Patents

Literature

108results about How to "Improve cylindricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

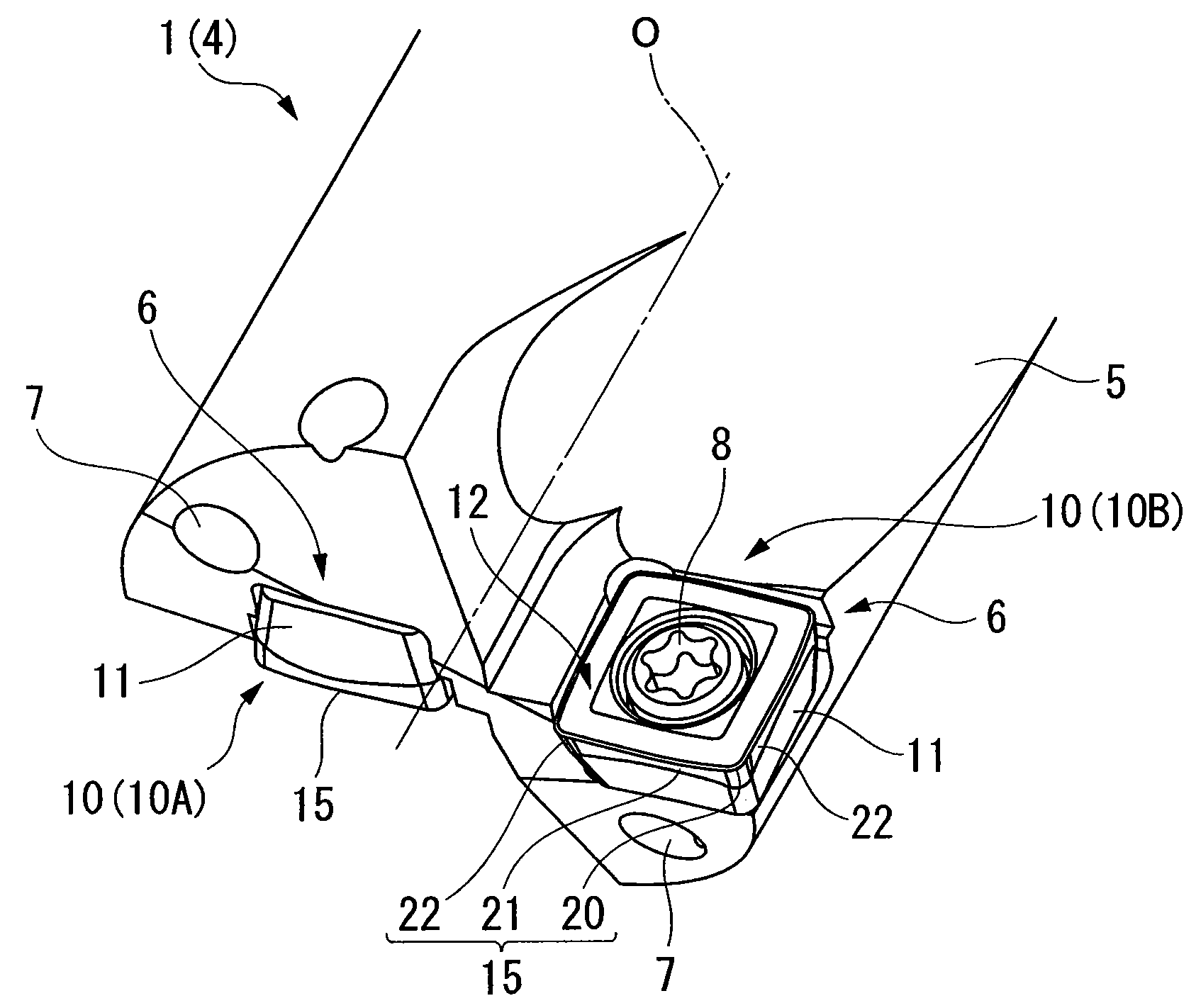

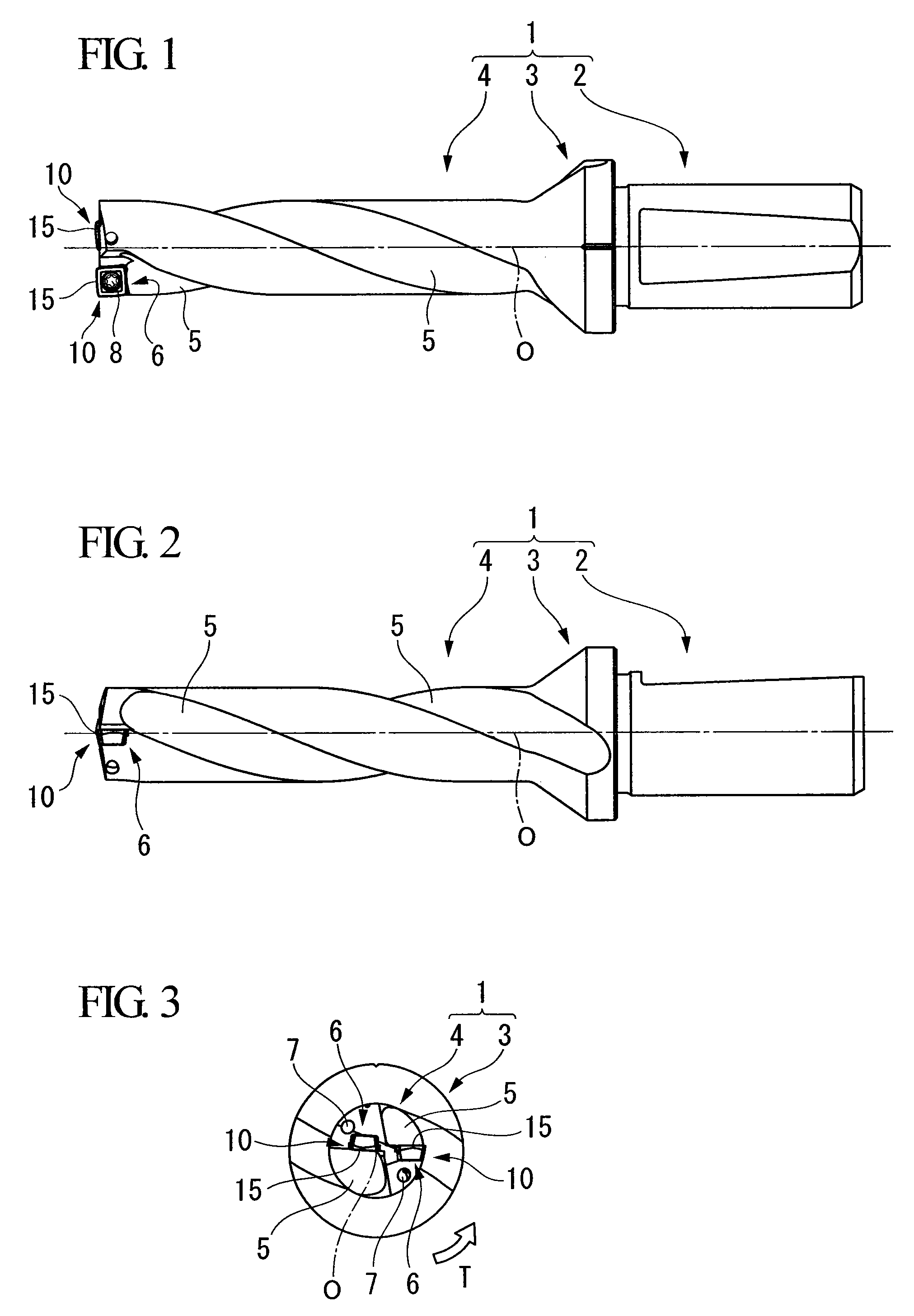

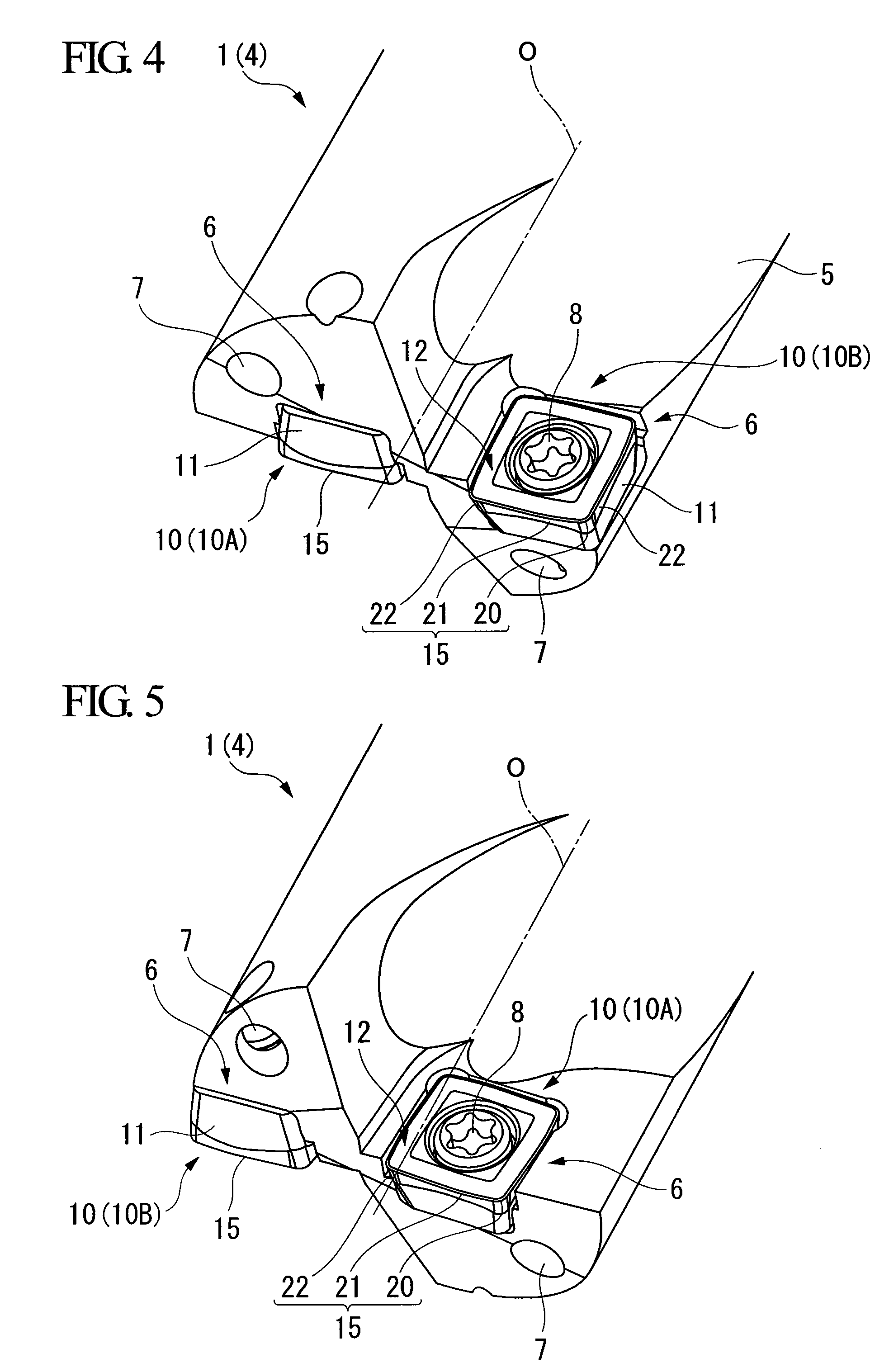

Insert for drill and indexable insert drill

ActiveUS20090245949A1Improve surface qualityHigh concentricityTransportation and packagingCutting insertsCurve shapeEngineering

An insert for a drill in which one of the cutting edges respectively formed at four side ridge portions of a rake face of a square flat plate-shaped insert body is made to protrude toward the tip of the drill body of the indexable insert drill while being detachably attached is provided. Each of the cutting edges has a corner cutting edge located at a corner of the rake face, and a major cutting edge and a wiper edge which extend substantially toward one peripheral direction of the rake face from a corner cutting edge. The major cutting edge has a first major cutting edge portion which has a convexly curved shape and extends from the corner cutting edge, and a second major cutting edge portion which smoothly touches the first major cutting edge portion and extends linearly, as seen from a direction facing the rake face. The wiper edge has a straight shape intersecting the second major cutting edge portion at an obtuse angle.

Owner:MITSUBISHI MATERIALS CORP

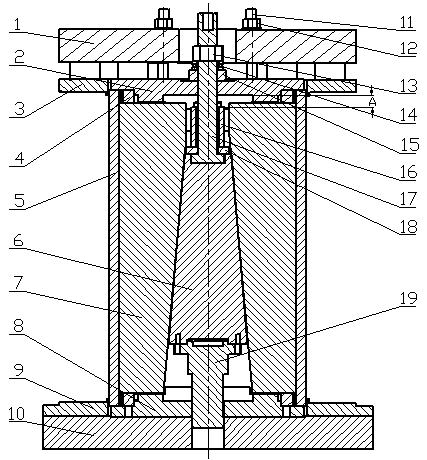

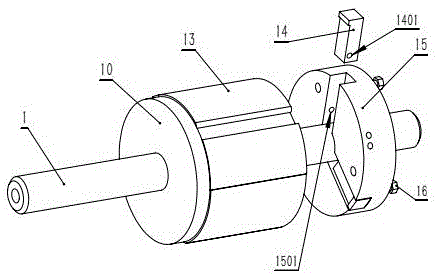

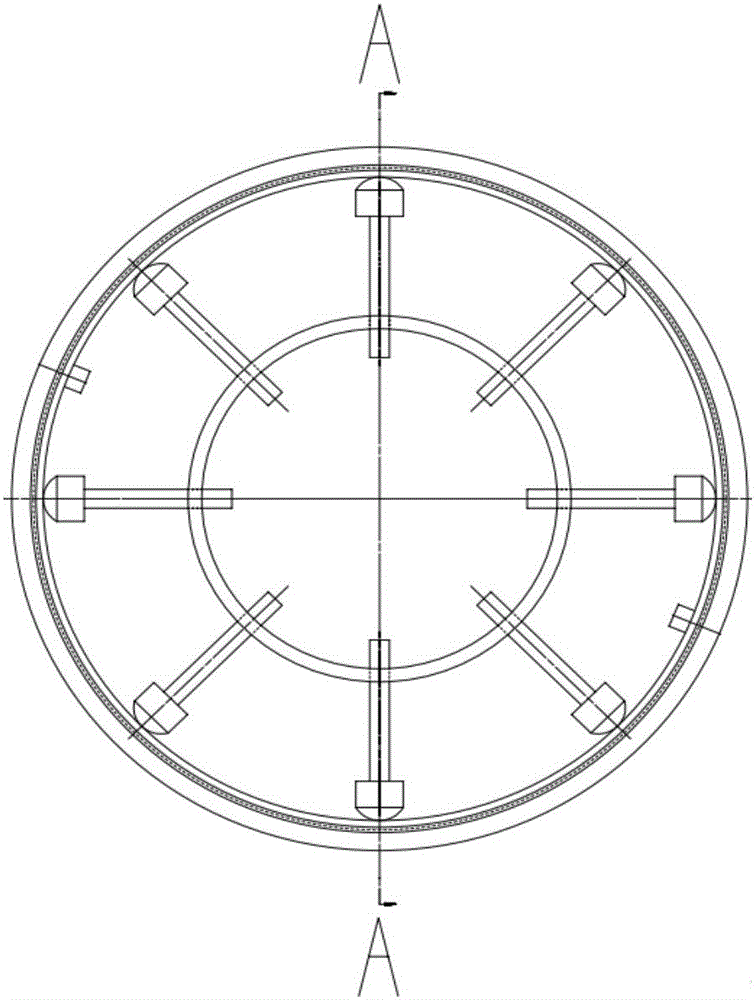

Overlying tool for large motor stator iron core

ActiveCN105515299AReduce gapHigh concentricityManufacturing stator/rotor bodiesEngineeringMechanical engineering

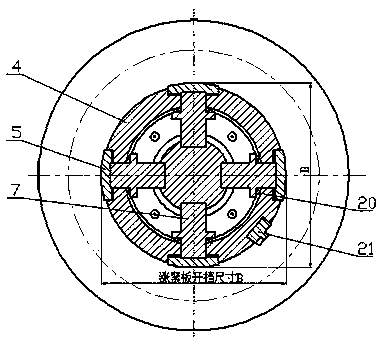

The invention relates to the technical field of motor stator laminations, in particular to an overlying tool for a large motor stator iron core. A vertical wedge-shaped expander structure is adopted in the overlying tool design. Four equant rectangular holes are formed in a cylinder, groove shapes are correspondingly formed through cutting, one end face of each of four wedge-shaped plates is machined into a 5-degree slope, four grooves with 5-degree slopes are machined in a spindle in an equant mode, and the wedge-shaped plates are in slide fit with the slopes of the spindle and embedded in the rectangular holes of the cylinder; a pull rod is connected to the top of the spindle, and the spindle can move up and down under the action of an adjusting nut to drive four tensioning plates to synchronously stretch or retract in the circumferential direction so that laminations can be positioned centrally and break away.

Owner:CHANGZHOU SHENLI MOTOR

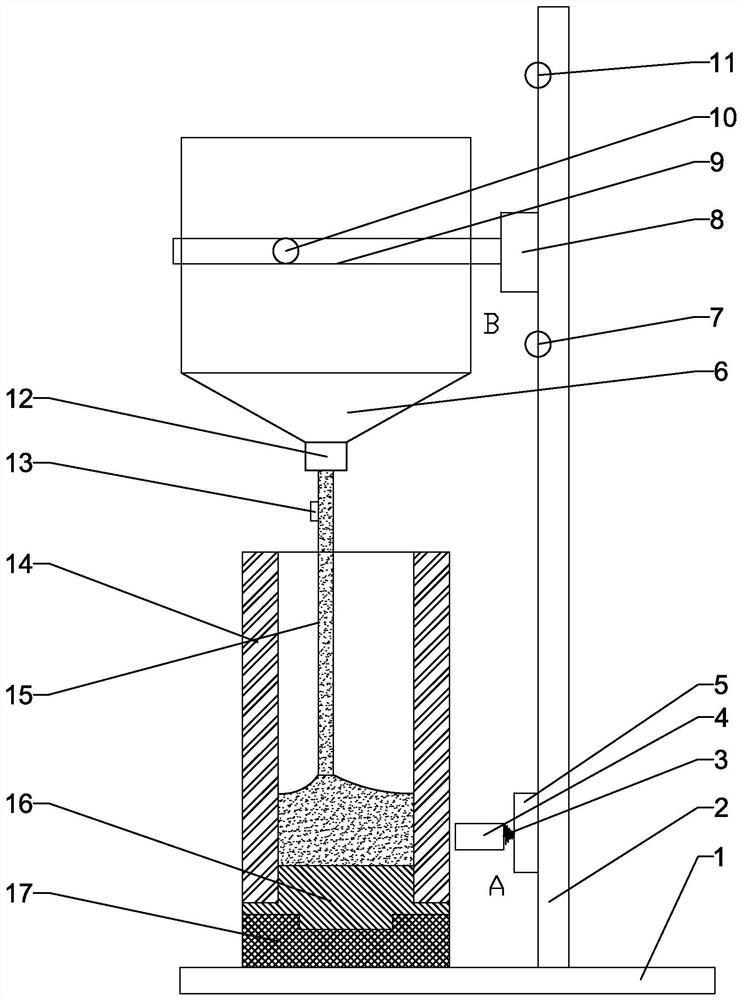

Precision plunger metering pump

InactiveCN101709693AHigh surface hardnessImprove cylindricityPumpsPositive-displacement liquid enginesRubber ringEngineering

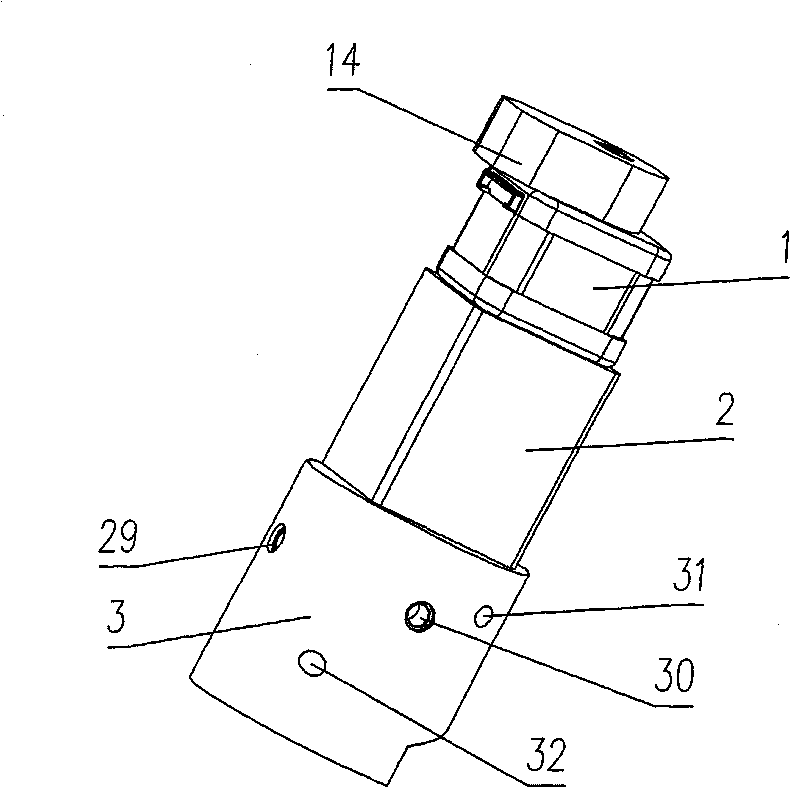

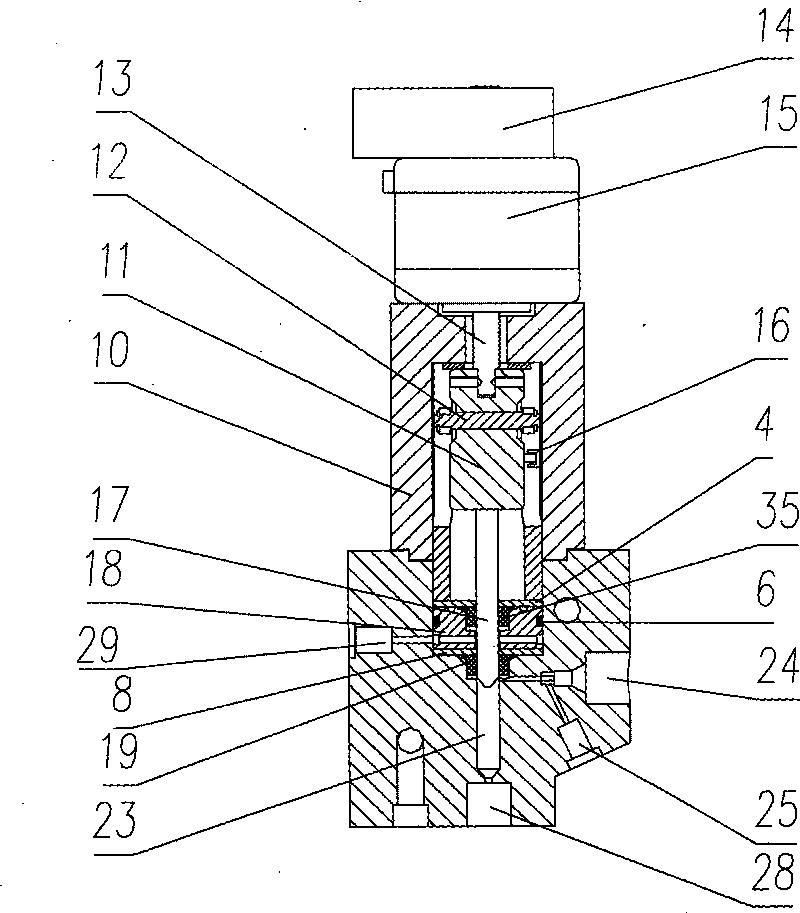

The invention relates to a precision plunger metering pump, comprising three parts, including a driving mechanism, a sealing mechanism and a pump head, wherein by utilizing a photoelectric encoder, the driving mechanism accurately controls the movement of a stepper motor, thereby effectively preventing the error of pump output caused by the falling out of step or the idling of the motor from being generated; a sealing ring in the sealing mechanism is matched with a plunger piston to realize precision fit, and the sealing ring based on a stainless steel spring enclasping mechanism solves the problems of low enclasping force and easy aging of a traditional rubber ring and prolongs the service life; the pump head has the design of water washable airtight cabin, realizes the washing and sealing functions of the plunger piston and the sealing ring and prolongs the sealing life; the technic level of processing the plunger piston and slab rubber achieves the purpose that a miniature precision plunger metering pump can provide 20MPa pressure intensity; and the slab rubber has good polishing performance, extremely high transparency, compact structure, small volume and delicate appearance. The precision plunger metering pump can be applied to the precise metering of fluid in the fields of medication, sanitation, biology and chemistry.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

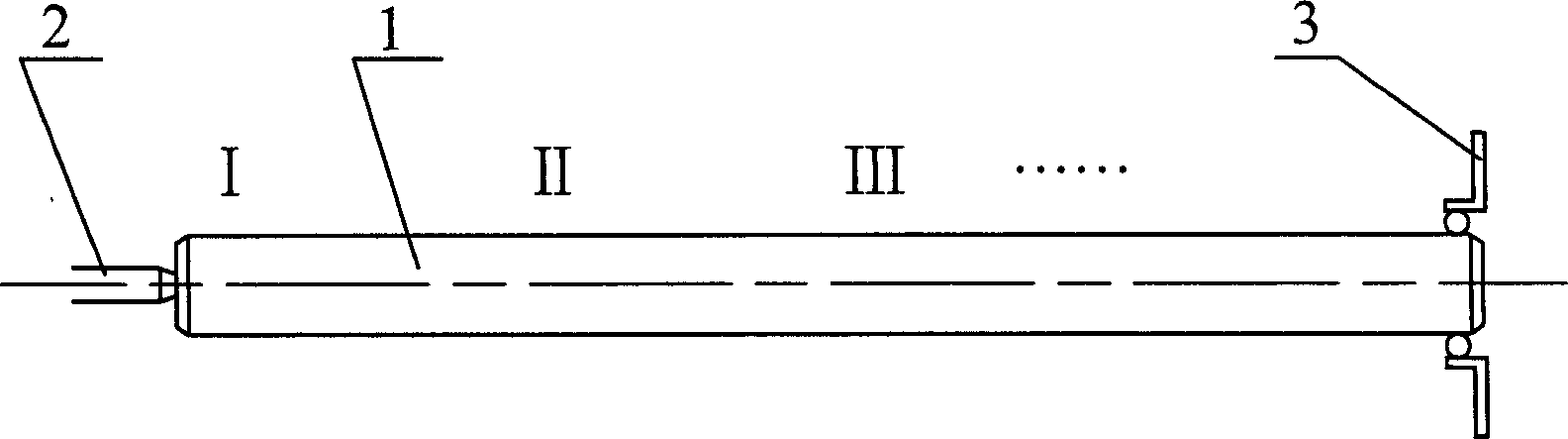

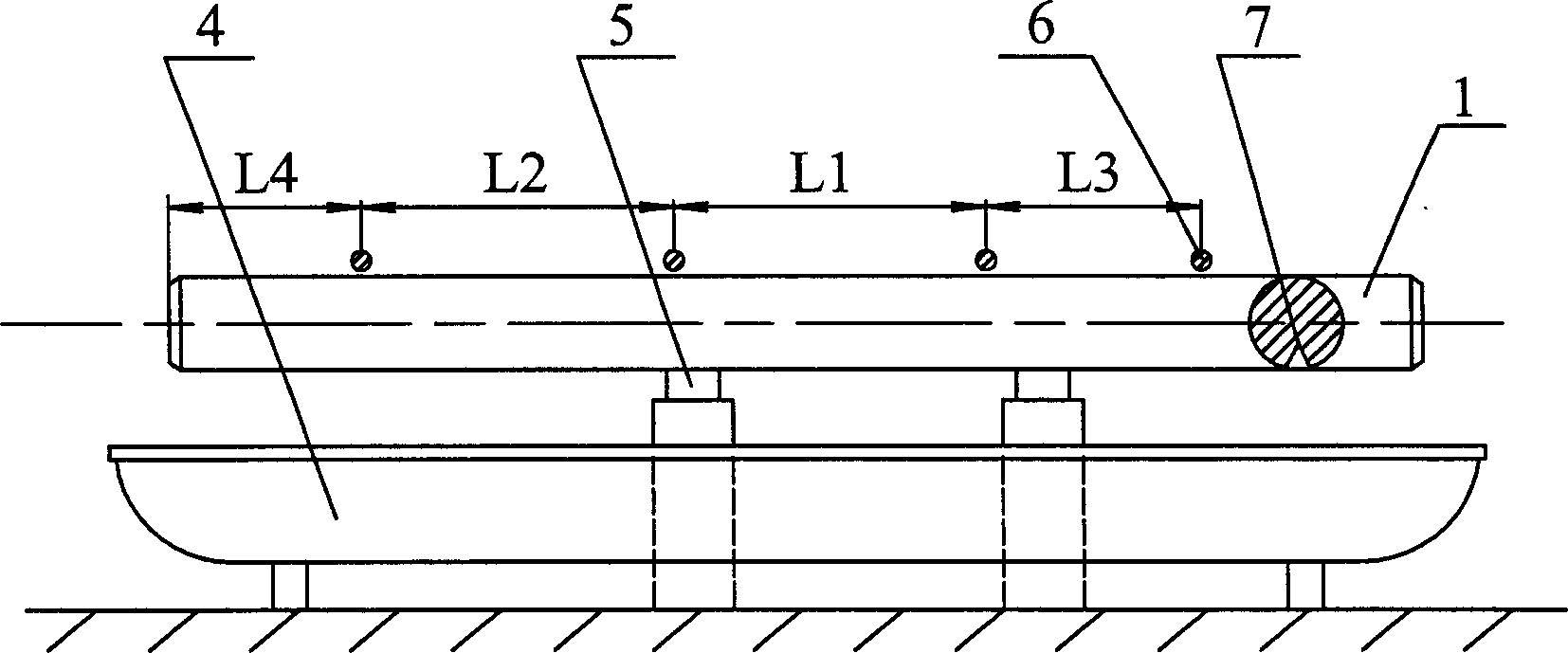

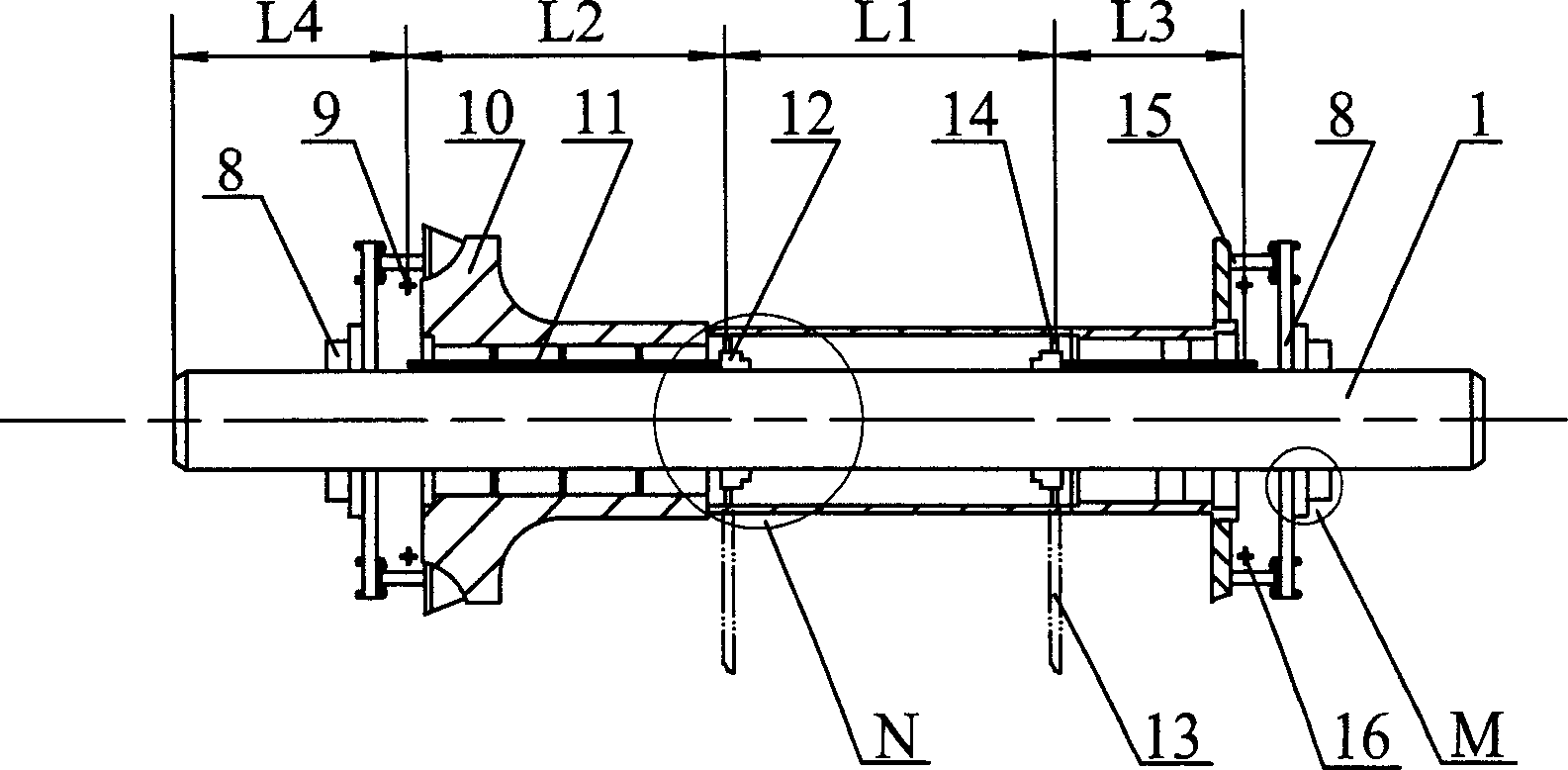

Marine stern axle tube boring technological equipment erecting process

ActiveCN1775434AAchieve high-precision assemblyReduce labor intensityPositioning apparatusMetal-working holdersEngineeringCantilever

The present invention belongs to a ship stern tube boring tool mounting process. Said process includes the following several procedures: defining the position of intermediate support of boring bar in the stern tube to be machined; measuring straightness of boring bar; simulatively measuring flexibility value of cantilevers of two ends of said boring bar; and mounting boring tool. Said invention also provides the concrete steps of the above-mentioned every procedure.

Owner:中国船舶集团渤海造船有限公司

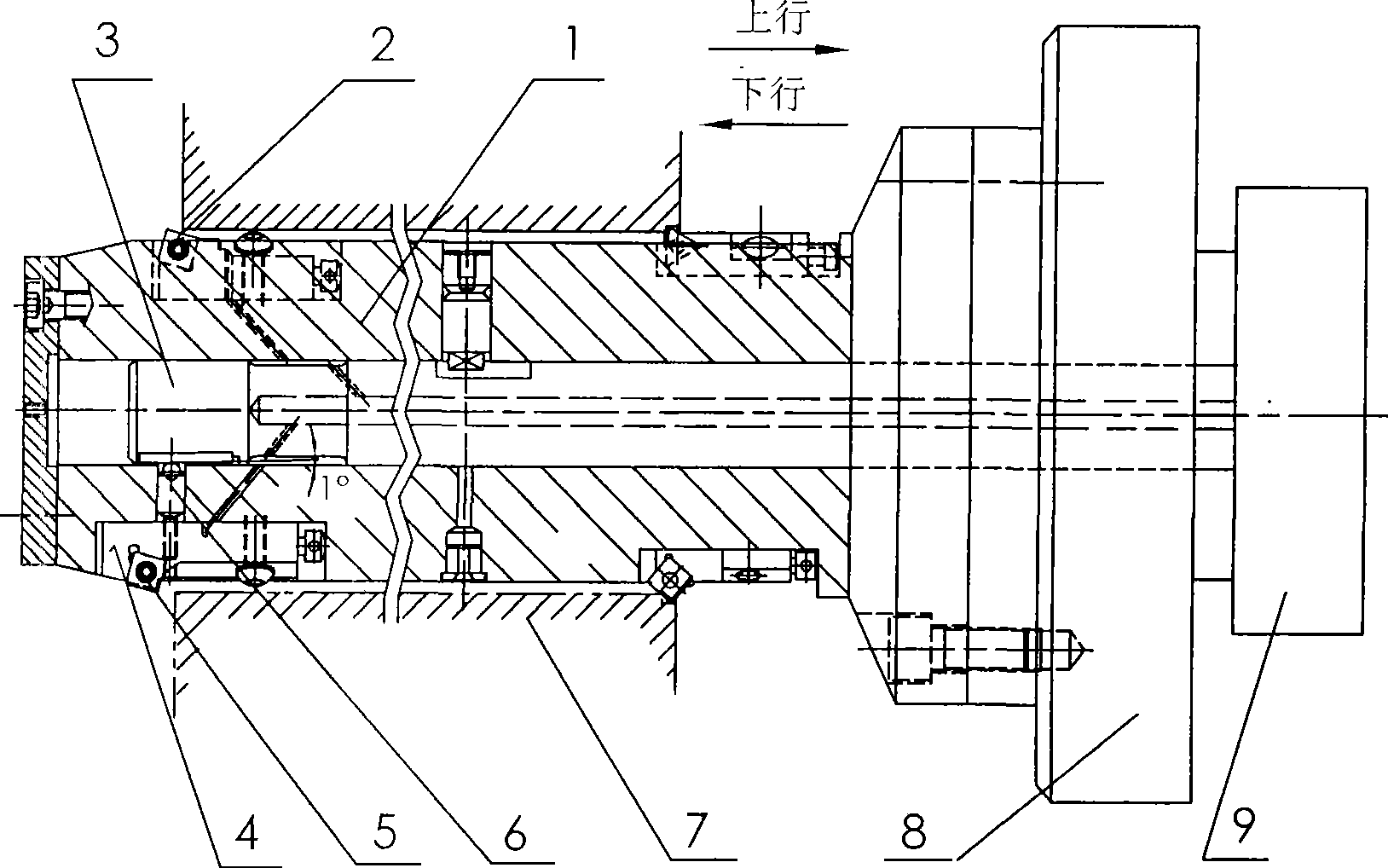

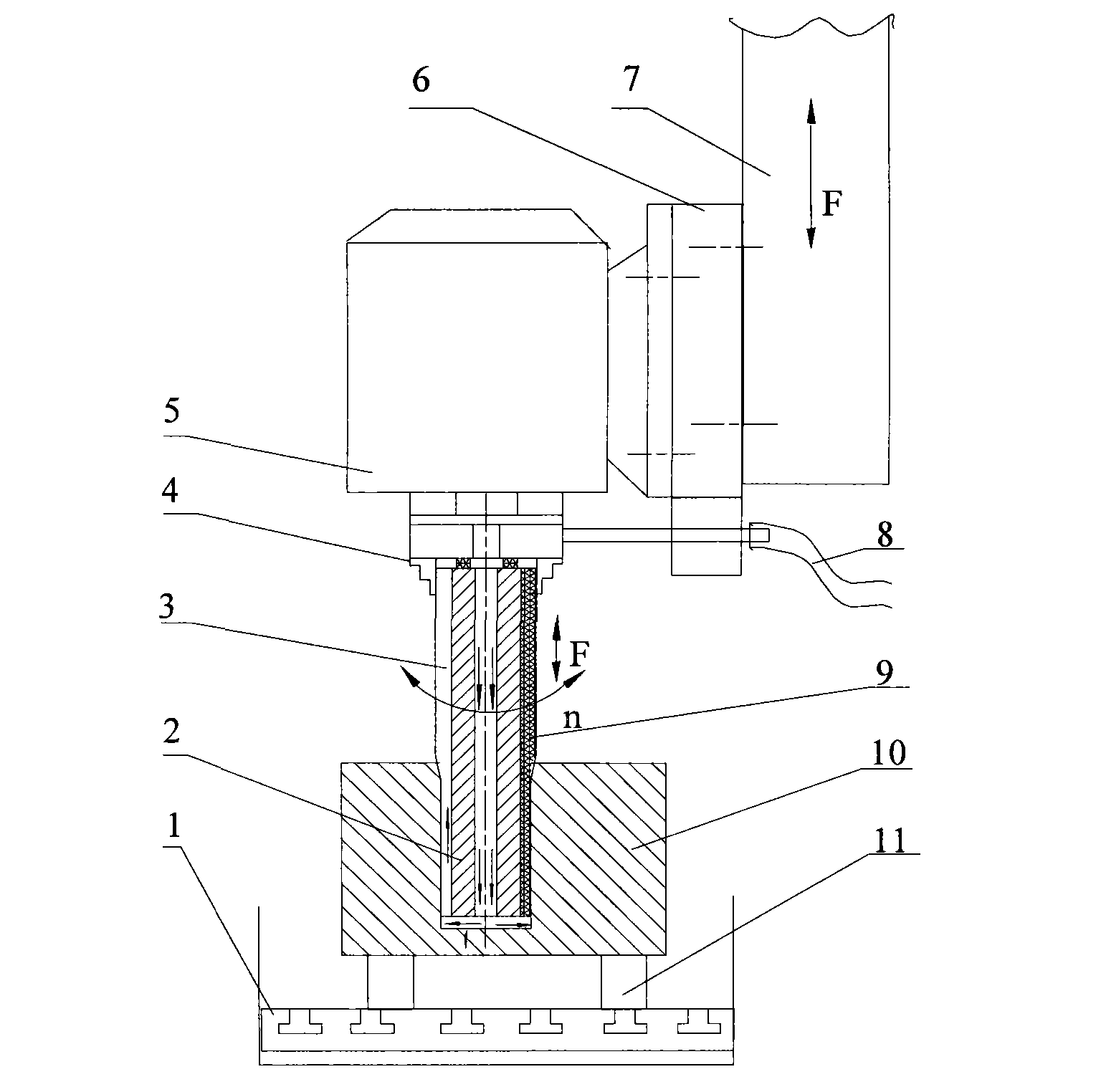

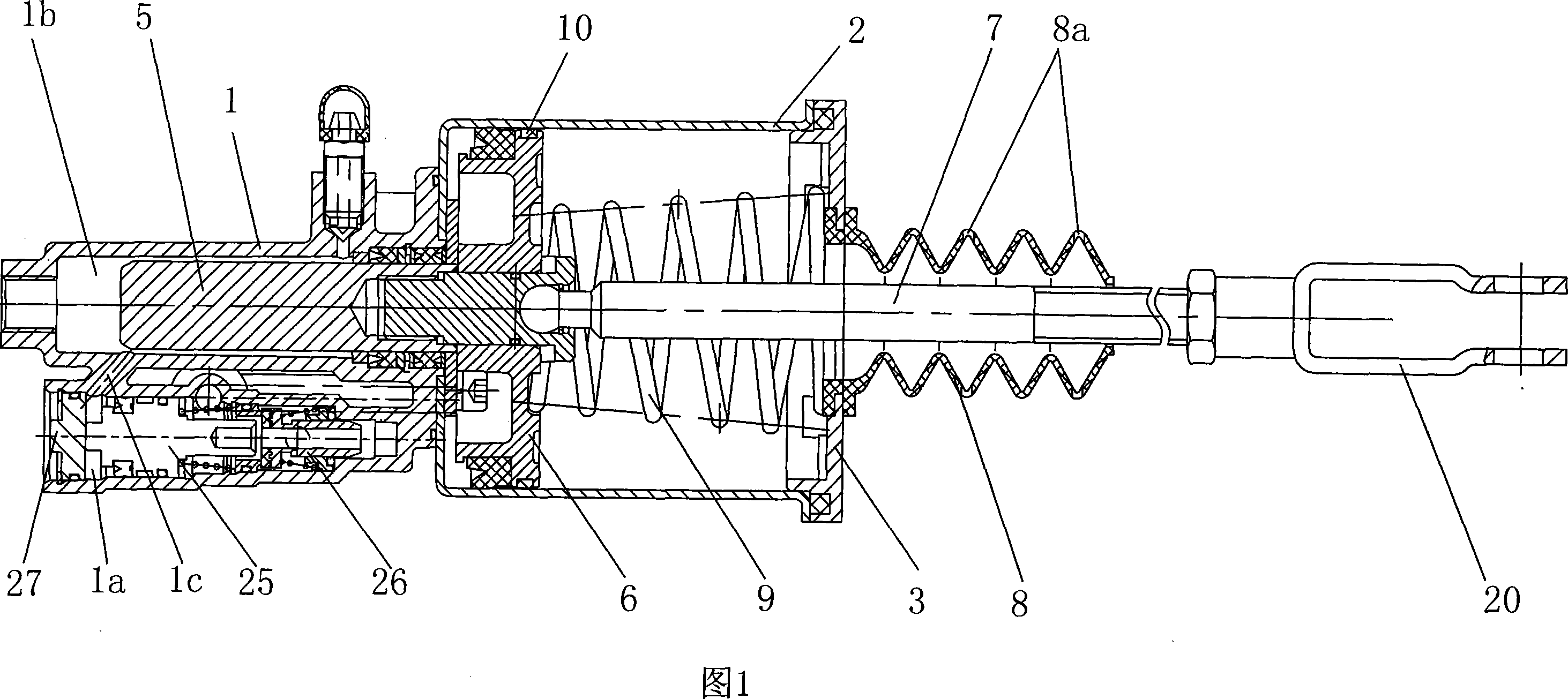

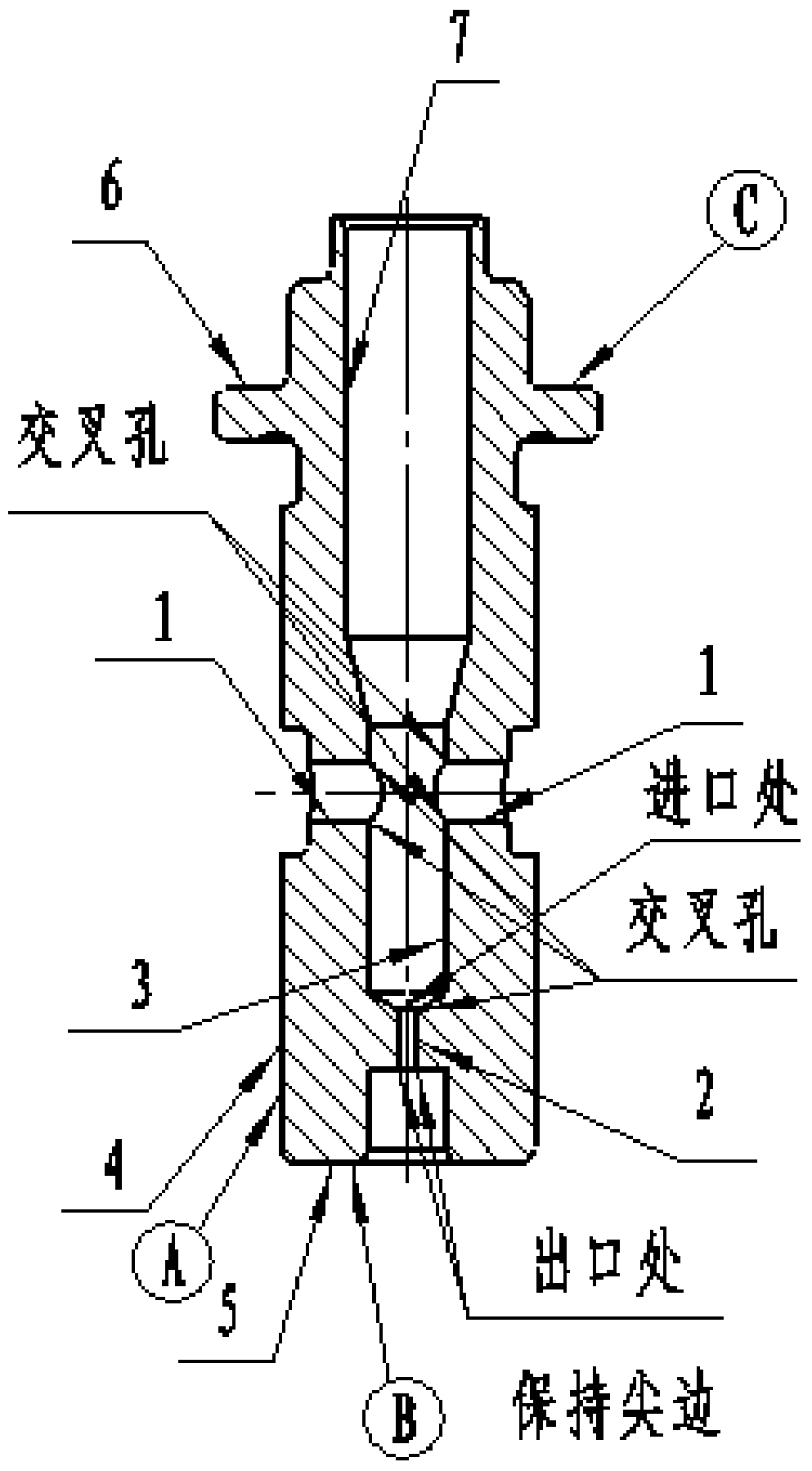

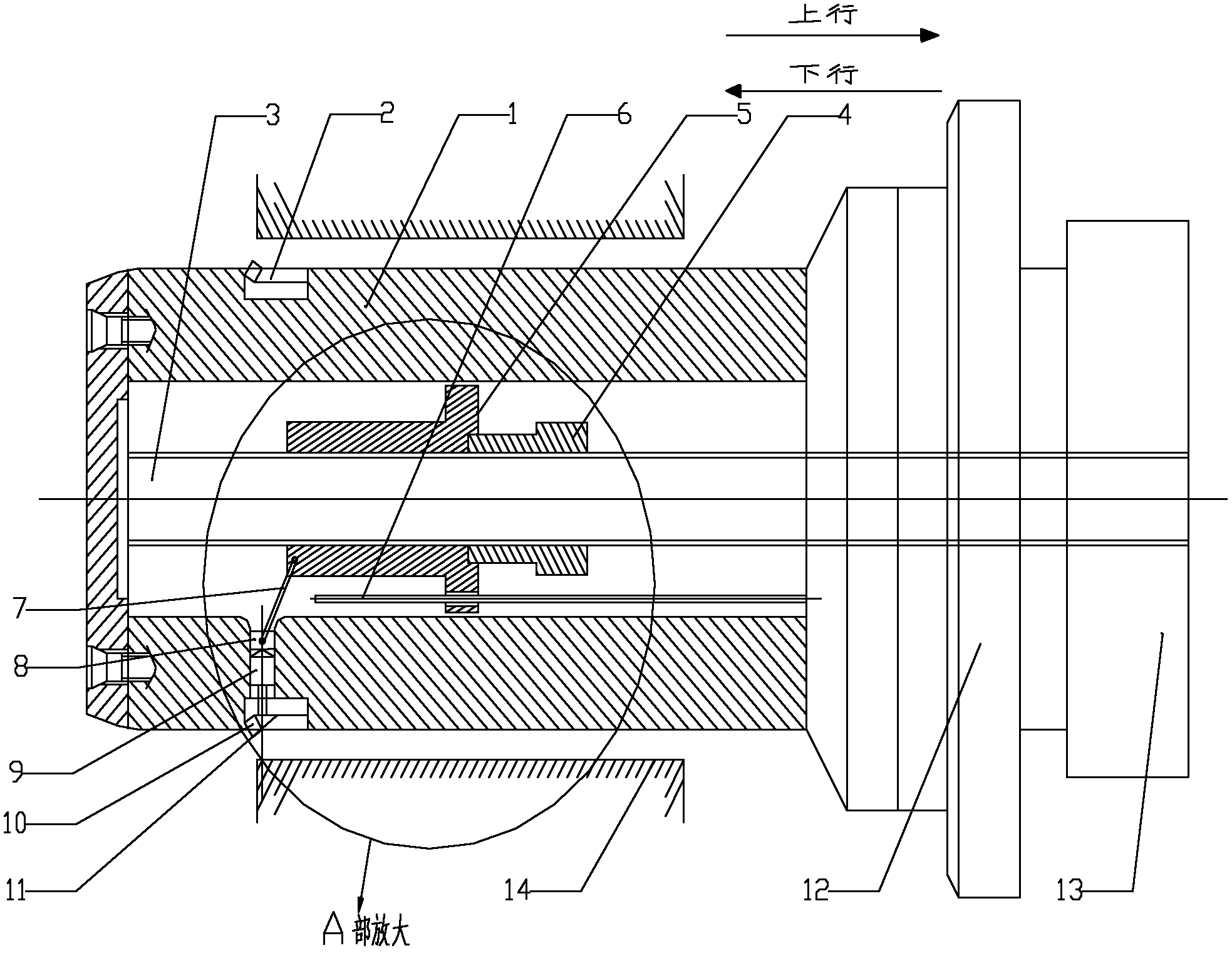

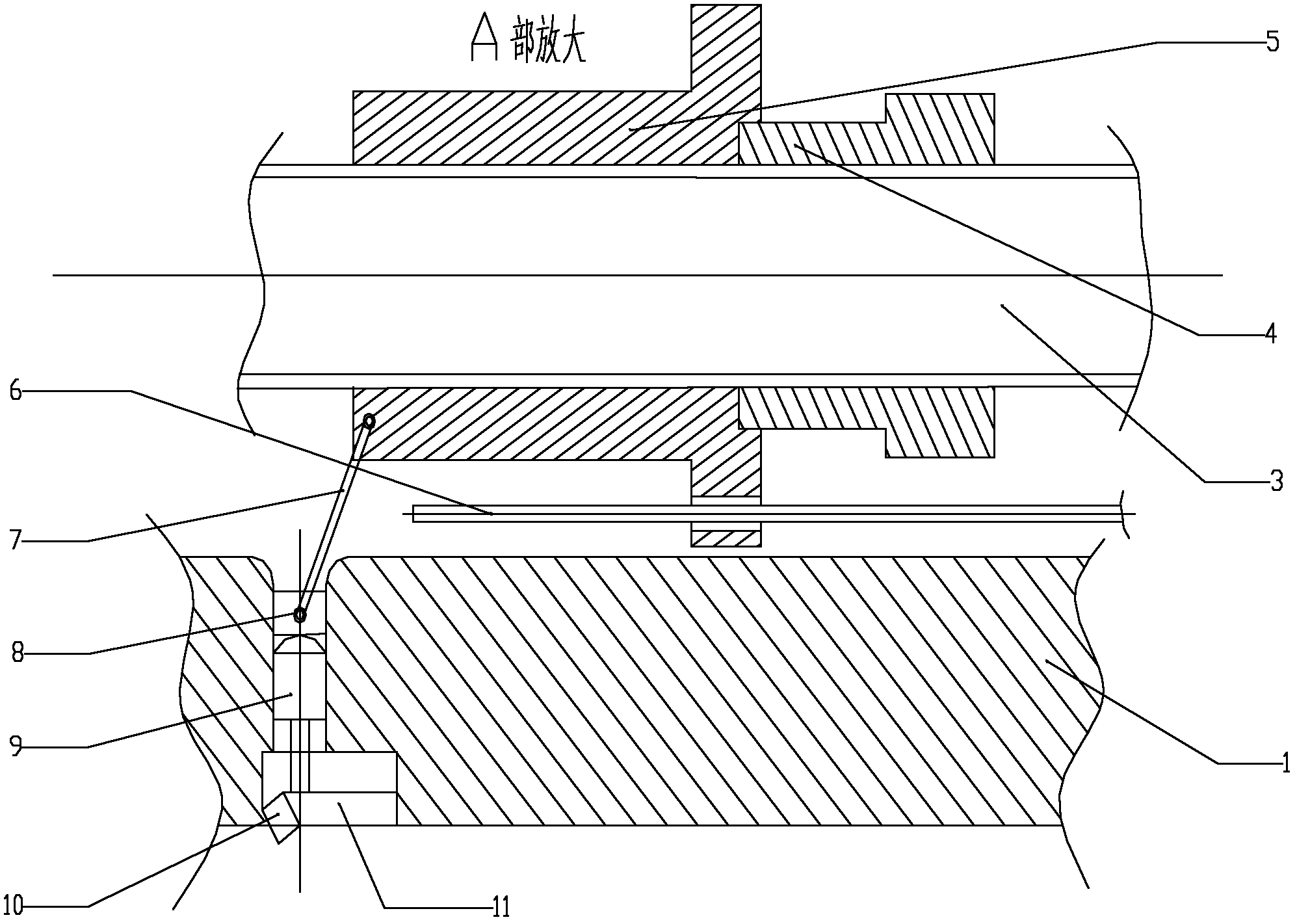

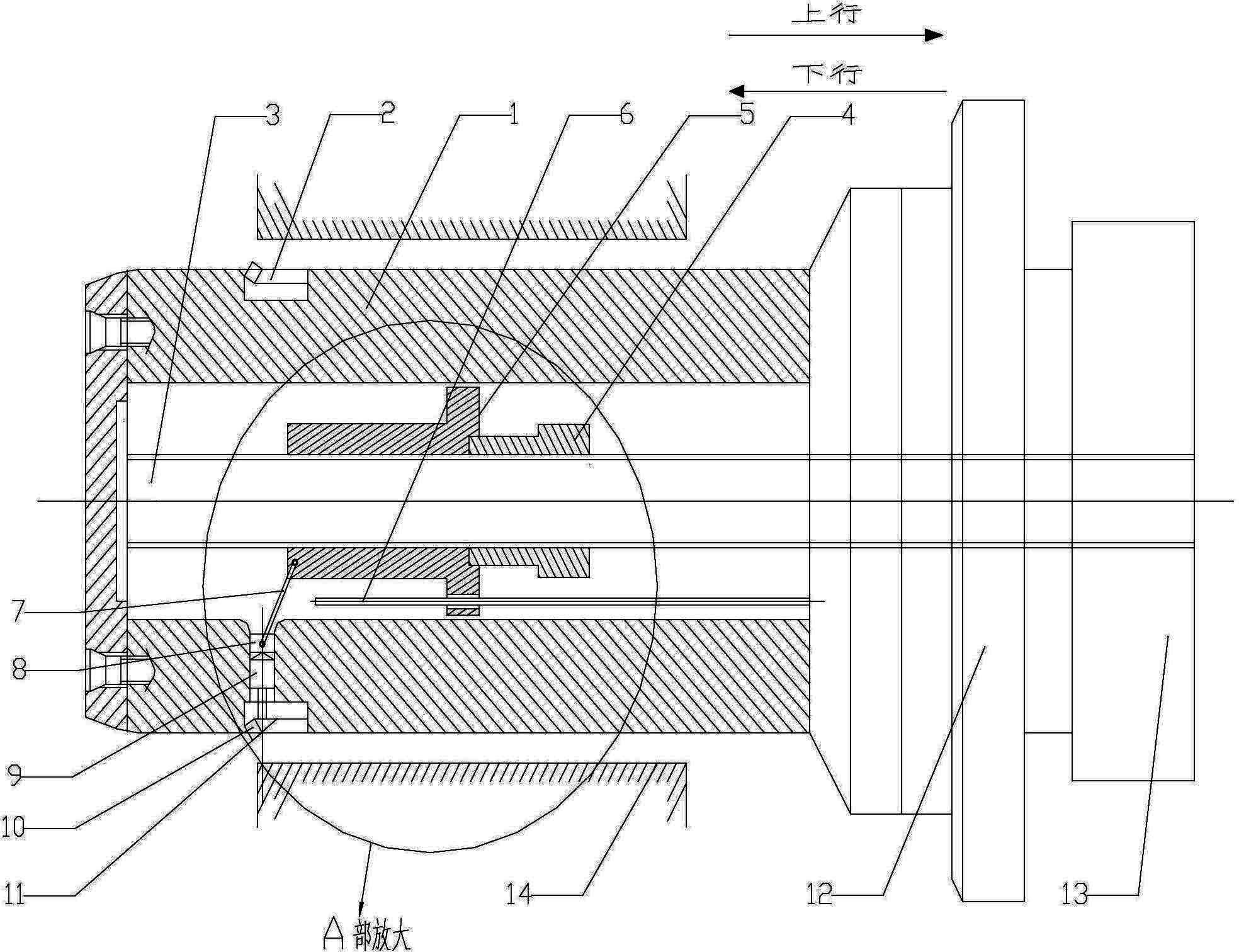

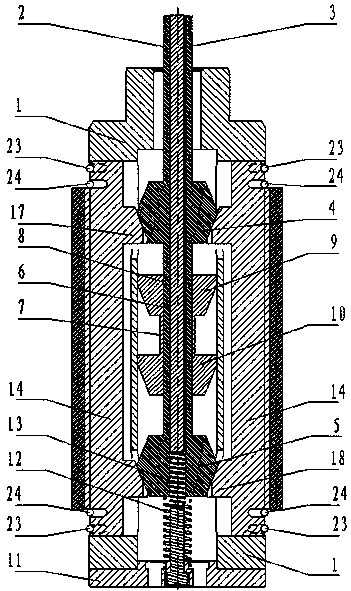

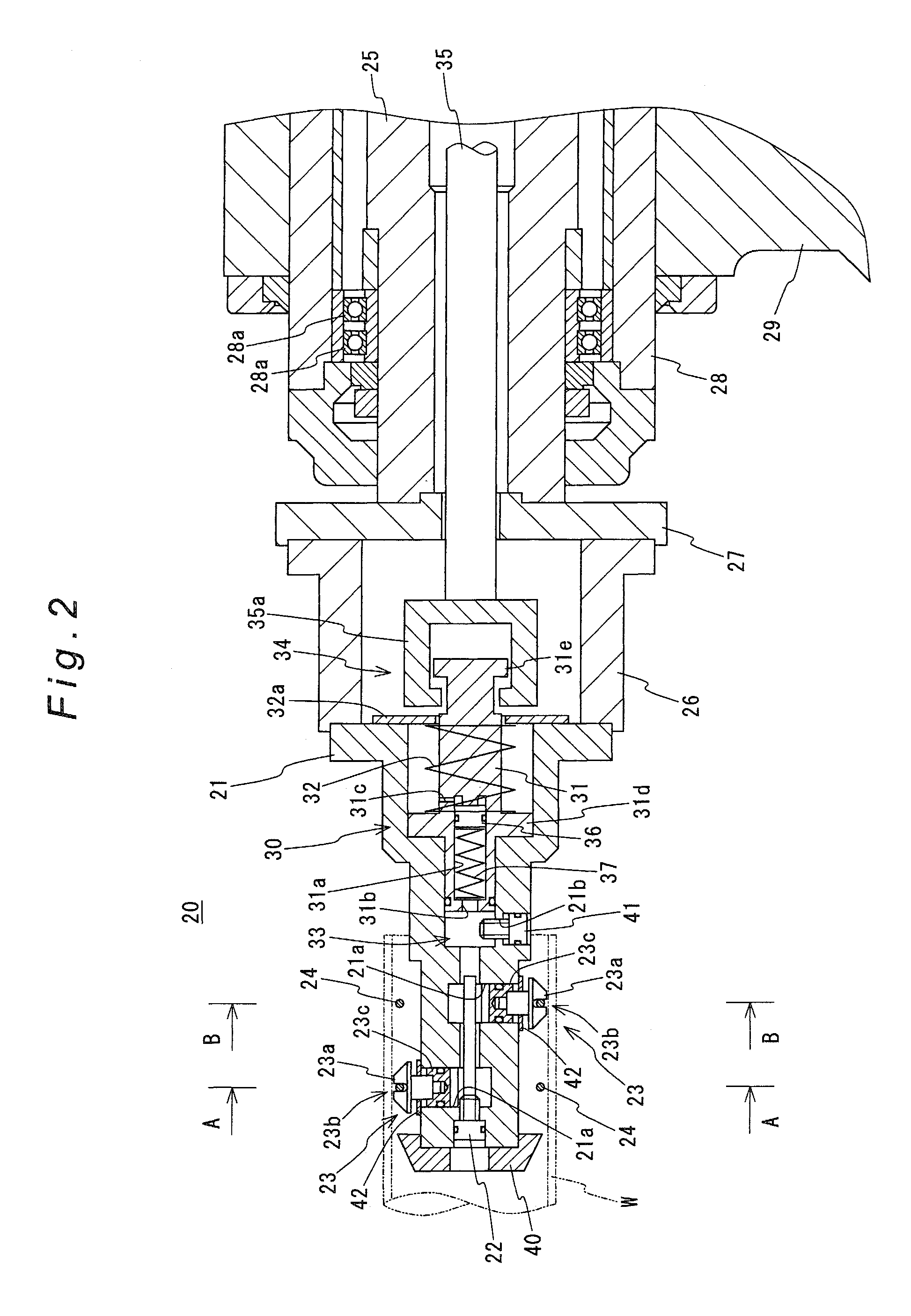

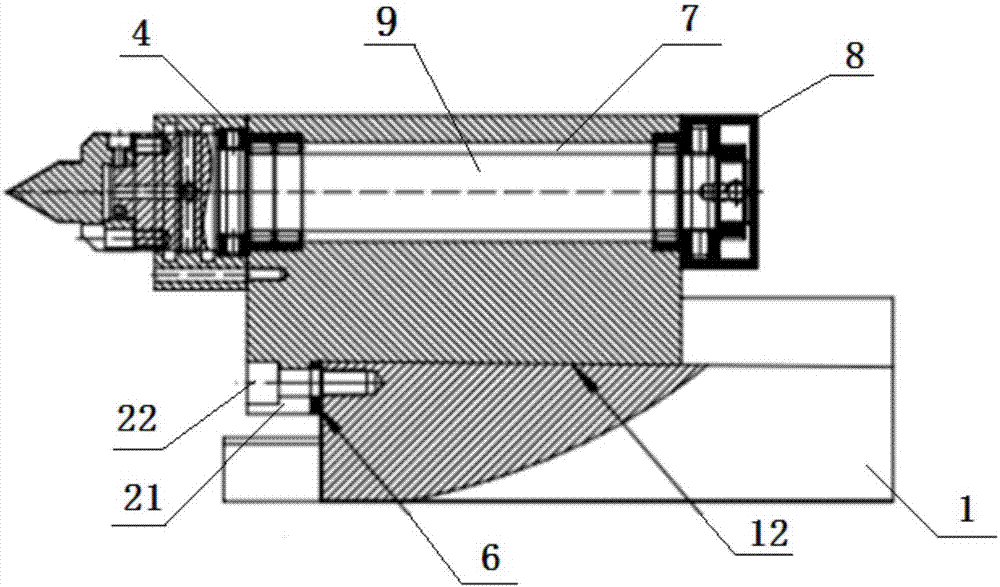

Compensation mechanism of finish boring hole cylindricity error

InactiveCN101450390AGuaranteed SpecificationsImprove cylindricityAutomatic control devicesFeeding apparatusPush and pullGeneratrix

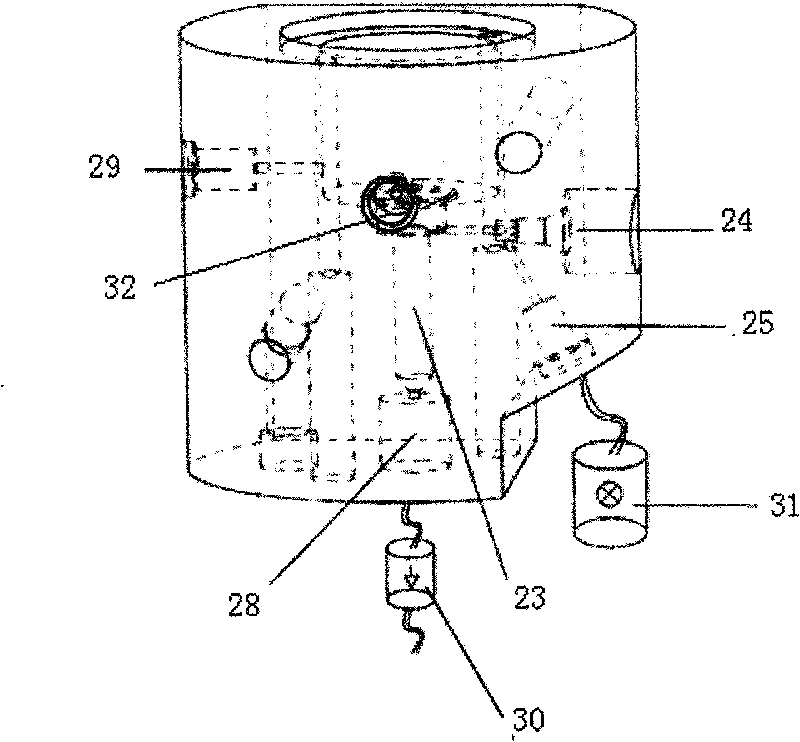

The invention provides a compensation mechanism for the cylindricity errors of fine-bored holes. As the radial wall thickness in the axis direction of an engine cylinder hole is not uniform in distribution, after the engine cylinder hole is linearly bored by a conventional machining method, the cylindricity of the hole is in a waist-drum shape. Parameters of an inverse waist-drum shape are input into a numerical control program after measurement, analysis and calculation. The cylinder hole is subjected to coaxial graded semi-fine boring and fine boring by pushing and pulling a boring bar, and rapid semi-fine boring can be carried out to the cylinder when the boring bar goes down. When the boring bar 1 goes up, a compensation servo motor 9 is started, the expansion amount of a pull rod 3 on the core part of the boring bar is accurately positioned and controlled through the servo motor; a 1-degree inclined plane on the pull rod 3 pushes a fine-boring cutter table 4 to elastically stretch out so as to enable a fine boring cutter 5 to be in a working position of fine boring size; and the fine boring cutter completes the final fine boring of the cylinder hole according to a parameter program of the inverse waist-drum shape, so that the cylindricity of the cylinder hole is effectively improved. Through the setting of the program, the side generatrix of the fine-bored holes can be a curved line or an irregular straight line by programming.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD +1

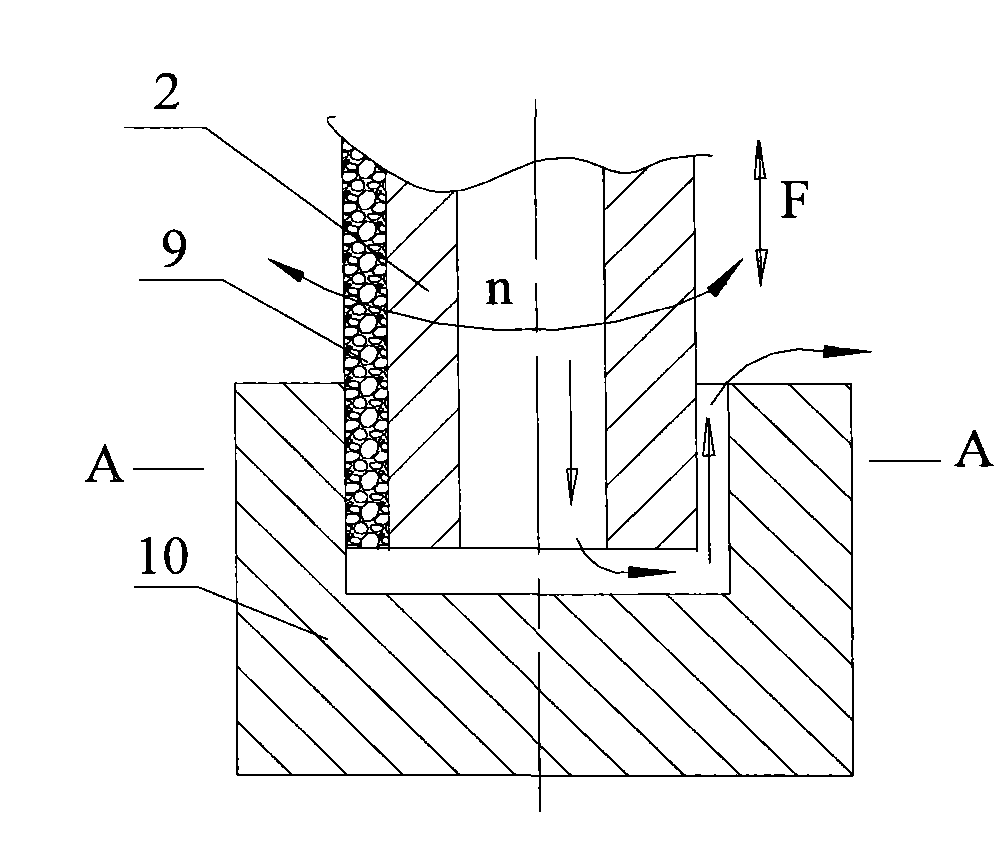

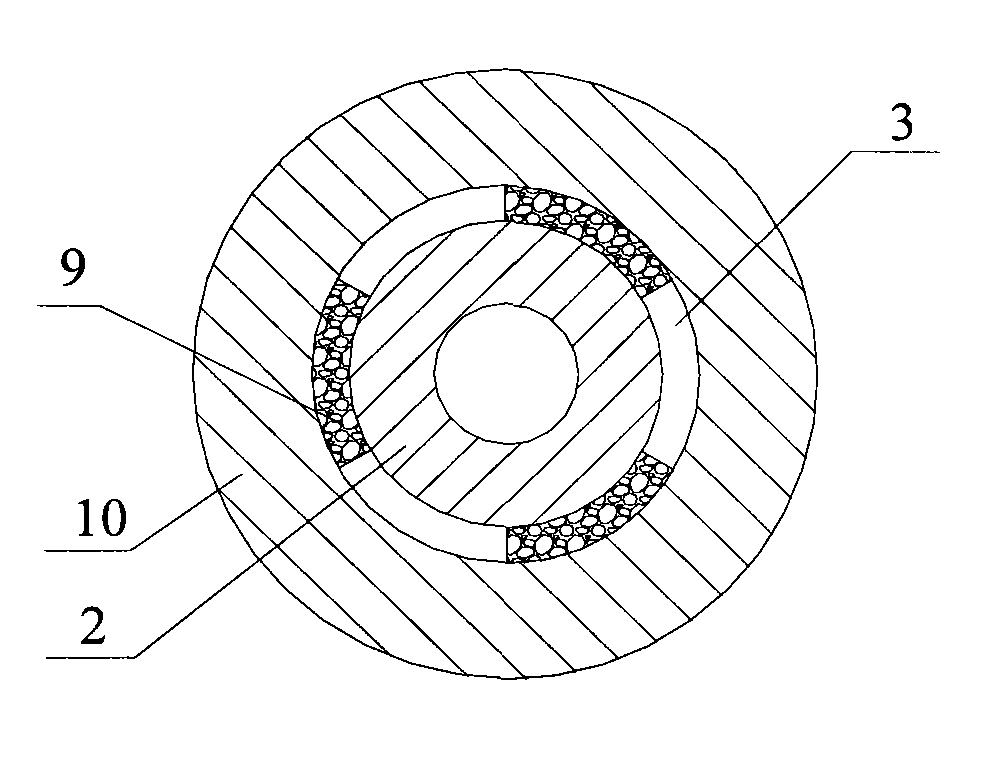

Electrode and machine tool dedicated for combined machining of electric spark shaping of inner round bore and elastic honing

InactiveCN102059417AImprove processing efficiencyImprove machining accuracyMetallic materialsEngineering

The invention discloses a electrode dedicated for combined machining of electric spark shaping of an inner round bore and elastic honing, comprising a tool electrode (2) of metal material, wherein the tool electrode is axially provided with an inner bore of electric spark operating fluid; the end surface of the tool electrode forms an electric spark discharging zone; and the outer side surface of the tool electrode (2) is covered with an elastic material grinding layer (9) provided with an outlet path (3) for the electric spark operating fluid. On the basis, the invention also discloses a machine tool for combined machining of electric spark shaping of an inner round bore and elastic honing, which is used for integrally and synchronously carrying out rough machining for the electric spark shaping of the inner round bore and fine machining for the elastic honing, and is favorable for improving the machining efficiency and the machining precision of a workpiece.

Owner:GUANGDONG IND TECHN COLLEGE

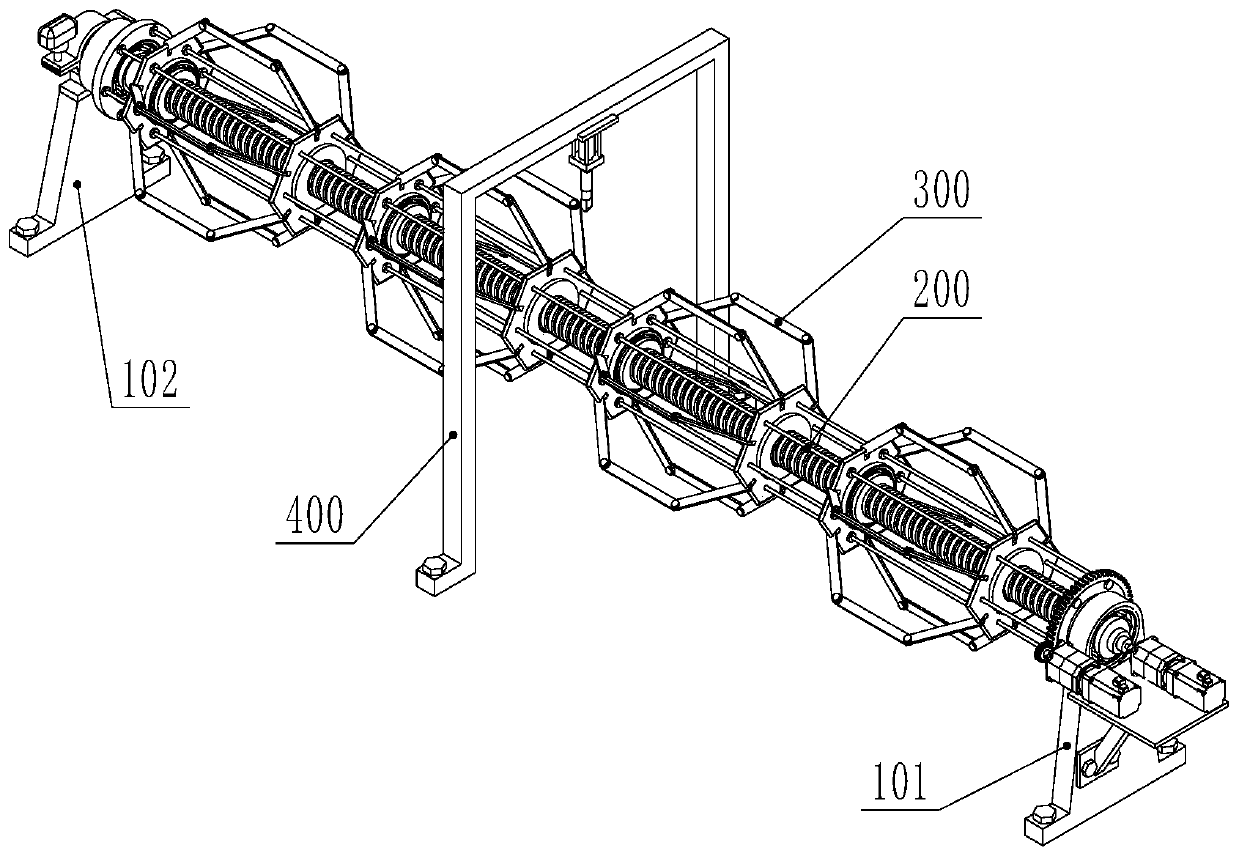

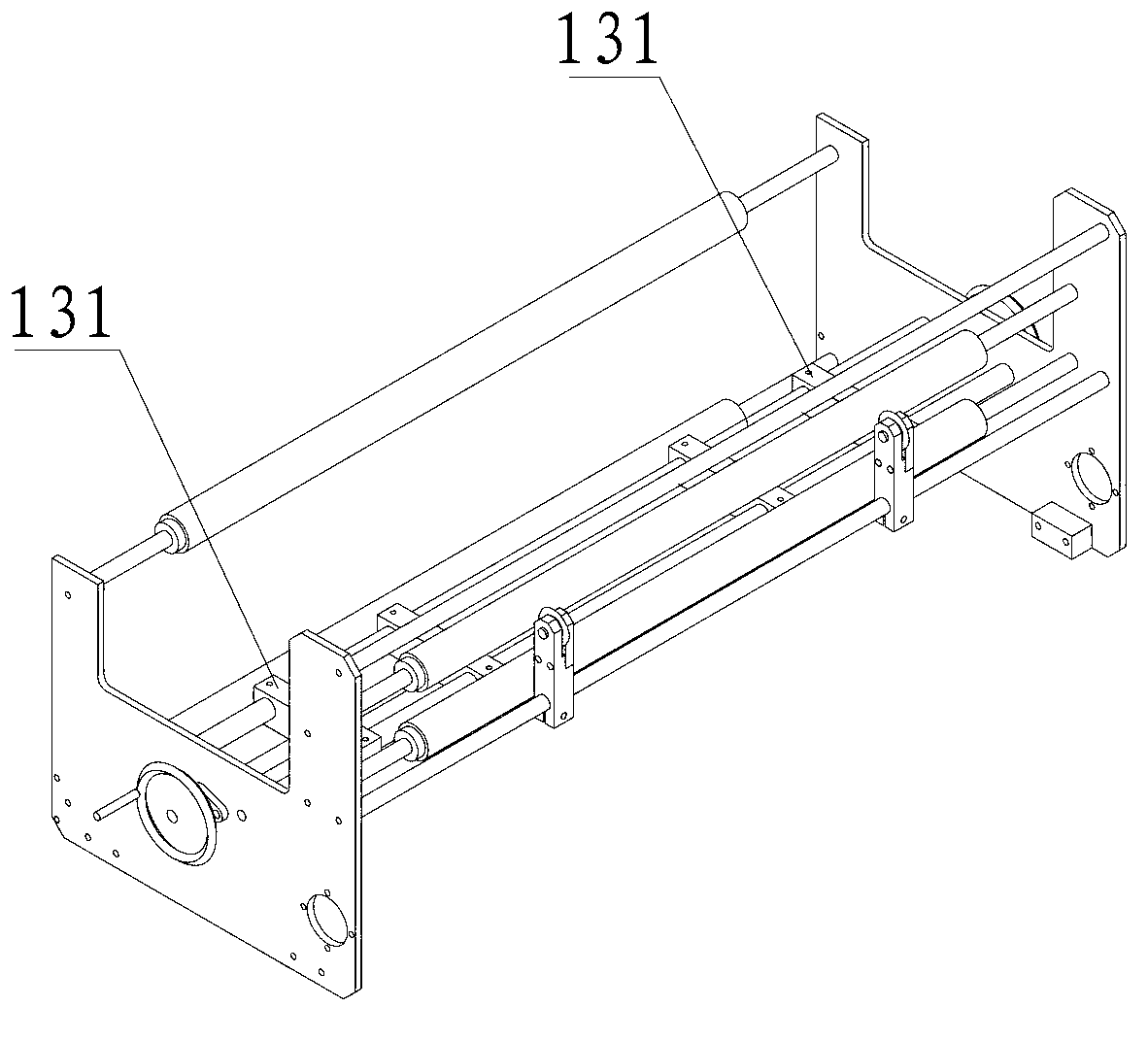

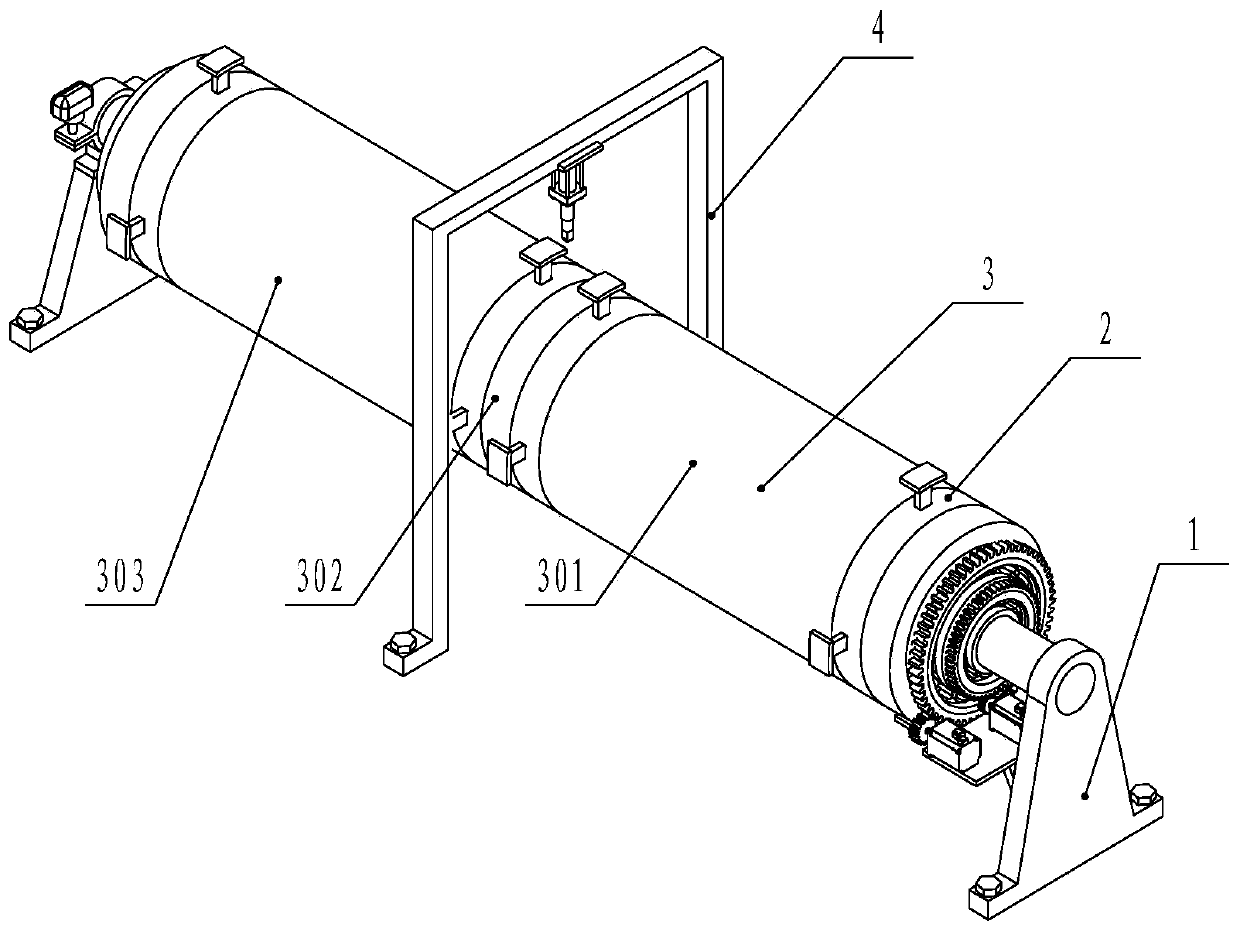

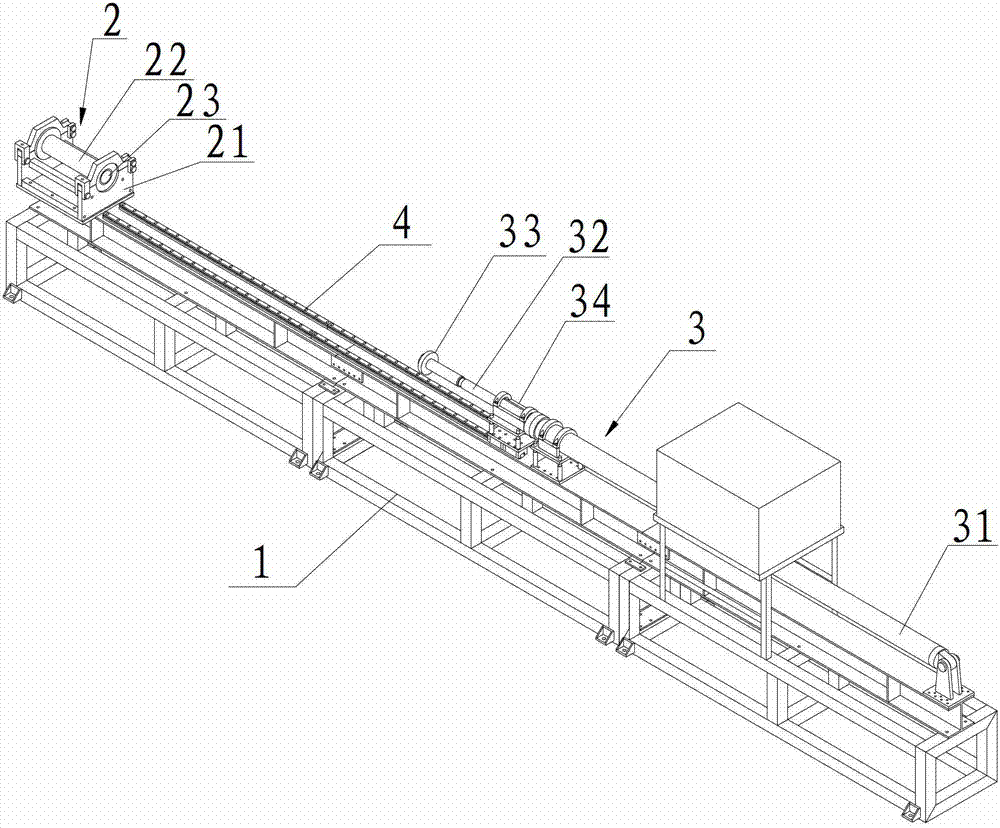

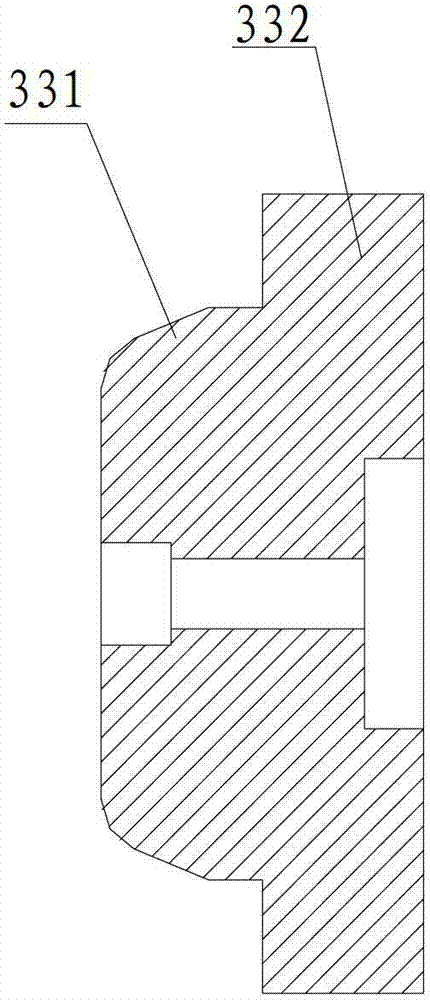

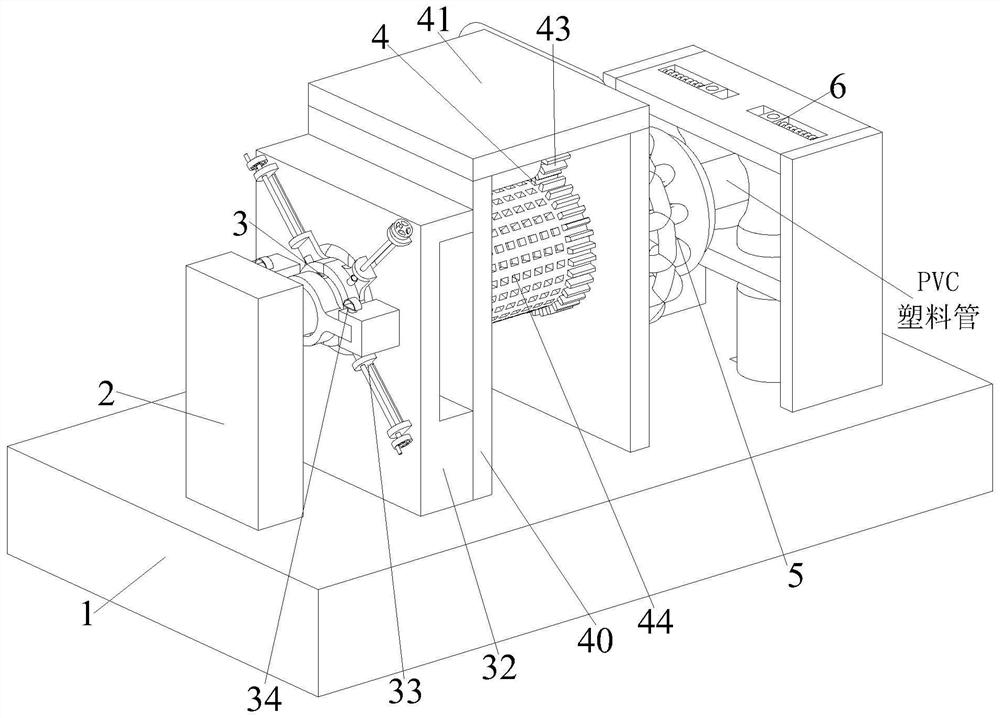

Lead screw clamping type metal hard tube rotary cutter

The invention provides a lead screw clamping type metal hard tube rotary cutter comprising a supporting device, a lead screw device, at least two expanding devices and a cutting device. The supportingdevice is located at the front and back ends of the whole cutter and fixedly connected with the ground. The front and back ends of the lead screw device are erected on the supporting device and can rotate relative to the supporting device. The expanding devices are both arranged on the lead screw device in a sleeving manner and connected with the lead screw device through threads. The expanding devices are sleeved with a to-be-cut metal hard tube. The cutting device is arranged between the two adjacent expanding devices. The supporting device is provided with an early operation motor and a later operation motor. The two motors can control the lead screw and the expanding devices to rotate correspondingly. The cutter is provided with multiple connection rod structures adopting expanding connection rods and front and back rockers to clamp the metal hard tube, a longer contact area is obtained in the length direction of the metal hard tube, and therefore the lead screw clamping type metal hard tube rotary cutter is suitable for to-be-cut metal hard tubes of different lengths, guarantees reliable clamping and avoids deformation.

Owner:HEBEI UNIV OF TECH

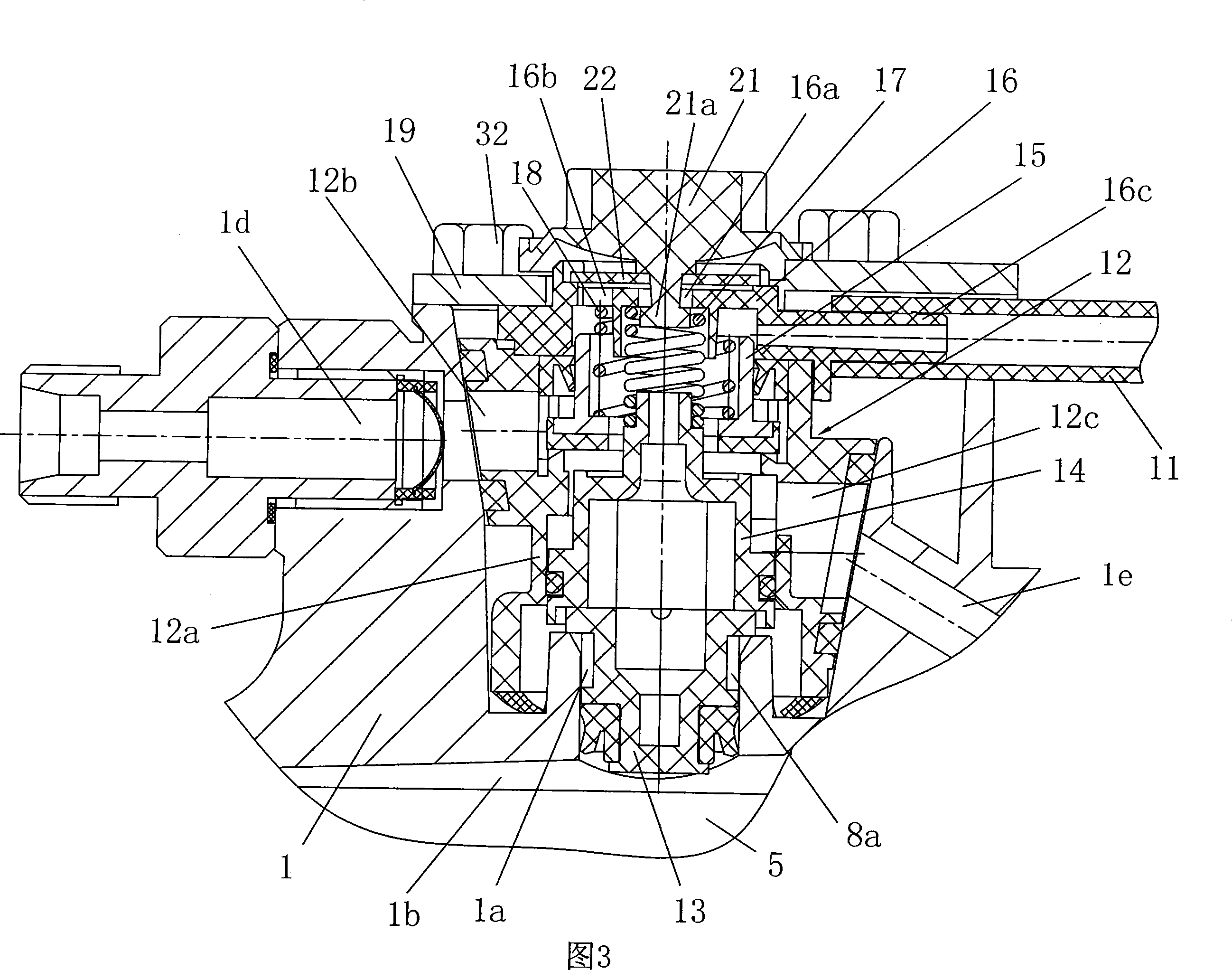

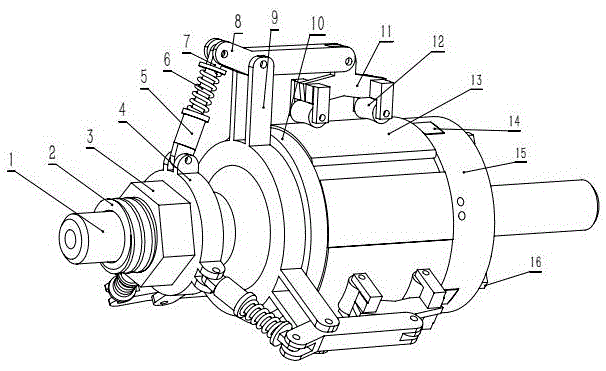

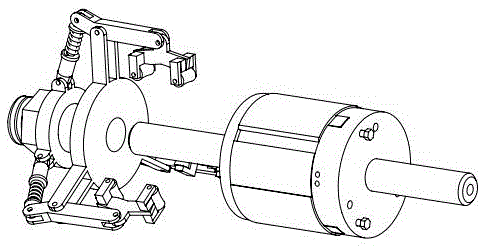

Clutch assistor for car

The present invention provides an auto clutch booster, including an oil cylinder case and a cylinder fixed on the front of the oil cylinder case, the front of the cylinder is a ring flange, a valve chamber extending outwards is set at the middle and front of the oil cylinder case, gas valve assembly is packed in the valve chamer, the inner wall of the cylinder is plated with hard chrome layer, concave grooves are set on two sides of the boosting pistion; the front of the pushing rod is covered with adjusting threaded sleeve via right-hand threaded sleeve, the other end of the adjusting threaded sleeve is connected with the separating fork via minus screw, the pushing rod and the separating fork of the adjusting screw sleeve are covered with right-hand screw and the left-hand screw respectively. The cylinder of the invention has a better wear resistance, easy process, lower manufacturing cost; the booster can conveniently quick adjust the length of the pushing rod and the separating fork un-detachably after being mounted on the body; the cylinder also effectively dustproof, avoiding strain, jammed and invalid of cylinder and gas valve caused by dust inlet; the mounting position of the ring flange is adjusted, having better popularity.

Owner:曾忠莉

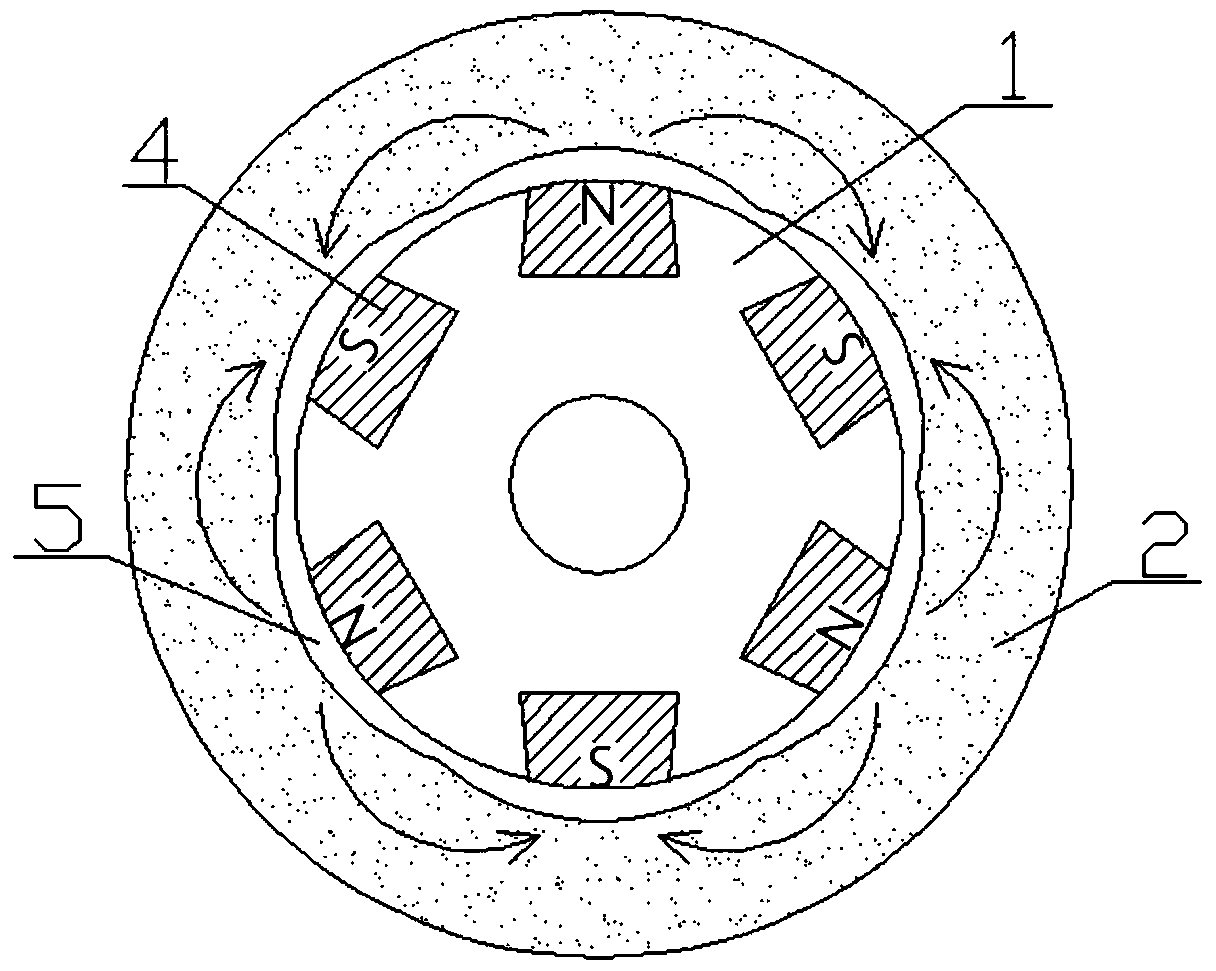

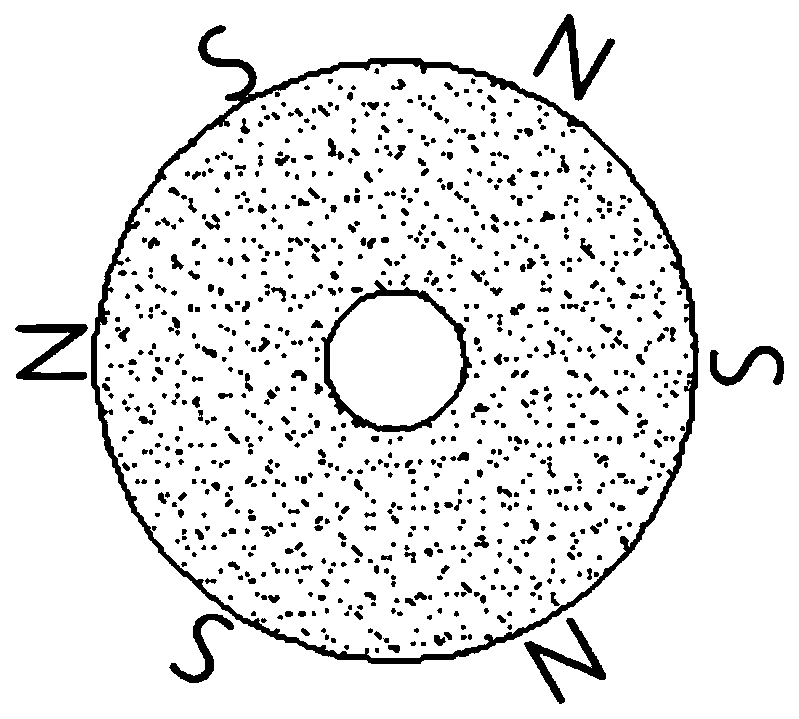

Low-cost anisotropic sintered permanent magnetic ferrite radial multi-pole magnetic ring forming mould and method

InactiveCN110265215AImprove cylindricityReduce wasteAuxillary shaping apparatusPermanent magnet manufactureShrinkage rateMaterials science

The invention discloses a low-cost anisotropic sintered permanent magnetic ferrite radial multi-pole magnetic ring near-net forming mould and a method. The forming mould mainly comprises magnetic yokes, ferrite magnetic powder, a core rod, neodymium-iron-boron magnetic blocks, and a mould wall; the inner side of the mould wall is filled with the ferrite magnetic powder; the core rod is arranged in the center of the inner side of the mould wall; the neodymium-iron-boron magnetic blocks are uniformly distributed on the circumference of the outer side of the mould wall; and the magnetic yokes are arranged on the outer sides of the neodymium-iron-boron magnetic blocks. The forming mould considering the difference of the shrinkage rates of one circle of a magnetic ring is adopted, so that the working surface side of the sintered blank magnetic ring has good cylindricity; the high-performance neodymium-iron-boron permanent magnetic blocks are adopted as orientation clamp magnetic field generation sources, so that the magnetic field is stable, and the orientation of the poles of the ferrite magnetic ring is ensured to be uniform; the advantages are more obvious in preparation of a series of products such as radial two-pole, four-pole, six-pole, eight-pole and ten-pole products and the like; and the forming mould is suitable for outer circular anisotropic radial multi-pole magnetic rings and inner circular anisotropic radial multi-pole magnetic rings, and has high universality.

Owner:HANGZHOUSNNER MACHINERY EQUIP

Machining method for abrasive flow deburring of bushing-like components

The invention relates to a machining method for abrasive flow deburring of bushing-like components. According to a procedure of abrasive flow deburring of the inner chamber of the bushing, burrs at the crossed parts of radial holes and an oil inlet holeand a crossed part of a small hole and the oil inlet hole are removed; an excircle 4A and an end face 5B are used for positioning, and the upper surface 6C of a mounting edge is compressed. In a forward cycle, abrasive is fed from a large hole and is discharged from the radial holes; and in a reverse cycle, the abrasive is fed from the radial holes and discharged from the large hole. According to an optimal abrasive flow procedure, the abrasive is preheated for 20-40min and cycles for 4 times, system pressure P is 10MPa, and working pressure P is 7MPa. The machining method has the advantages that via a test of abrasive flow deburring process, the surface roughness of a component inner chamber crossed hole transition part R, inspected by using a bar type endoscope, reaches Ra0.8, the surface roughness and cylindricity of the inner chamber are obviously improved, and burrs at the crossed hole transition part are basically removed. The deburring quality is steady. The primary assembly percent of pass of valve components is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

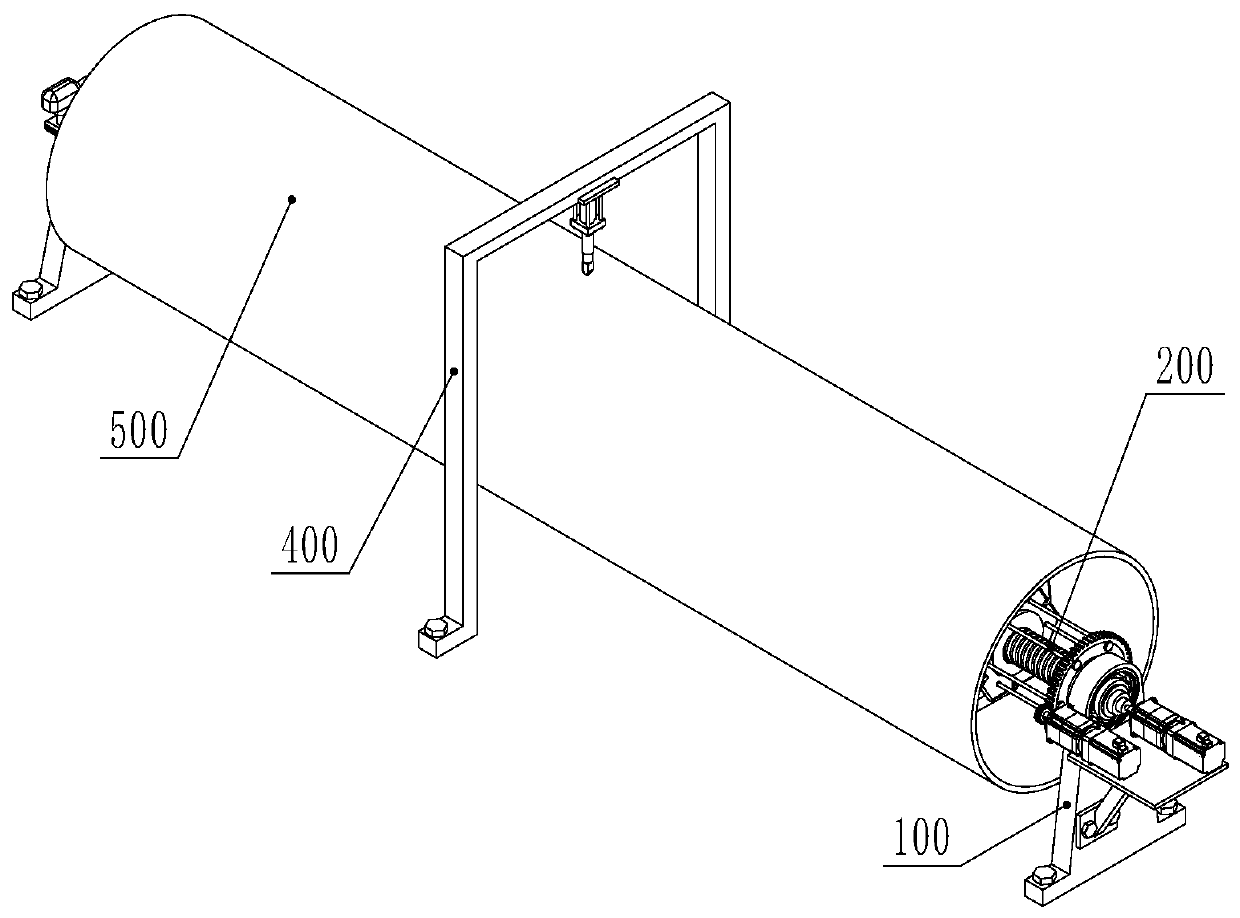

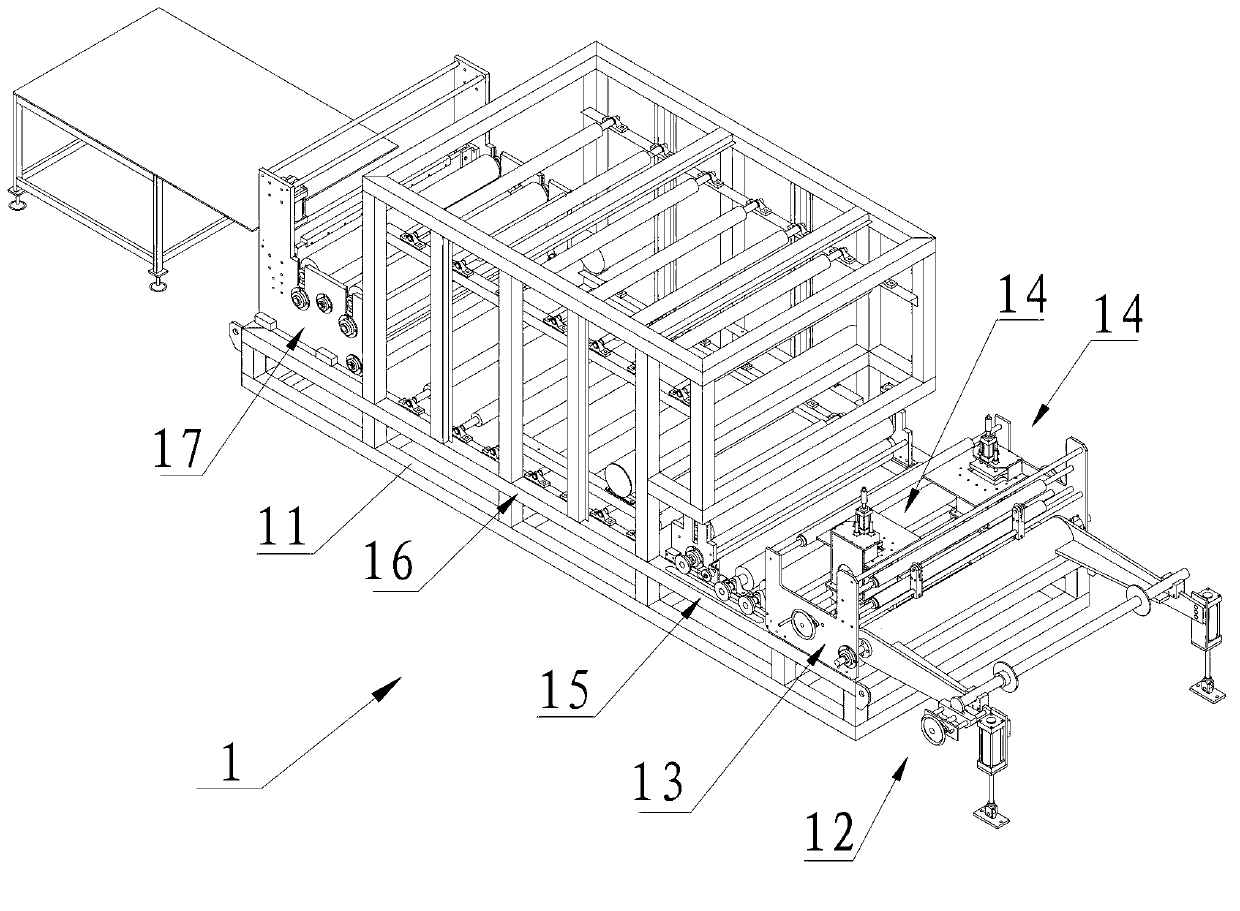

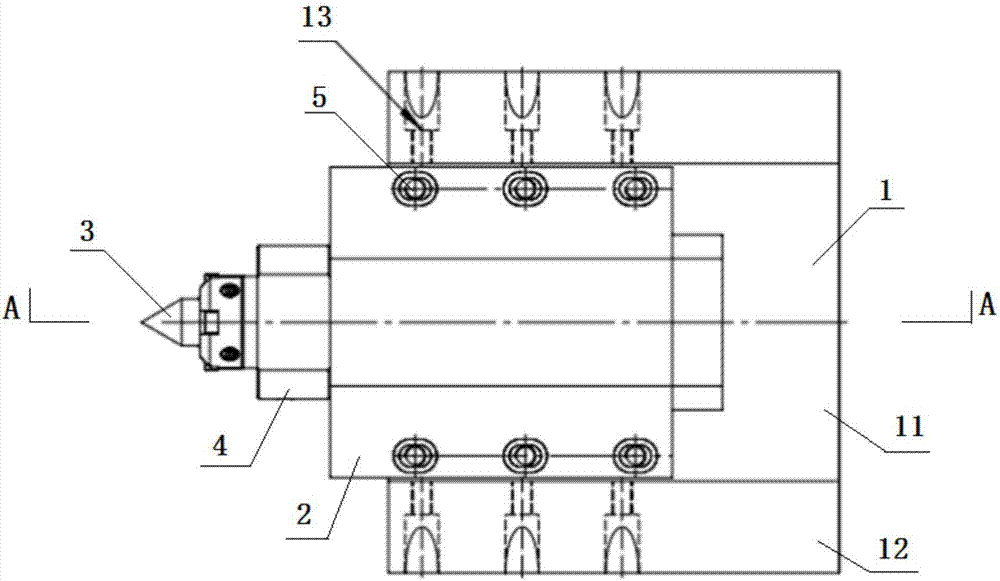

Seamless paper pipe production line

InactiveCN102950818AExcellent overall performanceReduce wastePaper/cardboard wound articlesPaper sheetCopper foil

The invention discloses a seamless paper pipe production line, which comprises paper processing equipment, a paper sizing device, a paper pipe covering pipe, a paper pipe waxing device and a paper pipe calendaring device. At first, the paper processing equipment processes paper so that the two sides of the paper become thin, the surface flatness and hardness of the paper can be improved, and then, the paper is chopped into be in a proper dimension for standby; and the paper sizing device sizes the surface of one side of the paper, the sized paper is covered on the peripheral surface of the outer side of a paper pipe through the paper pipe covering device, the edge parts of the two sides of the paper, which become thin, are clung with each other, and in this way, a seamless paper pipe can be formed. After the paper pipe waxing device waxes on the peripheral surface of the outer side of the seamless paper pipe, the seamless paper pipe becomes smooth; and the seamless paper pipe is subjected to calendaring by the paper pipe calendaring machine, so that the seamless paper pipe has good straightness and cylindricity. When the seamless paper pipe is used for winding a thin film, a copper foil and other thinner materials, the materials can not be wrinkled, so that the waste caused by the damaged materials can be greatly reduced.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

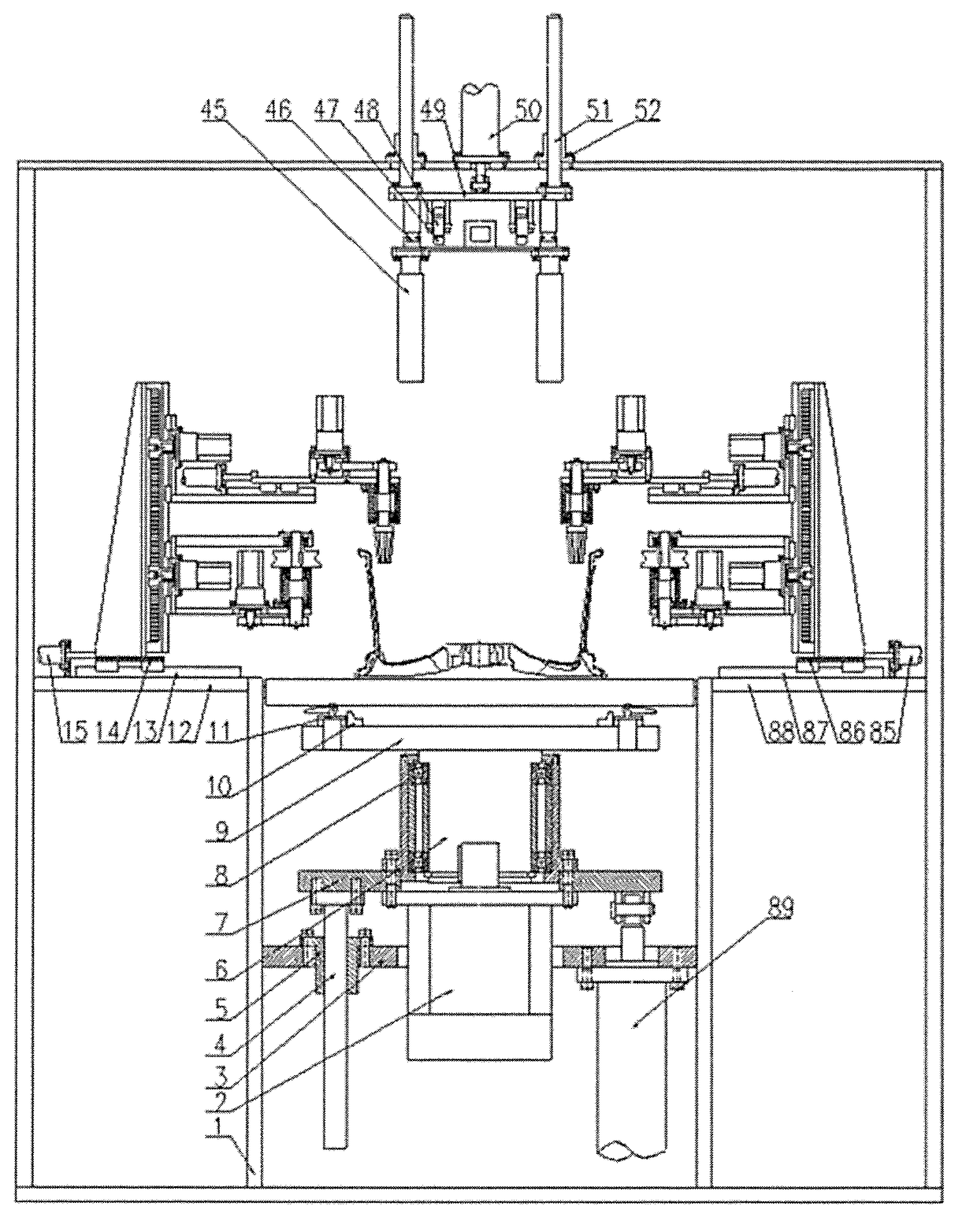

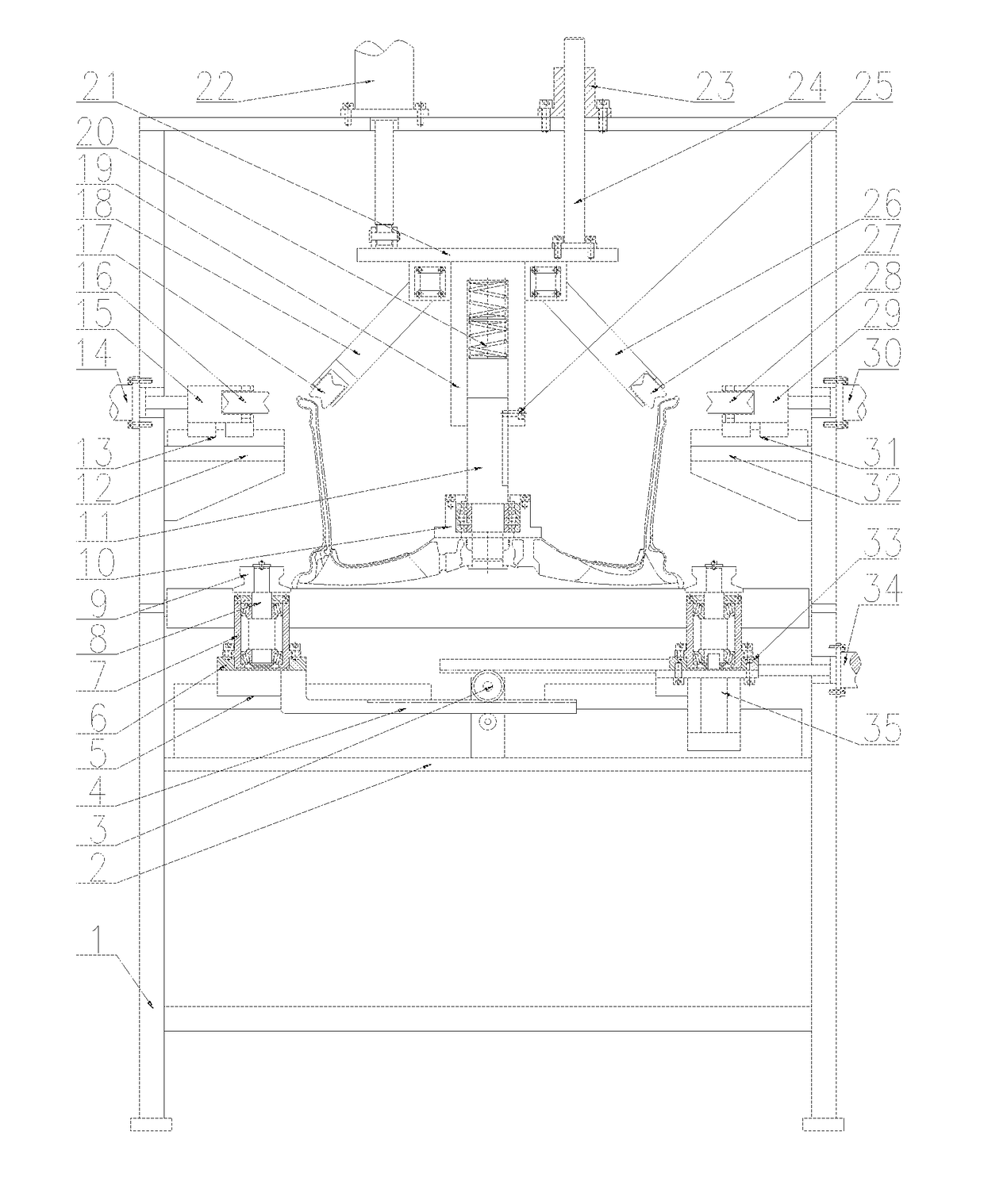

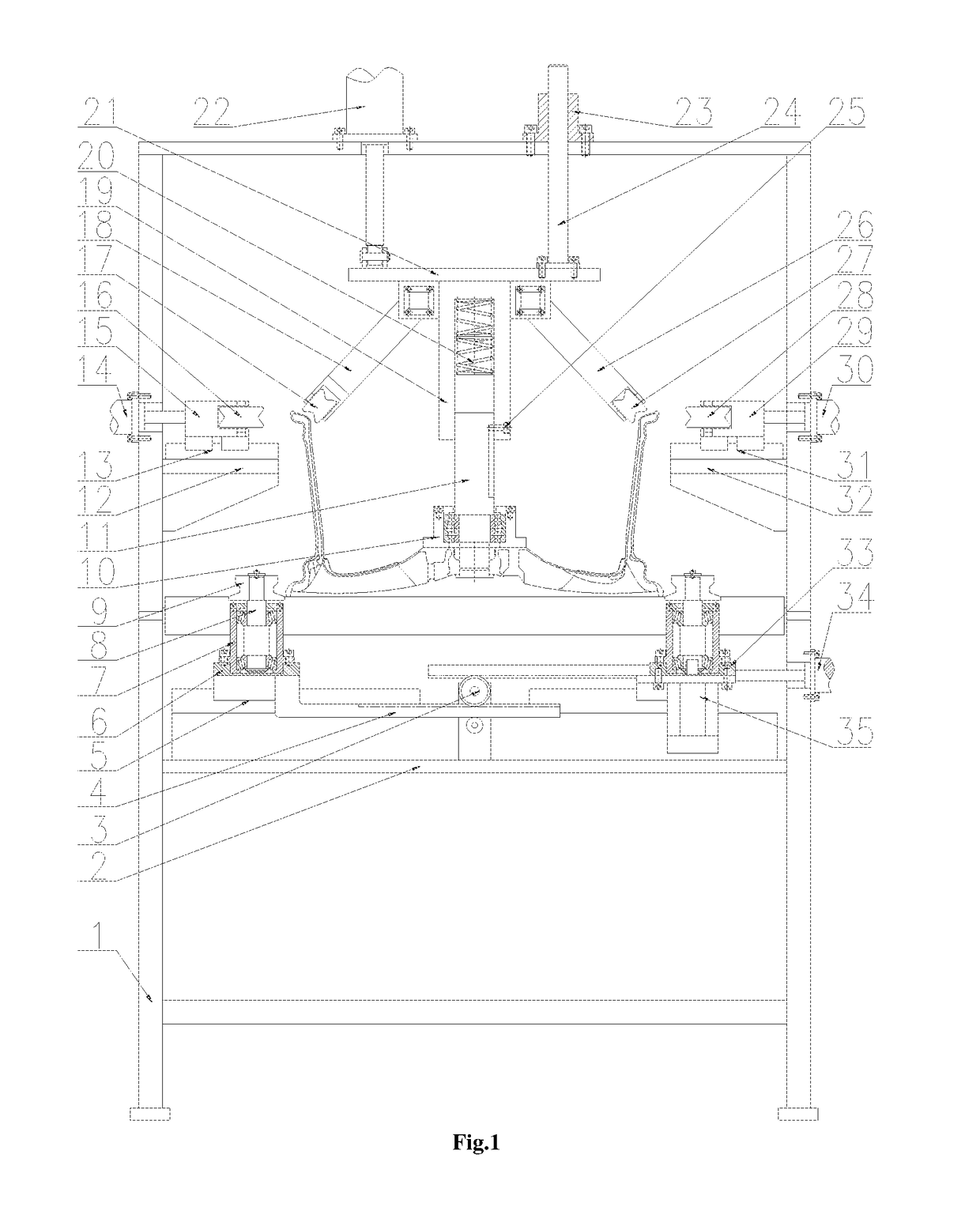

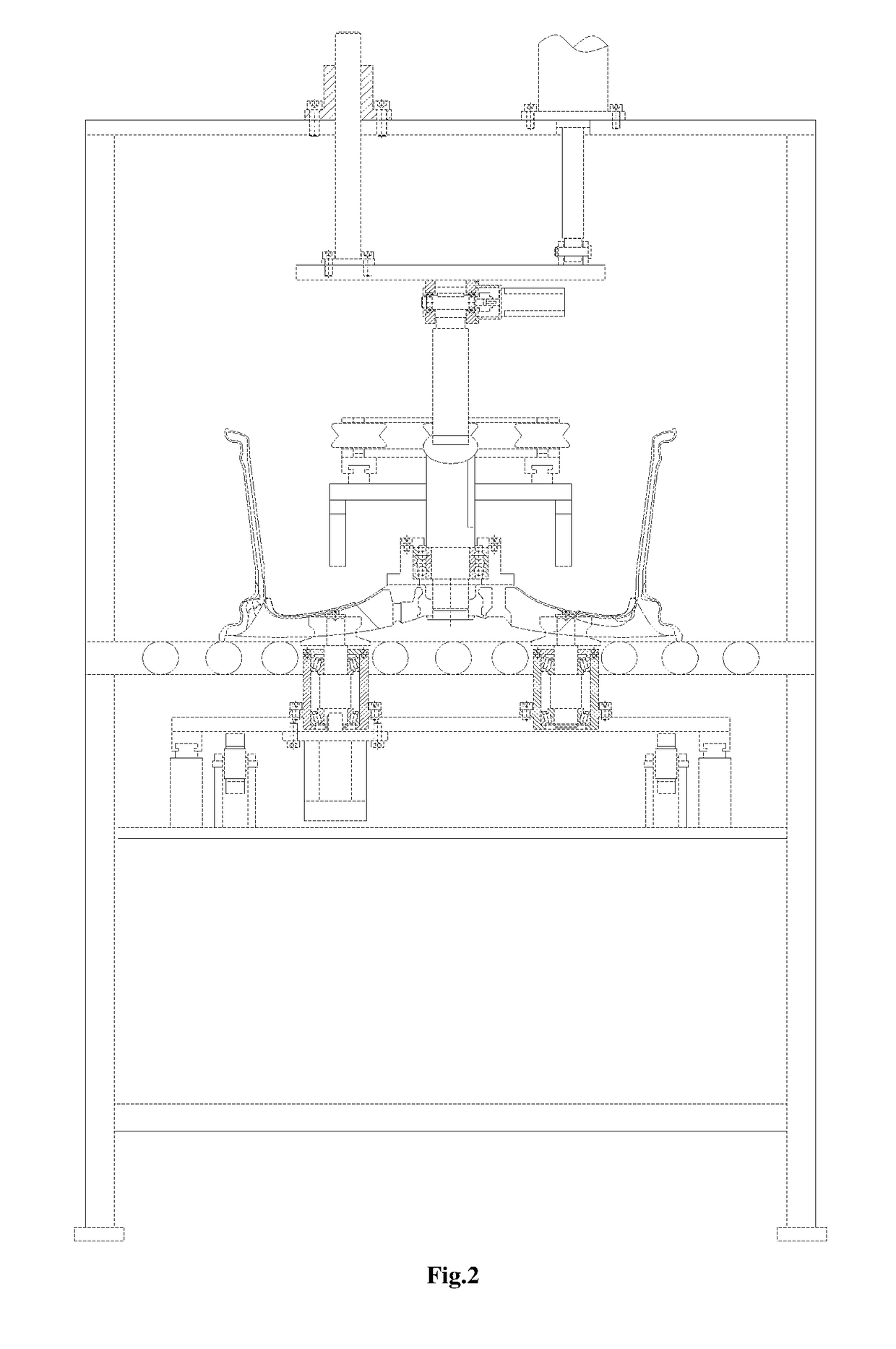

Online roundness correcting device for semifinished wheel

ActiveUS20170182543A1Improve roundnessImprove cylindricityRimsMetal-working apparatusEngineeringUltimate tensile strength

The present invention relates to an online roundness correcting device for a semifinished wheel, which consists of a jacking and rotating system, a left correcting system, a right correcting system and a central locating system. According to the online roundness correcting device provided by the present invention, in service, an online roundness correcting function for the semifinished wheel can be achieved, and the corrected wheel has good roundness and cylindricity, so that not only can the labor intensity for workers be lowered, but also the online roundness correcting device has the characteristics of high degree of automation, advanced process, simple structure and safe and stable performance.

Owner:CITIC DICASTAL

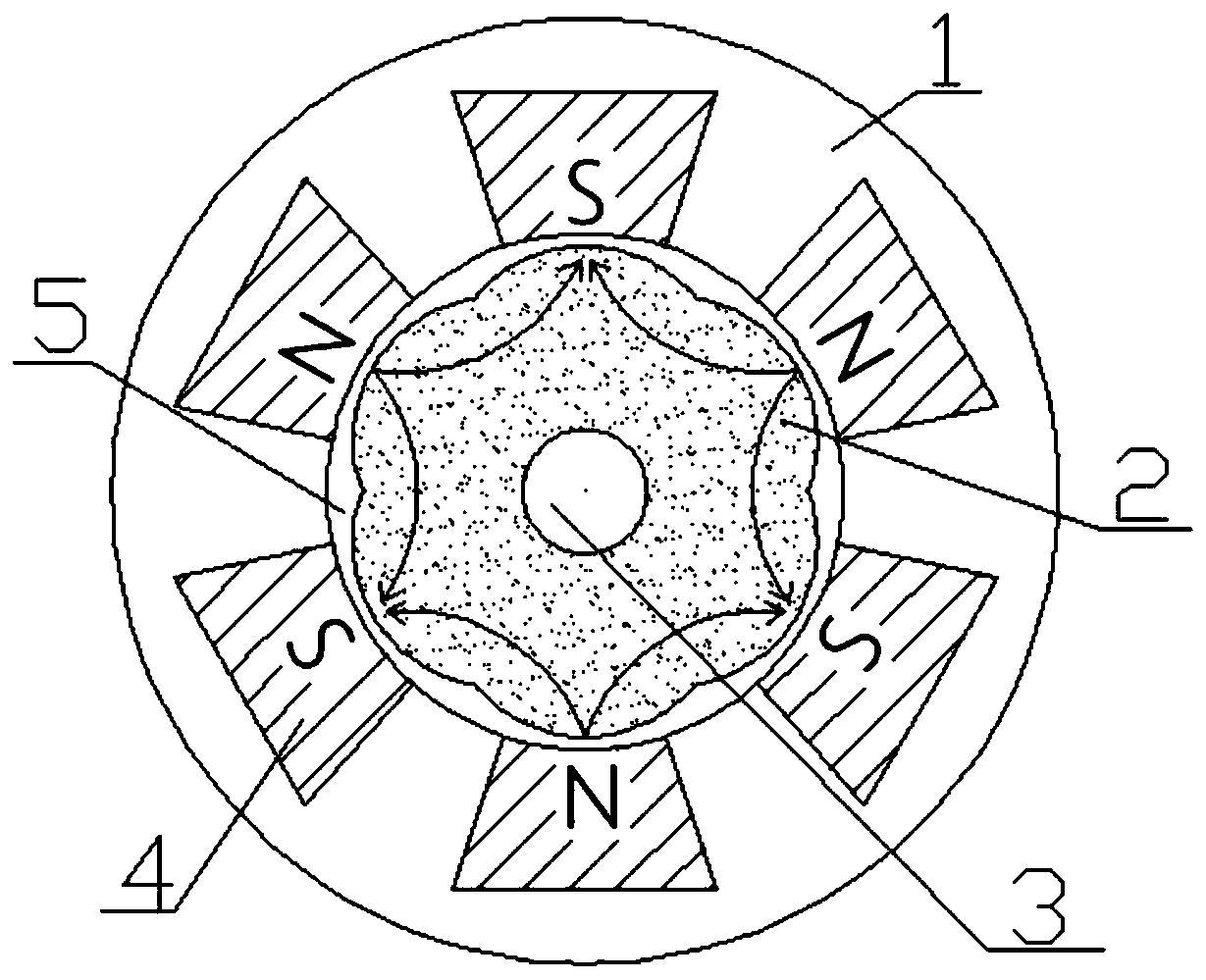

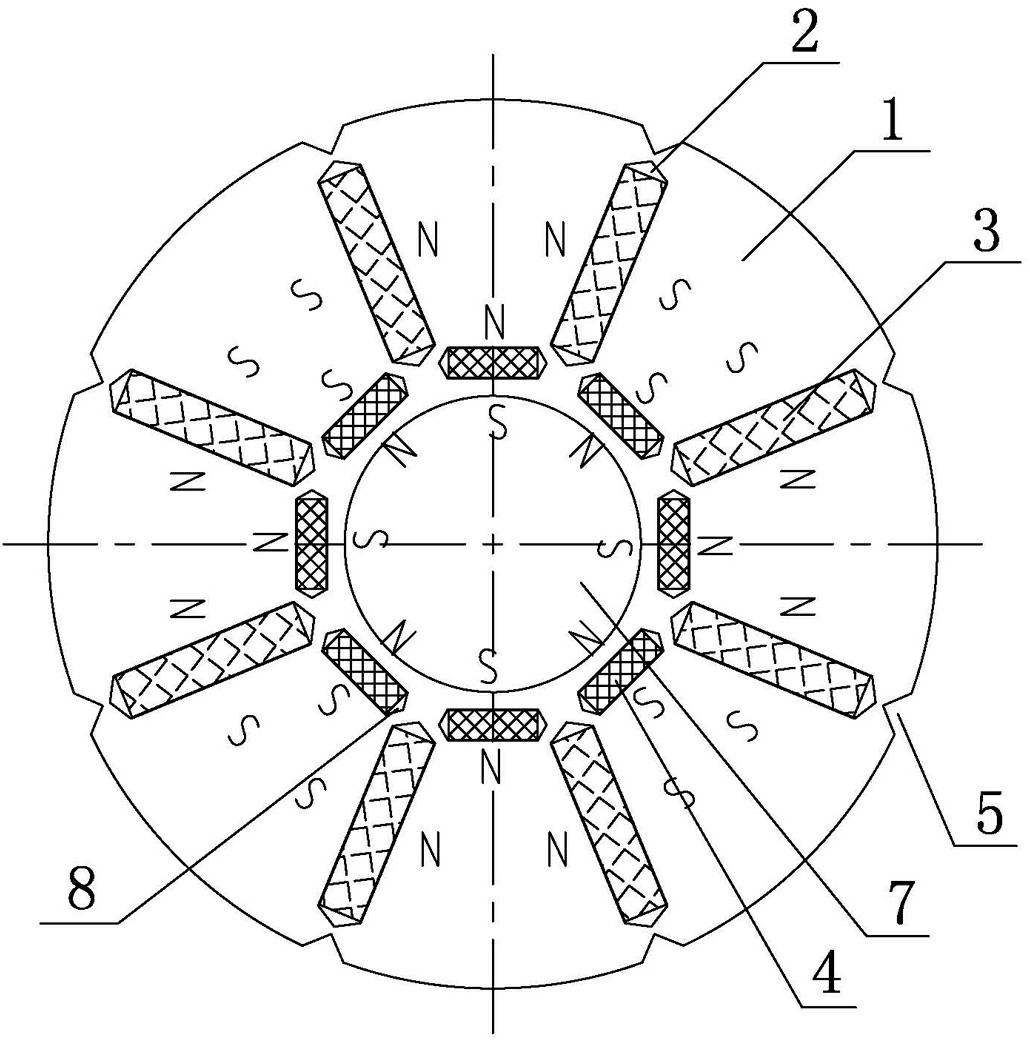

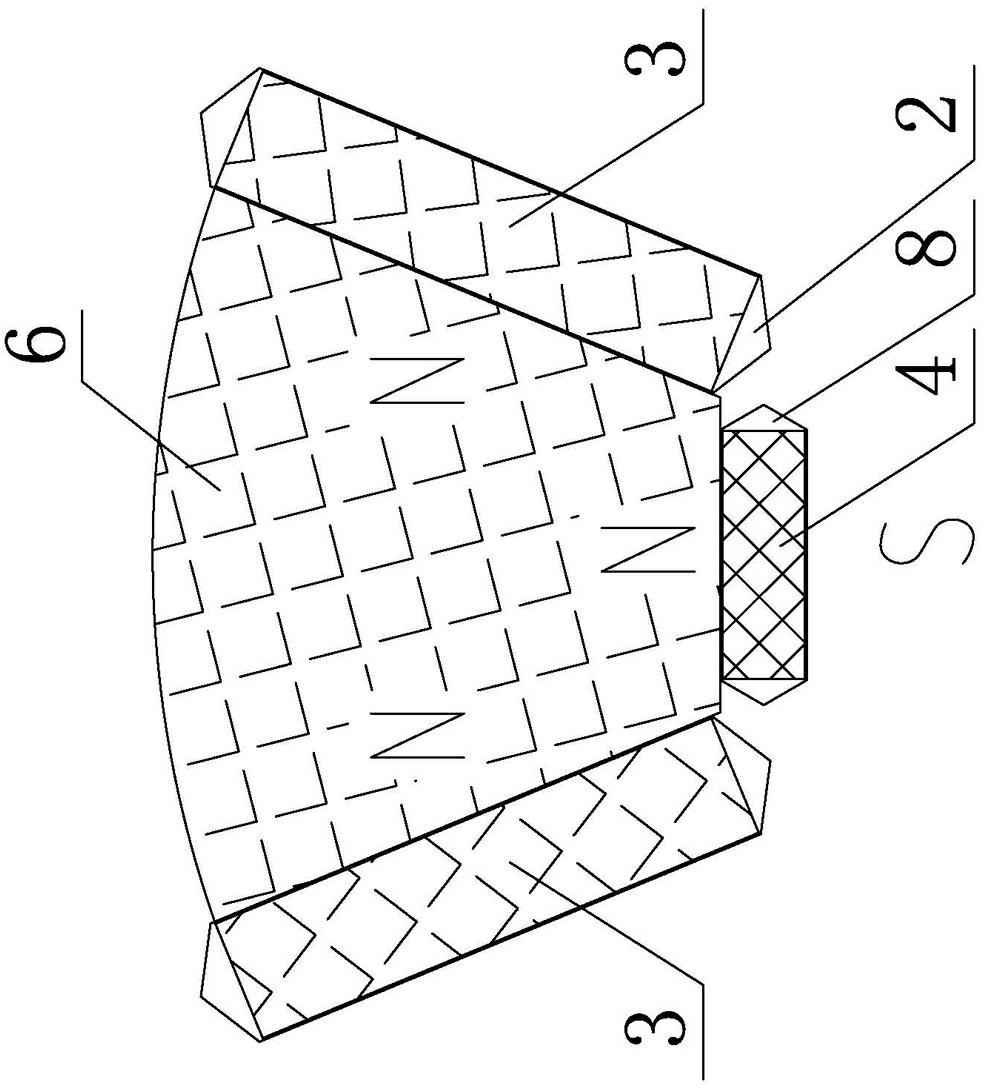

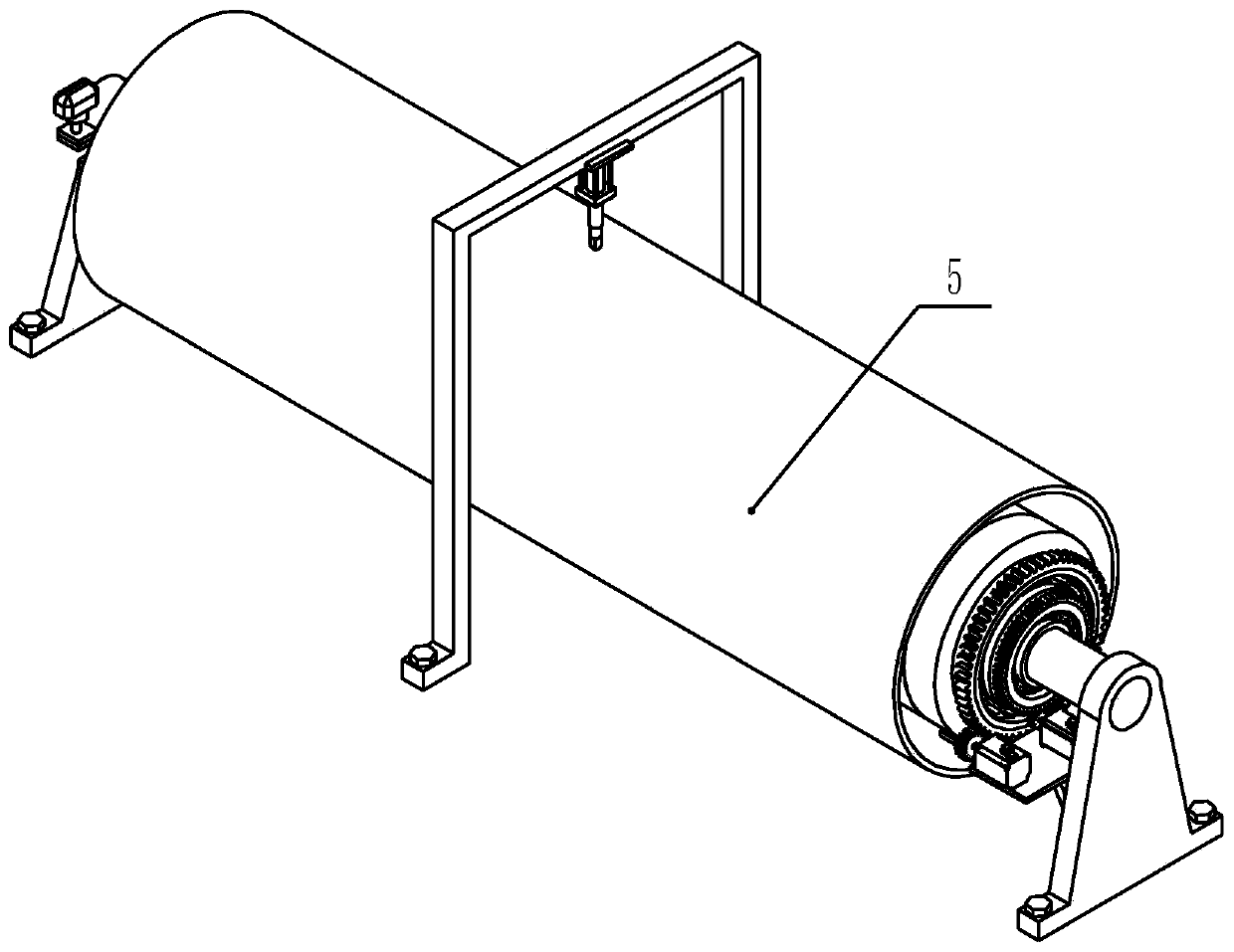

Rotor of resultant magnetic field

InactiveCN102647038AReduce weightRaise the magnetic levelMagnetic circuit rotating partsElectric machinesElectric machineVehicle driving

The invention relates to a rotor of a resultant magnetic field, which is simple in structure, small in volume, convenient to process, high in magnetic energy level and magnetic shoe utilization rate and capable of greatly reducing usage quantity of magnets and silicon sheets and production cost under same efficiency and power levels. The technical scheme is that the rotor of the resultant magnetic field comprises a rotor core and a rotor spindle which are arranged coaxially. The rotor is characterized in that main magnetic steels in even numbers are arranged evenly on the rotor core along a radial direction, the opposite faces of two adjacent main magnetic steels are both North poles or South poles, a magnet sealing device which is used for reducing magnet leakage is arranged between two adjacent main magnetic steels, and the magnet sealing device is arranged symmetrically, and an symmetry axis of two adjacent main magnetic steels serves as a reference axis. The rotor of the resultant magnetic field is applicable to the field of electrical motors or mechanical manufacture and the application classification belongs to electrically driven vehicle driving and industrial application technologies.

Owner:HANGZHOU ZHONGJUN AUTOMOBILE

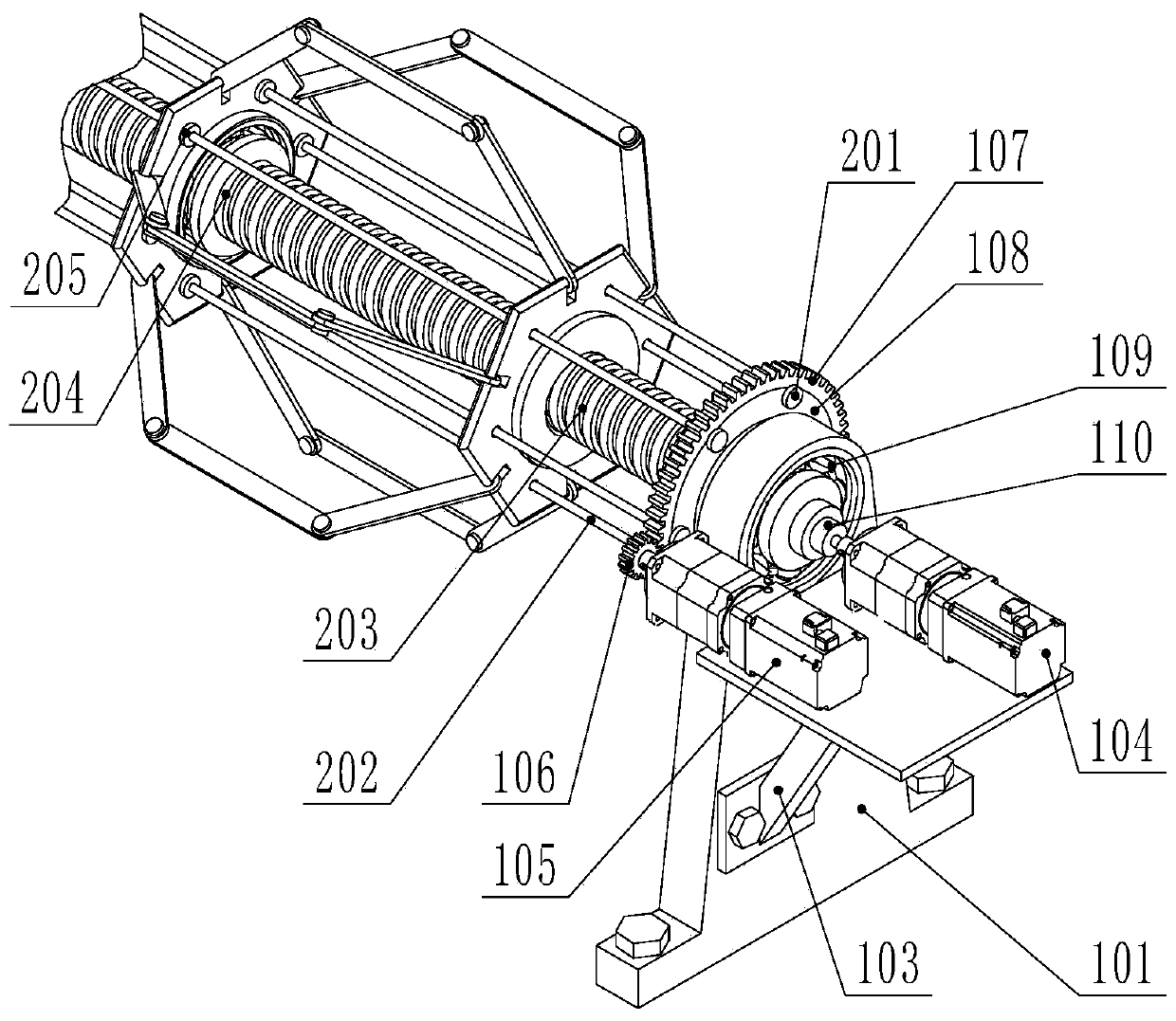

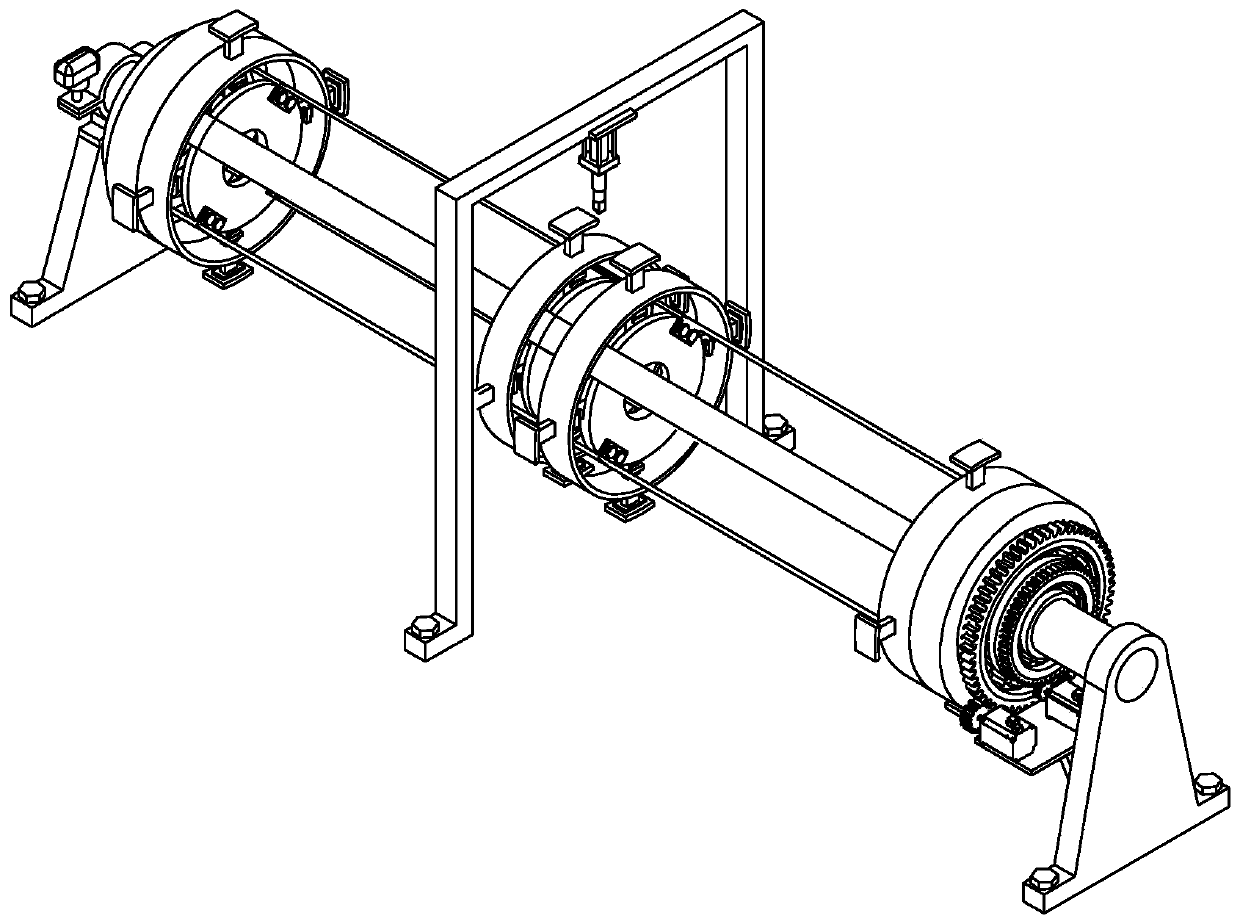

Chuck expansion type metal hard tube rotary cutting machine

InactiveCN110064790AUniform clamping forceAvoid clamping deformationTube shearing machinesShearing machine accessoriesEngineeringGrinding wheel

The invention provides a chuck expansion type metal hard tube rotary cutting machine. The rotary cutting machine comprises a supporting device, a sleeve device, a cutting device and at least four expansion devices, wherein a plurality of expansion devices are sequentially connected and arranged on the same axis through connecting frames, two expansion devices located at two ends are connected withthe supporting device, every two adjacent expansion devices are connected by sleeve pipes of the sleeve device in a sleeving mode, and the cutting device is arranged between two adjacent expansion devices. The expansion devices can expand from the inside of the metal hard tube to achieve the purpose of fixing the metal hard tube, and all lengths of the metal hard tube can be fixed, so that an existing equipment which can only clamp and fix the cut part is replaced, the clamping force is more uniform, and the clamping deformation is prevented; the expansion devices can drive the metal hard tube to rotate together, and then the cutting wall thickness distance can be achieved through feeding movement of a cutting knife, so that the cutting task can be completed, a cutting mode that an existing cutting grinding wheel pieces enter the inner part of the metal hard tube is replaced, and the situation that a cut surface is burned and worn is avoided.

Owner:HEBEI UNIV OF TECH

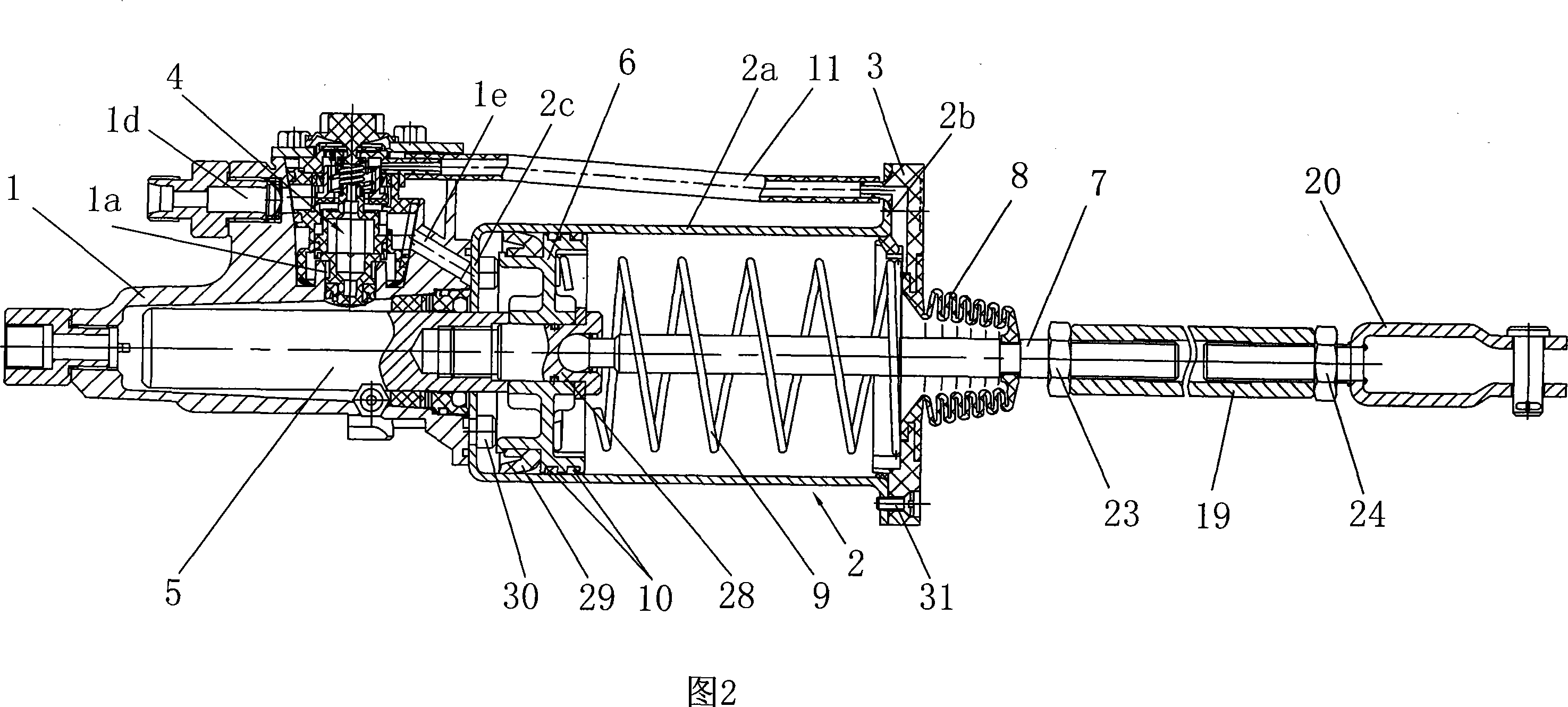

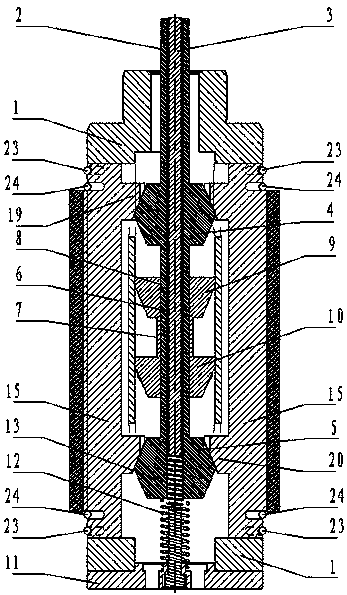

Boring cutter rod error compensating device with slide block structure

InactiveCN102672535AAvoid stayingPrecise wear compensationAutomatic control devicesFeeding apparatusBall screw driveRelative motion

The invention discloses a boring cutter rod error compensating device with a slide block structure. The boring cutter rod error compensating device comprises a boring cutter rod and a cutter compensation servo motor, wherein the boring cutter rod is provided with an axial central hole; one end of a ball screw is connected with an output shaft of the cutter compensation servo motor; the other end of the ball screw stretches into the central hole; a screw nut assembly which can move relatively is sleeved on the ball screw; the ball screw drives the screw nut assembly to move in a straight line relatively; a connecting rod is connected with the screw nut assembly; a slide block is connected with one end of the connecting rod far away from the screw nut assembly; a straight hole slide groove is arranged on the side wall of the boring cutter rod; the slide block is arranged in the straight hole slide groove and can be driven by the connecting rod to slide in the straight hole slide groove; a ball pin is arranged in the straight hole slide groove; one end of the ball pin props against the slide block through an end part ball; and the other end of the ball pin is connected with the boring cutter on the side wall of the boring cutter rod. With the boring cutter rod error compensating device, rough and finish machining can be accomplished for one time; the abrasion of the fine boring cutter is reduced; and precise compensation to the cutter abrasion and the cylinder hole cylindrical form error is realized.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

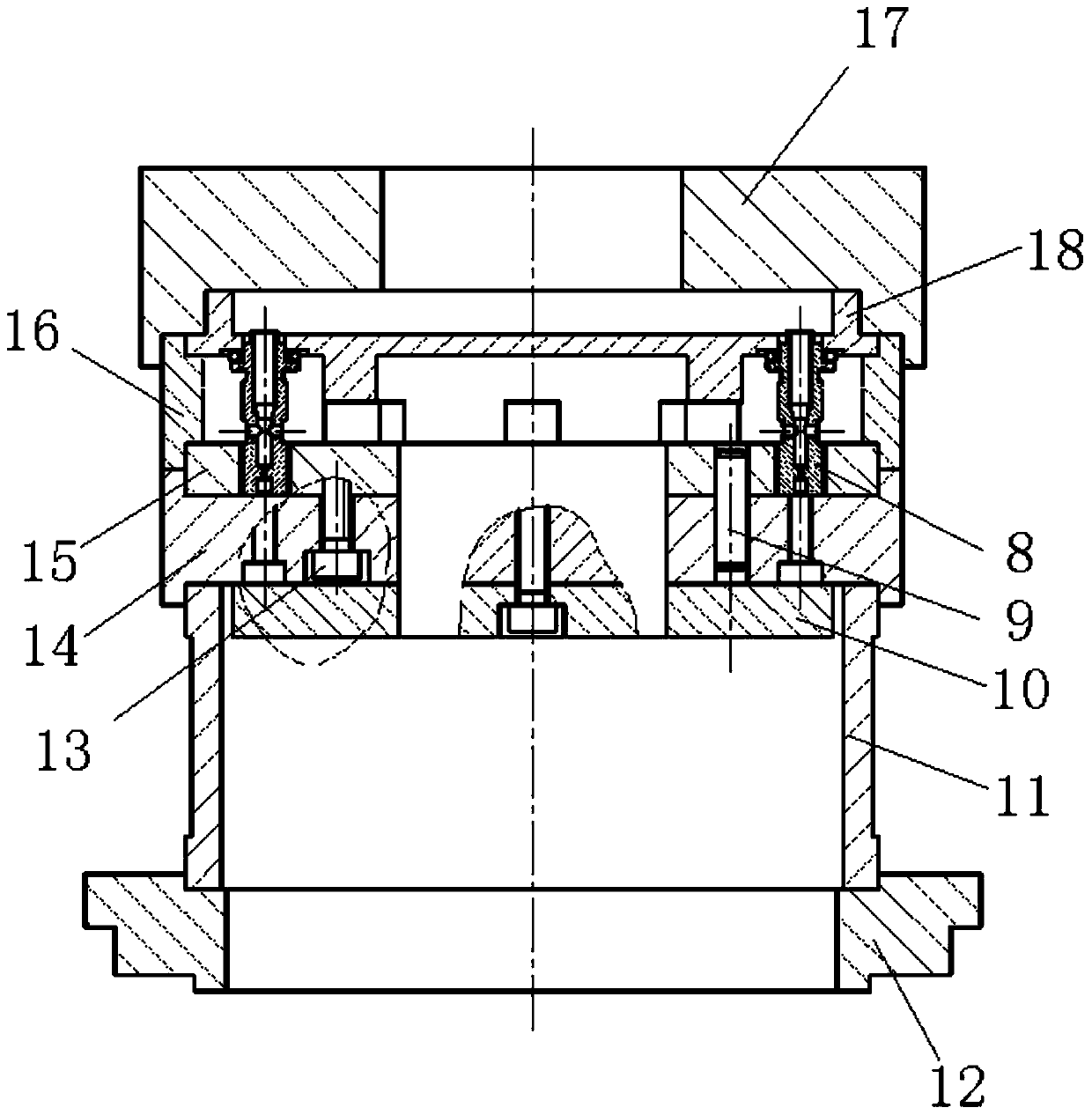

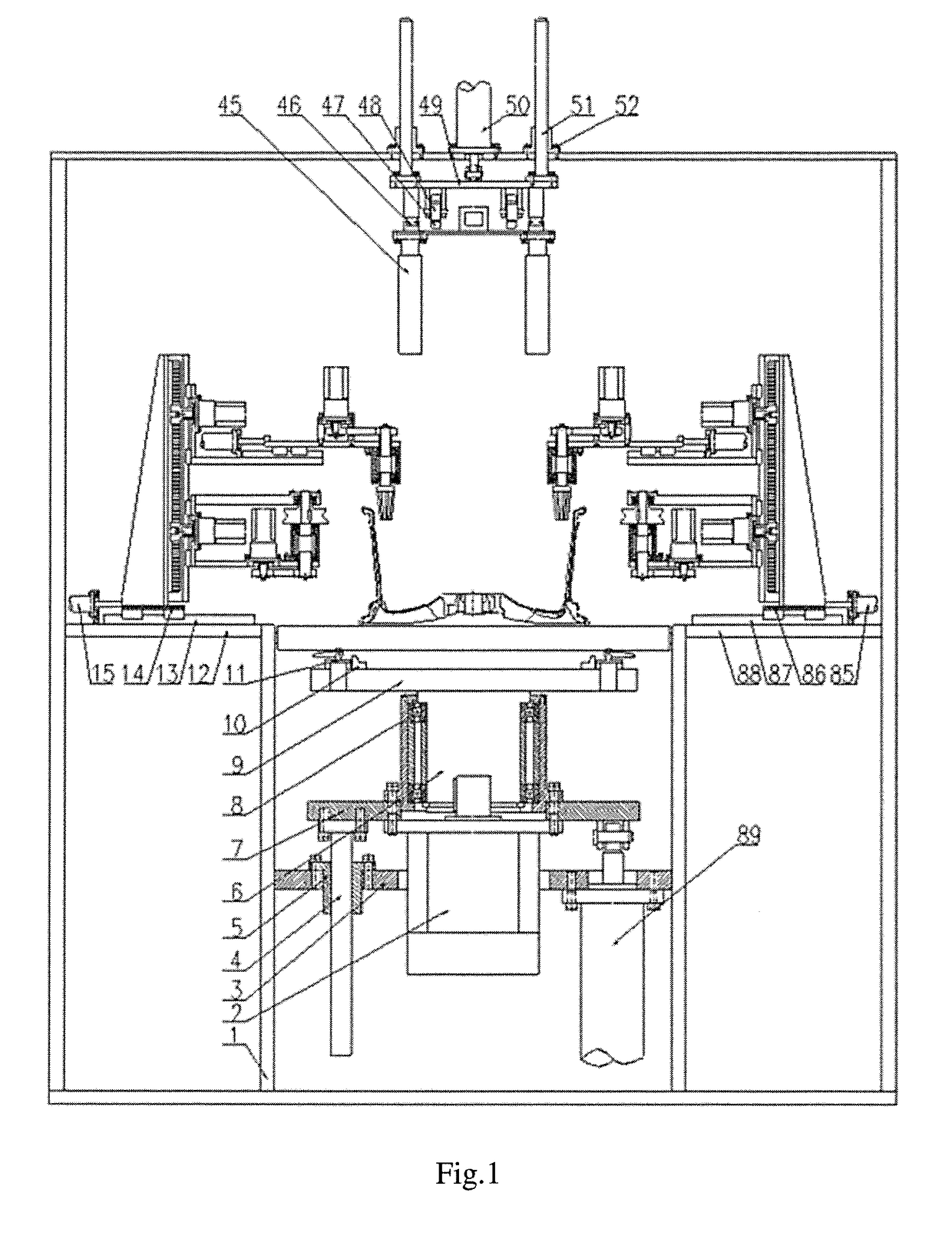

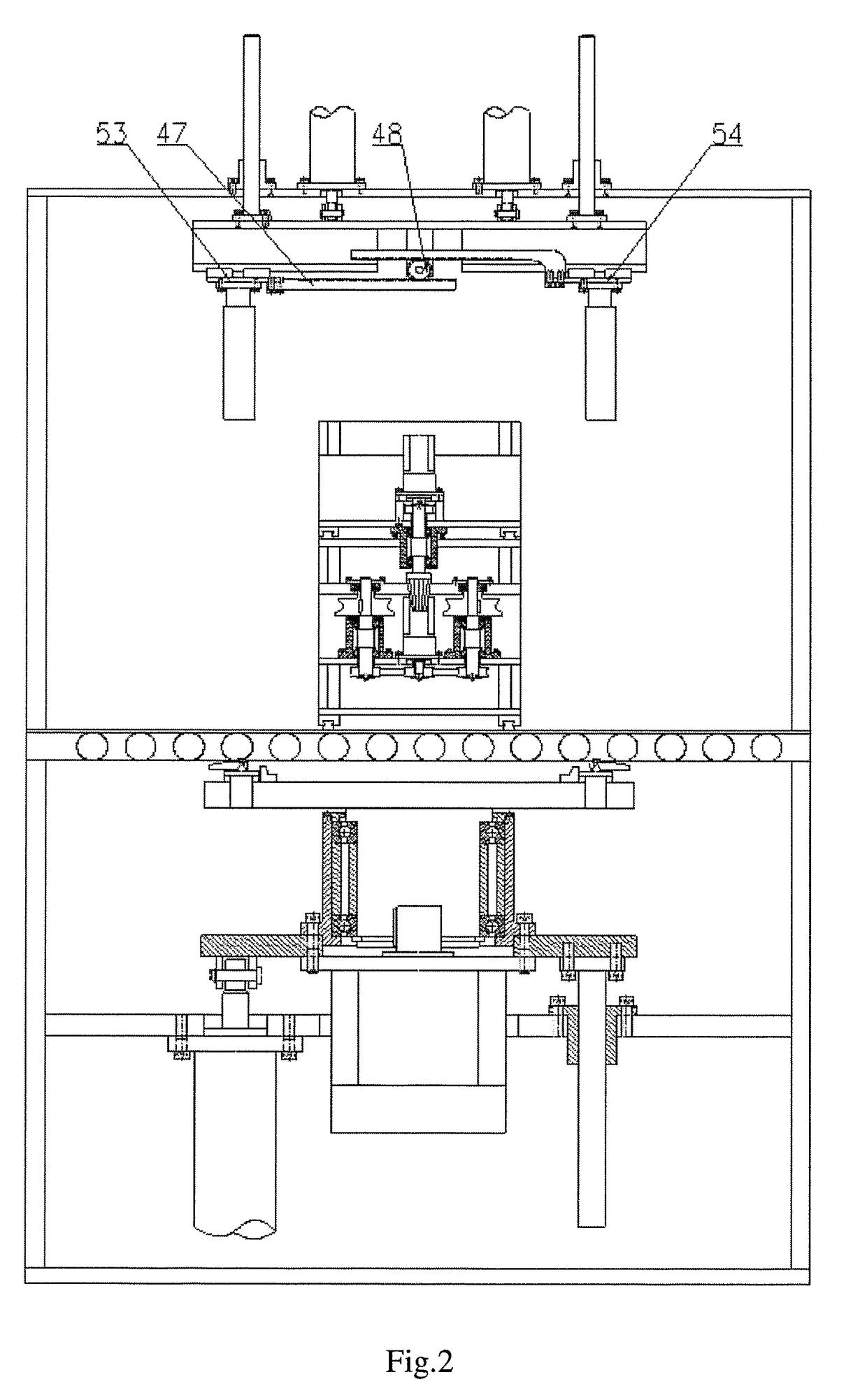

Inner-supporting-type Online Roundness Correcting Device for Semifinished Wheel

ActiveUS20170182618A1Improve roundnessImprove cylindricityEdge grinding machinesRimsHydraulic cylinderEngineering

The present invention provides an improved inner-supporting-type online roundness correcting device for a semifinished wheel, which comprises a machine frame, hydraulic cylinders, guide rails, servo motors and correcting wheels. When a bulge of the wheel is met, angles of left correcting wheels II are adjusted through a left servo motor, the left correcting wheels II are kept to be in contact with an inner rim of the wheel all the time and remain stationary in the position, and then, a left hydraulic cylinder enables a left correcting wheel Ito press the bulge of the wheel, so as to recover the roundness of the bulge; and when a depression of the wheel is met, right correcting wheels I are kept to be in contact with an outer rim of the wheel all the time and remain stationary in the position through a right hydraulic cylinder, the angle of a right correcting wheel II is adjusted through a right servo motor, and compressing hydraulic cylinders enable the right correcting wheel II to press the depression of the wheel, so as to recover the roundness of the depression.

Owner:CITIC DICASTAL

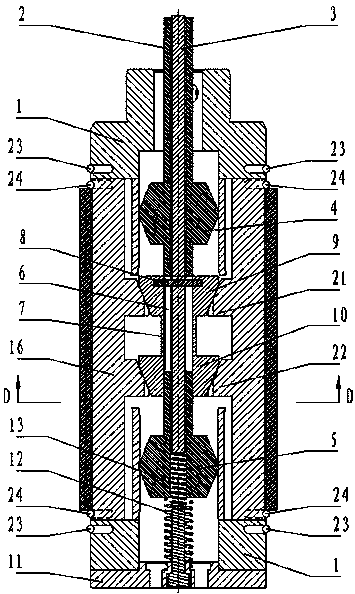

Three-expansion honing head for honing machine

PendingCN110370164ACompact structureImprove the qualified rate of texture parametersHoning toolsHoning machinesEngineering

The invention belongs to the technical field of honing machines, and particularly relates to a three-expansion honing head for a honing machine. The three-expansion honing head comprises a body. An outer expansion rod is arranged in the body, and an inner expansion rod is sleeved with the outer expansion rod. A first expansion core and a second expansion core are fixedly arranged on the outer expansion rod coaxially. The outer expansion rod is coaxially sleeved with an expansion sleeve, and the inner expansion rod is connected with the expansion sleeve. A third expansion core and a fourth expansion core are arranged at the two ends of the expansion sleeve. A bottom cover is arranged at the bottom of the body, and a large spring and a small spring are arranged at the lower ends of the outerexpansion rod and the inner expansion rod. A sand strip seat A, a sand strip seat B and a sand strip seat C are cooperatively arranged on the body. The two ends of the sand strip seat A and the sandstrip seat B are sleeved with first tension springs, and the two ends of the sand strip seat C are sleeved with second tension springs. The three-expansion honing head for the honing machine can complete fine grinding-coarse grinding-fine grinding on the same machine in the same procedure at a time.

Owner:中原内配集团鼎锐科技有限公司

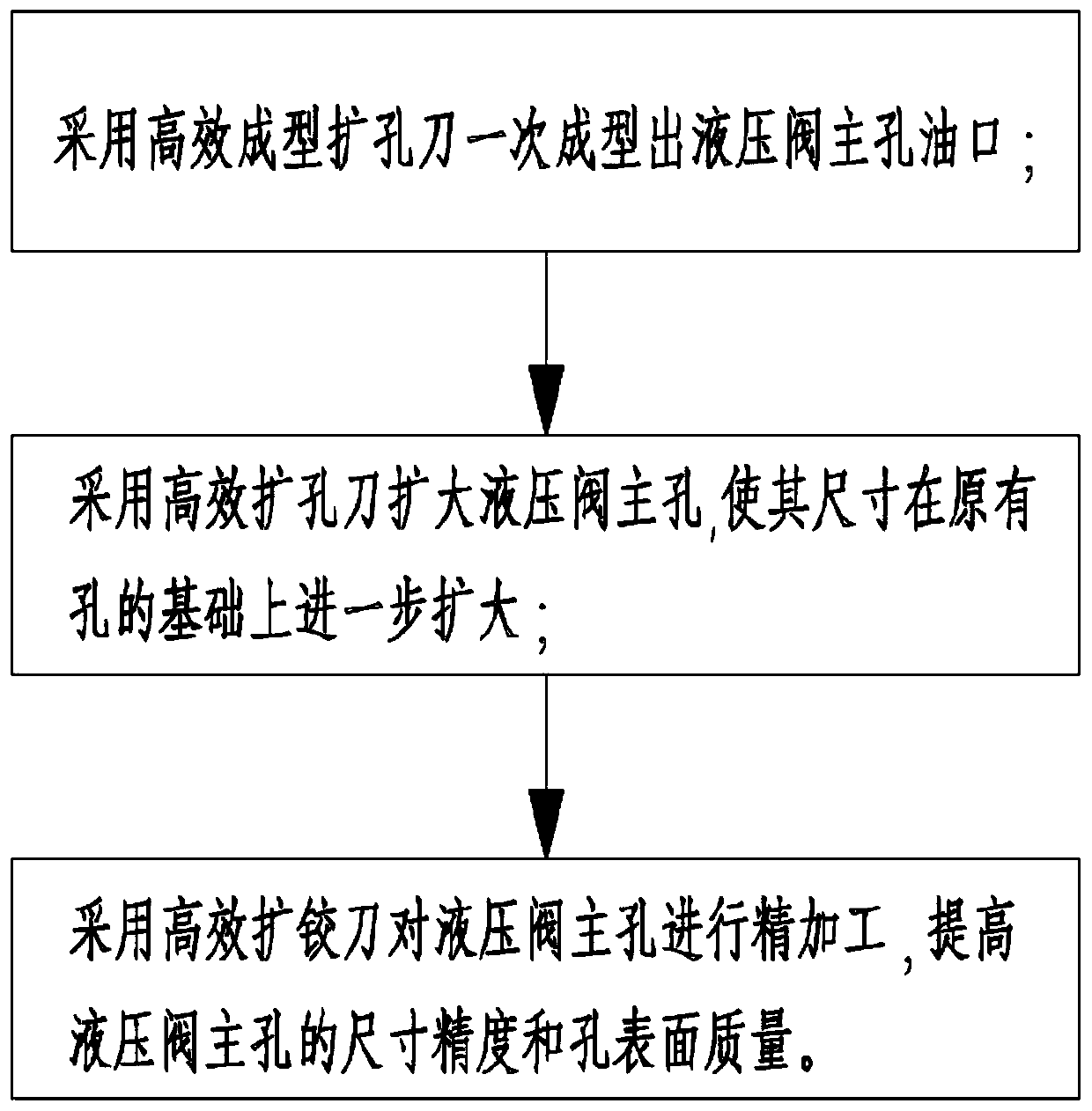

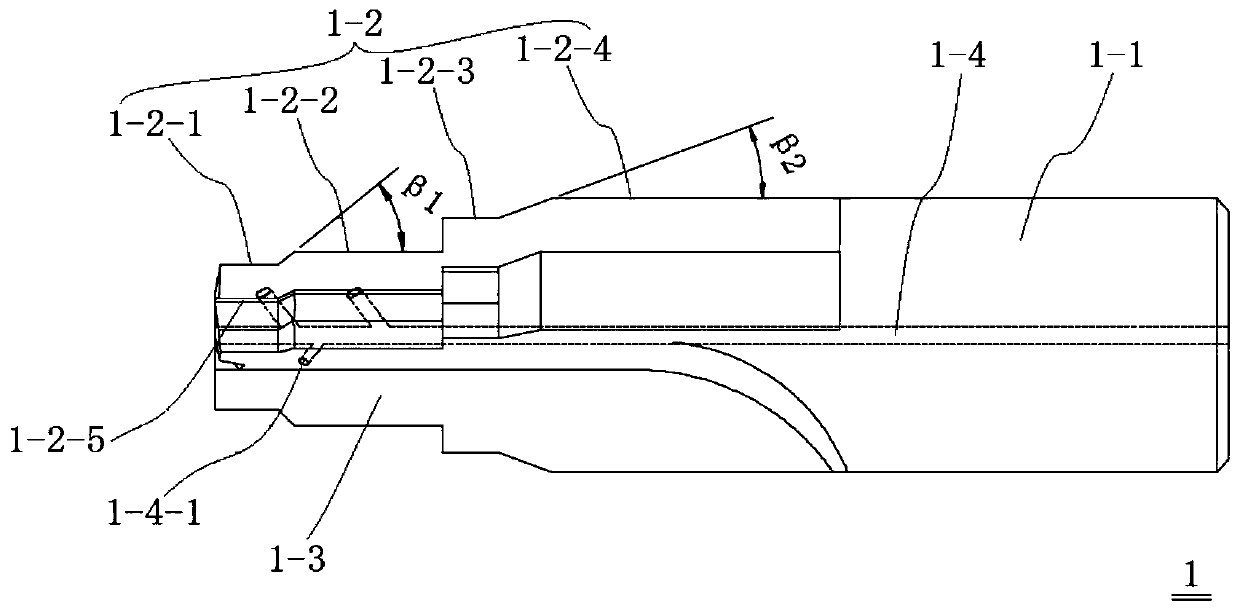

Efficient and long-service-life hydraulic valve main hole machining method

ActiveCN111002003AGood concentricityHigh surface finishCutting insertsWorkpiecesReamerStructural engineering

The invention discloses an efficient and long-service-life hydraulic valve main hole machining method, and belongs to the hole machining technology field. In the machining method, an oil port three-blade forming cutter, a three-blade chambering cutter and an eight-blade expanding reamer are sequentially used for machining a main hole of a hydraulic valve. One-time forming of a forming hole is guaranteed through the oil port three-blade forming cutter, a service life is long, and cutting efficiency is high. An unequal design of the three-blade chambering cutter is matched with a layered structure design so that chambering cutting vibration is reduced, a chambering machining allowance is large, concentricity of the main hole of an intermittent hydraulic valve is ensured, and machining precision and machining efficiency are high. Unequal parts of the eight-blade expanding reamer are combined with unequal teeth so that vibration of a cutter of expanding and reaming is greatly reduced, andsurface roughness and cylindricity of the main hole of the hydraulic valve, the reaming processing allowance and the cutting efficiency are improved; and the method has the advantages of high machining efficiency, good machining precision, a long service life of the cutter and the like, and a problem that hydraulic valves are scrapped due to blockage of ducts by residual cuttings is effectively solved.

Owner:CHANGZHOU LEAD CUTTING TECH CO LTD

Processing process for small crescent block of inner meshing gear pump

ActiveCN105563049AImprove processing efficiencyGuaranteed verticalityGrinding work supportsEngineeringHardness

The invention discloses a processing process for a small crescent block of an inner meshing gear pump. The processing process comprises the steps of: preparing a striped small crescent block profile by a hot extrusion process, cutting into a semicircular small crescent block, placing the semicircular small crescent block in an end surface grinding clamp, grinding one end surface of a plane grinding machine, reversely clamping a ground product, grinding the other end surface, then clamping the product with an excircle grinding clamp, roughly grinding an excircle and finely grinding. By arranging the end surface grinding clamp, the verticality between the end surfaces and the excircle of the small crescent block can be ensured, and the end surface processing efficiency is improved; and by adopting the hot extrusion process, the material compactness is better, the hardness is improved, the wear resistance is increased, and the production efficiency is improved by 5-10 times in comparison with that of line cutting.

Owner:淮安福斯特液压科技有限公司

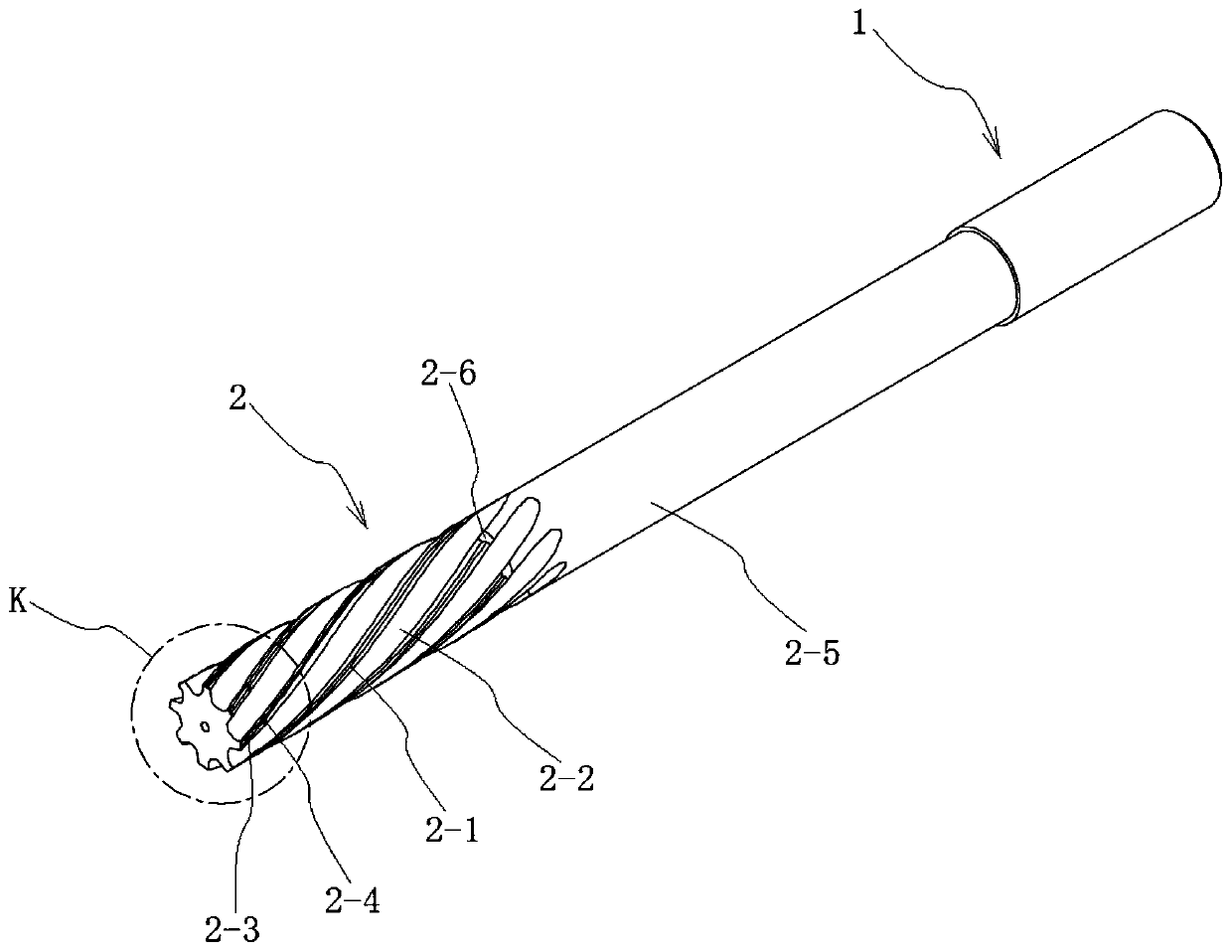

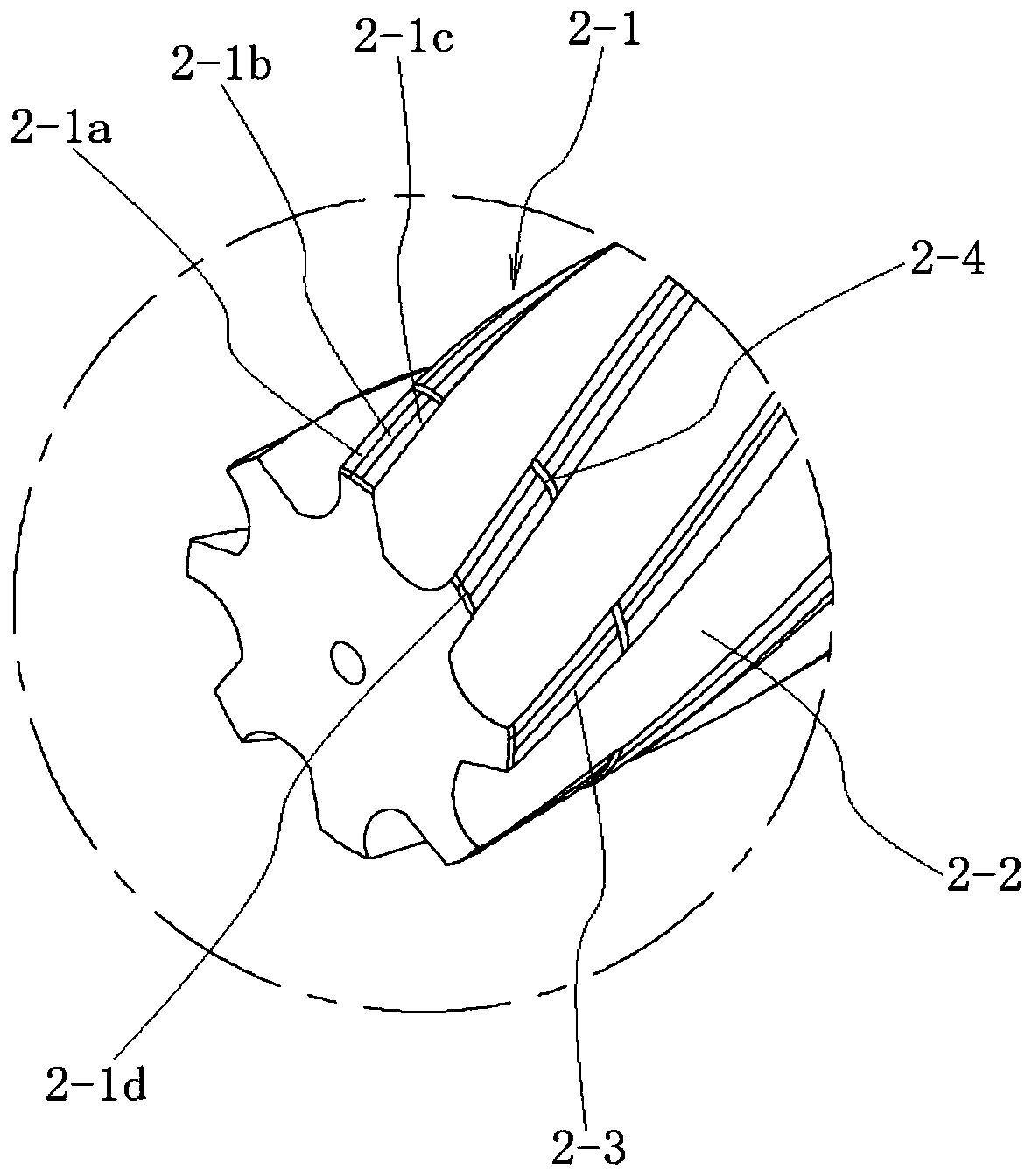

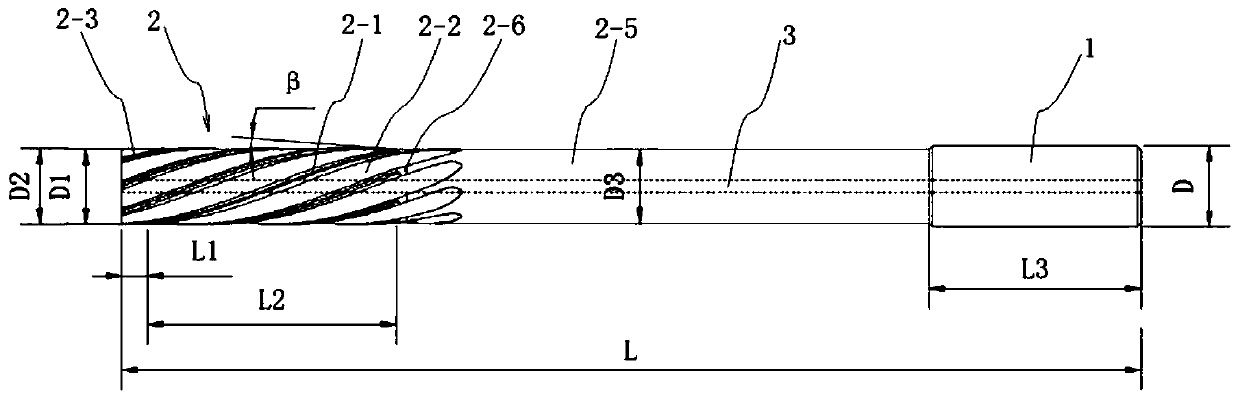

High-efficiency unequal multi-blade expanding reamer

PendingCN110893488AImprove seismic performanceReduce vibrationReaming toolsStructural engineeringChip formation

The invention discloses a high-efficiency unequal multi-blade expanding reamer, and belongs to the technical field of reamers. The multi-edge reamer comprises a reamer handle and a cutting part, the cutting part is provided with a plurality of spiral cutting edges distributed in the circumferential direction, and in the cross section of the cutting part, the difference between the maximum tooth pitch included angle between two adjacent cutting edges and the minimum tooth pitch included angle between two adjacent cutting edges ranges from 6 degrees to 9 degrees; and the tooth width of each cutting edge and the tooth pitch included angle in the rear side in the rotary cutting direction of the cutting edge satisfy corresponding change rules. By adopting the design of combining multi-blade unequal division with multi-blade unequal teeth, the surface roughness and cylindricity of a machined hole are improved, the reaming allowance and cutting efficiency can be improved, and the intermittentand efficient finish machining requirements of a (deep) hole are met; the front end of the multi-edge reamer is of a layered structure, the machining allowance is increased, the machining reliabilityof the reamer is enhanced, chips can be broken and small, cleaning of the chips in a hole is facilitated, and the multi-edge reamer is particularly suitable for multi-channel interrupted hole machining.

Owner:CHANGZHOU LEAD CUTTING TECH CO LTD

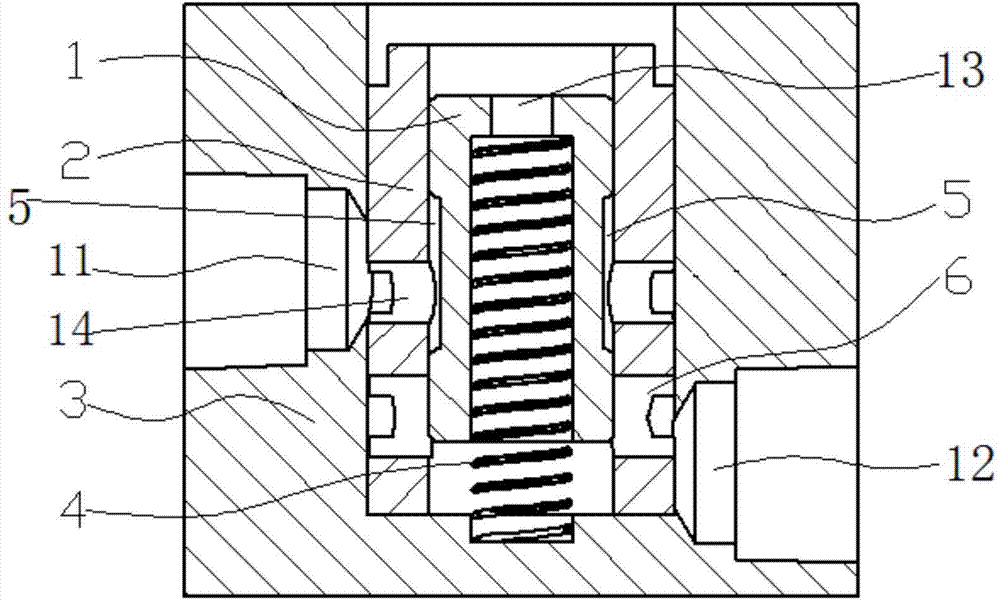

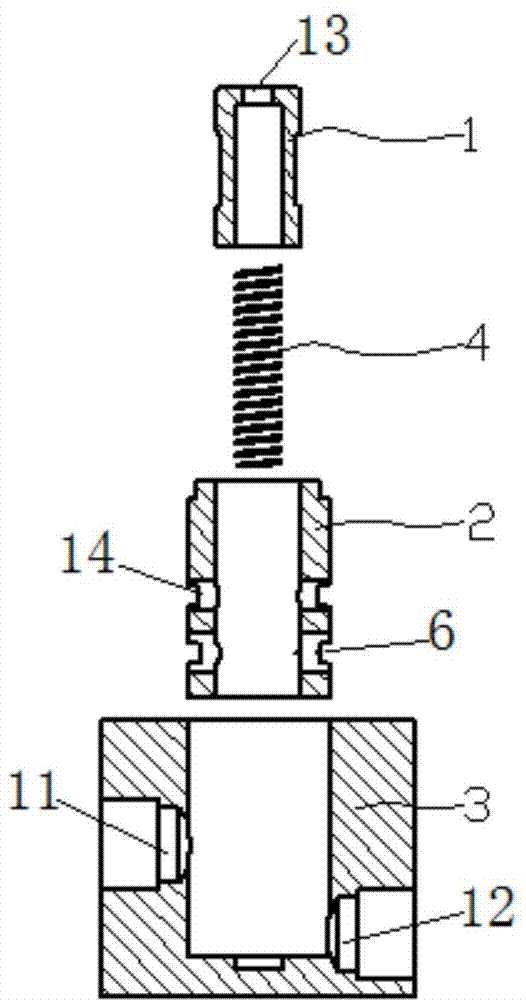

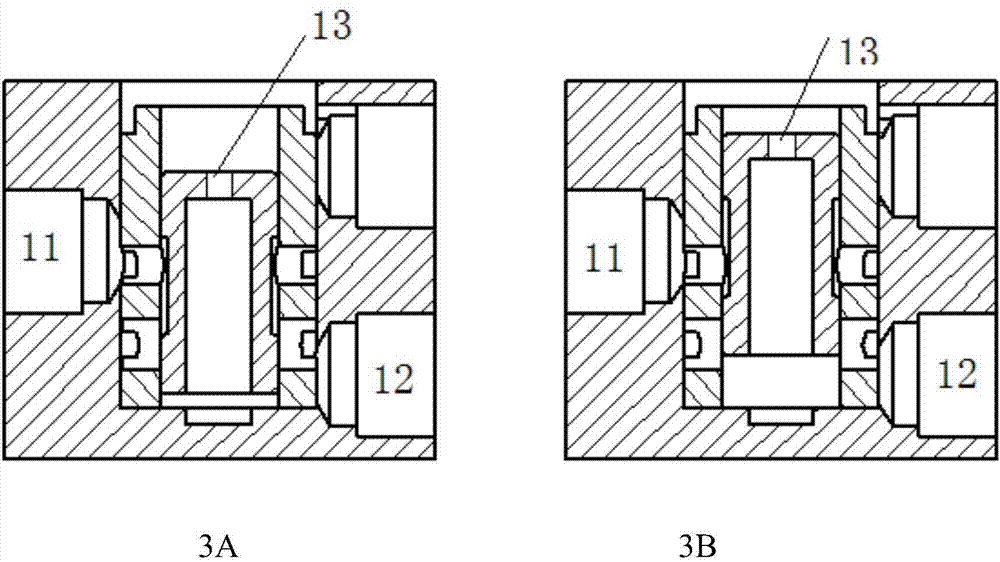

Two-position three-way valve and vibration isolation system with same

ActiveCN104763820AHigh adjustment accuracyGuaranteed to slide up and downSpringsMultiple way valvesVibration isolationMechanical engineering

The invention discloses a two-position three-way valve and a vibration isolation system with the same and belongs to the technical field of valves. The valve comprises a valve body lower cover, a valve sleeve fixed in the valve body lower cover and a valve core arranged in the valve sleeve in a sliding mode. An air inlet and an air outlet which are staggered in position are formed in the side of the valve body lower cover. A first air vent and a second air vent are formed in the corresponding positions of the air inlet and the air outlet respectively. An exhaust port is formed in the upper surface of the valve core, a first ventilation groove is formed in the circumference of the side of the valve core, and the height of the first ventilation groove is larger than the distance between the first air vent and the second air vent. The height of a lower shaft shoulder of the valve core is identical to the height of the second air vent. By means of the system, switching between different states can be achieved by moving the valve core for small travel vertically, and accordingly, the adjusting accuracy is high.

Owner:BEIJING U PRECISION TECH +1

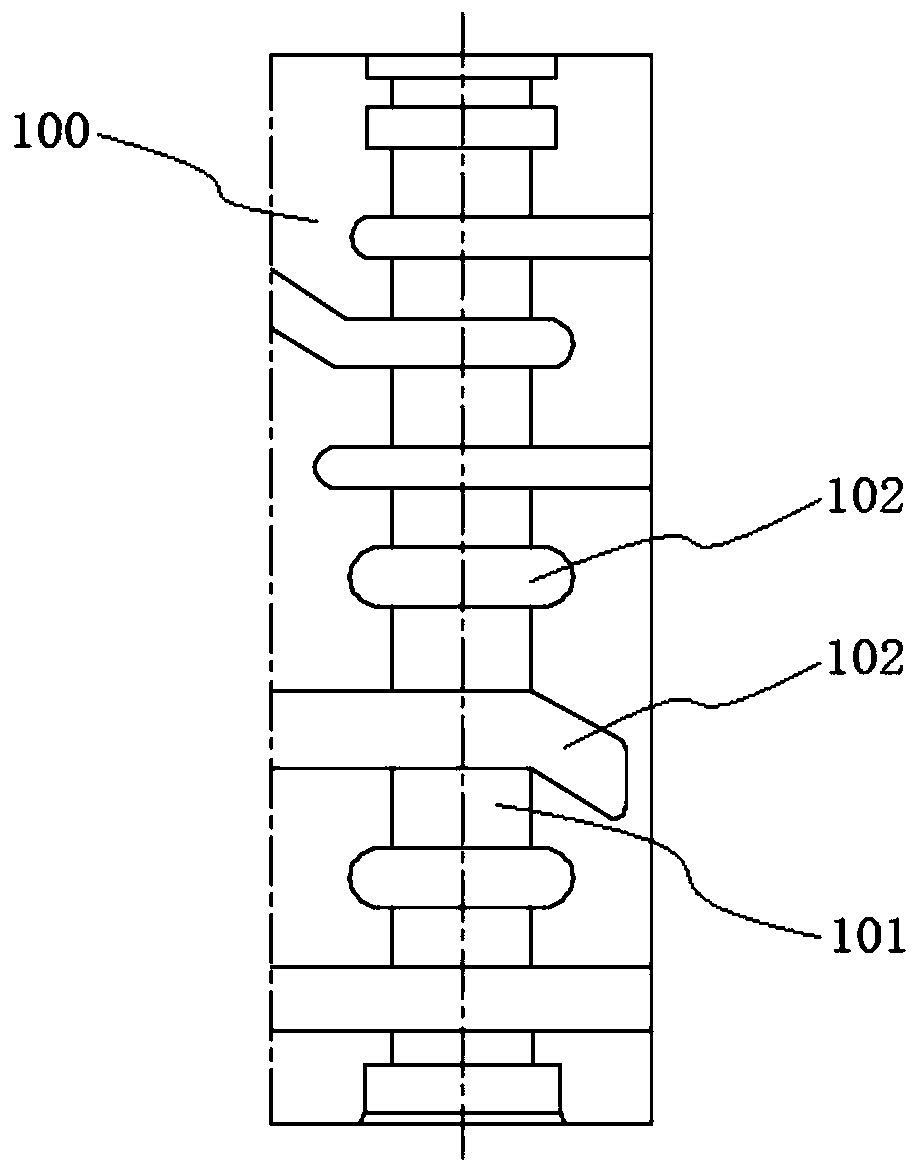

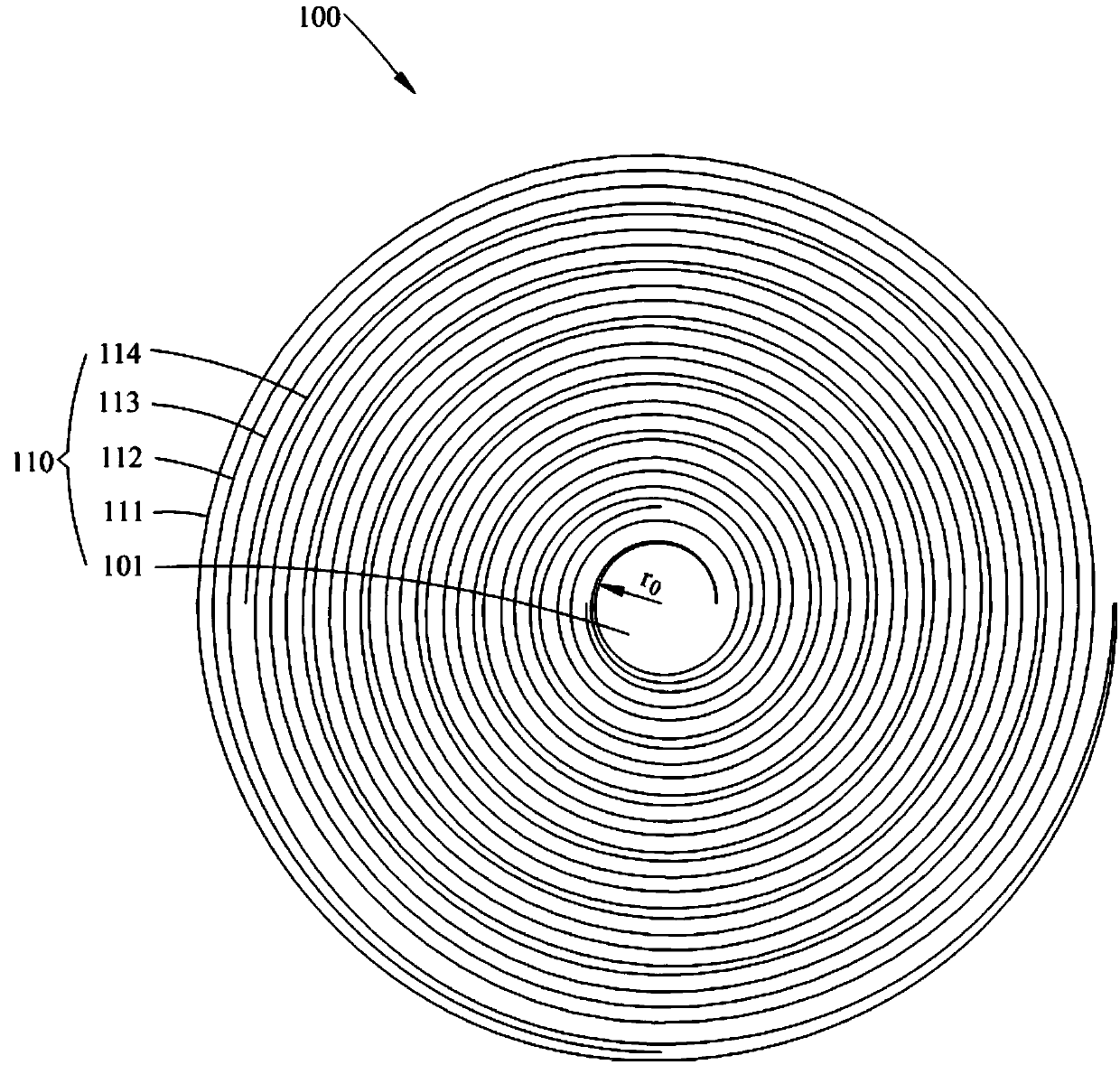

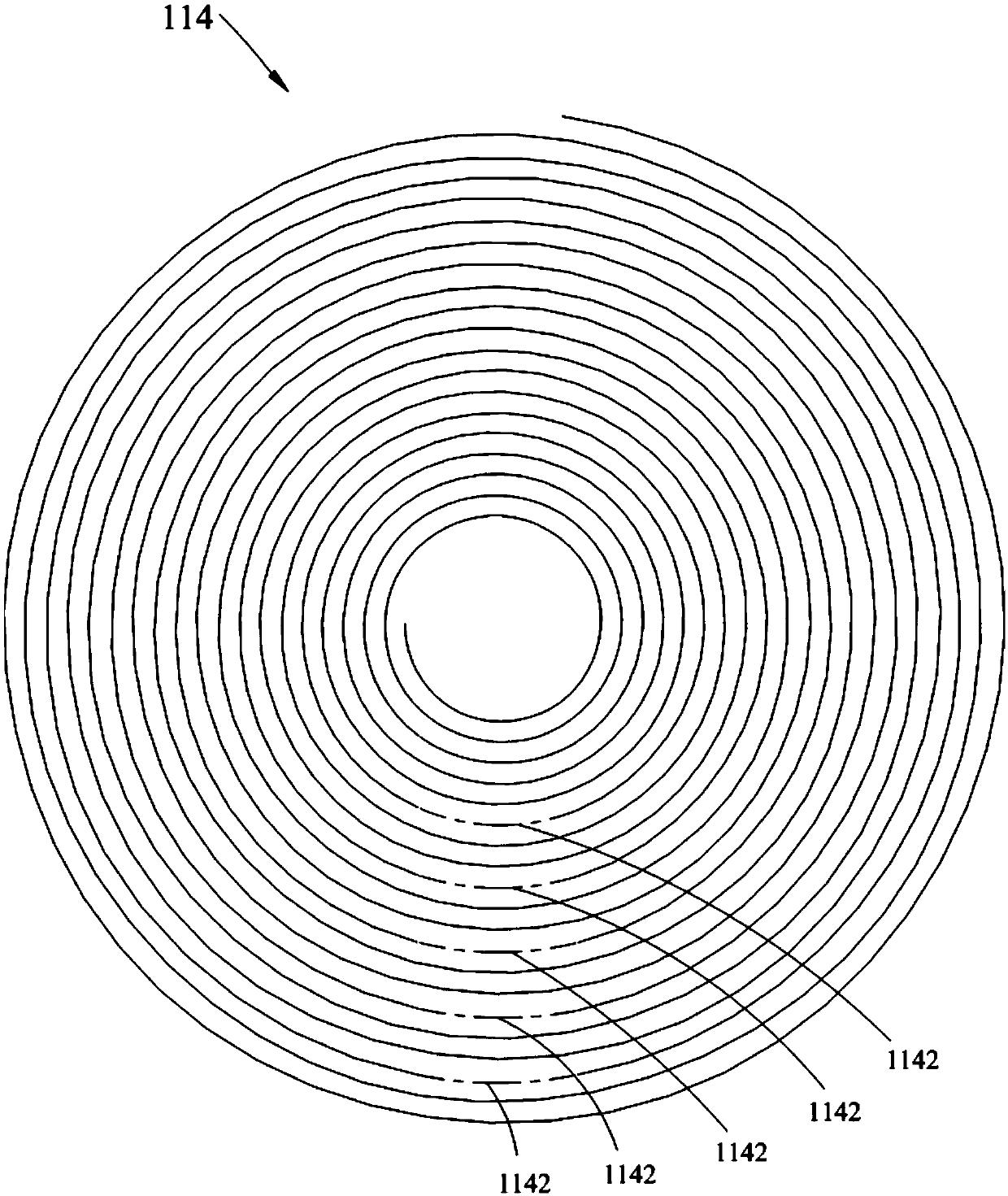

Battery core and method for manufacturing battery core, and lithium ion battery

PendingCN109659480AImprove cylindricityMeet the requirements of high rate charge and discharge performanceFinal product manufactureSecondary cellsEngineeringLithium-ion battery

The invention is applicable to the field of lithium ion batteries, and discloses a battery core and a method for manufacturing a battery core, and a lithium ion battery. The battery core comprises a core body having a hollow inner hole, and the core body comprises a first diaphragm, a negative electrode sheet, a second diaphragm and a positive electrode sheet. The positive electrode sheet comprises a positive electrode metal substrate, positive electrode ears and a positive electrode coating layer coating the positive electrode metal substrate. The negative electrode sheet comprises a negativeelectrode metal substrate, negative electrode ear and a negative electrode coating layer coating the negative electrode metal substrate. There are at least two positive electrode ears and negative electrode ears, and the positive electrode ears are located at the same side of the hollow inner hole in the radial direction of the core body, the negative electrode ears are located at the same side of the hollow inner hole in the radial direction of the core body, each positive electrode ear is integrated with the positive electrode metal substrate, and each negative ear is integrated with the negative electrode metal substrate. The coating areas of the coating layers on the pole sheets are added to improve the capacity of the lithium ion battery and improve the cylindricity of the battery core.

Owner:SHENZHEN ZHUONENG NEW ENERGY TECH

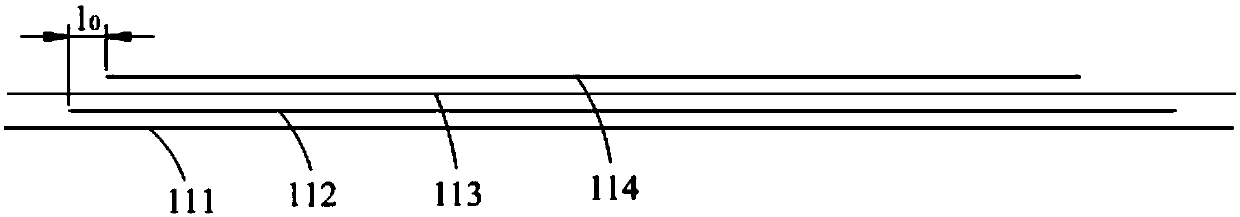

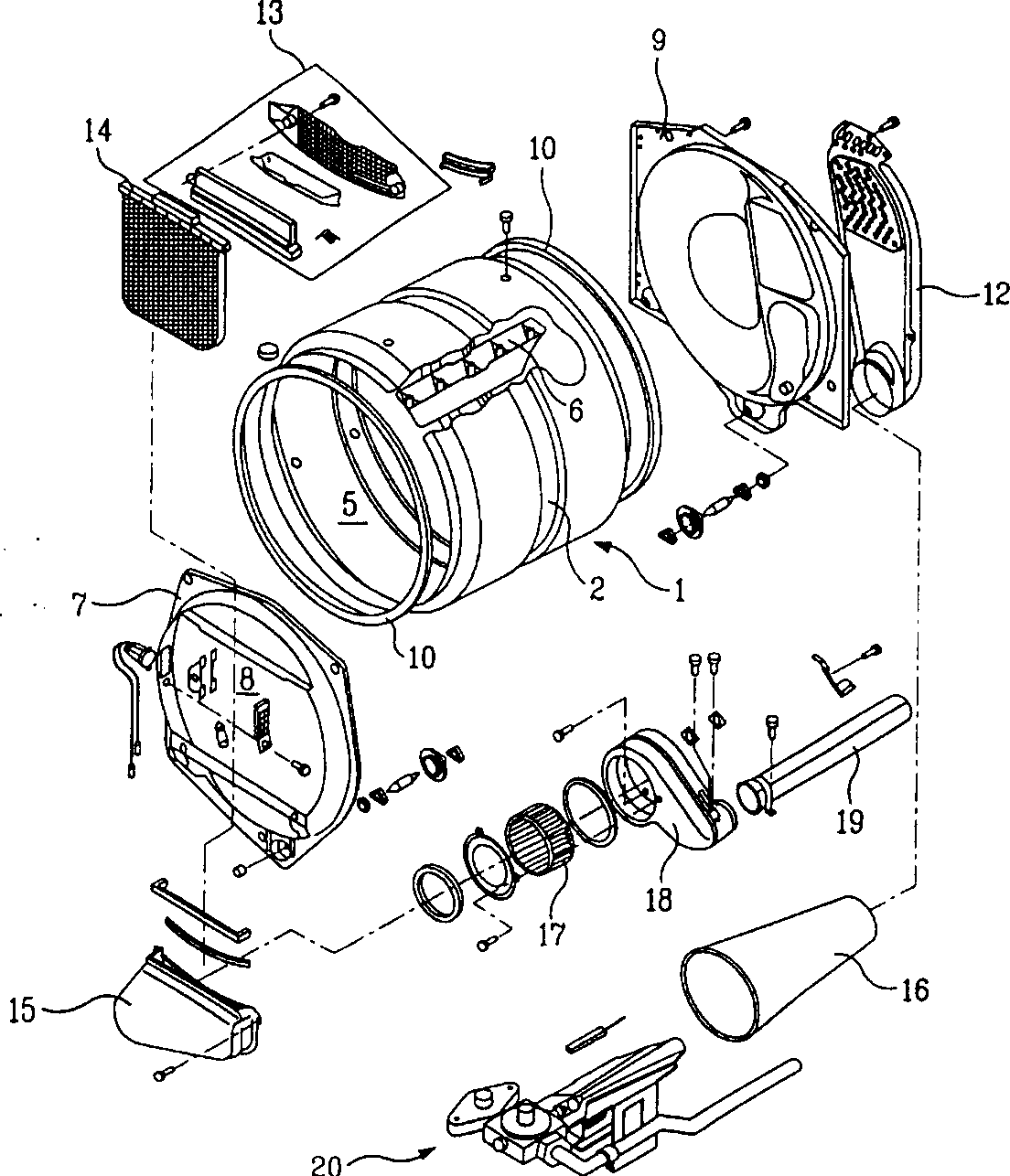

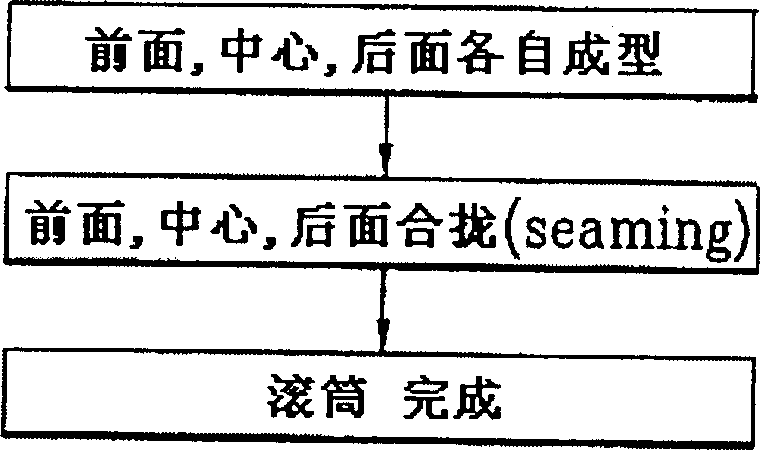

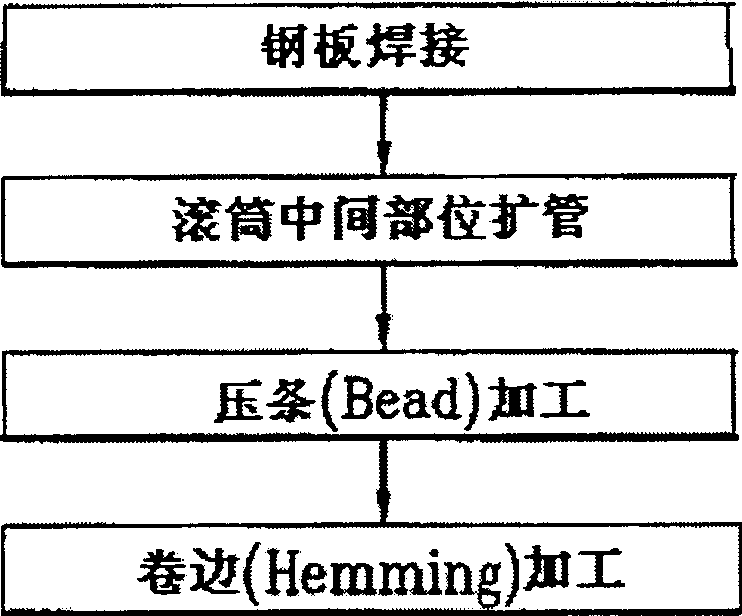

Shaping method for drum of drying machine and rolled drum structure according to it

InactiveCN1724785AImprove reliabilityImprove cylindricityTextiles and paperLaundry driersMetallic materialsMechanical engineering

The invention supplies rolling barrel molding method of a dryer that has no mould separating trace. The proper circle rate of the entire rolling barrel is improved. And the inside scuffing of the rolling barrel would be avoided in the molding process. The molding method includes the following steps: the molding stage of the rolling barrel; two ends of the rolling barrel expanding pipe and molding stage, processing and layering at the center of the rolling barrel stage, and bending collapsing beading process stage. The dryer rolling barrel includes column barrel, opening section, layering section and beading section.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Isostatic pressing soft die sleeve weight-limiting isovolumetric powder filling process and device

The invention discloses an isostatic pressing soft die sleeve weight-limiting isovolumetric powder filling process and device. The process adopts the cooperation of spiral powder filling and synchronous rapping, adopts a multi-section feeding mode, and realizes the weight-limiting isovolumetric powder filling of hard alloy isostatic pressing powder through the real-time monitoring of the powder density and the variable-frequency ultrasonic compaction. According to the process, the powder density uniformity of all positions in a die sleeve in the powder loading process can be improved, the diameter difference of a final pressed blank at different positions is reduced, the roundness and cylindricity of the pressed blank are improved, and the casting yield and the size controllability of a rod blank are improved.

Owner:厦门金鹭硬质合金有限公司

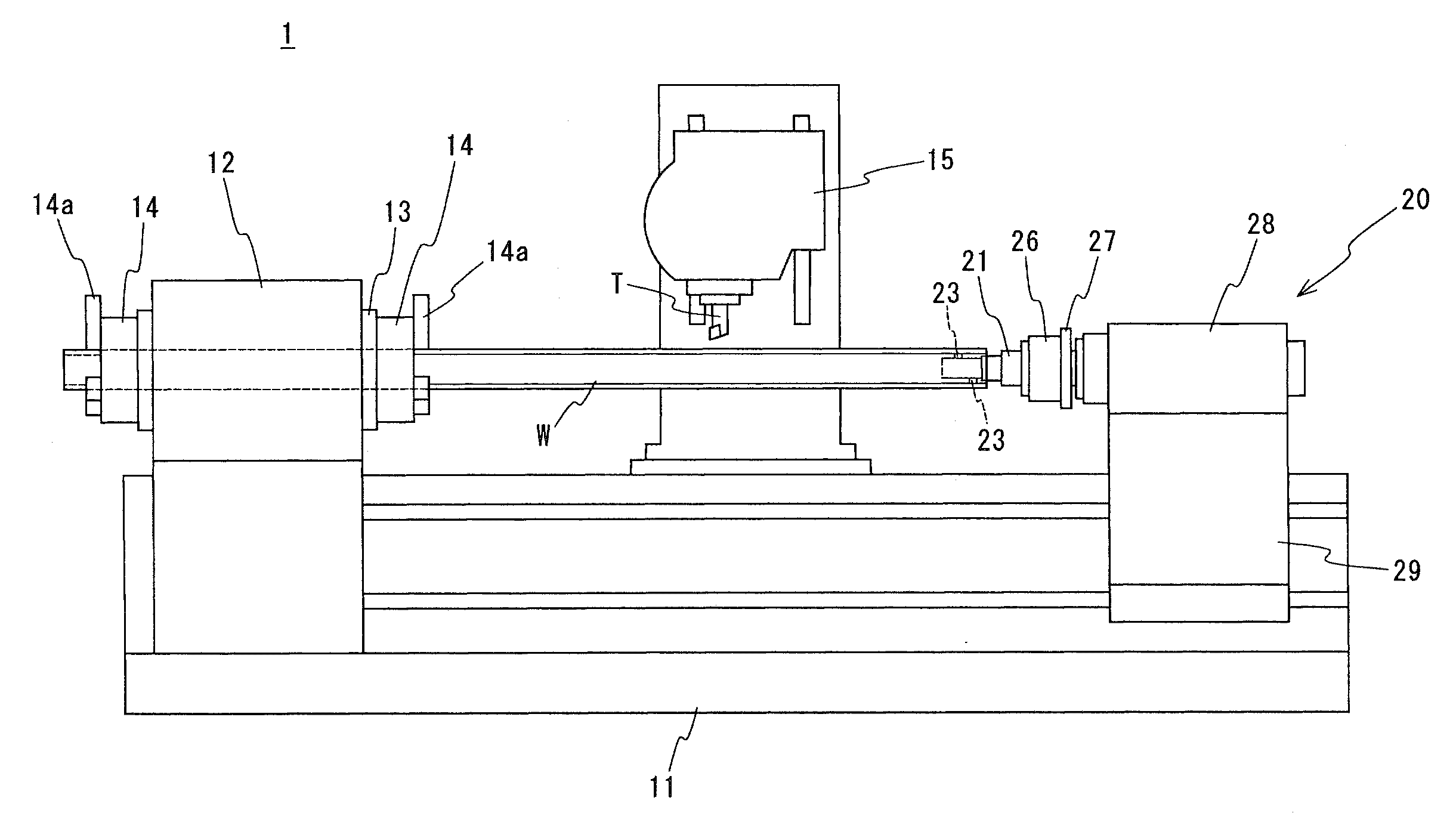

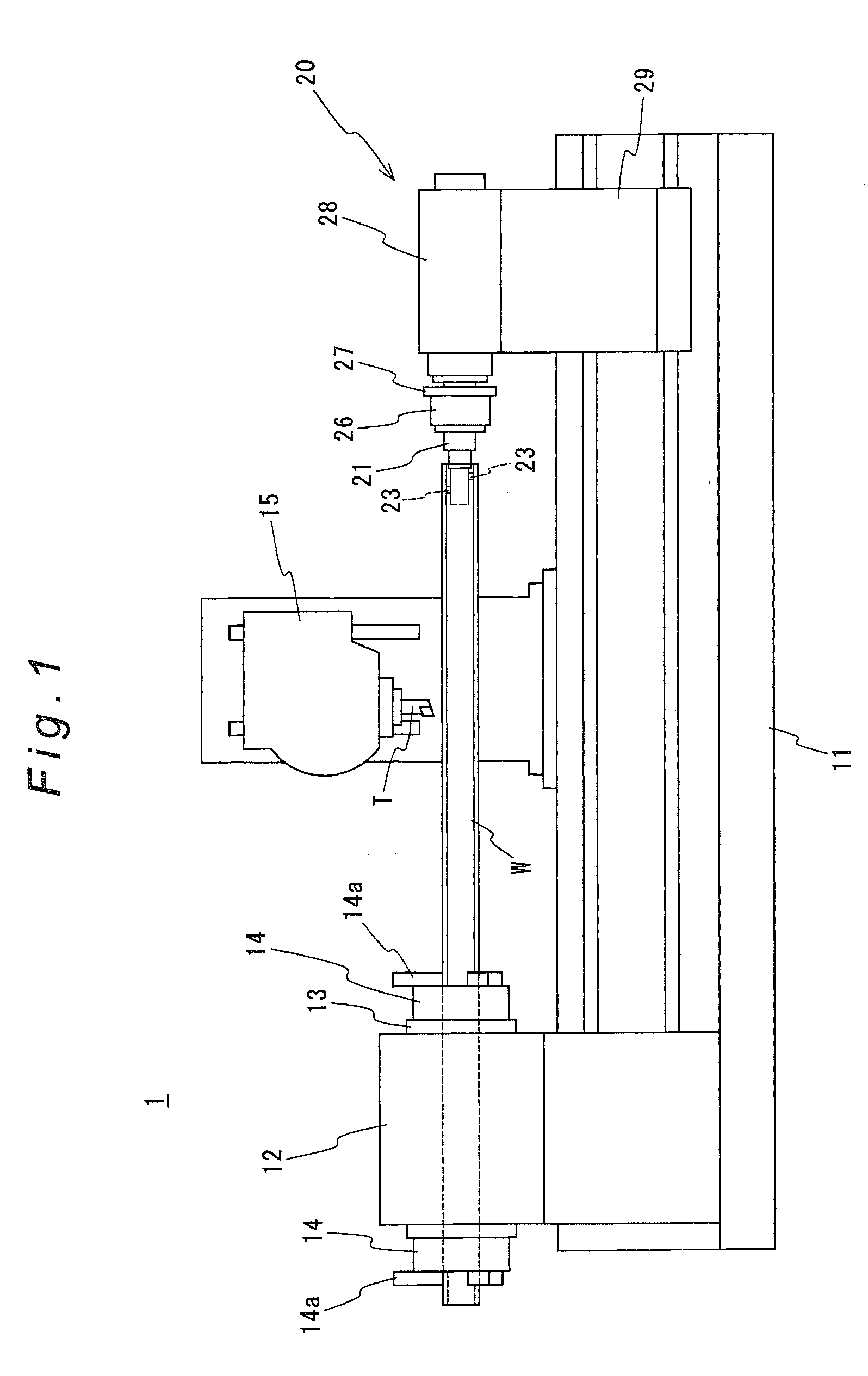

Lathe

InactiveUS20080156154A1Reduce pressureEasy to take backLathesTailstocks/centresFree rotationEngineering

Owner:DMG MORI CO LTD

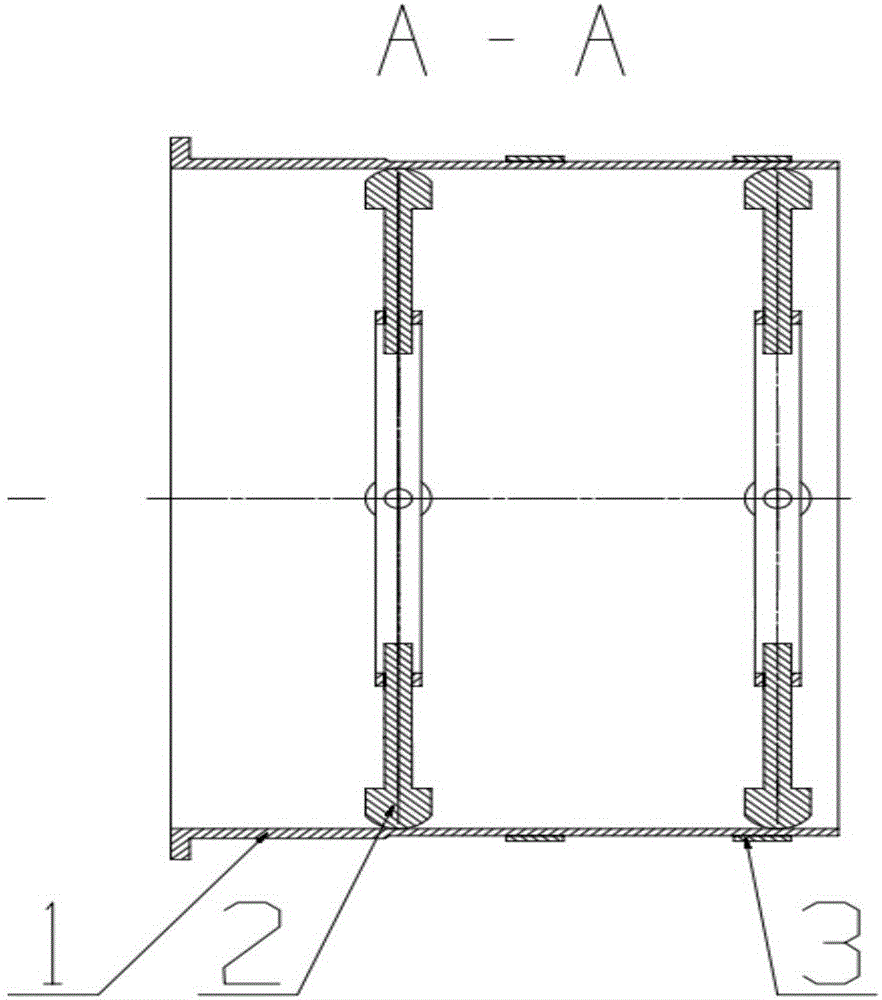

Technological method for reducing deformation of sectioning thin-walled cylinder type workpieces

The invention relates to a technological method for reducing deformation of sectioning thin-walled cylinder type workpieces. According to structural characteristics of the sectioning thin-walled cylinder type workpieces, by means of the combination of various methods of beforehand sizing, sizing and time keeping, auxiliary supporting, rough and fine machining, aging treatment and the like, the cylinder type workpieces are better in cylindricity after being sized, the requirement for working allowance is met after sizing, meanwhile, machining allowance is uniform, machining stress is uniform, and deformation is uniform; the thin-walled cylinder type workpieces are placed under application of a special sizing tool for a period of time before being roughly machined, welding deformation of the thin-walled cylinder type workpieces is better eliminated; the thin-walled cylinder type workpieces are placed again under application of the special sizing tool for a period of time before being finely machined, workpiece deformation caused after stress release in aging treatment is further reduced; meanwhile, the sizing tool is used as a machining auxiliary supporting tool, the workpiece strength is increased, and machining deformation is reduced.

Owner:HARBIN ELECTRIC MASCH CO LTD

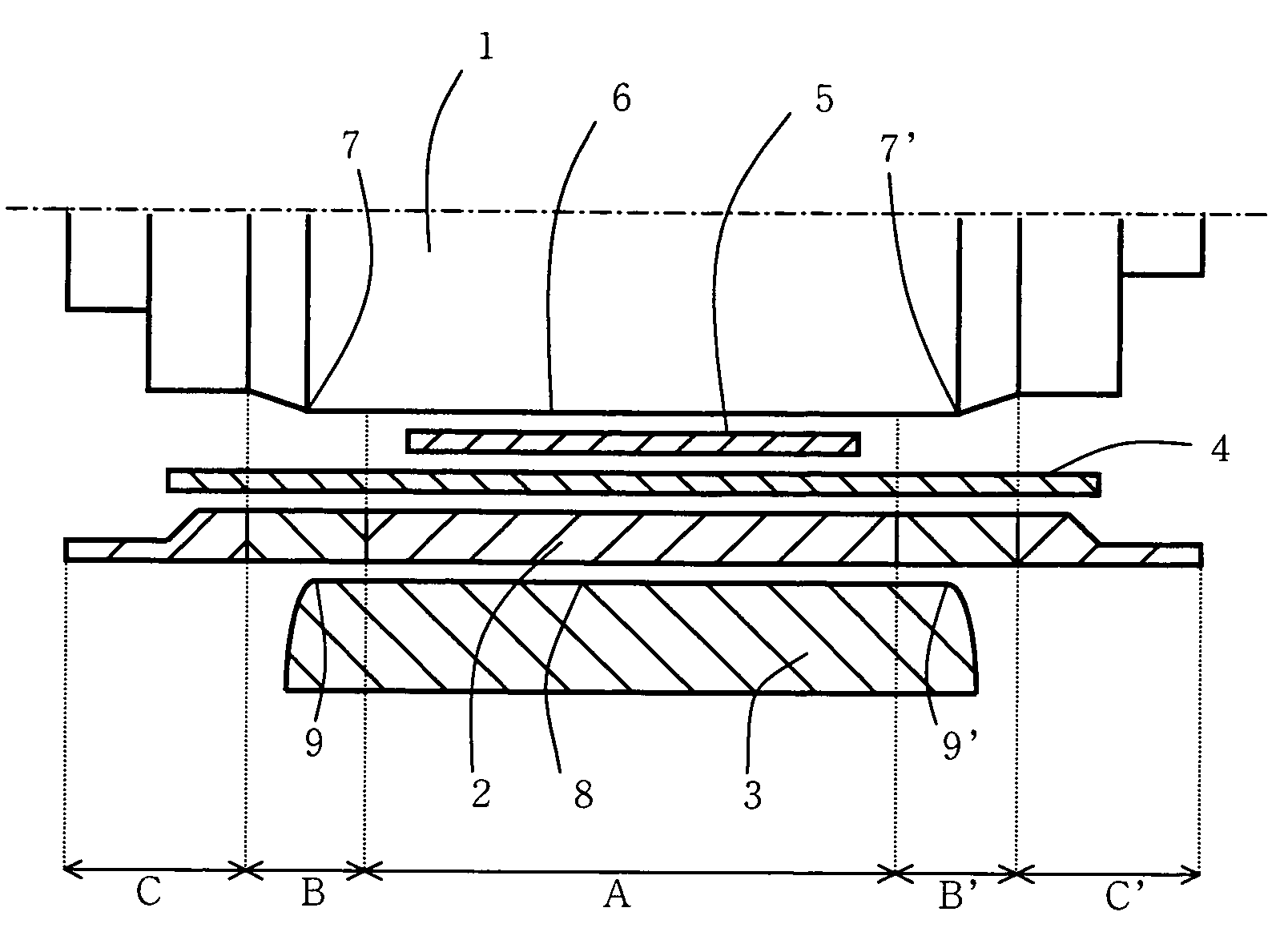

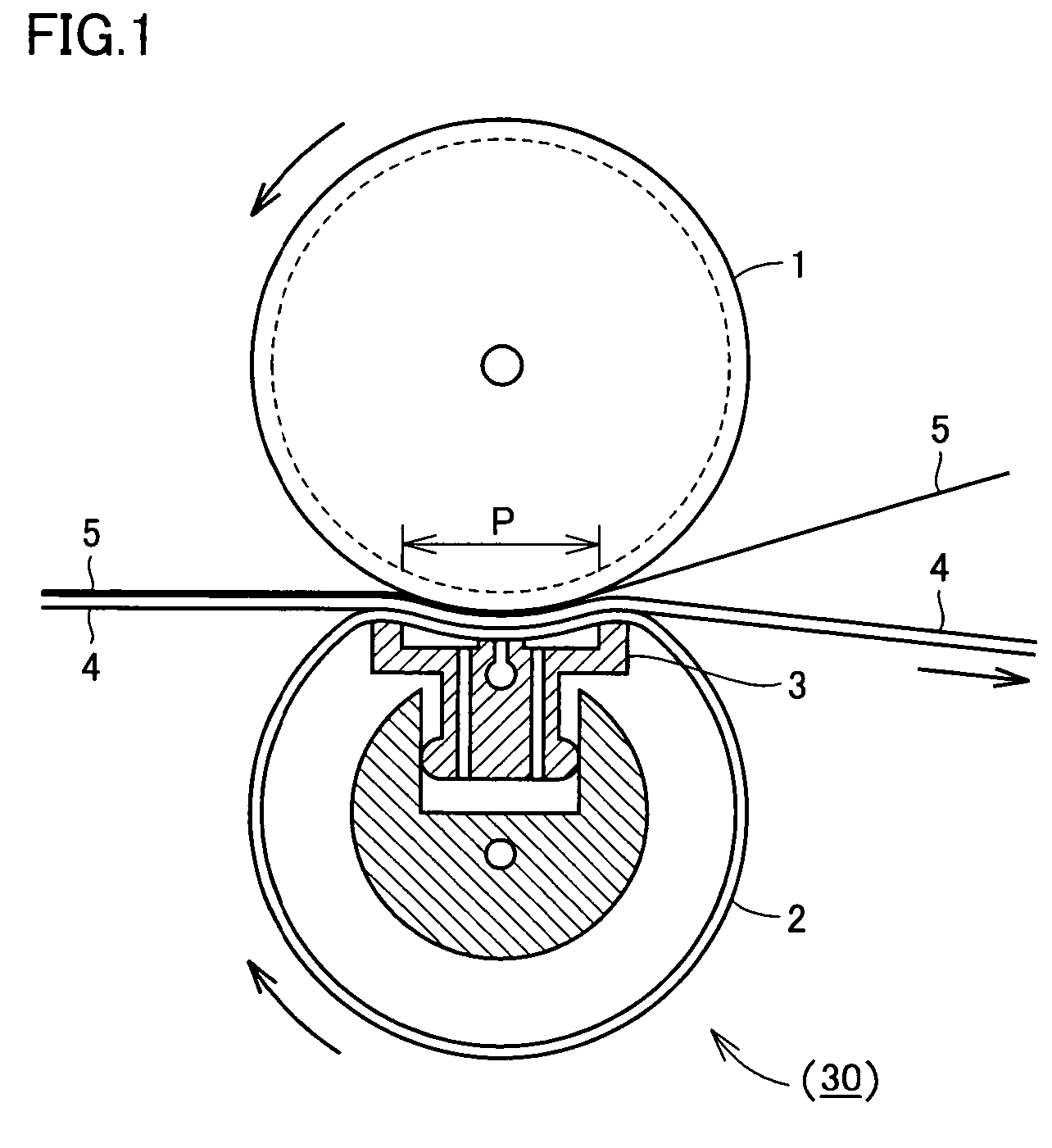

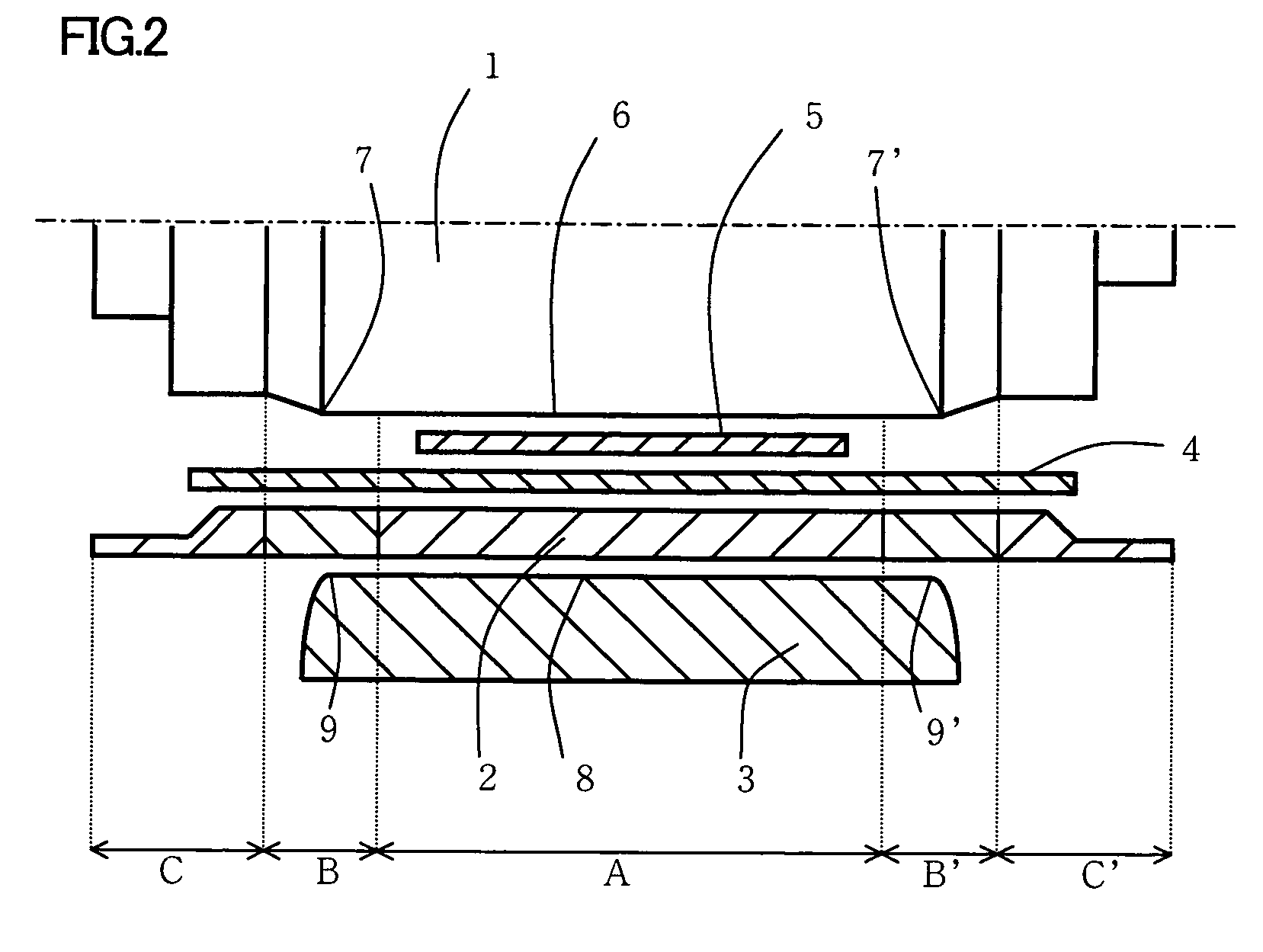

Press belt, process for producing the same and shoe press roll using the press belt

InactiveUS7611608B2Improve cylindricityIncrease pressureMechanical working/deformationPaper/cardboardCrack resistanceHydrogen

A press belt having superior cracking resistance, wear resistance and pressure deflection resistance and an excellent traveling property and a method of manufacturing the same as well as a shoe press employing the same are provided. A press belt in a press comprising a rotatively traveling endless press belt and pressing means, including terminal corresponding areas (B, B′) corresponding to both ends of the pressing means in the cross direction and a central area (A) located between the terminal corresponding areas and mainly composed of thermosetting polyurethane obtained from a thermosetting polyurethane material containing a phenylene isocyanate derivative having an isocyanate group (NCO) on an end and a hardener having an active hydrogen group (H) on an end with the equivalent ratio (H / NCO) between the active hydrogen group and the isocyanate group set relatively high on the terminal corresponding areas and relatively low on the central area and a method of manufacturing the same.

Owner:YAMAUCHI CORP

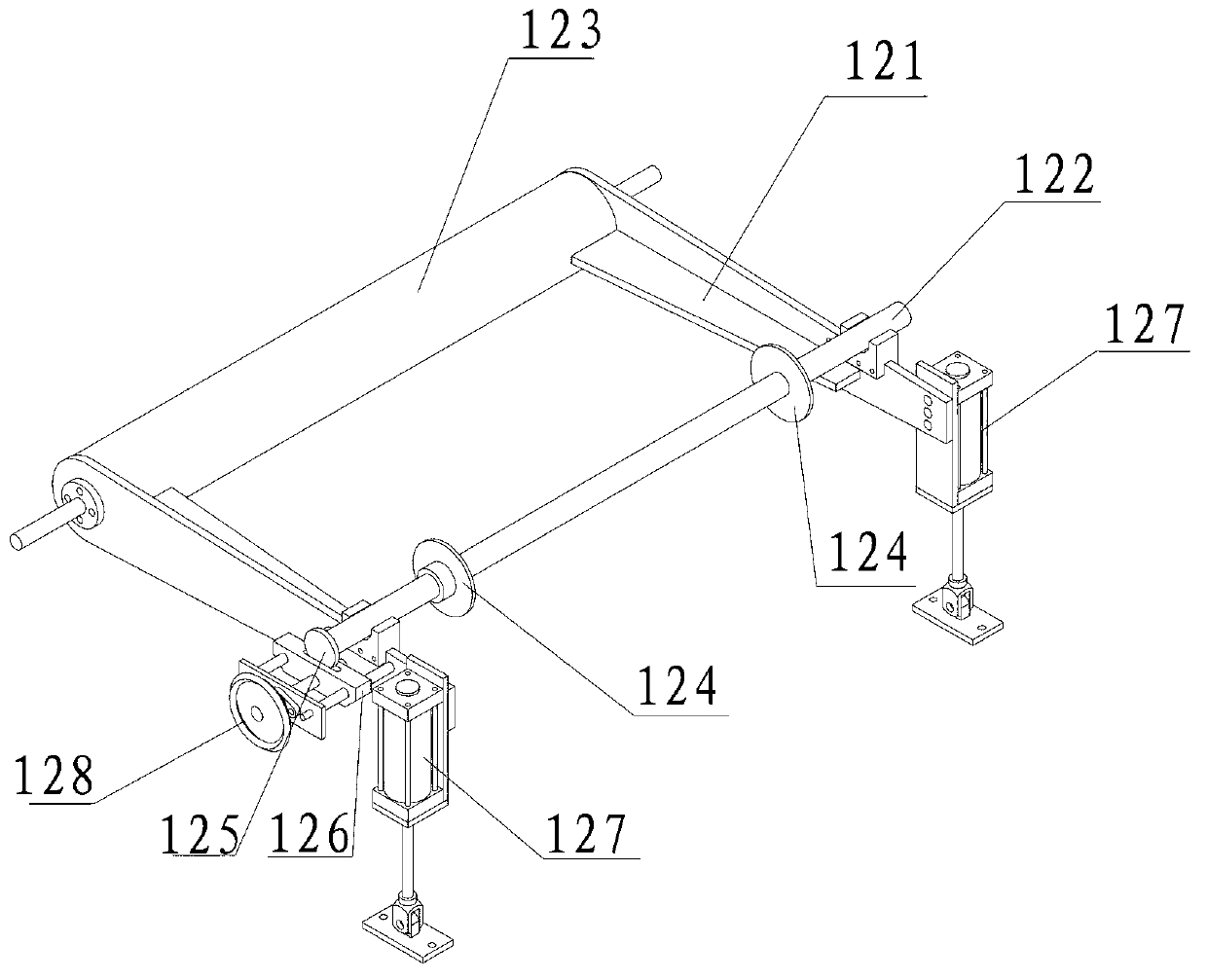

Paper tube calender

InactiveCN102950817ASimple structureEasy to usePaper/cardboard wound articlesStructural engineeringMechanical engineering

The invention discloses a paper tube calender, which comprises a supporting seat, a paper tube support arranged on the supporting seat, wherein the paper tube is supported on the paper tube support; the paper tube is provided with a central through hole penetrating along an axial direction; the calender further comprises a material-pressing component comprising a material tube seat and a calendering tube fixedly arranged on the material tube seat, wherein the material tube seat is fixedly arranged on the supporting seat; the calendering tube is provided with a through hole penetrating along an axial direction and is supplied for the paper tube to penetrate correspondingly and cooperatively, wherein the through hole and the paper tube are distributed along the same axial direction; the calendar further comprises a pressing mechanism capable of pressing the paper tube into the through hole along the axial direction; the pressing mechanism and the material-pressing component are respectively arranged on the supporting seat and located on two sides of the paper tube support. The paper tube calendar is simple in structure and convenient to use; and is adopted to calender the paper tube, thereby improving linearity and cylindricity of the paper tube.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

Tailstock tip device capable of adjusting machining accuracy

InactiveCN107414108AImprove machining accuracyHigh positioning accuracyTailstocks/centresTip positionTailstock

The invention discloses a tailstock tip device capable of adjusting the machining accuracy. The device moves in the length direction of the device under the effect of a driving mechanism and is pushed on a center hole of one end of a circular-shaft workpiece, and the other end of the circular-shaft workpiece is clamped by a three-claw chuck. The three-claw chuck can rotate and drive the circular-shaft workpiece to rotate. The device comprises a base, a supporting block, a tail seat sleeve, a main shaft and a tip. The supporting block is arranged on the base, the tail seat sleeve is connected to the supporting block, and the main shaft is arranged in the tail seat sleeve and can rotate relative to the tail seat sleeve. The tip is fixedly arranged at the end of the main shaft and located on the outer portion of the tail seat sleeve, and an axial adjusting mechanism and a radial adjusting mechanism which are used for adjusting the tip position accuracy are arranged between the supporting bock and the base. According to the tailstock tip device, the left-right position accuracy and the front-rear position accuracy of the tip can be adjusted.

Owner:YANCHENG QINCHUAN HUAXING MACHINE TOOL

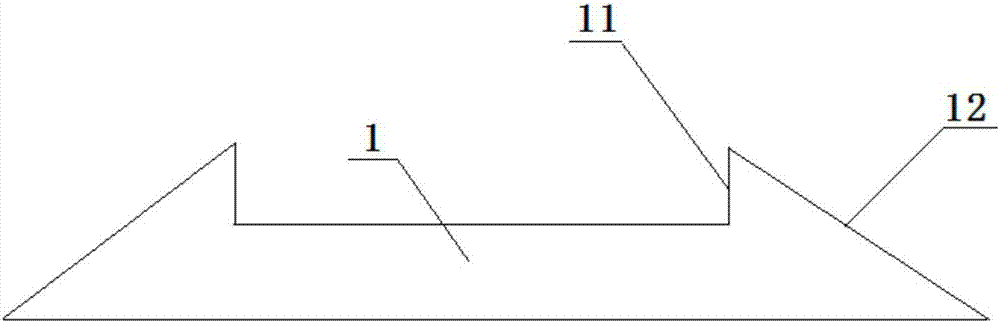

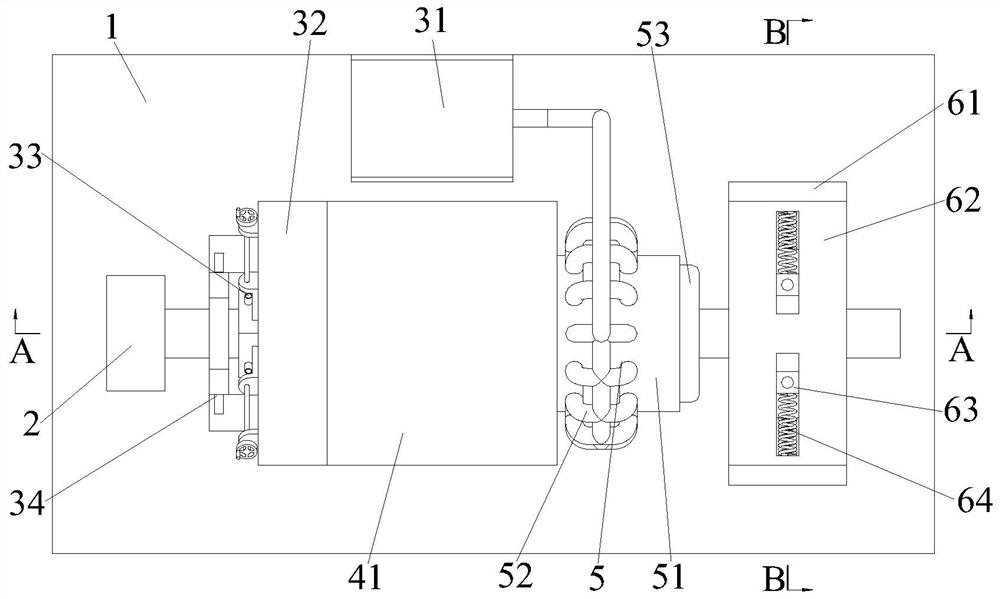

PVC plastic pipe manufacturing and forming method

InactiveCN112549489AAvoid cumbersome processImprove cylindricityRevolution surface grinding machinesGrinding drivesManufacturing efficiencyEngineering

The invention relates to a PVC plastic pipe manufacturing and forming method. A bottom plate, a hot melting extruder, a cooling device, a grinding device, a cleaning device and a driving device are arranged to cooperatively manufacture a PVC plastic pipe. According to the PVC plastic pipe manufacturing and forming method, the problems that when existing PVC plastic pipe manufacturing equipment isused for manufacturing the PVC plastic pipe, the PVC plastic pipe subjected to hot melting extrusion is directly cooled, the existing PVC plastic pipe manufacturing equipment can only cool the PVC plastic pipe with the single diameter, when the PVC plastic pipes with different diameters are cooled, a mold needs to be replaced, the mold replacement process is tedious, consequently, the PVC plasticpipe manufacturing efficiency is low, the existing PVC plastic pipe manufacturing equipment directly cools and collects the PVC plastic pipe, the deformed PVC plastic pipe in the cooling process is not corrected, consequently, the diameters of the same PVC plastic pipe are different, and use of the PVC plastic pipe is affected can be solved.

Owner:陆红华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com