Preparation method of anti-corrosion liquid-cooled heat dissipation cold plate

A liquid-cooled heat dissipation and anti-corrosion technology, used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve problems such as corrosion and blockage, and achieve the effects of avoiding protective treatment, highlighting corrosion resistance, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

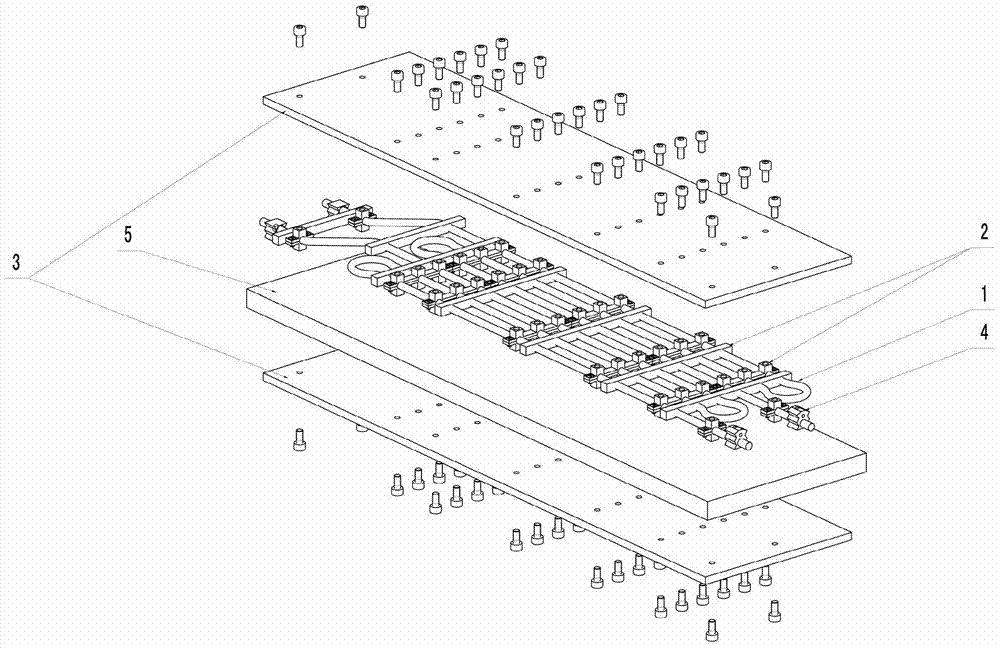

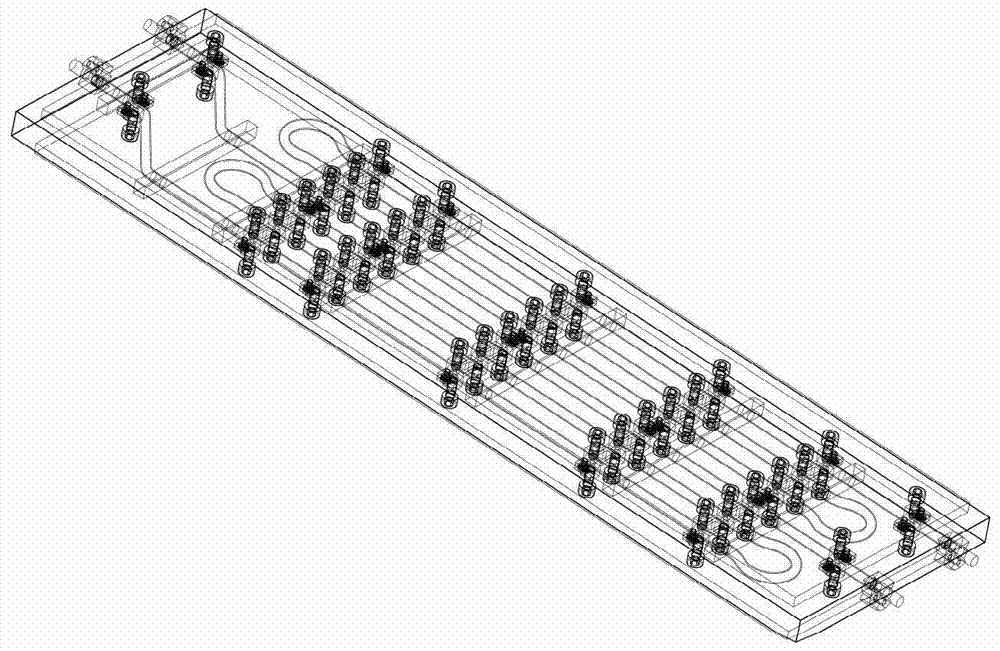

[0019] see Figure 1-Figure 2 . In an embodiment of a method for processing dissimilar materials by buried pipe casting of a corrosion-resistant liquid-cooled heat-dissipating cold plate given below, it mainly includes five aspects: structural shape, pipeline layout, cold plate joint design, pipeline clamping tooling, and integrated casting. a component. In order to improve the reliability of the liquid-cooled heat dissipation cold plate, the liquid-cooled heat dissipation cold plate flow channel titanium tube 1 and the cold plate heat dissipation plate 5 are formed by investment casting of dissimilar materials. The liquid-cooled heat-dissipating cold plate runner titanium tube 1 is made of high-temperature and corrosion-resistant titanium alloy pipes, and the cold plate heat-dissipating plate 5 is made of cast aluminum ZL101A. The liquid-cooled heat-dissipating cold plate flow channel titanium tube 1 is the liquid flow carrier of the liquid-cooled heat-dissipating cold plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com