A kind of online desulfurization method of sintering process

A technology of sintering process and desulfurization agent, which is applied in the field of desulfurization, can solve problems such as difficulty in industrial field application, deterioration of sinter technical indicators, and great influence on sinter quality, so as to improve desulfurization efficiency, high cloth distribution accuracy, and cloth distribution accuracy And uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

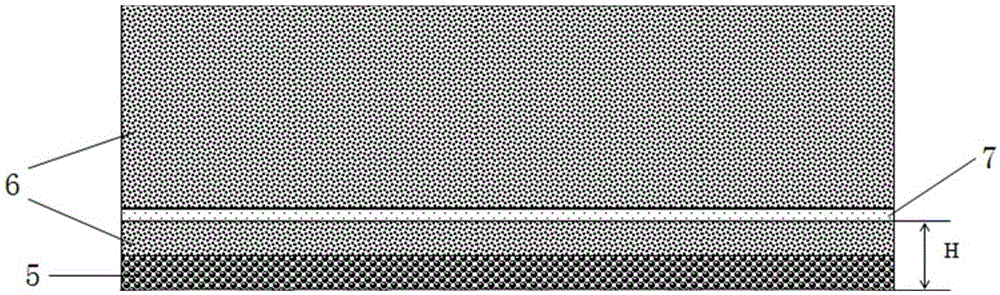

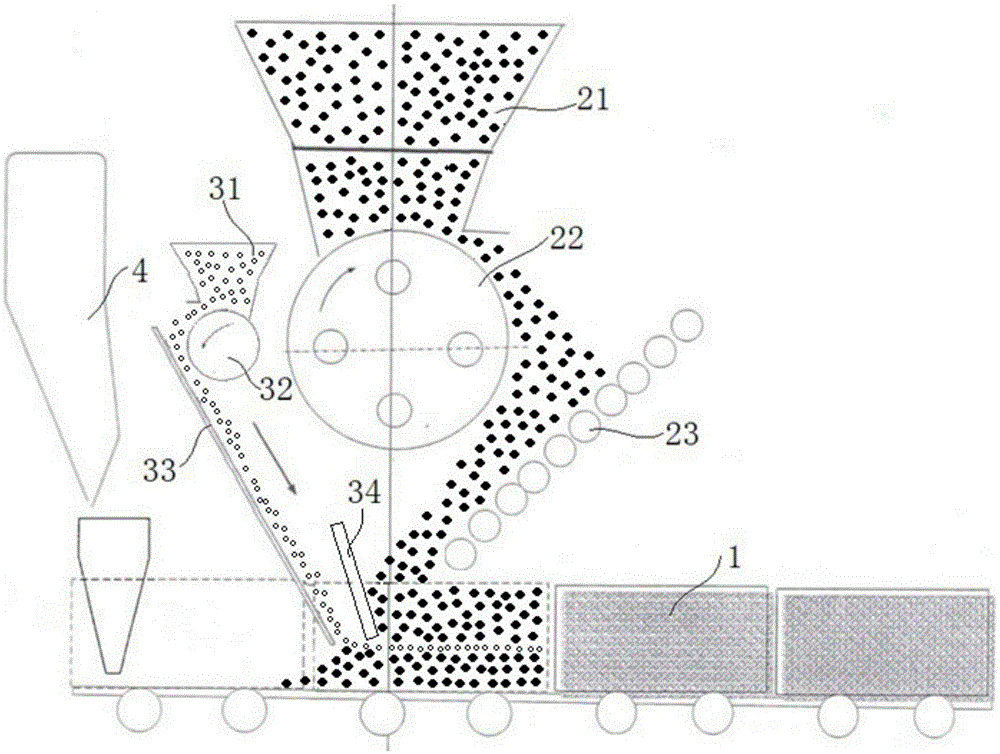

[0028] Such as figure 1As shown, an online desulfurization system for a sintering process in this embodiment includes a sintering trolley 1, a desulfurizing agent adding device, a mixture distributing device and a bed material distributing device 4, and the desulfurizing agent adding device is located in the mixture distributing device Between the bottom material distributing device 4, the mixture distributing device includes a mixture mine tank 21, a mixture feeder 22 and a mixture distributor 23.

[0029] The desulfurizing agent adding device in this embodiment comprises a desulfurizing agent silo 31, a desulfurizing agent feeder 32 and a desulfurizing agent material guiding mechanism 33, and the outlet of the desulfurizing agent silo 31 and the feed of the desulfurizing agent feeder 32 The outlet of the desulfurizing agent feeder 32 is connected to the feeding end of the desulfurizing agent material guiding mechanism 33, and the discharging end of the desulfurizing agent ma...

Embodiment 2

[0083] The online desulfurization system of a sintering process of this embodiment has the same basic structure as that of Embodiment 1, the difference is that it also includes a stopper mechanism 34, and the stopper mechanism 34 is located at the flow output of the discharge end of the desulfurizer material guide mechanism 33 Specifically, in this embodiment, the material blocking mechanism 34 is a material blocking plate, which is located at the output of the material flow at the discharge end of the desulfurizing agent material guide mechanism 33, and is used to block the mixture, so that it can further ensure that the desulfurizing agent reaches When the discharge end of the desulfurizer material guide mechanism 33 has reached the specified height, the specified height can be adjusted by the tilt angle adjustment mechanism. In this embodiment, a height position adjustment mechanism is installed on the baffle plate to facilitate It can be adjusted with the change of the incl...

Embodiment 3

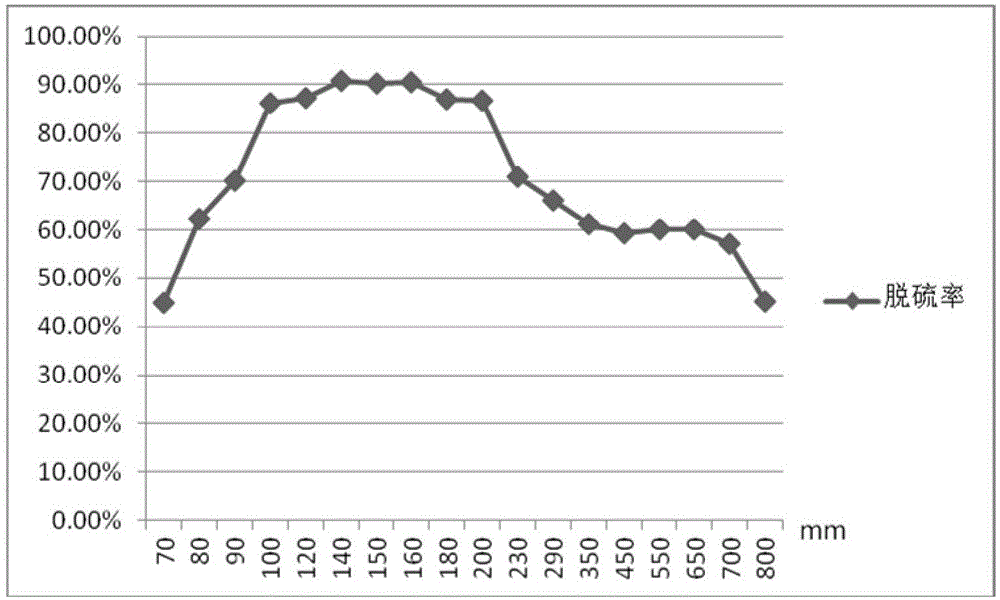

[0086] An online desulfurization system in the sintering process of this embodiment has the same basic structure as that of Embodiment 2, except that the acute angle formed by the stopper mechanism 34 and the vertical direction is 10 degrees. The basic process of the on-line desulfurization method is the same as in Example 1, except that the total height of the sintered material layer is 800 mm, the distance H between the desulfurizing agent layer 7 and the bottom of the sintering trolley 1 is 120 mm, and the quality of the desulfurizing agent layer 7 is the mixture Layer 6 contained the same mass of sulfur. After the test, the technical indicators of the sintered ore were detected, and the indicators were basically the same as those in Example 1, indicating that the technical indicators of the sintered ore were almost not affected, and the desulfurization rate was 87.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com