Patents

Literature

34results about How to "Low cost of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

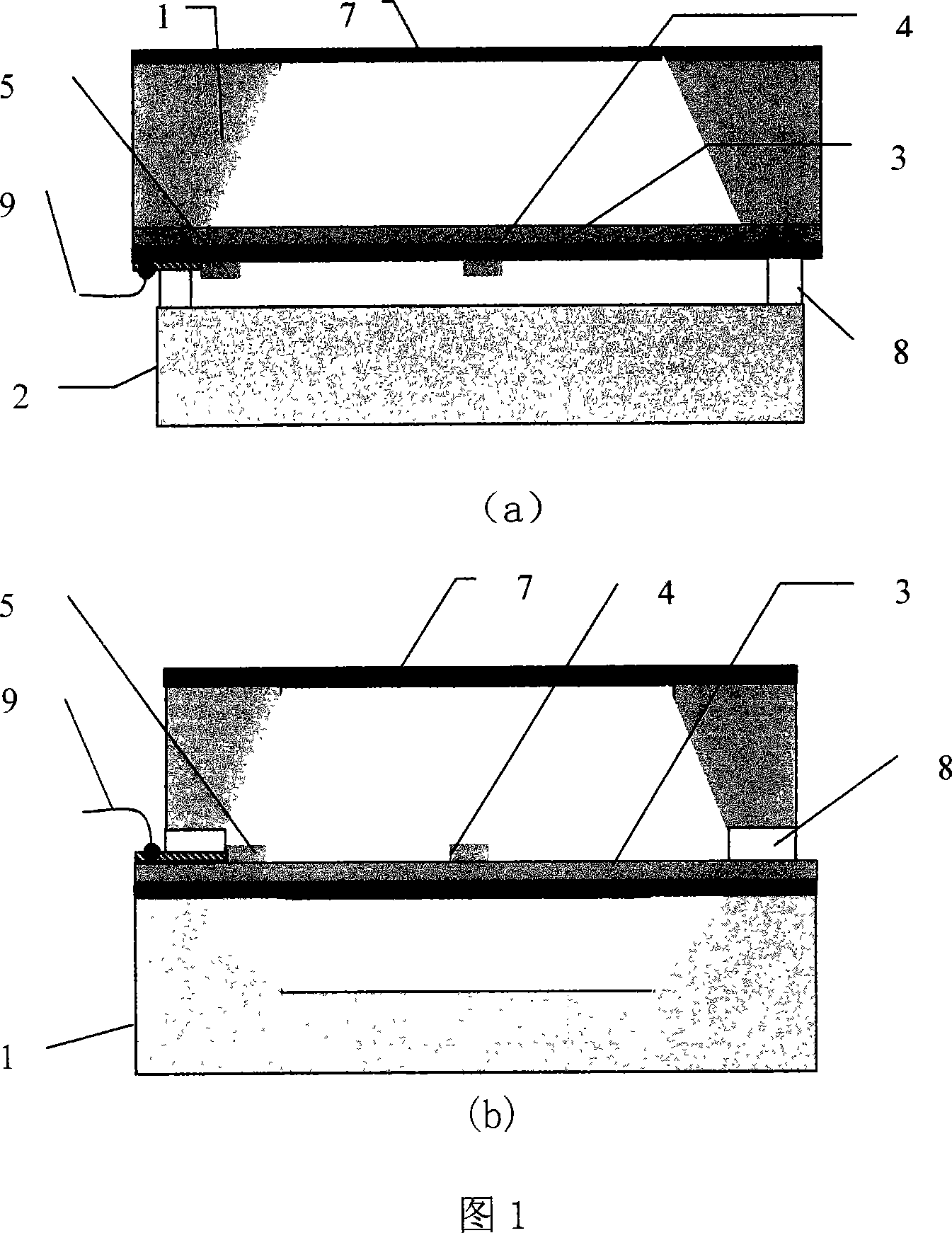

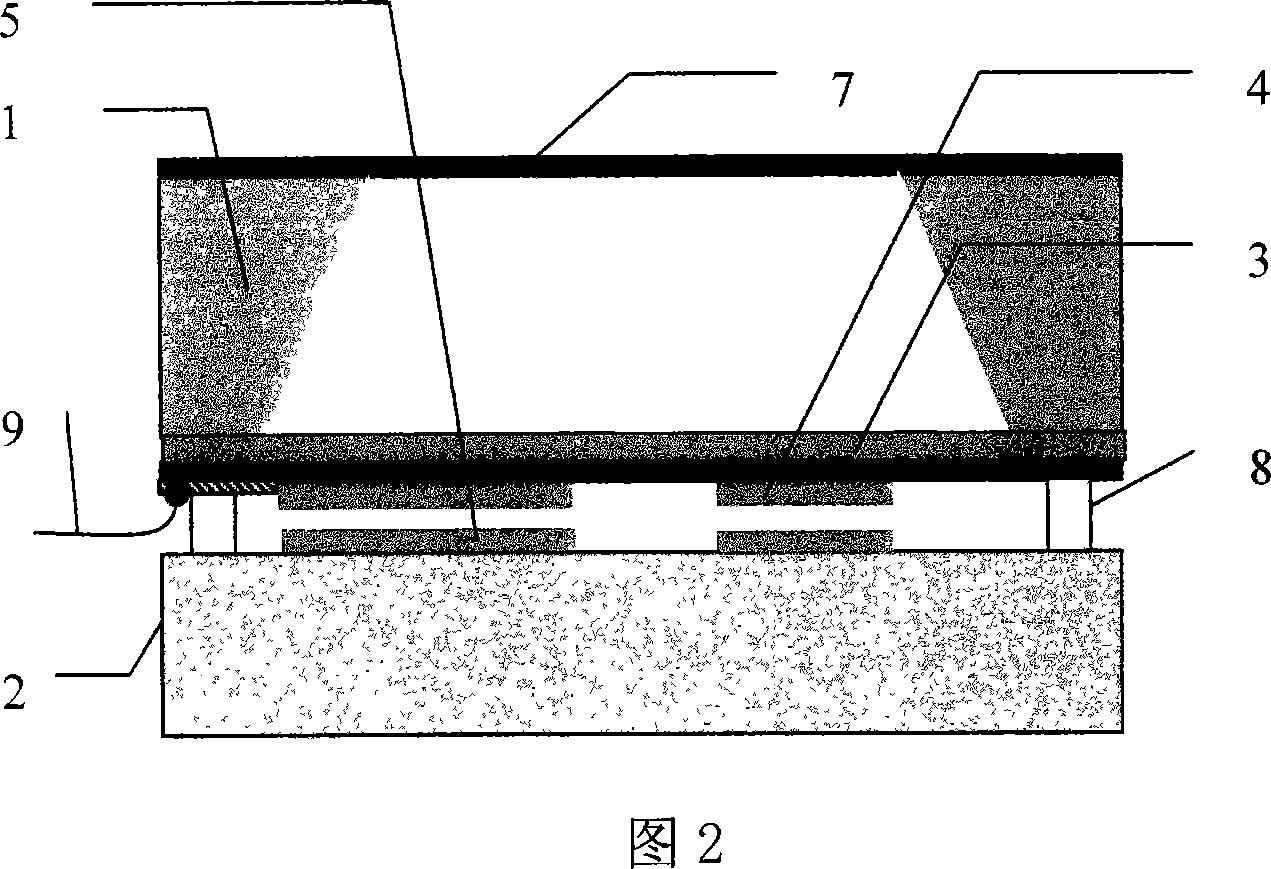

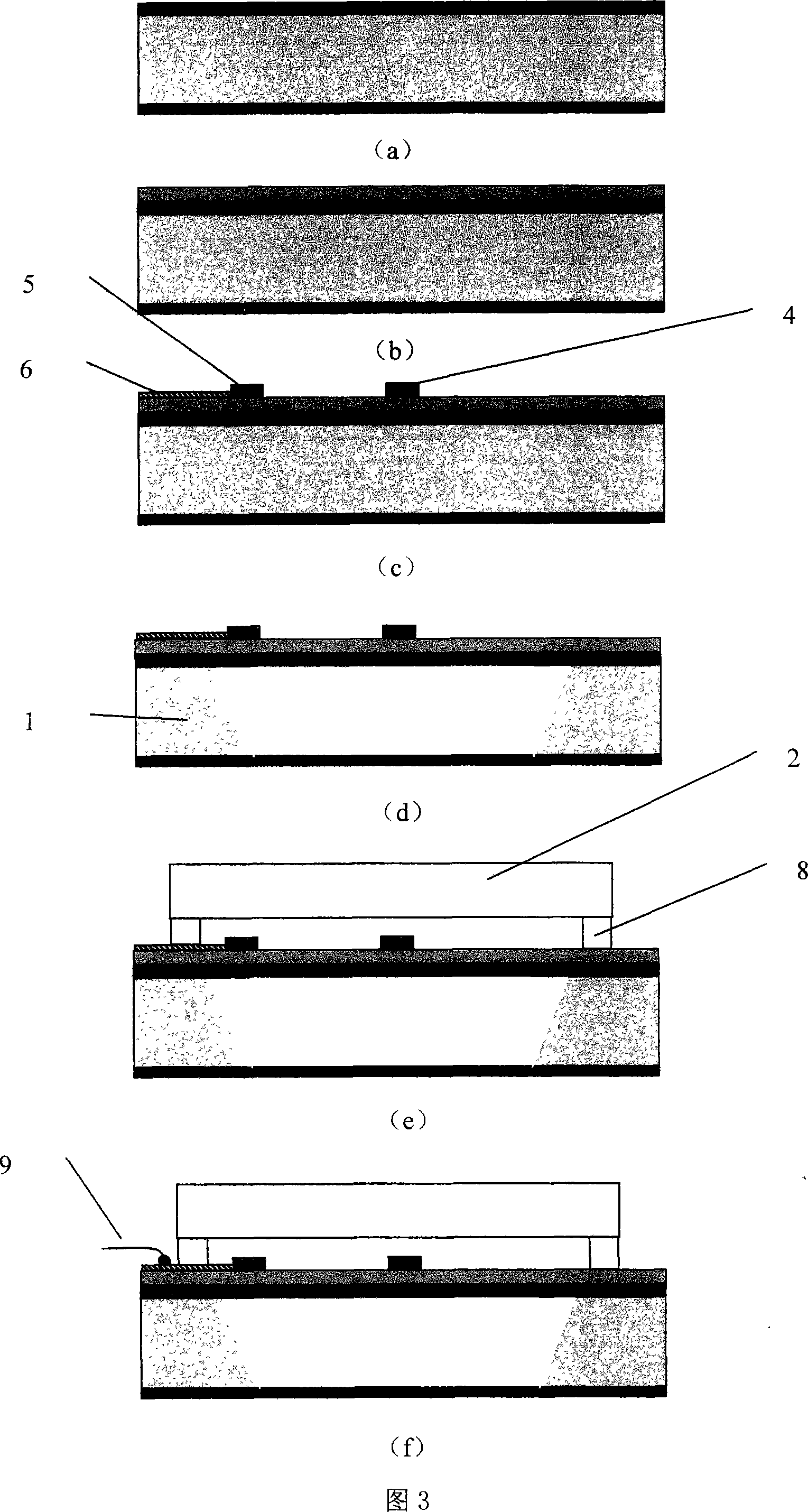

Infrared detector structure based on micro-bridge resonator and manufacturing method

InactiveCN101063630AImprove the detection rateImprove response ratePyrometry using electric radation detectorsHigh volume manufacturingImage resolution

This invention discloses one infrared detector structure and process method based on micro mechanic bridge resonance device, wherein the detector is composed of bridge resonance chip and cover board through vacuum sealing technique or gas sealing technique; the incidence infrared line is to micro mechanic bridge surface through infrared incidence window to lead the bridge temperature rise and to add axis stress force and to lower resonance frequency to reflect incidence infrared strength.

Owner:CHINA JILIANG UNIV

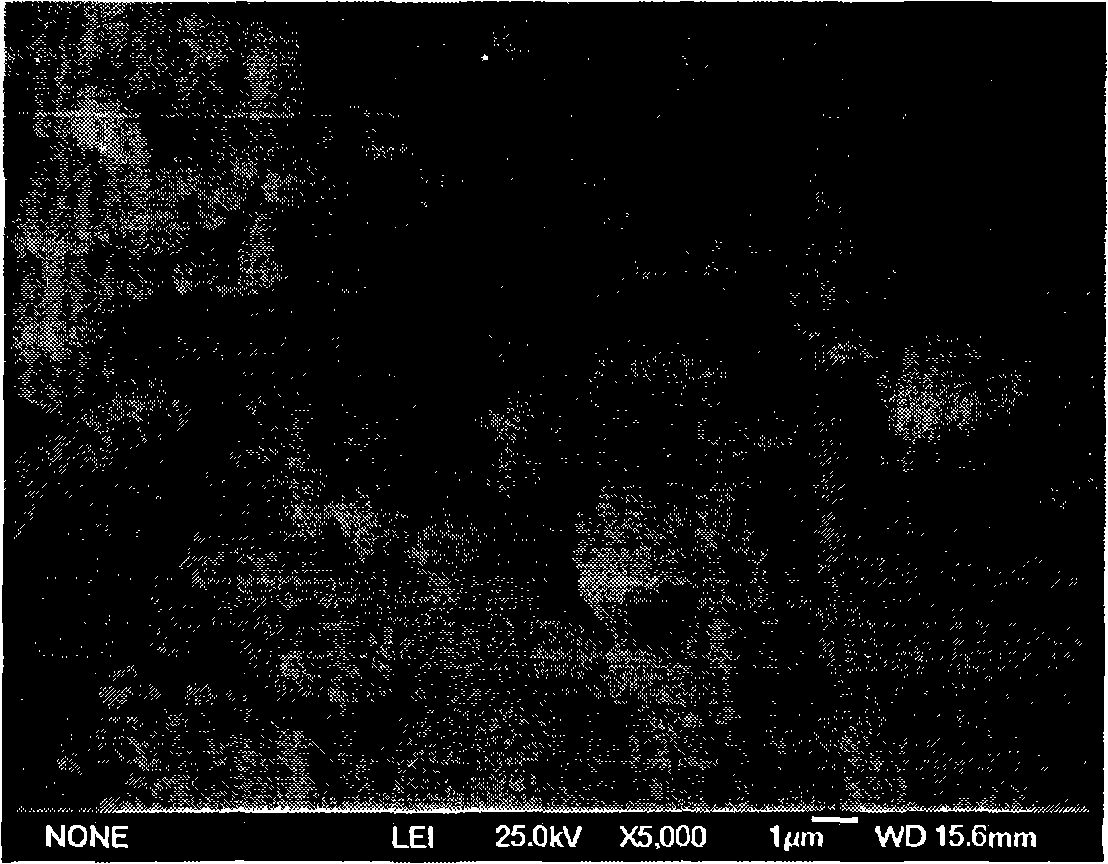

Al alloy material for preparing hydrogen with water at room temperature and method of use thereof

InactiveCN101358309AMaintain stabilityConvenient storage and transportationHydrogen productionHydrogenRoom temperature

The invention discloses an Al alloy material which reacts with water at room temperature to prepare hydrogen, and a use method thereof; the Al content in the alloy material is 3 weight percent to 95 weight percent, and the rest are one type or more than one type among Sn, Zn, Bi, Pb, Mg, Ca and In elements; when Ca and In are contained, the content of Ca and In is not more than 10 weight percent; the alloy material is prepared by melting alloy and then mechanically processing alloy cast ingots into foil-like or sheet-like materials; the material is taken as the raw material for preparing hydrogen, improves the hydrogen preparation capability when the cost is quite low, can prepare hydrogen on a large scale, and is easy to be stored and transported.

Owner:ZHENGZHOU UNIV

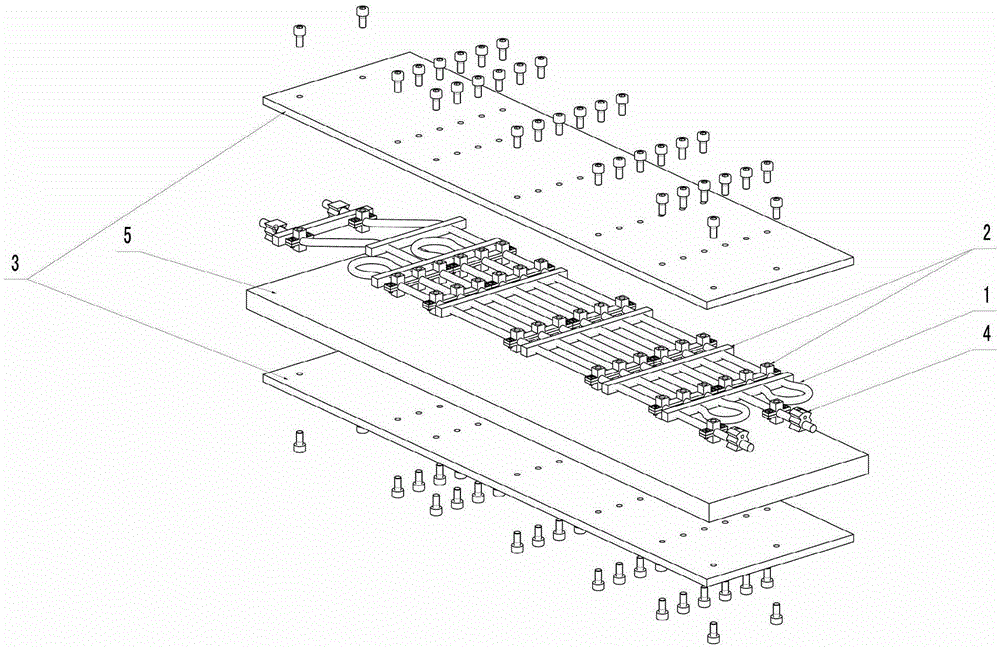

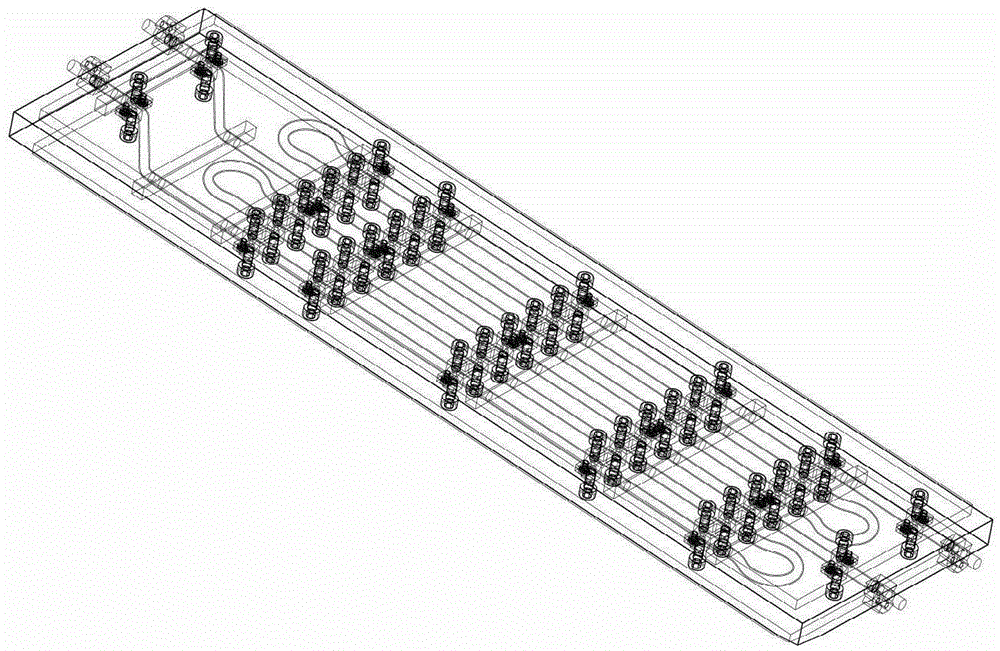

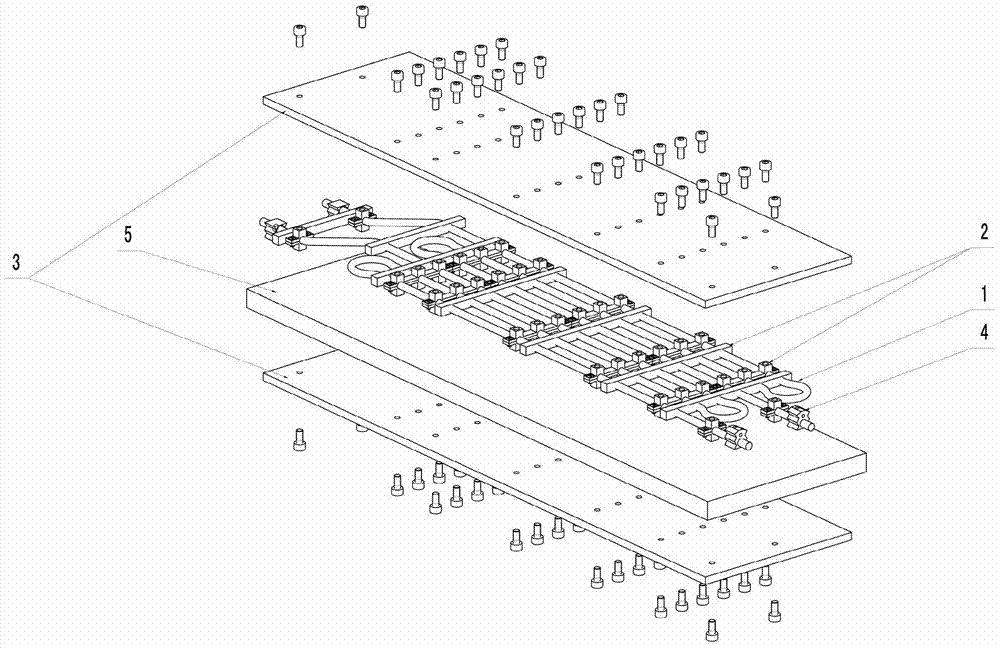

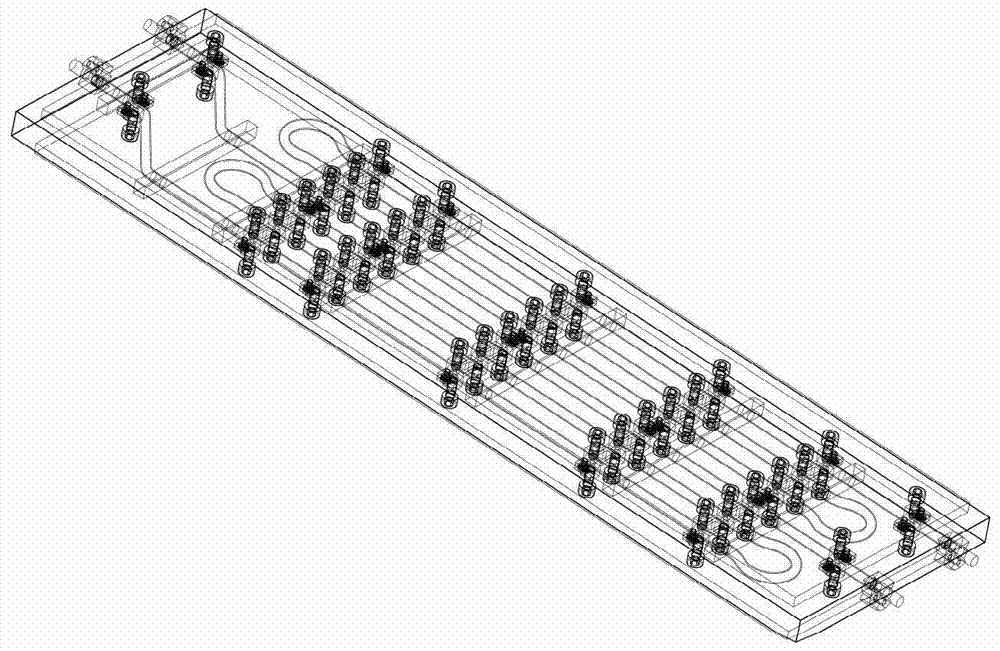

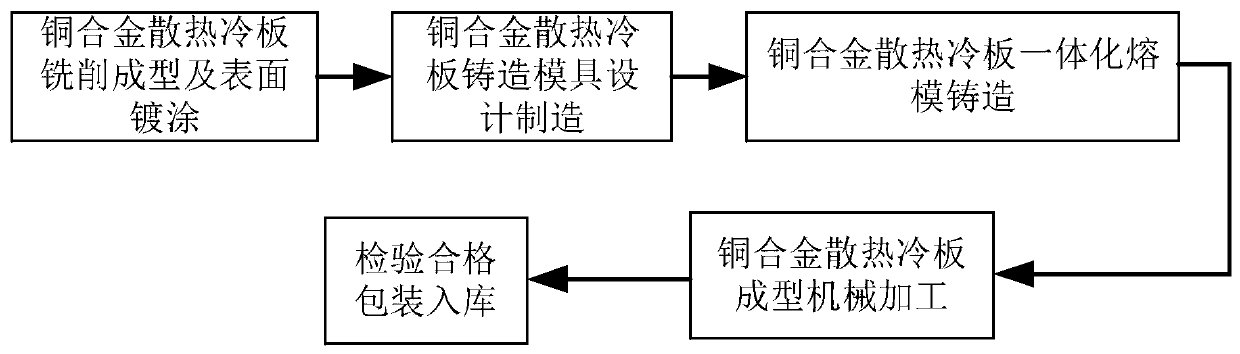

Preparing method for corrosion-resistant liquid cooling heat dissipation cold plate

ActiveCN105268918AEnsure coplanarityLittle structural requirementsFoundry mouldsFoundry coresWeld seamEngineering

The invention discloses a preparing method for a corrosion-resistant liquid cooling heat dissipation cold plate and aims at providing a cold plate preparing method which is free of tedious treatment before welding and has prominent corrosion-resistant capability and long-term work reliability. According to the technical scheme, the two sides of a bottom transverse pipe commonly communicated serve as the starting points respectively, two sets of parallel pipes are longitudinally arranged continuously in a bent manner, and the bending radius of bent circular arc rings on the two longitudinal sides is larger than the distance between every two parallel pipelines; the free ends of each set of parallel pipes are fixedly connected through respective connector flanges; and the two sets of parallel pipes are fixed, clamped and positioned through pipeline clamping tools which are longitudinally arranged at intervals, die positioning plates with screw holes are adopted, wax patterns wrapping runner titanium pipes and connector flange assemblies are clamped between the two die positioning plates, and the runner titanium pipes and the connector flange assemblies are put into a smelting furnace, and a rectangular flat plate is formed through lost foam casting. The preparing method solves the problem that during traditional cold plate welding, a welding seam is prone to cracking, and consequently a cooling agent leaks.

Owner:10TH RES INST OF CETC

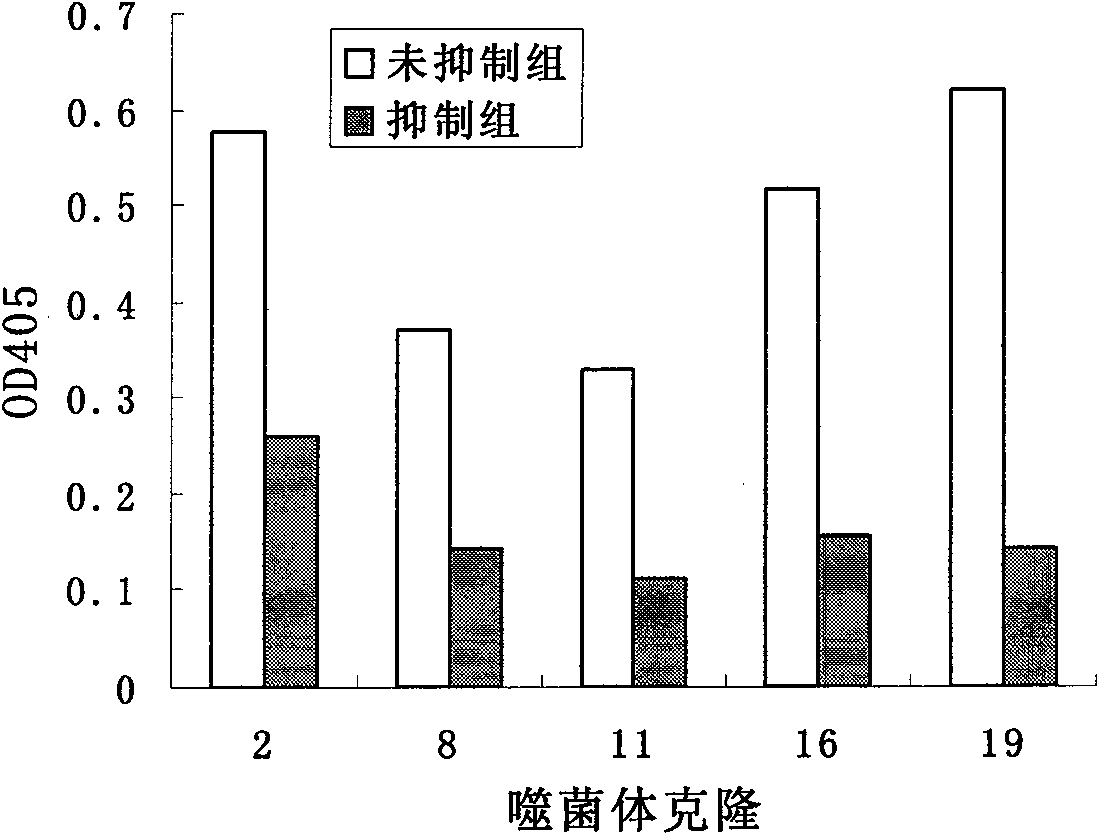

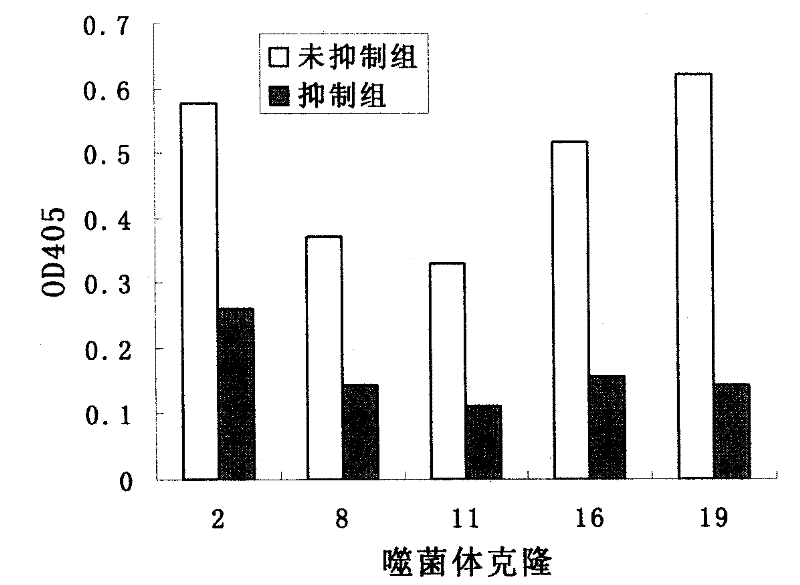

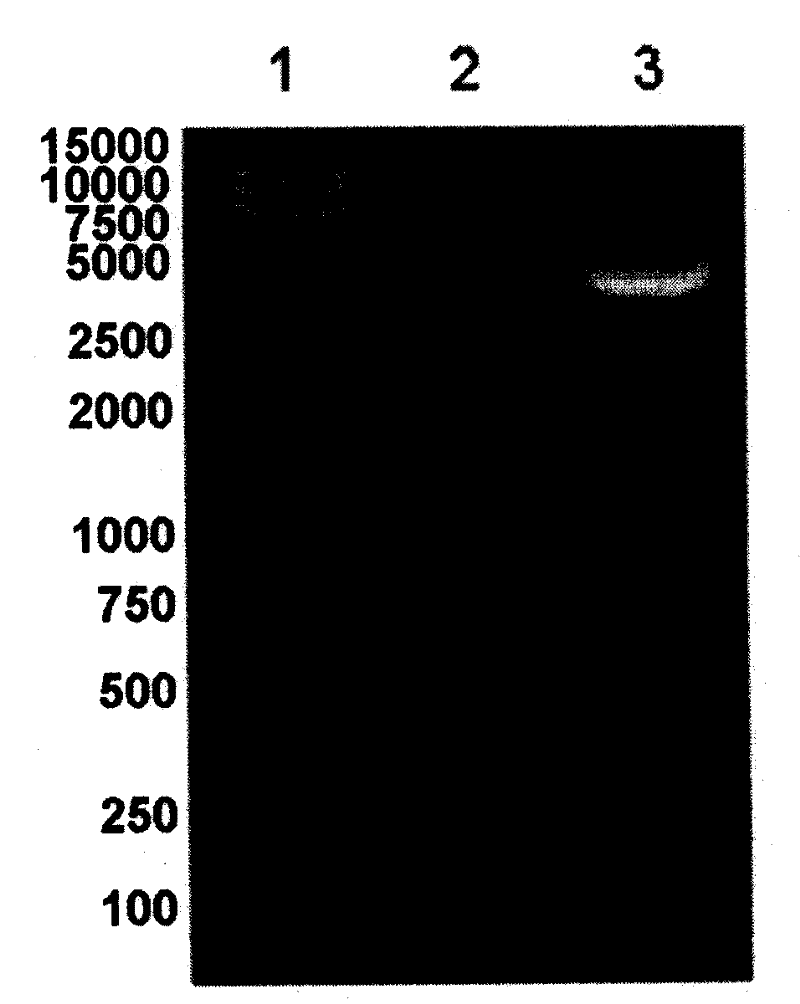

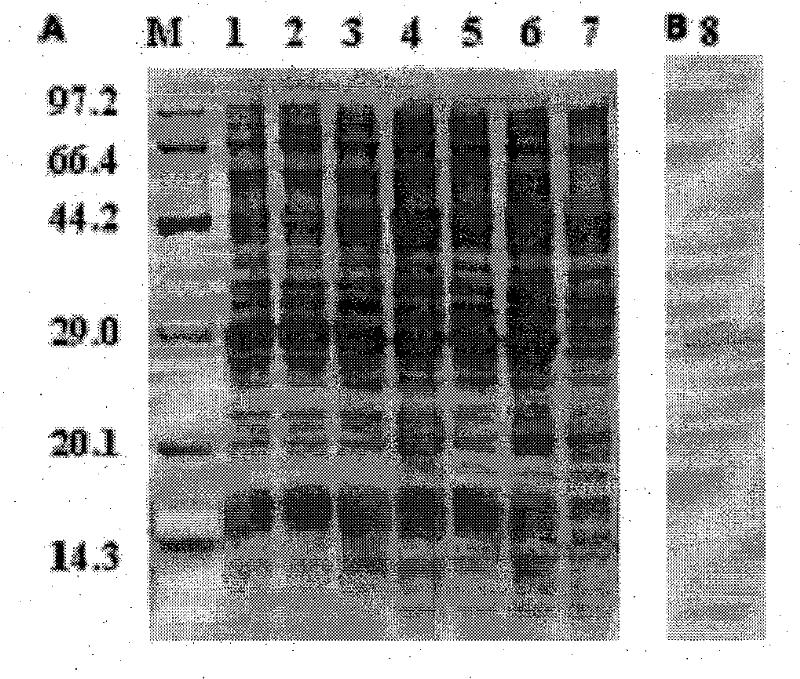

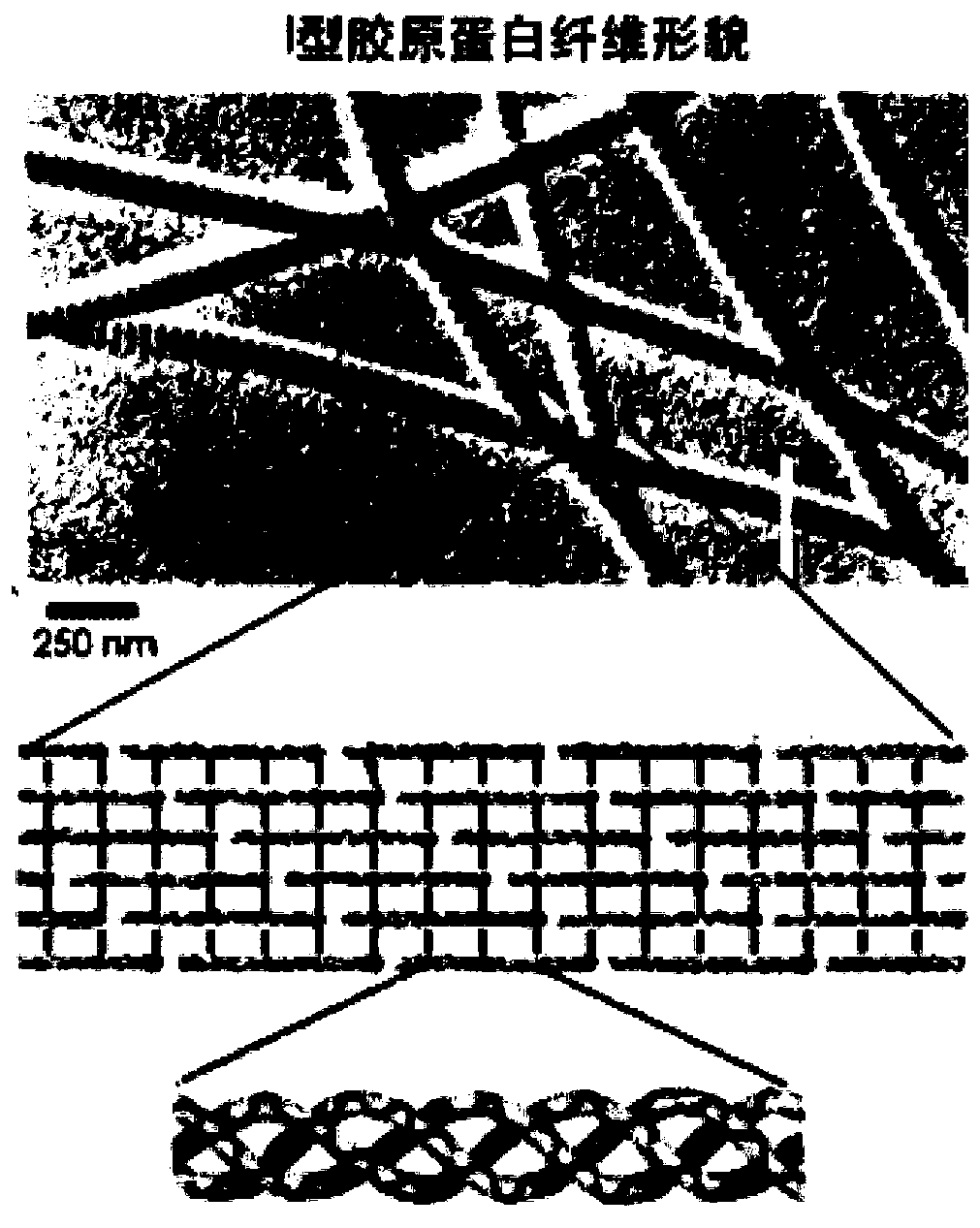

O-type foot and mouth disease virus antigen epitope molecular mimic peptide and application thereof

InactiveCN101597327AAntigenicNon-toxicAntiviralsPeptidesVirulent characteristicsMolecular Immunology

The invention relates to the molecular immunology field. Although the existing foot-and-mouth disease weak poison vaccines and inactivated vaccines and other routine vaccines have good immunogenicity, but the vaccines have some unsafe factors such as reversion of virulence, incomplete virus blanching, the escape of live-virus from a preparation factory and the like so that people are motivated to find a more safe and effective FMD vaccine. In the molecular mimic peptide invention, phage display techniques are used to sieve effective FMDV epitopes to provide an O-type foot and mouth disease virus antigen epitope molecular mimic peptide and the invention also provides an application thereof in preparing immunogen and swine foot-and-mouth disease epitope peptide vaccine. The FMDV epitope peptide vaccine using the molecular mimic peptide of the invention has the antigenicity of target molecule without toxicity, is very safe and has low mass production cost and good economic effect and social effect.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

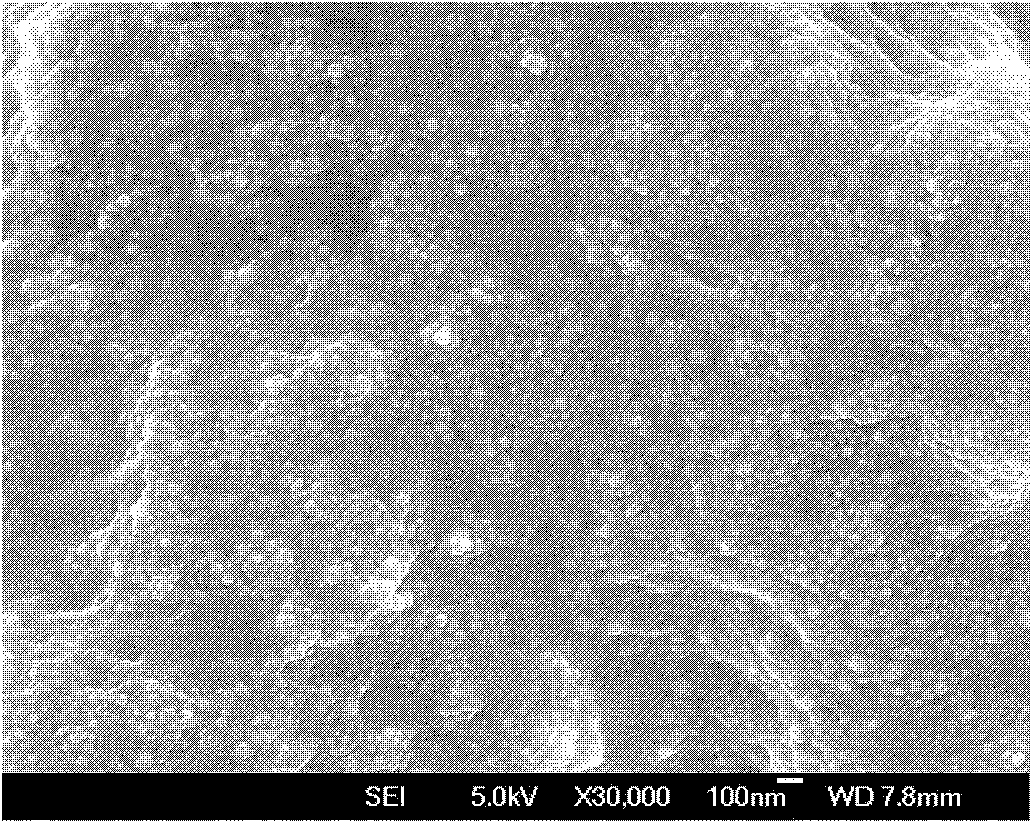

Preparation method for polypyrrole and graphene oxide based sponge structural material

The invention discloses a polypyrrole and graphene oxide based sponge structural material and a preparation method for the same. The preparation method for the polypyrrole and graphene oxide based sponge structural material is characterized by including the steps: 1) respectively adding the graphite oxide, dye and pyrrole monomers into deionized water so as to obtain solution A; 2) adding 15-30mL aqueous solution containing oxidant into the 10-20mL solution A with stirring for 2-5 minutes, and then allowing the stirred solution to stand for 24-36 hours at the temperature of 0-20 DEG C, wherein the concentration of the aqueous solution containing the oxidant is 0.1-1mol / L; and 3) filtering, respectively scrubbing precipitate with methanol, diluted acid and distilled water for three times, and then subjecting the scrubbed precipitate to vacuum drying for 24 hours at the room temperature, namely, obtaining the polypyrrole and graphene oxide based sponge structural material. The preparation method is mild in reaction conditions, simple in process and low in large-scale production cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for synthesizing polypyrrole-chitosan-metal nanoparticle composite film on surface of cathode by one-step process

InactiveCN102220622AThickness is easy to controlMild reaction conditionsElectrolytic inorganic material coatingComposite filmPolypyrrole

The invention relates to a method for preparing a polypyrrole-chitosan-metal nanoparticle composite film, which comprises the following steps: 1) dissolving the chitosan in 0.01 to 1 mol / L nitric acid solution to obtain solution A, wherein the mass percentage concentration of the chitosan in the solution A is 0.5 to 5 percent; 2) adding a pyrrole monomer and a divalent metal salt into the solution A to obtain solution B, wherein the concentration of the pyrrole monomer in the solution B is 0.1 to 0.4mol / L and the concentration of the divalent metal salt in the solution B is 0.1 to 0.3 mol / L; and 3) placing the cathode into the solution B, energizing under protection of nitrogen, performing electrochemical synthesis to synthesize the composite film on the surface of the cathode by a one-step process. In the invention, the reaction conditions are mild, the process is simple, the cost of large-scale production is low, the thickness of the composite film and the component content in the composite film can be controlled, and the method has a bright application prospect in the field of film materials.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

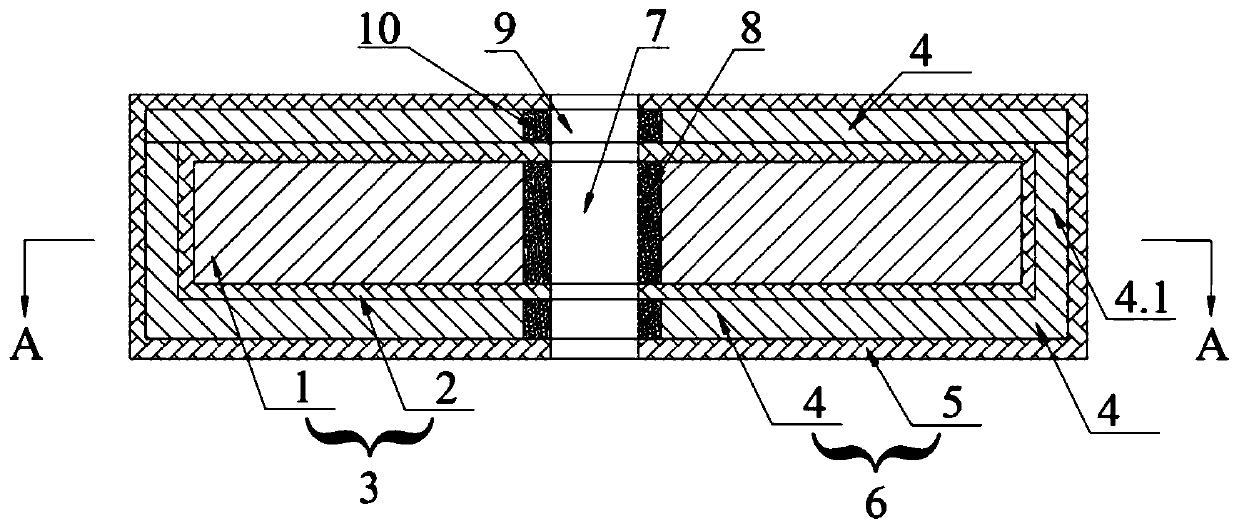

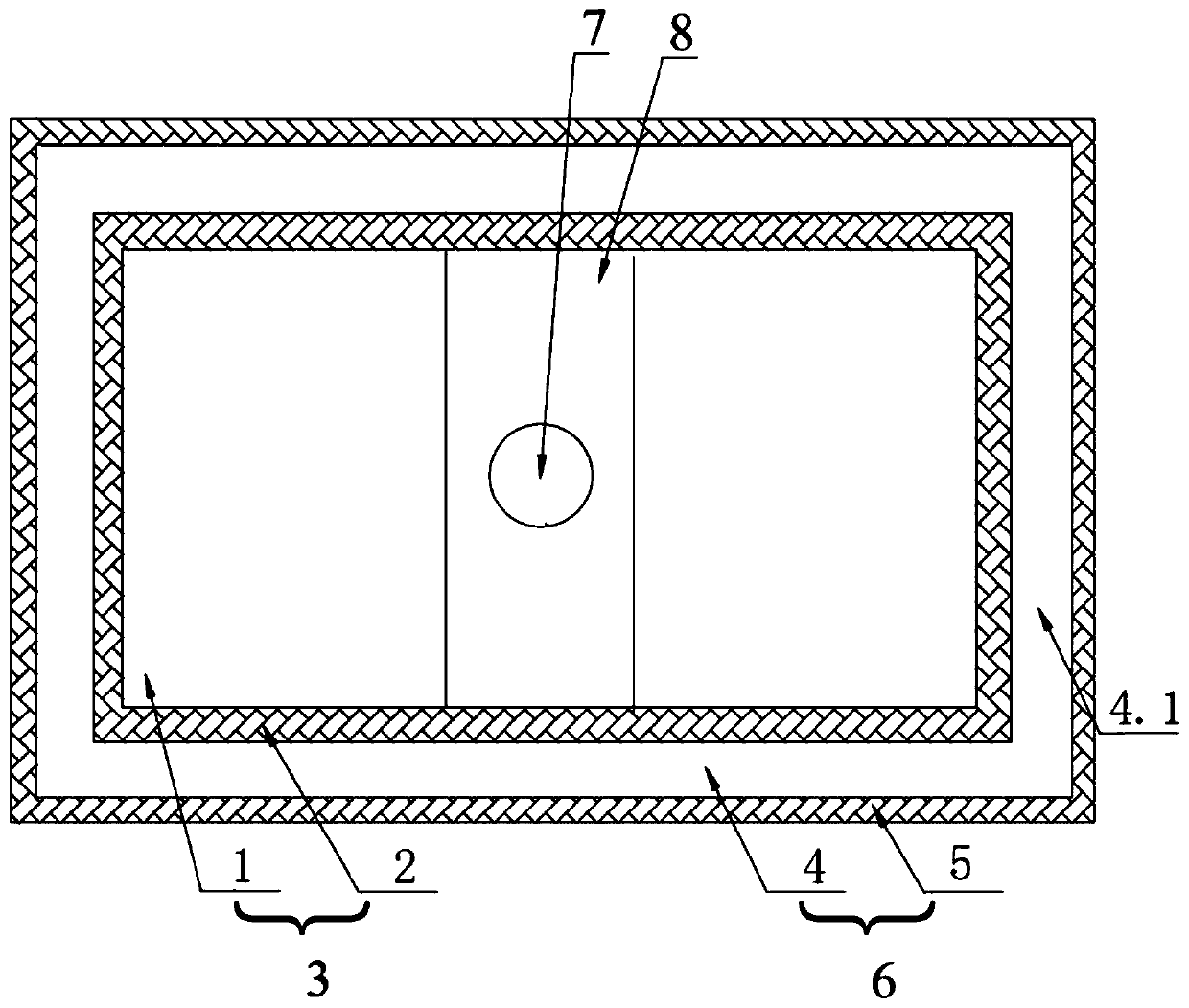

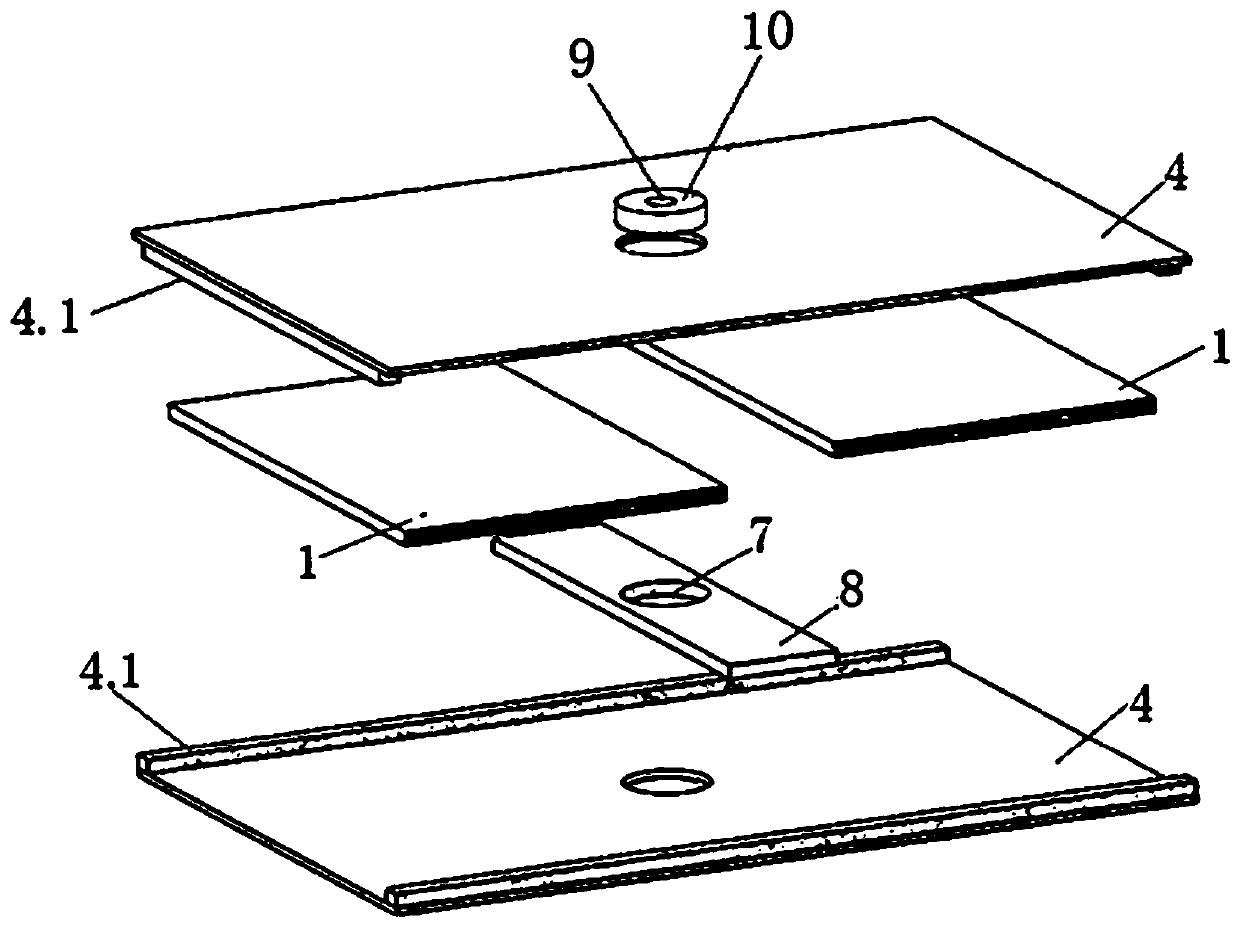

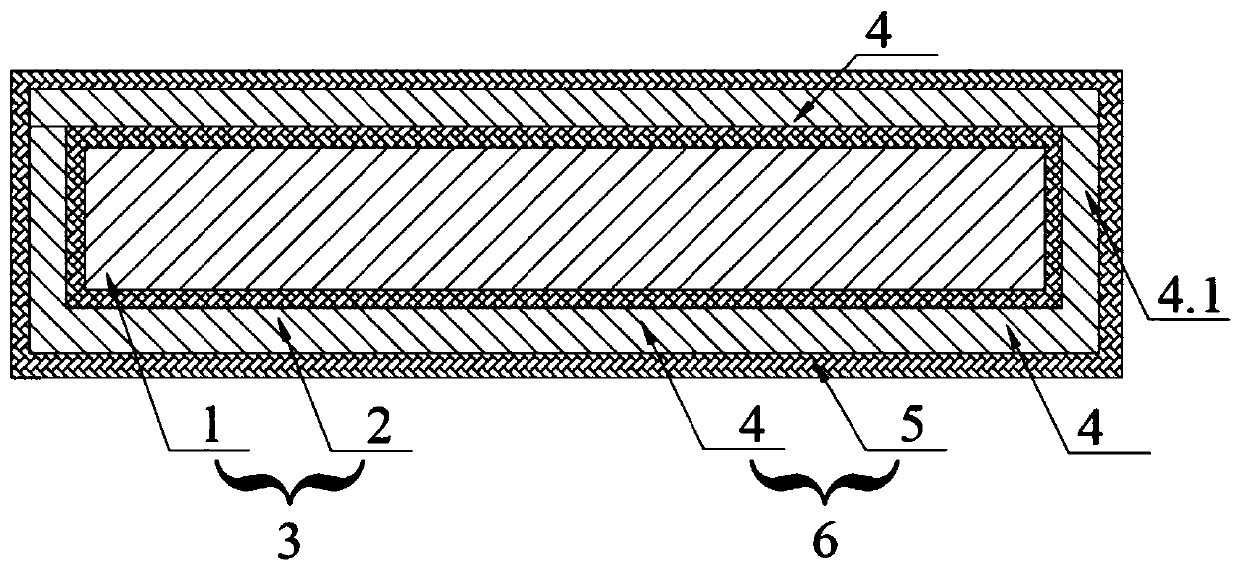

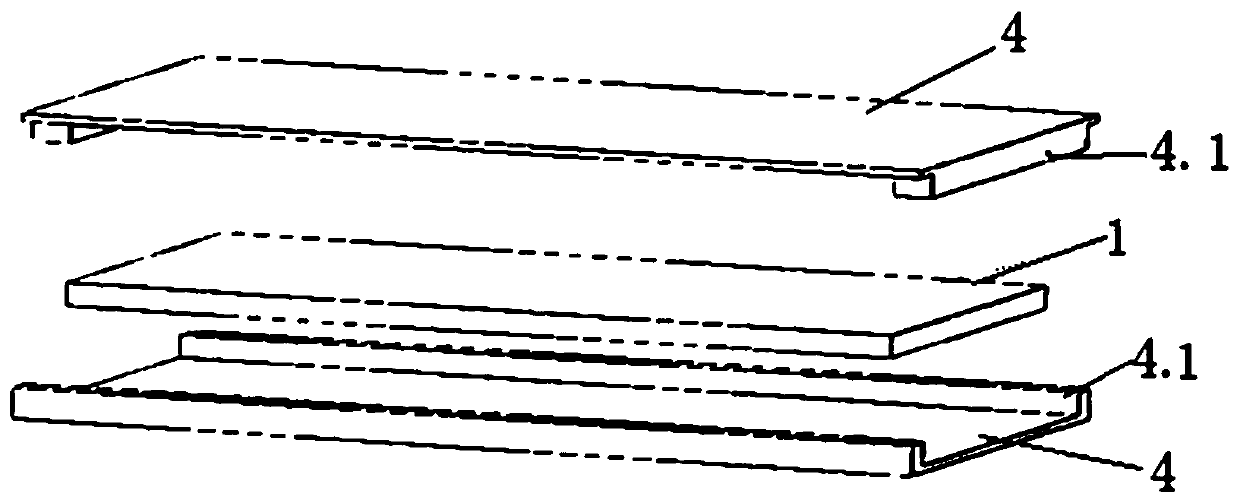

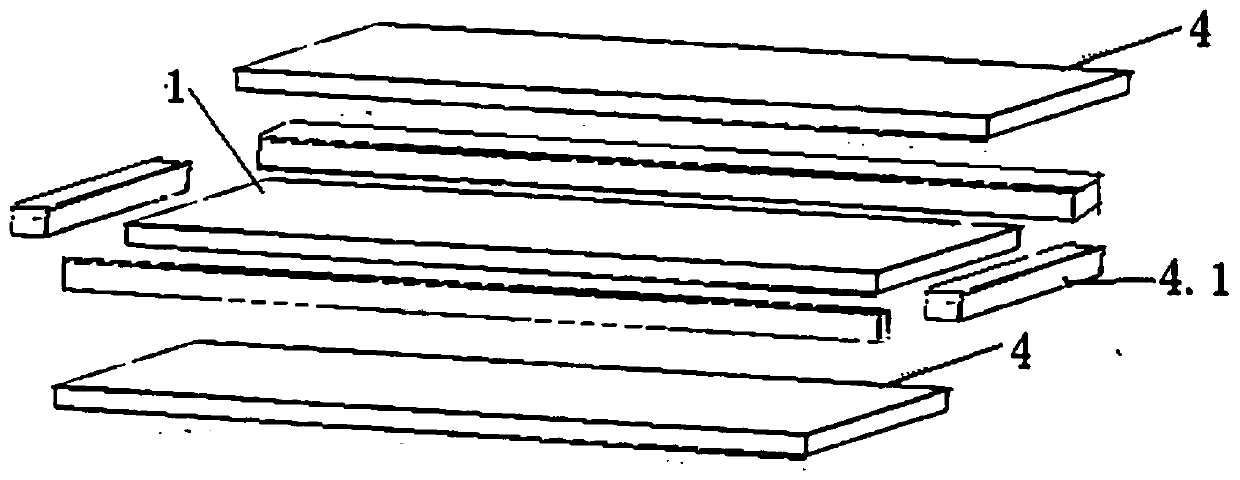

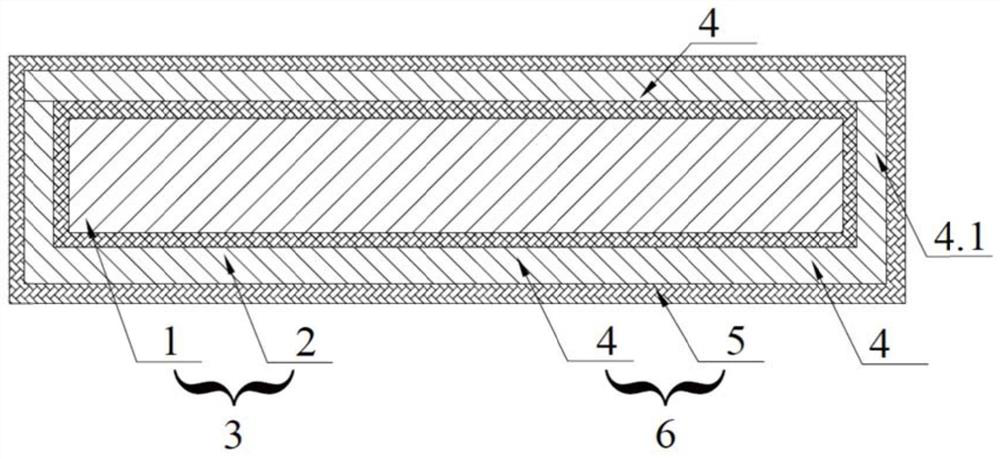

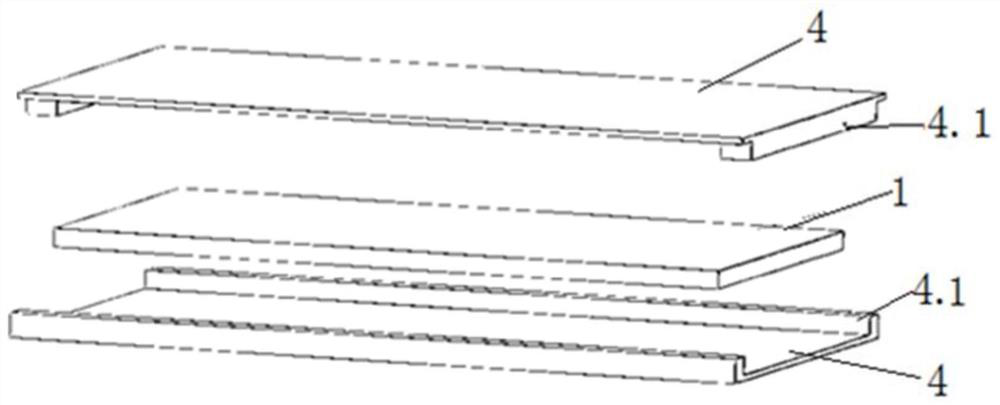

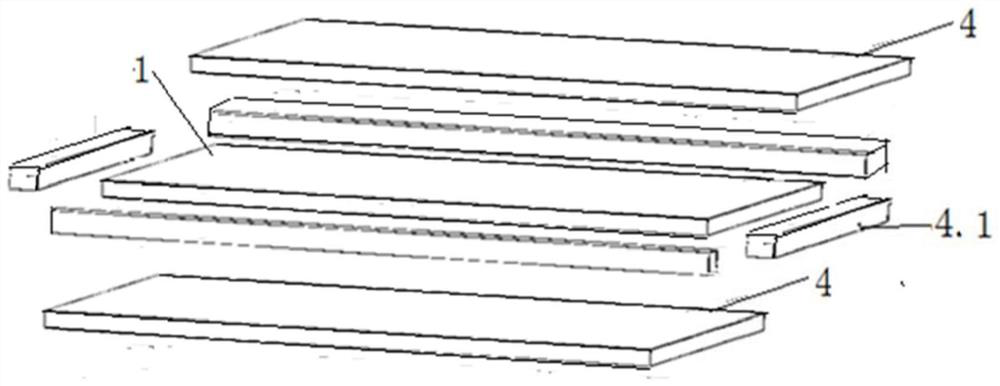

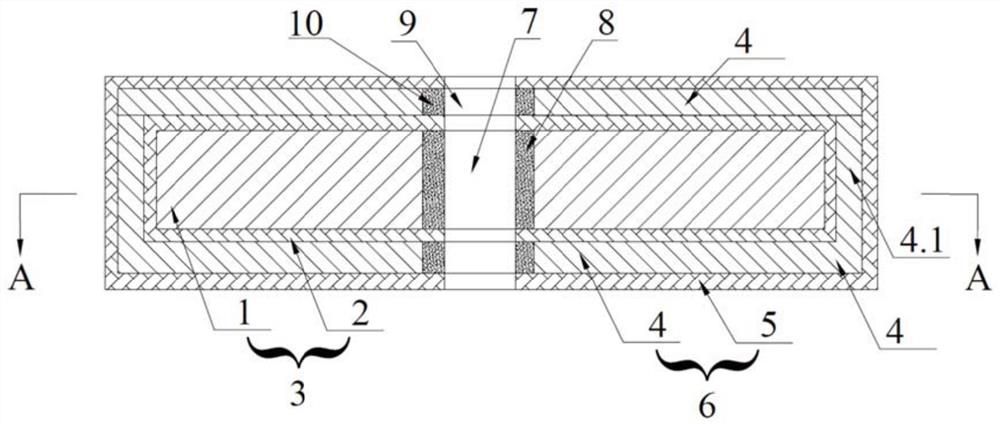

Vacuum thermal insulation plate with mounting holes and without fear of surface damage and processing technology

ActiveCN110792880ASimple structureGood insulation effectThermal insulationSynthetic resin layered productsEngineeringHot pressing

The invention discloses a vacuum thermal insulation plate with mounting holes and without fear of surface damage and a processing technology. The vacuum thermal insulation plate comprises an inner vacuum structural layer and at least one outer vacuum structural layer wrapped around the outer side of the inner vacuum structural layer, the inner vacuum structural layer is composed of an inner core plate body and a high vacuum barrier film wrapped around the outer side of the inner core plate body, the inner core plate body is prepared from materials such as glass fibers through a carding hot pressing or dispersion wet process and a vacuum technology, and the inner vacuum structural layer is prepared by using high vacuum heat sealing equipment; each outer vacuum structural layer is composed of an outer core plate body and a high vacuum barrier film wrapped around the outer side of the outer core plate body, each outer core plate body is prepared from materials such as glass fibers througha mixing dispersion wet process through a vacuum forming technology, a gettering material can be embedded into each outer core plate body, then each outer core plate body is put into the corresponding high vacuum barrier film, and the outer vacuum structural layers are prepared by using the high vacuum heat sealing equipment; and for mounting hole parts, the mounting holes are separated from thecore plate layers by using partition plates provided with through holes. The vacuum thermal insulation plate does not bulge, does not swell, does not absorb water and can retain the thermal insulationperformance after the surface of the vacuum thermal insulation plate is damaged.

Owner:安徽百特新材料科技有限公司

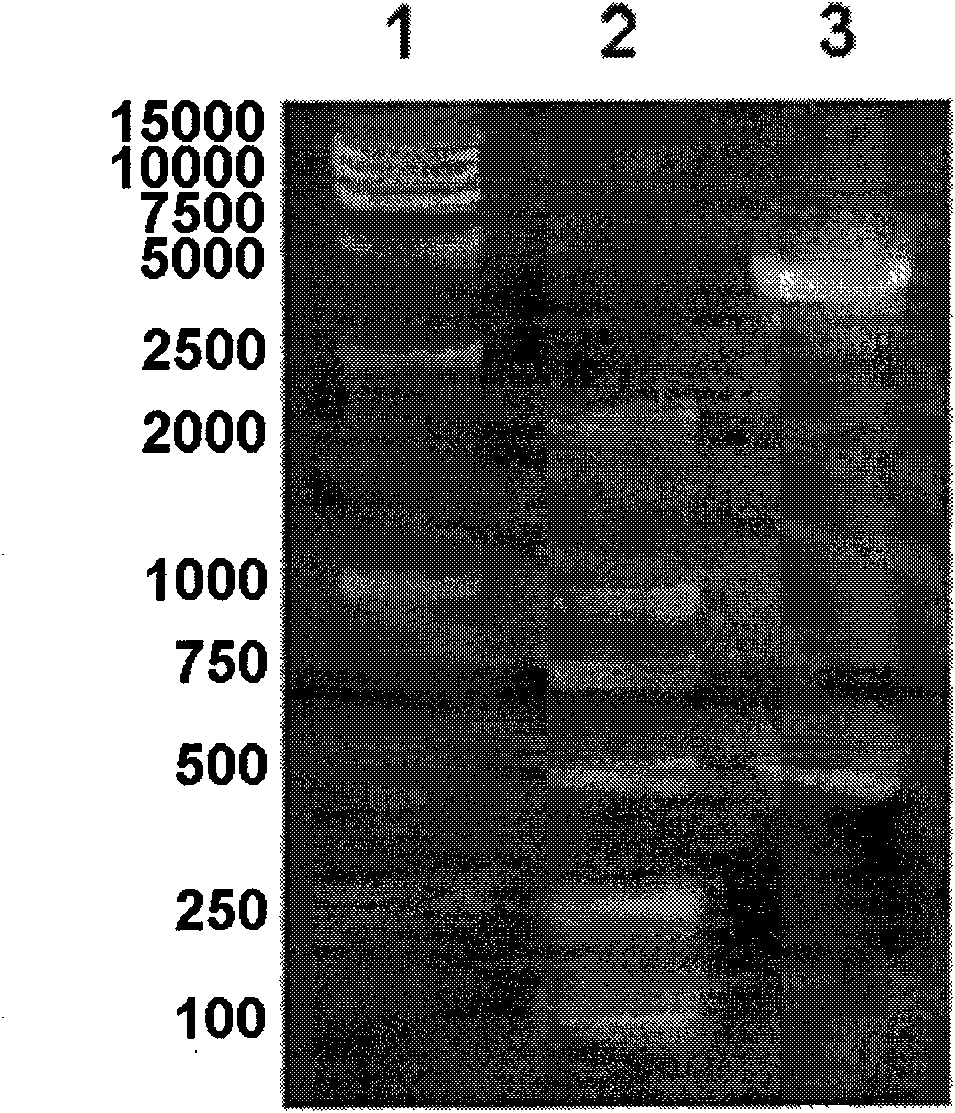

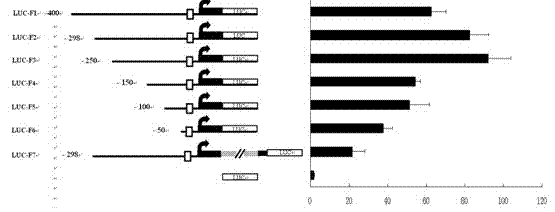

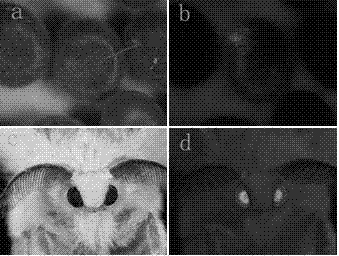

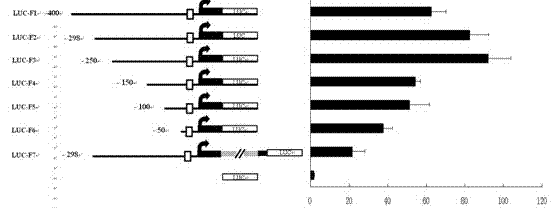

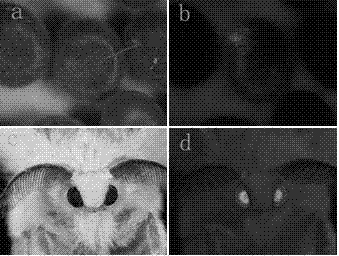

Silkworm Bmlp3 gene promoter and use thereof

ActiveCN102191249AIncrease incomeFeatures are not affectedVector-based foreign material introductionDNA/RNA fragmentationFat bodiesControllability

The invention relates to the technical field of biology, in particular to a silkworm Bmlp3 gene promoter represented by SEQ ID No.1. The promoter can be used for expressing an extrinsic protein in a fat body. The invention also comprises a preparation method of a microscopic injection carrier for expressing the extrinsic protein in the fat body of silkworms, which comprises: constructing a recombinant expression vector containing a silkworm Bmlp3 gene promoter and an expression cassette; and preparing the microscopic injection carrier. The Bmlp3 gene promoter can realize the expression of the extrinsic protein in a development period in which the fat body is the most developed. The method can realize the controllability of an expression period; the transgenosis-mediated by a transposons derived from pggBac has characteristics of high stability, high heritability and the like; and through continuous rearing, colony can be enlarged quickly, and a quantitative guarantee for purification of the EQ ID No.1. The promoter can be used for expressing an extrinsic protein is provided.

Owner:SOUTHWEST UNIV

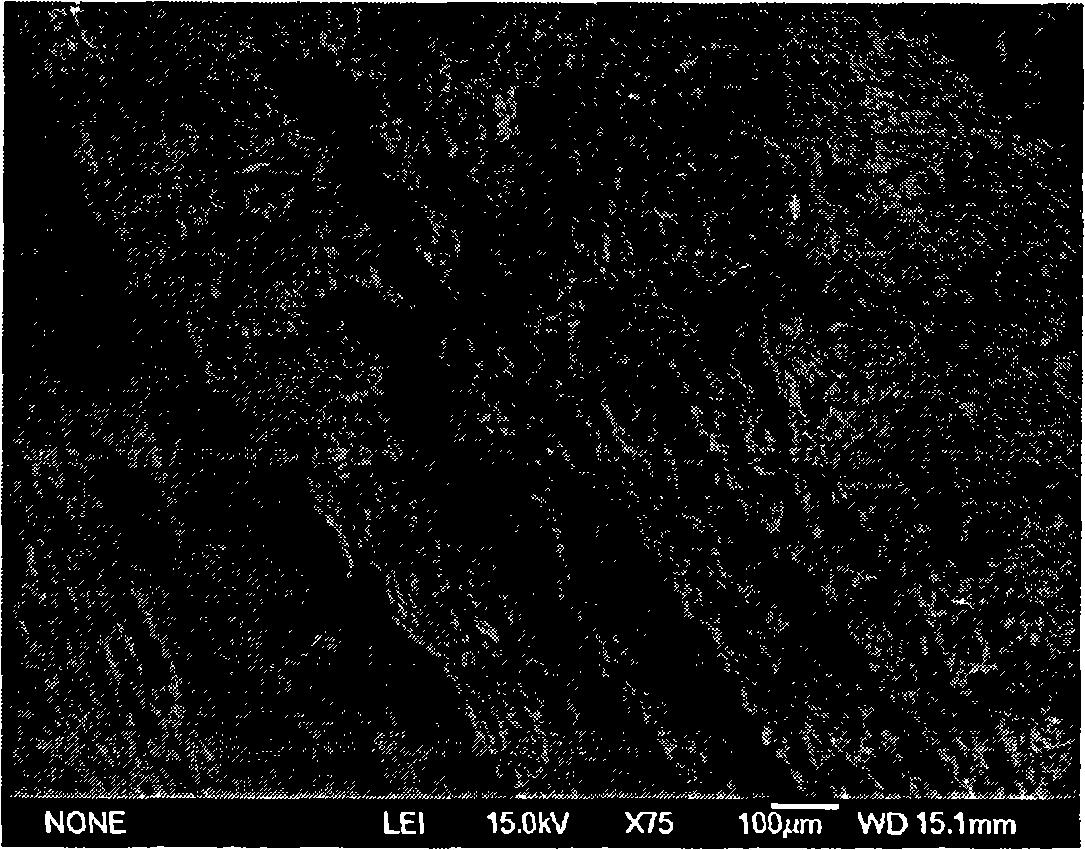

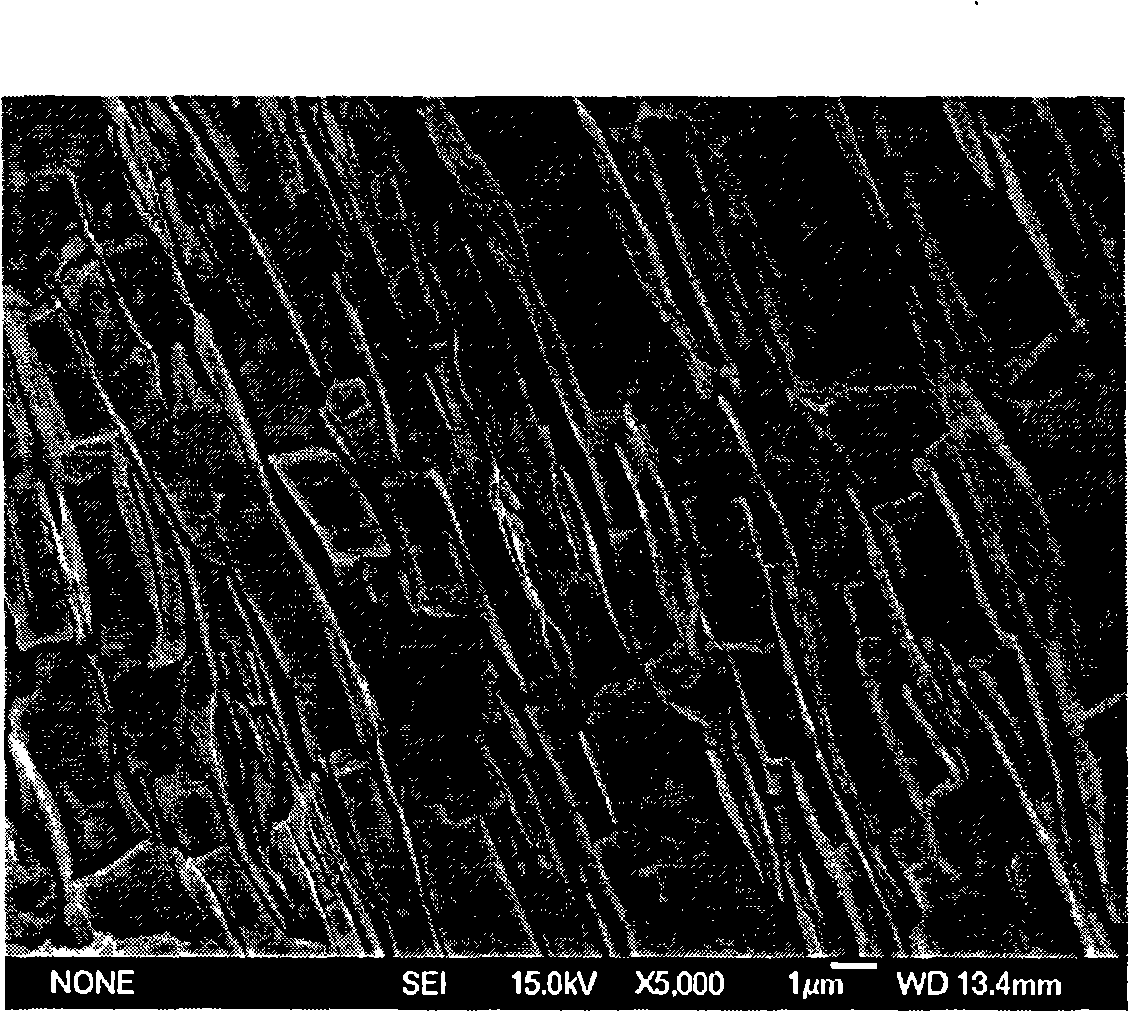

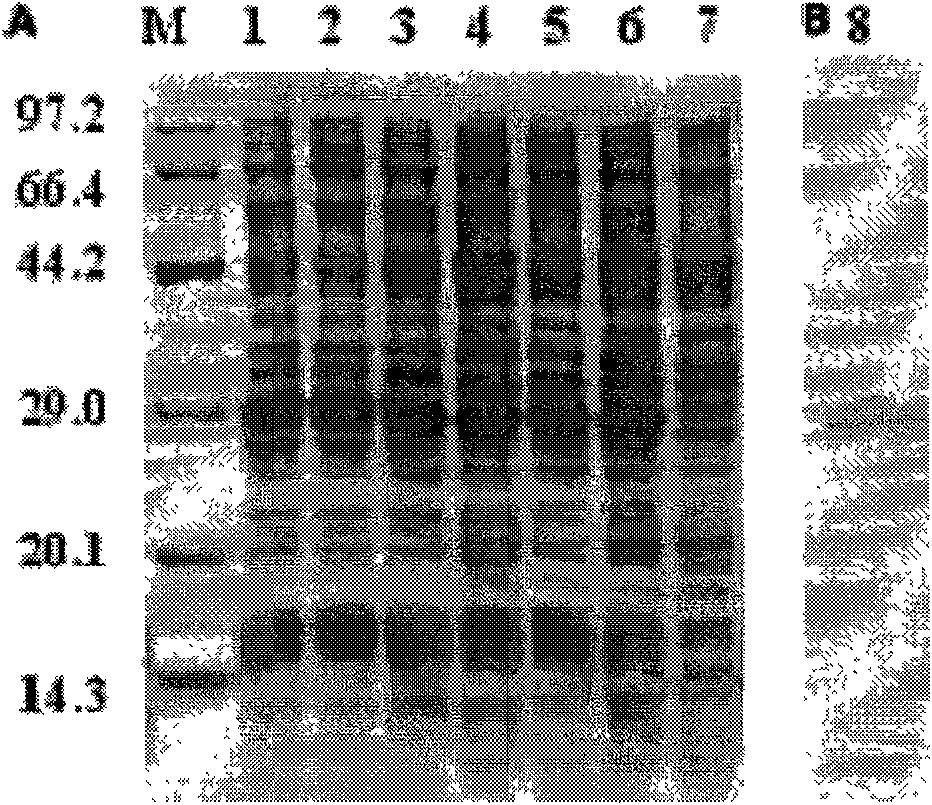

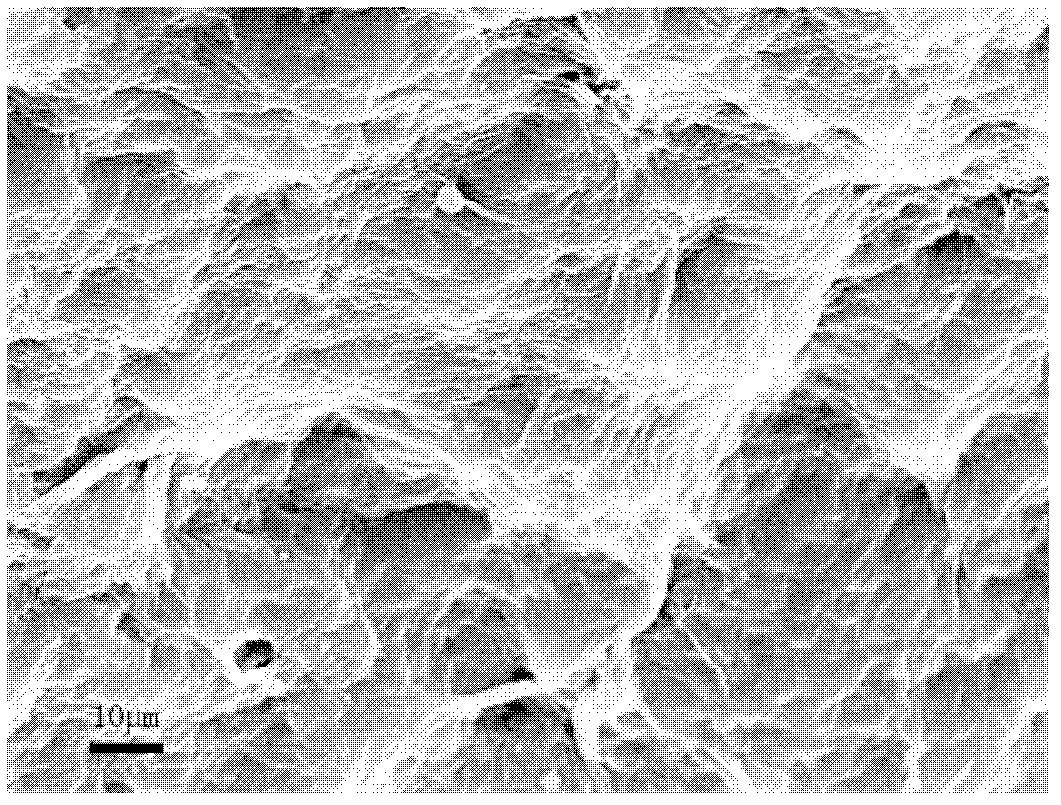

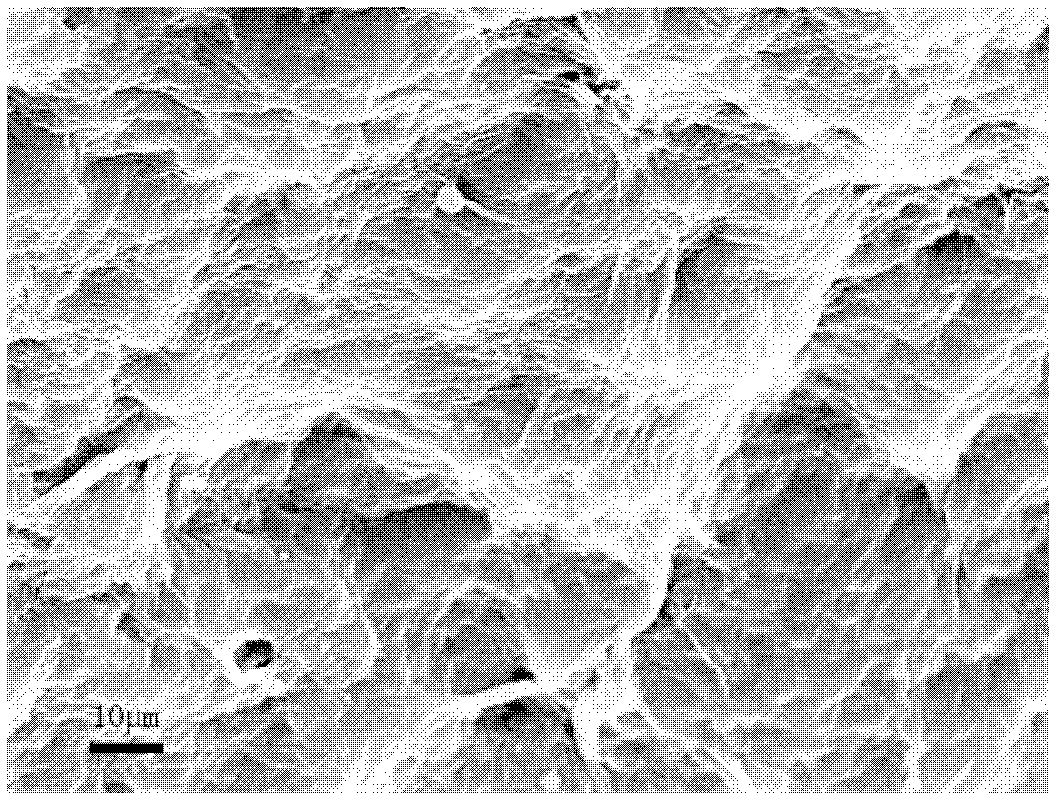

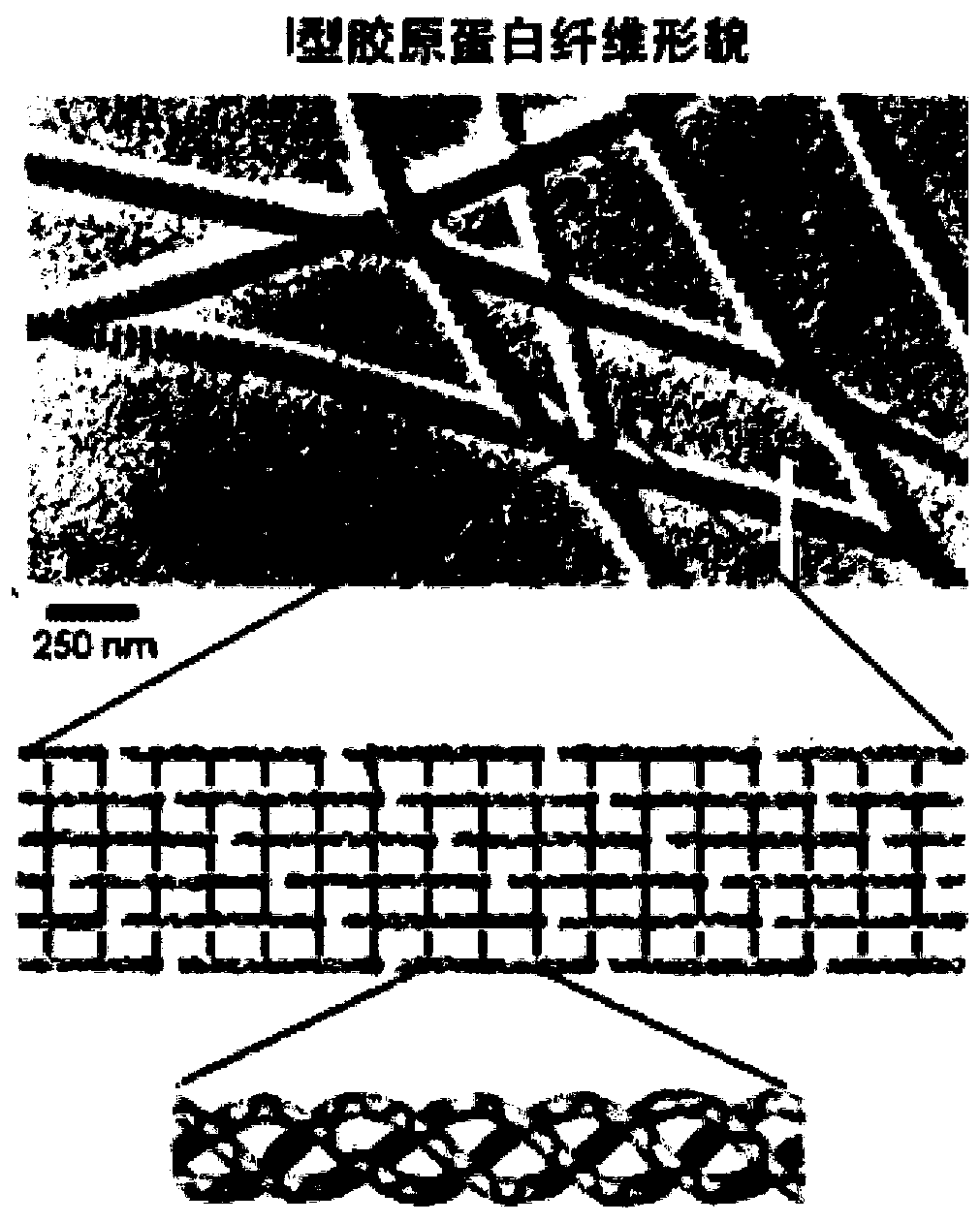

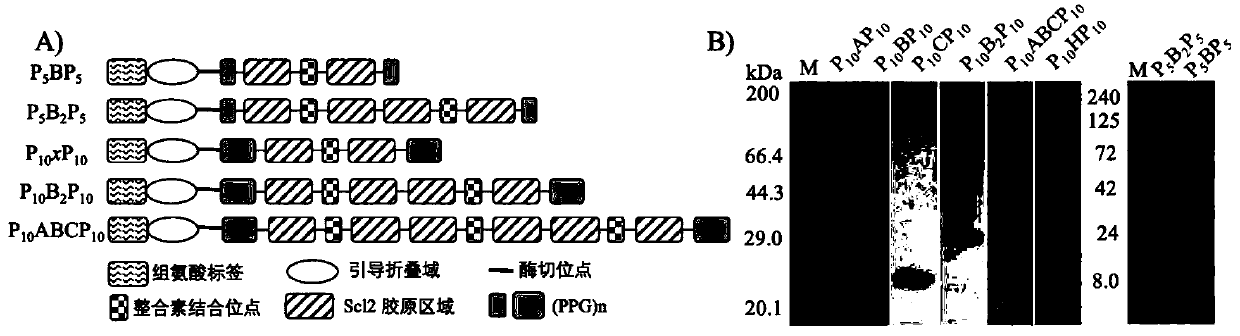

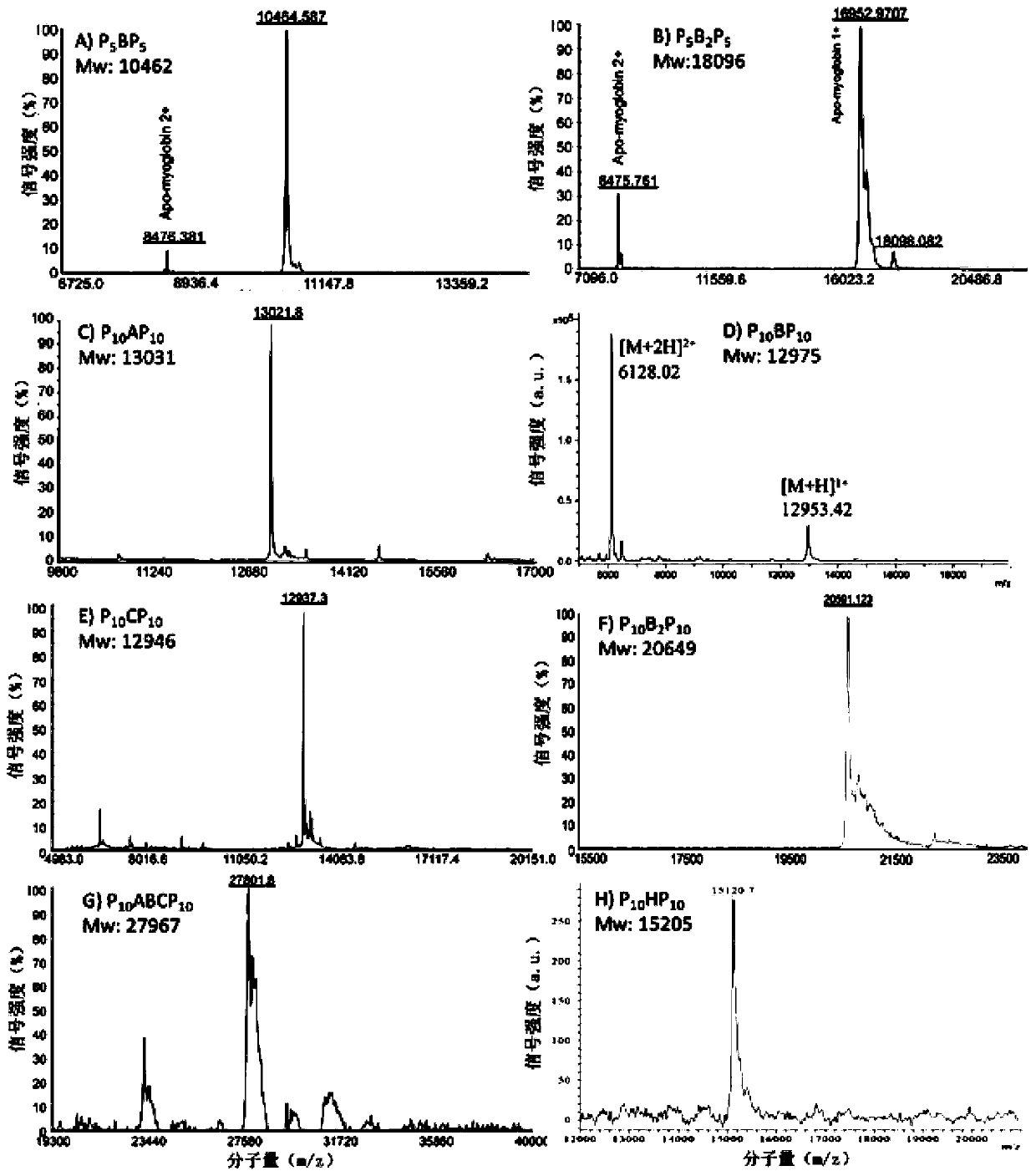

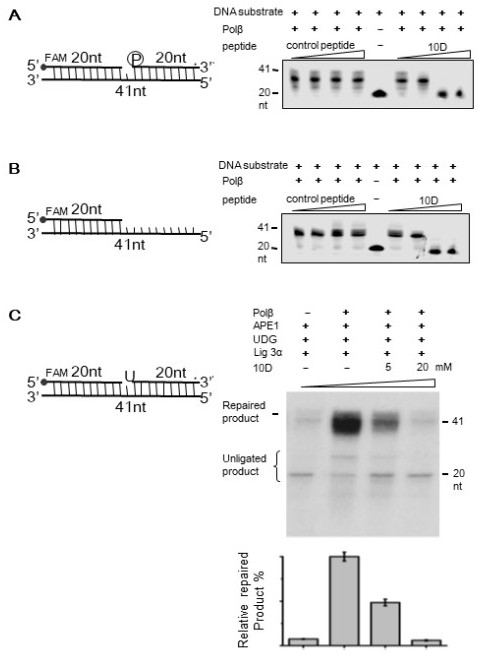

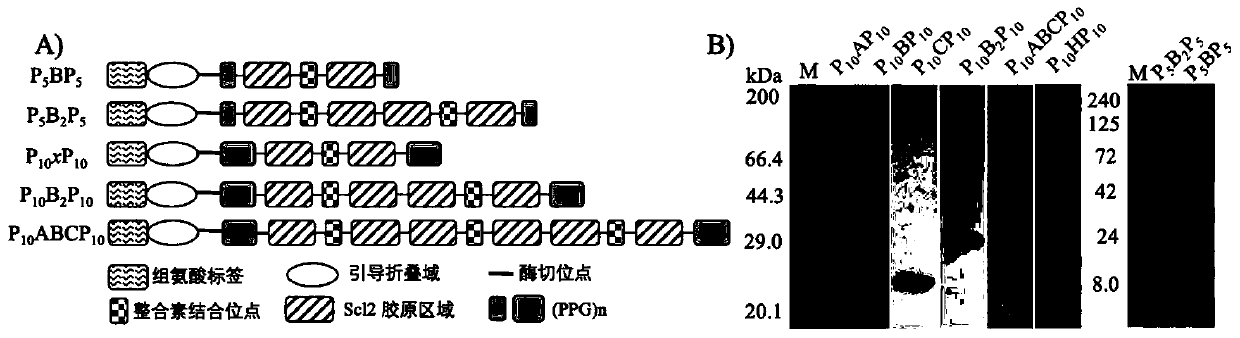

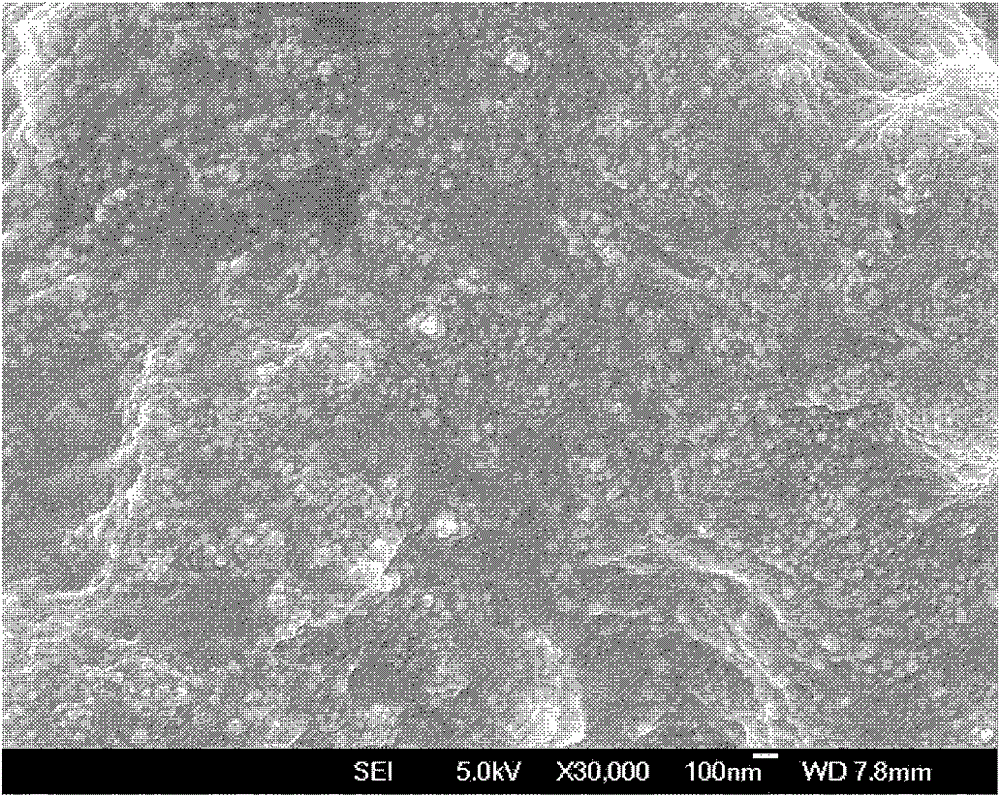

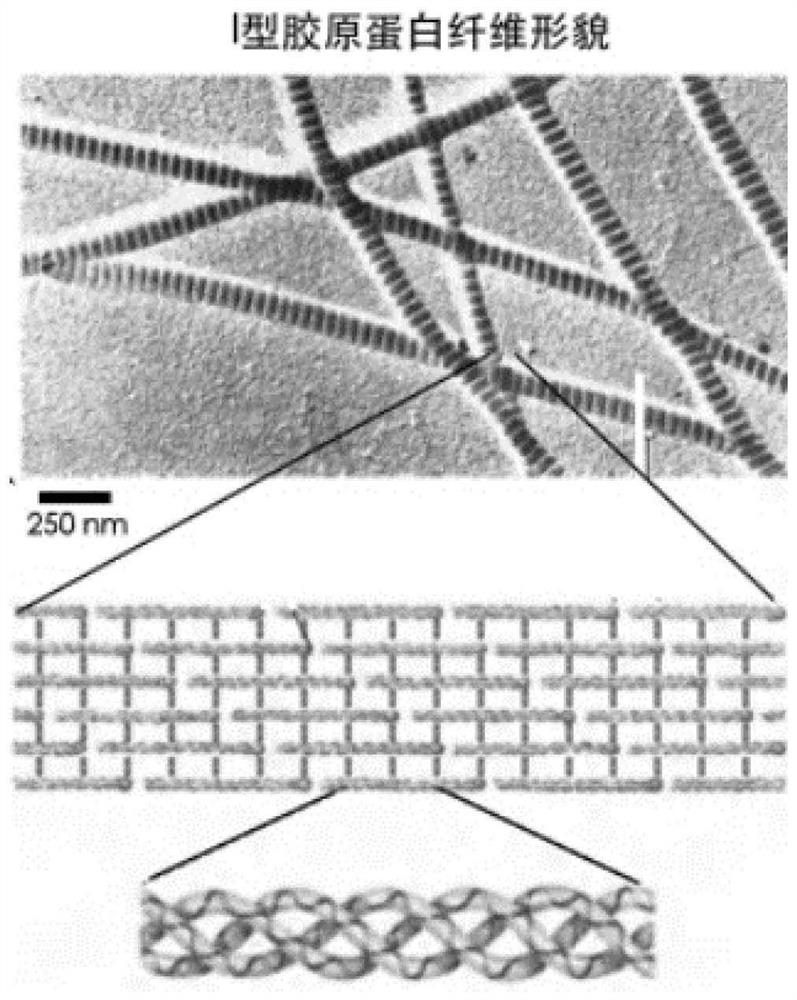

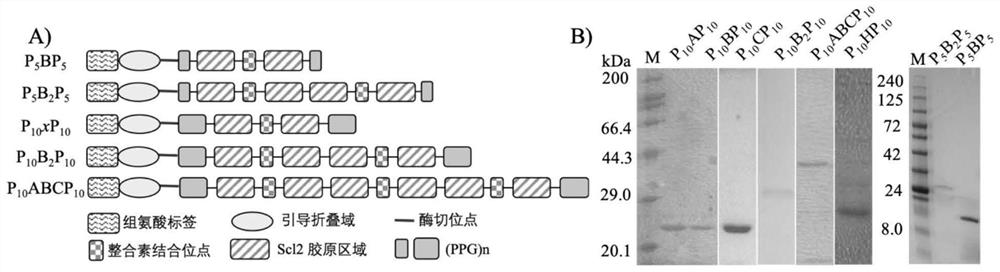

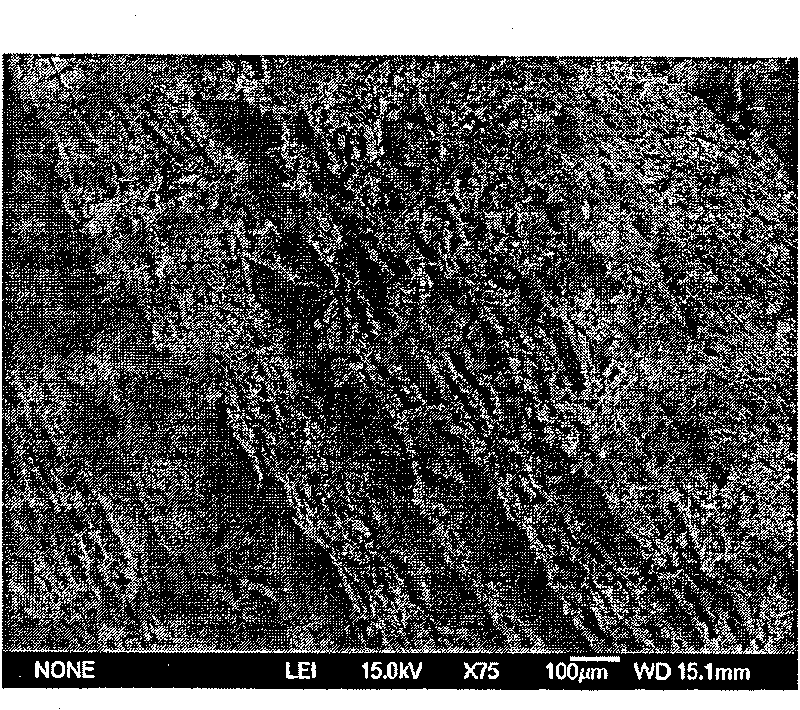

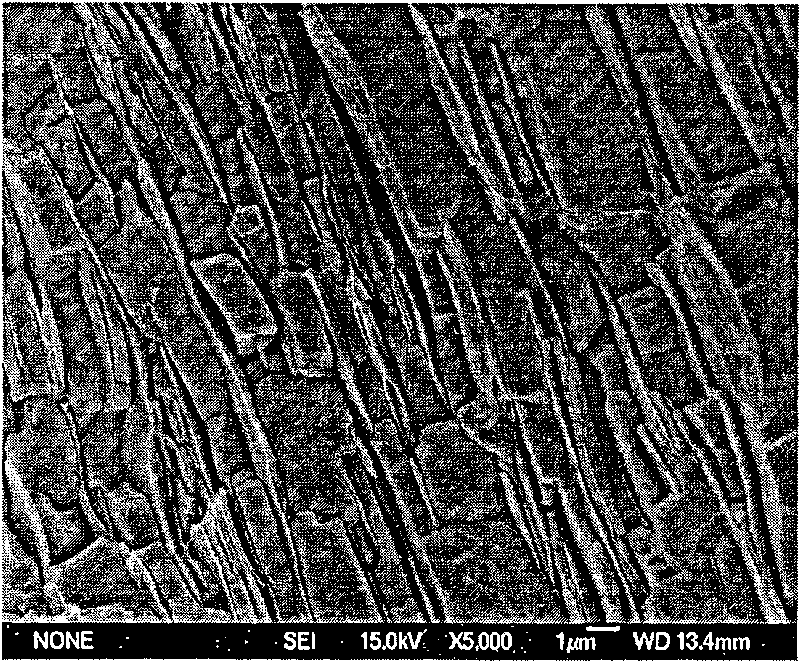

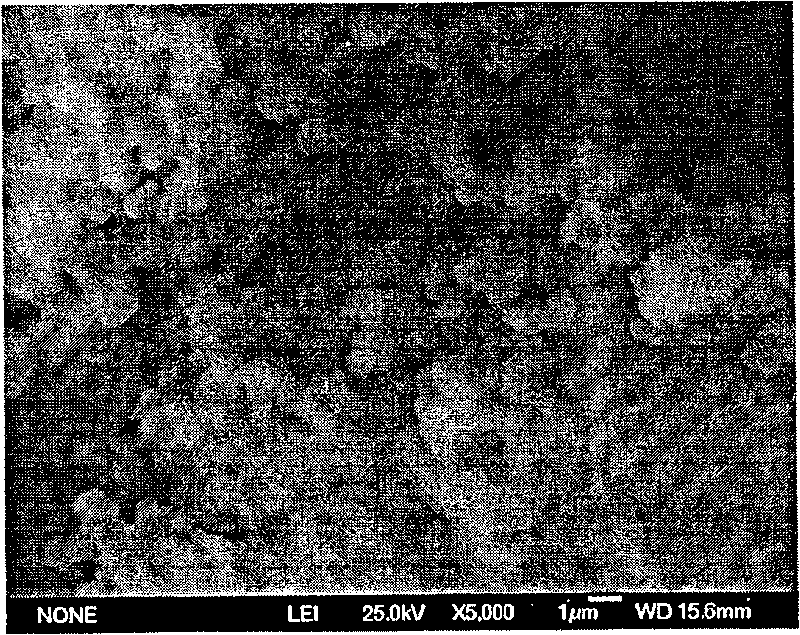

Preparation method of type I collagen-like fiber

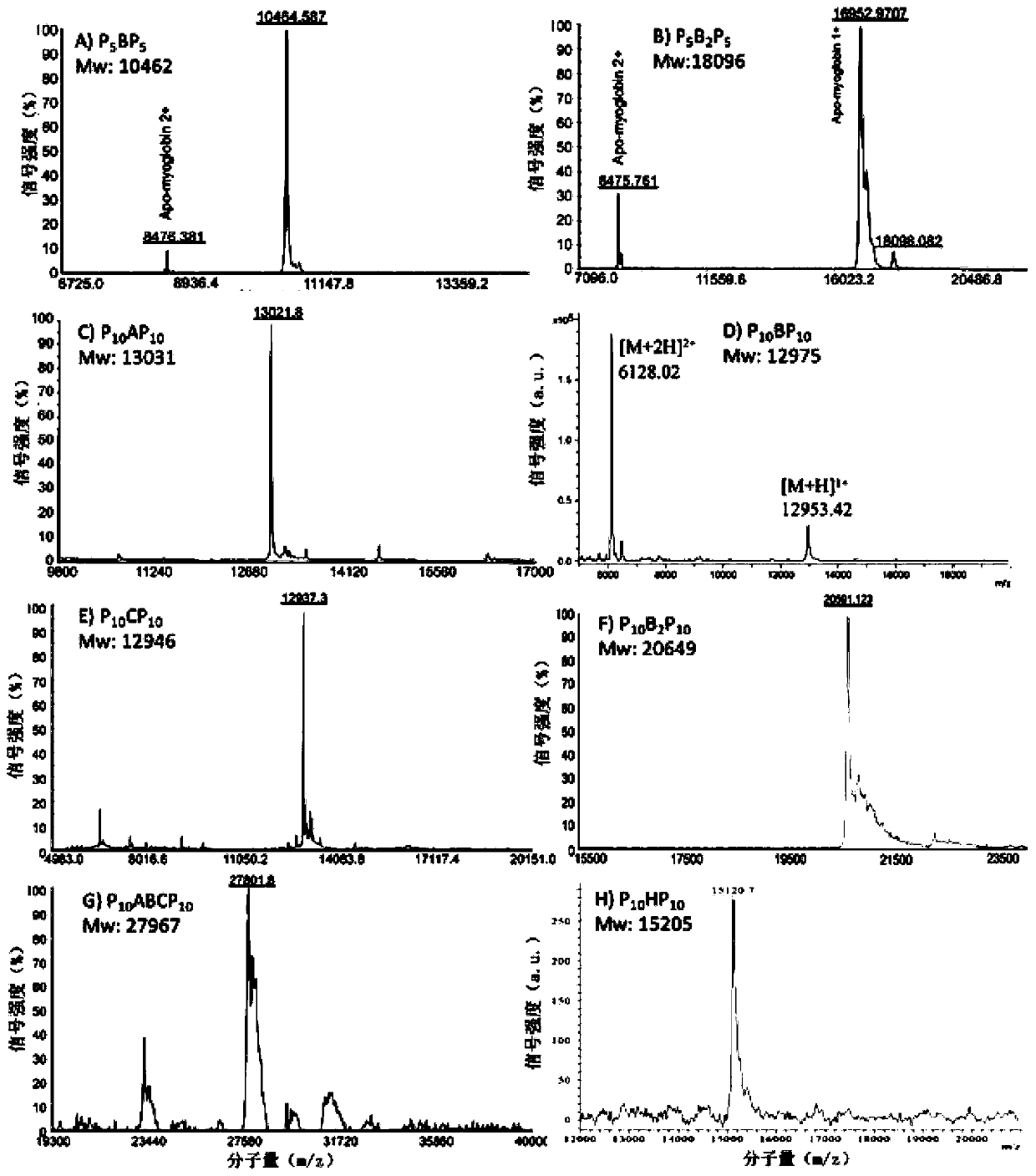

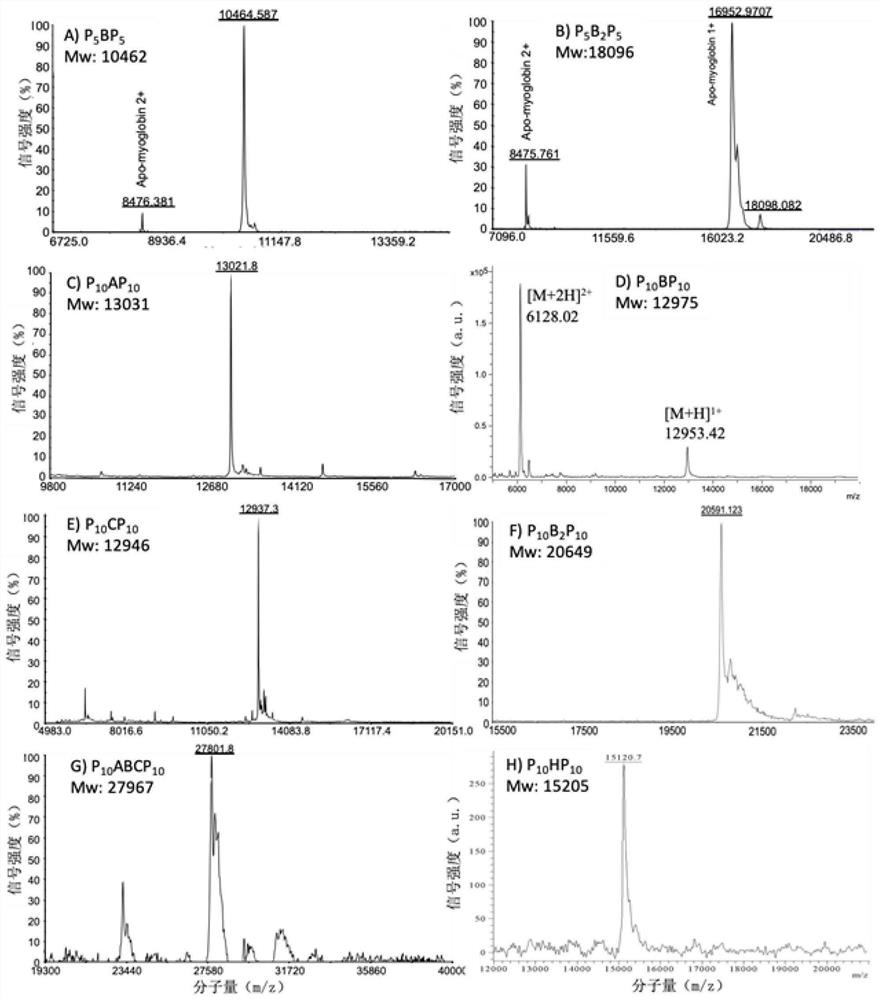

ActiveCN111333715ASimple preparation processLow cost of mass productionConnective tissue peptidesBacteriaFiberTriple helix

The invention discloses a preparation method of a type I collagen-like fibers, belonging to the technical field of gene engineering. On the basis of a (GPP)<n> sequence of N and C terminals, a continuous collagen sequence of a Gly-Xaa-Yaa triplet is inserted into the middle of the (GPP)<n> sequence to form a three-section type chimeric collagen P-CL-P mode. Self-assembly is driven through interaction among triple helixes of the (GPP)<n> of the N and C terminals, so the strip-shaped fiber with periodically bright and dark stripes is formed. The method provided by the invention can be used for preparing the clean-source fiber which can be self-assembled to form the periodically bright and dark stripes, and the structure of the fiber is similar to the structure of type I collagen; the preparation method is simple in process; and the collagen fiber with low cost can be produced on a large scale and has wide application prospects in the field of biological materials.

Owner:JIANGNAN UNIV +1

Preparation method of polypyrrole hydrogel

The invention discloses a polypyrrole hydrogel and a preparation method thereof. The preparation method of the polypyrrole hydrogel is characterized by including the following steps of: 1) adding 2-10 mmol of pyrrole monomer and 0.5-3 mmol of a dye respectively into 10-30 mL of deionized water, and then slowly adding 10-30 mL of an oxidant-containing aqueous solution with a concentration of 0.2-1 mol / L, and standing for 24 to 36 hours at 10-20 DEG C; and 2) purifying and balancing the product obtained by the step 1) in distilled water for 1 week, and changing water every 24 hours, so as to obtain the polypyrrole hydrogel. The invention has advantages of mild reaction conditions, simple process, low cost on mass production and excellent water absorbing property of the polypyrrole hydrogel.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Vacuum insulation panel with no fear of surface damage

InactiveCN110792878ASimple structureGood insulation performanceCovering/liningsThermal insulationInsulation layerEngineering

The invention discloses a vacuum insulation panel with no fear of surface damage. The vacuum insulation panel comprises at least two vacuum insulation layers, namely, an inner vacuum insulation structure layer and at least one outer vacuum insulation structure layer covering the outside of the inner vacuum insulation structure layer, wherein the inner vacuum insulation structure layer comprises aninner core plate, the inner core plate is provided with an installation groove of a getter material, the installation groove is internally provided with the getter material, the inner core plate withthe getter material is externally sleeved with an inner high barrier gas film bag, the inner high barrier gas film bag provided with the inner core plate is vacuumized and is heat sealed through a high vacuum heat sealing device to form the inner vacuum insulation structure layer; outer core plates and outer high vacuum barrier films covering the outsides of the outer core plates are vacuumized and heat sealed through the high vacuum heat sealing device to form the outer vacuum insulation structure layers. The vacuum insulation panel with no fear of surface damage has the advantages and the beneficial effects of simple structure, good insulation effect, no bulge, no expansion and no water absorption after the surface is damaged, and can keep the thermal insulation performance good.

Owner:安徽百特新材料科技有限公司

Preparation method of lactate catalyst and application

InactiveCN1919823ASynthetic conditions are mildRaw materials are easy to getOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsInorganic saltsHomosalate

The invention discloses a lactic catalyst and application in the esterification reaction and lactone synthetic course, which comprises the following steps: blending lactic acid and metal oxide or inorganic salt; adding fitful water; reacting for several hours; adopting recrystallization method to produce lactate.

Owner:CHONGQING UNIV

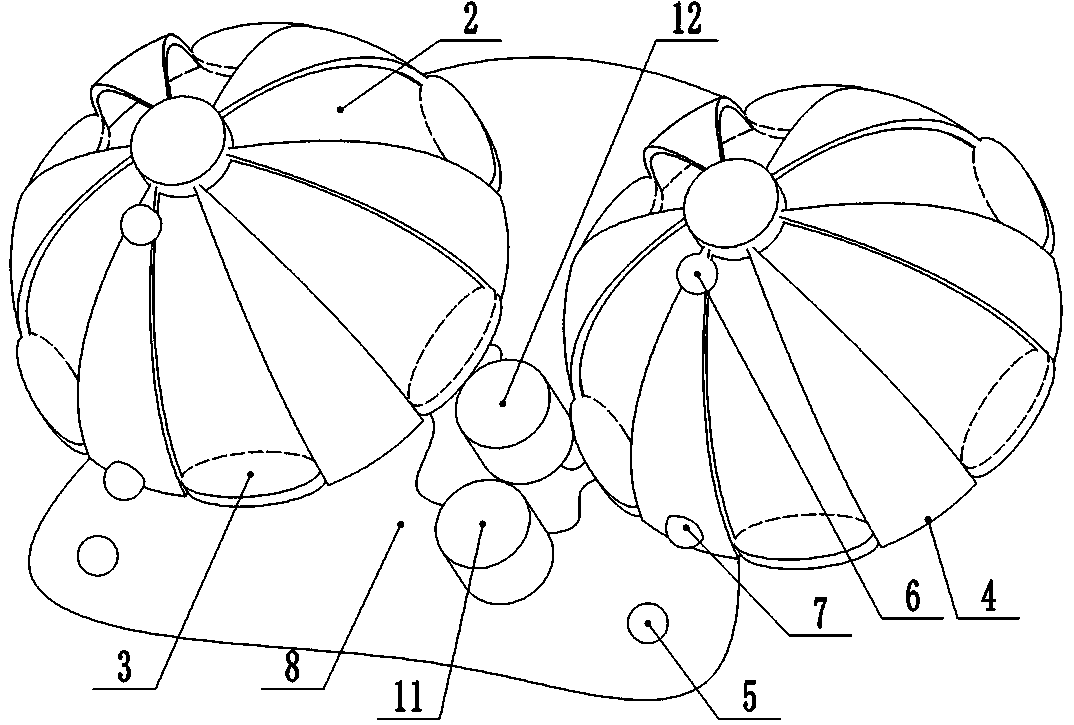

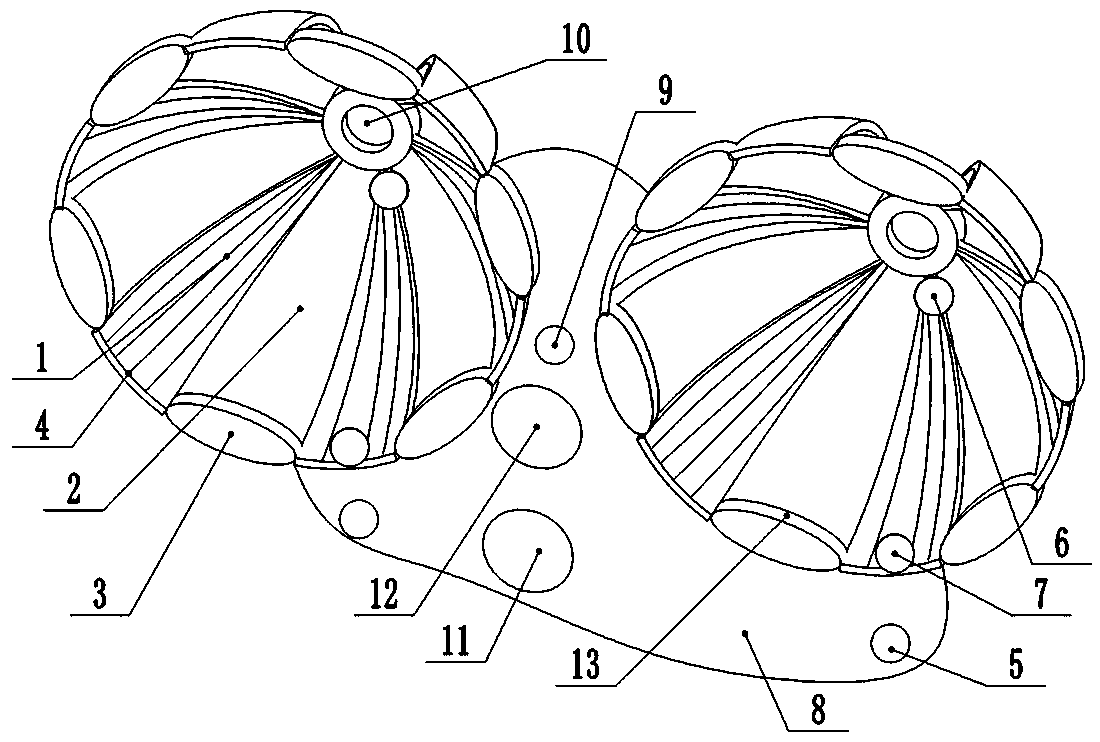

Medicine massage breast-dredging patch

The present invention discloses a medicine massage breast-dredging patch. The medicine massage breast-dredging patch comprises a certain amount of strip-shaped medicine strips and bowl-shaped positioning covers, the medicine strips are provided with connecting structures to be fixed on the positioning covers in a detachable mode, and the positioning covers can be fixed on a bra. Beneficial effectsof the design are that the medicine massage breast-dredging patch can be arranged on the bra and is convenient to wear, the medicine strips are internally provided with breast-dredging and delectation medicines capable of being singly changed and saving costs, gaps are formed between the medicine strips to play a fine ventilation effect, the medicine strips are provided with hook and loop fasteners or double-faced adhesive tapes to be sticky to the positioning covers, the positioning covers can be fixed on the bra through the hook and loop fasteners or positioning clips, the positioning covers is further provided with elastic ropes with adjustable sizes to satisfy use of populations with breasts of different sizes. The medicine massage breast-dredging patch can be subjected to mass production and is low in costs, and the positioning covers can avoid the medicines polluting the bra and play a protection function on the bra.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

Intelligently-adjusted photovoltaic module mounting support

InactiveCN104601098AOptimize shadow areaOptimize the amount of shadingPhotovoltaic supportsClimate change adaptationElectricityProduction rate

The invention provides an intelligently-adjusted photovoltaic module mounting support. The intelligently-adjusted photovoltaic module mounting support comprises a supporting frame for mounting a photovoltaic module, supporting rods fixed on the ground, a driving device and a control device, wherein the supporting frame is mounted on the supporting rods through bearings, and a motor is arranged on one of the supporting rods. The intelligently-adjusted photovoltaic module mounting support has the advantages that the mounting support can enable the photovoltaic module to be adjusted in a full range automatically continuously relative to a sun incident angle, so that solar irradiance can be used maximally to generate electricity; or shaded area of the ground below the photovoltaic module can be optimized to promote growth of crops, so that moisture evaporation is reduced; light shading capacity of a photovoltaic (or other materials) visor on a building, and balance among light shading, electricity generation and lighting can be optimized; meanwhile, the intelligently-adjusted photovoltaic module mounting support is simpler in design structure, wide in applicable range and lower in large-scale manufacturing cost correspondingly, and promotes application of BIPV (building integrated photovoltaics), photovoltaic and agricultural integration and the like; by the mounting support, productivity is increased, production cost is saved and energy conservation and environmental protection are achieved.

Owner:李元雄 +1

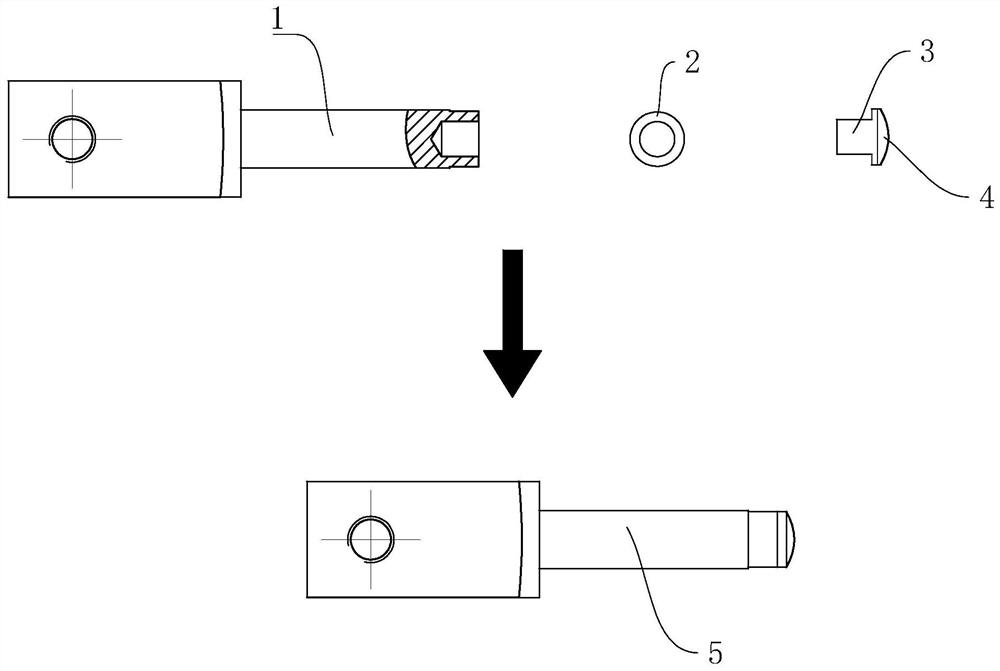

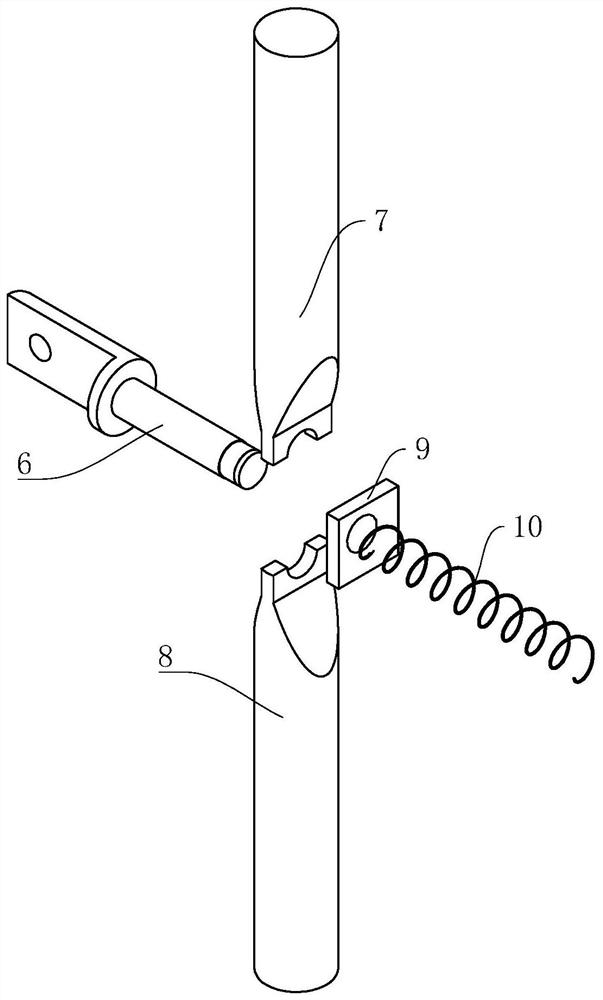

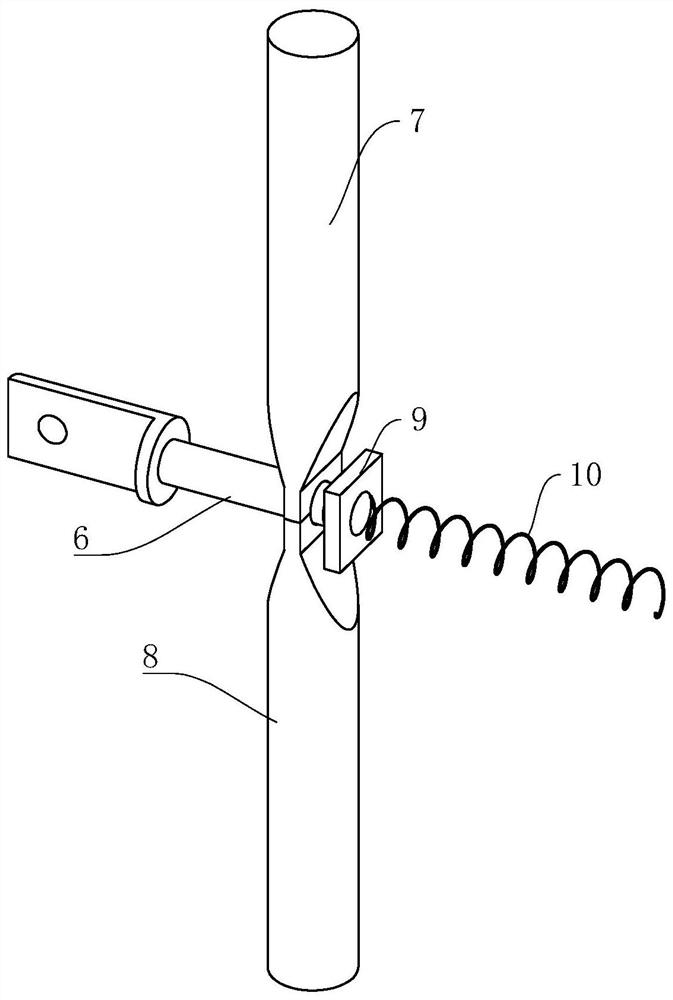

A welding method for industrial plug socket contact assembly

ActiveCN112643162BWon't leaveGentle and stable heating methodWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceGraphite

The invention belongs to the technical field of welding of contact assemblies, and in particular relates to a welding method of an industrial plug socket contact assembly including the following steps: (1) preparing solder, the solder is in the shape of an annular sheet, and its inner diameter is larger than that of a rivet contact nail foot diameter, and the outer diameter is smaller than the diameter of the rivet contact nail head; (2) Prepare welding electrodes, the material of the welding electrodes is three high graphite, the welding electrodes have two, and the ends of the two welding electrodes are set There are two grooves that match the outer circumference of the nickel-plated terminal; (3) Assembly: soak the nickel-plated terminal with flux, put the solder on the contact pin of the silver alloy copper-clad rivet, and then apply the silver alloy copper-clad The rivet contact pins are inserted into the positioning holes of the nickel-plated terminals soaked in flux to complete the assembly of the contact assembly; (4) Place the assembled contact assembly into the two matching welding electrodes so that the welding electrodes The end is 1-4mm away from the head of the rivet contact, and then resistance brazing is performed to finally complete the welding of the contact assembly.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Preparation method of anti-corrosion liquid-cooled heat dissipation cold plate

ActiveCN105268918BEnsure coplanarityLittle structural requirementsFoundry mouldsFoundry coresWaxWeld seam

The invention discloses a preparing method for a corrosion-resistant liquid cooling heat dissipation cold plate and aims at providing a cold plate preparing method which is free of tedious treatment before welding and has prominent corrosion-resistant capability and long-term work reliability. According to the technical scheme, the two sides of a bottom transverse pipe commonly communicated serve as the starting points respectively, two sets of parallel pipes are longitudinally arranged continuously in a bent manner, and the bending radius of bent circular arc rings on the two longitudinal sides is larger than the distance between every two parallel pipelines; the free ends of each set of parallel pipes are fixedly connected through respective connector flanges; and the two sets of parallel pipes are fixed, clamped and positioned through pipeline clamping tools which are longitudinally arranged at intervals, die positioning plates with screw holes are adopted, wax patterns wrapping runner titanium pipes and connector flange assemblies are clamped between the two die positioning plates, and the runner titanium pipes and the connector flange assemblies are put into a smelting furnace, and a rectangular flat plate is formed through lost foam casting. The preparing method solves the problem that during traditional cold plate welding, a welding seam is prone to cracking, and consequently a cooling agent leaks.

Owner:10TH RES INST OF CETC

A kind of molecular mimetic peptide of O-type foot-and-mouth disease virus epitope and its application

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Silkworm Bmlp3 gene promoter and use thereof

ActiveCN102191249BCharacteristic impactAffects SimplicityVector-based foreign material introductionDNA/RNA fragmentationForeign proteinTransgenesis

The invention relates to the technical field of biology, in particular to a silkworm Bmlp3 gene promoter represented by SEQ ID No.1. The promoter can be used for expressing an extrinsic protein in a fat body. The invention also comprises a preparation method of a microscopic injection carrier for expressing the extrinsic protein in the fat body of silkworms, which comprises: constructing a recombinant expression vector containing a silkworm Bmlp3 gene promoter and an expression cassette; and preparing the microscopic injection carrier. The Bmlp3 gene promoter can realize the expression of the extrinsic protein in a development period in which the fat body is the most developed. The method can realize the controllability of an expression period; the transgenosis-mediated by a transposons derived from pggBac has characteristics of high stability, high heritability and the like; and through continuous rearing, colony can be enlarged quickly, and a quantitative guarantee for purification of the EQ ID No.1. The promoter can be used for expressing an extrinsic protein is provided.

Owner:SOUTHWEST UNIV

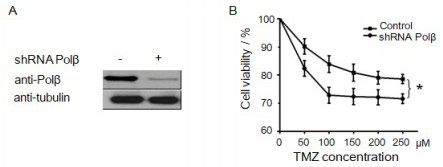

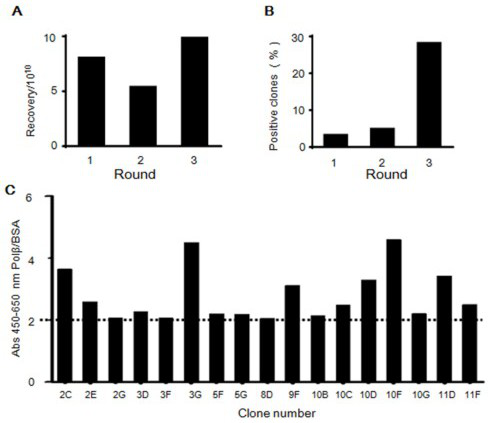

Pol beta inhibitor and application thereof

InactiveCN113480609AReduce volumeHigh affinityOrganic active ingredientsPeptide/protein ingredientsDepressantOncology

The invention discloses a pol beta inhibitor and application thereof, belongs to the technical field of medicines. The invention provides the pol beta inhibitor which is a small molecule polypeptide with an amino acid sequence as shown in SEQ ID No.1. The pol beta inhibitor has a close relationship with temozolomide drug resistance and can be used for preparing drugs for treatment and / or adjuvant treatment of tumors, or can be used for enhancing the chemosensitivity of temozolomide or reducing the chemoresistance of temozolomide. A small peptide 10D provided by the invention can be used as a novel pol beta inhibitor, which can enhance the anti-tumor effect of TMZ on colorectal cancer. Therefore, the small peptide 10D is expected to become a candidate drug for improving TMZ treatment and auxiliary optimization of brain metastatic CRC chemotherapy.

Owner:南京科瑞斯生物科技有限公司

Method for regulating and controlling cycle length of type-I-collagen-like fiber stripes

ActiveCN111499729ASimple preparation processLow cost of mass productionConnective tissue peptidesBacteriaFiberEngineering

The invention discloses a method for regulating and controlling the cycle length of type-I-collagen-like fiber stripes, and belongs to the technical field of gene engineering. According to the invention, N-terminal and C-terminal (PPG)n sequences are used as the basis; a continuous collagen sequence with different numbers of Gly-Xaa-Yaa triplets is inserted into the middle of the N-terminal and C-terminal (PPG)n sequences; a three-section type chimeric collagen P-CL-P mode is formed. Self-assembly is driven through interaction between N-terminal and C-terminal (PPG)n three-strand spirals, andthe strip-shaped fibers with different dark stripe lengths and periodical bright and dark stripes is formed. The method disclosed by the invention is simple in preparation process, can be used for producing collagen fibers with low cost on a large scale, and has the broad application prospect in the field of biological materials.

Owner:JIANGNAN UNIV +1

A Processing Technology of Vacuum Thermal Insulation Panel Not Afraid of Surface Damage

ActiveCN110792879BGuaranteed SpecificationsAchievement of technical indicatorsCovering/liningsThermal insulationGlass fiberMechanical engineering

The invention discloses a vacuum insulation board with no fear of surface damage and a processing technology thereof. The vacuum insulation board comprises an inner vacuum structural layer and at least one outer vacuum structural layer wrapped outside the inner vacuum structural layer, wherein the inner vacuum structure layer is composed of an inner core plate and a high vacuum barrier film wrapped outside the inner core plate, the inner core plate inner vacuum structure layer is composed of the inner core plate and the high vacuum barrier film wrapped outside the inner core plate, the inner core plate is prepared from a material such as glass fibers through carding hot pressing or dispersion wet method and a vacuum process, the inner core plate and a getter material are placed into the high vacuum barrier film to be made into the inner vacuum structure layer through high vacuum heat sealing equipment, the outer vacuum structure layer is composed of the inner vacuum structure, an outercore plate and a high-vacuum barrier film wrapped outside the outer core plate, and the outer core plate is made of glass fiber and other materials through wet-process mixed dispersion through a vacuum forming process. The vacuum insulation board has the characteristics of being good in heat preservation effect, safe, light, simple in construction, and capable of opening holes and the like, and after the surface is damaged, no drum, no expansion, no water absorption, and good retention and heat insulation performance are reserved.

Owner:安徽百特新材料科技有限公司

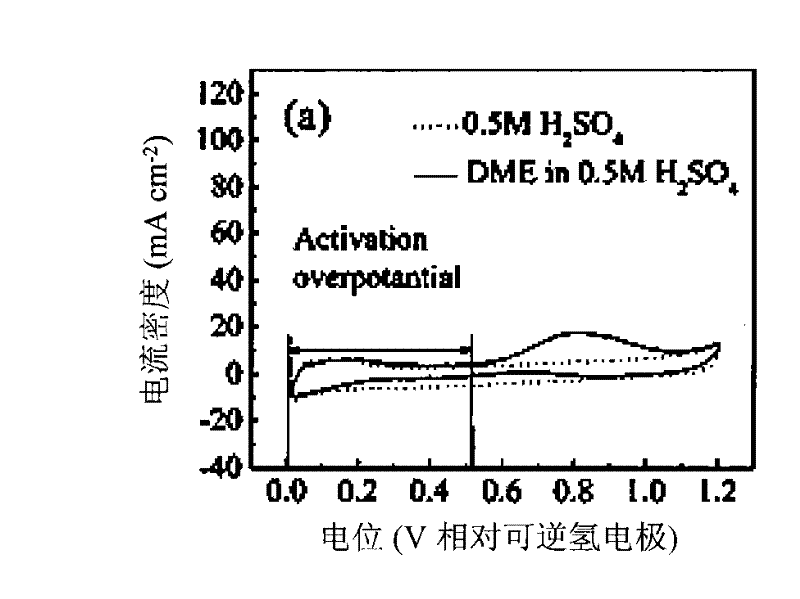

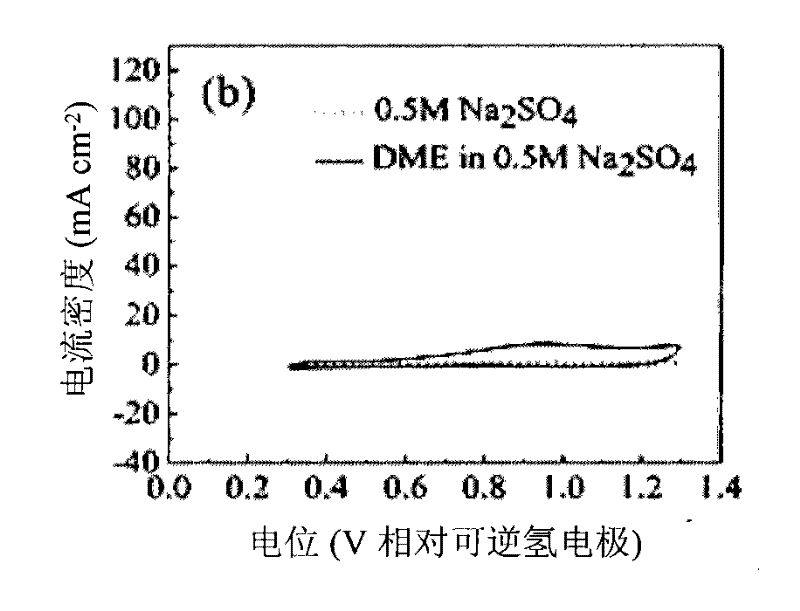

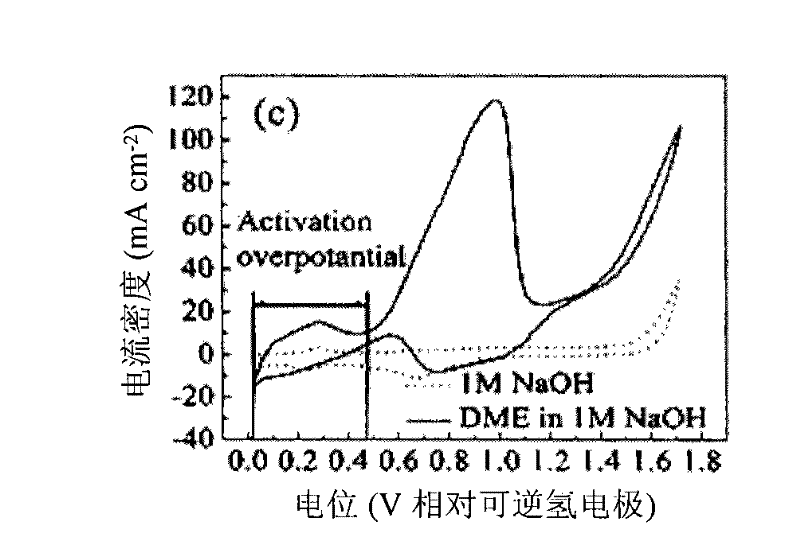

Alkaline direct dimethyl ether fuel cell

InactiveCN101800325BHigh reactivityWide variety of sourcesOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesFuel cellsCO poisoning

The invention relates to an alkaline fuel cell, which aims to provide an alkaline direct dimethyl ether fuel cell. A cation exchange membrane or an anion exchange membrane is used as a membrane of the fuel cell for partitioning an anode and a cathode, an alkaline dimethyl ether solution contained in an anode catalyst carrier is used as an electrolyte, and the alkaline dimethyl ether solution is an aqueous solution in which dimethyl ether is saturated and the concentration of NaOH or KOH is 1-6 mol / L. In the invention, the dimethyl ether dissolved in lye is used as fuel, which can greatly improve the power generation performance of the direct dimethyl ether fuel cell. The alkaline direct dimethyl ether fuel cell can be applied to portable and mobile power supplies in large-scale commercialapplications. An anode catalyst is beneficial to exerting the performance of a cocatalyst on improving the Co poisoning resisting performance of Pt, thereby improving the activity of the catalyst andimproving the power generation performance of the dimethyl ether fuel cell. Likewise, the activity of a cathode catalyst can be improved, and the oxygen reduction reaction kinetics can be improved, thereby improving the power generation performance of the dimethyl ether fuel cell.

Owner:ZHEJIANG UNIV

Method for synthesizing polypyrrole-chitosan-metal nanoparticle composite film on surface of cathode by one-step process

InactiveCN102220622BThickness is easy to controlMild reaction conditionsElectrolytic inorganic material coatingComposite filmPolypyrrole

The invention relates to a method for preparing a polypyrrole-chitosan-metal nanoparticle composite film, which comprises the following steps: 1) dissolving the chitosan in 0.01 to 1 mol / L nitric acid solution to obtain solution A, wherein the mass percentage concentration of the chitosan in the solution A is 0.5 to 5 percent; 2) adding a pyrrole monomer and a divalent metal salt into the solution A to obtain solution B, wherein the concentration of the pyrrole monomer in the solution B is 0.1 to 0.4mol / L and the concentration of the divalent metal salt in the solution B is 0.1 to 0.3 mol / L; and 3) placing the cathode into the solution B, energizing under protection of nitrogen, performing electrochemical synthesis to synthesize the composite film on the surface of the cathode by a one-step process. In the invention, the reaction conditions are mild, the process is simple, the cost of large-scale production is low, the thickness of the composite film and the component content in the composite film can be controlled, and the method has a bright application prospect in the field of film materials.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

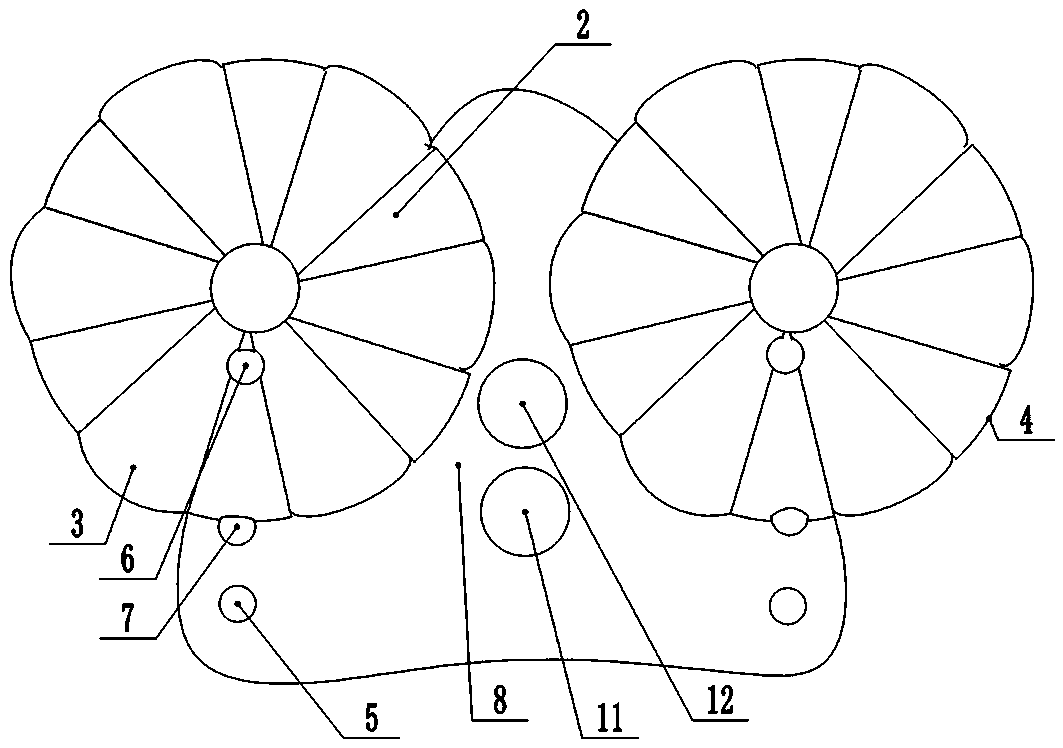

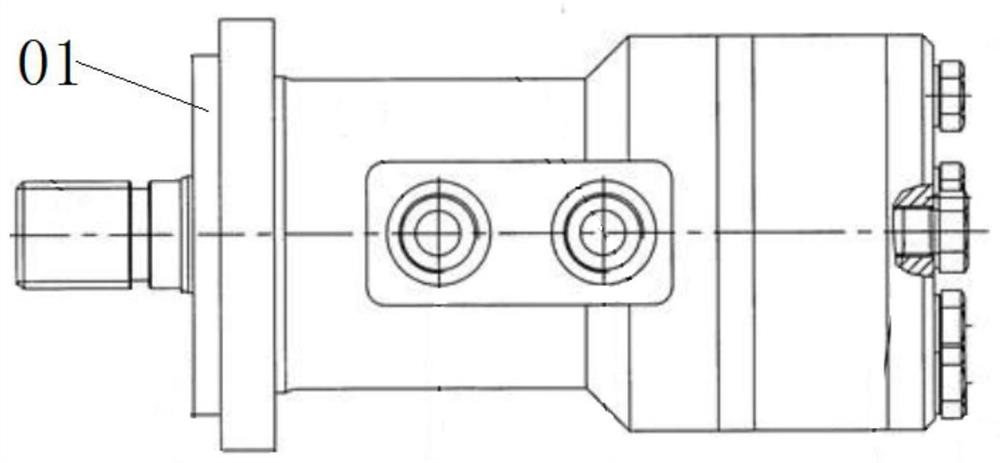

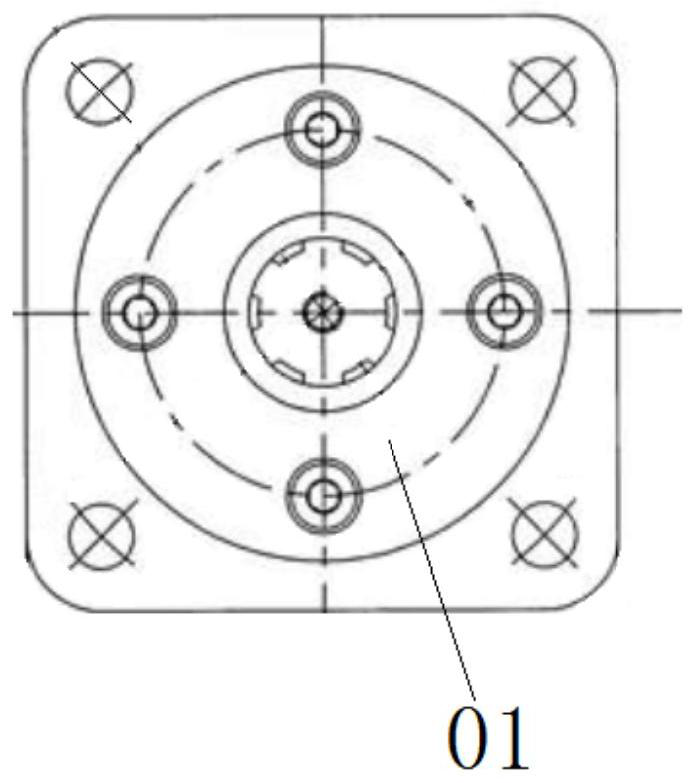

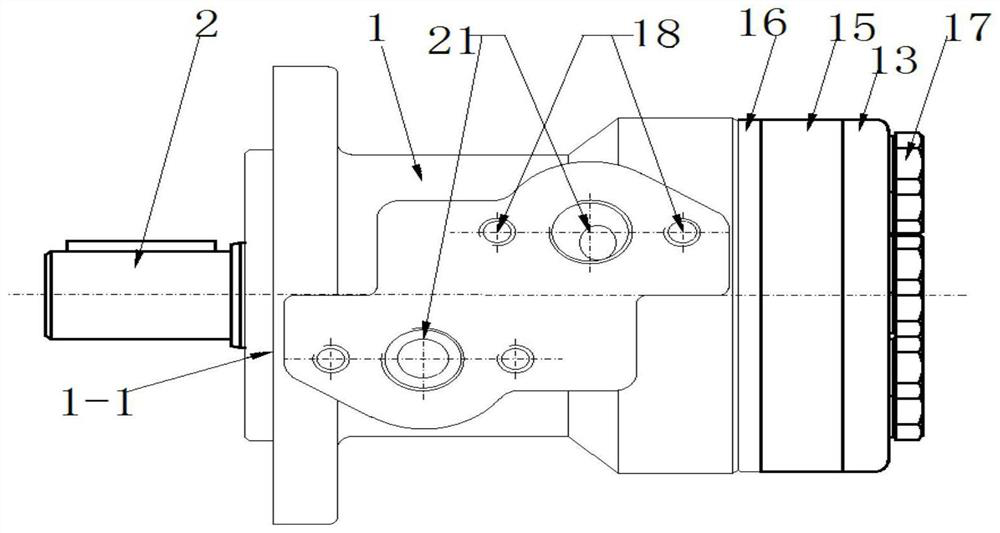

Integral backpressure-resistant cycloid hydraulic motor structure

PendingCN114087120AEasy to manufactureLow cost of mass productionRotary piston enginesHydraulic motorControl engineering

The invention relates to an integral backpressure-resistant cycloid hydraulic motor structure, and belongs to the field of hydraulic motors. according to the technical scheme, the integral backpressure-resistant cycloid hydraulic motor structure comprises a shell and a stator-rotor assembly; an output shaft is mounted in the shell; the shell is integrally formed and manufactured; the diameter of an inner cavity of the shell is matched with the diameter of the output shaft transmission part. A baffle part is formed at one end of the shell; a baffle hole is formed in the center of the baffle part; the aperture of the baffle hole is matched with the diameter of the output part of the output shaft; the transmission part is located in the shell, and the output part penetrates out of the shell through the baffle hole. The stator-rotor assembly is arranged at one end of the shell away from the baffle part. The invention has the beneficial effects that the shell is integrally formed, and the baffle part of the shell serves as the front end cover, so that the strength of the shell is greatly improved, the problem that the front end cover is prone to oil seepage and oil leakage is thoroughly solved, and the high-back-pressure working requirements of series connection of hydraulic motors and the like can be met; meanwhile, the assembling difficulty is reduced, and manufacturing and using are more convenient.

Owner:SHANDONG RNOMAC HYDRAULIC MACHINERY

A processing technology for vacuum heat insulation panels with installation holes and not afraid of surface damage

ActiveCN110792880BSimple structureGood insulation performanceThermal insulationSynthetic resin layered productsGlass fiberEngineering

The invention relates to a processing technology of a vacuum heat insulation panel with installation holes and without fear of surface damage. The vacuum heat insulation panel includes an inner vacuum structure layer and at least one outer vacuum structure layer wrapped around it. The inner vacuum structure layer consists of an inner core board It is composed of a high-vacuum barrier film wrapped on the outside. The inner core board is made of glass fiber and other materials by combing hot-pressing or dispersing wet and vacuum processes. The inner vacuum structure layer is made of high-vacuum heat-sealing equipment; the outer vacuum The structural layer is composed of an outer core board and a high-vacuum barrier film wrapped outside it. The outer core board is made of glass fiber and other materials by mixing and dispersing wet method and vacuum forming process. The air-absorbing material can be embedded on the outer core board and then loaded into the outer core board. Inside the high-vacuum barrier film, the outer vacuum structure layer is made with high-vacuum heat-sealing equipment. The installation hole is separated from the core layer by a partition plate provided with a through hole. After the surface of the vacuum heat insulation board is damaged, it does not bulge, does not expand, does not absorb water, and can retain heat preservation and heat insulation performance.

Owner:安徽百特新材料科技有限公司

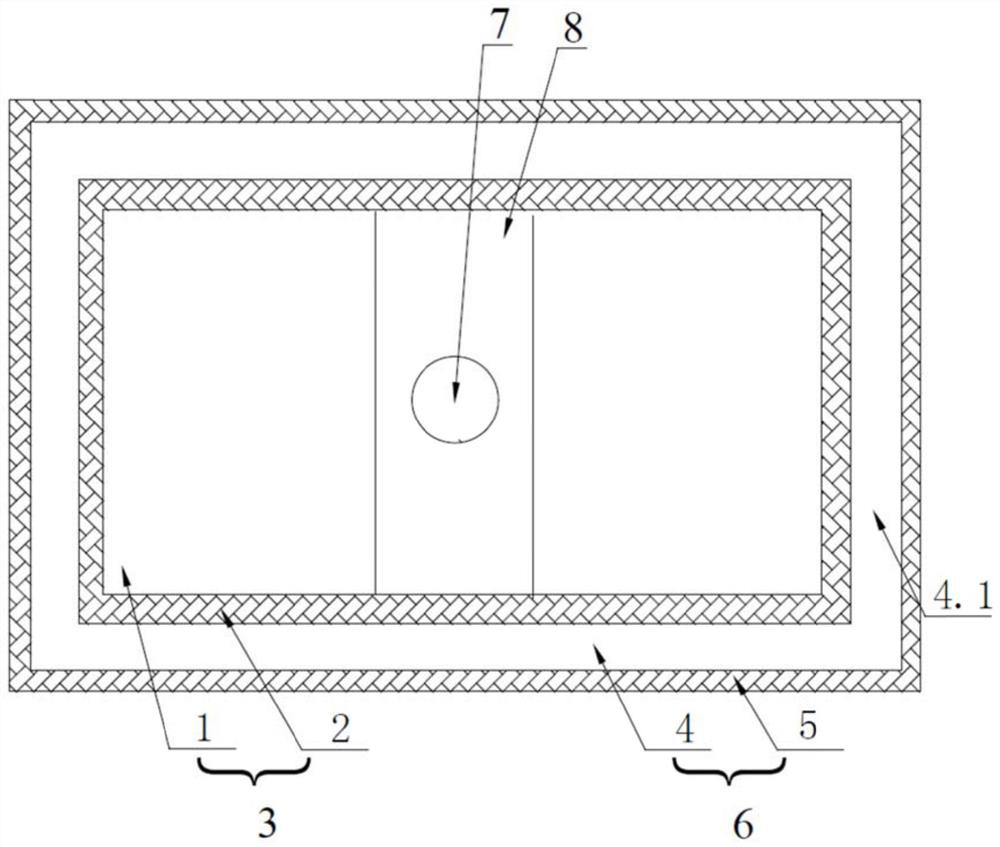

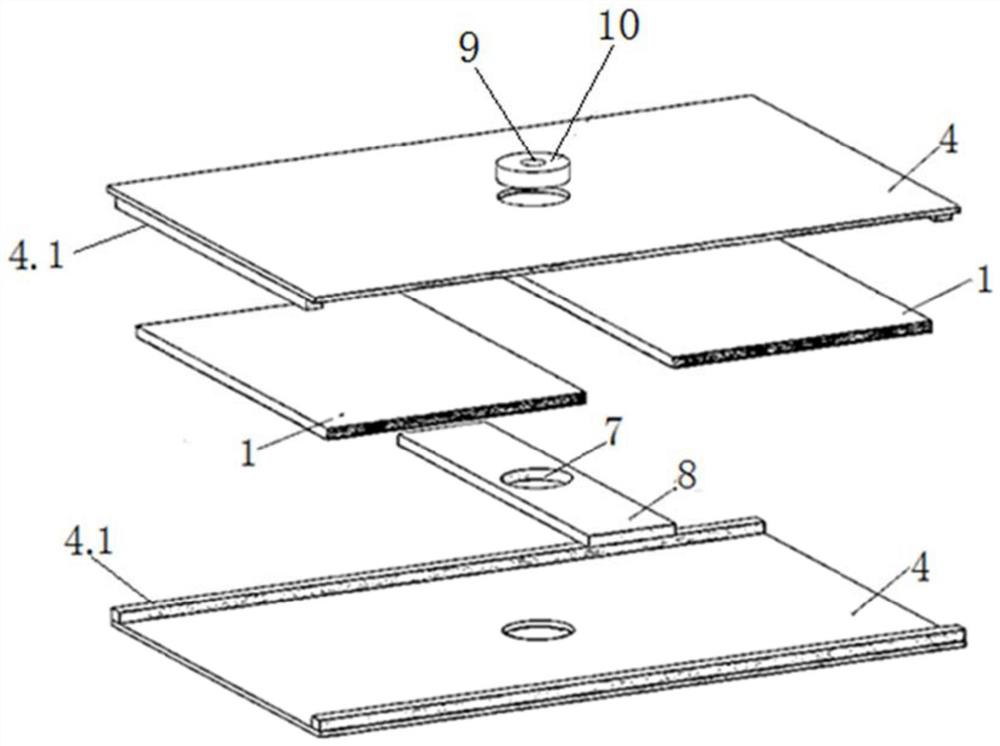

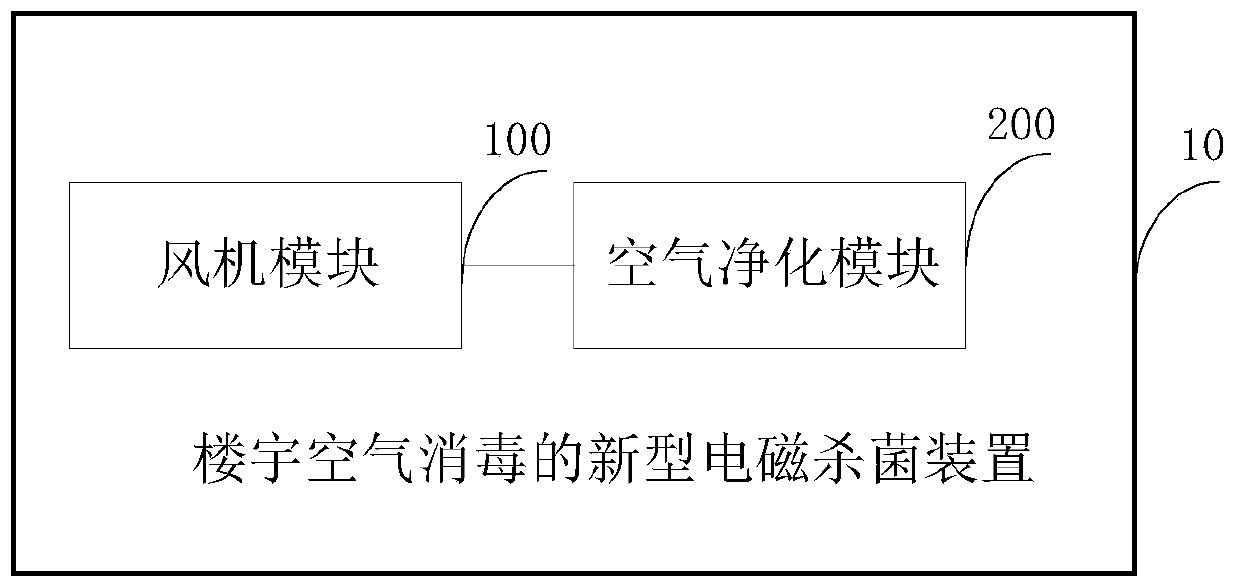

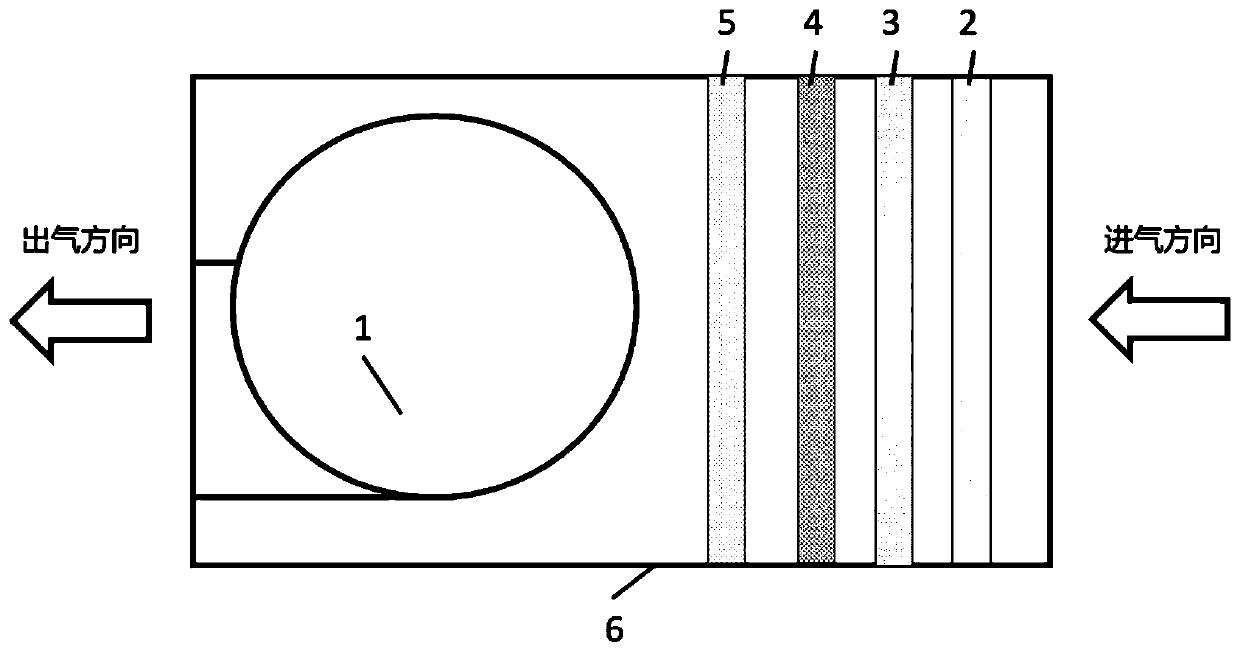

Novel electromagnetic sterilizing device for building air sterilization

PendingCN111536615AAddress workplace safety issuesSimple preparation processMechanical apparatusLighting and heating apparatusAir decontaminationConstruction engineering

The invention discloses a novel electromagnetic sterilizing device for building air sterilization. The novel electromagnetic sterilizing device for building air sterilization comprises a fan module arranged in a building ventilation system, and an air purification module arranged in the building ventilation system, correspondingly arranged with the fan module and used for sterilizing the gas in the building ventilation system. The device has no consumable or secondary pollution, can meet the requirement of air disinfection and purification in facilities such as isolation wards, shelter hospitals and the like, can also meet the urgent requirement of safe reworking and reproduction in the later period of the epidemic situation, and has the advantages of simple matched part manufacturing process, low mass production cost and high capacity amplification, so that the safety problem of a building working environment after reworking can be solved, and cross infection of air in hospital buildings can be avoided.

Owner:TSINGHUA UNIV

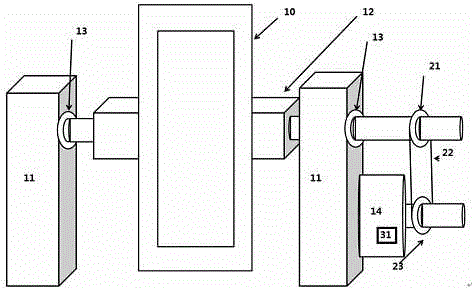

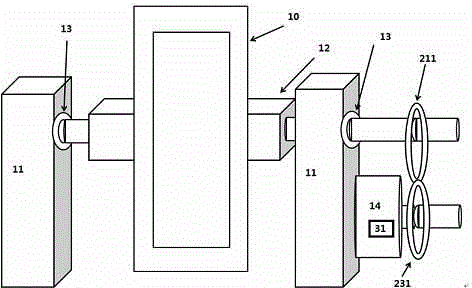

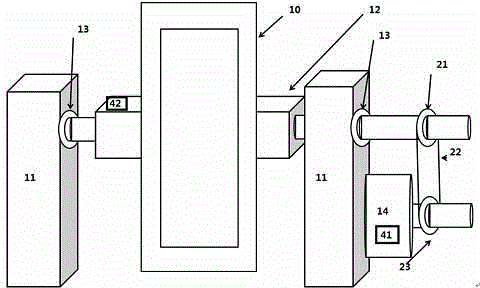

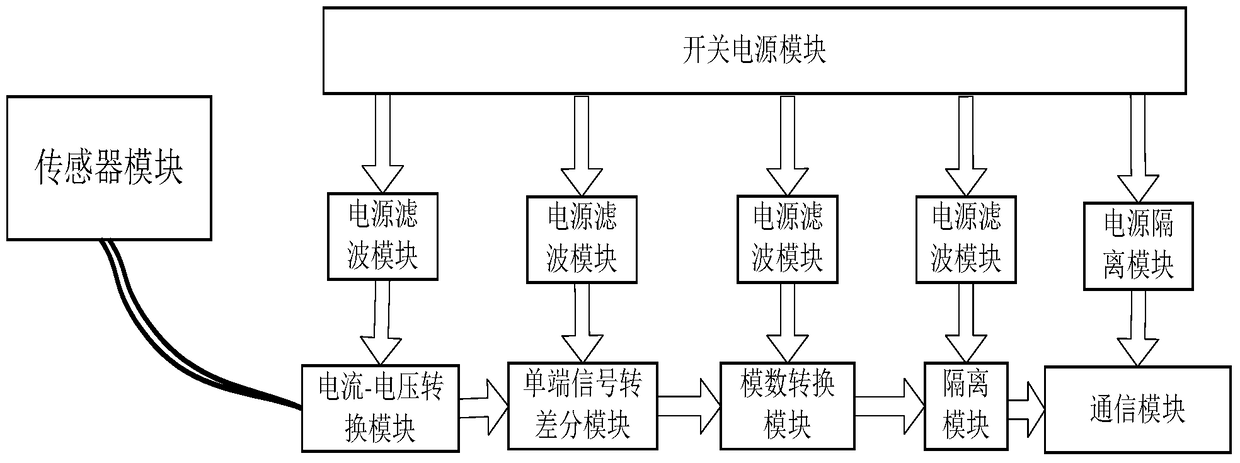

SF6 circuit breaker state monitoring method and thionyl fluoride gas concentration monitoring device

ActiveCN105093103BSimple wayEffective diagnosisMaterial analysis by electric/magnetic meansCircuit interrupters testingEngineeringGas concentration

The invention relates to an SF6 breaker state monitoring method and a thionyl fluoride gas concentration monitoring device, wherein the method is used for detecting the concentration of thionyl fluoride which is the decomposer of SF6 in an SF6 breaker, and the state of the SF6 breaker is judged by the concentration of the thionyl fluoride. The monitoring device which implements the above method comprises an information acquisition and processing unit and a processing unit, wherein the information acquisition and processing unit comprises a sensor module, a current-to-voltage conversion module and an analog-to-digital conversion module are connected in sequence, the processing unit is a controller, and the output end of the analog-to-digital conversion module is connected with the input end of the controller. The gas concentration monitoring device provided by the invention has the advantages of small size, low cost and lower cost especially in mass production and is easy to carry. The device also can well and easily detect the gas concentration, is suitable for practical engineering application, and has high detection accuracy, wide detection range and good electromagnetic disturbance resistance.

Owner:PINGGAO GRP +2

A method for regulating the period length of type I collagen fiber striations

ActiveCN111499729BSimple preparation processLow cost of mass productionConnective tissue peptidesBacteriaFiberTriple helix

The invention discloses a method for regulating the period length of type I collagen fiber striations, and belongs to the technical field of genetic engineering. The present invention uses N and C terminal (PPG) n Based on the sequence, a continuous collagen sequence with different numbers of Gly‑Xaa‑Yaa triplets is inserted in the middle to form a three-segment chimeric collagen P‑CL‑P pattern, through the N and C-terminal (PPG) n Interactions among the triple helices drive self-assembly to form ribbon-like fibers with periodic alternating light and dark stripes of varying dark stripe lengths. The method of the invention has a simple preparation process, can produce collagen fibers with low cost on a large scale, and has broad application prospects in the field of biomaterials.

Owner:JIANGNAN UNIV +1

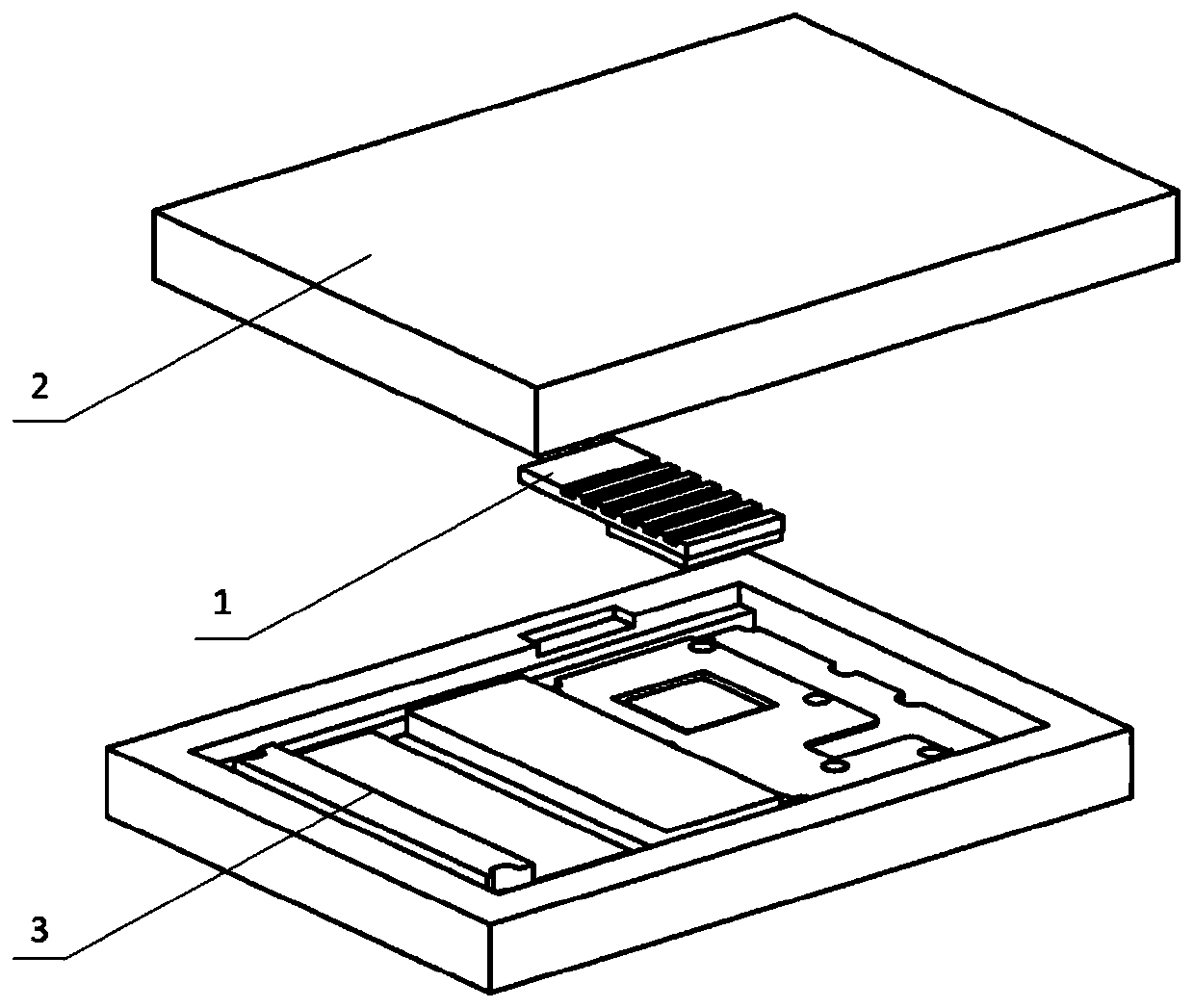

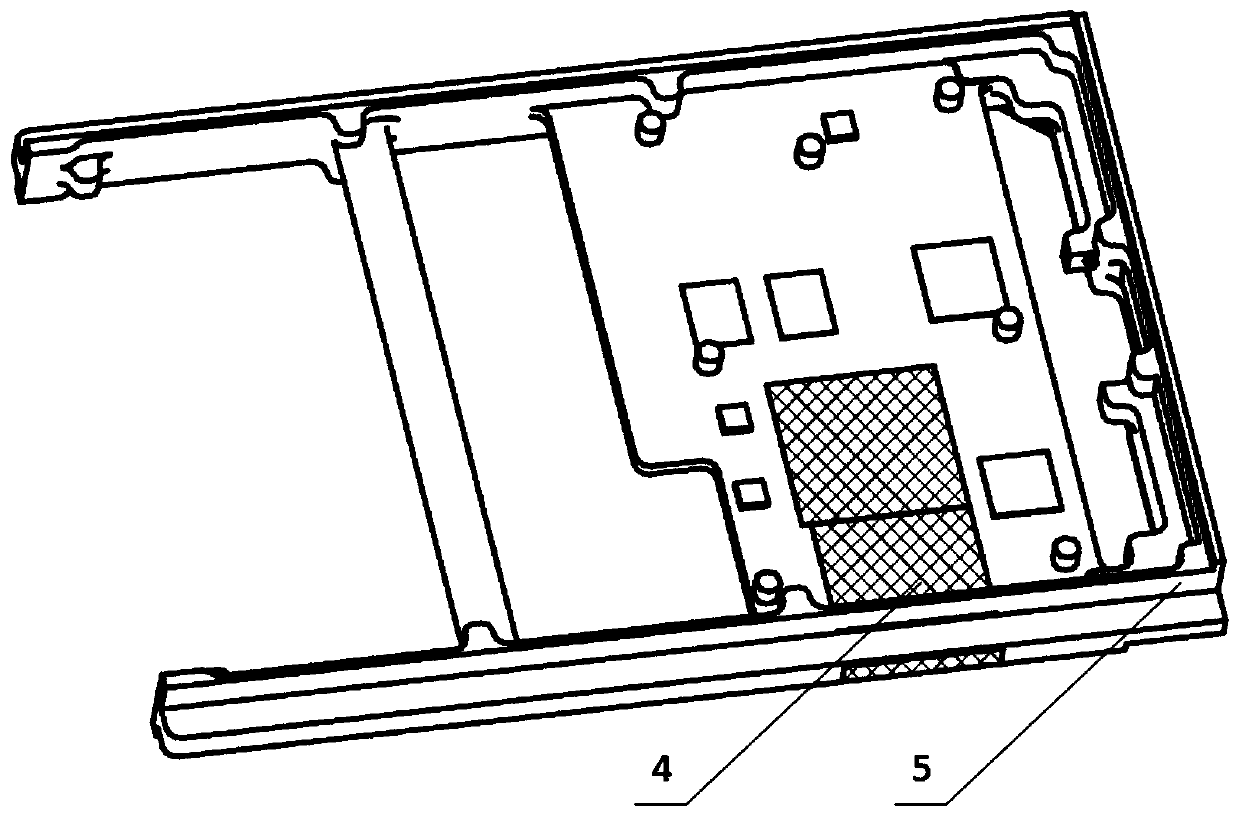

Method for manufacturing high-reliability heterogeneous heat-dissipating cold plate

InactiveCN110430717AGuaranteed positionSimple methodModifications by conduction heat transferWaxInvestment casting

The invention discloses a method for manufacturing a heat-dissipating cold plate with high thermal conductivity and high reliability and aims to provide a preparation method which requires no complicated pre-welding treatment, and is simple and low in batch production cost. The method comprises the following steps of: determining the position of the heat-dissipating cold plate corresponding to a high heat component according to the design requirement of a heat dissipation channel, and producing, on a copper alloy insert, a conduction heat dissipation path of a horizontal strip piece which increases the contact area with a box body, wherein the horizontal strip piece extends to the position of the mounting rib of the box body; embedding the copper alloy insert in a right wax mold of a casting mold upper cavity and a casting mold lower cavity, and by using a gypsum-type investment casting process, performing integrated investment casting on the copper alloy insert and the box body in a vacuum pouring tank; finally, machining a casted heat-dissipating cold plate blank according to molding elements to prepare the high-reliability heterogeneous heat-dissipating cold plate.

Owner:10TH RES INST OF CETC

Method for preparing hydrogen with Al alloy material at room temperature

InactiveCN101358309BEasy to useLow water quality requirementsHydrogen productionHydrogenRoom temperature

The invention discloses an Al alloy material which reacts with water at room temperature to prepare hydrogen, and a use method thereof; the Al content in the alloy material is 3 weight percent to 95 weight percent, and the rest are one type or more than one type among Sn, Zn, Bi, Pb, Mg, Ca and In elements; when Ca and In are contained, the content of Ca and In is not more than 10 weight percent;the alloy material is prepared by melting alloy and then mechanically processing alloy cast ingots into foil-like or sheet-like materials; the material is taken as the raw material for preparing hydrogen, improves the hydrogen preparation capability when the cost is quite low, can prepare hydrogen on a large scale, and is easy to be stored and transported.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com