Quick double-brake self-locking type strain clamp

A tension clamp and double brake technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of waste of hardware and wires, non-removal, operation and maintenance workload and hidden dangers, and achieve the effect of uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

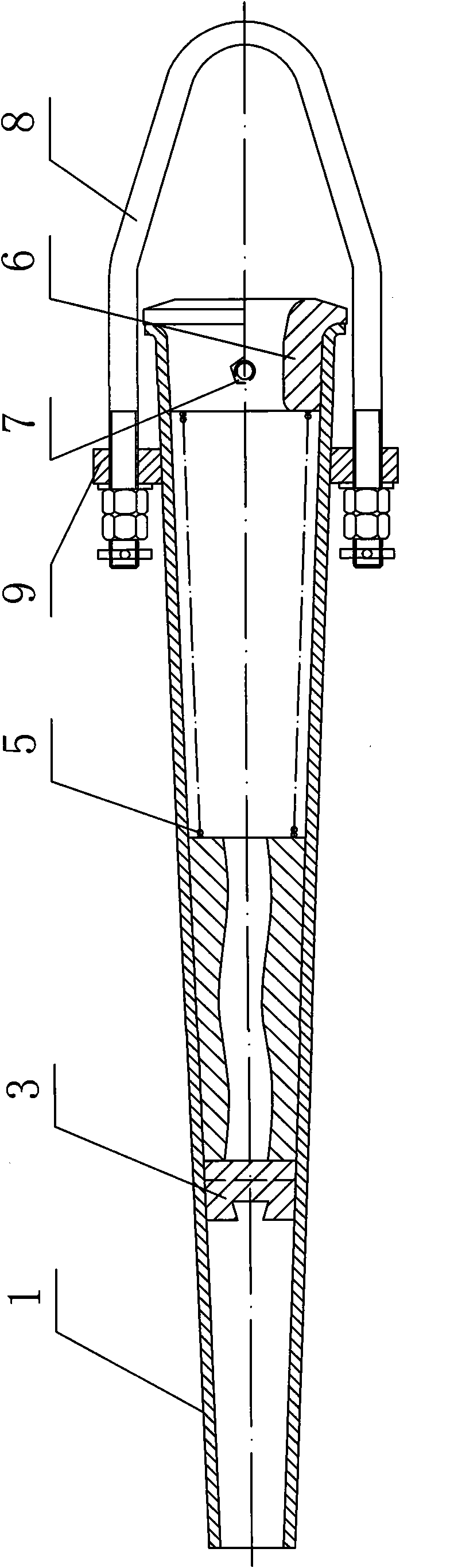

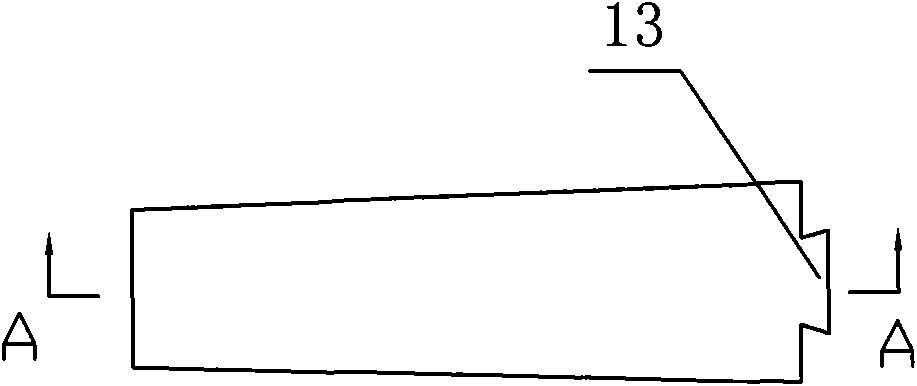

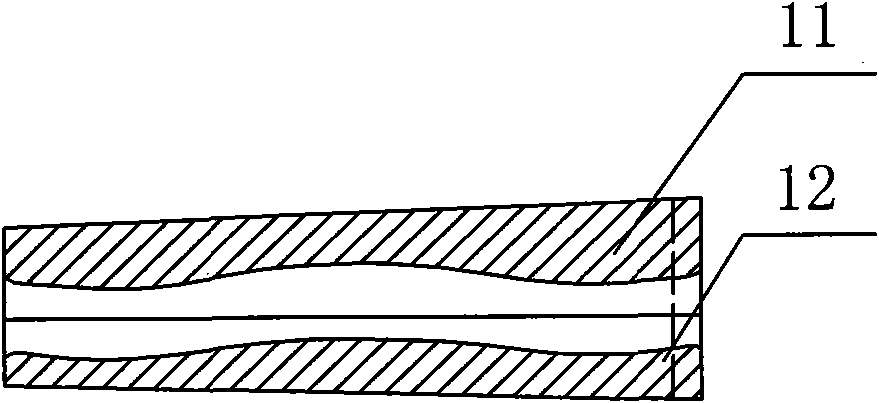

[0020] Such as figure 1 As shown, a fast double-braking self-locking tension clamp includes a tapered pipe body 1, a reaction force spring 5, clamps and U-shaped bolts 8, and the clamps are divided into left and right groups of four Parts, the first curve clamp 11, the second curve clamp 12, the third curve clamp 21, the fourth curve clamp 22, such as figure 2 , 3 As shown, the first curved clamp 11 and the second curved clamp 12 are combined to form a tapered pipe body, and its outer circumference matches the inner wall of the tapered pipe body 1, and the combined vertebral bottom is provided with a first dovetail boss 13; if Figure 4 , 5 As shown, the third curved clip 21 and the fourth curved clip 22 are merged to form a tapered pipe body, the outer circumference of which matches the inner wall of the tapered pipe body 1, and the merged vertebral top is provided with a second dovetail boss 23; A clamp connection block 3 is provided in the middle of the two sets of cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com