A method for preparing a high-temperature-resistant packaging frame for a silicon carbide diode

A technology of silicon carbide diodes and high temperature resistance, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of reduced production efficiency and increased energy consumption, and achieve high welding yield and reduced thermal resistance , the effect of expanding the application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

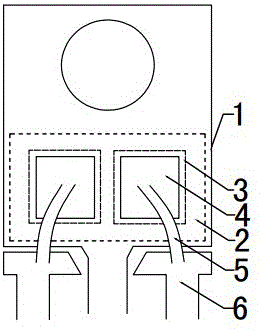

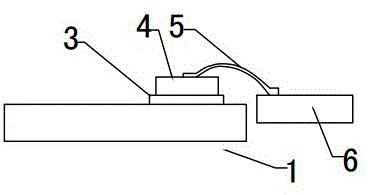

[0031] Other implementation mode 1: the basic structure and connection relationship are the same as the above-mentioned attached figure 1 , 2 As shown, the difference is that a nano-silver paste soldering layer 3 is provided on the crystal-bonding area 2, and a silicon carbide grain 4 and leads 5 connected to the left and right pins are welded on the nano-silver paste soldering layer 3.

Embodiment approach 2

[0032] Other implementation mode 2: the basic structure and connection relationship are the same as the above-mentioned attached figure 1 , 2 As shown, the difference is that the copper wires of the leads 5 are all replaced by aluminum wires.

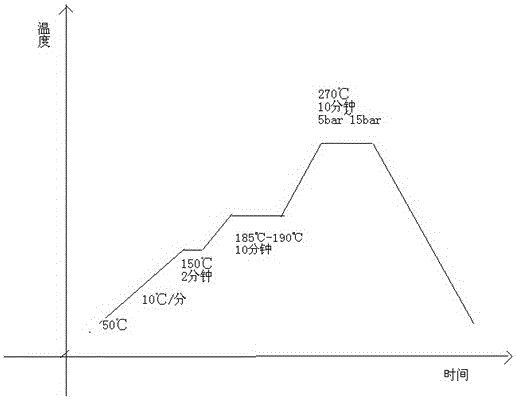

[0033] Below through specific embodiment and in conjunction with appendix figure 1 The preparation method of a high-temperature-resistant packaging frame for a silicon carbide diode of the present invention will be further described, and the first embodiment is the best.

Embodiment 1

[0035] 1) Grain cutting: first paste the whole wafer on the UV film, use a laser cutting machine to cut the silicon carbide grain along the position of the grain cutting line, take it out and clean the surface of the silicon carbide grain 4 with pure water and dry it; The UV film used in the process has a high viscosity, 8000mN~10000mN, which is convenient for grain cutting and cleaning, and there will be no grain displacement or bruising;

[0036] 2) Screen printing: use a screen printing machine to evenly brush the nano-silver paste in the crystal-bonding area 2 on the copper frame to obtain the nano-silver paste welding layer 3;

[0037] 3) Solid crystal: Use a solid crystal machine to absorb silicon carbide grains 4 from the UV film irradiated by UV light and place them on the frame main body 1; after the UV film is illuminated, the viscosity becomes lower to 1000mN, and the solid crystal is made It is easy to absorb the die, and it is not easy to stick to the residual glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com