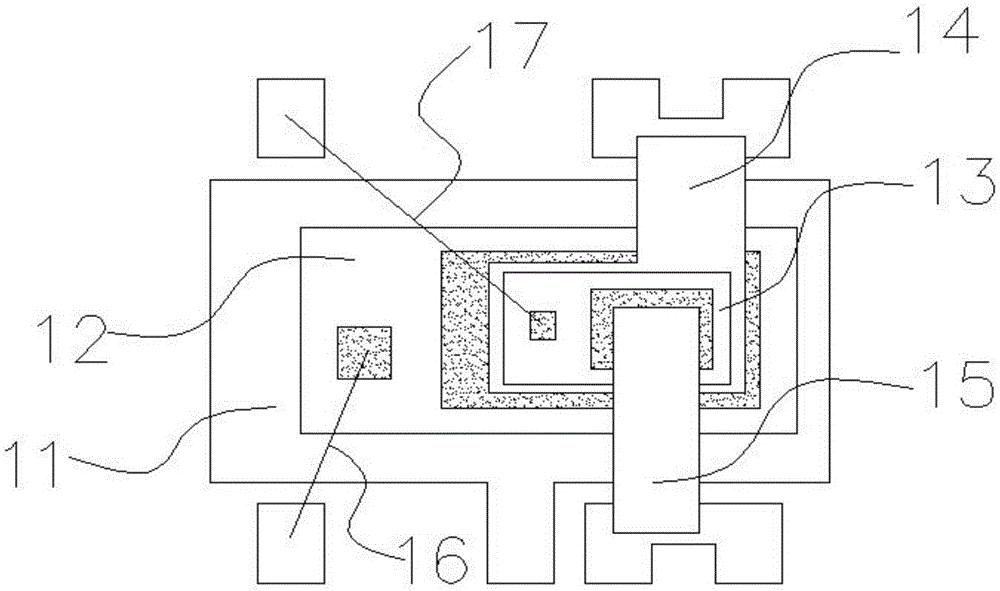

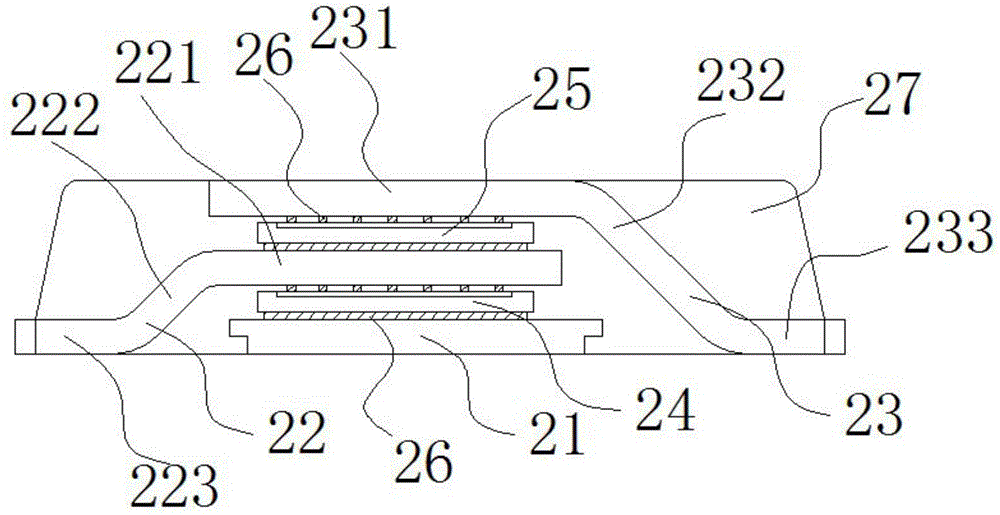

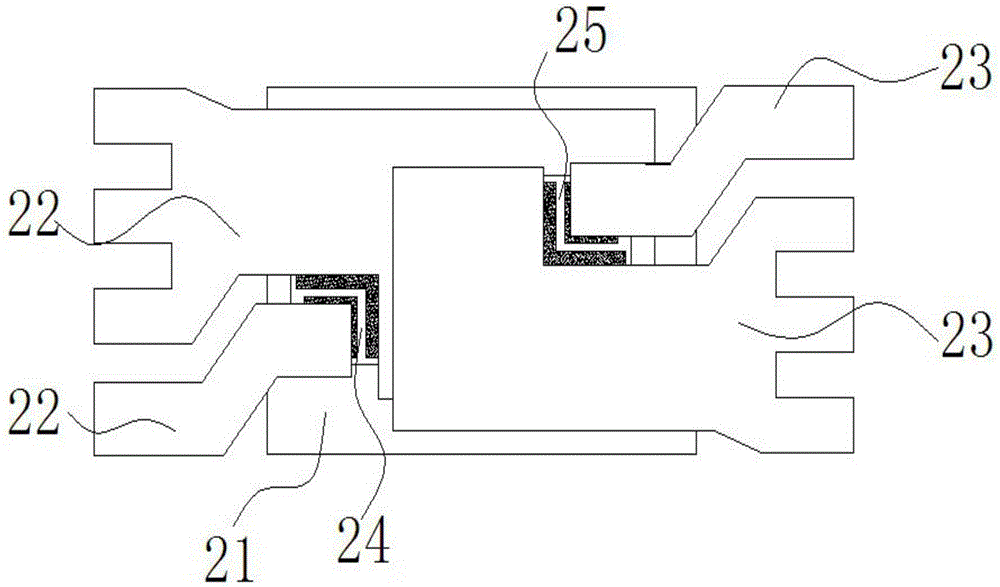

Multi-chip upright stack sandwich package structure with exposed frame and technique for multi-chip upright stack sandwich package structure

A technology of packaging structure and process method, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of poor welding, low manufacturing efficiency, welding dumping, etc., and achieves reduced packaging resistance, improved production efficiency, The effect of reducing the interconnection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0080] As shown in Fig. 8(a) to Fig. 8(n), a process method of a frame-exposed multi-chip stacked sandwich packaging structure in this embodiment, the specific process steps are as follows:

[0081] Step 1, see Figure 8 (a), provide the first lead frame, the material of the first lead frame is alloy copper material, pure copper material, aluminum copper plated material, zinc plated copper material, nickel-iron alloy material, or other CTE The range is 8*10^-6 / ℃~25*10^-6 / ℃ conductive material;

[0082] Step 2, see Figure 8(b), apply solder paste on the base island area of the first lead frame by screen printing, the purpose is to realize the bonding with the base island after the first chip is implanted. Thickness and opening area can precisely control the thickness, area and position of solder paste;

[0083] Step 3, referring to FIG. 8(c)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com