Integrally arranged latex cotton production system and method for cutting latex cotton

A production system, latex technology, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as errors of several centimeters or tens of centimeters, difficulty in meeting specifications, inconsistent sizes, etc. Achieve the effects of high yield, easy specifications and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

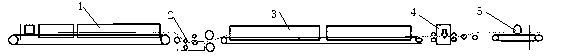

[0035] The present invention includes a shaping section 1 , a cleaning and dehydration section 2 , a drying section 3 , a punching section 4 and a cutting section 5 .

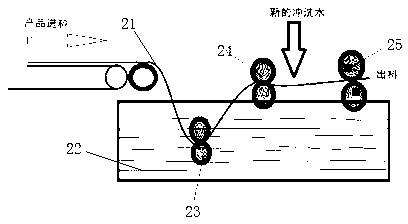

[0036] Cleaning and dehydration section 2 of the present invention: the latex cotton 21, a continuous sheet material stripped from the previous process, is guided into the water tank 22 with the support of the conveying wheel shaft, and is squeezed by a pair of final shafts 23 in the water to perform a cleaning process of desulfurization and water absorption. , lead to the water surface and then clamped by a pair of clamping shaft group-24 to remove sewage once. Introduce a pair of relatively powerful large-scale clamping shaft group II 25 to clamp and compress drainage. At the same time, because the gap between the two sides of the latex cotton and the clamping shaft group is easy to store water, two air guns are installed to form an impact force and discharge in the direction of feeding. Remaining water, in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com