Electrode and machine tool dedicated for combined machining of electric spark shaping of inner round bore and elastic honing

A compound machining and EDM technology, which is applied in the field of non-traditional machining technology, can solve the problems that affect the machining efficiency and machining accuracy of workpieces, and can not realize the combined EDM machining of inner holes, so as to reduce the number of clamping times of workpieces, improve cylindricity, The effect of process concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

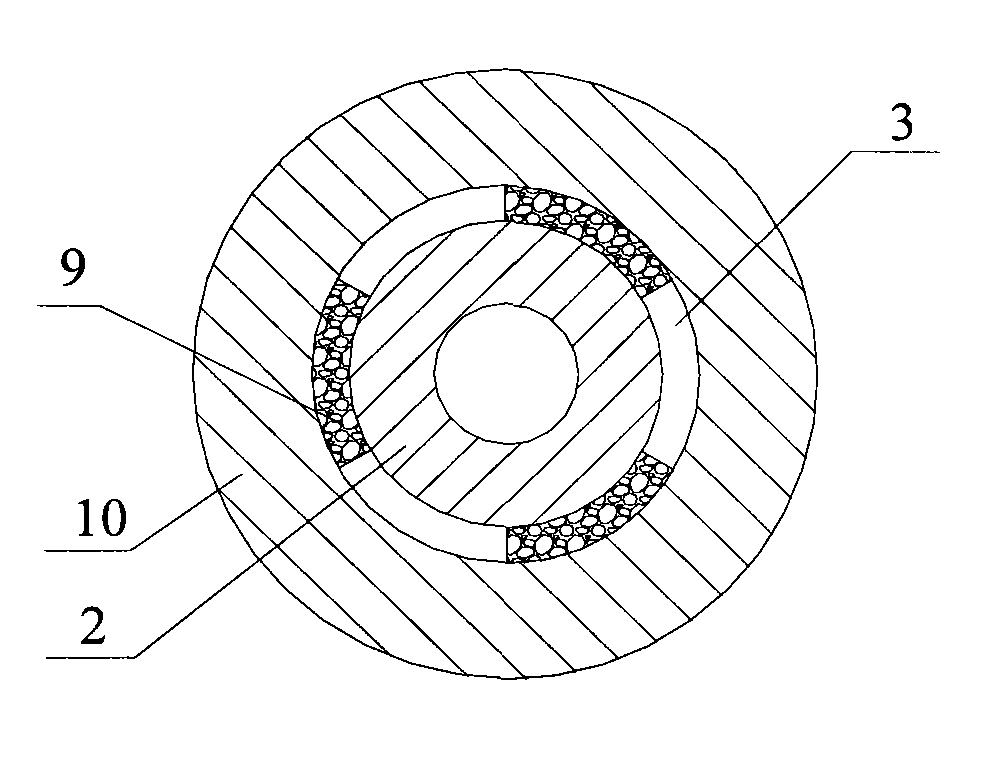

[0031] The core of the present invention is, aiming at the inner hole of conductive material, design a kind of special-purpose electrode and machine tool that integrates EDM rough machining and elastic abrasive honing finishing, including the following two aspects:

[0032] First, the working principle and method of the composite processing technology integrating EDM inner round hole rough machining and elastic precision honing and polishing;

[0033] Second, realize the structure design, material selection and production method of special electrodes for EDM and elastic honing, lapping and polishing composite processes.

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

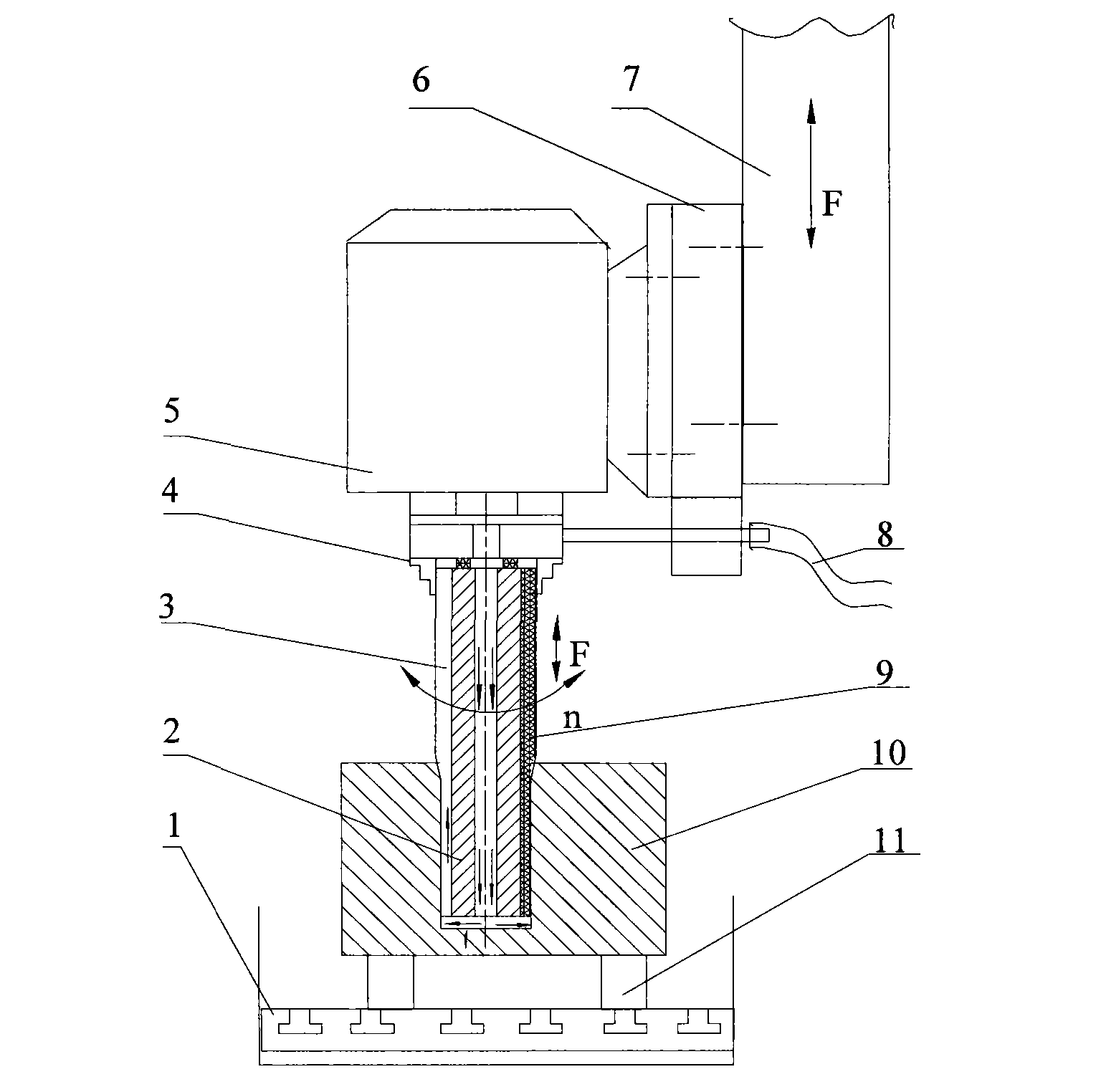

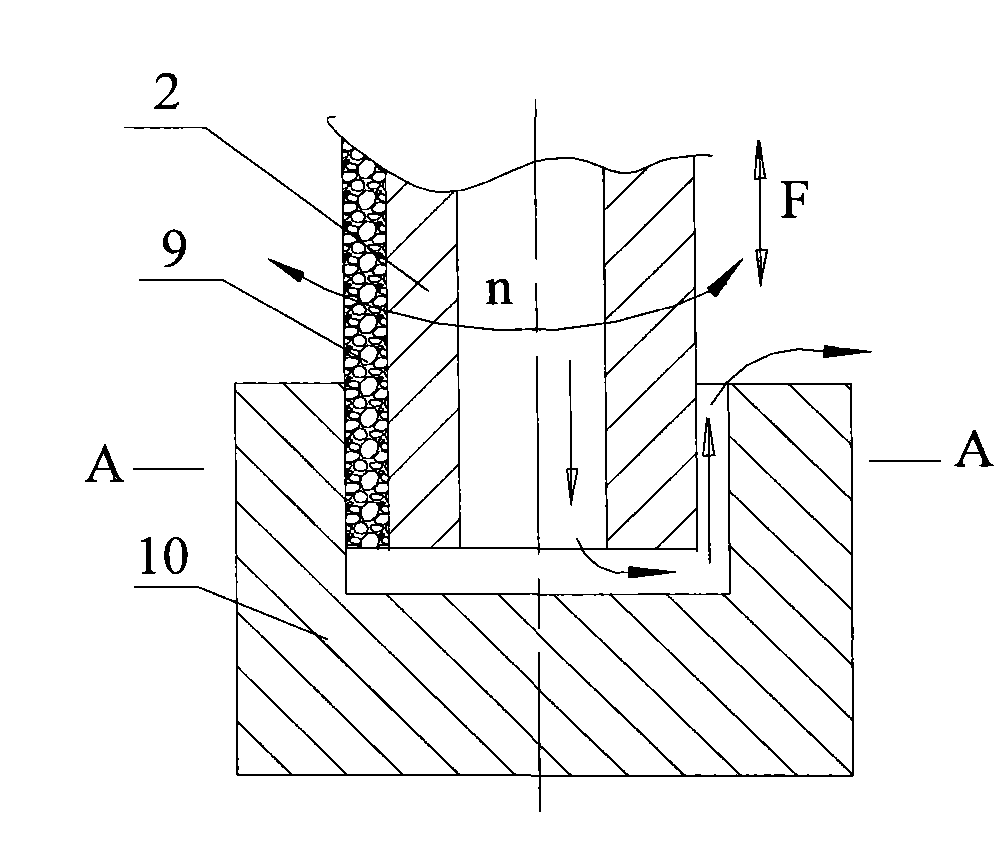

[0035] see figure 1 , shows the structure of the compound machining machine tool for electric discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com