Patents

Literature

47results about How to "Ensure coplanarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

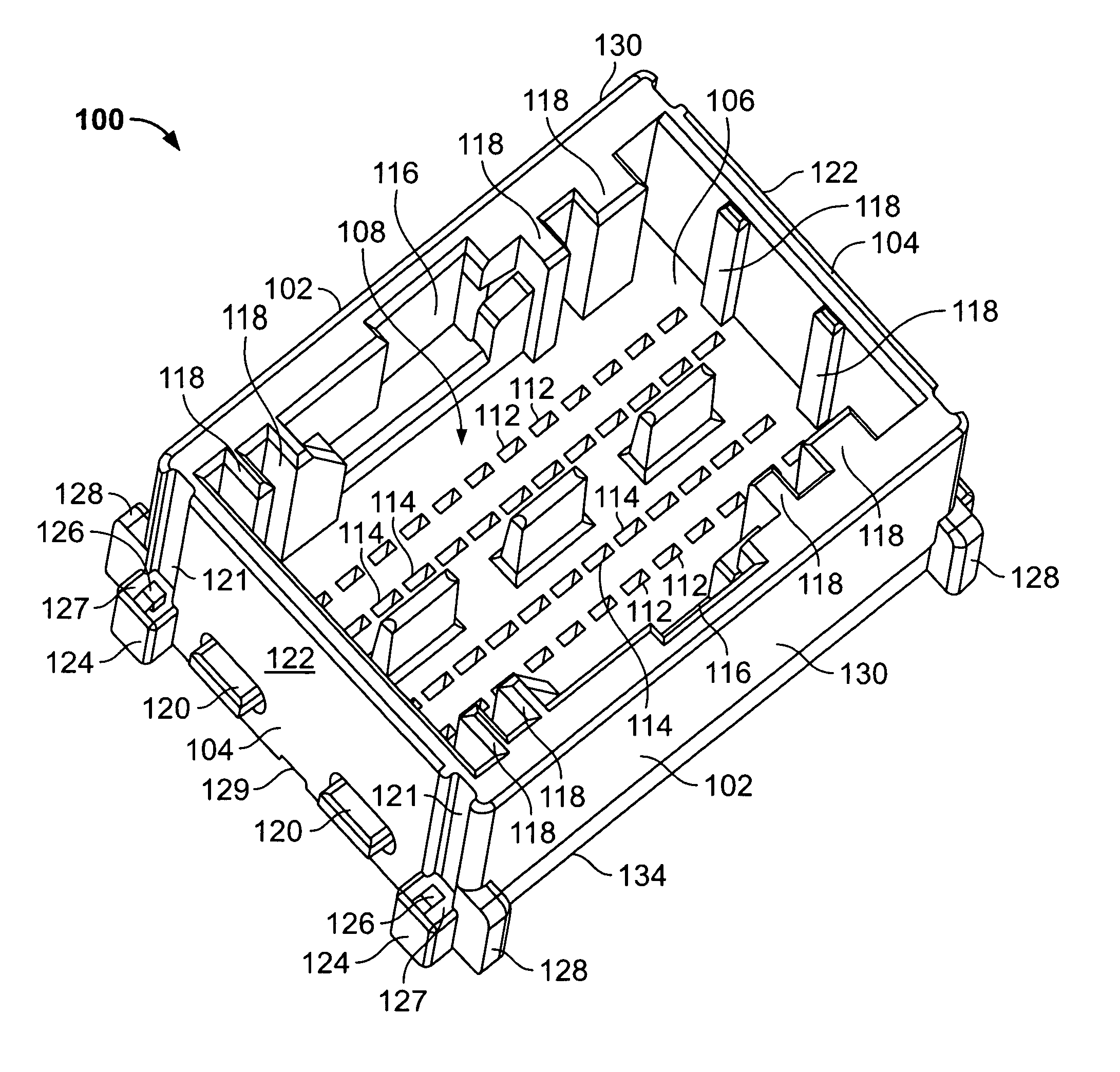

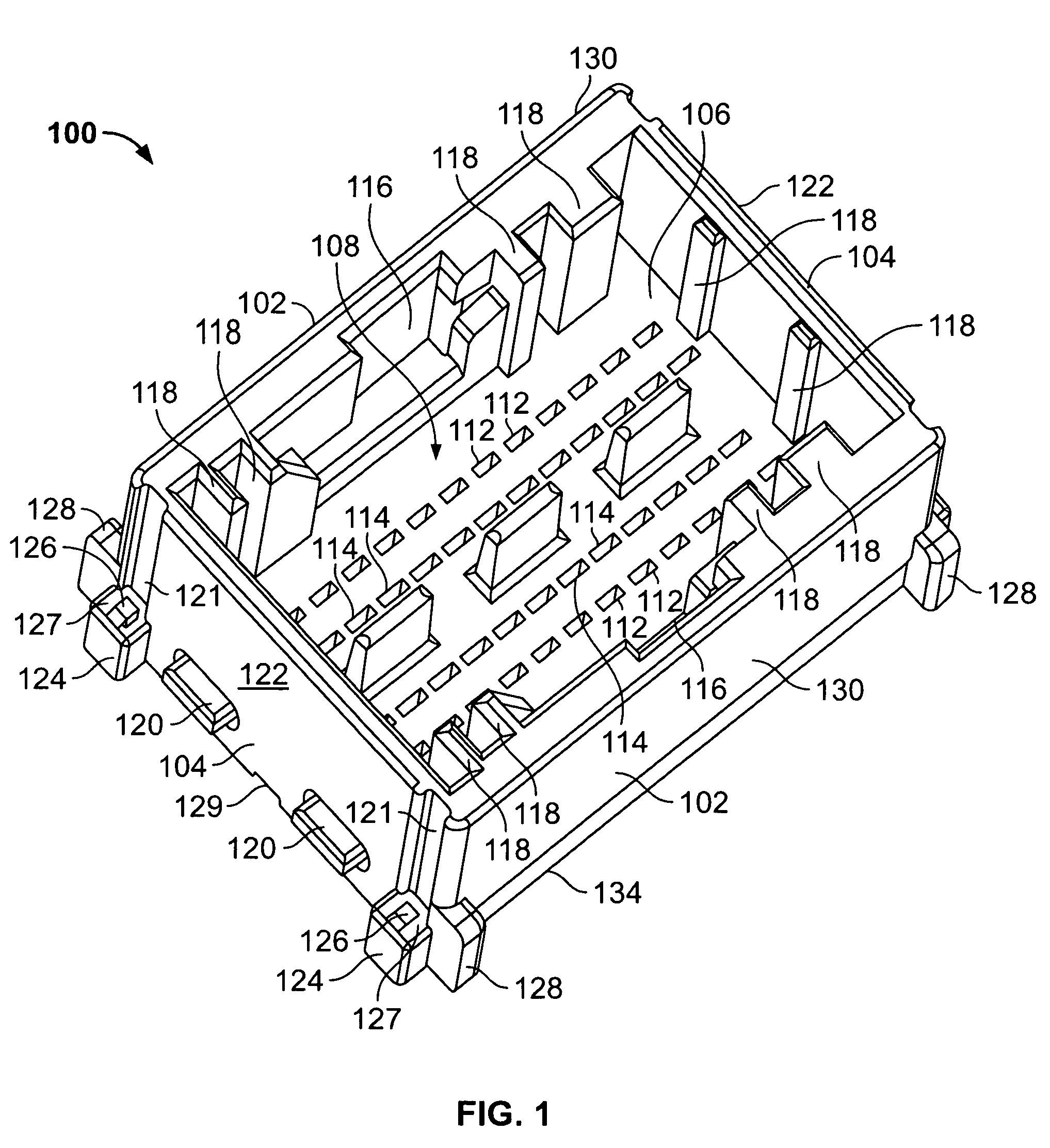

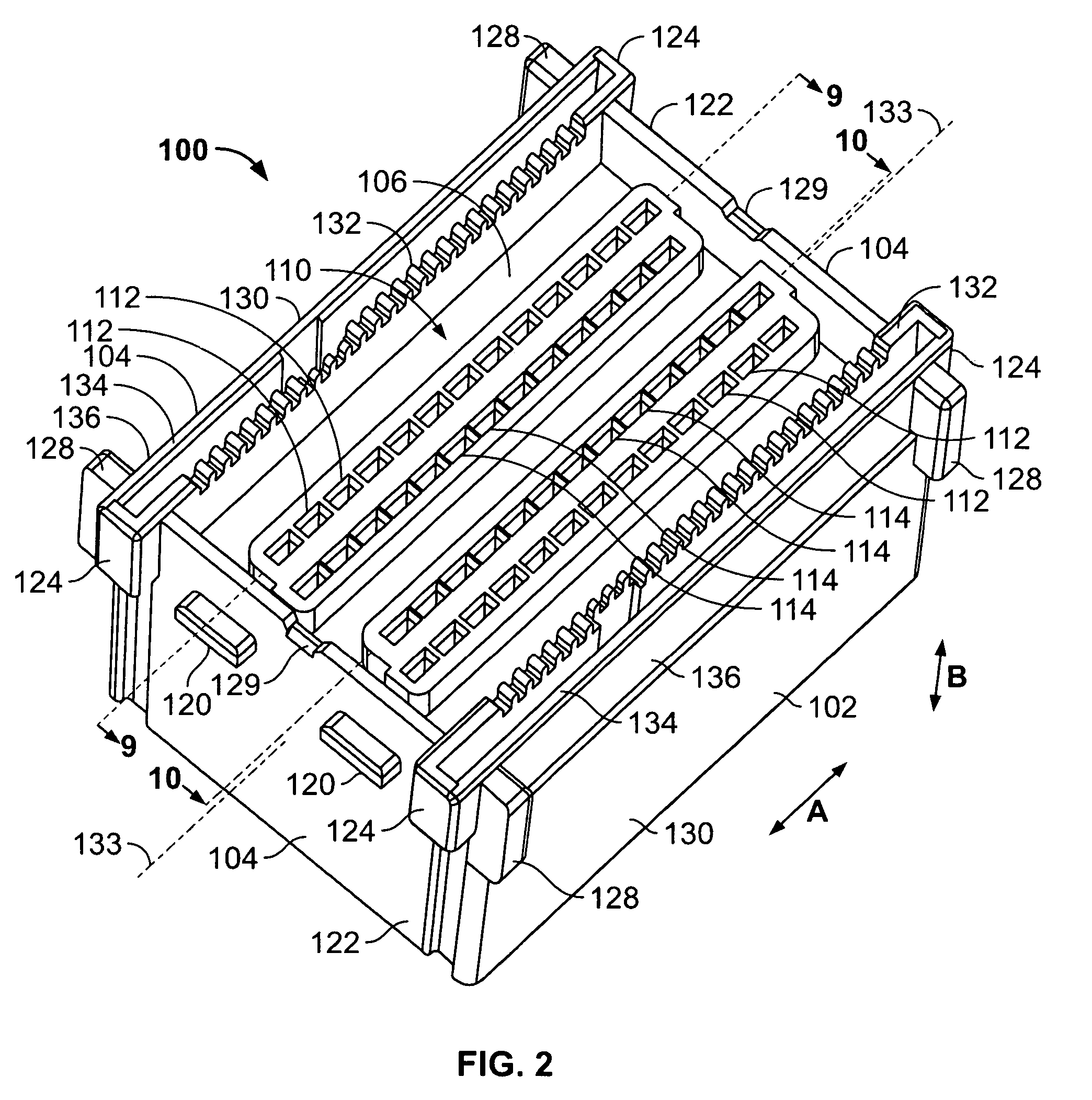

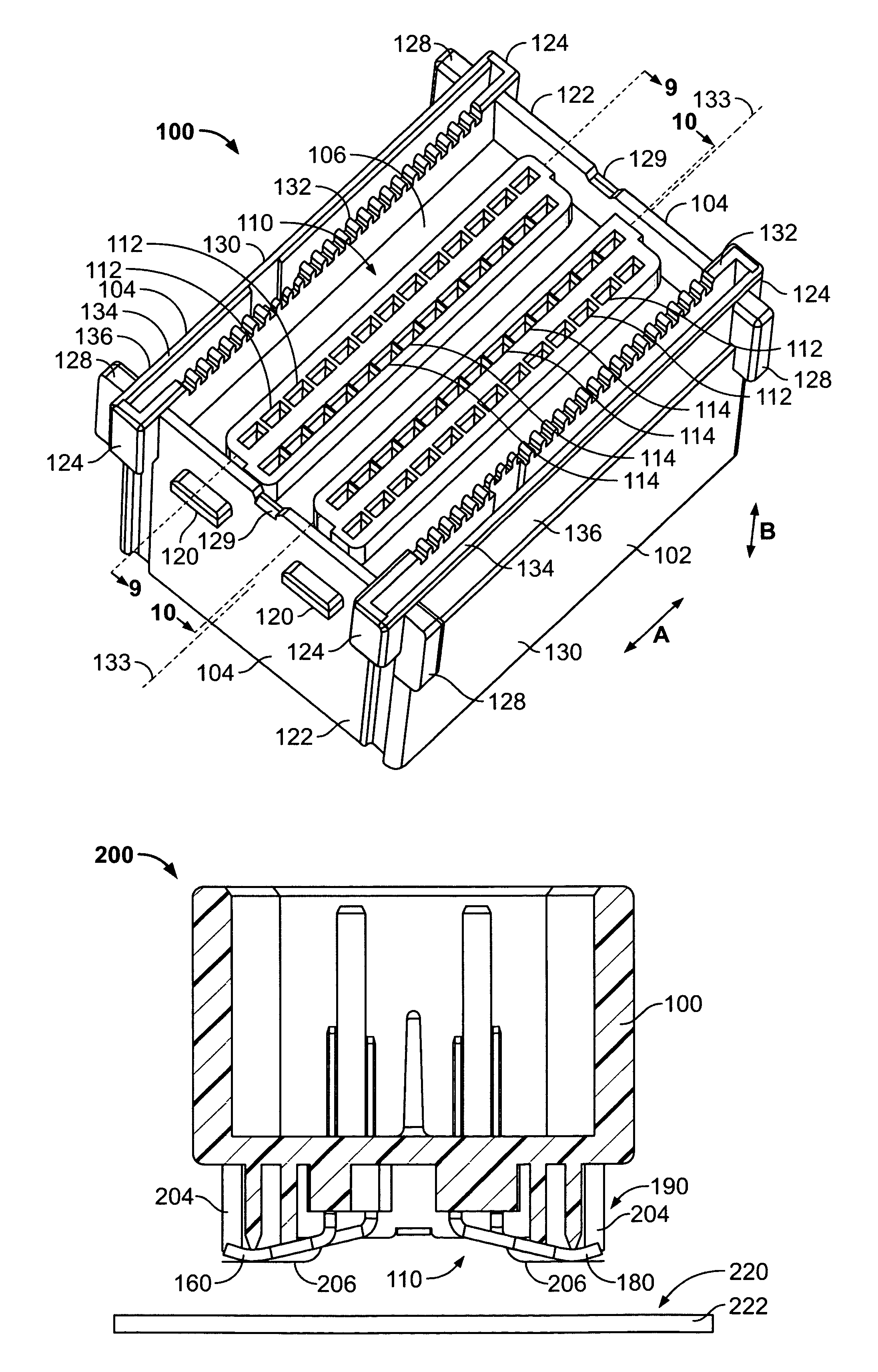

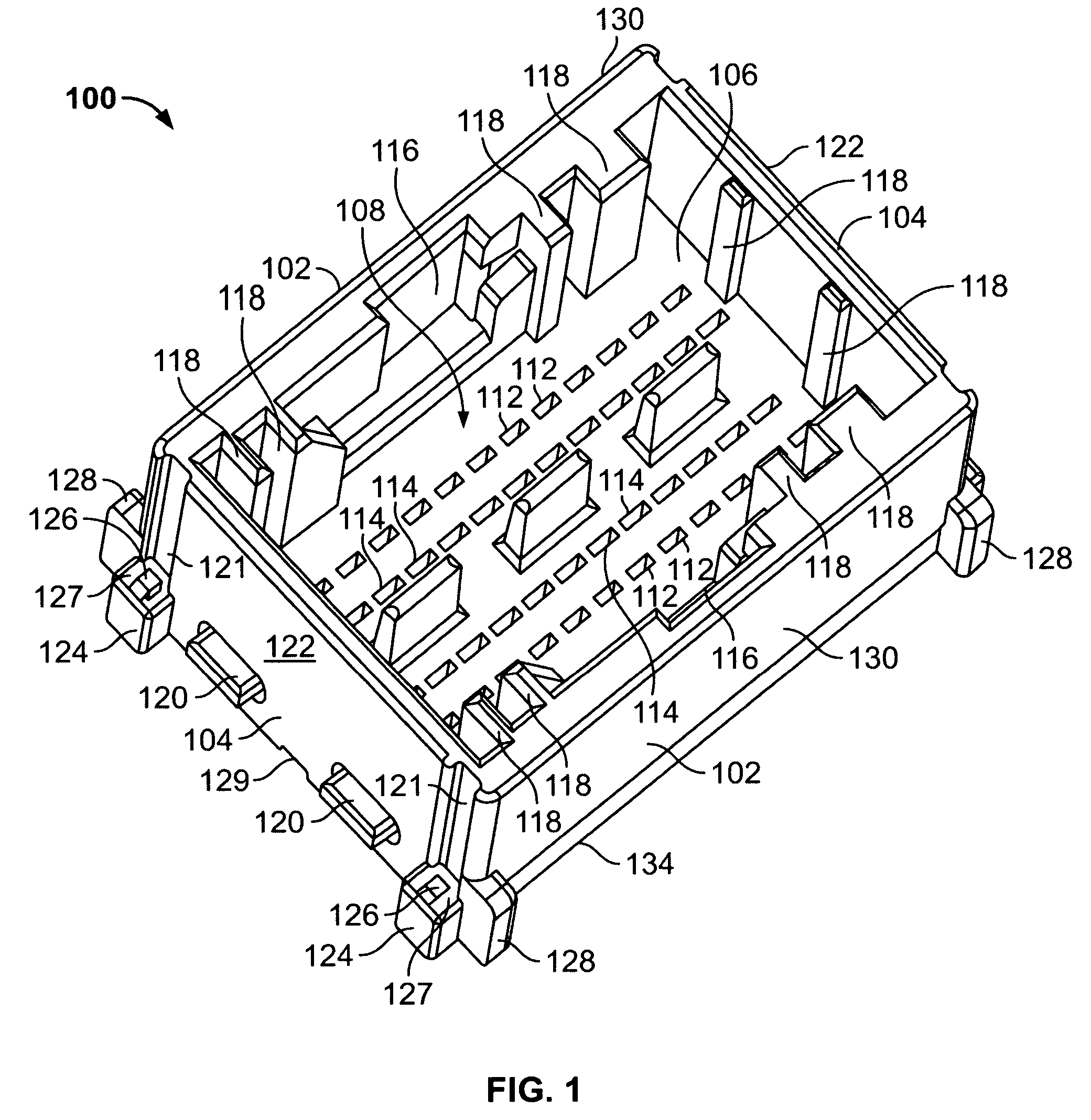

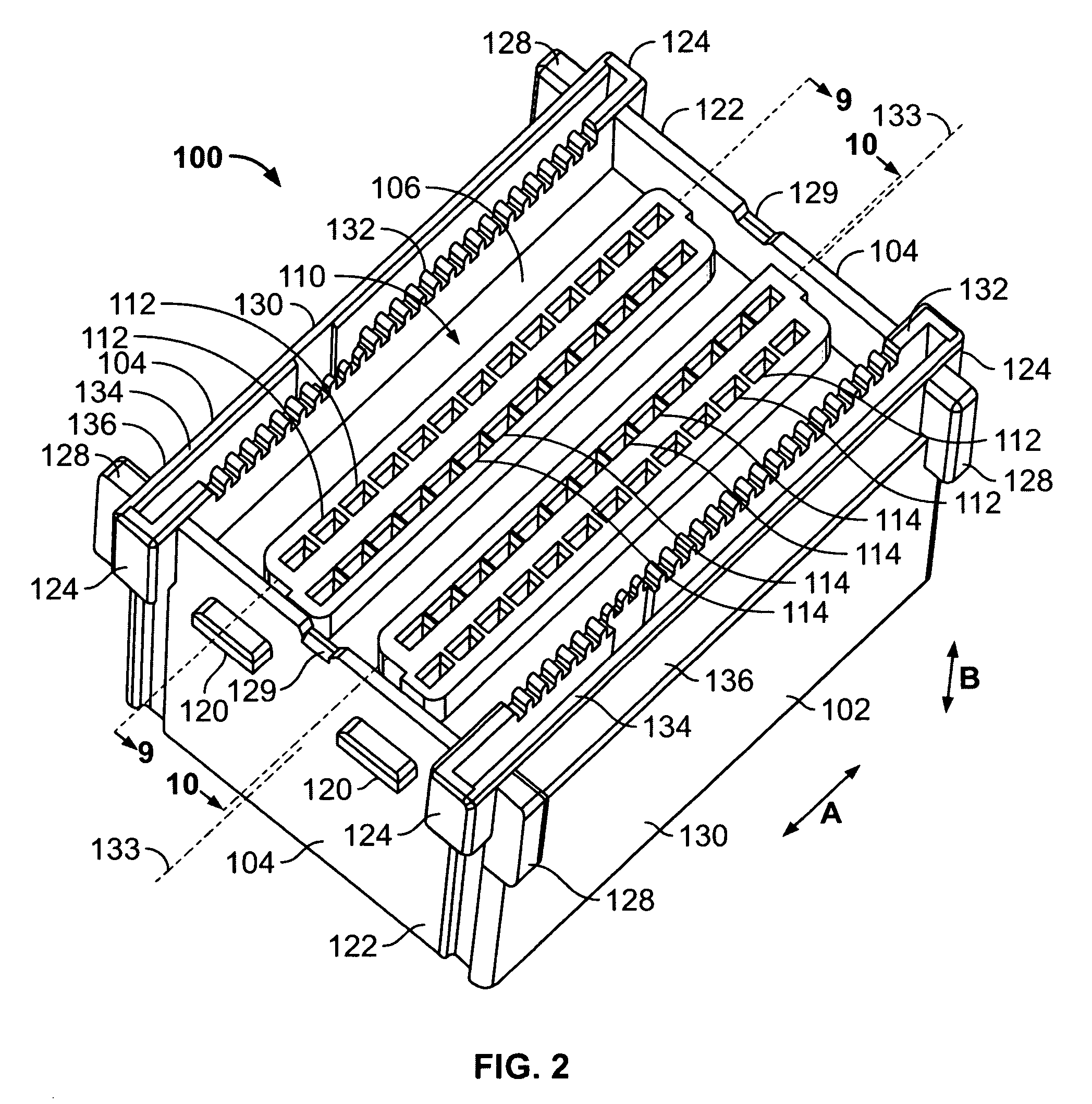

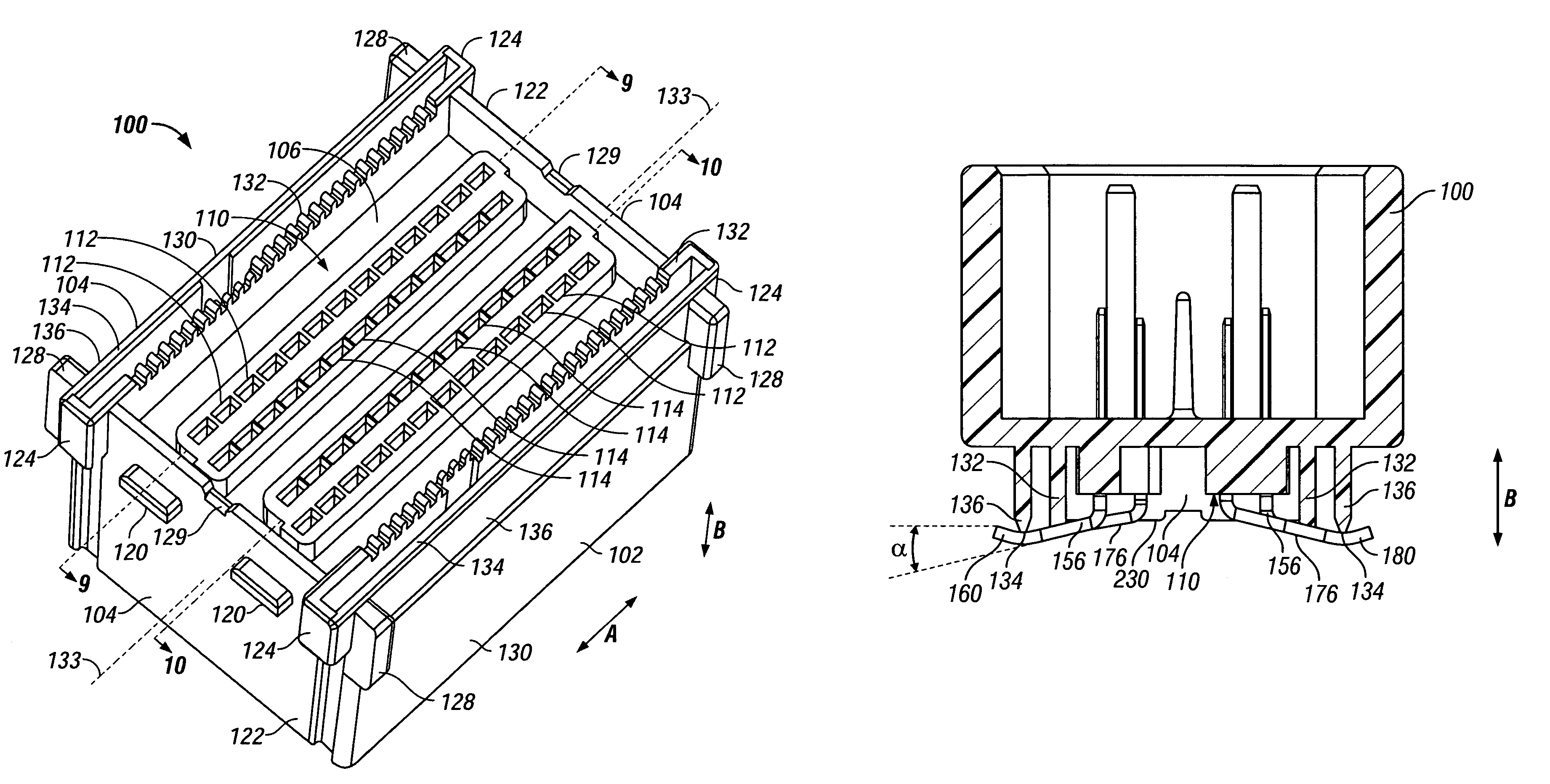

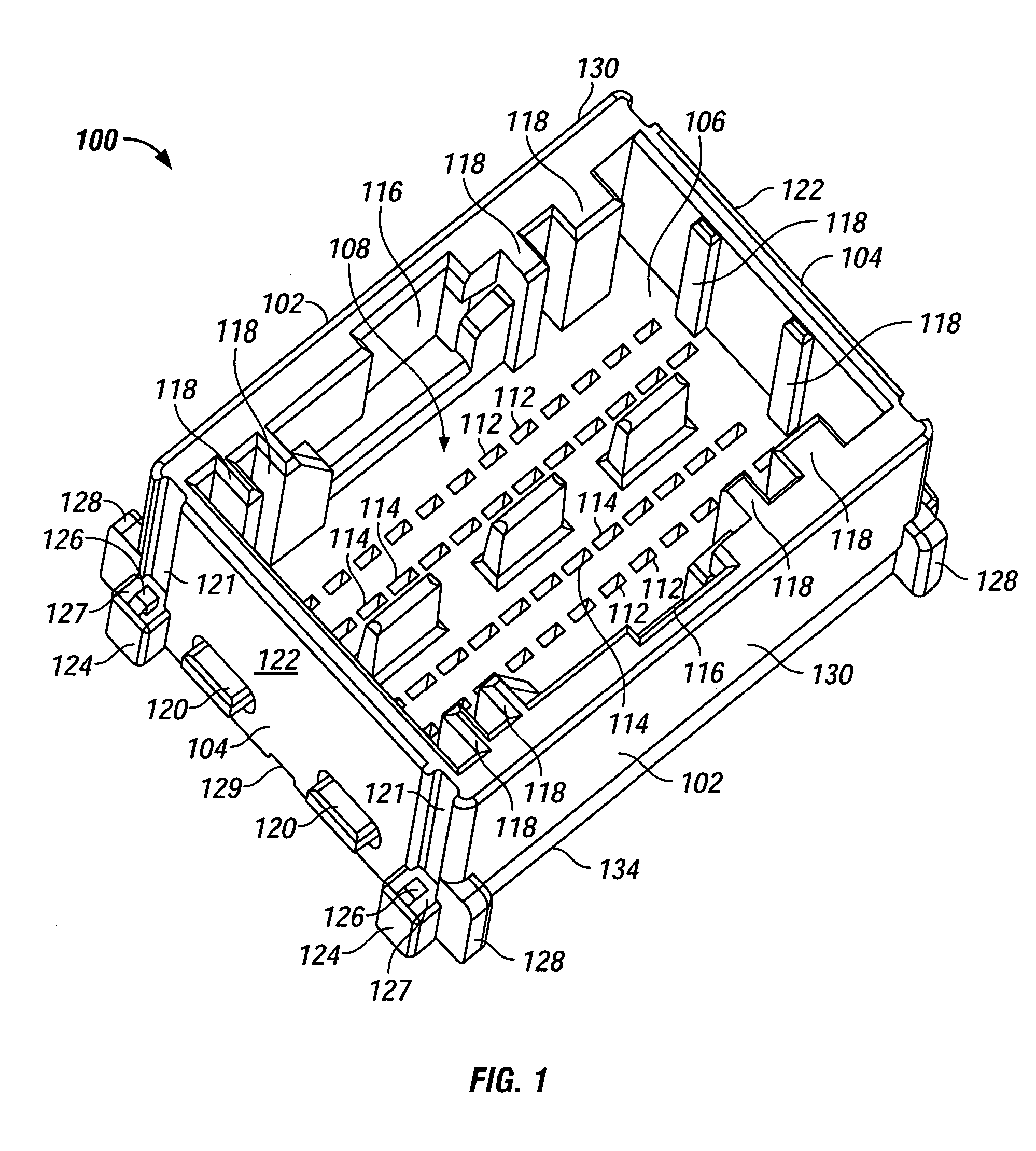

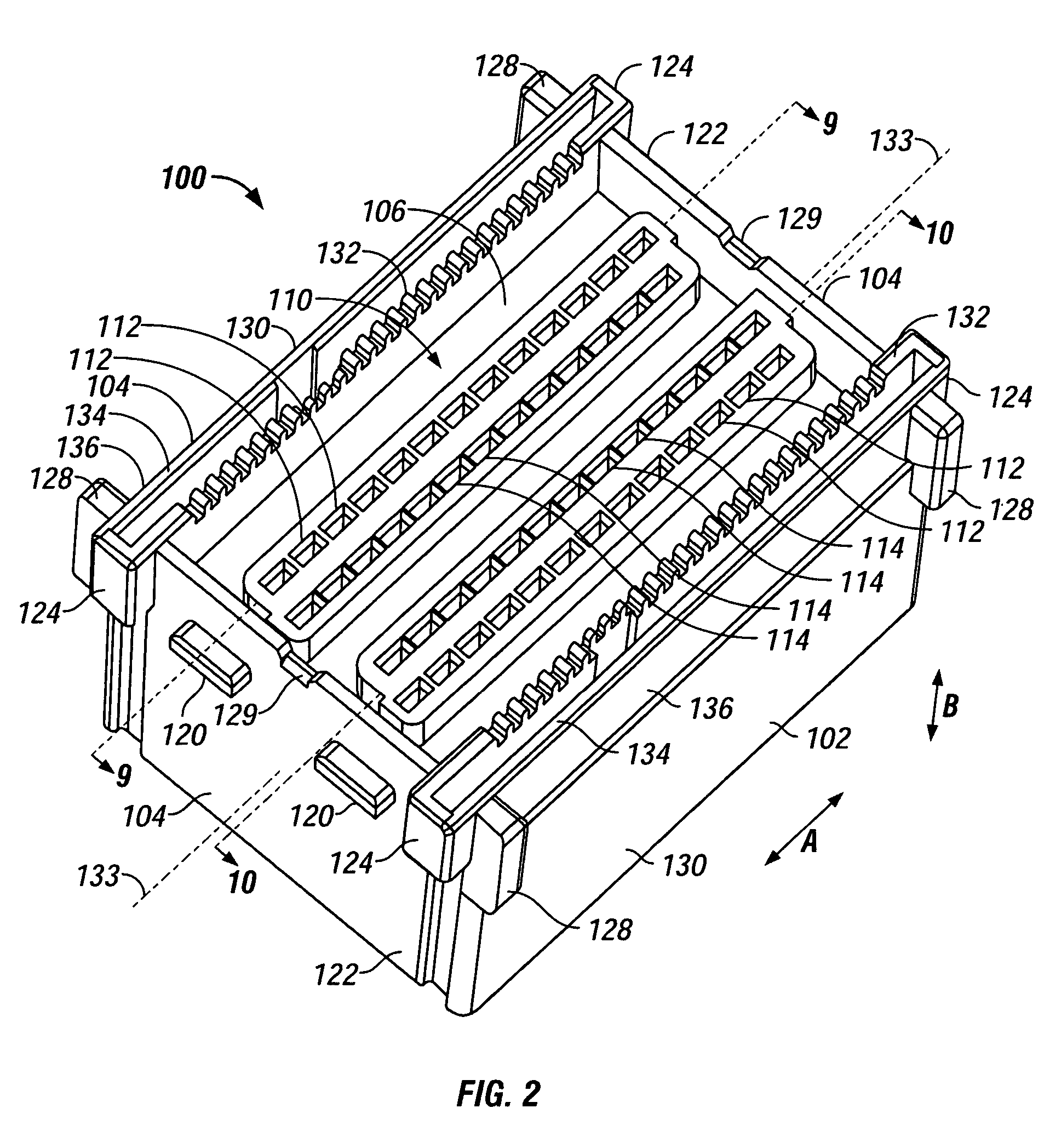

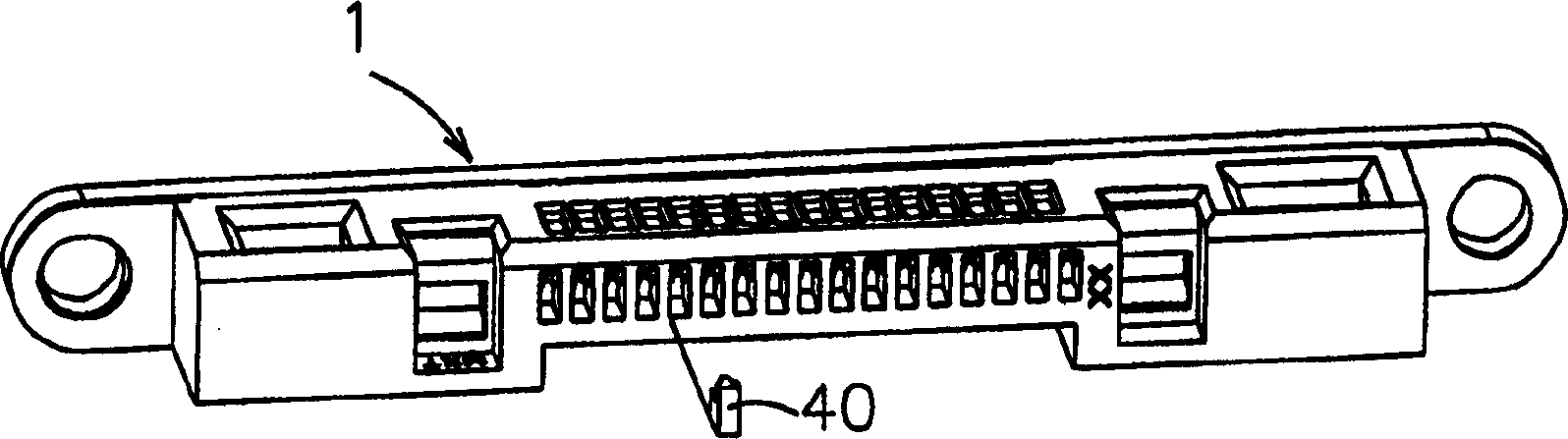

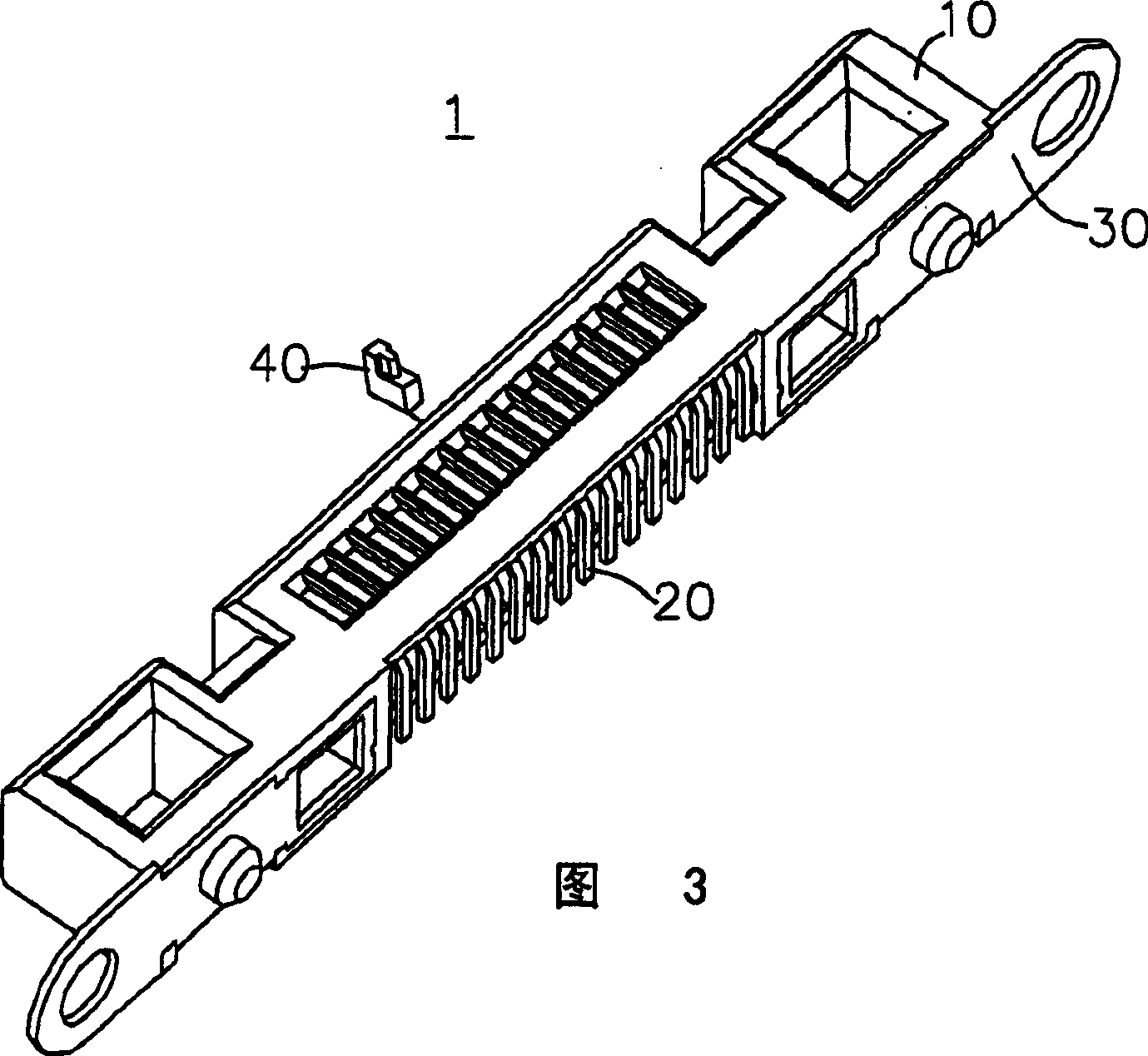

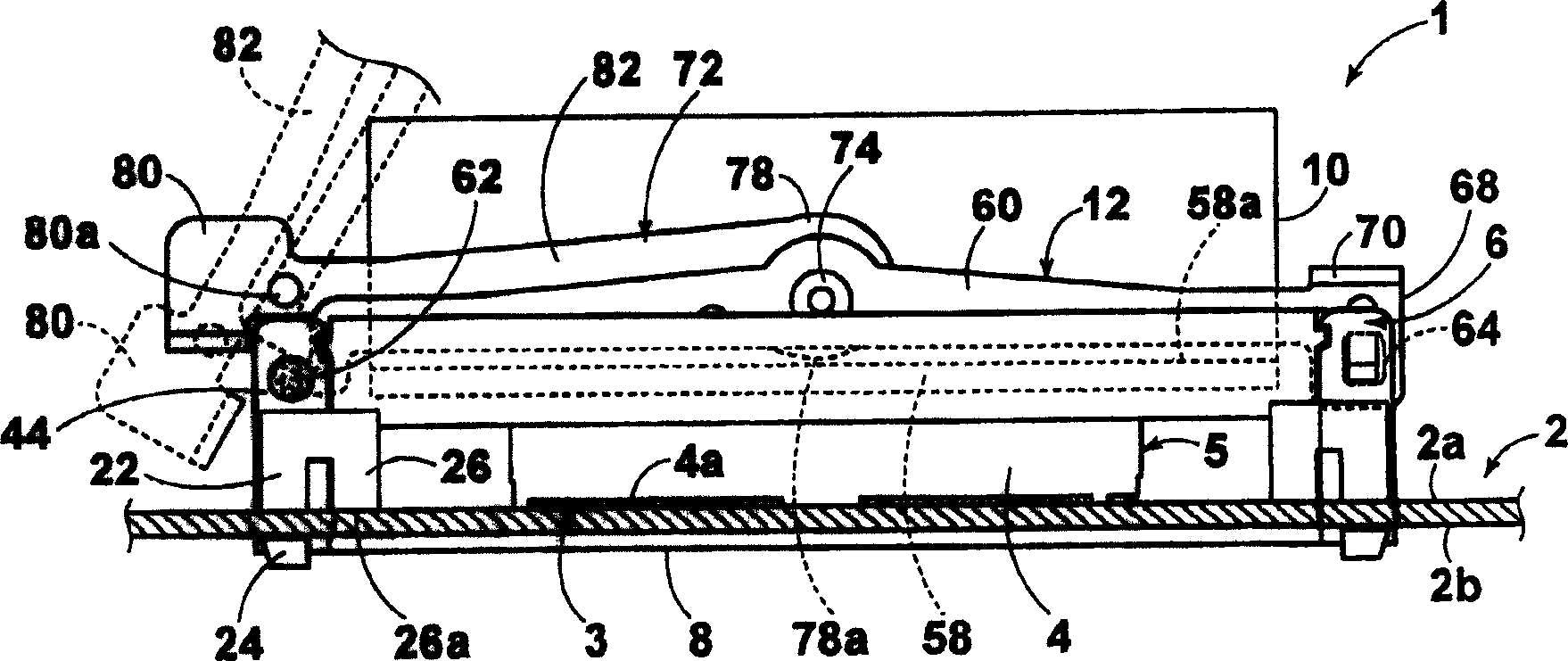

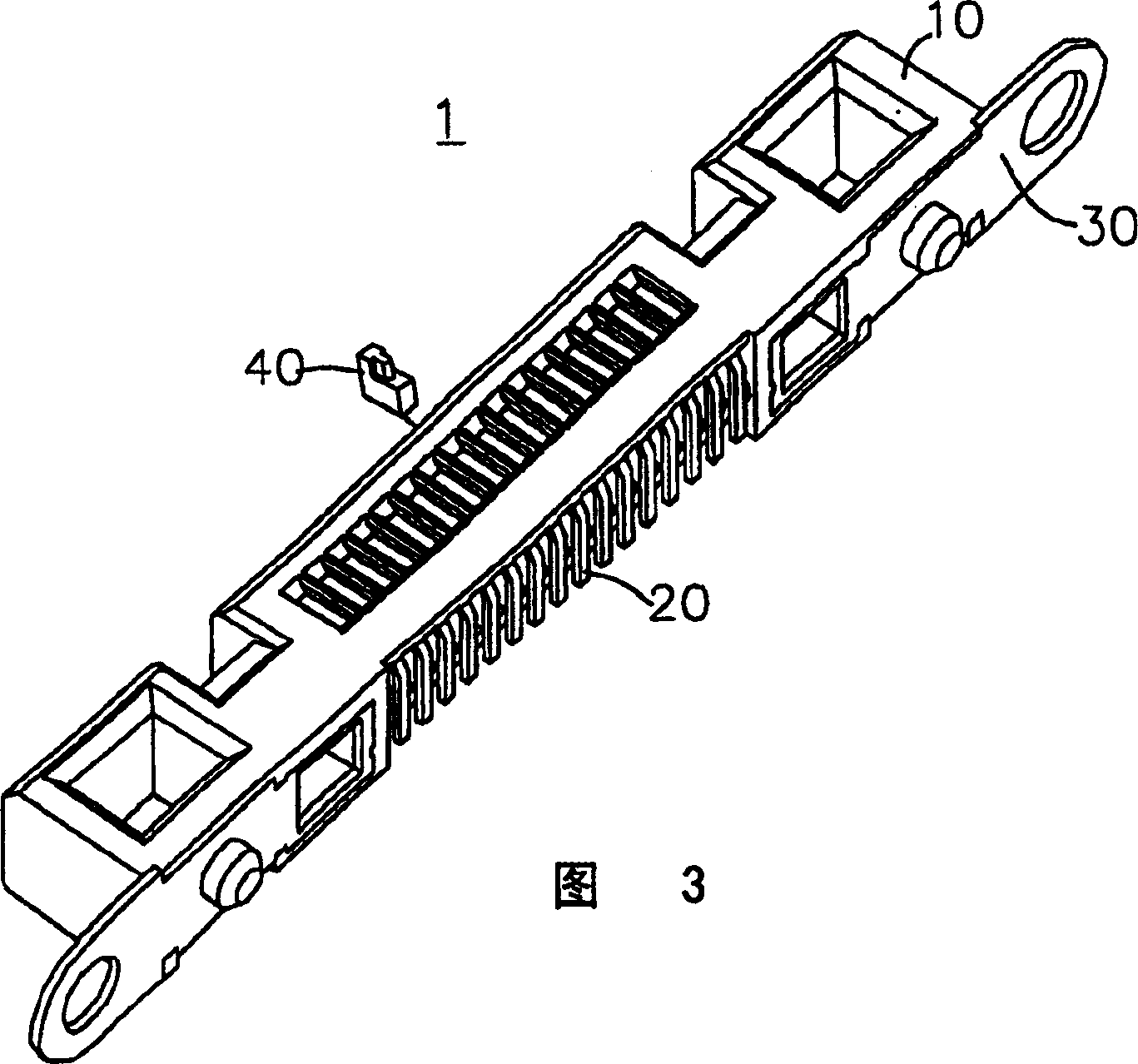

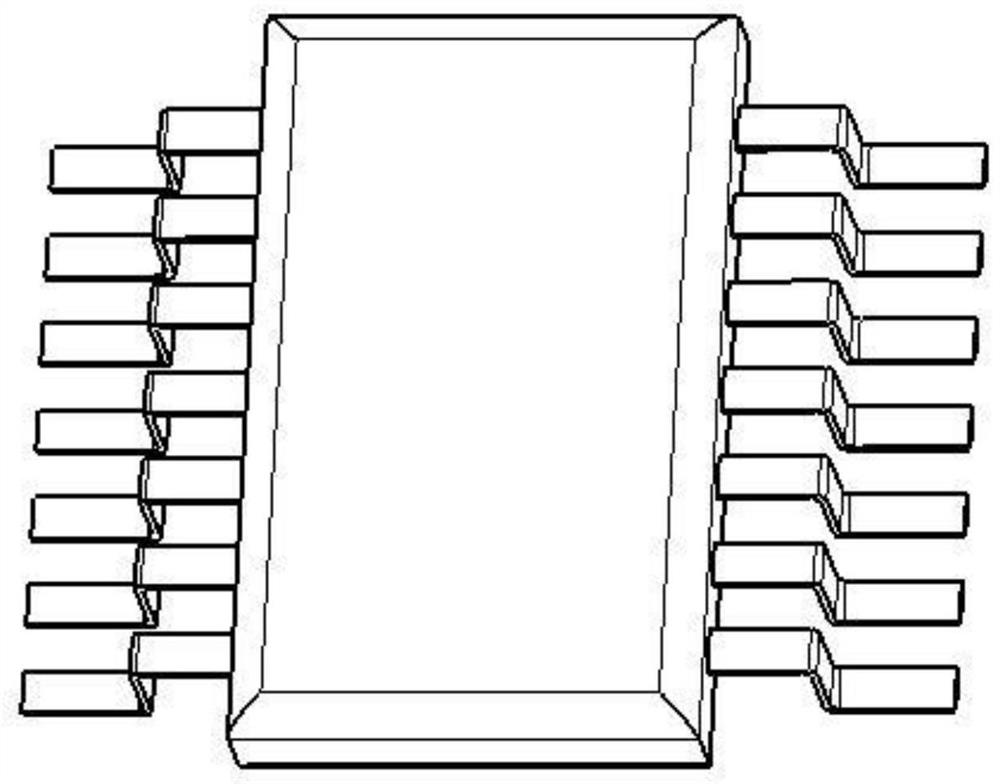

Two piece surface mount header assembly having a contact alignment member

InactiveUS7086872B2Ensure coplanarityVehicle connectorsContact member assembly/disassemblySurface mountingEngineering

A header assembly includes an insulative contact housing having a plurality of walls defining an interior cavity and an insulative alignment housing having at least one alignment rib extending on an exterior surface thereof. The alignment housing is separately provided and independently mounted to the contact housing. A plurality of contacts are included within the cavity and extend through one of the walls to an exterior of the contact housing wherein the contacts flex against the alignment housing and abut the alignment rib, thereby ensuring coplanarity of the contacts for surface mounting to a circuit board.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

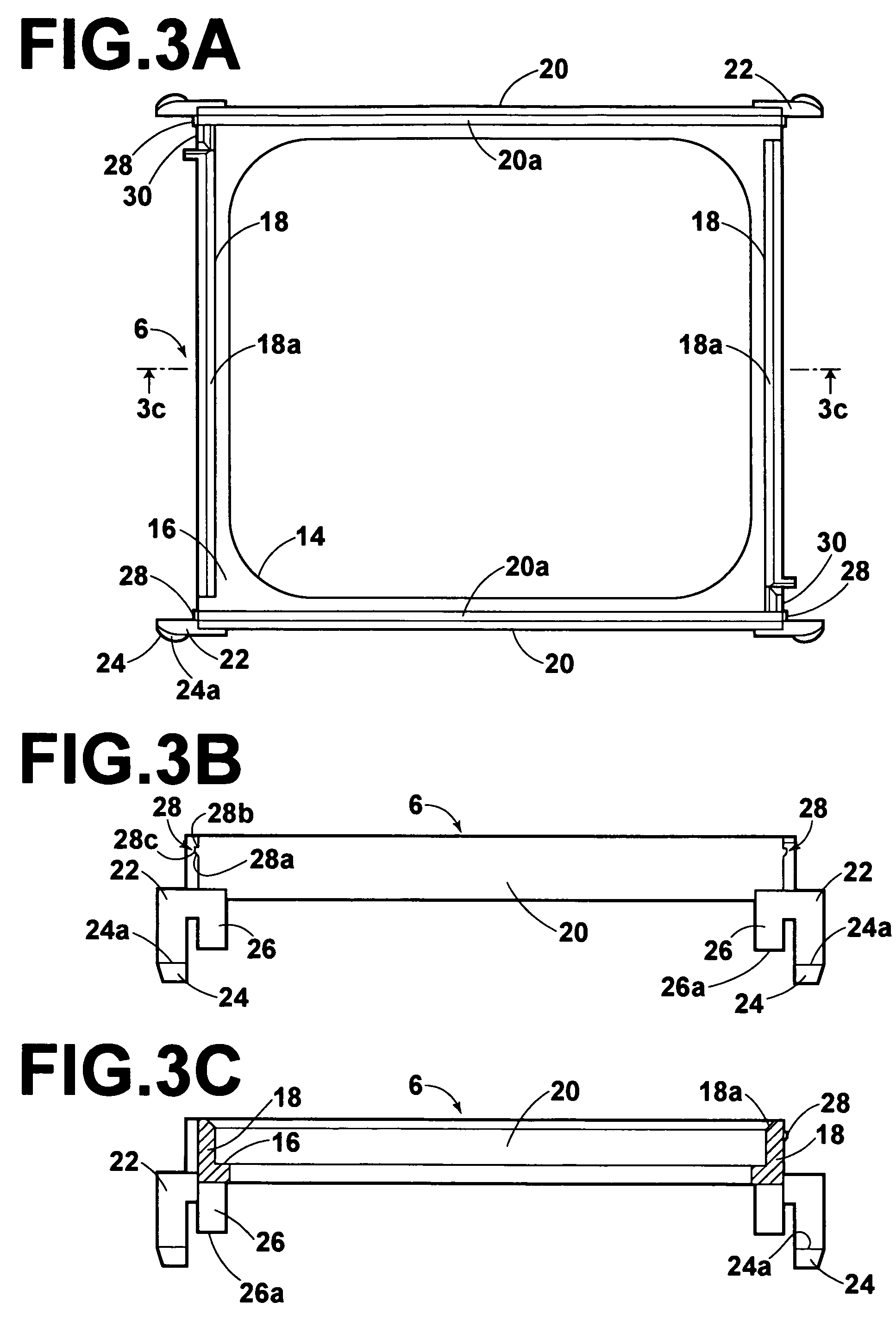

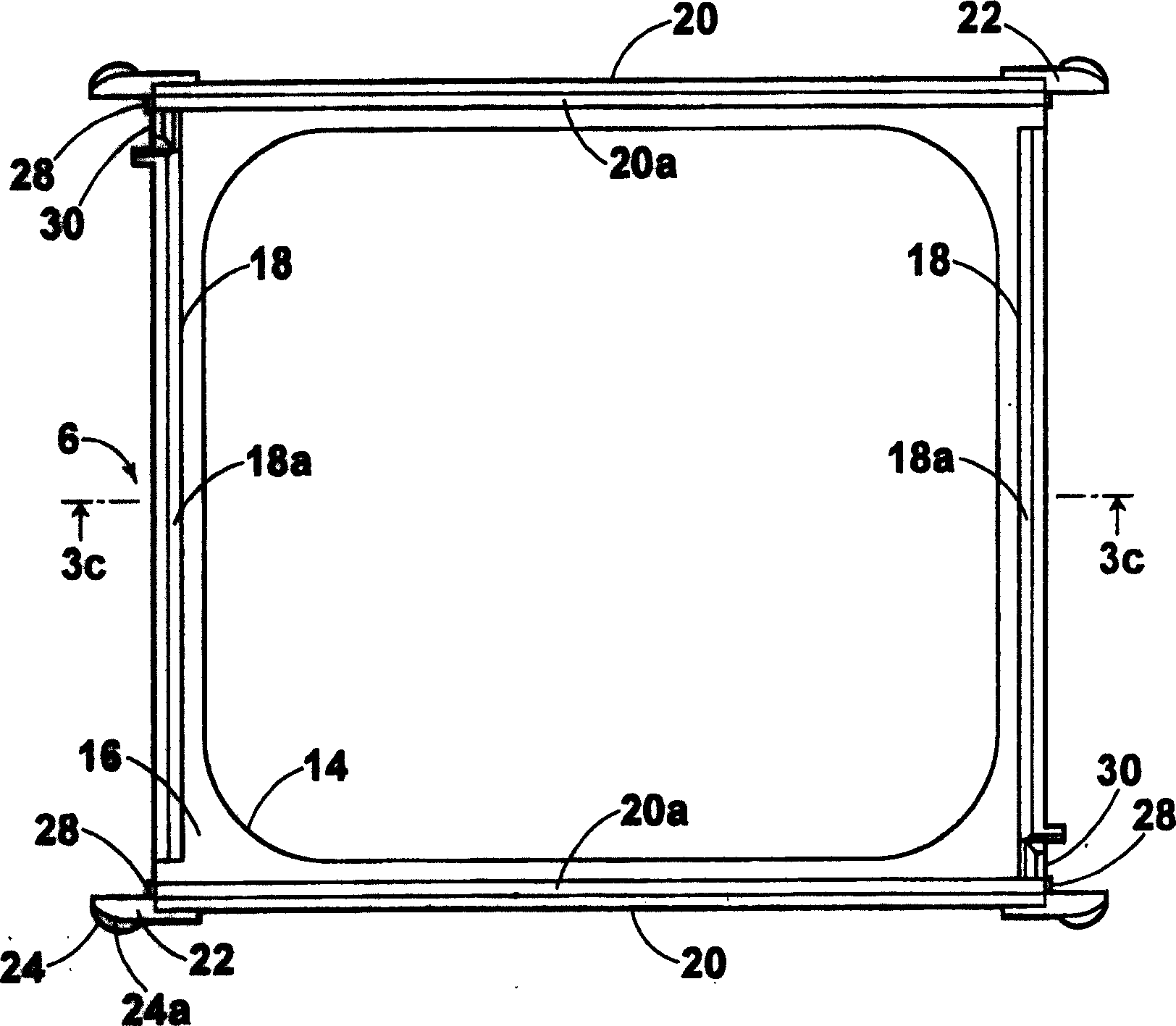

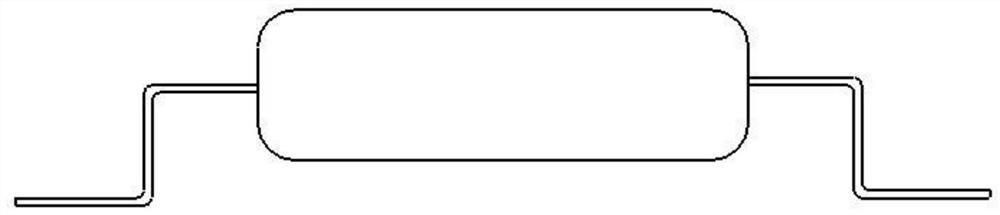

Surface mount header assembly having a planar alignment surface

InactiveUS7086913B2Ensure coplanarityCoupling device connectionsLine/current collector detailsSurface mounting

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

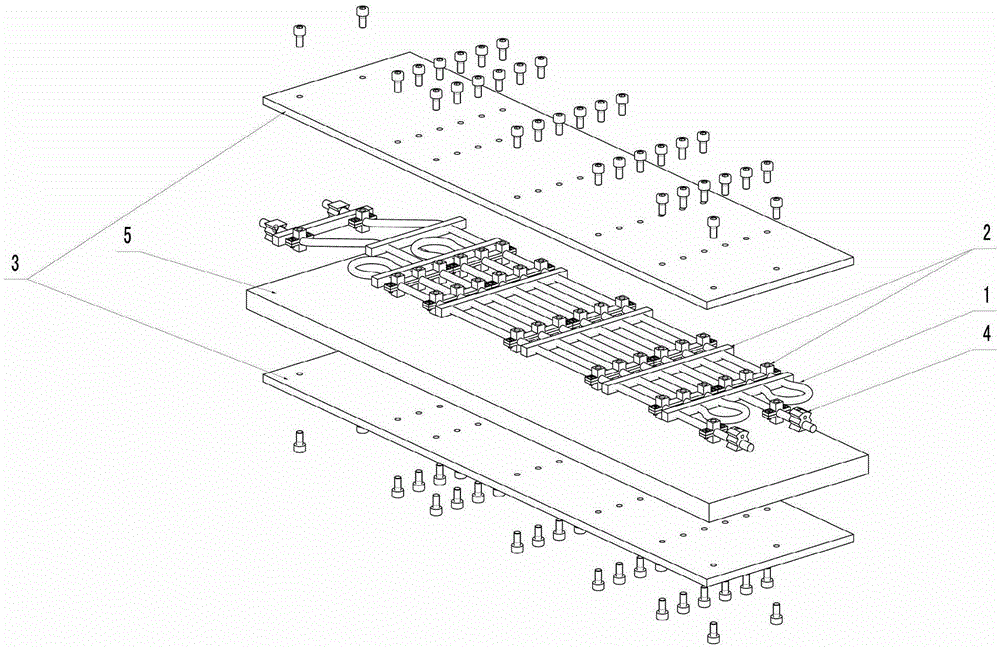

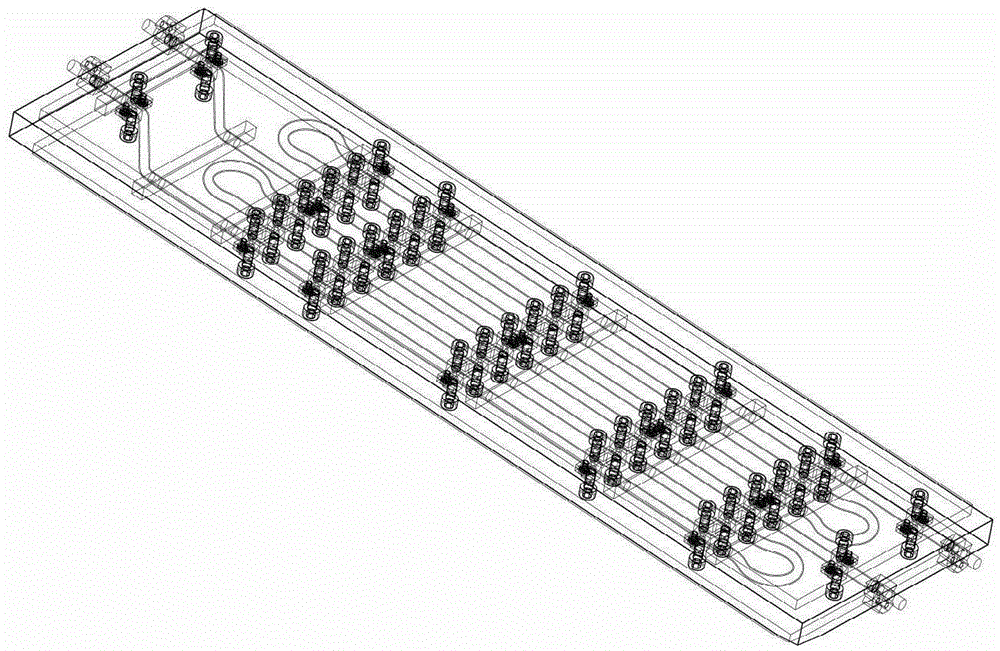

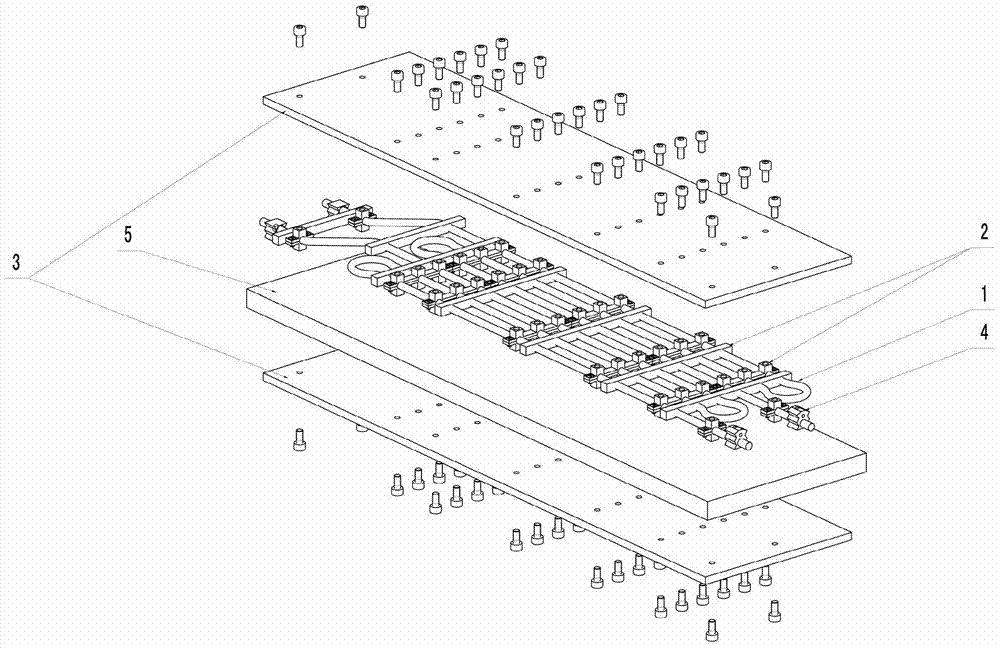

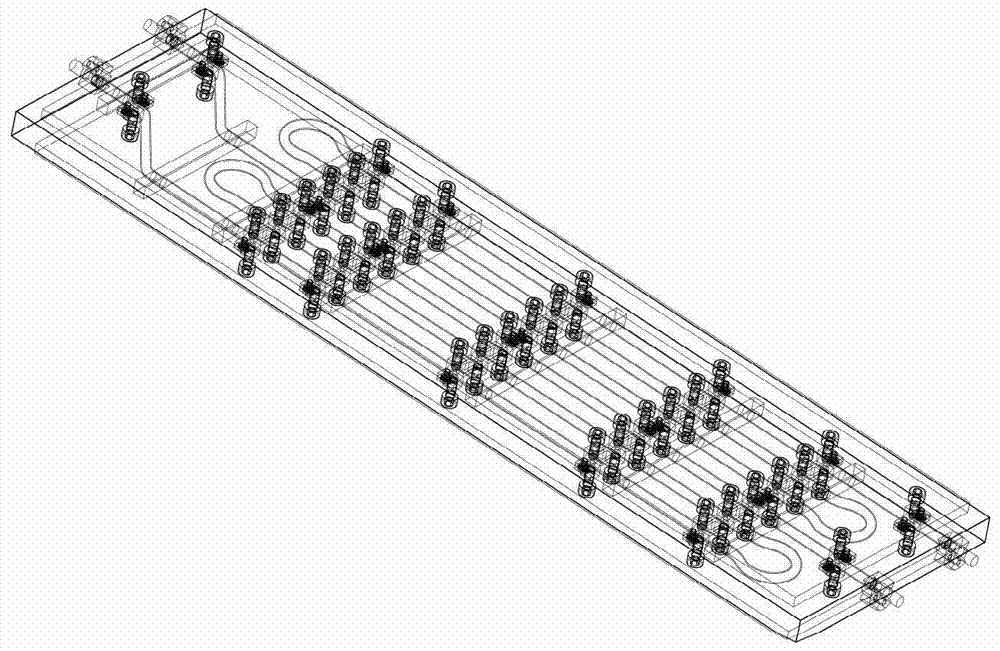

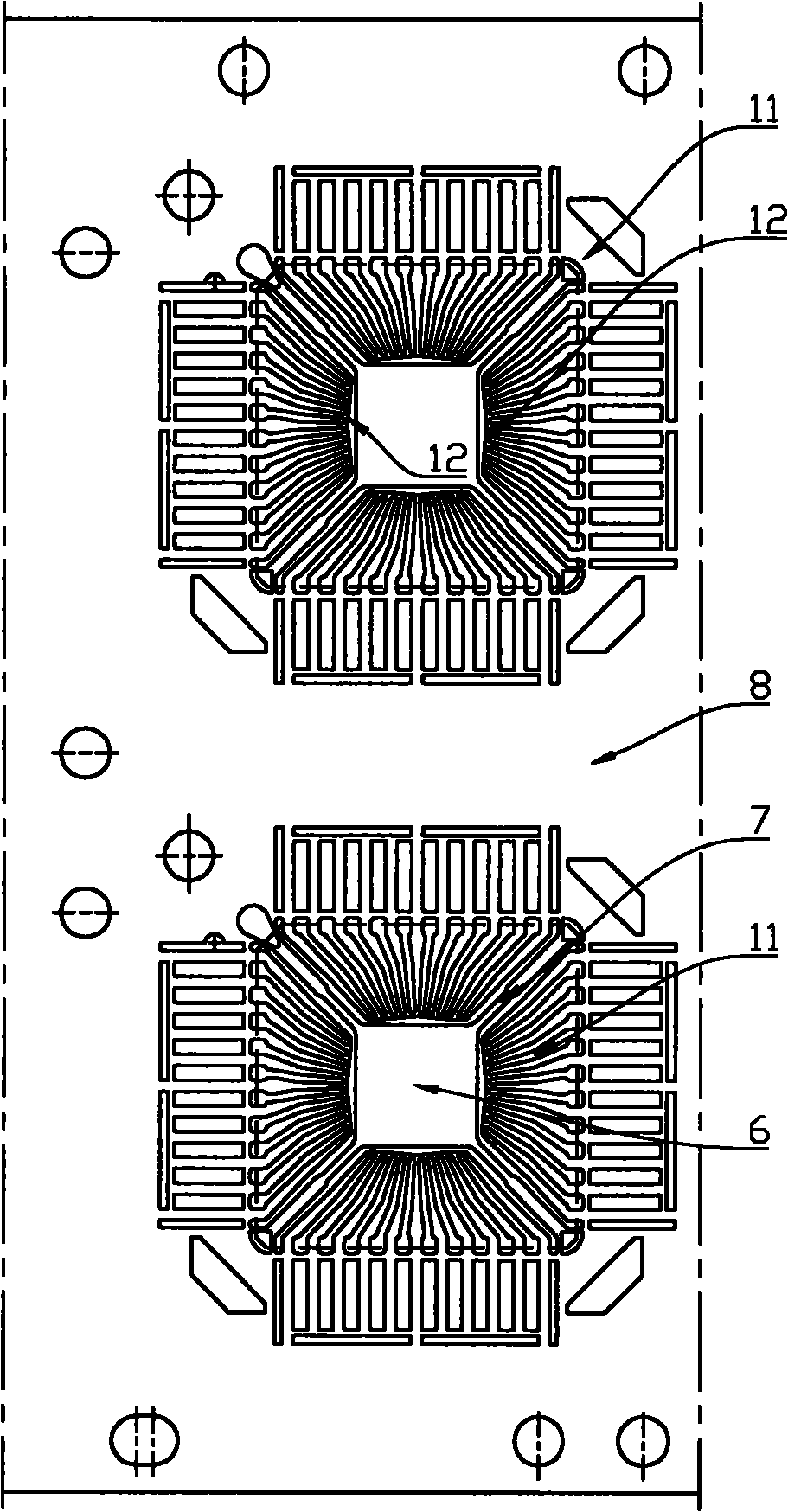

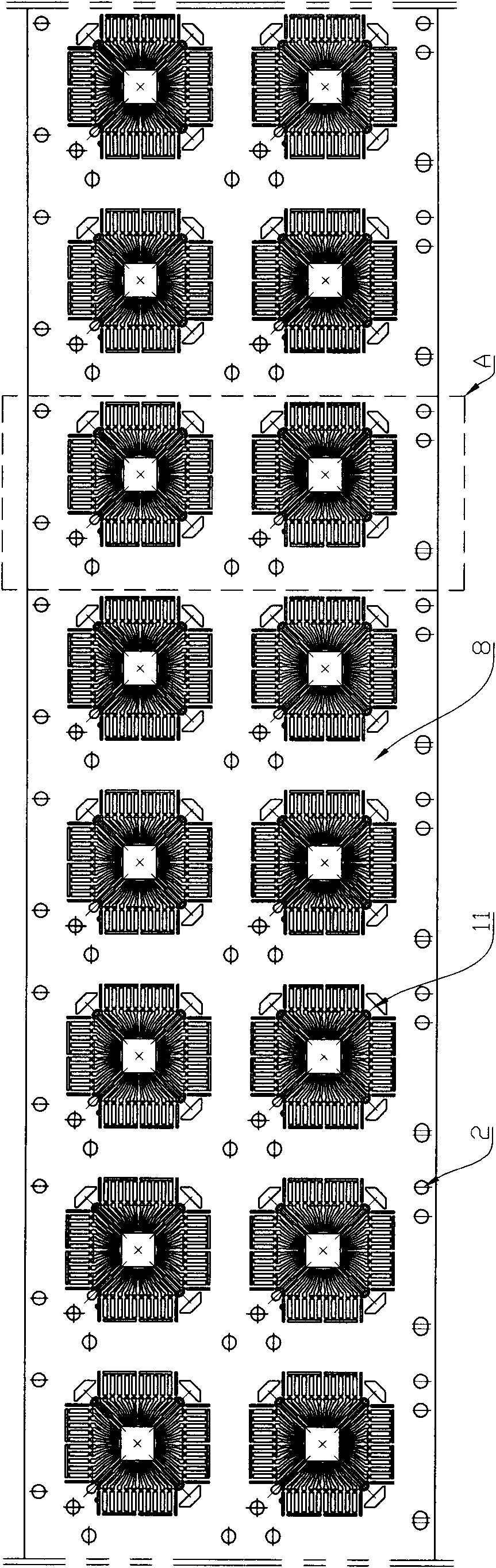

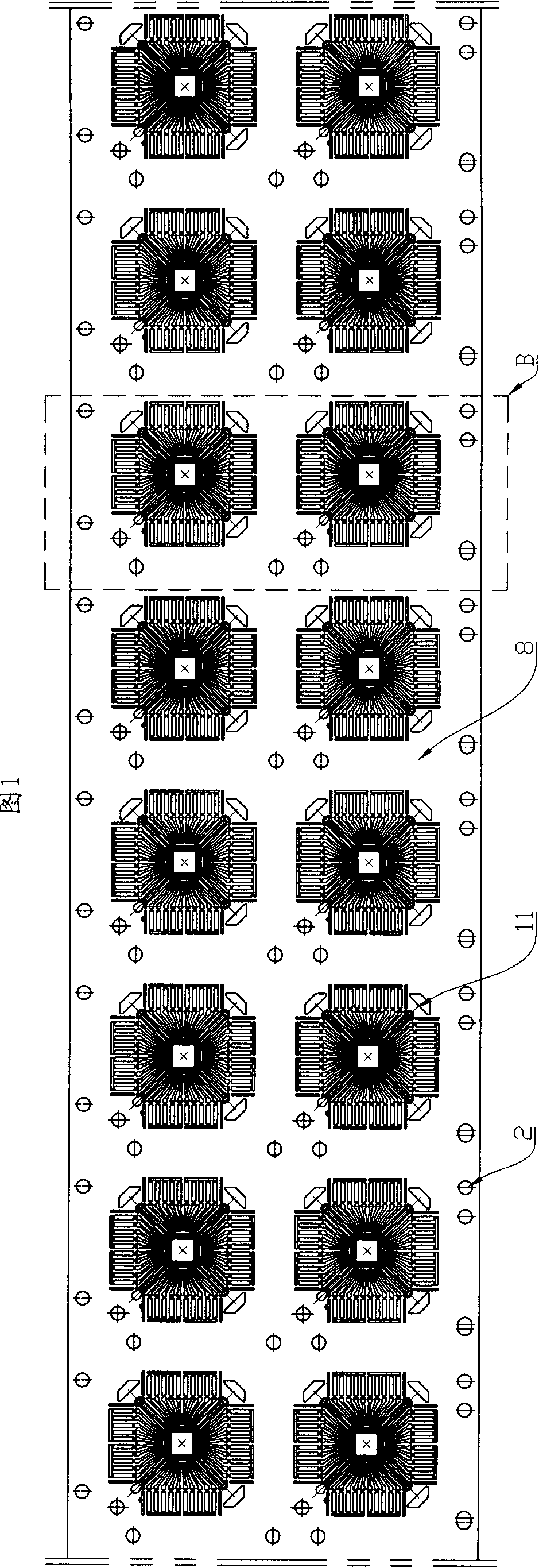

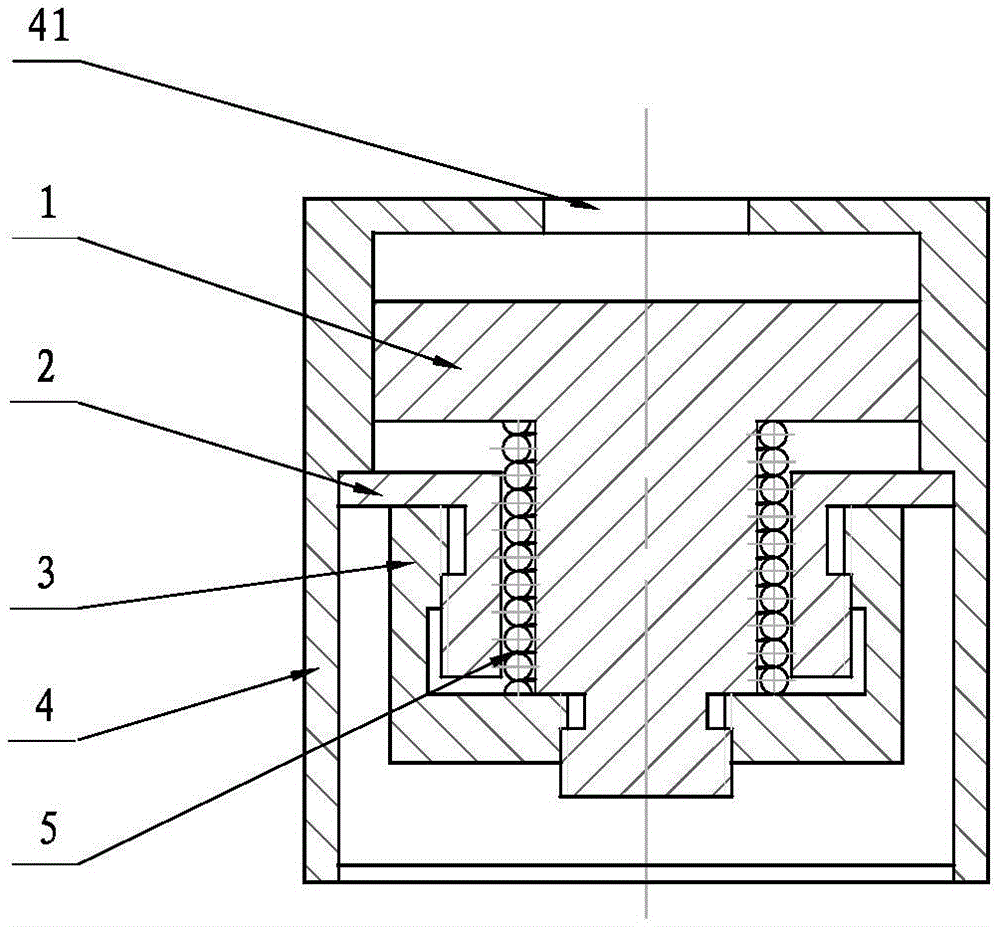

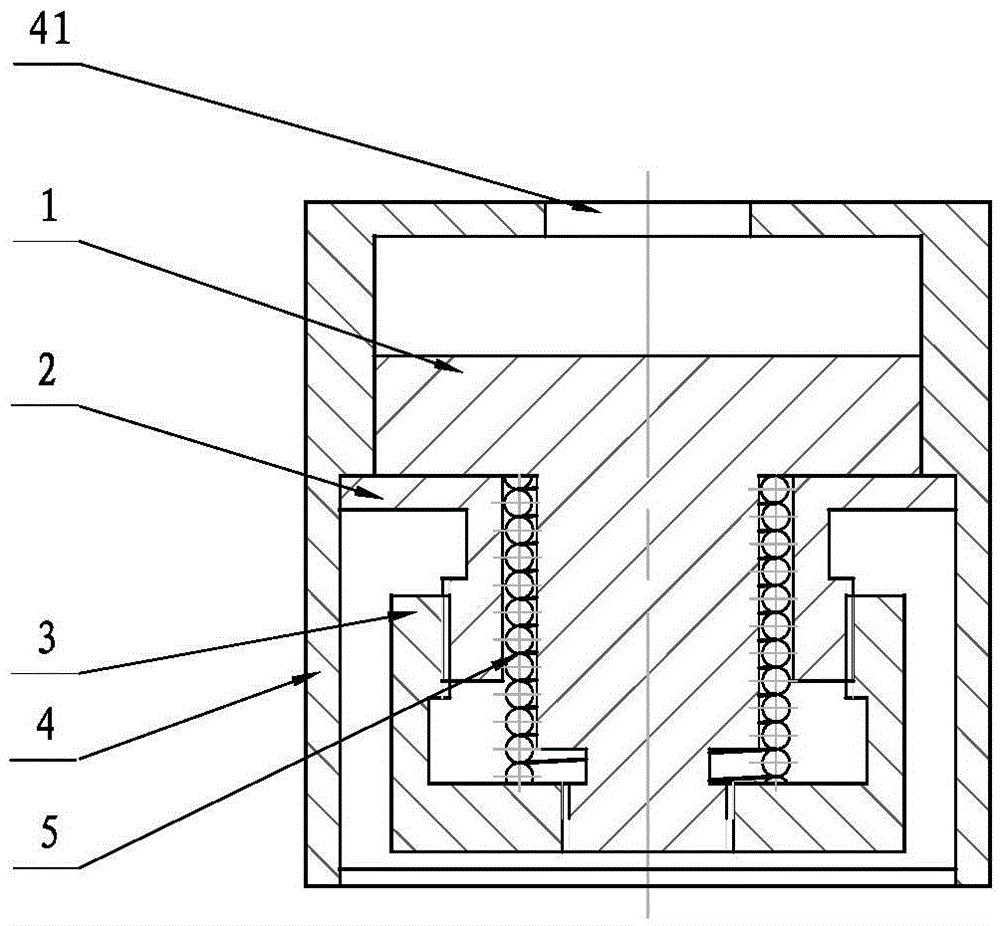

Preparing method for corrosion-resistant liquid cooling heat dissipation cold plate

ActiveCN105268918AEnsure coplanarityLittle structural requirementsFoundry mouldsFoundry coresWeld seamEngineering

The invention discloses a preparing method for a corrosion-resistant liquid cooling heat dissipation cold plate and aims at providing a cold plate preparing method which is free of tedious treatment before welding and has prominent corrosion-resistant capability and long-term work reliability. According to the technical scheme, the two sides of a bottom transverse pipe commonly communicated serve as the starting points respectively, two sets of parallel pipes are longitudinally arranged continuously in a bent manner, and the bending radius of bent circular arc rings on the two longitudinal sides is larger than the distance between every two parallel pipelines; the free ends of each set of parallel pipes are fixedly connected through respective connector flanges; and the two sets of parallel pipes are fixed, clamped and positioned through pipeline clamping tools which are longitudinally arranged at intervals, die positioning plates with screw holes are adopted, wax patterns wrapping runner titanium pipes and connector flange assemblies are clamped between the two die positioning plates, and the runner titanium pipes and the connector flange assemblies are put into a smelting furnace, and a rectangular flat plate is formed through lost foam casting. The preparing method solves the problem that during traditional cold plate welding, a welding seam is prone to cracking, and consequently a cooling agent leaks.

Owner:10TH RES INST OF CETC

Surface mount header assembly having a planar alignment surface

InactiveUS7044812B2Ensure coplanarityCoupling device connectionsLine/current collector detailsSurface mountingEngineering

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

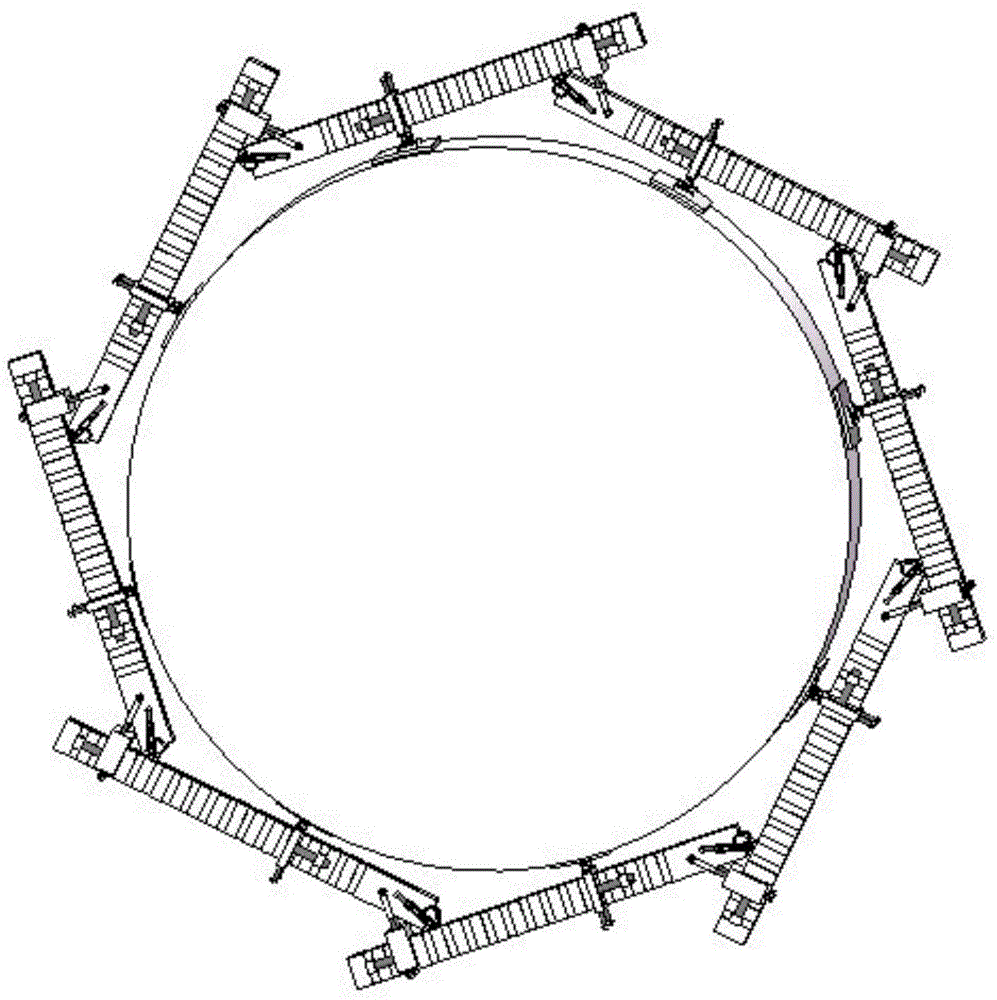

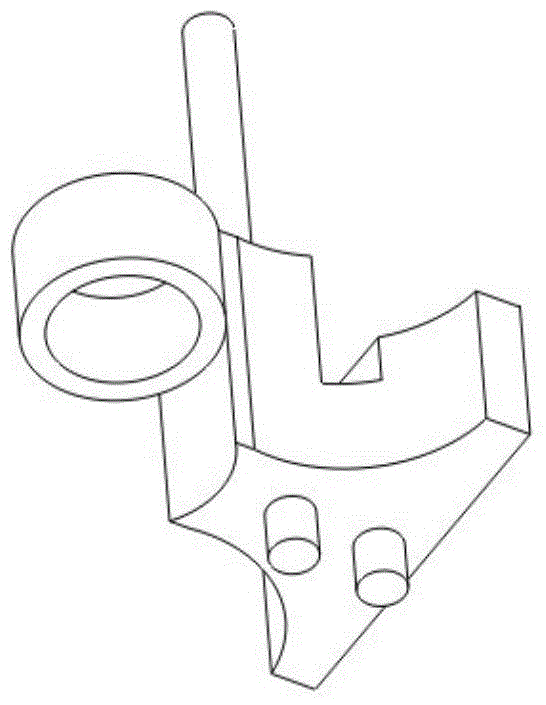

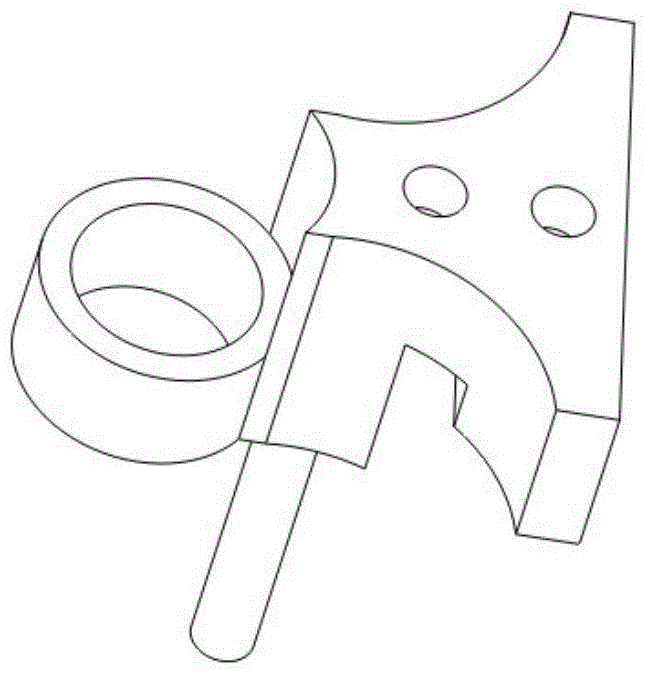

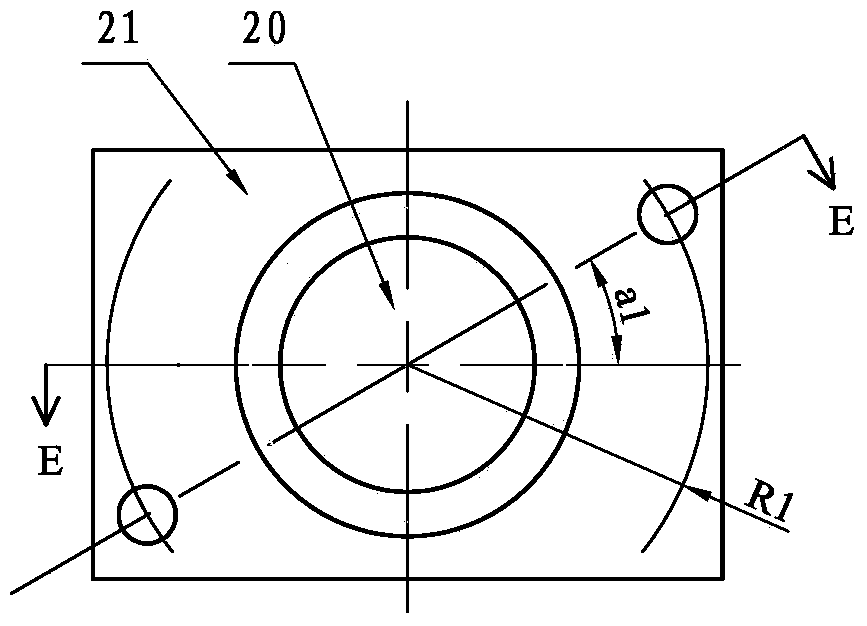

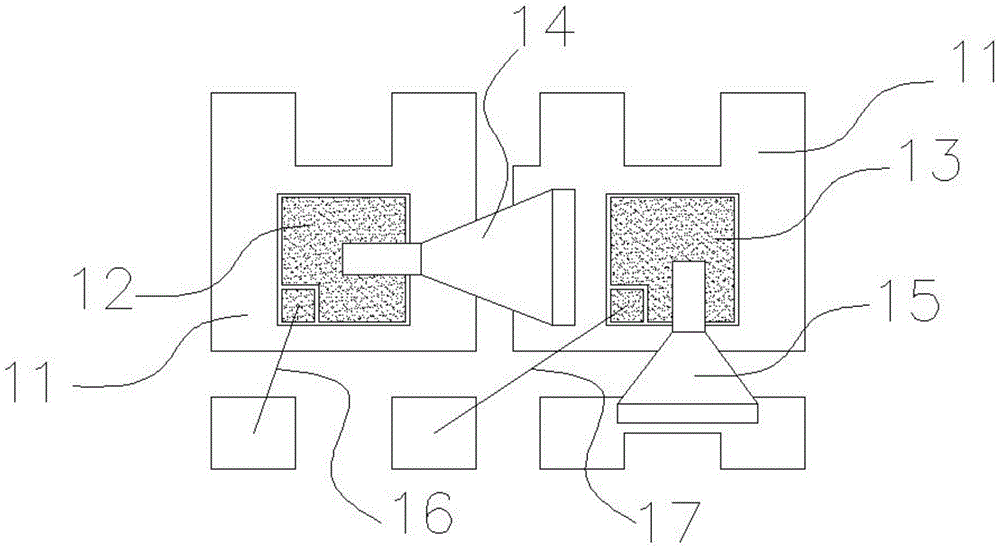

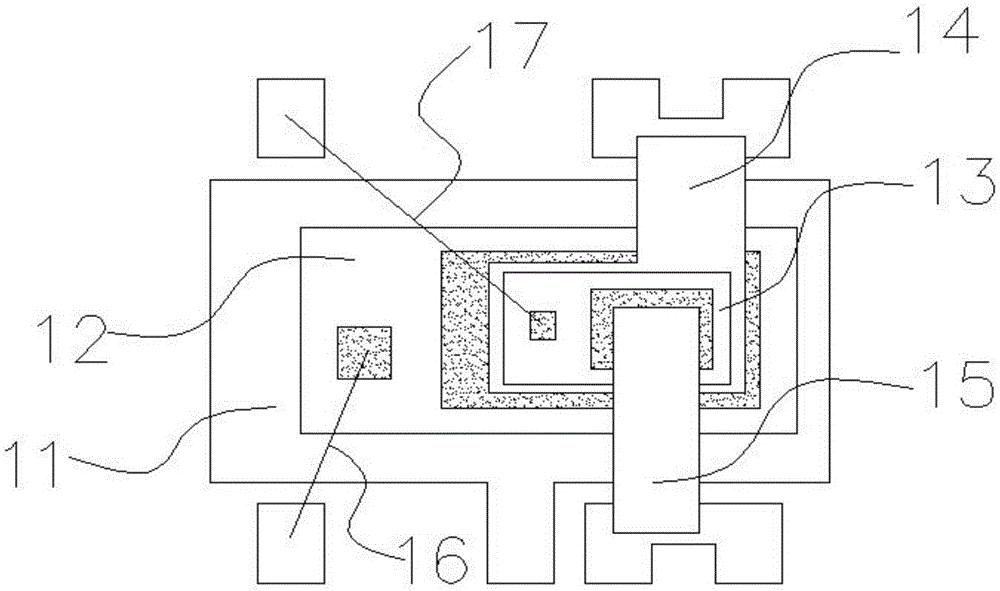

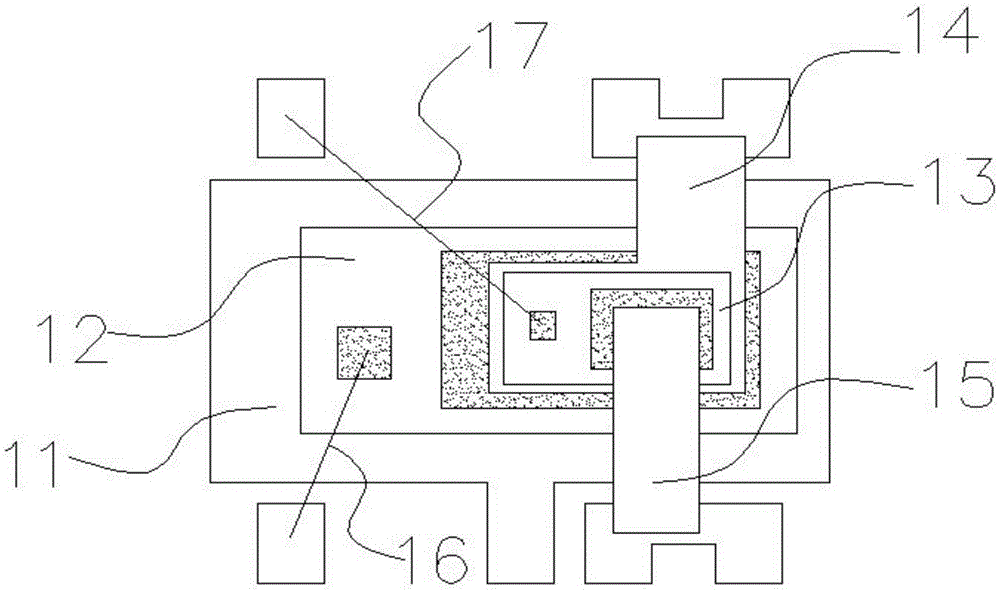

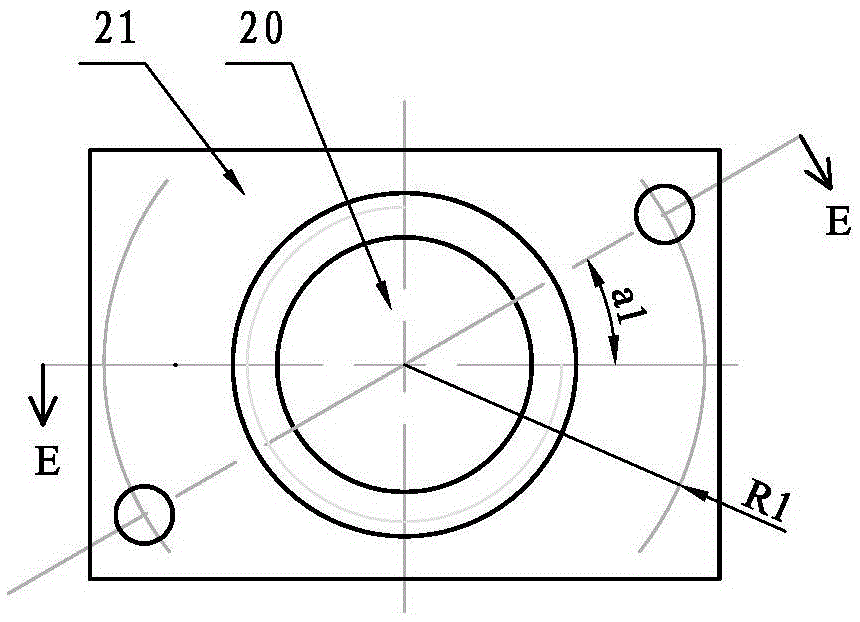

Multi-parameter adjustable clamp device for ECT sensor

The invention relates to a multi-parameter adjustable clamp device for an ECT sensor and belongs to the field of auxiliary detection. The clamp mainly comprises a rotating joint, a rod piece, a clamping sliding block, a flat-end screw, a locating clamping part, a bolt, a T-shaped turning piece, a hexagon nut, a pole plate pressing block, an angle locating buckle, an L-shaped supporting rod and a supporting sliding block. The multi-parameter adjustable clamp device enables each pole plate of the sensor to be in tight contact with a pipeline and be firmly fixed and be easy to assemble and disassemble; the coplanarity of each pole plate of the sensor on the circumferential plane and distribution uniformity of a pole plate array (the central angle between adjacent probes is the same) can be guaranteed; and the multi-parameter adjustable clamp device can be suitable for installing cylindrical pipelines of different diameters. The designed clamp can be used for auxiliary measurement of the capacitance of the specific ECT sensor; and the clamp has a certain universality and is flexible and convenient.

Owner:BEIJING UNIV OF TECH

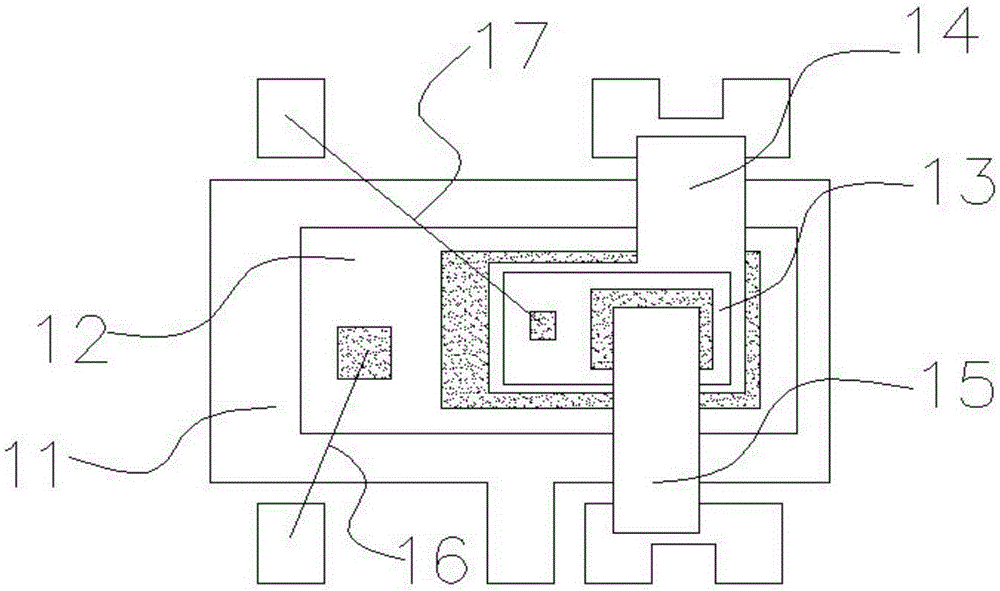

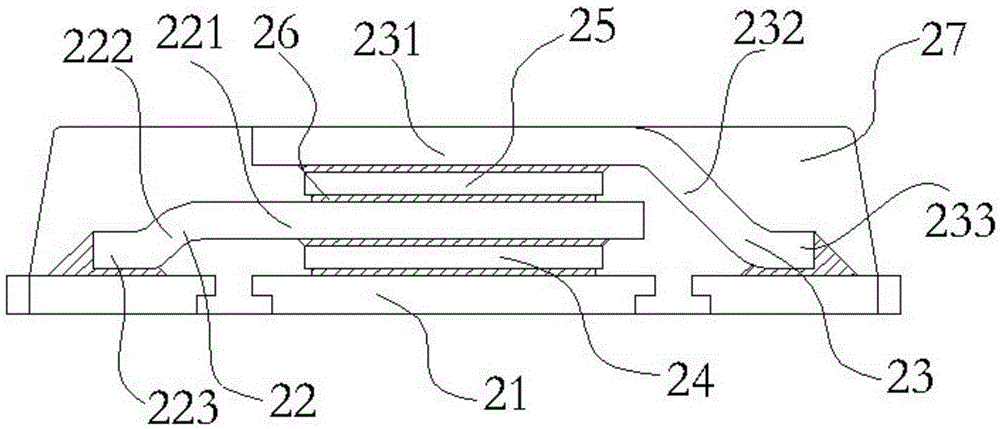

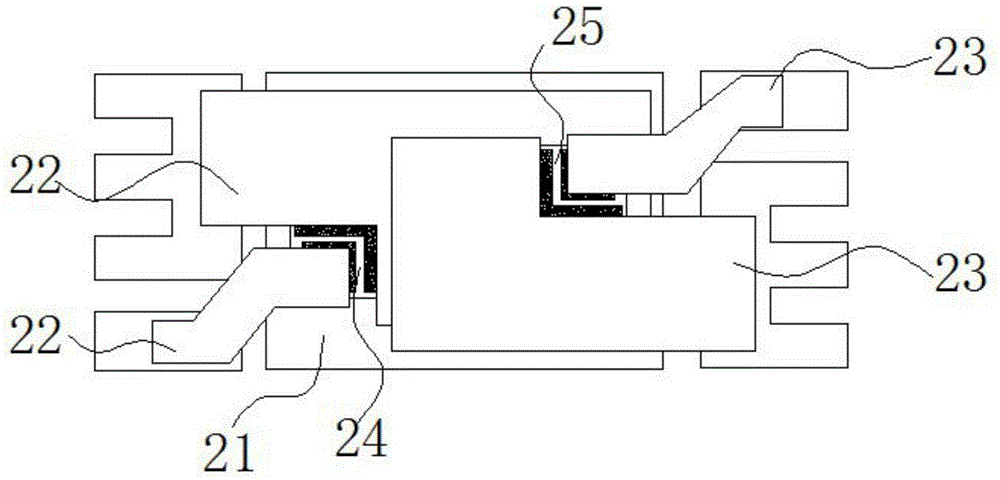

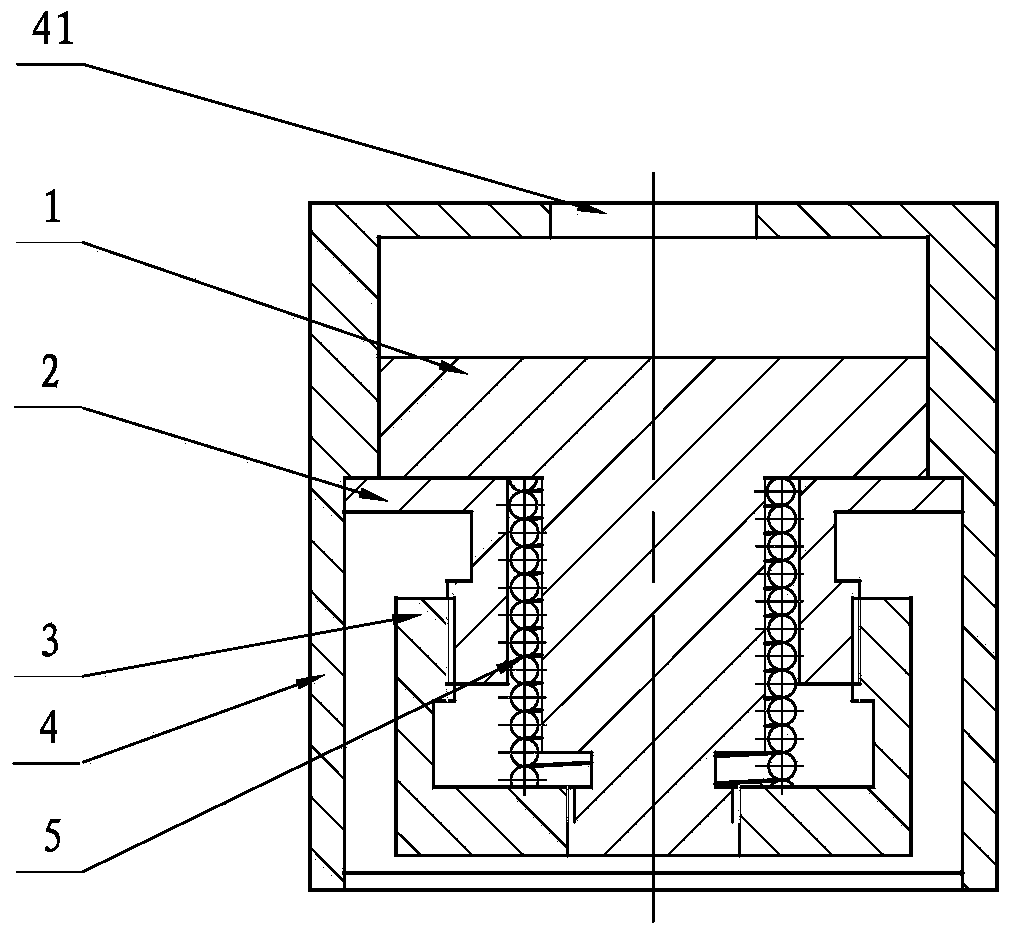

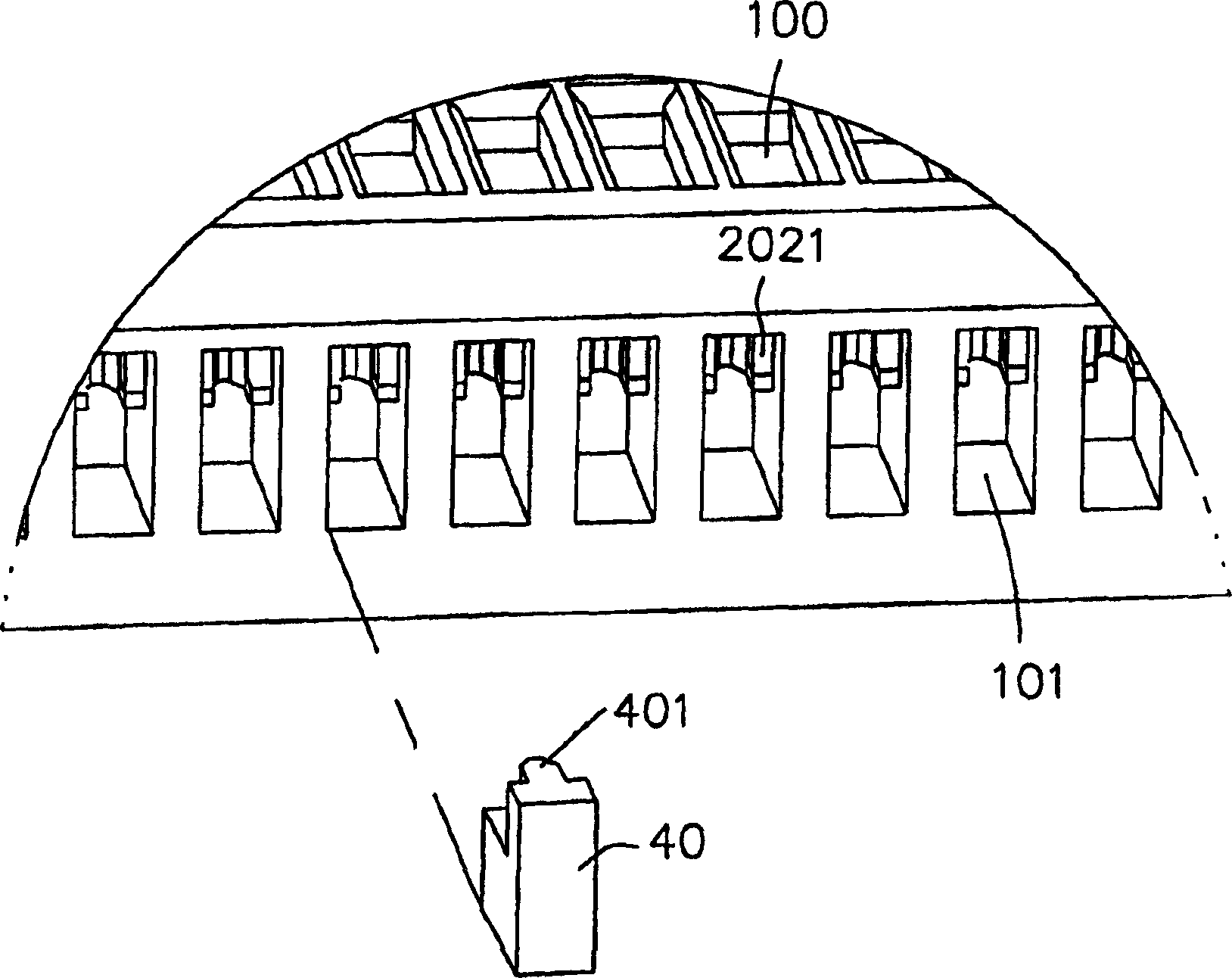

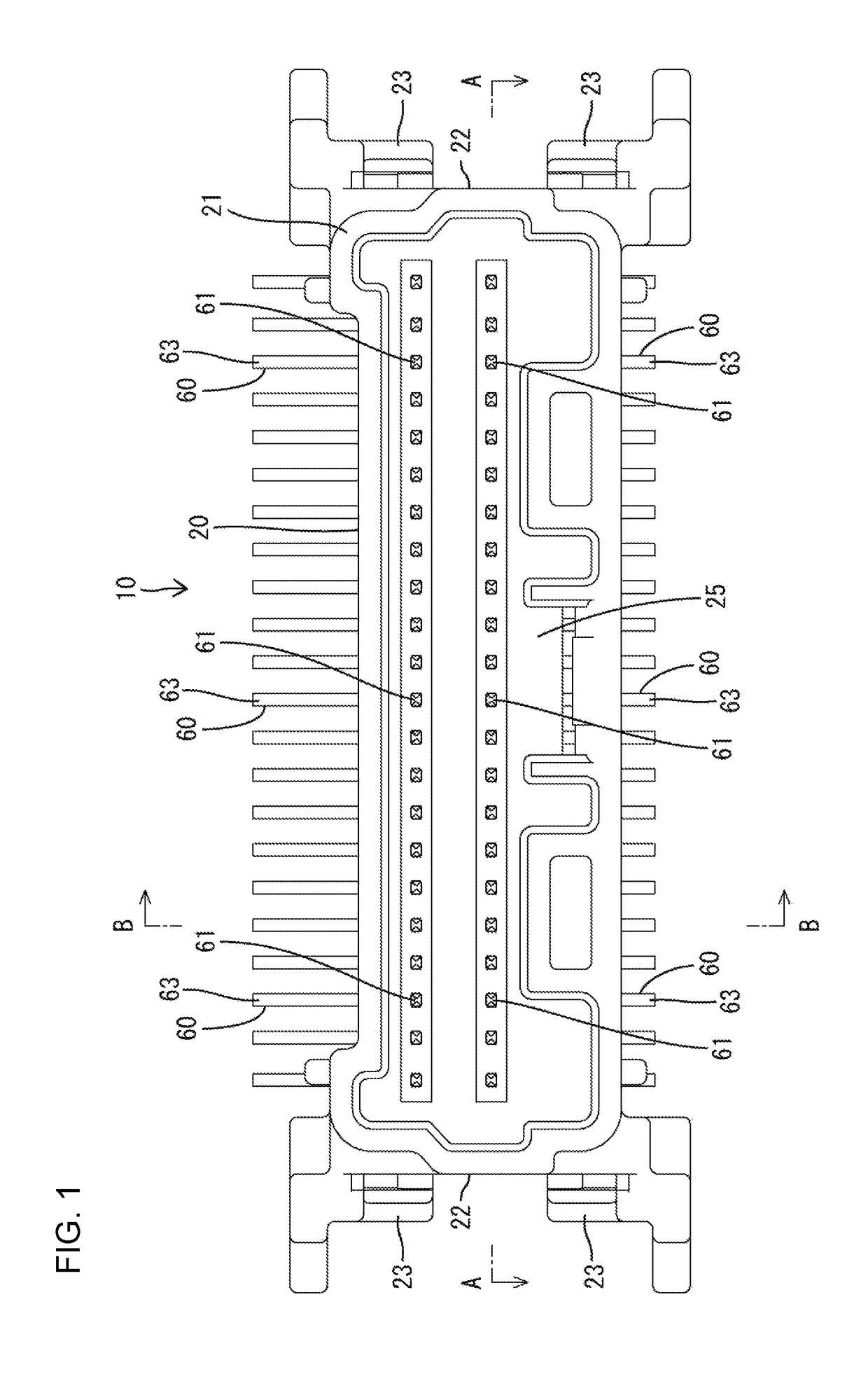

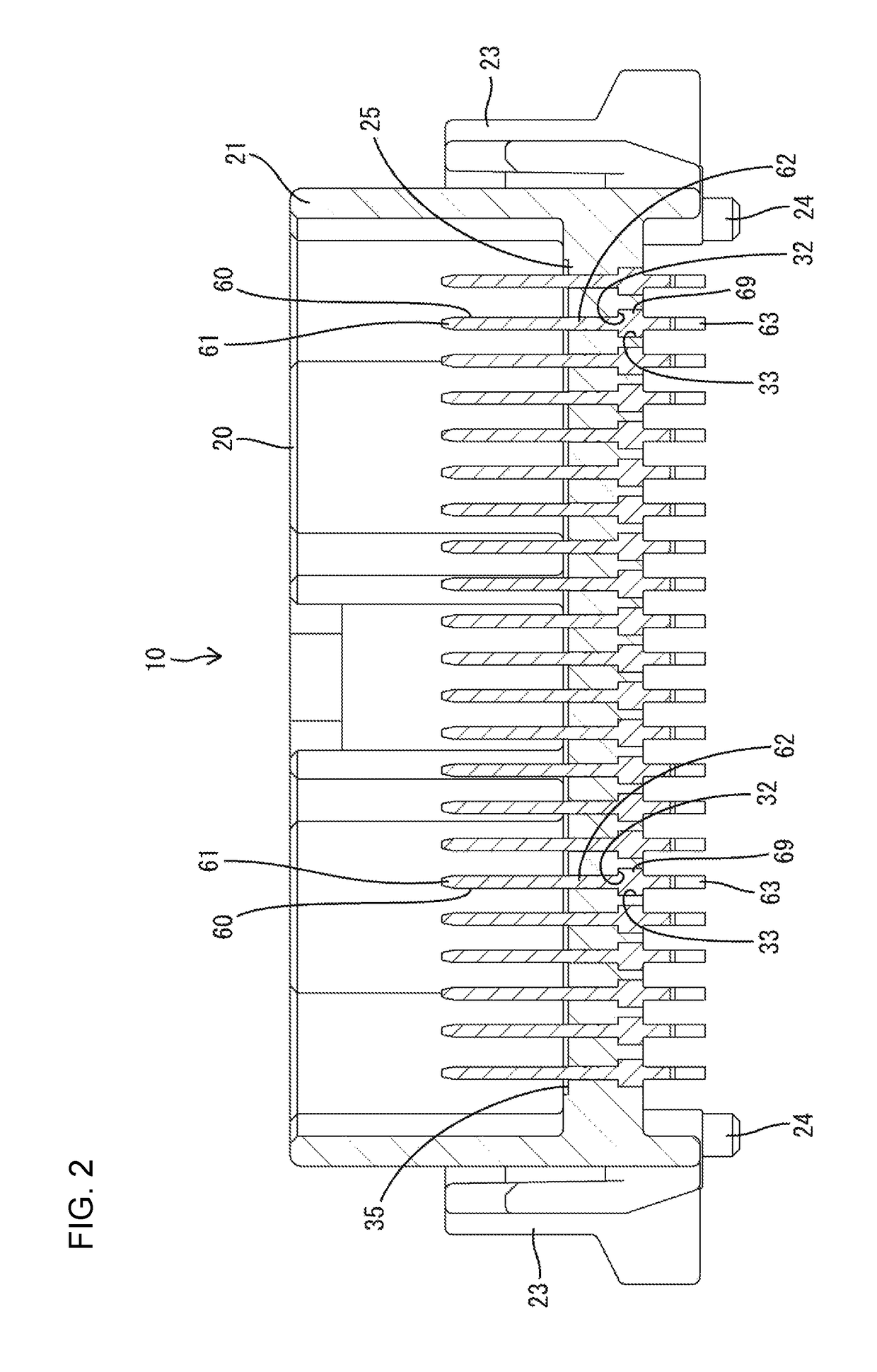

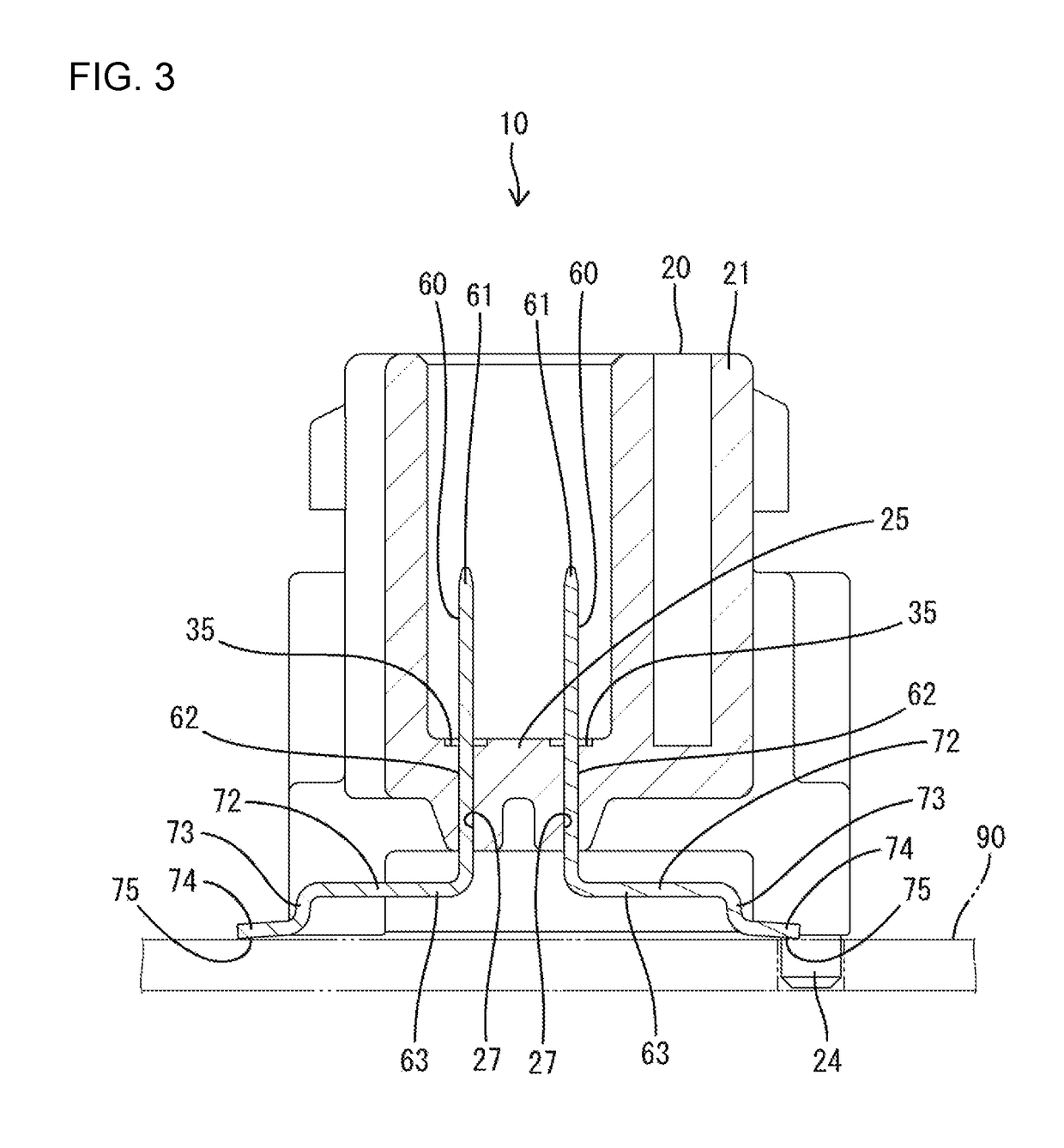

IC socket assembly

InactiveUS7349217B2Reduce warpageEnsure coplanarityCoupling device connectionsElectric discharge tubesBackplaneEngineering

The IC socket assembly includes the heat sink for abutting the upper surface of an IC package to dissipate heat generated thereby, and a fixing member for fixing the heat sink to the housing. The fixing member includes: a frame, mounted on a surface of the circuit board, on which the housing is mounted; a back plate, mounted on the opposite surface of the circuit board, having engaging arms, which are inserted through apertures of the circuit board and engage the frame; a pair of loading beams, fixed to the engaging arms; and a pair of levers, axially supported by the loading beams, for urging the heat sink toward the housing.

Owner:TYCO ELECTRONICS JAPAN GK

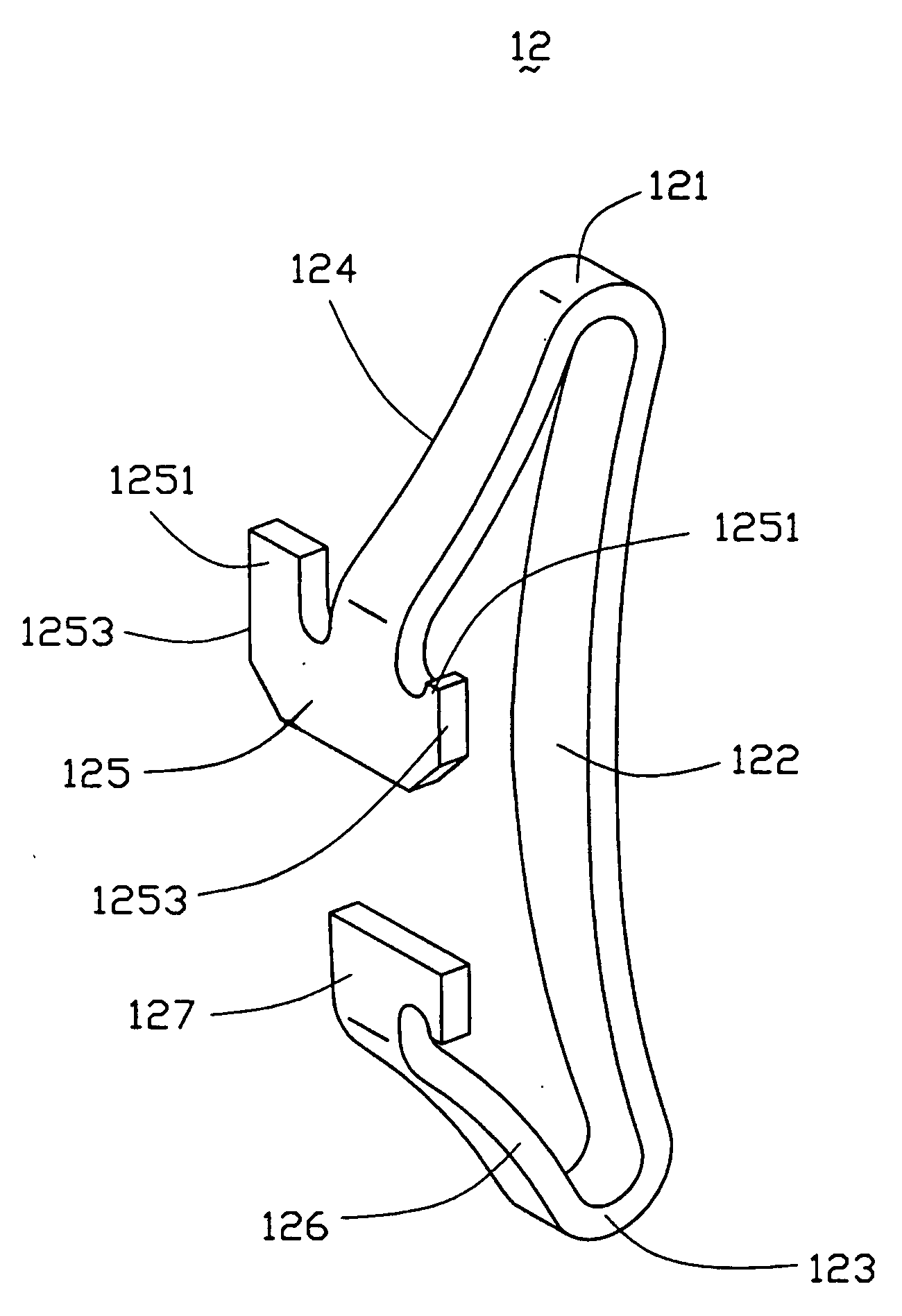

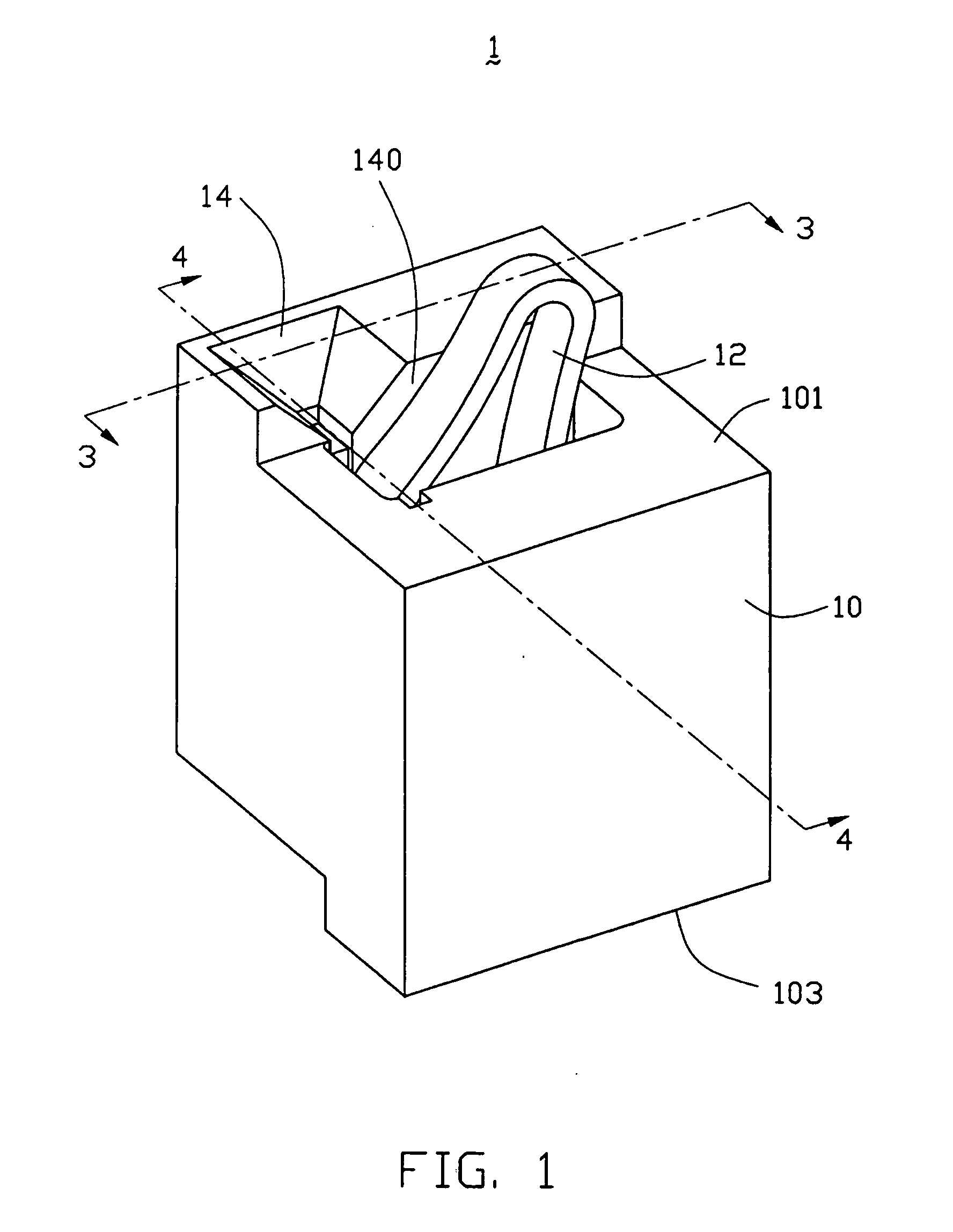

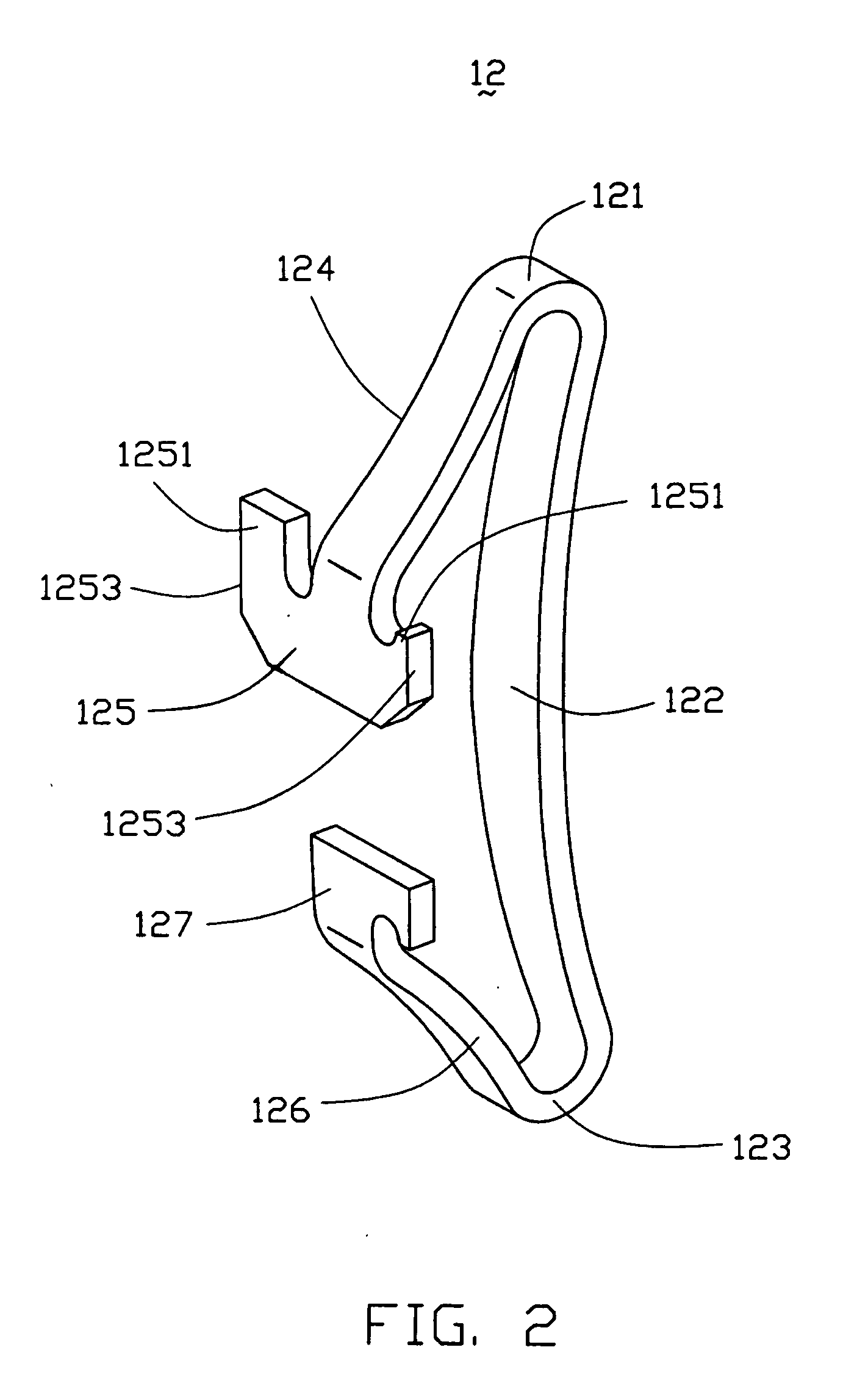

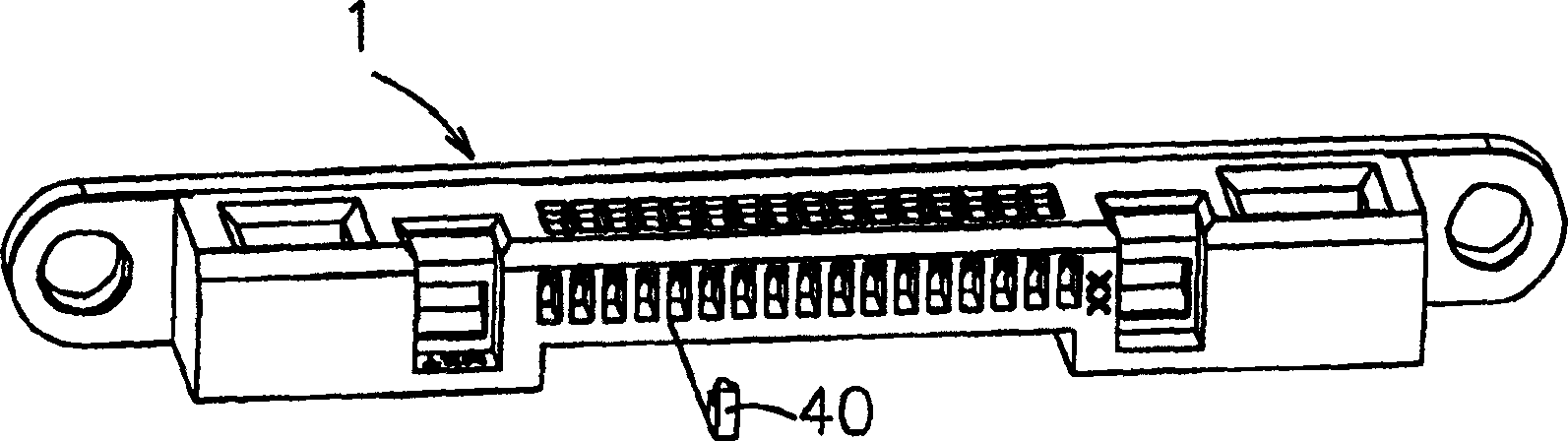

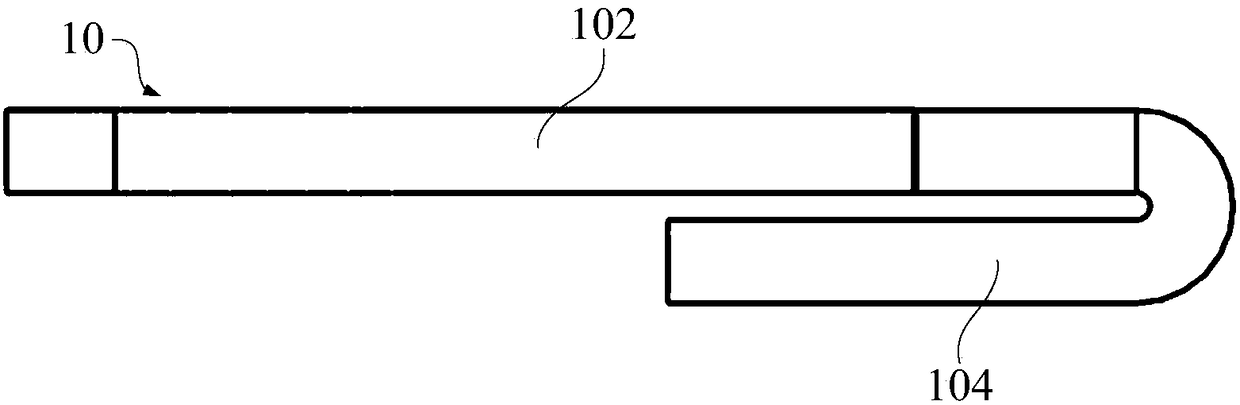

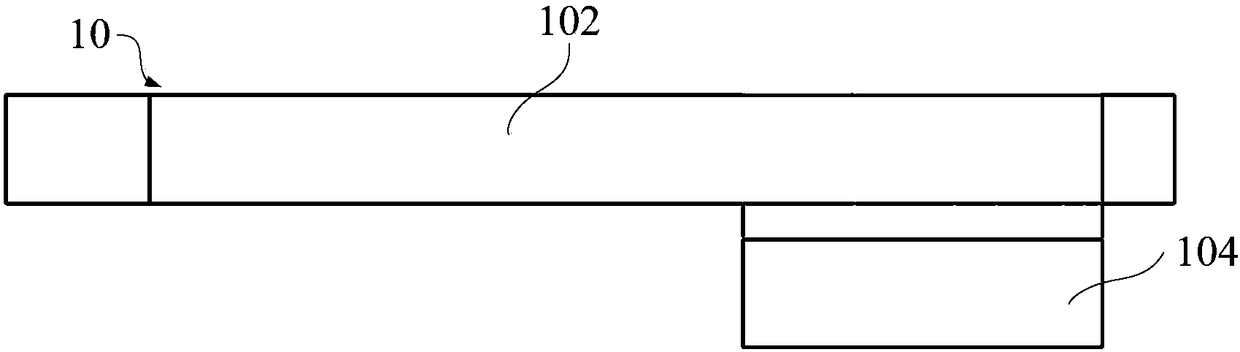

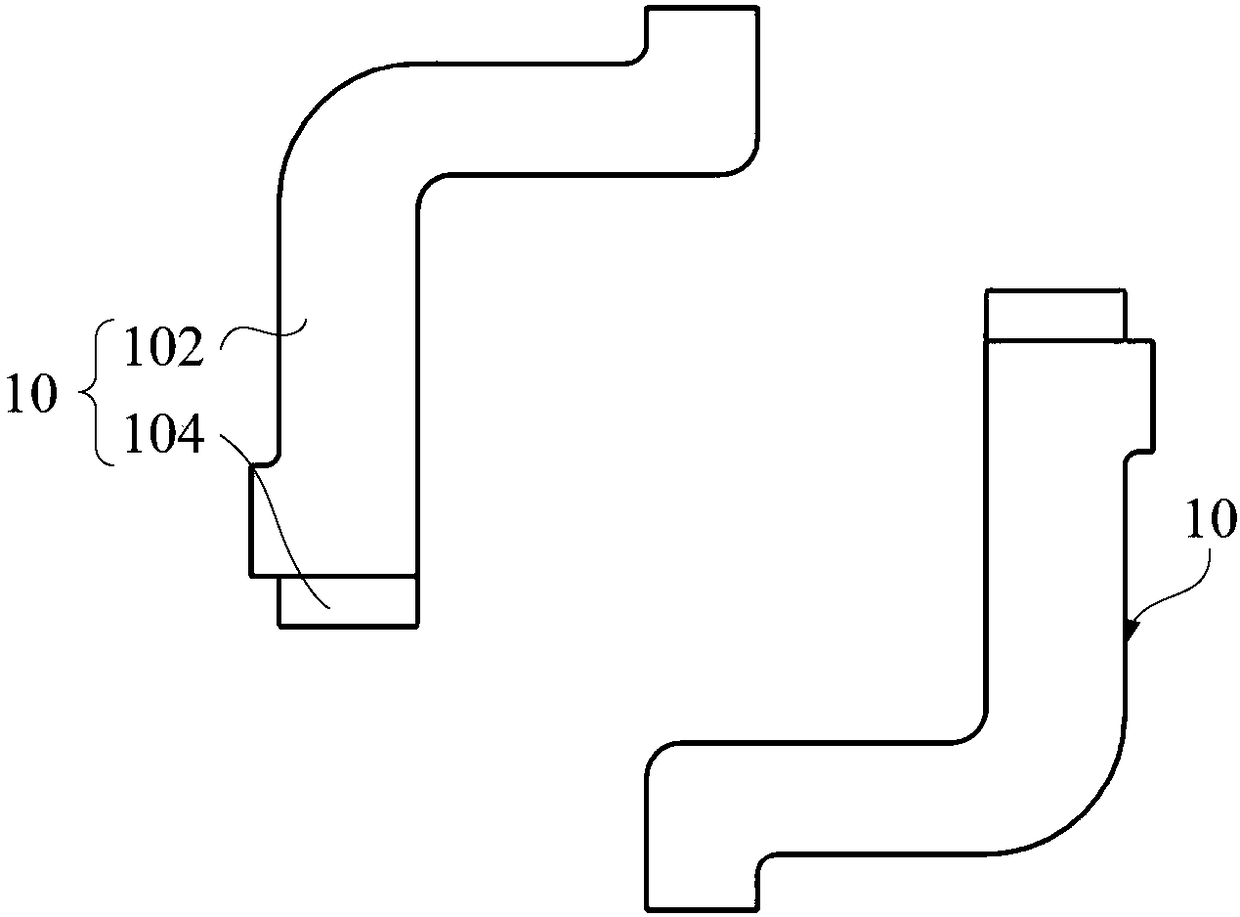

Contact for an electrical connector

InactiveUS20080050939A1Ensure coplanaritySecuring/insulating coupling contact membersPrinted circuitsMechanical engineeringElectrical bonding

An electrical connector (1) includes an insulative housing (10) and a plurality of stamped contacts (12) resided therewithin. The conductive contact includes a central spring beam (122), a side spring beam (124) located at one side of the central spring beam, and a contact portion (121) formed between the central spring beam and the side spring beam for electrically mating with a mating component. The central spring beam extends inwardly of the contact portion and towards an end portion of the side spring beam. Such a configuration of the central spring beam will ensure that the conductive contact has a predetermined robustness thereof while possessing the required spring properties for the stamped contact.

Owner:HON HAI PRECISION IND CO LTD

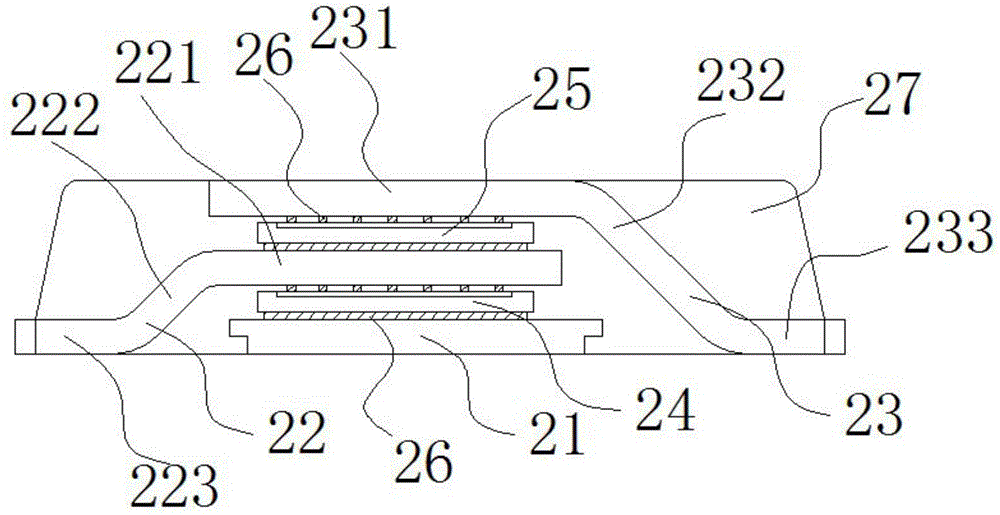

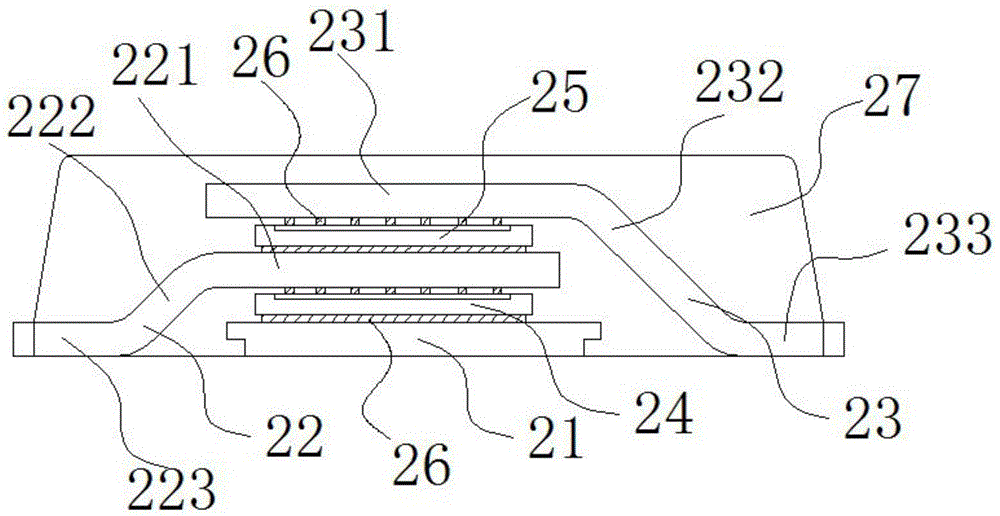

Sandwich packaging technique for preventing chip from deviating

InactiveCN105489508AControl thicknessControl areaSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingWork in process

The invention relates to a sandwich packaging technique for preventing a chip from deviating. The sandwich packaging technique comprises the following steps: (1) providing a first lead frame; (2) coating an island region of the first lead frame with a solder paste; (3) implanting the chip into the first lead frame; (4) providing a second lead frame; (5) coating the second lead frame with the solder paste; (6) laminating the second lead frame on the chip on the upper surface of the first lead frame to form an overall frame; (7) pressing the upper surface and the lower surface of the overall frame formed in the step (6) with pressure plates and carrying out reflow soldering; (8) carrying out plastic packaging on the overall frame which is subjected to reflow soldering in the step (7); and (9) carrying out cutting or punching operation on a semi-finished product which is subjected to plastic packaging in the step (8), cutting or punching an original array-type plastic package body for separation, so as to prepare a sandwich package structure for preventing the chip from deviating. The sandwich packaging technique has the beneficial effect that the thickness, the area and the position of the solder paste can be easily controlled.

Owner:JCET GROUP CO LTD

Shield terminal and shield connector

ActiveUS20200274299A1Improve shielding effectSuitable for useTwo pole connectionsCoupling contact membersElectrical conductorStructural engineering

Owner:SUMITOMO WIRING SYST LTD

Multi-chip and multi-shingle stacked sandwich package structure with exposed frames and technique of multi-chip and multi-shingle stacked sandwich package structure

InactiveCN105405834AReduce package resistanceReduction of interconnection processSemiconductor/solid-state device detailsSolid-state devicesPunchingPlastic packaging

The invention relates to a multi-chip and multi-shingle stacked sandwich package structure with exposed frames and a technique of the multi-chip and multi-shingle stacked sandwich package structure. The method comprises the following steps: (1) providing a first lead frame; (2) coating the first lead frame with a tin paste; (3) implanting a first chip into the tin paste of the first lead frame; (4) providing a second lead frame, coating the second lead frame with the tin paste; (5) laminating the second lead frame on the first chip; (6) carrying out reflow soldering; (7) coating the second lead frame with the tin paste; (8) implanting a second chip into the second lead frame; (9) providing a third lead frame, coating the third lead frame with the tin paste; (10) laminating the third lead frame on the second chip; (11) carrying out reflow soldering; (12) carrying out plastic packaging with a molding compound; and (13) carrying out a cutting or punching operation. The multi-chip and multi-shingle stacked sandwich package structure with the exposed frames have the beneficial effects that the heat dissipating ability of a product is increased; and the package resistance of the product is reduced.

Owner:JCET GROUP CO LTD

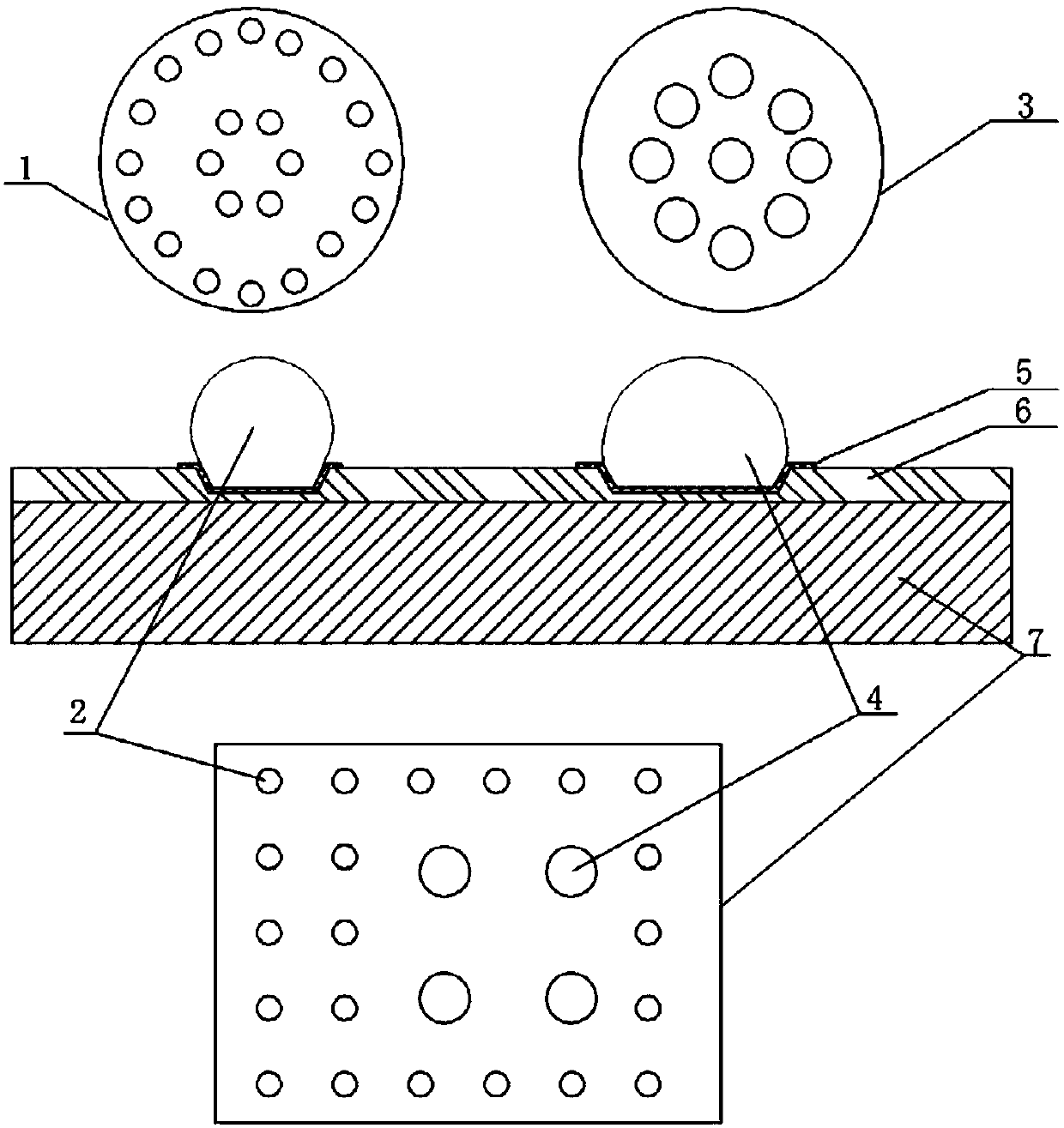

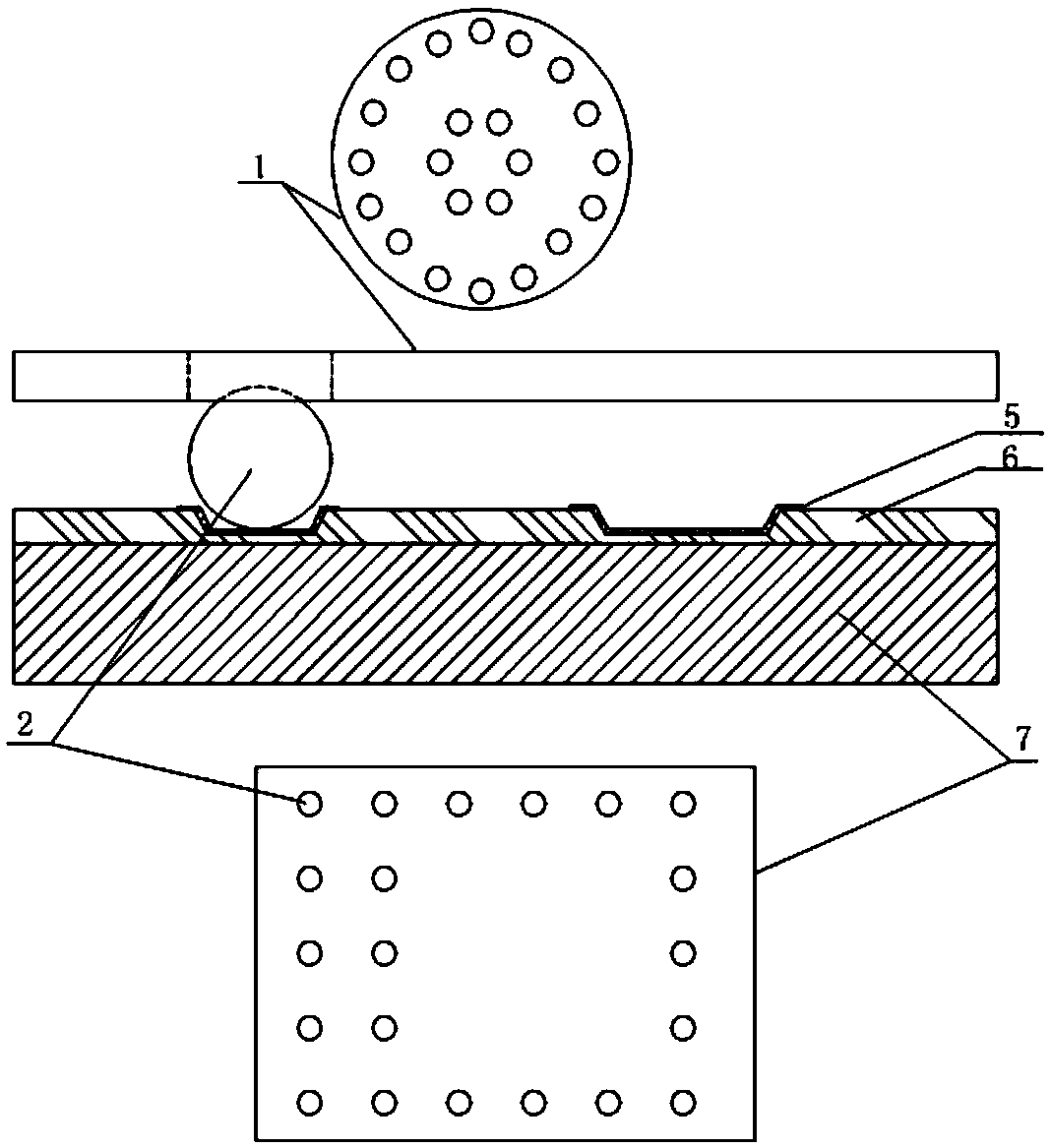

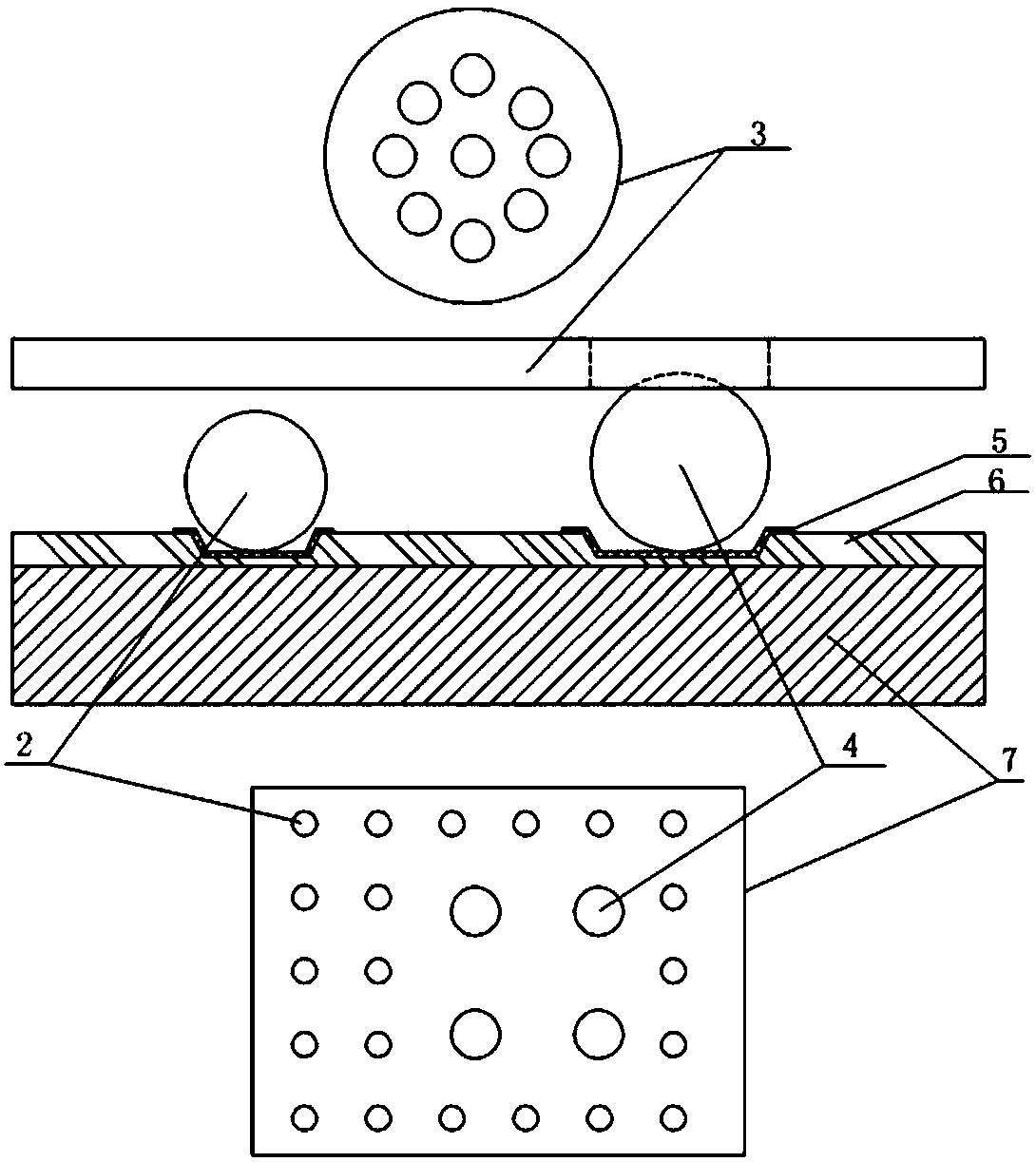

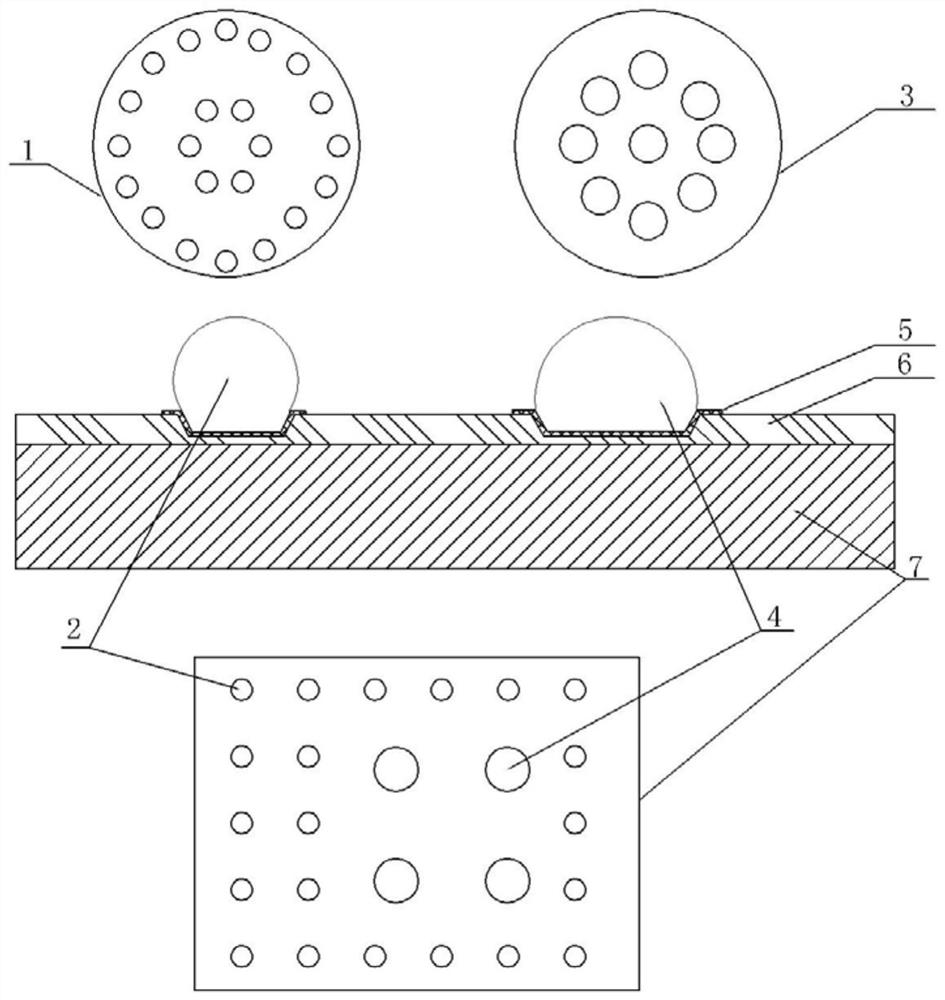

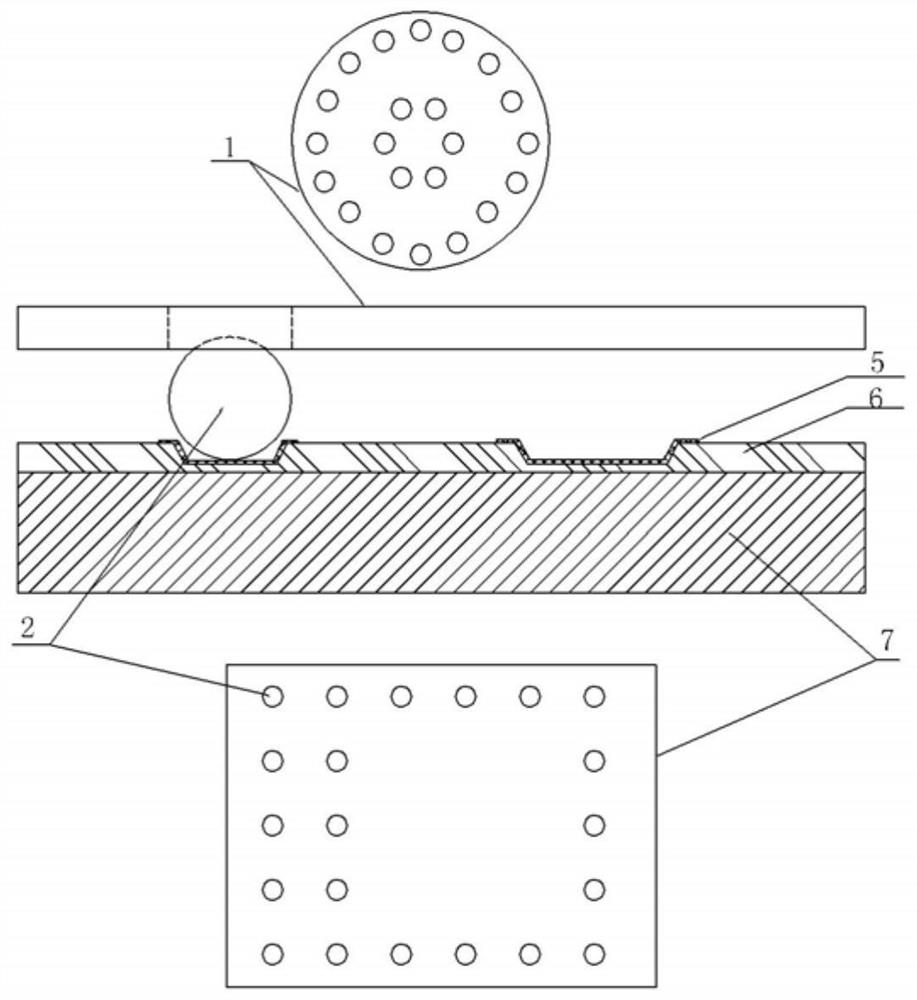

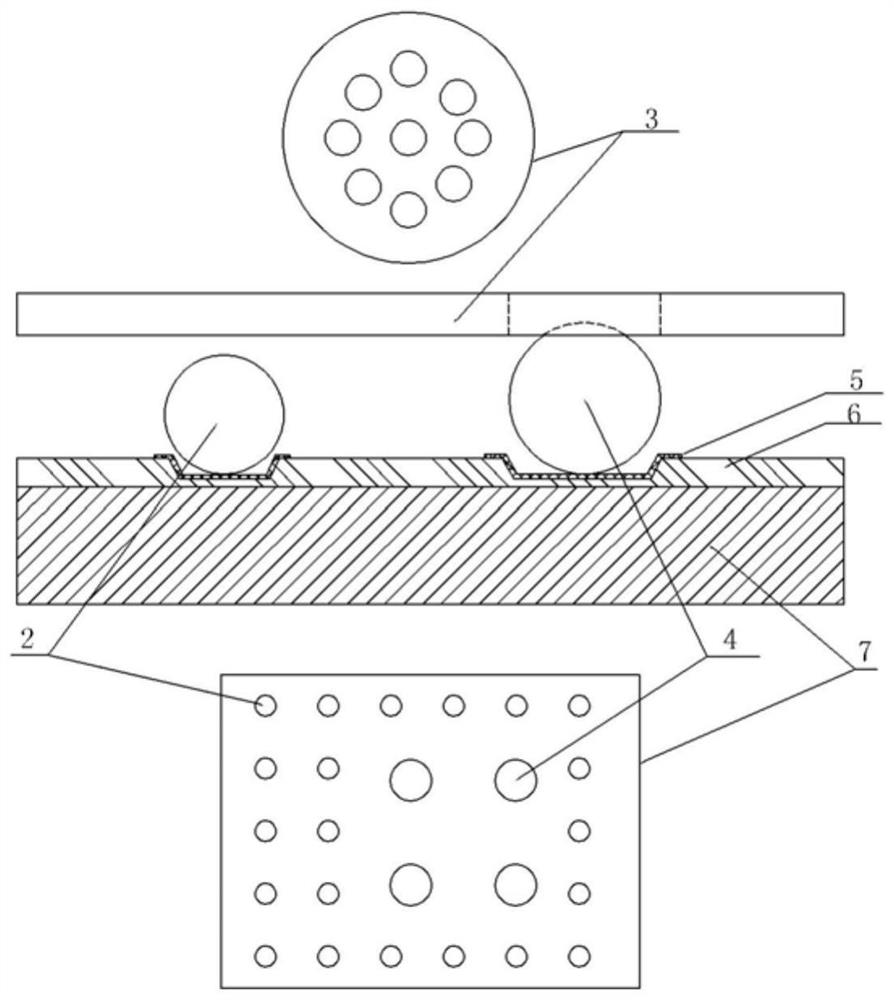

Method for preparing wafers having bumps with different diameters

ActiveCN109637990ASimple methodImprove yield and reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention discloses a method for preparing wafers having bumps with different diameters. The method includes the following steps: for wafers having the bumps with the same composition and different diameters, adopting a small-opening ball placing net plate to complete the placing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing of a large-sized solder ball, and performing uniform refluxing on the whole wafers; and for the wafers having the bumps with different compositions and different diameters, adopting a small-opening ball placing net plate to complete the placing and refluxing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing and refluxingof a large-sized solder ball. According to the scheme of the invention, the bumps with various diameters and different compositions can be prepared on the same wafer by switching the ball placing netplates, and thus the advantages of simple process, high yield and high reliability can be achieved.

Owner:BEIJING MXTRONICS CORP +1

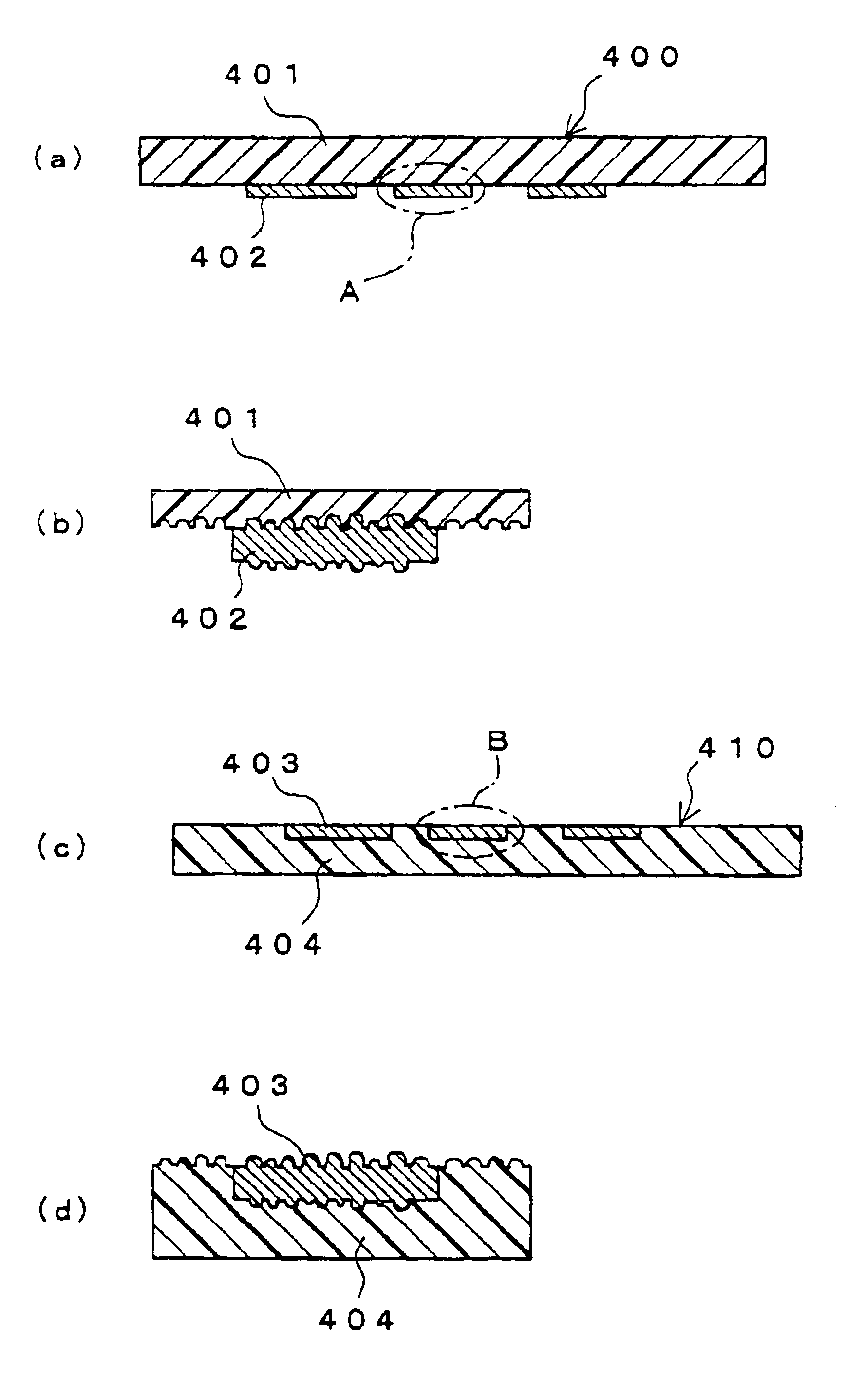

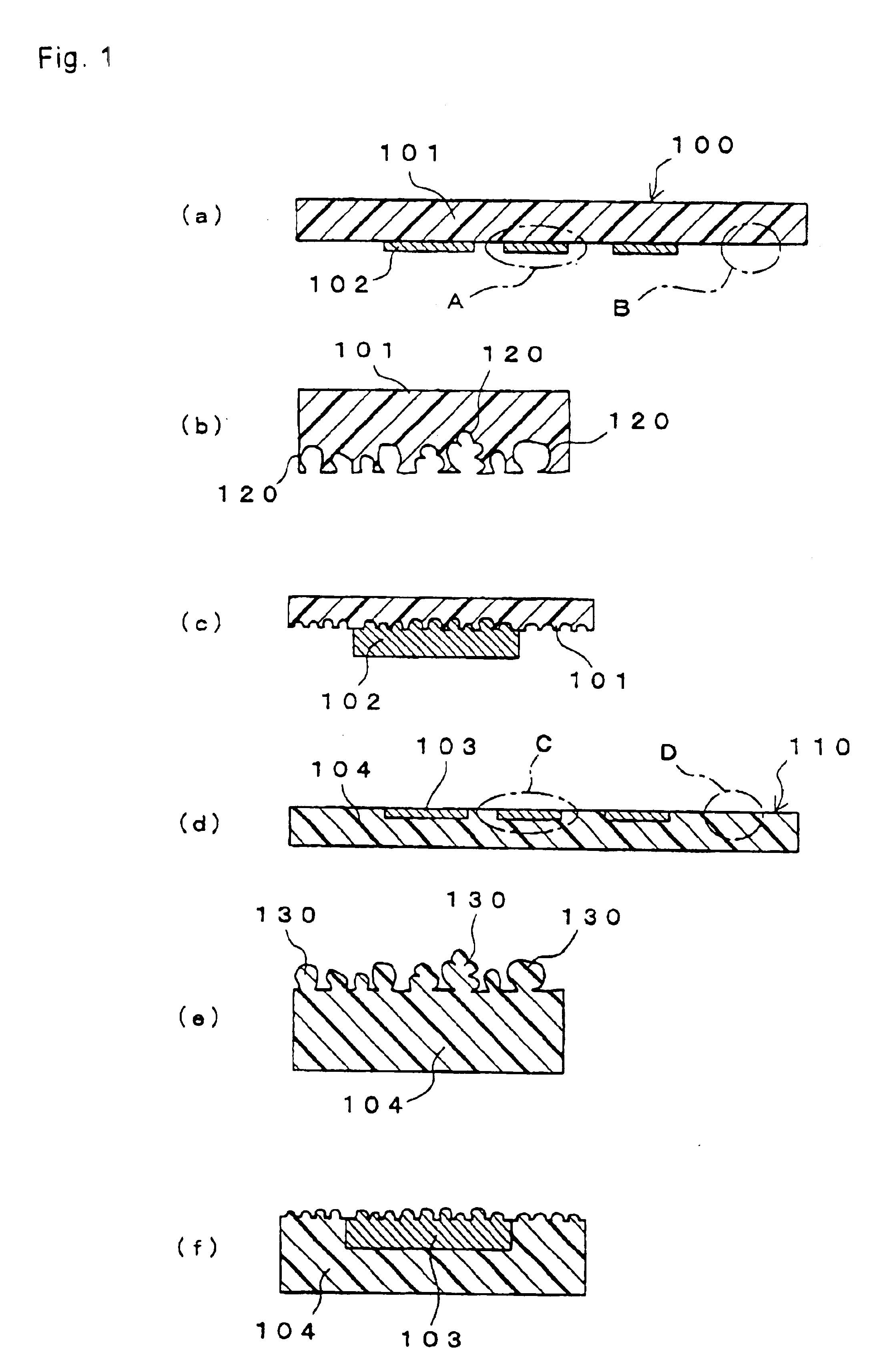

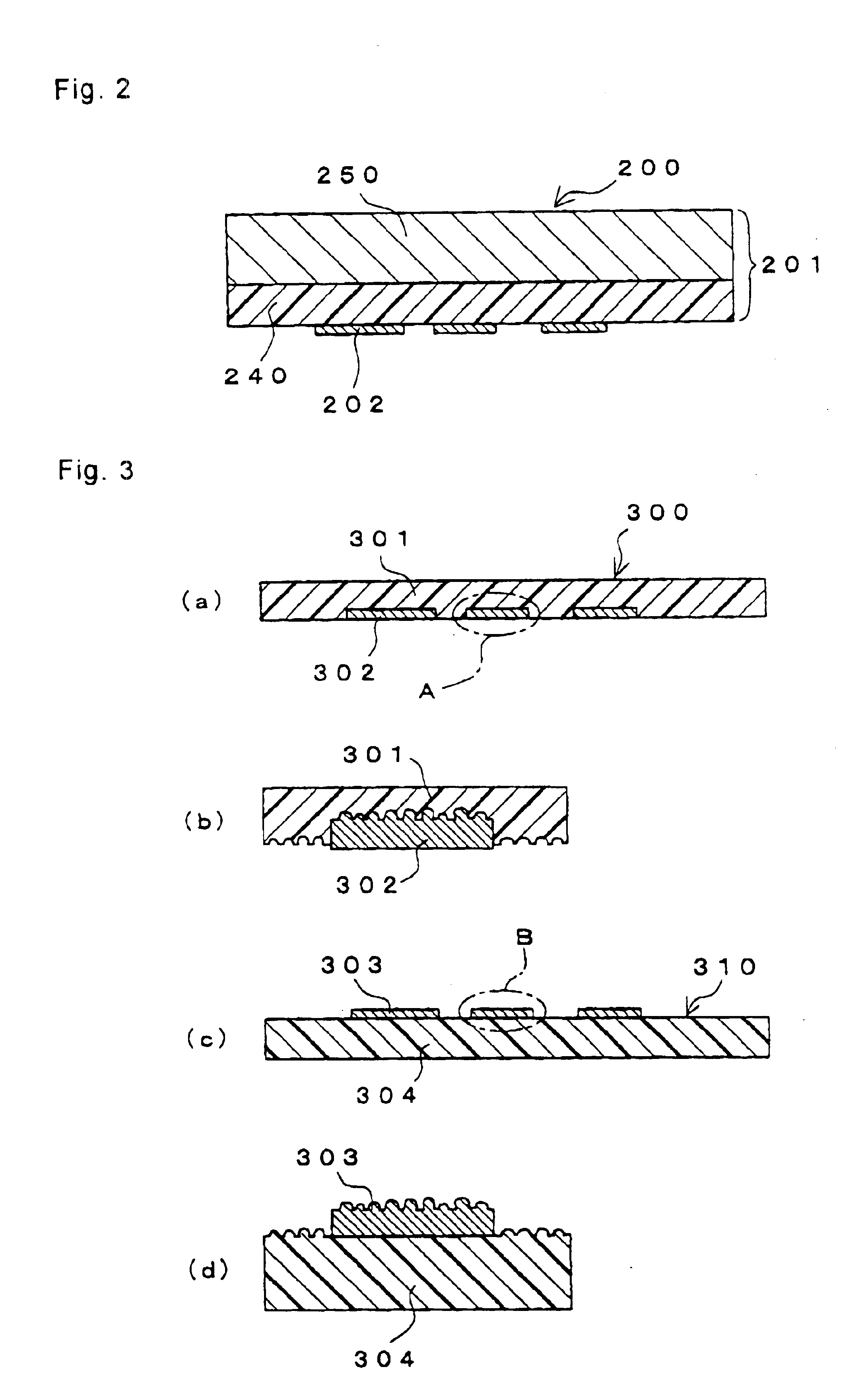

Wiring transfer sheet and method for producing the same, and wiring board and method for producing the same

InactiveUS6926789B2Improve adhesionHigh density mountingDecorative surface effectsSemiconductor/solid-state device detailsElectronic componentSurface structure

A wiring transfer sheet including a carrier base and a wiring layer formed thereon is produced so that an exposed area of a surface of the carrier base on which the wiring layer is formed has a plurality of concavities. By transferring the wiring layer to an electrically insulating substrate with this wiring transfer sheet, convexities which are complementary to the concavities are formed on the electrically insulating substrate. The convexities improve adhesion between a wiring board and a resin stacked thereon. Therefore, the wiring board thus obtained has surface coplanarity suitable for mounting a semiconductor bare chip and an electronic component as a whole, and a microscopical surface structure which adheres to a material stacked thereon.

Owner:PANASONIC CORP

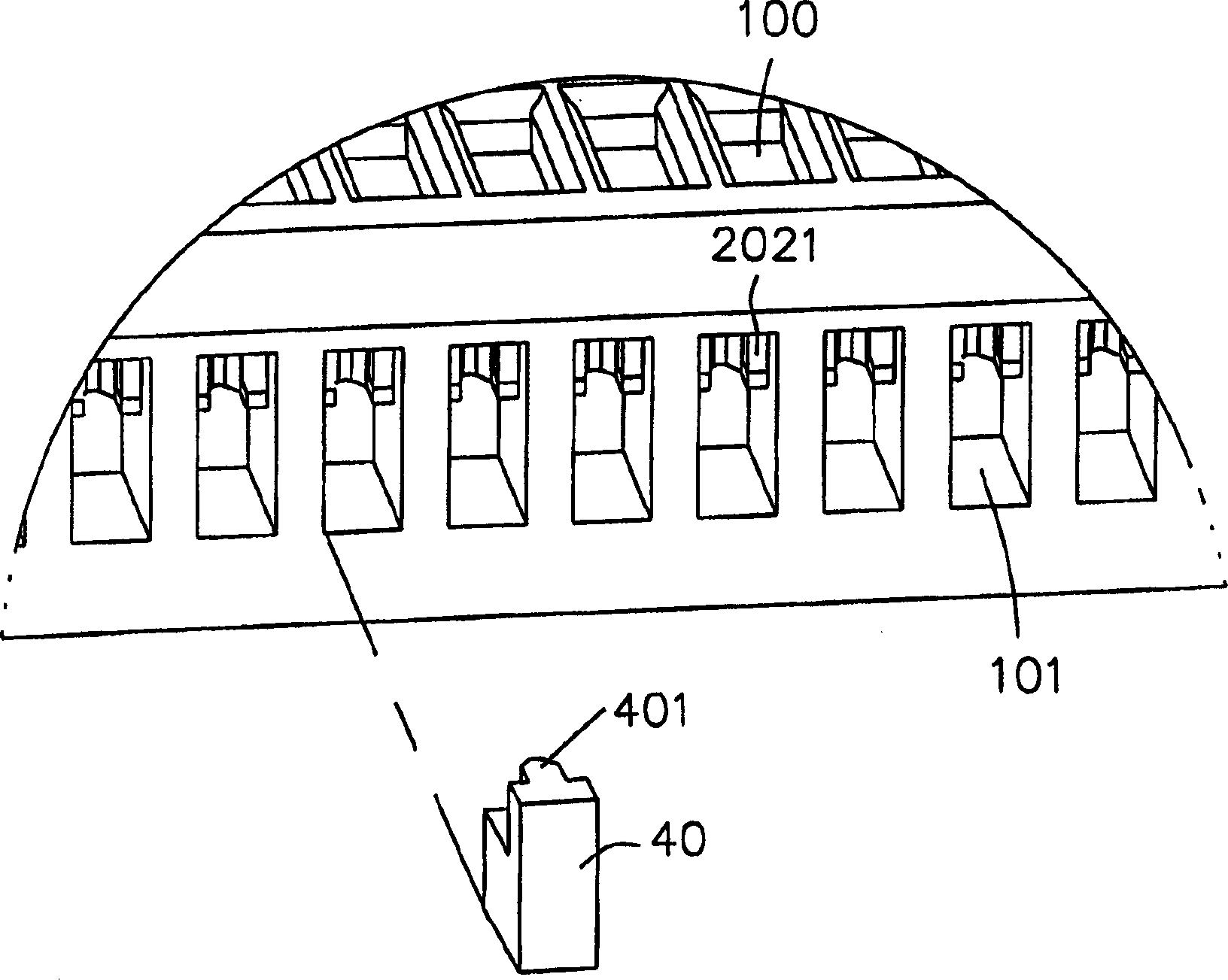

Differential screw height-adjustable LED (light emitting diode) lamp base and T-shaped calibrating form board using same

ActiveCN104033863AEasy to useEnsure coplanarityMeasurement devicesLighting support devicesMicrometerDifferential screw

The invention provides a differential screw height-adjustable LED (light emitting diode) lamp base and a T-shaped calibrating form board using the same, relates to a vision calibrating form board, and belongs to the technical field of vision measurement. The differential screw height-adjustable LED lamp base consists of a height-adjustable lamp base body, a fixed seat, an adjusting sleeve, a shell and an anti-rotating spring. On the premise that LED spots do not rotate, the LED spots are only adjusted along a vertical direction of a coplane by 0.5mm when the adjusting sleeve rotates at an angle of 360 degrees, and if instruments such as a high-precision coordinate measuring machine and the like are adopted, 5-micrometer coplane adjusting precision of the LED spots can be achieved by manually adjusting the adjusting sleeve. The calibrating form board comprises a planar T-shaped calibrating form board structure consisting of five coplanar infrared LED spots. The differential screw height-adjustable LED lamp base and the T-shaped calibrating form board using the same are suitable for the field of vision measurement on camera parameter calibration by using the form board.

Owner:HARBIN INST OF TECH

Method for mfg. electric connector containing multi-conducting terminals and metal frame by plugging shaping method

InactiveCN1459893AGood coplanarityFixed spacingContact member cases/bases manufactureElectricityMetal framework

An insertion method for manufacturing the electric connector containing multiple electric conducting terminals and a metallic framke includes assembling said terminals and metallic frame together, putting it in mould cavity, inserting the detachable first and second fixers between adjacent terminals from their free ends and tail ends, espectively, and filling the fused resin in the mould cavity to form an insulating casing.

Owner:MOLEX INC

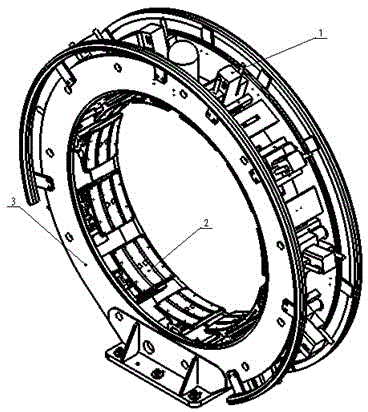

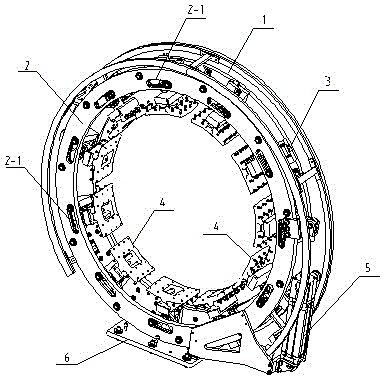

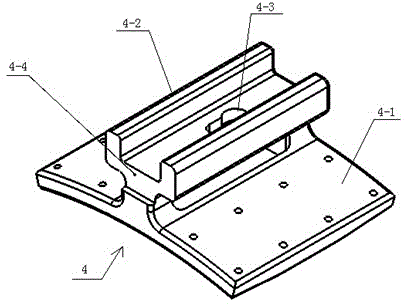

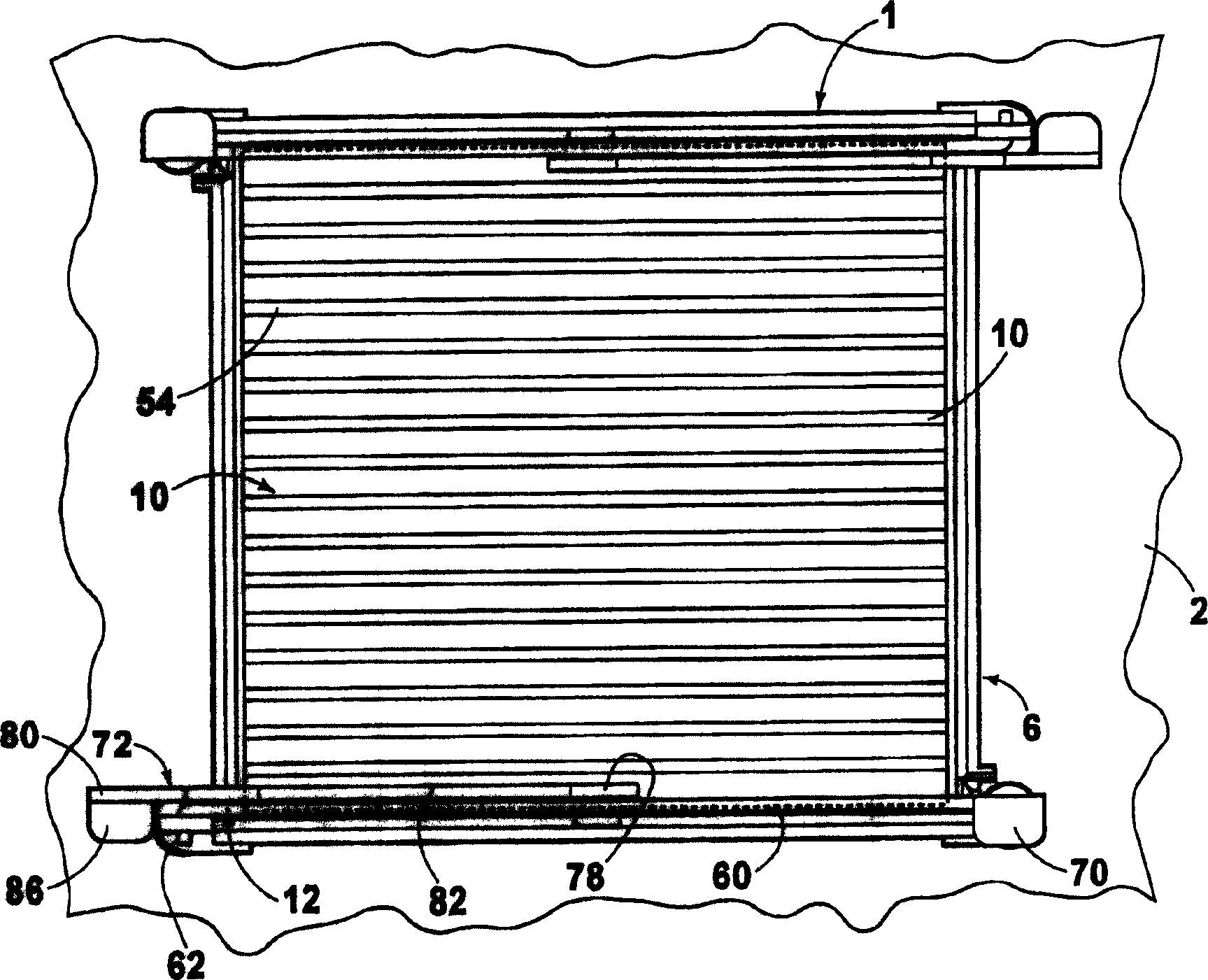

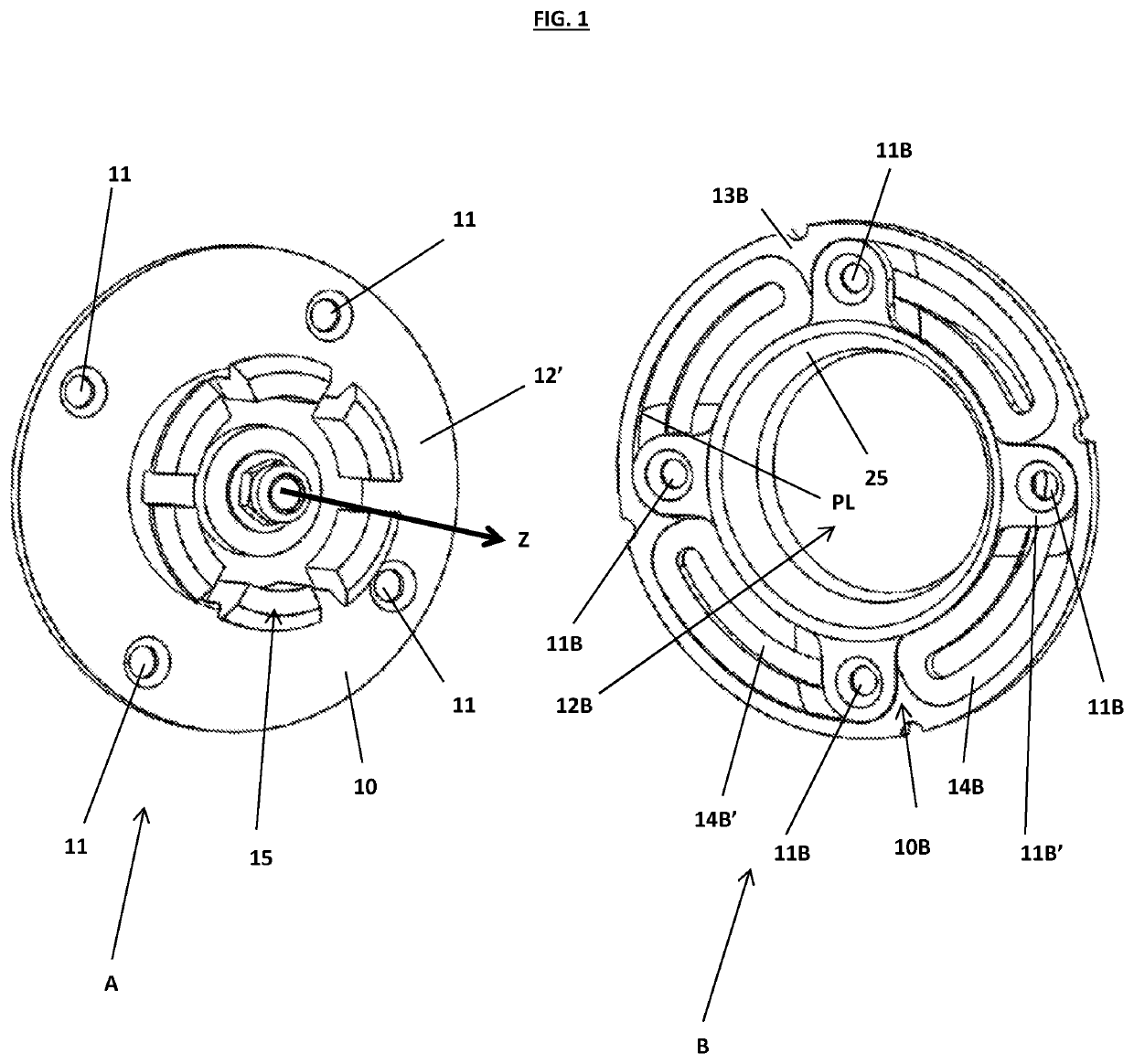

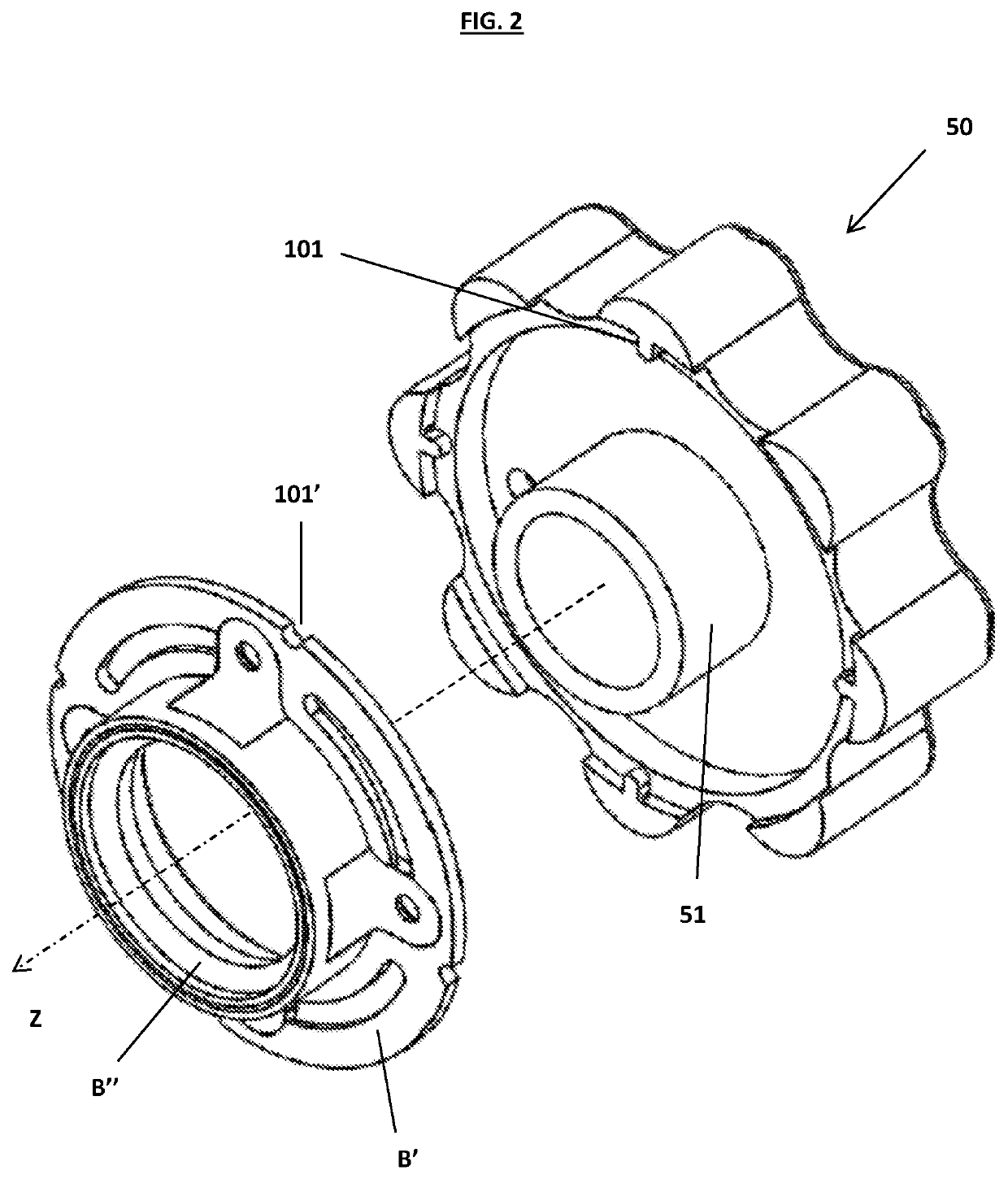

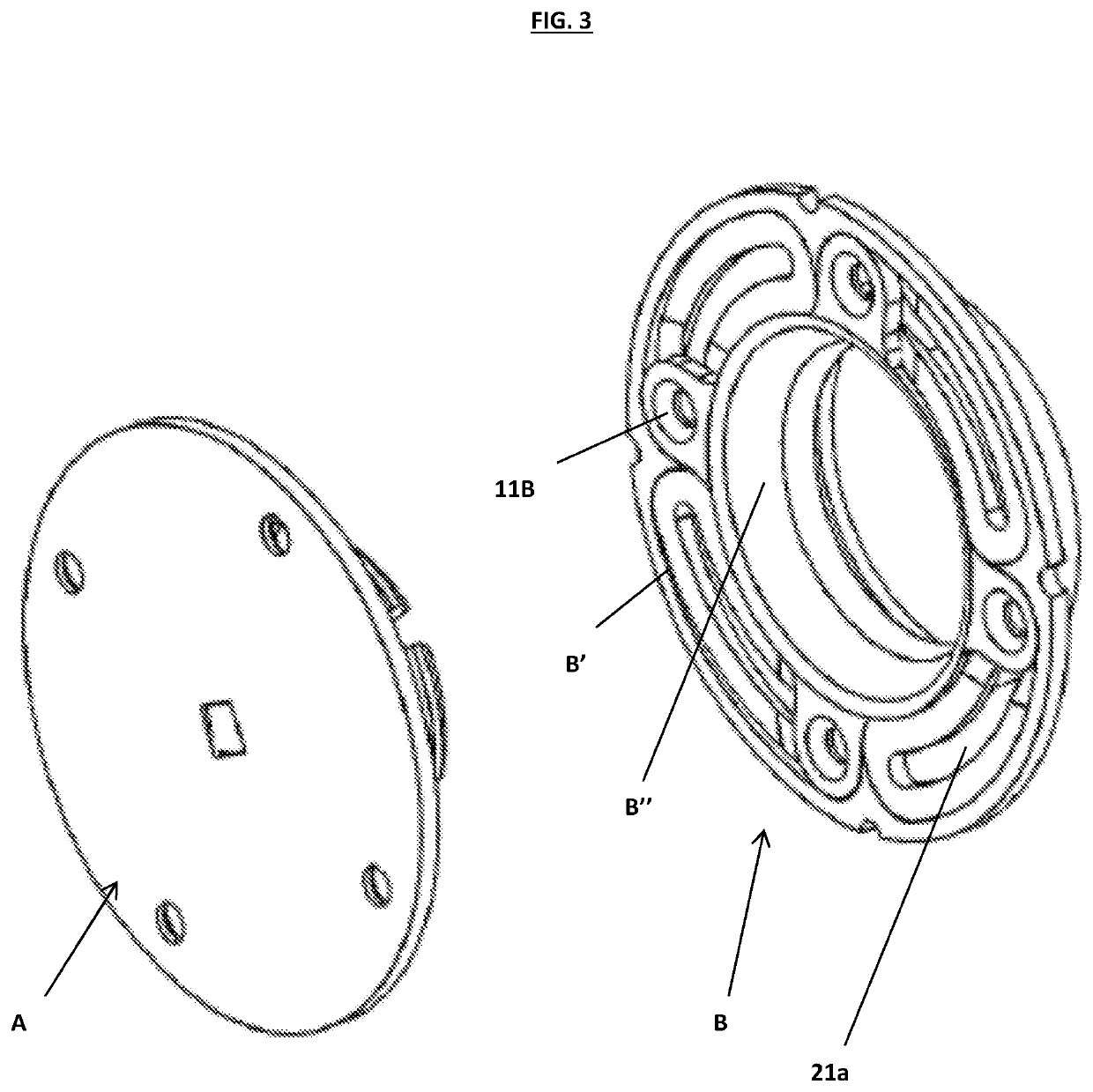

Belted layer transferring ring

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

Multi-chip upright tile sandwich package structure and technique therefor

InactiveCN105551982AReduce package resistanceReduction of interconnection processSemiconductor/solid-state device detailsSolid-state devicesReflow solderingSolder paste

The invention relates to a multi-chip upright tile sandwich package structure and a technique therefor. The technique comprises the following steps: (1) providing a first lead frame; (2) coating the first lead frame with a solder paste; (3) implanting a first chip into the solder paste of the first lead frame; (4) providing a second lead frame; (5) coating the second lead frame with the solder paste; (6) laminating the second lead frame on the first chip; (7) carrying out reflow soldering; (8) coating the second lead frame with the solder paste; (9) implanting a second chip into the second lead frame; (10) providing a third lead frame; (11) coating the third lead frame with the solder paste; (12) laminating the third lead frame on the second chip; (13) carrying out reflux soldering; (14) carrying out plastic package by a molding compound; and (15) carrying out cutting or punching operation. The technique has the beneficial effects that the heat dissipation capacity of a product is improved and the package resistance of the product is reduced.

Owner:JCET GROUP CO LTD

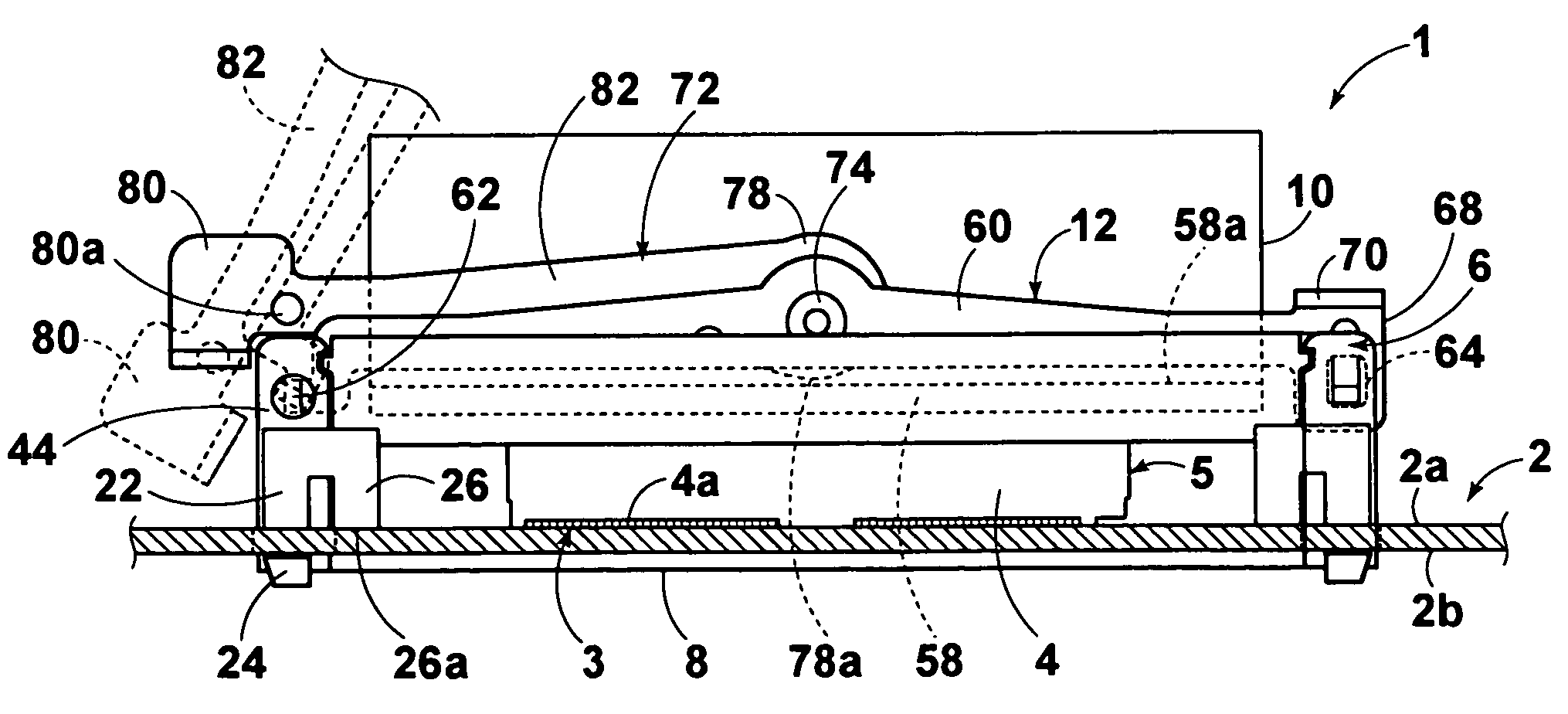

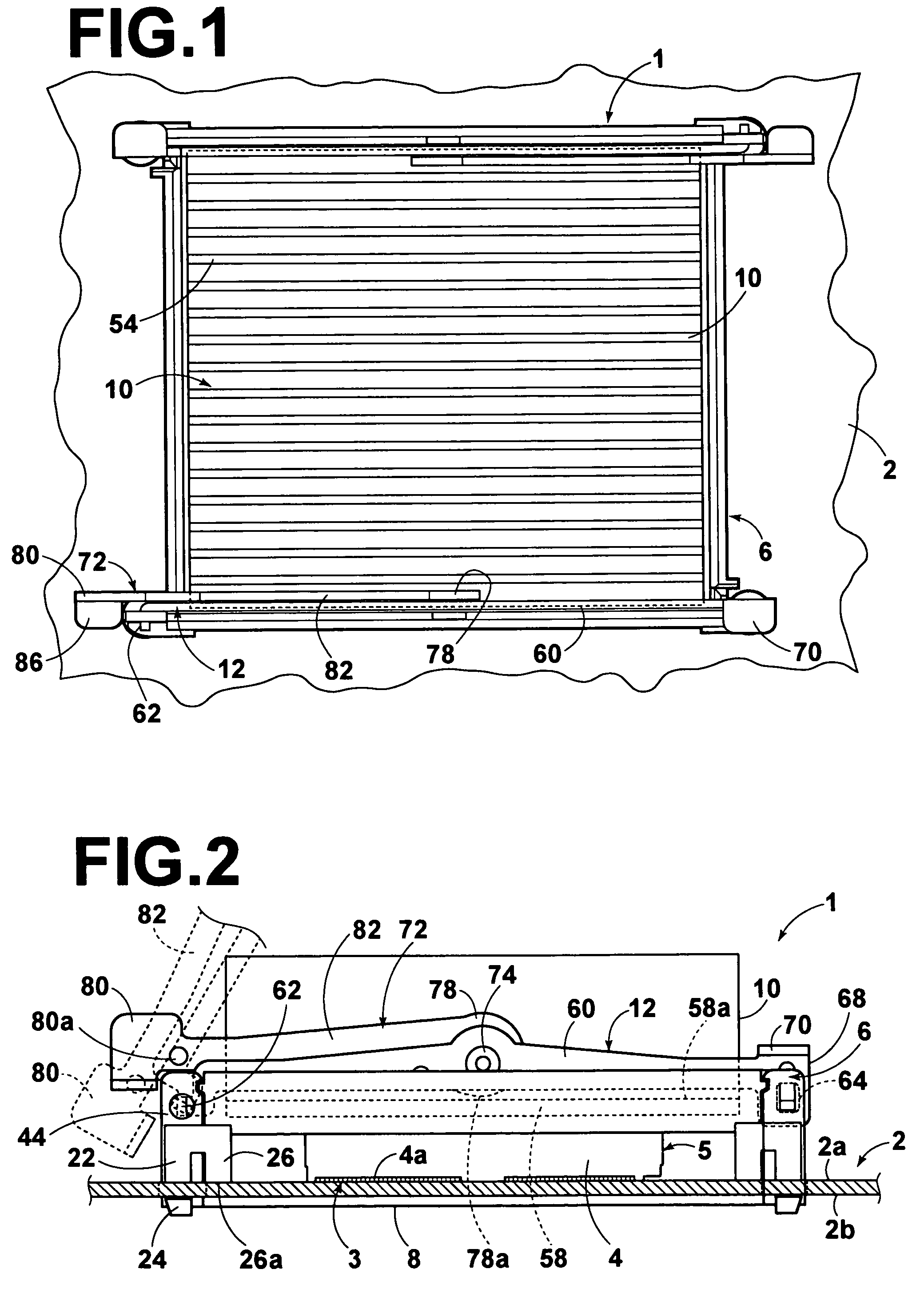

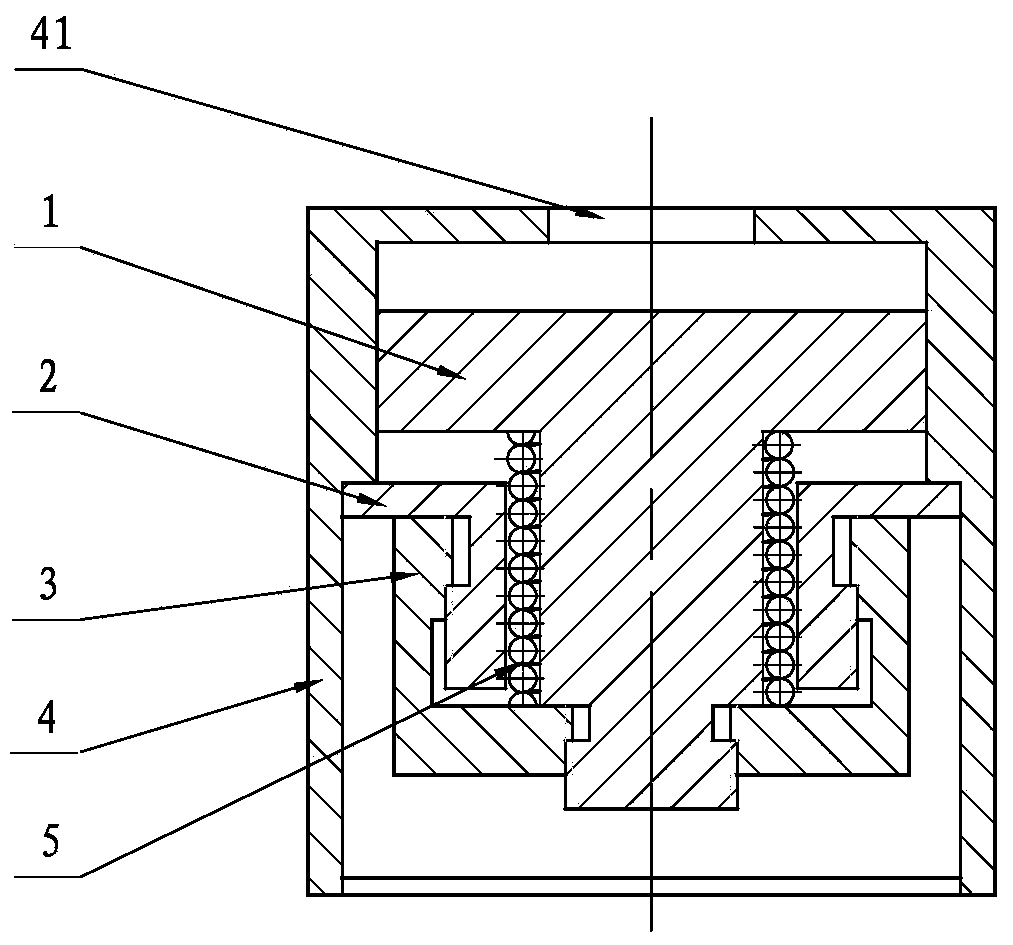

IC socket assembly

InactiveCN1571223AReduce warpageReduce distortionElectric discharge tubesSemiconductor/solid-state device detailsEngineeringHeat spreader

The IC socket assembly includes the heat sink for abutting the upper surface of an IC package to dissipate heat generated thereby, and a fixing member for fixing the heat sink to the housing. The fixing member includes: a frame, mounted on a surface of the circuit board, on which the housing is mounted; a back plate, mounted on the opposite surface of the circuit board, having engaging arms, which are inserted through apertures of the circuit board and engage the frame; a pair of loading beams, fixed to the engaging arms; and a pair of levers, axially supported by the loading beams, for urging the heat sink toward the housing.

Owner:TYCO ELECTRONICS JAPAN GK

Method for mfg. electric connector containing multi-conducting terminals and metal frame by plugging shaping method

InactiveCN1280958CGood coplanarityFixed spacingContact member cases/bases manufactureDomestic articlesElectricityEngineering

Owner:MOLEX INC

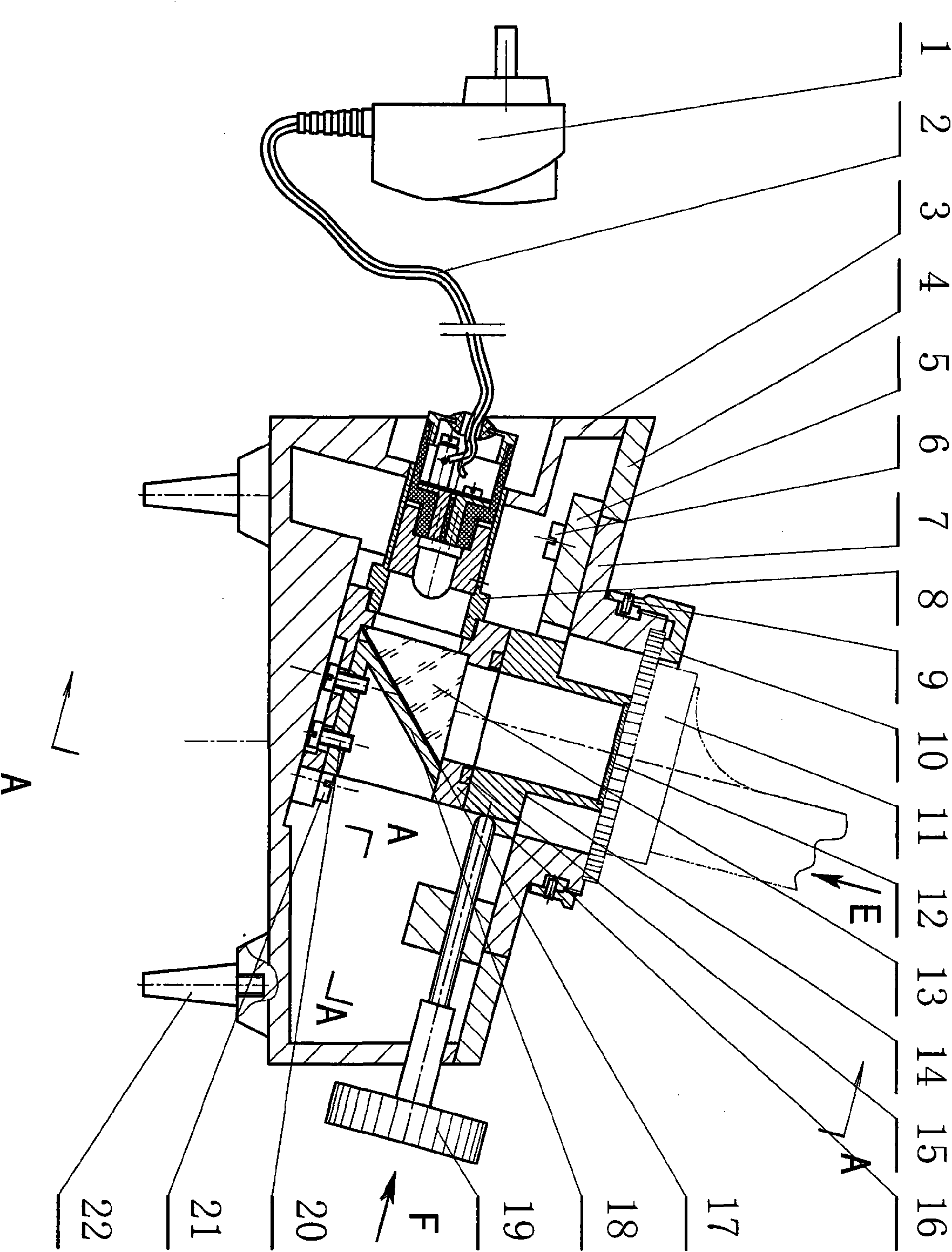

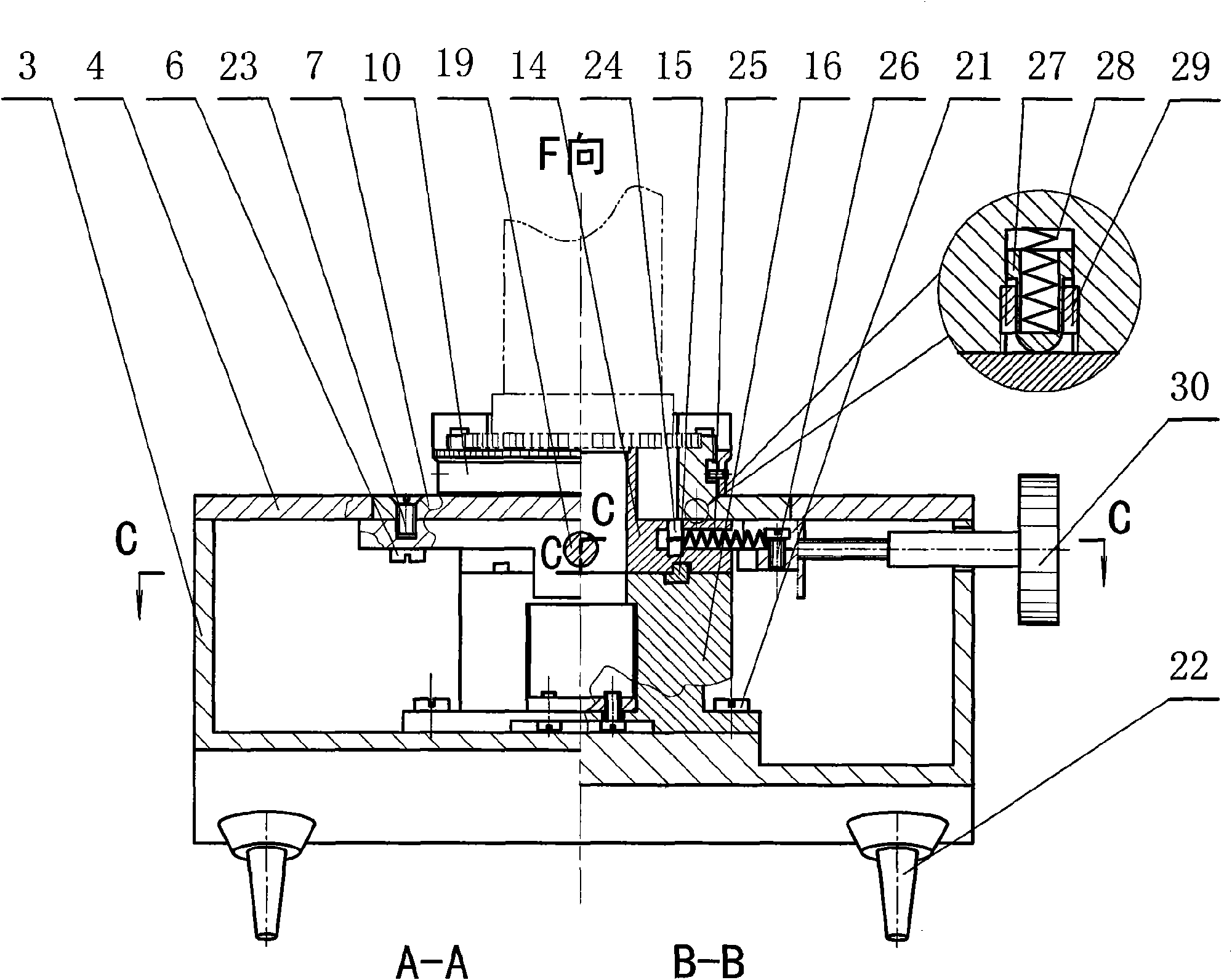

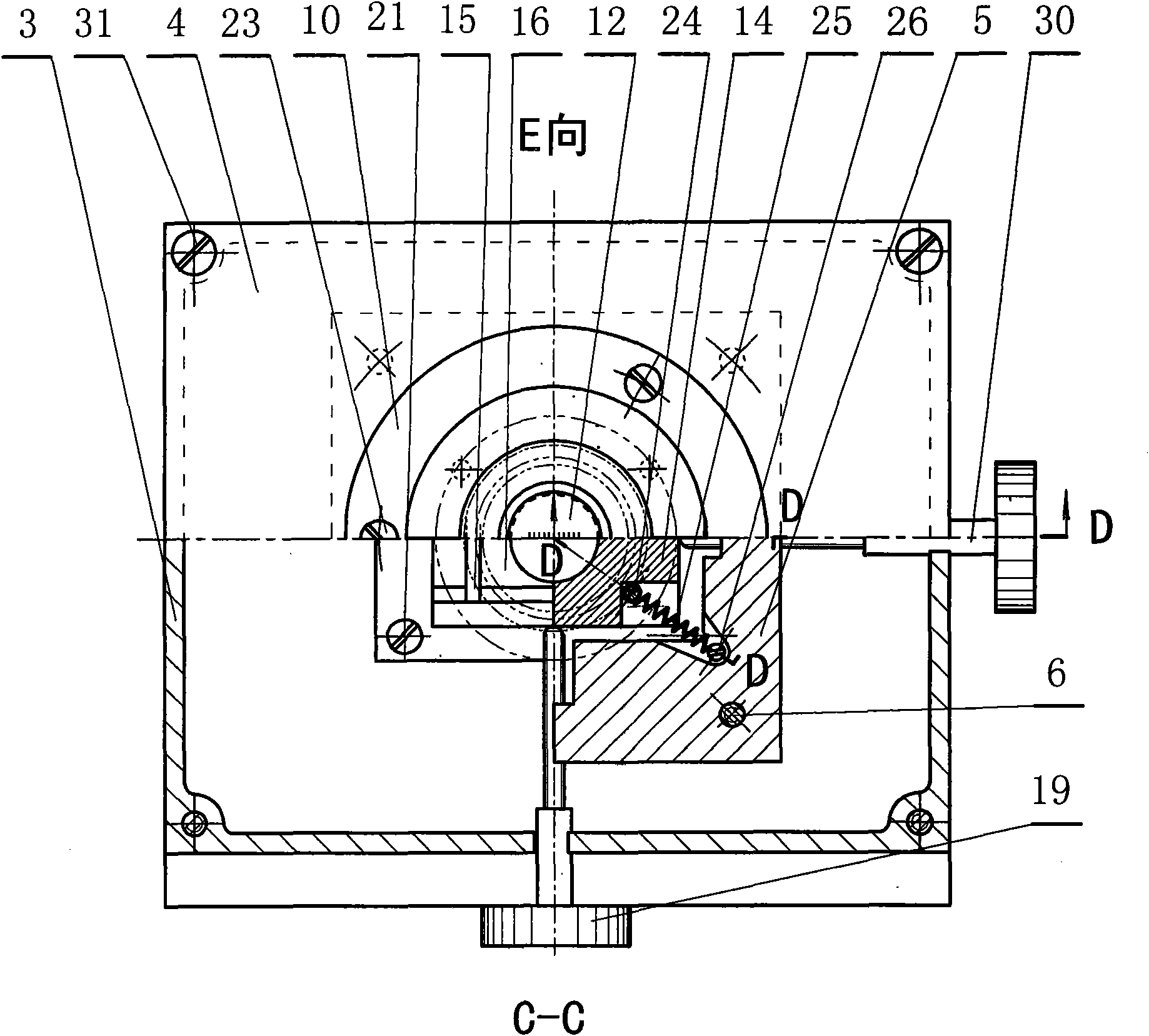

Reading microscope calibrating device

InactiveCN101639340AReasonable structurePrinciples of ScienceUsing optical meansMeasuring instrumentLighting system

The invention relates to a reading microscope calibrating device, and belongs to the technical field of precise calendar design and measuring instrument detection. Aiming at the nonexistence of an integral special calibrating device, the invention deliberately provides a special calibrating device of an autonomic system for calibration of a reading microscope. The reading microscope calibrating device consists of five parts comprising a body part, a clamping mechanism, a longitudinal and transverse motion mechanism, an illumination system and a light source part. The body part forms a main body of the device and is provided with an 'interface' for integrating other parts; and the clamping mechanism arranged above the device is used for firmly clamping the reading microscope on the device.The longitudinal and transverse motion mechanism arranged in the abdomen of the device is used for adjusting the relative positions of a scale and the reading microscope; and the illumination system and the light source part which are arranged at the lower rear part inside the device are used for illuminating the scale which cannot be illuminated by use of natural light and external light. The device ensures that the axis of the clamped reading microscope is inclined forwards at 15 degrees by virtue of the structural design so as to facilitate human eye observation and measurement.

Owner:GUANGDONG INST OF METROLOGY

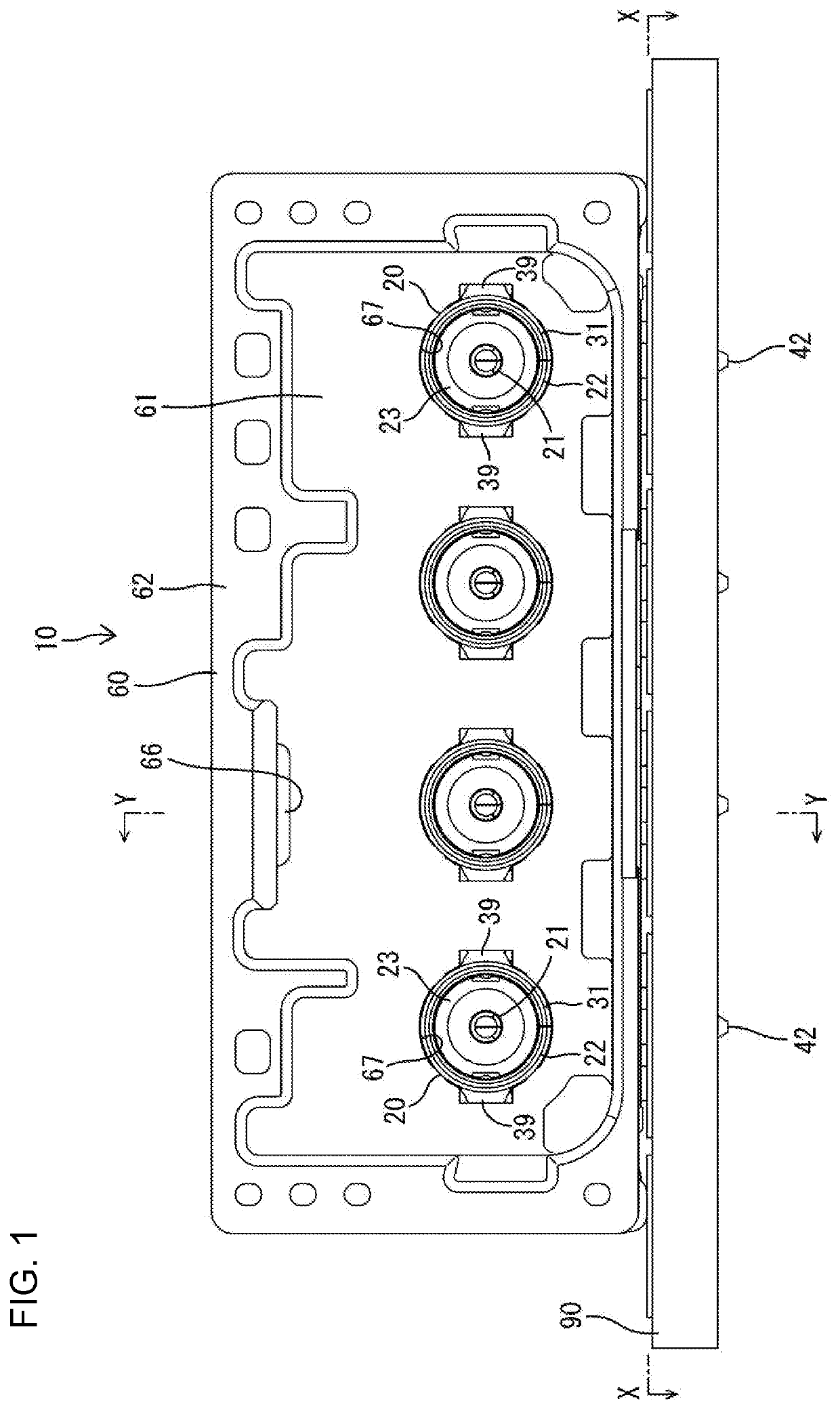

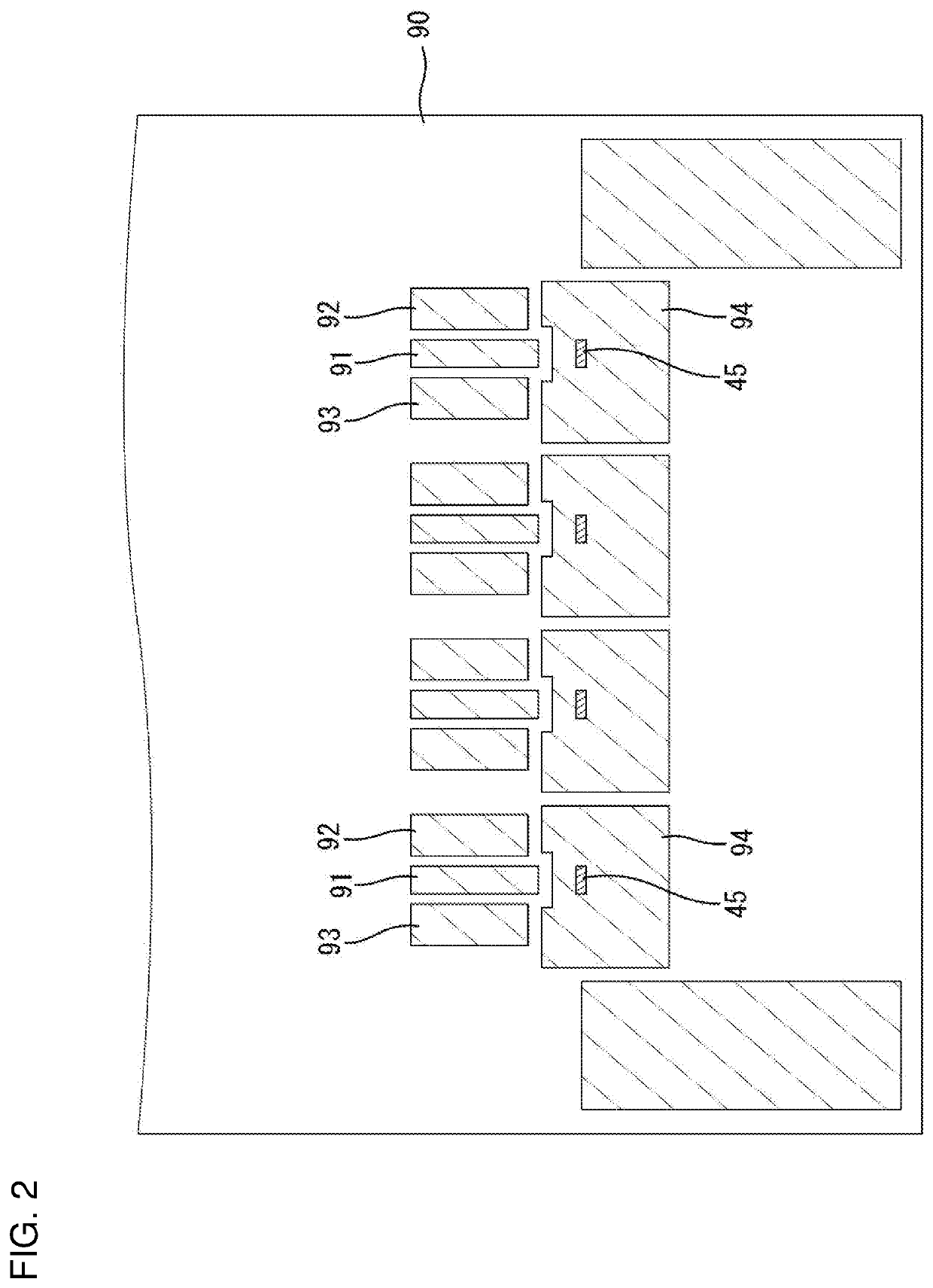

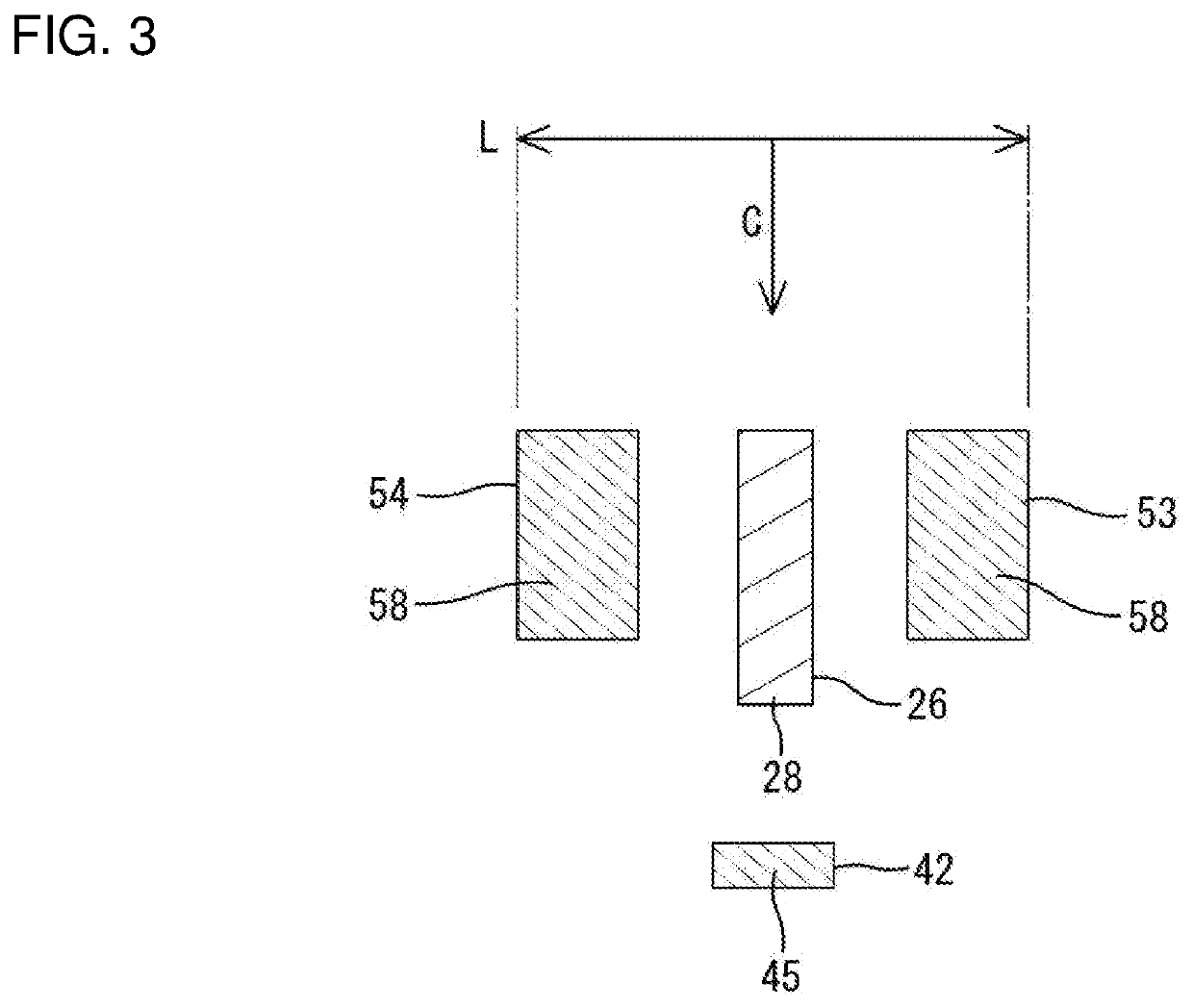

Board connector

ActiveUS10224664B2Increase changeEnsure coplanaritySecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

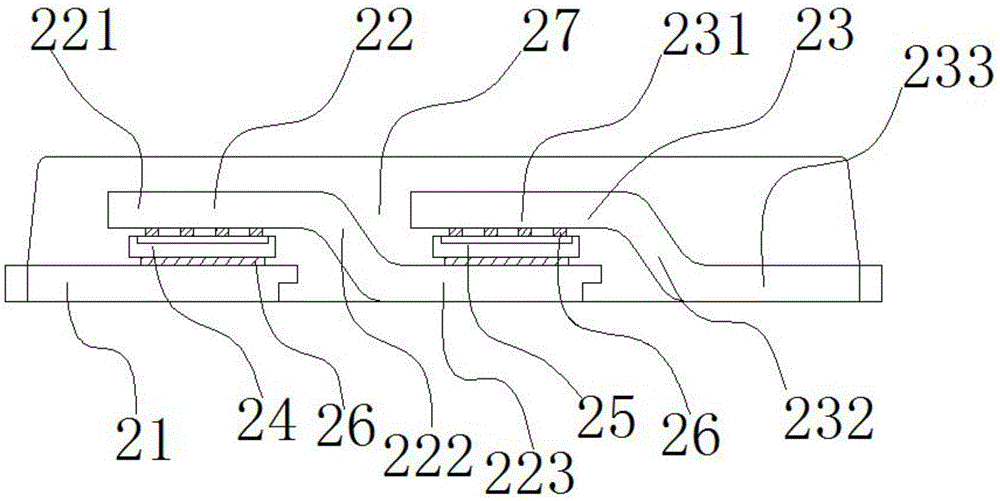

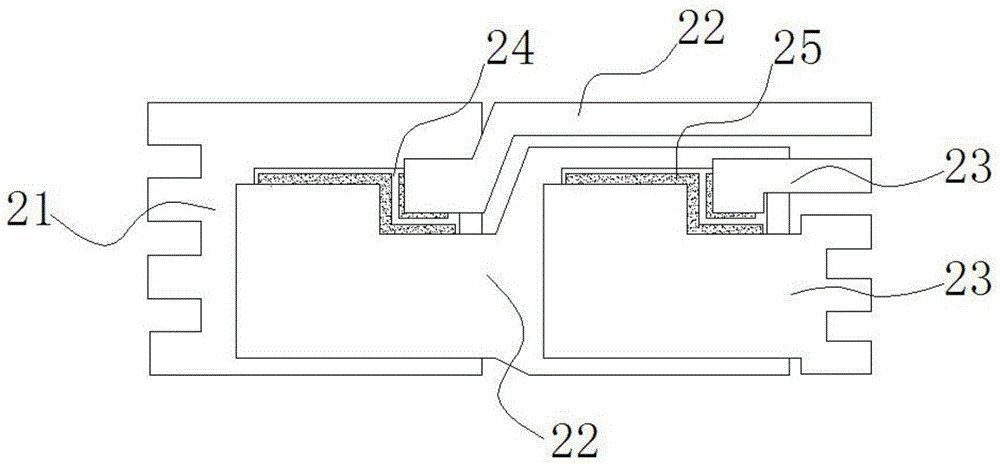

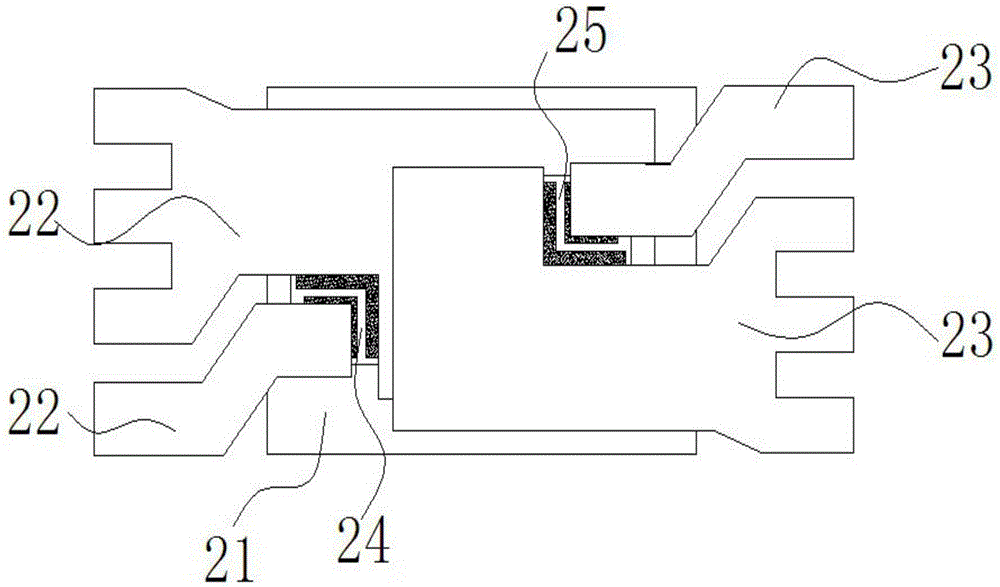

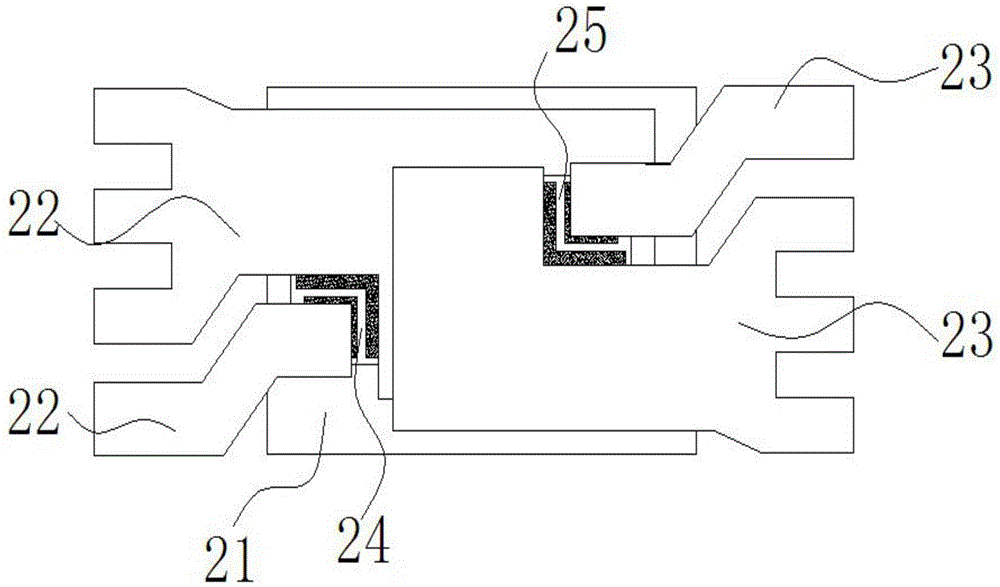

FP type chip pin forming device and forming method

PendingCN112845957AGuaranteed no lateral displacementEnsure coplanarityEngineeringStructural engineering

The invention relates to an FP type chip pin forming device and a forming method. The device comprises a clamping device, an upper die and a lower die; the lower die comprises a bottom plate, two first convex ribs and a convex strip, the convex strip is located in the center of the bottom plate, and the two first convex ribs are symmetrically distributed on the two sides of the convex strip; the upper die comprises a top plate, two first flanges and two second flanges, and the two first flanges and the two second flanges are symmetrically distributed with respect to the central axis of the top plate; the heights of the first convex ribs, the convex strip and the bottom plate of the lower die are sequentially decreased; and the heights of the top plate, the two first flanges and the two second flanges of the upper die are sequentially increased. According to the FP type chip pin forming device and the forming method, the forming mode is one-time forming, so that the lateral displacement of a chip pin caused by repeated bending when the chip pin is bent by tweezers is avoided.

Owner:大连长丰实业总公司

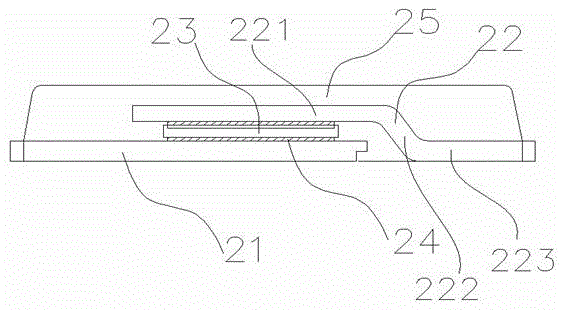

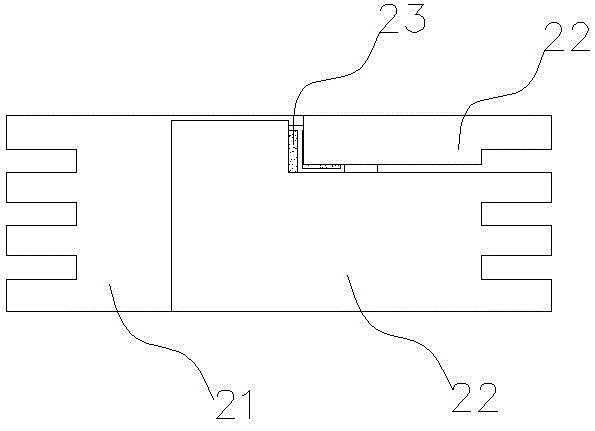

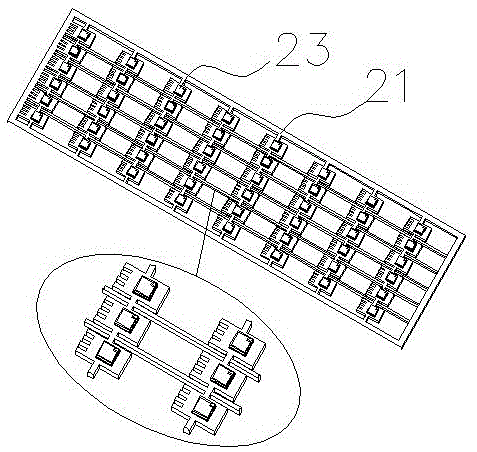

Weld leg component, arrayed weld leg module and key component

PendingCN108417425AIncrease the difficulty of the production processEnsure coplanarityElectric switchesMechanical engineering

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

Multi-chip upright stack sandwich package structure with exposed frame and technique for multi-chip upright stack sandwich package structure

InactiveCN105551983AReduce package resistanceReduction of interconnection processSemiconductor/solid-state device detailsSolid-state devicesPunchingEngineering

The invention relates to a multi-chip upright stack sandwich package structure with an exposed frame and a technique for the multi-chip upright stack sandwich package structure. The technique comprises the following steps: (1) providing a first lead frame; (2) coating the first lead frame with a solder paste; (3) implanting a first chip into the solder paste of the first lead frame; (4) providing a second lead frame; (5) coating the second lead frame with the solder paste; (6) laminating the second lead frame on the first chip; (7) carrying out reflow soldering; (8) coating the second lead frame with the solder paste; (9) implanting a second chip into the second lead frame; (10) providing a third lead frame; (11) coating the third lead frame with the solder paste; (12) laminating the third lead frame on the second chip; (13) carrying out reflux soldering; (14) carrying out plastic package by a molding compound; and (15) carrying out cutting or punching operation. The technique has the beneficial effects that the heat dissipation capacity of a product is improved and the package resistance of the product is reduced.

Owner:JCET GROUP CO LTD

Wafer preparation method with bumps of different diameters

ActiveCN109637990BEasy to implementImprove work efficiencySemiconductor/solid-state device detailsSolid-state devicesWaferSolder ball

The invention discloses a method for preparing wafers having bumps with different diameters. The method includes the following steps: for wafers having the bumps with the same composition and different diameters, adopting a small-opening ball placing net plate to complete the placing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing of a large-sized solder ball, and performing uniform refluxing on the whole wafers; and for the wafers having the bumps with different compositions and different diameters, adopting a small-opening ball placing net plate to complete the placing and refluxing of a small-sized solder ball first, and then switching to a large-opening ball placing net plate to complete the placing and refluxingof a large-sized solder ball. According to the scheme of the invention, the bumps with various diameters and different compositions can be prepared on the same wafer by switching the ball placing netplates, and thus the advantages of simple process, high yield and high reliability can be achieved.

Owner:BEIJING MXTRONICS CORP +1

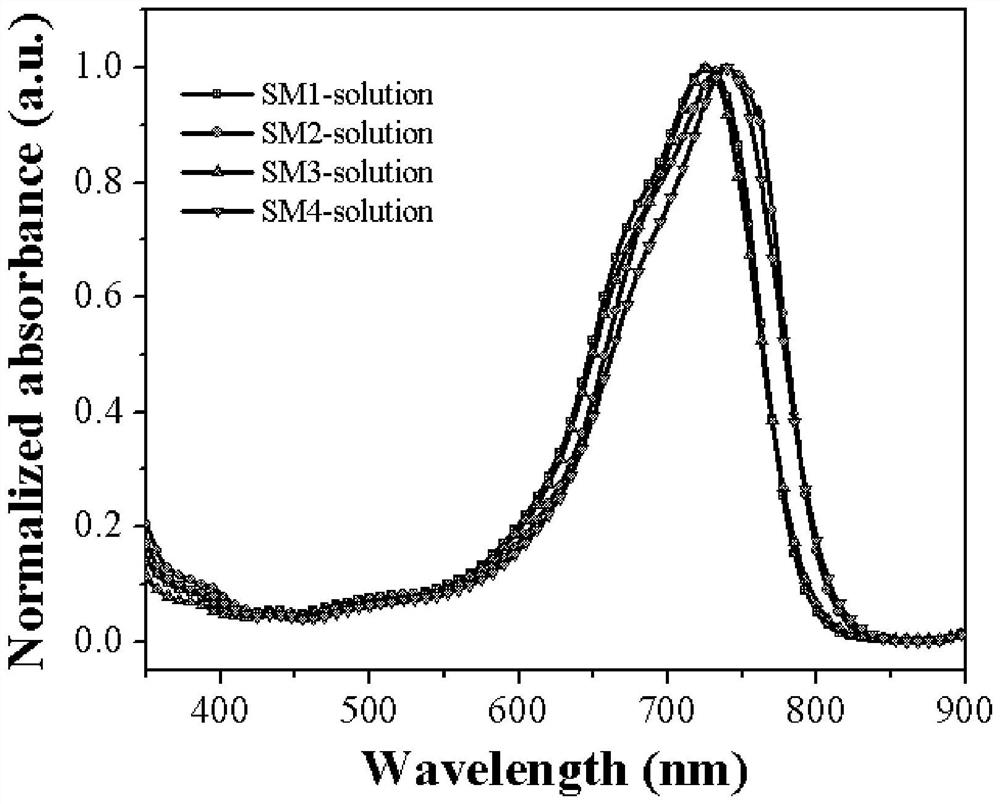

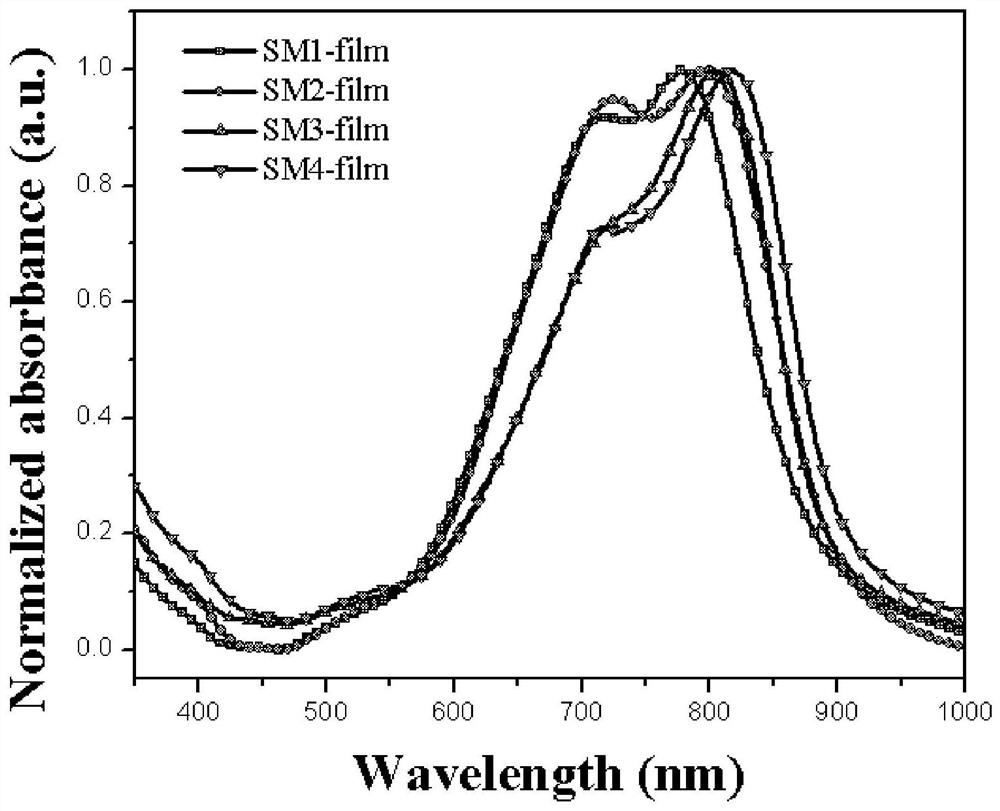

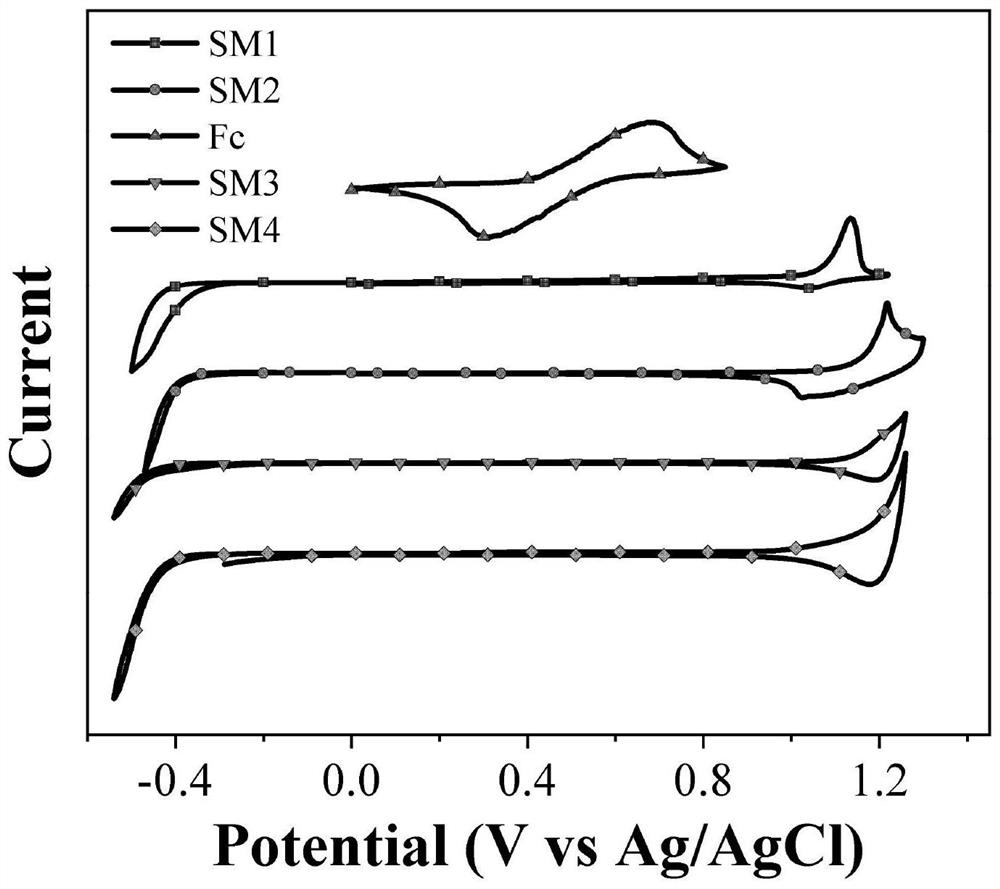

A kind of a-d-d′-a type asymmetric organic photovoltaic acceptor material and its application

ActiveCN113563362BEnsure coplanarityExpand the range of delocalizationOrganic chemistrySolid-state devicesOrganic solar cellHeterojunction

The invention belongs to the technical field of organic photovoltaics, in particular to a class of A-D-D'-A type asymmetric organic photovoltaic acceptor materials and applications thereof. Alkoxyindenothiophene and cyclopentadienodithiophene double-electron donor (D-D') units are used to jointly construct a skeleton containing non-covalent bond configuration locks, and 3-( Dicyanomethylene)inden-1-one modifies its terminus. Acceptors containing only simple fused rings have many advantages such as coplanar framework, low energy disorder and J-aggregation tendency, and the optical bandgap of such asymmetric small molecule acceptors is controllable in the range of 1.30-1.45eV tuned, can be combined with most donor materials to construct efficient bulk heterojunction binary organic solar cells. When the donor material is polymer PM6, the energy conversion efficiency of the binary OSCs device is as high as 13.67%, the open circuit voltage is 0.85eV, E loss Only 0.50V.

Owner:CHANGZHOU UNIV

Multi-chip integrated stacked sandwiched packaging structure and technological method therefor

InactiveCN105552042AReduce package resistanceReduction of interconnection processSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductancePunching

The invention relates to a multi-chip integrated stacked sandwiched packaging structure and a technological method therefor. The technological method comprises the following steps of step 1, providing a first lead frame; step 2, coating the first lead frame with solder paste; step 3, implanting a first chip into the first lead frame solder paste; step 4, providing a second lead frame; step 5, coating the second lead frame with the solder paste; step 6, enabling the first chip to be laminated by the second lead frame; step 7, performing reflow soldering; step 8, coating the second lead frame with the solder paste; step 9, implanting a second chip into the second lead frame solder paste; step 10, providing a third lead frame; step 11, coating the third lead frame with the solder paste; step 12, enabling the second chip to be laminated by the third lead frame; step 13, performing reflow soldering; step 14, performing plastic package by a plastic package material; and step 15, performing a cutting or punching operation. The technological method has the beneficial effects that the thermal dissipation capability of products is improved, and the packaging resistance of the products is lowered.

Owner:JCET GROUP CO LTD

Pressure fixing device of panel-works, in particular covering panels in nautical field

PendingUS20220307530A1Ensure coplanaritySmooth rotationWashersSheet joiningFisheryStructural engineering

A fixing device for fixing of two bodies to each other, for example a panel to a wall or two panels to each other, includes a male element having a support base and an engaging element, the support base having a rear surface for leaning onto one of the two bodies to be connected and a front surface from which the engaging element protrudes; and a female element having a support base with a rear surface for leaning and fixing onto the other body and a receiving channel for receiving the engaging element of the male element so that the engaging element, when inserted into the receiving channel, snaps inside it detachably, thus enabling the releasable coupling of the two bodies. The fixing device is configured for selecting two or more different distances along the axis defined by the rear surfaces of the male and female elements when coupled.

Owner:BC CONSULTING SRL

Preparation method of anti-corrosion liquid-cooled heat dissipation cold plate

ActiveCN105268918BEnsure coplanarityLittle structural requirementsFoundry mouldsFoundry coresWaxWeld seam

The invention discloses a preparing method for a corrosion-resistant liquid cooling heat dissipation cold plate and aims at providing a cold plate preparing method which is free of tedious treatment before welding and has prominent corrosion-resistant capability and long-term work reliability. According to the technical scheme, the two sides of a bottom transverse pipe commonly communicated serve as the starting points respectively, two sets of parallel pipes are longitudinally arranged continuously in a bent manner, and the bending radius of bent circular arc rings on the two longitudinal sides is larger than the distance between every two parallel pipelines; the free ends of each set of parallel pipes are fixedly connected through respective connector flanges; and the two sets of parallel pipes are fixed, clamped and positioned through pipeline clamping tools which are longitudinally arranged at intervals, die positioning plates with screw holes are adopted, wax patterns wrapping runner titanium pipes and connector flange assemblies are clamped between the two die positioning plates, and the runner titanium pipes and the connector flange assemblies are put into a smelting furnace, and a rectangular flat plate is formed through lost foam casting. The preparing method solves the problem that during traditional cold plate welding, a welding seam is prone to cracking, and consequently a cooling agent leaks.

Owner:10TH RES INST OF CETC

Method for manufacturing large-scale integrated circuit lead frame

ActiveCN101630644BAlleviate and reduce warpageAvoid hook misalignment and deformationSemiconductor/solid-state device detailsSolid-state devicesState of artSingle plate

The invention discloses a method for manufacturing a large-scale integrated circuit lead frame, which overcomes the defect of lower index qualification rate of the coplanarity and the displacement of pins of a lead frame manufactured in the prior art. The method comprises the following steps: (1) continuously stamping: continuously stamping a zone ring with a lead frame original blank on a die; (2) continuously electroplating: electroplating the zone ring with the lead frame original blank, wherein the electroplating area comprises the root welding area of the pins and the front surface of the chip island; and (3) slicing and confirming the size: cutting and flaking the electroplated zone ring to obtain a single plate lead frame piece, wherein in the step of continuous stamping, a connecting rib for connecting the end parts of a plurality of pins at each side into a whole is retained at one end of the pins in the lead frame original blank approaching to the four sides of the chip island, and in the step of slicing and confirming the size, when the zone ring is cut and the size is confirmed, the connecting rib of the end parts of the pins approaching to the four sides of the chip island is also cut off to obtain a finished lead frame. The invention can greatly improve the qualification rate of the coplanarity and the displacement of the pins of the finished lead frame.

Owner:NINGBO HUALONG ELECTRONICS

Differential spiral height adjustment LED lamp holder and T-shaped calibration template using the differential spiral lamp holder structure

ActiveCN104033863BEasy to useEnsure coplanarityMeasurement devicesLighting support devicesVisual field lossLight spot

A T -type calibration template that uses the differential spiral lamp structure with the differential spiral lamp structure, which involves a visual calibration template, which belongs to the field of visual measurement technology.The invention provides a highly adjustable spiral spiral high LED lamp holder, and a T -shaped calibration template with the differential spiral lamp structure.The differential spiral lamp holders are composed of raising lamp holders, fixed seats, adjustments, shells, and anti -rotating spring. Under the premise of ensuring that the LED light spot does not rotate, the LED is achieved when the adjustment sleeve rotates 360 degrees 360 degrees.The light spots are adjusted by 0.5mm per vertical direction in the common surface. If the instrument and other instruments such as high -precision coordinate measuring machines are used, the co -adjustment accuracy of the LED light spot 5 microns can be achieved by manual adjustment and adjustment.The calibration template includes a plane T -type calibration template structure composed of 5 co -infrared LED light points.The present invention is suitable for the field of visual measurement in the use of the template for camera parameter calibration.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com