Method for synthesizing polypyrrole-chitosan-metal nanoparticle composite film on surface of cathode by one-step process

A technology of metal nanoparticles and cathode surface, which is applied in the direction of electrolytic inorganic material coating, electrolytic coating, coating, etc., can solve the problems of long preparation cycle, high cost, complicated preparation process, etc., and achieve low production cost, mild reaction conditions, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) chitosan is dissolved in 0.1mol / L nitric acid solution to obtain solution A, and the mass percentage concentration of chitosan in solution A is 1%;

[0020] 2) After adding pyrrole monomer and copper sulfate to solution A, solution B is obtained, the concentration of pyrrole monomer in solution B is 0.1mol / L, and the concentration of copper sulfate in solution B is 0.2mol / L;

[0021] 3) Put the nickel strip as the cathode in solution B, electrify under the protection of nitrogen for electrochemical synthesis, the potential is -0.8V, the electrodeposition time is 10 minutes, and the polypyrrole-chitosan-metal is obtained in one step on the surface of the cathode Copper nanoparticles composite film.

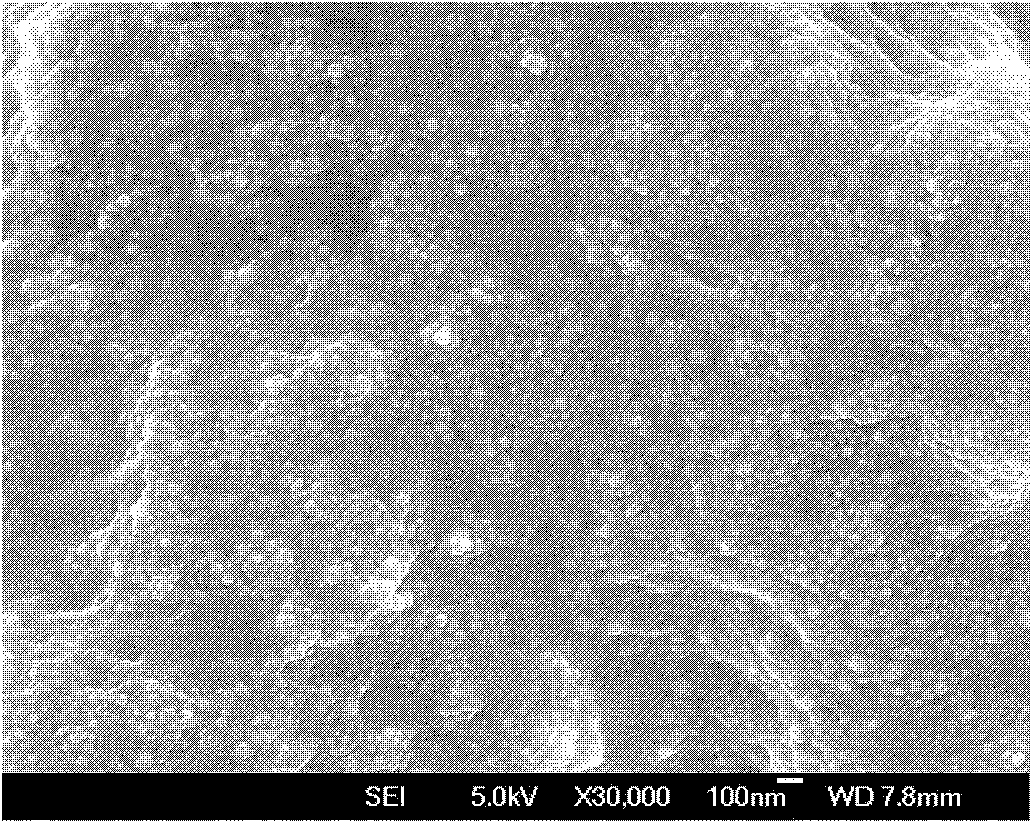

[0022] The surface was observed with a scanning electrode, and the polypyrrole-chitosan-metal copper nanoparticle composite film contained uniformly distributed copper nanoparticles.

Embodiment 2

[0024] 1) with step 1 in embodiment 1;

[0025] 2) with step 2 in embodiment 1;

[0026] 3) Place indium tin oxide conductive glass as the cathode in solution B, and conduct electrochemical synthesis under the protection of nitrogen, with a potential of -1.2V and an electrodeposition time of 20 minutes, and obtain polypyrrole-chitopolymer on the surface of the cathode in one step. Sugar-metal copper nanoparticle composite films.

[0027] The surface was observed with a scanning electrode, and the polypyrrole-chitosan-metal copper nanoparticle composite film contained uniformly distributed copper nanoparticles.

Embodiment 3

[0029] 1) with step 1 in embodiment 1;

[0030] 2) After adding pyrrole monomer and copper nitrate to solution A, solution B is obtained, the concentration of pyrrole monomer in solution B is 0.2mol / L, and the concentration of copper sulfate in solution B is 0.3mol / L;

[0031] 3) Same as step 3 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com