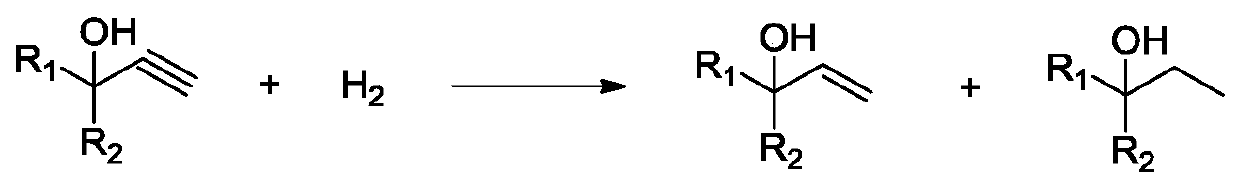

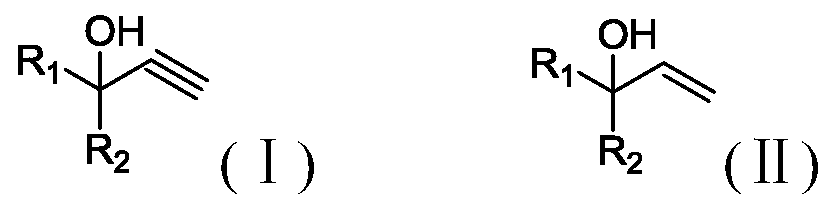

Catalyst for preparing enol from alkynol through partial hydrogenation, preparation method of the catalyst, and method for preparing enol by using the catalyst

A hydrogenation catalyst and catalyst technology are applied in hydrogenation preparation, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., and can solve the problems of affecting product odor, increasing equipment investment, and difficulty in separation, etc. The quality and odor achieved are not affected, the effect is long-lasting, and the product selectivity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First, 100 g of ethanol, 1.0 g of 5% Pd-5% Pb palladium-calcium carbonate catalyst, and 0.5 g of 1 wt % zinc acetate aqueous solution were added to the autoclave, and the autoclave was sealed and replaced with nitrogen 6 times. Use synthesis gas containing carbon monoxide and hydrogen with a volume ratio of 1:1 to replace 6 times, turn on the stirring paddle, keep the pressure of synthesis gas (absolute pressure) 0.2MPa, and keep the inner temperature of the reactor at 30°C for 12 hours. Stop stirring and vent gas. A catalyst for the partial hydrogenation of acetylenic alcohols to enols is obtained after filtration.

[0051] First, add 294.5 g of dehydroisophytol, 2.0 g of a catalyst for enol preparation by partial hydrogenation of acetylenic alcohols, and 250 g of ethanol to the autoclave, seal the autoclave, replace 6 times with nitrogen, and then replace 6 times with hydrogen, and turn on the stirring paddle. Keep the hydrogen pressure at 2.0 MPa (gauge pressure), k...

Embodiment 2

[0053] First, 100 g of n-hexane, 1.0 g of 5% Pd-5% Pb palladium-calcium carbonate catalyst, 0.5 g of 0.5 wt % triiron dodecacarbonyl ethanol solution were added to the autoclave, and the autoclave was sealed and replaced with nitrogen 6 times. Use synthesis gas containing carbon monoxide and hydrogen with a volume ratio of 1:1 to replace 6 times, turn on the stirring paddle, keep the pressure of synthesis gas (absolute pressure) at 1.0 MPa, and keep the inner temperature of the reactor at 30°C for 12 hours. Stop stirring and vent gas. A catalyst for the partial hydrogenation of acetylenic alcohols to enols is obtained after filtration.

[0054] First, add 184.3 g of dehydrolinalool, 1.0 g of a catalyst for preparing enol by partial hydrogenation of acetylenic alcohol, and 500 g of n-hexane into the autoclave, seal the autoclave, replace 6 times with nitrogen, and then replace 6 times with hydrogen, and turn on the stirring paddle , keep the hydrogen pressure at 1.0MPa (gauge ...

Embodiment 3

[0056] First, 100 g of ethanol, 1.0 g of 5% Pd-0% Pb palladium-calcium carbonate catalyst, and 1.74 g of 1 wt % ferrous acetate aqueous solution were added to the autoclave, and the autoclave was sealed and replaced with nitrogen 6 times. Use synthesis gas containing carbon monoxide and hydrogen with a volume ratio of 6:4 to replace 6 times, turn on the stirring paddle, keep the pressure of synthesis gas (absolute pressure) 0.5MPa, and keep the inner temperature of the reactor at 30°C for 8 hours. Stop stirring and vent gas. A catalyst for the partial hydrogenation of acetylenic alcohols to enols is obtained after filtration.

[0057] First, add 154.1 g of dihydrodehydrolinalool, 3.0 g of a catalyst for preparing enol by partial hydrogenation of acetylenic alcohol, and 450 g of ethanol into the autoclave, seal the autoclave, replace 6 times with nitrogen, and then replace 6 times with hydrogen, and start stirring paddle, keep the hydrogen pressure at 2.0 MPa (gauge pressure),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com