Method for solving welding deviation and welding equipment thereof

A technology of welding equipment and welding head, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of high bit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

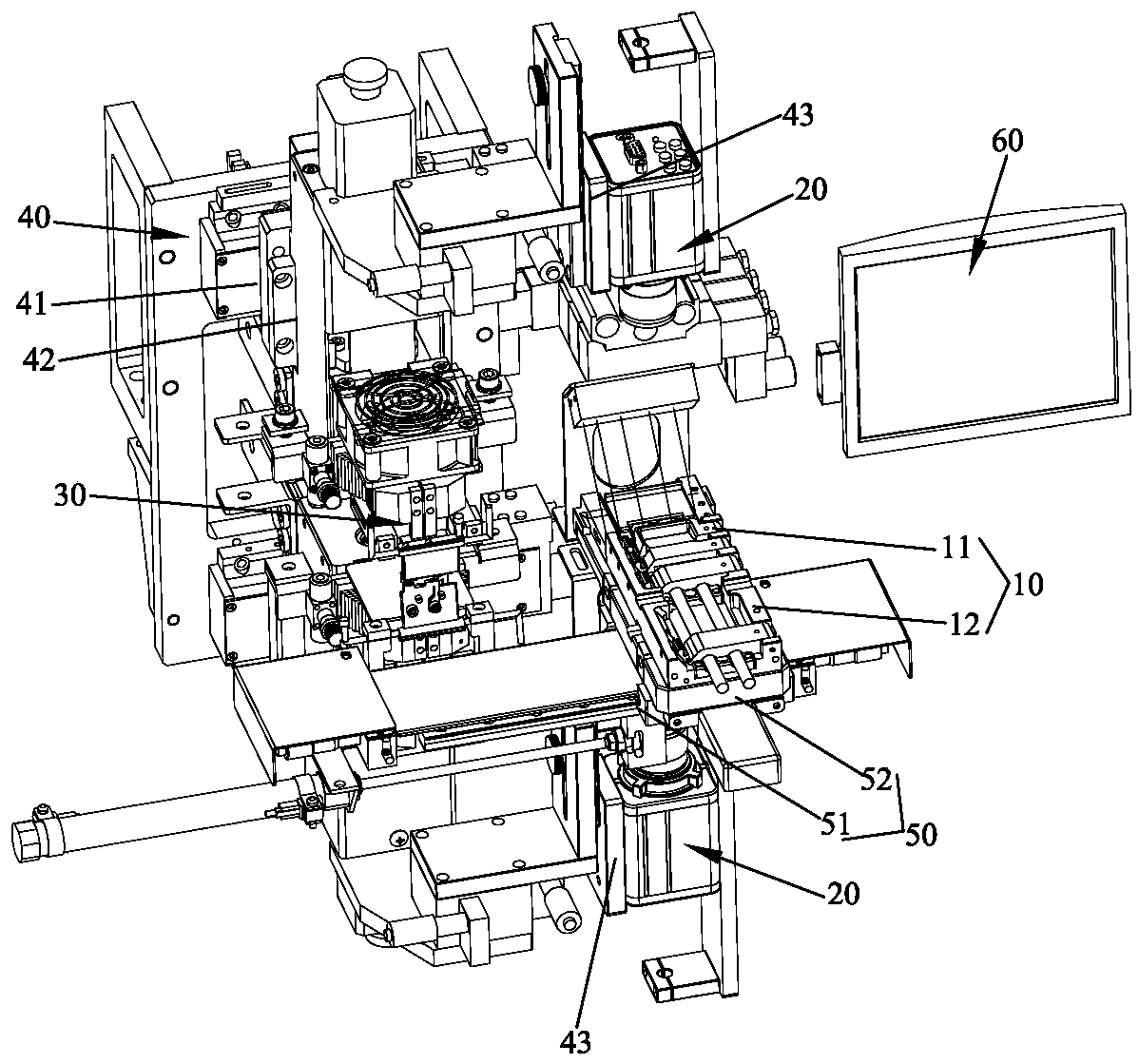

[0051] Embodiment 1: The image of the workpiece taken by the CCD device is displayed on the display screen, and it is judged whether the reference point A of the workpiece coincides with the standard reference point B stored in the CCD device; If they do not coincide, adjust the position deviation C displayed by the reference point B and the reference point A so that the reference point B coincides with the reference point A, and then translate the workpiece fixing device to the set distance to the position of the welding head. .

Embodiment approach 2

[0052] Embodiment 2: The image of the workpiece taken by the CCD device is displayed on the display screen, and it is judged whether the reference point A of the workpiece coincides with the standard reference point B stored in the CCD device; The position is enough; if they do not coincide, drive the workpiece fixing device to move through the conveying mobile device, so that the reference point B of the workpiece coincides with the reference point A;

Embodiment approach 3

[0053] Embodiment 3: The workpiece image captured by the CCD device is compared with the sample image stored on the display screen, the CCD device transmits the actual workpiece image to the control unit, and the control unit compares the actual workpiece image with the standard workpiece image, calculates the deviation value, and displays it on the display On the screen; the control unit automatically adjusts the welding head and the workpiece fixing device to compensate according to the deviation value, and moves the workpiece fixing device to the bottom of the welding station; and then performs welding.

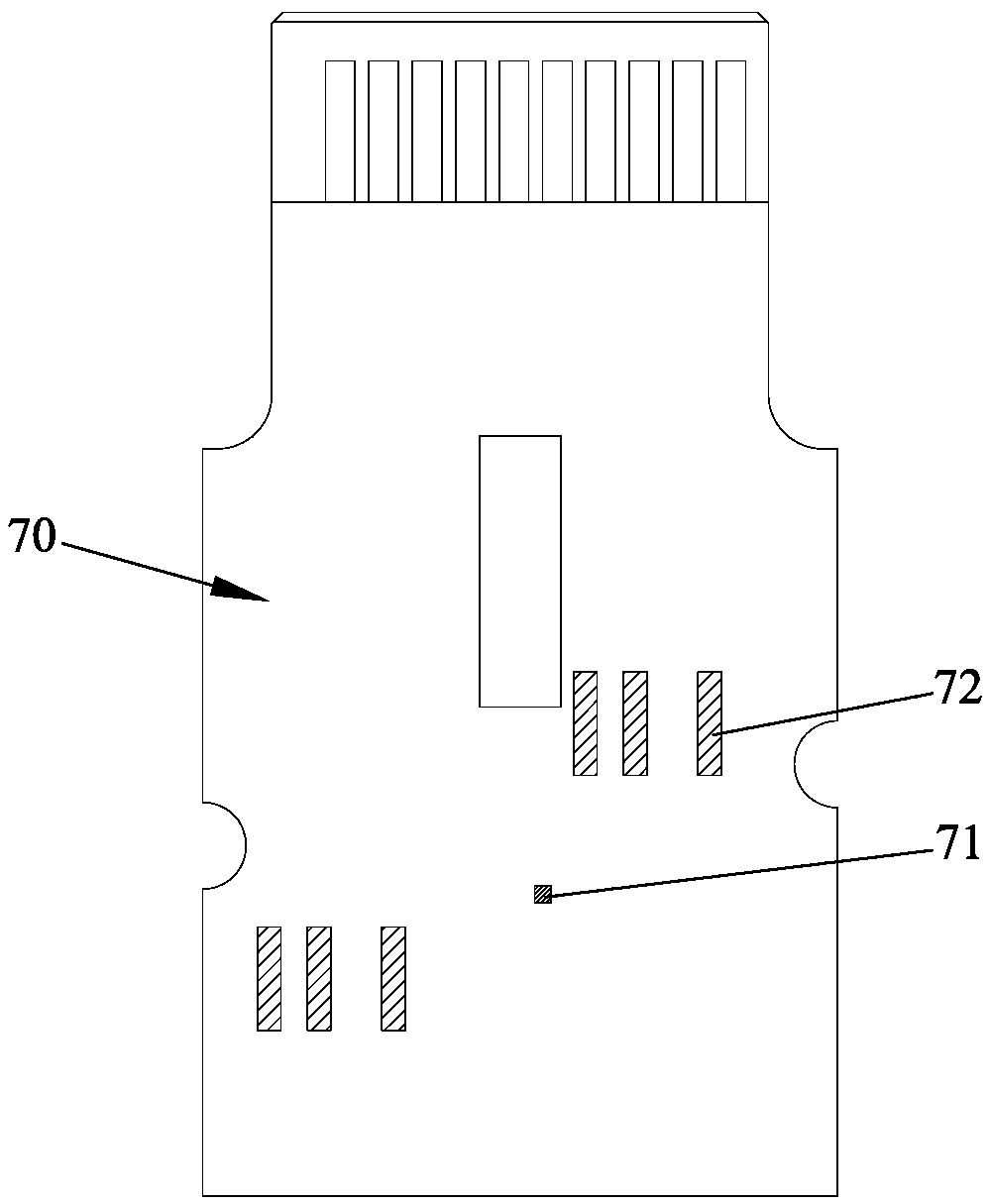

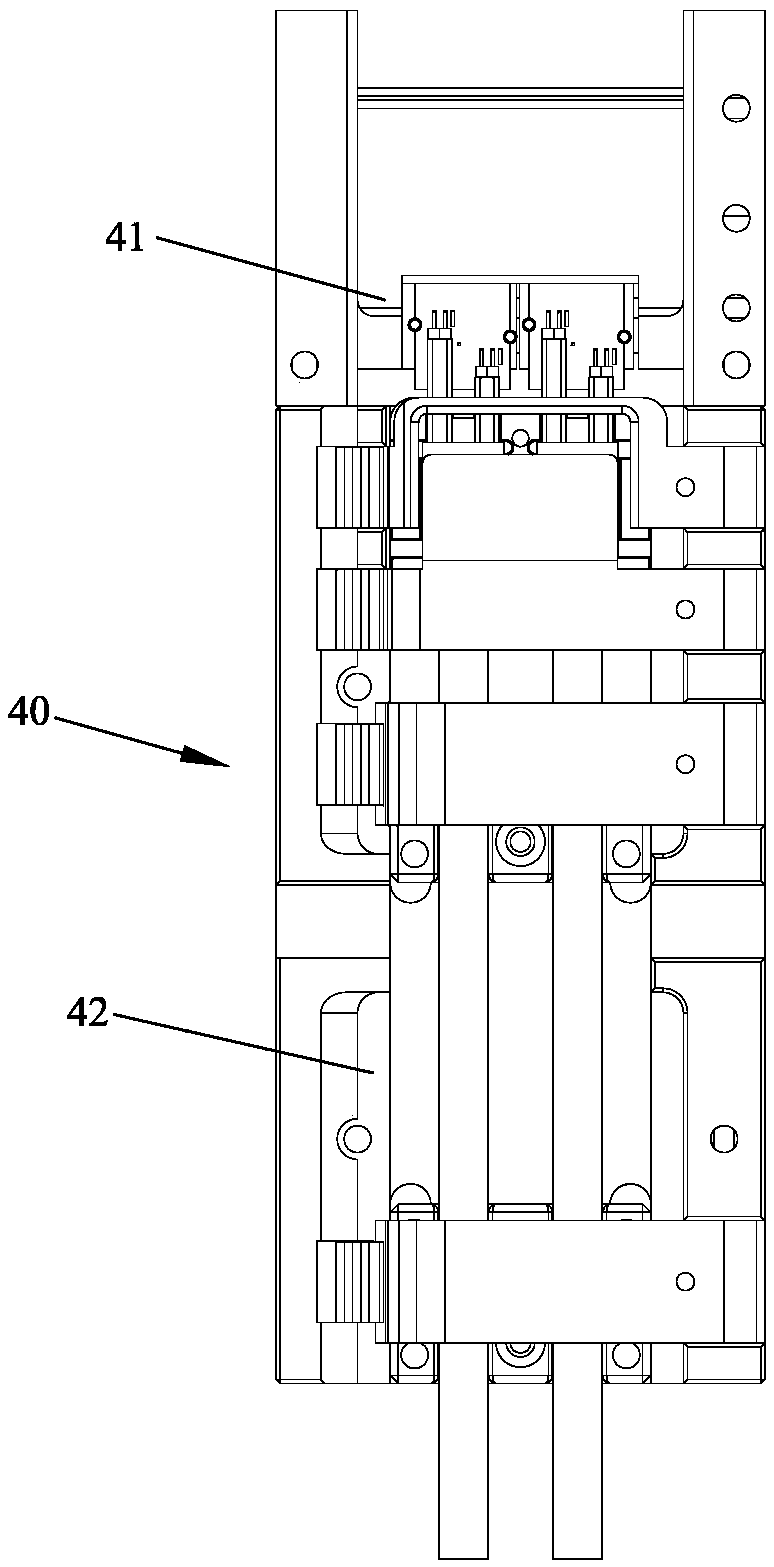

[0054] The welding equipment has a correction station and a welding station; the correction station is provided with a workpiece fixture 10, and above or below the workpiece fixture 10 is provided with a CCD device 20 for taking images of the workpiece; the welding station is provided with a welding head 30, the welding head 30 or the workpiece fixing device 10 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com