Upper die clamping device of bending machine

A technology of clamping device and bending machine, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems affecting the quality of bending products, inconvenience, and inconsistency of the center of the bending upper die, etc., to improve work efficiency and bending product quality, fast and convenient use, and uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

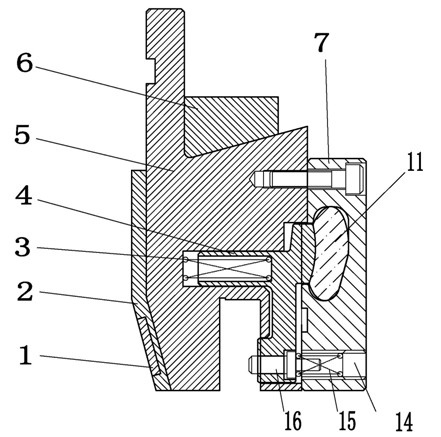

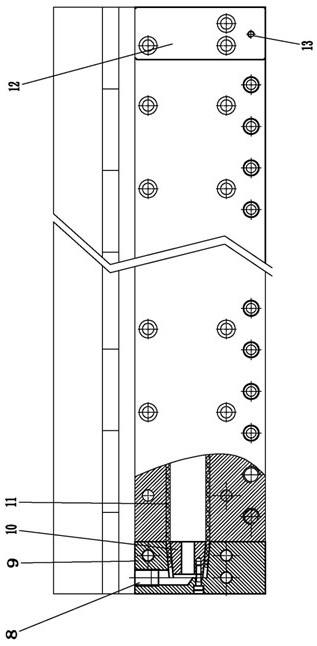

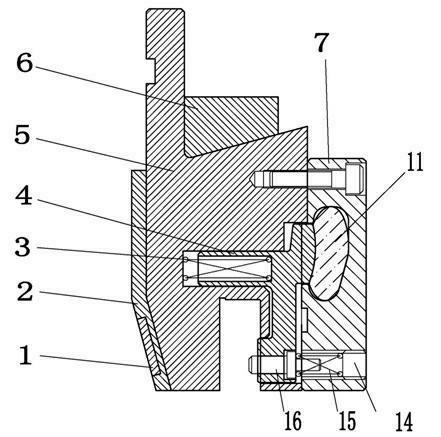

[0021] like figure 1 , figure 2 As shown, the clamping device for the upper mold of the bending machine of the present invention includes a clamping body 5 connecting the upper part to the bending machine and the lower part to connecting the upper die of the bending mold. The clamping block 4 of the upper mold of the mold, the lower end of the clamping block 4 is elastically connected to the clamping body 5 through the ejector pin 16, and the upper end of the clamping block 4 is connected to a hydraulic pipeline system for providing clamping power; The pipeline system includes a pressure-resistant hose 11 placed in the rear main cover 7 and an oil valve 8 placed on the rear left end cover 9, and the port of the pressure-resistant hose 11 is provided with a pressure-resistant hose for sealing and fixing. 11, the oil pipe pressing wedge 10, the oil pipe pressing wedge 10 is provided with a through hole for communicating with the oil valve 8 and the pressure-resistant hose 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com