Method for preparing wafers having bumps with different diameters

A bump and wafer technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of inability to prepare bumps with different components, difficult preparation process and high cost, and improve the accuracy of ball drop. , high yield and reliability, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

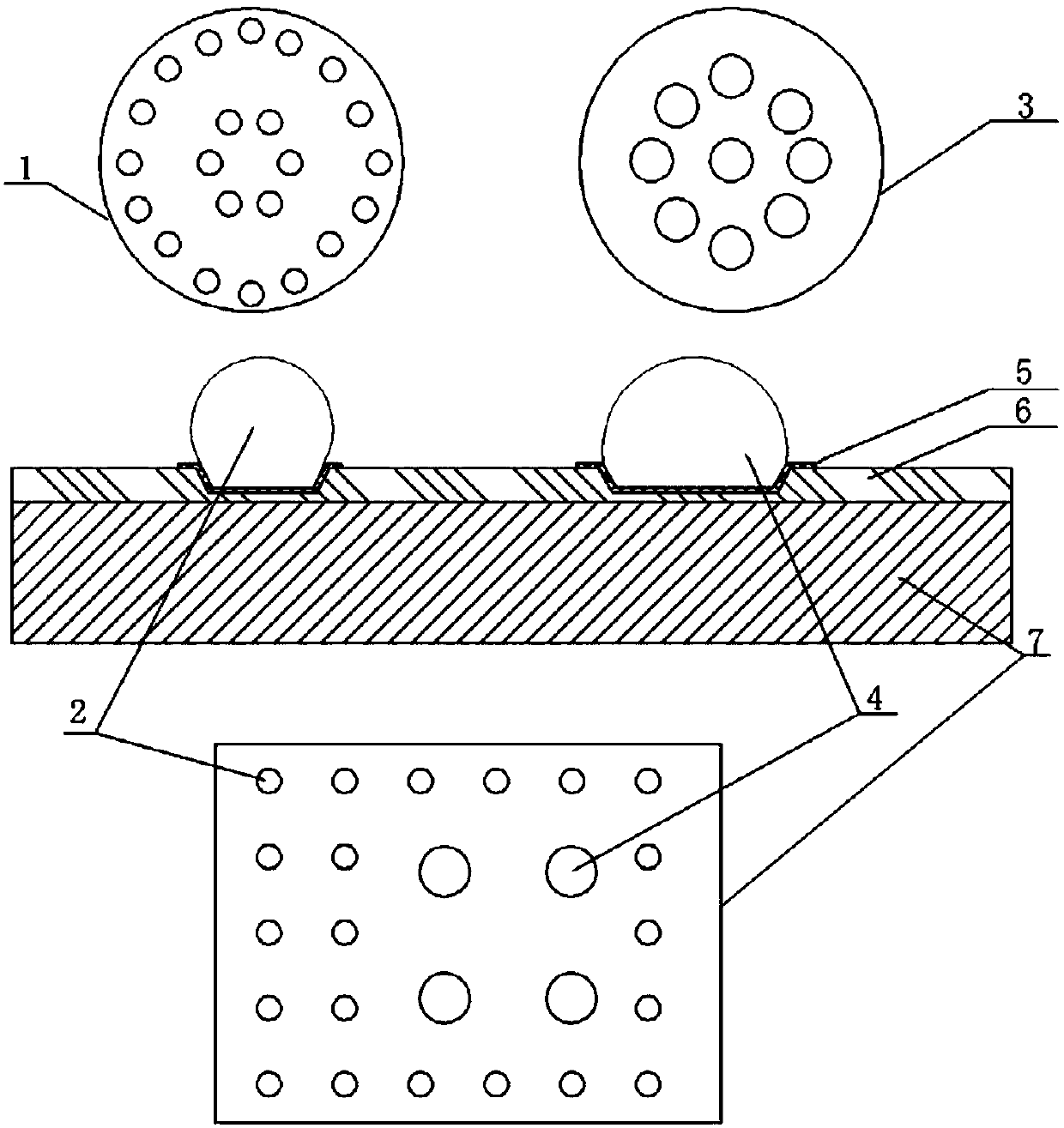

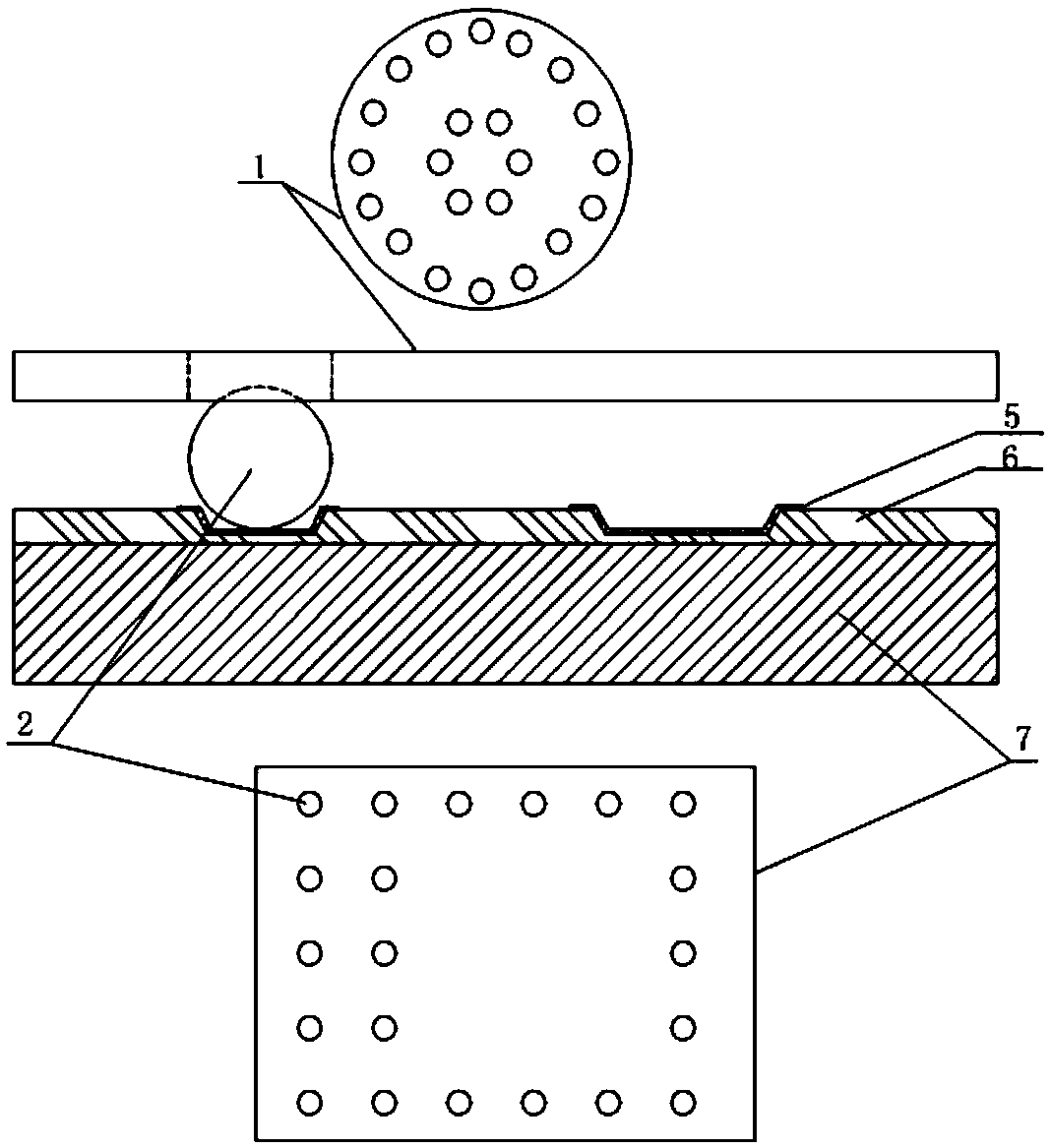

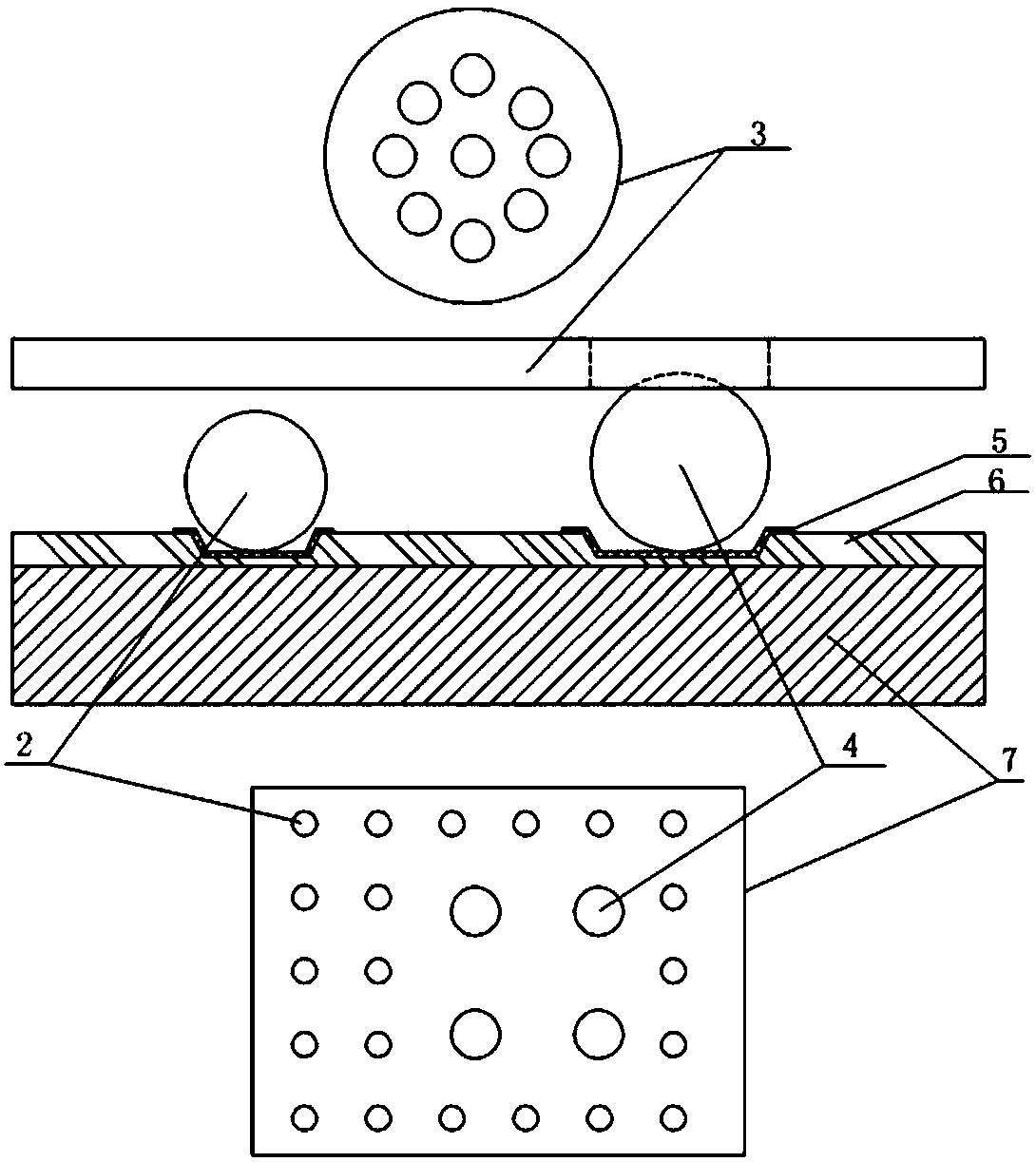

[0045] Such as Figure 2(a) ~ Figure 2(c) As shown, for the case where the bump components are the same, in this embodiment, the under-bump metallization layer is prepared according to the difference in the size of the bumps with different diameters, and then the ball screen with a smaller opening is used to place small-sized solder joints at the required positions. Balls, and then use a large-opening ball-setting screen to place large-size solder balls at the required positions, reflow the wafers with solder balls of different diameters, and complete the bump preparation. Finally, the bumps on the wafer surface are co-processed Face detection. This "drop-drop-back" technological process has a simple implementation method and high work efficiency, yield and reliability. The method specifically includes the following steps:

[0046] (1), preparing the UBM layer 5 at the corresponding position on the insulating layer 6 on the surface of the wafer 7;

[0047] The UBM layer is ...

Embodiment 2

[0059] For the case where the bump components are different, in this embodiment, the solder flux is first printed on the surface of the wafer prepared with the UBM layer, and a small-sized solder ball is placed on the required position by using a ball placement screen with a smaller opening. Wafer reflow is carried out first to complete the preparation of small-sized bumps, and then flux is sprayed on the position of large-sized bumps, and then large-sized solder balls are missed by using a ball-setting screen with a larger opening, and finally the wafer is reflowed to complete large-sized bumps. Bump preparation, this "drop-back-drop-back" process can effectively avoid the impact of the second ball placement on the first placement of the solder balls, and at the same time can realize the preparation of bumps with different components, and can prepare melting point Taller small size bumps, followed by larger size bumps with lower melting points. Specifically include the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com