A fringe image transformation tube mounting tool and mounting method

A technology for changing image tubes and racking, which is applied in the direction of image conversion/image enlargement tubes, electrode devices and related components, screen tubes, etc., which can solve the problems of large mounting errors, reduce material consumption, improve efficiency and yield , saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

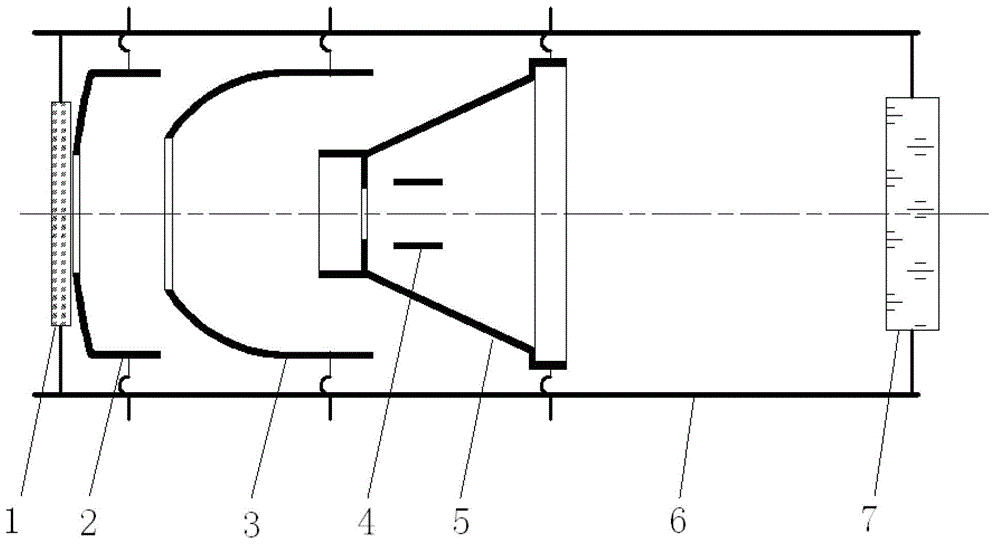

[0037] figure 1 Shown is the structural diagram of the stripe image transformation tube, including the tube casing 6, and the cathode 1, the grid 2, the focusing electrode 3, the deflection electrode 4, the anode 5, and the fluorescent screen 7 are welded in sequence in the axial direction from one end of the tube casing to the other end.

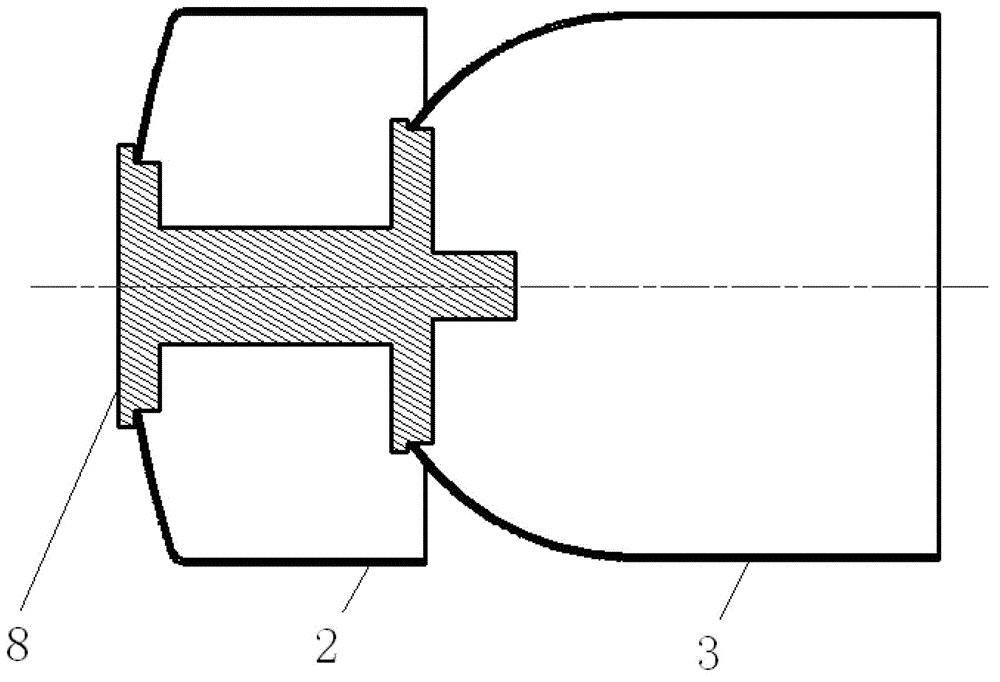

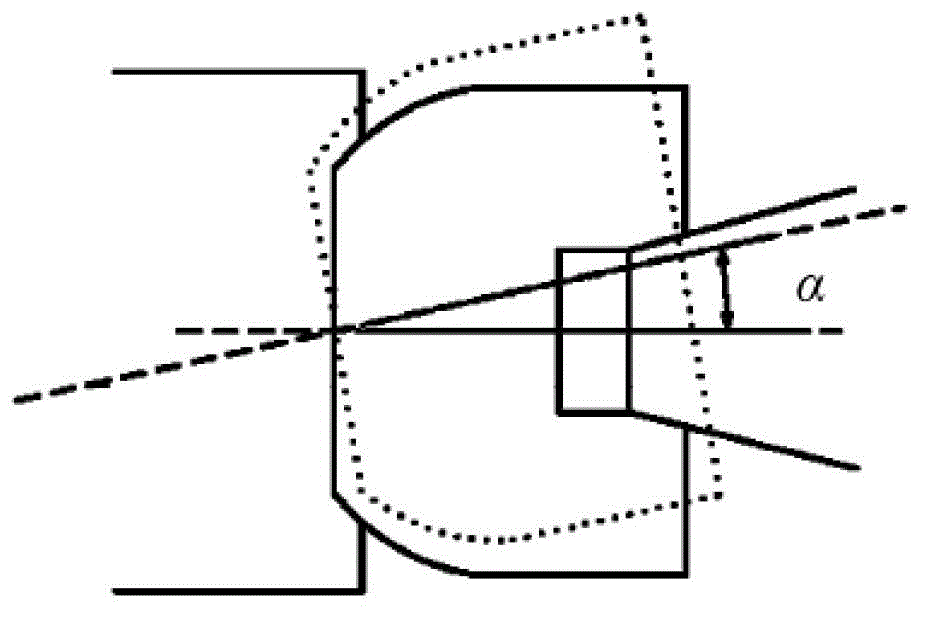

[0038] Aiming at the striped image transformation tube with this structure, the present invention provides a striped image transformation tube mounting tool, its structure is as follows: Figure 4 As shown, it includes a pair of round tubes 9 formed by interlocking, end caps 91 arranged at both ends of the round tube 9, and a first positioning device and a second positioning device coaxially arranged with the round tube. There is an annular step 92 equal to the number of electrodes in the image changing tube. The axial position of the annular step 92 is determined according to the position of each electrode in the image changing tube. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com