Vacuum thermal insulation plate with mounting holes and without fear of surface damage and processing technology

A technology of vacuum heat insulation and installation holes, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of low surface puncture resistance, bulging, poor toughness, etc., achieve good heat insulation effect, low manufacturing cost, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

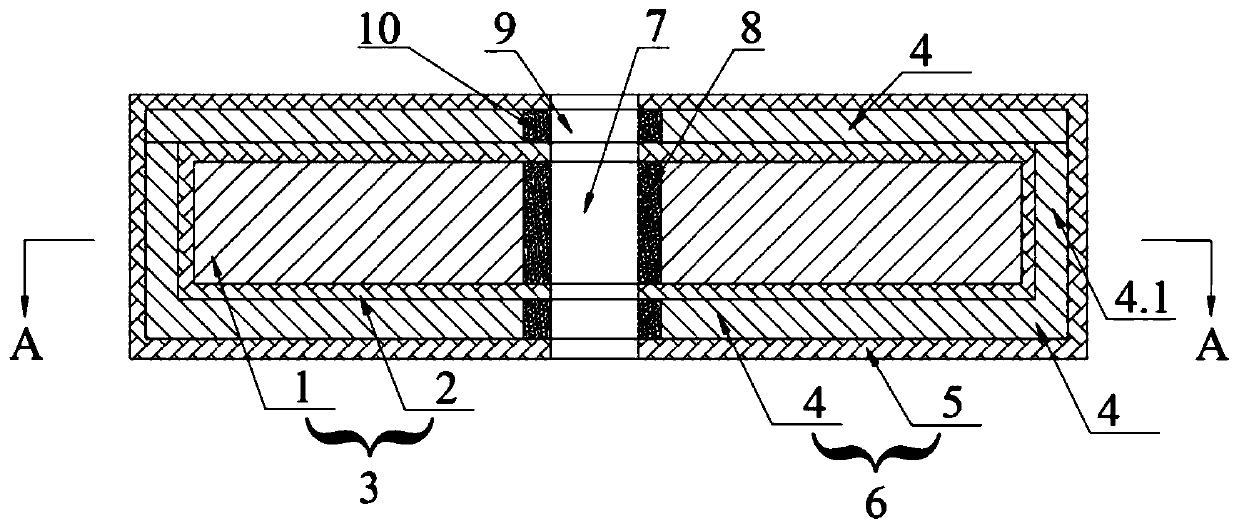

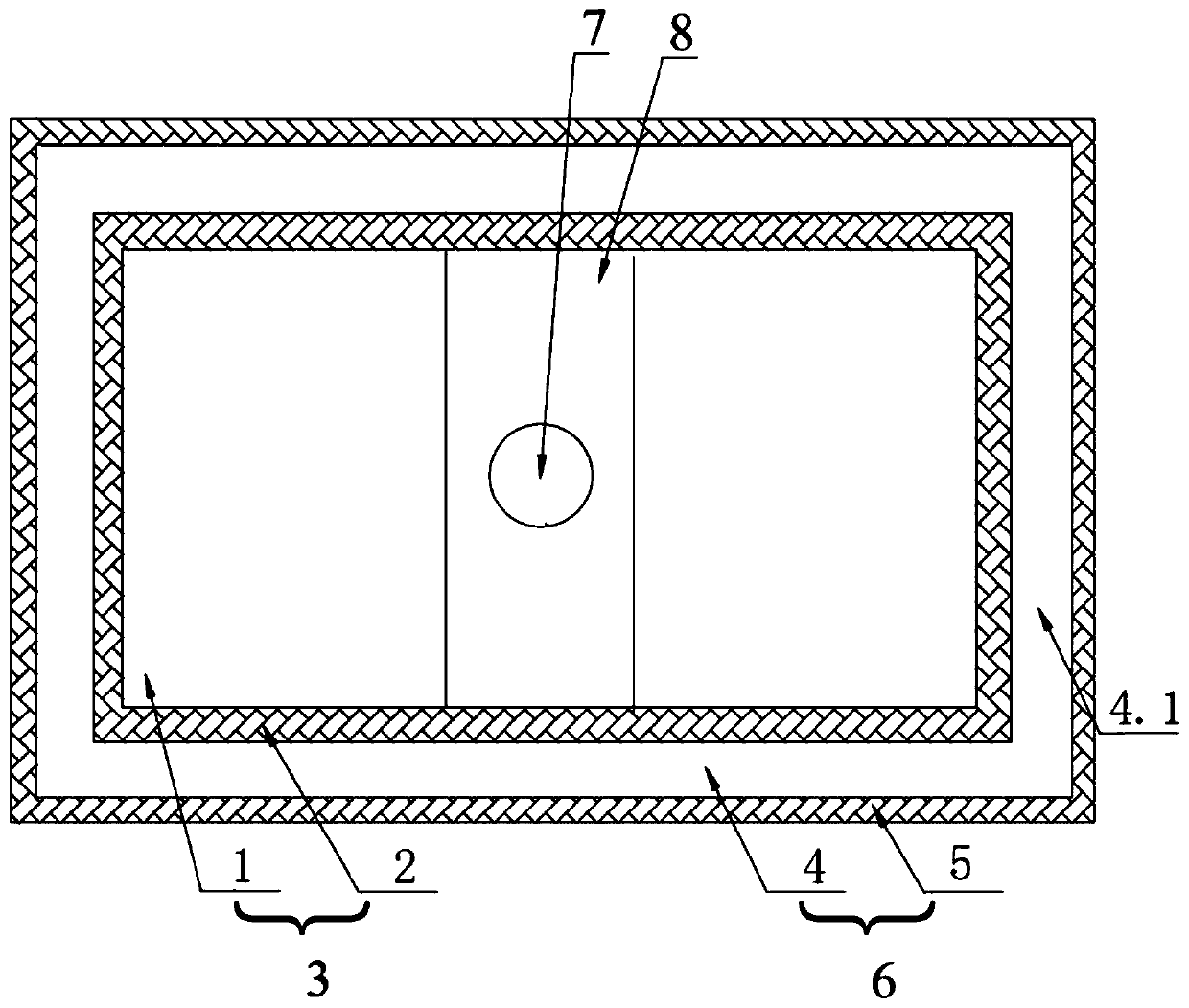

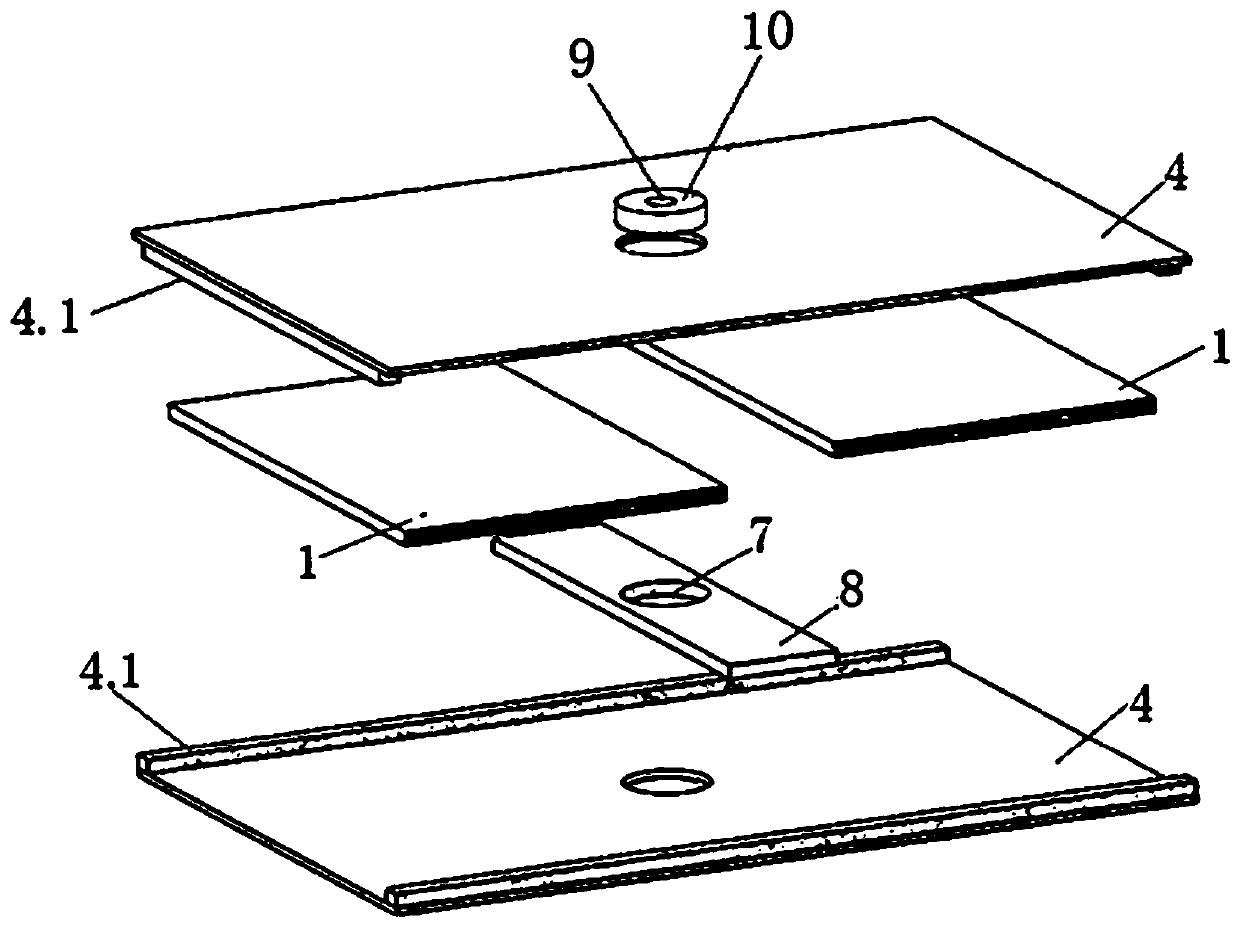

[0033] In order to achieve the above objectives, one of the technical solutions of the present invention is to design a vacuum insulation panel that has installation holes and is not afraid of surface damage. The vacuum insulation panel includes at least two layers of vacuum insulation structure, that is, the inner vacuum insulation structure layer 3 and at least one outer vacuum heat insulation structure layer 6 wrapped outside the inner vacuum heat insulation structure layer 3, the inner vacuum heat insulation structure layer 3 includes an inner core board 1, and the inner core board 1 is provided with an installation groove for a getter material, and the installation groove is filled with There is a getter material, and an inner high-barrier air film bag 2 is set outside the inner core board 1 installed with the getter material, and the inner high-barrier air film bag 2 equipped with the inner core board 1 is evacuated and heat-sealed by high-vacuum equipment The inner vacuu...

Embodiment 2

[0041] On the basis of Example 1, a vacuum insulation panel with installation holes and not afraid of surface damage, the difference from Example 1 is that the solid adhesive in the inner core panel 1 is hot-melt adhesive, pressure-sensitive adhesive, Mixing in cassava flour, the solid viscose accounts for 10% by weight of the inner core board 5, and the mica powder accounts for 10% by weight of the inner core board. 1. The ratio of the total thickness of the airgel layer and the filling layer in the natural state to the thickness of the core material after thermoforming is 4:1.

[0042] The raw material components of the wrapped outer core panel 4 include medium-alkali glass fiber chopped strands with a diameter of 4 μm, mineral wool with a fiber diameter of 8 μm, fumed silica, aerogel, solid viscose and mica powder. Use the wet method to mix evenly with water, form a net, roll, filter out water, and heat-press to form an outer core plate, and the outer core plate 4 is then d...

Embodiment 3

[0046] On the basis of Example 1, a vacuum insulation panel with installation holes and not afraid of surface damage, the difference from Example 1 is that the solid adhesive in the inner core panel 1 is hot-melt adhesive, pressure-sensitive adhesive, Mixing in cassava flour, solid viscose accounted for 12% by weight of the inner core board 3, mica powder accounted for 10% by weight of the inner core board, the glass fiber filaments, fumed silica, nano-microporous materials 1. The ratio of the total thickness of the airgel layer and the filling layer in the natural state to the thickness of the core material after thermoforming is 5:1.

[0047] The raw material components of the wrapped outer core panel 4 include medium-alkali glass fiber chopped strands with a diameter of 9 μm, mineral wool with a fiber diameter of 12 μm, fumed silica, aerogel, solid viscose and mica powder. Use the wet method to mix evenly with water, form a net, roll, filter out water, and heat-press to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com