Synthetic real training device for chemical industry operation

A training device and chemical technology, applied to the simulation device of space navigation conditions, transportation and packaging, instruments, etc., can solve problems that affect product quality, explosion, single function, etc., to achieve normal operation, troubleshooting, eliminate The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

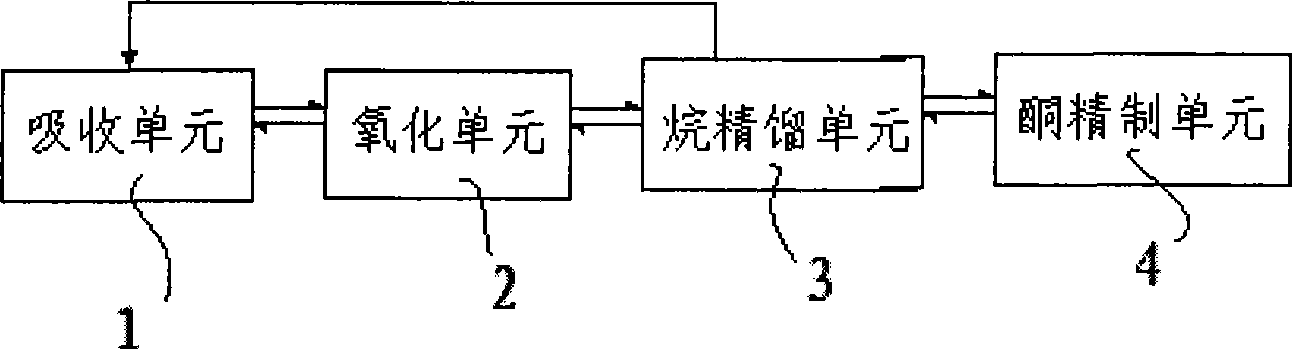

[0016] The present invention is a comprehensive training device for chemical industry operations, which organically combines units such as fluid transportation, heat transfer, absorption, oxidation, alkane rectification, and ketone refinement to form a circulation loop by setting the process of cyclohexane oxidation to cyclohexanone. And the disturbance points of connections are added in the unit to simulate the failures that often occur during operation.

[0017] refer to figure 1 , Chemical operation comprehensive training device, the absorption unit 1 is connected to the oxidation unit 2, the oxidation unit 2 is connected to the alkane rectification unit 3, the alkane rectification unit 3 is connected to the ketone refining unit 4, and the alkane rectification unit is connected to the absorption unit.

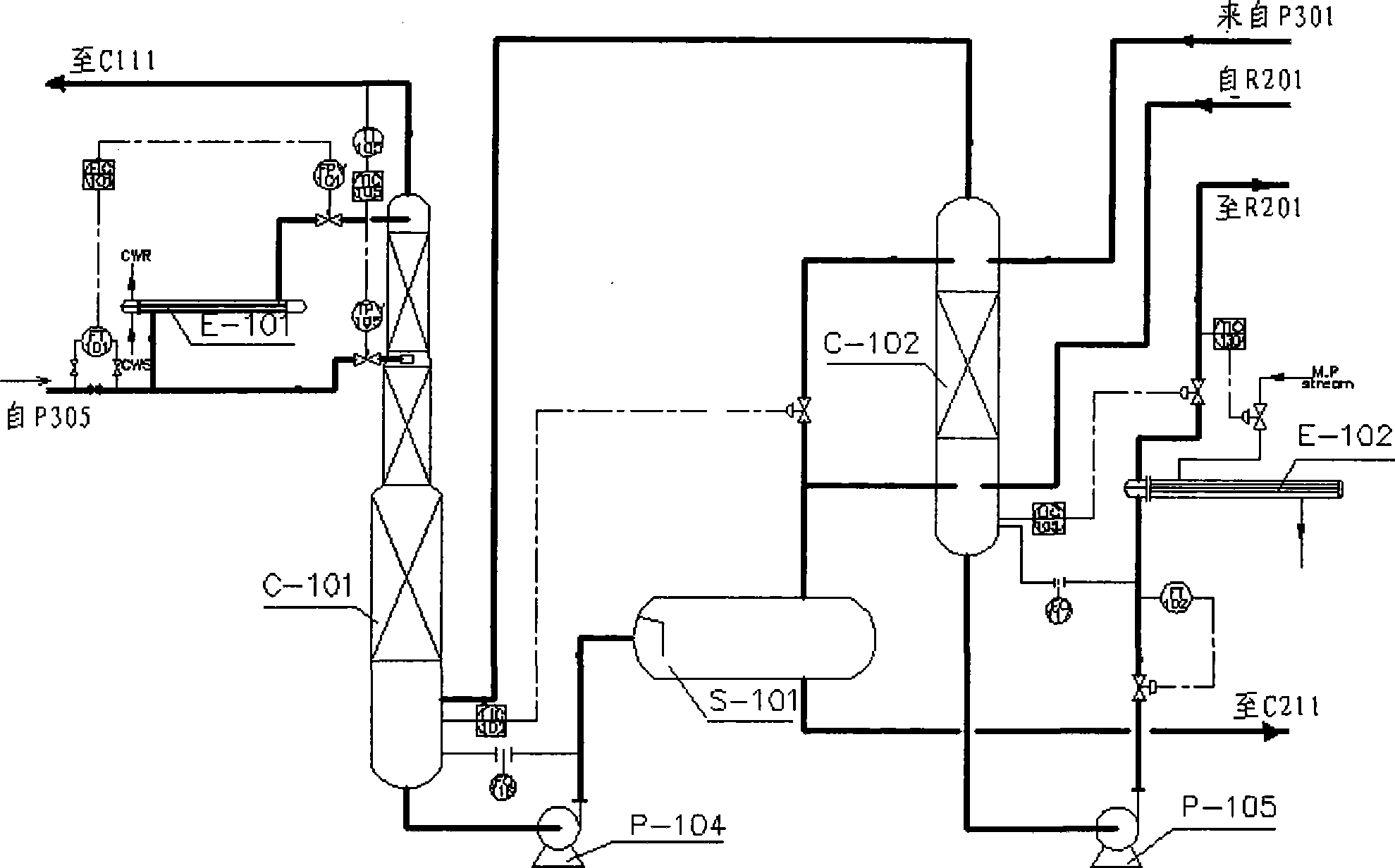

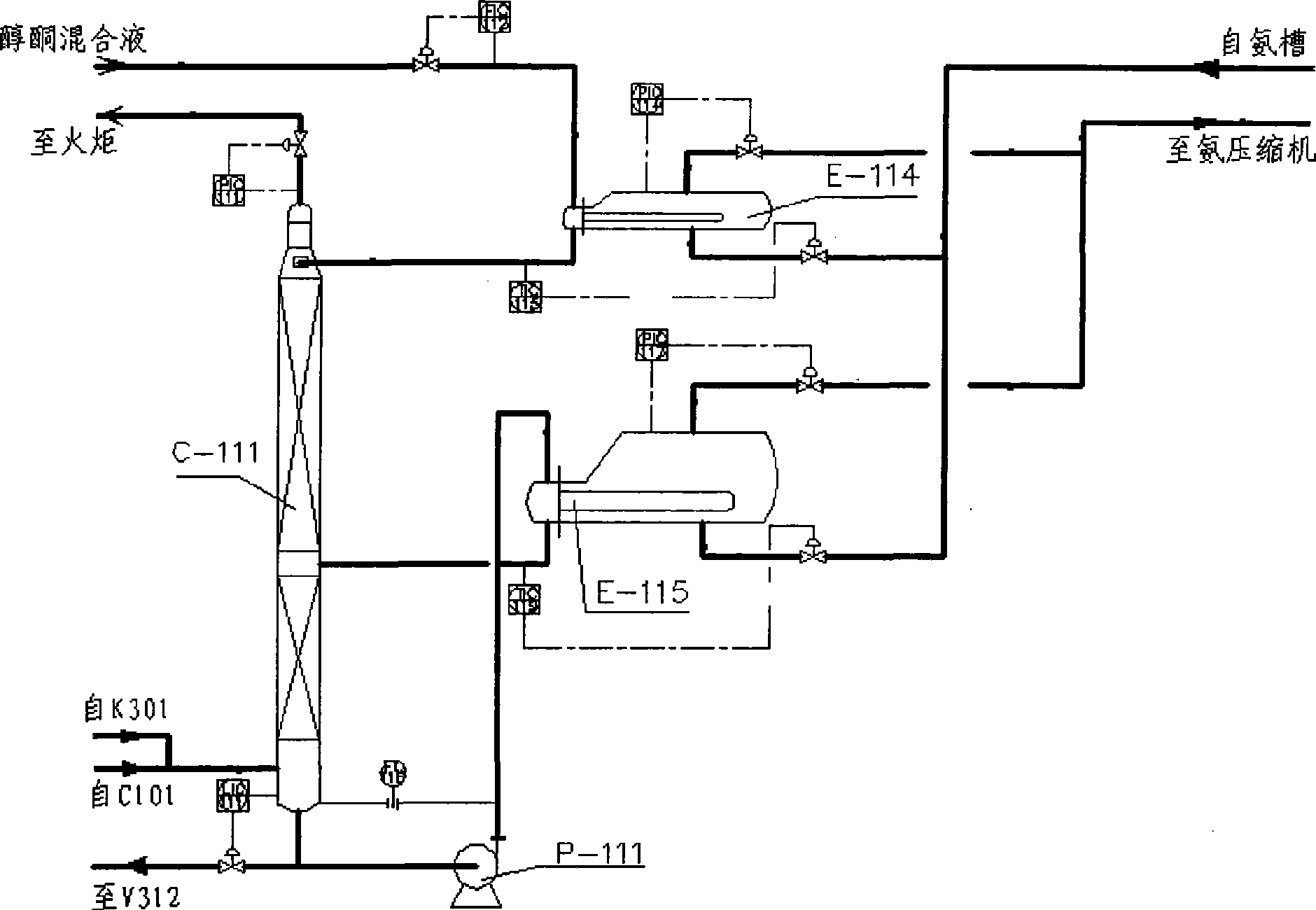

[0018] Figure 2a and Figure 2b is a schematic diagram of the split structure of the absorption unit 1;

[0019] The working process of the absorption unit is: the absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com