Assembly error ultrasonic detection method and waveguide ultrasonic assisted assembly method

An ultrasonic detection and assembly error technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, re-radiation of sound waves, radio wave measurement systems, etc., can solve the problems of rework assembly, long assembly time, unstable quality, etc., and achieve high-precision assembly. , the effect of improving assembly quality and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

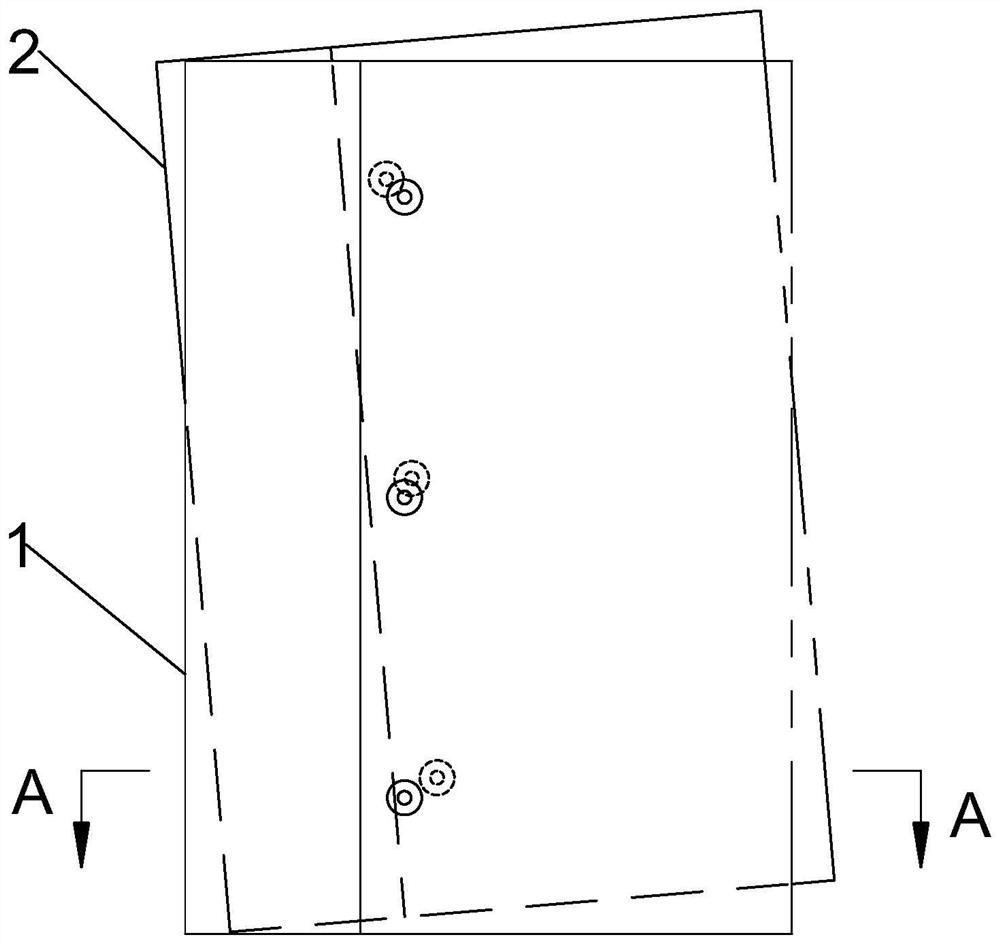

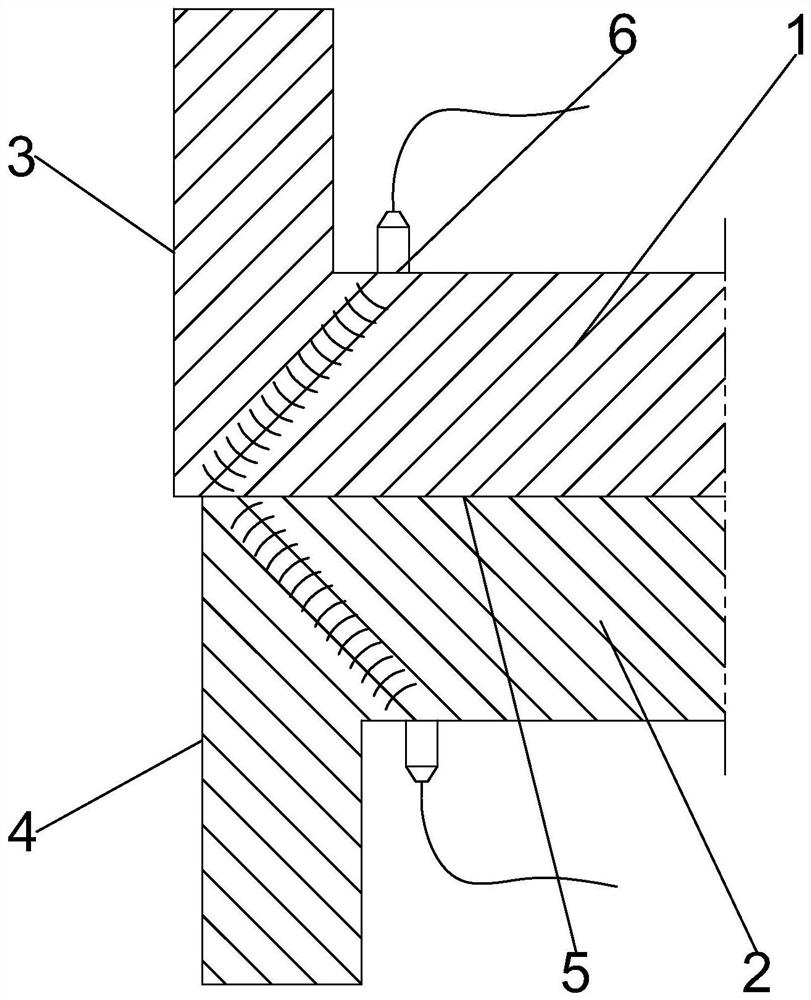

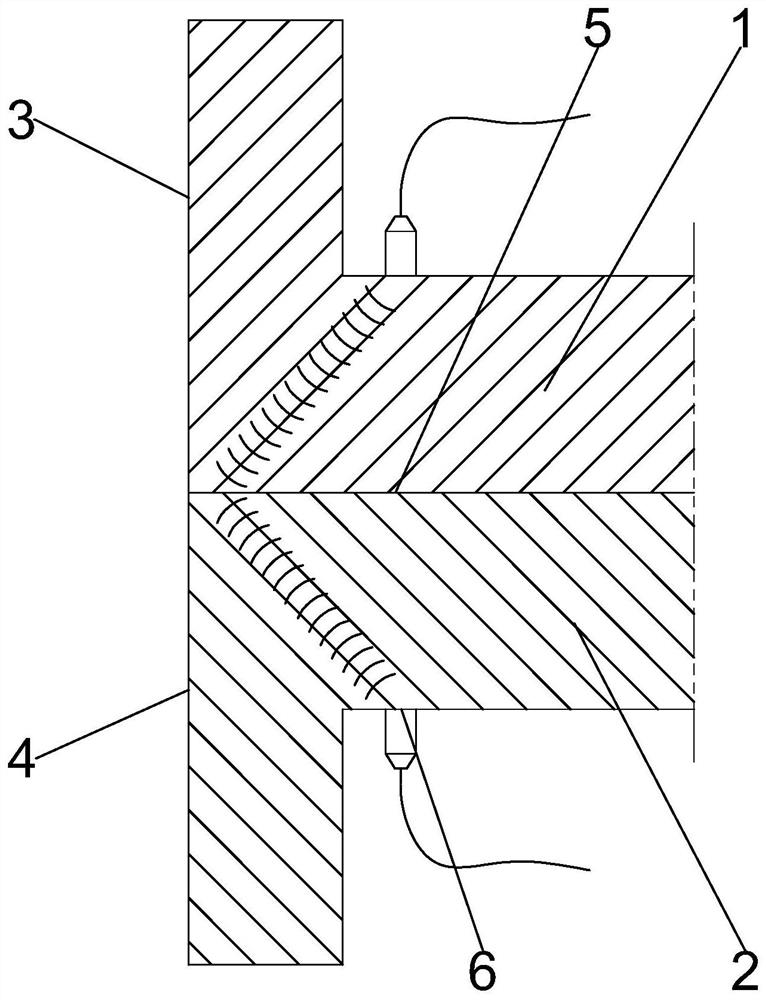

[0050] In the assembly error ultrasonic detection method of this embodiment, if at least one assembly alignment surface is respectively provided on the two assembly workpieces, and the two assembly alignment surfaces are relative to the distance between the two assembly workpieces after the two assembly workpieces are assembled in place. The first assembly mating surface 5 is symmetrically arranged; then two ultrasonic detection point groups can be symmetrically arranged on both sides of the first assembly mating surface 5, and the two ultrasonic detection point groups are respectively located on two assembly workpieces. The detection point group includes at least two first ultrasonic detection points 6 arranged at intervals, and all the first ultrasonic detection points 6 belonging to the same ultrasonic detection point group are at the same distance from the first assembly mating surface 5 and belong to the same ultrasonic detection point All the first ultrasonic testing poin...

Embodiment 2

[0072] In the assembly error ultrasonic detection method of this embodiment, if two assembly workpieces are respectively provided with at least two assembly alignment surfaces, and the two assembly alignment surfaces on the same assembly workpiece are arranged in axisymmetric manner, and when the two assembly alignment surfaces After the two assembly workpieces are assembled in place, the axisymmetric planes of the two assembly alignment surfaces respectively arranged on the two assembly workpieces are coplanar, and the second assembly mating surface 13 between the two assembly workpieces is perpendicular to the axisymmetric plane, Then, two ultrasonic testing point groups can be respectively symmetrically arranged on both sides of the axisymmetric plane, and the two ultrasonic testing point groups are located on the same assembly workpiece, and each ultrasonic testing point group includes at least two second For the ultrasonic testing point 14, all the ultrasonic testing point...

Embodiment 3

[0089] In the waveguide ultrasonic-assisted assembly method of this embodiment, a central through hole 15 is provided in the waveguide. The cross section of the central through hole 15 is square and includes a first assembly alignment surface group and a second assembly alignment surface group perpendicular to each other. Both the first assembly alignment face group and the second assembly alignment face group include two assembly alignment faces parallel to each other. Specifically, the first assembly alignment surface group in this embodiment includes the seventh assembly alignment surface 16 and the eighth assembly alignment surface 17 , and the second assembly alignment surface group includes the ninth assembly alignment surface 18 and the tenth assembly alignment surface 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com