Patents

Literature

90results about How to "Guaranteed Specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

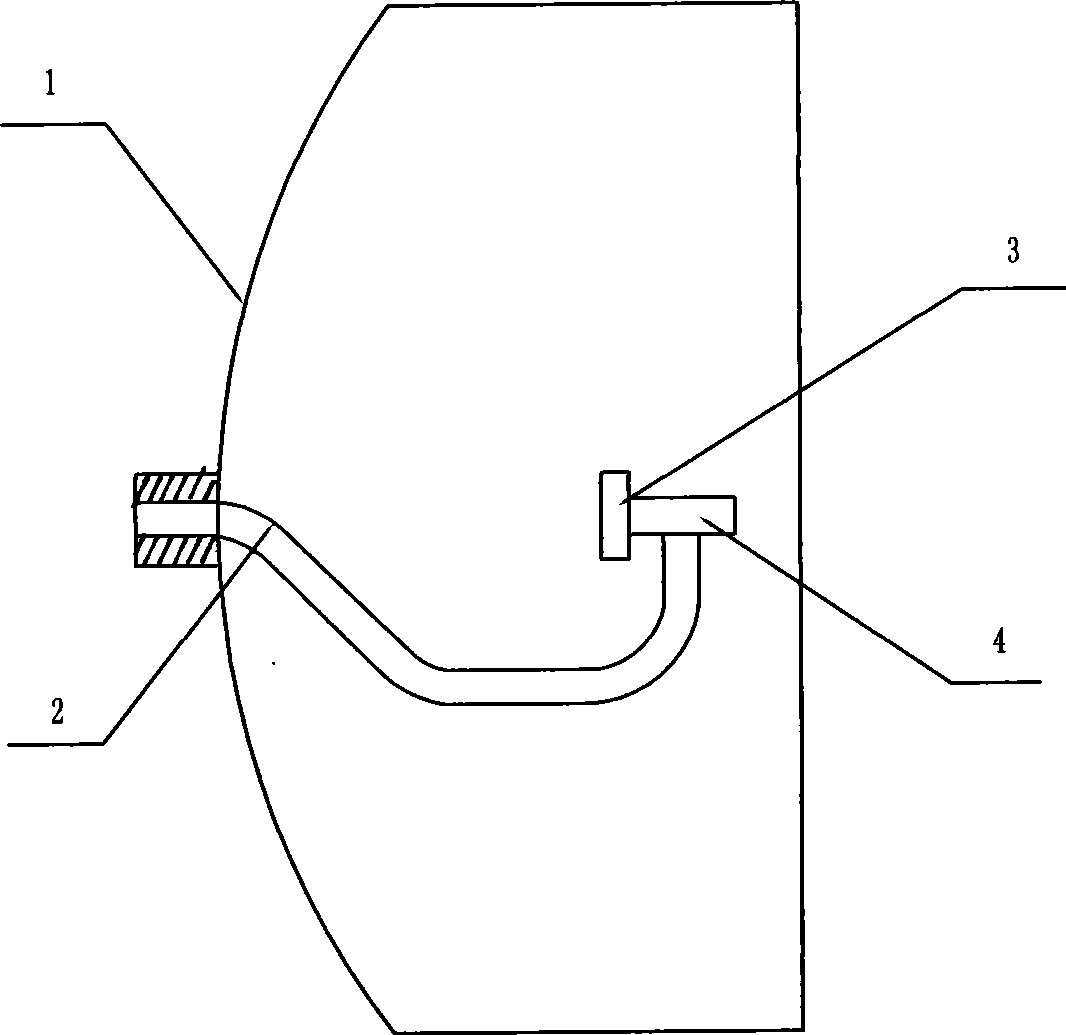

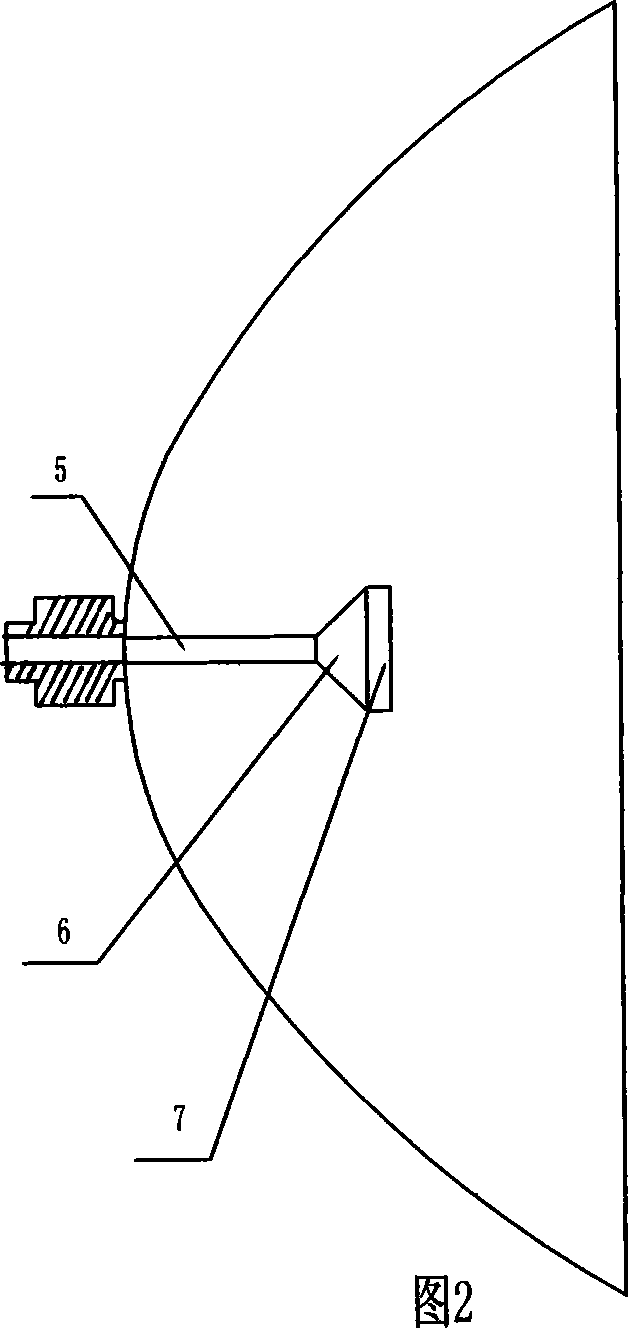

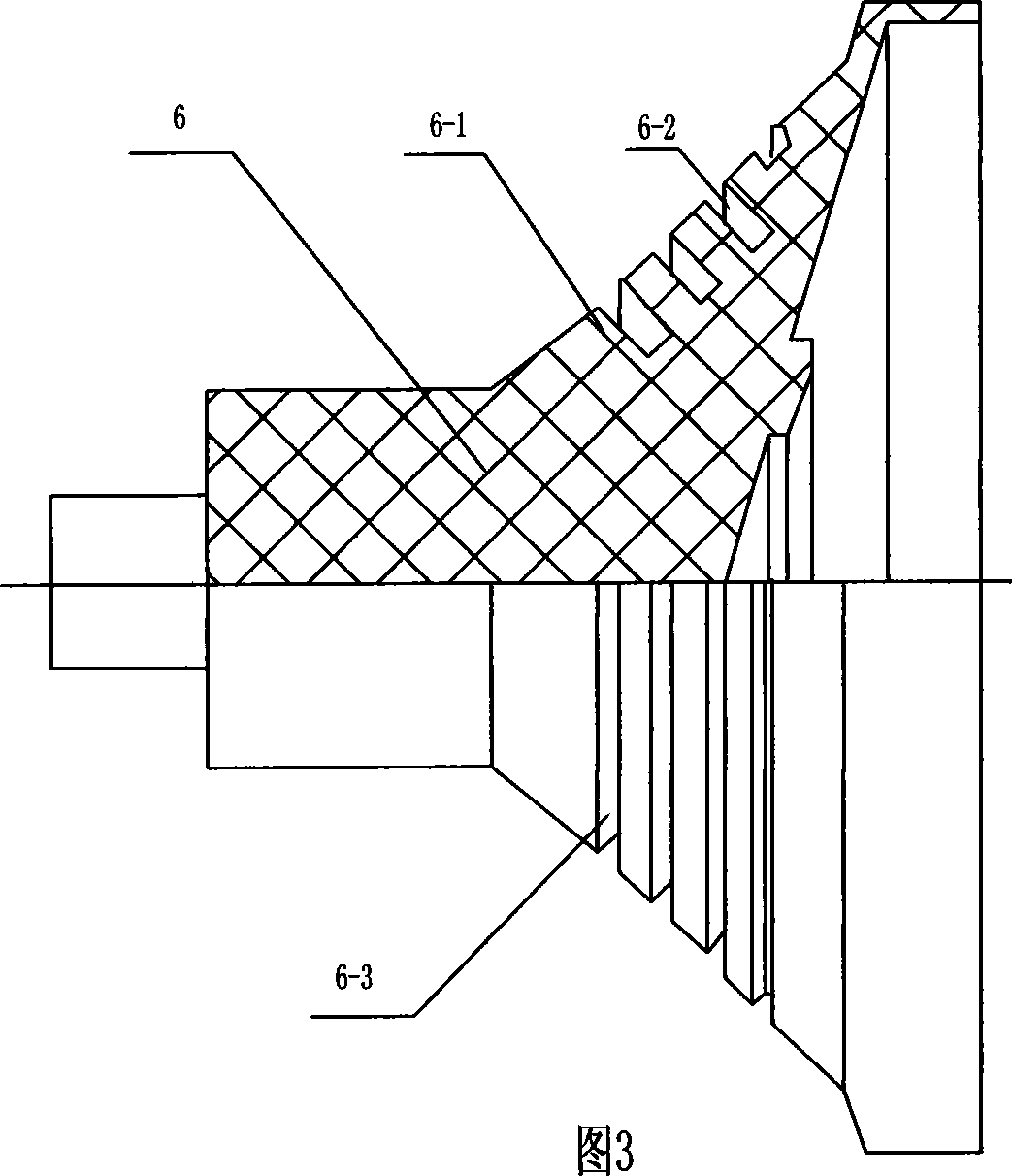

Microwave feeding source of ultra-high performance antenna

InactiveCN101383451AChange the local electromagnetic wave distributionChange the distribution of electromagnetic wavesWaveguide hornsHigh rateMicrowave

The invention discloses a feedback type round wave-guide feed source for a microwave antenna, which comprises a round wave-guide, a taper medium support and a subreflector. The three parts are positioned on a same axial line, and tight compression-joint cooperation is adopted between the round wave-guide and the medium support and between the medium support and the subreflector. The feedback type round wave-guide feed source is characterized in that the parts are on the same axial line after being assembled; a plurality of annular grooves are processed at certain positions on the conical surface of a taper medium connecting block and a taper of the metal subreflector. Through the annular grooves processed on the subreflector and the conical surface of medium support, the invention changes the transmission direction of part reflected wave and reduces the electromagnetic energy entering the inside of a round wave-guide opening, thereby improving the standing wave ratio index of the feed source and having no influence on other indexes. The feed source with the structure has high rate of finished product for the production and processing, low cost and favorable generalizing value.

Owner:GUANGDONG SHENGLU TELECOMM TECH

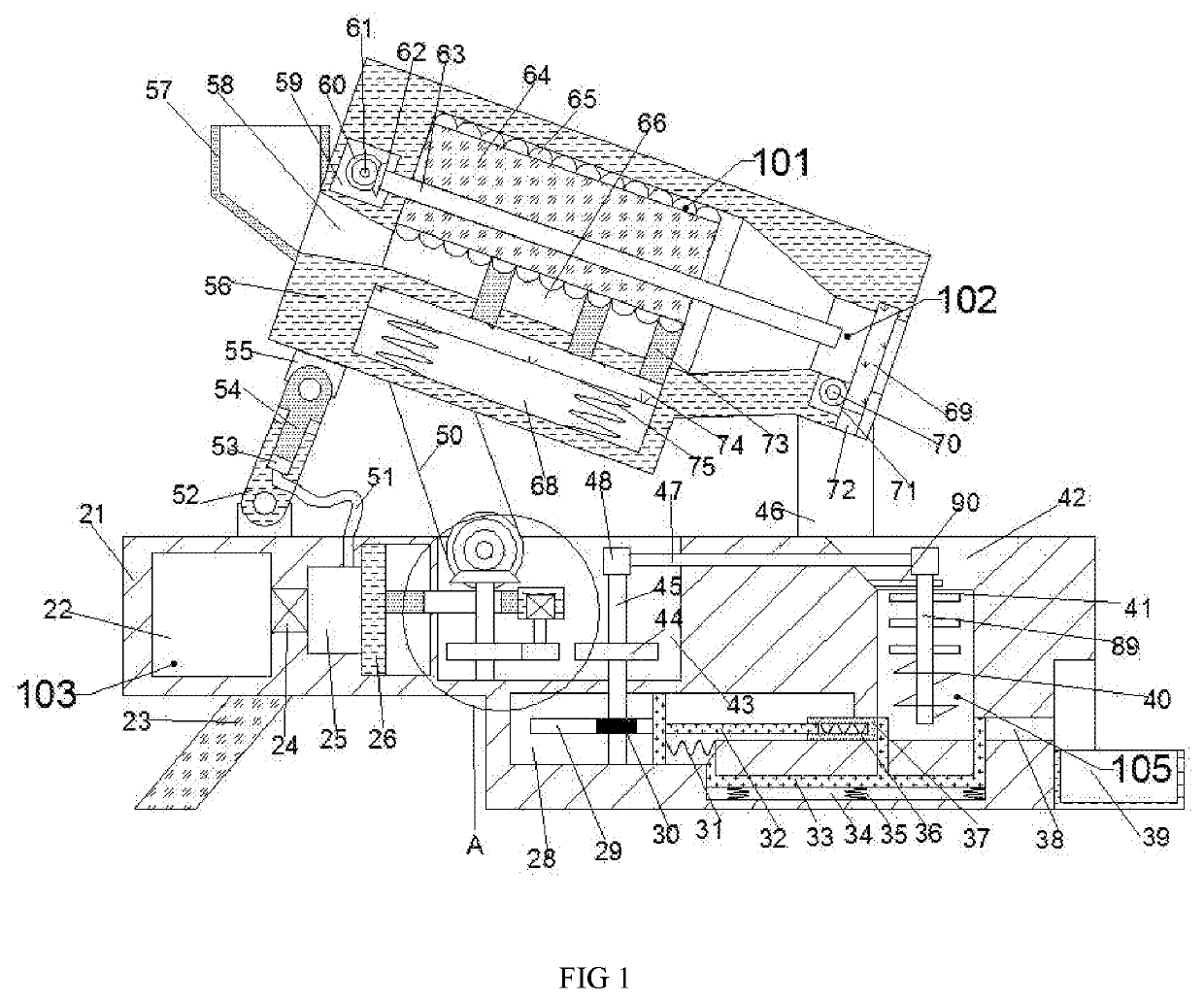

Mechanism bamboo charcoal processing apparatus

InactiveUS20200147832A1Uniform particle sizeEnsure qualityCane mechanical workingWood working apparatusCarbonizationEngineering

The invention discloses a mechanism bamboo charcoal processing apparatus, which includes a machine body. A rotating rod is rotatably connected to the top surface of the machine body. The rotating rod is provided with an oil groove, and a sliding plate is slidably connected to the oil groove. The fixed block is rotatably connected. The carbonized bamboo block and bamboo joint are first put into the feeding port through the feeding port, and then the power motor is turned on. This device can grind the initially carbonized bamboo block and bamboo joint into a uniform particle. Compared with ordinary machines, the bamboo charcoal powder milled by this device is screened layer by layer to ensure that the particle size of the milled bamboo charcoal powder can be uniform, thereby ensuring the quality of the later-processed charcoal. The bamboo charcoal powder and the combustion promoter are mixed uniformly, and then pressed into uniform-sized machine-made charcoal.

Owner:ZENG DI

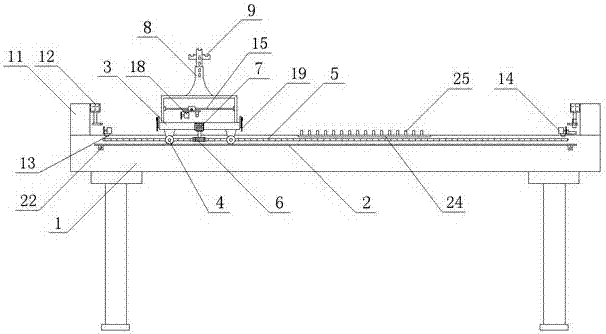

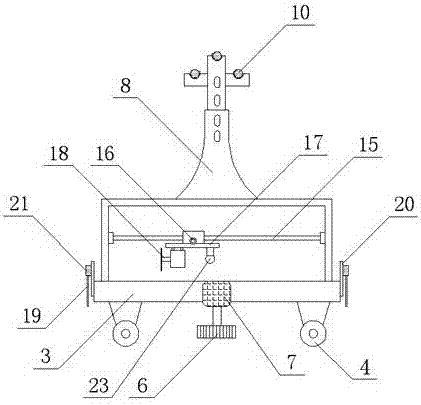

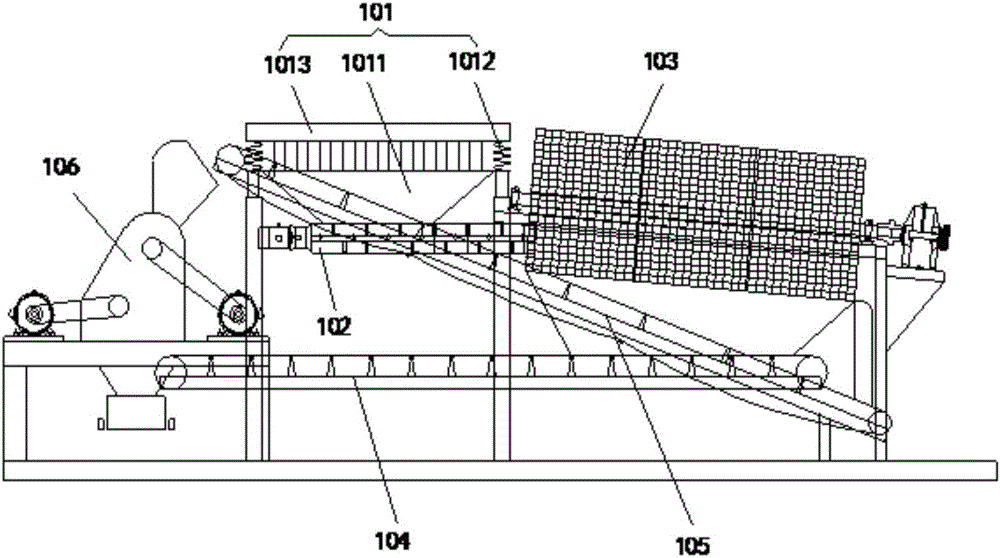

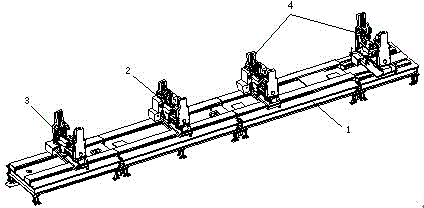

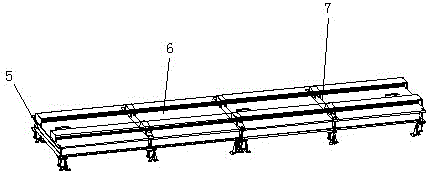

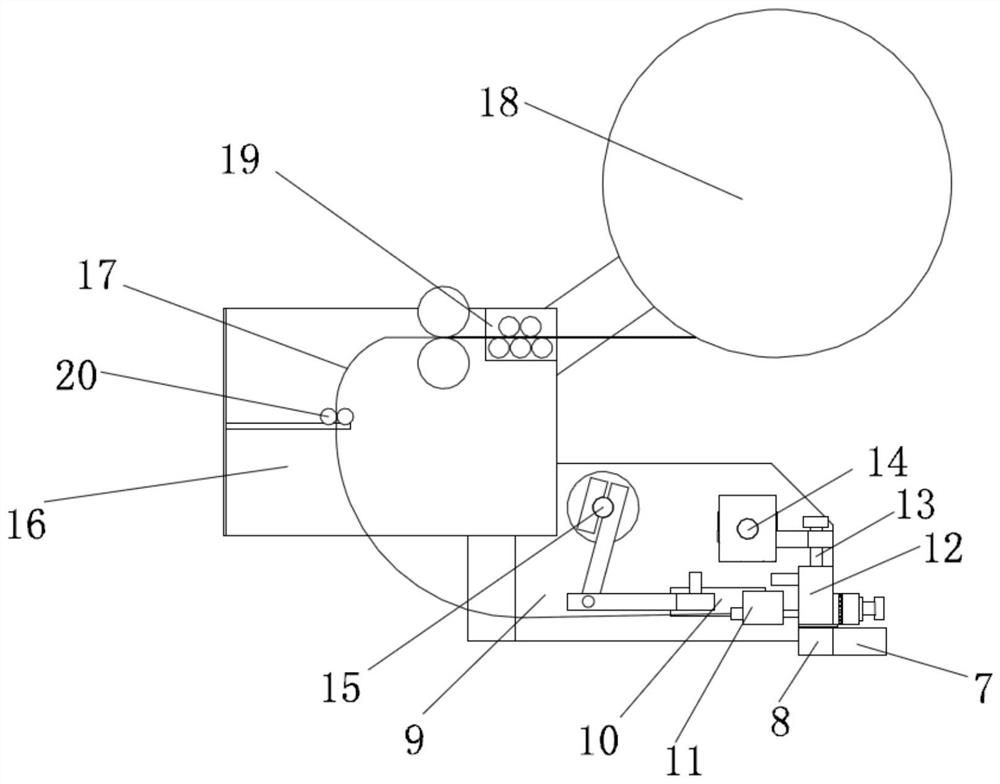

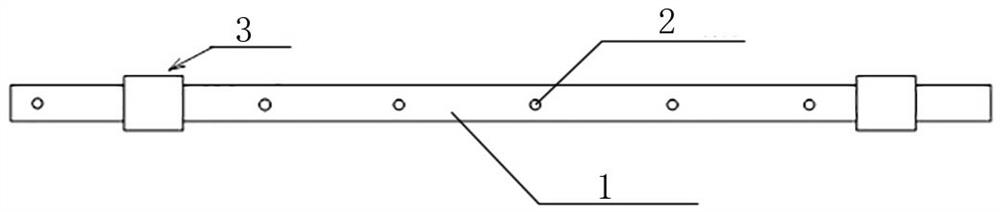

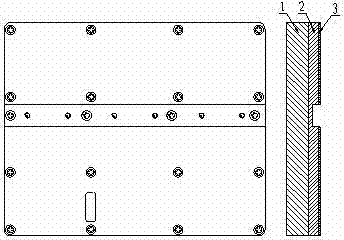

Full-automatic cloth-pulling and tailoring equipment

ActiveCN107190494ARealize unwindingAccurately cut off the materialSevering textilesUltimate tensile strengthAutomation

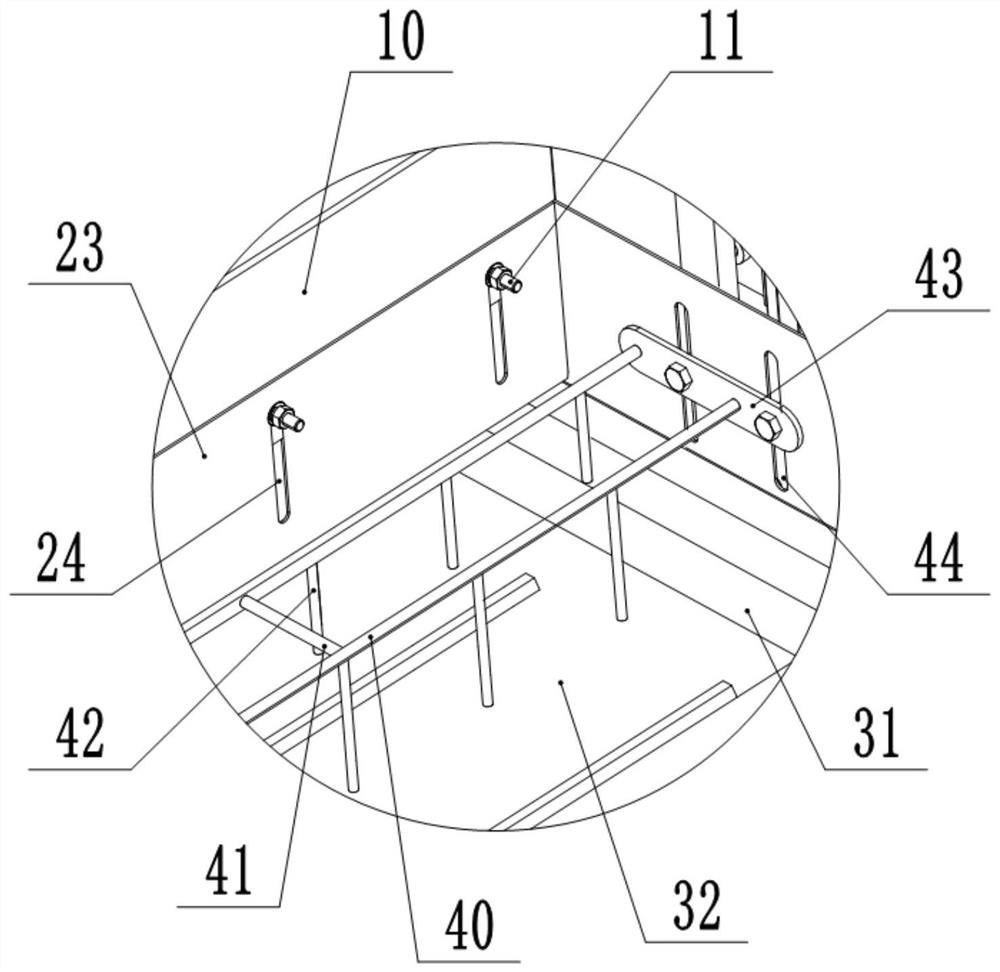

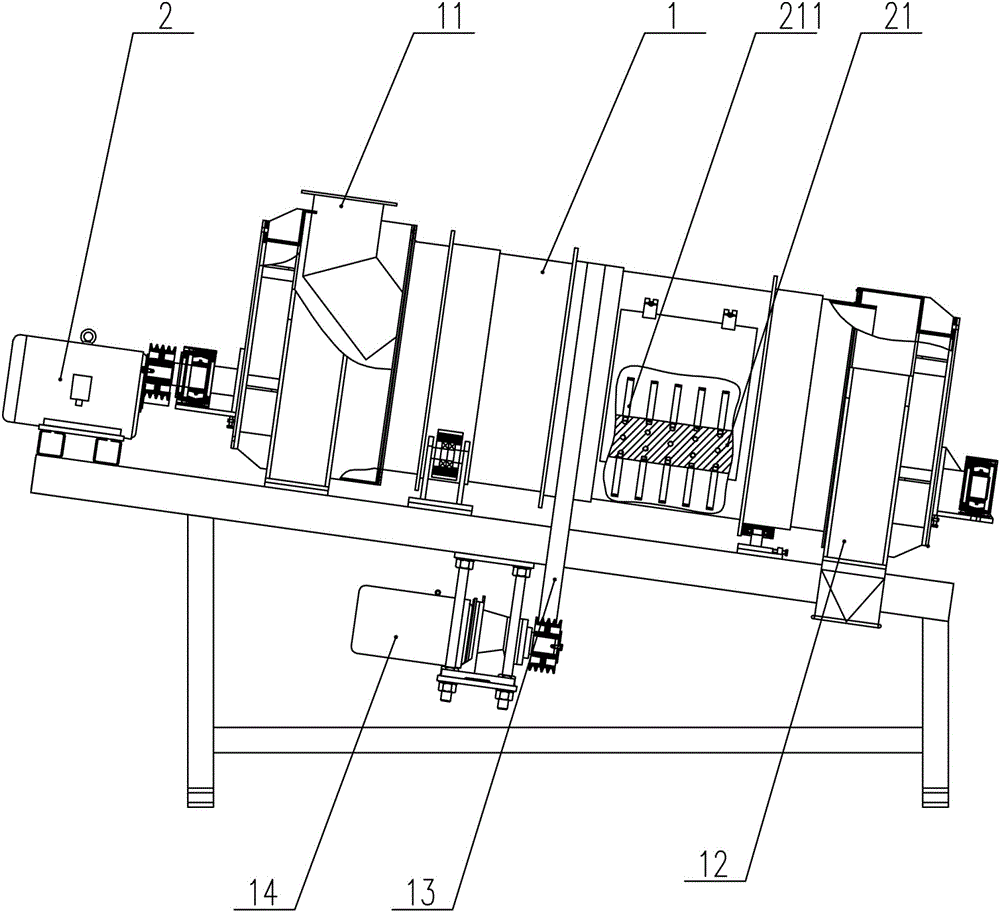

Disclosed is full-automatic cloth-pulling and tailoring equipment. The full-automatic cloth-pulling and tailoring equipment comprises a cloth-pulling platform (1) and is characterized in that a side face rail (2) is horizontally fixed to the bottom of the side face of the cloth-pulling platform (1), the side face rail (2) is provided with a multifunctional sliding table (3), rollers (4) installed on the multifunctional sliding table (3) are located on the side face rail (2), a side face gear rack (5) is fixed to the position, parallel to the side face rail (2), of the side face of the cloth-pulling platform (1), a stepping motor (7) is installed on the multifunctional sliding table (3), an output shaft of the stepping motor (7) is fixedly provided with a transmission gear (6), and the transmission gear (6) is meshed with the side face gear rack (5). The full-automatic cloth-pulling and cutting equipment is compact in structure, positioning, clamping and cutting of cloth can be automatically completed, after unwinding and cutting are completed, the cloth can be automatically tailored on the cloth-pulling platform, the automation degree is high, the labor intensity of workers is greatly reduced, the tailoring quality and specifications are ensured, and the processing efficiency is high.

Owner:JIHUA 3506 TEXTILE & APPL

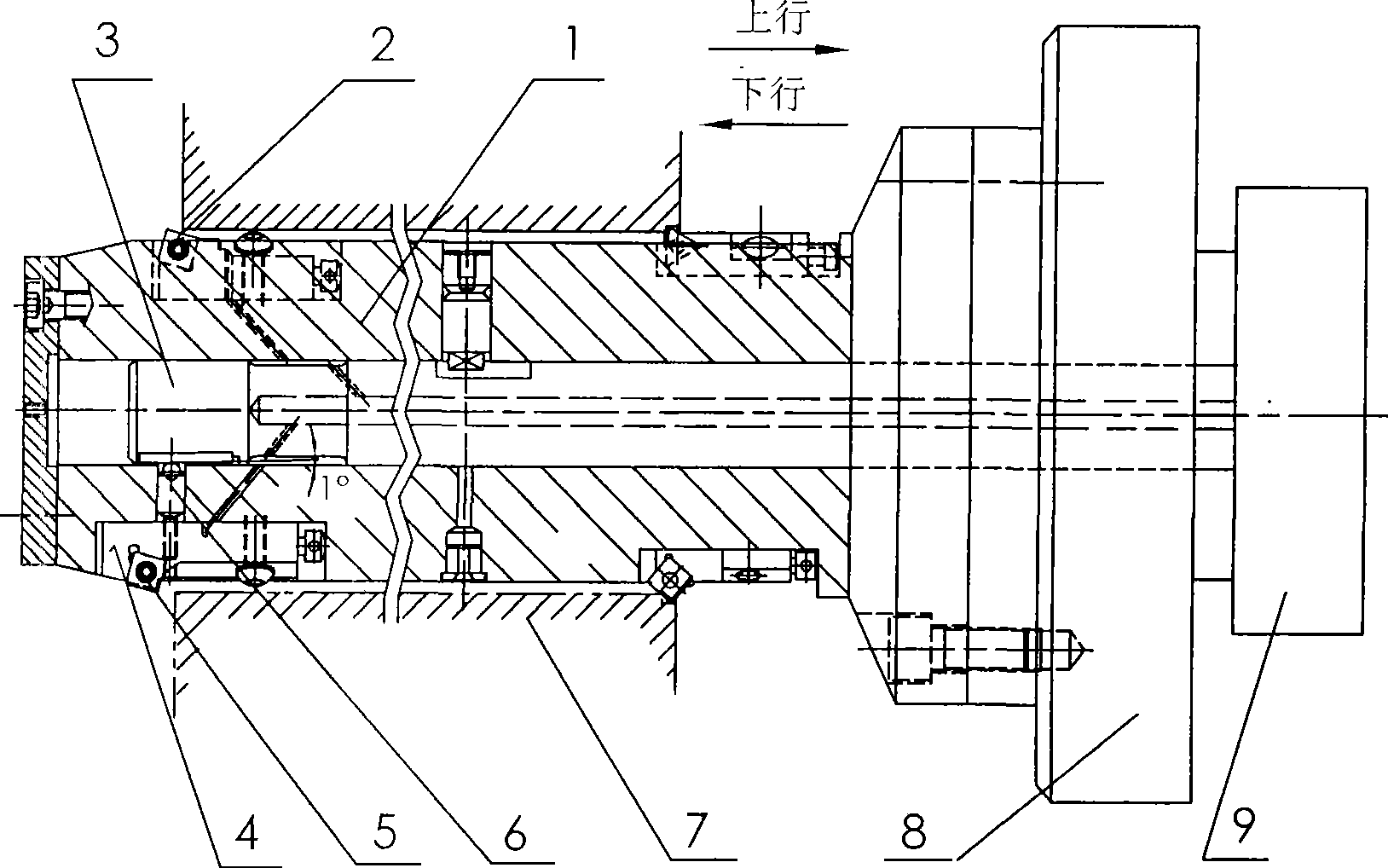

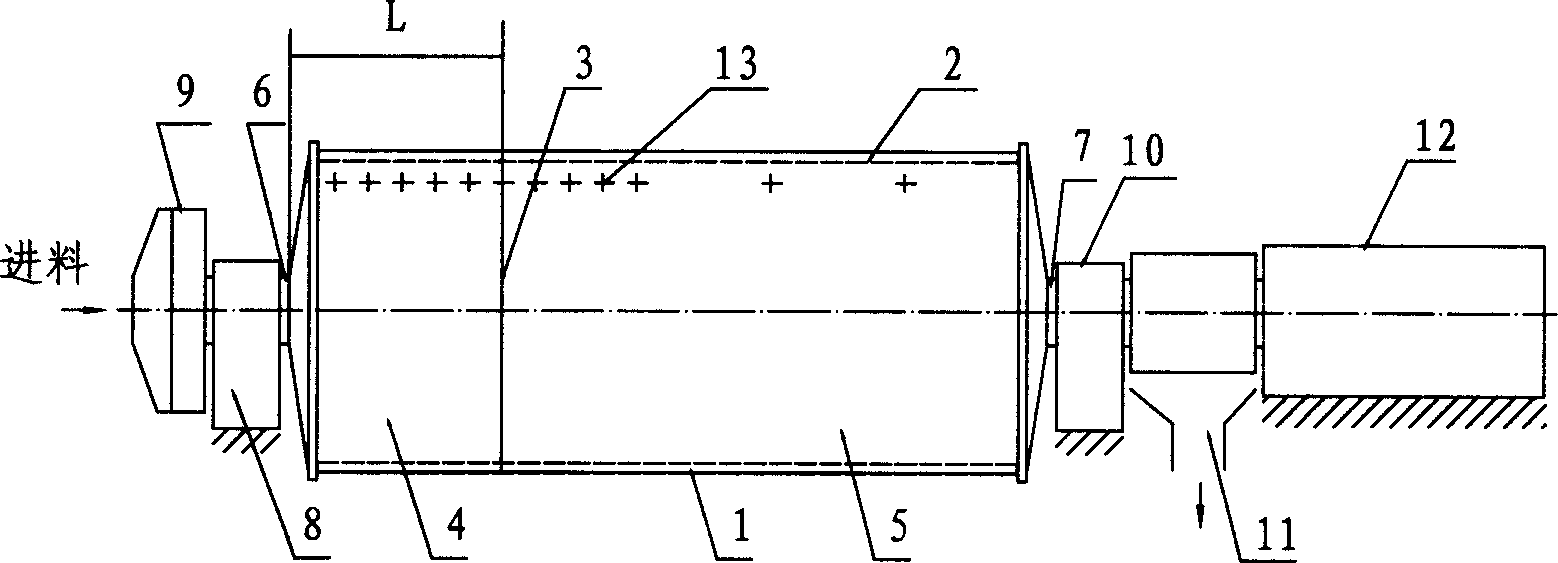

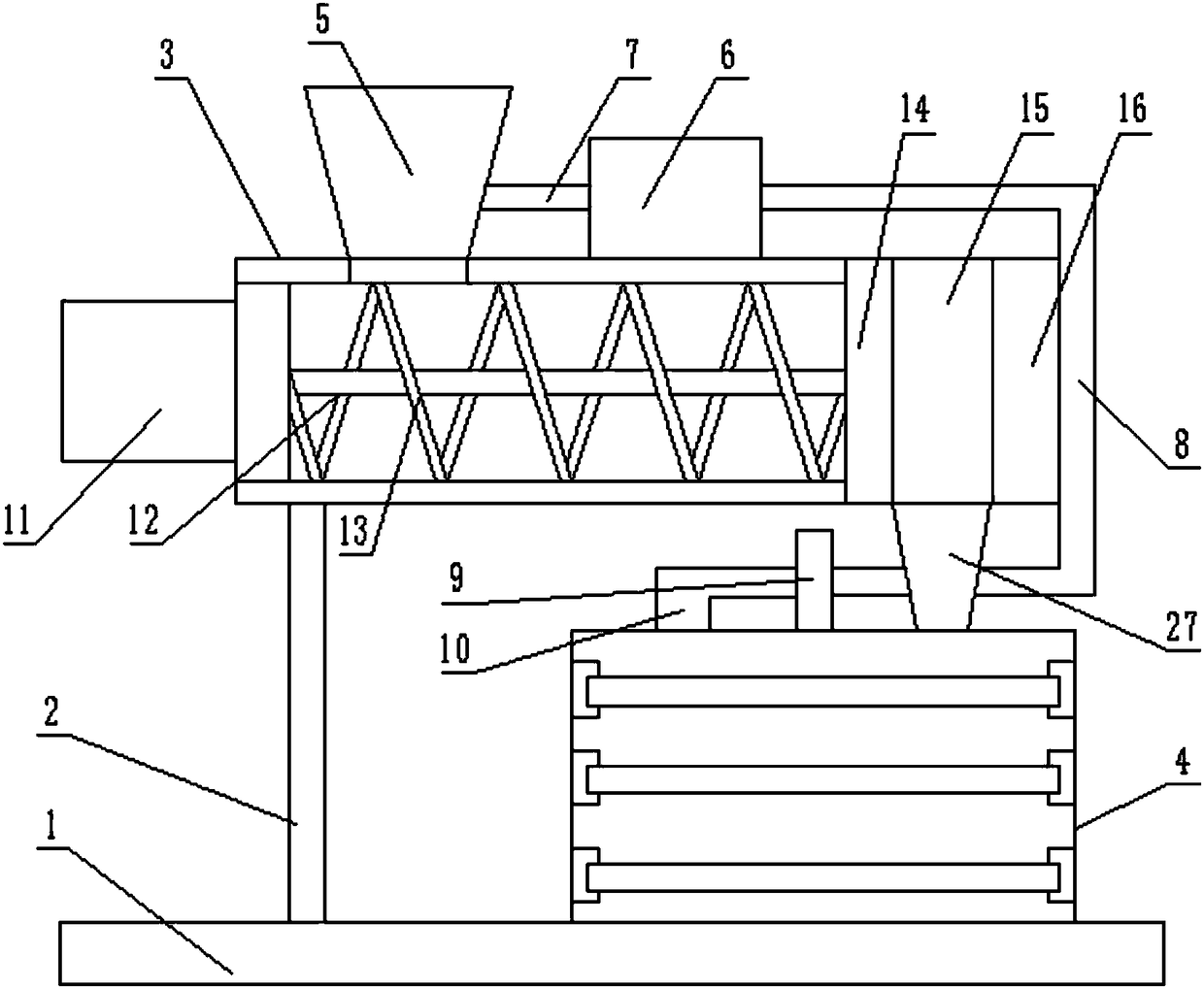

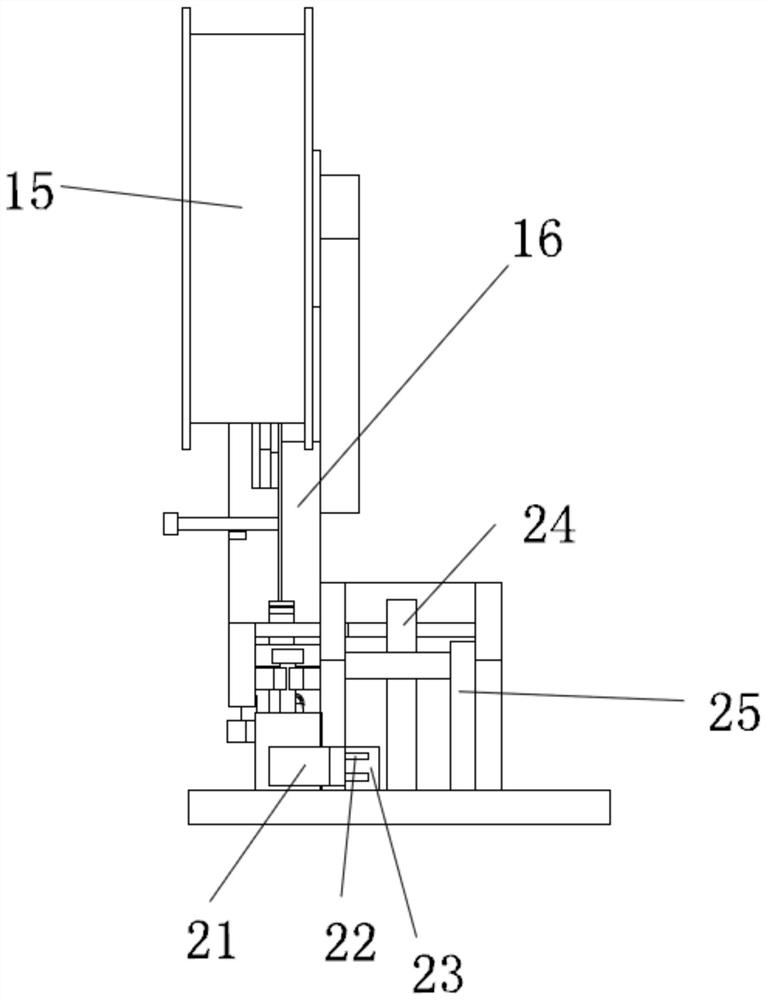

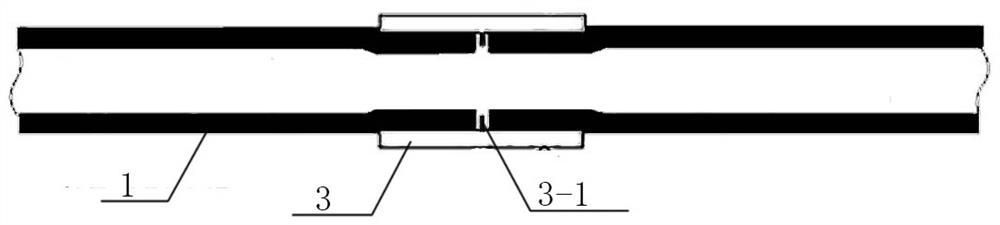

Compensation mechanism of finish boring hole cylindricity error

InactiveCN101450390AGuaranteed SpecificationsImprove cylindricityAutomatic control devicesFeeding apparatusPush and pullGeneratrix

The invention provides a compensation mechanism for the cylindricity errors of fine-bored holes. As the radial wall thickness in the axis direction of an engine cylinder hole is not uniform in distribution, after the engine cylinder hole is linearly bored by a conventional machining method, the cylindricity of the hole is in a waist-drum shape. Parameters of an inverse waist-drum shape are input into a numerical control program after measurement, analysis and calculation. The cylinder hole is subjected to coaxial graded semi-fine boring and fine boring by pushing and pulling a boring bar, and rapid semi-fine boring can be carried out to the cylinder when the boring bar goes down. When the boring bar 1 goes up, a compensation servo motor 9 is started, the expansion amount of a pull rod 3 on the core part of the boring bar is accurately positioned and controlled through the servo motor; a 1-degree inclined plane on the pull rod 3 pushes a fine-boring cutter table 4 to elastically stretch out so as to enable a fine boring cutter 5 to be in a working position of fine boring size; and the fine boring cutter completes the final fine boring of the cylinder hole according to a parameter program of the inverse waist-drum shape, so that the cylindricity of the cylinder hole is effectively improved. Through the setting of the program, the side generatrix of the fine-bored holes can be a curved line or an irregular straight line by programming.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD +1

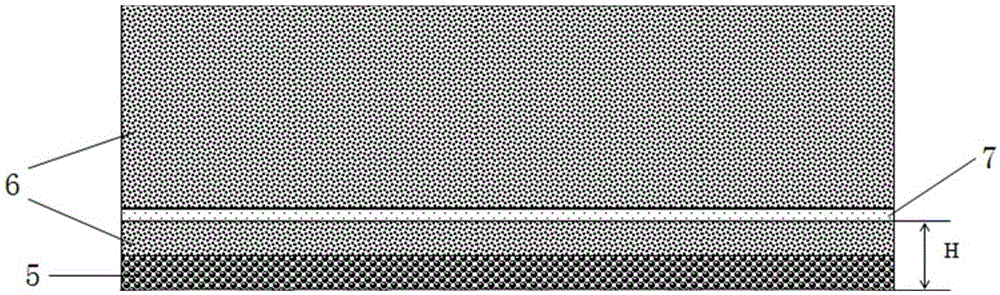

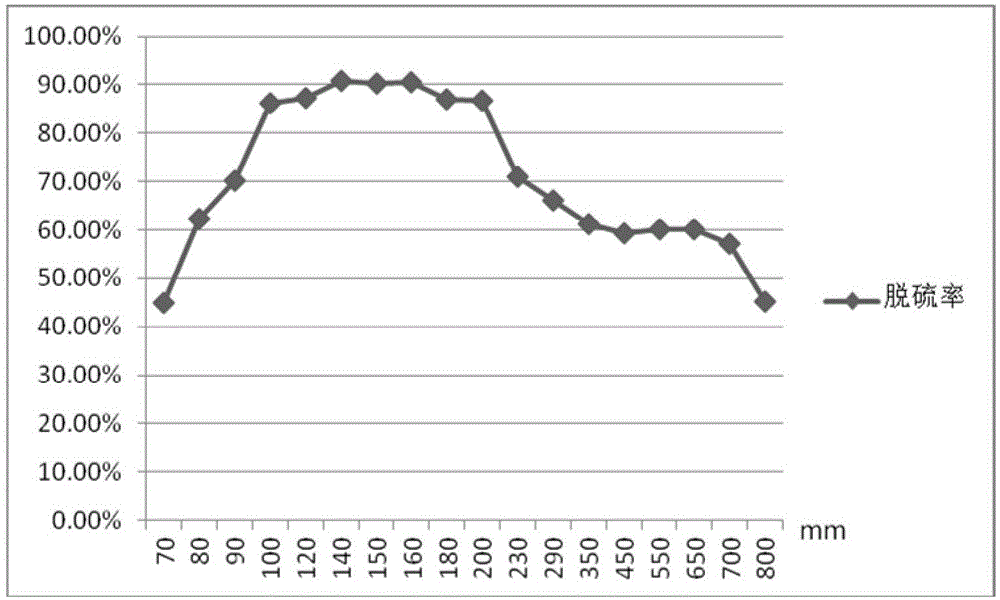

A kind of online desulfurization method of sintering process

The invention discloses an online desulphurization method for a sintering process, and belongs to the technical field of desulphurization. According to the online desulphurization method for the sintering process, a grate-layer material layer is laid at the bottom of a sintering pallet, and a mixed material for sintering is laid on the grate-layer material layer to form a mixed material layer, wherein a desulphurization agent layer is also laid in the mixed material layer; the distance between the desulphurization agent layer and the bottom of the sintering pallet is 1 / 8 to 1 / 4 of the total height of the mixed material layer; and a desulphurization agent in the desulphurization agent layer is a particulate matter from which ammonium can be decomposed, and is particulate urea with an average particle size of 0.30 to 0.80mm. According to the method, the particulate desulphurization agent is added to a specific position, so that the desulphurization efficiency of the sintering process can be maximally improved, each technical index of sintered ore can be ensured, and influence on the quality of the sintered ore is substantially avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

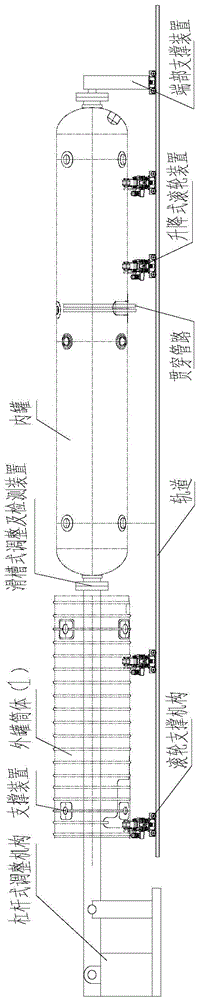

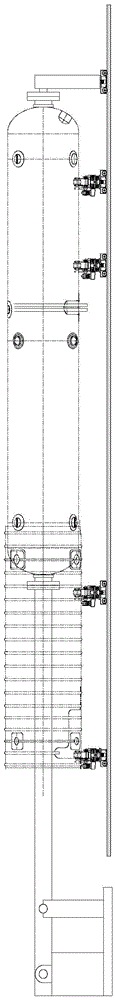

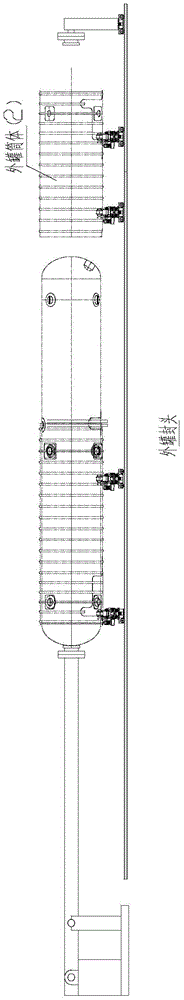

Tank sleeving technological method of railway tank car of double-layer structure

ActiveCN105458609AReduce quality riskAvoid defective productsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing efficiencyProcess control

The invention relates to a tank sleeving technological method of a railway tank car of a double-layer structure. The technological method includes the steps that firstly, one side of an inner tank body and one side of an outer-tank barrel matched with the inner tank body are assembled, wherein one side of the inner tank body and one side of an outer tank body are adjusted by supporting and positioning one side of the outer-tank barrel, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; secondly, the other side of the inner tank body and the other side of the outer-tank barrel matched with the inner tank body are assembled, wherein the other side of the outer-tank barrel and the other side of the inner tank body are adjusted to move relatively, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; thirdly, the two sides of the completely-sleeved outer-tank barrel are overall adjusted, and a circular seam at a combined portion is welded; and finally, end sockets on the two sides are assembled and welded. According to the tank sleeving technological method, quality risks are reduced, all the technical indexes can be more easily guaranteed, and defective products are avoided; the influences of human factors on the quality are eliminated to the maximum degree, and process control is more easily controlled; and the influence of auxiliary time on the production takt is reduced, and the product manufacturing efficiency is improved.

Owner:CRRC YANGTZE CO LTD

Silk hot-air non-woven fabric

The invention discloses a silk hot-air non-woven fabric which prepared by fine-denier fibers, silk fibers and ES fibers through a hot-air bonding technology.Non-hot melting silk fibers are adopted as the silk fibers, and the melting point of the ES fibers is 130 DEG C.A preparation method of the silk hot-air non-woven fabric comprises the following steps that 1, the ES fibers and the silk fibers are mixed and carded into a web to obtain a fiber web; 2, hot-air bonding reinforcing is performed on the fiber web obtained in the step 1 to obtain the hot-air non-woven fabric; in the carding process of the step 1, the obverse side of the fabric adopts messy carding, and the reverse side of the fabric adopts a dual-carding technology comprising messy carding and vertical carding.The non-woven fabric is comfortable in handfeel, silky and not prone to be fluffed, and the silk fibers can directly make contact with the skin, so that the skin friendliness is achieved; the breakthrough of producing a natural fiber non-woven fabric through a hot-air technology is achieved, the using performance of the silk hot-air non-woven fabric is improved, and the great application prospect is achieved.

Owner:SHANGHAI FENGGE NONWOVEN

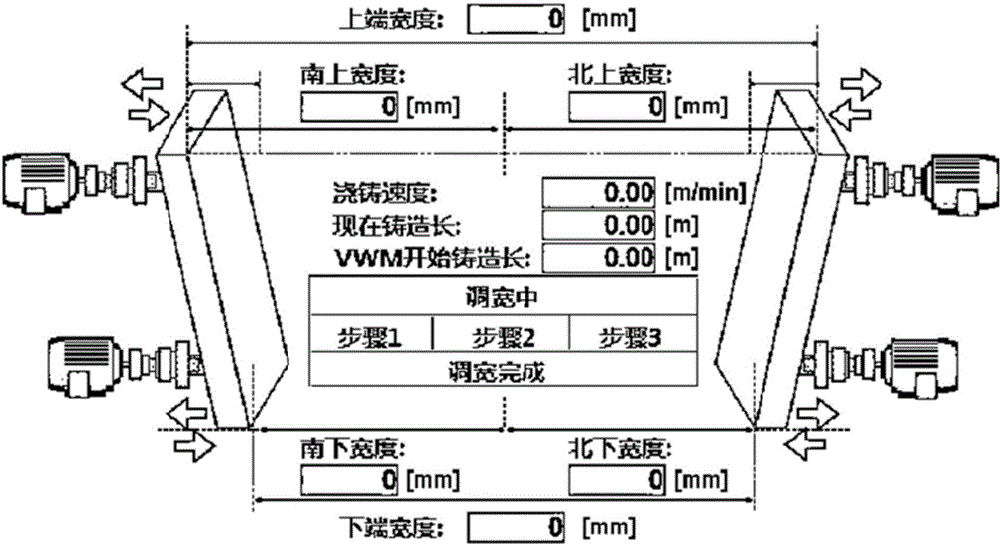

Online continuous casting billet preset width setting and tracking method

ActiveCN104942250AGuaranteed hot charging and hot delivery rateQuality improvementMetallurgyImage quality

The invention provides an online continuous casting billet preset width setting and tracking method. According to the method, casting plans, furnace orders, plate blank orders and other information are collected through an MES system, casting speeds, plate blank cutting performance, furnace cutting performance and other information are collected through a basic automated system, the width adjusting information and tendency in a whole CAST are worked out, and then the position and information of width adjusting plate blanks are locked. Basic data are provided for optimization of cutting length models, and indications are provided for operating personnel, so that the online width adjusting quality is better controlled, the plate quality is greatly corrected, the hot charging hot delivery rate of the plate blanks under high quality is guaranteed, and a better guarantee is provided for subsequent steel rolling products.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

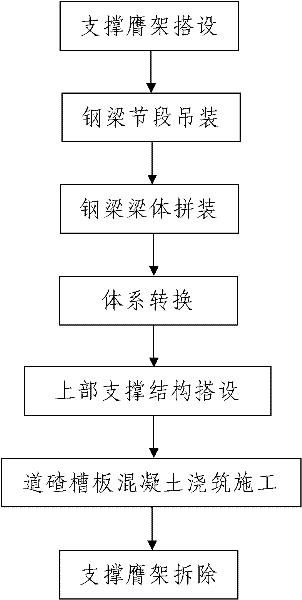

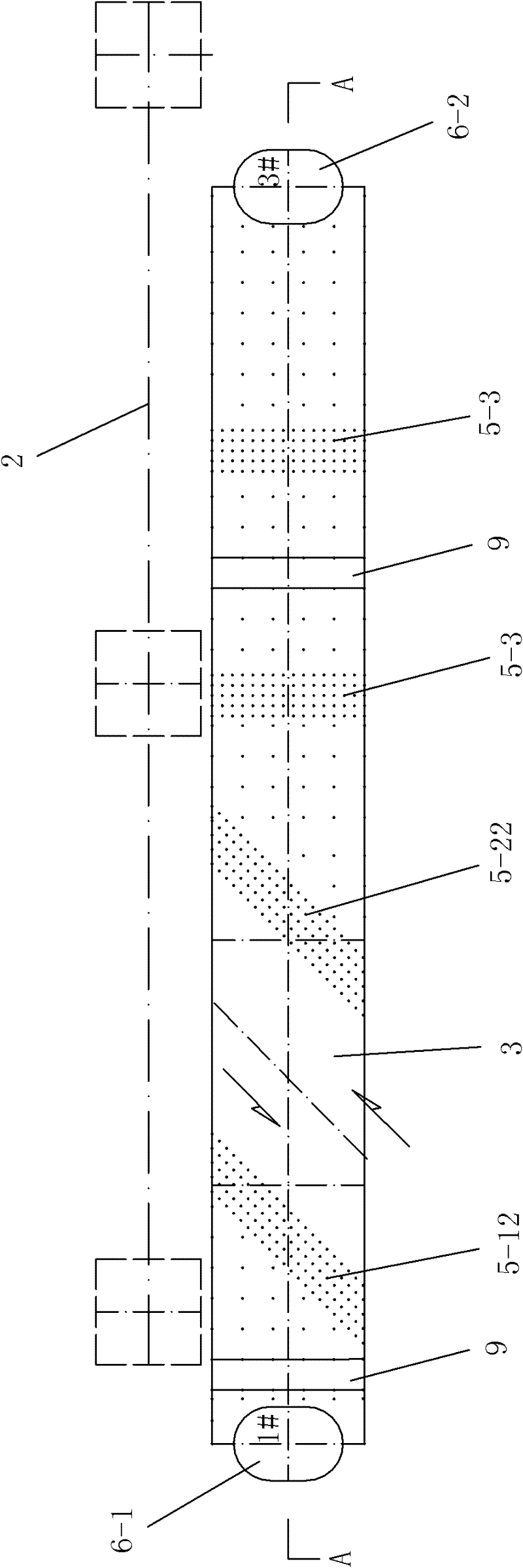

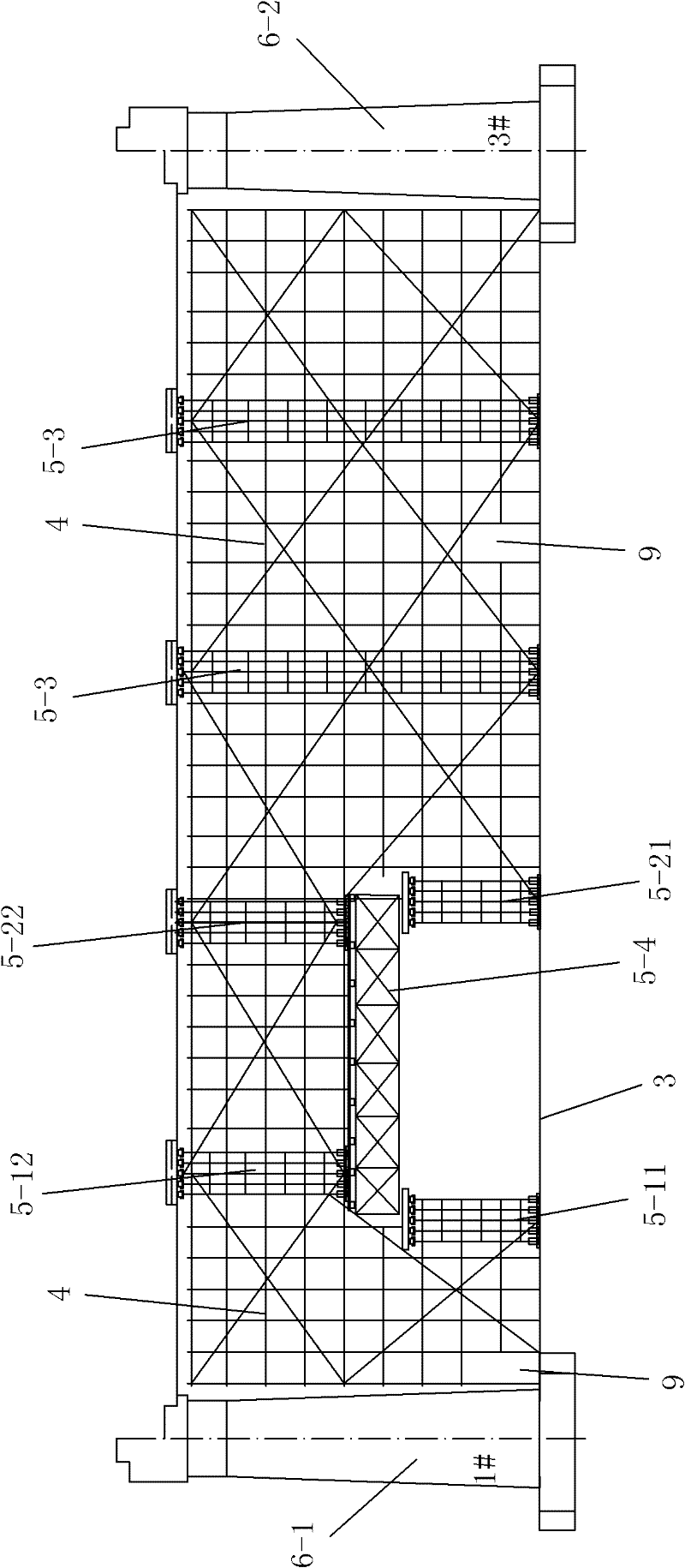

Steel-concrete composite girder construction technology striding current lines and being parallel to existing lines

InactiveCN102220741AReasonable designSimplify construction stepsBridge erection/assemblyButtressFalsework

The invention discloses a steel-concrete composite girder construction technology striding over current line and being parallel to existing lines, which comprises the flowing steps: firstly, erecting a supporting falsework, wherein the supporting falsework comprises a plurality of temporary buttresses which are distributed between two buttresses from left to right, and the distribution positions of the plurality of temporary buttresses respectively correspond to the connection position of two adjacent steel grinder sections of a steel grinder body in a construction steel-concrete composite girder; secondly, hoisting the steel grinder sections, wherein a plurality of steel grinder sections constituting the steel grinder body are hoisted in place one by one; thirdly, splicing the steel grinder body, wherein splicing is conducted on the steel grinder body after linetype adjustment and camber adjustment; fourthly, converting the system; fifthly, conducting concrete pouring construction on a ballast channel plate; and sixthly, detaching the supporting falsework. The steel-concrete composite girder construction technology has reasonable design, convenience in the construction, low investment cost, good using effect, high construction efficiency, short construction period and low safety risk, and the adopted supporting falsework has a simple structure and high satiability and is economical and practical.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

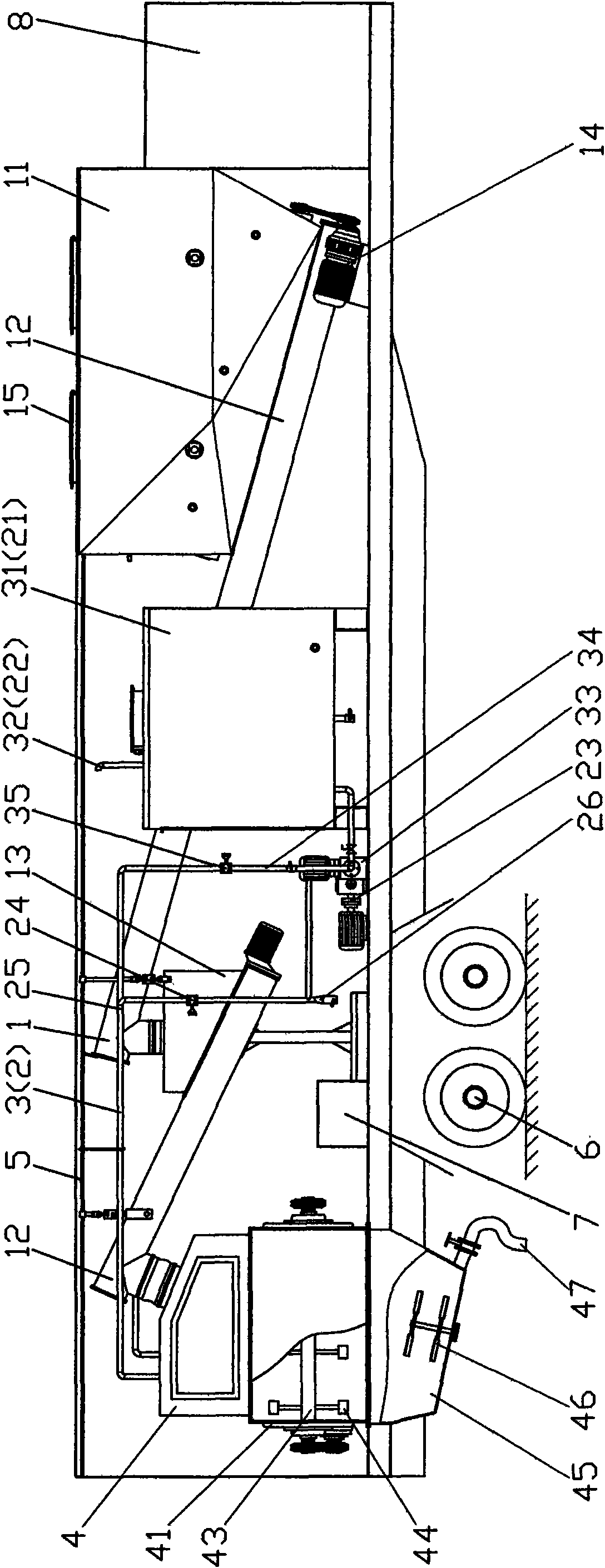

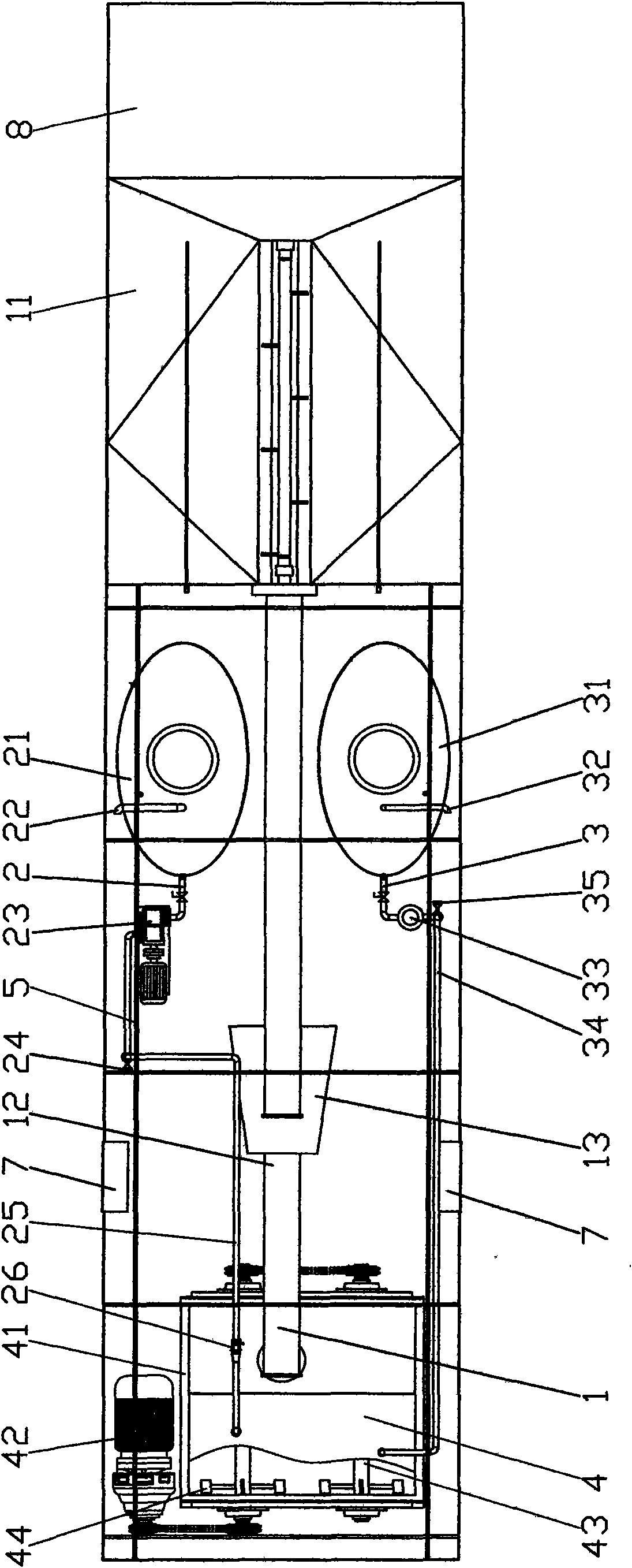

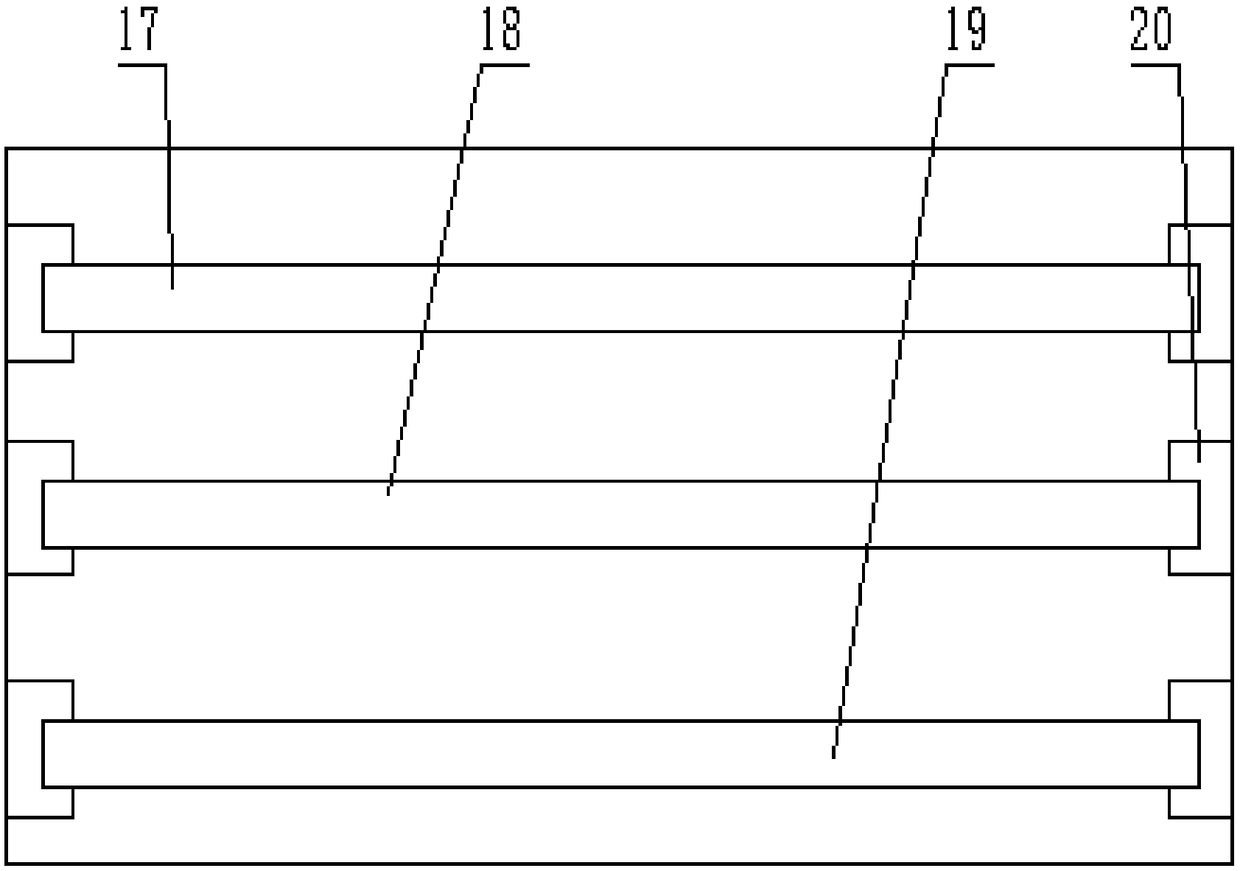

Movable type agitator for CA mortar

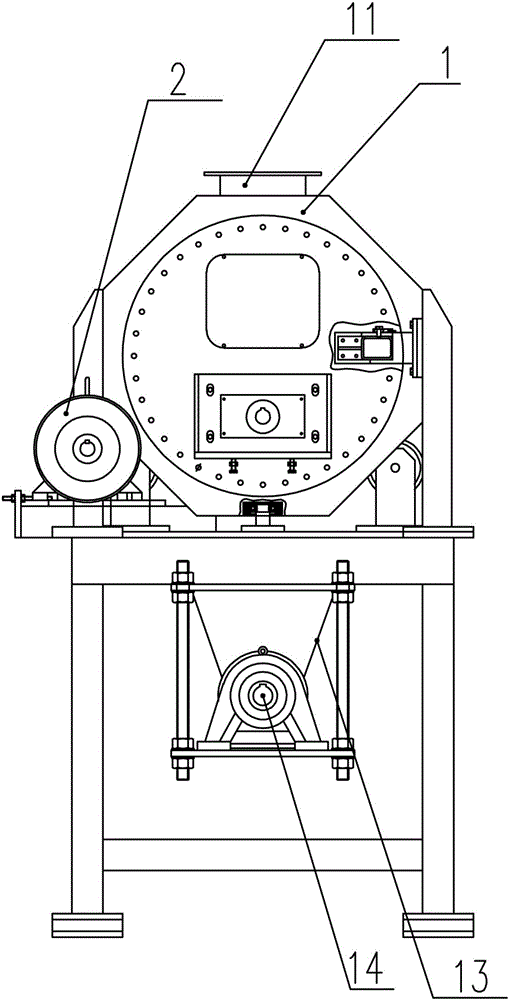

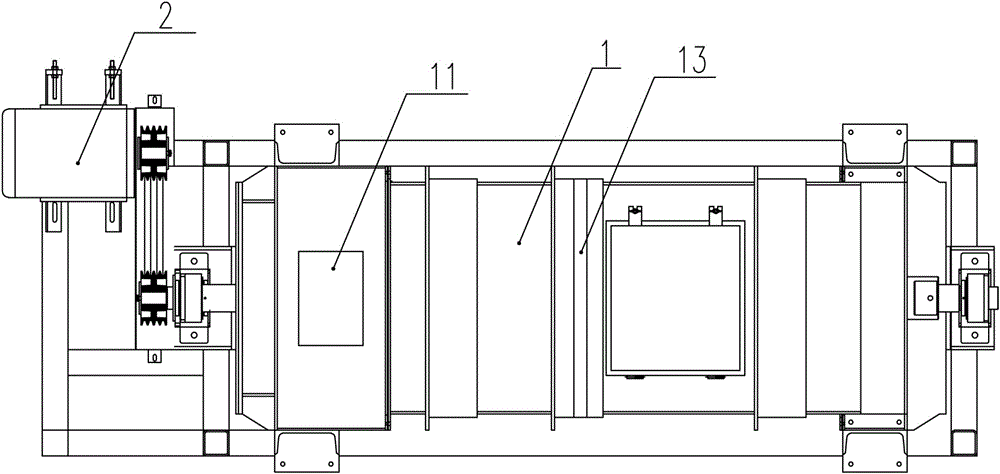

InactiveCN101642938AGuaranteed SpecificationsGuarantee the construction qualityDischarging apparatusMixing operation control apparatusManufacturing technologyMovable type

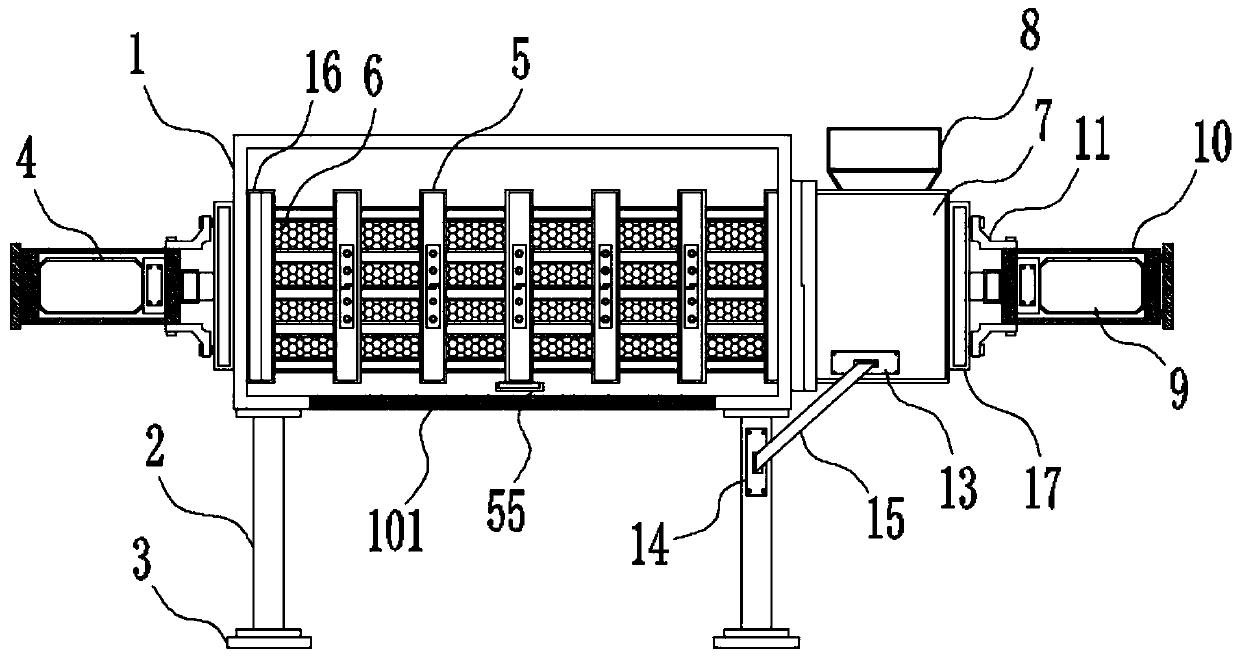

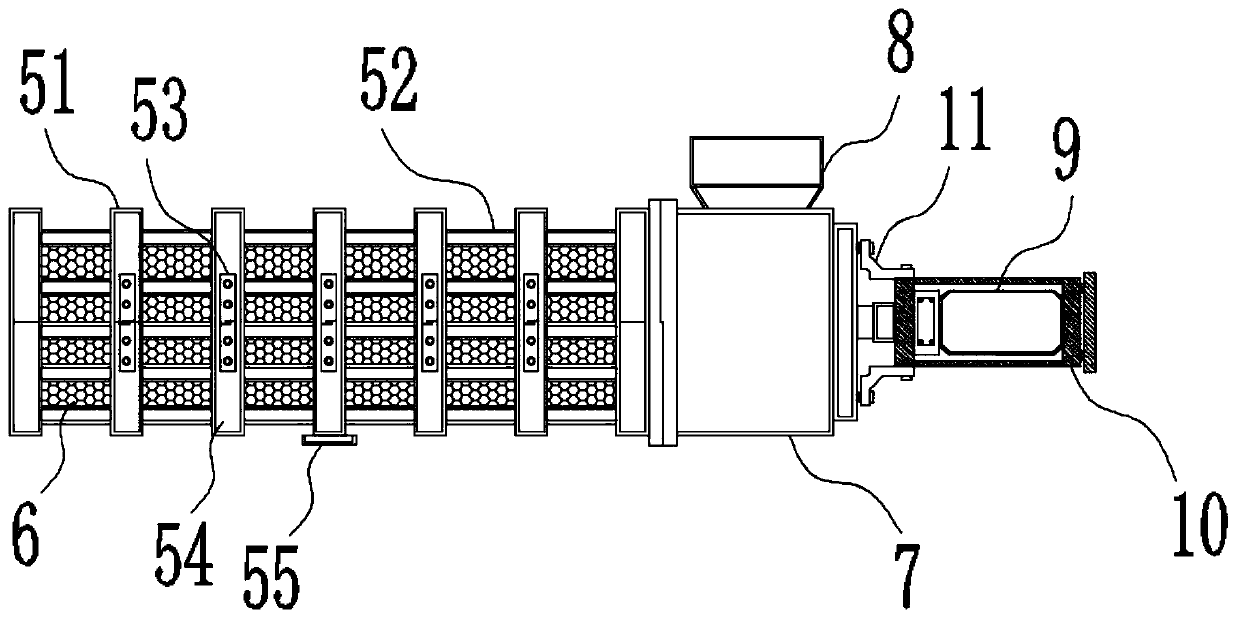

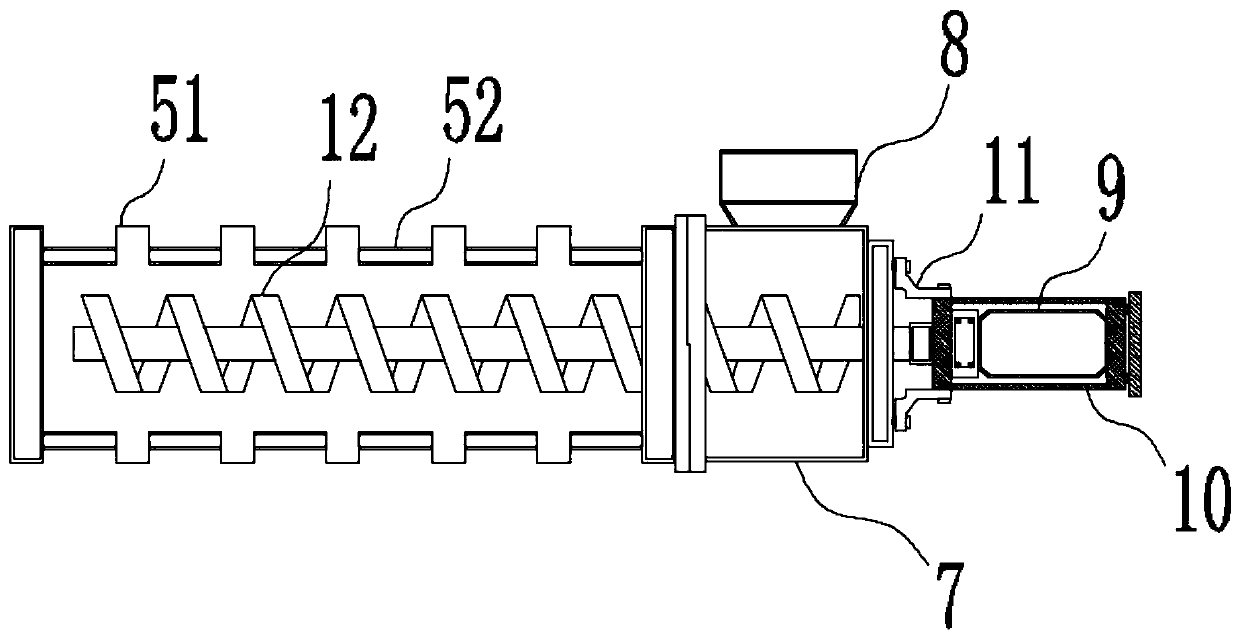

The invention relates to a movable type agitator for CA mortar, belonging to the field of manufacturing technology of cement asphalt mortar processing equipment. The agitator mainly comprises a vehicle carriage body (5) provided with wheels (6) at the bottom, an aggregate storing and conveying device (1) arranged inside the vehicle carriage body (5), an emulsified asphalt storing and conveying device (2), a water storing and conveying device (3), a mortar stirring device (4), a control device (7) arranged outside the vehicle carriage body (5), a generating set (8) and the like. The movable type agitator has reasonable whole structure and design, integrating the functions of storing and conveying aggregate, emulsified asphalt and water as well as stirring the mortar, convenient operation, continuous conveying and accurate metering; when being mixed and stirred in the field of construction site, the CA mortar can be poured for construction when being mixed and stirred, thus guaranteeingthe technical index and construction quality of the CA mortar.

Owner:ZHEJIANG LANTING HI TECH

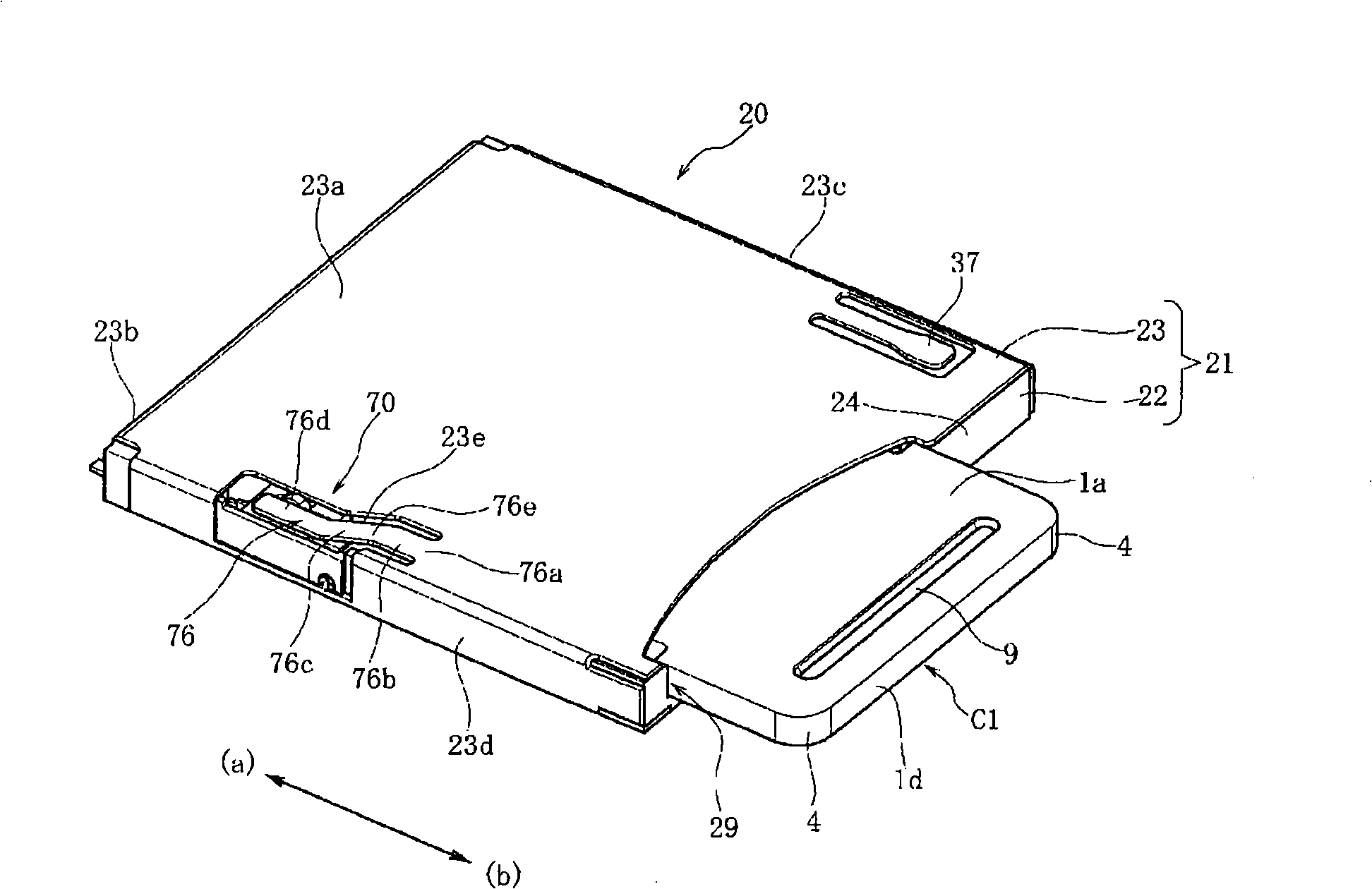

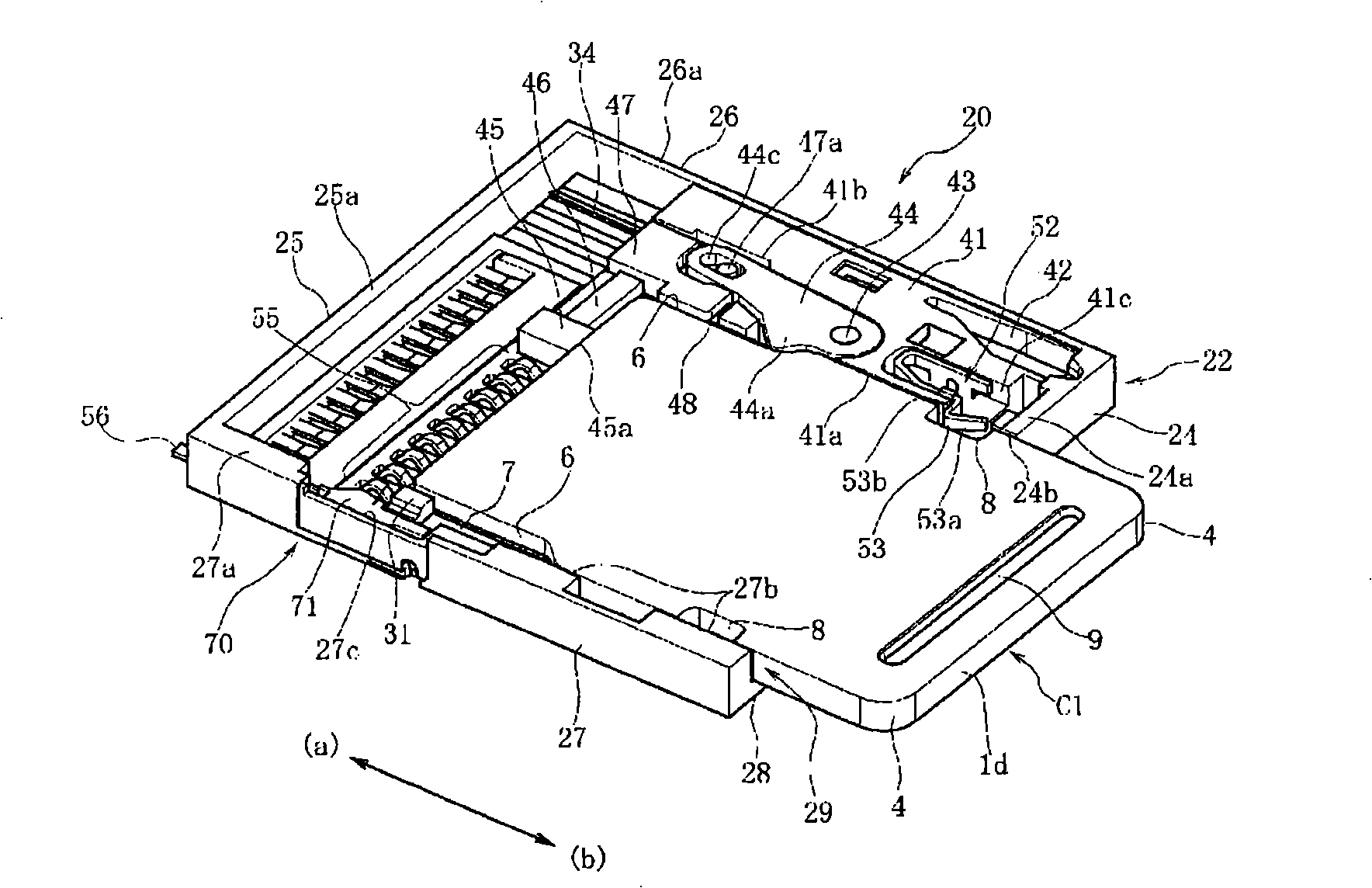

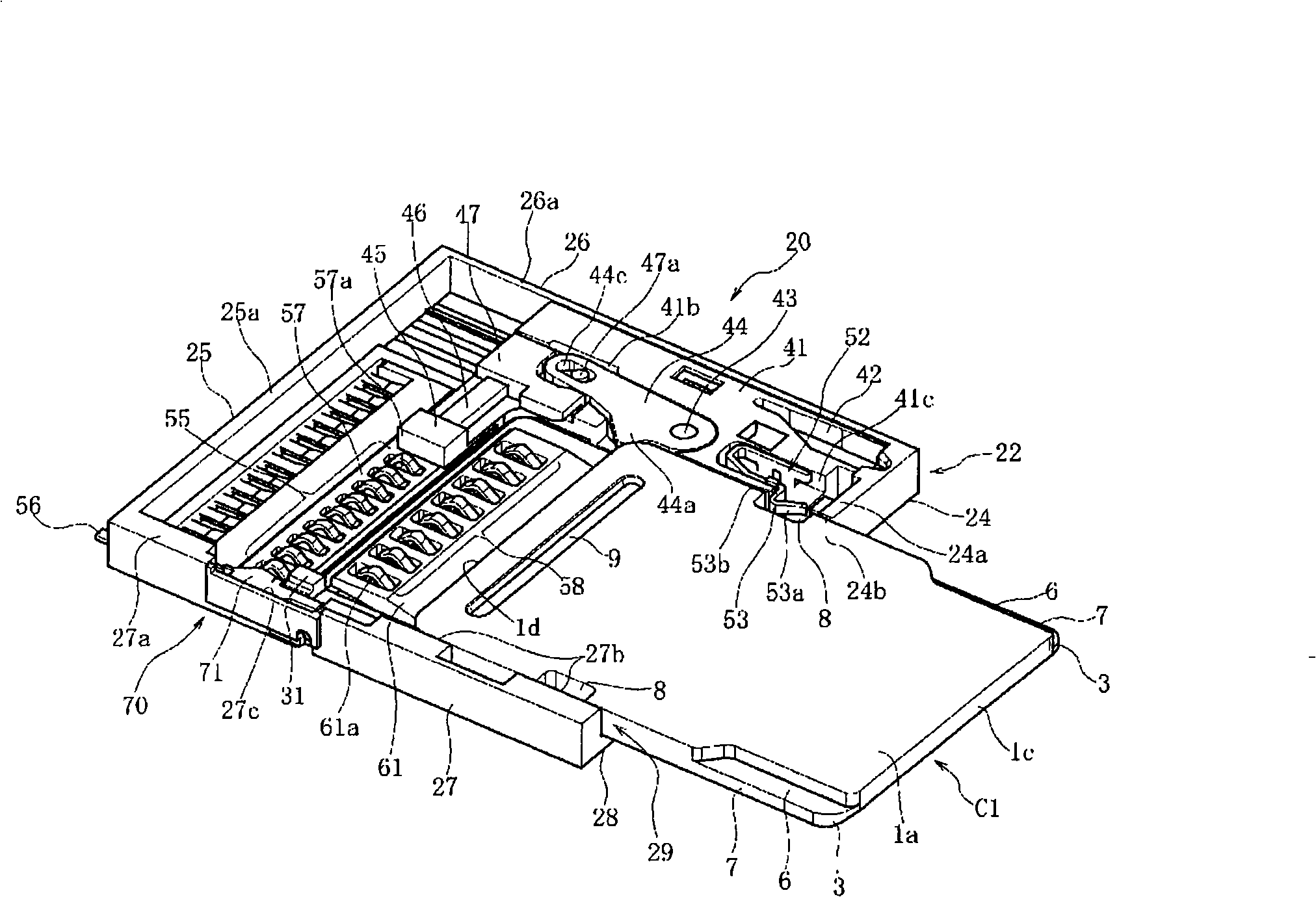

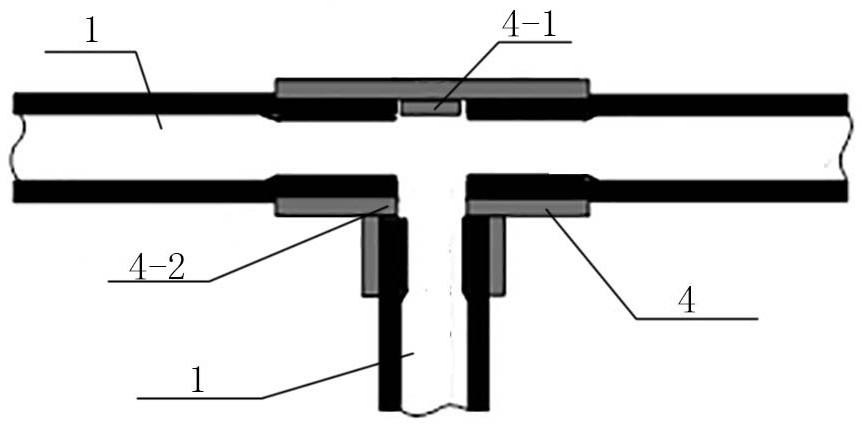

Electronic functional card and card connecting device

InactiveCN101404068AEasy to operateGuaranteed SpecificationsConveying record carriersCoupling device detailsEngineeringCam

The present invention provides an electronic function card and a card connector mounted with the electronic function card. The card is a thin type electronic function card housed with a storage chip and the like, the shape of the cards are almost the same, and the card can easily identify the type of the internal electronic circuits. The housing (1) of a first card (C1) is in a zygomorphic rectangle shape clipping a central line (O-O). A guide identification slots (6, 6) is formed by retracting in the thickness midway from a surface (1a) at a right side section (1e) and a left side section (1f), and an intermediate dent (8, 8) is formed by retracting in the thickness midway from a surface (1a) at the rear side. The length dimensions (L1) of the guide identification slot (6, 6) are different from the categories of the internal circuit. Thus, in a guide identification slot, when the guide identification slot (6, 6) is used to guide, the type of the internal electronic circuits cam be identified by detecting the length of the guide identification slot (6, 6).

Owner:ALPS ALPINE CO LTD

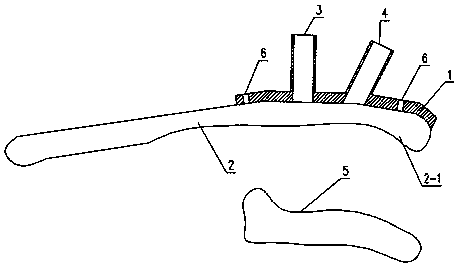

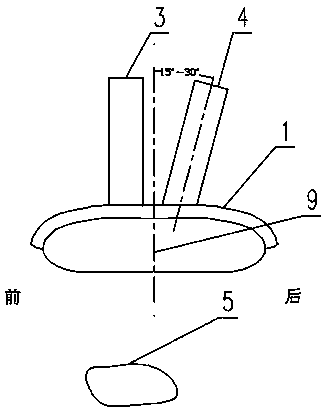

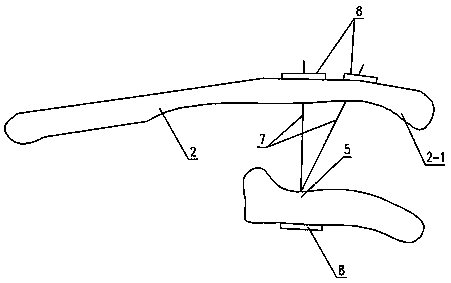

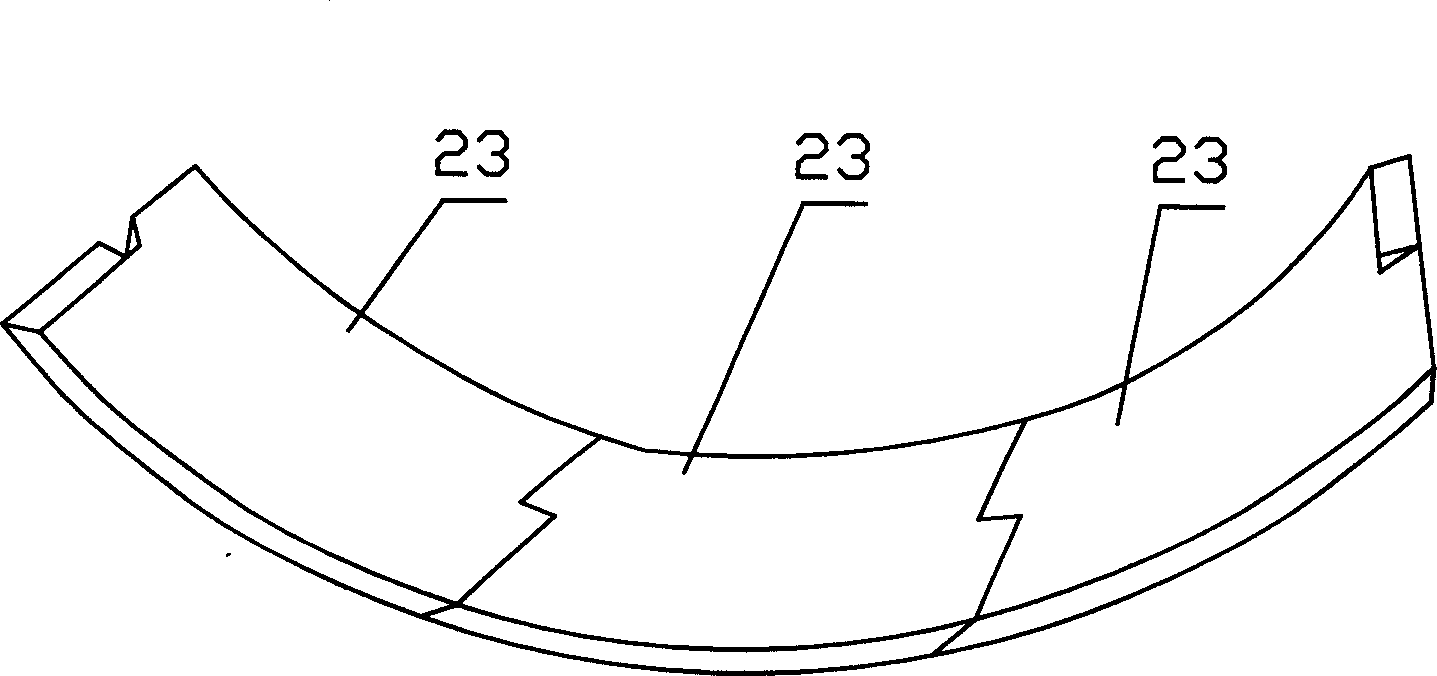

Surgical guide in coracoclavicular ligament reconstruction and manufacturing method thereof

ActiveCN109480955AGuaranteed SpecificationsGuaranteed sizeInstruments for stereotaxic surgeryBone drill guidesBone tunnelComputed tomography

The invention relates to the technical field of medical instruments, in particular to a surgical guide in coracoclavicular ligament reconstruction and a manufacturing method thereof. The surgical guide comprises a base. The base is a thin-wall curved plate, and the thin-walled curved surface of the plate fits and covers the surface of the area from the distal clavicle to the middle. The ratio of the length of the base to the total length of the clavicle is 0.38-0.42. The base is further provided with a first channel and a second channel. The position of the first channel is the position at thebottom of the coracoids corresponding to the central axis direction of the clavicle, the ratio of the length from the second channel to the distal clavicle and the total length of the clavicle is 0.14, and the direction is inclining by 15-30 degrees from the central axis of the clavicle. The surgical guide has the advantages of being accurate in positioning, reducing damage, saving the operationtime, reducing pains of patients and the like. The surgical guide is manufactured by adopting CT scanning and 3D printing methods, which can ensure that specification and size of the surgical guide conform to a patient, avoid the defects of the traditional unsatisfactory bone tunnel establishment position, simplify the operation and reduce the time for newcomers to learn the coracoclavicular ligament reconstruction.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

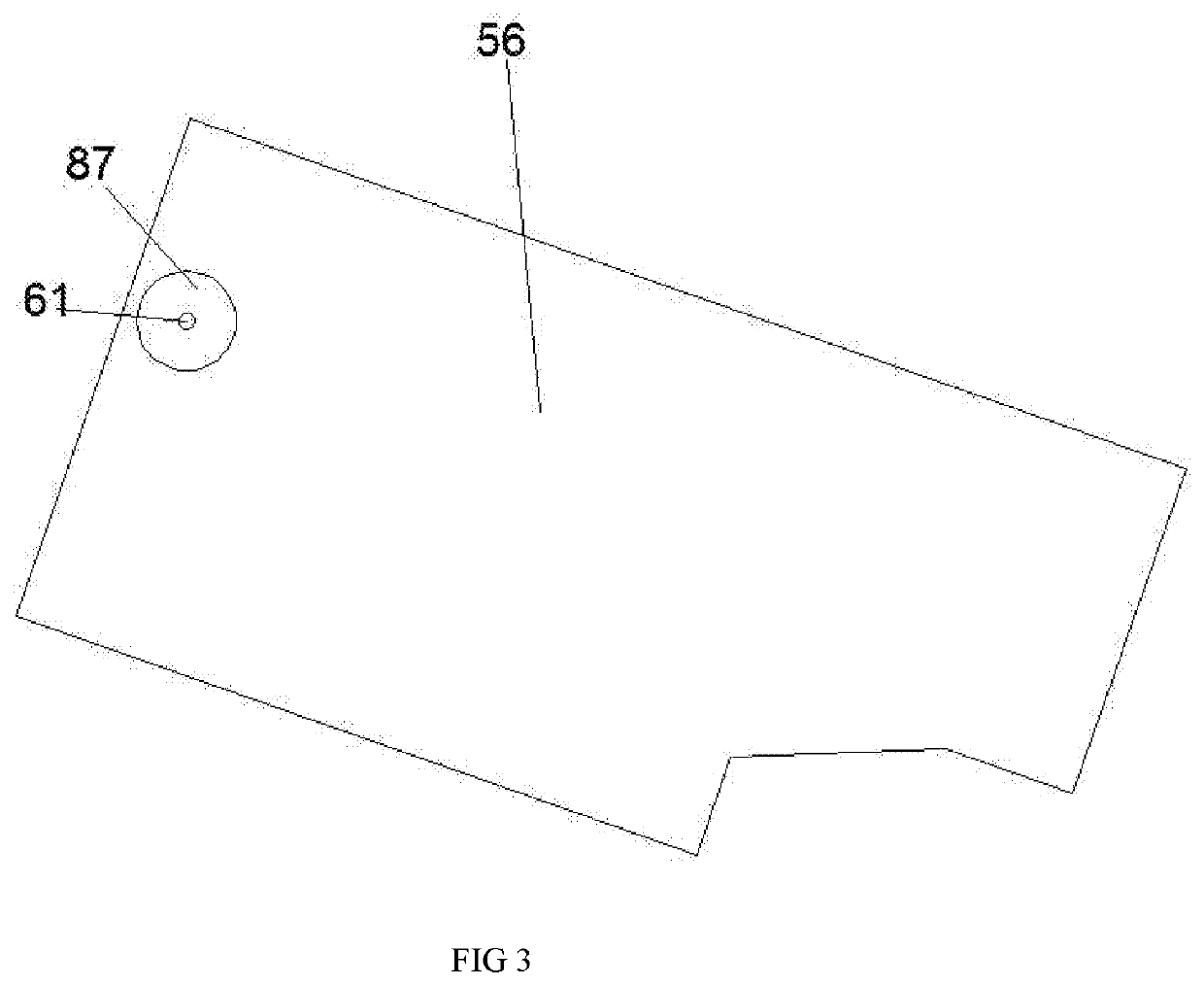

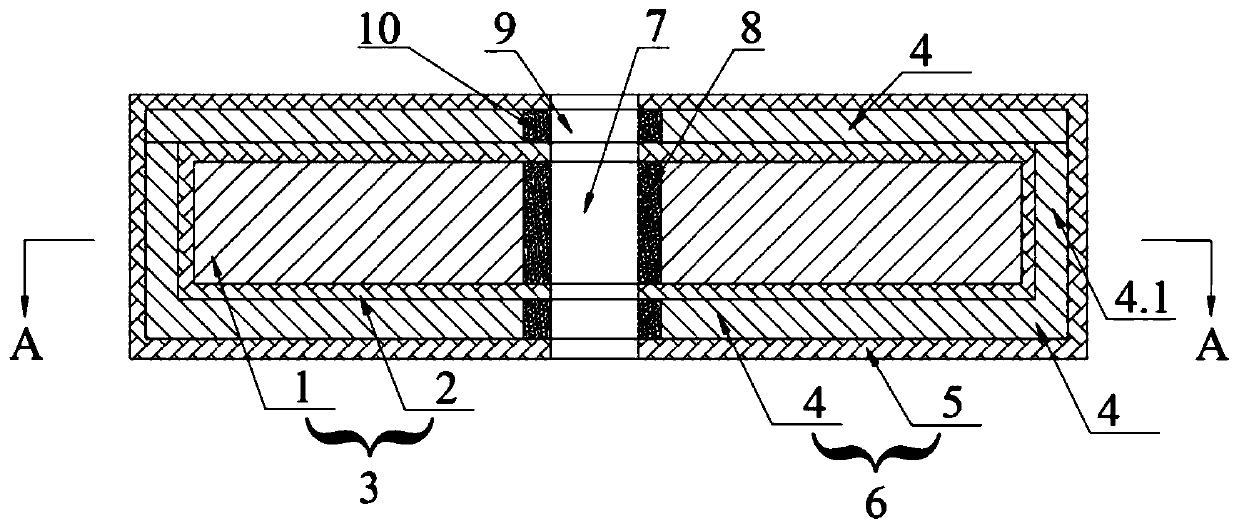

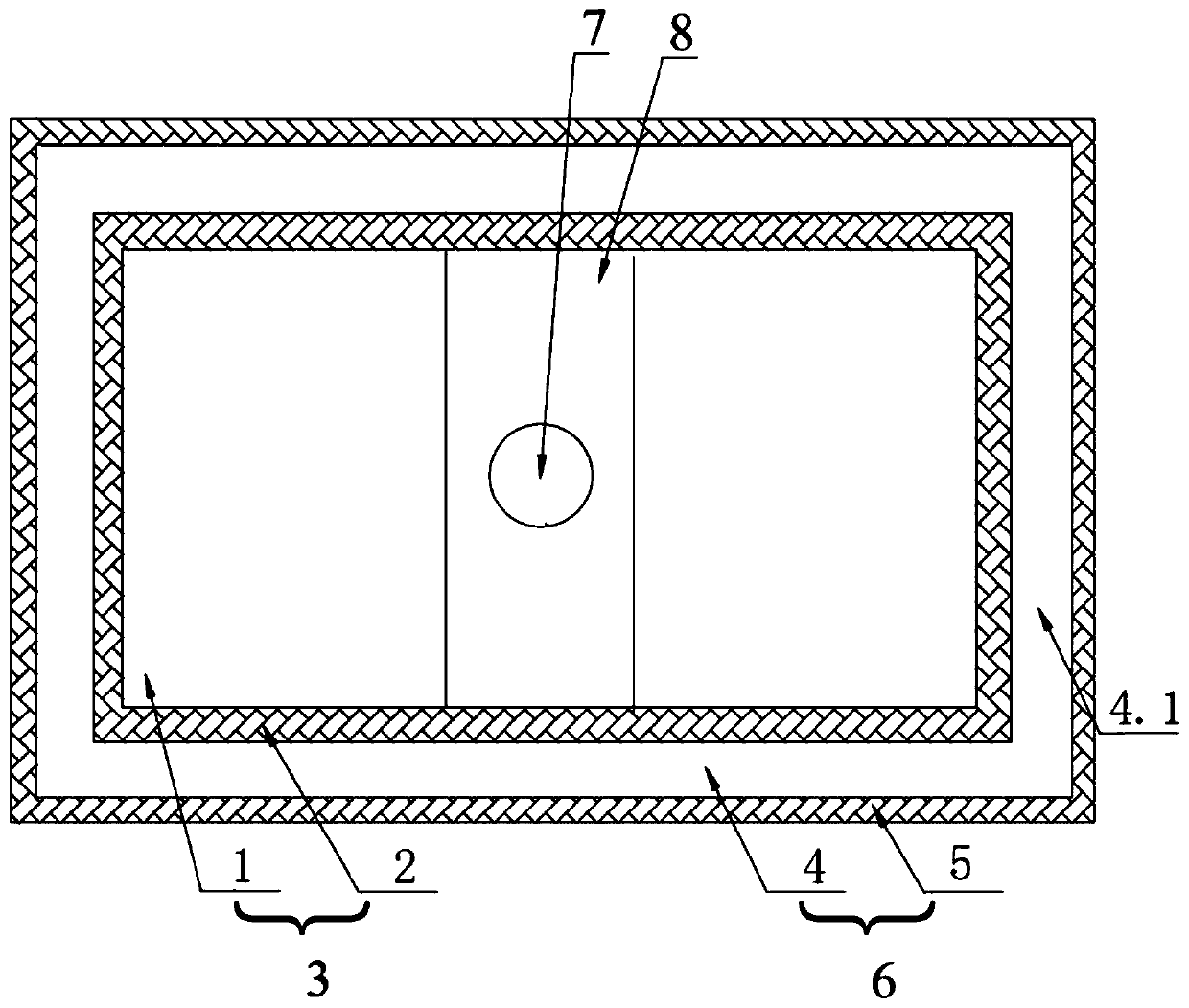

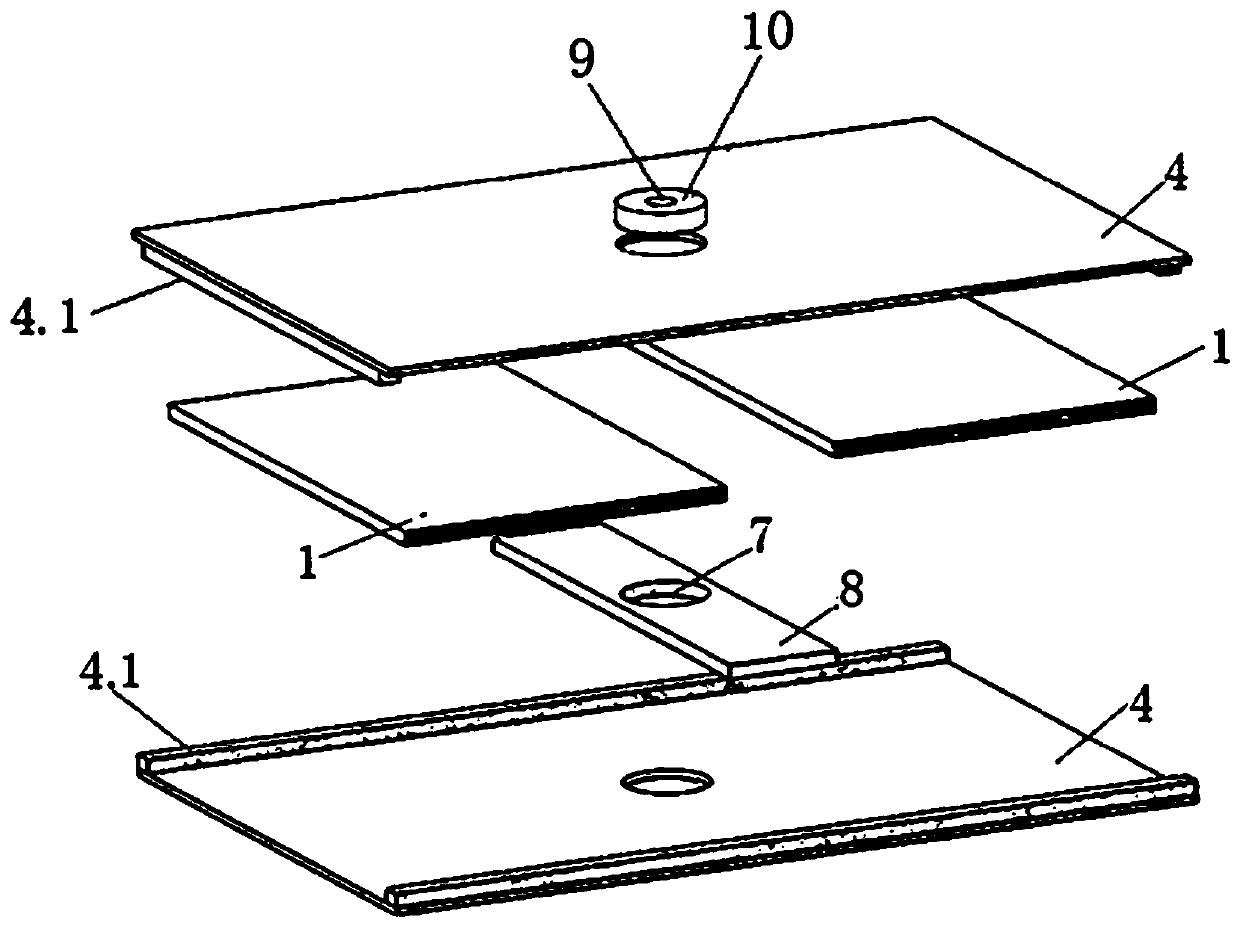

Vacuum thermal insulation plate with mounting holes and without fear of surface damage and processing technology

ActiveCN110792880ASimple structureGood insulation effectThermal insulationSynthetic resin layered productsEngineeringHot pressing

The invention discloses a vacuum thermal insulation plate with mounting holes and without fear of surface damage and a processing technology. The vacuum thermal insulation plate comprises an inner vacuum structural layer and at least one outer vacuum structural layer wrapped around the outer side of the inner vacuum structural layer, the inner vacuum structural layer is composed of an inner core plate body and a high vacuum barrier film wrapped around the outer side of the inner core plate body, the inner core plate body is prepared from materials such as glass fibers through a carding hot pressing or dispersion wet process and a vacuum technology, and the inner vacuum structural layer is prepared by using high vacuum heat sealing equipment; each outer vacuum structural layer is composed of an outer core plate body and a high vacuum barrier film wrapped around the outer side of the outer core plate body, each outer core plate body is prepared from materials such as glass fibers througha mixing dispersion wet process through a vacuum forming technology, a gettering material can be embedded into each outer core plate body, then each outer core plate body is put into the corresponding high vacuum barrier film, and the outer vacuum structural layers are prepared by using the high vacuum heat sealing equipment; and for mounting hole parts, the mounting holes are separated from thecore plate layers by using partition plates provided with through holes. The vacuum thermal insulation plate does not bulge, does not swell, does not absorb water and can retain the thermal insulationperformance after the surface of the vacuum thermal insulation plate is damaged.

Owner:安徽百特新材料科技有限公司

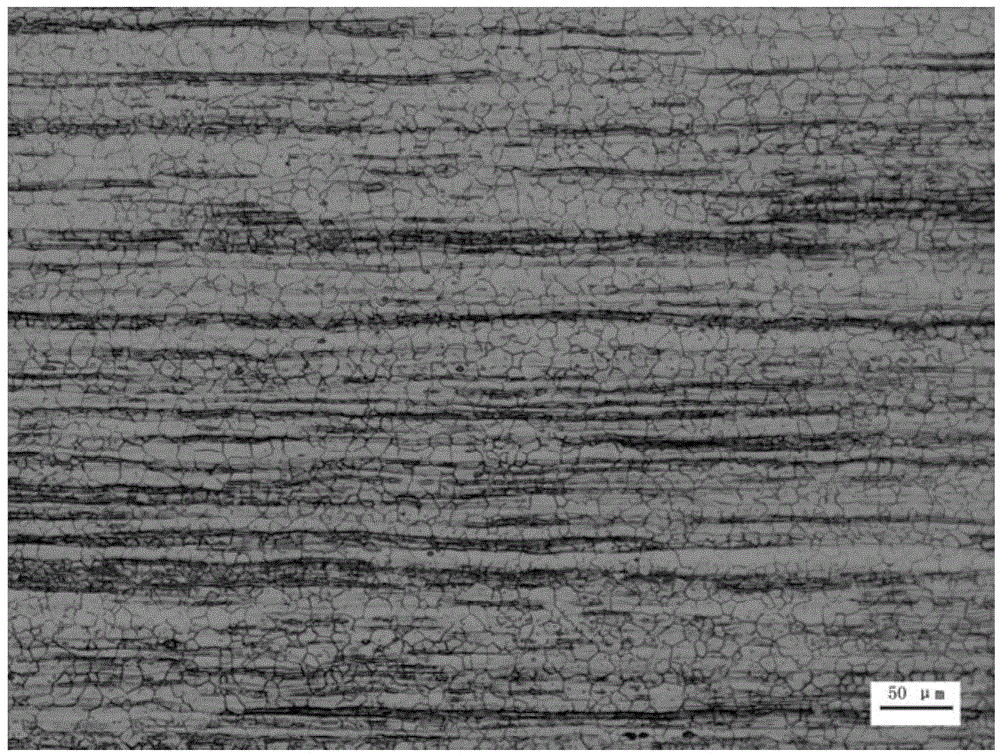

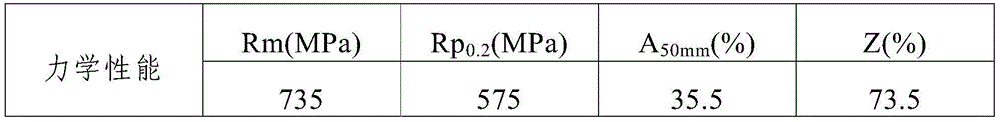

Manufacturing method for austenitic stainless steel bar used for nuclear power reactor

The invention provides a manufacturing method for an austenitic stainless steel bar used for a nuclear power reactor. The manufacturing method includes the following steps that firstly, first roller die drawing is conducted on the austenitic stainless steel bar, and a first drawing bar blank is obtained; secondly, first solid solution treatment is conducted on the first drawing bar blank; thirdly, second roller die drawing is conducted, and a second drawing bar blank is obtained; fourthly, the second drawing bar blank is subjected to fixed die drawing; fifthly, second solid solution treatment is conducted; and sixthly, electric heating stretcher straightening and roller type straightening are conducted, and the austenitic stainless steel bar used for the nuclear power reactor is obtained. According to the manufacturing method, the dimensional tolerance of the manufactured austenitic stainless steel bar used for the nuclear power reactor is not larger than 0.02 mm, linearity is not larger than 0.2 mm / m, the mechanical performance completely meets the requirement for ASTM A276 technology conditions, a microscopic structure is uniform and small, a crystal boundary is clear, and obvious carbide precipitation does not exist.

Owner:西安诺博尔稀贵金属材料股份有限公司

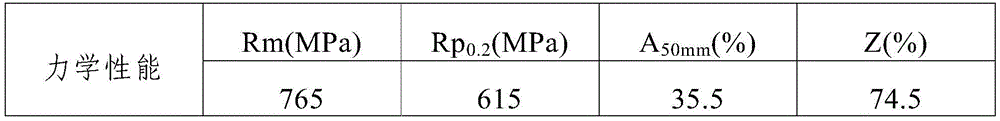

Bauxite grinding technology and apparatus thereof

The bauxite grinding process includes the following steps: feeding bauxite ore, lime and evaporation mother liquor into two-bin overflow grinding mill, breaking, coarse grinding, fine grinding, overflow discharging the ground ore slurry and feeding the ore slurry into intermediate slurry groove, then pumping the ore slurry into cyclone separator, sorting, discharging coarse granules slurry out from bottom outlet of cyclone separator and back returning the coarse granules slurry into two-bin overflow grinding mill and further grinding, screening fine granules slurry and feeding the fine granules slurry into finished product groove to make storage.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Solid waste crushing and screening skid-mounted equipment

The invention discloses solid waste crushing and screening skid-mounted equipment. The solid waste crushing and screening skid-mounted equipment comprises a hopper, a roller screen communicated with a discharging hole of the hopper by virtue of a packing auger, a first conveyor belt communicated with a fine material discharging hole of the roller screen and a second conveyor belt communicated with a coarse material discharging hole of the roller screen, wherein a discharging end of the first conveyor belt is communicated with a material storage bin at the lower end of a crushing machine, a discharging end of the second conveyor belt is communicated with a feeding hole of the crushing machine. In a working process, materials enter a hopper, then is pushed into the roller screen by virtue of the packing auger below the hopper and is screened into a fine material with the particle size meeting the requirement and a coarse material with larger particle size under the action of a screen plate in the roller drum, the fine material directly enters the material storage bin at the lower end of the crushing machine when being driven by the first conveyor belt, the coarse material enters the crushing machine when being driven by the second conveyor belt and is further crushed by virtue of the crushing machine, and a small particle material is formed, so that the specification of the material can meet usage requirement.

Owner:北京华飞兴达环保技术有限公司

Plastic pelletizing device

The invention discloses a plastic pelletizing device. The plastic pelletizing device comprises a base, an extrusion cylinder and a screening chamber. The extrusion cylinder is fixed to the base through a supporting rod, and the screening chamber is fixed to the base and located below the extrusion cylinder. The extrusion cylinder comprises a cylindrical barrel body, a heating and feeding hopper and a hot air chamber are arranged on the top of the extrusion cylinder, the lower end of the heating and feeding hopper communicates with the interior of the extrusion cylinder, a combustion cavity isformed in the hot air chamber, and the hot air chamber communicates with the heating and feeding hopper through an air supply pipe. The plastic pelletizing device is exquisite in structure, can conduct step-by-step screening on pelletized particles, and conveniently conducts collection and reprocessing in the later period. Due to the arrangement of a plurality of pipelines in the material fallingprocess, the operation of quick cooling, energy recycling and the like can be conducted, the energy utilization rate is greatly improved, and the pollution is reduced. The situation that tool edges ofmaterial cutting tools are sharp, and the material cutting tools rotate at a uniform speed can be guaranteed by means of the arrangement of sliding pieces and a material scraping block, and thereforethe specification of pelletizing is guaranteed, and then the percent of pass of products is guaranteed.

Owner:王会恩

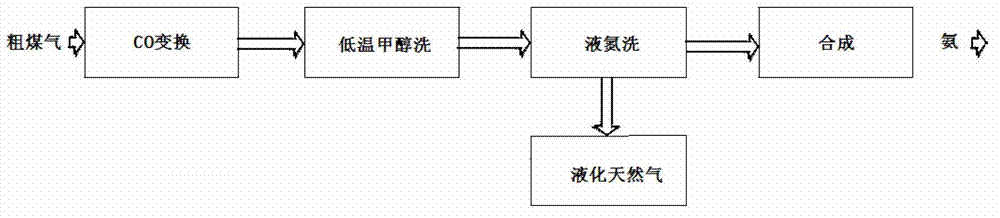

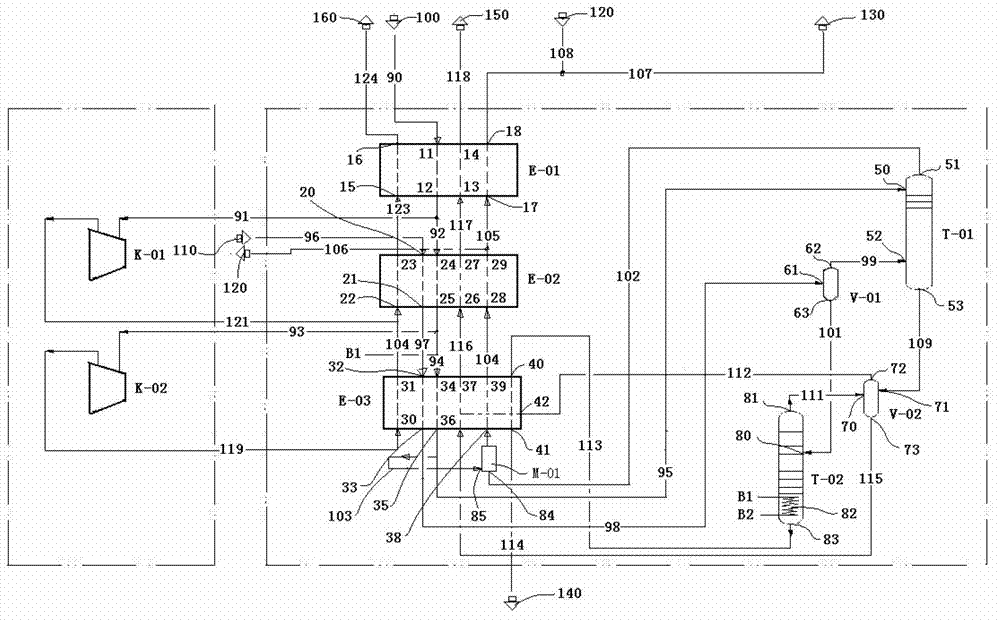

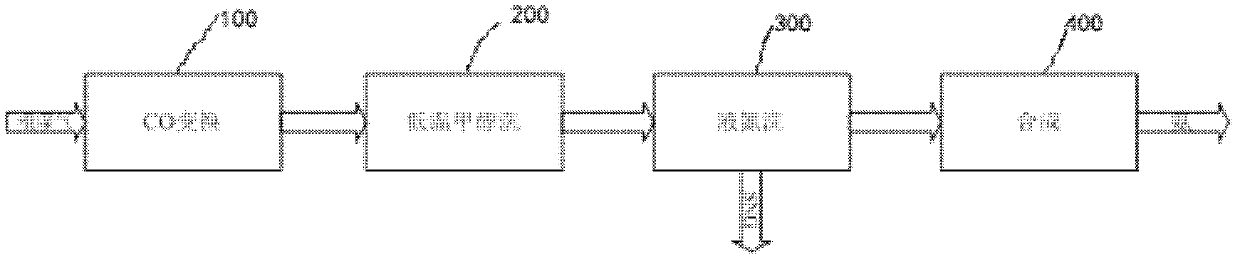

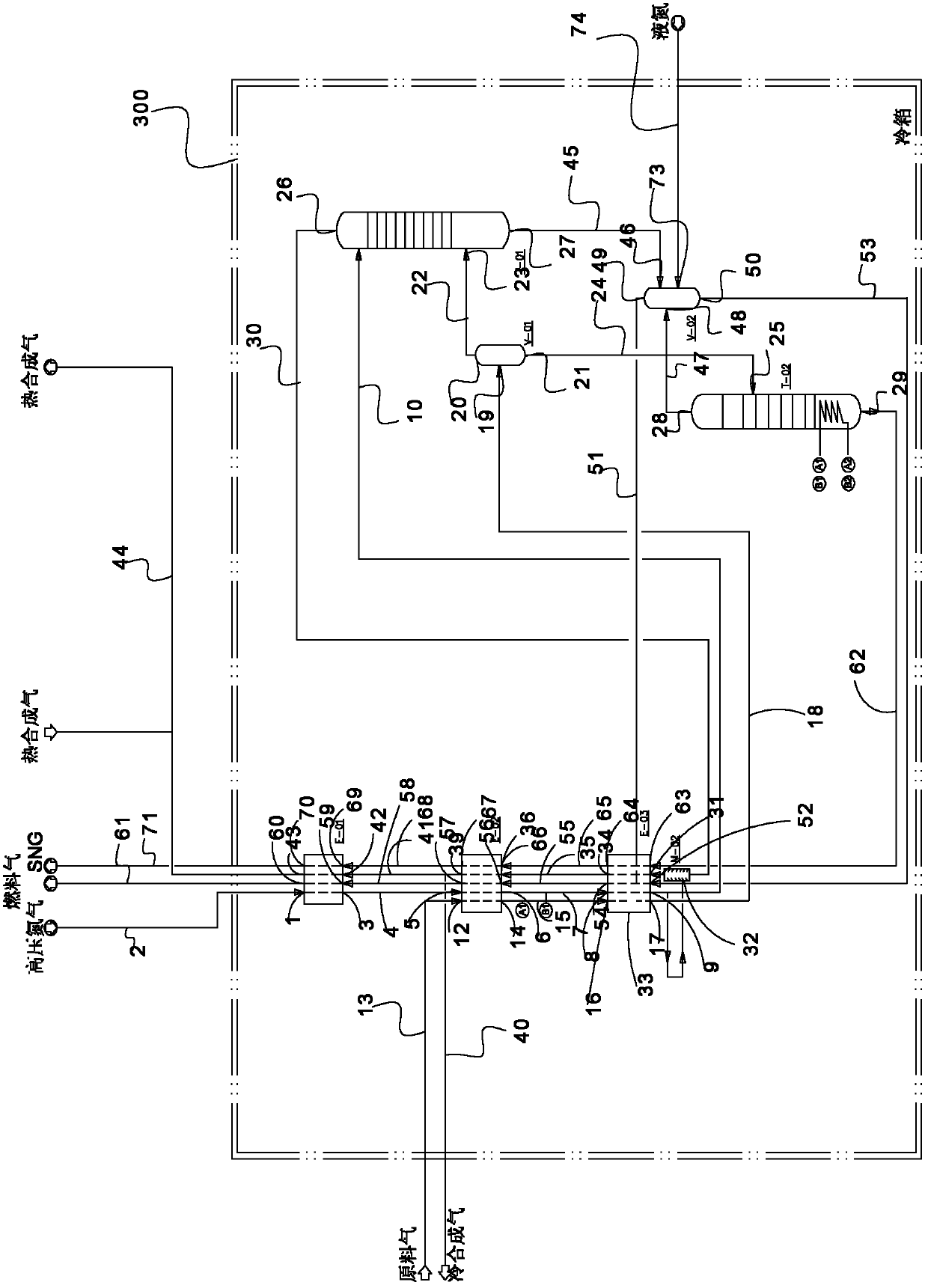

Method and device for cogeneration of synthesis ammonia gas and liquefied natural gas prepared through pressure gasification of crushed coal in fixed bed

ActiveCN102757016ASame sizeLess investmentHydrogen separation using liquid contactGaseous fuelsFixed bedCogeneration

The invention discloses a method for cogeneration of synthesis ammonia gas and liquefied natural gas prepared through pressure gasification of crushed coal in a fixed bed. In the method, through appropriate allocation of the processes among a high-pressure nitrogen gas cooler, raw material gas coolers, a nitrogen gas expander, a nitrogen washing column, flash tanks and methane rectifying columns, the cogeneration of the liquefied natural gas is achieved, so that the effects of low investment, low energy consumption, high heating value and high efficiency are achieved. The invention further discloses a device for cogeneration of synthesis ammonia gas and liquefied natural gas prepared through pressure gasification of crushed coal in the fixed bed.

Owner:SHANGHAI INT ENG CONSULTING

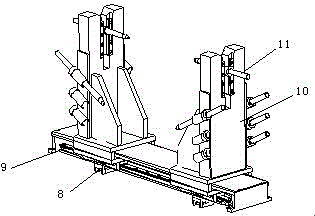

Electric truck frame assembly fixing and assembling platform

The invention discloses an electric truck frame assembly fixing and assembling platform. The electric truck frame assembly fixing and assembling platform is characterized by comprising a base platform, a positioning trolley, a first clamping trolley, second clamping trolleys, an electric cylinder driving device and an PLC system, wherein the base platform provides an assembling platform benchmark and can enable the positioning trolley, the first clamping trolley and the second clamping trolleys to move forwards and backwards in the longitudinal direction; the base platform is composed of a first BASE assembly, a second BASE assembly and adjustable landing legs; the positioning trolley comprises a rolling wheel assembly, a linear sliding rail assembly, a width-limiting baffle, a guide groove and a positioning pin; the first clamping trolley comprises a first rolling wheel assembly, a first linear sliding rail assembly, a first right width-limiting baffle, a first left width-limiting baffle, a first servo electric cylinder assembly, a second servo electric cylinder assembly and a left-right inner-supporting four-bar mechanism. According to the electric truck frame assembly fixing and assembling platform, a truck frame assembly is assembled on the assembling platform, and therefore all technical indexes for truck frame assembling are guaranteed.

Owner:JILIN SAIJINDE INTELLIGENT MACHINERY MFG

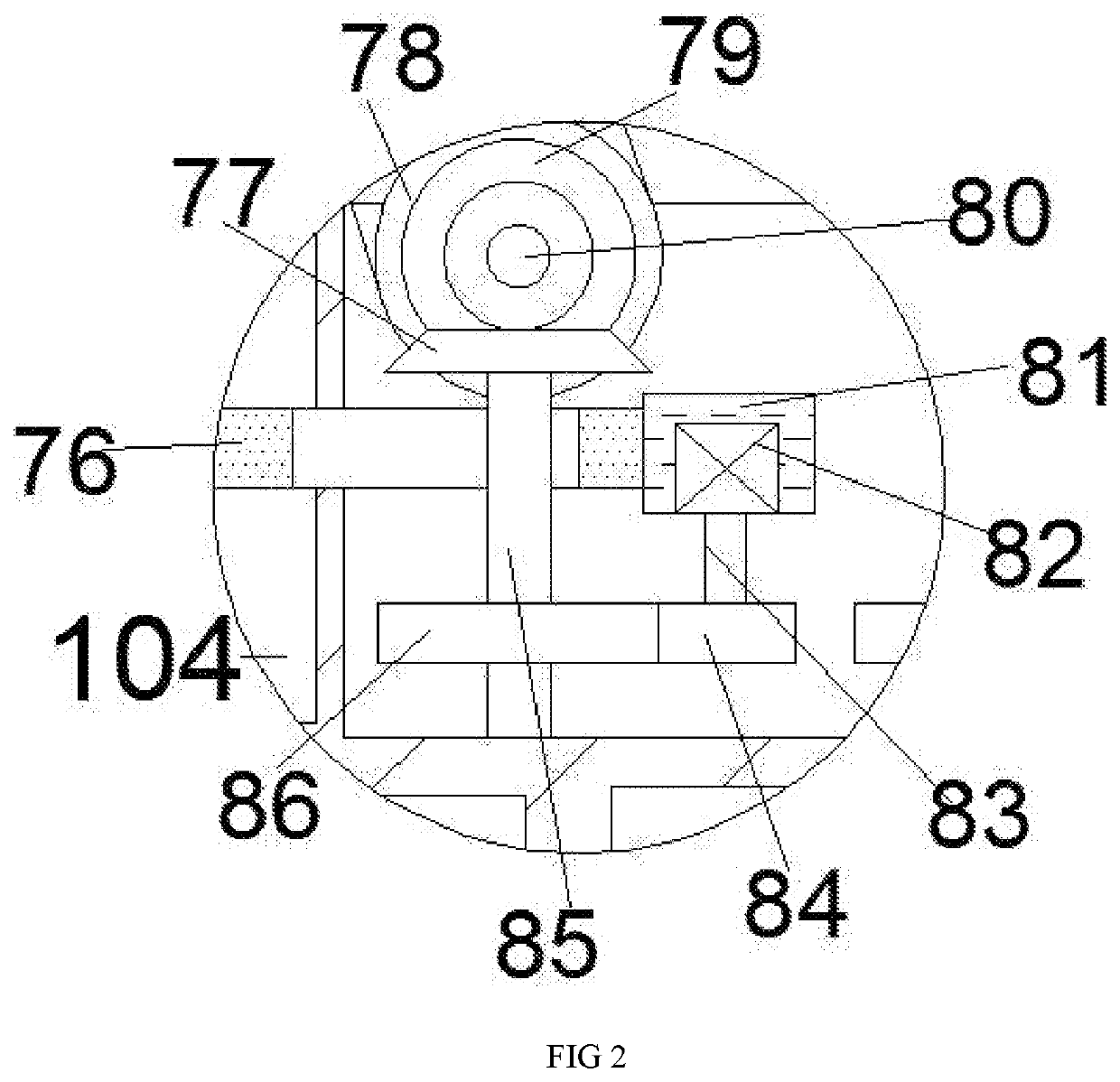

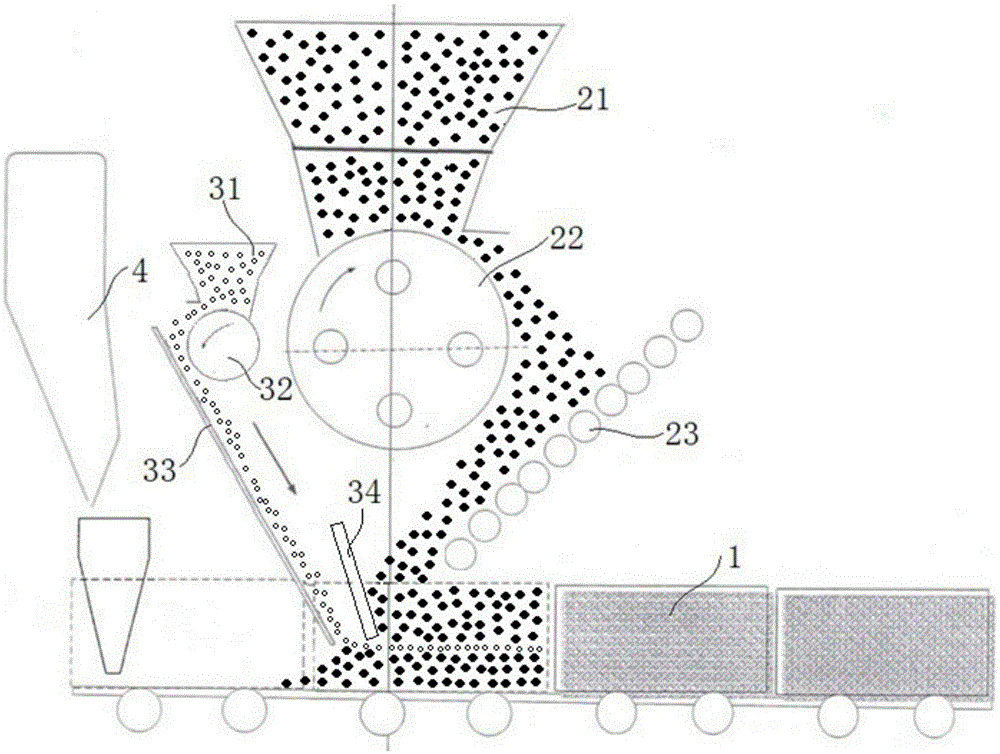

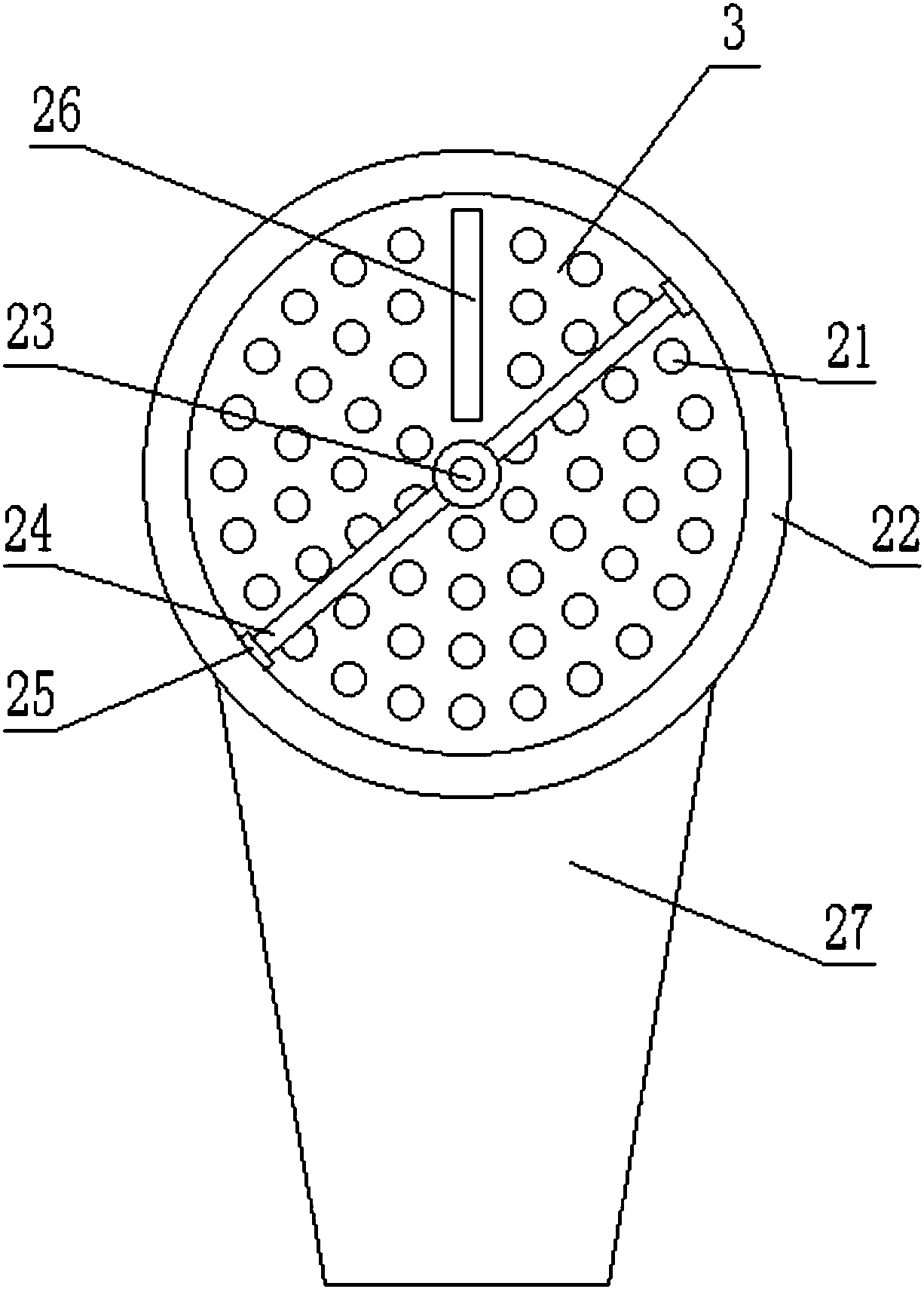

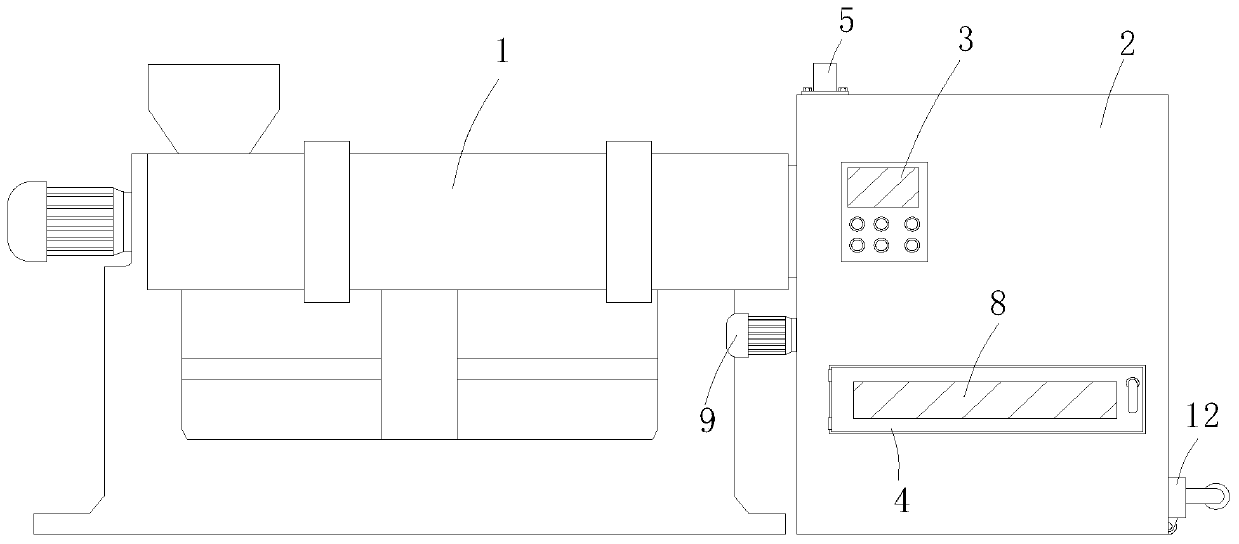

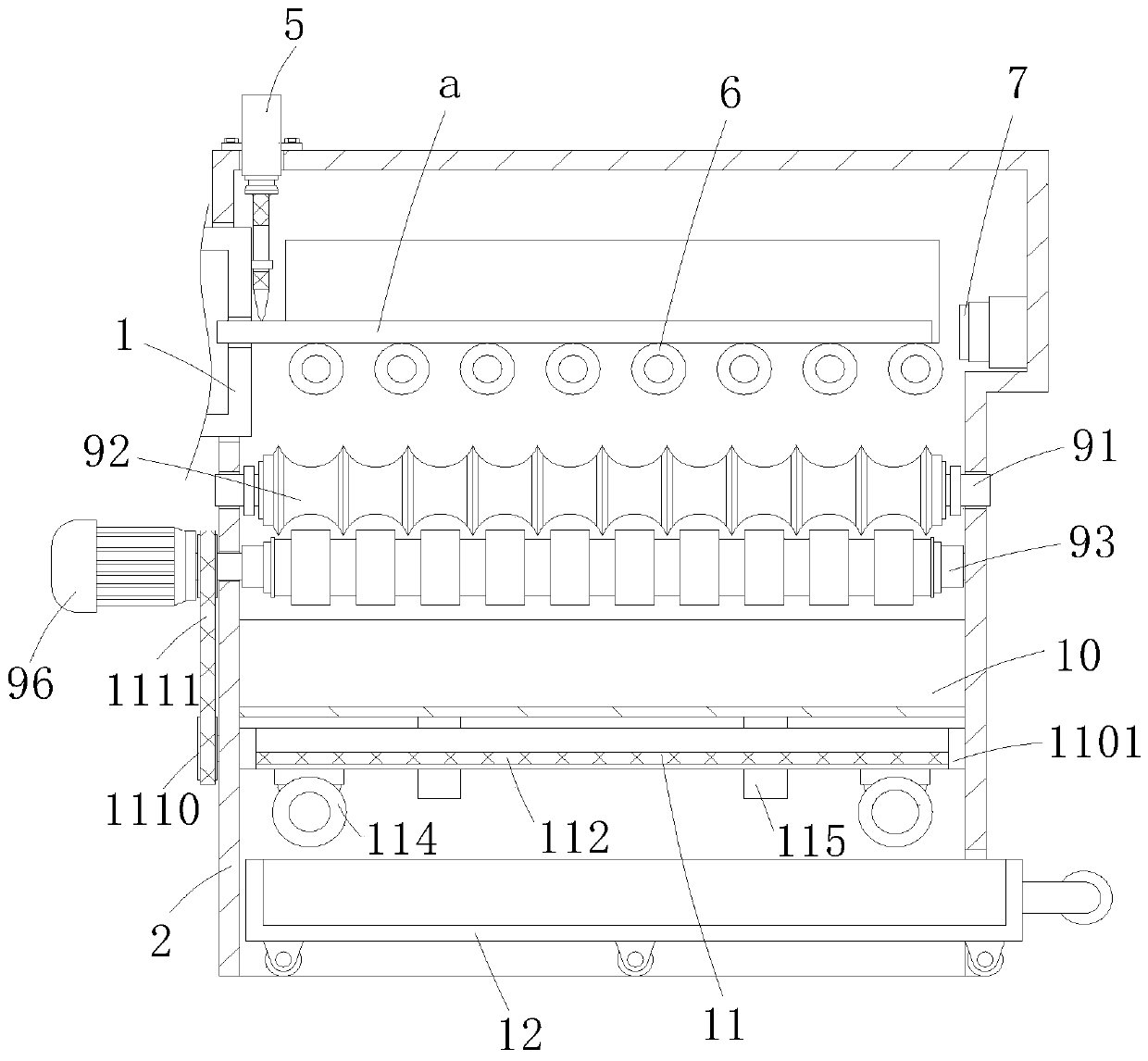

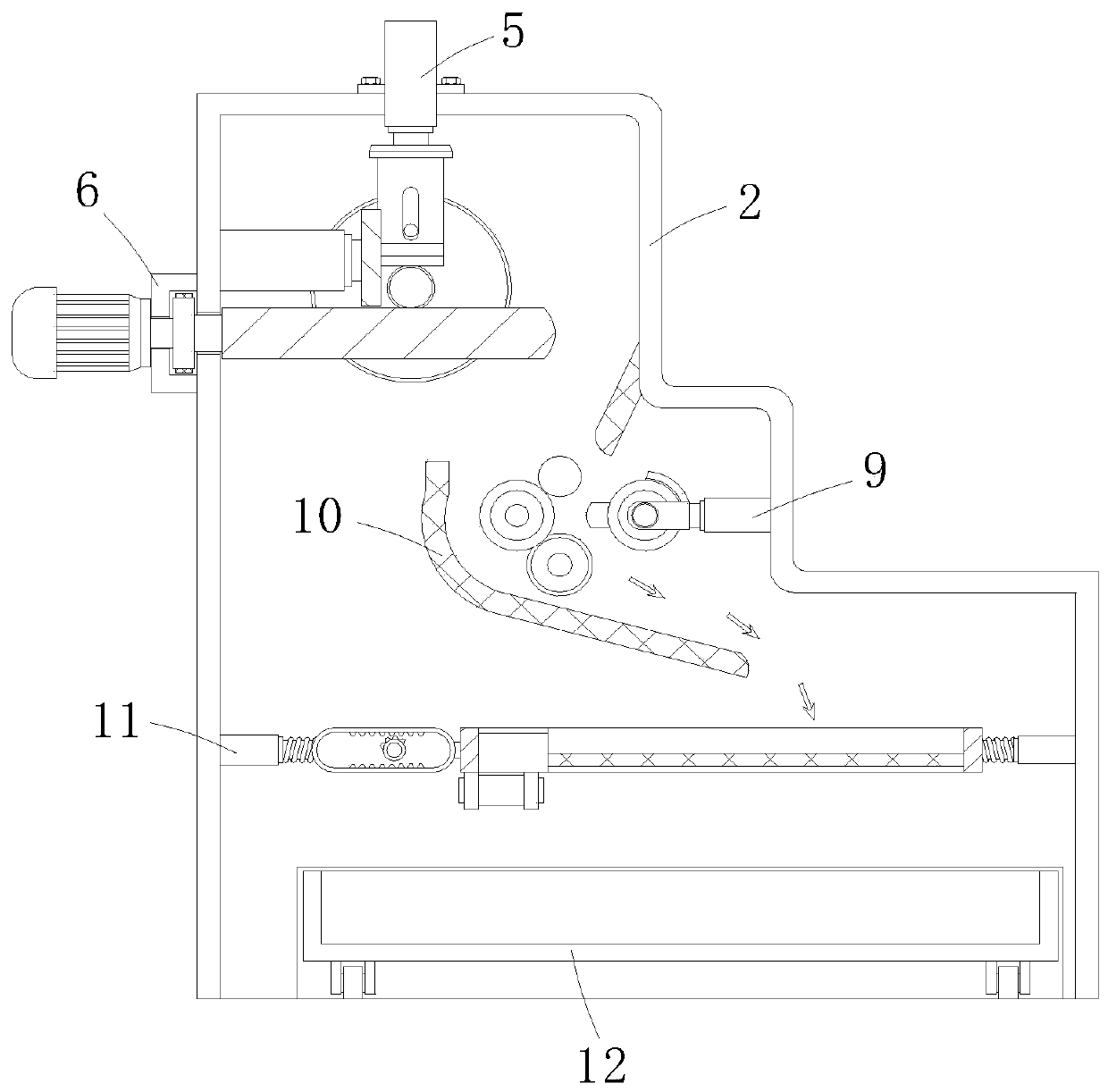

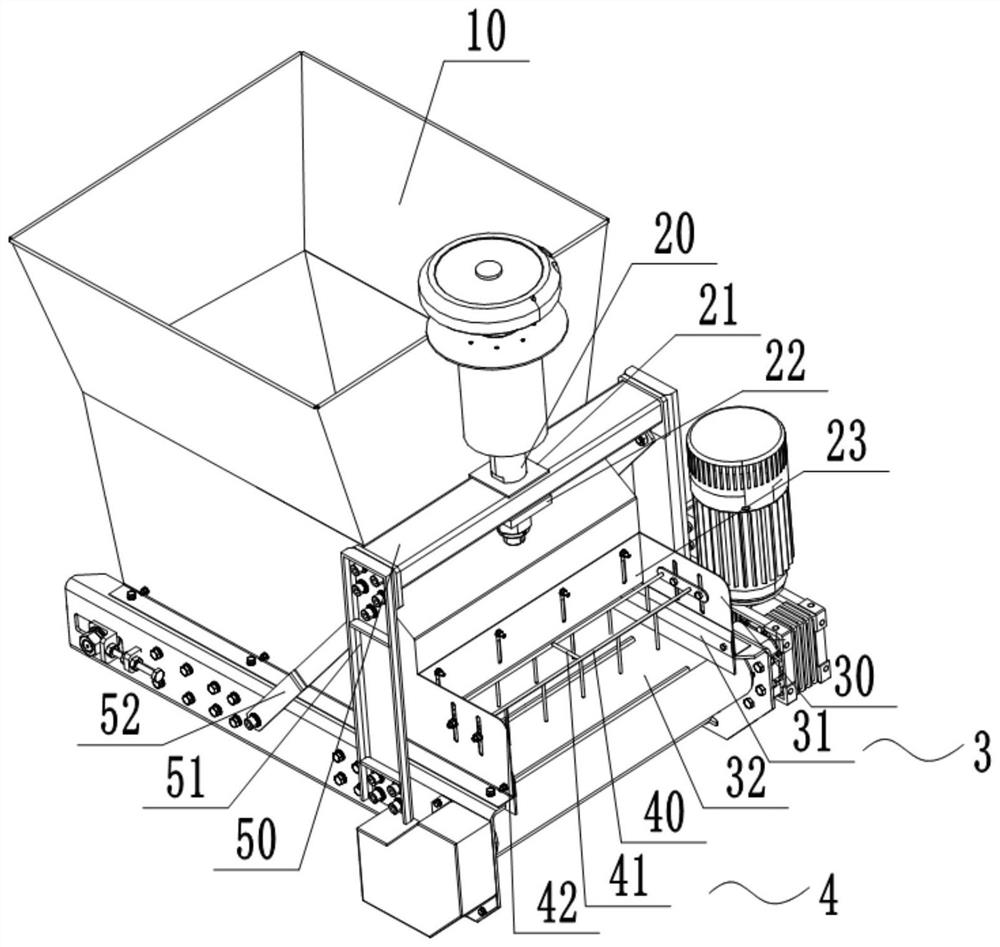

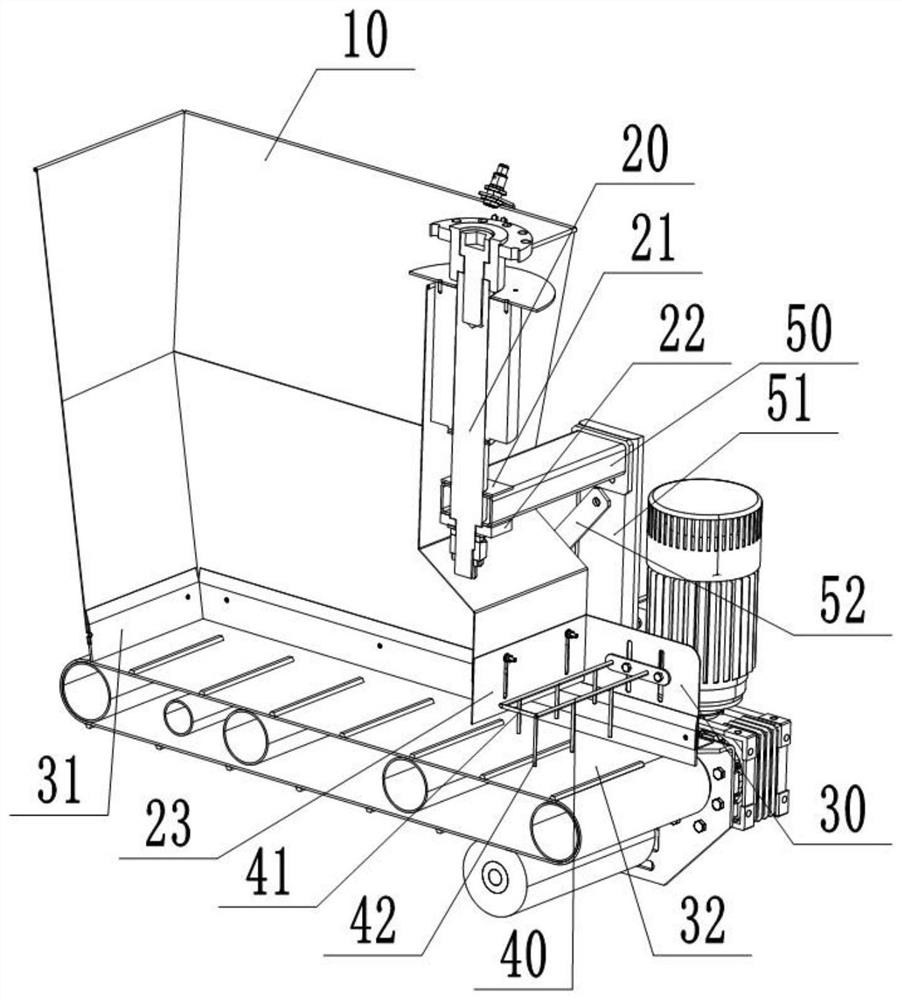

Pill making and selecting device for pill medicine production

ActiveCN111467237AFast pillingEasy to make pillsPharmaceutical product form changeDomestic articlesTraditional medicinePill

The invention relates to the technical field of pill production equipment, provides a pill making and selecting device for pill medicine production, and aims at solving the problems that in existing pill making equipment, one type of pill making equipment has relatively large production scale and is high in price although automatic mass production can be achieved, and the other type of pill makingequipment is relatively simple and crude in structure and is not provided with a pill selecting mechanism, so that the pill making effect is not ideal and the rejection rate is relatively high. The pill making and selecting device for pill medicine production comprises a screw extruder and a pill making machine box connected with the output end of the screw extruder in a penetrating mode, whereina medicine strip conveying mechanism is arranged on an inner cavity of the pill making machine box; a pill making mechanism and the pill selecting mechanism are sequentially arranged below the medicine strip conveying mechanism; a pill collecting trolley is arranged below the pill selecting mechanism; one side of the pill collecting trolley extends to an outer cavity of the pill making machine box and is provided with a push-pull handle; and the medicine strip conveying mechanism comprises a plurality of conveying rollers. The pill making and selecting device for pill medicine production is particularly suitable for pill making and selecting production of pill medicines, and has the relatively high social use value and application prospect.

Owner:HUIYINBI GROUP ANHUI PHARMA

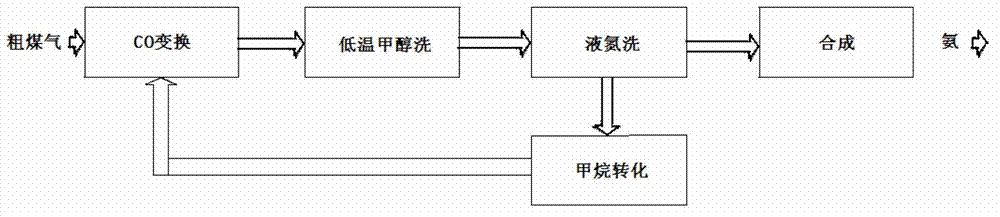

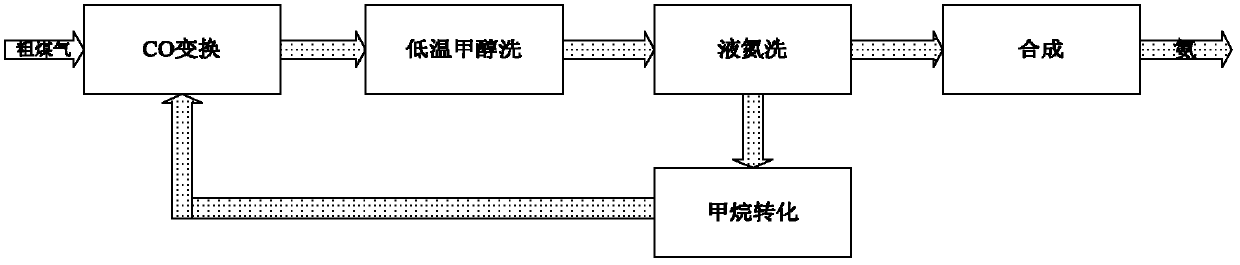

Method and device for combined production of ammonia synthesis gas and SNG by fixed bed crushed coal pressurization and gasification

ActiveCN102701148ASame sizeLess investmentGaseous fuelsHydrogen productionSeparation technologyFixed bed

The invention discloses a method for combined production of ammonia synthesis gas and SNG by fixed bed crushed coal pressurization and gasification; raw coal gas is subject to a CO shift step, a low-temperature methanol washing step, and a liquid nitrogen washing step, and then is delivered to an ammonia synthetic step for ammonia synthesis, and a by product of SNG is obtained in the liquid nitrogen washing step. The method omits a complicated methane conversion working section in a traditional synthesis gas production process by using a liquid nitrogen washing device and low-temperature separation technology; inert gas in the synthesis gas is removed, and the methane fraction is separated into liquid methane; finally the synthesis gas is reheated and flows out of a cold box, and reaches the specification for artificial natural gas (SNG) as clean energy. In addition, raw material gas is subject to purification and methane separation, which not only reduces the influence of inert gas in a synthetic loop, reduces waste gas discharge, but also causes no addition of additional mobile equipment, realizes combined production of synthetic ammonia and SNG, and has significant economic and social benefits. The invention also discloses a device used in the method.

Owner:SHANGHAI INT ENG CONSULTING

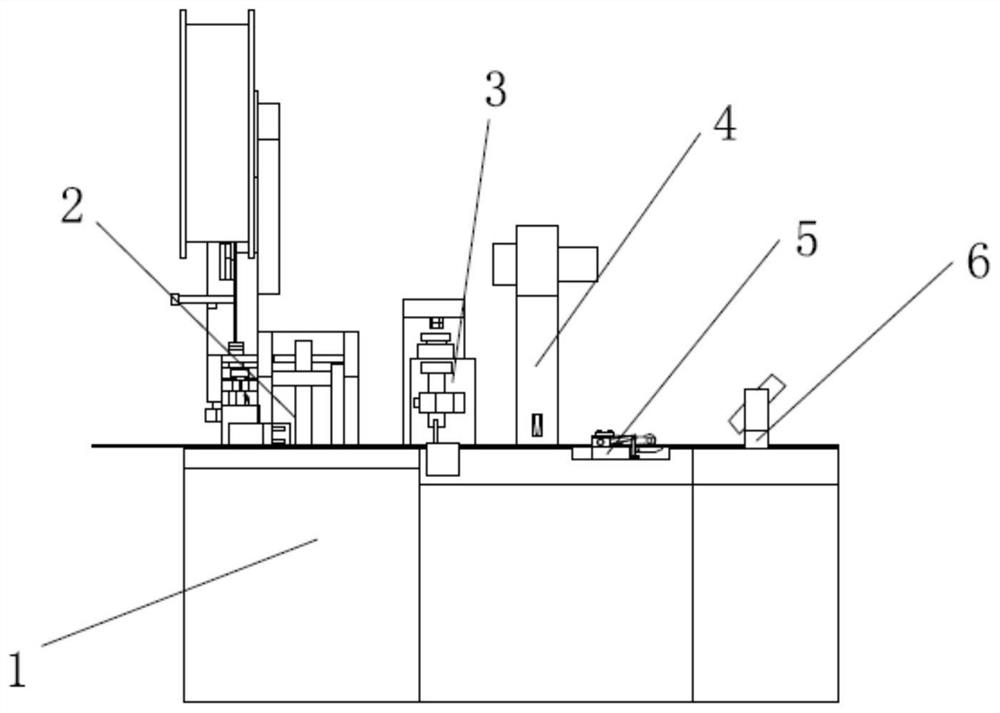

Full-automatic reed welding machine

ActiveCN113441808ARealize automatic cut offHigh degree of automationWelding/cutting auxillary devicesUsing mechanical meansWire cuttingEngineering

The invention relates to a full-automatic reed welding machine. The full-automatic reed welding machine comprises a machine table, a reed transmission platform and a contact welding machine, the reed transmission platform used for reed installation is installed on the upper end face of the machine table, the contact welding machine, a contact welding force detection machine, a contact trimming machine, a reed transmission machine and a detection structure are installed on the reed transmission platform from left to right, a silver wire transmission arm, a silver wire cutting-off base and a welding copper block are arranged in the contact welding machine, the silver wire transmission arm moves front and back, the front end of the silver wire transmission arm conveys a silver wire into the silver wire cutting-off base located on the reed transmission platform, the cut silver wire is welded into a reed structure in the reed transmission platform through the welding copper block with the rear portion moving downwards in an inclined mode, a shifting piece matched with a contact on the reed structure is arranged in the contact welding force detection machine, and a contact trimming rod capable of moving up and down is arranged on the contact trimming machine. The full-automatic reed welding machine has the characteristics of low energy consumption, stable reed transmission, high production efficiency, accurate positioning, improvement of product quality and the like.

Owner:BULL GRP CO LTD +1

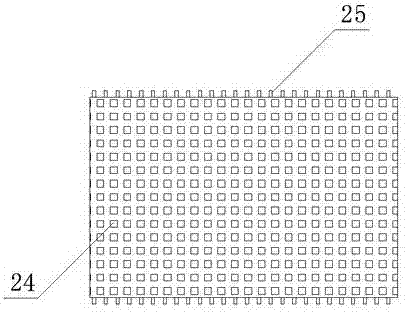

Raw material screening device for 3D printing consumable production

InactiveCN110961340AAvoid accumulationGuaranteed SpecificationsSievingAdditive manufacturing apparatusElectric machineMechanical engineering

The invention discloses a raw material screening device for 3D printing consumable production. The device comprises a housing and a first motor. Screening mechanisms are movably mounted on the inner walls of the two sides of the housing through bearings correspondingly. The screening mechanism comprises an upper ring sleeve, a framework and a lower ring sleeve; transmission plates are welded on the surfaces of the upper ring sleeve and the lower ring sleeve which are arranged at one end of the screening mechanism; the output end of the first motor is welded and fixed to the transmission plate;the upper ring sleeve and the lower ring sleeve arranged at the other end of the screening mechanism are movably connected with one end of a feeding cylinder; a feeding mechanism is arranged on the surface of the feeding cylinder; a third motor is installed at one end of the feeding cylinder; and the output end of the third motor is in transmission connection with one end of a spiral feeding rodthrough a shaft coupler. The feeding mechanisms and the screening mechanisms are matched with each other, so that consumable raw materials are continuously scattered and turned over through the spiralfeeding rod in the screening process, and the screening effect is improved through cooperation of the mode.

Owner:WUHU AISANDI ELECTRONICS TECH CO LTD

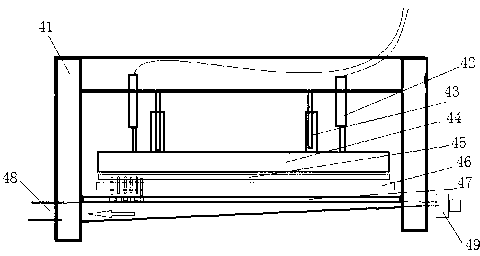

Integrally arranged latex cotton production system and method for cutting latex cotton

ActiveCN103340534AImprove desulfurization effectGuaranteed punching qualityStuffed mattressesSpring mattressesPunchingEngineering

The invention relates to a gantry punching machine applied to a latex cotton product. The gantry punching machine comprises a gantry frame, wherein a fixed lower pinhole plate is arranged at the lower part of the frame; a needle plate and a needle sleeve plate, which are orderly arranged from top to bottom and arranged correspondingly to the lower pinhole plate, are arranged at the upper part of the frame; the needle plate and the needle sleeve plate can move up and down; a controller for containing the latex cotton is formed between the needle sleeve plate and the pinhole plate. The gantry punching machine has the advantages that 1) the lower pinhole plate and the needle sleeve plate are utilized to guide each needle arranged on the needle plate, so that each needle can keep synchronous, and can move downwards at an accurate angle in the punching process, so as to ensure the punching quality; 2) a beam is further arranged on the gantry punching machine, so that the strength of the entire punching device is enhanced; the inaccurate punching phenomenon caused by inconsistent deformation due to up-and-down movements, rigidity and the like when the needle plate is directly connected to the gantry frame is avoided. Therefore, the problem is well avoided due to existence of an upper beam; the punching quality is further ensured.

Owner:JIANGSU AIDEFU LATEX PROD

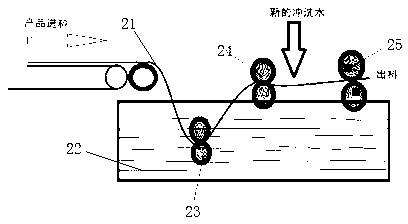

Vinasse stacking fermentation material scattering device, system and method

PendingCN112961743AUniform feedingImprove uniformityAlcoholic beverage preparationLoading/unloadingEngineeringVinasse

The invention discloses a vinasse stacking fermentation material scattering device, system and method. The vinasse stacking fermentation material scattering device comprises a belt conveyor and a hopper connected to the upper portion of a rack of the belt conveyor, wherein the bottom of the hopper is open and is opposite to the upper conveying face of the belt conveyor, and an opening facilitating the conveying face of the belt conveyor to send out materials from the interior of the hopper is formed in the end face of the front end of the hopper. The vinasse stacking fermentation material scattering device is operated to spread the materials according to the vinasse stacking fermentation material scattering method, so that uniform blanking and uniform spreading of the vinasse are realized; and therefore, the situations that the vinasse rolls into vinasse balls due to one-time dumping of the vinasse, follow-up fermentation is not facilitated and the vinasse balls roll to the periphery are avoided, the material scattering speed and uniformity are increased, and the labor intensity of workers is reduced.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

Powder crushing method and device

The invention discloses a powder crushing method and device. The device comprises a roller obliquely arranged downwards in the feeding direction, a crushing spindle and a crushing motor driving the crushing spindle to rotate. The roller comprises a roller body, a feeding device, a discharging device and a rolling motor driving the roller body to rotate, wherein the feeding device and the discharging device are arranged at the two ends of the roller body. The crushing spindle extends into the roller body and is axially parallel to the roller. A plurality of crushing needles are arranged on the crushing spindle and used for crushing powder. The crushing needles are evenly distributed on the crushing spindle in a surrounding mode at intervals. When the crushing needles rotate to the powder in the roller body, the length of the crushing needles are set in the mode that the crushing needles exactly make contact with the coarse powder on the upper layer and do not make contact with the fine powder on the lower layer. When the roller rotates, the coarse powder and the fine powder are separated into the upper layer and the lower layer, due to the fact that the length of the crushing needles are set in the mode that the crushing needles exactly make contact with the coarse powder on the upper layer and do not make contact with the fine powder on the lower layer, the fineness of the crushed coarse powder and the fine powder are more uniform, the fine powder is not subjected to secondary crushing, the specification of the fine powder is ensured, and the quality of finished ceramics is improved.

Owner:广东博晖华升科技有限公司

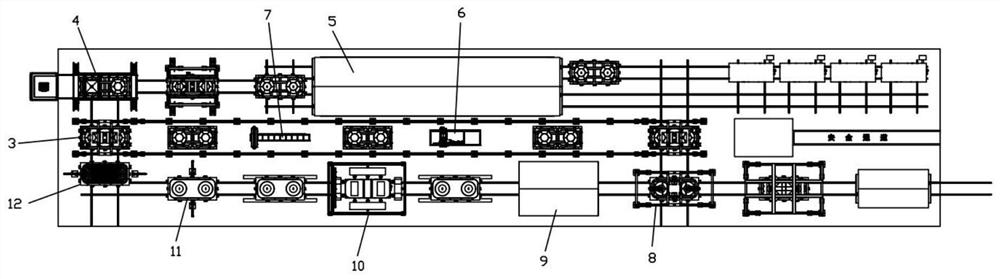

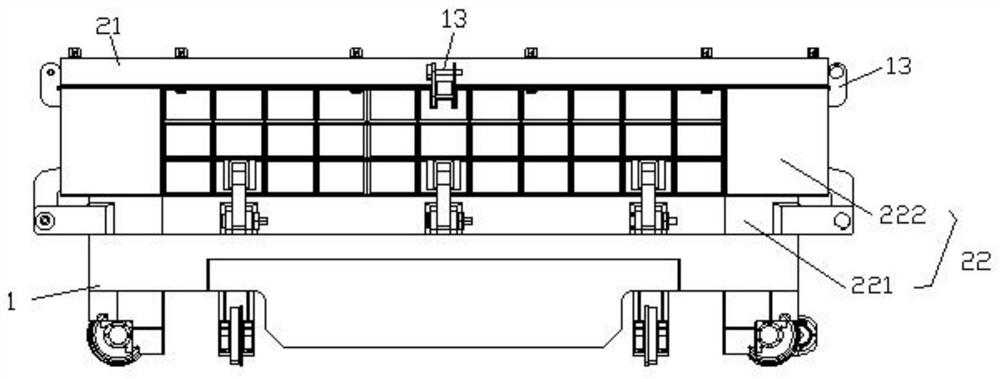

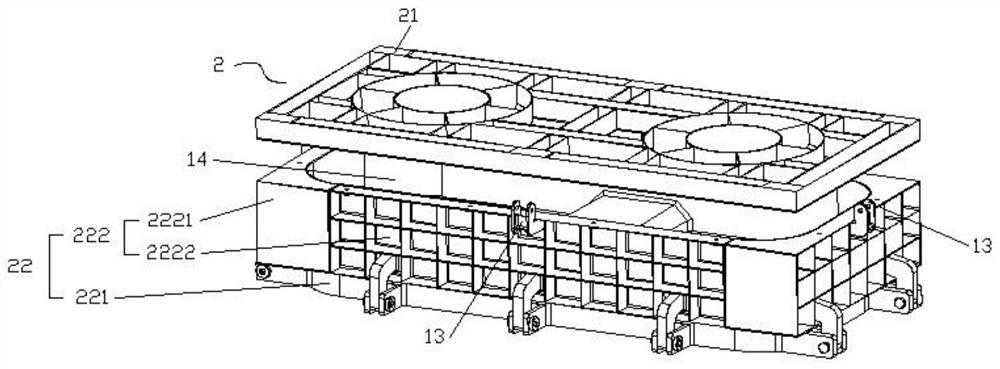

Bent cap production line system

ActiveCN113878703AShorten the production cycleGuaranteed SpecificationsGrinding carriagesMouldsManufacturing lineStructural engineering

The invention relates to a bent cap production line system. The bent cap production line system comprises a bent cap split mold placed on an AGV trolley, and further comprises an upper mold plate opening / closing station, a concrete pouring and vibrating station, a maintenance station, an upper mold plate polishing station, an upper mold plate spraying station, a lower mold plate opening station, a lower mold plate polishing station, a lower mold plate spraying station, a long mold plate closing station and a short mold plate closing station which are arranged on a production line. By means of the bent cap production line system, factory type operation is conducted on bent caps, and the bent cap production period is short; a bottom mold plate, side mold plates and an upper mold plate of the bent cap split mold are mutually independent, so that the bent cap split mold is easy to maintain and clean; the specification and quality of the bent caps are ensured, so that the precision of bridge engineering is improved; and the number of workers participating in bent cap production is reduced, and the construction safety is improved.

Owner:北京好运达智创科技有限公司

Environment-friendly anti-corrosion large grounding grid with adjustable grounding impedance and construction method

PendingCN112582810AExtend safe operating lifeLower impedanceLine/current collector detailsConnection contact member materialGrounding gridHazardous substance

The invention relates to an environment-friendly anti-corrosion large grounding grid with adjustable grounding impedance. A voltage-sharing bus is made of a seamless steel tube of which the inner walland the outer wall are subjected to conductive and antiseptic treatment, and release holes are uniformly distributed in the tube; the grounding grid comprises a circle of outer edge voltage-sharing bus buried at the outermost edge of a whole area and a grounding grid main body buried in an device area, the grounding grid main body comprises a tubular voltage-sharing bus and a grounding wire whichare buried in the device area, and an outer edge voltage-sharing bus and a grounding grid main body voltage-sharing bus are communicated with each other; a steel pipe vertically communicated with thevoltage-sharing buses is mounted above the ground of each device area to serve as an injection hole, the top end of each injection hole is of a sealed structure, and a grounding electrode which is vertically communicated with the tubular voltage-sharing bus and is downwards inserted into the ground is arranged on the tubular voltage-sharing bus of the grounding grid. According to the invention, the problems of oxidation and disconnection of the grounding grid caused by electrochemical erosion of harmful substances in soil can be effectively prevented, and the safe operation period of the large grounding grid can be prolonged exponentially.

Owner:高政

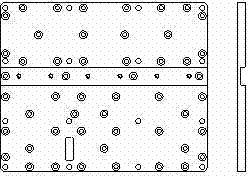

Method for reducing grounding resistance and thermal resistance of printed board

InactiveCN102573323AReduce ground resistance and thermal resistanceGuaranteed specifications and reliabilityPrinted circuit assemblingElectronic informationSolder paste

The invention discloses a method for reducing grounding resistance and thermal resistance of a printed board, belonging to the field of electronics assembly technology in an electronic information industry; the method comprises the steps of manufacturing a red copper substrate of which the area is more than that of the circuit printed board, using an alcohol cotton ball to clean the circuit printed board; using the alcohol cotton ball to clean the circuit printed board; uniformly coating solder paste on the back of the cleaned printed board by a silk screen; fixing the printed board coated with solder paste and the red copper substrate together on a cavity by a screw under conditions that the fixation is not too tight and is justly proper, and small amount of the solder paste flows out; using the alcohol cotton ball to clean the outflowed solder paste; putting the fastened chamber, the substrate and the printed board to a high-temperature box to bake for 5 min at 240 DEG C; after baking, taking out to cool, and then using the alcohol cotton ball to clean; welding a high-power transistor and other component on the printed board and the substrate. The method has the advantage that the grounding resistance and the thermal resistance of the printed board can be reduced and the technical index and the reliability of a transmitter are ensured.

Owner:SICHUAN LONGRUI MICROELECTRONICS

Anchor large-size low-cement concrete formula

InactiveCN110467392AHigh compressive strengthReduce manufacturing costWater reducerMaterials science

The invention discloses an anchor large-size low-cement concrete formula. The anchor large-size low-cement concrete formula is composed of following raw materials, by weight, 100 to 150 parts of cement, 90 to 110 parts of ore powder, 130 to 170 parts of fly ash, 700 to 800 parts of sand, 1000 to 1200 parts of broken stone, 130 to 160 parts of water, and 3.5 to 4.5 parts of a water reducer. The advantages are that: the 7d compressive strength of the concrete produced based on the anchor large-size low-cement concrete formula reaches 35.4, 28d compressive strength reaches 55.3, concrete compressive strength is high, anchor using requirements are satisfied completely, concrete working performance and technology index are ensured, and at the same time, the per cubic metre cement using amount (lower than 150kg / m3) is reduced greatly, and enterprise production cost is reduced greatly.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com