Electrode plate and application thereof

A technology of electrode sheets and tabs, which is applied in the direction of battery electrodes, electrode carriers/collectors, non-aqueous electrolyte battery electrodes, etc., can solve problems such as inability to conduct current collectors, improve rate charge and discharge performance, reduce welding resistance, The effect of increasing mass energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] The lithium-ion battery of the present embodiment is obtained through the following steps:

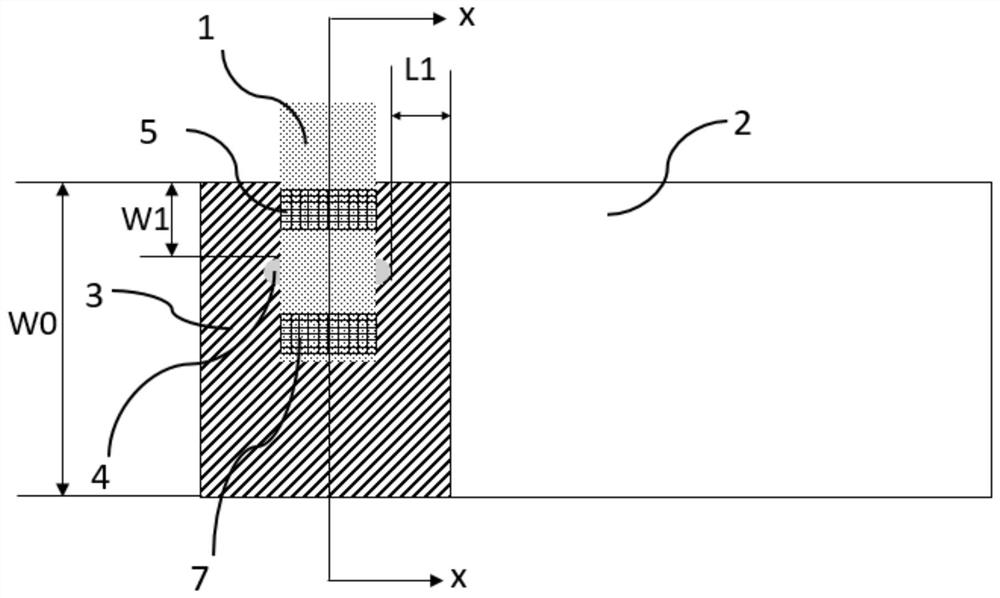

[0103] 1) Preparation of positive electrode sheet

[0104] The positive current collector is a current collector with Al-PET-Al structure, such as Figure 9 and Figure 10 As shown, the positive electrode current collector includes the first tab region 3 and the first active layer region 2 in the length direction, the second tab region 6 is arranged corresponding to the first tab region 3, and the second active layer region 9 is connected to the first tab region. An active layer area 2 is provided correspondingly, and the first tab area 3 is provided with a through hole 4 penetrating to the second tab area 6, and the shape of the through hole 4 is elliptical;

[0105] Apply the lithium cobaltate active slurry on the first active layer area 2 and the second active layer area 9, paste the protective adhesive tape on the first tab area 3 and the second tab area 6, and then place ...

Embodiment 2

[0113] The lithium-ion battery of the present embodiment is obtained through the following steps:

[0114] 1) Preparation of positive electrode sheet

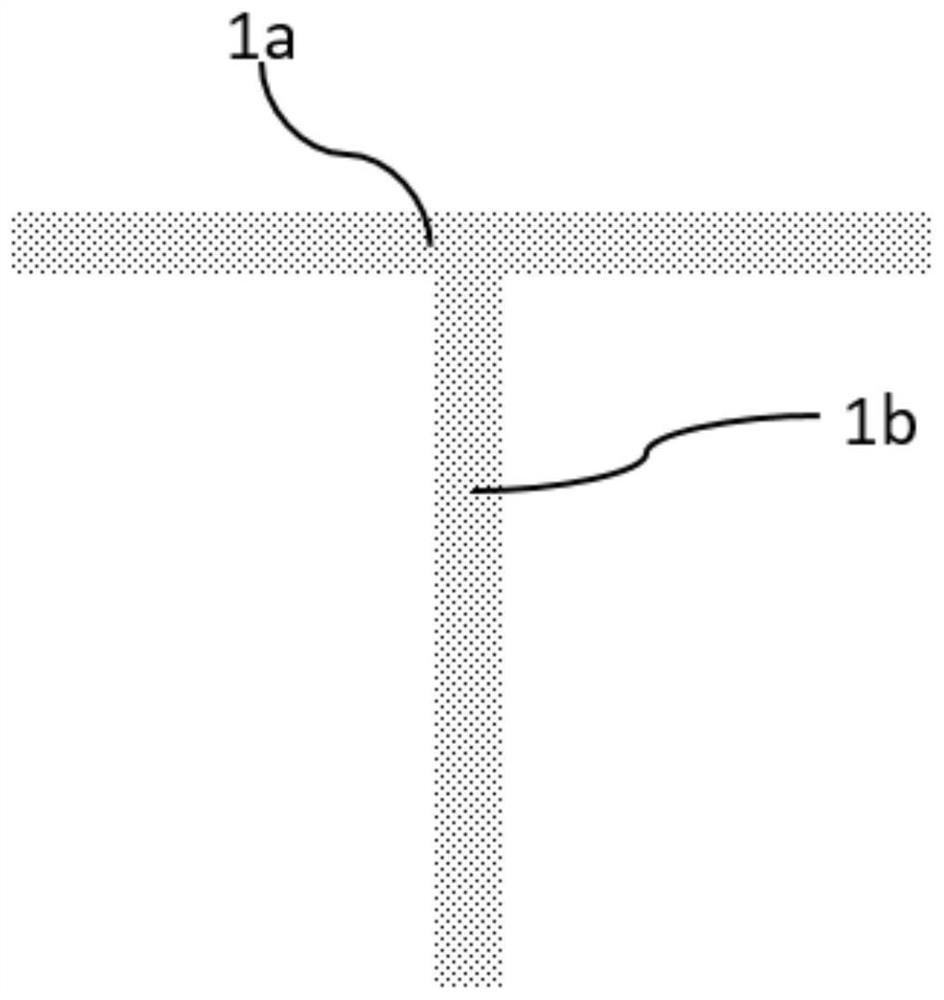

[0115] The positive current collector is Al-Al 2 o 3 -PET-Al 2 o 3 -Current collector of Al structure, such as Image 6 and Figure 8 As shown, the positive current collector includes a first tab region 3 and a first active layer region 2 in the width direction, and the three sides of the first tab region 3 are adjacent to the first active layer region 2; the second tab region 6 is set corresponding to the first tab area 3, the second active layer area 9 is set corresponding to the first active layer area 2, the first tab area 3 is provided with a through hole 4 penetrating to the second tab area 6, and the through hole 4 is oval in shape;

[0116] The lithium cobaltate active slurry is coated on the first active layer region 2 and the second active layer region 9, wherein the mass composition of the lithium cobaltate ac...

Embodiment 3

[0124] The lithium-ion battery of the present embodiment is obtained through the following steps:

[0125] 1) Preparation of positive electrode sheet

[0126] The positive current collector is a current collector with Al-PP-Al structure, such as Figure 7 with Figure 8 As shown, the positive electrode current collector includes a first tab area 3 and a first active layer area 2 in the width direction, and one side of the first tab area 3 is adjacent to the first active layer area 2; the second tab area 6 is set corresponding to the first tab area 3, the second active layer area 9 is set corresponding to the first active layer area 2, the first tab area 3 is provided with a through hole 4 penetrating to the second tab area 6, and the through hole 4 is oval in shape;

[0127] The lithium cobaltate active slurry is coated on the first active layer region 2 and the second active layer region 9; wherein, the mass composition of the lithium cobaltate active slurry is lithium cob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com