Chuck expansion type metal hard tube rotary cutting machine

A cutting machine and metal technology, applied in the direction of metal processing equipment, pipe shearing device, shearing device, etc., can solve the problems of radial deformation of steel pipe, unqualified steel pipe, flattening of steel pipe end, etc., and achieve convenient replacement and high cylindricity , Guarantee the effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further explain the present invention below in conjunction with embodiment and accompanying drawing.

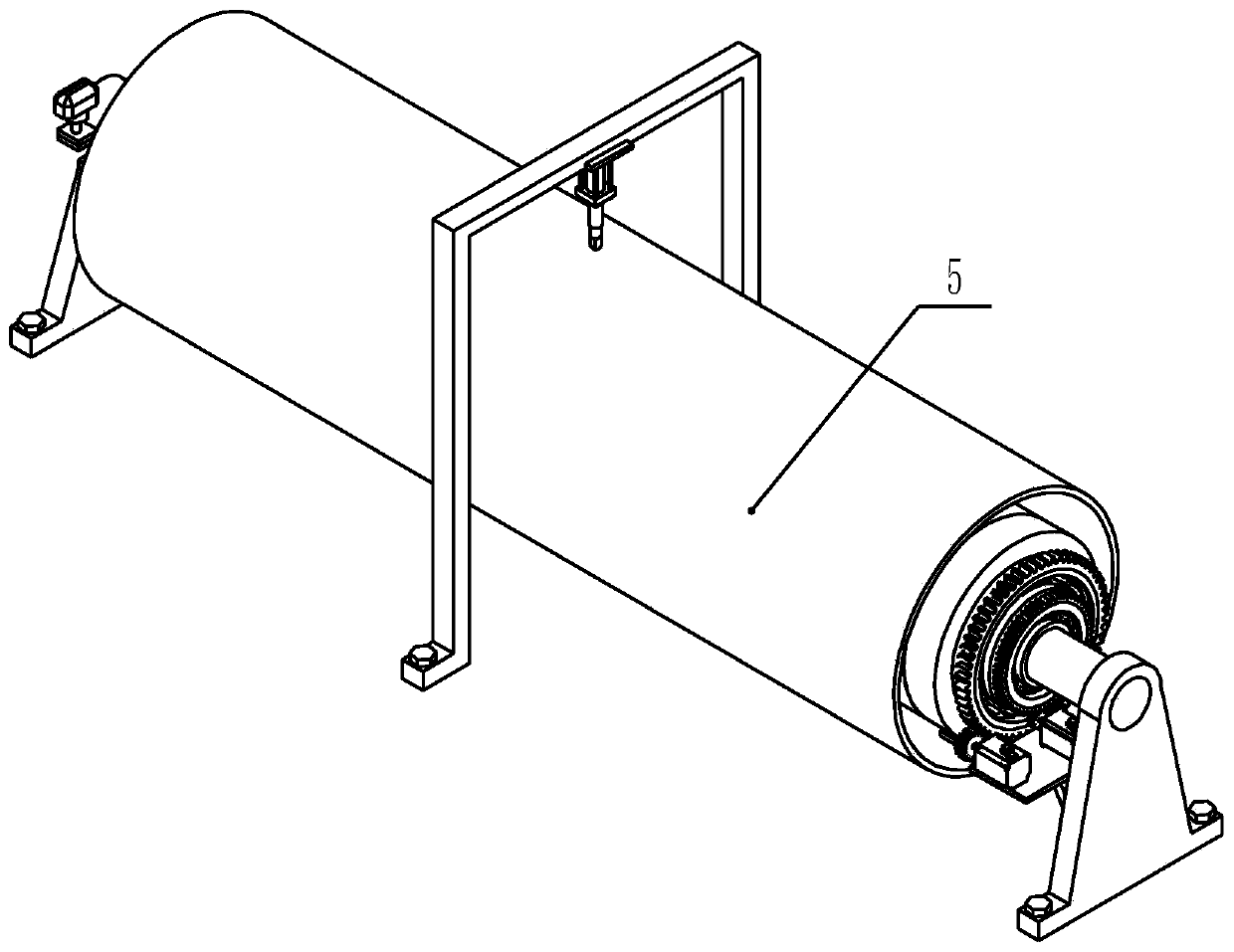

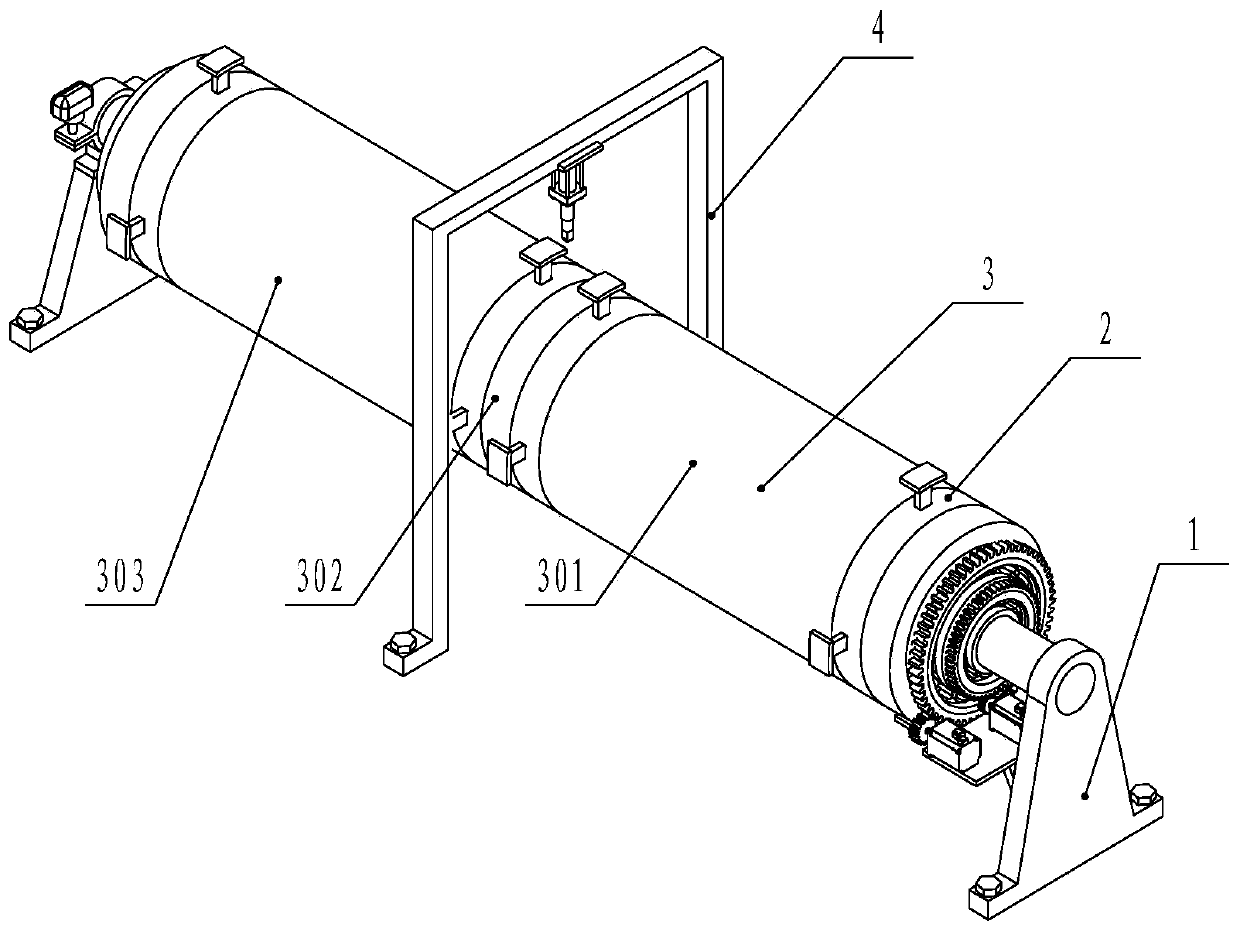

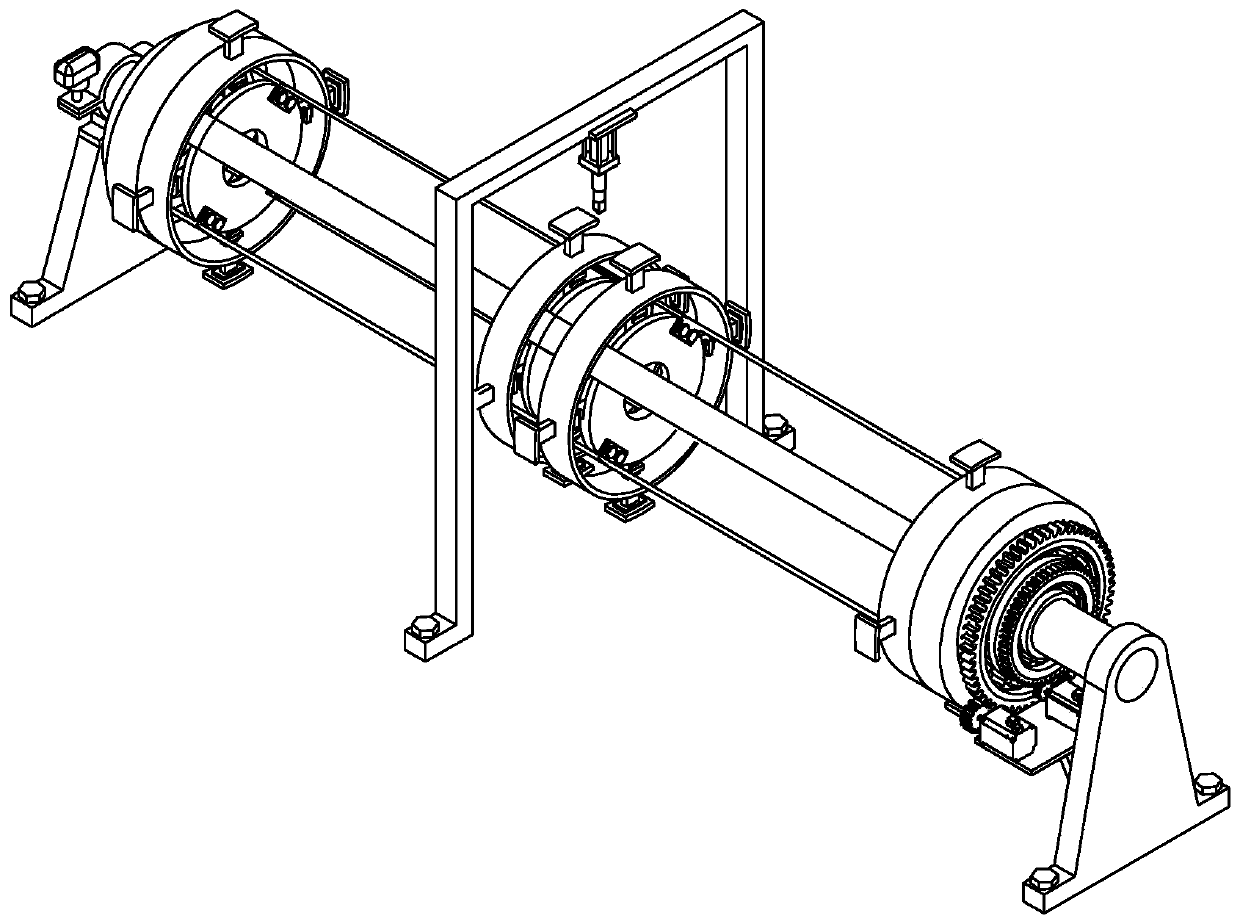

[0041] The present invention is a chuck expansion type metal hard tube rotary cutting machine (referred to as cutting machine, see Figure 1-10 ) includes a support device 1 , an expansion device 2 , a cannula device 3 and a cutting device 4 .

[0042] Described support device 1 comprises front support frame 101, front support shaft 102, inner connection ring 104, outer connection ring 111, advance motor 107, rear travel motor 109, rear support frame 112, large connection ring 115, large bearing 121, small Connecting ring 114, small bearing 113, rear support shaft 117.

[0043] For convenience of description, it is stipulated that the position of the front support frame 101 relative to the rear support frame 112 is front.

[0044] Front support frame 101 is fixed on the ground by anchor bolts, and a circular through hole is arranged on the top of front support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com