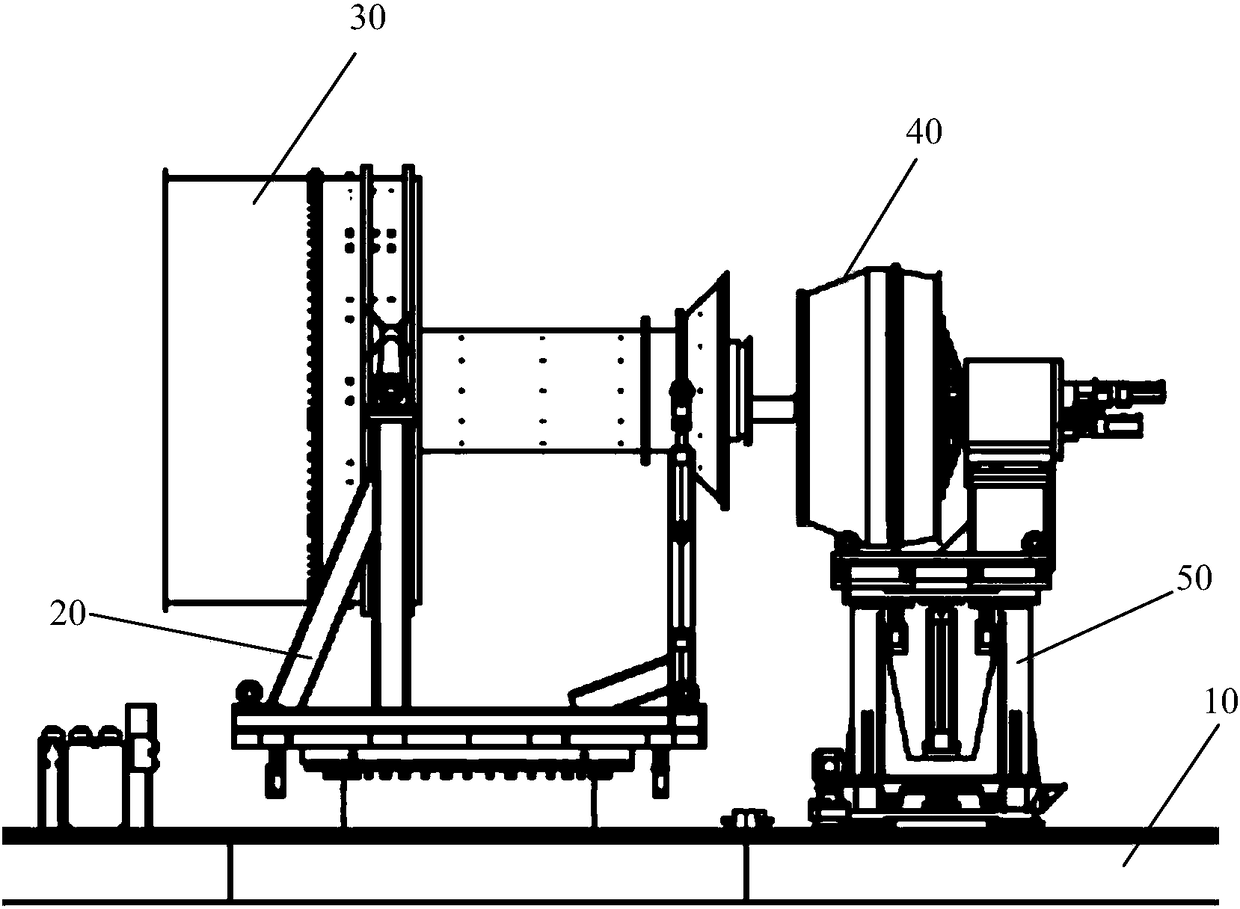

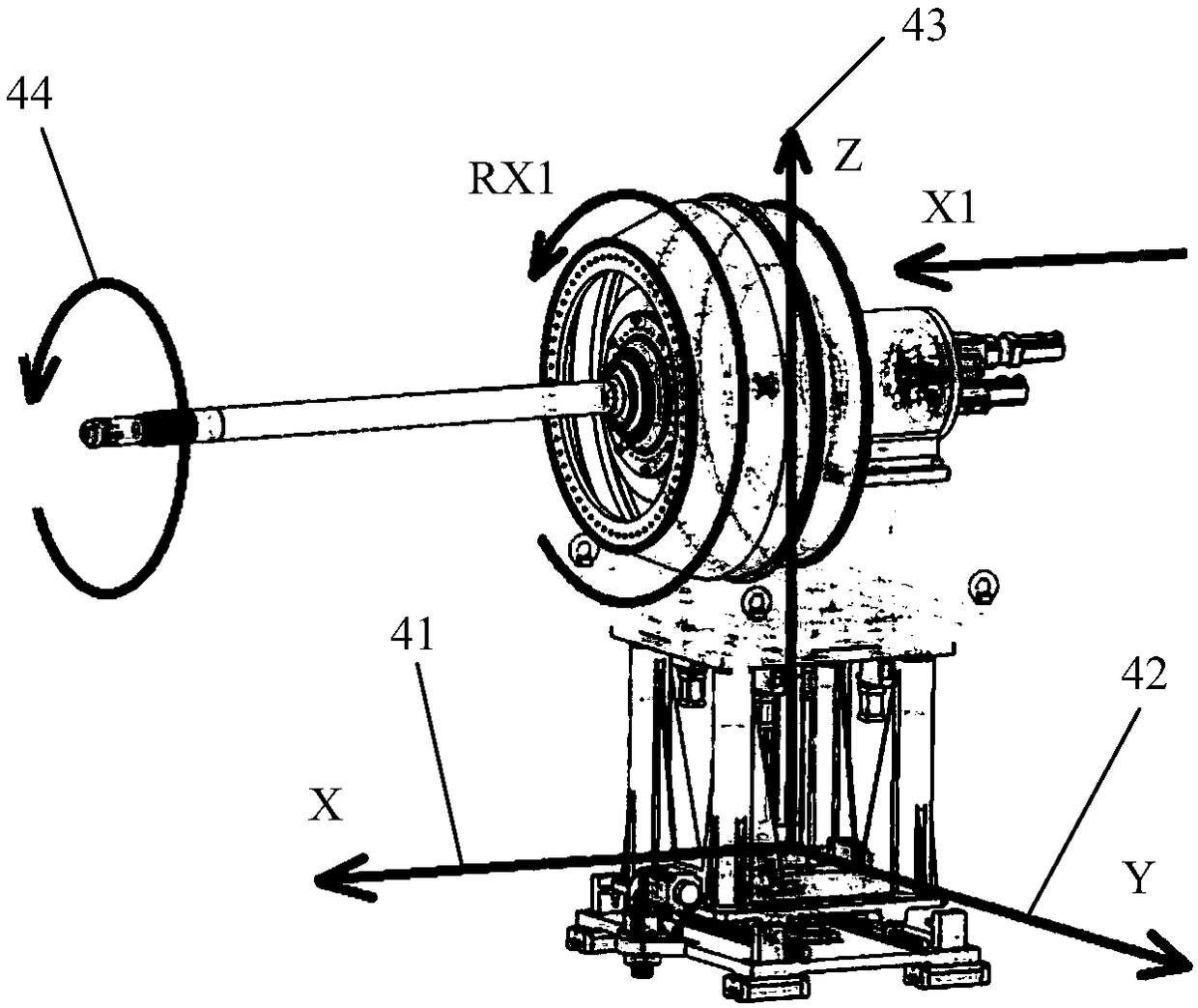

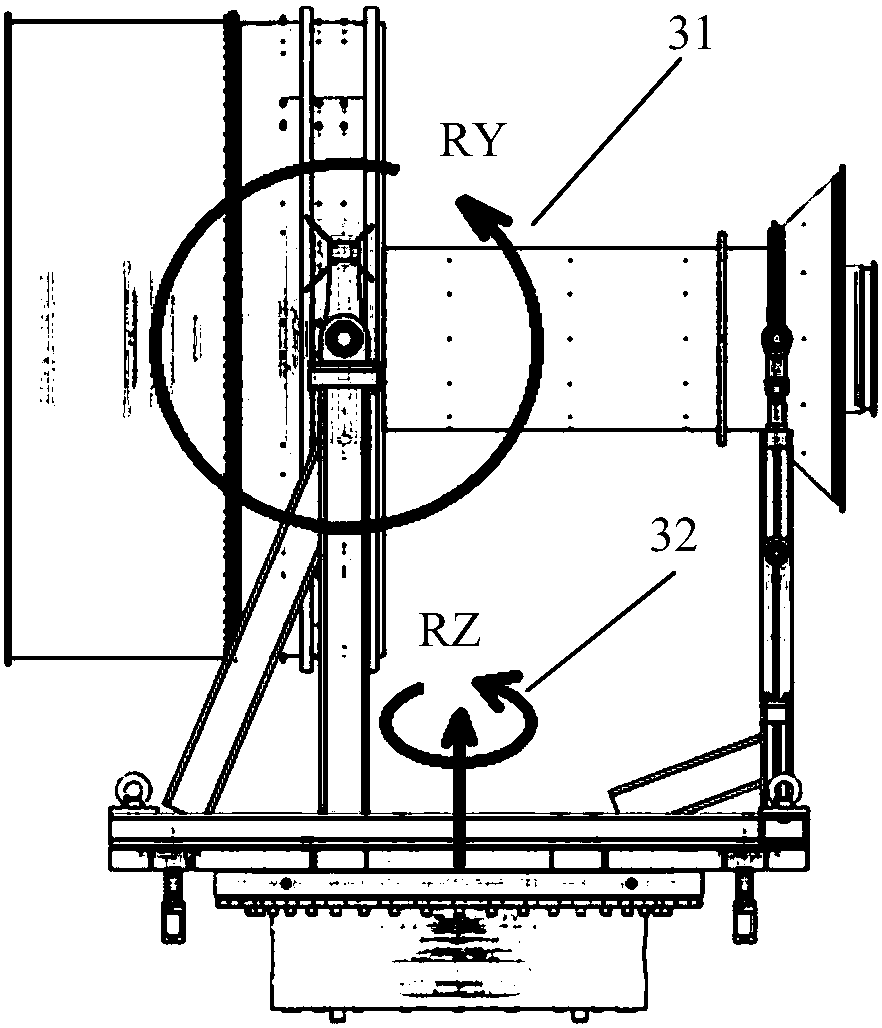

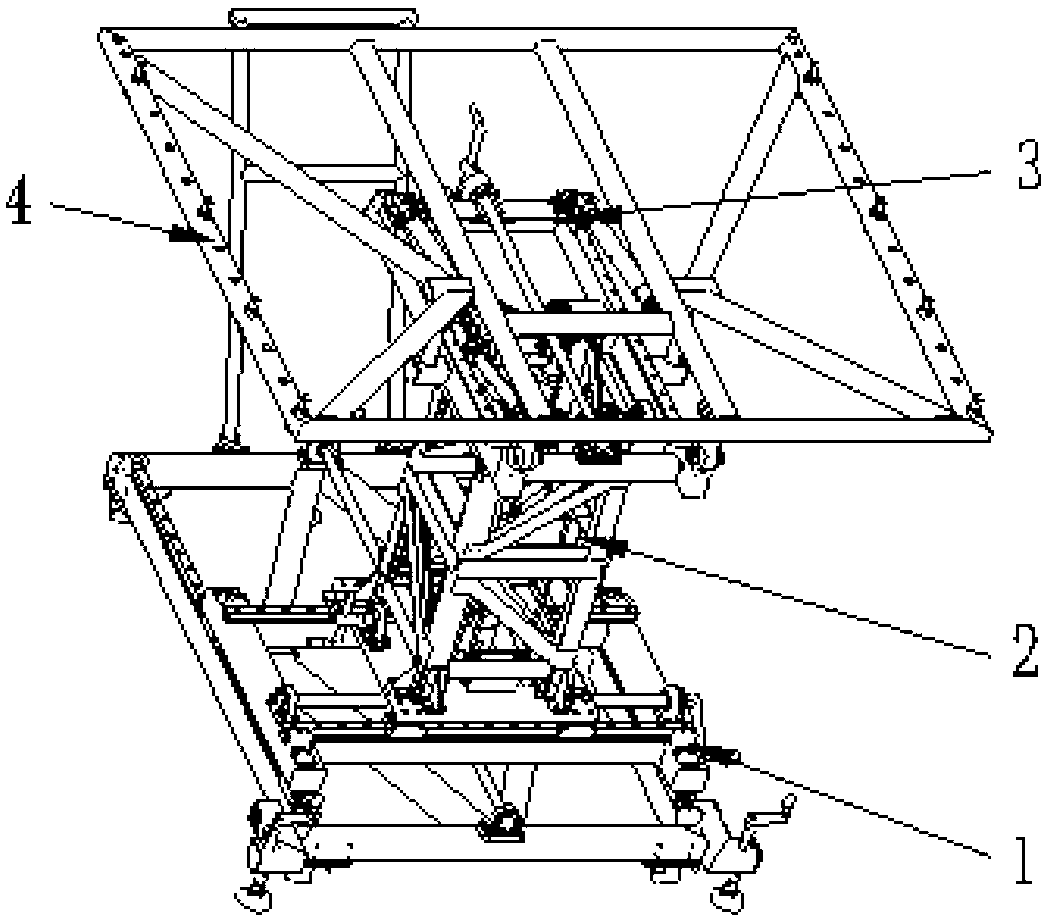

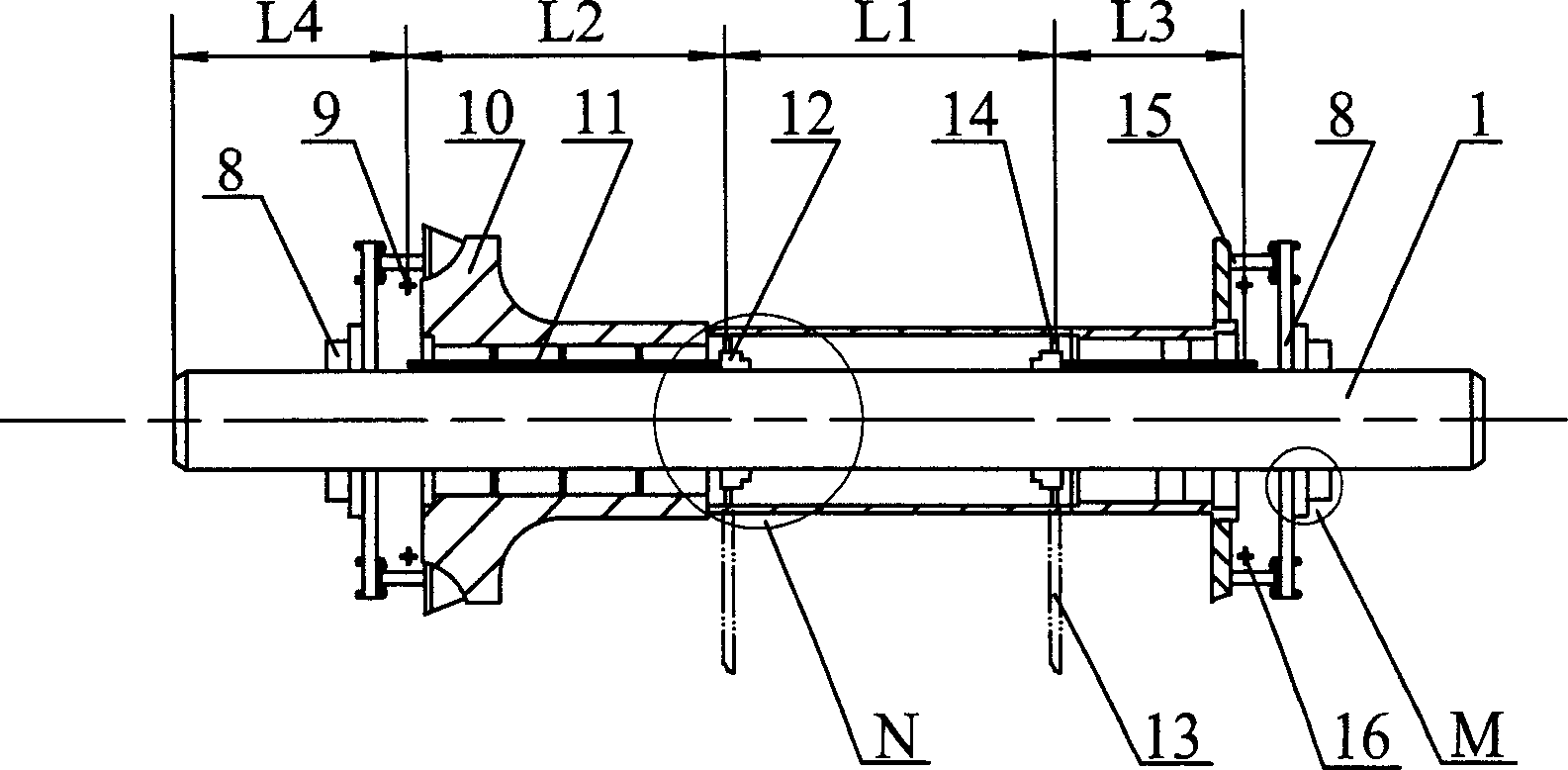

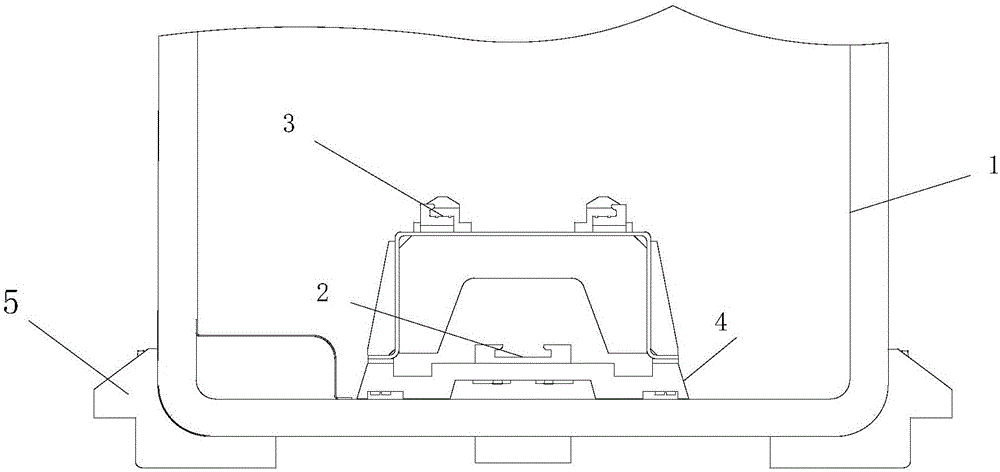

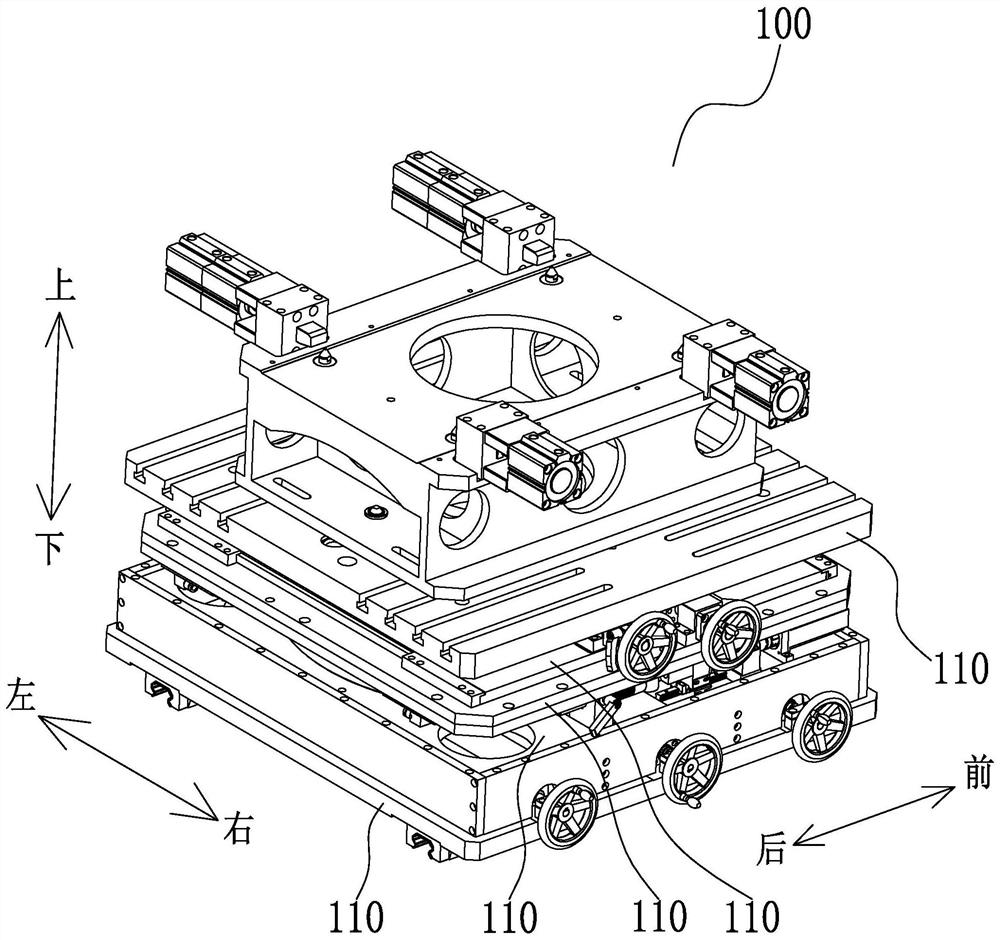

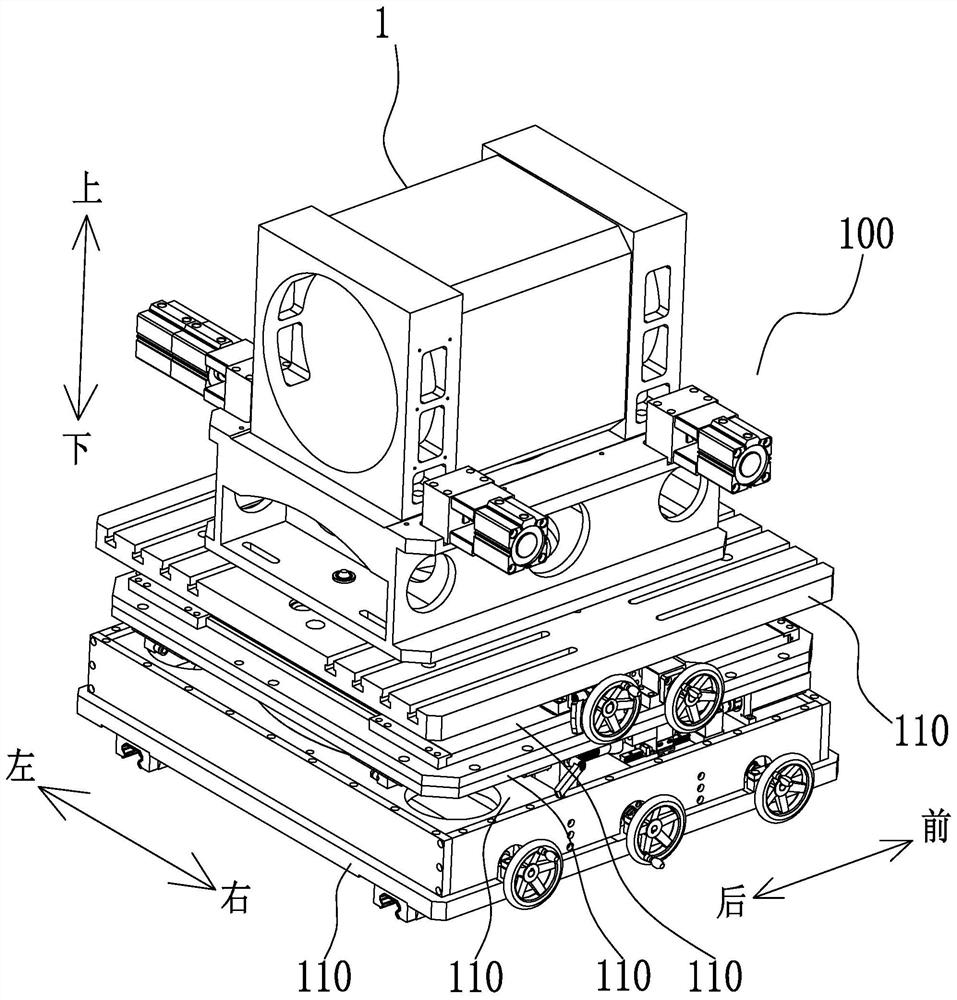

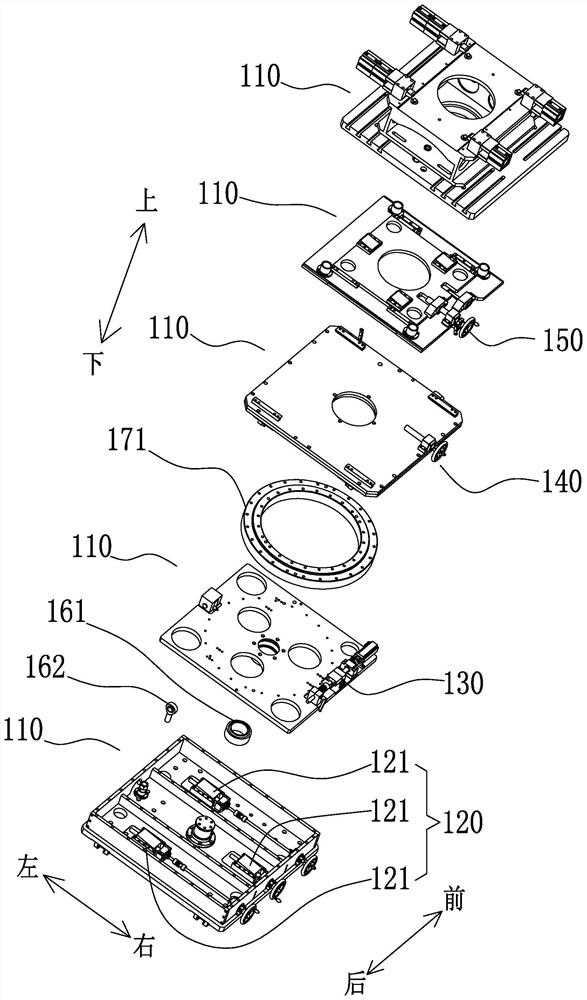

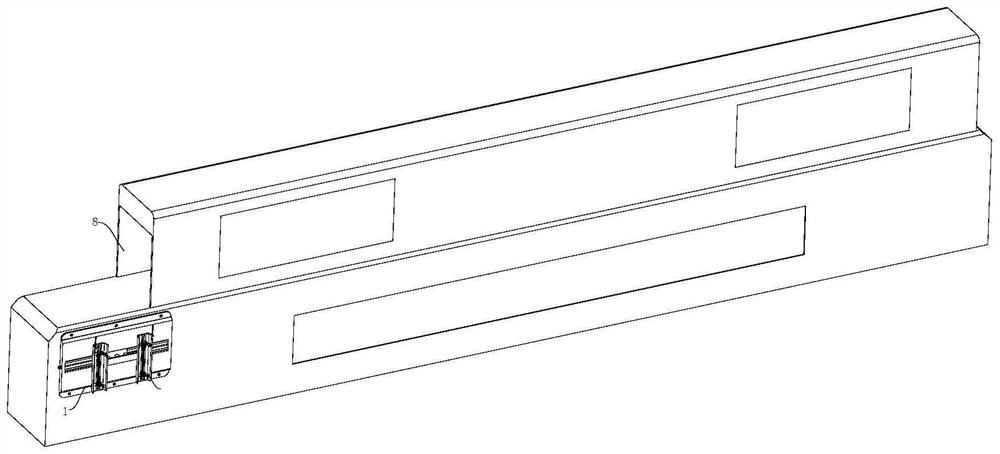

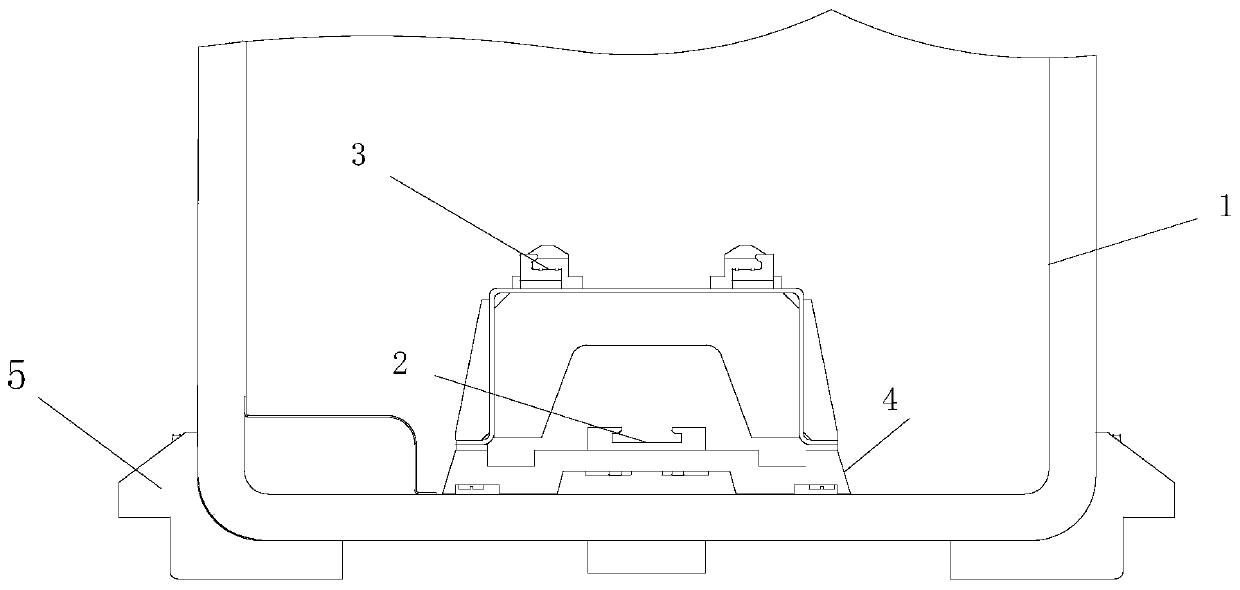

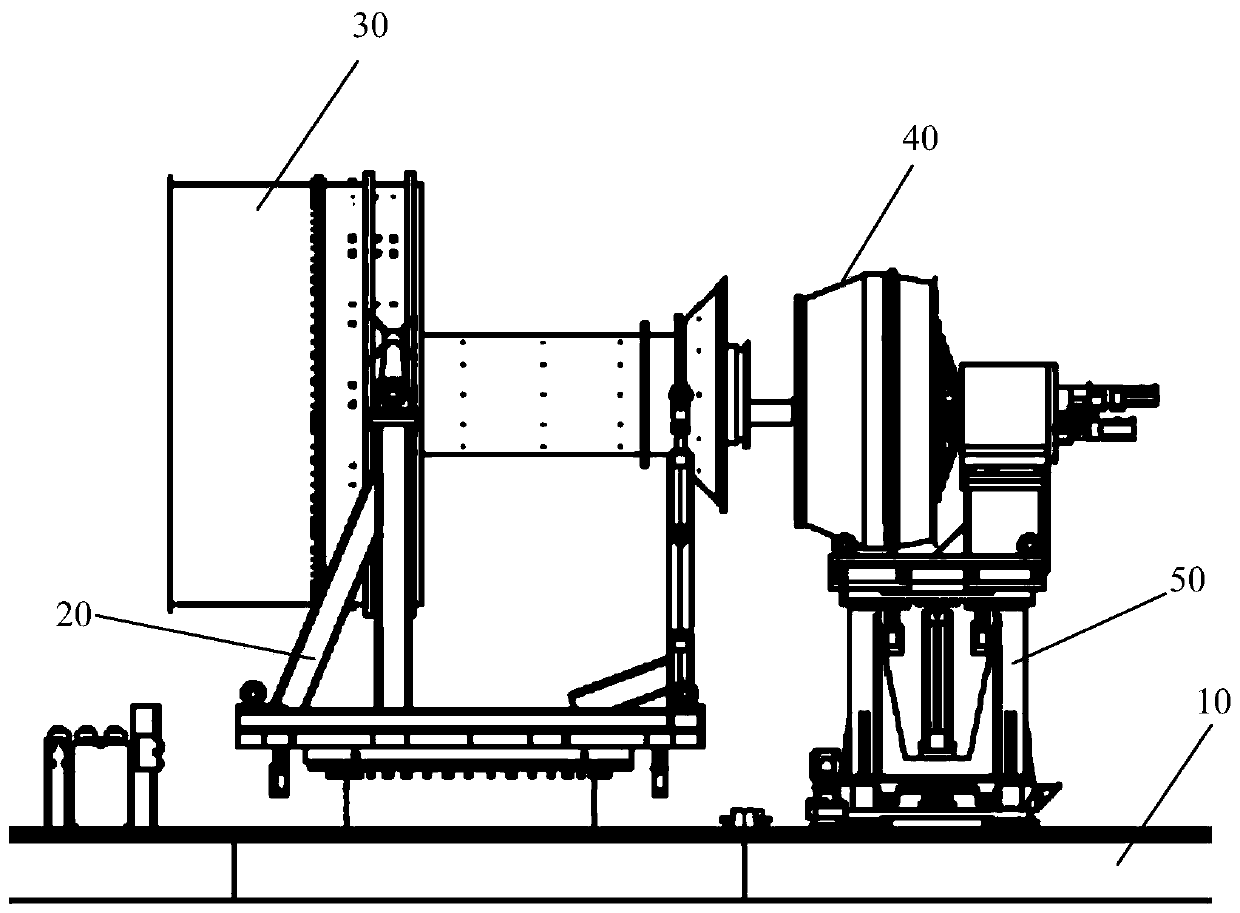

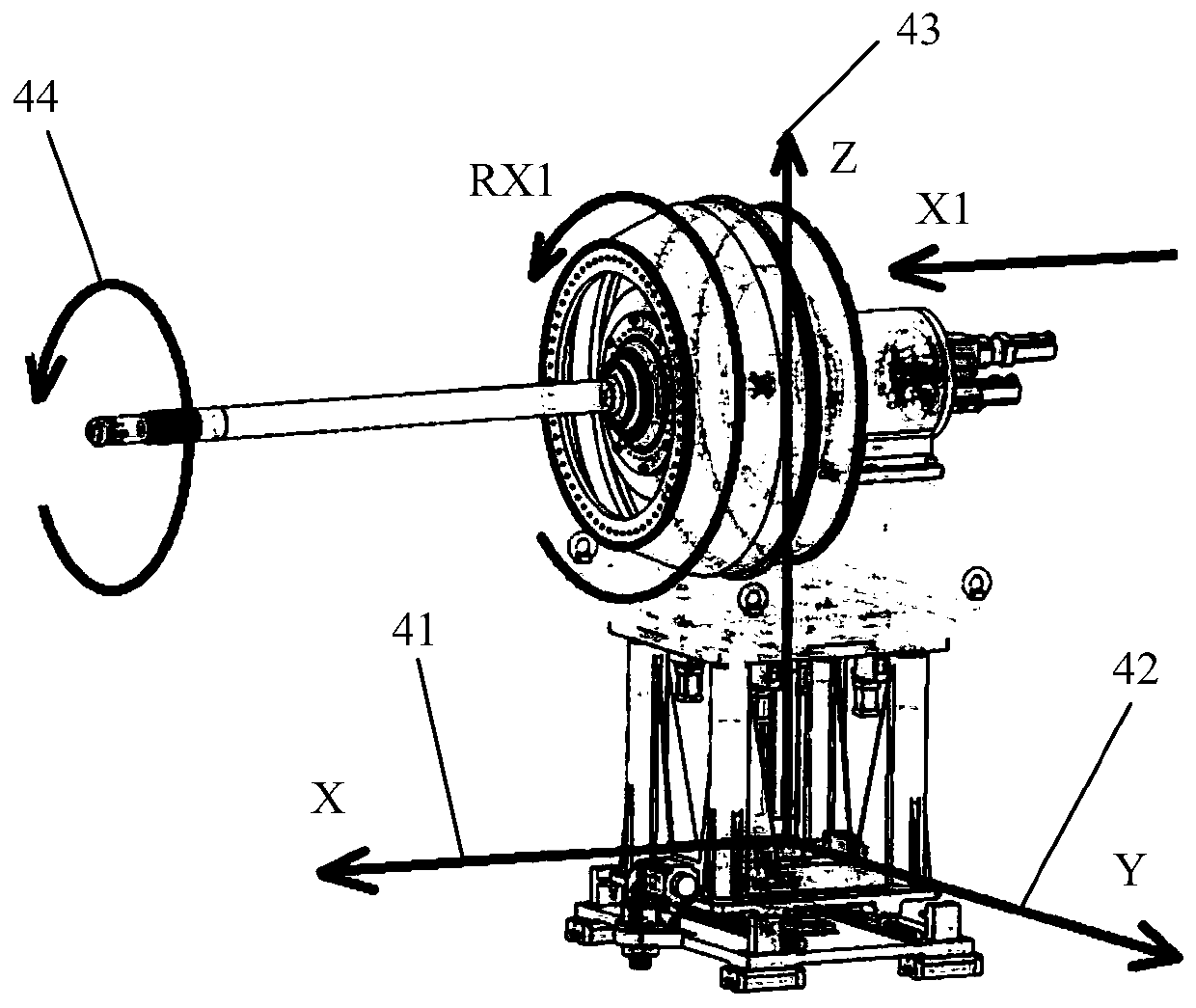

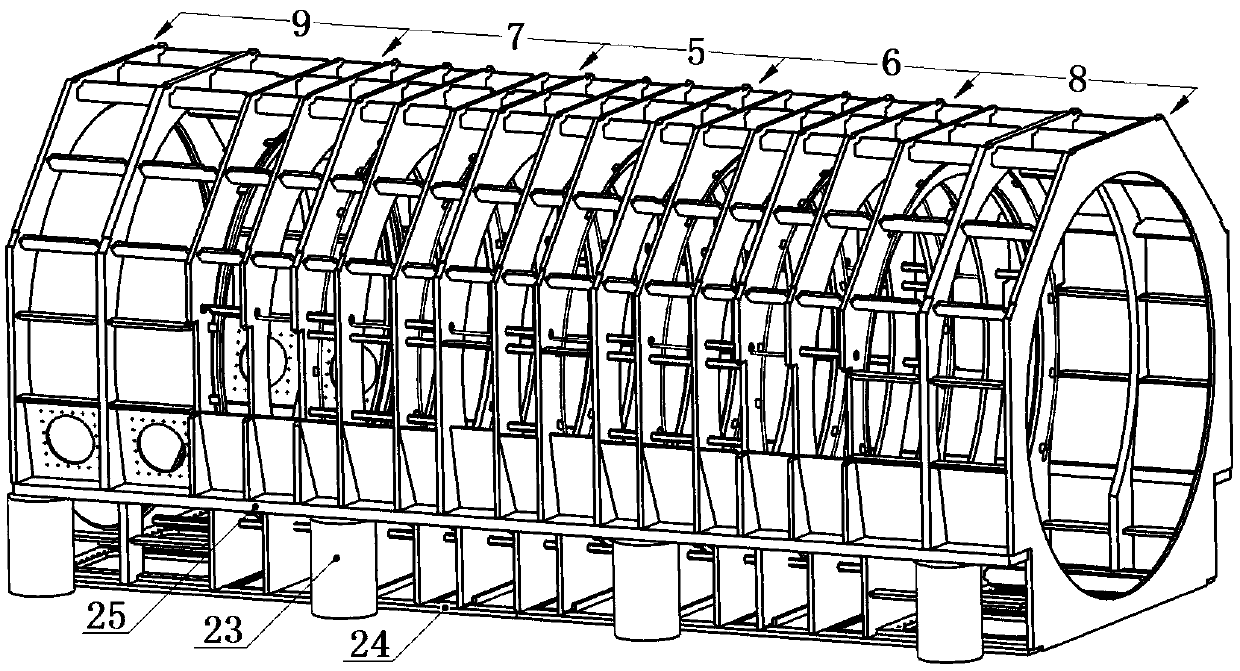

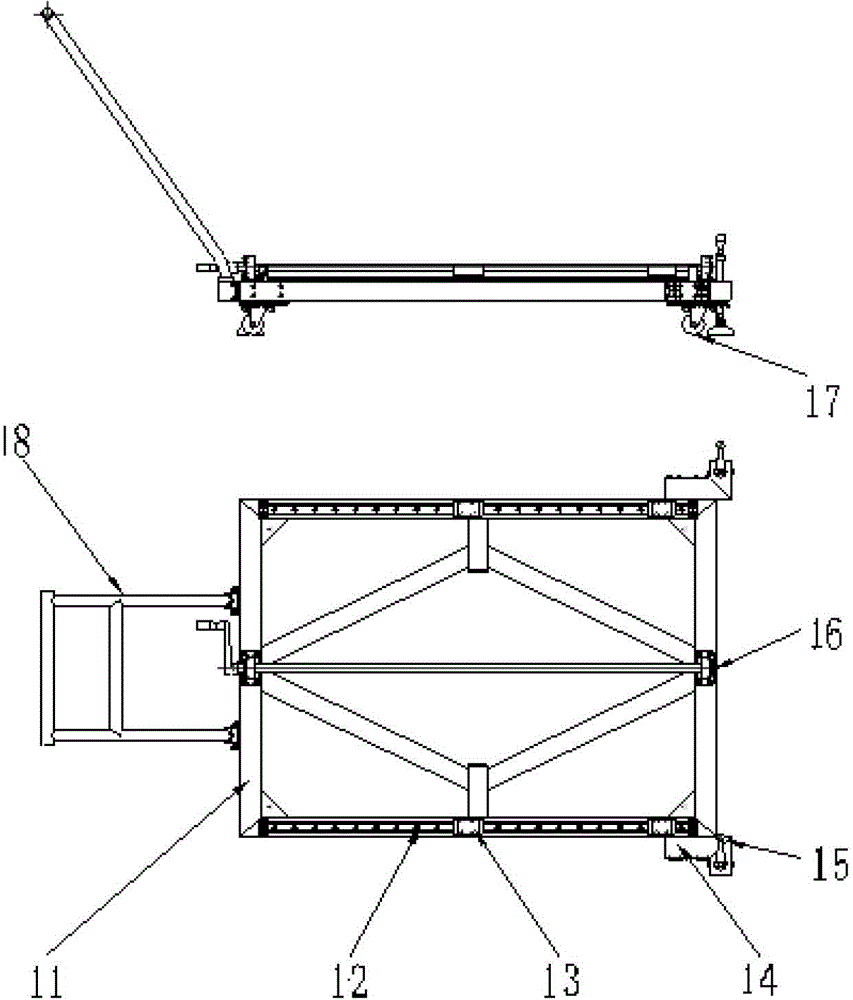

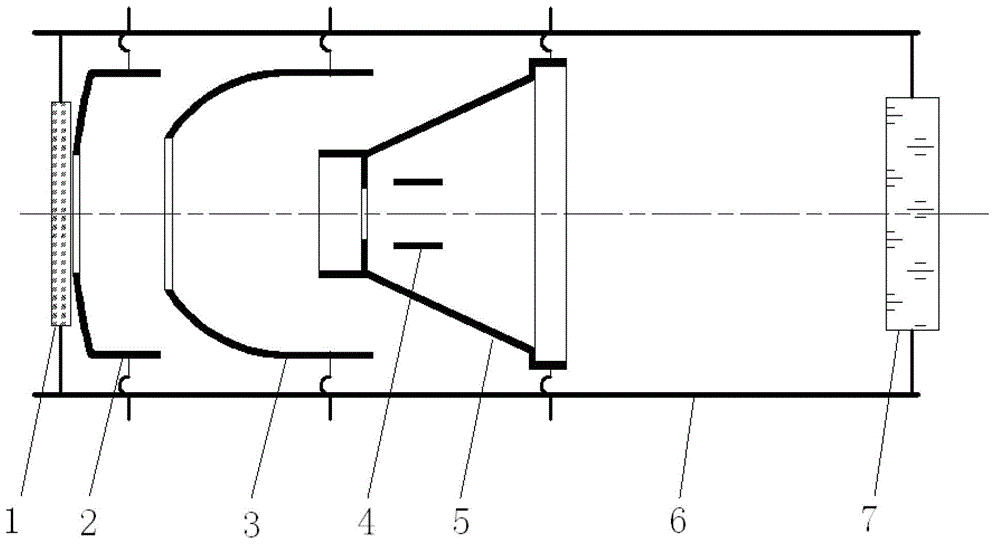

Intelligent assembly platform for low-pressure turbine module

ActiveCN109093379AImprove assembly accuracyAchieve high-precision assemblyAircraft componentsAssembly machinesDegrees of freedomTurbine

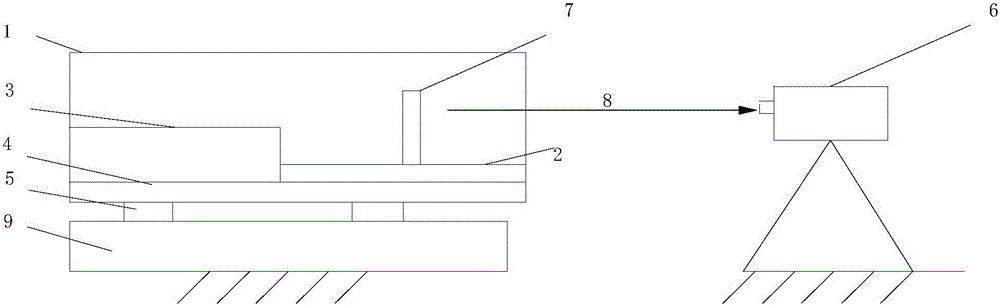

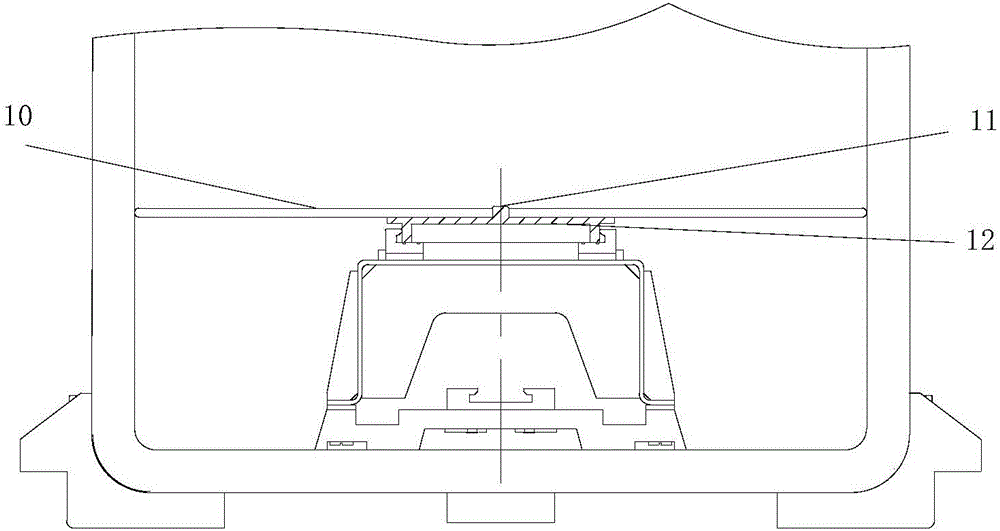

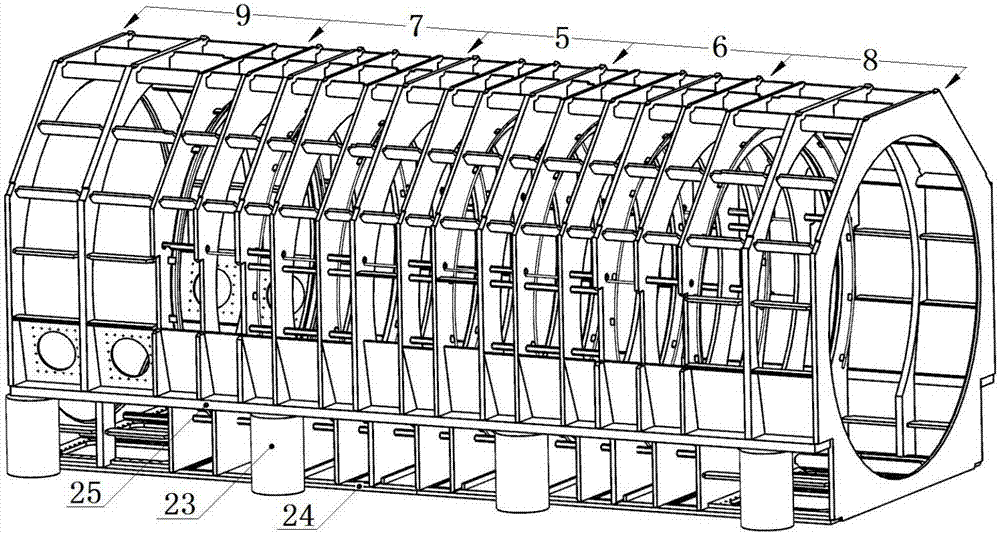

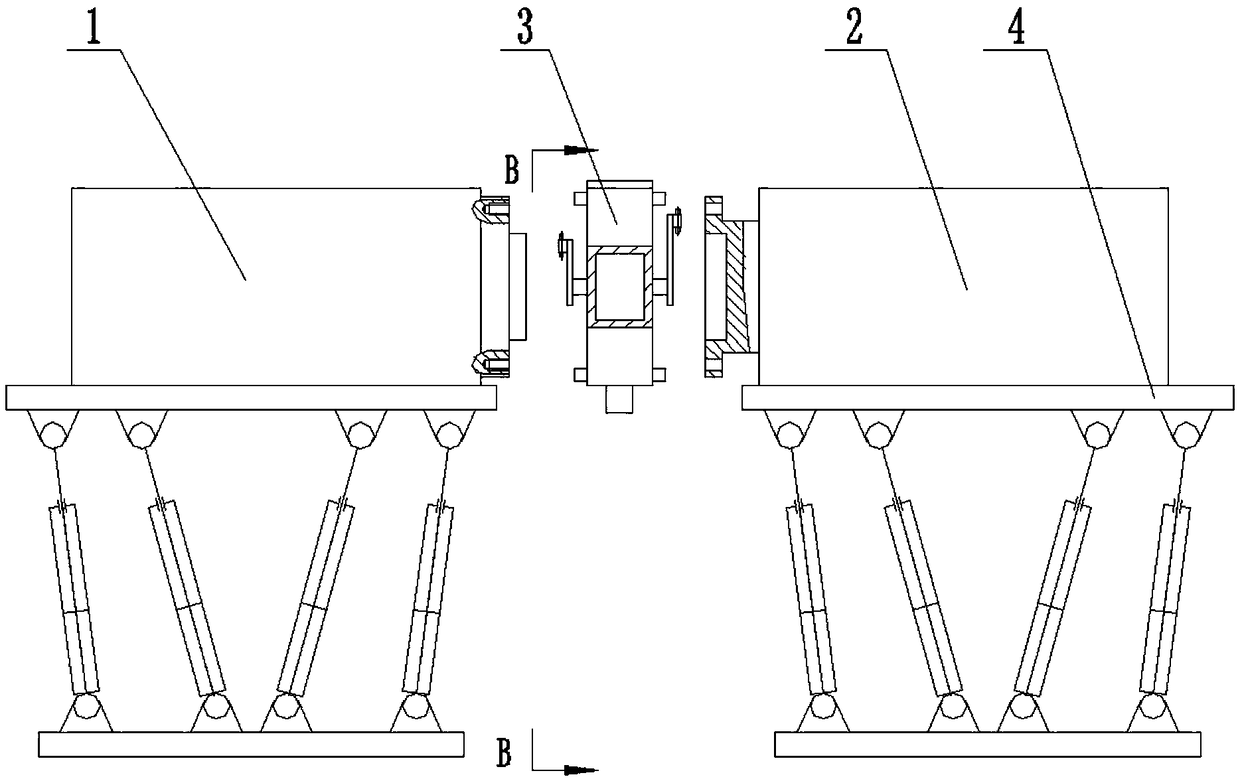

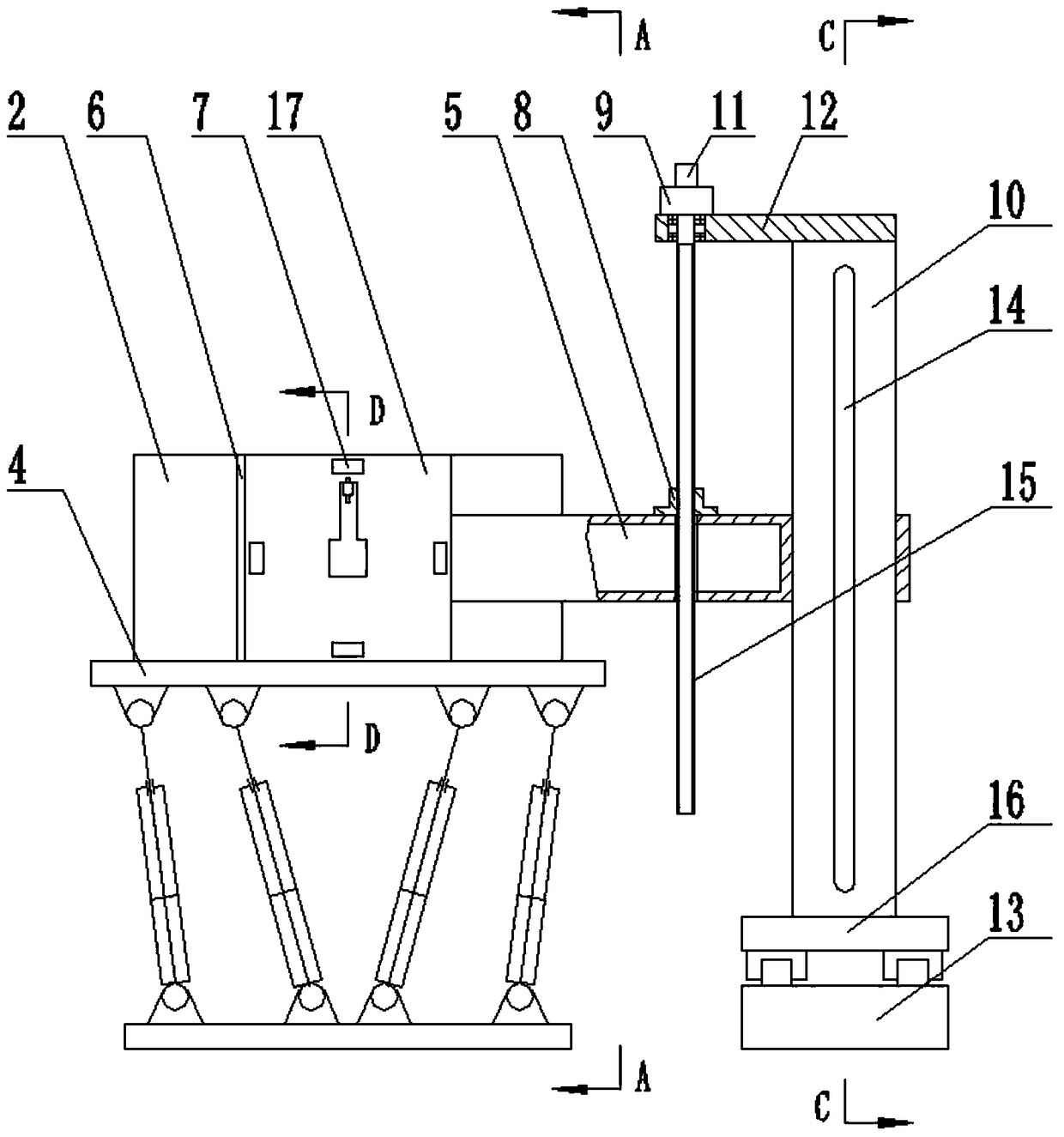

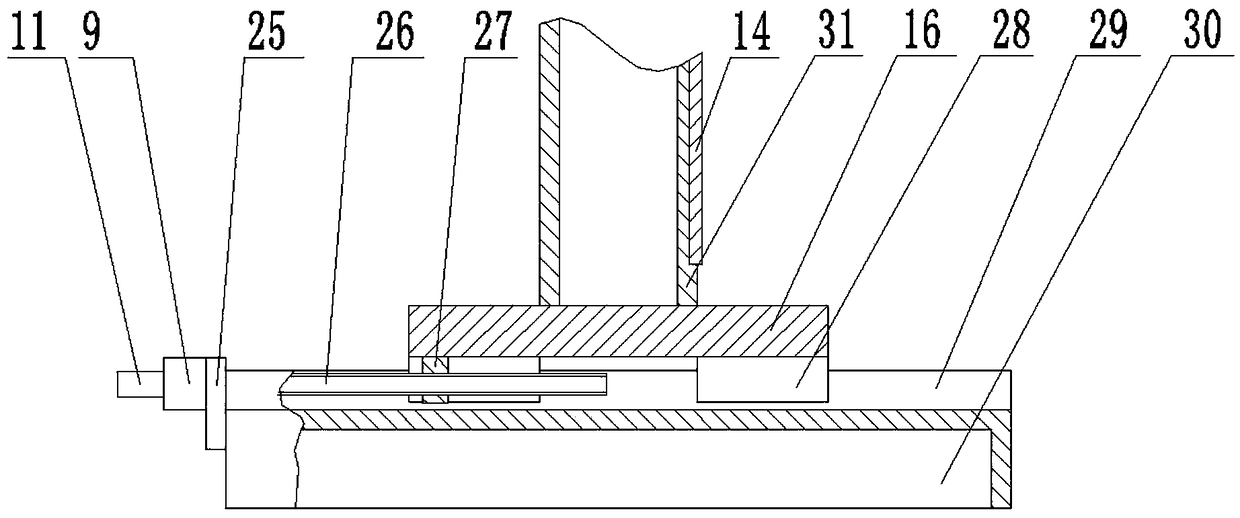

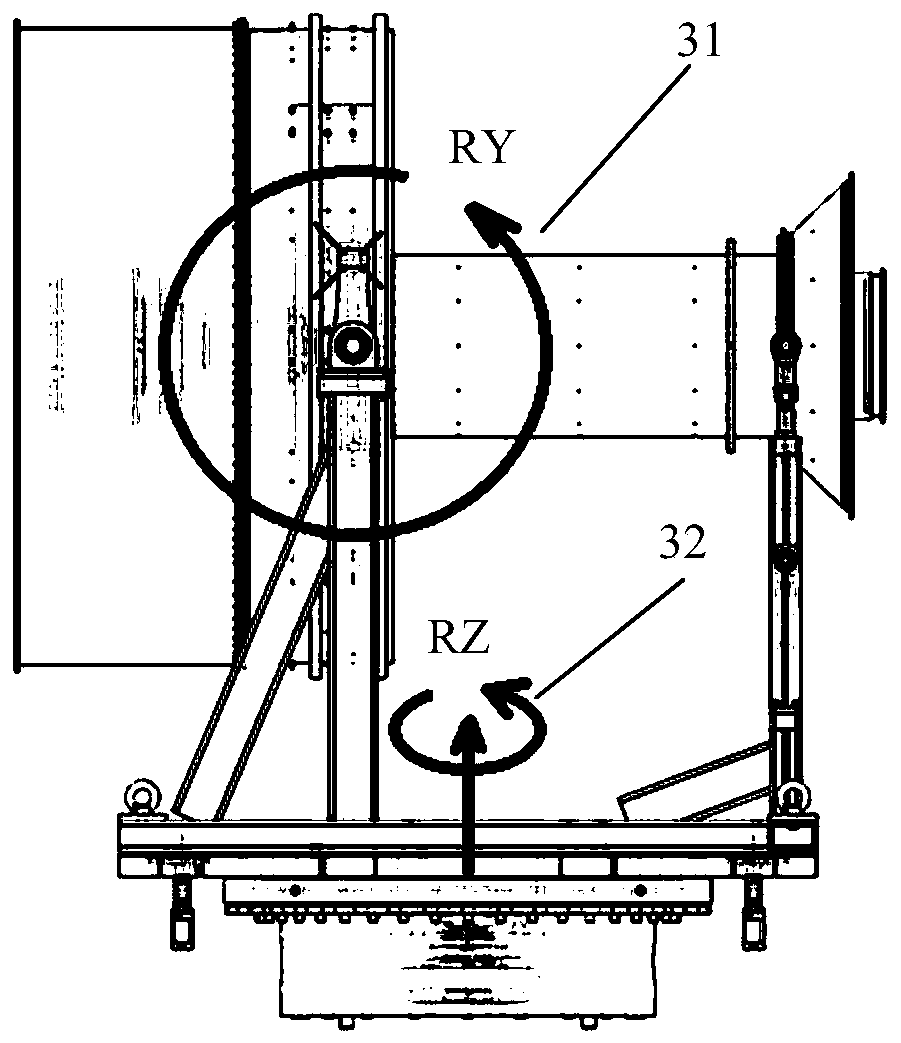

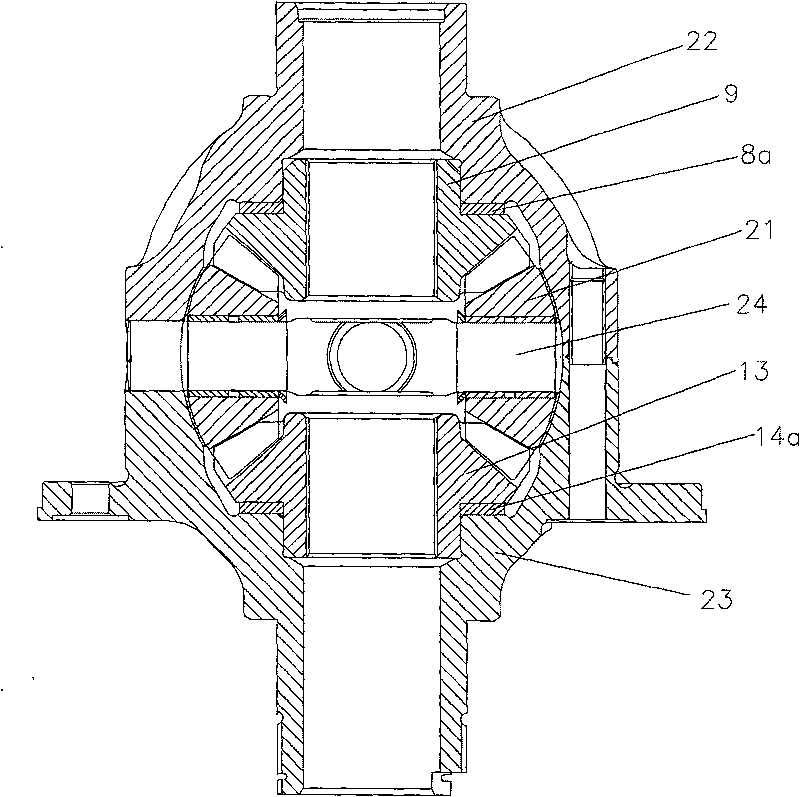

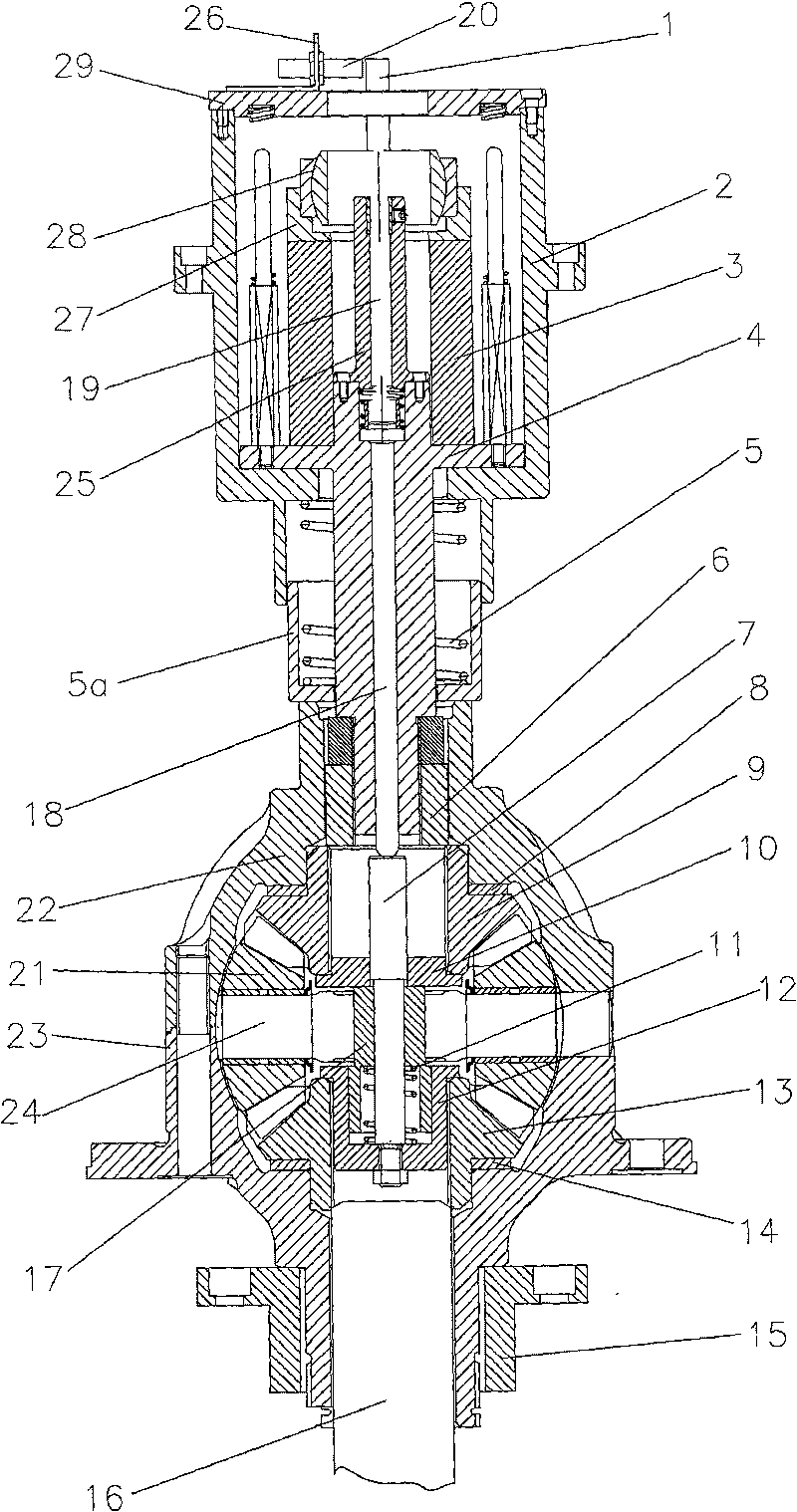

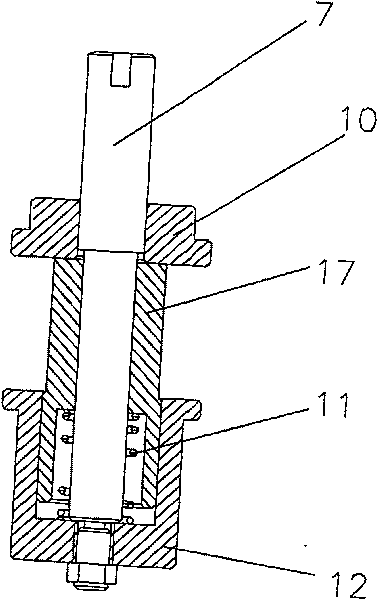

The invention provides an intelligent assembly platform for a low-pressure turbine module, and is used for the assembly of the whole aeroengine. The platform comprises a base, a fan core machine attitude adjustment system and a low-pressure turbine module position adjustment system. The fan core machine attitude adjustment system is fixed on one end of the base, and a fan core machine is installedon the fan core machine attitude adjustment system. The low-pressure turbine module position adjustment system is fixed on the other end of the base, and a low-pressure turbine module is installed onthe low-pressure turbine module position adjustment system; and the low-pressure turbine module is connected with the fan core machine, the low-pressure turbine module has four degrees of freedom ofmovement, and the fan core machine has two degrees of freedom of movement. The intelligent assembly platform for the low-pressure turbine module can improve the assembly precision, reduce the damage to parts, improve the assembly efficiency and reduce the amount of assembly labor.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

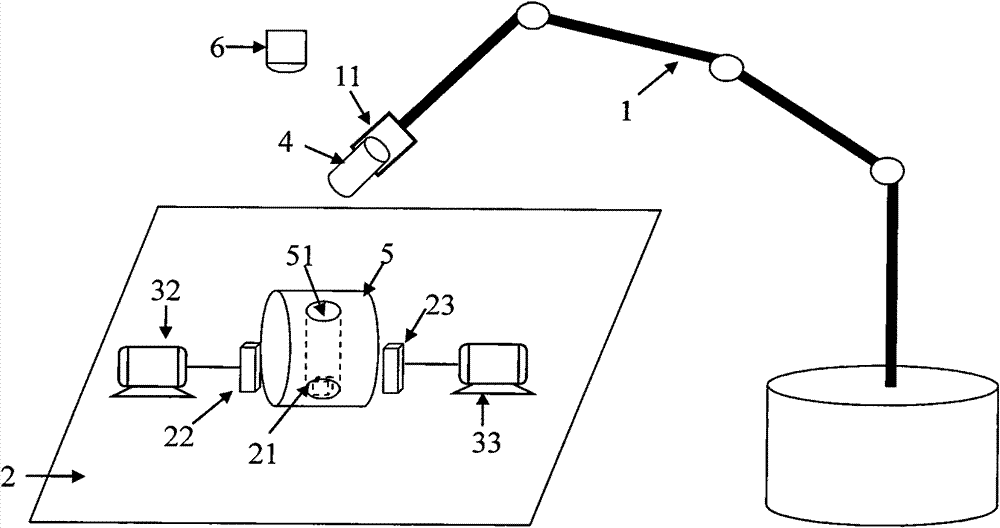

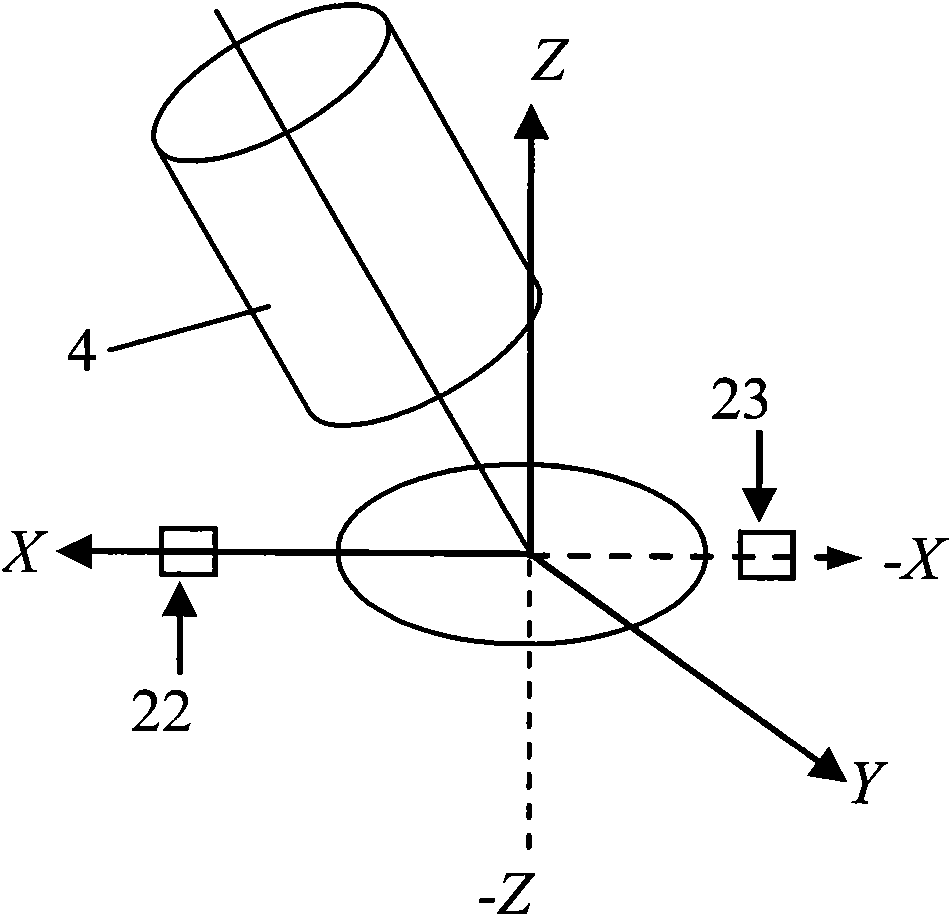

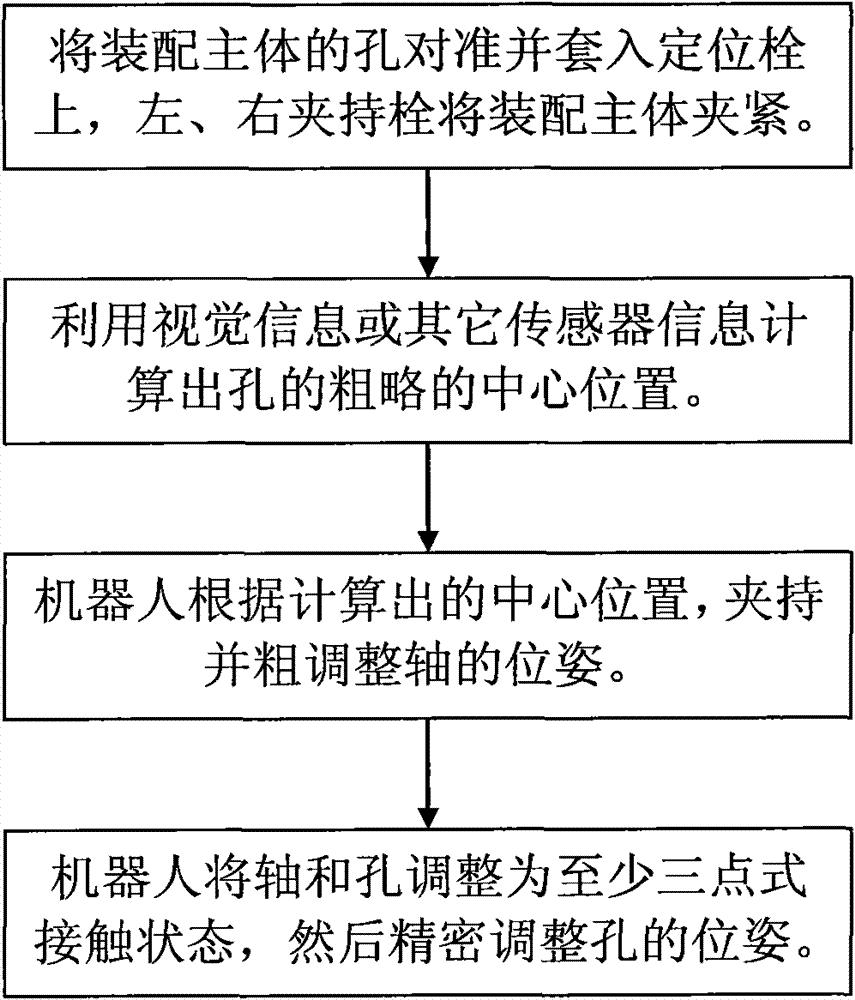

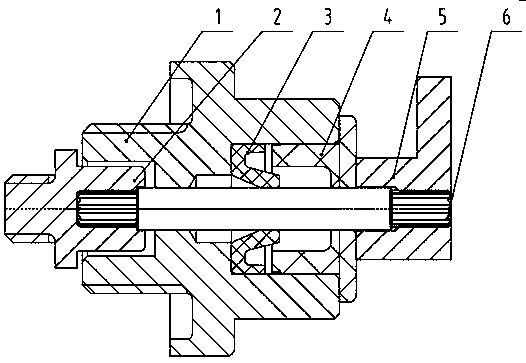

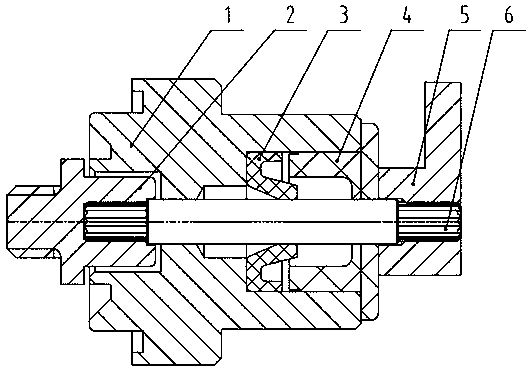

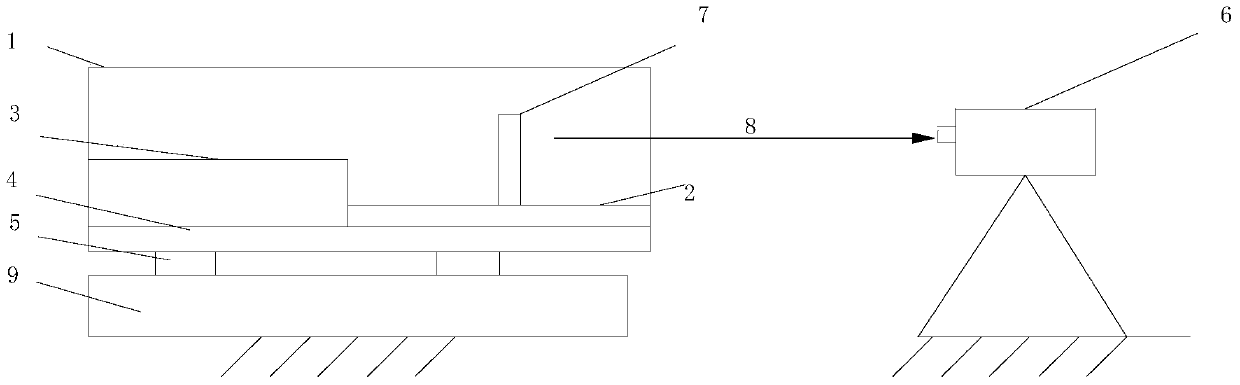

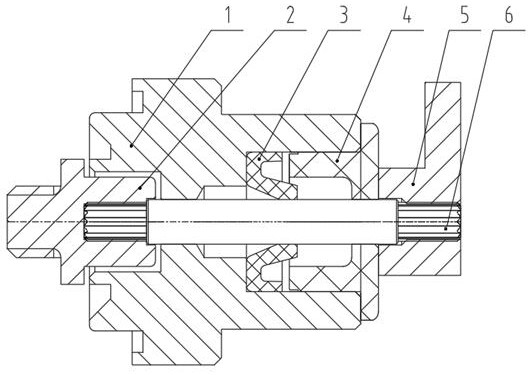

Device and method for realizing axle hole assembly by utilizing flexibility of robot

InactiveCN102218652BRemove location uncertaintyAchieve high precision assemblyProgramme-controlled manipulatorMetal working apparatusSimulationVision sensor

The invention discloses a device and method for realizing axle hole assembly by utilizing flexibility of a robot. The device comprises a base, at least two sets of clamping mechanisms, a robot and a vision sensor, wherein the vision sensor is used for sending a center position of an obtained hole to a controller of the robot; the robot is provided with four freedom degrees which comprise the freedom degree translated along the direction of three shafts of a three-dimensional coordinate system established by utilizing the center position of the hole as a circle centre and the freedom degree rotated around at least one shaft; and the controller of the robot can be used for increasing the gain of a position ring moving along the three shafts so that a claw installed at the tail end of the robot obtains the flexibility for automatically regulating claw gestures under the action of a reacting force applied by the shafts while in contact with the shafts.

Owner:JIANGSU SANLI HYDRAULIC MACHINERY

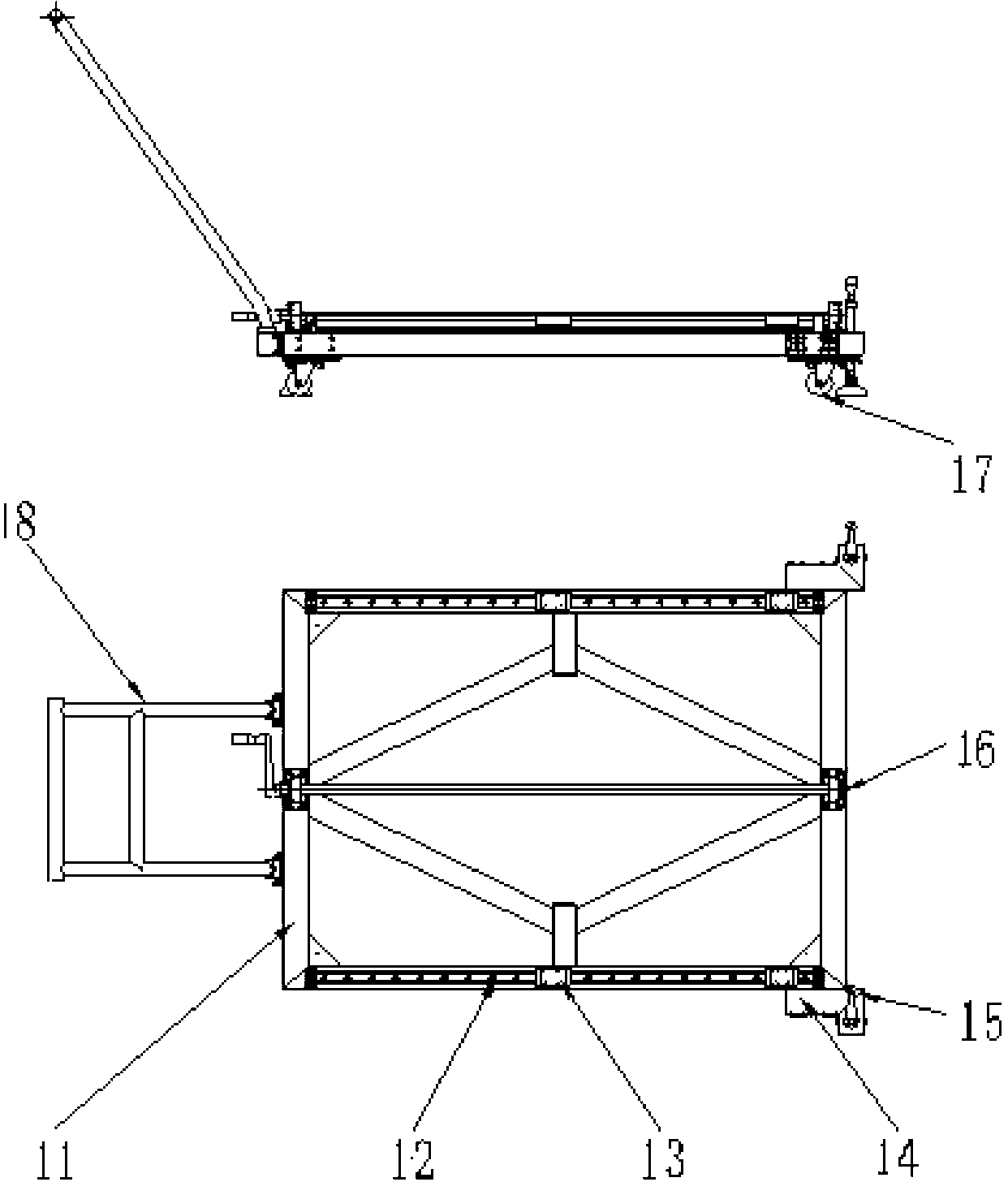

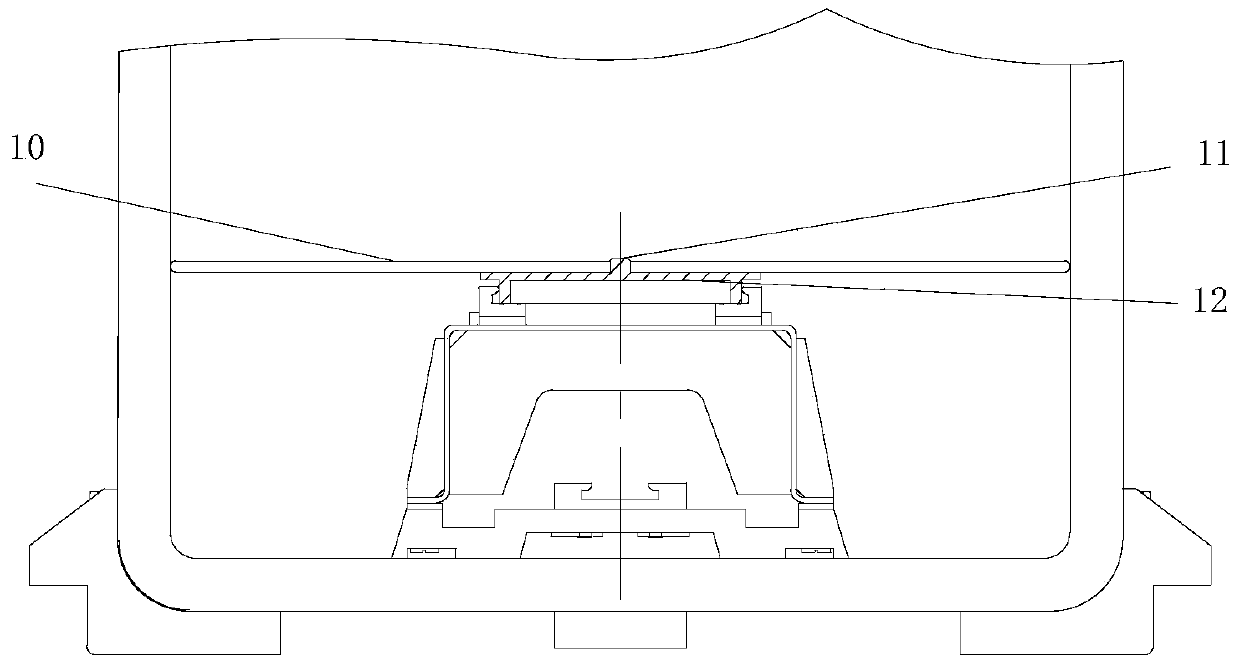

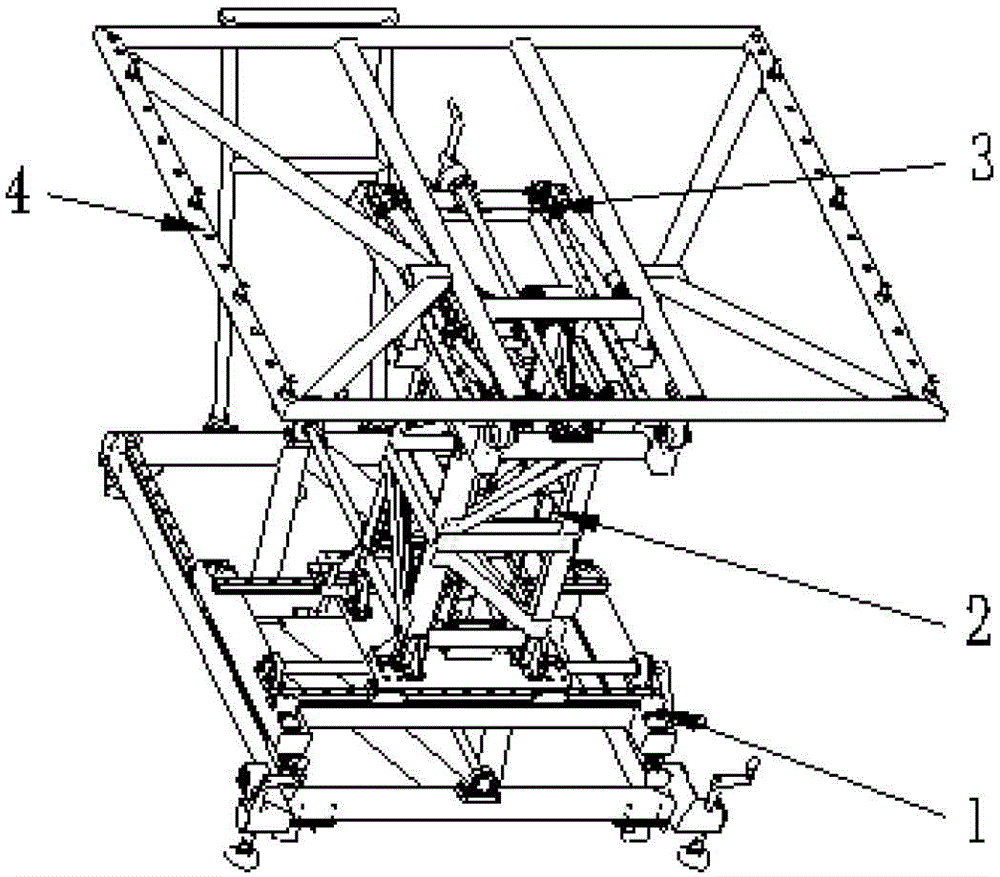

Side plate installing vehicle for omnidirectional fine-tuning satellite instrument

ActiveCN103009337AImprove securityEasy to operateMetal-working hand toolsOmnidirectional antennaSatellite

The invention provides a side plate installing vehicle for an omnidirectional fine-tuning satellite instrument. The side plate installing vehicle comprises a base assembly (1), a lifting function assembly (2), a turnover function assembly (3) and a side plate installing frame assembly (4), wherein the lifting function assembly (2), the turnover function assembly (3) and the side plate installing frame assembly (4) are arranged on the base assembly (1). The side plate installing vehicle can be adjusted in three linear directions of front and back, left and right and up and down and two angular directions of pitching and rolling through mechanisms such as an adjustable leg support, a screw rod, a linear guide rail and a lifter, and can be used for installing side plates of various satellite instruments on satellites.

Owner:SHANGHAI YUDA IND

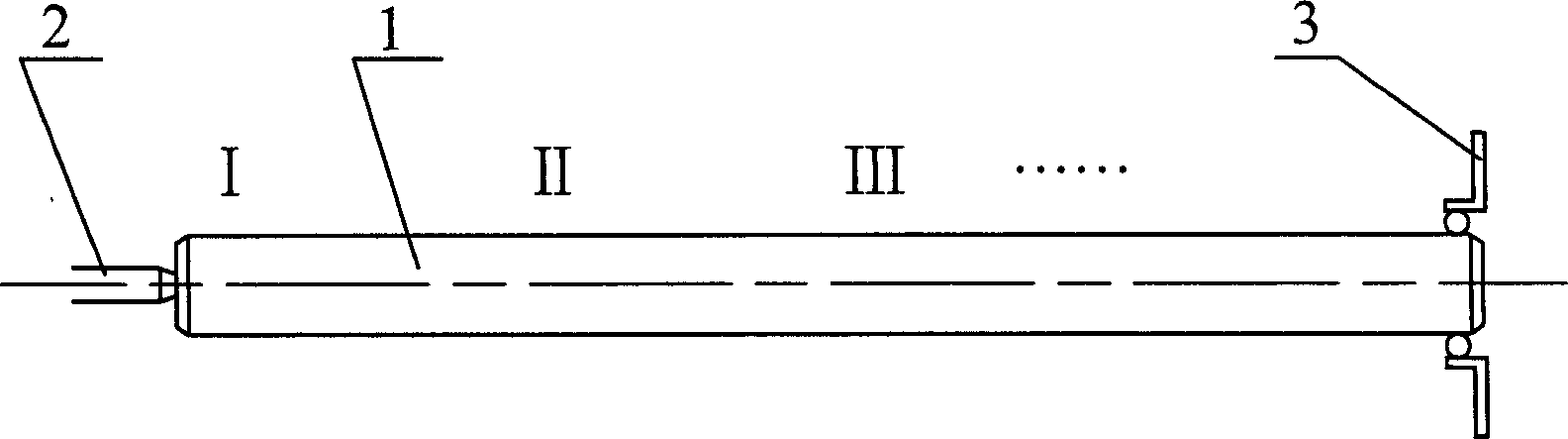

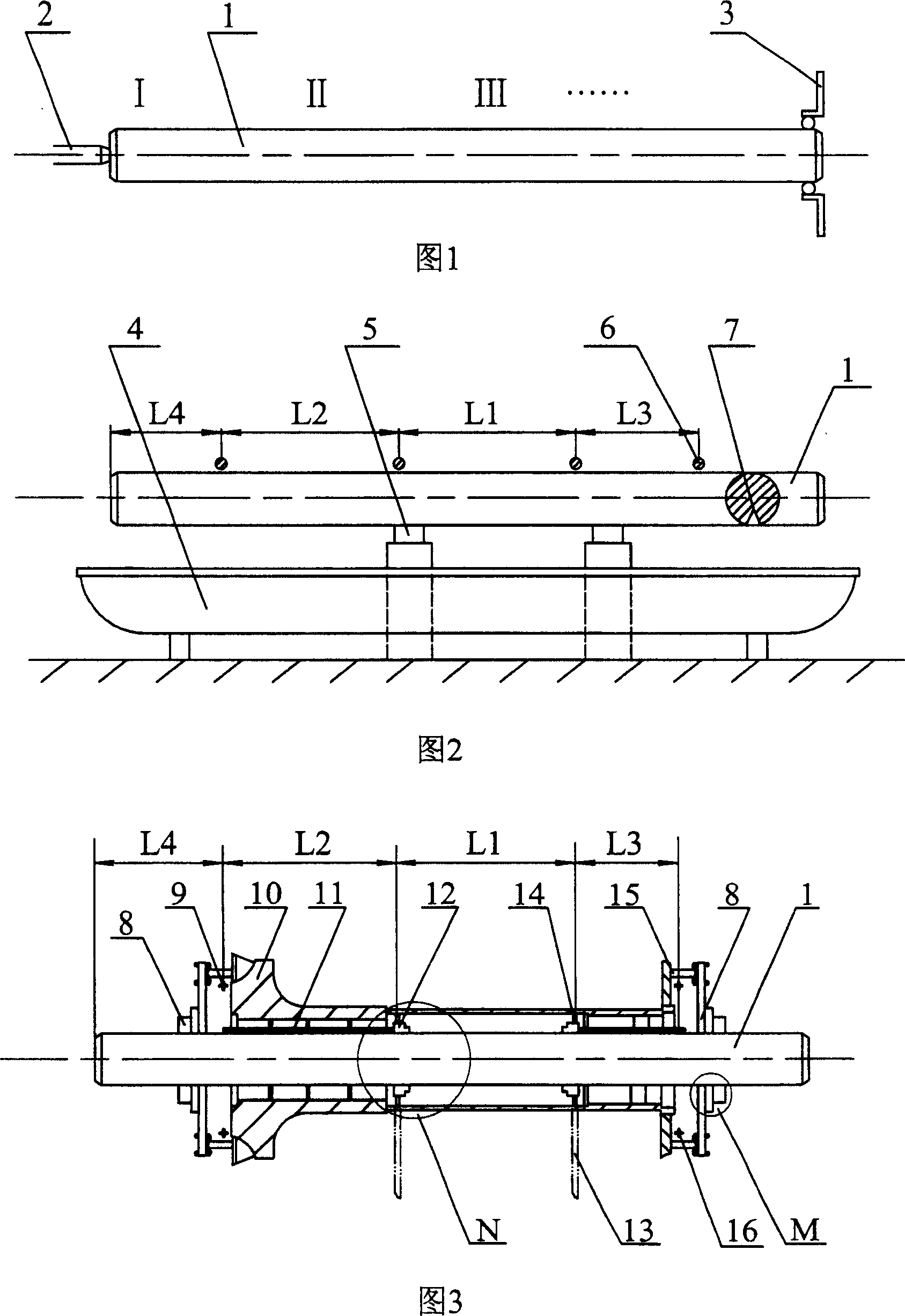

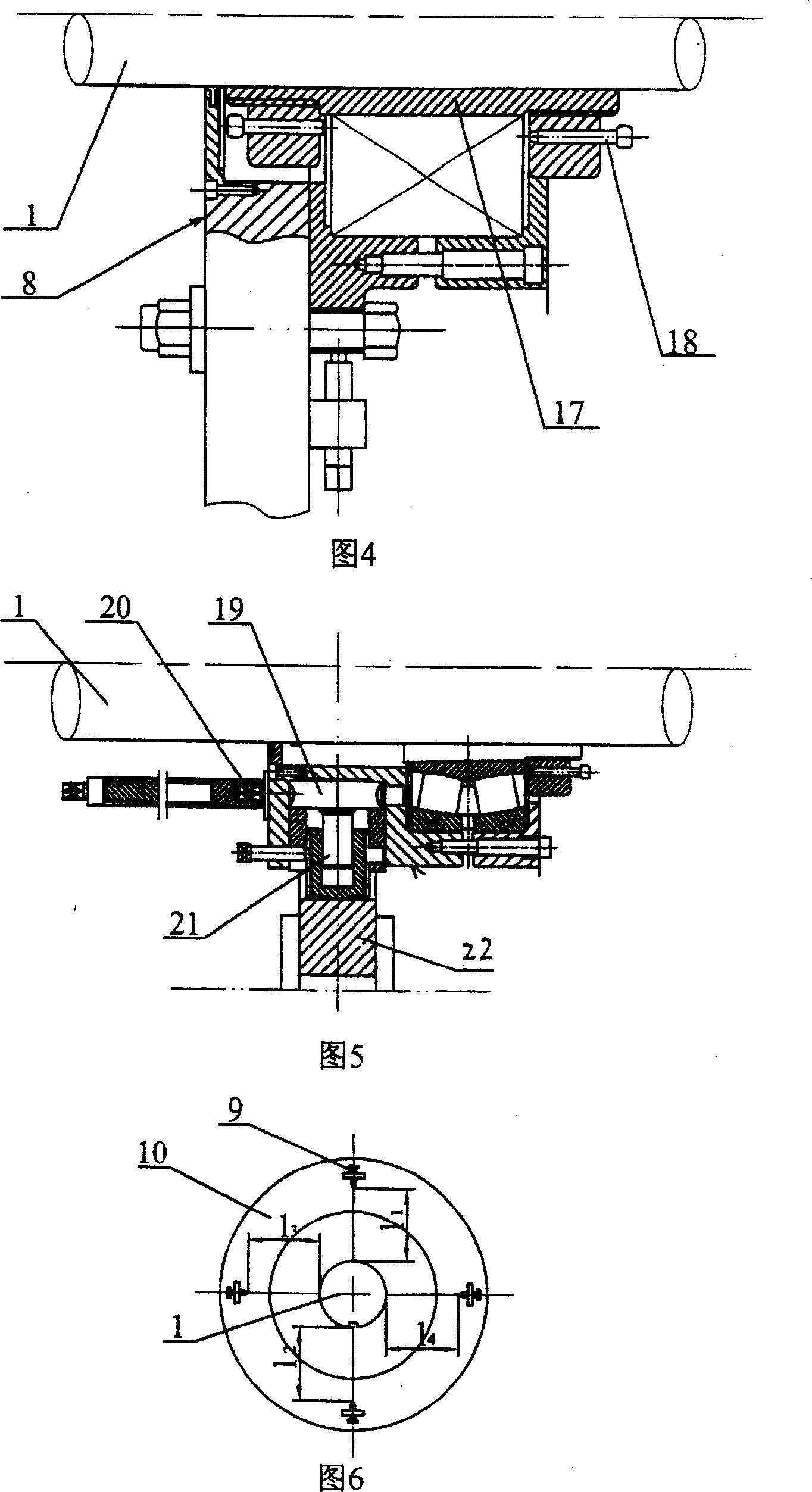

Marine stern axle tube boring technological equipment erecting process

ActiveCN1775434AAchieve high-precision assemblyReduce labor intensityPositioning apparatusMetal-working holdersEngineeringCantilever

The present invention belongs to a ship stern tube boring tool mounting process. Said process includes the following several procedures: defining the position of intermediate support of boring bar in the stern tube to be machined; measuring straightness of boring bar; simulatively measuring flexibility value of cantilevers of two ends of said boring bar; and mounting boring tool. Said invention also provides the concrete steps of the above-mentioned every procedure.

Owner:中国船舶集团渤海造船有限公司

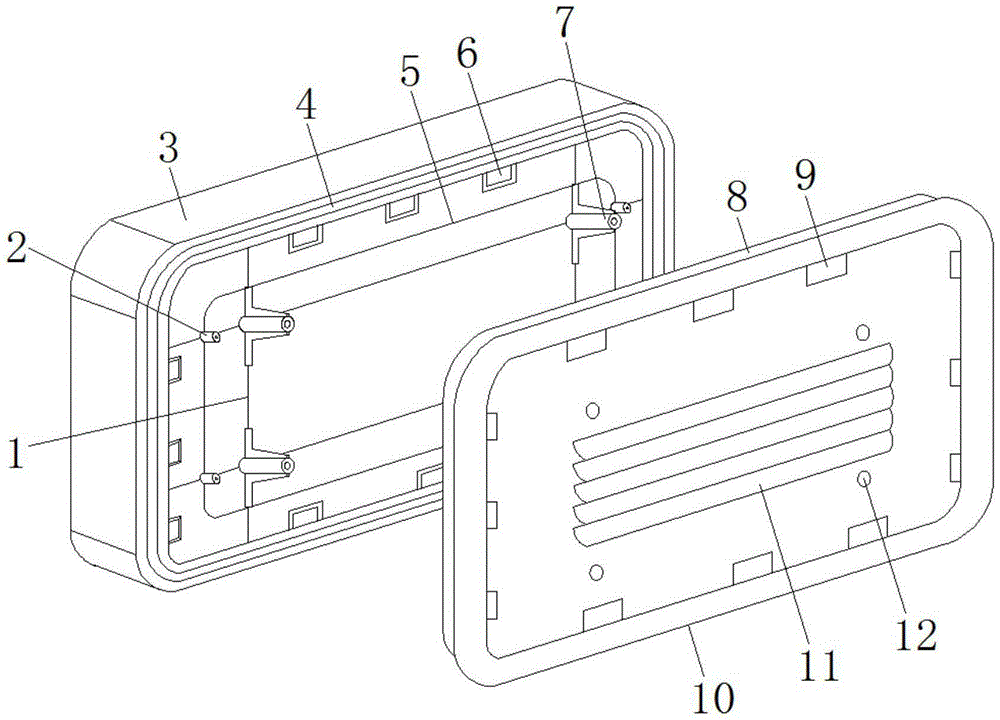

High-precision assembling housing

InactiveCN104902706ACompact structureEasy assemblyCasings/cabinets/drawers detailsDislocationBiochemical engineering

Disclosed in the invention is a high-precision assembling housing comprising a housing body, grooves, a mounting plate, a protruding rib, and a housing cover. Reinforced ribs are arranged inside the housing body and are vertically arranged by using threaded columns as centers; and the threaded columns are fixed at the housing body. The mounting plate is arranged inside the housing body; and a plurality of fixation columns extend out of the back of the mounting plate externally. A plurality of clamp grooves are formed in the inner wall of the housing body. The housing cover is arranged at one side of the housing body; clamp hooks are arranged at positions, corresponding to the clamp grooves, inside the housing cover; threaded holes corresponding to the threaded columns are formed in the housing cover; cooling fins are arranged at the outer wall of the housing cover; and the protruding rib is arranged at the end surface of the housing cover. The grooves are formed in the end surface of the housing body correspondingly. The provided high-precision assembling housing has advantages of compact structure and simple assembling. High-precision assembling of the housing is realized; the positioning is accurate; dislocation is prevented; the connecting strength after assembling is high; fixation is firm; the practical property is improved; and the heat radiation effect is good.

Owner:廖婕

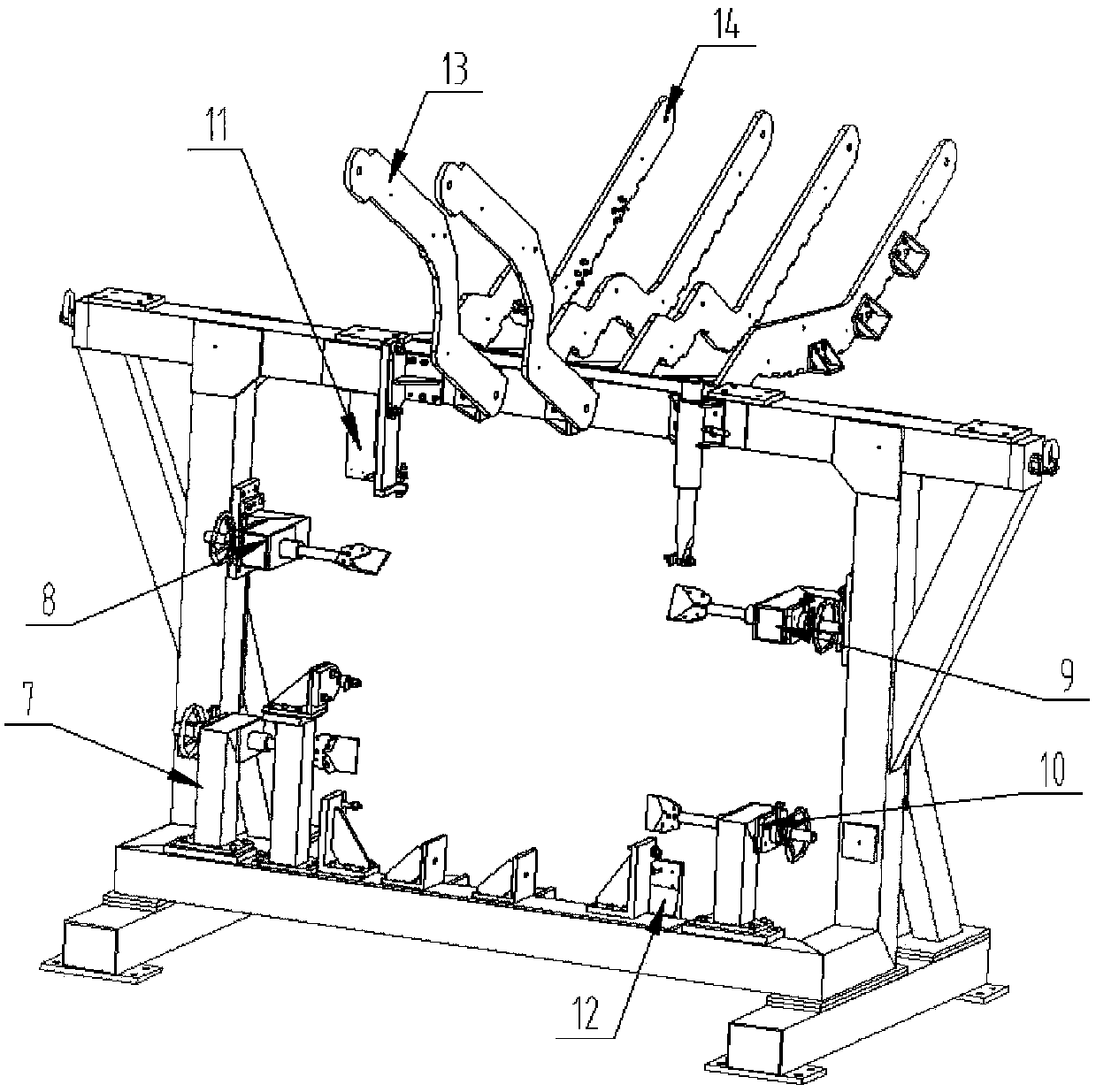

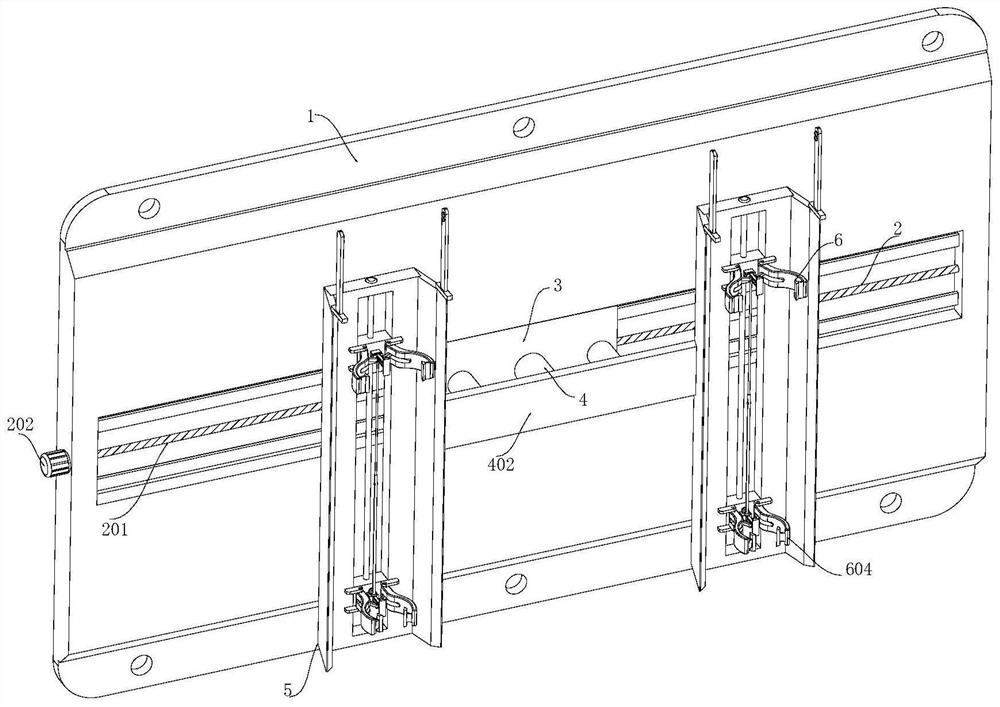

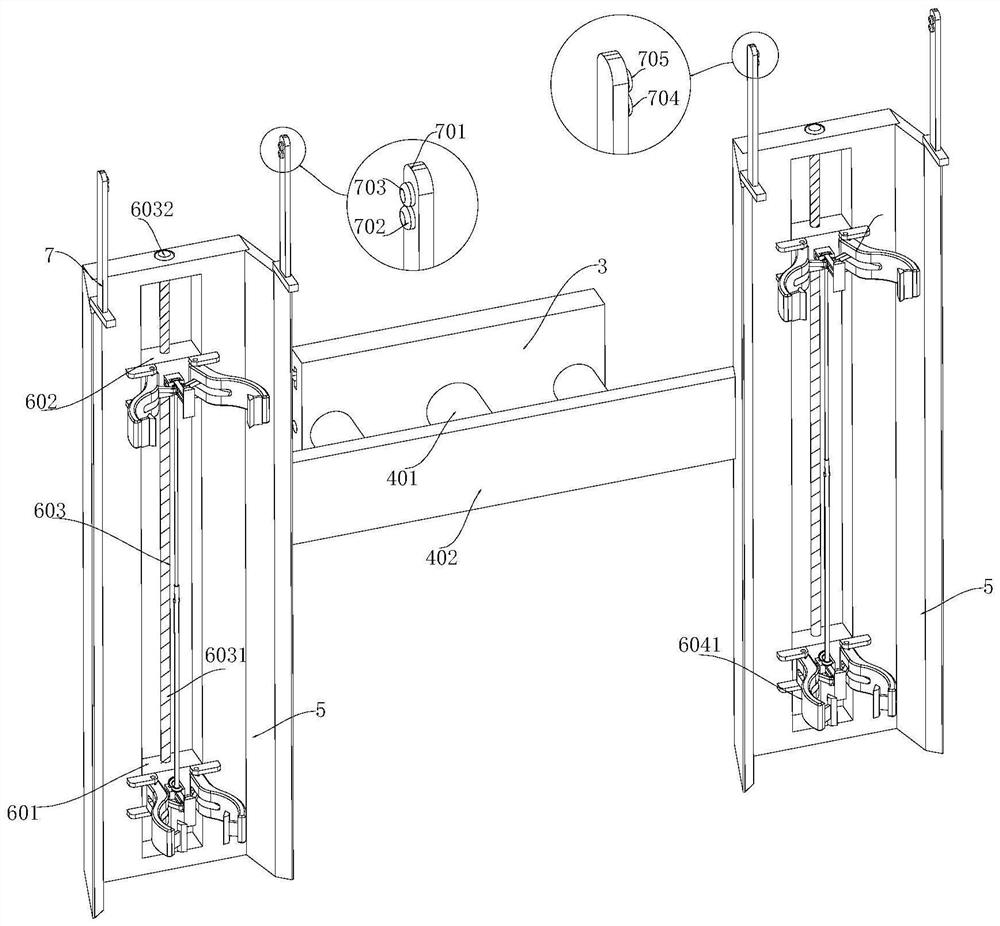

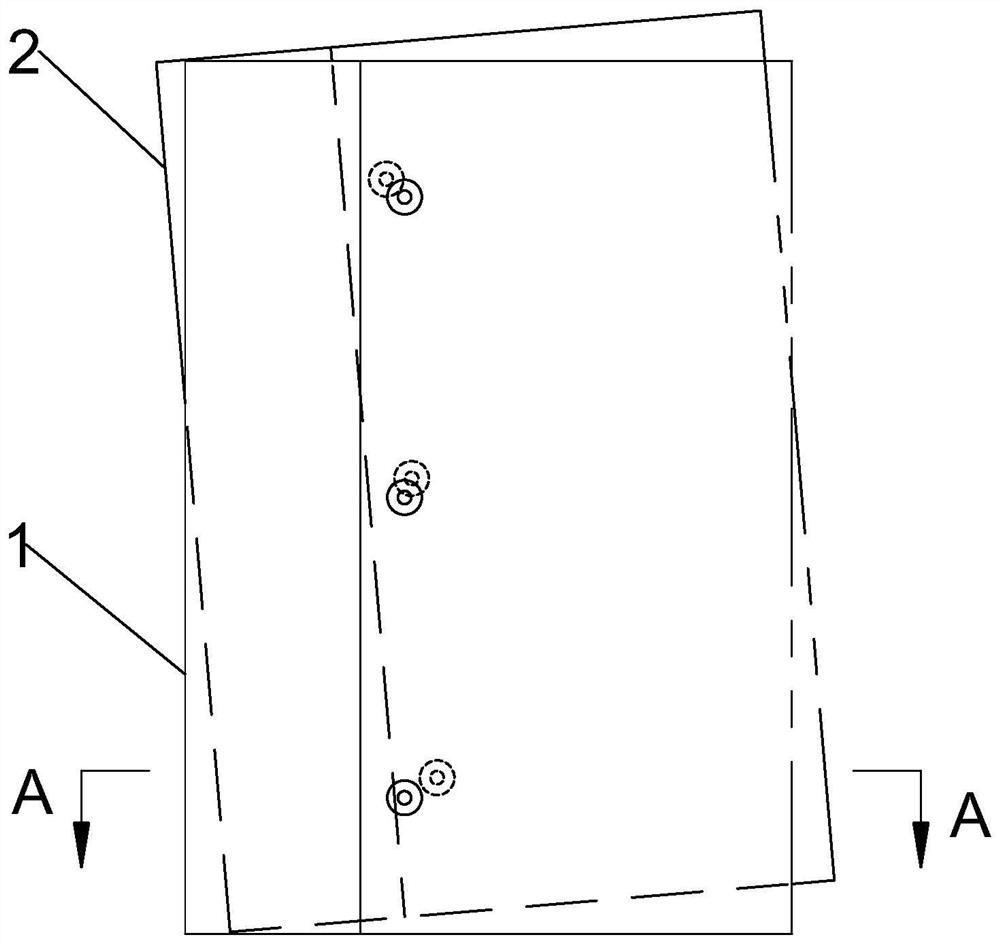

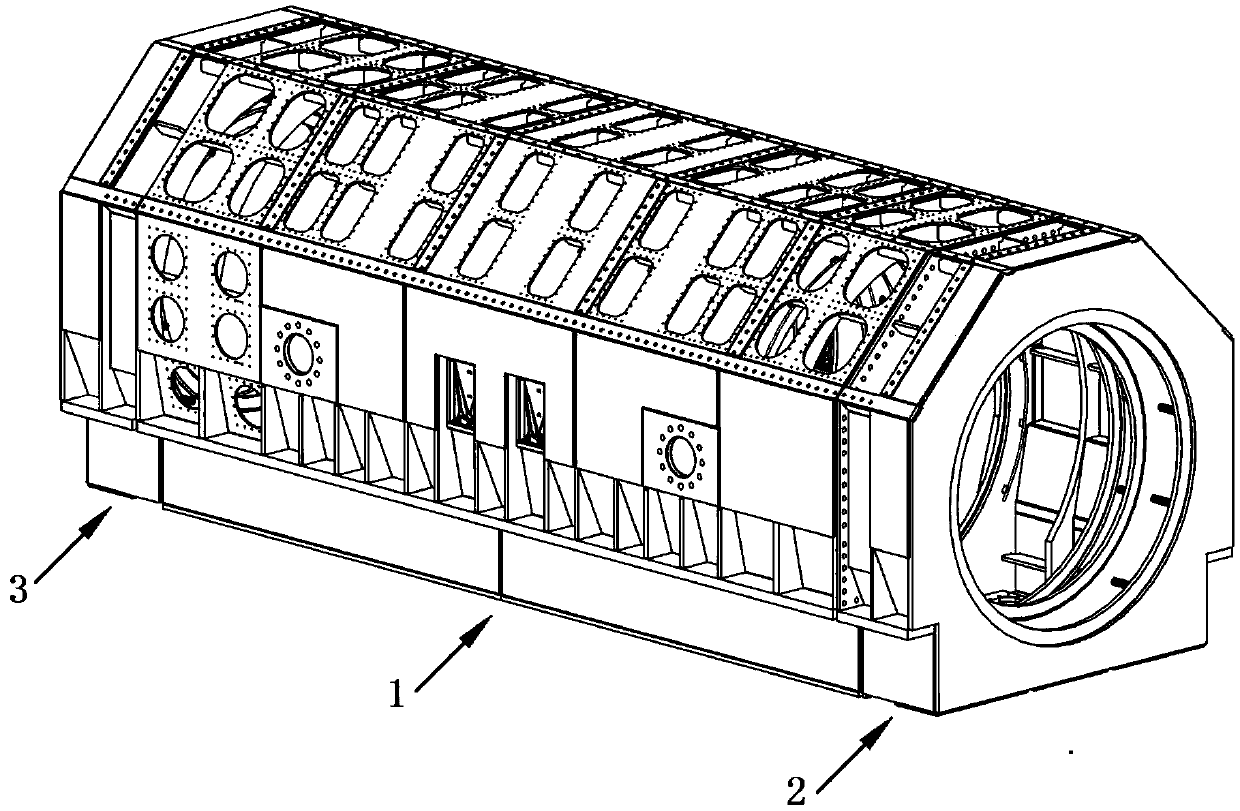

Assembling clamp for carbon fiber composite aircraft cabin door

PendingCN108382605AHigh precision assemblyAvoid relative position deviationWork holdersAircraft assemblyAirplaneCarbon fiber composite

The invention provides an assembling clamp for a carbon fiber composite aircraft cabin door. The assemble assembling clamp has the function of assembling five metal joints on the composite cabin doorthrough a riveting bonding mode, and the outline precision of the tooth-shaped edge relative to five joint holes, and the relative position degree and the coaxial degree among the joint holes are ensured. Through the assembling clamp, high precision assembling of the carbon fiber composite cabin door and the metal joints can be achieved, relative position deviation caused by the unreasonable positioning and clamping mode or the rebound and super poor precision of a manufactured piece caused by large state deviation between the state of the manufactured workpiece and the state after the manufactured workpiece is removed from a frame during assembling is avoided, meanwhile, the mode of a frame-type structure combined positioning assembly has the enough openness, the operation space can be ensured, the structure can be simplified as far as possible, and the manufacturing cost is reduced.

Owner:HENGSHEN

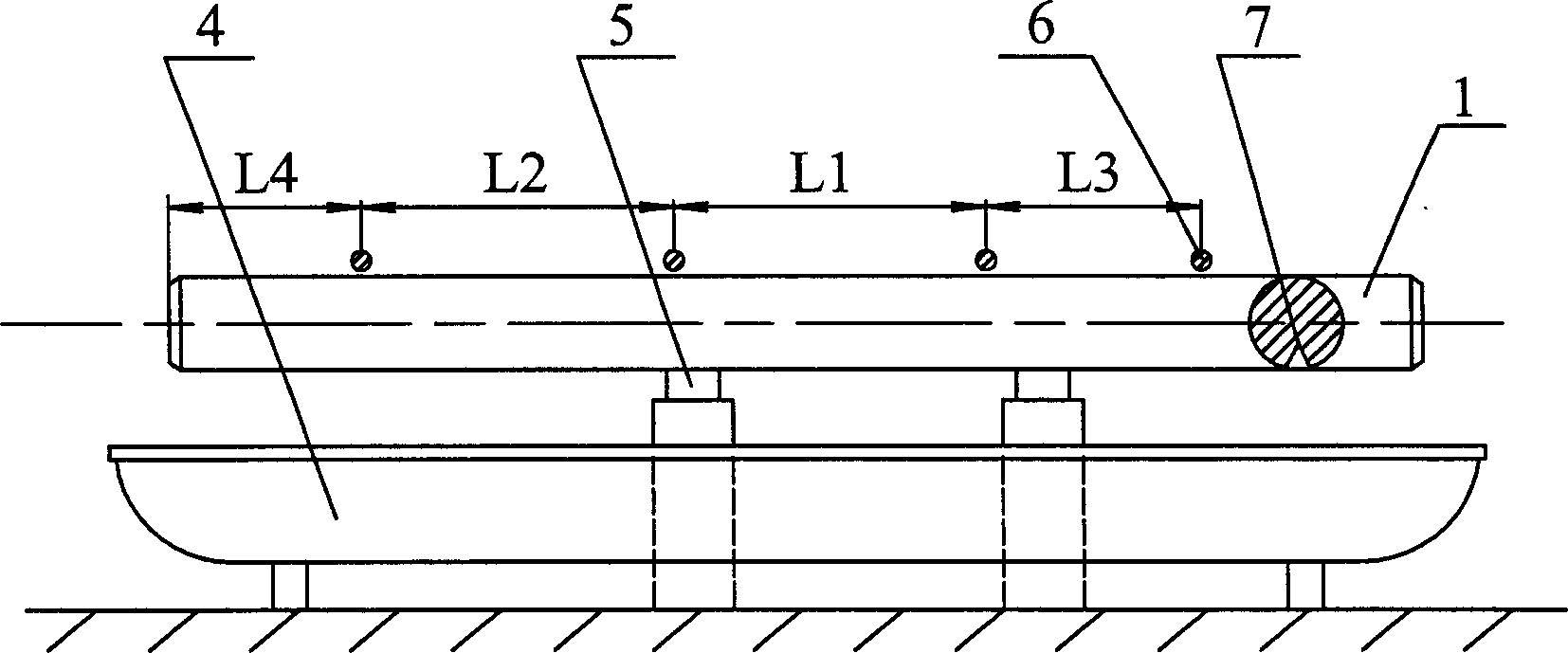

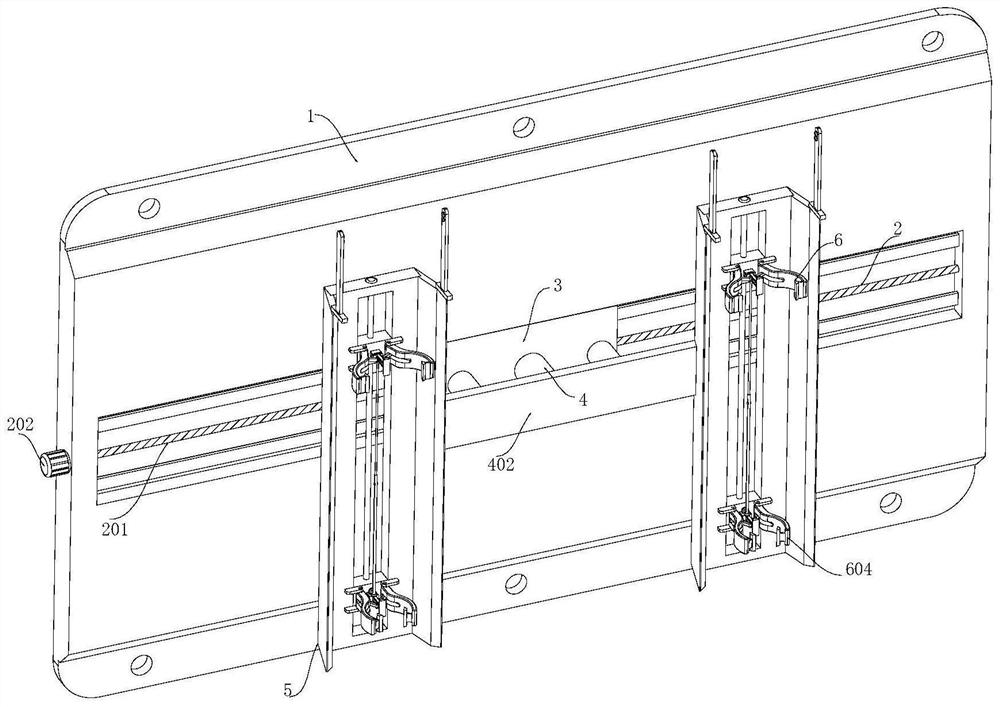

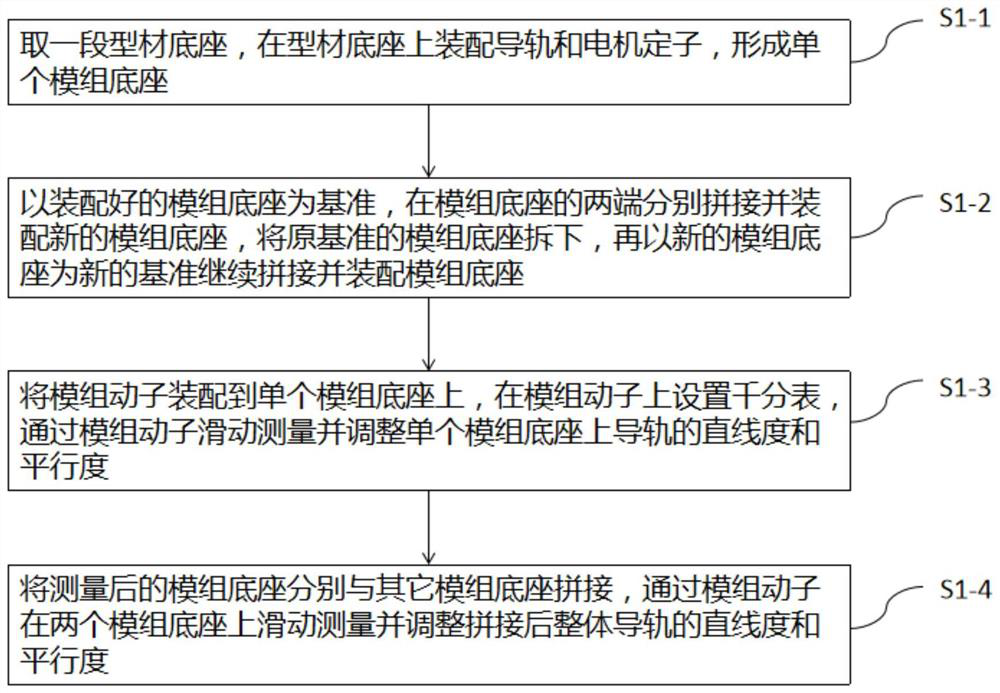

Guide rail assembling technological method for large composite box

ActiveCN105806192AAchieve high-precision assemblyEliminate error accumulationMechanical measuring arrangementsHeight differenceMechanical engineering

The invention provides a guide rail assembling technological method for a large composite box, and relates to the technical field of guide rail assembling technologies for large composite boxes.The dimension of an inner cavity of the composite box is 8000 mm*1000 mm*1200 mm, a front guide rail and a rear guide rail are installed on the inner surface of the I quadrant of the box through guide rail bases, and the front guide rail and the rear guide rail are connected to the inner wall of the box through the guide rail bases.The guide rail assembling reference of the composite box is determined to adjust related dimensions of bottom corner parts, errors generated by tipping and defection of the composite box are eliminated, and the assembling precision of the guide rails relative to the installation reference is ensured; the inner wall of the box serves as the assembling reference to ensure the symmetry degree of the guide rails relative to the center of the box; a digital level gage is used for conveniently, rapidly and accurately measuring the parallelism and height difference dimensions of the guide rails, and a symmetry degree detection tool is used for achieving quick and effective guide rail precision detection.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

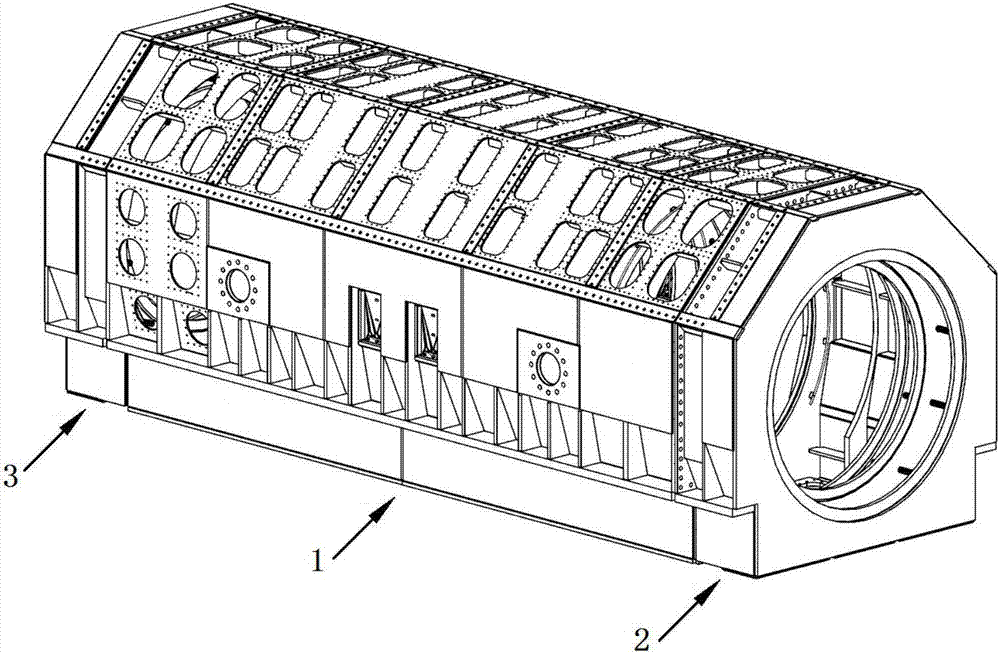

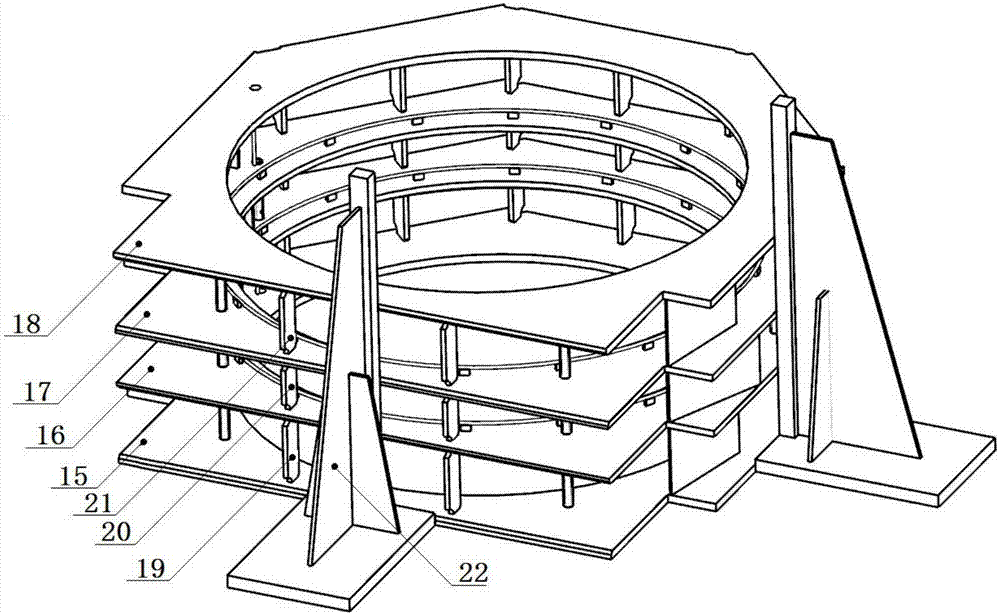

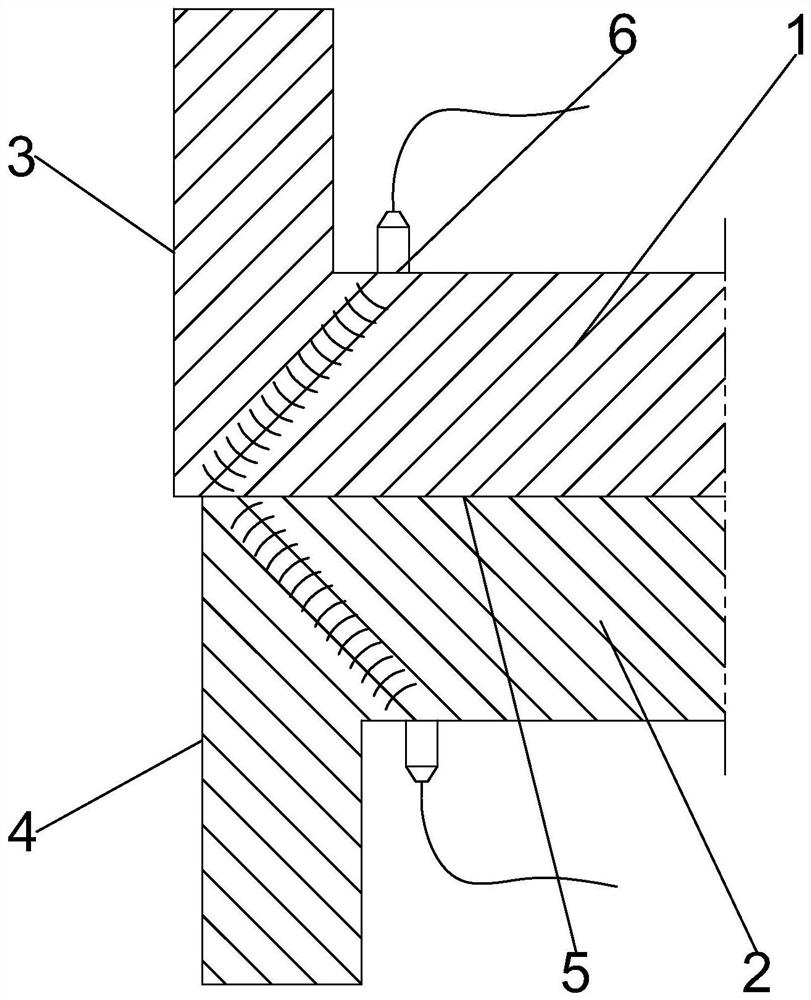

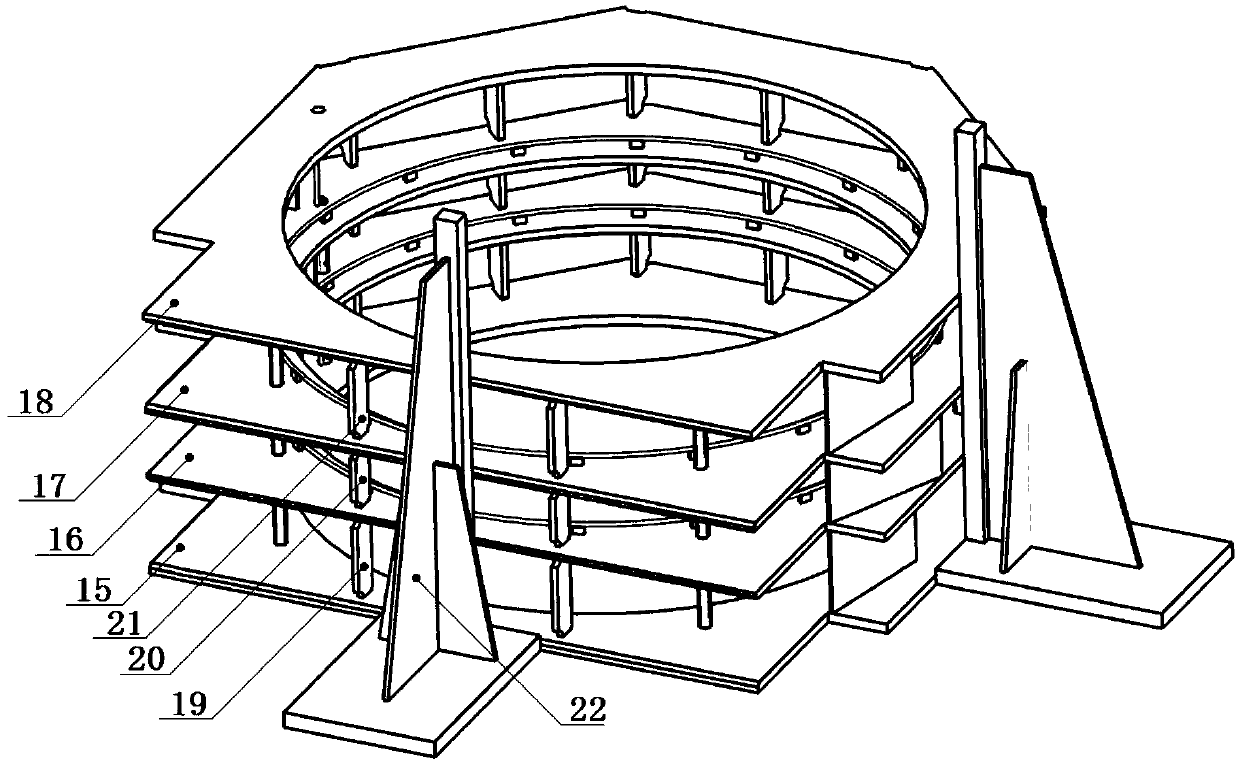

Air-cooled turbogenerator stator frame assembling and welding method

ActiveCN107222074AShorten the construction periodImprove welding efficiencyManufacturing dynamo-electric machinesWelding apparatusBaseboardTurbine

The invention provides an air-cooled turbogenerator stator frame assembling and welding method. The air-cooled turbogenerator stator frame is composed of three parts of a middle-section frame (1), a turbine-end frame (2) and an excitation-end frame (3), the three parts carry out assembling and welding respectively, and then, final assembling is carried out. According to the structural characteristics of the stator frame in a new structure, a composite assembly method with vertical assembly and horizontal assembly combined is adopted, the assembling and welding quality of the stator frame is improved, and the operation and the construction are convenient; section assembling and welding are carried out for the stator frame, each section operates independently, parallel assembling and welding are realized, the construction period is shortened, and the assembling and welding efficiency is improved; and the stator frame baseboard is used as an assembly reference, the concentricity accuracy requirements of the whole frame body are ensured, and high-precision assembly of the stator frame is realized.

Owner:HARBIN ELECTRIC MASCH CO LTD

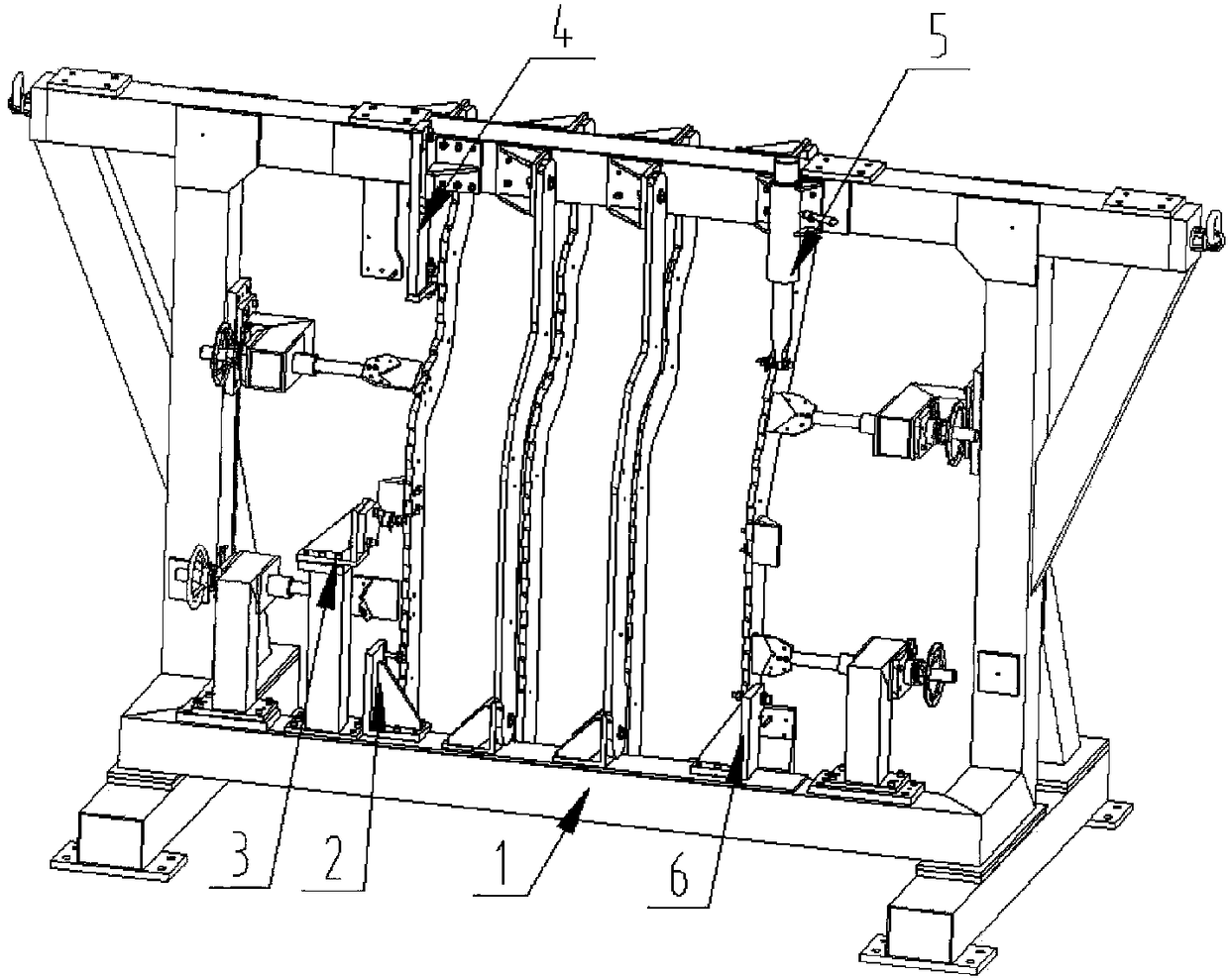

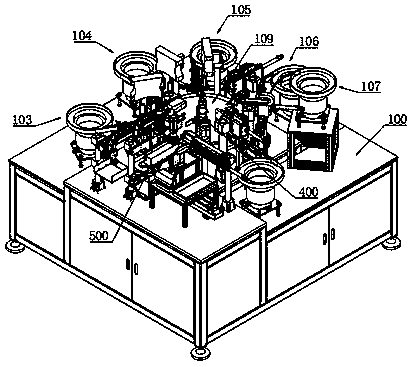

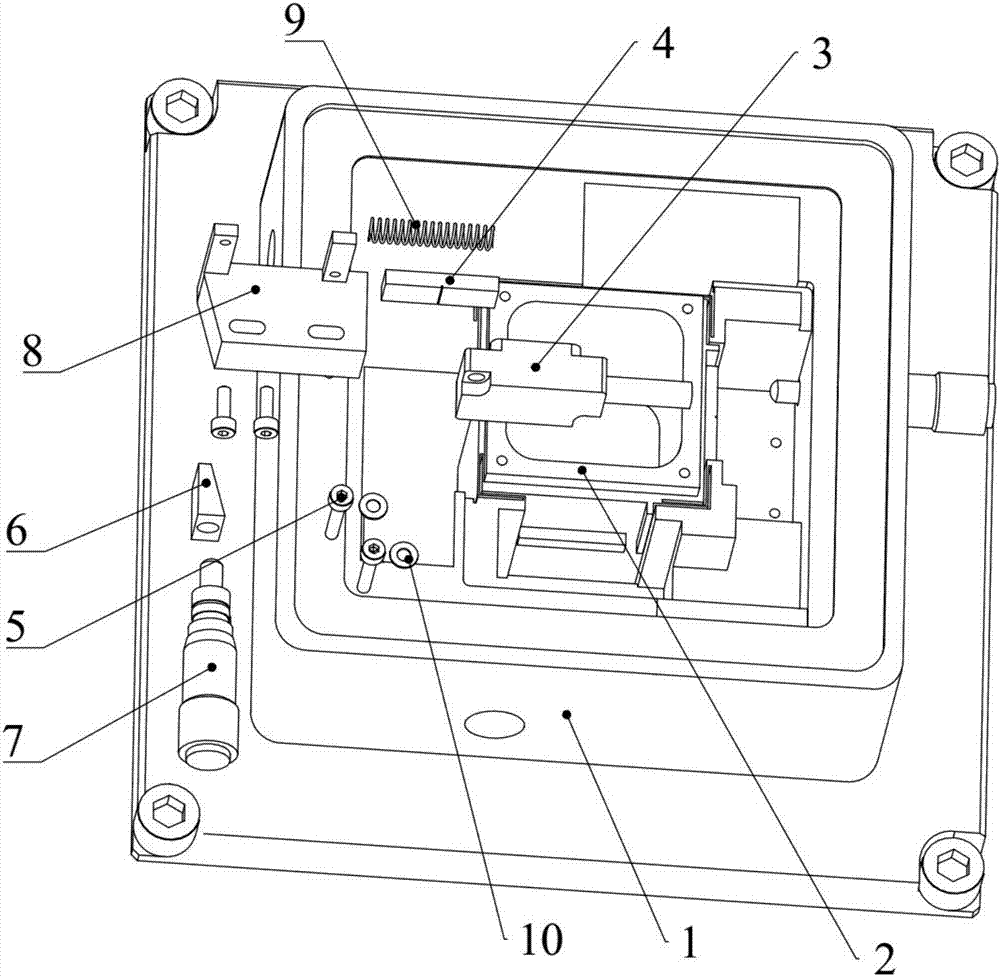

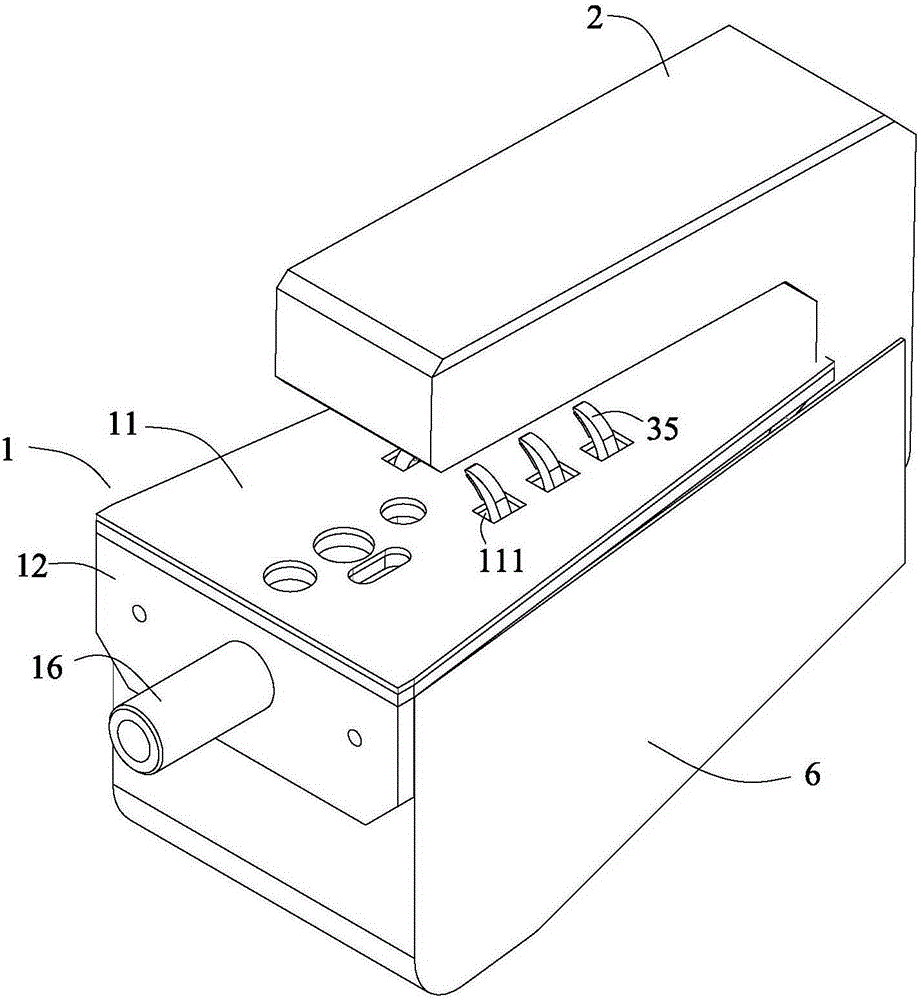

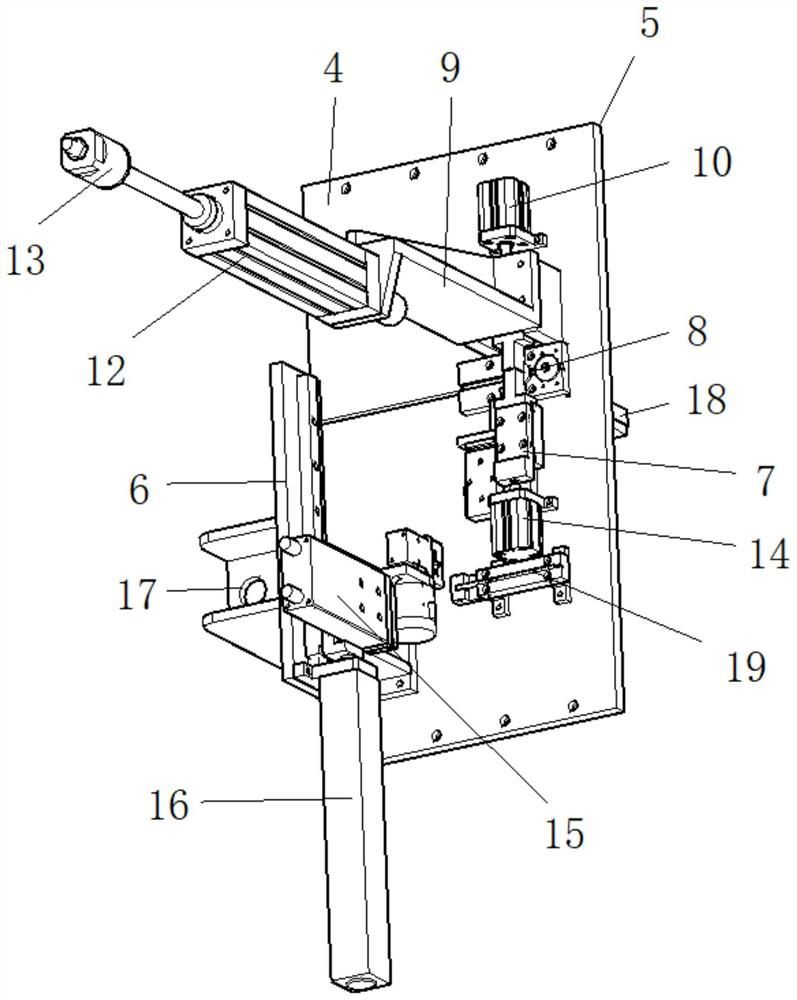

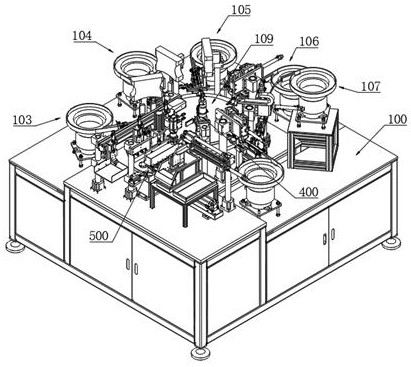

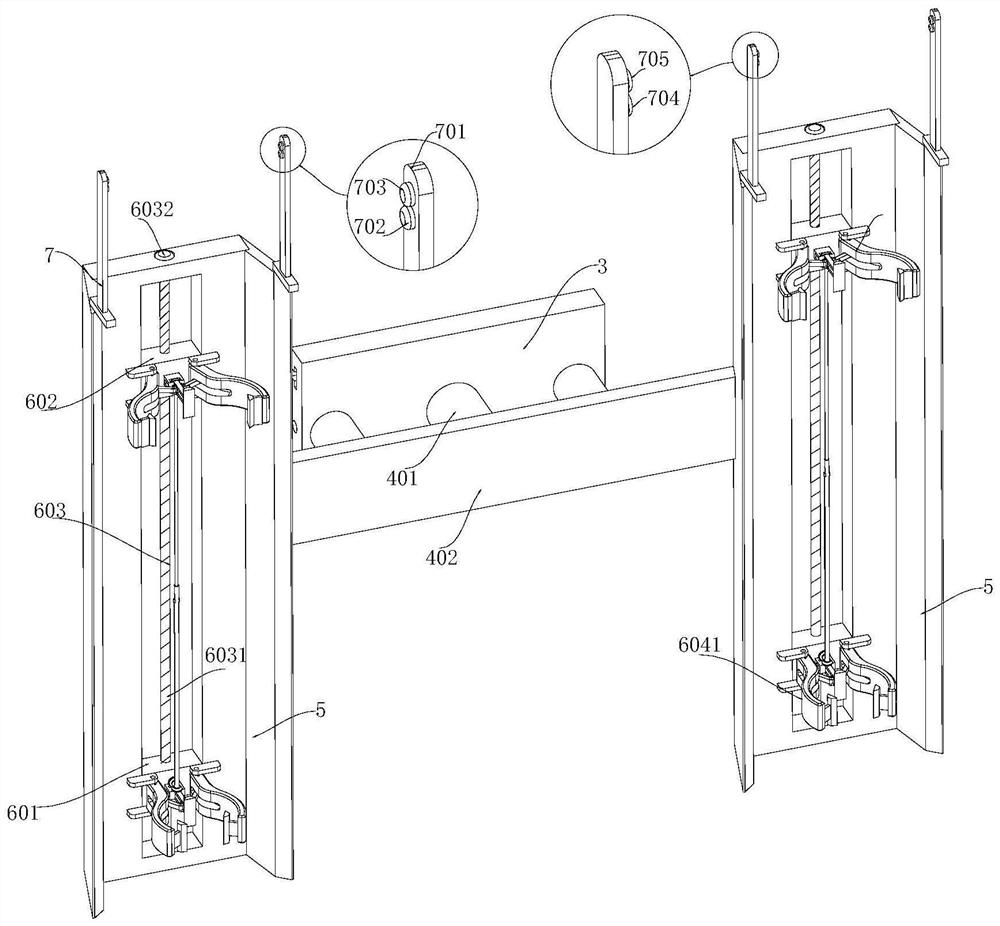

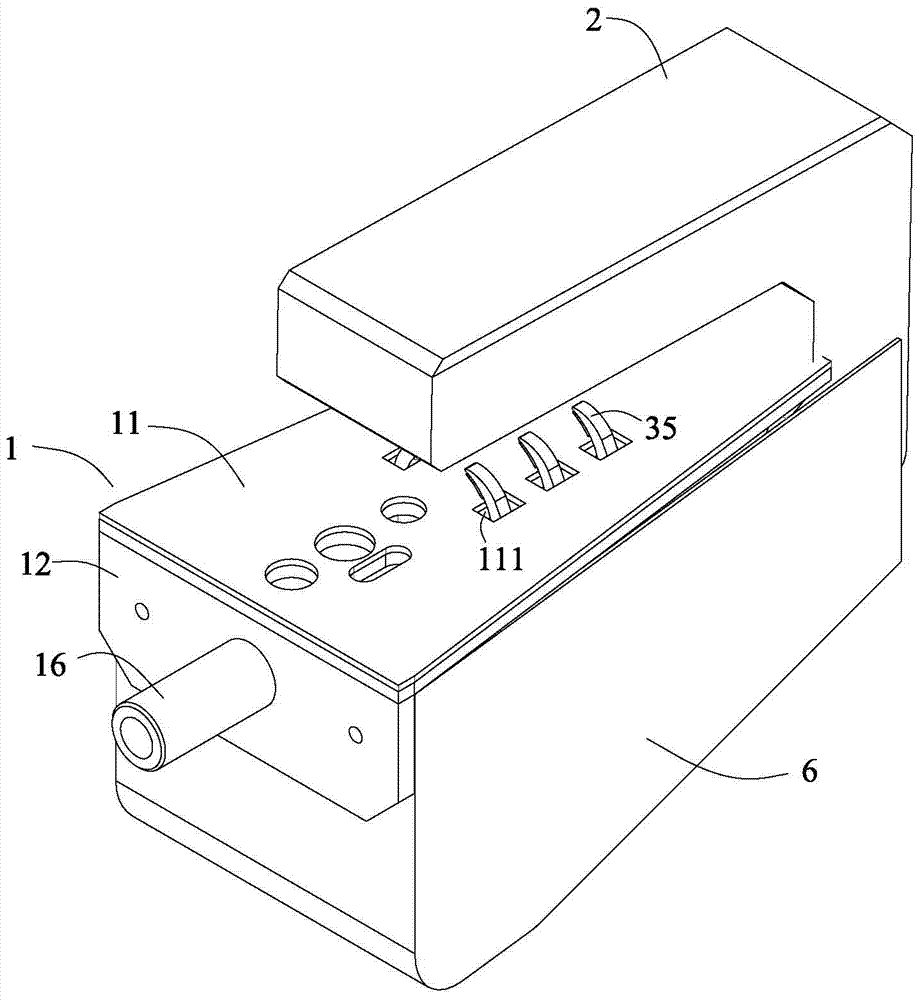

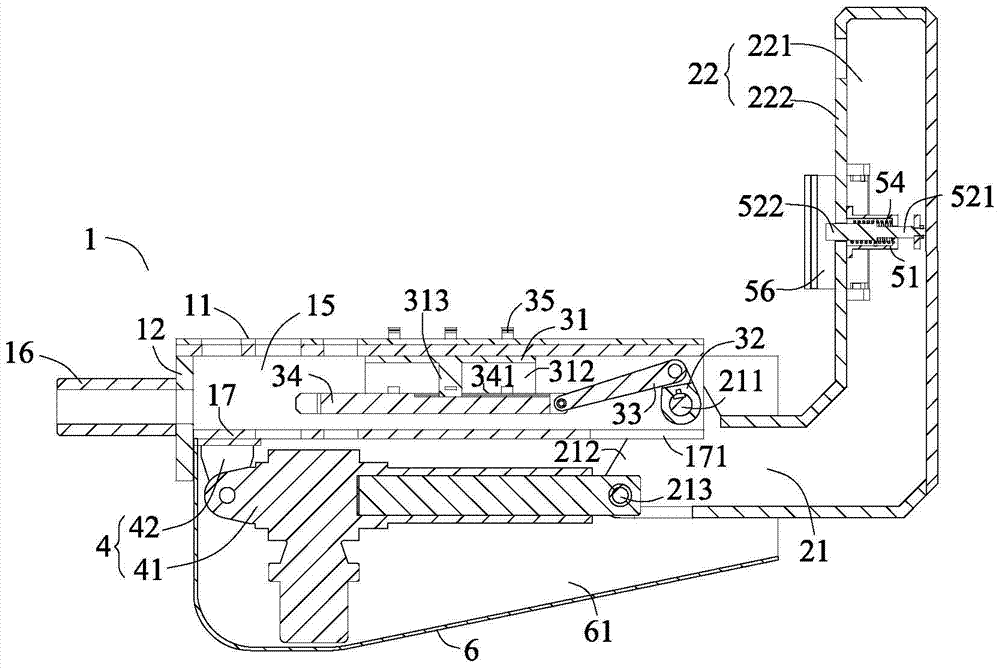

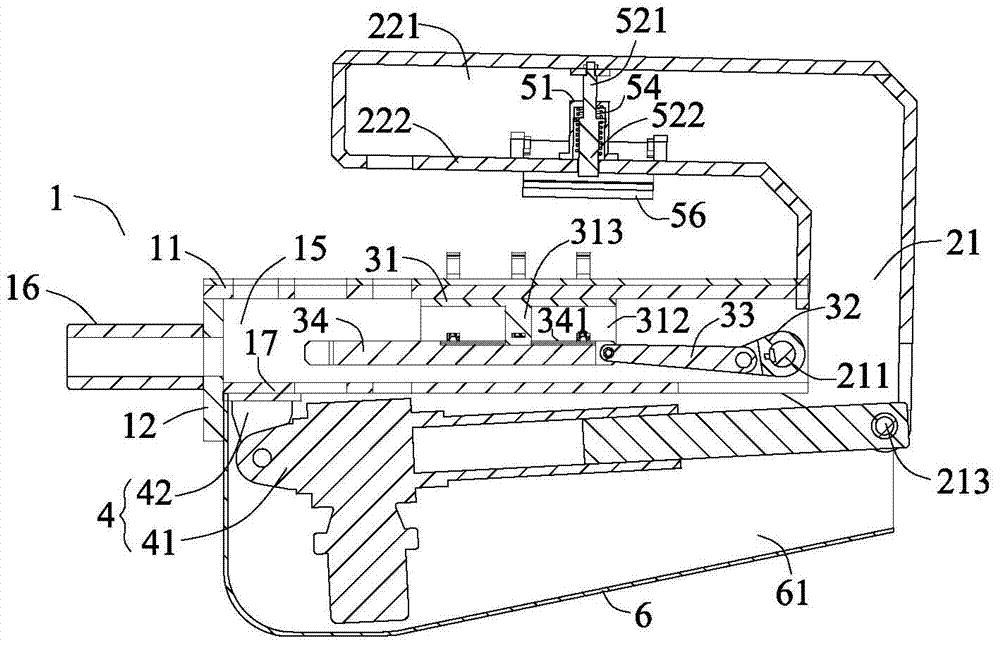

Automatic assembling machine for power compartment

ActiveCN108839727AAchieve high-precision assemblyReduce labor intensityVehiclesClosed loopDegrees of freedom

The invention relates to automatic assembling equipment for a power compartment and in particular to an automatic assembling machine for the power compartment. The automatic assembling machine for thepower compartment comprises a measuring machine, a detection device and degree-of-freedom platforms, wherein the measuring machine is provided with the detection device; two sides of the measuring machine are symmetrically provided with the degree-of-freedom platforms; the measuring machine is composed of an adjustment base, a support frame and a lifting cross beam. In the automatic assembling machine for the power compartment, a combined form of the freedom degree platforms and the detection device is adopted, a displacement sensor of the detection device located on a female end measurementarm and a six-degree-of-freedom platform drive system at the same position form a closed-loop control and the displacement sensor of the detection device located on a male end measurement arm and thesix-degree-of-freedom platform drive system at the same position form another closed-loop control, so that an engine and a transmission case are assembled in high precision; the adopted measuring machine, detection device and six-degree-of-freedom platforms are automatically operated, thereby greatly reducing the labor intensity of workers and guaranteeing the stability and safety in an assembly process.

Owner:YANSHAN UNIV

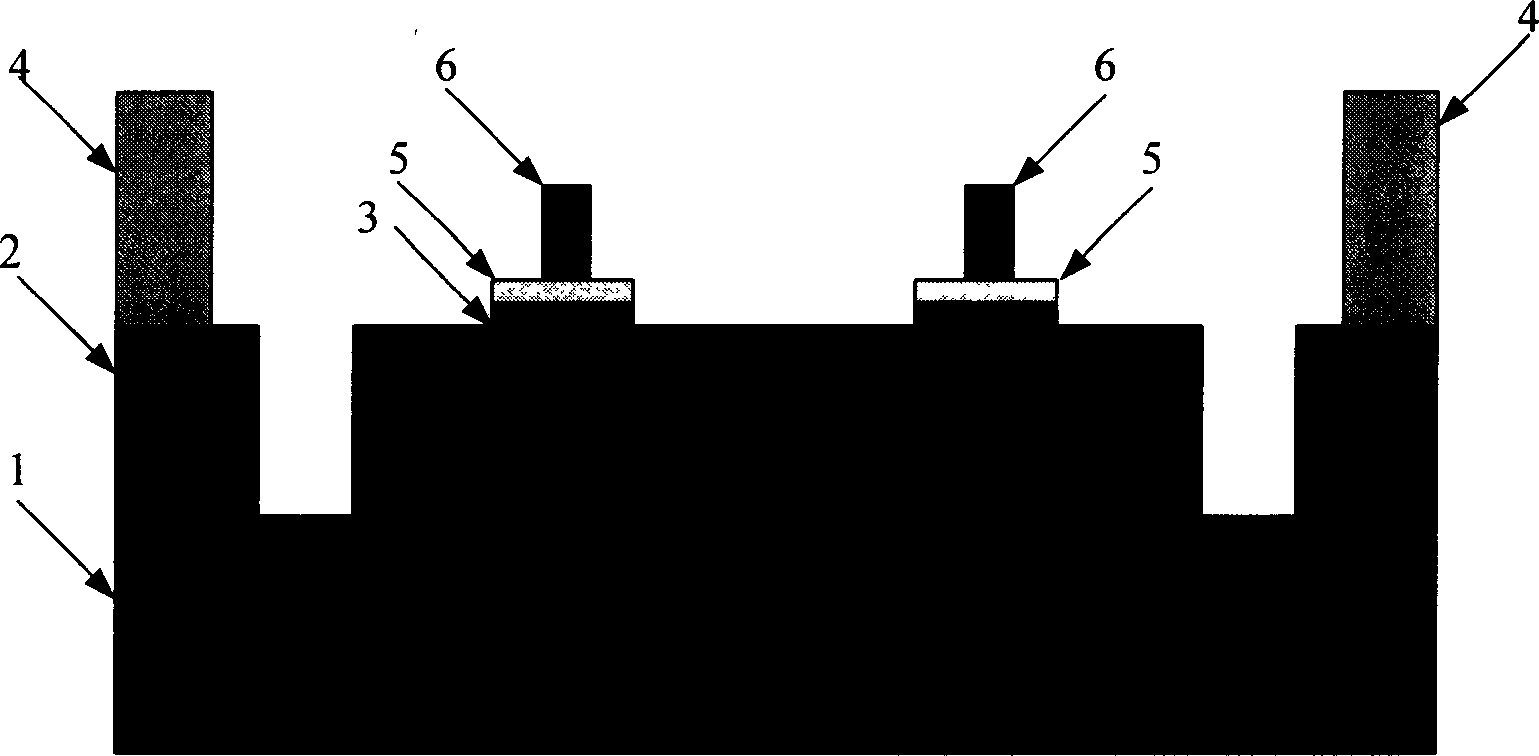

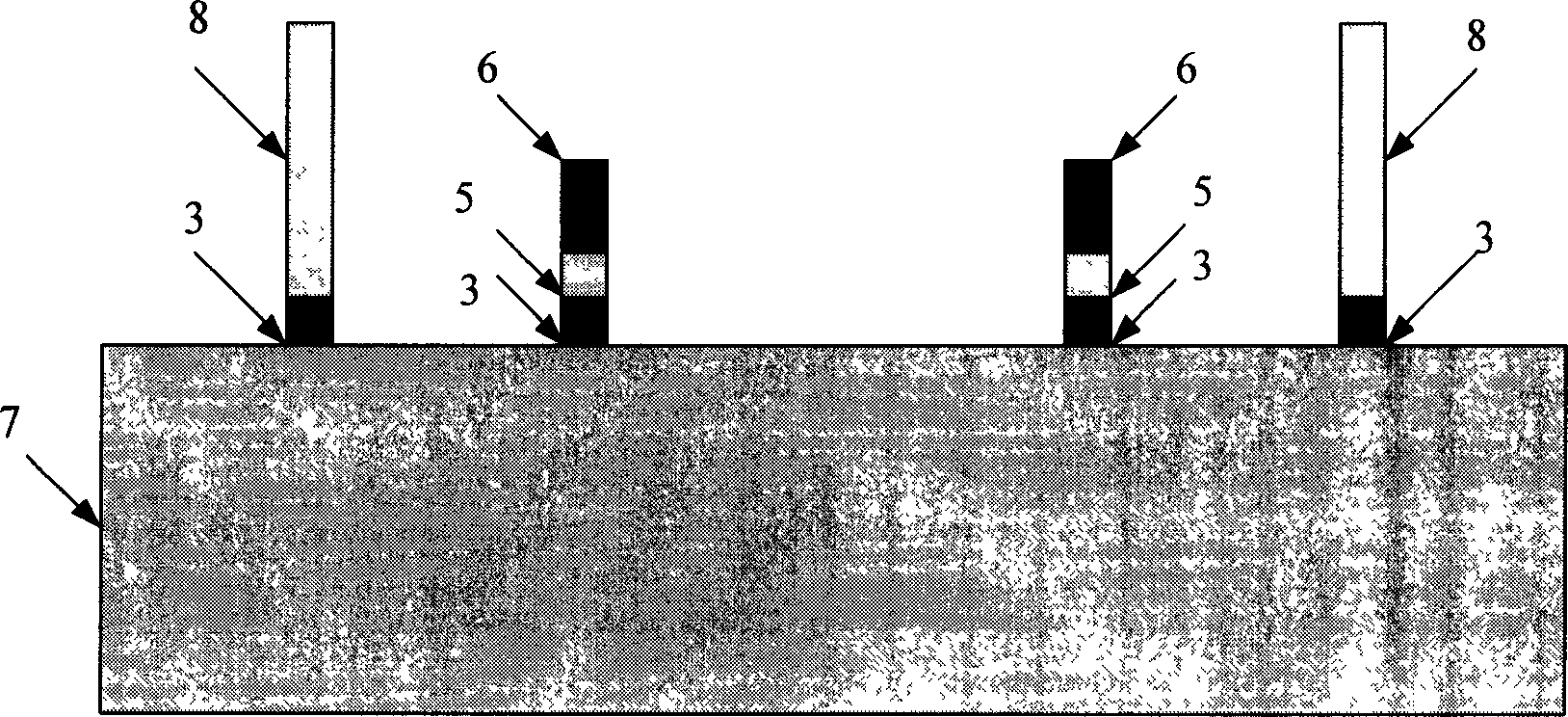

High-precision three-dimensional micro-assembling method and assembly parts based on MEMS

InactiveCN1803577AHigh precision assemblyAchieve high-precision assemblyPrecision positioning equipmentSoldering apparatusEngineeringSurface tension

The invention discloses a high-precision three-dimensional micro-assembly method and combined component based on MEMS, which comprises the following steps: setting a micro-clamp to match the loading chip; setting the alignment part and alignment accessory and welding button on the corresponding substrate and loading chip separately; injecting liquid in the micro-clamp; putting the chip in the micro-clamp back-off; locating the chip on the substrate through alignment part and alignment accessory and welding fusion reflux.

Owner:PEKING UNIV

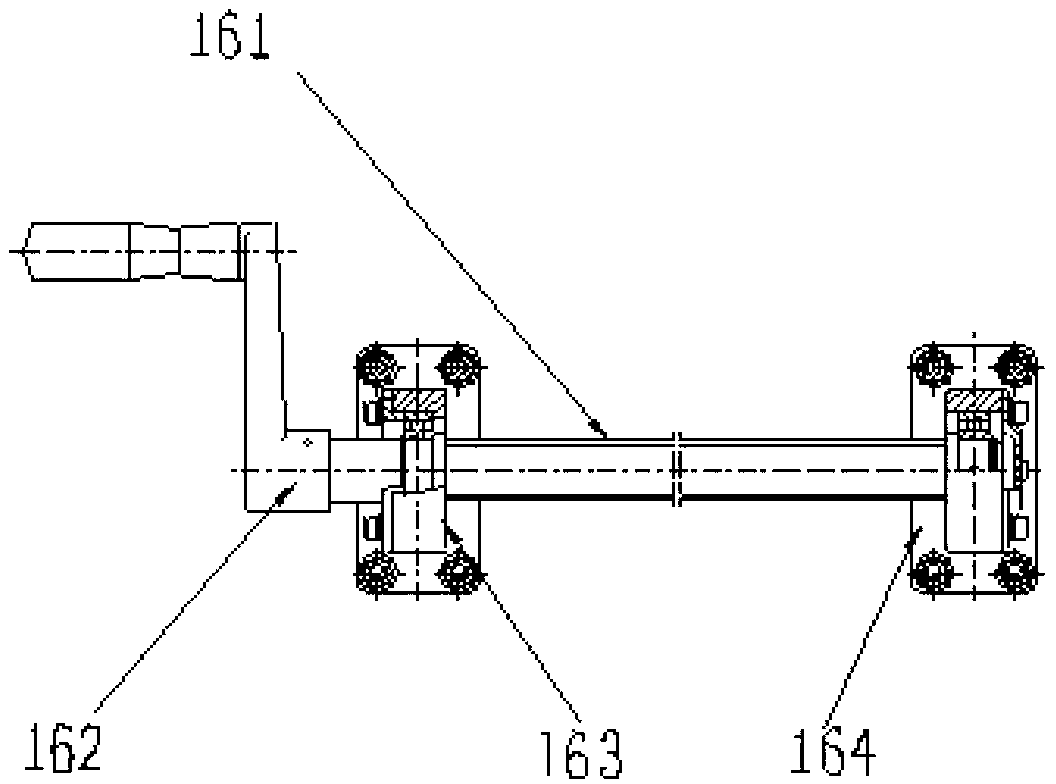

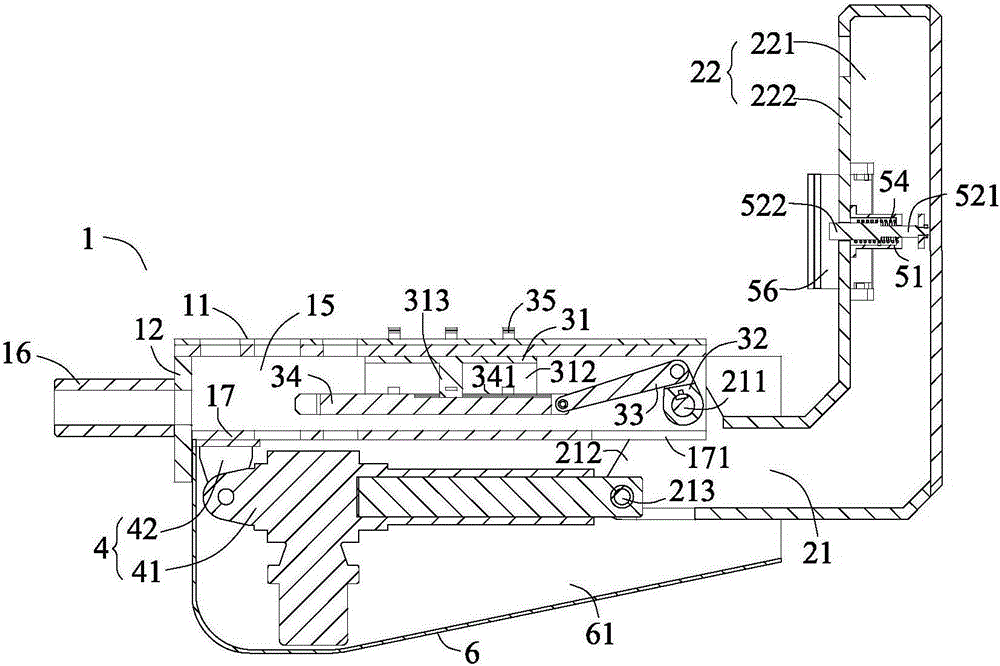

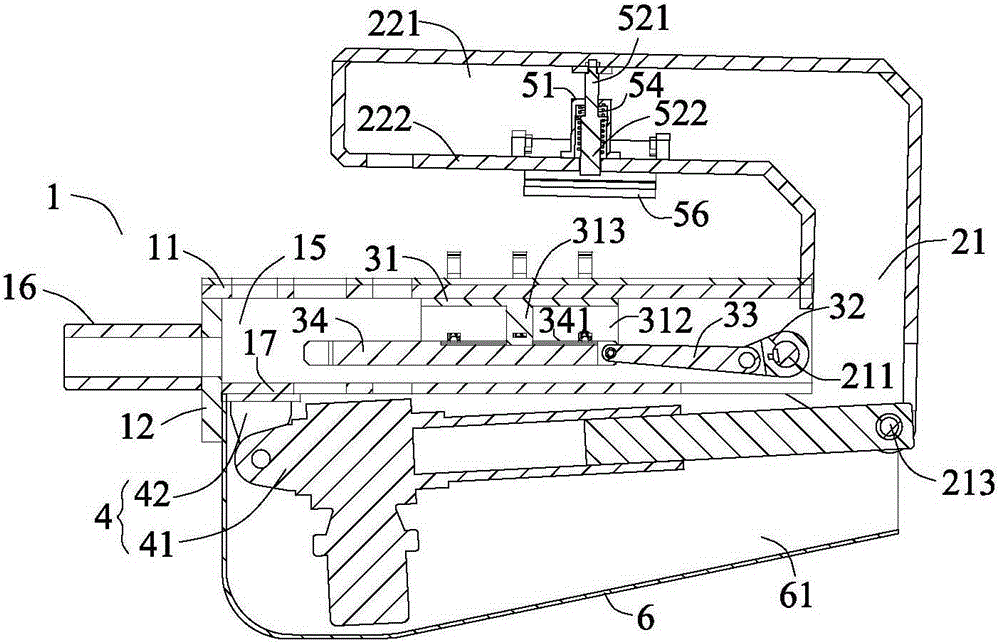

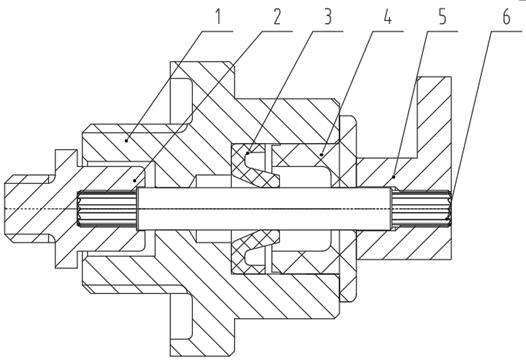

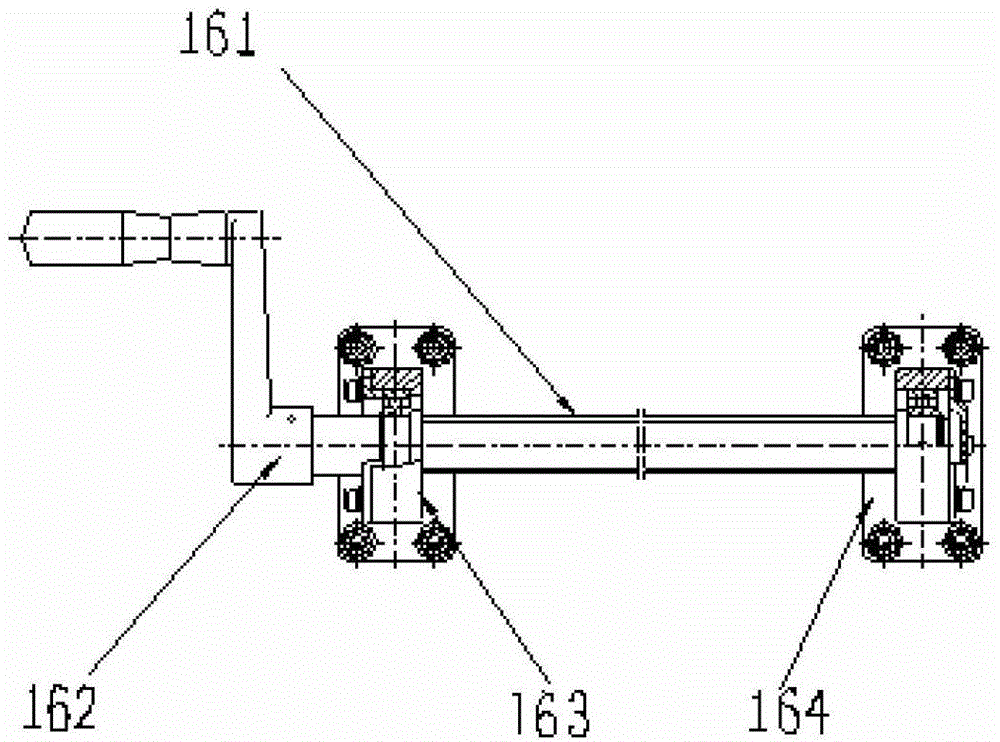

Transmission shaft assembling mechanism of direct transmission set assembling device

ActiveCN110802400AFast deliveryGuaranteed continuityAssembly machinesMetal working apparatusDrive shaftStructural engineering

The invention discloses a transmission shaft assembling mechanism of a direct transmission set assembling device. The transmission shaft assembling mechanism is characterized by comprising a vibrationdisc for transmission shafts, a first conveying pipe, a material receiving and positioning base for the transmission shafts and a transplanting mechanism for the transmission shafts, wherein the material receiving and positioning base for the transmission shafts comprises a base and a material receiving assembly, and the material receiving assembly comprises a material receiving protruding block,a material receiving sliding block, a transverse moving air cylinder for the material receiving sliding block and a jacking air cylinder for the transmission shafts; a jacking interval is formed between the lower surface of the material receiving sliding block and the lower side face of an inserting hole, and the height between the upper surface of the material receiving sliding block and the lower side face of the inserting hole is consistent with the length of the transmission shafts; and the upper end of the first conveying pipe communicates with a discharging port of the vibration disc for the transmission shafts, and the lower end of the first conveying pipe communicates with a blanking hole in the material receiving protruding block. The transmission shaft assembling mechanism of the direct transmission set assembling device has the beneficial effects that one-by-one sequential orderly output and precise positioning of the transmission shafts can be effectively guaranteed, and high-precision assembling of the transmission shafts can be better achieved.

Owner:深圳市睿荔科技有限公司

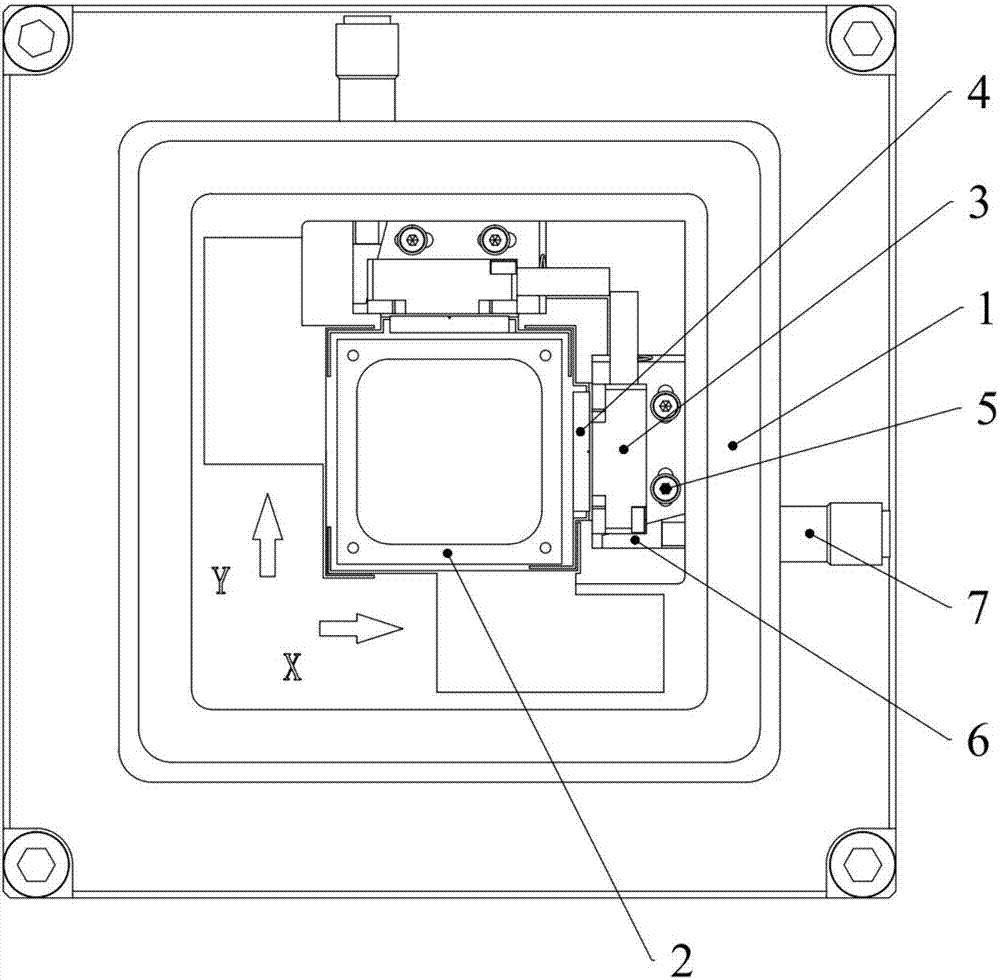

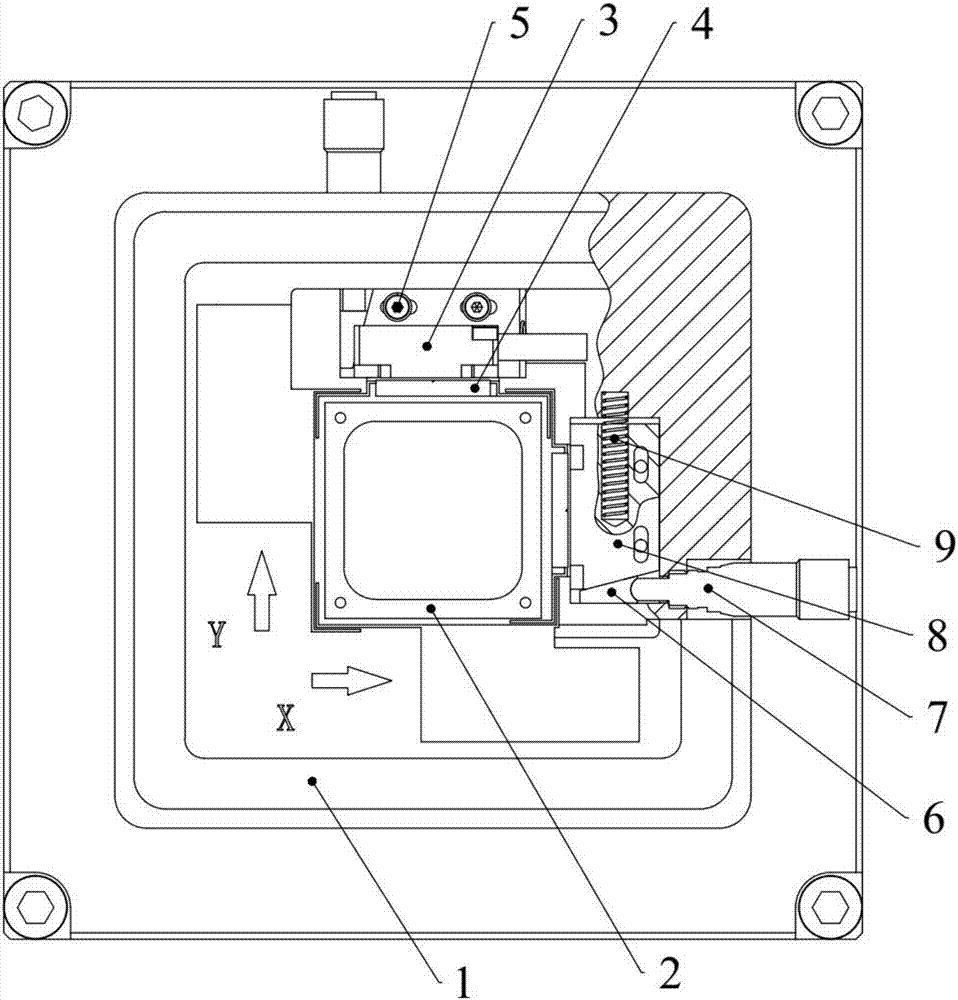

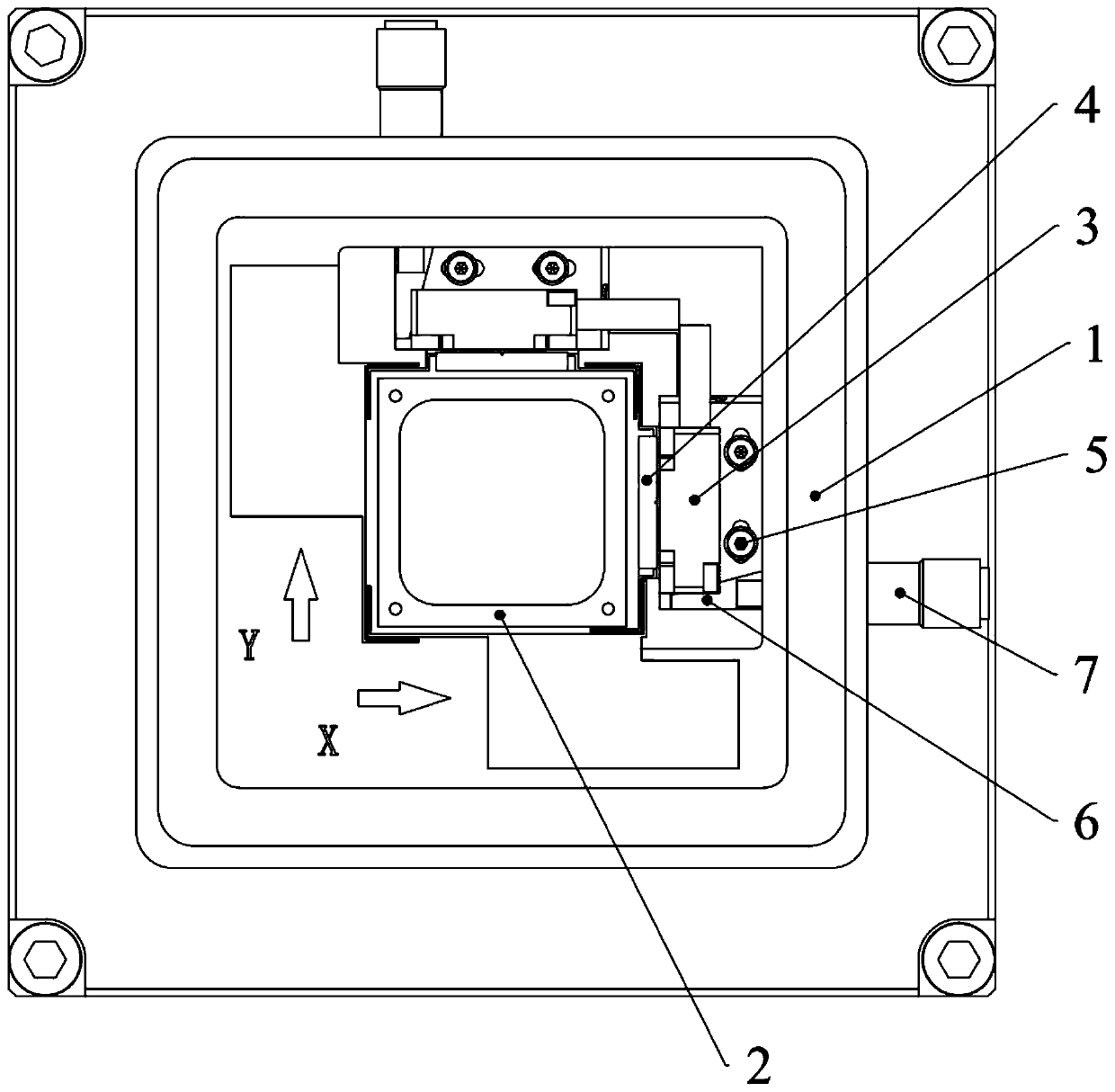

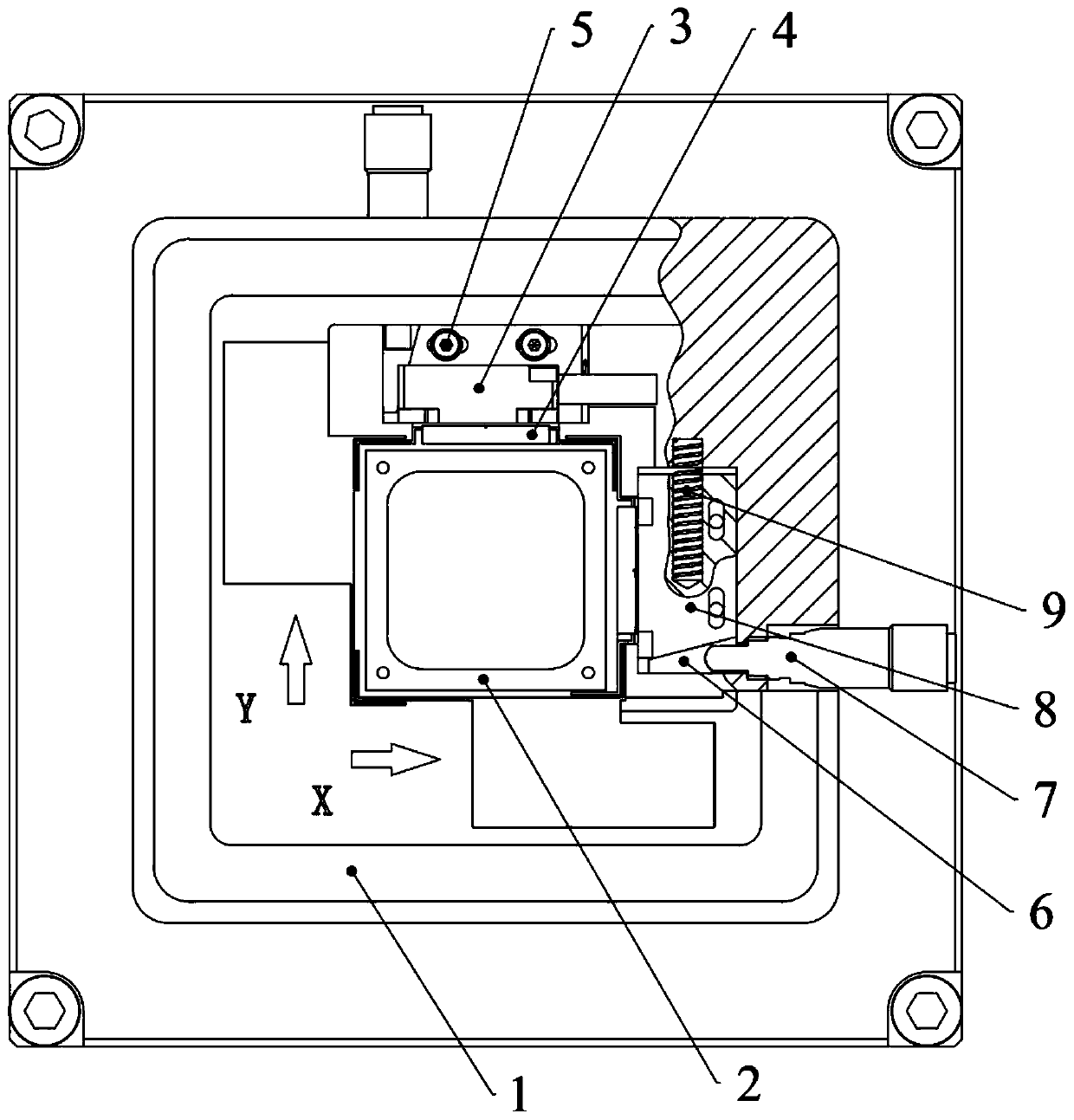

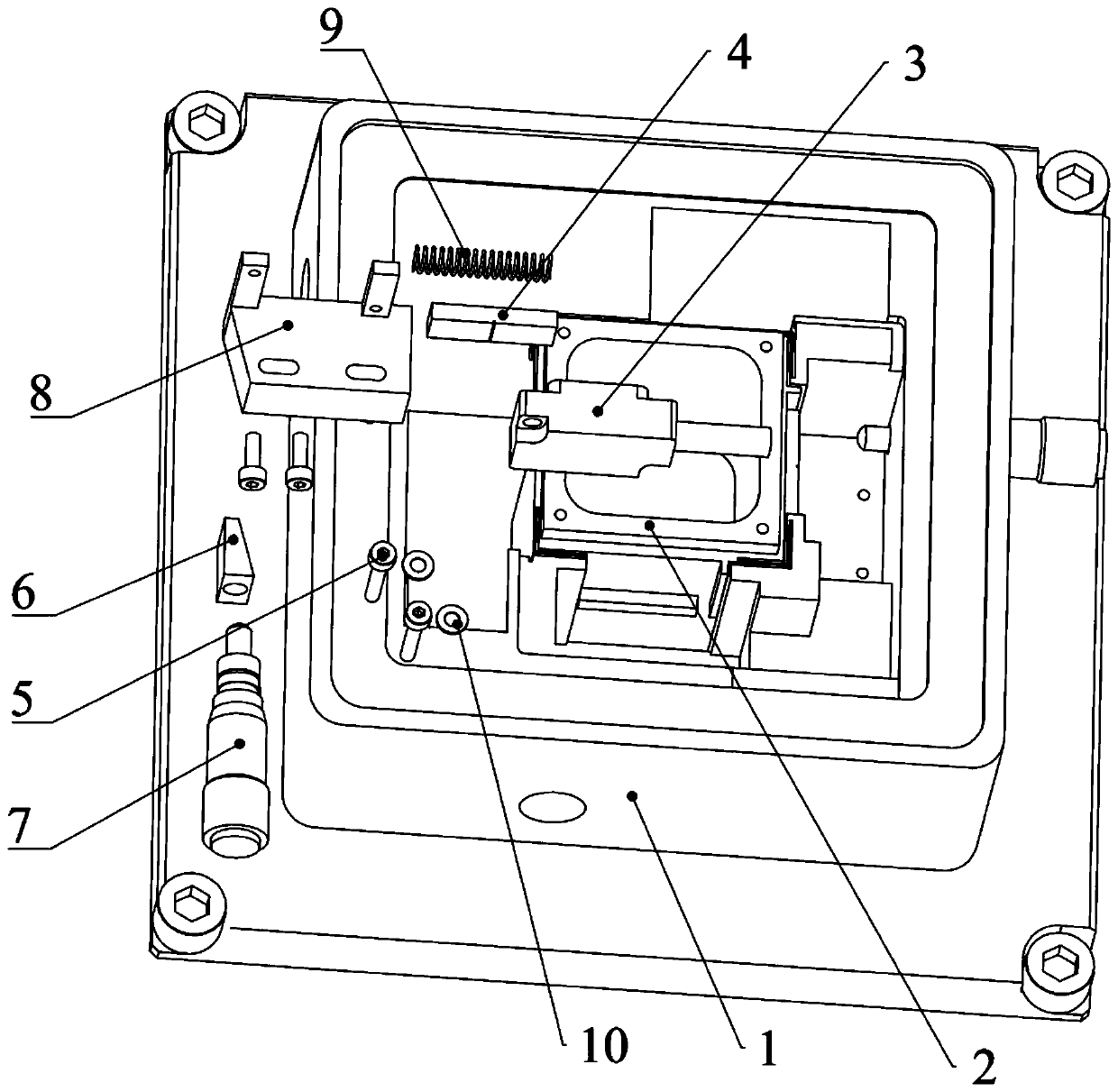

Zero-point fine tuning device for grating type micro-nano positioning platform

ActiveCN107504895AIncrease freedomAchieving Positioning AccuracyUsing optical meansMicro nanoGrating

The invention discloses a zero-point fine tuning device for a grating type micro-nano positioning platform. The zero-point fine tuning device comprises a platform body and a motion part. On the basis of cooperation between a pedestal and a return spring, the freedom degree of a grating read-in head in an actual application process is increased. With introduction of a differential head and a wedge block, fine tuning of the motion of the pedestal is realized by inclined-surface transmission; and the fine tuning displacement can be read directly by number reading by the differential head, so that the operability of the user is enhanced. Meanwhile, positioning bar structures are arranged at the sides of cooperation between the motion part and a grating ruler, so that the high positioning precision of the grating rule is realized. During actual assembling, high-precision assembling of the grating ruler is realized without any special clamping fixture, so that the requirement of the zero point position precision of the grating ruler is met.

Owner:SHANDONG UNIV

Clamping head

ActiveCN105171371AAvoid offsetAchieve high-precision assemblyMetal working apparatusEngineeringBall joint

The invention provides a clamping head which comprises a base, a turning support, a finger fixing mechanism, a driving mechanism and a press block fixing mechanism, wherein the base is mounted on an external driving mechanism, and comprises a top plate, an end plate, a left side plate, a right side plate and a first cavity in the interior; the turning support comprises a connecting part and a turning part; the finger fixing mechanism comprises a fixing platform, a crank, a connecting rod, a sliding platform, a plurality of mechanical fingers and a plurality of ball joint connecting rods; the driving mechanism comprises a push-rod motor; the press block fixing mechanism comprises a shaft sleeve, a core shaft, two bending arms, a spring, two short connecting rods and two press blocks; each press block comprises a press block connecting part and a contact part. According to the clamping head provided by the invention, the mechanical fingers of different shapes can effectively fix workpieces of different shapes, so that the adaptability is relative high; the mechanical fingers and the contact parts of the press block jointly act on the upper and lower parts of a workpiece, so that the workpiece can be automatically clamped and prevented from migrating in moving and assembly processes, and high-precision assembly of the workpiece can be realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Stator bearing platform and rotor and stator assembling machine comprising same

PendingCN112104173AAchieve high-precision assemblyMeet assembly requirementsManufacturing stator/rotor bodiesClassical mechanicsMachine

The invention discloses a stator bearing platform and a rotor and stator assembling machine comprising the same. The stator bearing platform comprises at least three seat bodies, the seat bodies are vertically superposed, the lowest seat body is configured as a base, the uppermost seat body is configured as a stator bearing seat, and the adjacent seat bodies are connected with each other. The connection modes formed between the seat bodies comprise two or more than two of connection capable of swinging back and forth and left and right relatively, connection capable of rotating relatively around a vertical shaft, connection capable of moving left and right relatively and connection capable of moving up and down relatively. An adjusting device is arranged between the seat bodies and is usedfor adjusting the relative position between the adjacent seat bodies. By the adoption of the stator bearing platform, the stator borne by the stator bearing platform can be adjusted in multiple directions according to the actual assembly condition, and therefore the assembly precision is improved.

Owner:ZHONGSHAN RWD PRECISION TECH CO LTD

Connecting tool for hose assembly and connecting system of connecting tool

ActiveCN113369843AAchieve high-precision assemblySave human effortWork holdersMetal working apparatusAssembly machineEngineering

The invention discloses a connecting tool for a hose assembly and a connecting system of the connecting tool. The connecting tool comprises a supporting plate installed at the feeding end of an assembly machine body through fastening bolts, a moving groove is formed in the supporting plate, a driving piece is arranged at the moving groove, the connecting end of the driving piece is connected with a supporting block, the supporting block moves relative to the position of the moving groove through the driving piece, the supporting block is connected with a telescopic connecting mechanism, the connecting end of the telescopic connecting mechanism is connected with two alignment shells, and the two alignment shells are each provided with an adjusting alignment mechanism. According to the connecting tool for the hose assembly and the connecting system of the connecting tool, a worker only needs to quickly place the two ends of a hose at the alignment shell, through the adjusting alignment mechanism, the height of the two ends of the hose can be moved and adjusted, after the two ends of the hose are kept at the same horizontal height, the hose is correspondingly moved to a feeding port of the assembly machine body through the supporting block, and high-precision assembly of the hose assembly is achieved; and meanwhile, manpower is effectively saved.

Owner:宁波迅腾流体动力有限公司

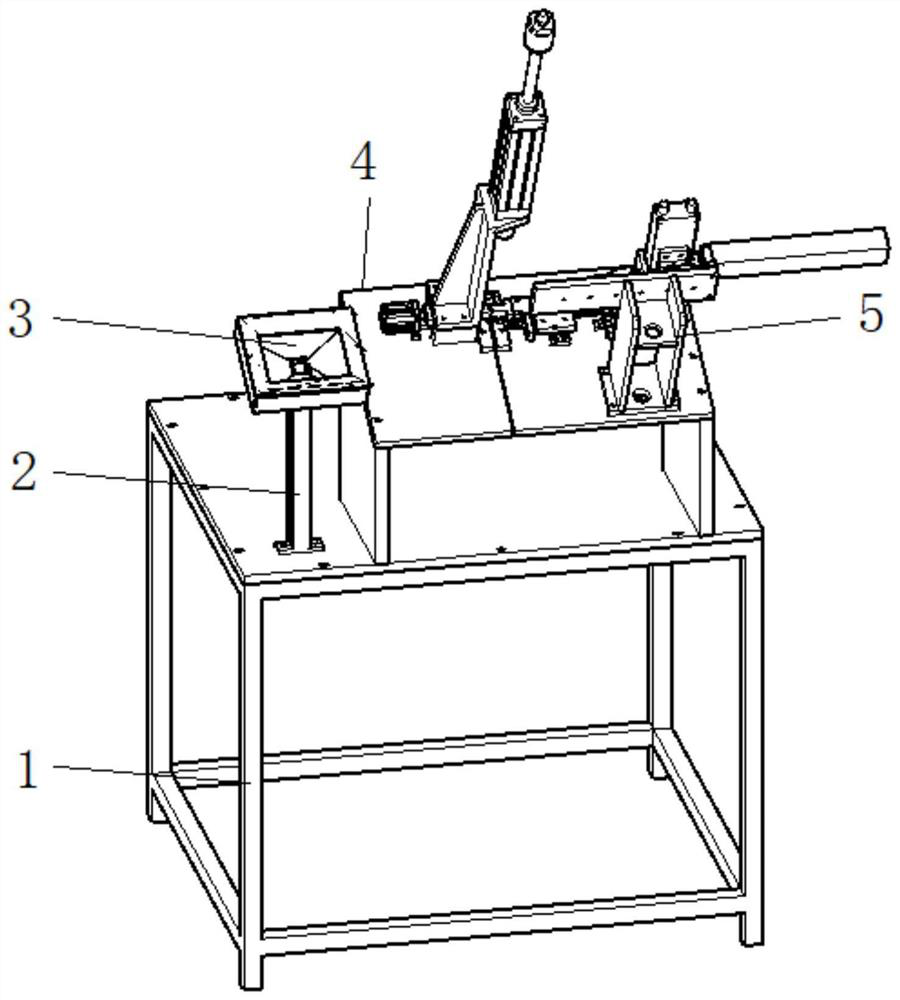

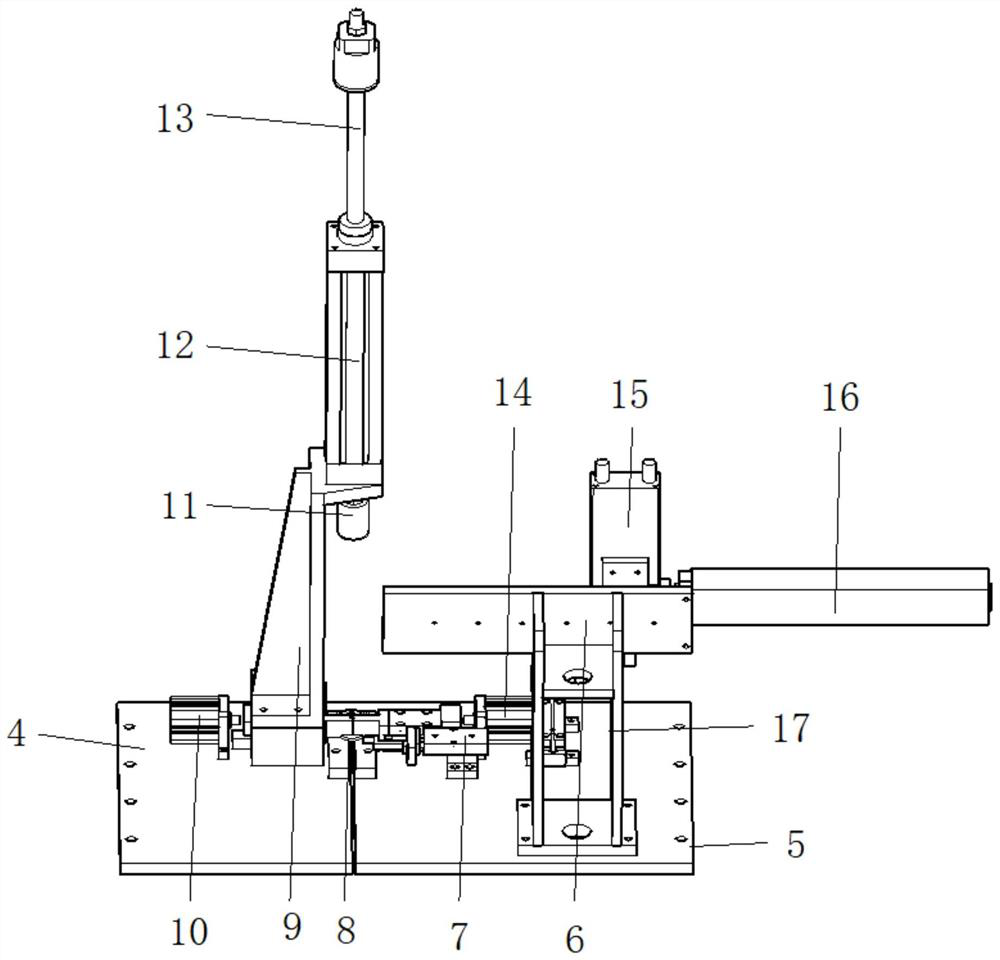

Assembling device for filing shaft and toy gear

InactiveCN112496717AQuick assemblyAchieve high-precision assemblyMetal working apparatusGear wheelElectric machinery

The invention discloses an assembling device for a filing shaft and a toy gear. The assembling device comprises a machine table and an assembling mechanism. The assembling mechanism is installed on the upper end face of the machine table, the assembling mechanism comprises a workbench, a second support and a first support are welded to the workbench, a second air cylinder is fixed to the second support through bolts, a stroke rod is installed on the second air cylinder, a stamping part is assembled at the front end of the stroke rod, a stroke protection plate is welded to the first support, afirst air cylinder is fixed to the outer end of the stroke protection plate through bolts, and a stamping mechanism is installed on a stroke rod of the first air cylinder. A second motor is fixed to the outer side, close to the second support, of the upper surface of the workbench through bolts, a first motor is fixed to the inner side, close to the first support, of the upper surface of the workbench through bolts, and a limiting plate and a base plate are installed on the upper surface of the workbench and located between the second support and the first support. According to the device, thepurpose of quickly assembling the filing shaft and the toy gear can be achieved.

Owner:王睿

Assembling process method of guide rail for large composite box body

ActiveCN105806192BAchieve high-precision assemblyEliminate error accumulationMechanical measuring arrangementsEngineeringHeight difference

The invention provides a guide rail assembling technological method for a large composite box, and relates to the technical field of guide rail assembling technologies for large composite boxes.The dimension of an inner cavity of the composite box is 8000 mm*1000 mm*1200 mm, a front guide rail and a rear guide rail are installed on the inner surface of the I quadrant of the box through guide rail bases, and the front guide rail and the rear guide rail are connected to the inner wall of the box through the guide rail bases.The guide rail assembling reference of the composite box is determined to adjust related dimensions of bottom corner parts, errors generated by tipping and defection of the composite box are eliminated, and the assembling precision of the guide rails relative to the installation reference is ensured; the inner wall of the box serves as the assembling reference to ensure the symmetry degree of the guide rails relative to the center of the box; a digital level gage is used for conveniently, rapidly and accurately measuring the parallelism and height difference dimensions of the guide rails, and a symmetry degree detection tool is used for achieving quick and effective guide rail precision detection.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Marine stern axle tube boring technological equipment erecting process

ActiveCN100358674CAchieve high-precision assemblyReduce labor intensityPositioning apparatusMetal-working holdersEngineeringCantilever

The present invention belongs to a ship stern tube boring tool mounting process. Said process includes the following several procedures: defining the position of intermediate support of boring bar in the stern tube to be machined; measuring straightness of boring bar; simulatively measuring flexibility value of cantilevers of two ends of said boring bar; and mounting boring tool. Said invention also provides the concrete steps of the above-mentioned every procedure.

Owner:中国船舶集团渤海造船有限公司

Low-pressure turbine unit intelligent assembly platform

ActiveCN109093379BImprove assembly accuracyAchieve high-precision assemblyAircraft componentsAssembly machinesControl engineeringControl theory

The invention provides an intelligent assembly platform for a low-pressure turbine module, and is used for the assembly of the whole aeroengine. The platform comprises a base, a fan core machine attitude adjustment system and a low-pressure turbine module position adjustment system. The fan core machine attitude adjustment system is fixed on one end of the base, and a fan core machine is installedon the fan core machine attitude adjustment system. The low-pressure turbine module position adjustment system is fixed on the other end of the base, and a low-pressure turbine module is installed onthe low-pressure turbine module position adjustment system; and the low-pressure turbine module is connected with the fan core machine, the low-pressure turbine module has four degrees of freedom ofmovement, and the fan core machine has two degrees of freedom of movement. The intelligent assembly platform for the low-pressure turbine module can improve the assembly precision, reduce the damage to parts, improve the assembly efficiency and reduce the amount of assembly labor.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

Differential gear pad-choosing measuring system and measuring method

ActiveCN101441071BImprove work efficiencyAchieve high-precision assemblyMachine gearing/transmission testingPressure.driveEngineering

The invention relates to a differential pad-selection measurement system and method, which are characterized in that: a differential left shell is arranged on a positioning bench, a lower simulation pad is arranged between the differential left shell and a lower semiaxis gear; planetary gears are sleeved on four ends of a cross axle of member to be measured and are arranged in a shaft hole of thedifferential left shell; a lower puller sleeve arranged in a shaft hole of the lower semiaxis gear is hung on the lower semiaxis gear through an upper edge shoulder of the lower puller sleeve, a measurement tappet is fixedly connected with the lower puller sleeve, a puller spring is arranged between the measurement tappet and the lower puller sleeve, a spring guide sleeve sleeves on the measurement tappet and is supported by the puller spring; an upper top board is arranged on the spring guide sleeve by press mounting manner; and a displacement sensor, a pressure sensor and a proximity switchare respectively arranged in a pressure driving body. The invention can automatically complete accurate measurement of thickness of the differential pad, and can increase product quality and production efficiency.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Zero-point fine-tuning device for grating-type micro-nano positioning platform

ActiveCN107504895BIncrease freedomAchieving Positioning AccuracyUsing optical meansMicro nanoGrating

The invention discloses a zero-point fine tuning device for a grating type micro-nano positioning platform. The zero-point fine tuning device comprises a platform body and a motion part. On the basis of cooperation between a pedestal and a return spring, the freedom degree of a grating read-in head in an actual application process is increased. With introduction of a differential head and a wedge block, fine tuning of the motion of the pedestal is realized by inclined-surface transmission; and the fine tuning displacement can be read directly by number reading by the differential head, so that the operability of the user is enhanced. Meanwhile, positioning bar structures are arranged at the sides of cooperation between the motion part and a grating ruler, so that the high positioning precision of the grating rule is realized. During actual assembling, high-precision assembling of the grating ruler is realized without any special clamping fixture, so that the requirement of the zero point position precision of the grating ruler is met.

Owner:SHANDONG UNIV

Transmission shaft assembly mechanism of direct drive group assembly device

ActiveCN110802400BFast deliveryGuaranteed continuityAssembly machinesMetal working apparatusDrive shaftShaft length

The invention discloses a transmission shaft assembly mechanism of a direct transmission group assembly device, which is characterized in that it includes a vibrating plate for the transmission shaft, a first conveying pipe, a material receiving positioning seat for the transmission shaft, and a transplanting mechanism for the transmission shaft; The material-receiving positioning seat includes a base and a material-receiving assembly, and the material-receiving assembly includes a material-receiving bump, a material-receiving slider, a traverse cylinder for the material-receiving slider, and a jacking cylinder for the transmission shaft; the lower surface of the material-receiving slider and There is a jacking interval between the lower sides of the socket, and the height between the upper surface of the receiving slider and the lower side of the socket is consistent with the shaft length of the transmission shaft; the upper end of the first conveying pipe and the transmission shaft use a vibration plate The discharge port of the first delivery pipe is connected, and the lower end of the first conveying pipe is connected with the blanking hole on the material receiving bump. The transmission shaft assembly mechanism of the direct transmission group assembly device of the present invention has the advantages of being able to effectively ensure the orderly output and precise positioning of the transmission shafts one by one, and help realize high-precision assembly of the transmission shaft.

Owner:深圳市睿荔科技有限公司

A connection tool for hose assembly and its connection system

ActiveCN113369843BAchieve high-precision assemblySave human effortWork holdersMetal working apparatusEngineeringAssembly machine

The invention discloses a hose assembly connecting tool and its connecting system, comprising a support plate installed at the feed end of the assembly machine body through fastening bolts, the support plate is provided with a moving groove, and the moving groove There is a driving piece at the place, the connecting end of the driving piece is connected with a supporting block, and the supporting block moves relative to the moving slot through the driving piece, the telescopic connecting mechanism is connected to the supporting block, and the connecting end of the telescopic connecting mechanism There are two alignment shells connected, and the two alignment shells are equipped with an adjustment alignment mechanism, which is used for the hose assembly connection tooling and its connection system. The staff only needs to quickly place the two ends of the hose After aligning the shell, adjust the alignment mechanism to move and adjust the height of both ends of the hose until the two ends of the hose are kept at the same level, then the support block moves the hose to the assembly machine body for feeding At the port, the high-precision assembly of the hose assembly is realized, and at the same time, manpower is effectively saved.

Owner:宁波迅腾流体动力有限公司

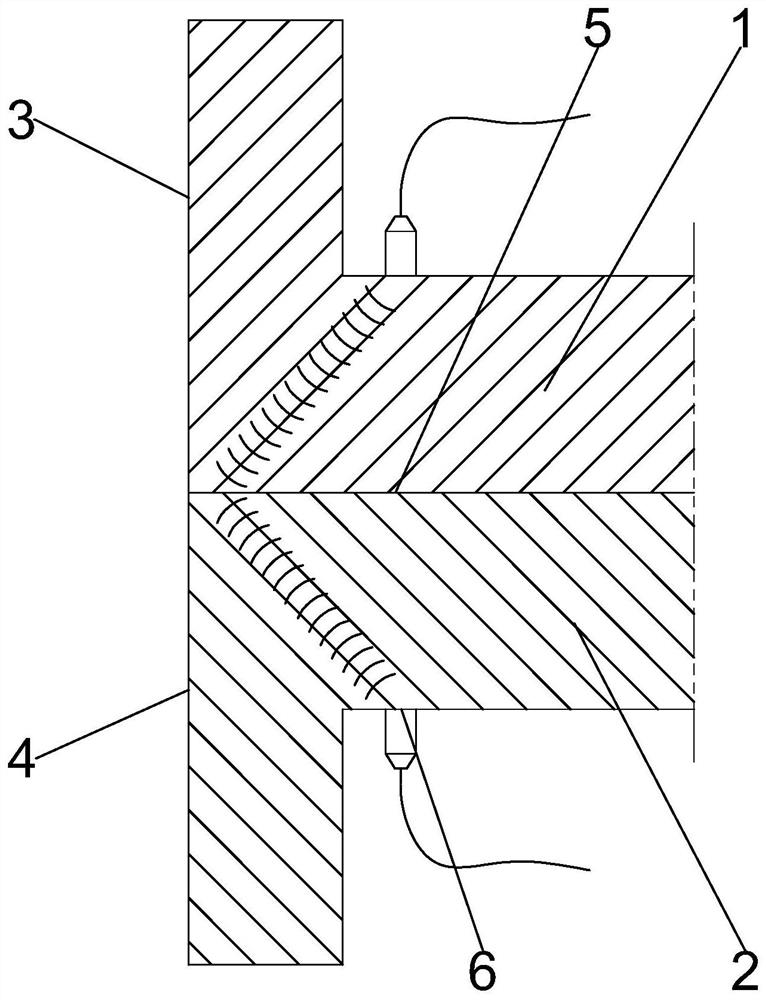

Assembly error ultrasonic detection method and waveguide ultrasonic assisted assembly method

ActiveCN111702447BAchieve high-precision assemblyImprove quality and efficiencyUsing subsonic/sonic/ultrasonic vibration meansMetal working apparatusUltrasonic assistedEngineering

Owner:广州多浦乐电子科技股份有限公司

clamping head

ActiveCN105171371BAvoid offsetAchieve high-precision assemblyMetal working apparatusSacroiliac jointBall joint

The invention provides a clamping head which comprises a base, a turning support, a finger fixing mechanism, a driving mechanism and a press block fixing mechanism, wherein the base is mounted on an external driving mechanism, and comprises a top plate, an end plate, a left side plate, a right side plate and a first cavity in the interior; the turning support comprises a connecting part and a turning part; the finger fixing mechanism comprises a fixing platform, a crank, a connecting rod, a sliding platform, a plurality of mechanical fingers and a plurality of ball joint connecting rods; the driving mechanism comprises a push-rod motor; the press block fixing mechanism comprises a shaft sleeve, a core shaft, two bending arms, a spring, two short connecting rods and two press blocks; each press block comprises a press block connecting part and a contact part. According to the clamping head provided by the invention, the mechanical fingers of different shapes can effectively fix workpieces of different shapes, so that the adaptability is relative high; the mechanical fingers and the contact parts of the press block jointly act on the upper and lower parts of a workpiece, so that the workpiece can be automatically clamped and prevented from migrating in moving and assembly processes, and high-precision assembly of the workpiece can be realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

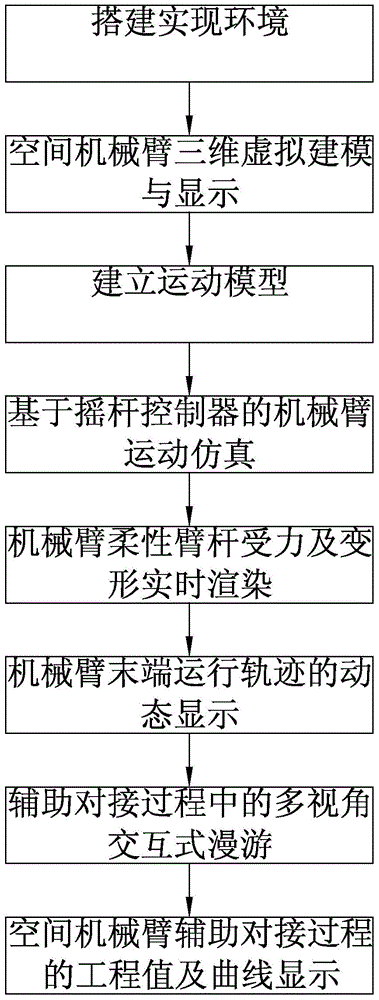

Three-dimensional dynamic simulation method for space manipulator assisted docking process

InactiveCN103870665BRealize detailed modelingRealize visual simulation3D-image rendering3D modellingCommand and controlButt joint

The invention discloses a method for three-dimensional dynamic simulation in the space manipulator auxiliary butt-joint process and relates to a method for three-dimensional dynamic simulation. The method is used for solving the problem that due to the fact that command and control personnel on the ground and an astronaut cannot visually see a manipulator, great trouble is brought for control over movement of the manipulator. The method comprises the specific steps of realization environment establishment, space manipulator three-dimensional virtual modeling and displaying, movement model establishment, manipulator movement simulation based on a rocking bar controller, real-time rendering of force-receiving and deformation of a manipulator flexible arm lever, dynamic display of a movement track of the tail end of the manipulator, multi-view interactive roaming in the auxiliary butt-joint process and project value and curve display in the space manipulator auxiliary butt-joint process. The method is applied to the technical field of computer analogue simulation.

Owner:HARBIN INST OF TECH

Method of Assembling and Welding the Stator Frame of Air-cooled Turbine Generator

ActiveCN107222074BHigh accuracy of assembly sizeGuarantee welding qualityManufacturing dynamo-electric machinesWelding apparatusEngineeringTurbine

The invention provides an air-cooled turbogenerator stator frame assembling and welding method. The air-cooled turbogenerator stator frame is composed of three parts of a middle-section frame (1), a turbine-end frame (2) and an excitation-end frame (3), the three parts carry out assembling and welding respectively, and then, final assembling is carried out. According to the structural characteristics of the stator frame in a new structure, a composite assembly method with vertical assembly and horizontal assembly combined is adopted, the assembling and welding quality of the stator frame is improved, and the operation and the construction are convenient; section assembling and welding are carried out for the stator frame, each section operates independently, parallel assembling and welding are realized, the construction period is shortened, and the assembling and welding efficiency is improved; and the stator frame baseboard is used as an assembly reference, the concentricity accuracy requirements of the whole frame body are ensured, and high-precision assembly of the stator frame is realized.

Owner:HARBIN ELECTRIC MASCH CO LTD

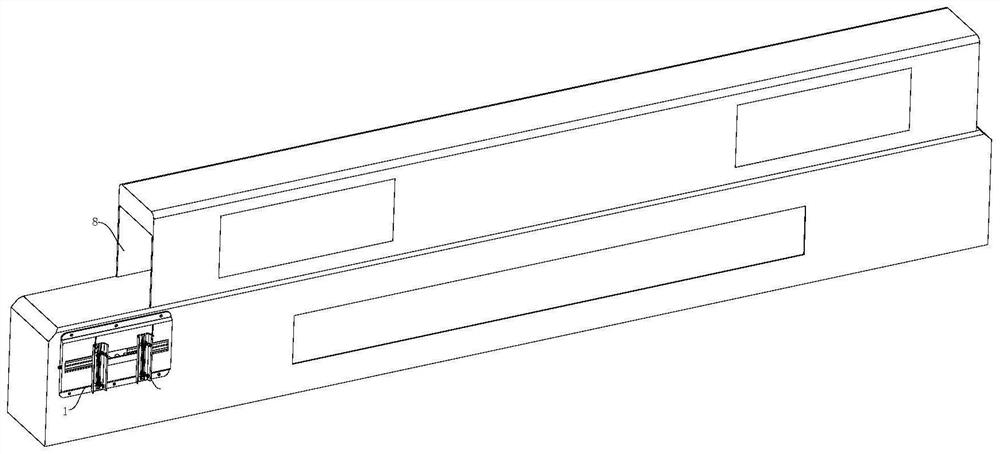

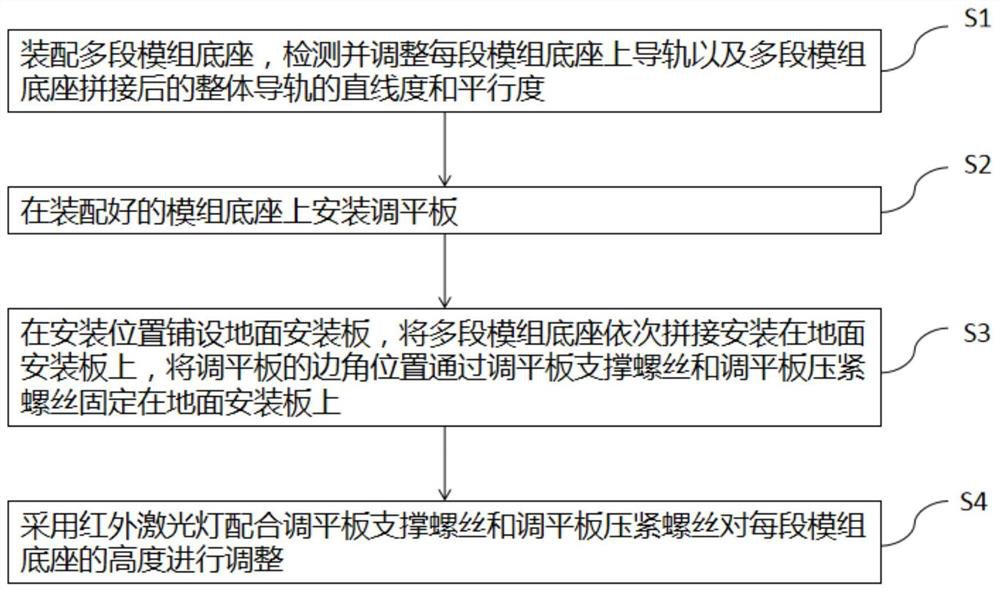

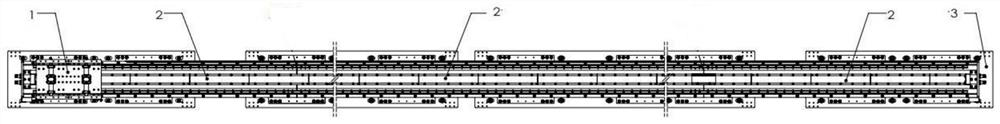

Long-stroke linear module and mounting method thereof

PendingCN114421720AEasy to useMeet the needs of useManufacturing dynamo-electric machinesPropulsion systemsIr laserStructural engineering

The invention relates to a long-stroke linear module and an installation method thereof.The long-stroke linear module comprises multiple sections of spliced module bases and a module mover sliding in the splicing extension direction of the module bases, and the installation method comprises the steps that the multiple sections of module bases are assembled; detecting and adjusting the straightness and parallelism of the guide rail on each section of module base and the whole guide rail after splicing of the plurality of sections of module bases; a leveling plate is installed on the assembled module base; the multiple sections of module bases are sequentially spliced and installed on the ground installation plate, and the corner positions of the leveling plate are fixed to the ground installation plate through leveling plate supporting screws and leveling plate pressing screws; an infrared laser lamp is matched with a leveling plate supporting screw and a leveling plate pressing screw to adjust the height of each section of module base. The modular mounting mode is adopted, the operation difficulty of long-stroke module mounting is effectively reduced, the mounting height of each module base can be adjusted, and therefore high-precision assembly of the long-stroke module according to a mounting scene is achieved.

Owner:AKRIBIS SYST SHANGHAI

Side plate installing vehicle for omnidirectional fine-tuning satellite instrument

ActiveCN103009337BAchieve high-precision assemblyRealize full degree of freedom fine-tuningMetal-working hand toolsOmnidirectional antennaMechanical engineering

The invention provides a side plate installing vehicle for an omnidirectional fine-tuning satellite instrument. The side plate installing vehicle comprises a base assembly (1), a lifting function assembly (2), a turnover function assembly (3) and a side plate installing frame assembly (4), wherein the lifting function assembly (2), the turnover function assembly (3) and the side plate installing frame assembly (4) are arranged on the base assembly (1). The side plate installing vehicle can be adjusted in three linear directions of front and back, left and right and up and down and two angular directions of pitching and rolling through mechanisms such as an adjustable leg support, a screw rod, a linear guide rail and a lifter, and can be used for installing side plates of various satellite instruments on satellites.

Owner:SHANGHAI YUDA IND

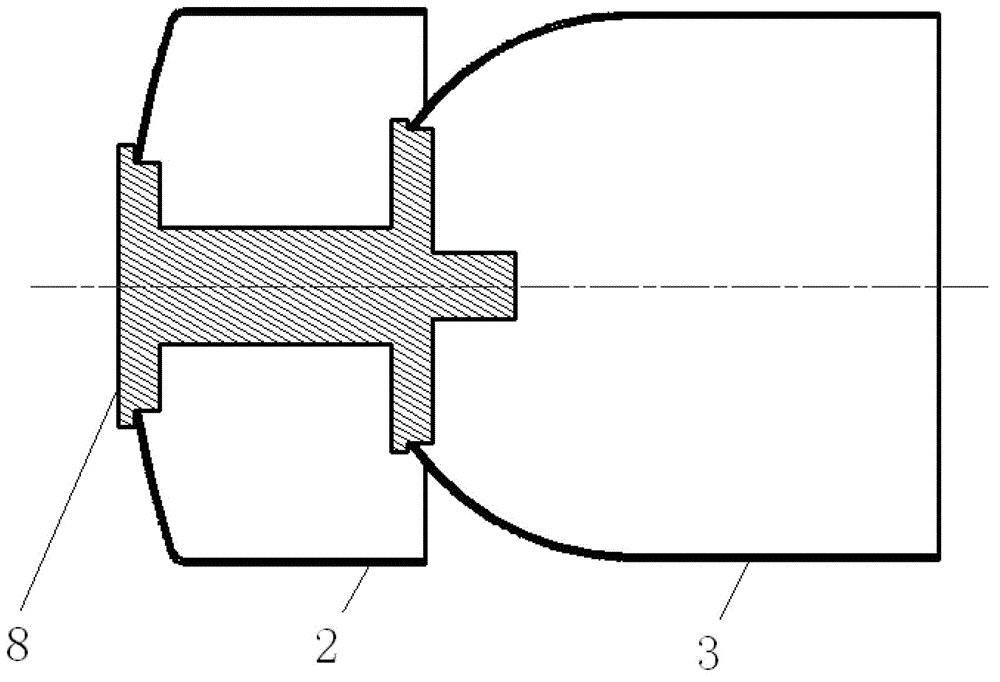

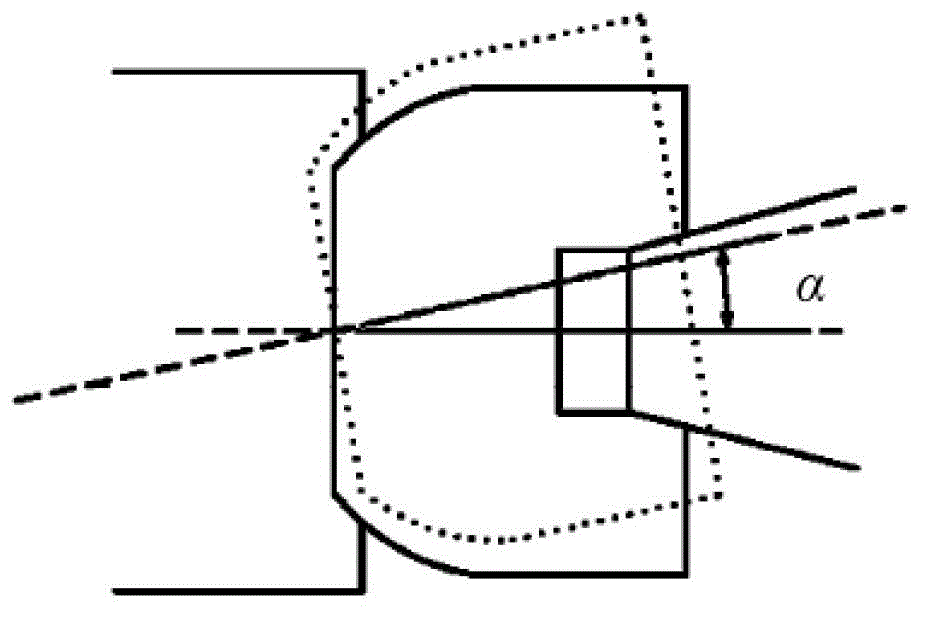

A fringe image transformation tube mounting tool and mounting method

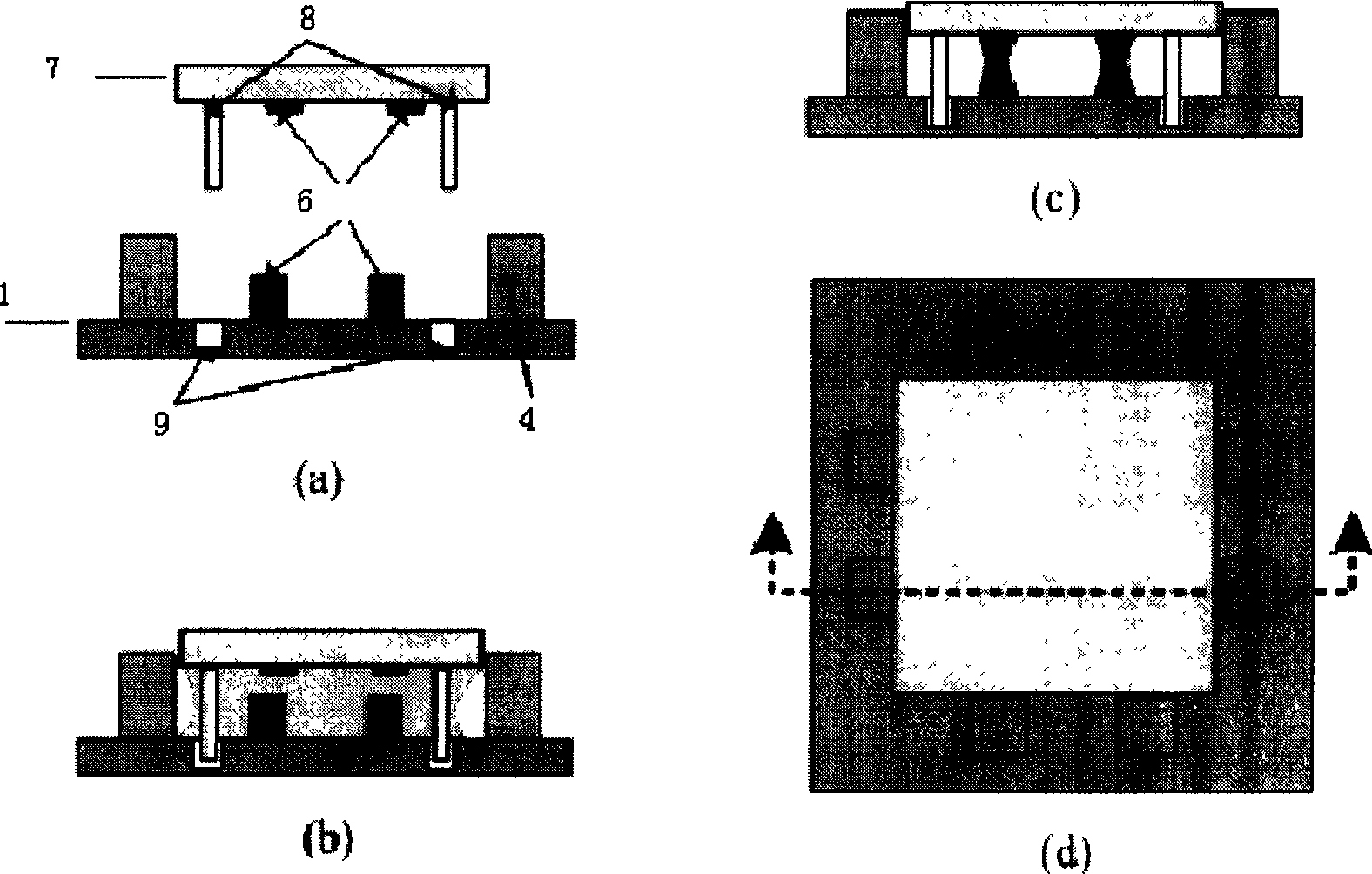

ActiveCN103077873BImprove consistencyImprove efficiencyElectrode and associated part arrangementsImage-conversion/image-amplification tubesEngineeringRadial deviation

The invention relates to a stripe image converter tube racking tool, which comprises a pair of circular tube formed by mutually buckled, a first end cover and a second end cover arranged on two ends of the circular tube, and a first locating device and a second locating device arranged coaxial to the circular tube, wherein annular steps with the number being equal to the number of electrodes in an image converter tube are arranged on an inner wall of the circular tube; axial positions of the annular steps are determined according to positions of the electrodes in the image converter tube; and inner holes of the annular steps are matched with the matched electrodes. According to the racking tool, the position accuracy including axial deviation, radial deviation, coaxiality and the like in a stripe tube racking process can be improved; an uncontrollable process link and manual operation are reduced, so that the consistency of racking is improved; and the efficiency for manufacturing stripe tubes and the yield are improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com