Long-stroke linear module and mounting method thereof

A linear module and installation method technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of high cost and cumbersome installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

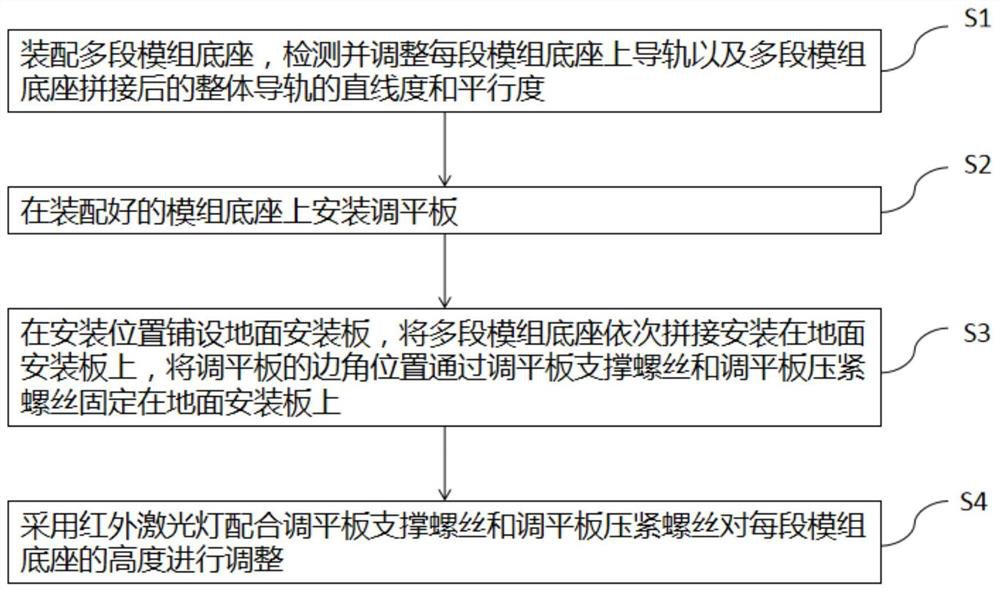

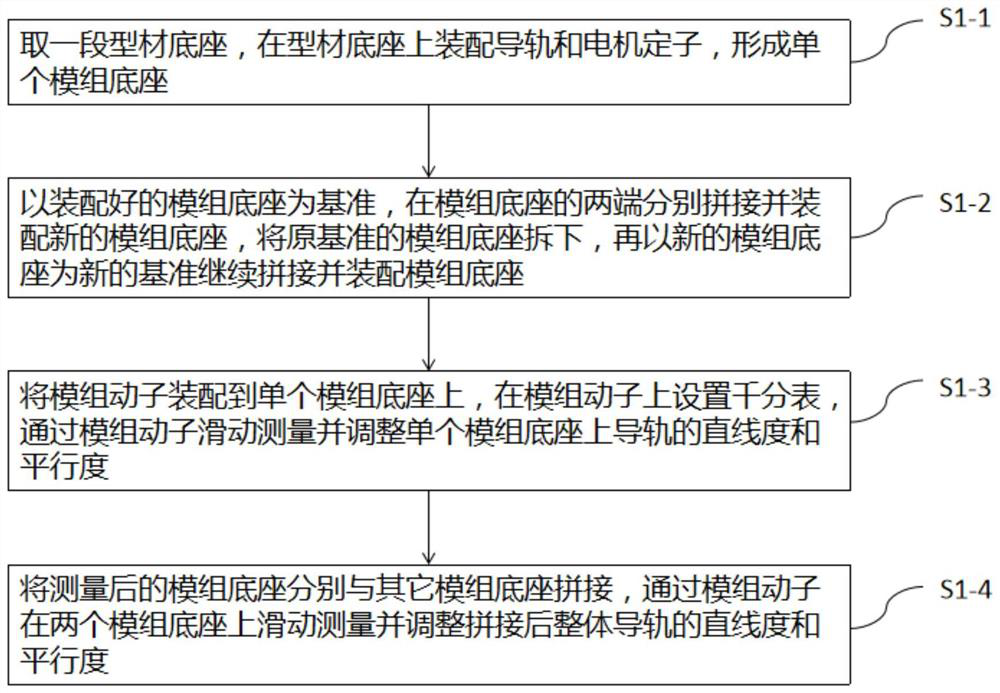

[0039] refer to figure 1 As shown, the installation method of the long-stroke linear module of the present invention, wherein the long-stroke linear module includes a multi-stage spliced module base 2 and a module mover 1 that slides along the splicing extension direction of the module base 2, the The installation method includes the following steps:

[0040] S1. Assemble the multi-segment module base 2, detect and adjust the straightness and parallelism of the guide rail on each segment of the module base 2 and the overall guide rail after the multi-segment module base 2 is spliced;

[0041] S2. Install the leveling plate 21 on the assembled module base 2;

[0042]S3. Lay the ground mounting plate 4 at the installation position, splice and install the multi-section module base 2 on the ground mounting plate in sequence, and fix the corner position of the leveling plate 21 on the ground through the leveling plate support screw 5 and the leveling plate pressing screw 6 On t...

Embodiment 2

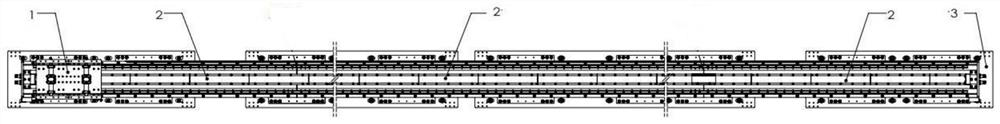

[0062] refer to image 3 As shown, in this embodiment, a long-stroke linear module is provided, which is suitable for the installation method in the above-mentioned embodiment 1. The long-stroke linear module includes a multi-stage spliced module base 2, and a spliced along the module base 2. The module mover 1 and the ground mounting plate 4 that slide in the extension direction are formed by splicing multiple module bases 2, which solves the problem of the actual use of long-stroke modules in the market and provides a new method for long-distance transportation. Scheme, the length of the module can be flexibly adjusted according to the needs, theoretically it can meet the needs of infinite travel.

[0063] refer to Figure 4 and Figure 5 As shown, the module base 2 includes a leveling plate 21, a profile base 22, a motor stator 23, a guide rail 24, a side cover 25, and a scale 26. The leveling plate 21, a motor stator 23, a guide rail 24, a side cover 25, The scales ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com