Paper tube calender

A calender and paper tube technology, which is applied in the direction of cardboard winding articles, etc., can solve the problems of unfavorable material winding, the straightness and cylindricity of the paper tube cannot meet the requirements, etc., and achieves simple structure, good practical performance, and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

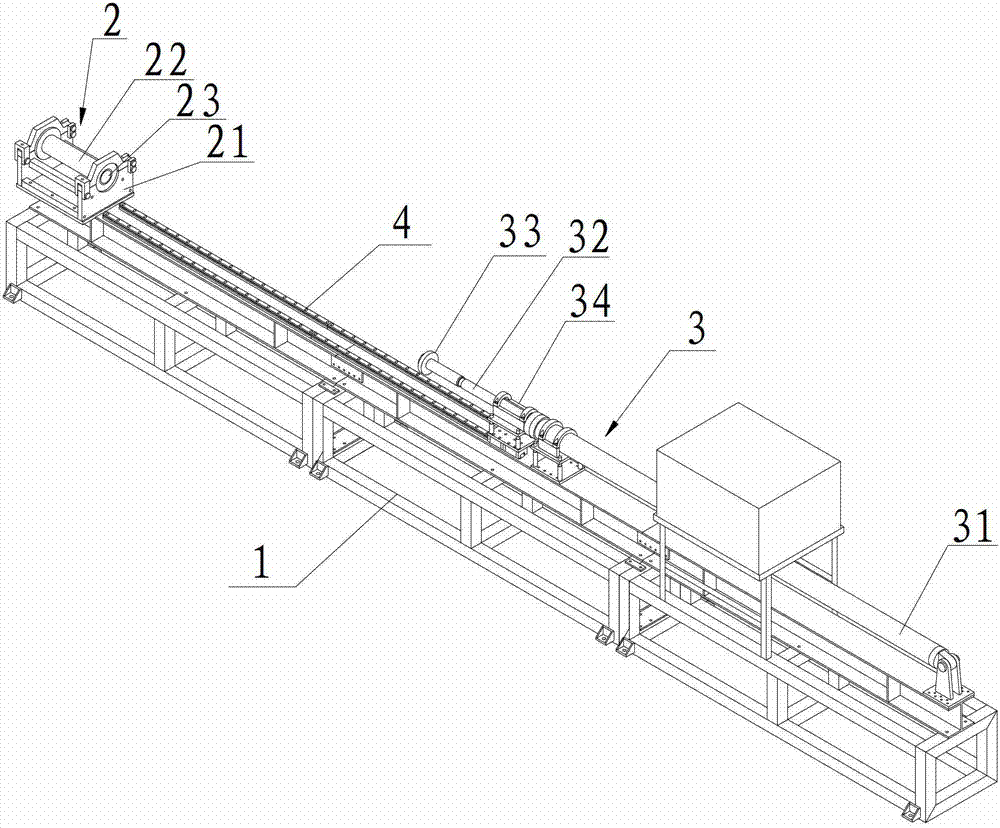

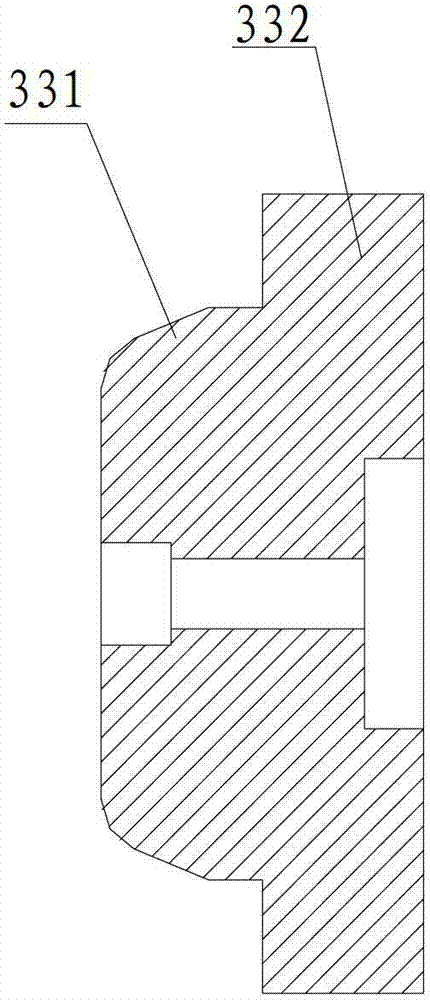

[0018] see figure 1 The paper tube calender shown, the paper tube calender includes a support base 1, a paper tube support (not shown in the figure) arranged on the support base 1, and the paper tube support to be calendered is arranged on the paper tube On the support, the paper tube has a central through hole penetrating in the axial direction. The calender also includes a pressing assembly 2 and a pressing mechanism 3, and the pressing assembly 2 and the pressing mechanism 3 are respectively arranged on the support seat 1 on both sides of the paper tube support. The pressing assembly 2 includes a material tube seat 21, a calendering tube 22 fixedly arranged on the material tube seat 21, the material tube seat 21 is fixedly arranged on the support seat 1, and the calendering tube 22 has a supply tube penetrating in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com