Patents

Literature

83results about How to "Eliminate deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

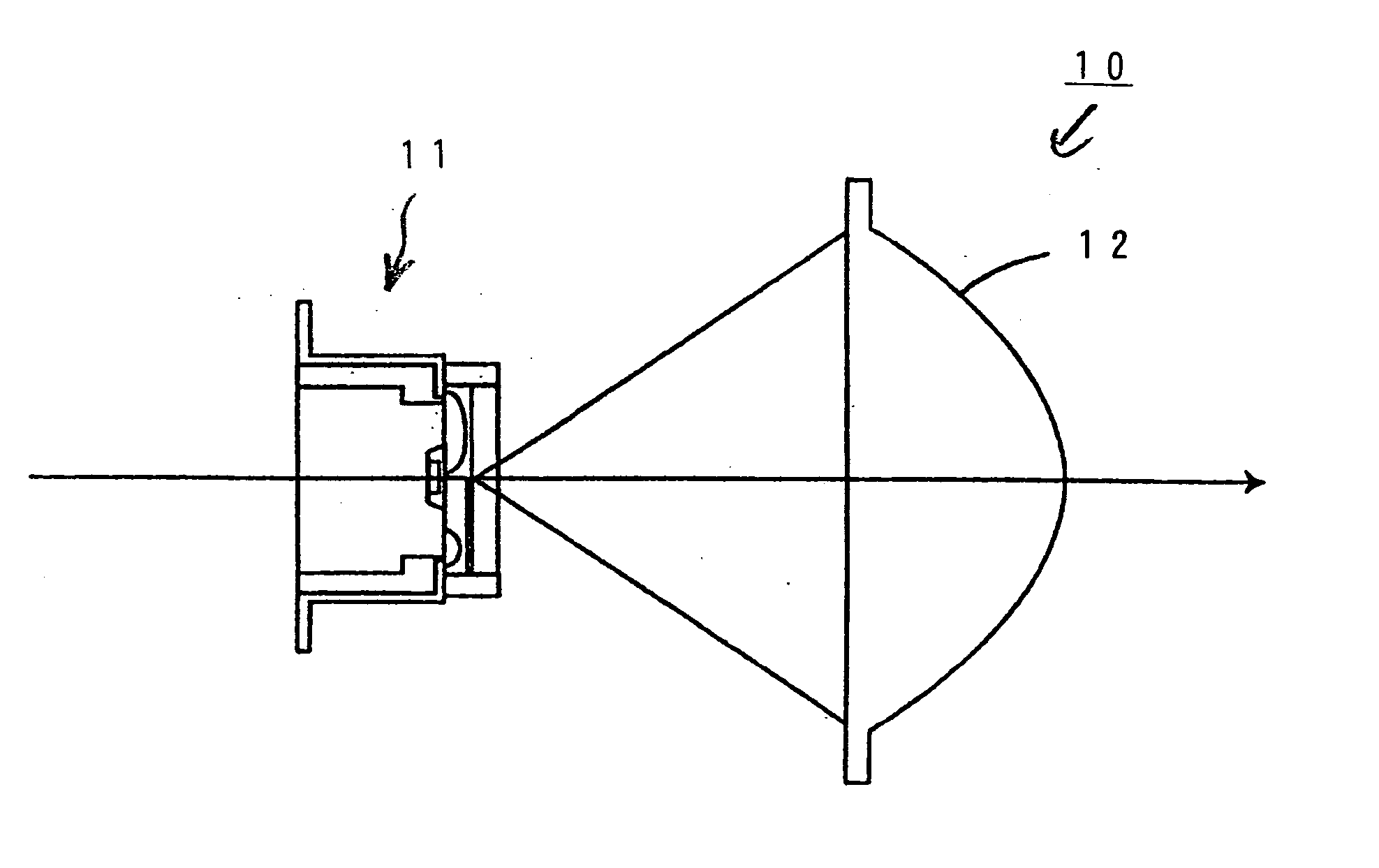

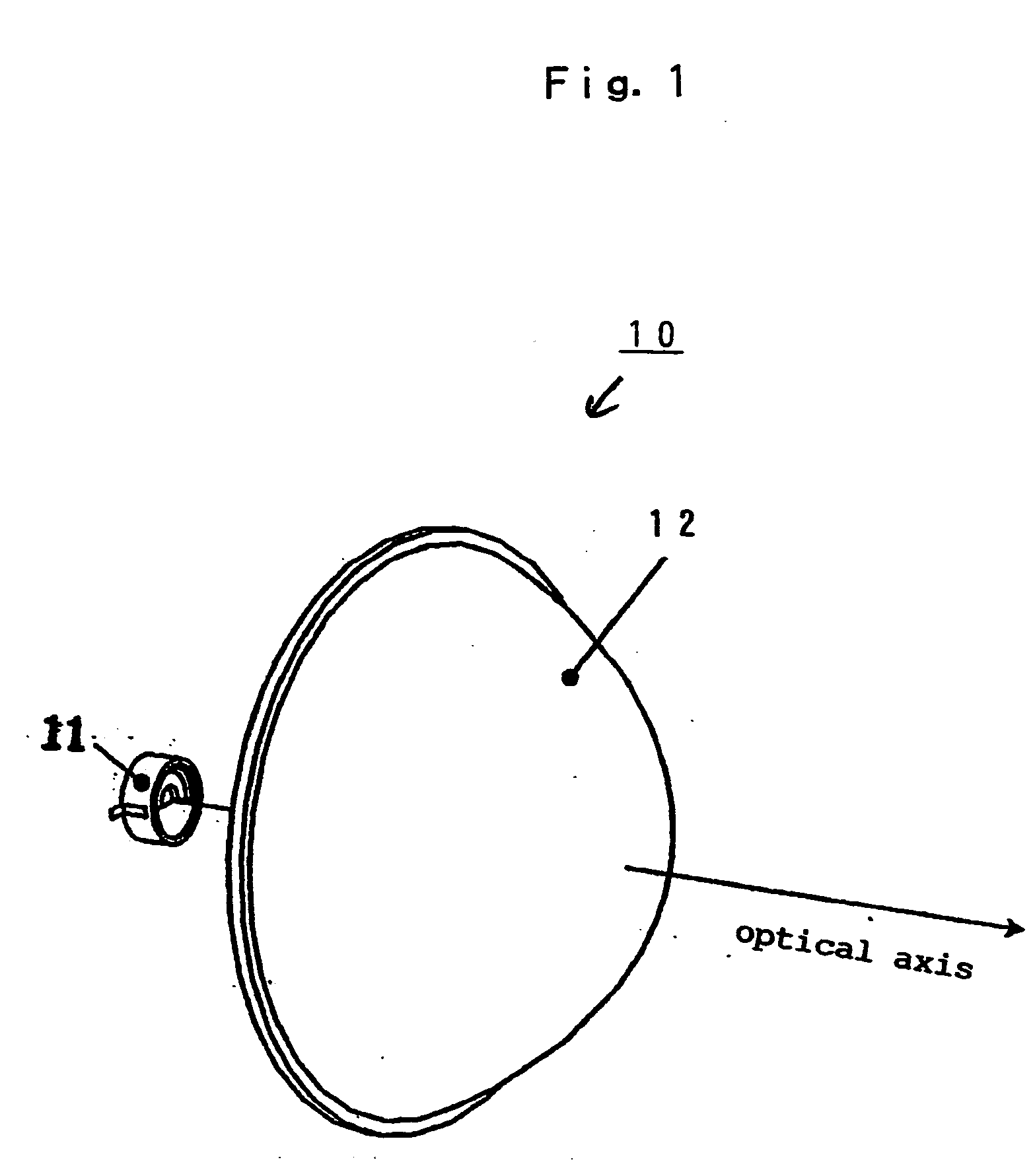

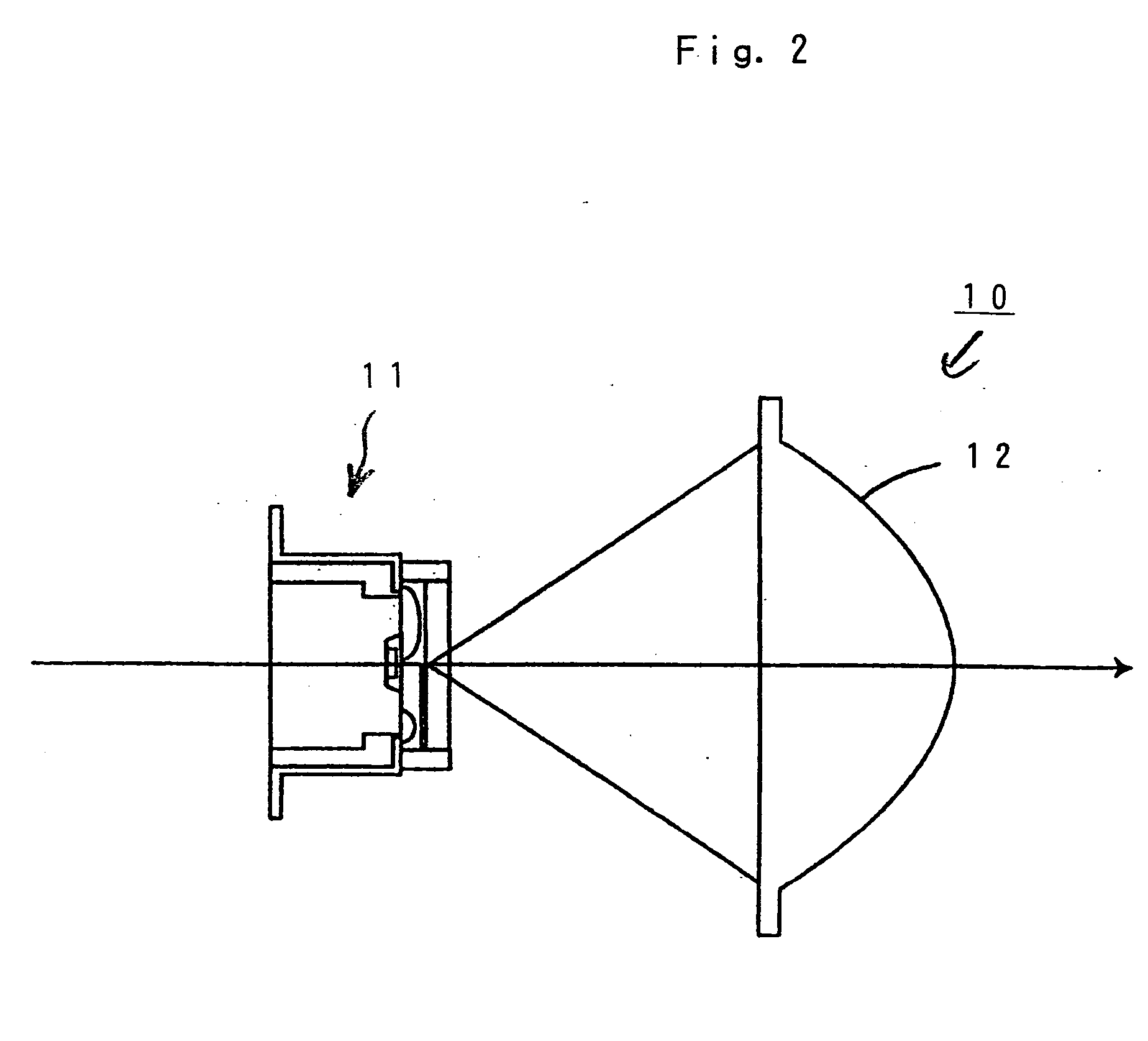

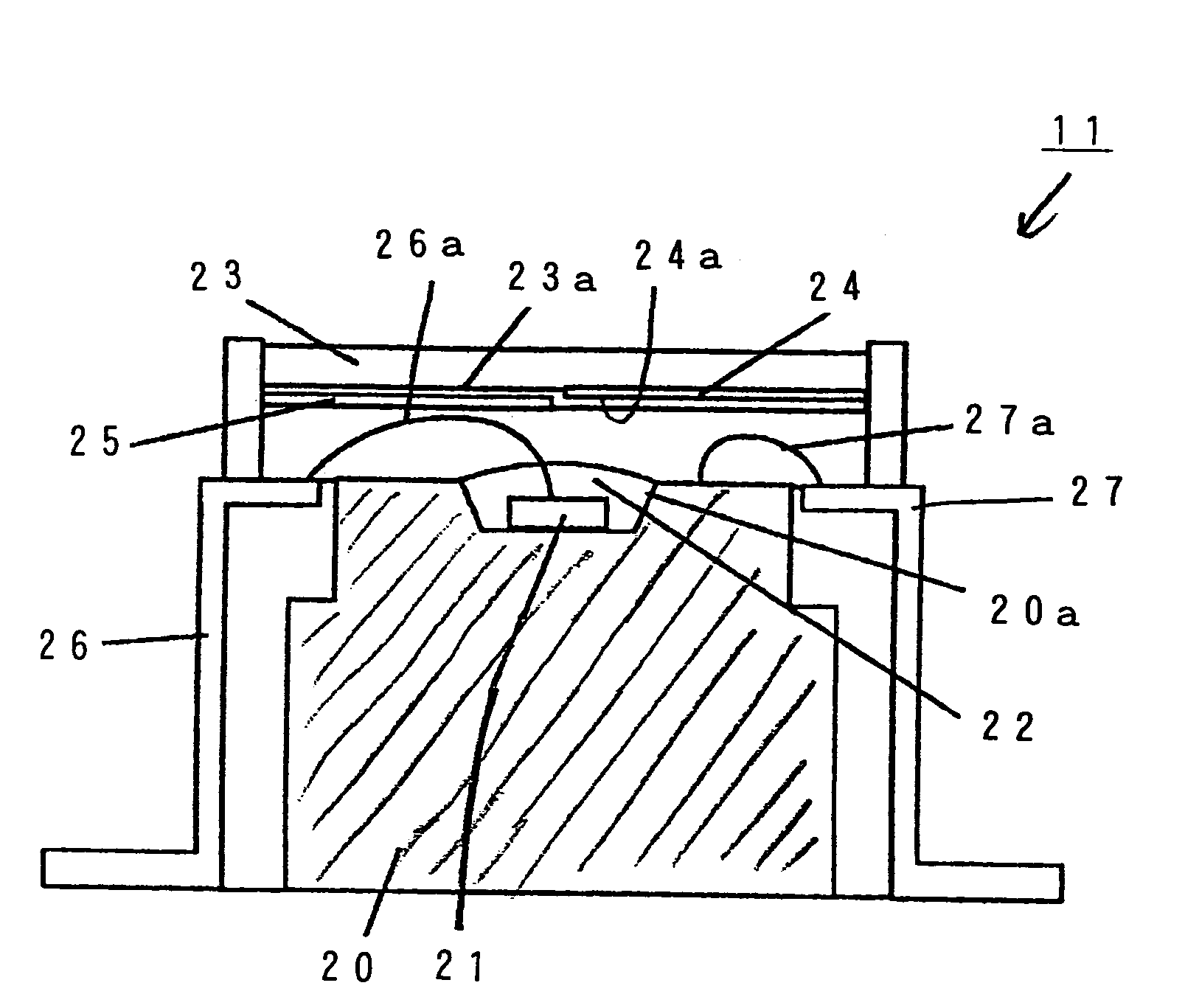

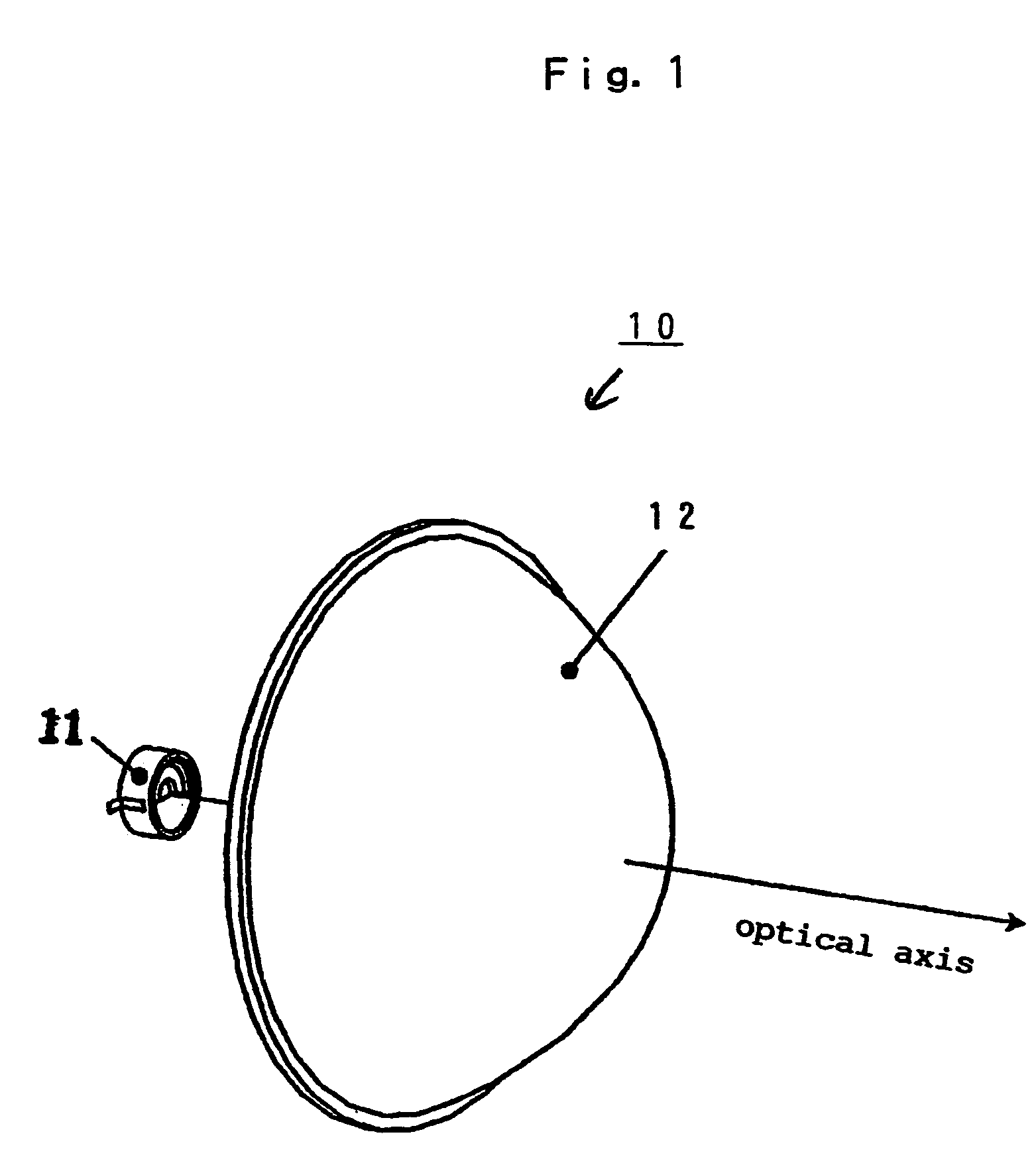

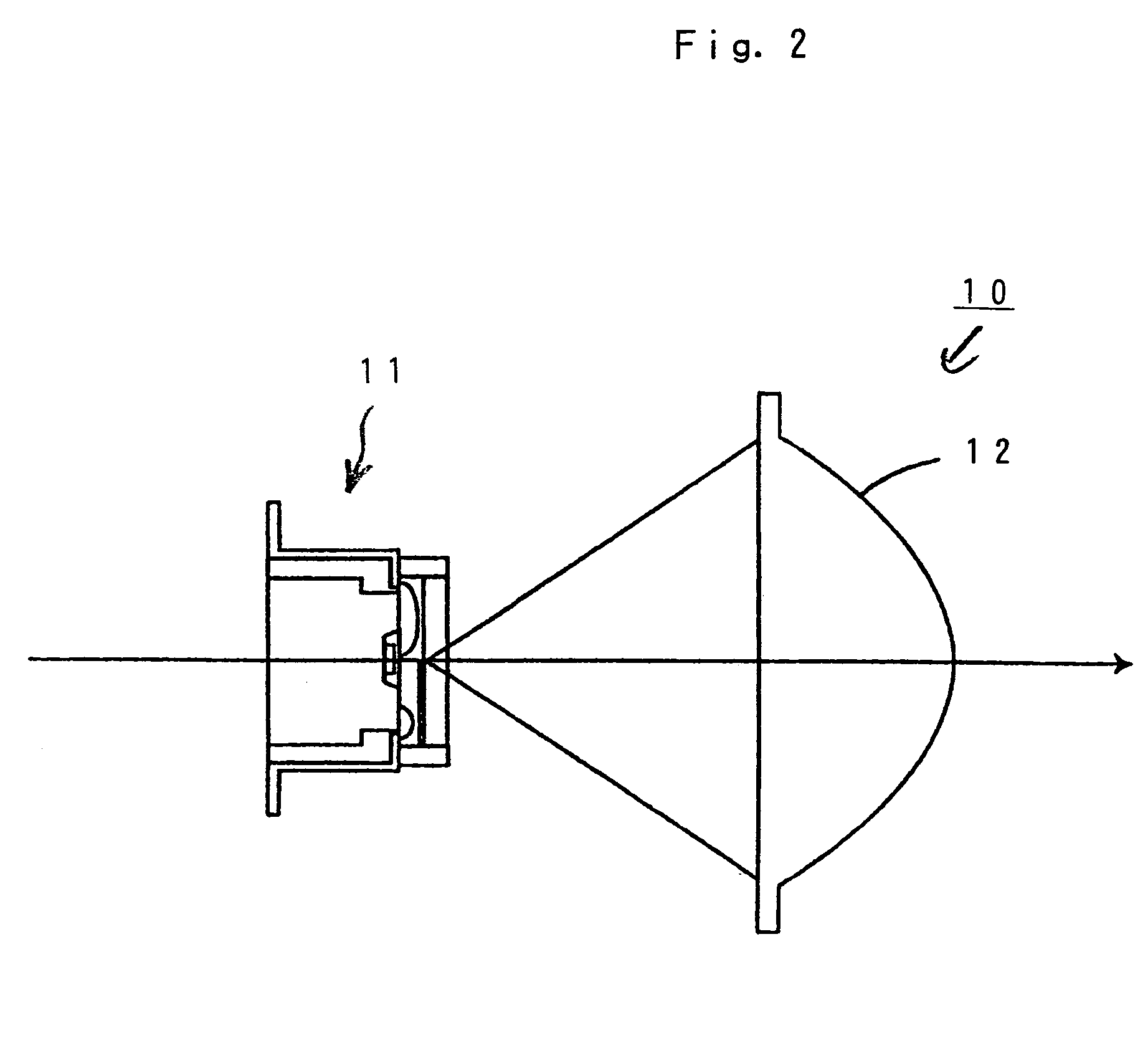

Light source and vehicle lamp

ActiveUS20050057917A1Improve utilization efficiencyInhibit temperature risePoint-like light sourceSolid-state devicesFluorescenceDistribution pattern

A light source for vehicles can include a base having a cavity formed on its upper surface, an LED chip mounted in the cavity of the base, a resin portion for sealing the LED chip in the cavity, an optical member disposed above the base and apart from the LED chip, a light shielding portion disposed on the inner surface of the optical member and which forms a cutoff suited for a light distribution pattern, and a fluorescent substance layer disposed at least in regions other than the light shielding portion on the inner surface of the optical member.

Owner:STANLEY ELECTRIC CO LTD

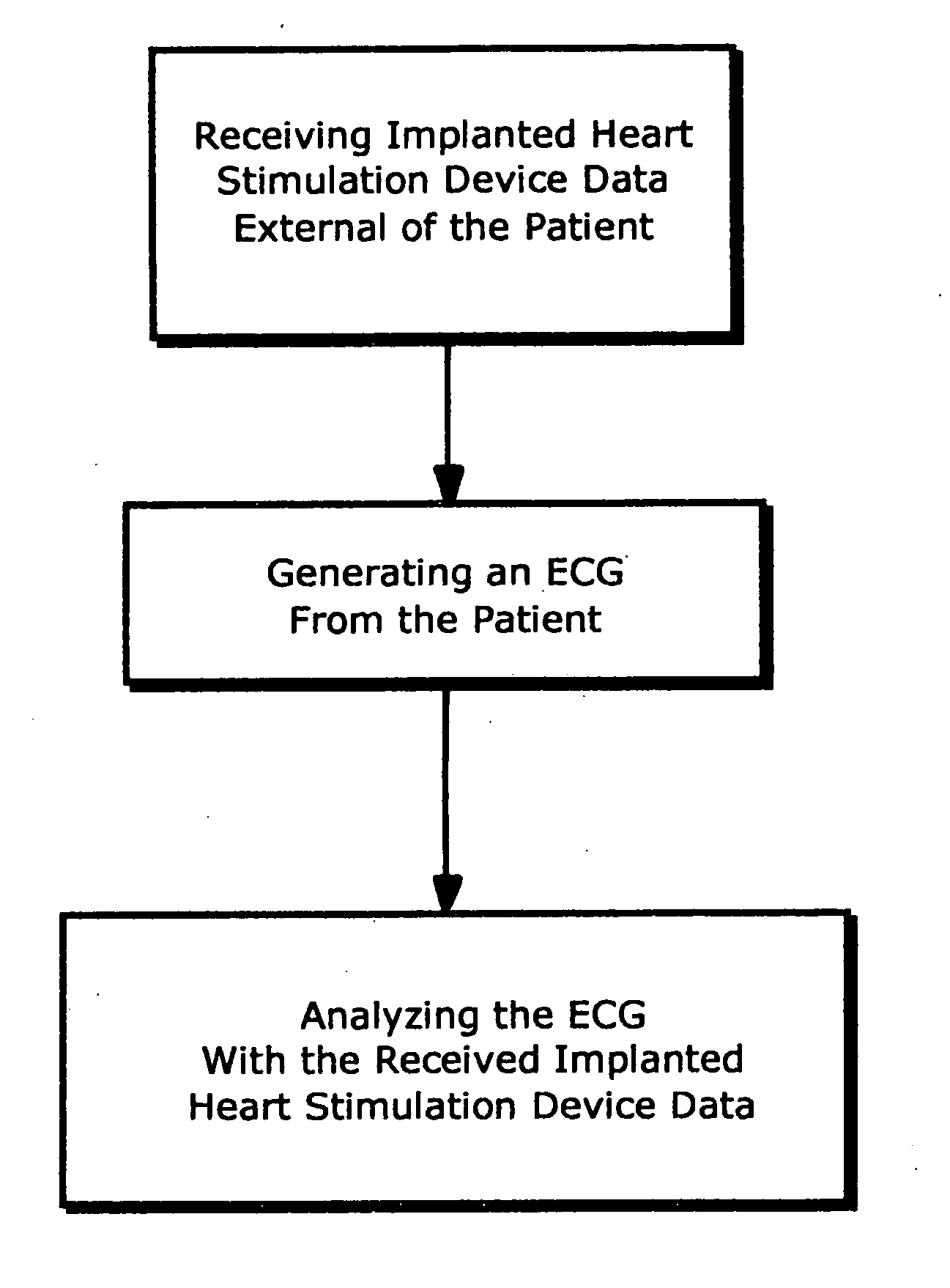

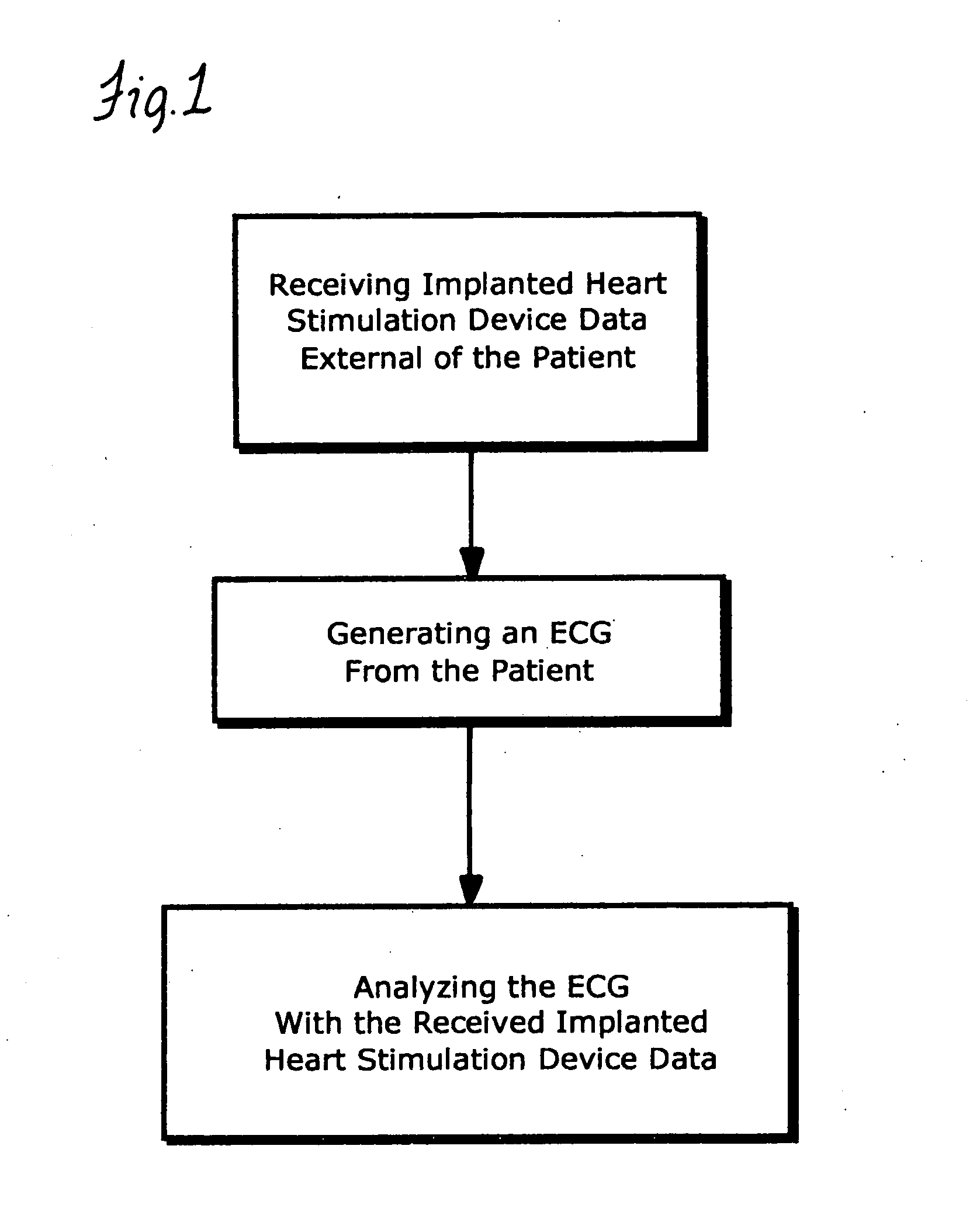

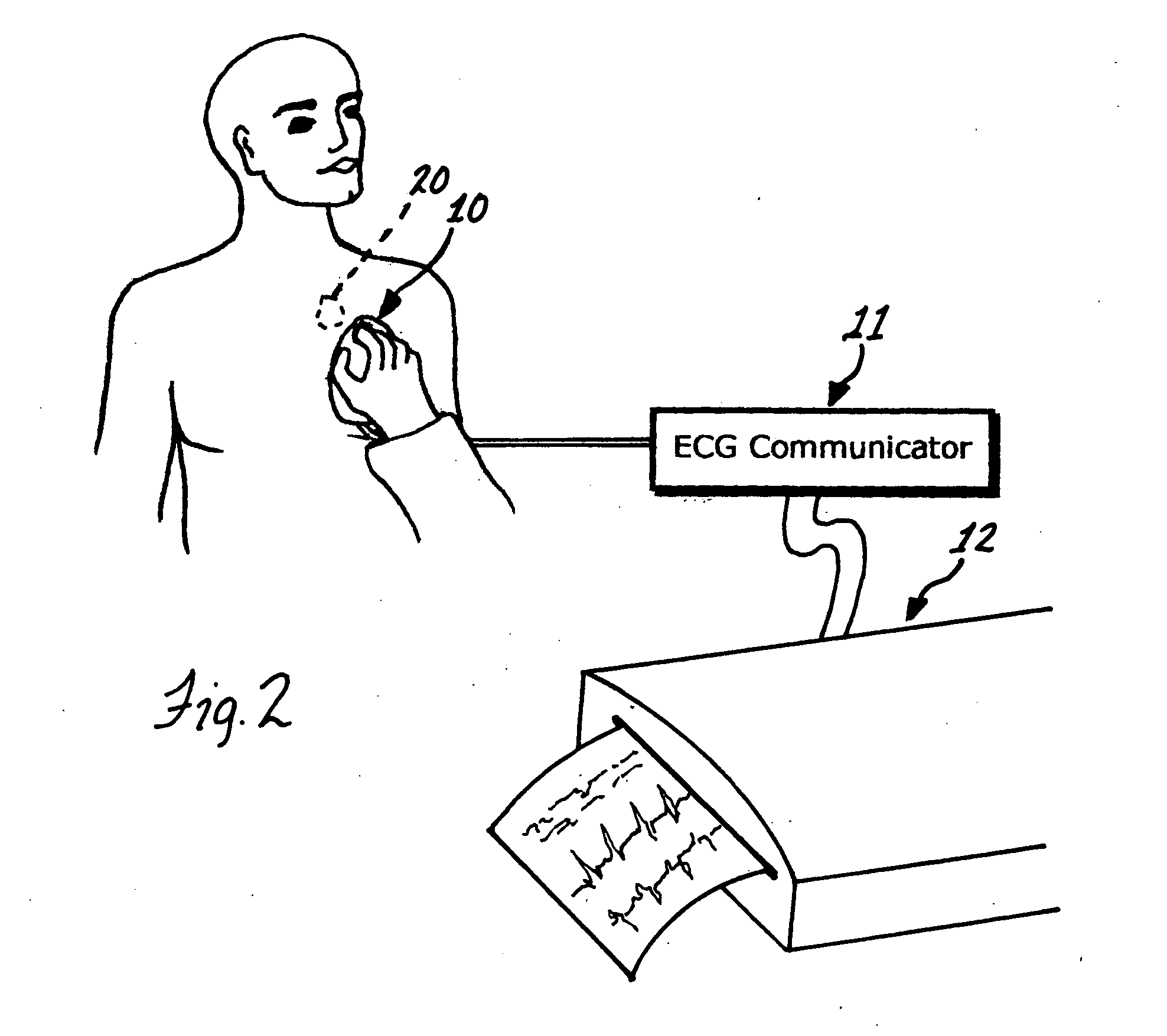

ECG diagnostic system and method

InactiveUS20050027204A1Prevent life-threatening bradyarrhythmiasEliminate of axis deviationElectrotherapyElectrocardiographyDiagnostic systemStandard ECG

A system and method are disclosed for providing enhanced ECG diagnosis for patients having an implanted heart stimulation device. The system acquires data relating to the device for use in the ECG diagnosis. In one preferred form, data is transferred from an implanted transponder programmed with the data to a standard ECG monitoring electrode applied to the patient's chest, and the read out generated by the ECG machine includes the transferred data.

Owner:KLIGFIELD PAUL D +1

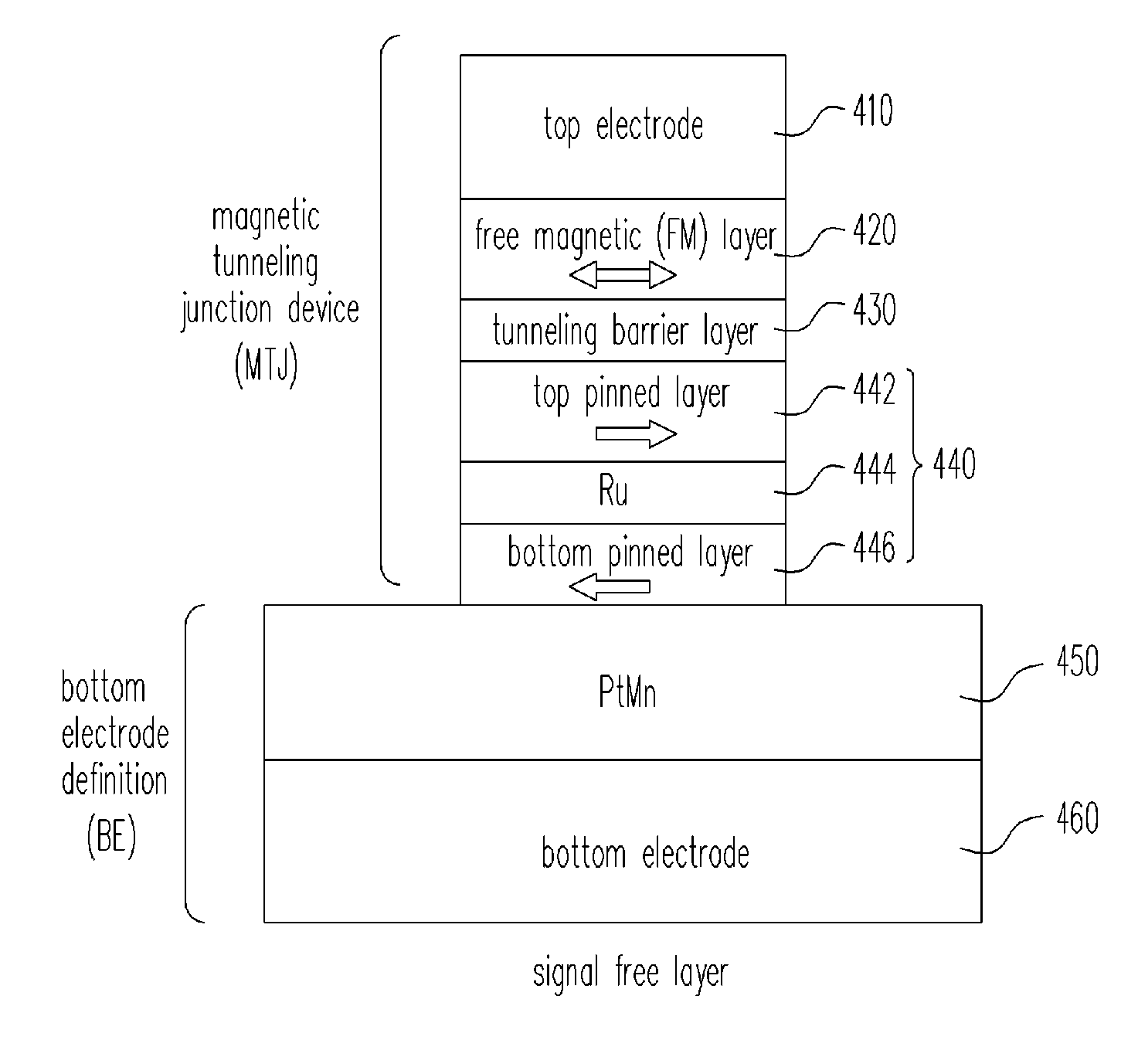

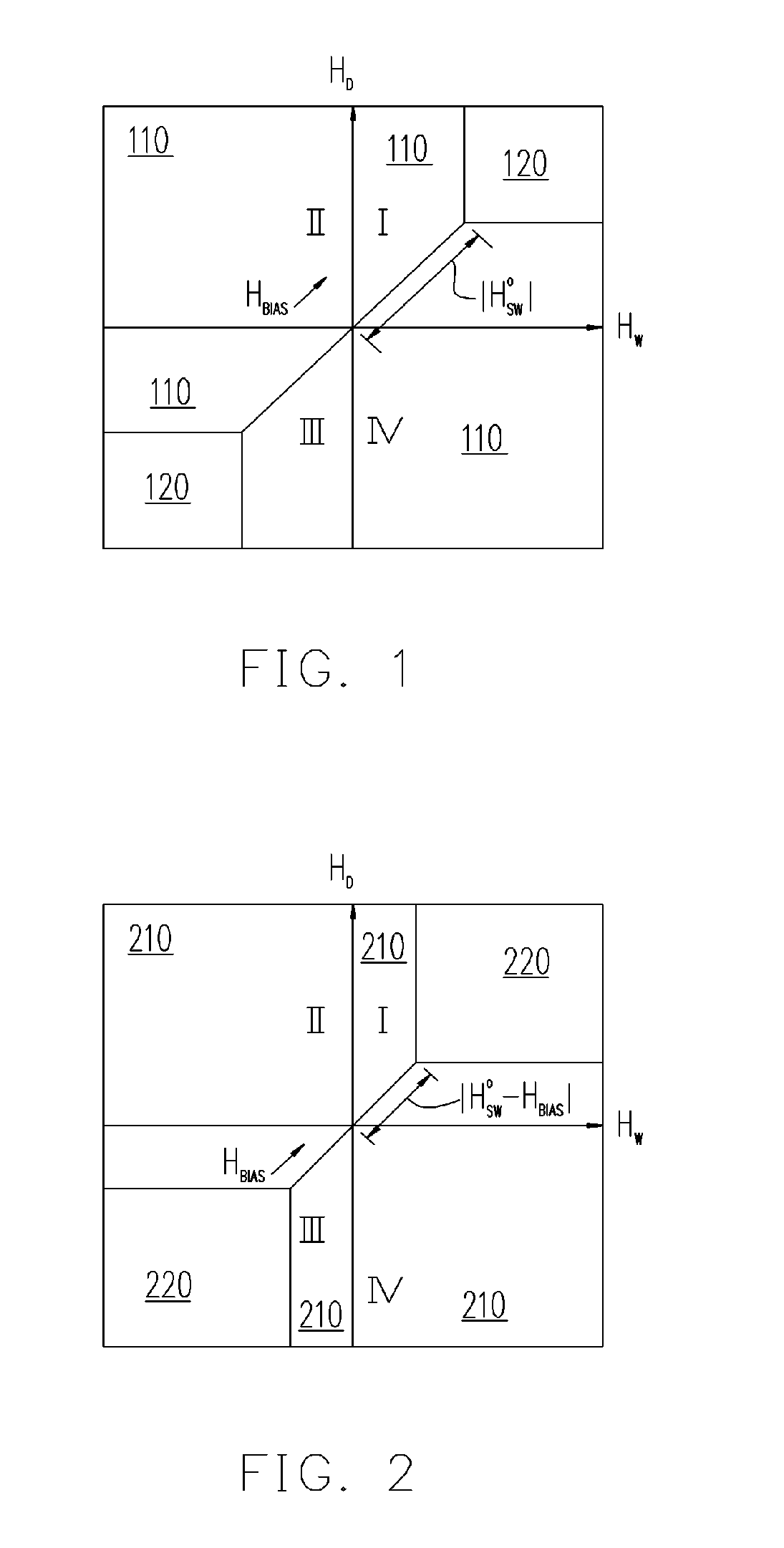

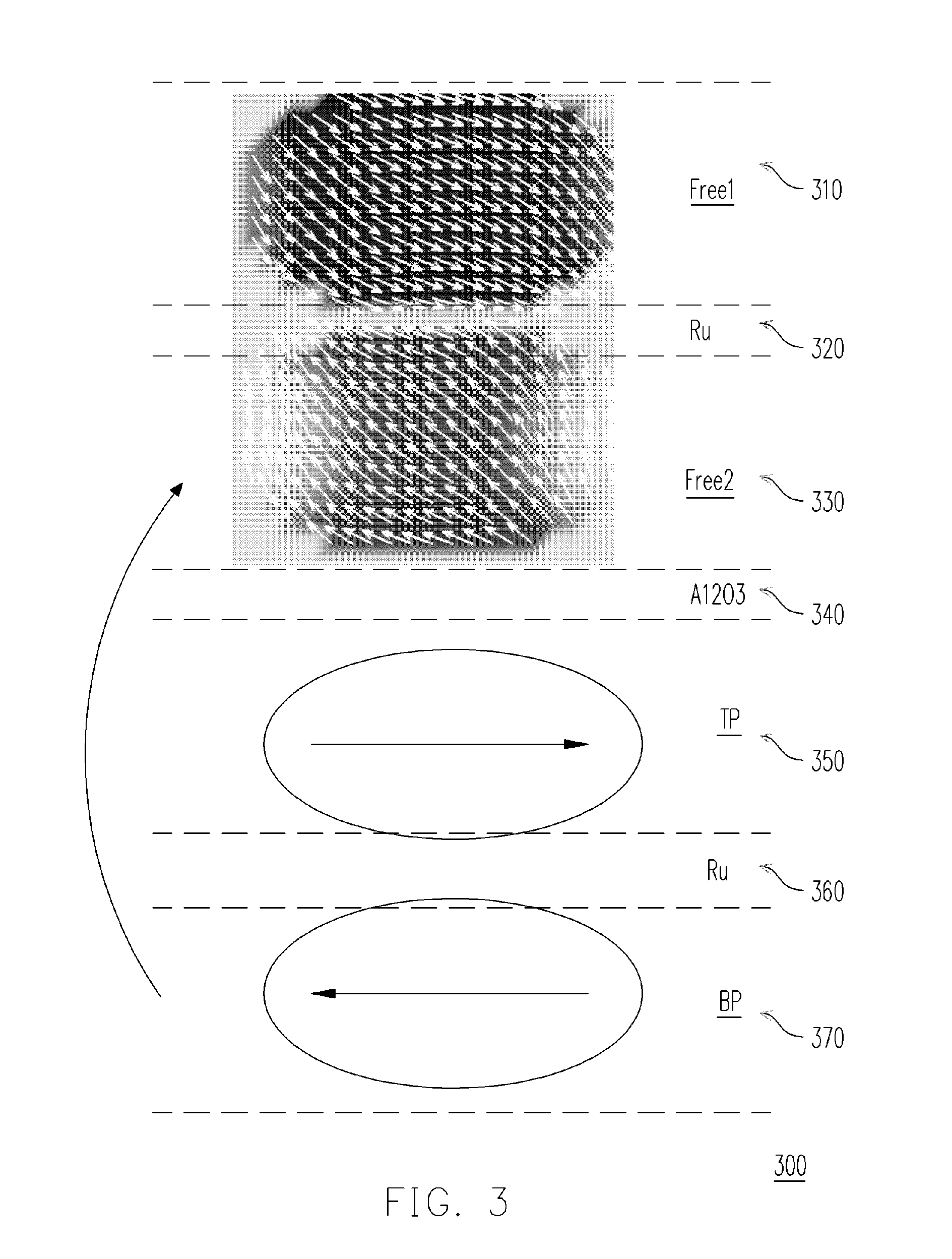

Magnetic memory cell and manufacturing method thereof

InactiveUS20070187785A1Eliminate deviationUniformly manufactureMagnetic-field-controlled resistorsSolid-state devicesPhysicsBias field

A magnetic memory cell and a manufacturing method for the magnetic memory cell are provided. In the magnetic memory cell, a pinned layer of a magnetic bottom electrode can be formed with sizes different from the free layer. The wider magnetic bottom electrode produces a preferable uniform bias field that will create a normal magnetization vector distribution in the end domain of the free layer, and thus achieving a preferred switching property. The above process can also be achieved through self-alignment. In addition, by adjusting the bias field of the bottom electrode, uniform field distribution over entire free layer can be significantly improved, and thus the magnetic memory cell will have a very low writing toggle current.

Owner:IND TECH RES INST

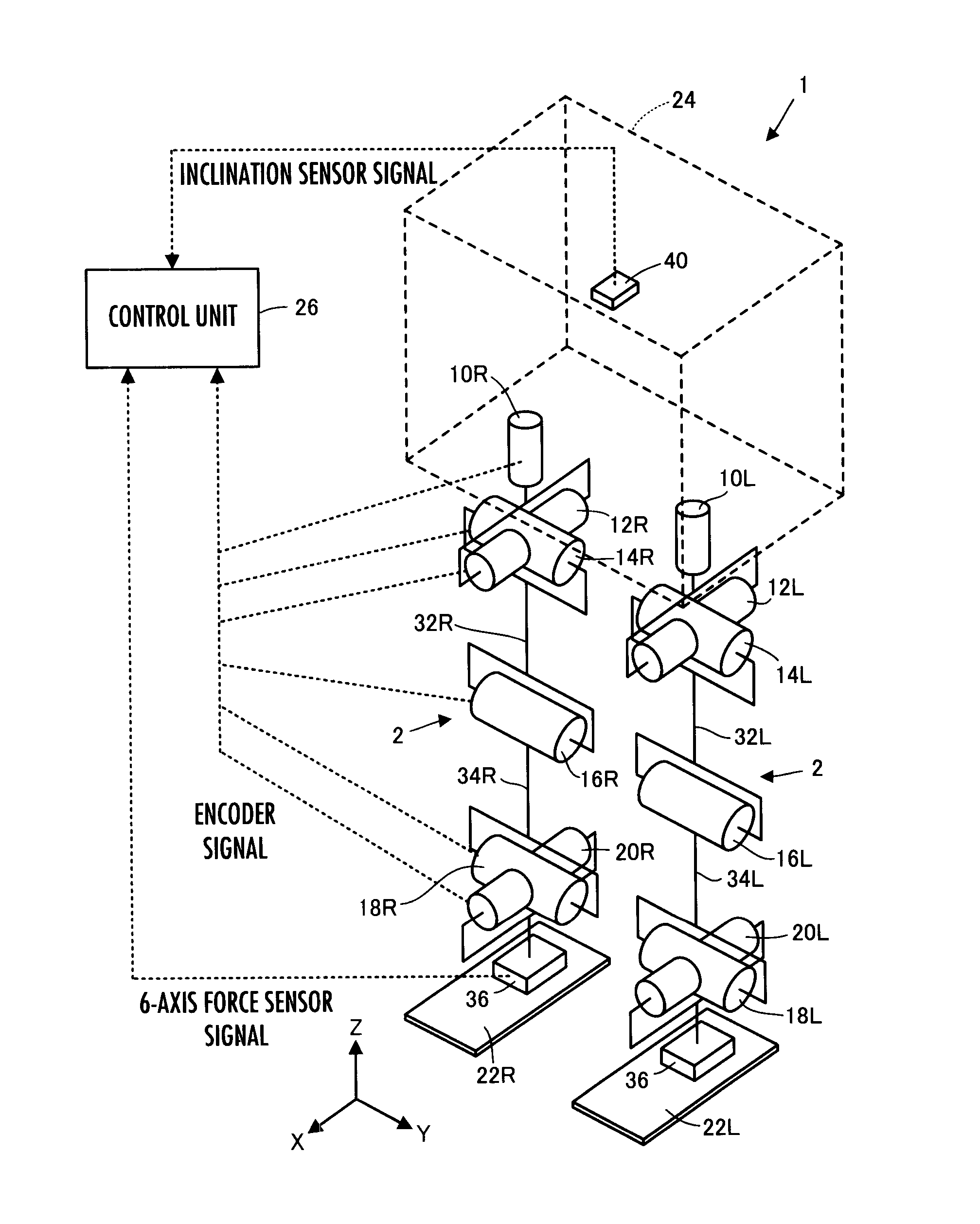

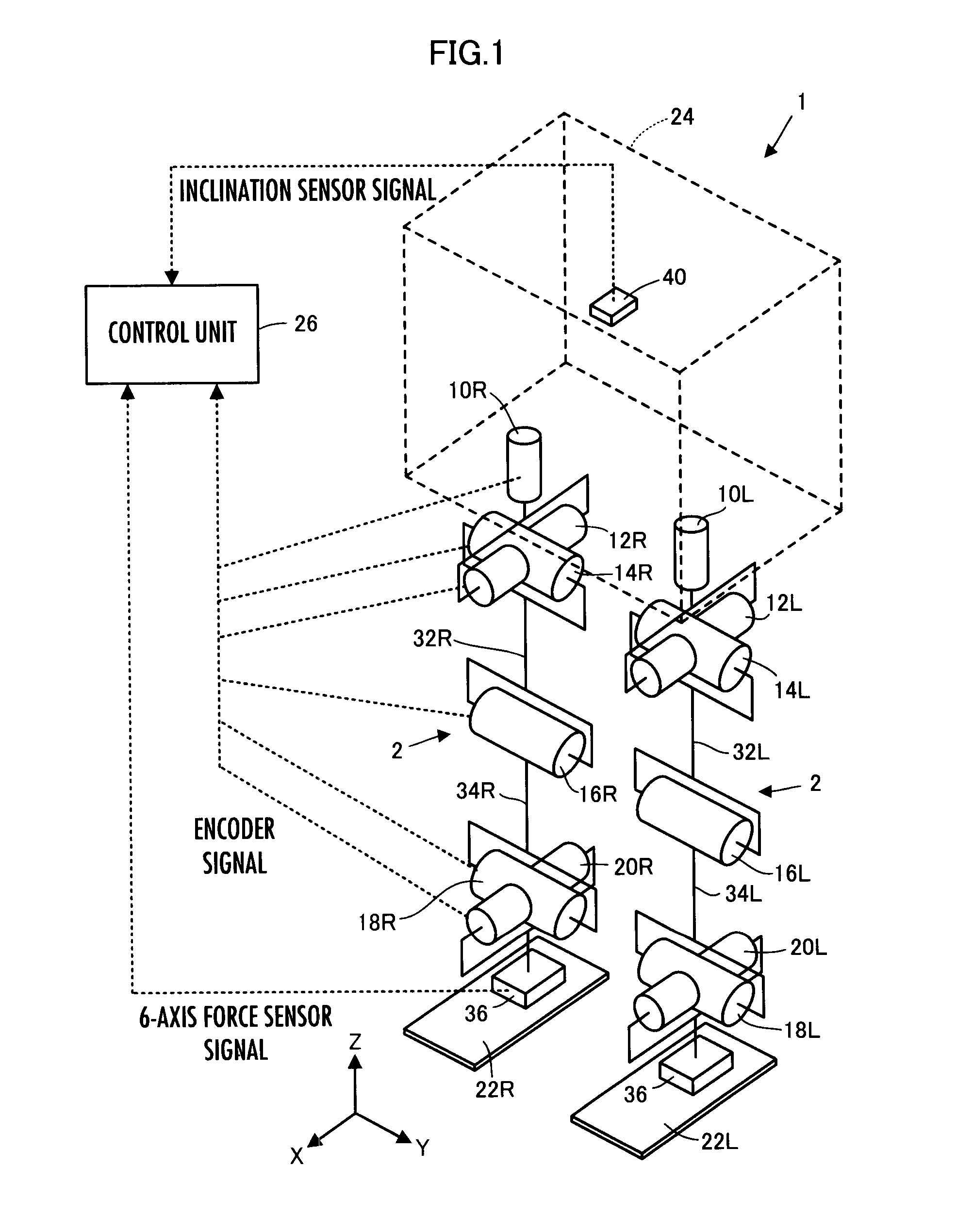

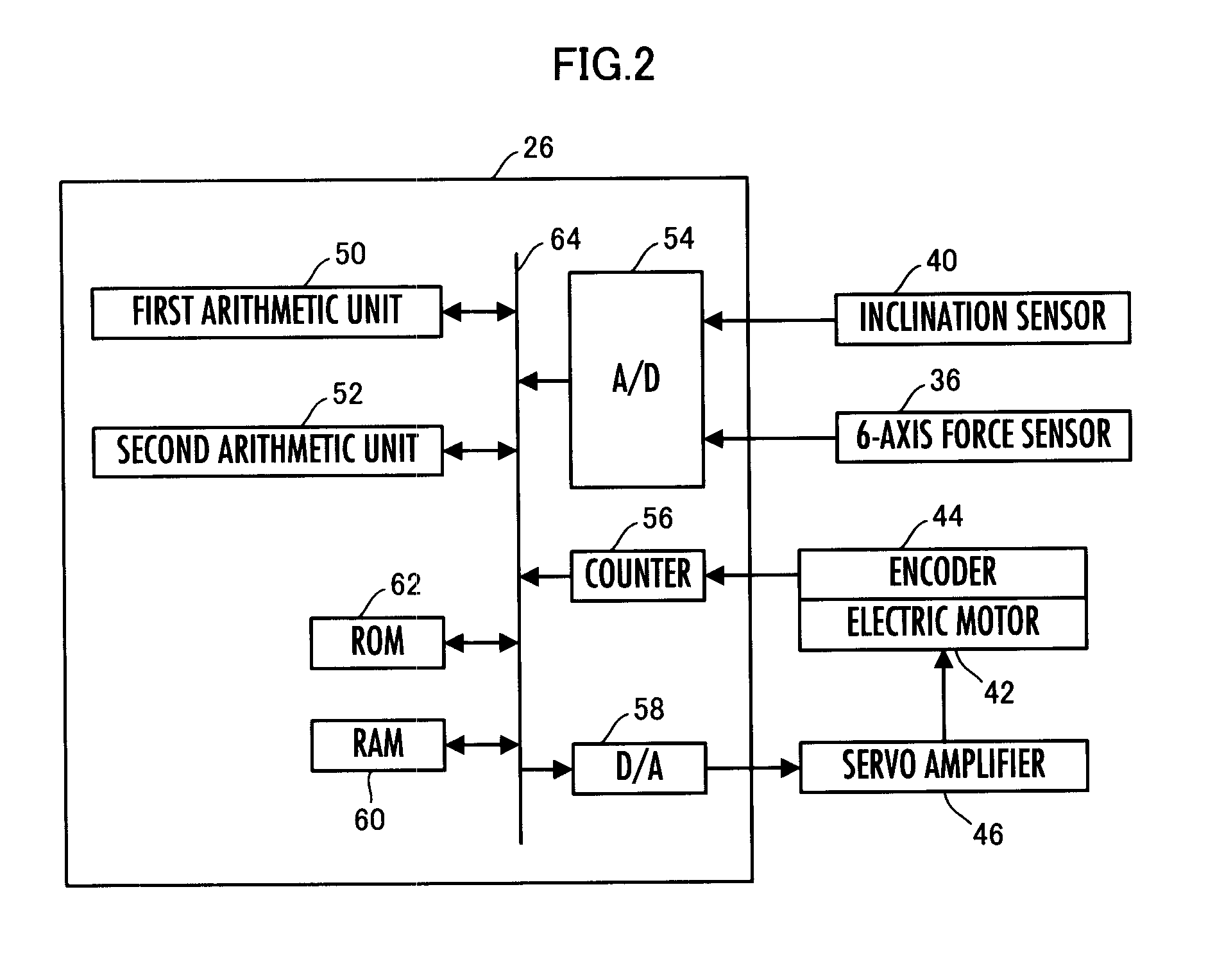

Control device for mobile body

ActiveUS20110022232A1Eliminate deviationSmoothly deviationSolid-state devicesMaterial analysis by optical meansCurrent timeTime of use

A control device for a mobile body makes it possible to smoothly correct the deviation of an actual posture of a base body of a mobile body, which travels with the base body thereof moving up and down, from a desired posture of the base body while restraining an overshoot or an undershoot from occurring. To determine a required manipulated variable according to a feedback control law in order to converge a state amount deviation related to the posture of the base body of the mobile body to zero, the feedback gain of the feedback control law is determined by using the time series in a period from current time to predetermined time in the future in the time series of a desired inertial force of the mobile body or the base body. The required manipulated variable is determined by the calculation of the feedback control law on the basis of the determined feedback gain and an observed value of the state amount deviation.

Owner:HONDA MOTOR CO LTD

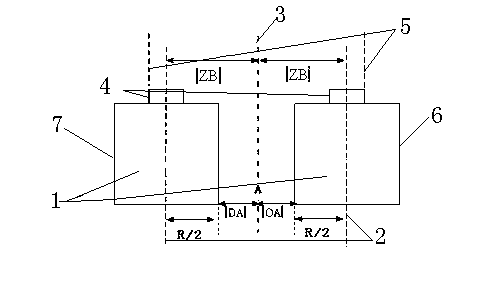

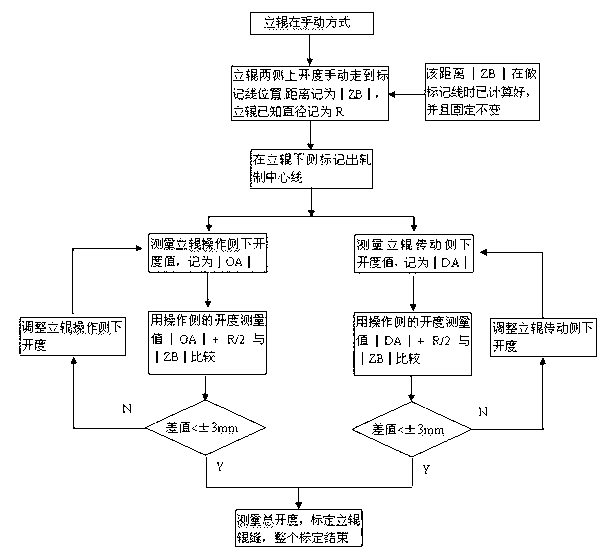

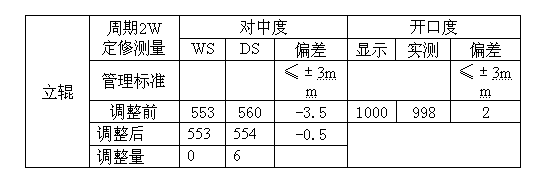

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792AProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelEngineering

The invention relates to a calibration method for clearance between rolls of hot-rolling vertical rolls, which mainly solves the technical problem that strip steel is deficient in quality because verticality and alignment to calibration of vertical rolls are not considered in current methods. The technical scheme is that the calibration method for clearance between rolls of hot-rolling vertical rolls comprises the steps of: 1, finding a rolling center line and marking; 2, additionally arranging two position marks on a transverse slipway of a hot-rolling vertical roll device, and marking the distance from the marks to the rolling center line as |ZB|; 3, hitting apertures on both sides of the vertical rolls to marked positions, wherein a roll block is inside a marking line and aligned with the marking line; 4, measuring the distance from the lower ends on both sides of the vertical rolls to the rolling center line, and marking the measuring point as a point A, the radius of the rolls as R / 2 and the distances from A to a vertical roll operating side and from A to a transmission side as |OA| and |DA|; 5, comparing the measured value |OA|+R / 2 on the operating side with |ZB|, wherein if the difference is in a precision range, the verticality is good, and if the difference is not in the precision range, the clearance between rolls on the operating side is adjusted so that the difference is in the precision control range; 6, adjusting the clearance between rolls on the transmission side by the adjusting method in the step 5; and 7, measuring the total aperture of the vertical rolls, inputting the measured values and calibrating the clearance between rolls of vertical rolls after adjusting the verticality and alignment.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

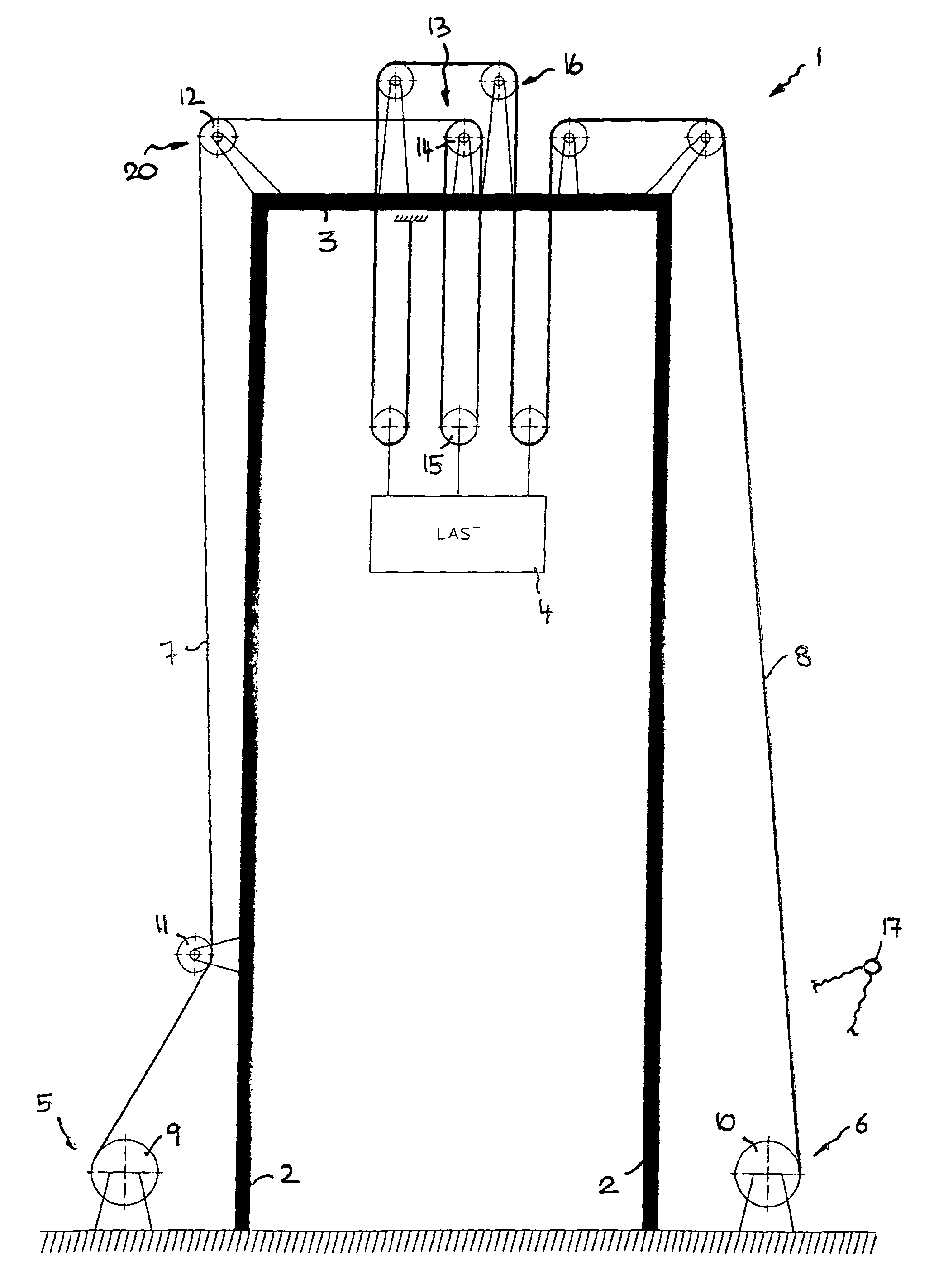

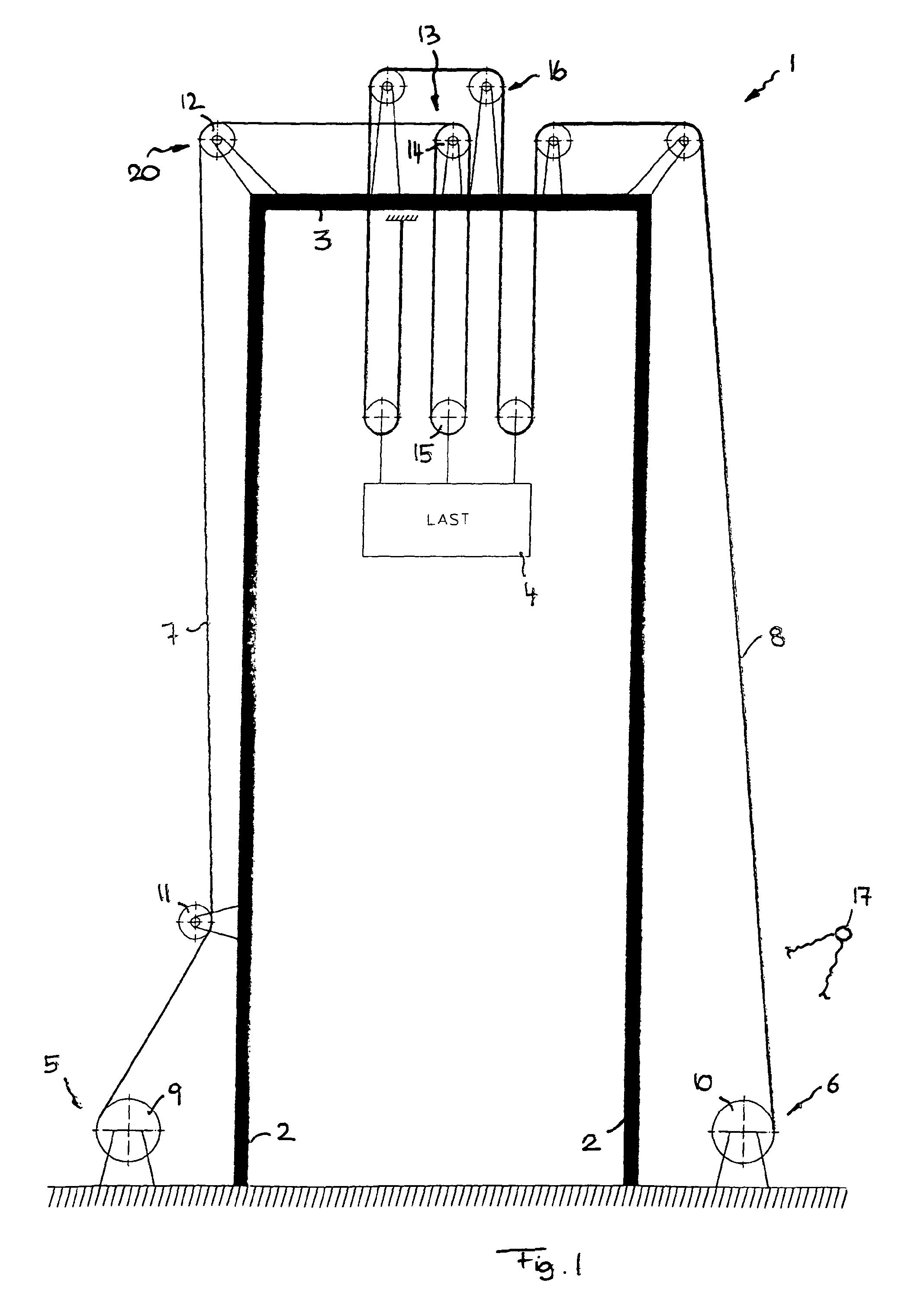

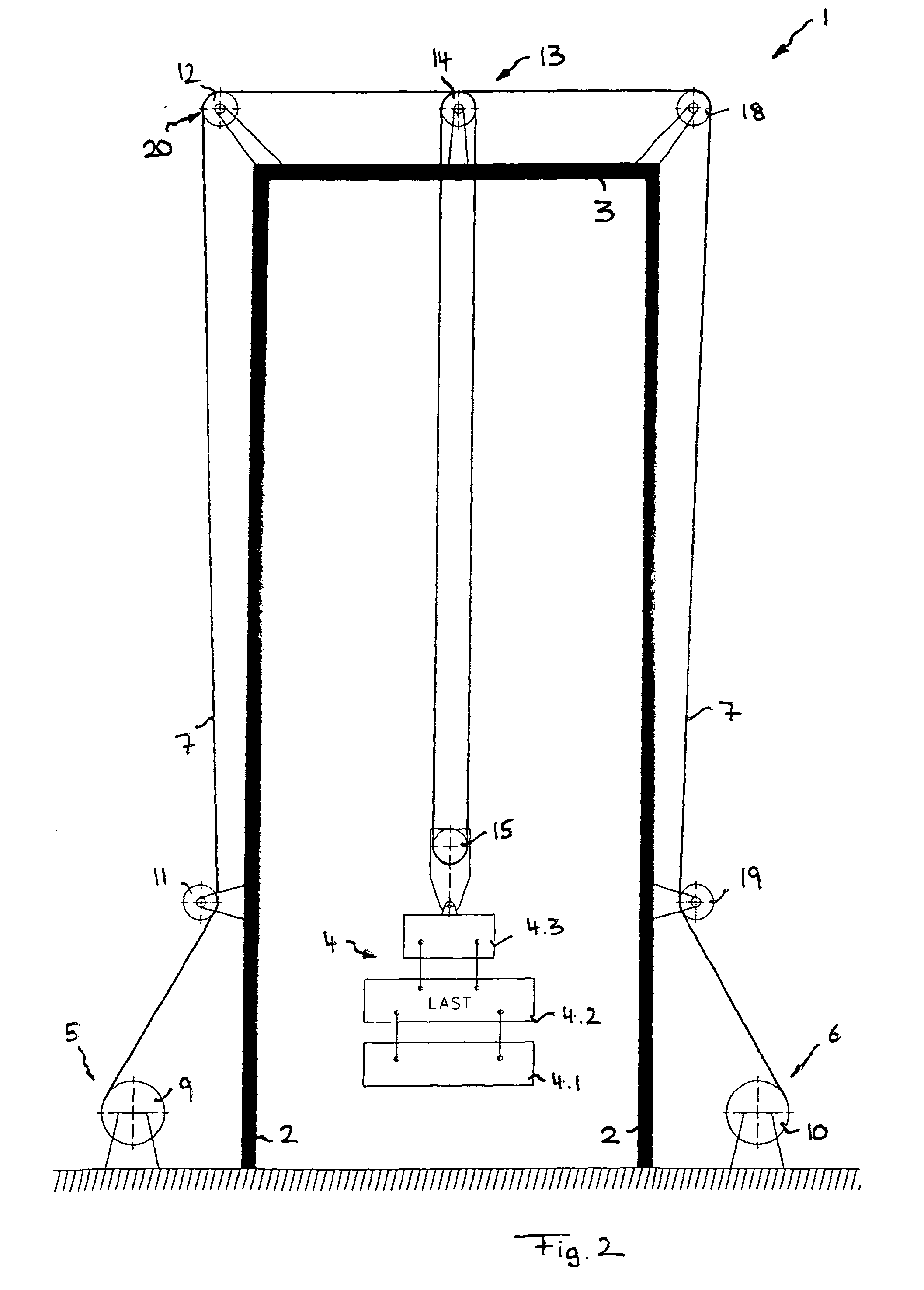

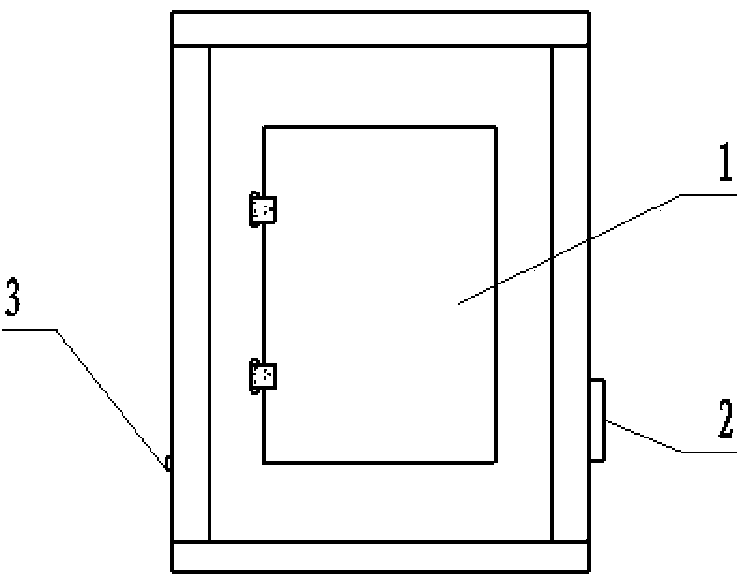

Rope Test Stand

ActiveUS20140109682A1Eliminate deviationEasy to changeMaterial strength using tensile/compressive forcesWinding mechanismsEngineeringTest bench

A cable test bench for testing a test cable to establish service life, replacement age, number of flex cycles, and / or winding behavior, has a deflection system including at least one deflector roll to deflect the test cable, one test cable drive to wind and unwind the test cable via the deflection system, and one test load to load the test cable. The cable test stand has an additional cable test drive for winding and unwinding a safety cable and / or the named test cable, and a control device for controlling the additional cable drive and / or the test cable drive in a manner wherein the two are adjusted to each other, in such a manner that the load of the test cable can be adjusted differently for different test cable segments and / or different winding directions and / or different winding cycles and / or different phases of a winding cycle.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

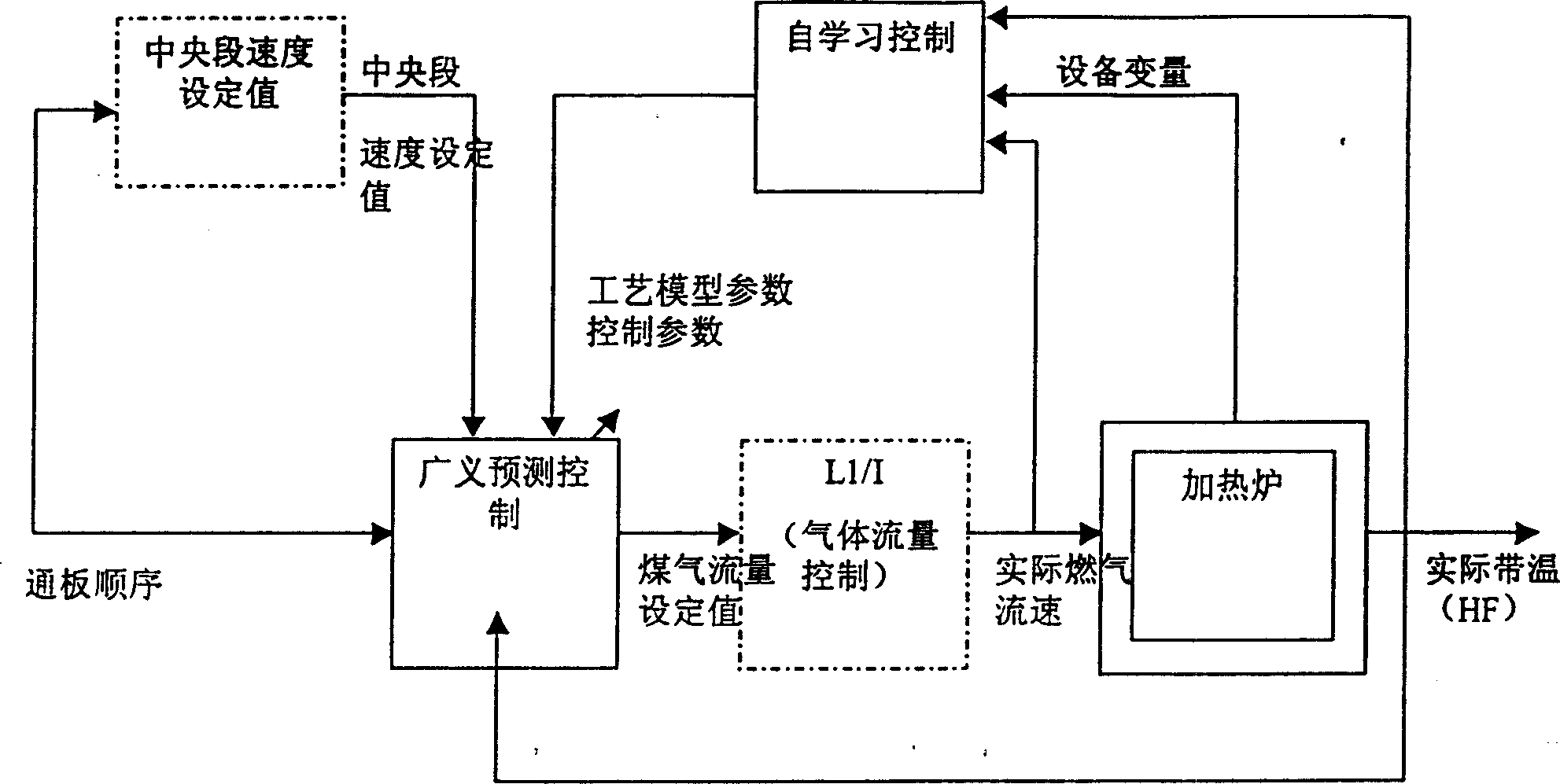

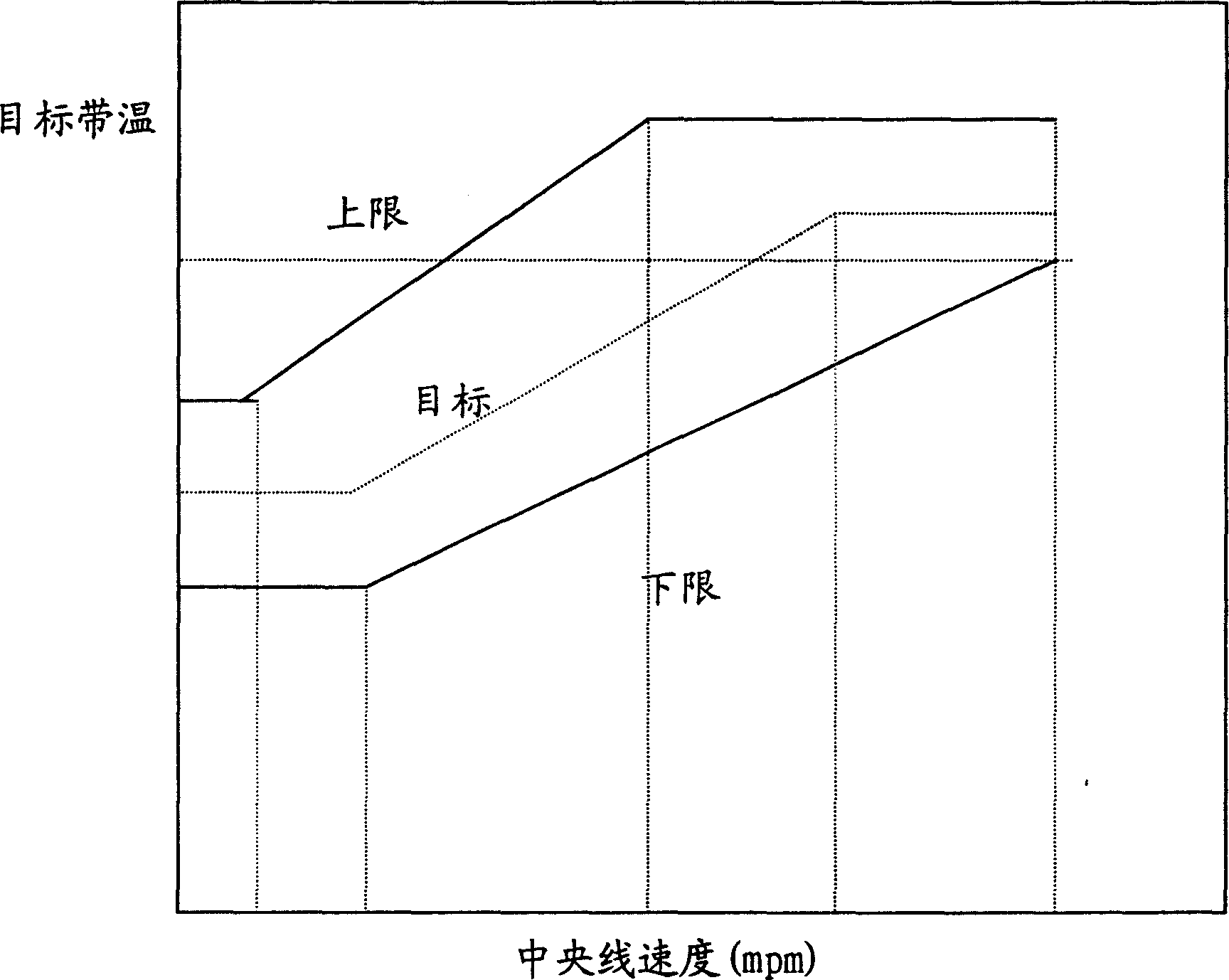

Process for controlling temperature of strip steel

ActiveCN1704487AFast and stable responseImprove applicabilityHot-dipping/immersion processesFurnace typesProduction lineDynamic models

The invention provides a process for controlling temperature of strip steel comprising the steps of, (1) forecasting the strip temperature of a certain future time based on strip temperature dynamic model, (2) calculating the needed gas flow variance so as to minimize the difference between the temperature of the destination strip steel and the forecasted strip temperature, (3) calculating gas flow configuration value according to the real gas flow and the gas flow deviation(4) sending the gas flow configuration value to the instrument control apparatus, (5) carrying out static model and dynamic model self-learning according to the real strip temperature, and calculating the gas flow configuration value again.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Dangling type micro-impulse testing device and method

InactiveCN104374506AEliminate the effects ofEliminate deviationApparatus for force/torque/work measurementElectrical resistance and conductanceAerodynamic drag

The invention discloses a dangling type micro-impulse testing device and method. A dangling system is fixed in a vacuum box, a thruster ignition power source, a circuit switch, a wire and a miniature thruster are integrated to the dangling system in a modularization mode, a dangling type micro-impulse testing system works in a vacuum environment, a remote control switch serves as a circuit switch to conduct remote control ignition, and influences of a miniature thruster ignition resistance wire power source and the wire on testing results are eliminated. A laser Doppler measurer is installed outside the vacuum box, a light path of a single beam laser head in the laser Doppler measurer is adjusted to be centered with a target reflector, the deviation of outgoing beams and incident beams is eliminated, displacement changes of the thruster are accurately measured, and influences of air friction during dangling are avoided. By means of the dangling type micro-impulse testing device and method, the working force of a miniature rocket motor in a short time can be tested, the micro impulses can be tested, and the impulse testing accuracy is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Light source and vehicle lamp

ActiveUS7246930B2Inhibit transferInhibit temperature risePoint-like light sourceSolid-state devicesFluorescenceDistribution pattern

Owner:STANLEY ELECTRIC CO LTD

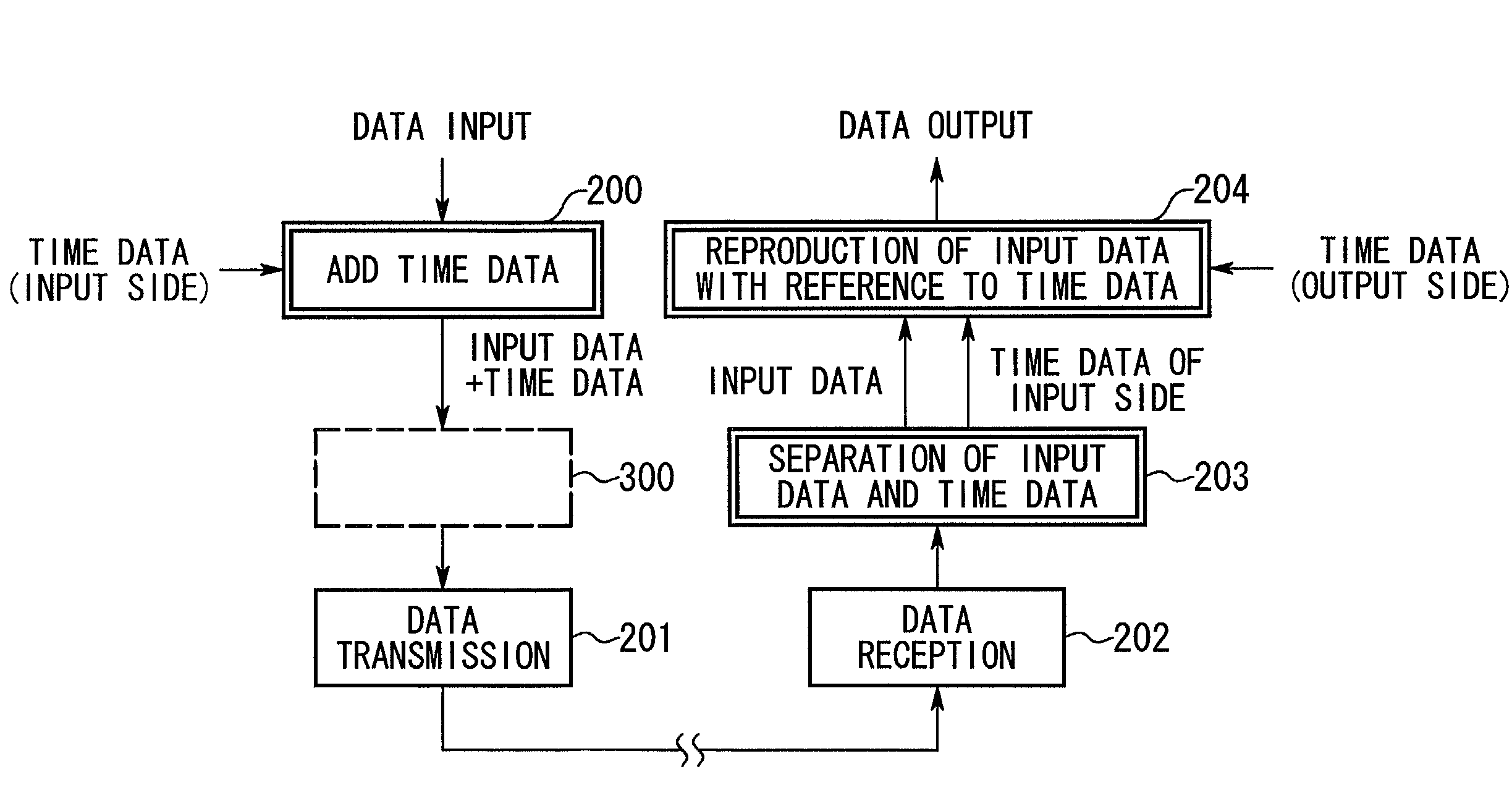

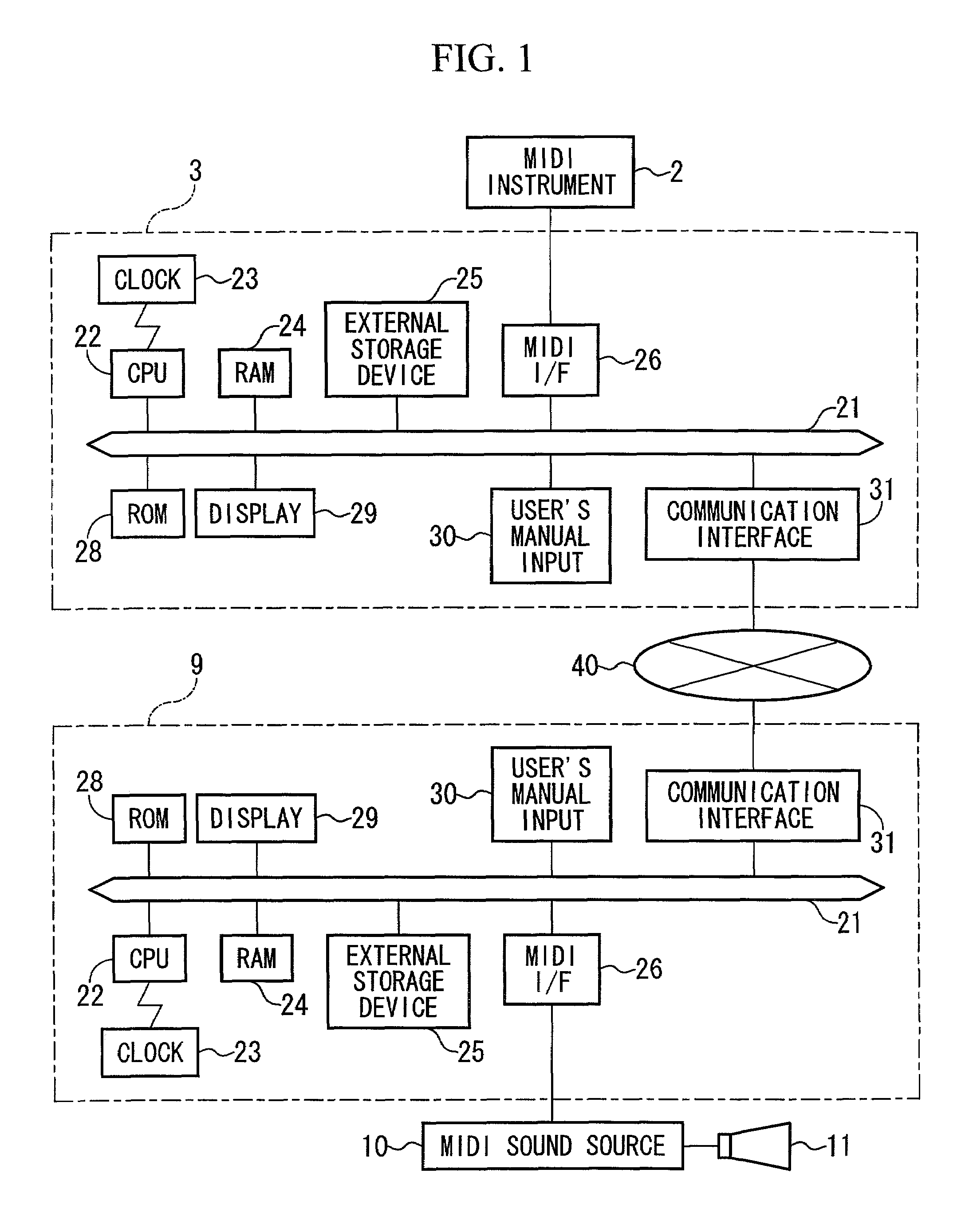

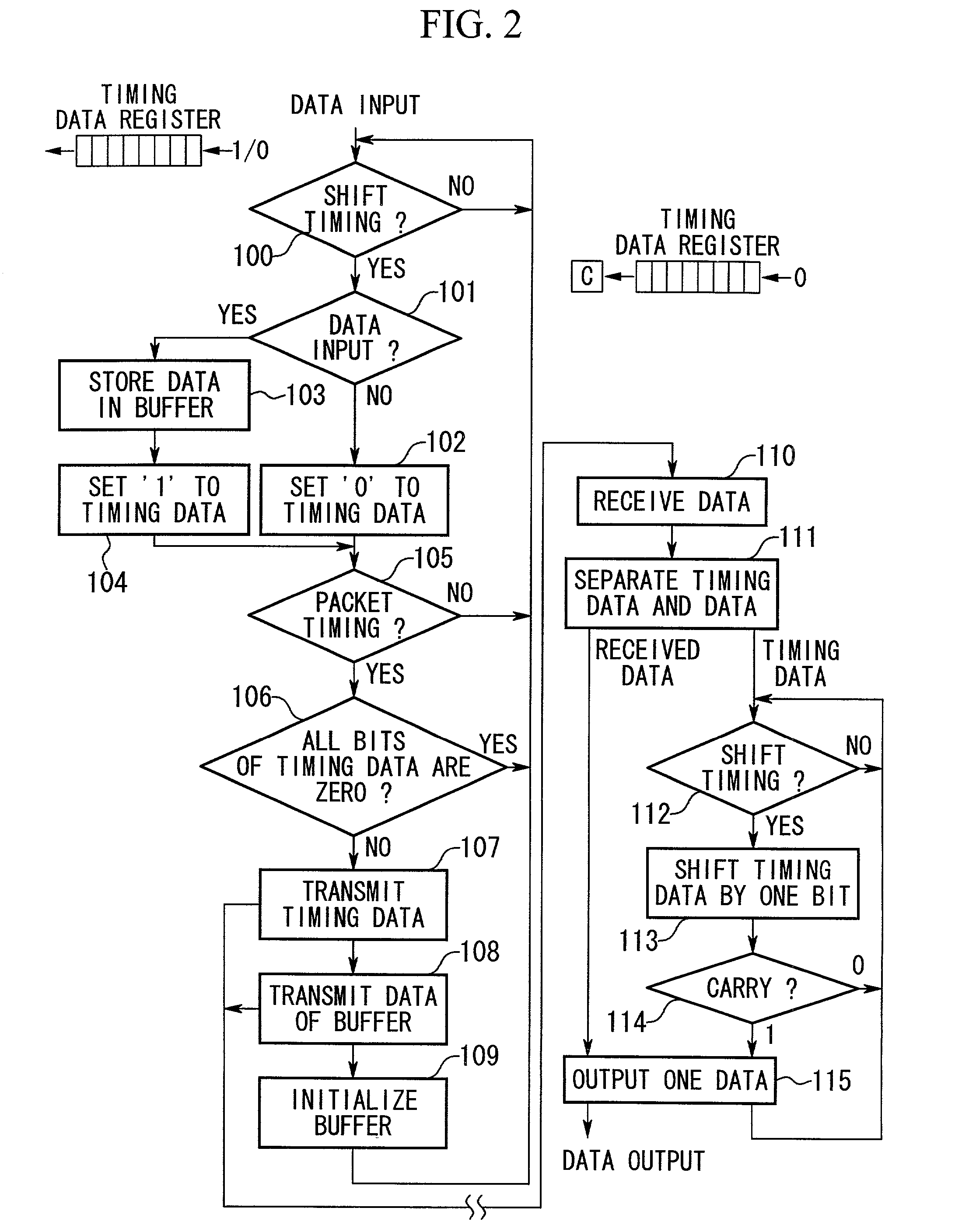

Communication method and system for transmission and reception of packets collecting sporadically input data

InactiveUS7254644B2Eliminate dispersionEliminate deviationElectrophonic musical instrumentsMultiple digital computer combinationsPacket communicationThe Internet

A server / client system provides packet communications between a server and a client by way of a network such as the Internet. The server inputs data such as MIDI data in a sporadic manner while storing timing data representing their input timings. Then, the server performs packetizing of the sporadically input data, which accompany the timing data and are subjected to transmission to the client. The client receives the packetized input data and then outputs them at timings based on the timing data. Thus, it is possible to completely secure the same time relationship of data during transmission and reception of the sporadically input data even though the client differs from the server on a time-axis basis.

Owner:YAMAHA CORP

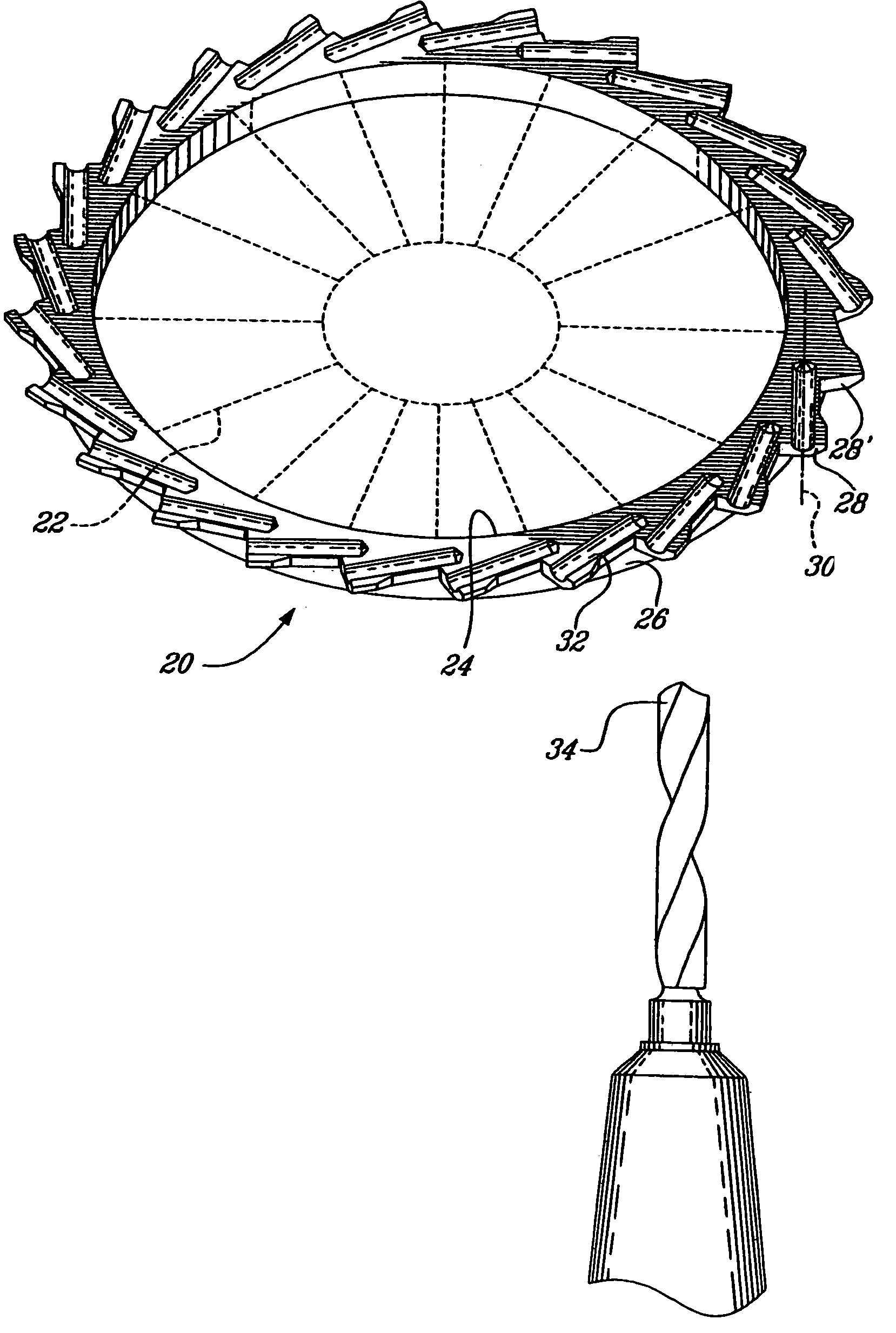

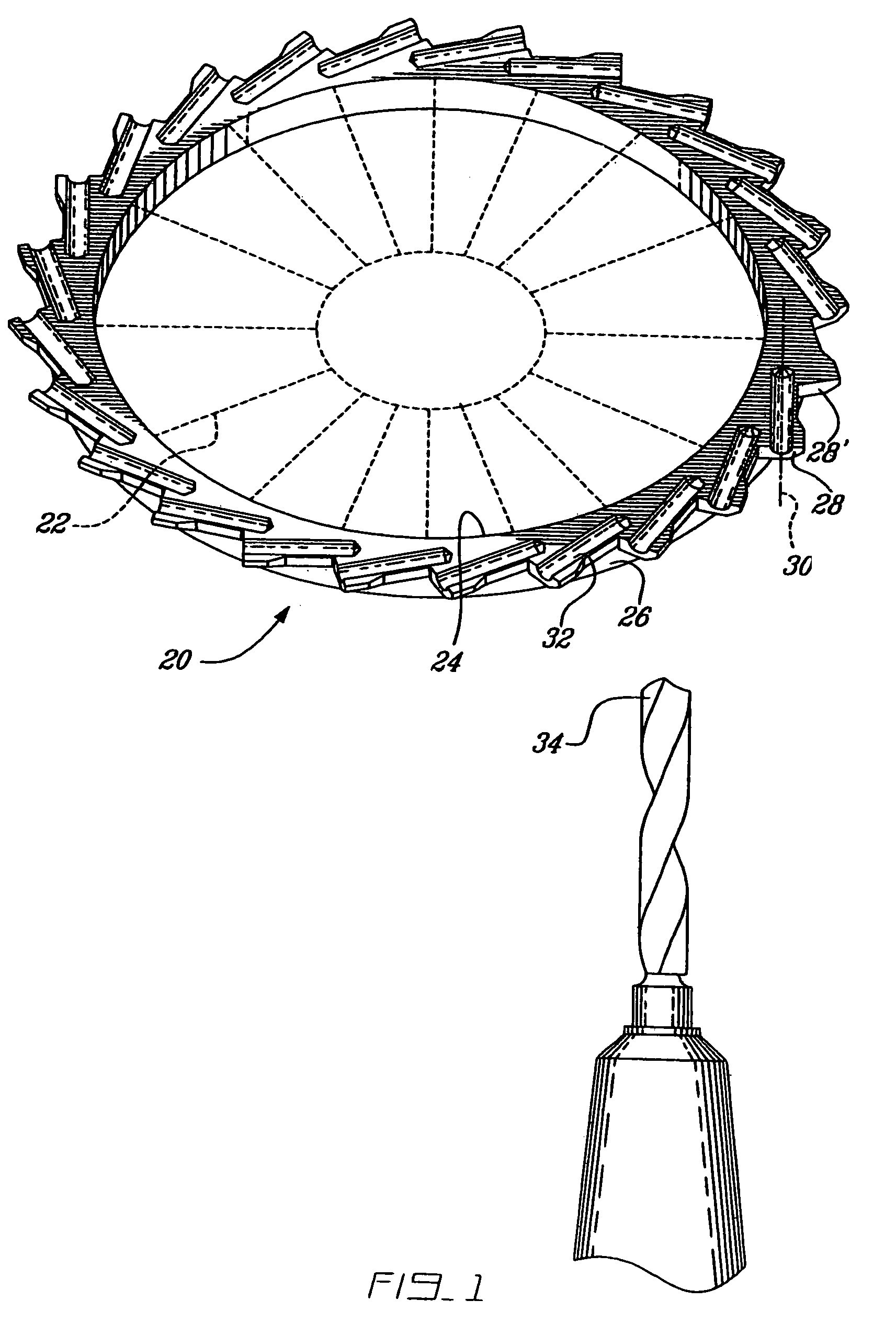

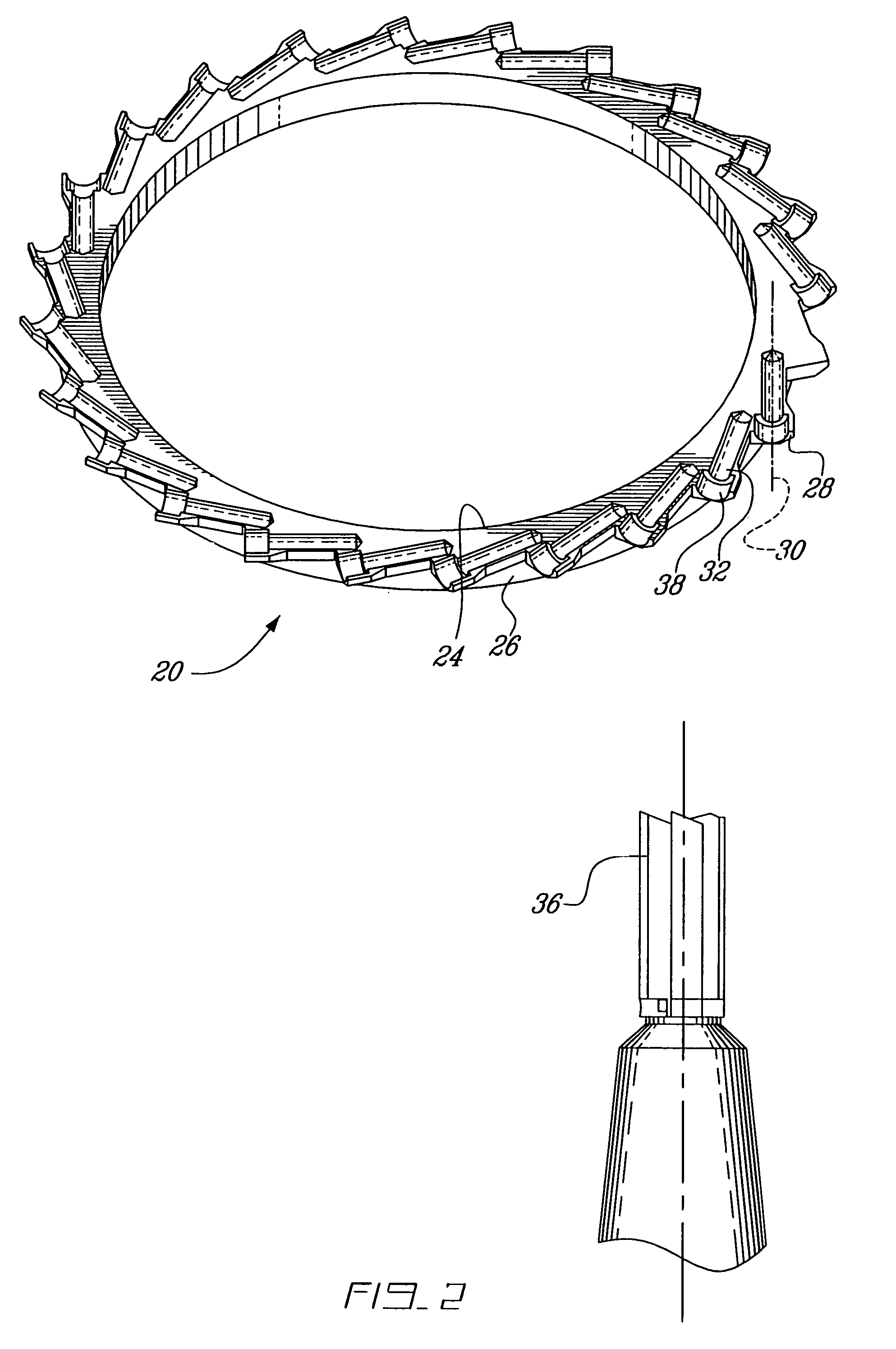

Method of making a gas turbine engine diffuser

InactiveUS7114255B2Minimizes tool deflectionMinimize deflectionEngine manufacturePump componentsTurbineGas turbines

Owner:PRATT & WHITNEY CANADA CORP

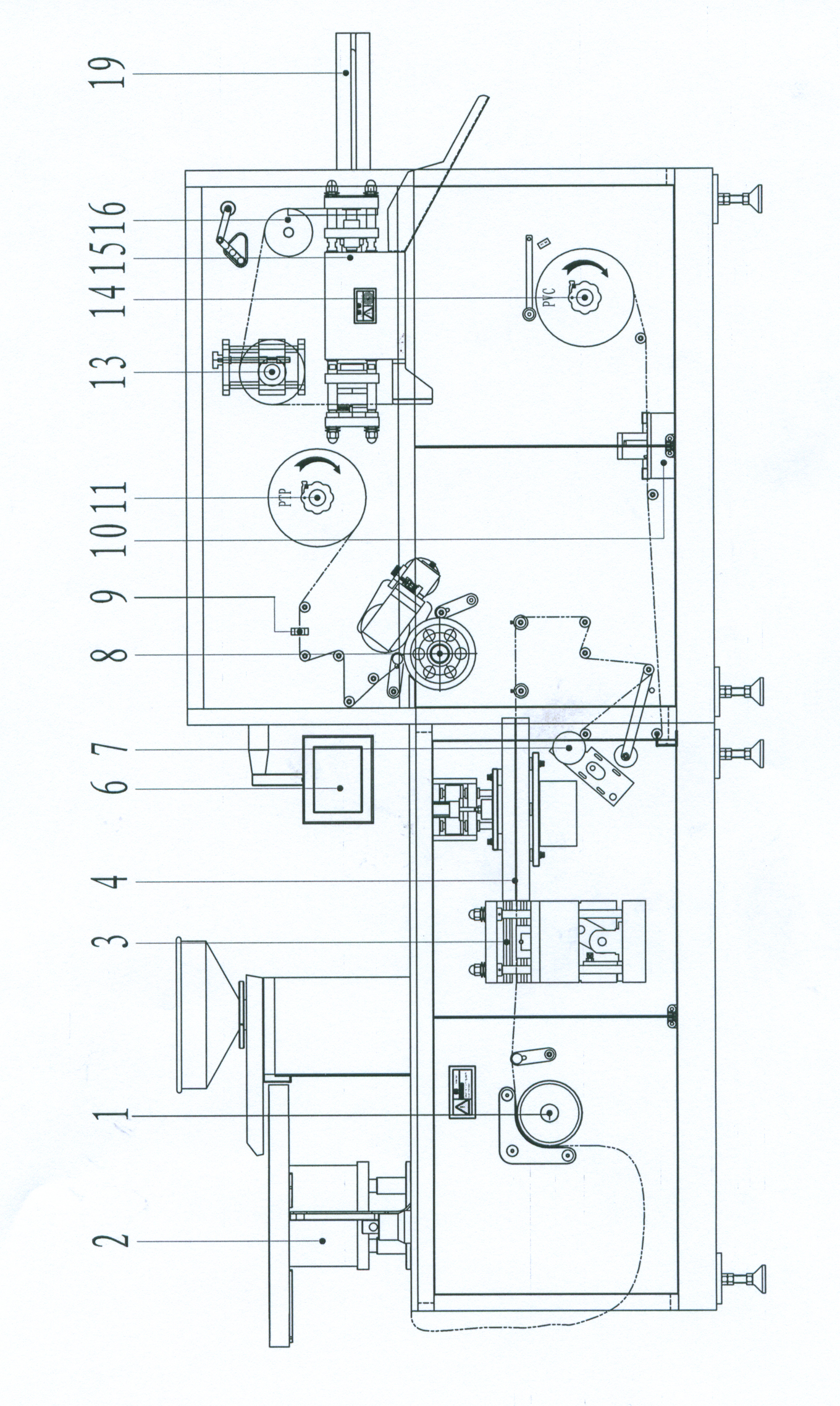

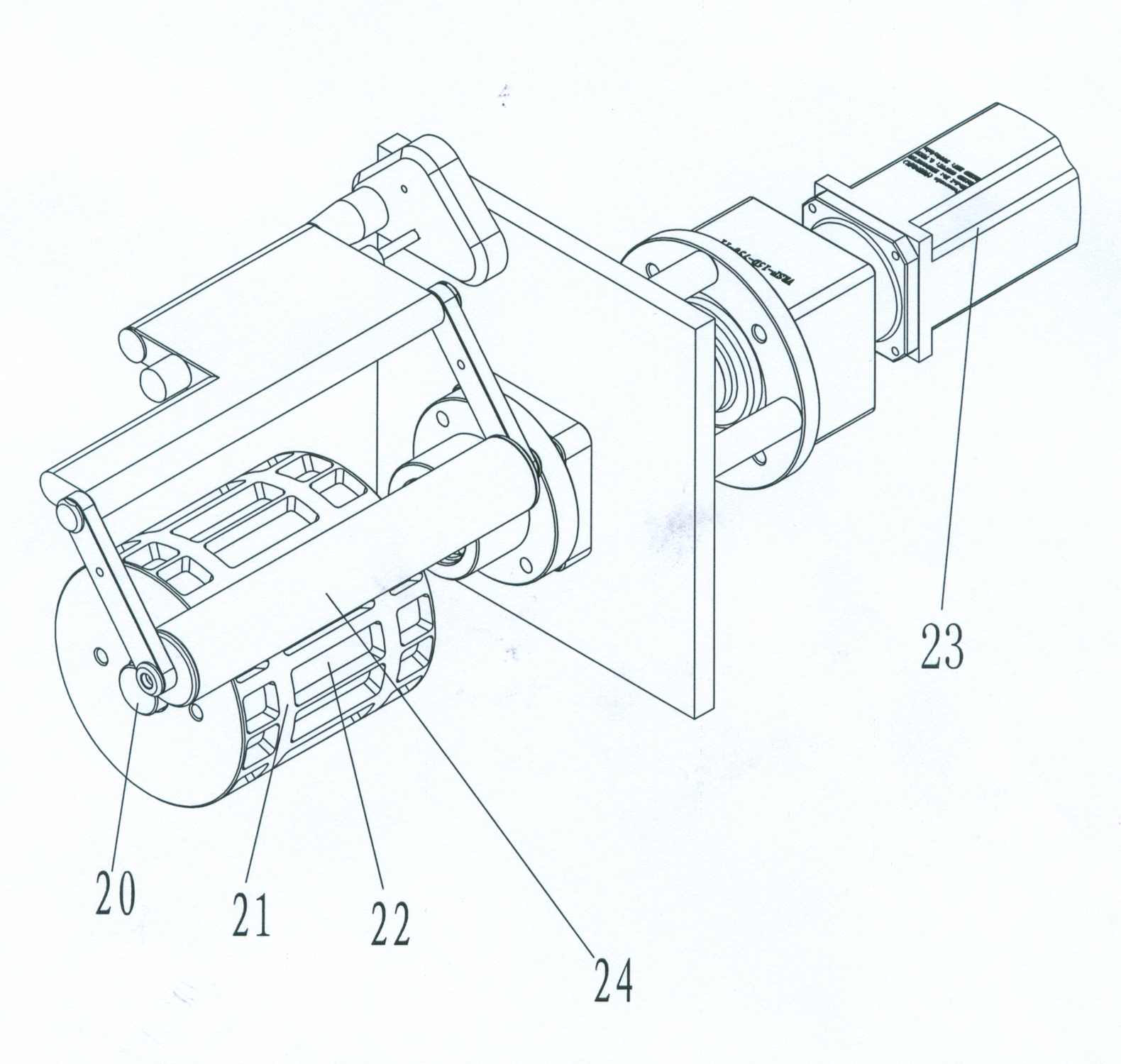

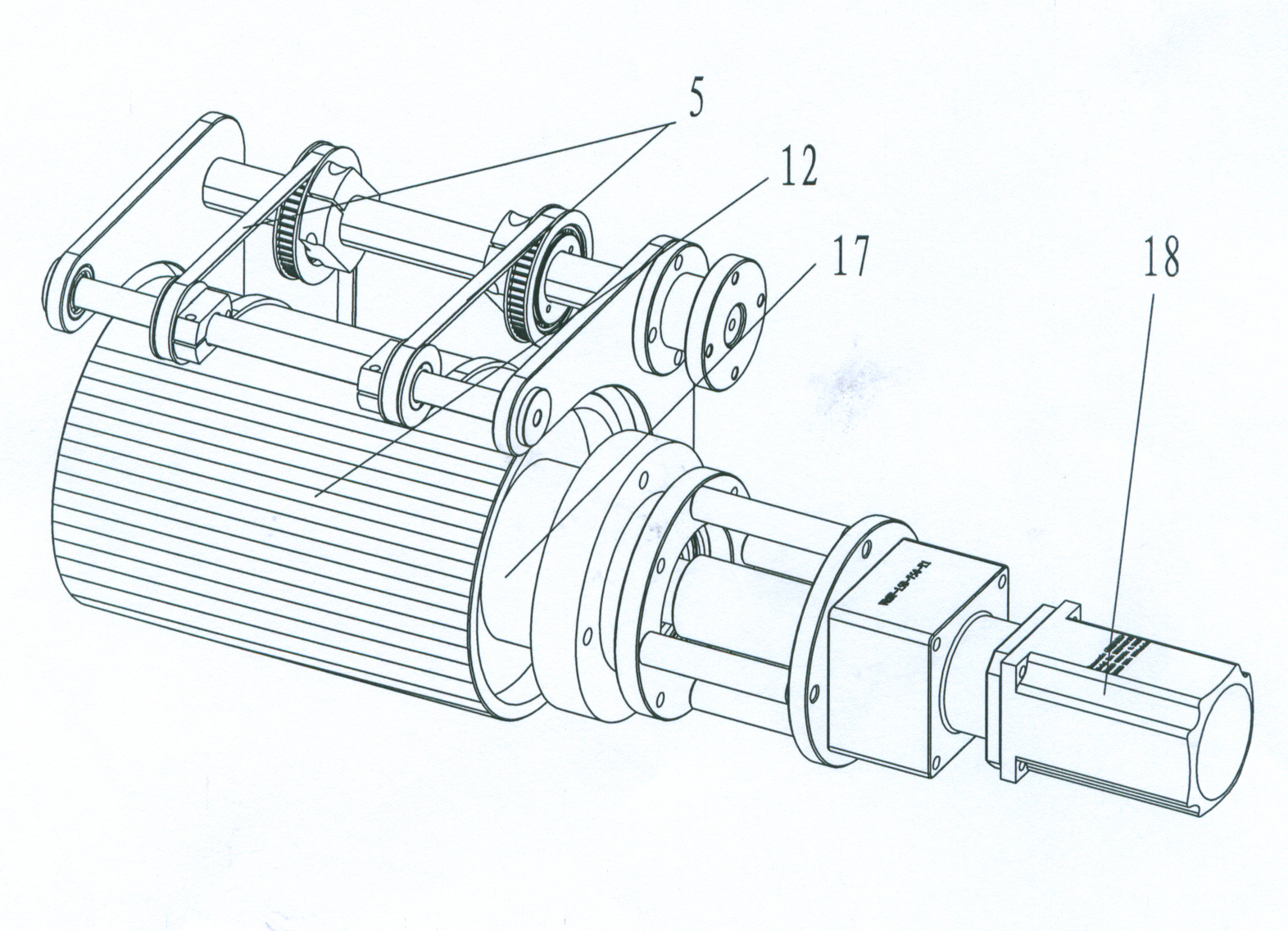

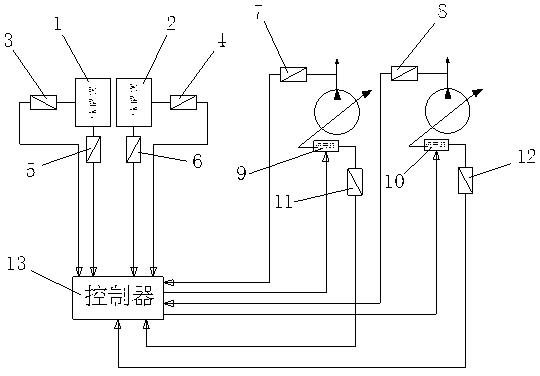

Intelligent high-speed rolled sheet type blister packing machine

ActiveCN101850857AIncrease frictionEliminate slippageWrapping material feeding apparatusWrappingPolyvinyl chlorideElectric machinery

The invention discloses an intelligent high-speed rolled sheet type blister packing machine, which is mainly characterized in that: lines are distributed on the roll surface of a traction roll of a polyvinyl chloride (PVC) forming traction mechanism; a hollowed blister hole is formed on the roll surface of a roll of a blister traction mechanism; the blister hole corresponds to a sealed board blister eye; the blister traction roll is in transmission connection with a driving motor; the roll surface of the blister traction roll is matched with that of a pressing roll; a heat-seal roll of a PVC and aluminium foil heat-seal mechanism is provided with a heat-seal anilox roll with a buffer spring; the heat-seal anilox roll is linearly contacted with the two roll surfaces of the heat-seal roll during heat seal; and the heat-seal anilox roll is provided with a driving device which can make the heat-seal anilox roll compress the heat-seal roll tightly. When drawing a PVC plastic sheet, the intelligent high-speed rolled sheet type blister packing machine can increase a friction force, without slipping and pass-line deflection; and after a spring device is installed, the pressure between the heat-seal anilox roll and the heat-seal roll is adjusted properly, so that the sealed board is clear and beautiful.

Owner:ZHEJIANG HOPING MACHINERY

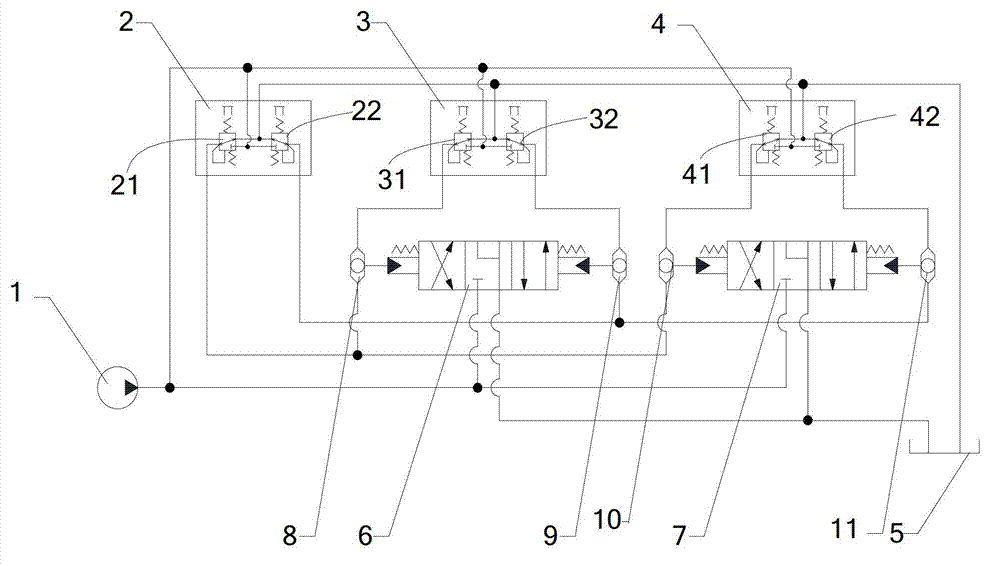

Running off tracking control system and method of excavator and excavator

InactiveCN102720239AEliminate deviationImprove work efficiencySoil-shifting machines/dredgersPower flowControl system

The invention discloses a running off tracking control system and a running off tracking control method of an excavator and the excavator and belongs to the technical field of running control of the excavator. The control method comprises the following steps that firstly, a controller collects the angle value of a pedal plate and the pilot pressure value of leftward and rightward running, and the output given pressure value of a proportional valve is calculated; then, the controller collects the output pressure values of the proportional valves of a front pump and a back pump, and in addition, the output pressure values of the proportional valves of the front pump and the back pump are compared; finally, when the output pressure values of the proportional valves of the front pump and the back pump are identical, the excavator normally runs straightly; when the output pressure values of the proportional valves of the front pump and the back pump are different, the output given pressure value of the proportional valve is used as a closed ring control object, and the given current of the front pump and the back pump output by a closed ring is modified and regulated until the output pressure feedback values of the proportional valves of the front pump and the back pump are identical. The system, the method and the excavator have the advantages that the off tracking failure of the excavator is eliminated, and the comfort of operators and the work efficiency of the excavator are improved.

Owner:SHANGHAI SANY HEAVY IND

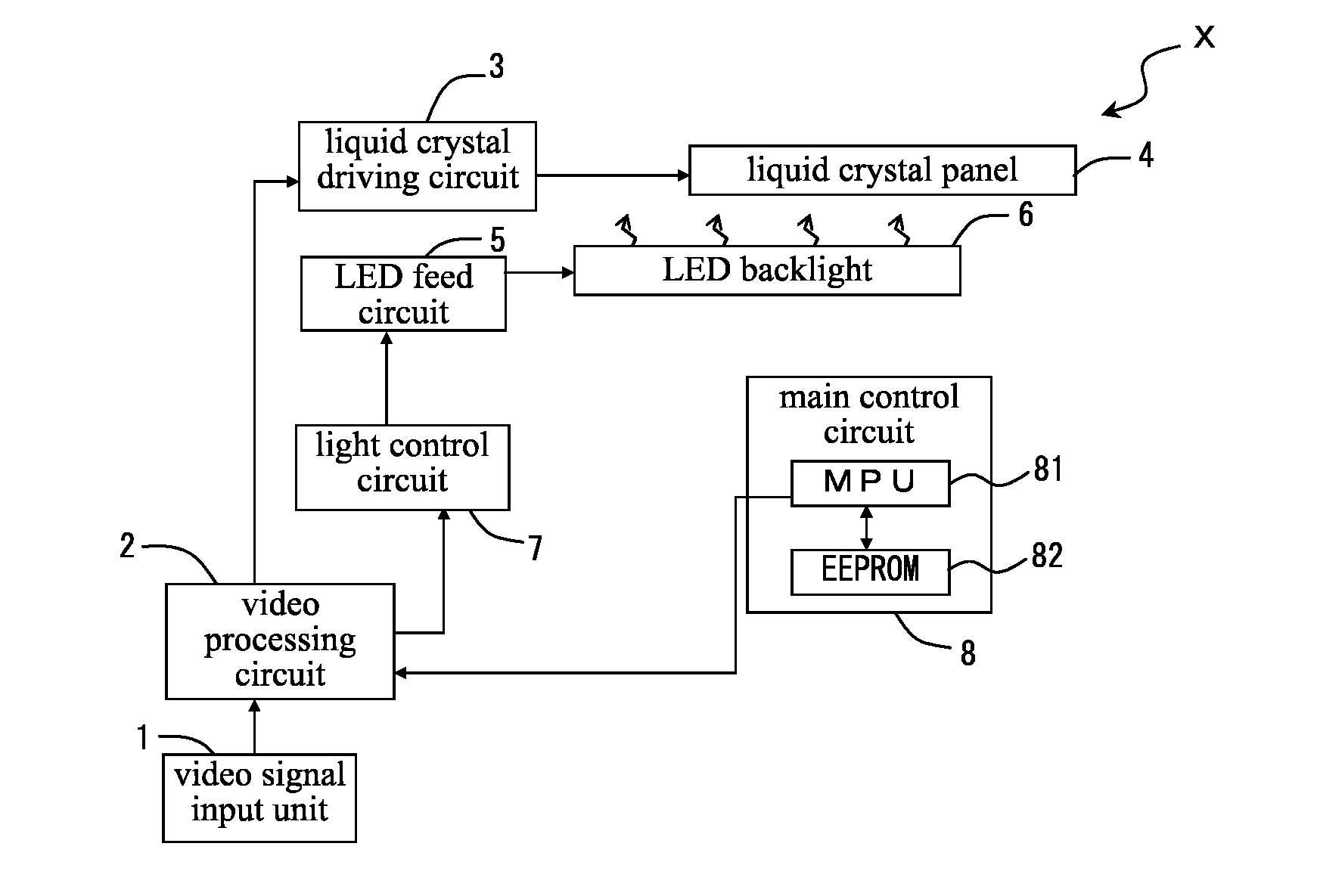

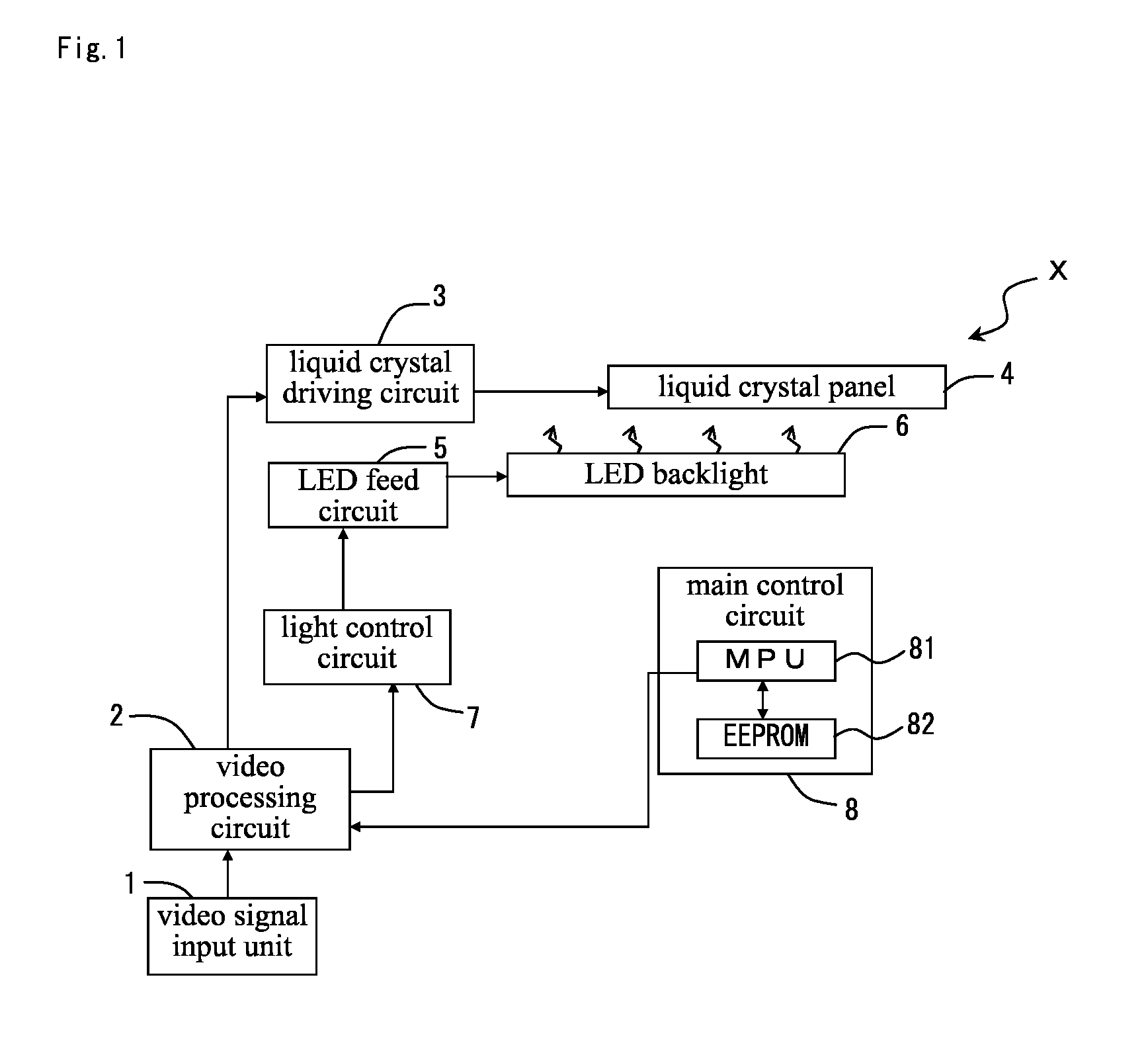

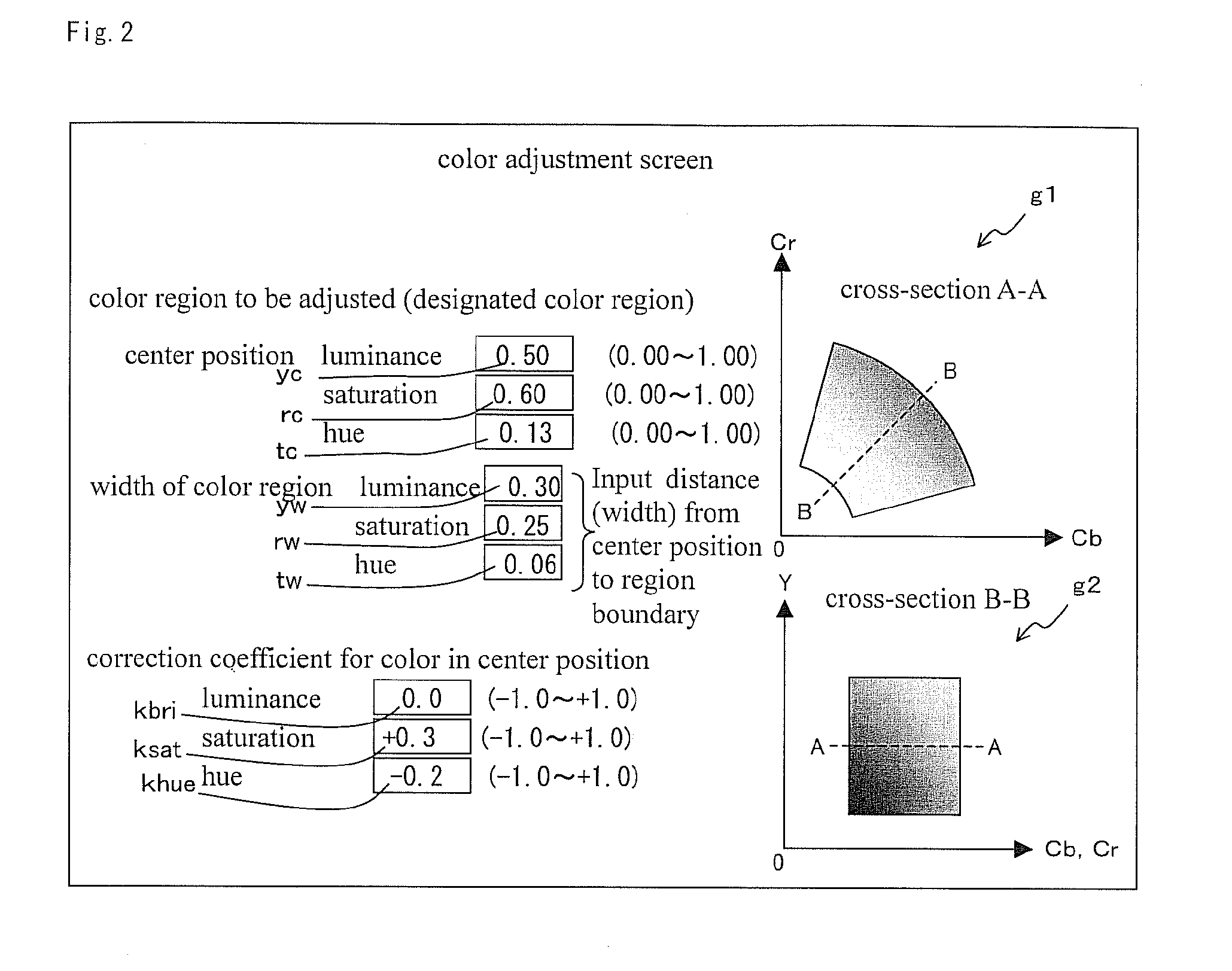

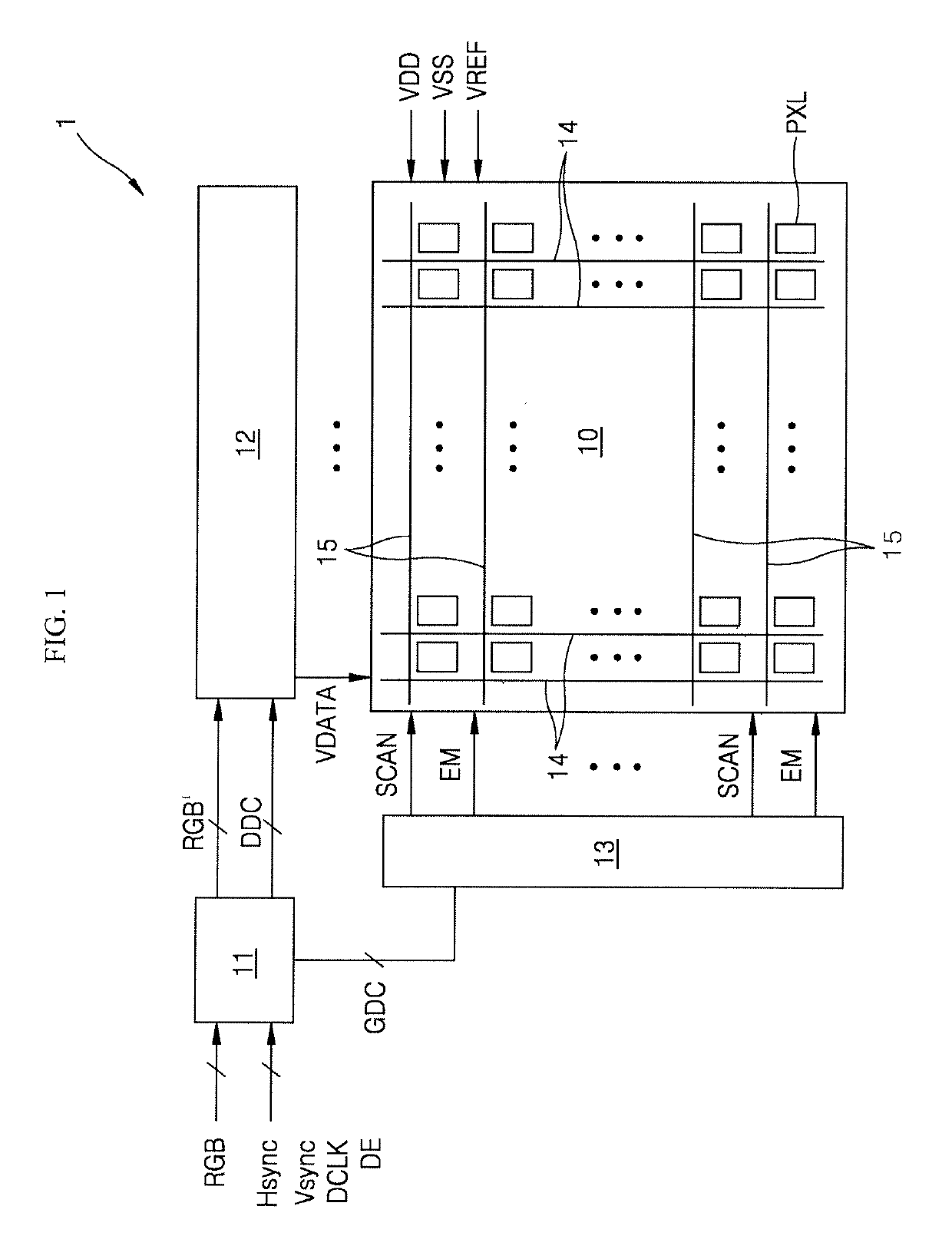

Video display device

InactiveUS20110187735A1Easy to identifyEasy to set upColor signal processing circuitsCathode-ray tube indicatorsDisplay deviceColor correction

In order to simply and easily implement an elimination of a color deviation and a color adjustment for a color correction to a favorable color in an arbitrary portion of a color region in a color reproduction range, a video processing circuit 2 corrects a luminance, a saturation and a hue of a color by the correction quantity corresponding to a reference correction coefficient with regard to a signal value of an input video signal indicating a color within a designated color region defined by a designated range of the luminance, the saturation and the hue when the color indicated by the signal value is a color in the center of the designated color region or at a core for occupying a predetermined range around the center. Otherwise, the video processing circuit 2 corrects the luminance, the saturation and the hue of the color of the signal value by the correction quantity gradually smaller as a position in a color space of the color indicated by the signal value approaches a boundary position of the designated color region.

Owner:SHARP KK

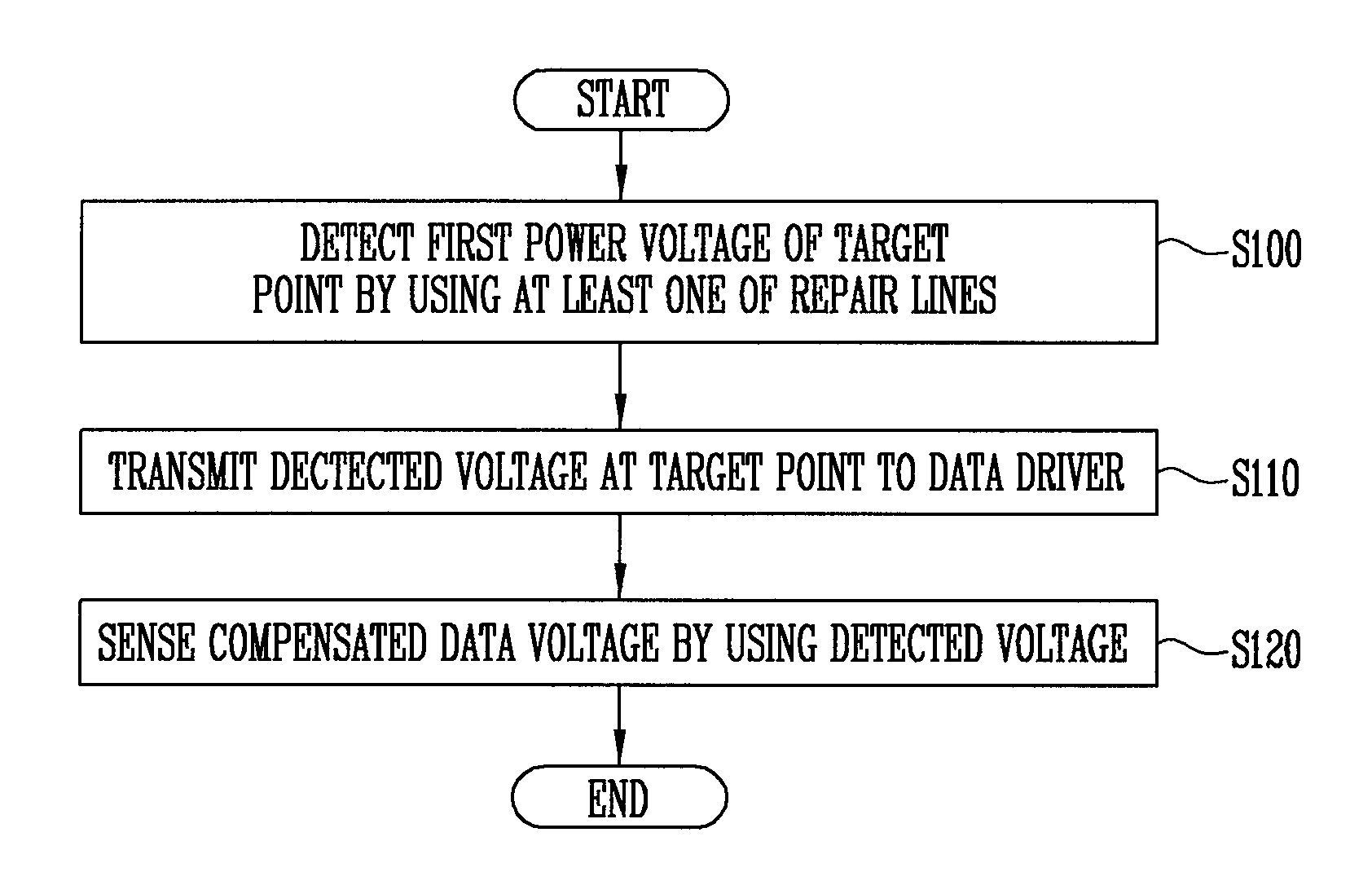

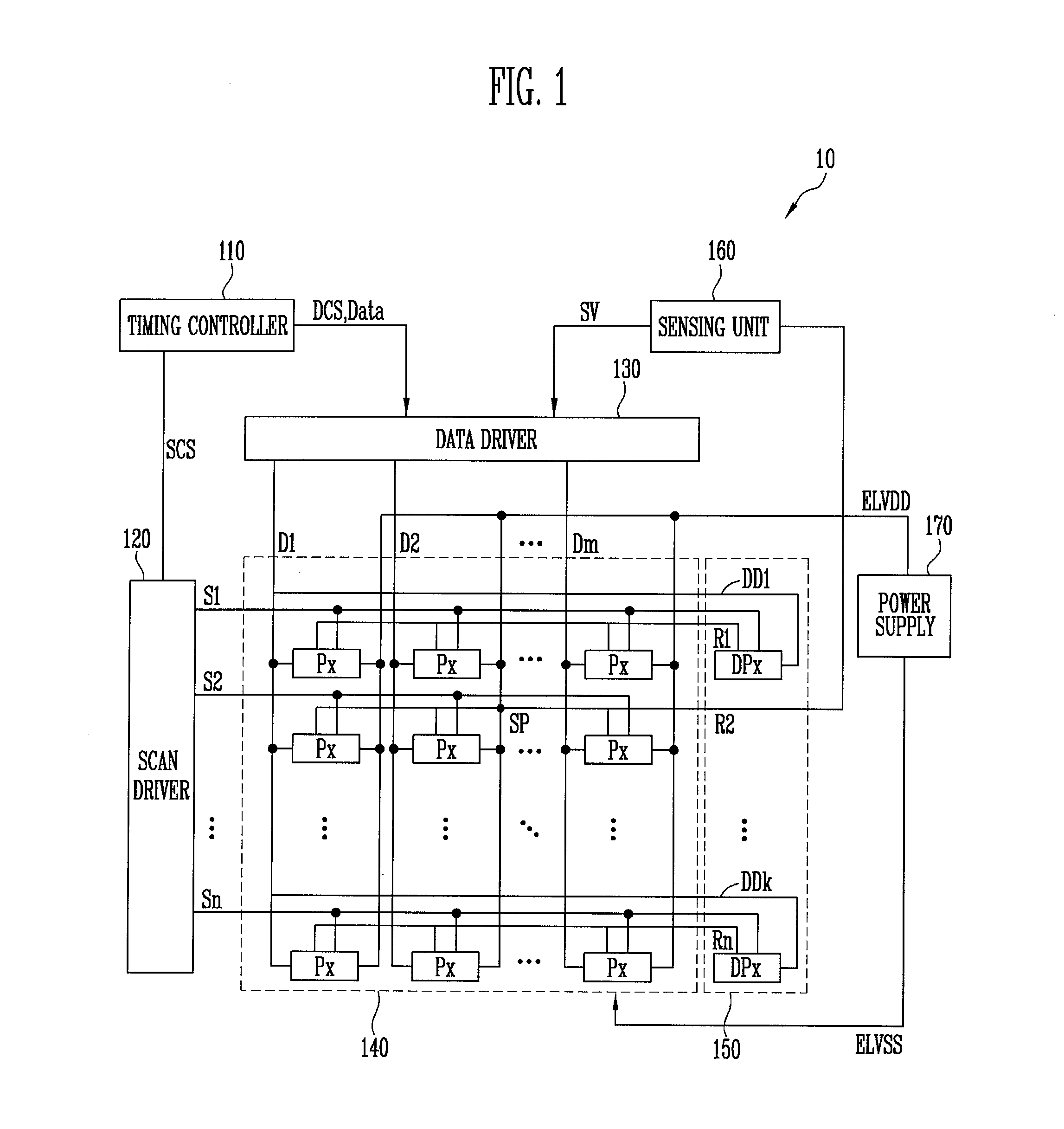

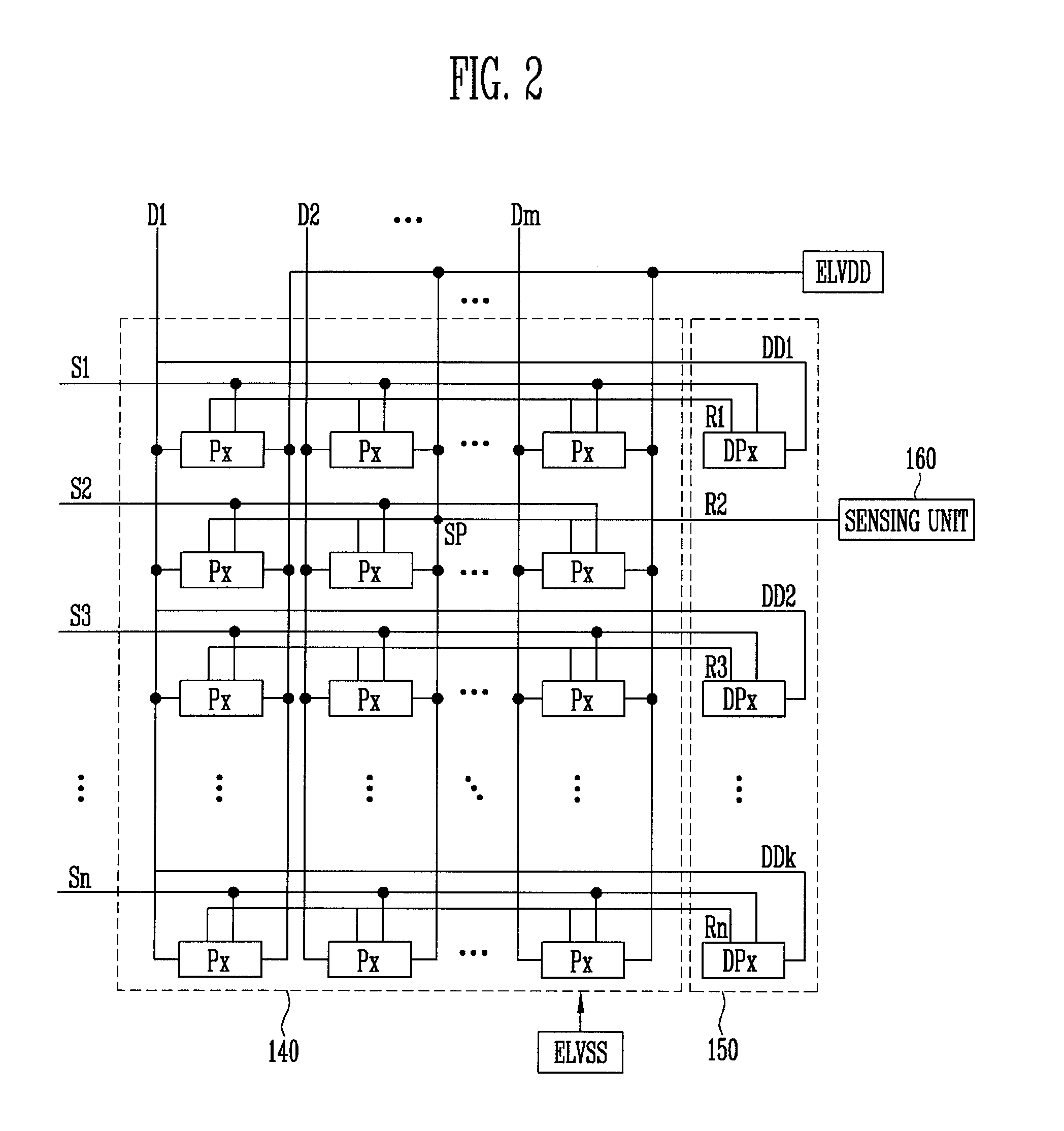

Display device and operating method thereof

ActiveUS20160365070A1Brightness deviationEliminate deviationCathode-ray tube indicatorsScan lineDisplay device

A display device includes a display area including pixels connected to scan lines and data lines, a power supply for supplying a first power voltage to the pixels through first power lines, repair lines in parallel with the scan lines, a dummy pixel unit including dummy pixels respectively connected to the repair lines, and a sensing unit coupled to one of the repair lines that is not connected to the dummy pixels, wherein the sensing unit measures the first power voltage at a target point through the one of the repair lines that is not connected to the dummy pixels.

Owner:SAMSUNG DISPLAY CO LTD

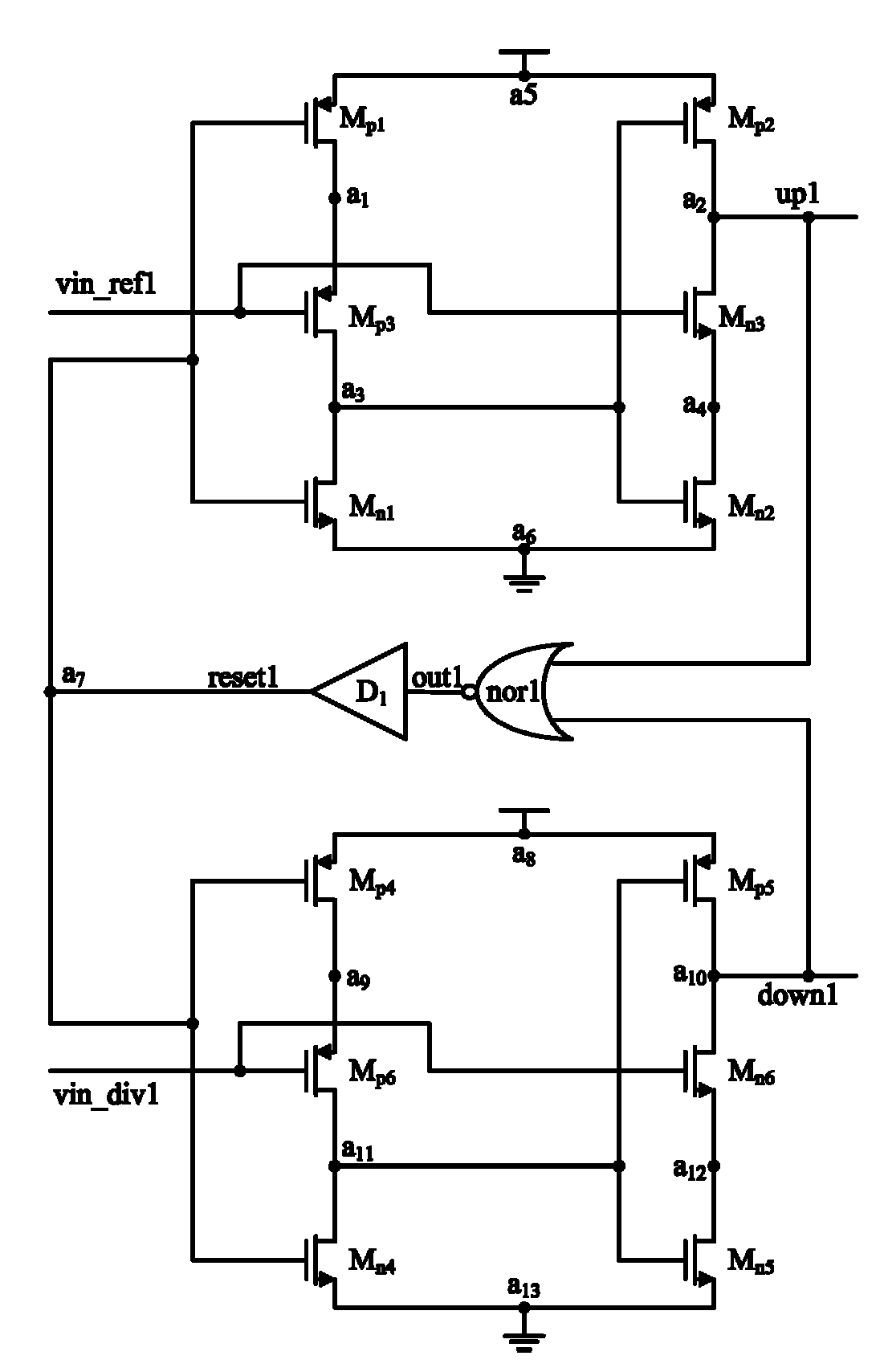

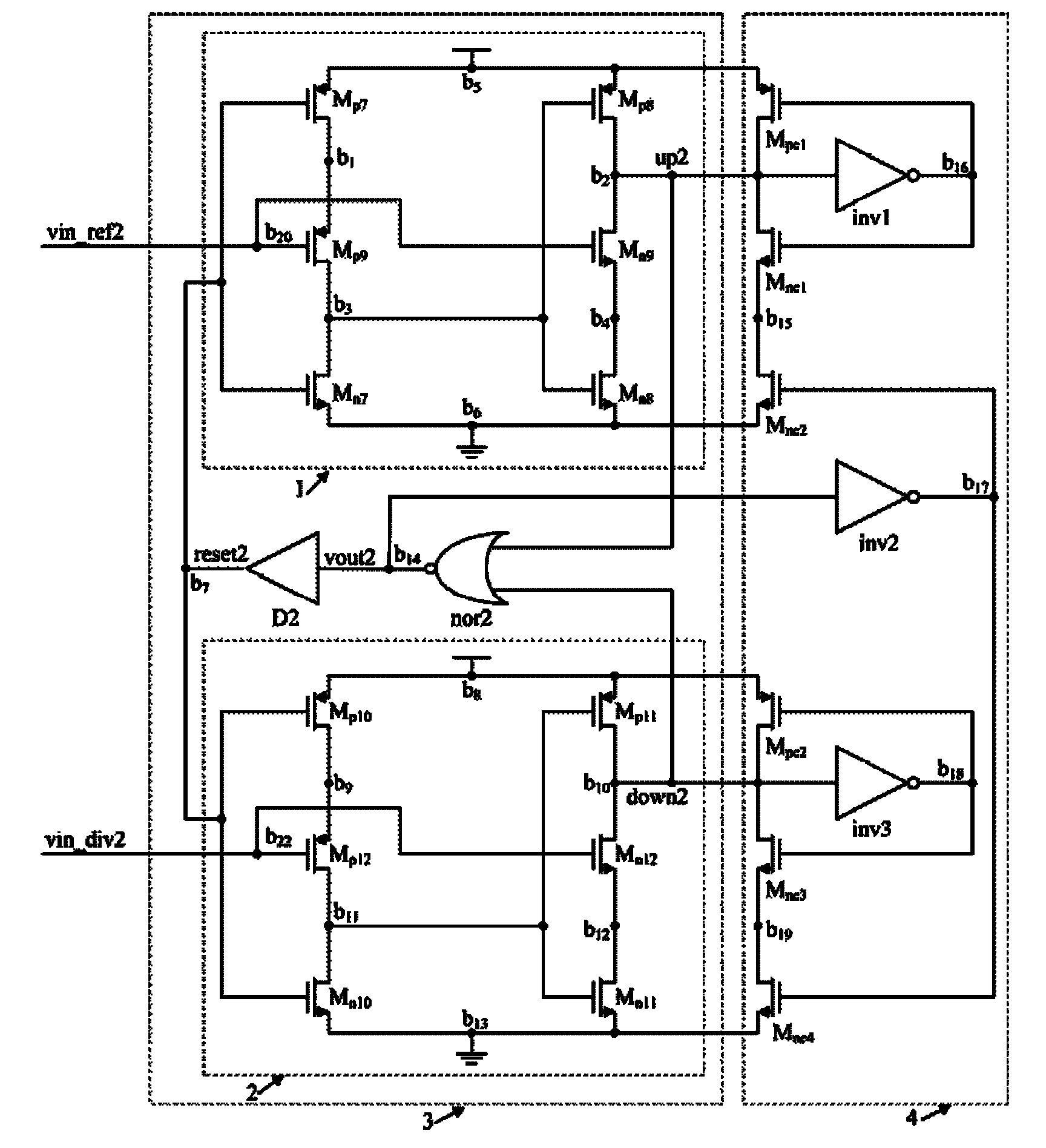

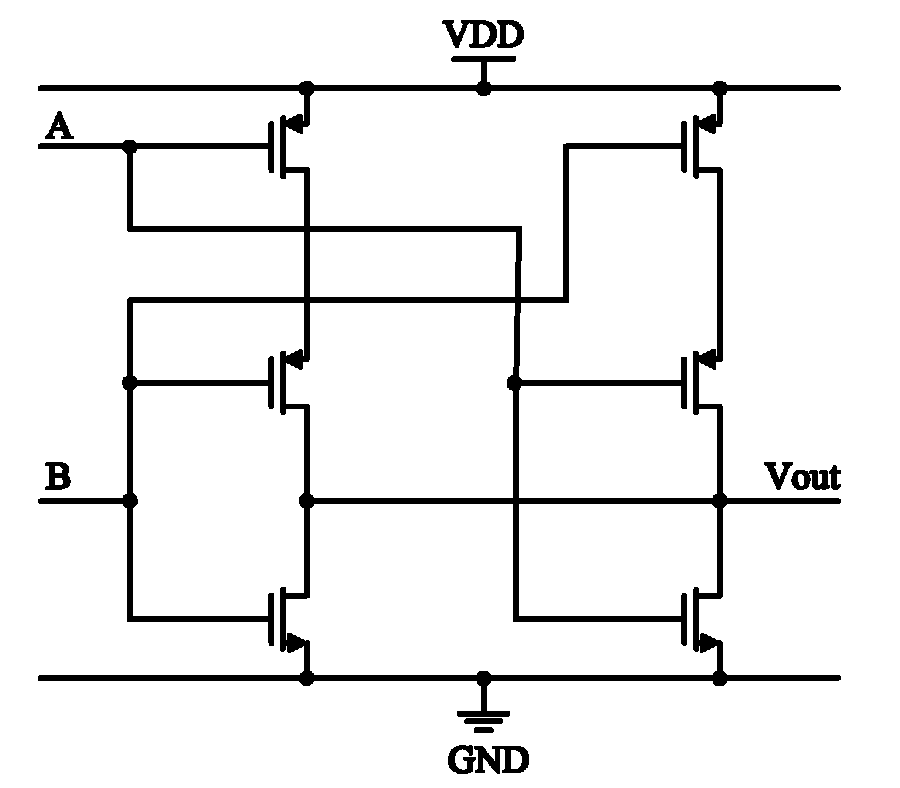

Precharge type phase-frequency detector

InactiveCN101841328AImprove anti-interference abilityEliminate output level deviationPulse automatic controlPhysicsThird phase

The invention discloses a precharge type phase-frequency detector, which comprises a precharge type phase-frequency detection circuit connected with a high resistance elimination circuit. The high resistance elimination circuit consists of a first phase inverter, a second phase inverter, a third phase inverter, a first P-type MOS tube, a second P-type MOS tube, a first N-type MOS tube, a second N-type MOS tube and a third N-type MOS tube which are connected. On the basis of the common precharge type phase-frequency detector, the high resistance elimination circuit is arranged, so on the one hand, high resistance nodes are eliminated, the output node clock of the circuit is connected to a power supply or earthed, the output node level is always definite level at any time and the antijamming capability of the circuit is greatly improved, on the other hand, the output level deviation caused by current competition is eliminated in the process that input signals are changed from high to low, and the output level is restored into standard level.

Owner:XI AN JIAOTONG UNIV

Organic light emitting display device and method for driving the same

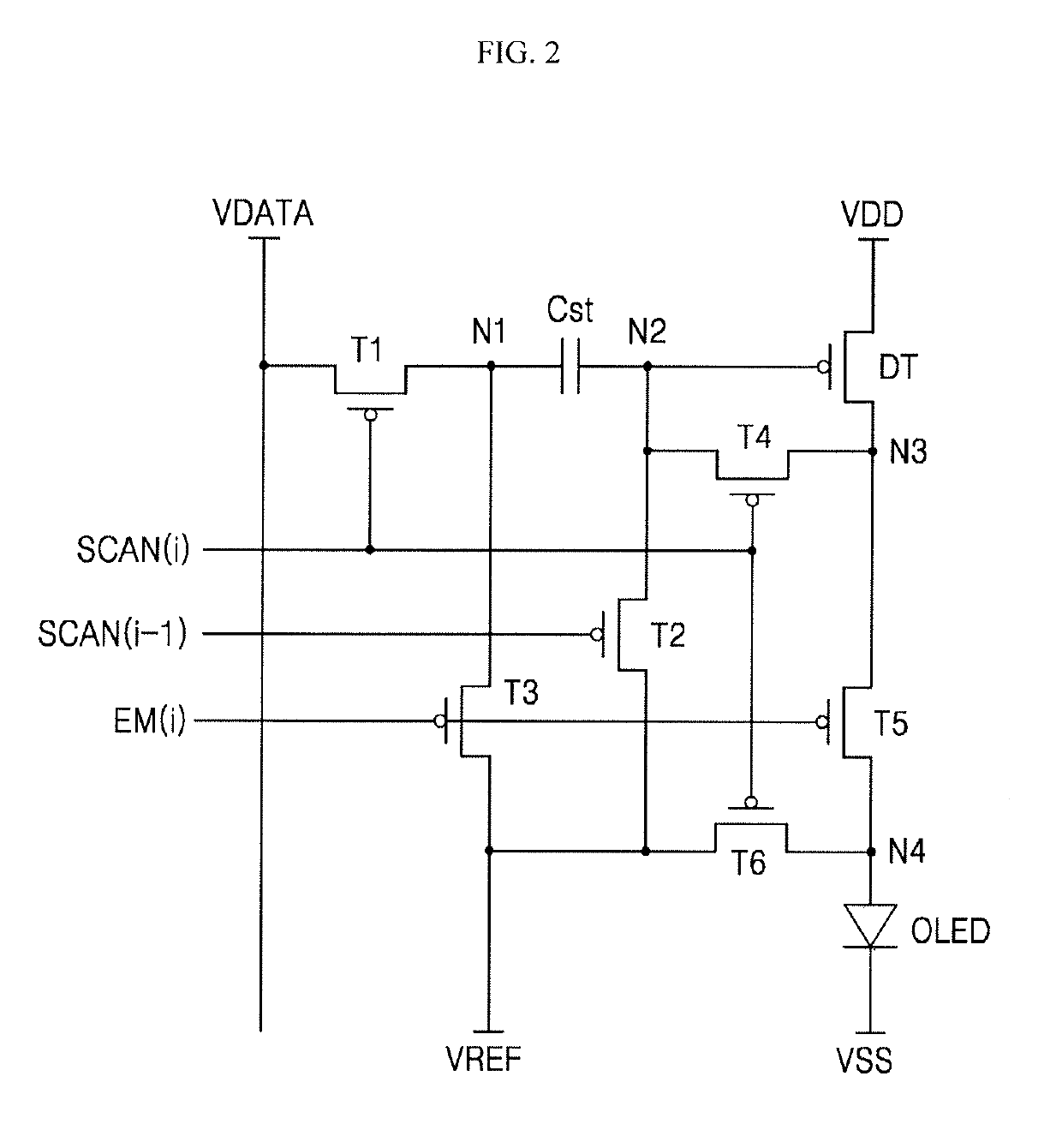

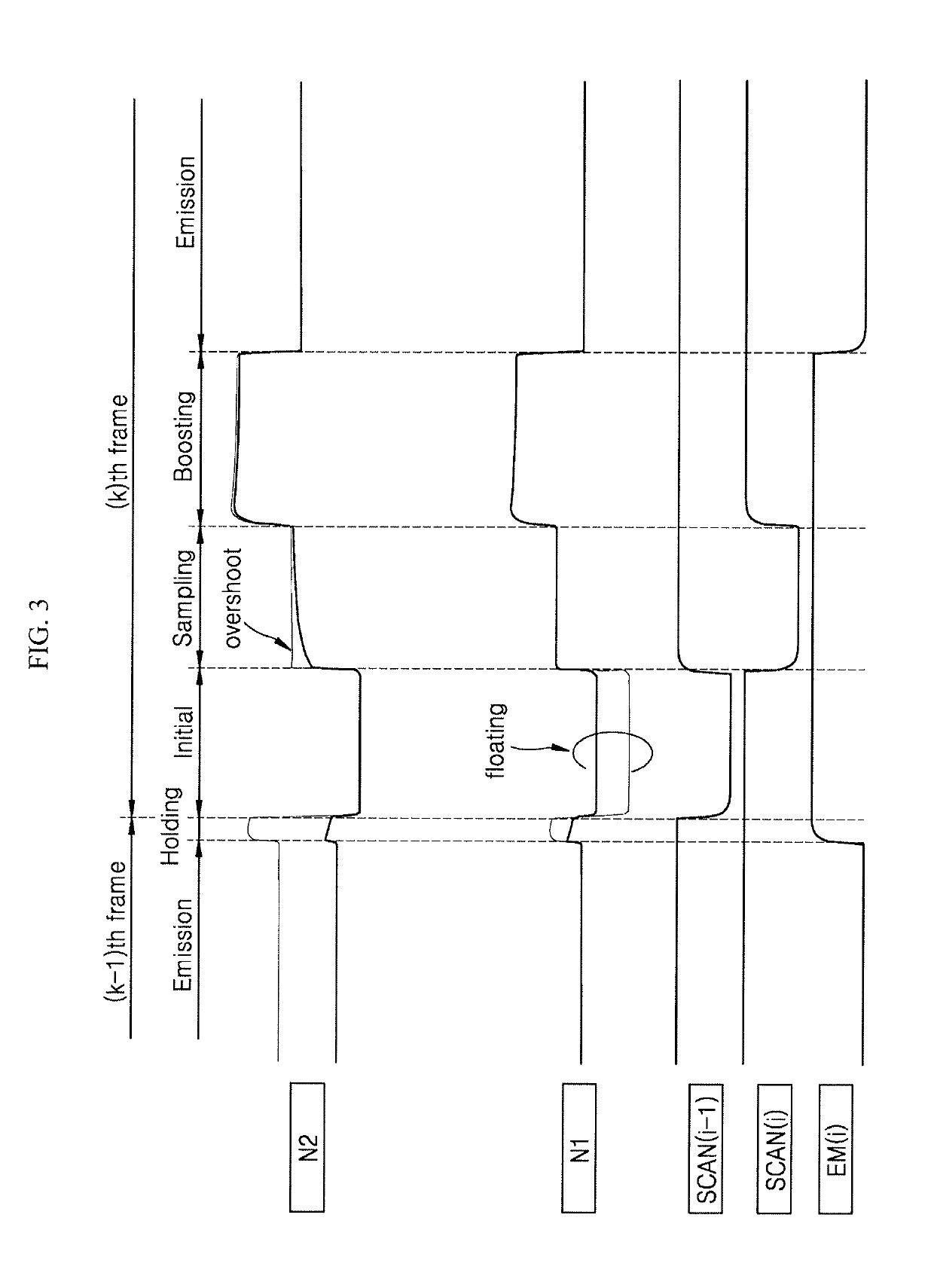

ActiveUS20190096336A1Suppress rippleRemove luminance deviationStatic indicating devicesSolid-state devicesScan lineDisplay device

An organic light-emitting display device can include an organic light-emitting element; a driving transistor connected in series with the organic light-emitting element, the driving transistor and the organic light-emitting element being between a first driving power supply line for supplying a first driving voltage and a second driving power supply line for supplying a second driving voltage lower than first driving voltage; a first transistor configured to turn on based on an i-th scan signal and supply a data voltage to a first node, where i is a natural number greater than or equal to 2 and less than or equal to N, and N is a number of scan-lines; a capacitor between the first node and a gate electrode of the driving transistor, the capacitor is configured to supply a turn-on signal of the driving transistor to the gate electrode of the driving transistor based on the data voltage; and a second transistor configured to turn on based on a (i−1)-th scan signal and supply a first reference voltage to a second node, in which the second node is disposed between the driving transistor and the capacitor, and the capacitor is between the first and second nodes.

Owner:LG DISPLAY CO LTD

Image-forming apparatus and optical scanner

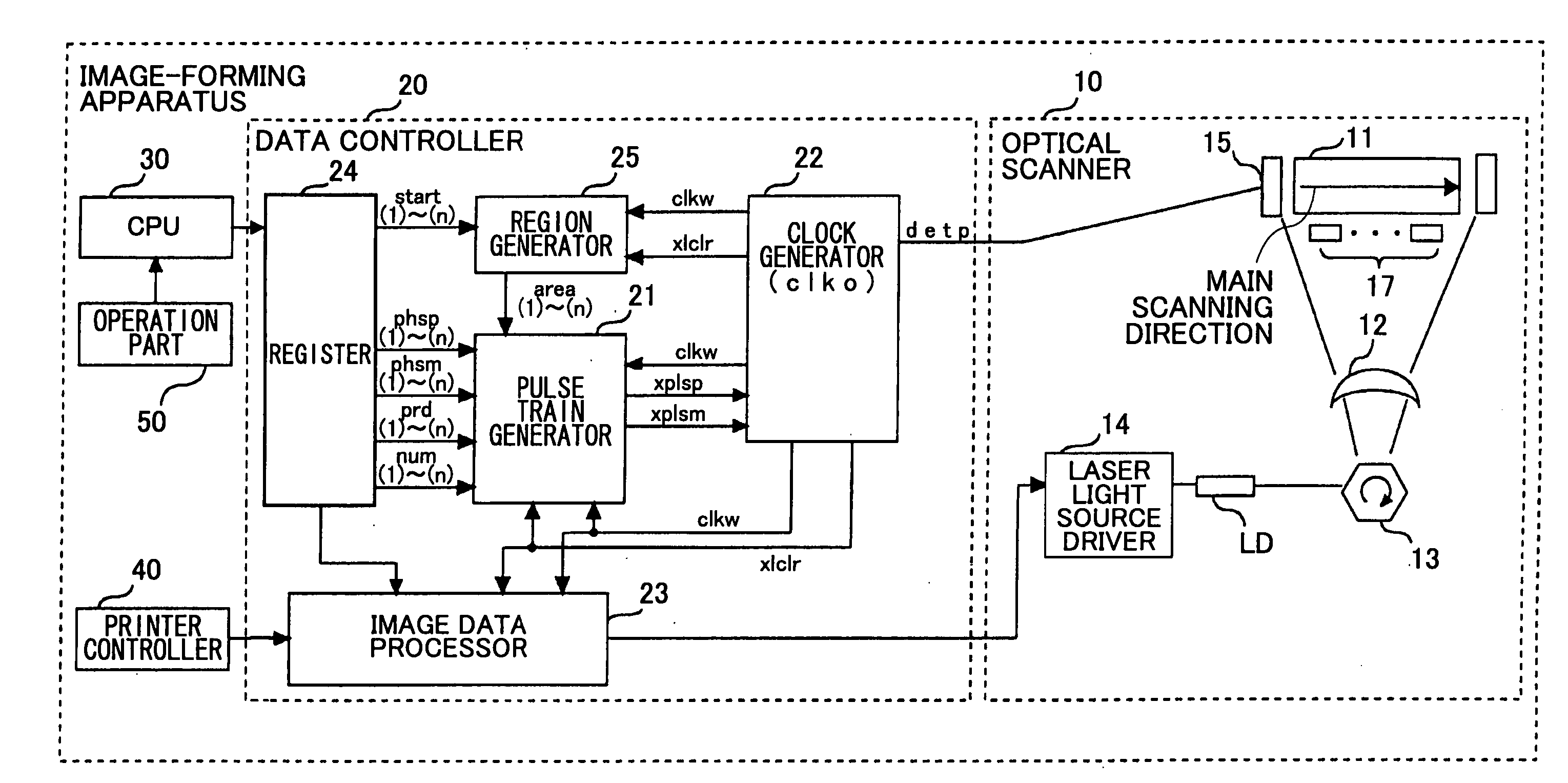

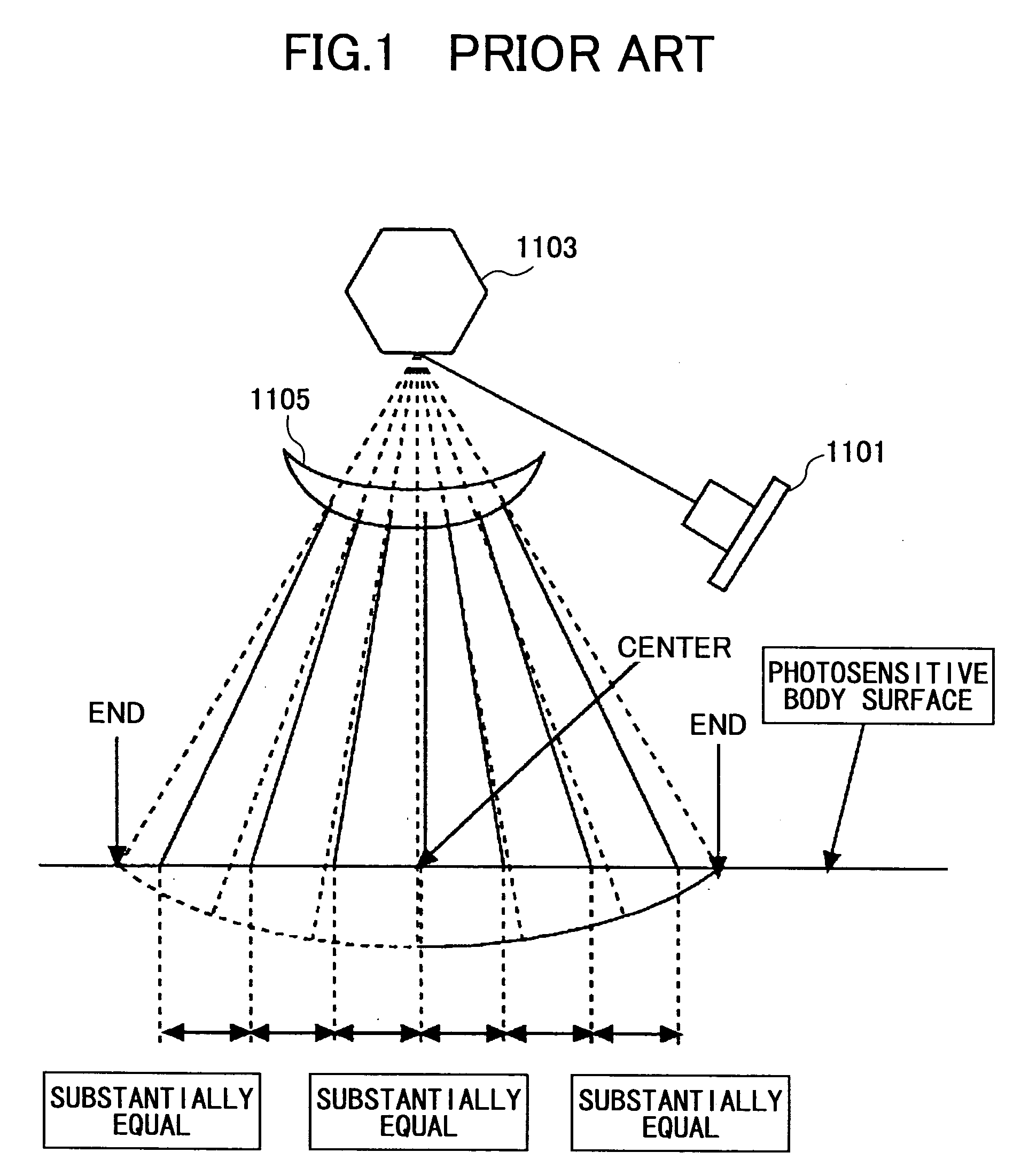

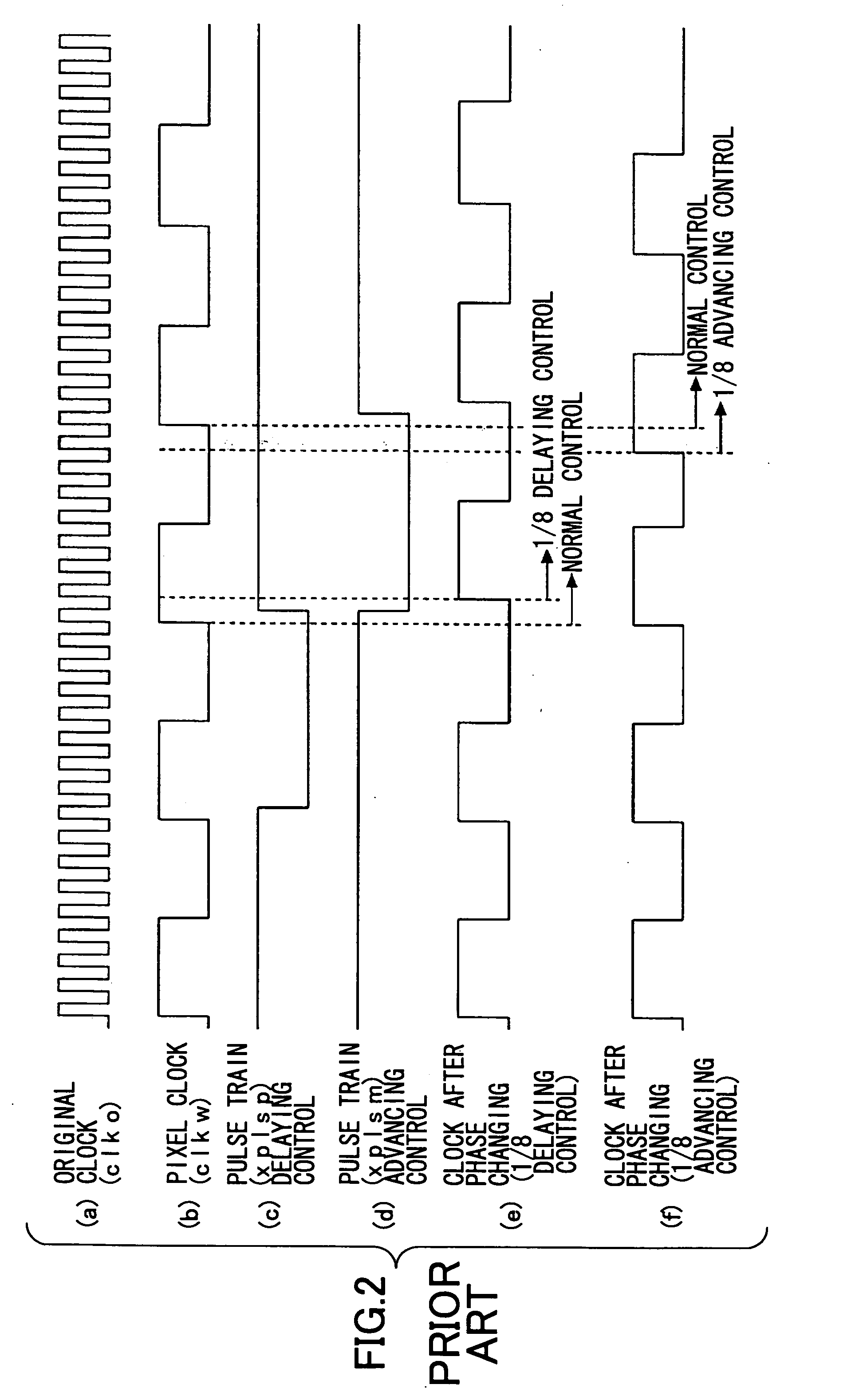

ActiveUS20050036028A1Eliminate color misregistrationEliminate magnification deviationElectrographic processes using charge patternPrintingLatent imageOptical scanners

An image-forming apparatus is disclosed that includes at least one imaging optical system forming an electrostatic latent image on the scanning surface of a medium moving in a sub scanning direction by scanning the scanning surface in a main scanning direction by periodically deflecting a laser beam with a rotary deflector, a pixel clock generation part generating a pixel clock signal for controlling the emission timing of the laser beam and changing the phase of the pixel clock signal, a region setting part setting the length of each of multiple regions based on image writing magnifications in a line in the main scanning direction, the regions being formed by dividing part of the scanning surface corresponding to the line in the main scanning direction, and a phase control part controlling the changing of the phase of the pixel clock signal region by region based on the image writing magnifications.

Owner:RICOH KK

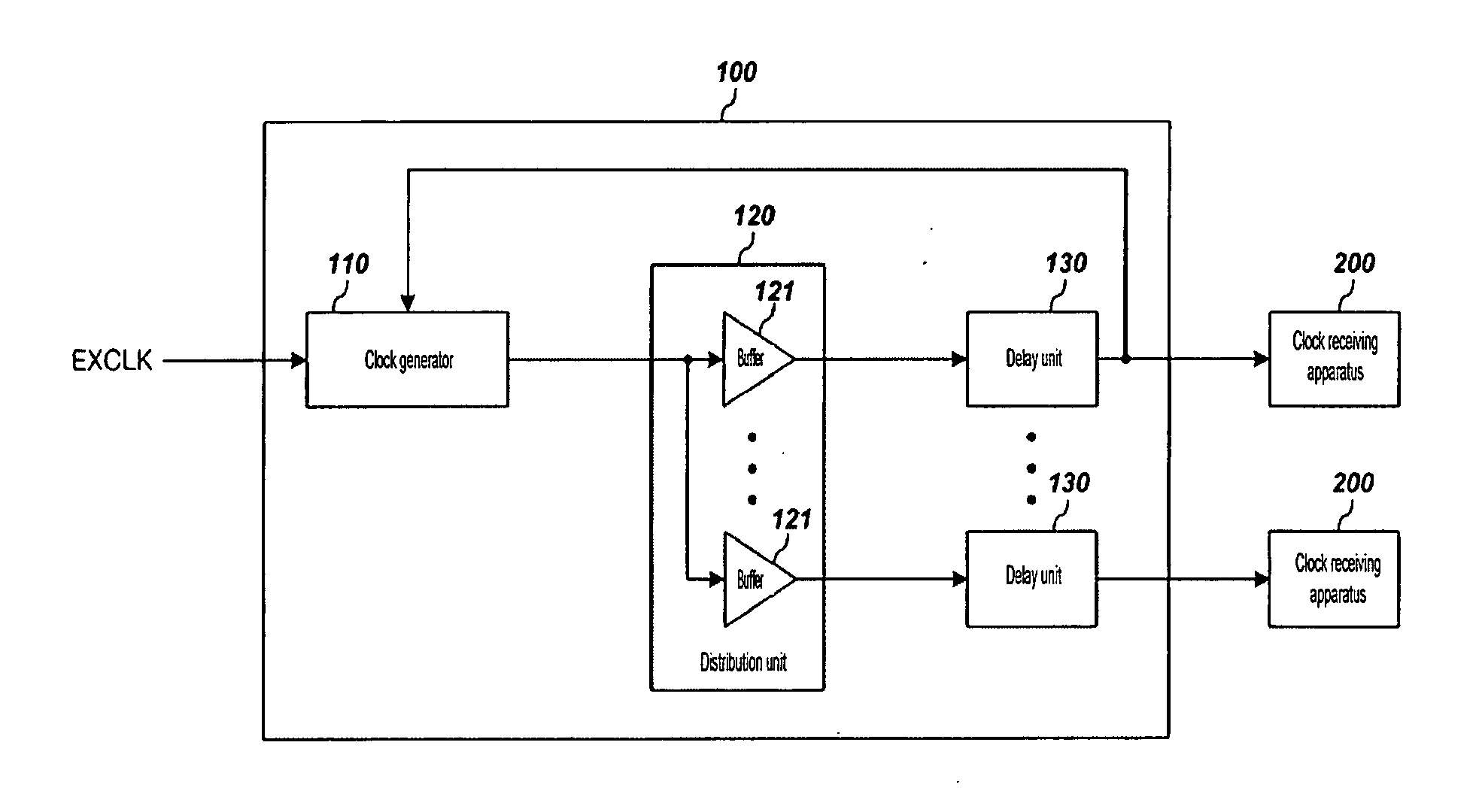

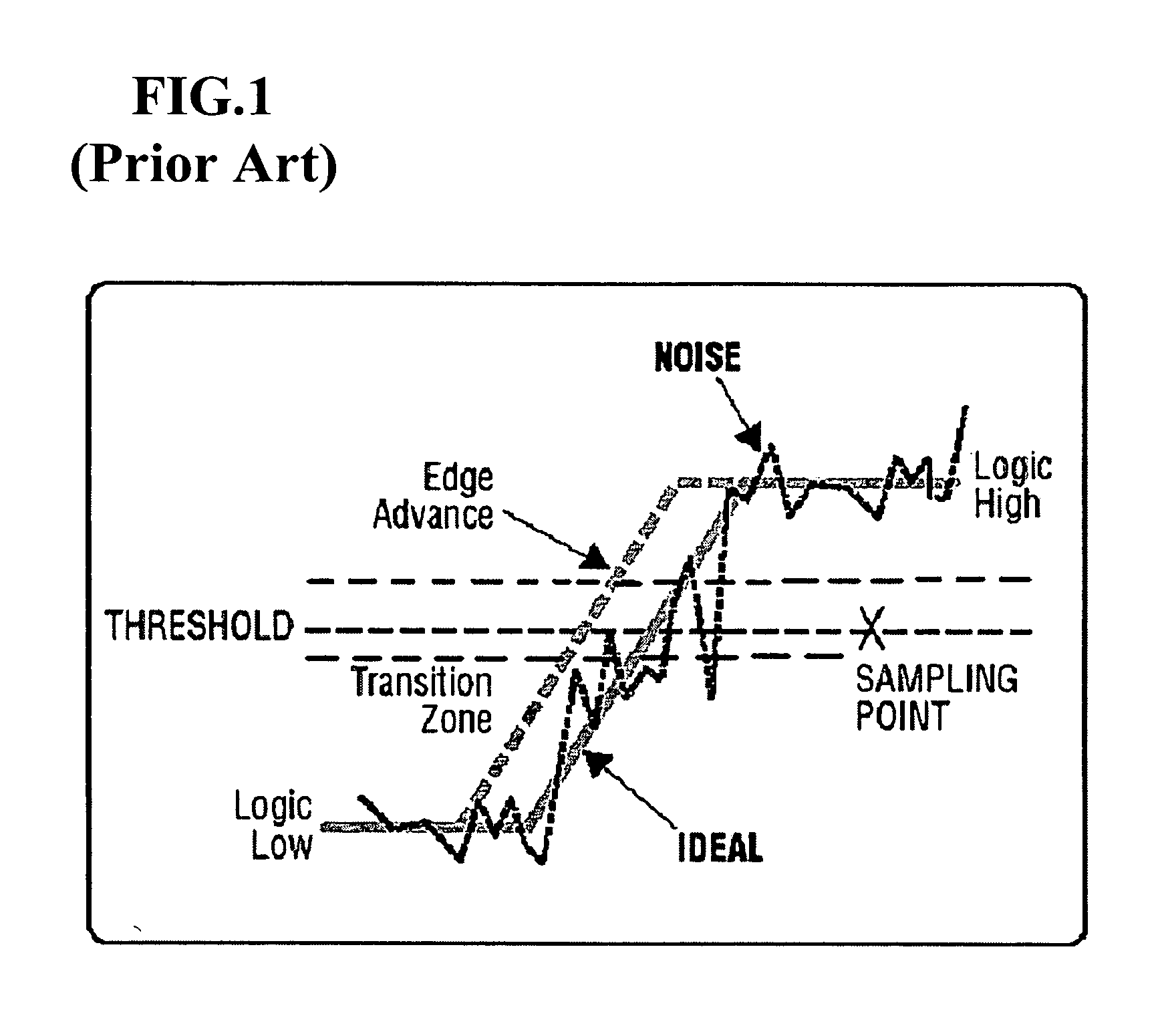

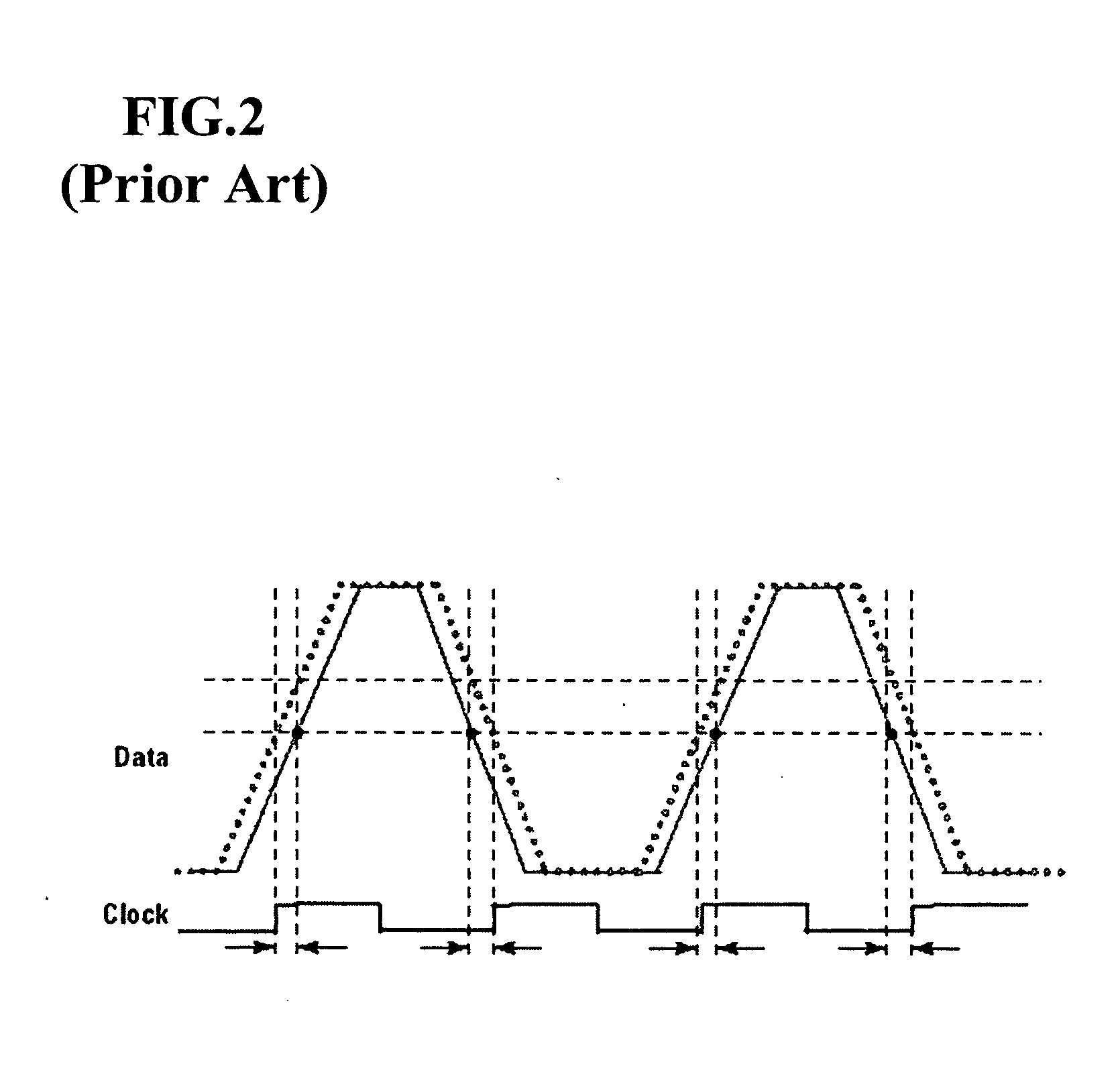

Clock signal generating apparatus and clock signal receiving apparatus

InactiveUS20070152727A1Cancel noiseEliminate deviationElectric pulse generatorPulse descriminationEngineeringPhase control

A clock signal generating apparatus including a clock generator, a distributor, a plurality of delay units, and generates a clock signal for synchronized driving of a system having a plurality of clock receiving apparatuses. The clock signal generator generates a clock signal for driving the system by using an external clock signal and a feedback clock signal. The distributor distributes the clock signal output to generate a plurality of distributed clock signals and outputs the plurality of distributed clock signals to the plurality of clock receiving apparatuses through a plurality of signal transmission paths. The plurality of delay units are respectively located on the plurality of signal transmission paths, control phases of the plurality of distributed clock signals to generate a plurality of phase-controlled clock signals, and transmit the plurality of phase-controlled clock signals to the plurality of clock receiving apparatuses.

Owner:SAMSUNG ELECTRONICS CO LTD +4

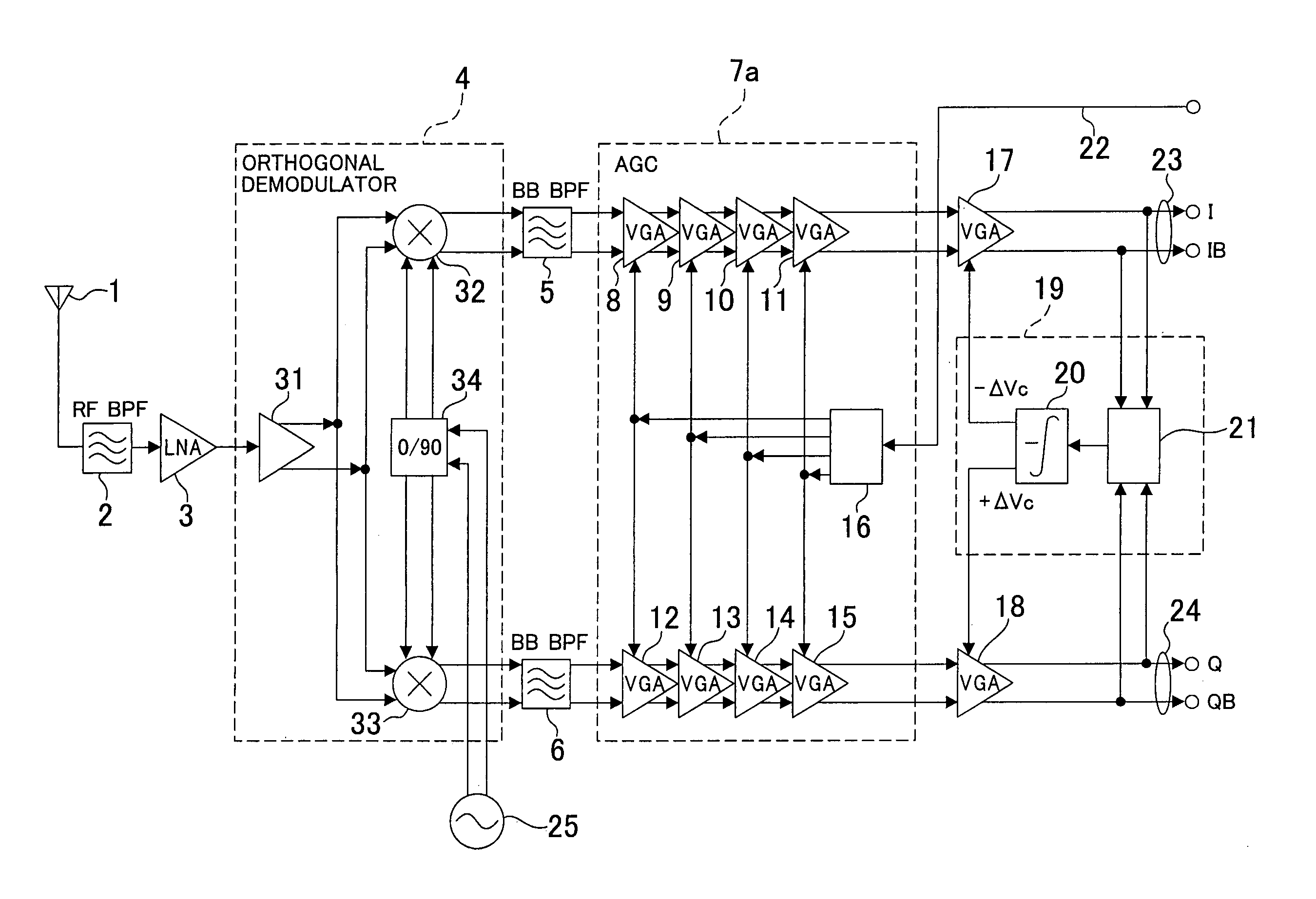

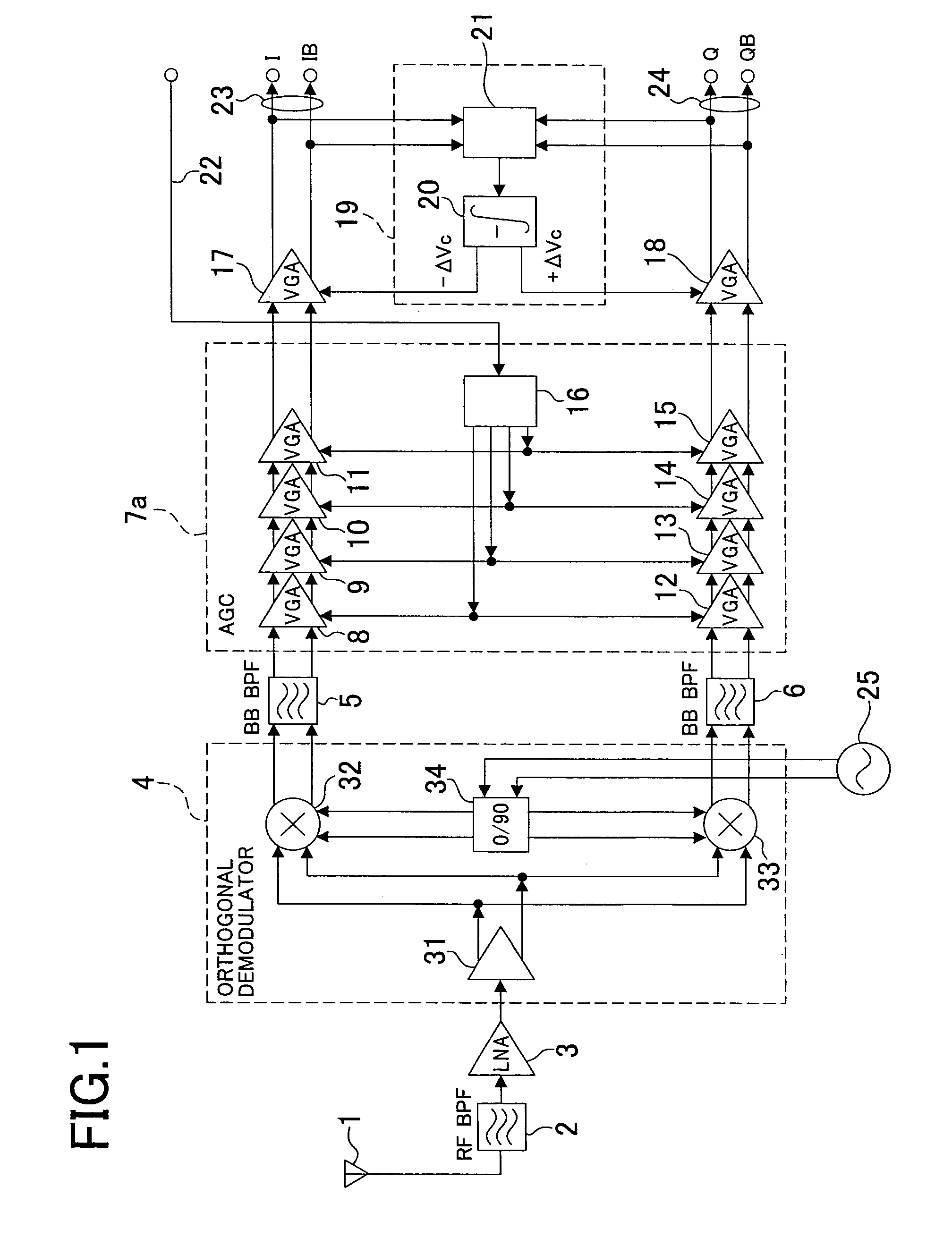

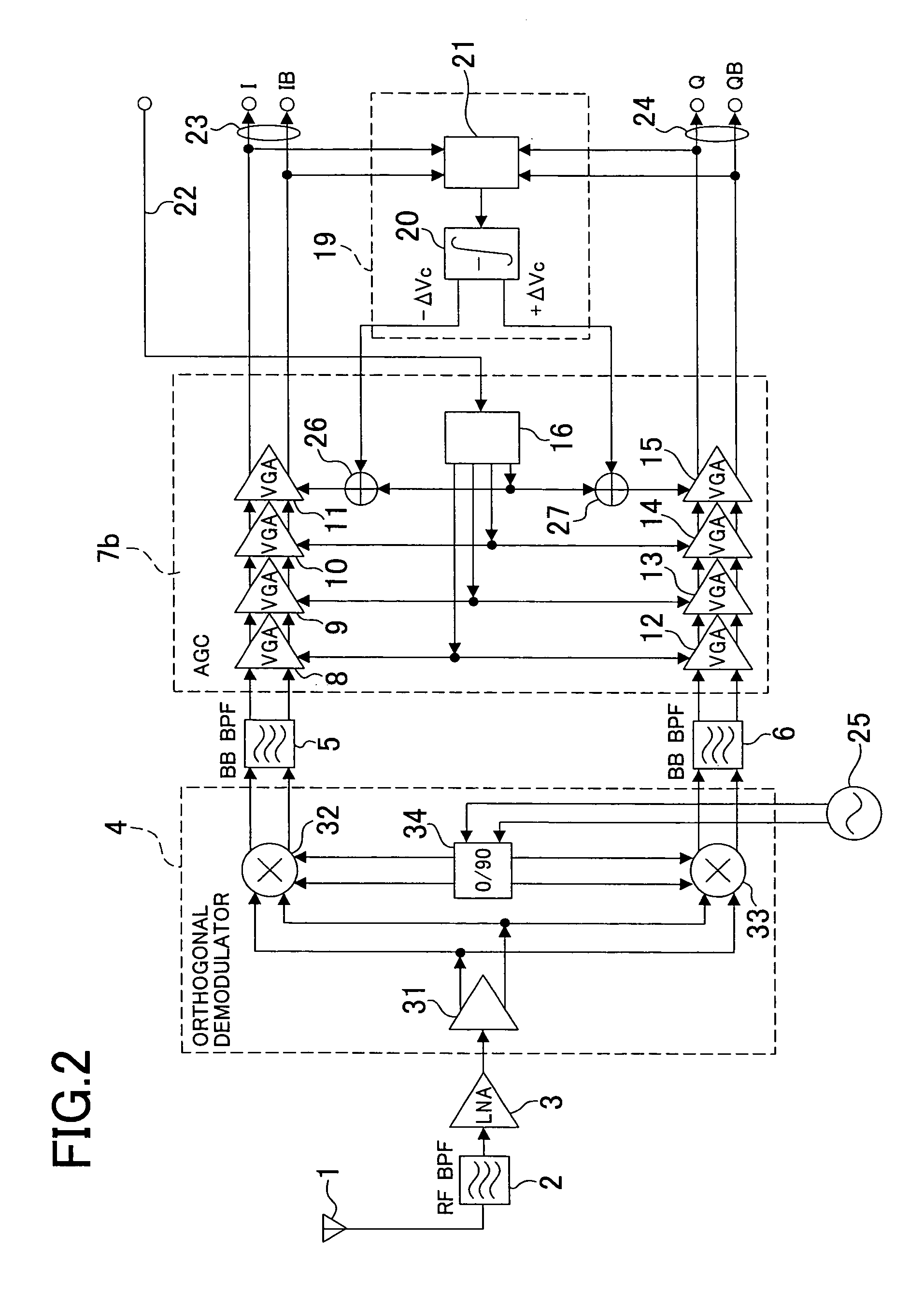

Amplitude deviation correction circuit

InactiveUS7206360B2Correct amplitude deviationCorrect deviationGain controlDc level restoring means or bias distort correctionAudio power amplifierVariable-gain amplifier

A novel amplitude deviation correction circuit which corrects an amplitude deviation between an I signal and a Q signal is disclosed. An average amplitude deviation between an I signal amplified by a variable gain amplifier and a Q signal amplified by another variable gain amplifier is detected by an amplitude comparison circuit, and +1 volt or −1 volt is outputted in response to a result of the detection. An integration circuit integrates the output of the amplitude comparison circuit and controls the gains of the variable gain amplifiers in response to a result of the integration.

Owner:NEC CORP

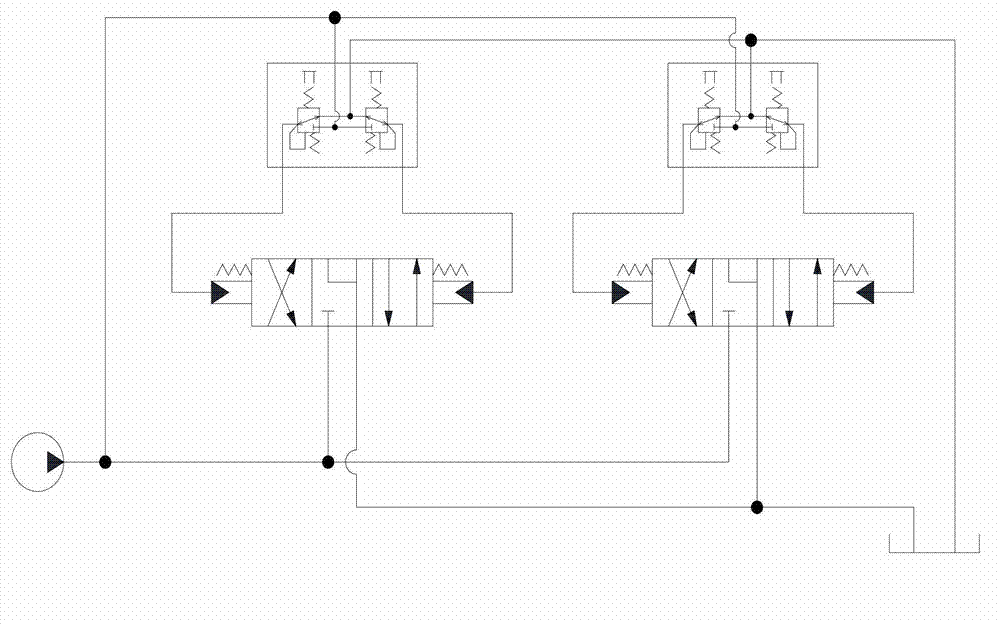

Running control loop and hydraulic excavator

InactiveCN102888875AReduce labor intensityEliminate deviationSoil-shifting machines/dredgersControl valvesControl theory

The invention discloses a running control loop and a hydraulic excavator. The running control loop comprises a first control oil way, a second control oil way and a third control oil way, wherein the first control oil way comprises a first pilot valve and a first running control valve which are connected with each other; the second control oil way comprises a second pilot valve and a second running control valve which are connected with each other; the third control oil way comprises a third pilot valve; and the third pilot valve is respectively connected with the first running control valve and the second running control valve. By the running control loop, a problem that the hydraulic excavator easily deflects when moving forwards or backwards is avoided, the operation efficiency is improved, and the labor intensity is reduced.

Owner:SANY HEAVY MACHINERY

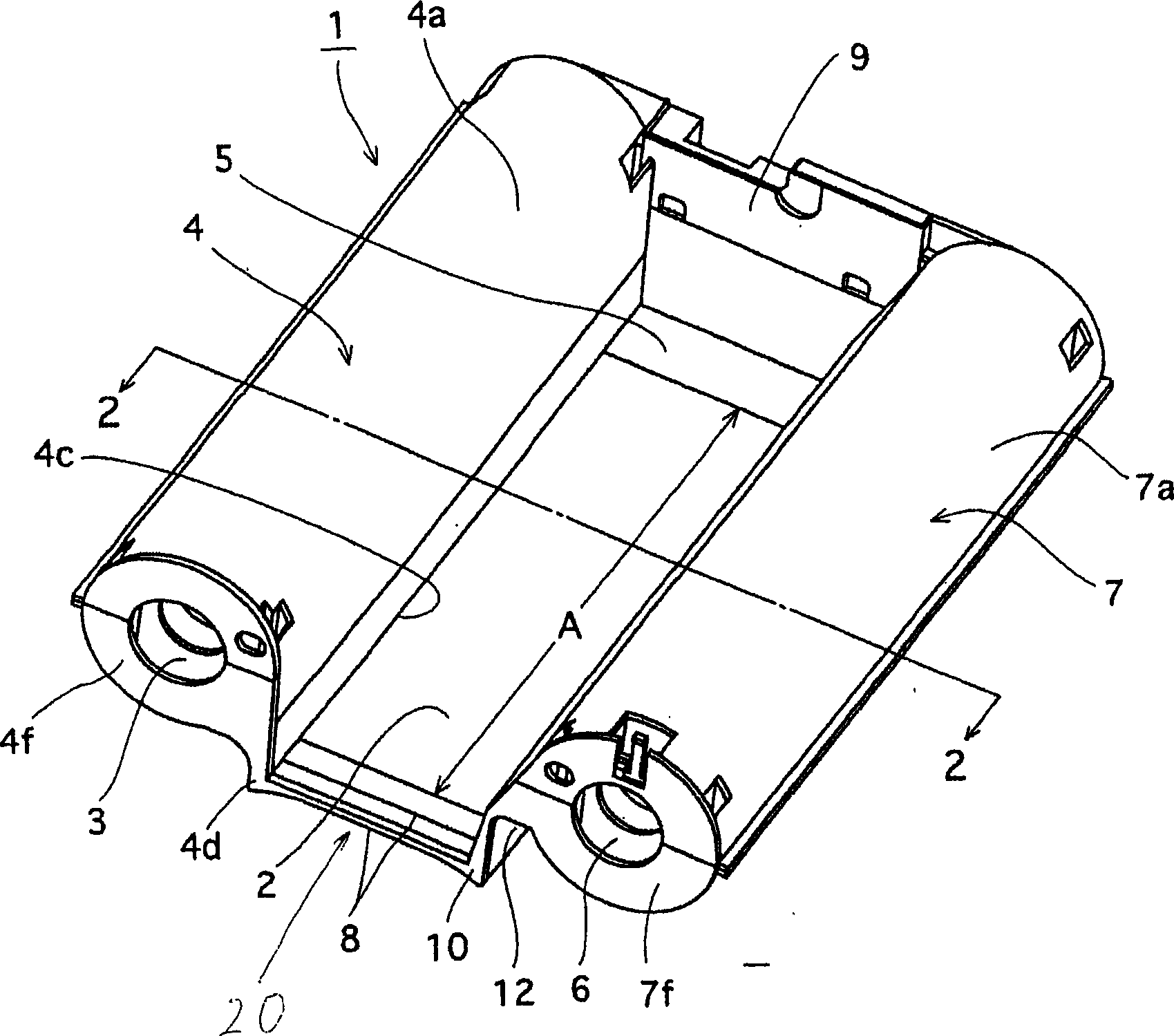

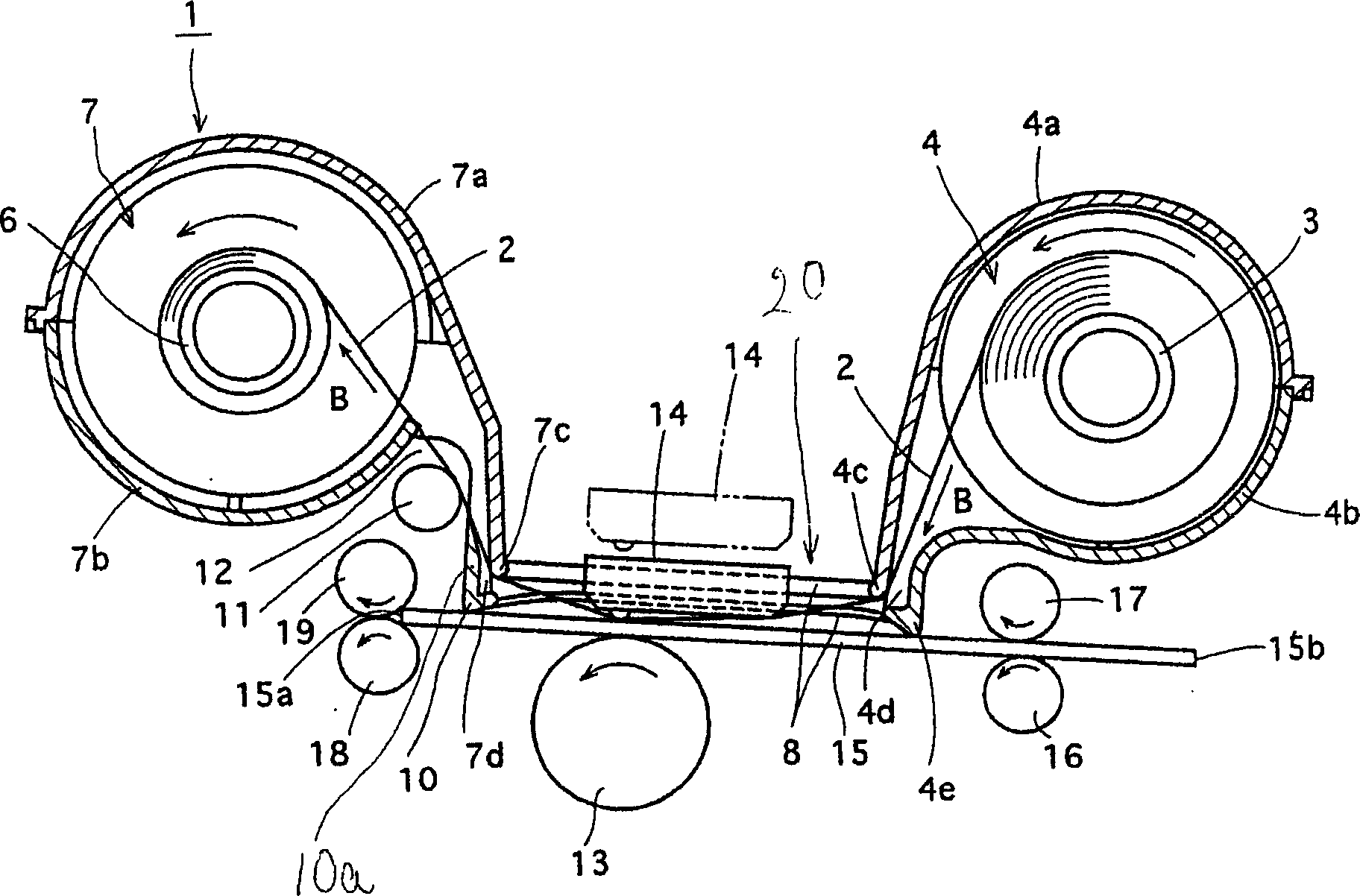

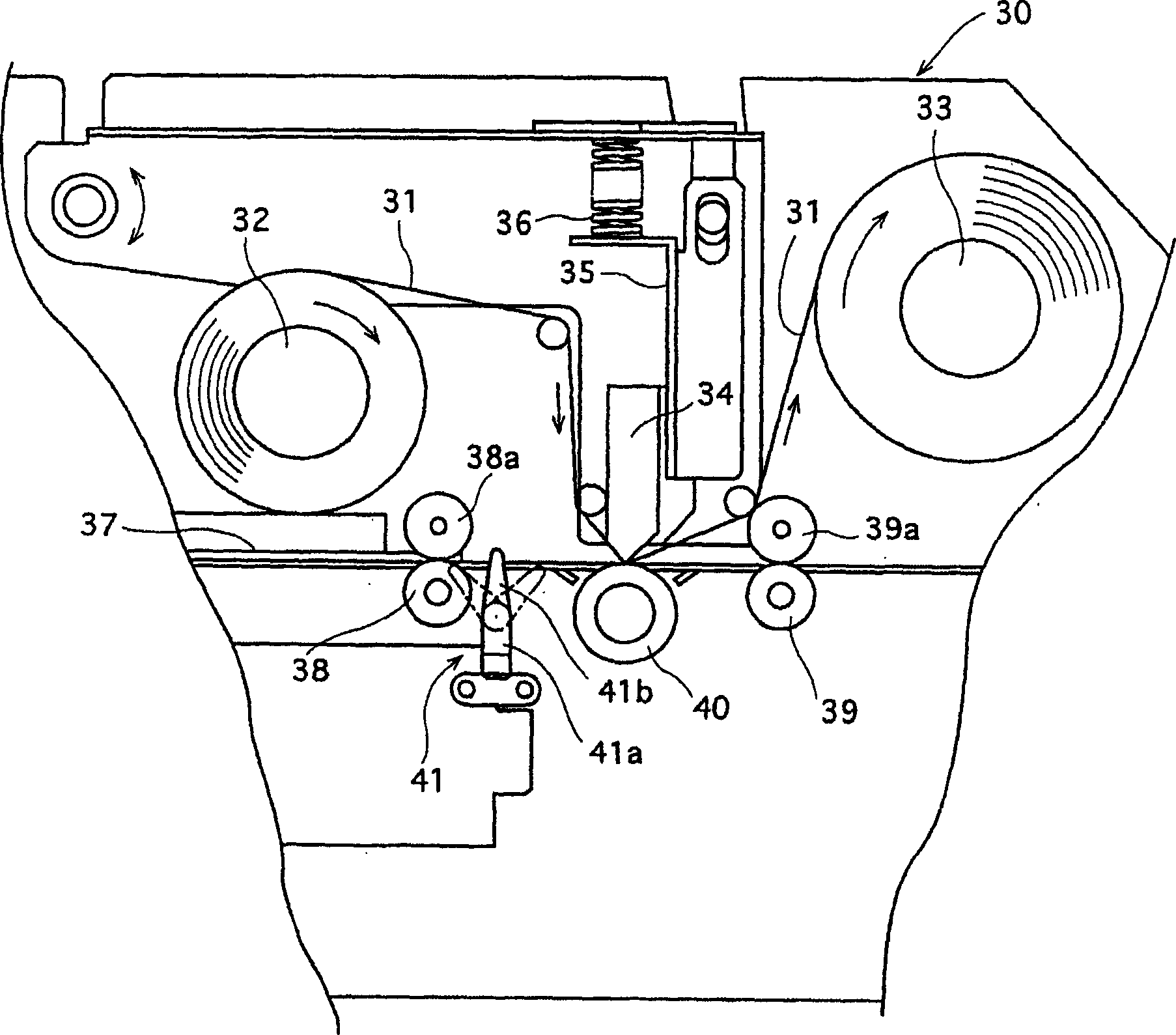

Ink ribbon cassette

InactiveCN1899840AEliminate deviationEliminate conveyance deviationInk ribbon cartridgesPrinting mechanismsPulp and paper industryPaper sheet

The invention provides an ink ribbon cassette which enables a high printing quality by guiding a recording paper during printing by paper guide parts, eliminating a gap of a bite timing to a paper feed roller, and eliminating a shift of conveyance of the recording paper during printing. A ribbon outlet (4d), through which an ink ribbon (2) wound on a feeding reel passes, is provided near a first ribbon-receiving part (4) of an ink ribbon cassette (1) of the invention in a head insertion opening. A ribbon winding opening (7d), through which the ink ribbon (2) drawn through the ribbon outlet (4d) passes to be wound on a take-up reel (6), is provided near a second ribbon-receiving part (7) in the head insertion opening. A first paper guide (10) is provided at the ribbon outlet (7d) and a second paper guide (4e) is provided at the ribbon winding opening (4d) so that a recording paper to be fed is guided by the first and second paper guides (4e,10).

Owner:ALPS ALPINE CO LTD

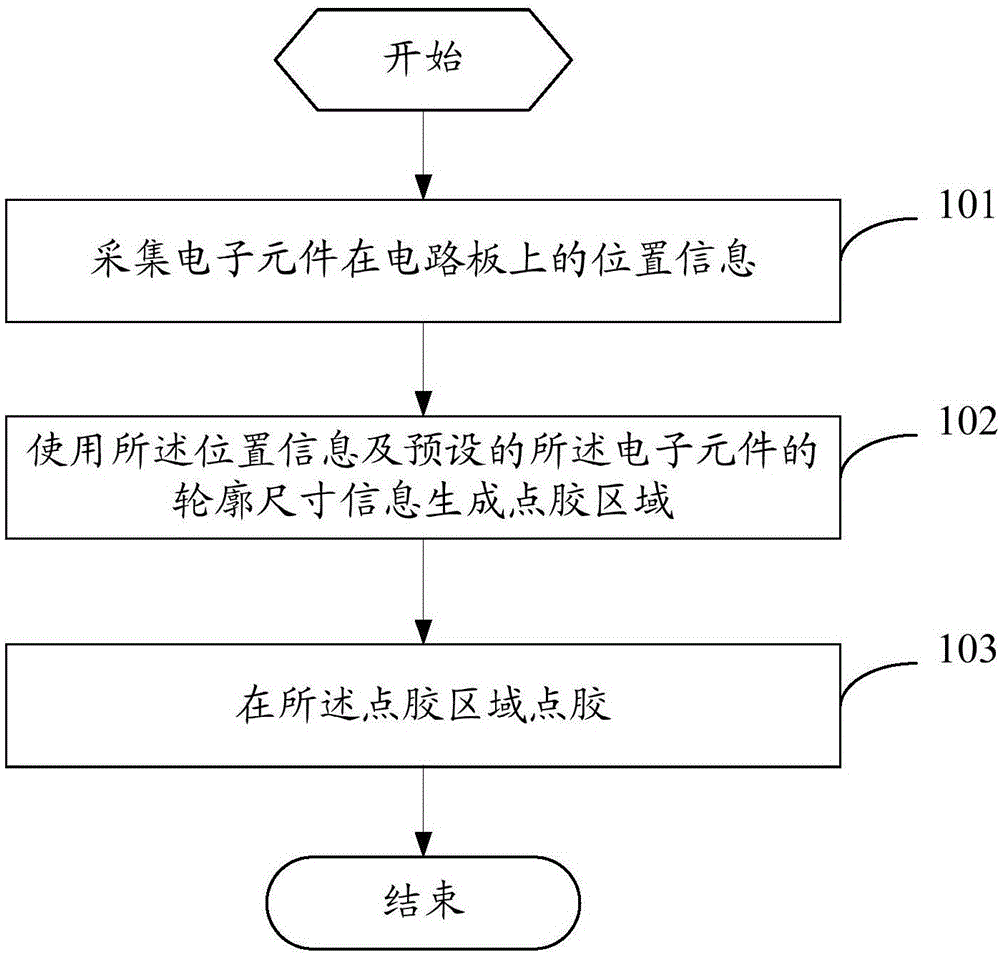

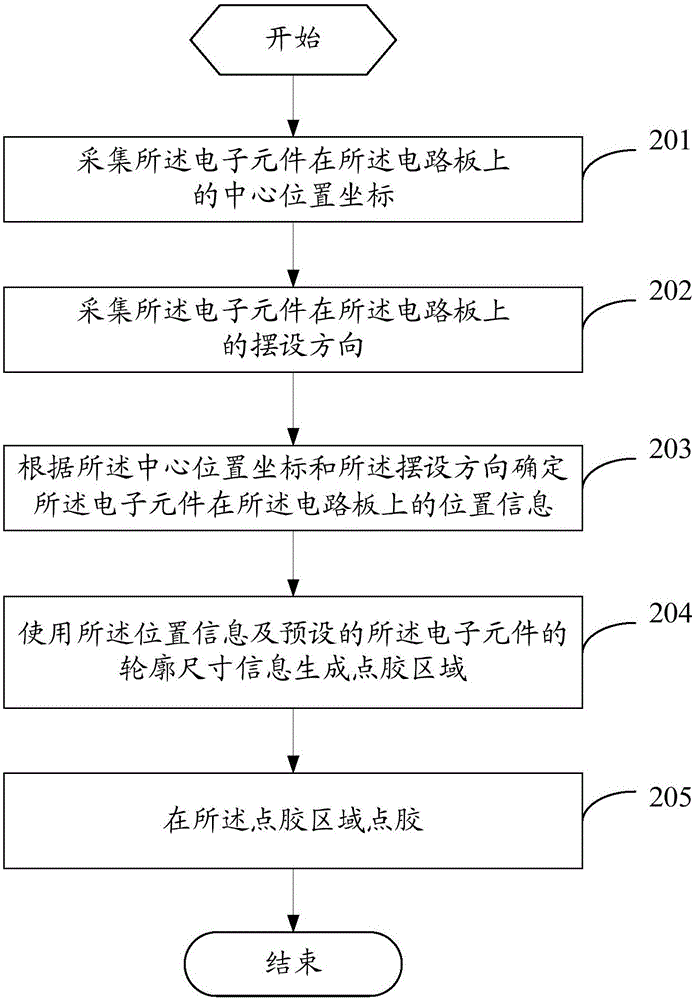

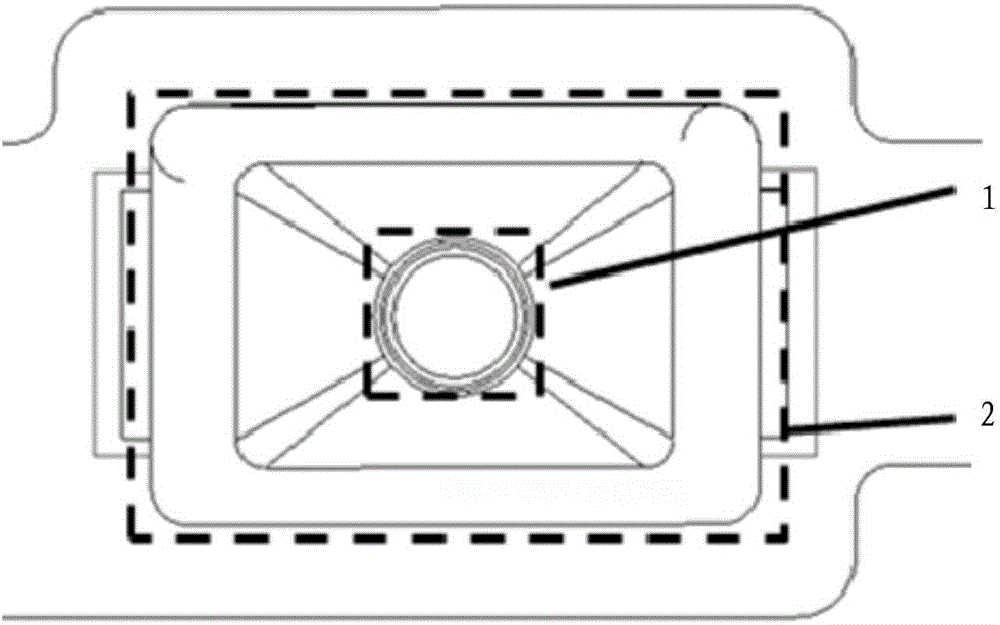

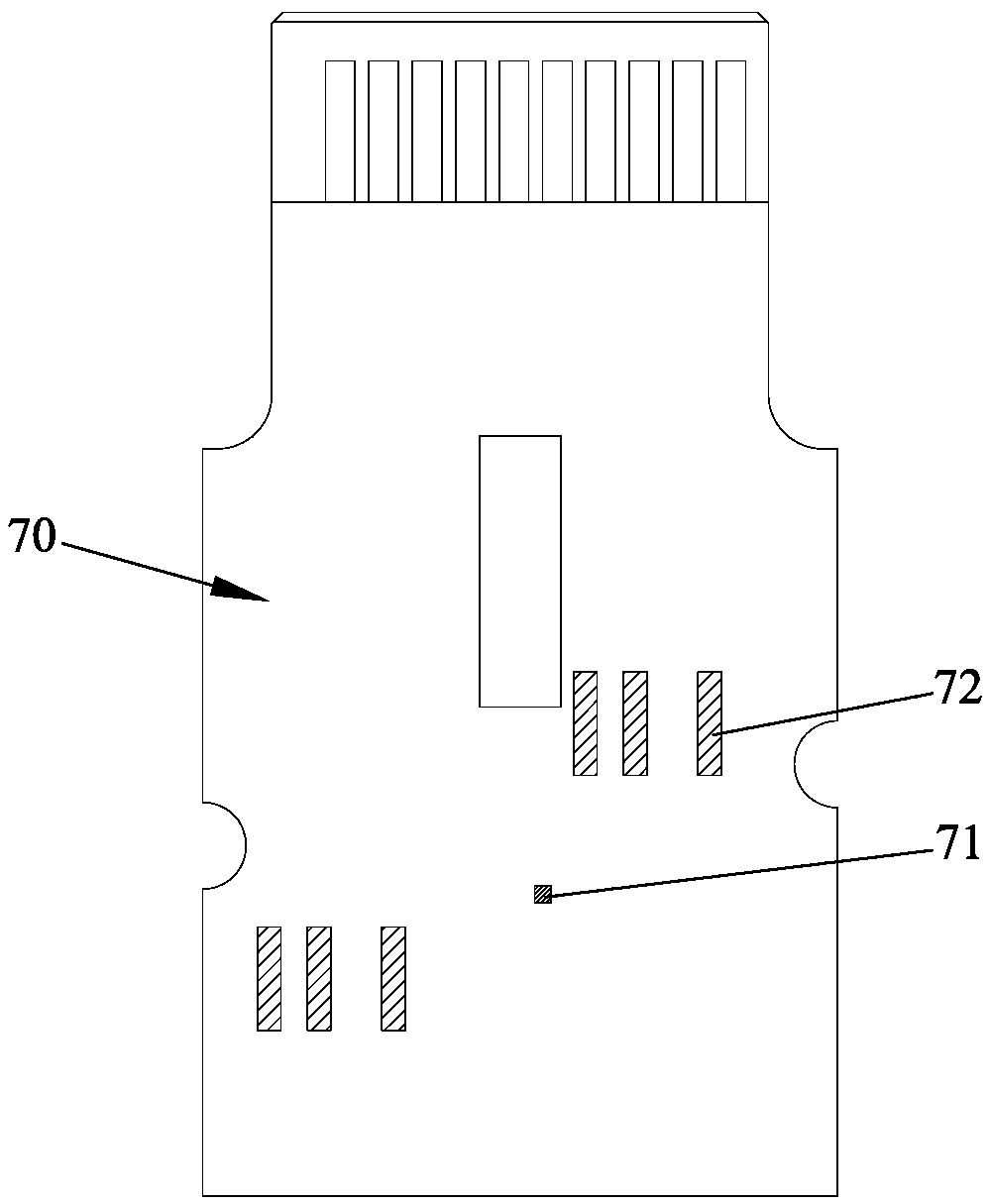

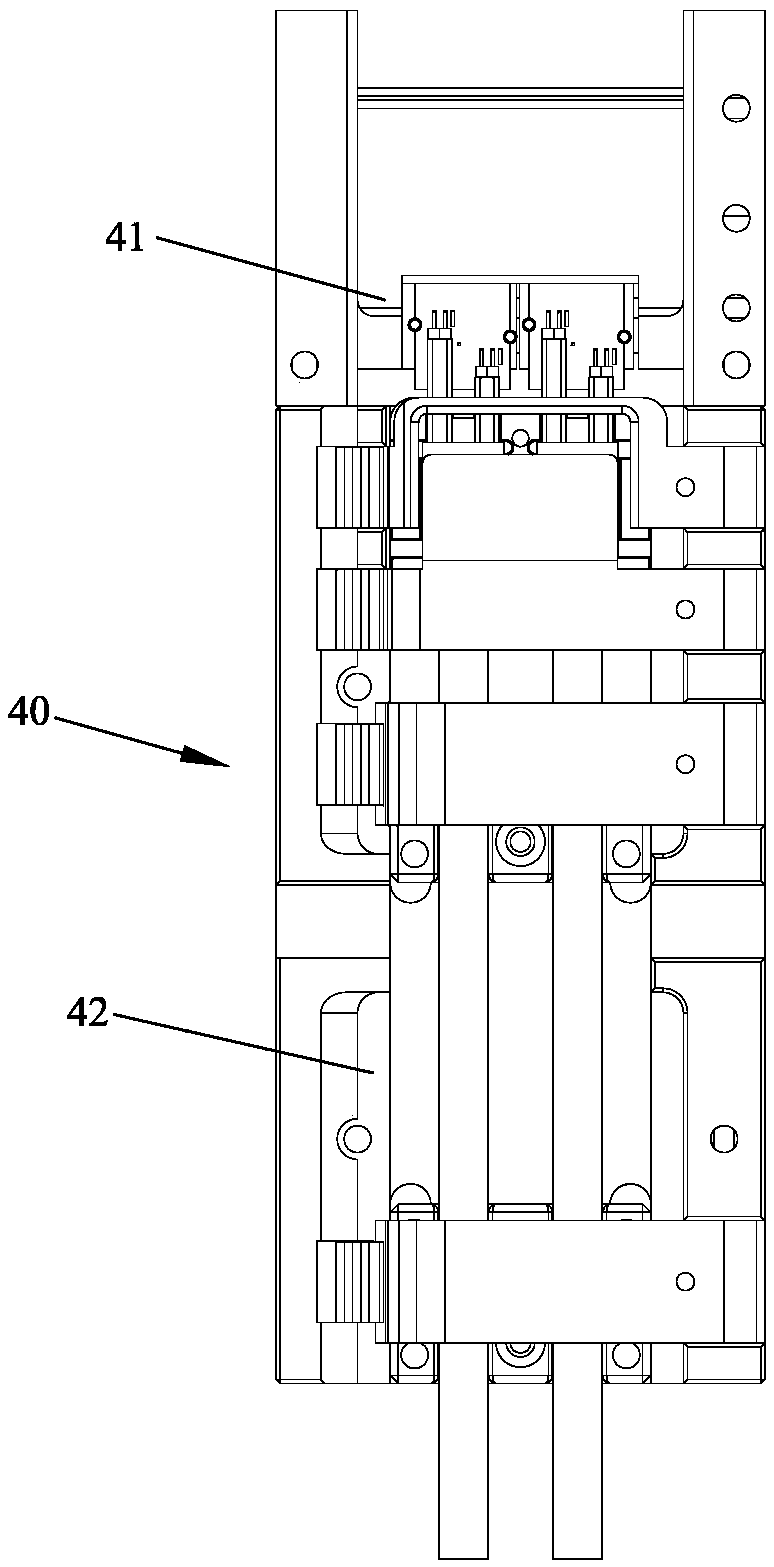

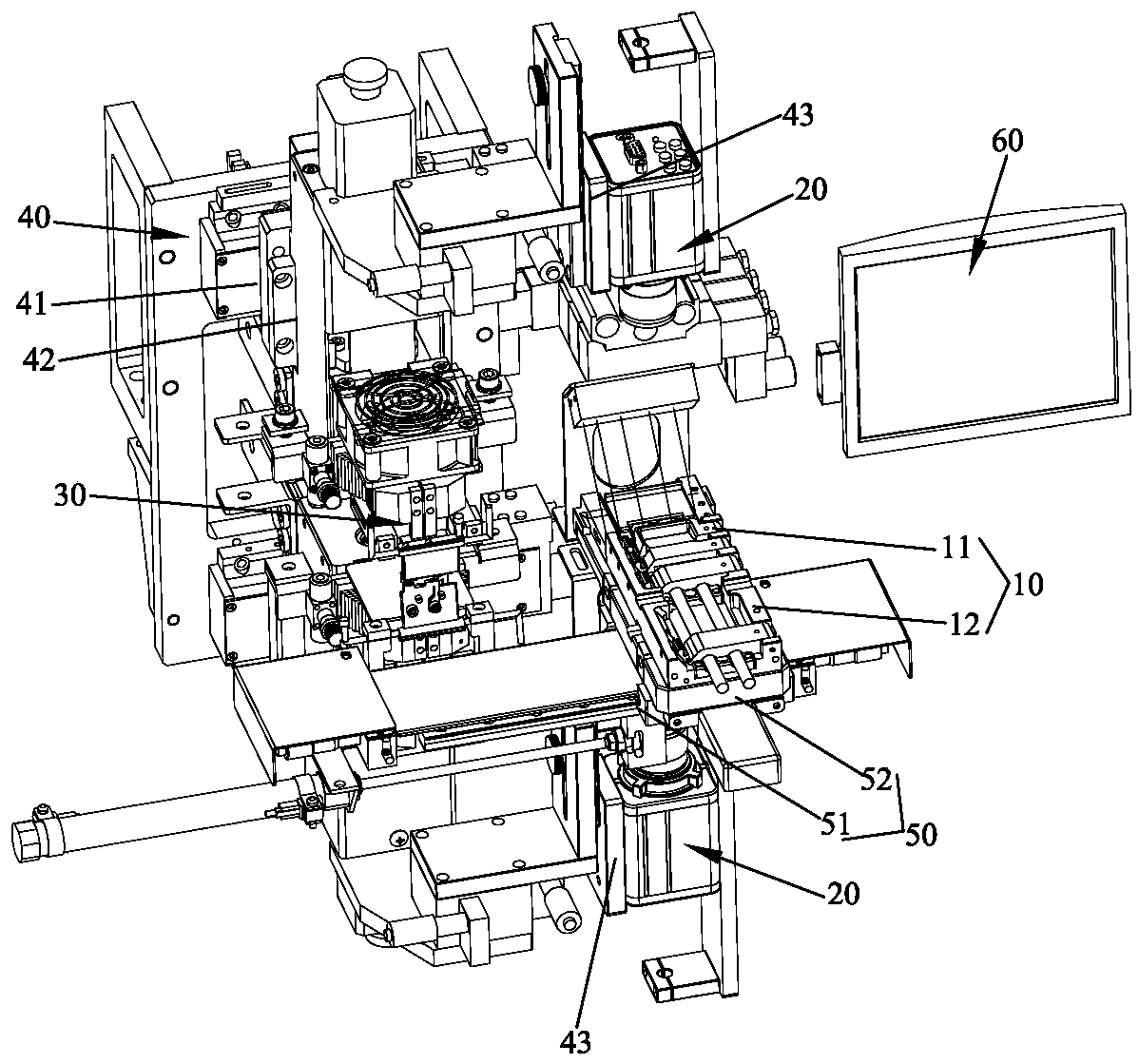

Glue dispensing method and device

Owner:VIVO MOBILE COMM CO LTD

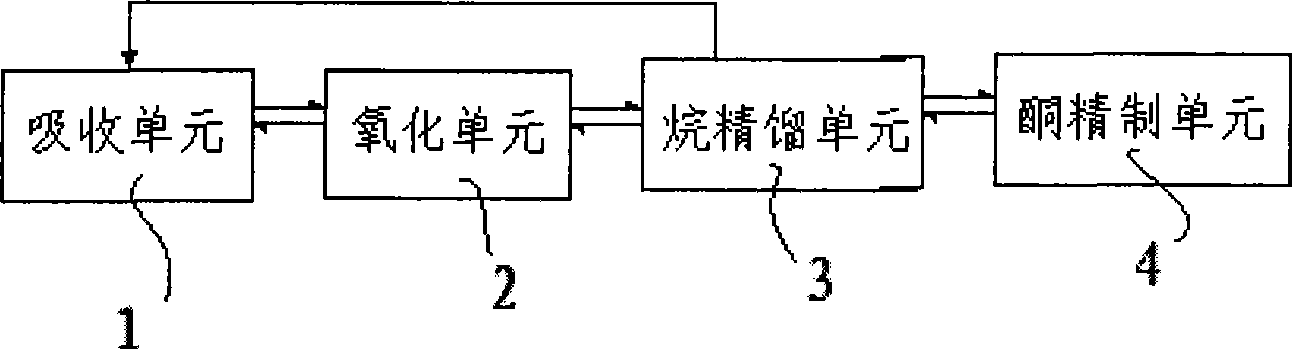

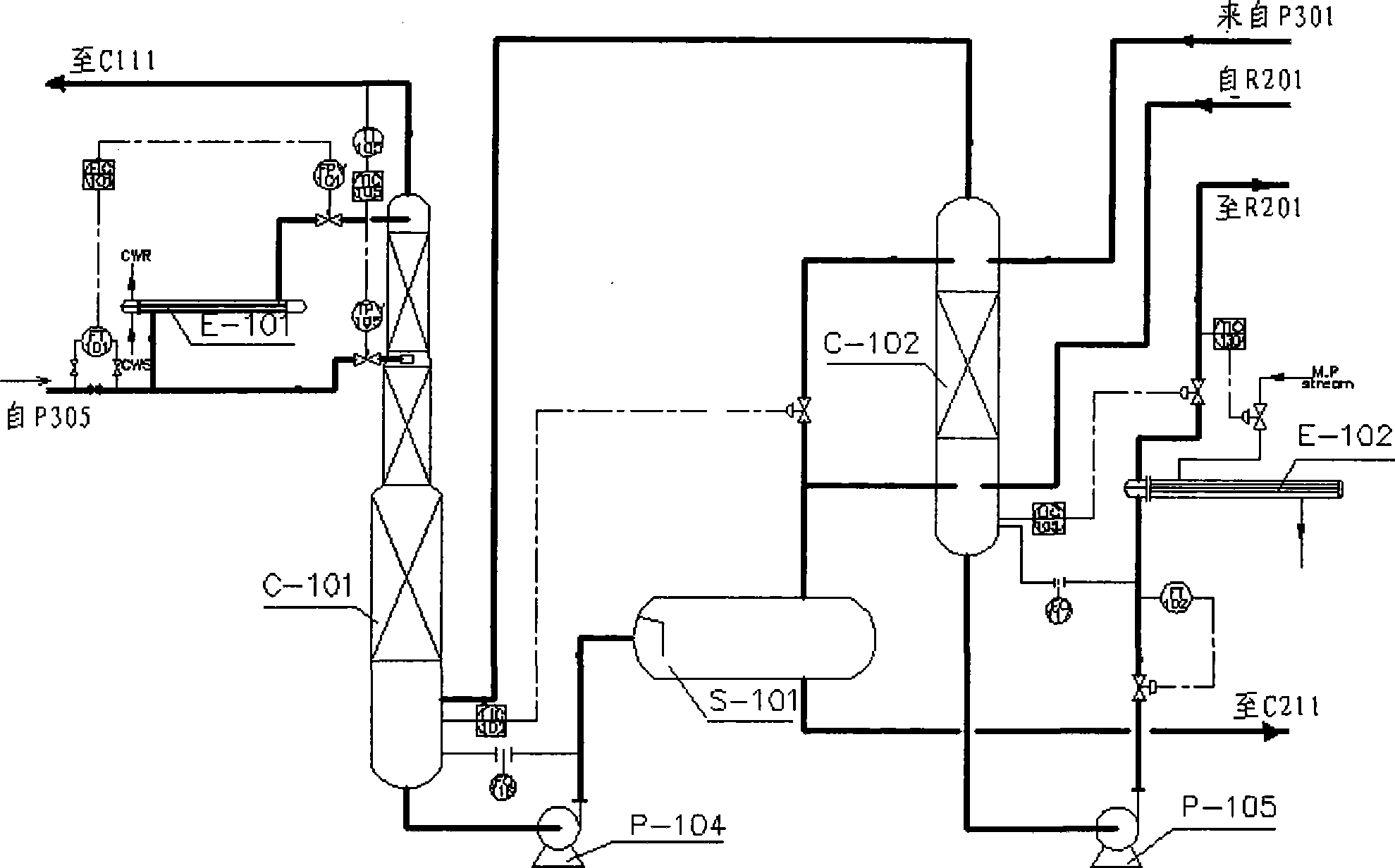

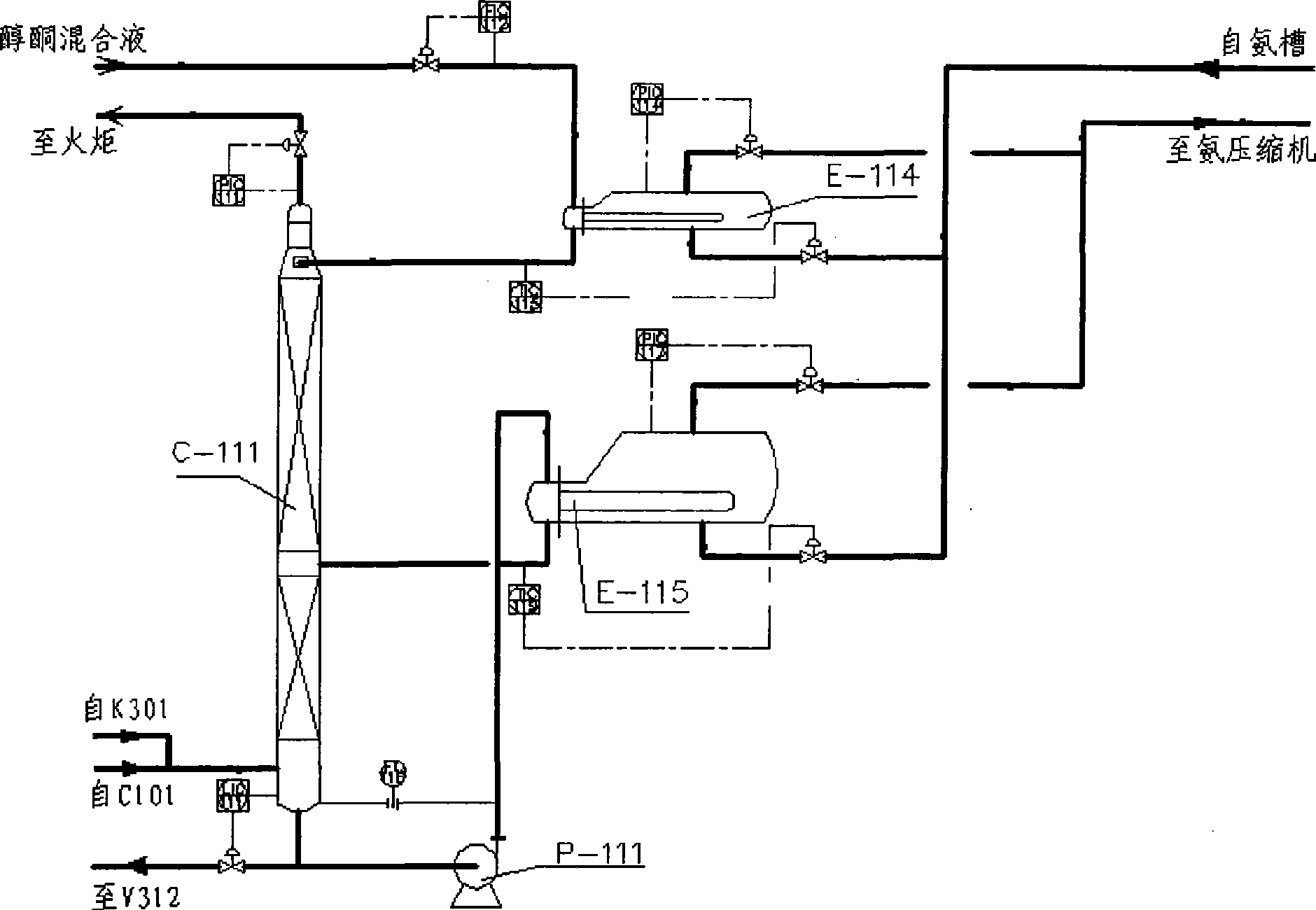

Synthetic real training device for chemical industry operation

InactiveCN101465070AEliminate deviationTroubleshootingCosmonautic condition simulationsSimulatorsChemical industryToxicity

The invention relates to a chemical operation comprehensive practical training device. An absorbing unit 1 is connected with an oxidizing unit 2, the oxidizing unit 2 is connected with an alkane rectifying unit 3, the alkane rectifying unit 3 is connected with an alkone refining unit 4, and the alkane rectifying unit 3 is connected with the absorbing unit 1. A heat exchange area failure is set in the absorbing unit; a valve sticking failure is set in the oxidizing unit; a heat exchange tube cracking failure is set in the alkane rectifying unit; a use amount failure of cooling water for a condenser is set in the alkone refining unit; and a pump suction pipeline leakage failure is set in the alkone refining unit. The invention can not only perform stable operation for all the units and the entire practical training device, but also set various failures, provide methods for eliminating the failures, create the true industrial environment and solve the problems that the driving, the parking, the failure reason searching and the failure eliminating training cannot be performed to the trainees due to the characteristics of high temperature, high pressure, flammability, explosion hazard and toxicity of the chemical production.

Owner:NANJING COLLEGE OF CHEM TECH

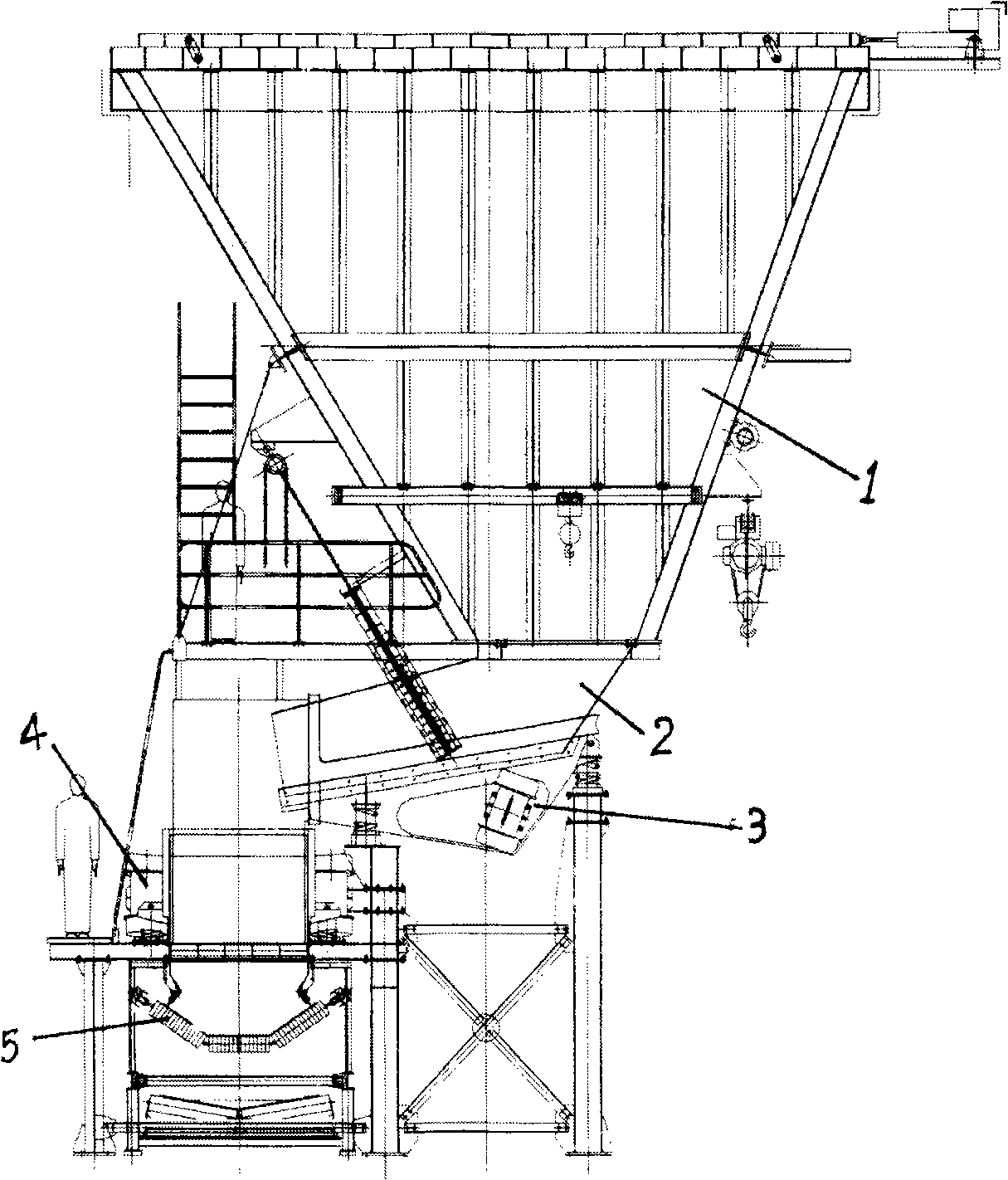

Double-layer shocking feeder

InactiveCN101332941AEliminate deviationGuaranteed uniformityLoading/unloadingConveyor partsEngineeringUpper floor

Owner:QINHUANGDAO PORT

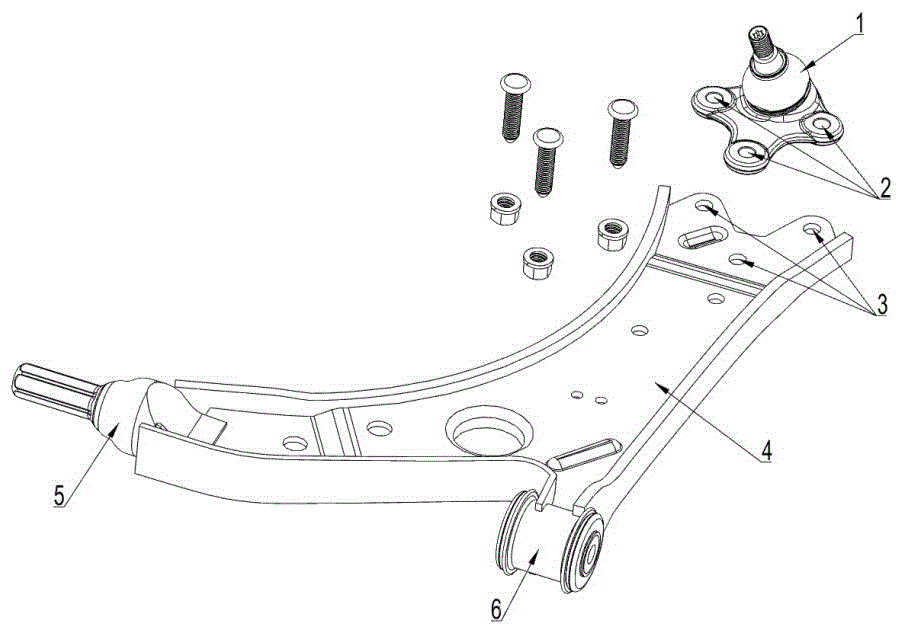

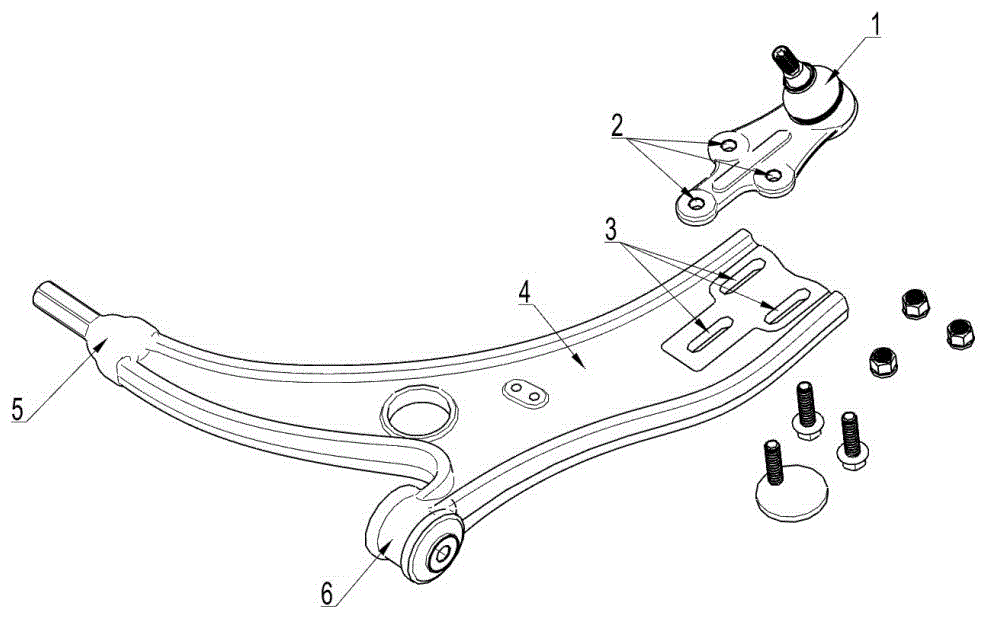

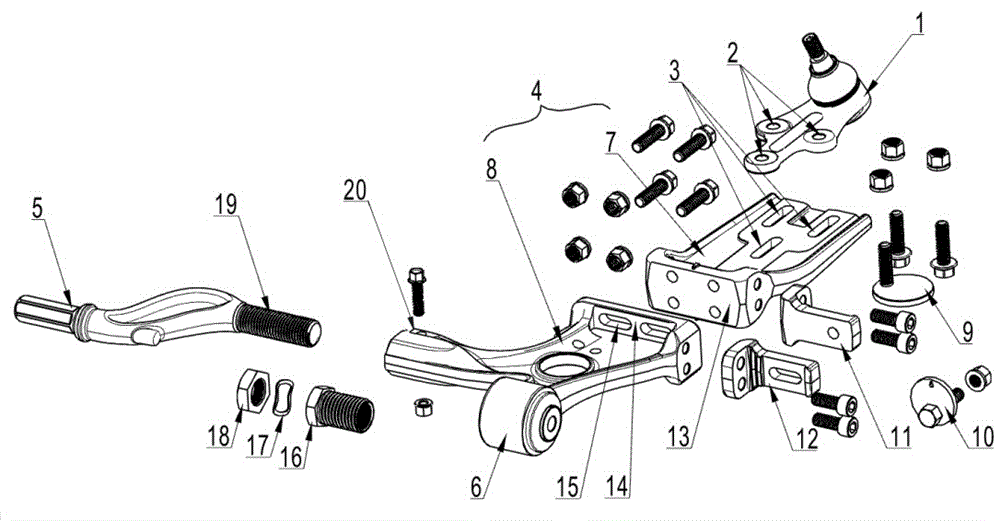

Triangular arm allowing angle of automobile wheel to be adjusted

ActiveCN106240266AReduced Grinding Tool DesignEliminate deviationSteering partsPivoted suspension armsCamber angleEngineering

The invention discloses a triangular arm allowing the angle of an automobile wheel to be adjusted. On the one hand, a connecting structure between a ball component assembly and a triangular arm body is improved so that the ball component assembly can move forwards and backwards on the triangular arm body; and one the other hand, the triangular arm body is improved to be of a split type structure so that the ball component assembly can move leftwards and rightwards, and accordingly the camber angle and the kingpin caster angle of the wheel can be adjusted conveniently and rapidly through forward, backward, leftward and rightward movement of the ball component assembly.

Owner:LUOYANG KAITAO METAL

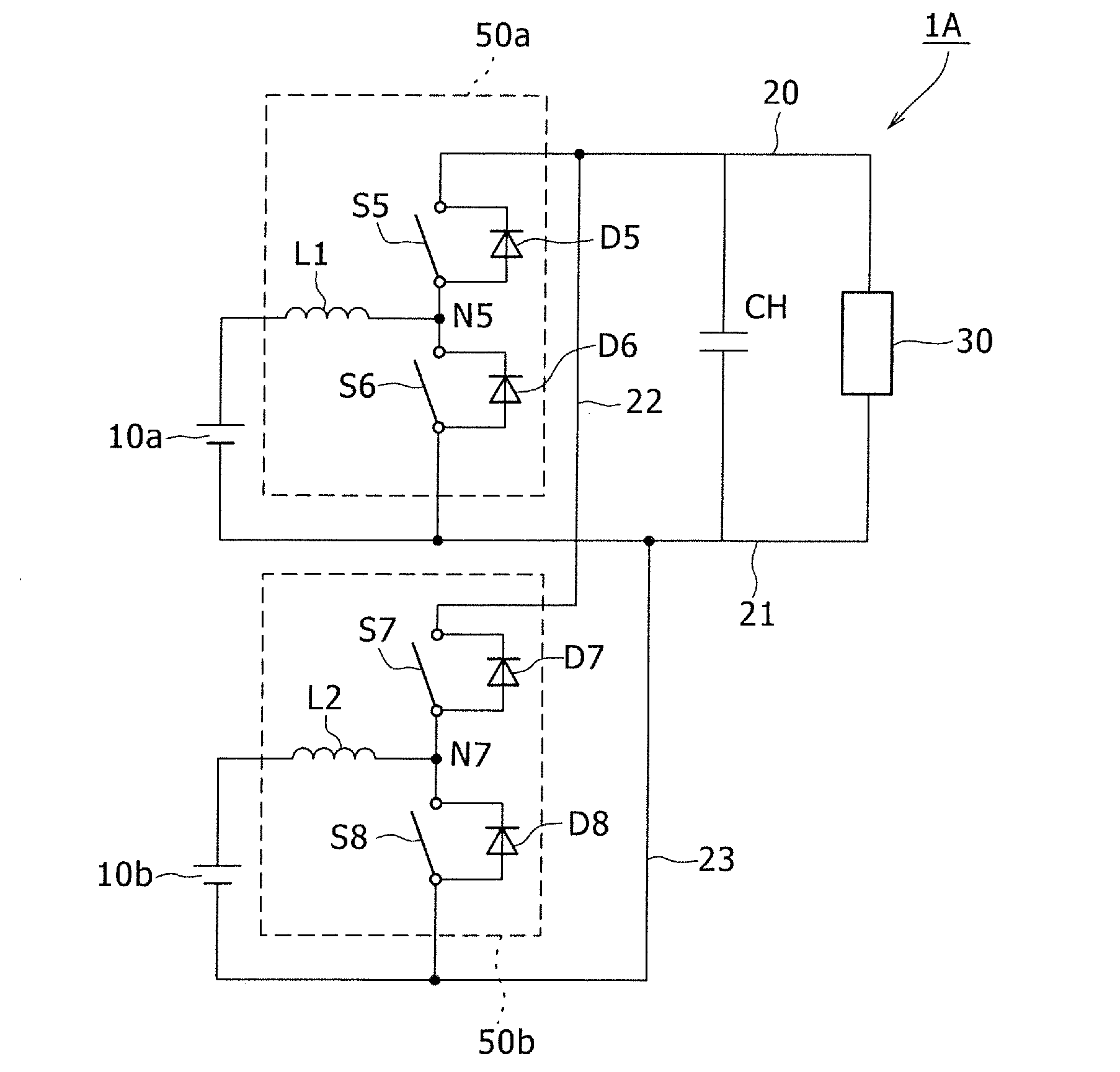

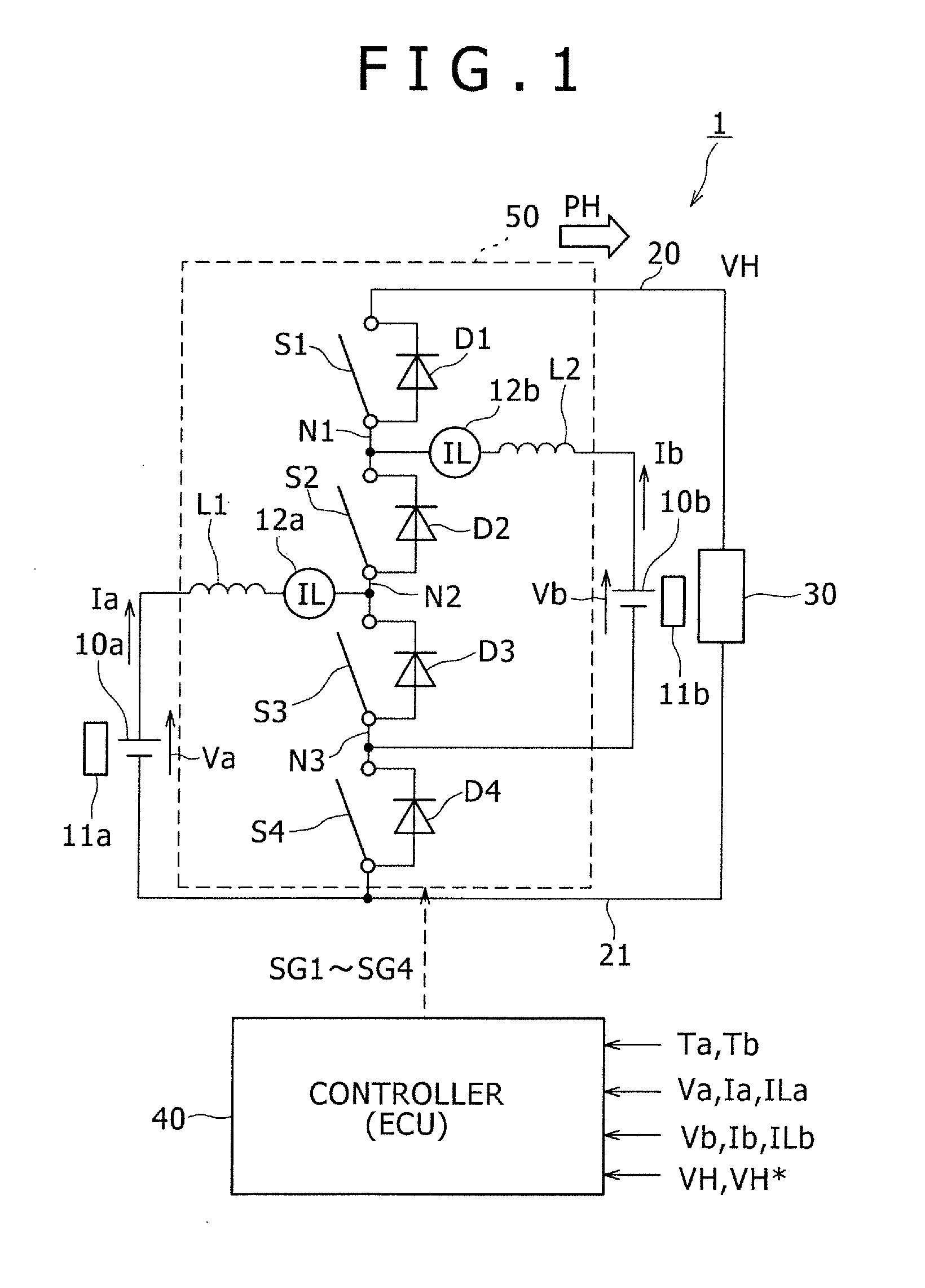

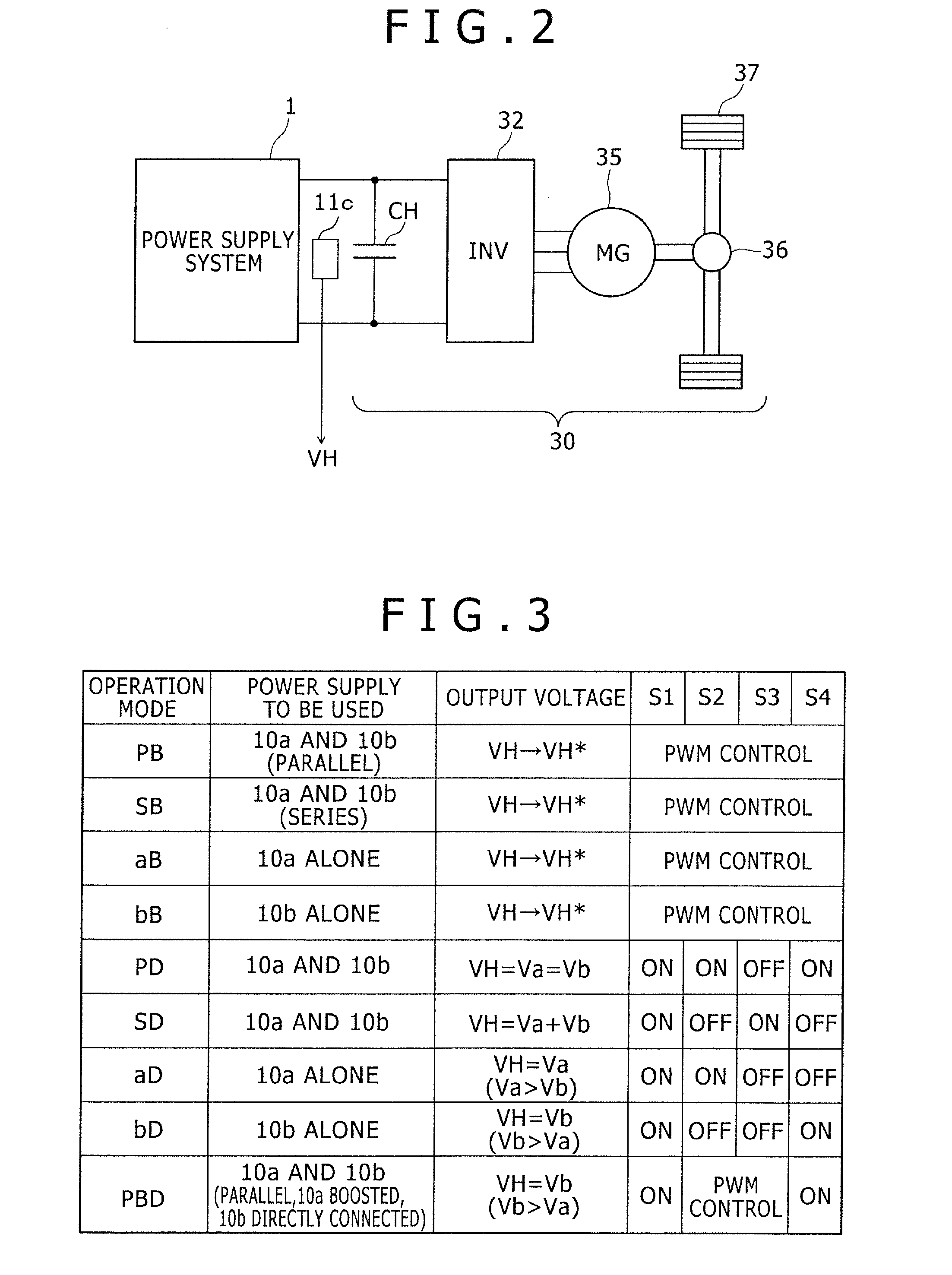

Power supply system

ActiveUS20160013644A1Eliminate deviationBatteries circuit arrangementsLoad balancing in dc networkElectric power systemEngineering

A power supply includes a load, an electric power line connected to the load, first and second DC power supplies which supply electric power to the load, an electric power converter connected between the electric power line and the first and the second DC power supplies, and a controller controlling the electric power converter. The first DC power supply serves for a voltage control, while the second DC power supply serves for an electric power control. The controller sets a difference between an electric power requested by the load and target output electric power of the first DC power supply as target output electric power of the second DC power supply, and compensates the target output electric power of the first DC power supply in accordance with a difference between the actual and the target output electric powers of the second DC power supply.

Owner:TOYOTA JIDOSHA KK

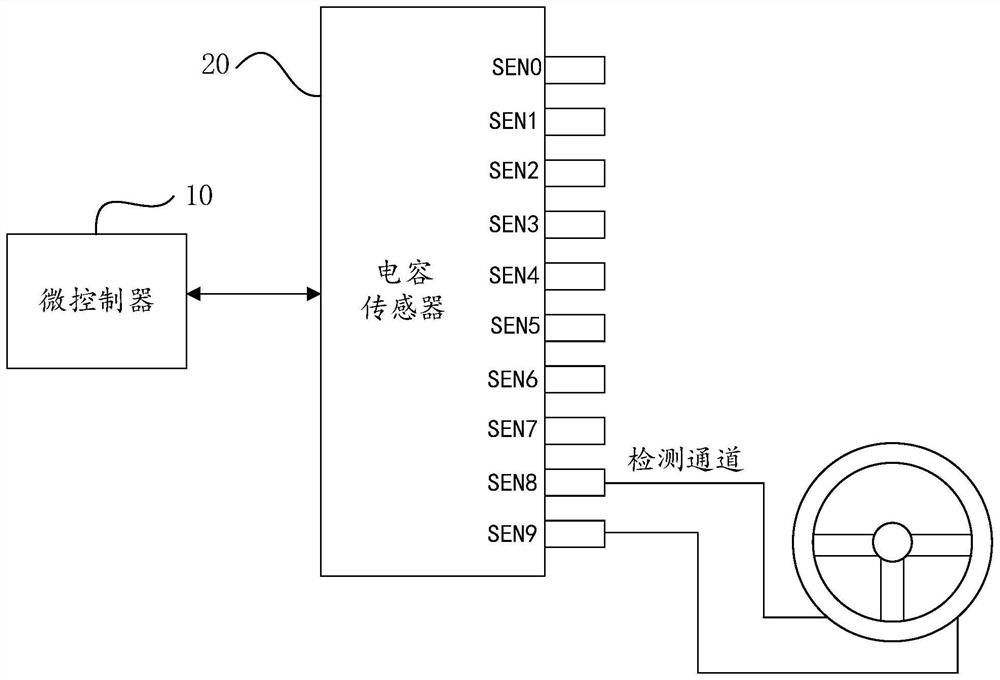

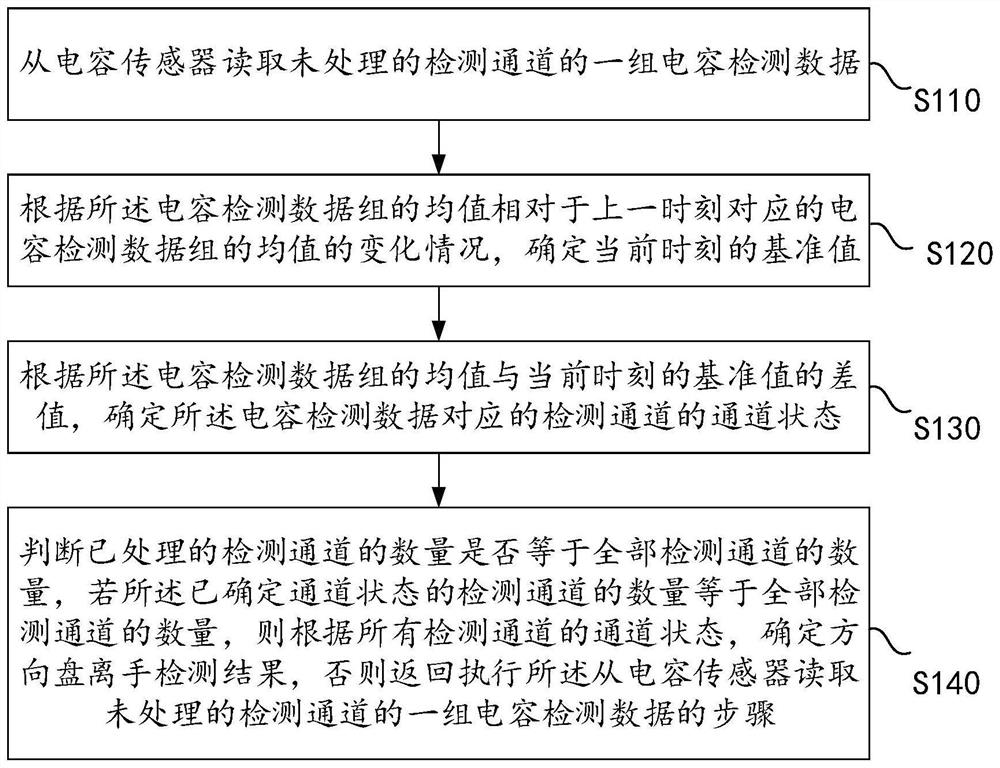

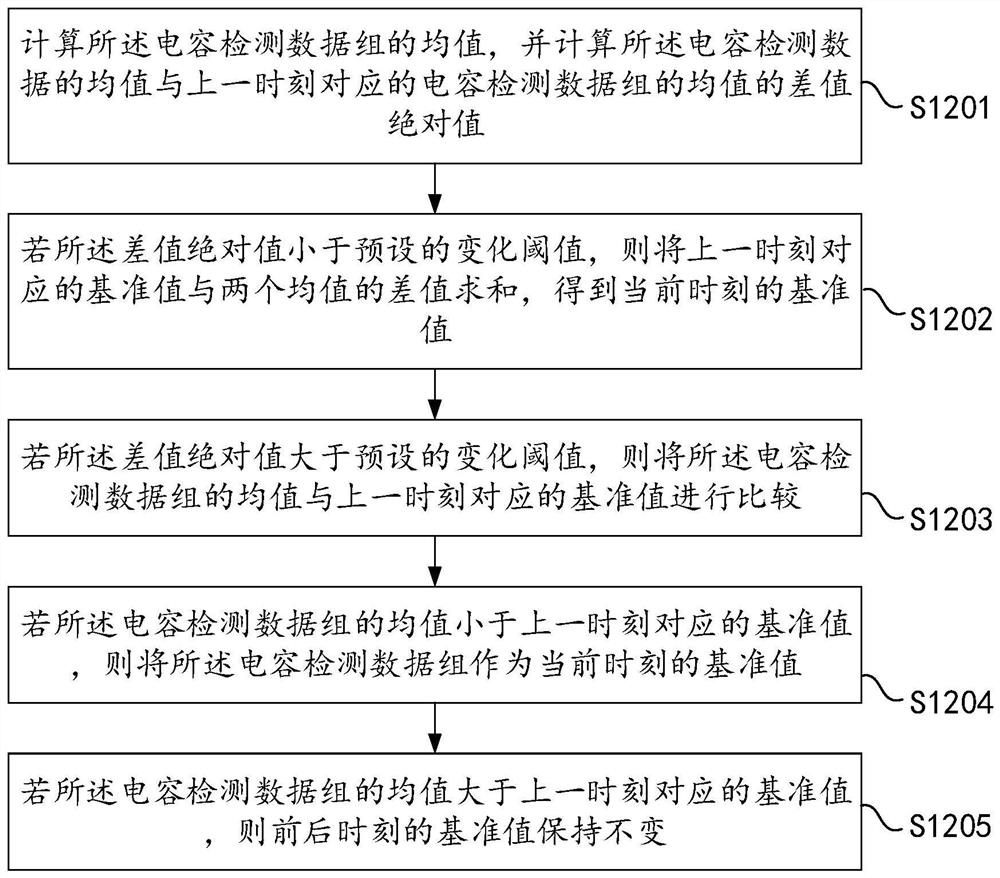

Automobile steering wheel off-hand detection system and method

PendingCN112684507APrevent deviationEliminate deviationElectric/magnetic detectionAcoustic wave reradiationMicrocontrollerSteering wheel

The embodiment of the invention discloses an automobile steering wheel off-hand detection system and method. The system comprises a capacitive sensor based on IQ modulation and a microcontroller, the capacitive sensor comprises a plurality of detection channels, the detection channels are connected to a steering wheel heating wire, and the data output end of the capacitive sensor is connected to the microcontroller. The capacitive sensor detects the capacitance value of the steering wheel heating wire through the detection channel and generates capacitance detection data, the microcontroller reads the capacitance detection data, and the microcontroller determines a steering wheel off-hand detection result according to the capacitance detection data and the capacitance reference data. Through the technical means, the influence of environment temperature change on the off-hand detection precision is eliminated, and the detection accuracy and reliability are improved.

Owner:GUANGZHOU ZHOULIGONG SCM DEV

Method for solving welding deviation and welding equipment thereof

PendingCN111468869AHigh positive rateImprove welding yieldWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWeld zone

The invention discloses a method for solving welding deviation and welding equipment thereof. The method comprises the steps of employing a CCD device to shoot a workpiece image, and judging a position deviation value between an actual workpiece image and a standard workpiece image; if no position deviation exists, starting welding; and if the position deviation exists, compensating the position deviation value by moving a welding head or a workpiece fixing device, and then starting the welding. Therefore, the problem that deviation exists between a welding area of the workpiece and the welding head due to the fact that positioning is conducted through appearance of the workpiece traditionally can be effectively eradicated; and a high aligning rate of workpiece welding can be ensured, so that the welding yield of the workpiece is further improved.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

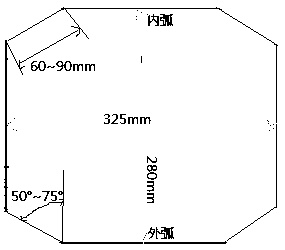

Continuous casting process capable of relieving internal quality defects of bearing steel bloom

The invention discloses a continuous casting process capable of relieving internal quality defects of bearing steel boom. The continuous casting process adopts a large chamfering crystallizer, a chamfering angle of the obtained large chamfered continuously cast bloom is 50-75 degrees, and length of a chamfered inclined surface is 60-90 mm. The adopted following pressing-down process is as follows: at a pressed-down start point position, central solid fraction fs is 0.55-0.65, and pressing-down amount is 1.0-2.0 mm; at a second pressing-down roller, central solid fraction fs is 0.65-0.75 and pressing-down amount is 3.0-5.0 mm; at a third pressing-down roller, central solid fraction fs is 0.75-0.85, and pressing-down amount is 2.0-4.0 mm; at a fourth pressing-down roller, central solid fraction fs is 0.85-0.95, and pressing-down amount is 2.0-3.0 mm; and at a fifth pressing-down roller, central solid fraction fs is 0.95-1.0, and pressing-down amount is 0-2.0 mm. The continuous casting process reduces casting, rolling and pressing-down force in a casting blank pressing-down process, and improves pressing-down efficiency, so that the effects of stably controlling quality defects such as center segregation, V-shaped segregation, central loosening and hole shrinkage of the bearing steel boom are achieved.

Owner:XINGTAI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com