Automatic assembling machine for power compartment

A technology for assembling machines and power cabins, which is applied in motor vehicles, transportation and packaging, etc., can solve the problems of low connection accuracy and high labor intensity of workers, and achieve the effect of reducing labor intensity and ensuring stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

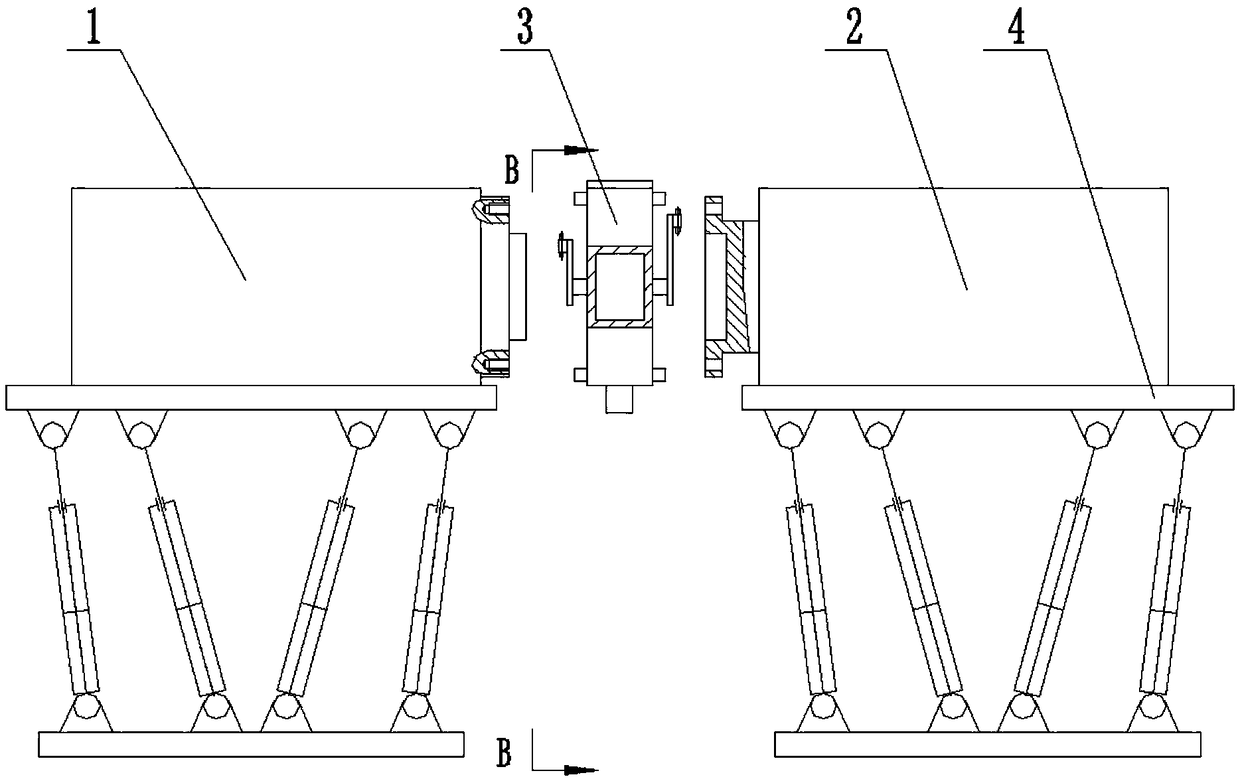

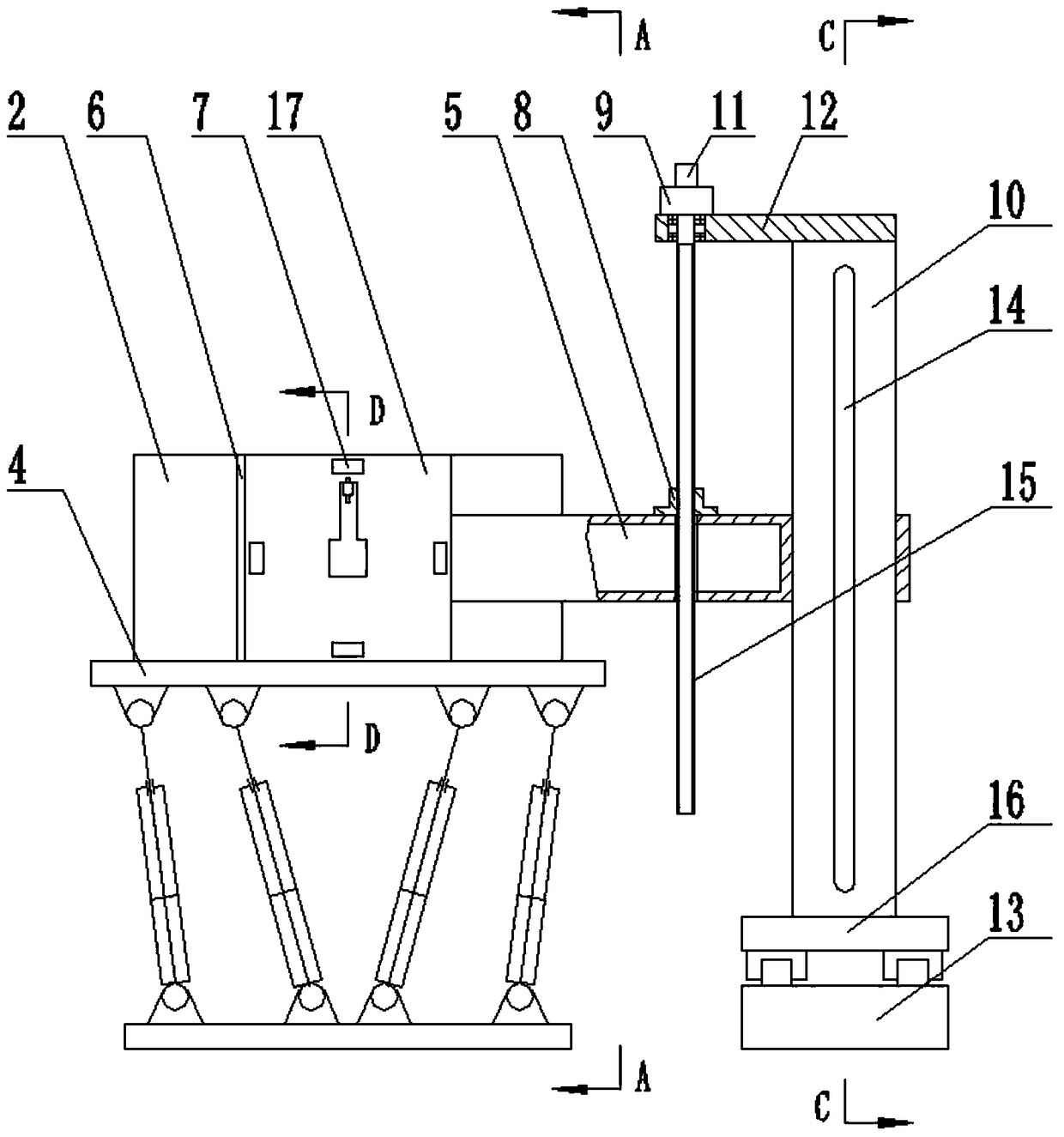

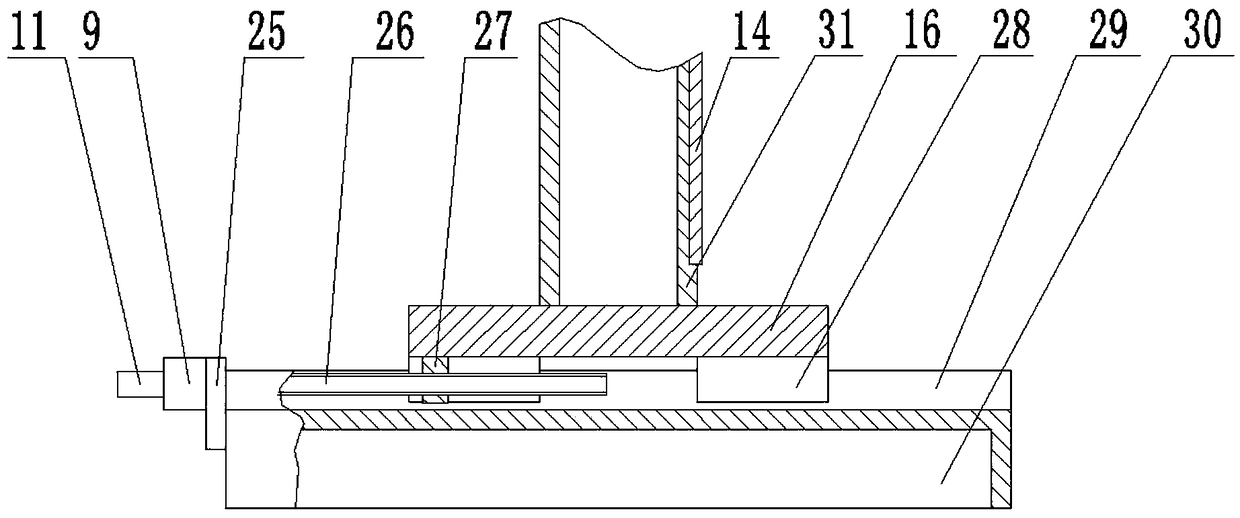

[0022] See attached Figure 1-5 , the present invention provides an automatic assembly machine for a power cabin, which is composed of a measuring machine, a detection device 3 and a six-degree-of-freedom platform 4. The detection device 3 is installed on the lifting beam 5 of the measuring machine, and the two sides of the measuring machine are symmetrical. Two six-degree-of-freedom platforms 4 are provided. The measuring machine is mainly used for loading the detection device 3 and adjusting the specific position of the detection device 3 during assembly. 1 and the transmission box 2 are assembled for position detection, and two six-degree-of-freedom platforms 4 are used to place the engine 1 and the transmission box 2 respectively, and cooperate with the detection device 3 during assembly.

[0023] The measuring machine is composed of an adjustment base 13, a support frame 10 and a lifting beam 5. The adjustment base 13 is located on the same plane as the six free platforms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com