Preparation method of benzaldehyde from cinnamaldehyde by continuous catalytic ozone oxidation

A technology of ozonation and cinnamaldehyde, applied in the field of continuous catalytic ozone oxidation of cinnamaldehyde to benzaldehyde, achieving the effects of high yield, high ozone utilization rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of continuous catalytic ozone oxidation cinnamaldehyde is the preparation method of benzaldehyde

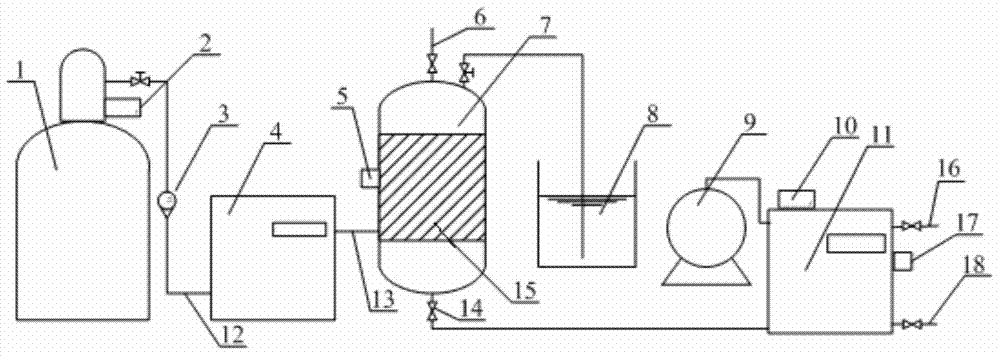

[0030] Taking cinnamaldehyde as raw material, the mixed solution of loading 50g cinnamaldehyde and dehydrated alcohol is in the continuous ozonation reactor (attached figure 1 ), adding 0.5% MnO 2 Catalyst, at -5°C, pass 0.05g of ozone per hour per gram of cinnamaldehyde to carry out ozonation reaction, after 10 minutes of reaction, use 50g·h -1 g cat -1 Continuously feed the mixed solution of cinnamaldehyde and dehydrated alcohol, their mass ratio is cinnamaldehyde: dehydrated alcohol=1:2, continuous reaction obtains liquid phase product, and liquid phase product passes through molecular distillation device, and at temperature is 10 ℃, Pressure is that distillation under 50Pa obtains the benzaldehyde 3g h that purity is more than 99wt% -1 .

Embodiment 2

[0032] A kind of continuous catalytic ozone oxidation cinnamaldehyde is the preparation method of benzaldehyde

[0033]Taking cinnamaldehyde as raw material, the mixed solution of loading 50g cinnamaldehyde and dehydrated alcohol is in the continuous ozonation reactor (attached figure 1 ), add 5.0% ZnO catalyst, at 20°C, pass 0.85g of ozone per hour per gram of cinnamaldehyde to carry out ozonation reaction, and react with 100g h -1 g cat -1 Continuously feed the mixed solution of cinnamaldehyde and dehydrated ethanol, their mass ratio is cinnamaldehyde: dehydrated alcohol=1:3), continuous reaction obtains the liquid phase product, and the liquid phase product passes through the molecular distillation device, at a temperature of 30 ℃ , the pressure is that distillation under 80Pa obtains the benzaldehyde 45g h that purity is more than 99wt% -1 .

Embodiment 3

[0035] A kind of continuous catalytic ozone oxidation cinnamaldehyde is the preparation method of benzaldehyde

[0036] Taking cinnamaldehyde as raw material, the mixed solution of loading 50g cinnamaldehyde and dehydrated alcohol is in the continuous ozonation reactor (attached figure 1 ), adding 2.5% Fe 2 o 3 Catalyst, at 10°C, pass 0.45g of ozone per hour per gram of cinnamaldehyde to carry out ozonation reaction, after 10 minutes of reaction, use 70g·h -1 g cat -1 Continuously feed the mixed solution of cinnamaldehyde and dehydrated alcohol, their mass ratio is cinnamaldehyde: dehydrated alcohol=1:6, continuous reaction obtains liquid phase product, and liquid phase product passes through molecular distillation device, and at temperature is 80 ℃, Distillation at a pressure of 150 Pa to obtain a purity of more than 99wt% benzaldehyde 6g h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com