Patents

Literature

30results about How to "Uniformly manufactured" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

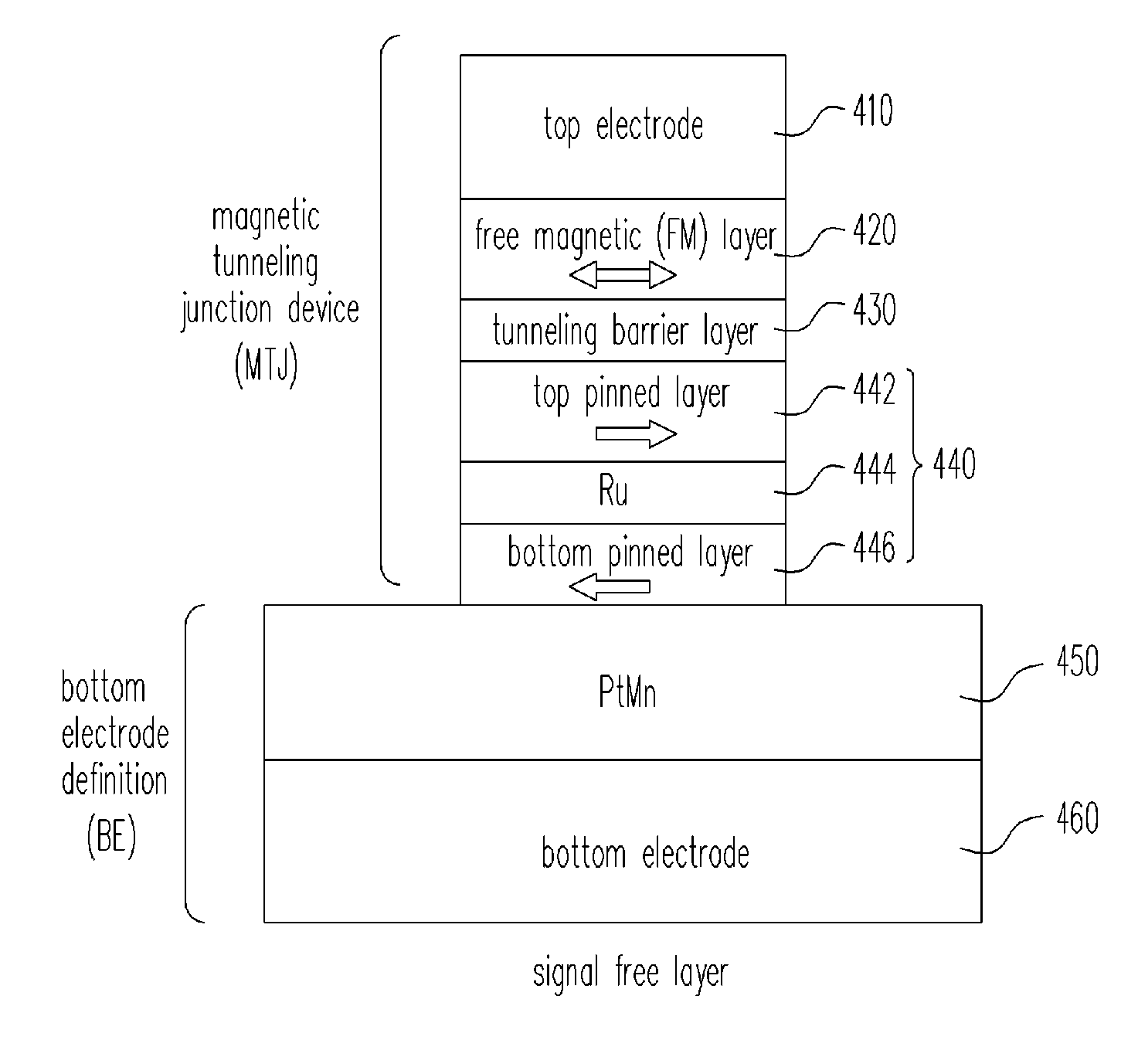

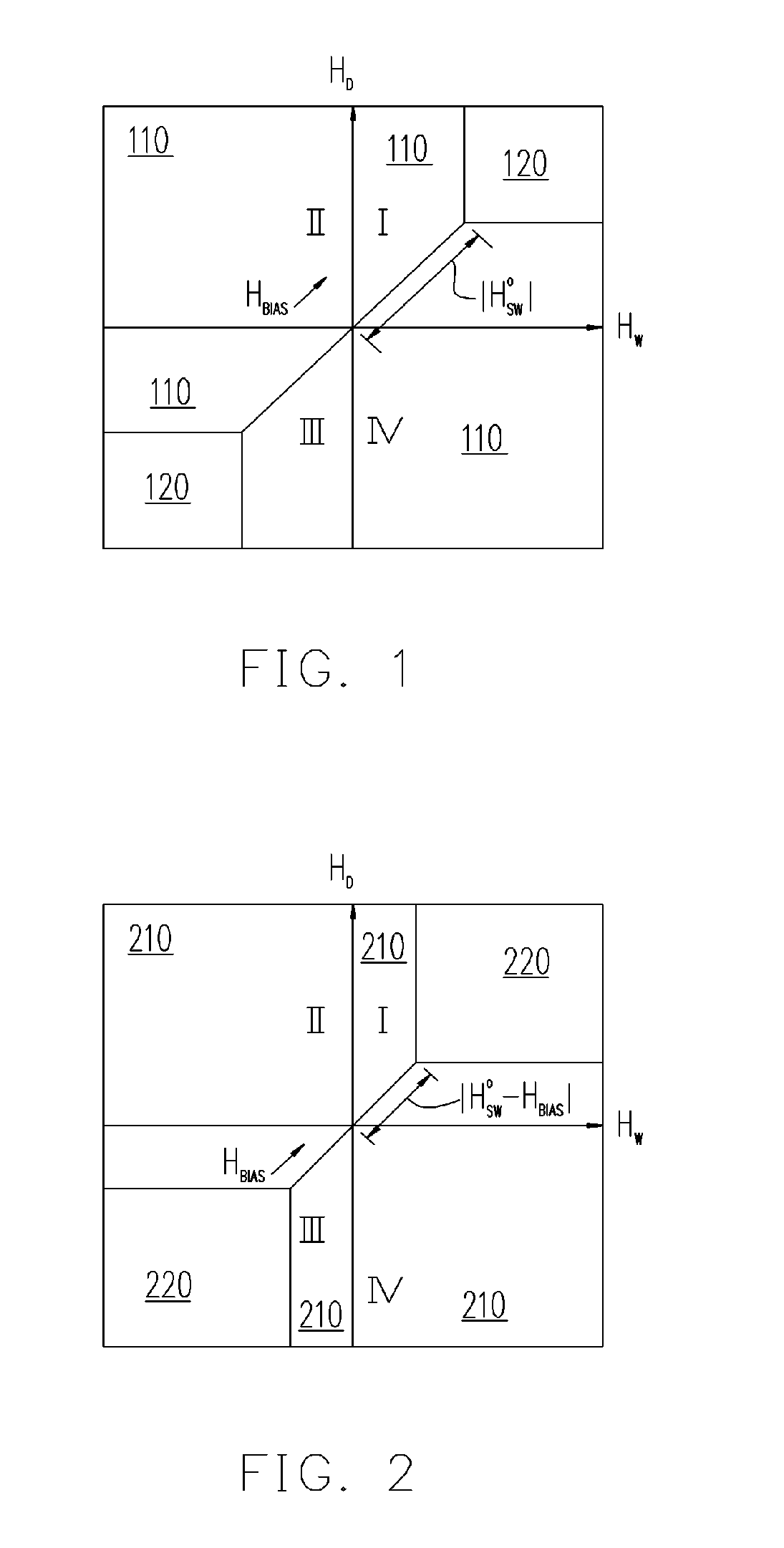

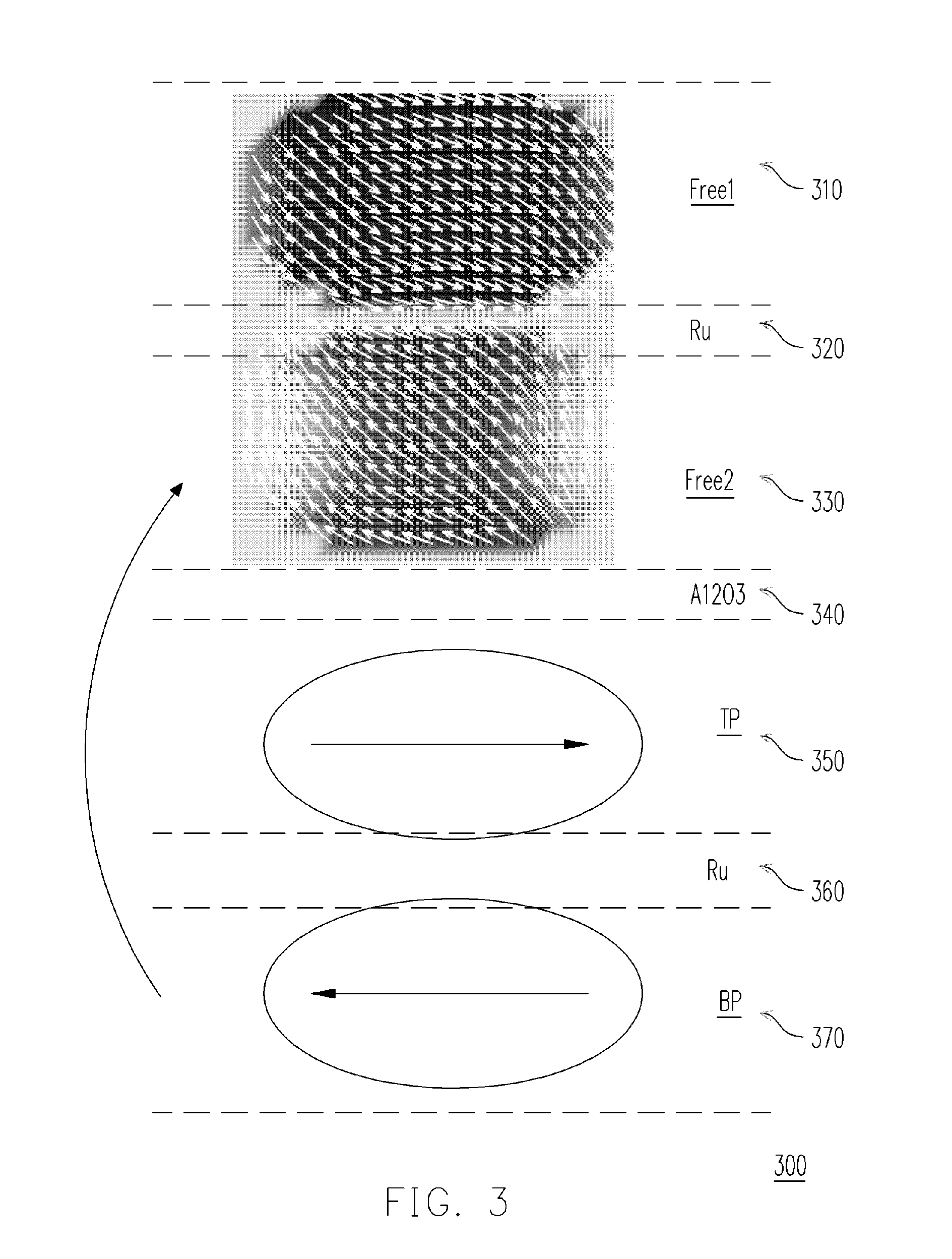

Magnetic memory cell and manufacturing method thereof

InactiveUS20070187785A1Eliminate deviationUniformly manufactureMagnetic-field-controlled resistorsSolid-state devicesPhysicsBias field

A magnetic memory cell and a manufacturing method for the magnetic memory cell are provided. In the magnetic memory cell, a pinned layer of a magnetic bottom electrode can be formed with sizes different from the free layer. The wider magnetic bottom electrode produces a preferable uniform bias field that will create a normal magnetization vector distribution in the end domain of the free layer, and thus achieving a preferred switching property. The above process can also be achieved through self-alignment. In addition, by adjusting the bias field of the bottom electrode, uniform field distribution over entire free layer can be significantly improved, and thus the magnetic memory cell will have a very low writing toggle current.

Owner:IND TECH RES INST

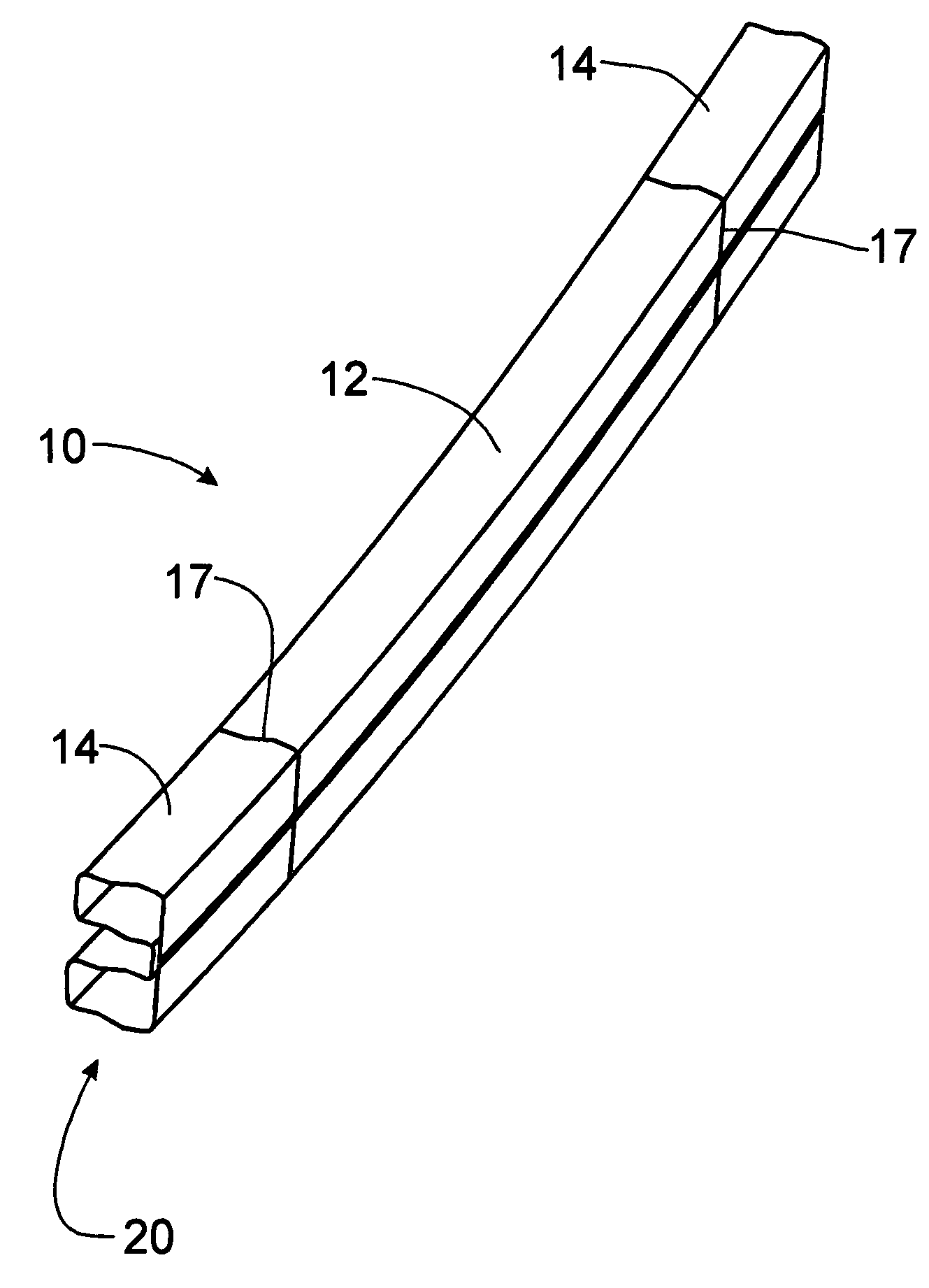

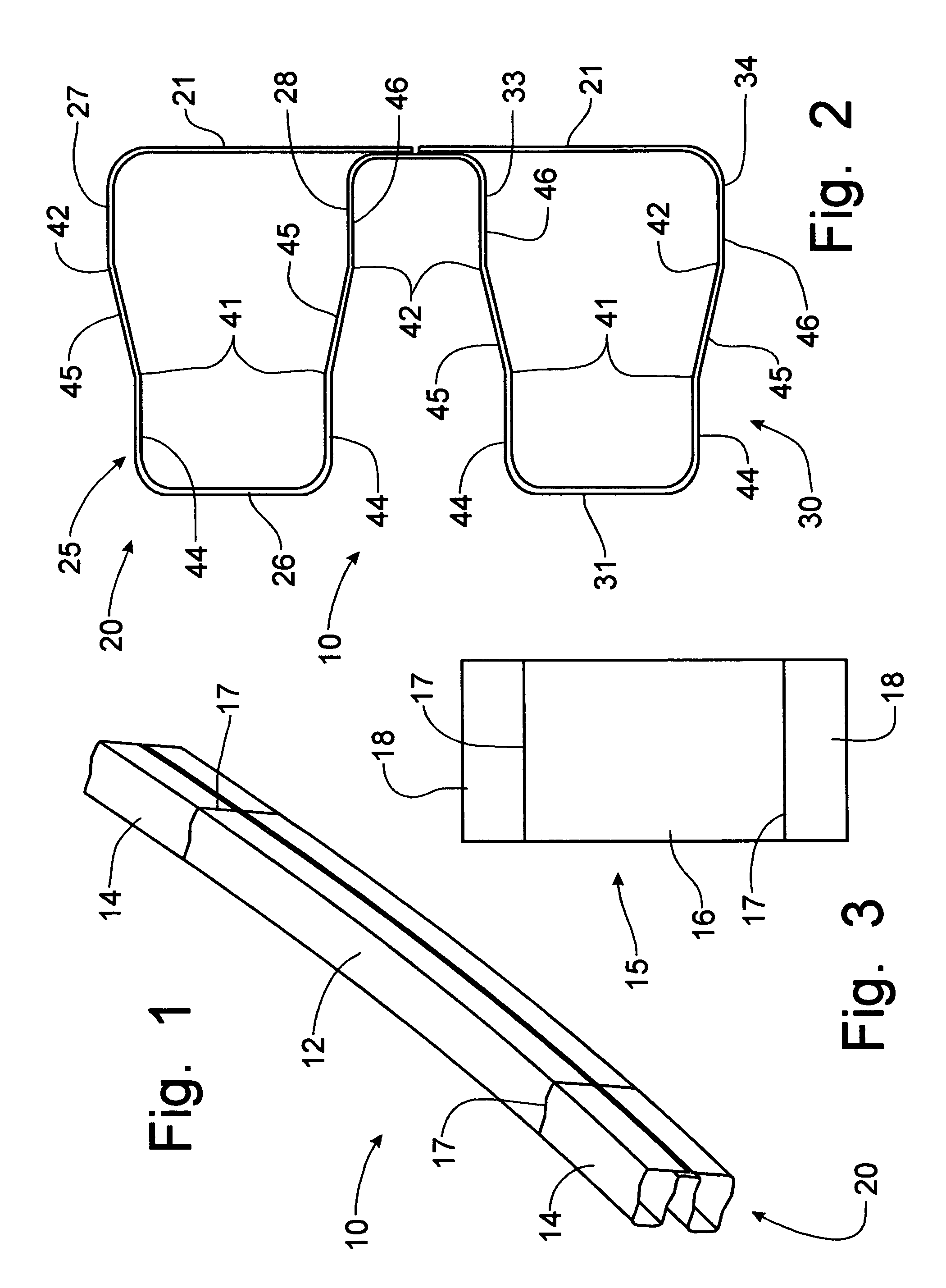

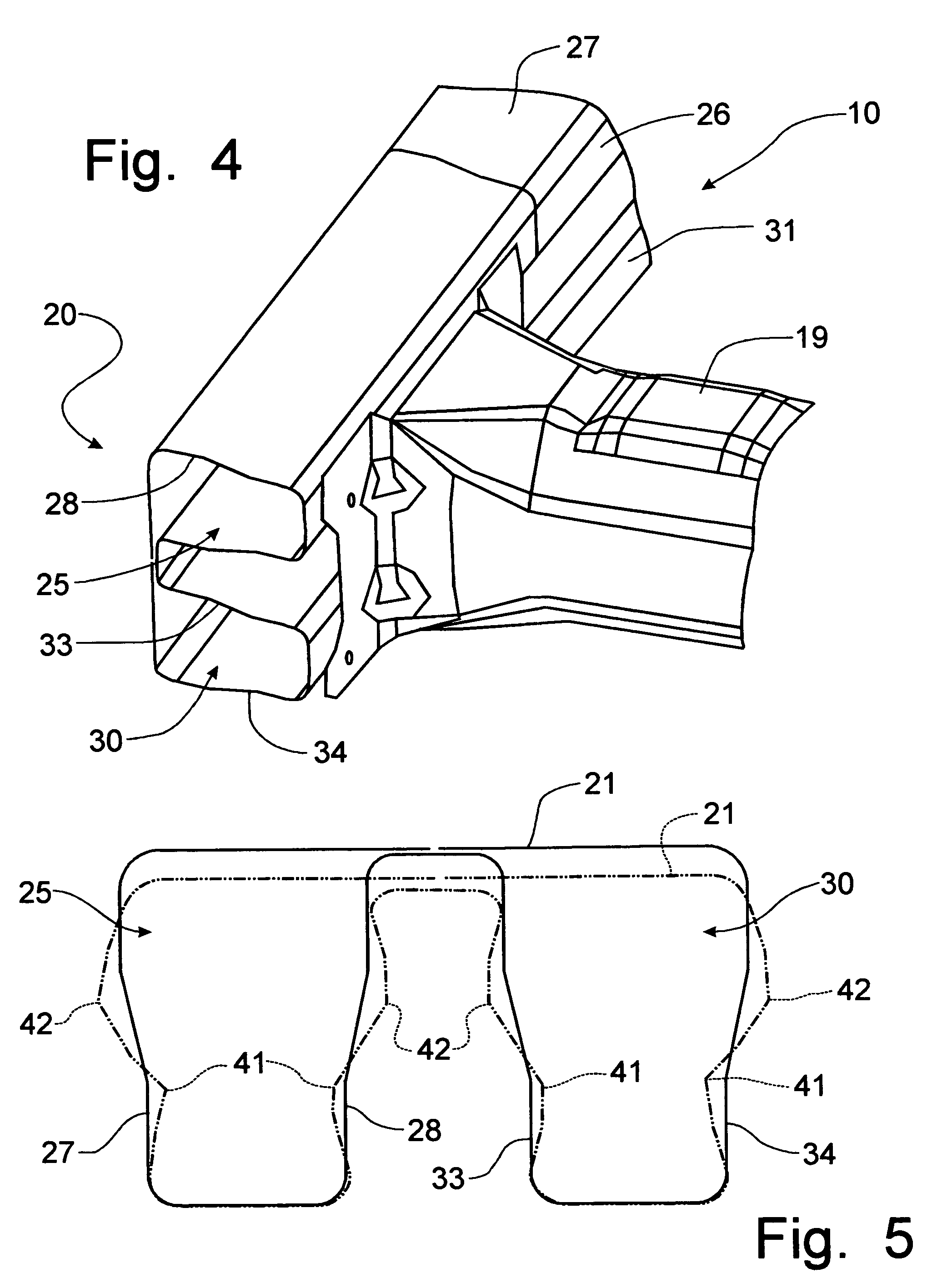

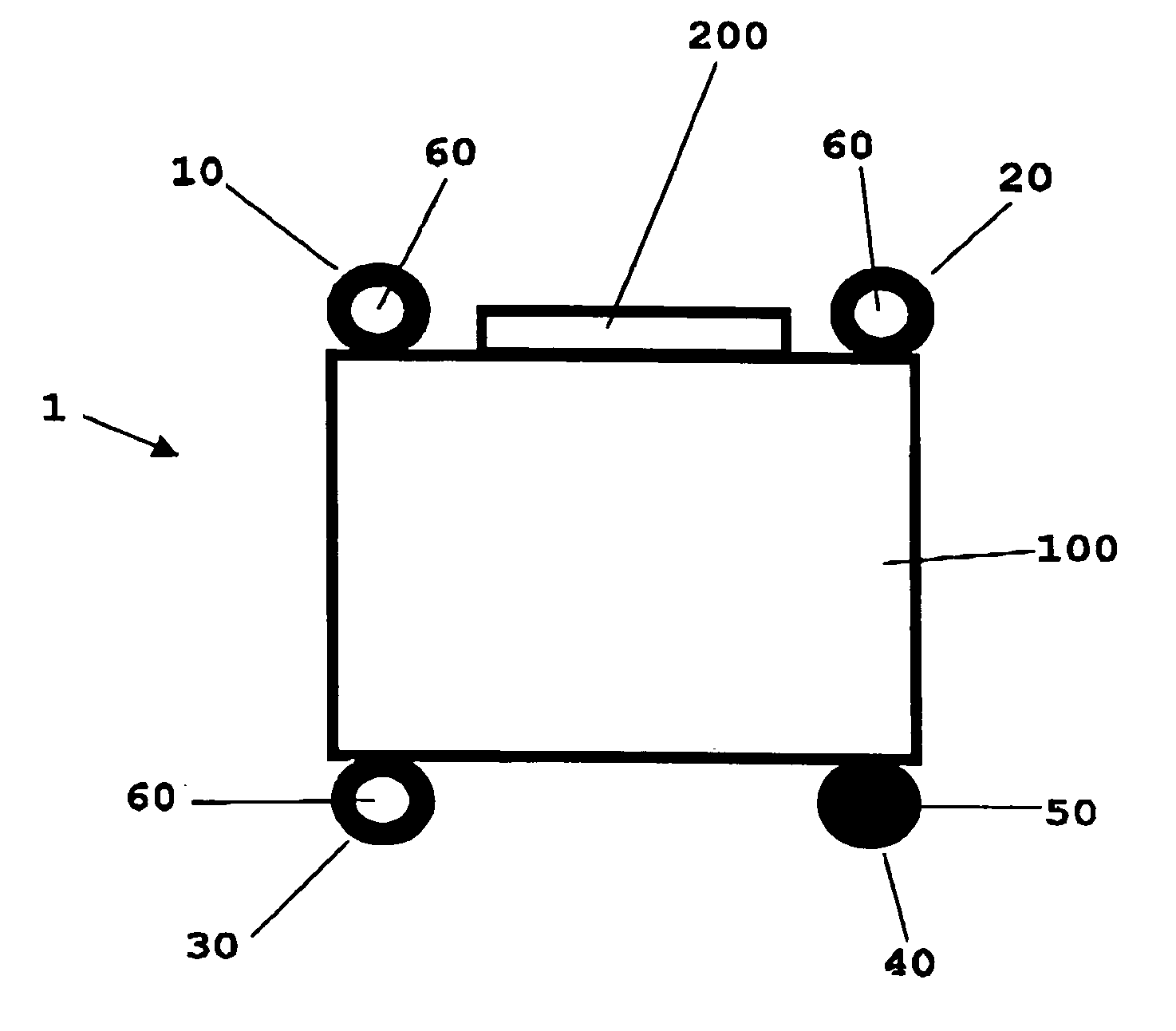

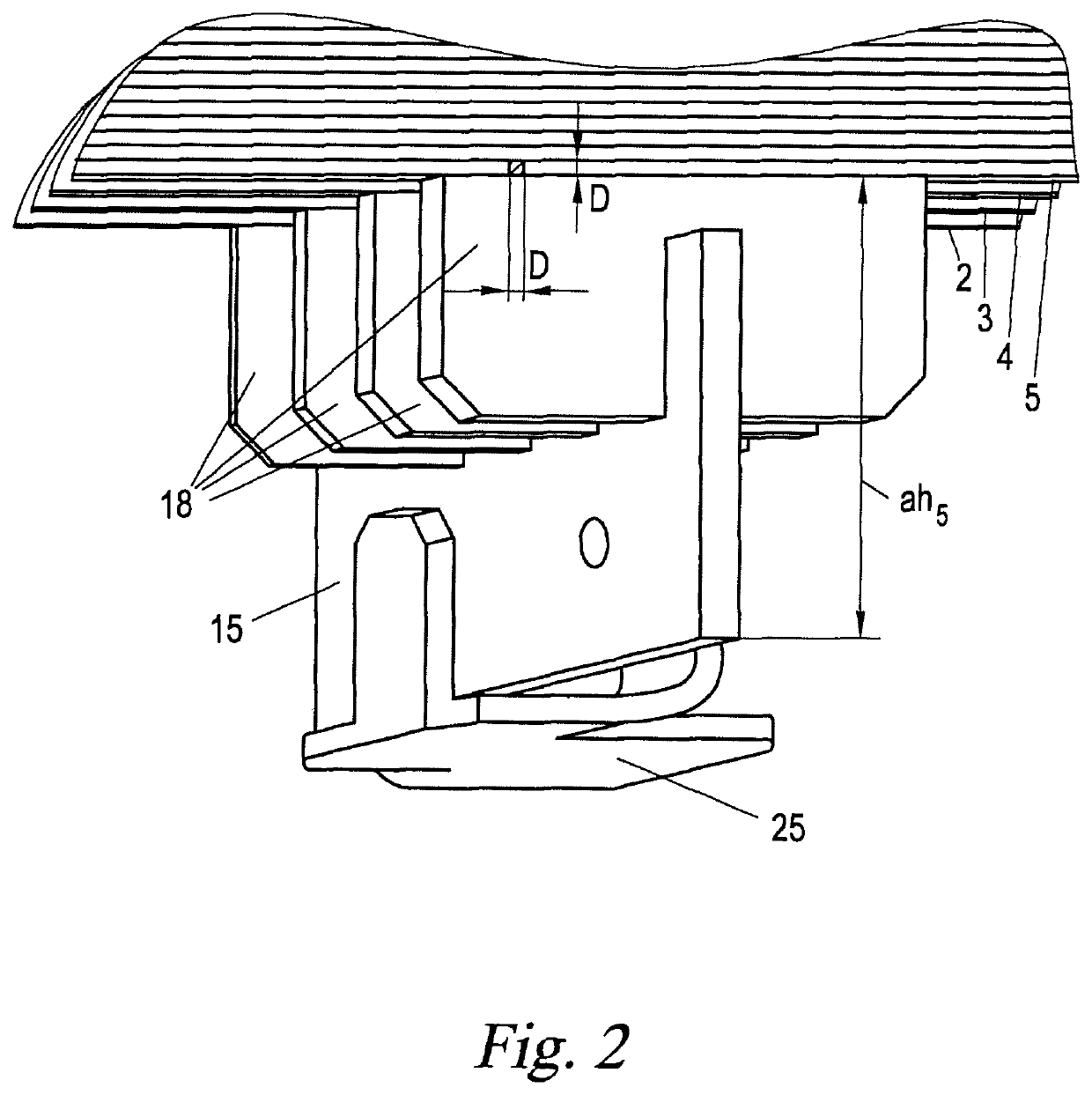

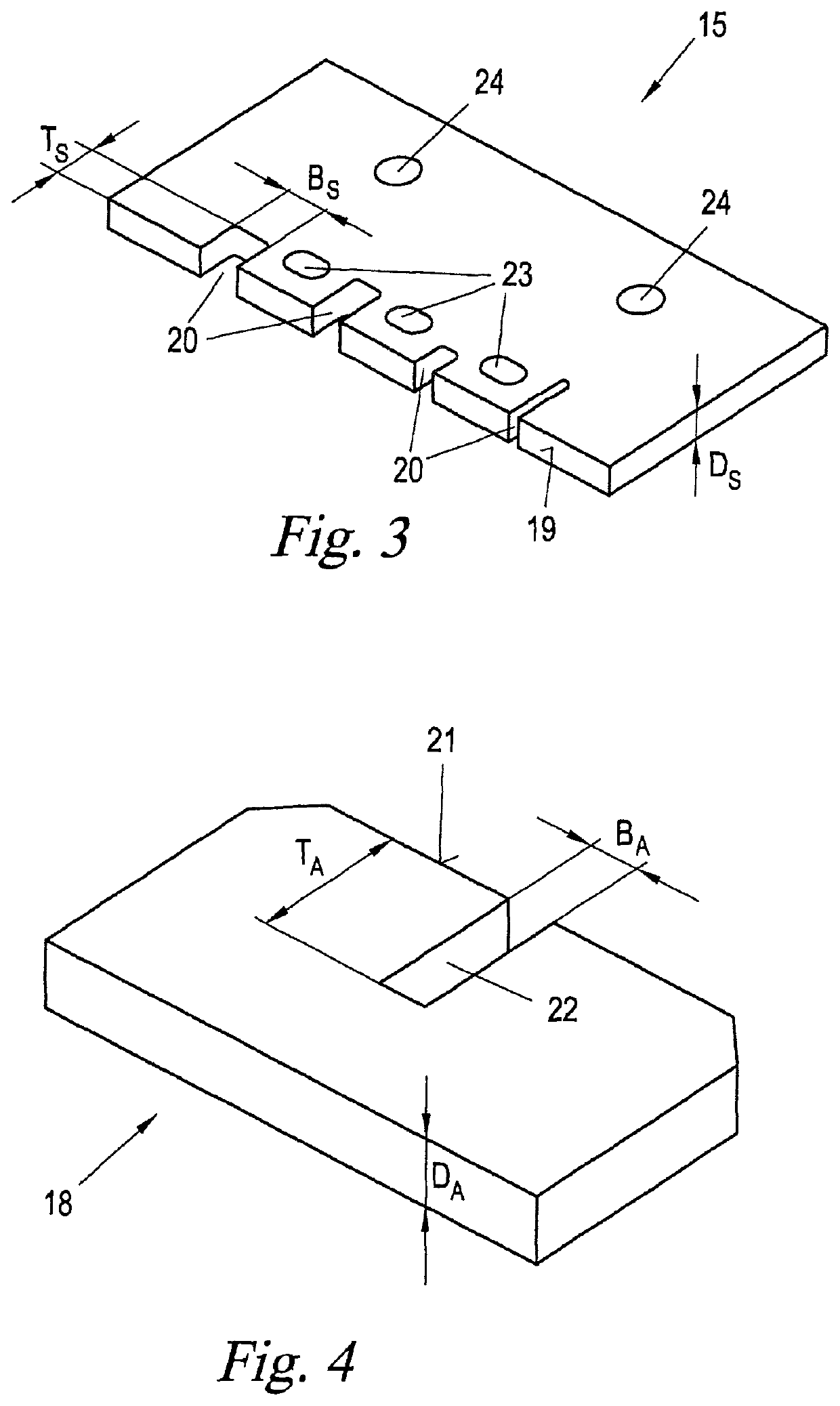

Lightweight bumper for automobiles

ActiveUS7210717B1Not sacrifice crash performanceImprove crash performanceBumpersEnergy absorptionEngineering

A bumper beam is formed from a tailor welded blank with thinner gage sheet metal laser welded to thicker gage sheet metal at opposing sides thereof. The tailor welded blank is then formed into a bumper beam having a uniform B-shaped cross-sectional configuration from one terminal end to the other. The heavier gage material in the tailor welded blank corresponds to the terminal ends of the bumper beam where the bumper beam is affixed to the lower frame rails of the vehicle chassis thus placing the greater energy absorption qualities for the bumper beam only at the locations in which they are needed without requiring reinforcement inserts.

Owner:FORD GLOBAL TECH LLC

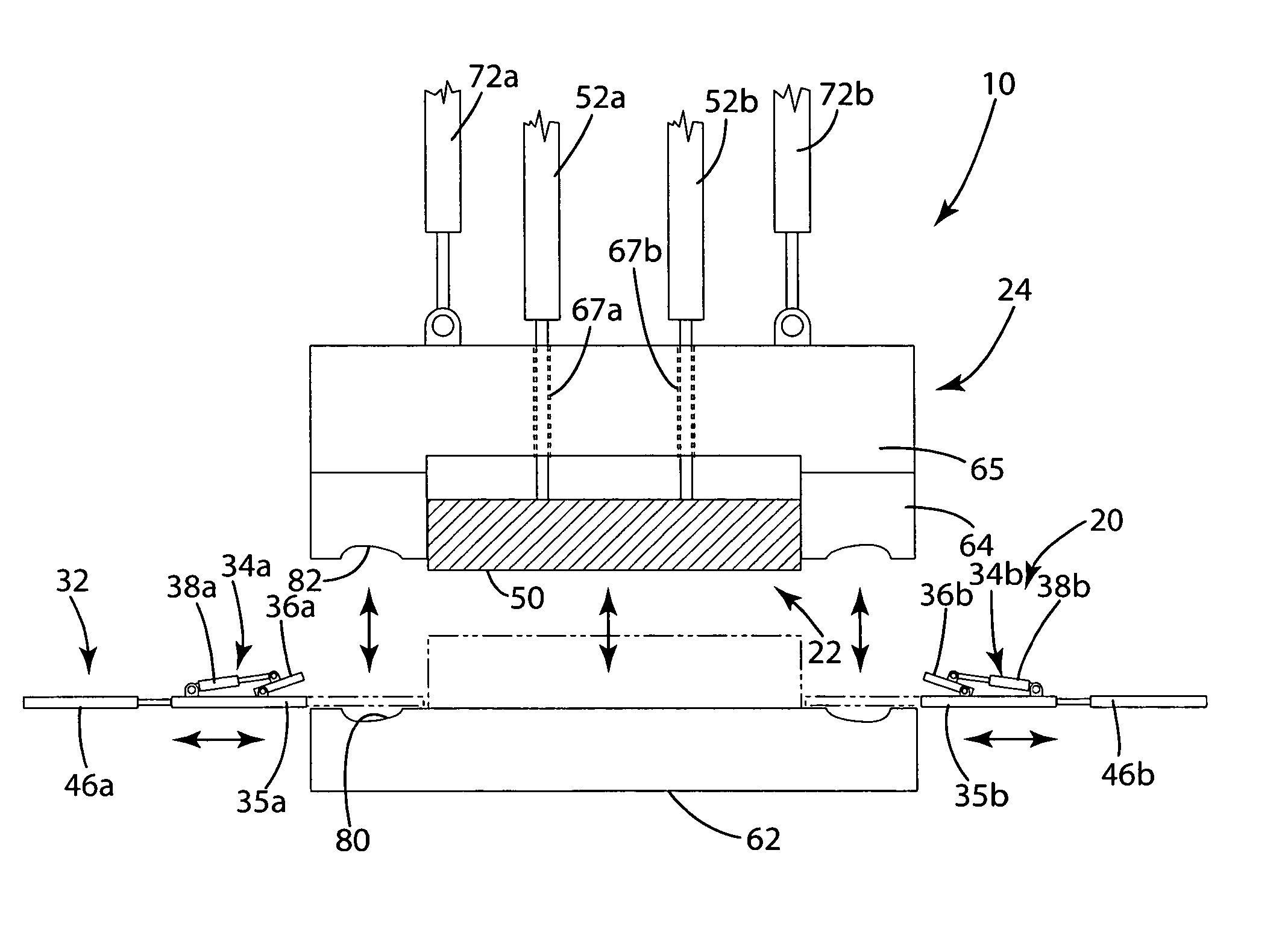

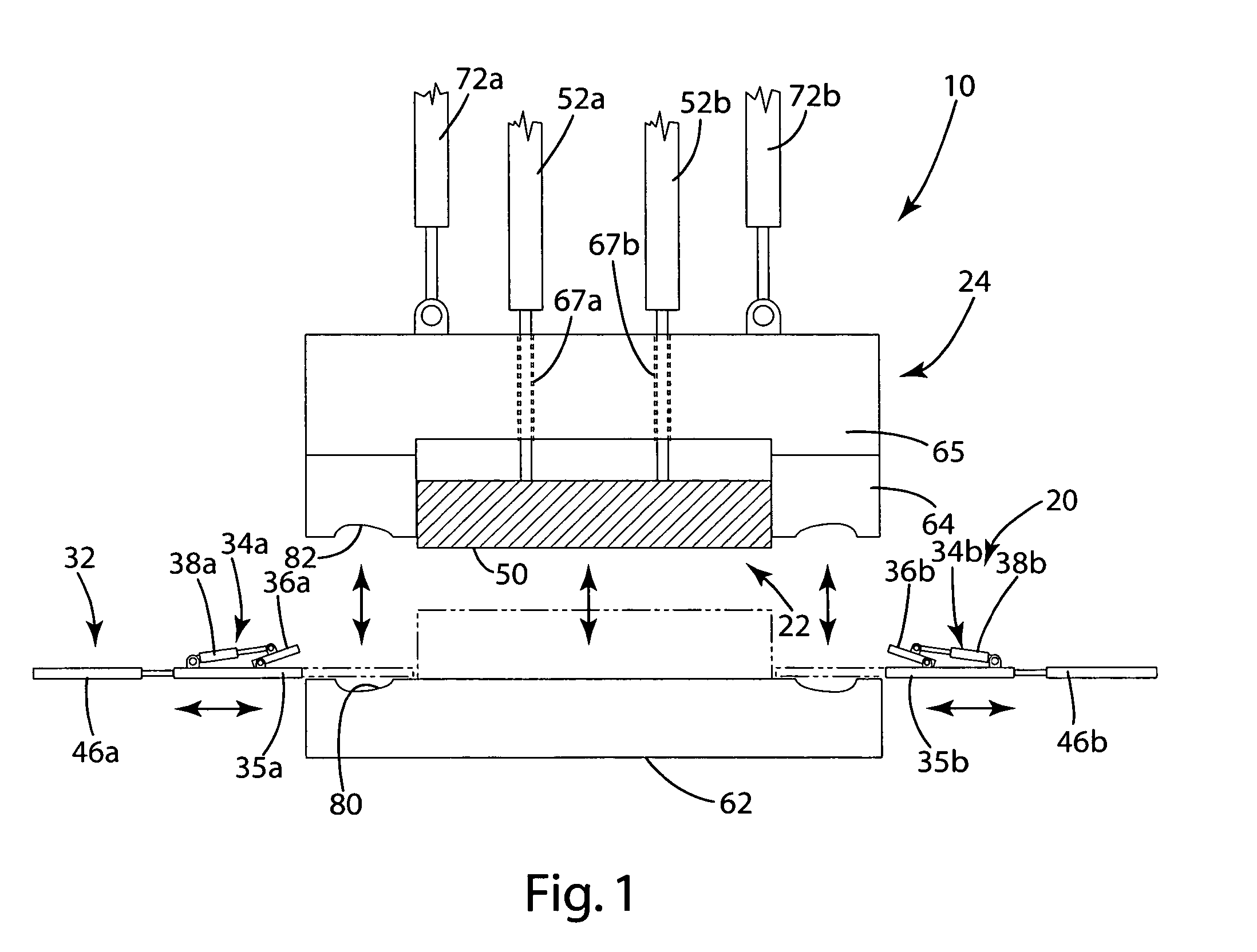

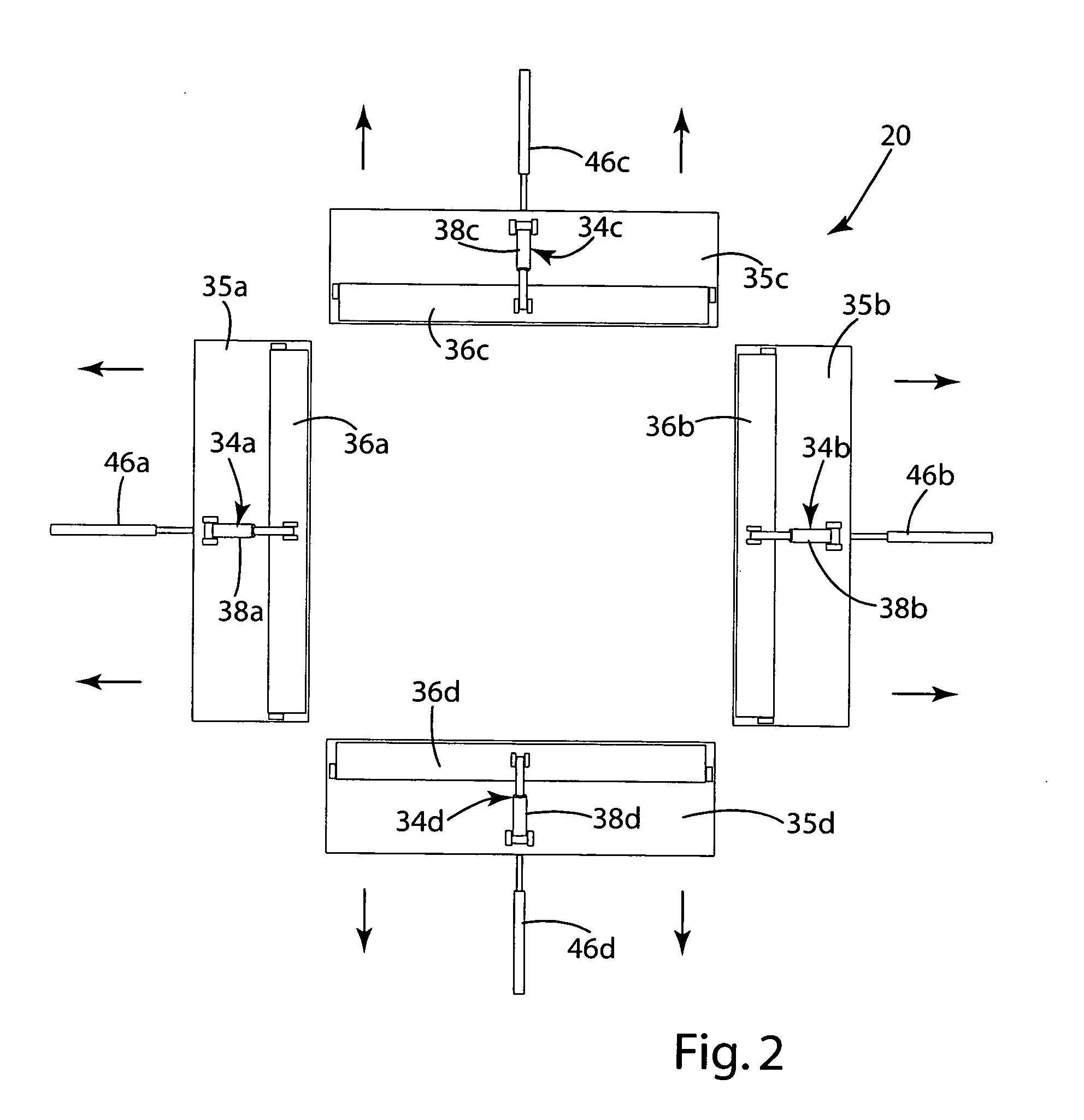

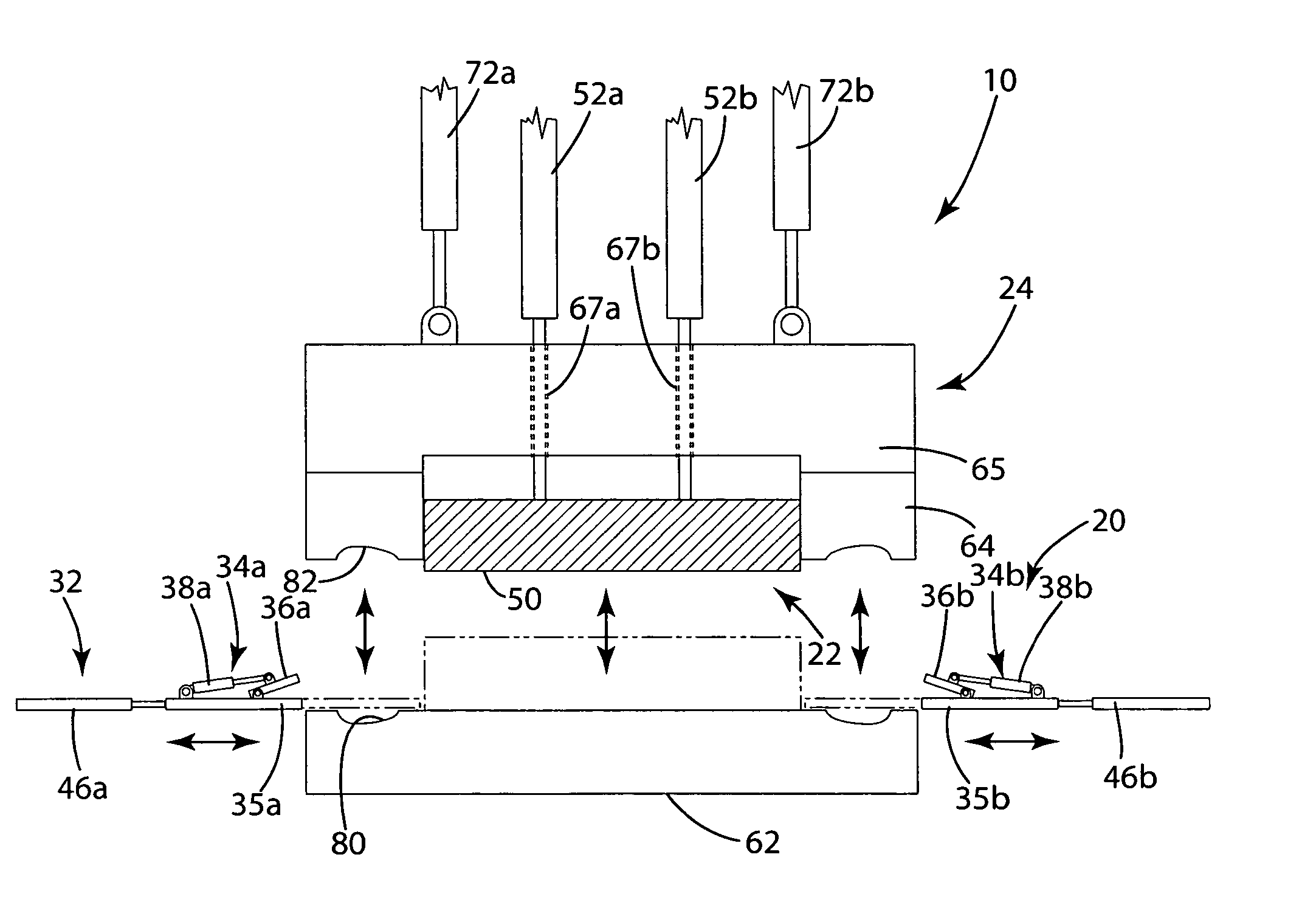

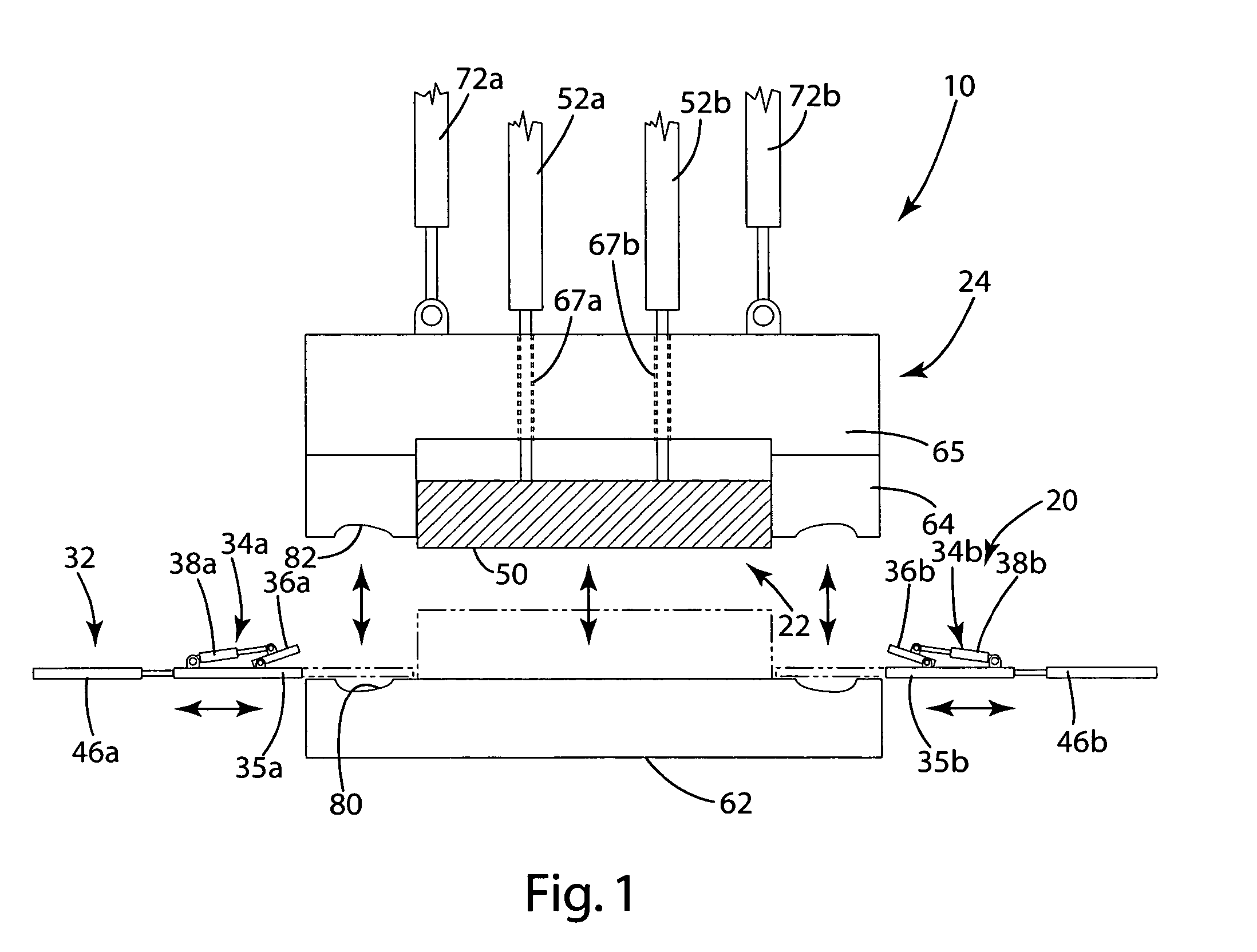

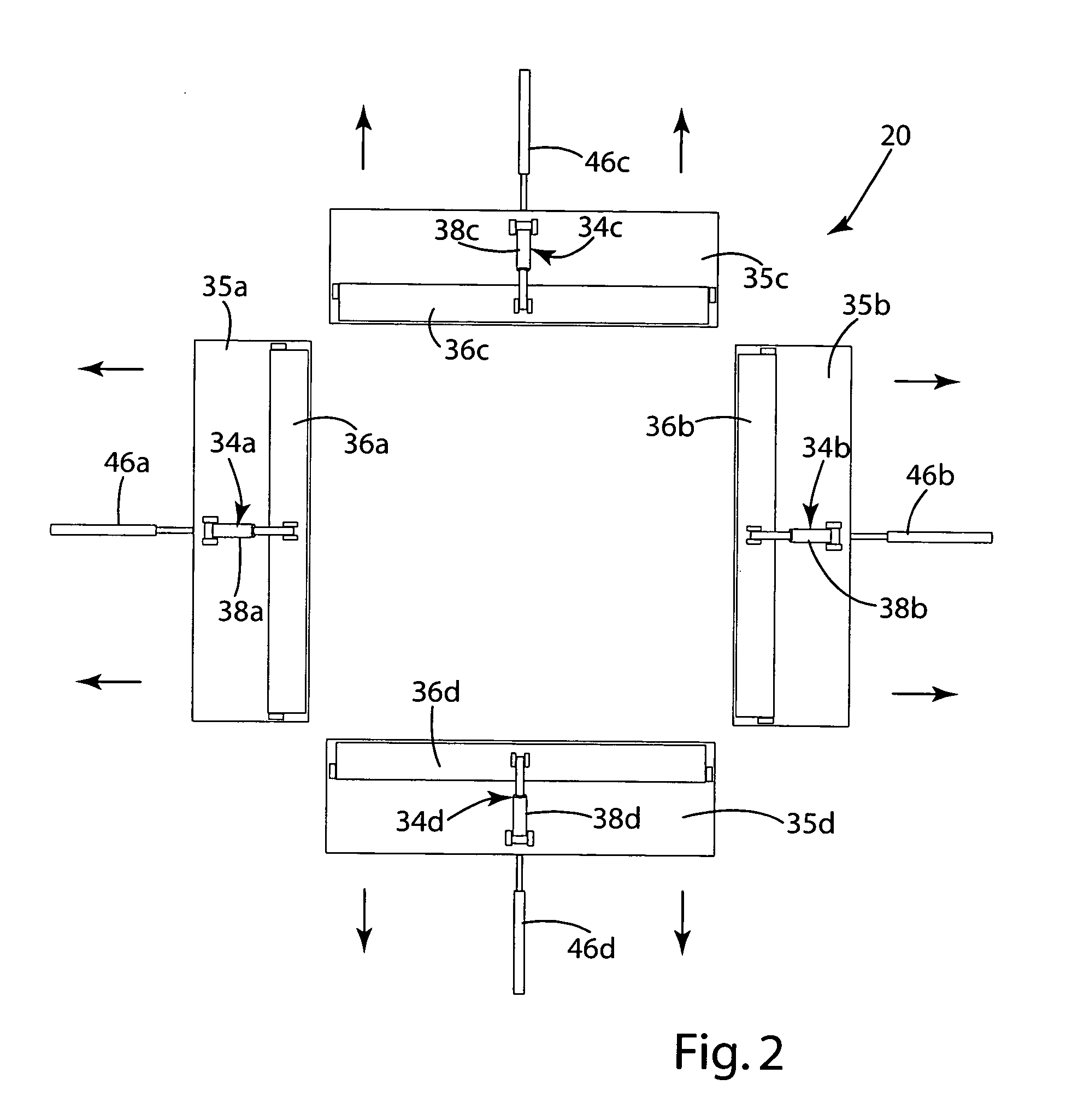

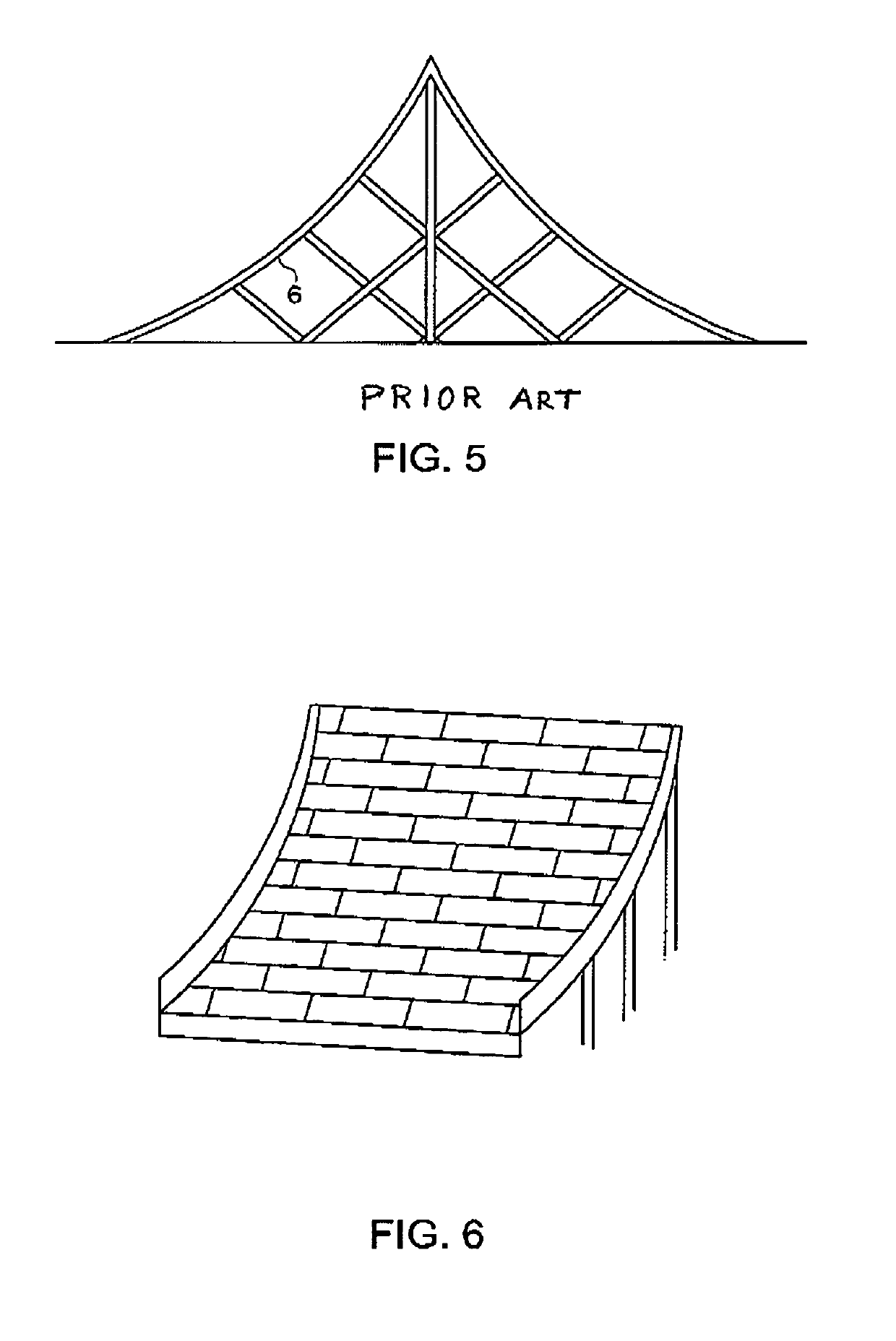

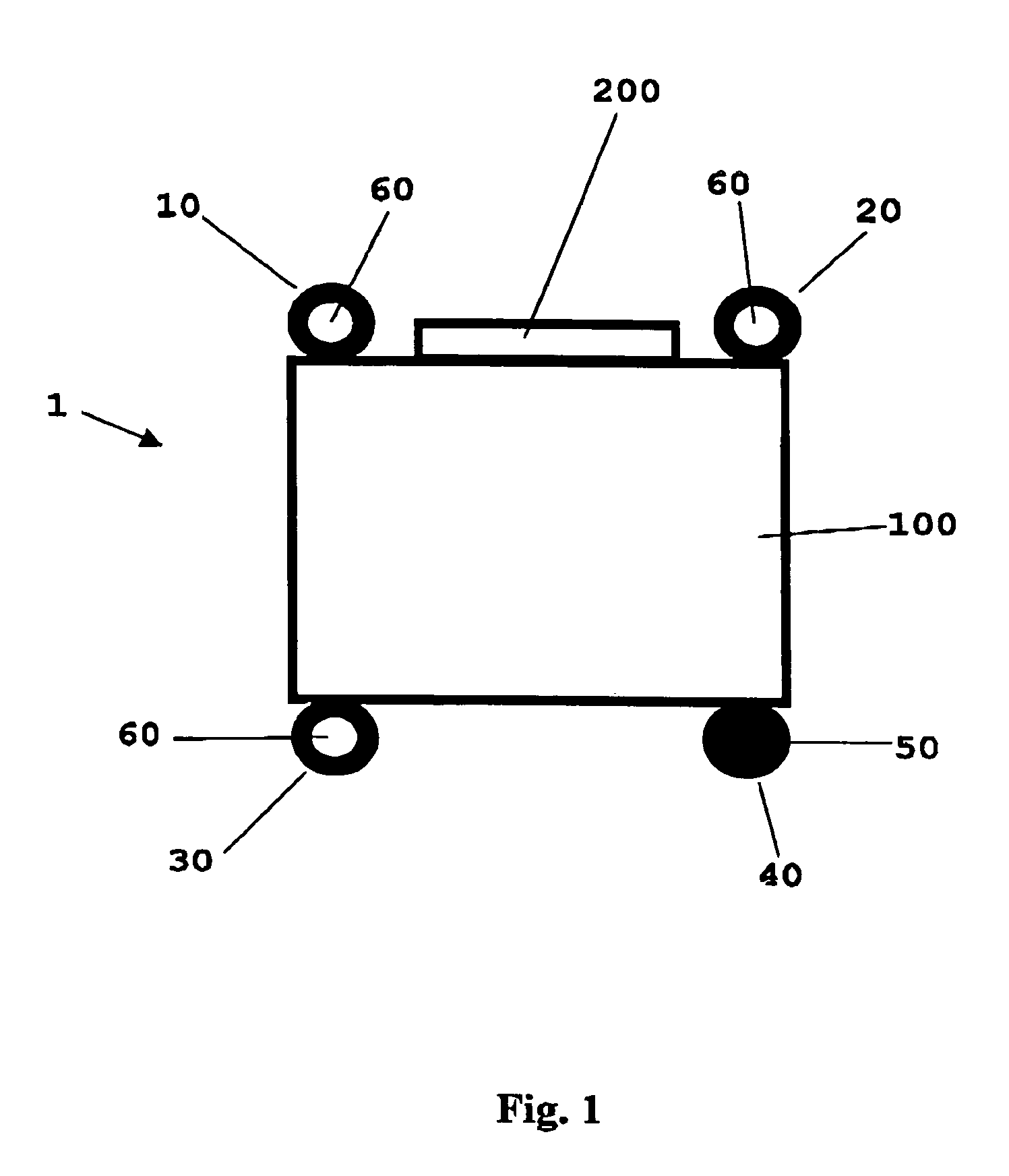

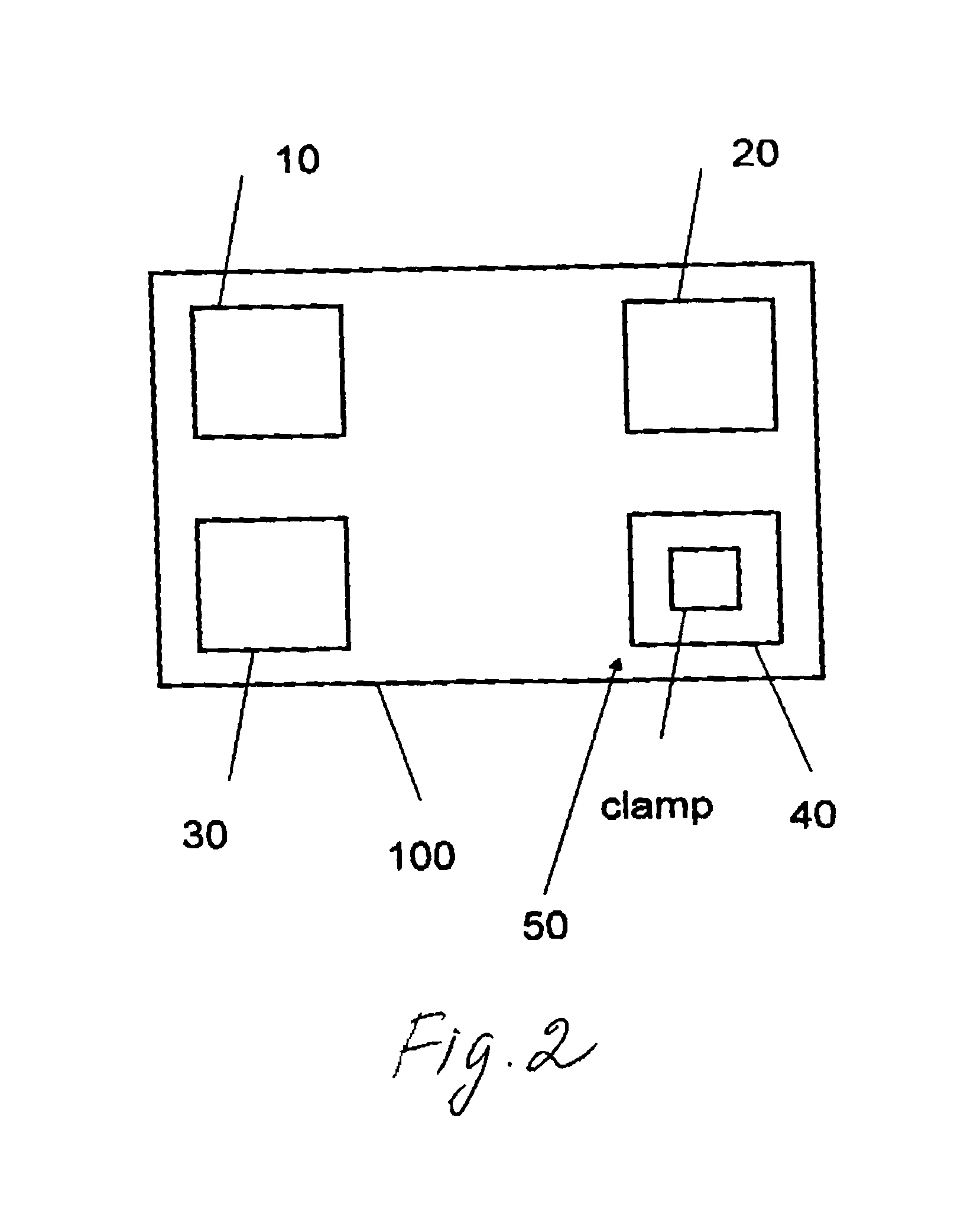

Method and apparatus for manufacturing load bearing fabric support structures

ActiveUS20070035064A1Efficient cycle timeEfficient and effectiveConfectioneryWood working apparatusEngineeringFabric structure

A method and apparatus for manufacturing load bearing fabric structures in which the peripheral edge of the load bearing fabric terminates with the mold cavity. The apparatus includes a stretching assembly for stretching the fabric, a fabric retaining assembly for holding the fabric in the stretched condition and a mold assembly for molding the frame about the periphery of the fabric. The method includes the steps of gripping the peripheral edge of the fabric in a stretching assembly, activating the stretching assembly to stretch the fabric in a location adjacent to the mold assembly, clamping the stretched fabric against a face of the mold assembly, releasing the peripheral edge of the fabric from the stretching assembly, moving the stretching assembly from the path of the mold assembly, closing the mold assembly on the fabric with the peripheral edge of the fabric terminating in the mold cavity and injecting molten material into the mold cavity to form the frame directly on the peripheral edge of the fabric.

Owner:ILLINOIS TOOL WORKS INC

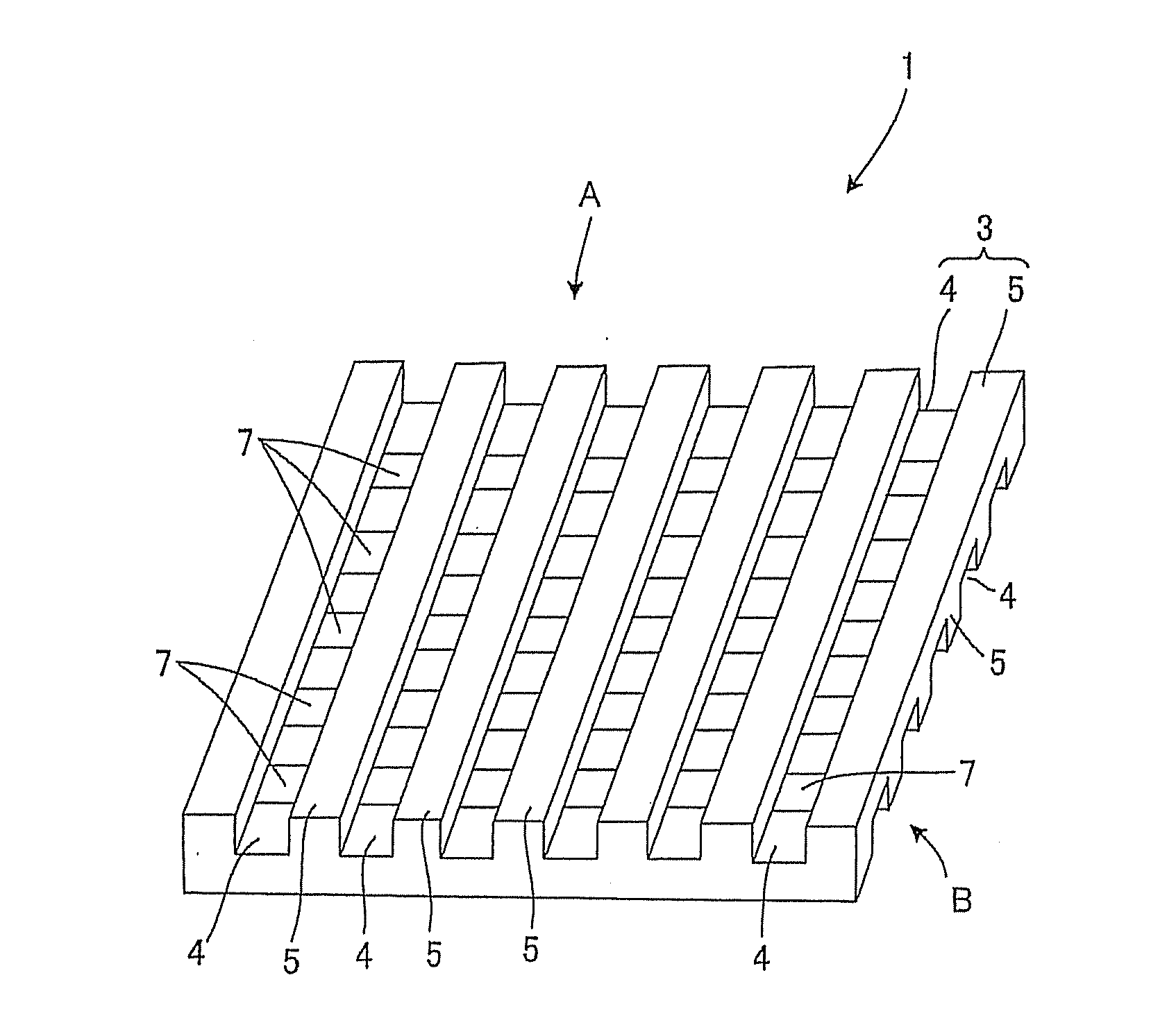

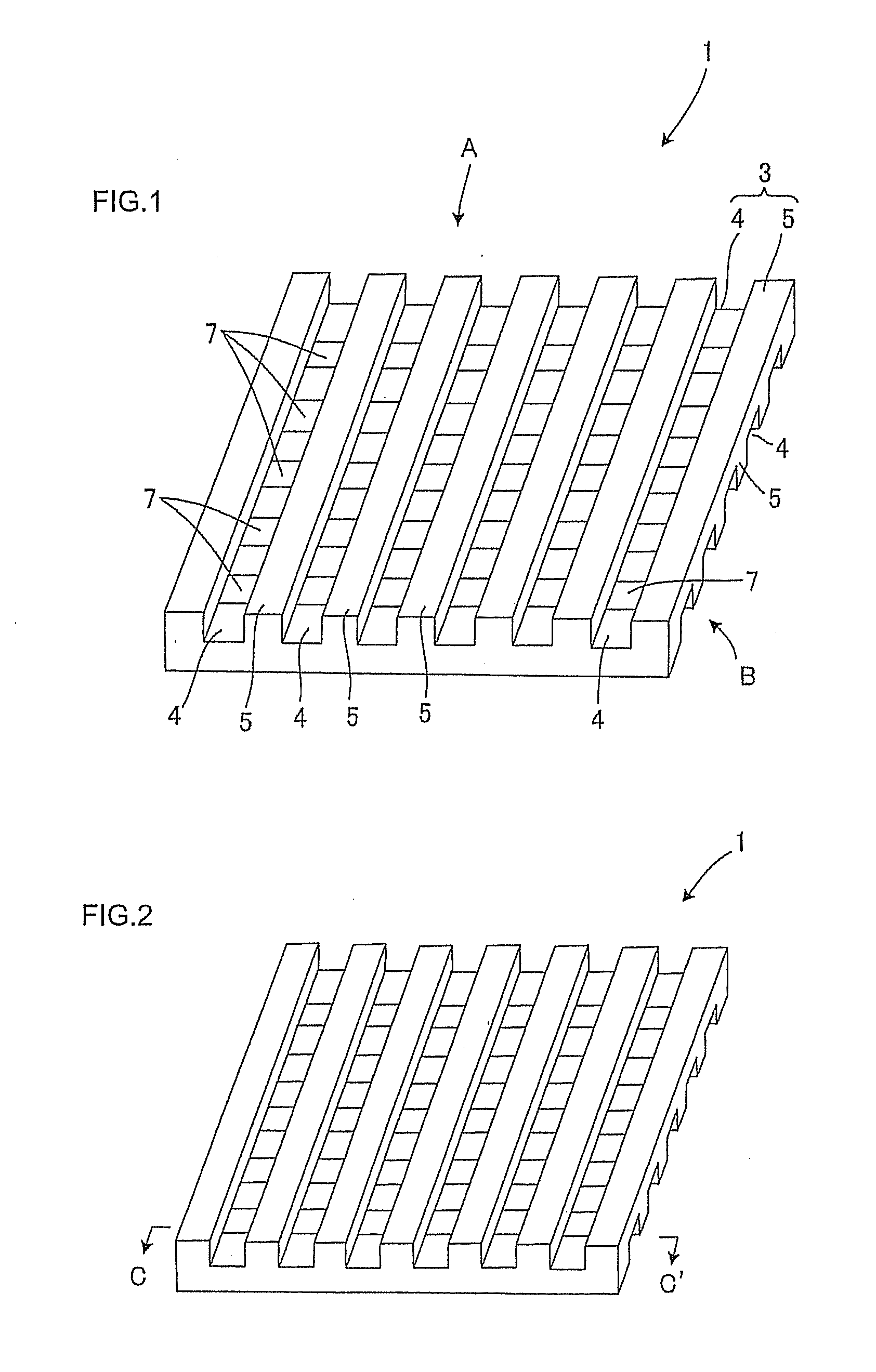

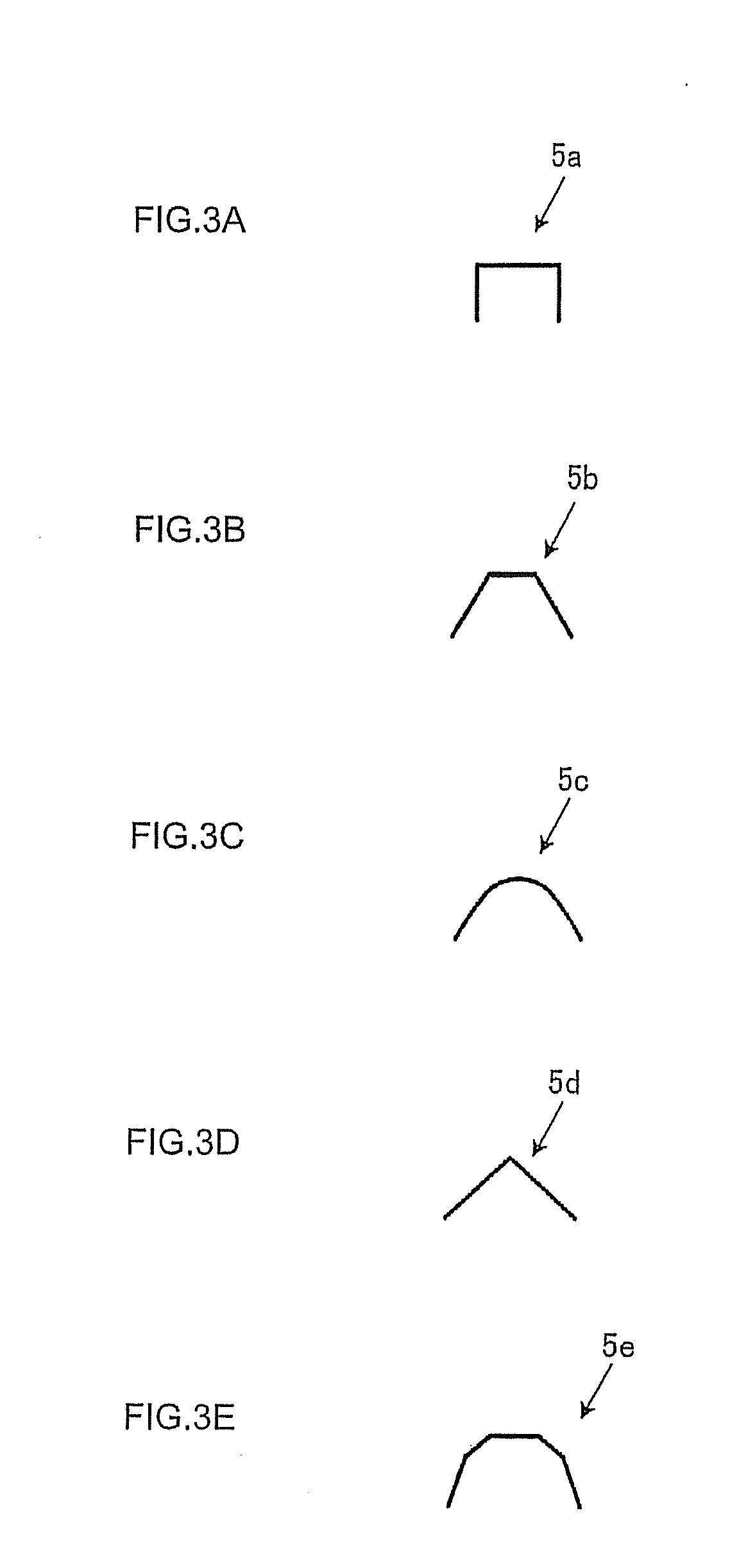

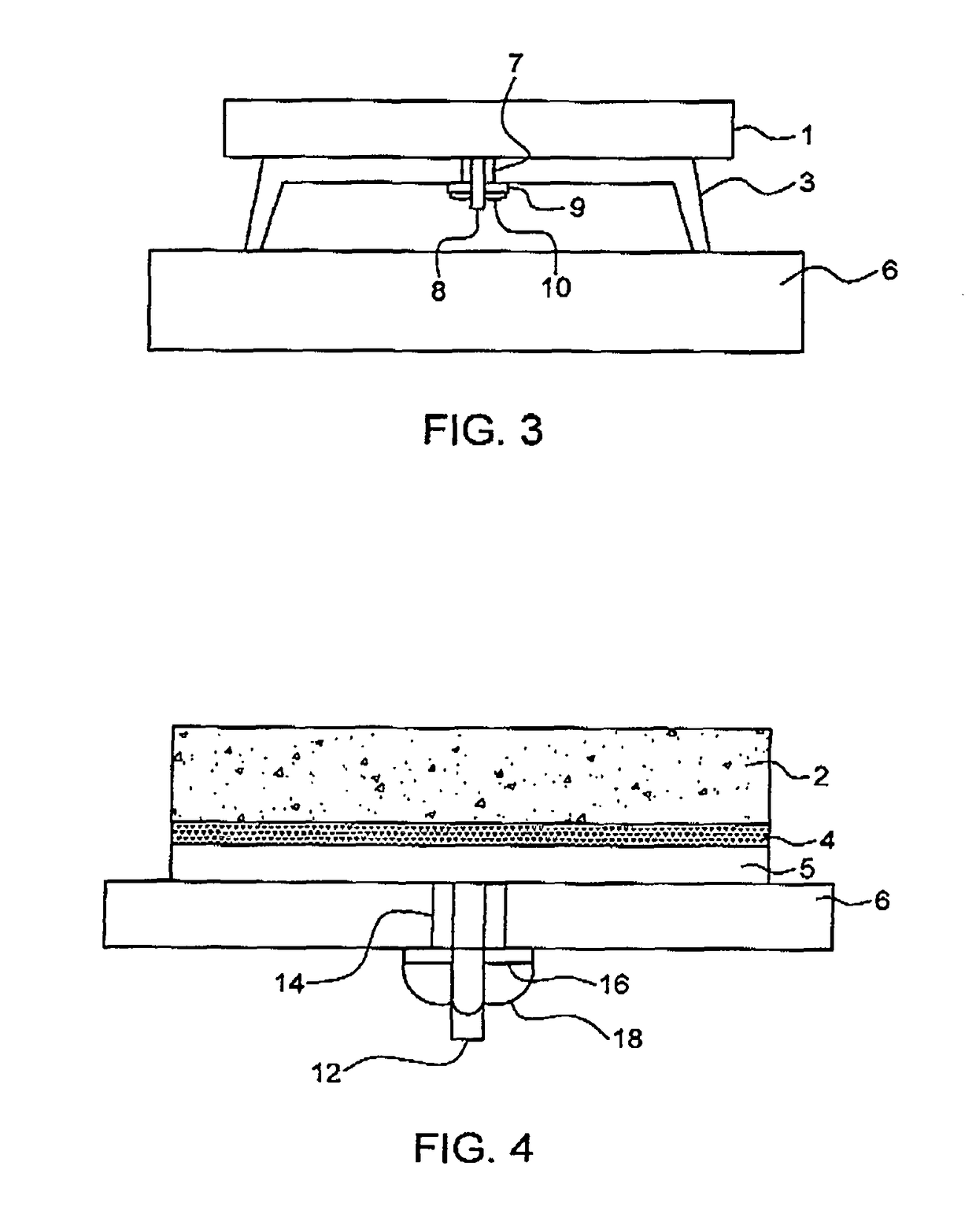

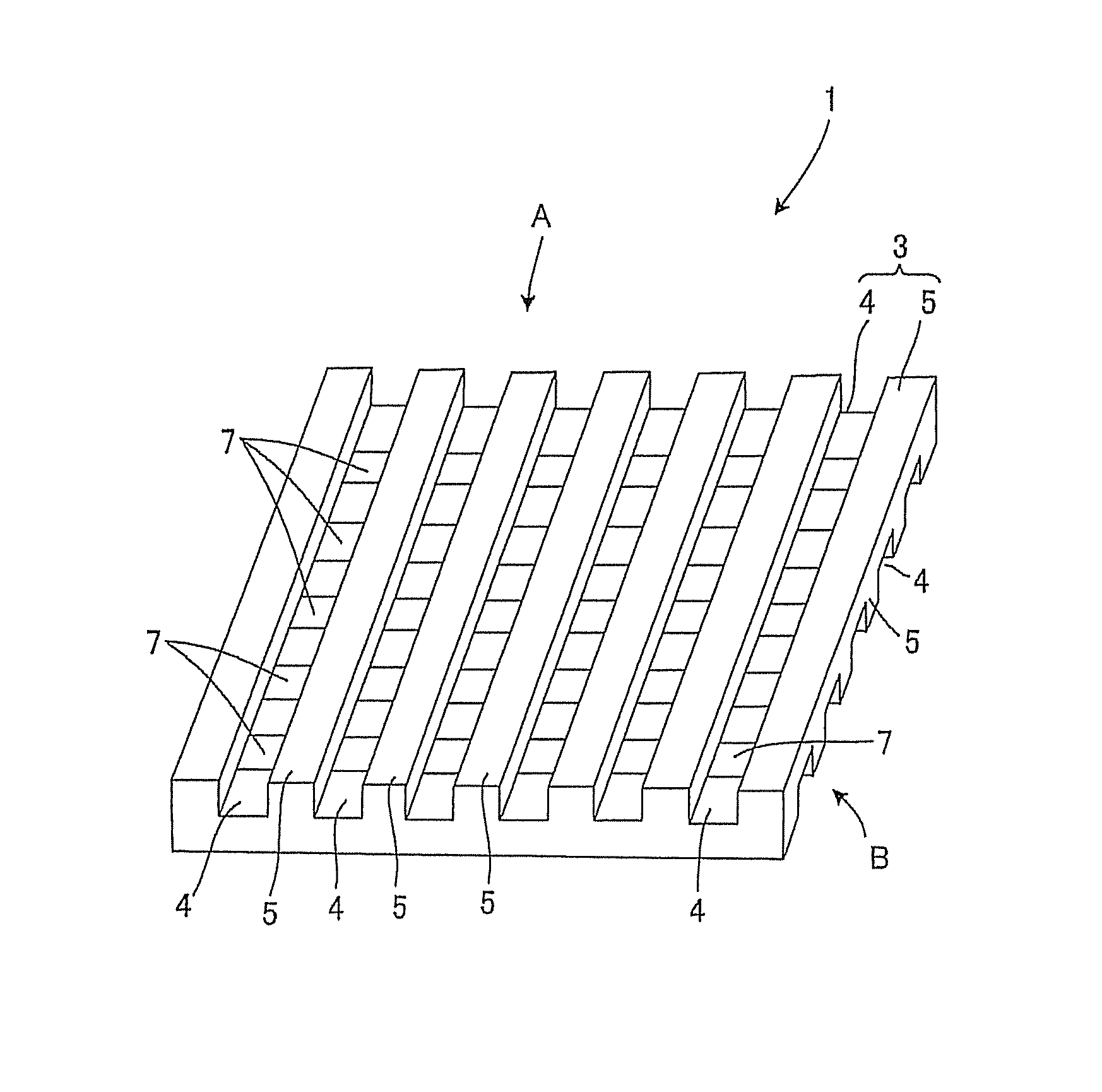

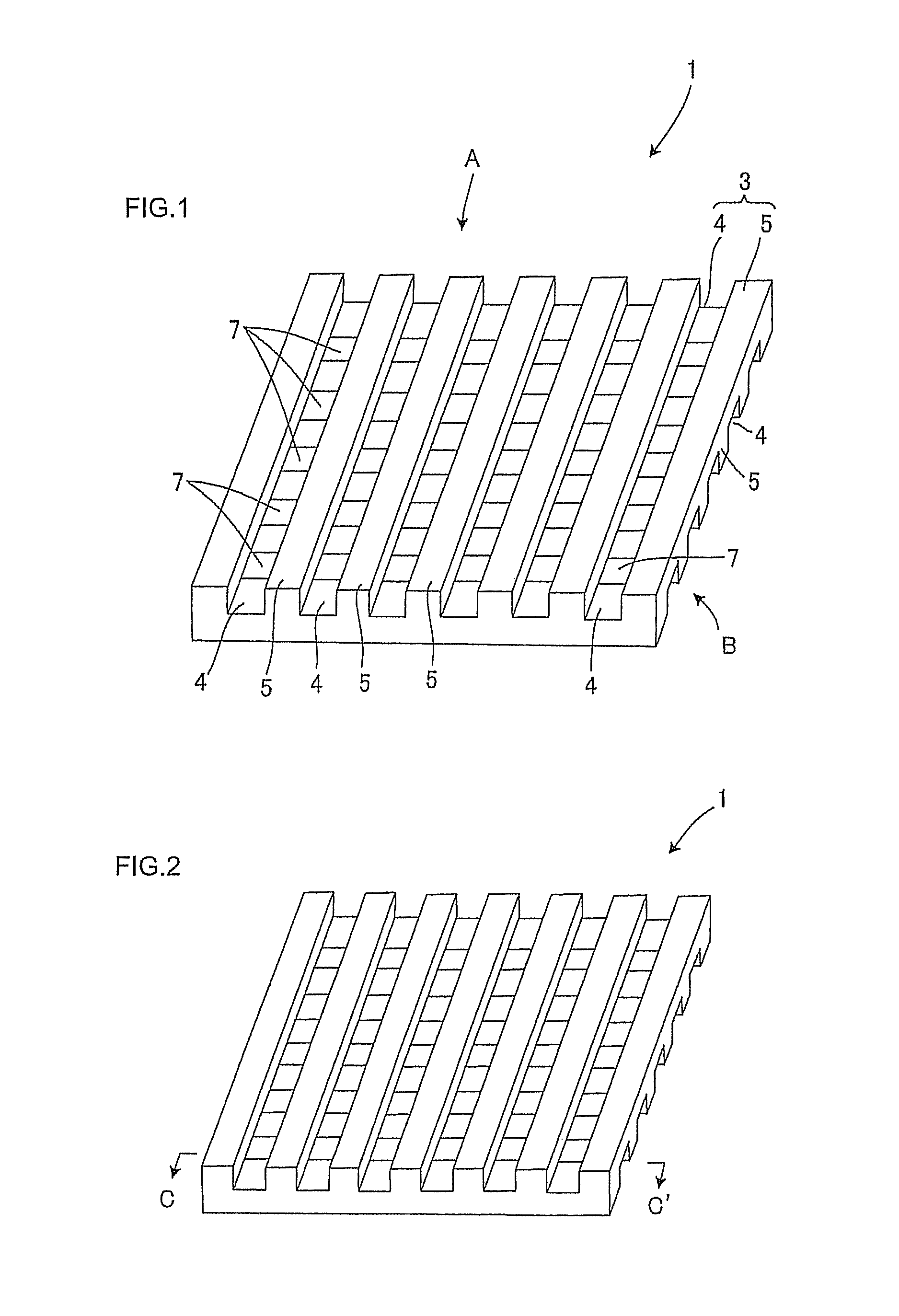

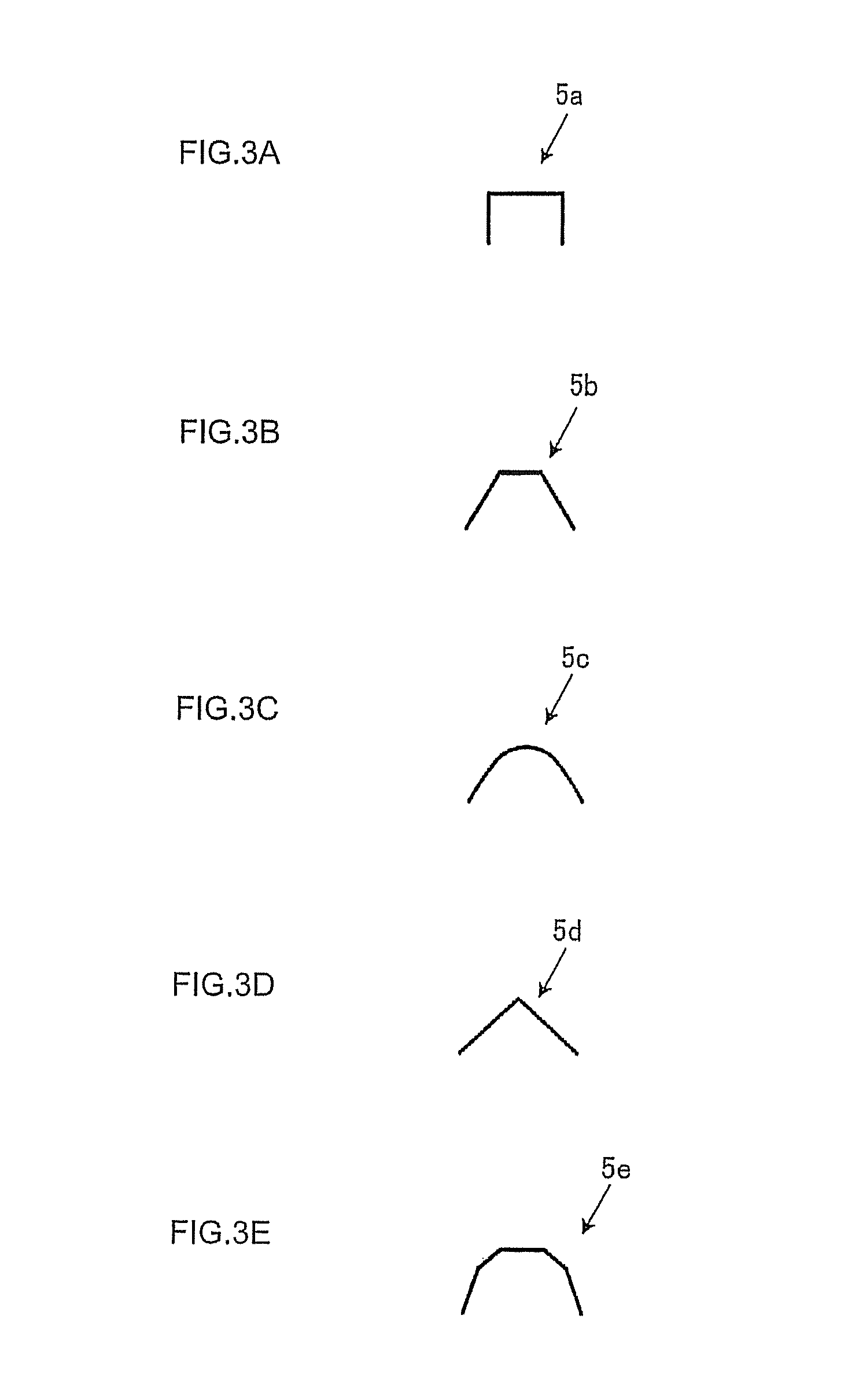

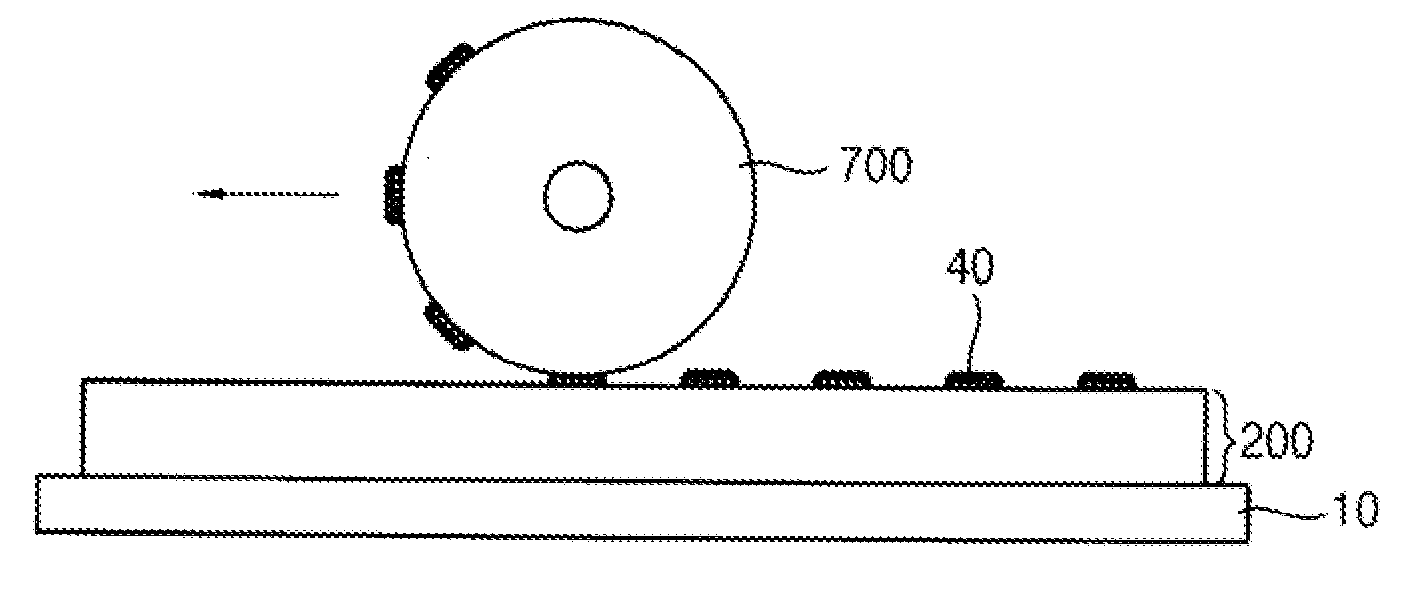

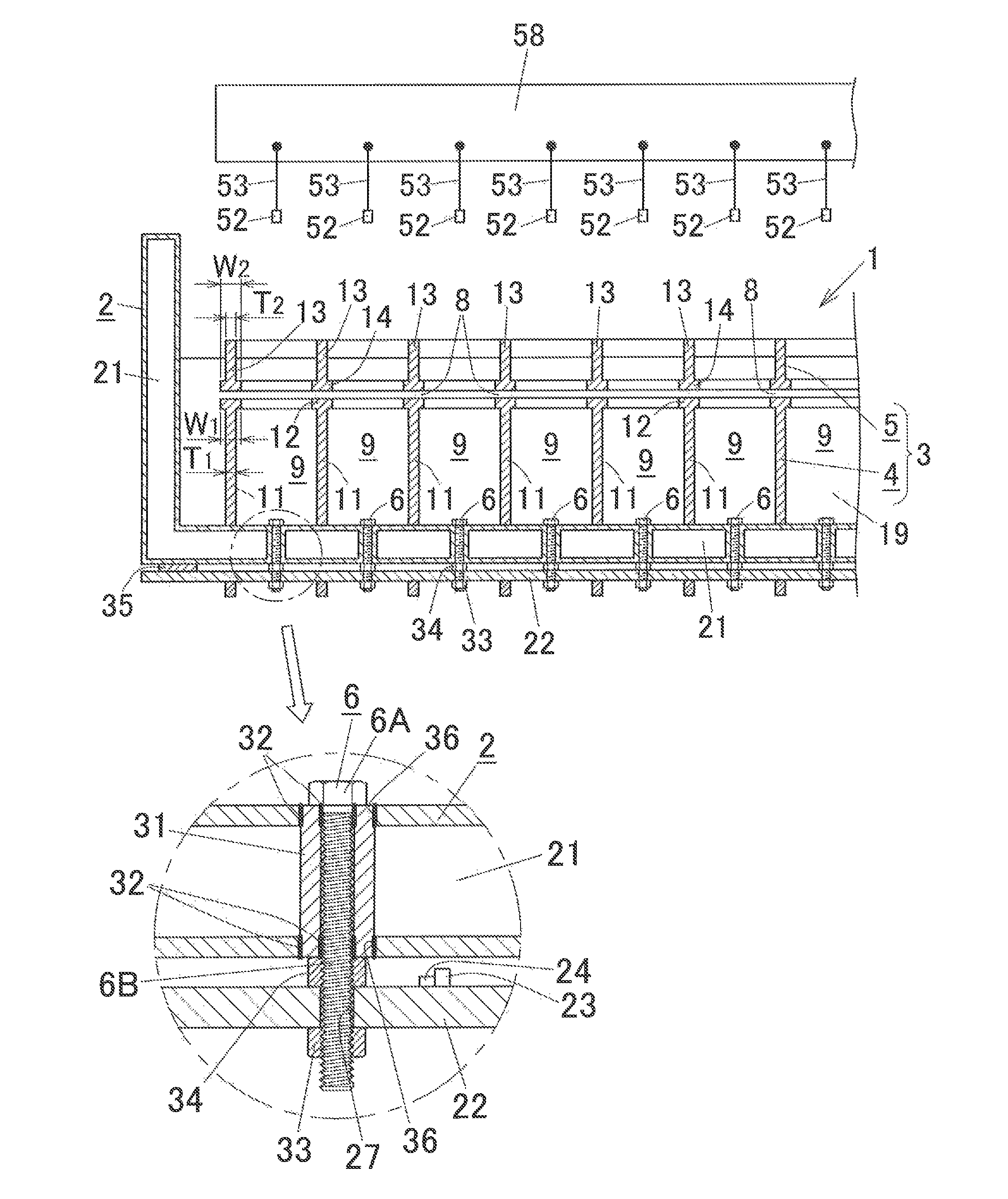

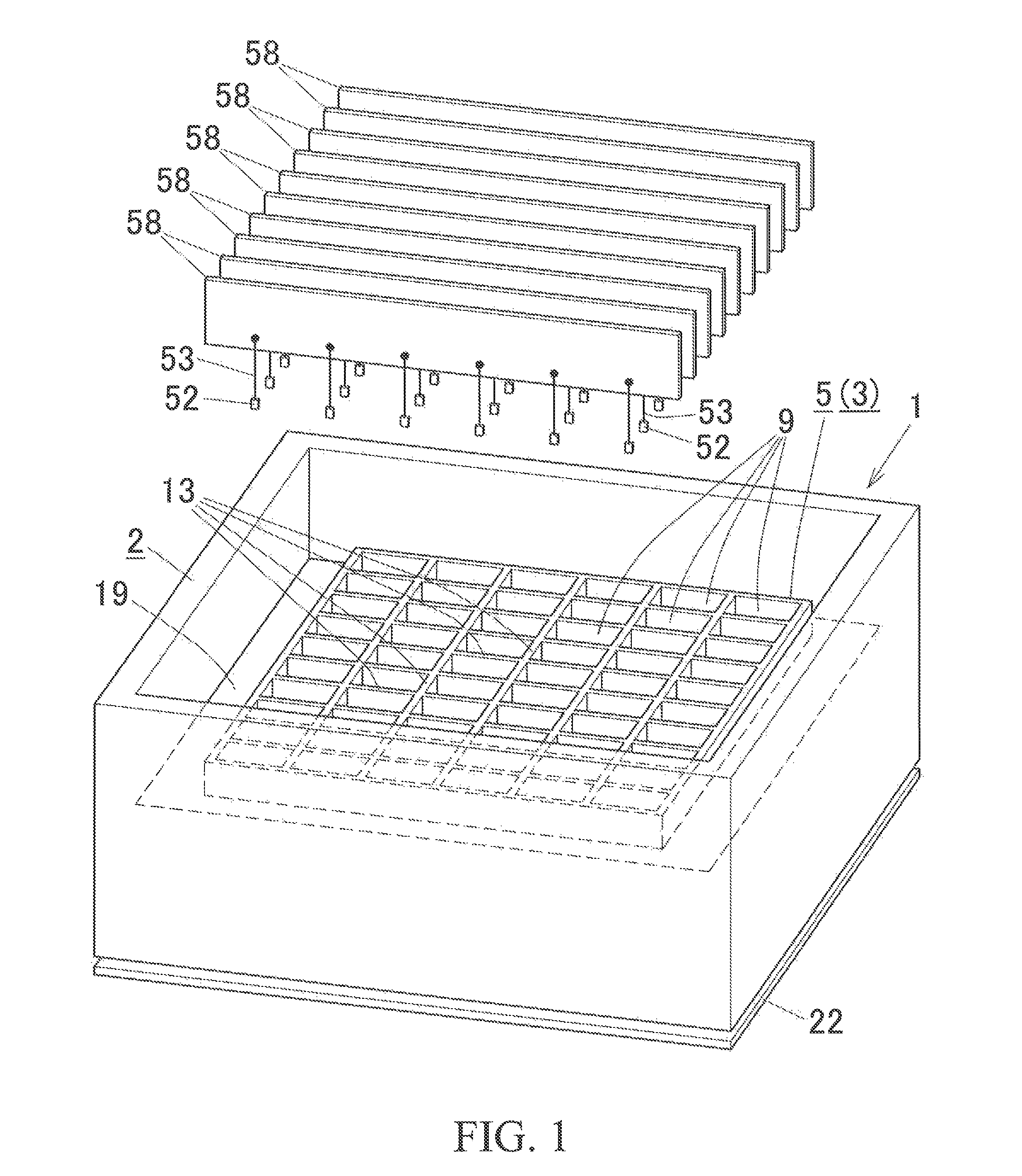

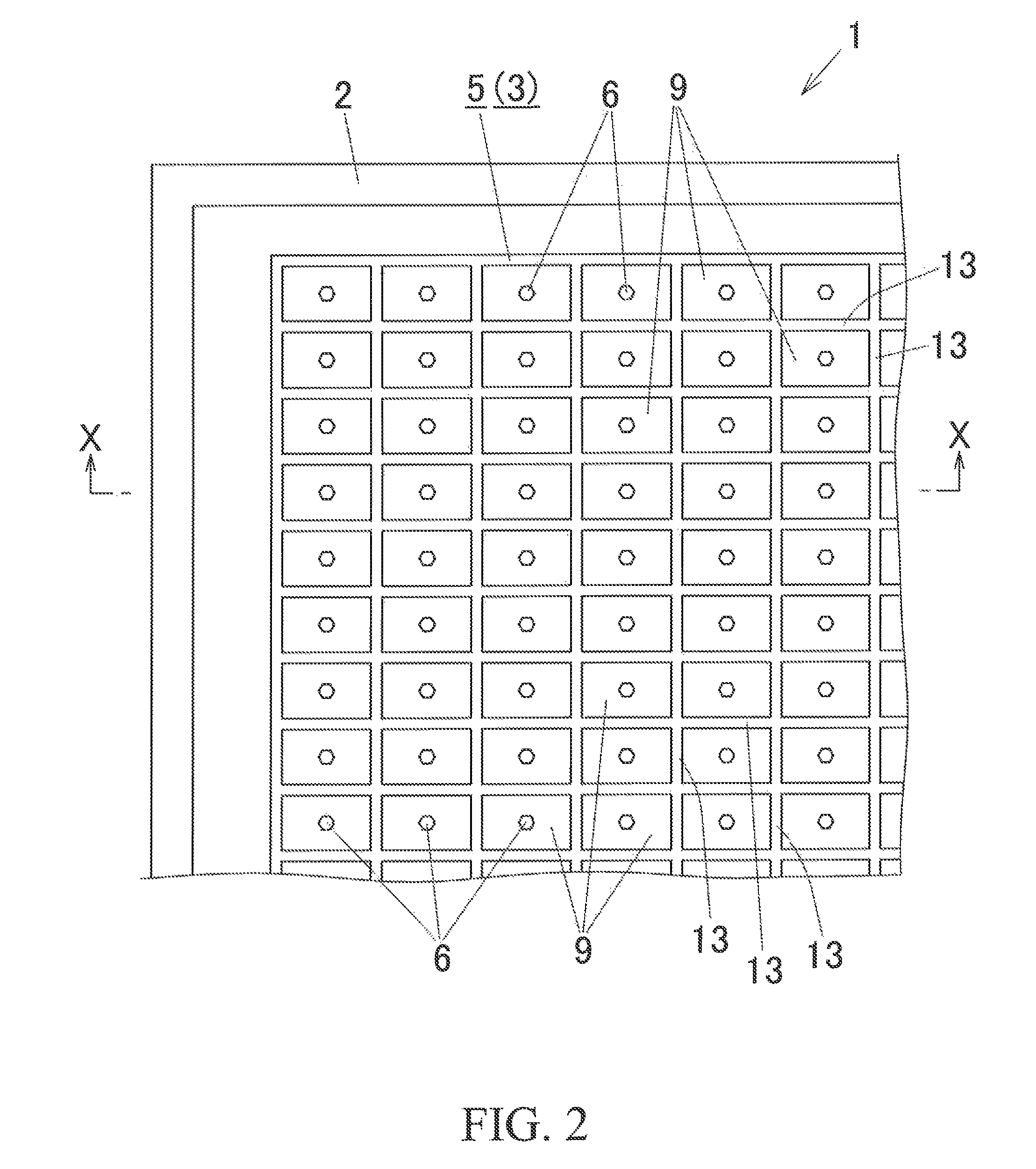

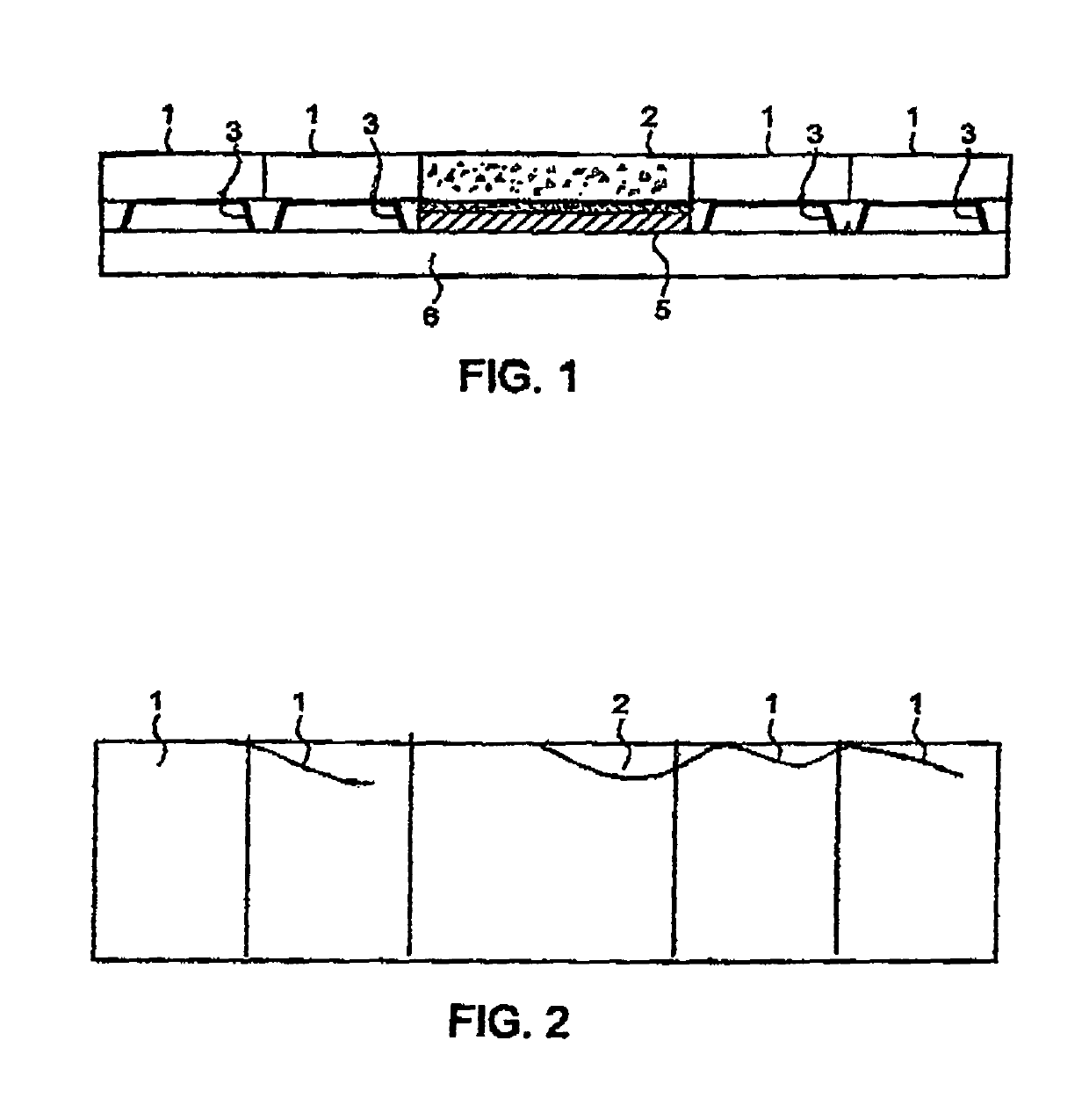

Kiln tool plate for firing ceramic material

ActiveUS20110039221A1Reduce heating capacityLow costCharge supportsCeramic shaping apparatusUltimate tensile strengthHeat capacity

A kiln tool plate 1 for firing a ceramic material used during the firing of an article to be fired, wherein at least uneven conformations 3 are imparted to a front surface side A on which the article to be fired is mounted and a back surface side B, and opening areas 7 are formed. In the ceramic material firing kiln tool plate 1, the decrease of heat capacity and the reduction of costs can be achieved, a contact area with the article to be fired is decreased to improve outgassing, and the atmosphere can be made uniform to uniformly manufacture the fired article. Above all, the kiln tool plate for firing the ceramic material has excellent thermal shock resistance, creep resistance, high strength at high temperature and oxidation resistance, and enables weight saving.

Owner:NGK INSULATORS LTD

Method and apparatus for manufacturing load bearing fabric support structures

ActiveUS7618572B2Efficient and effective and relatively inexpensiveUniformly manufacturedConfectioneryWood working apparatusEngineeringMechanical engineering

Owner:ILLINOIS TOOL WORKS INC

Electrospinning apparatus

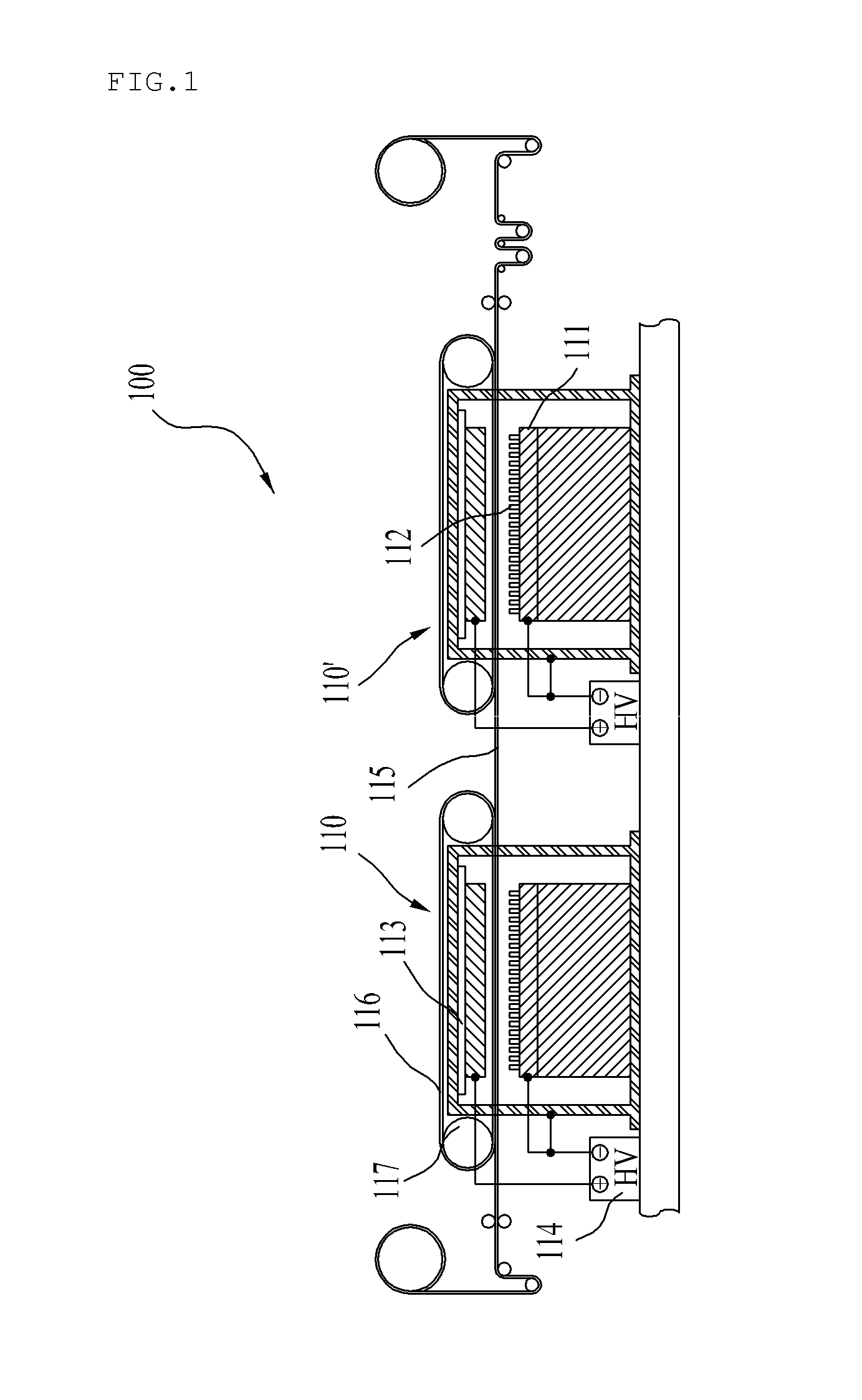

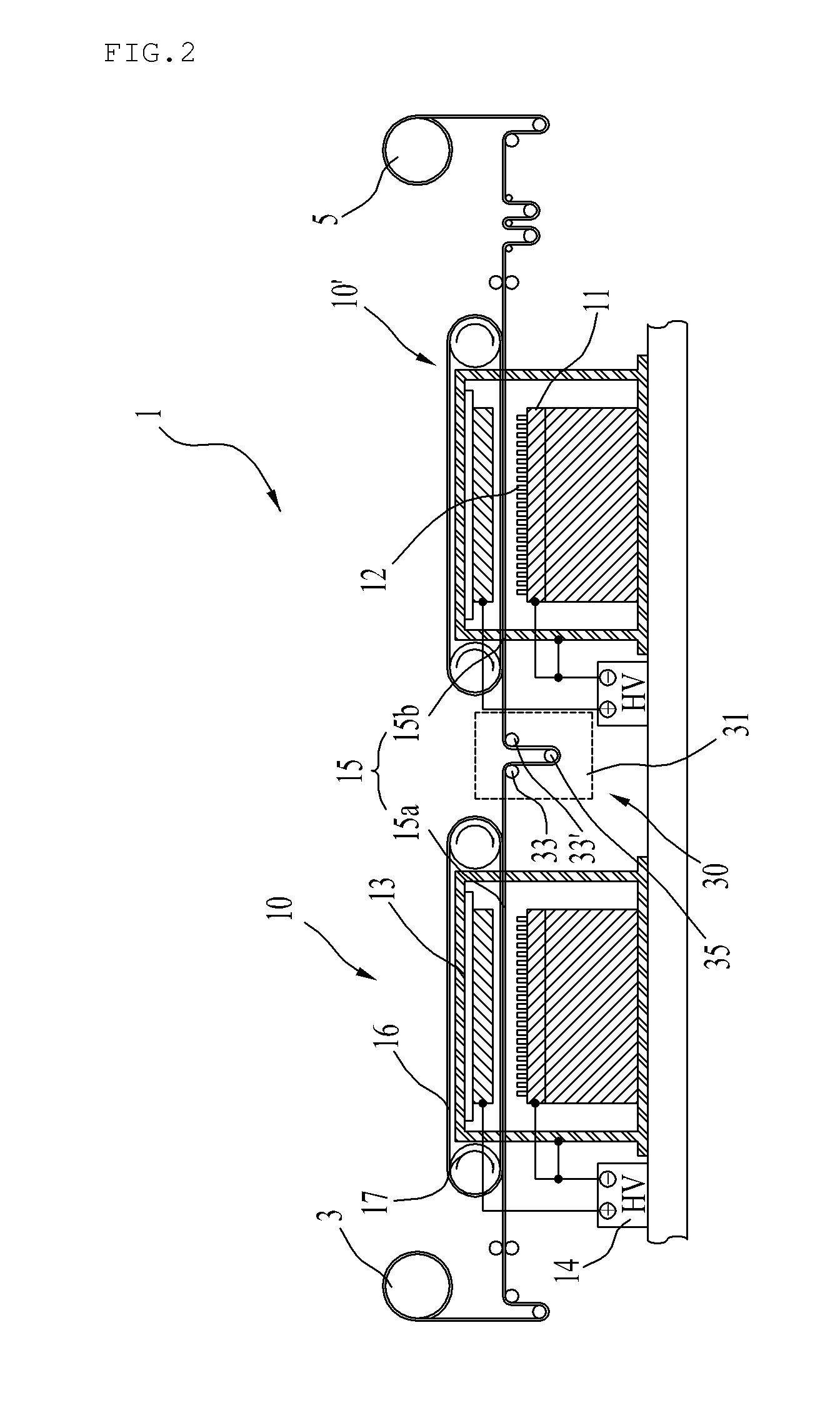

InactiveUS20160060790A1Quality improvementAvoid breakingArtificial thread manufacturing machinesWood working apparatusFiberElectrospinning

An electrospinning apparatus capable of: forming a buffer section between the respective units of the electrospinning apparatus and installing a vertically movable adjustment roller in the buffer section to adjust the transfer speed and time of a long sheet, which passes through the respective units, for each section and prevents the crumpling, sagging, snapping, breakage, and damage of the elongated sheet, avoiding abnormal transfer of the elongated sheet due to electrostatic attraction during electrospinning and, in a nanofiber production step, disposing an apparatus for detecting the sagging of the elongated sheet before and after a spinning zone, detecting the sagging of the elongated sheet, and transmitting the signal to an apparatus for assisting the transfer of the elongated sheet so as to adjust the transfer speed of the elongated sheet. This automatically improves the sagging of the sheet and thereby effectively prevent the problem caused by the sagging of the sheet.

Owner:FINETEX ENE

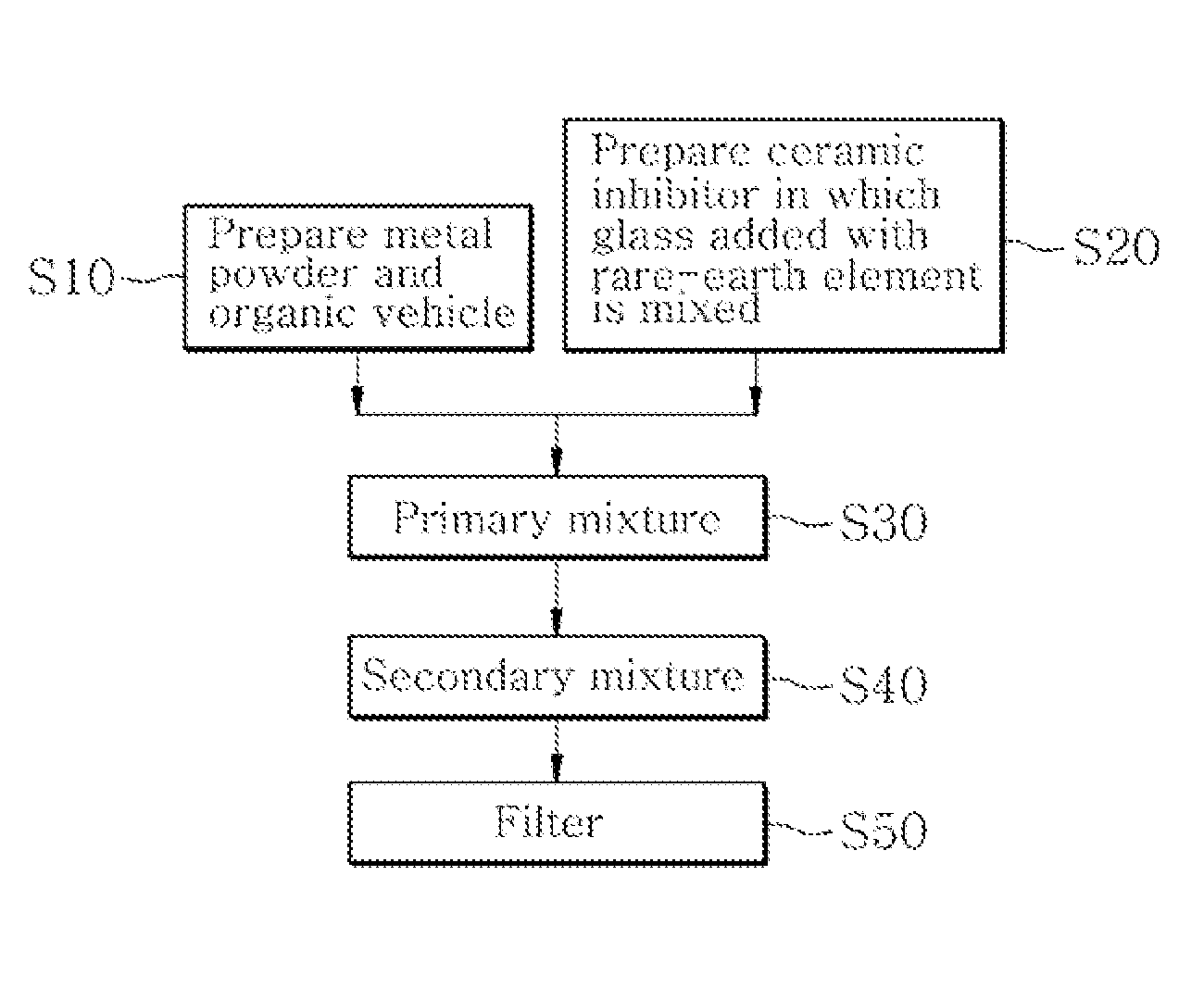

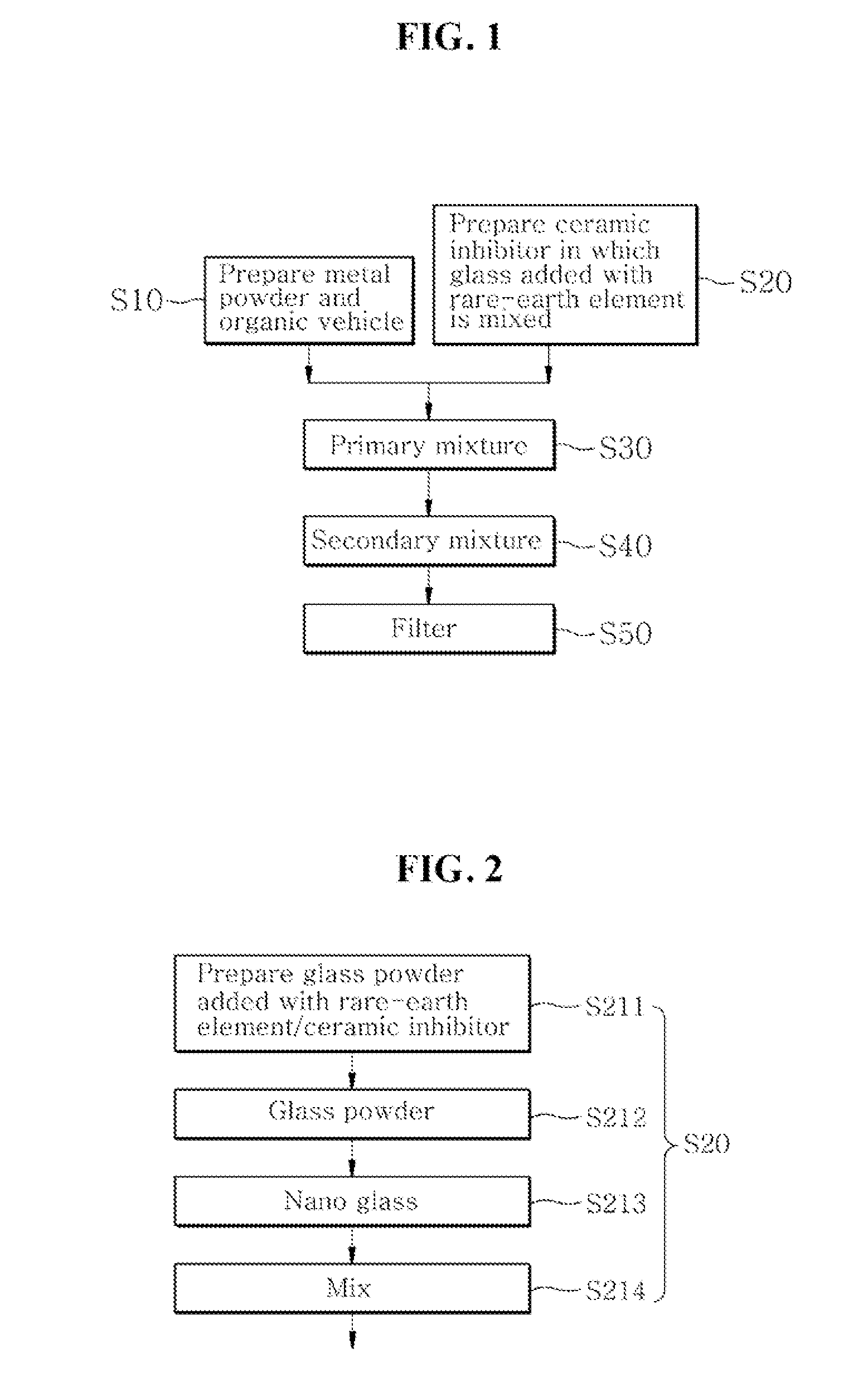

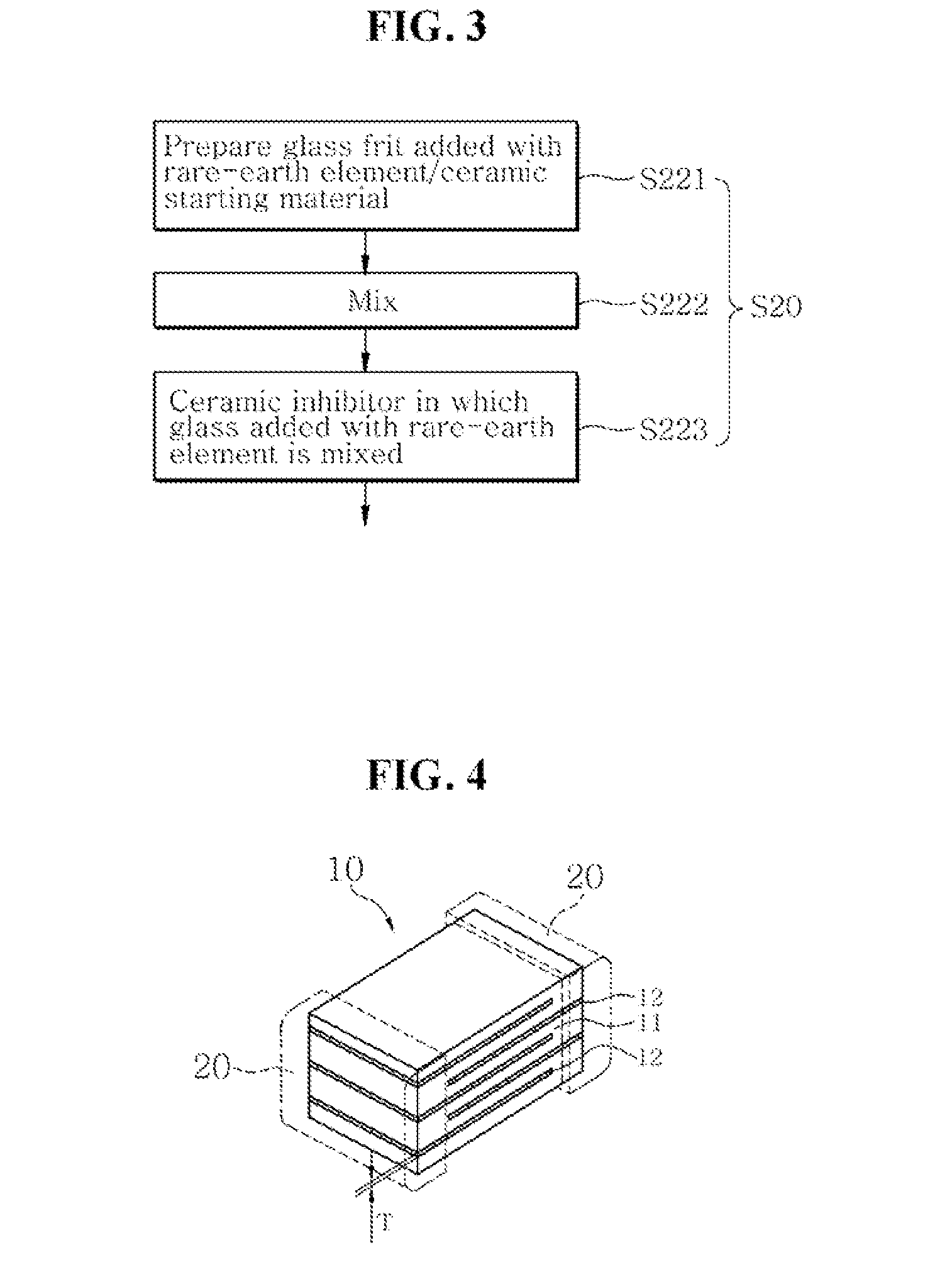

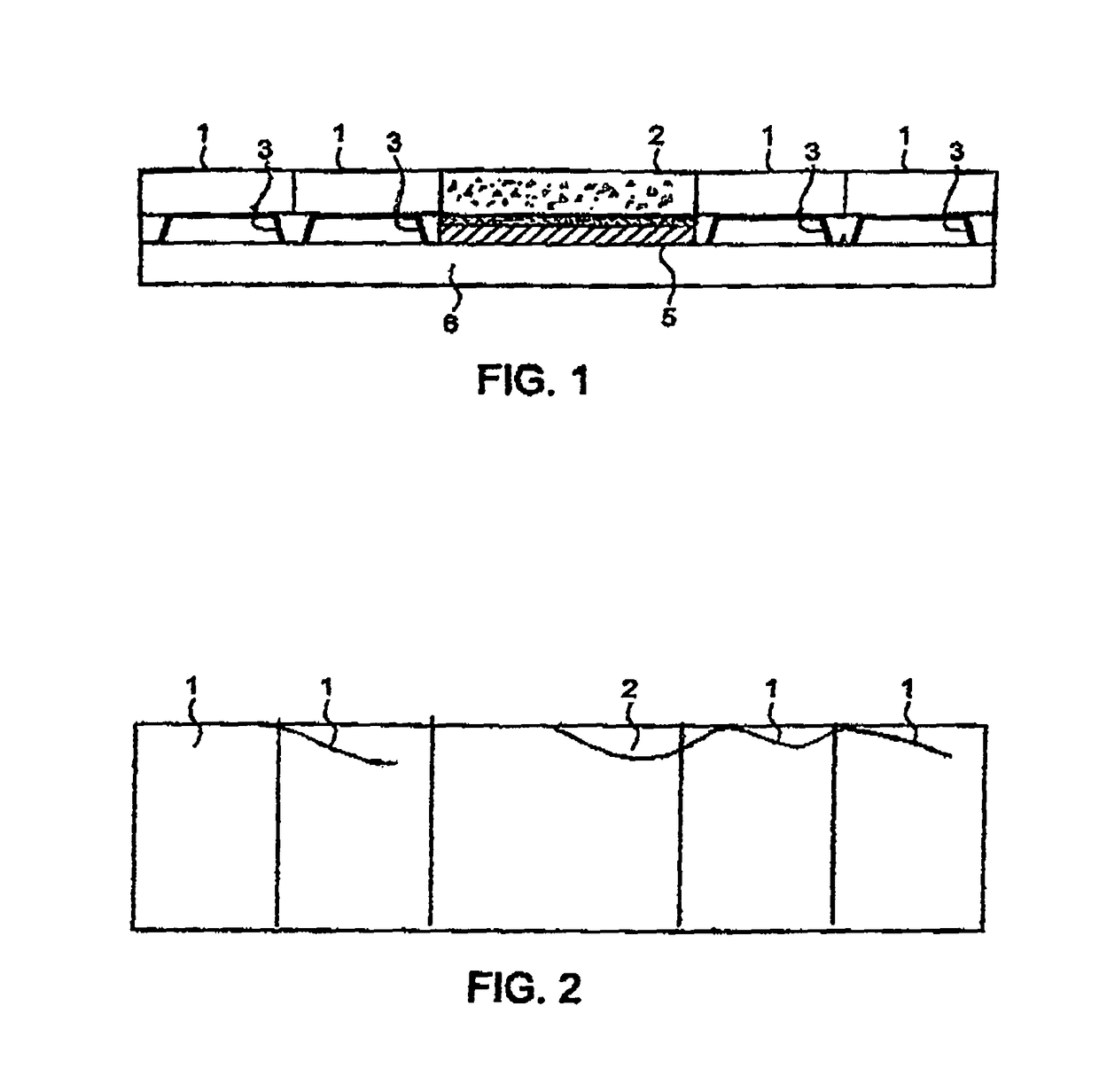

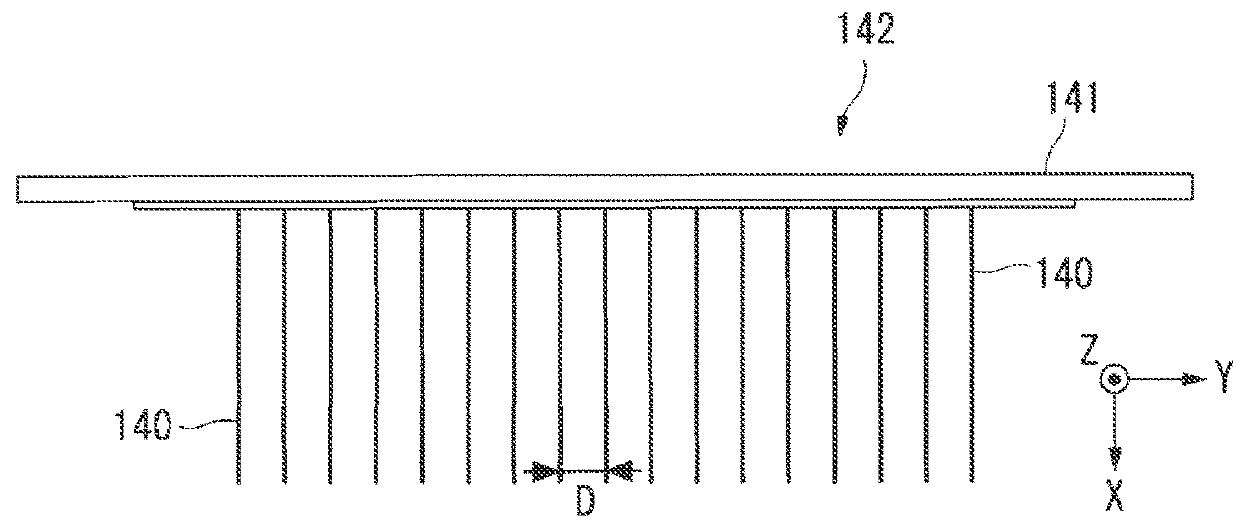

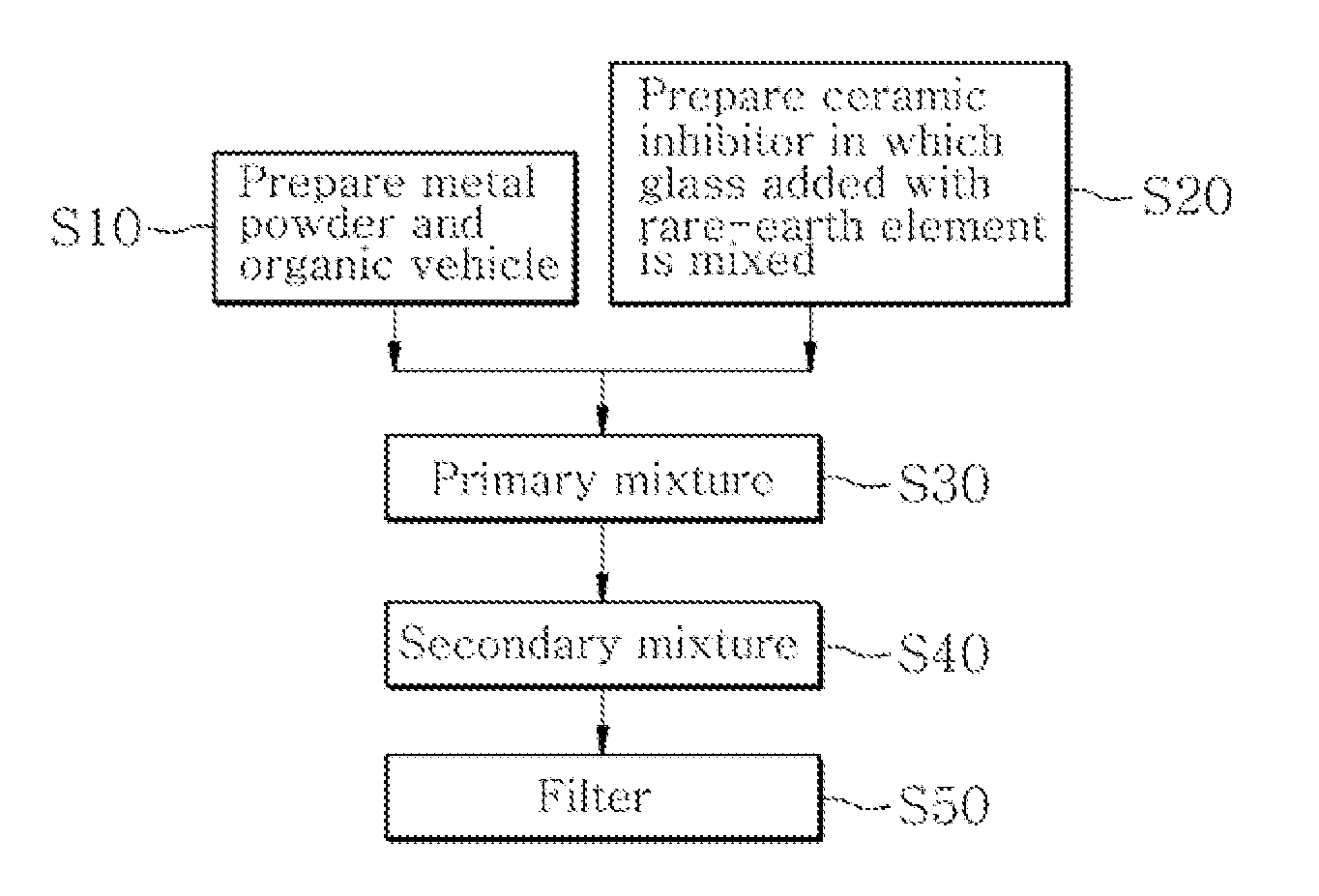

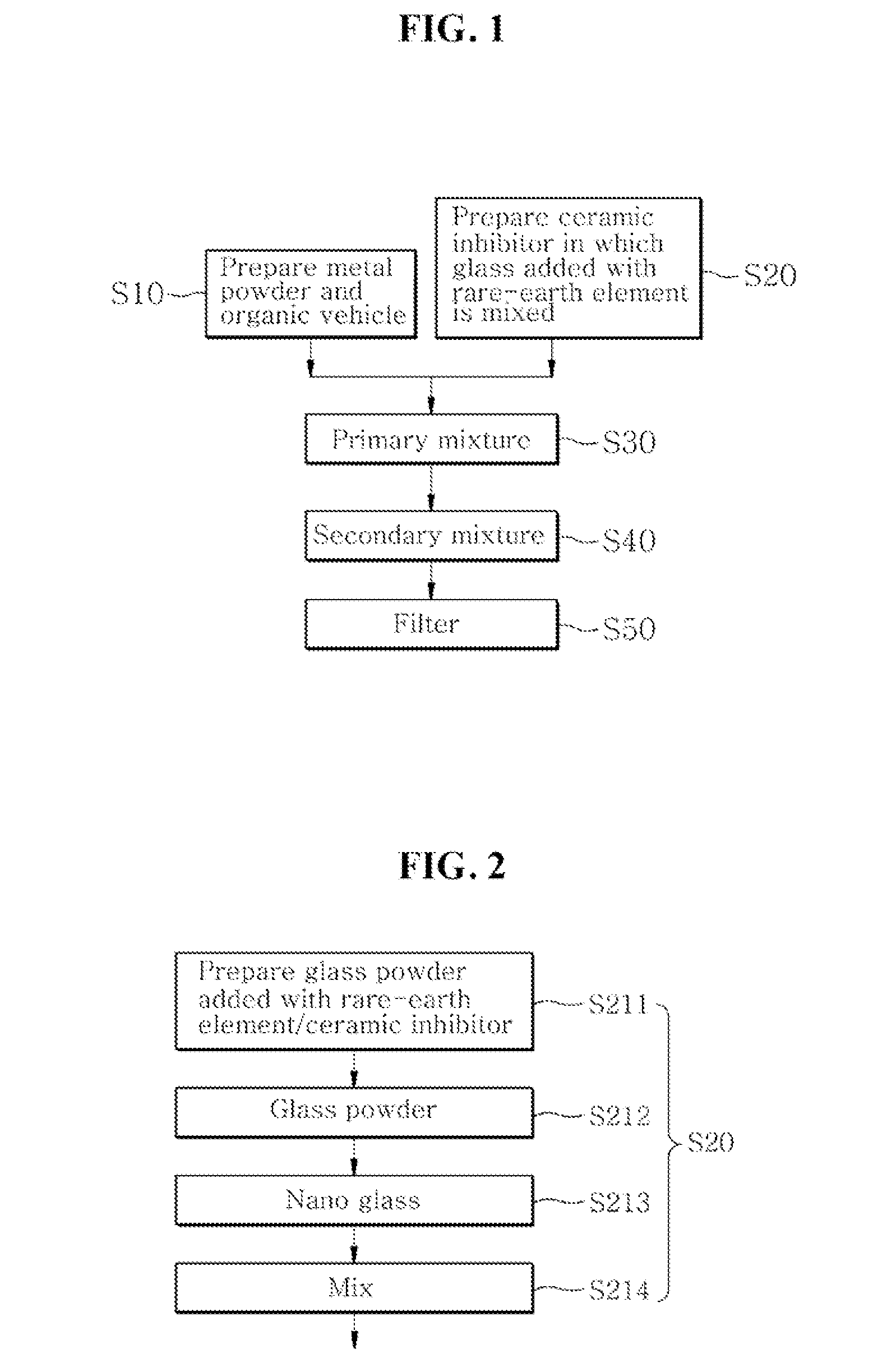

Metal paste manufacturing method for internal electrode of multi layer ceramic capacitor

InactiveUS20130277622A1Small particle sizeMinimizing reactionFixed capacitor dielectricStacked capacitorsRare-earth elementMetallurgy

A method of manufacturing a metal paste for an internal electrode according to the present invention includes preparing each of a metal powder and an organic vehicle; preparing a ceramic inhibitor powder in which a nano glass added with a rare-earth element is mixed; manufacturing a primary mixture by mixing the metal powder of 70 to 95 wt % and the ceramic inhibitor powder of 5 to 30 wt % when each of the metal powder, the organic vehicle, and the ceramic inhibitor powder in which the nano glass added with the rare-earth element is mixed is prepared; manufacturing a secondary mixture by mixing the primary mixture of 50 to 70 wt % and the organic vehicle of 30 to 50 wt % when the primary mixture is manufactured; and manufacturing the metal paste for the internal electrode by filtering the secondary mixture when the secondary mixture is manufactured.

Owner:SAMHWA CAPACITOR

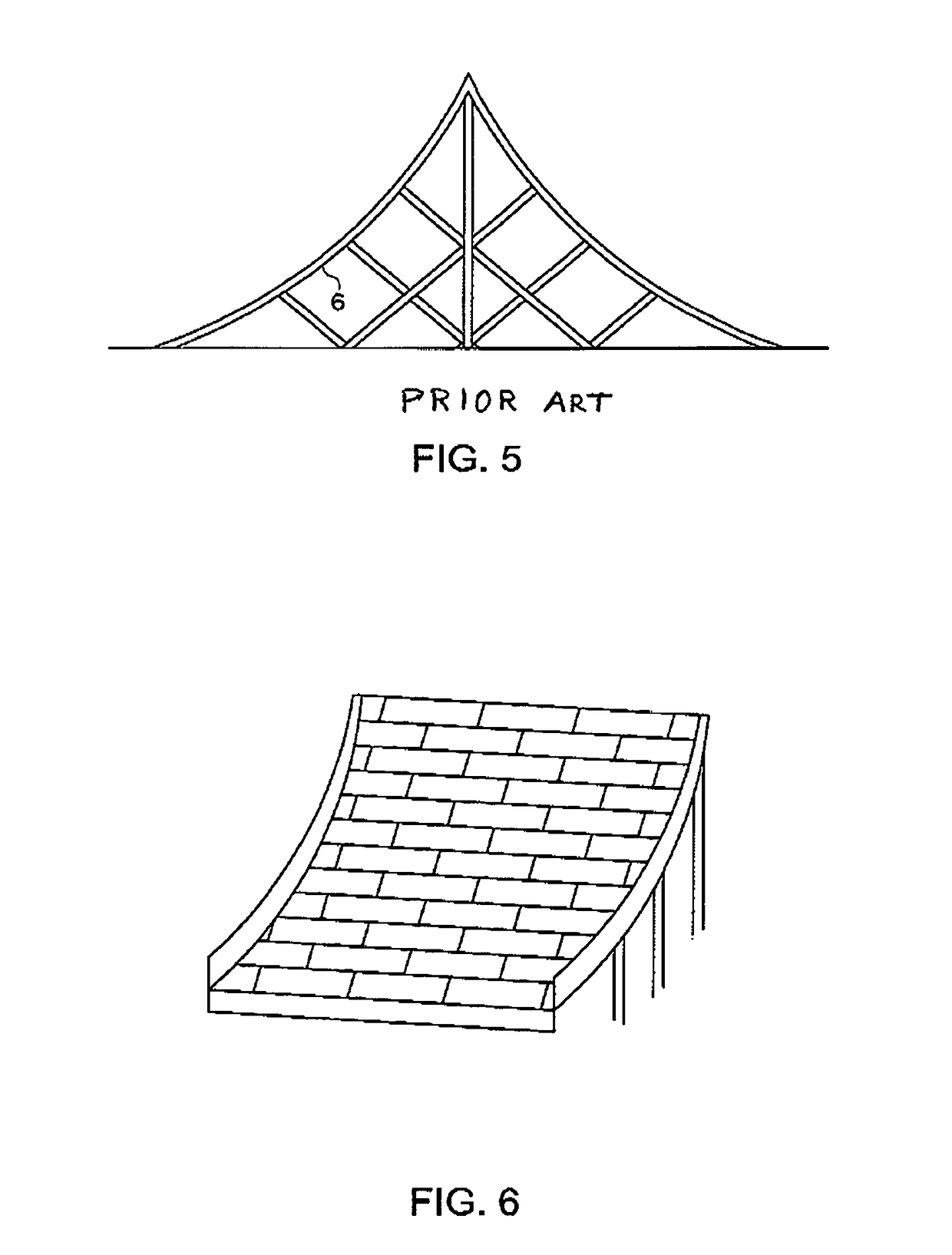

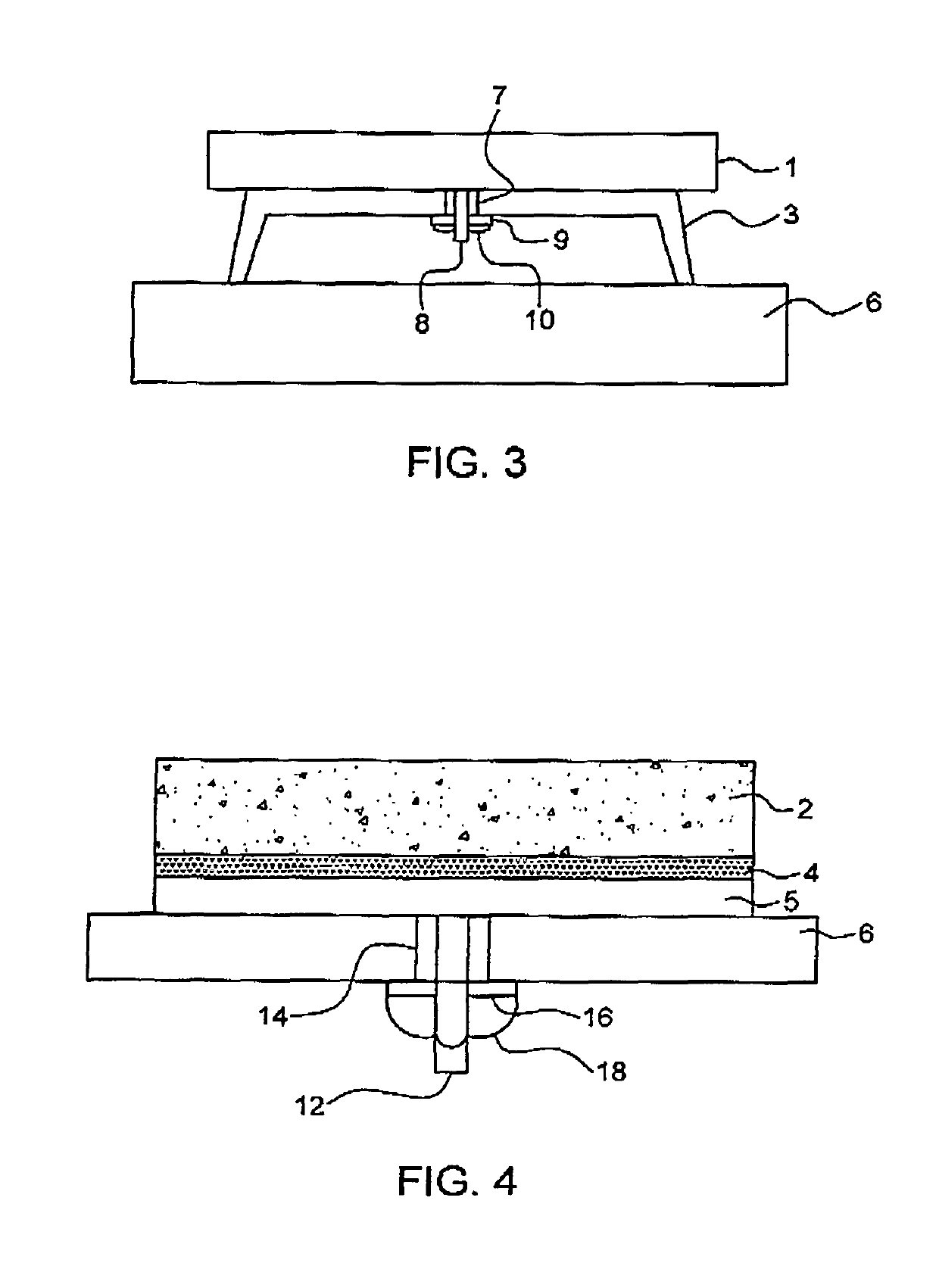

Launch pad flame deflector structure and method of making the same

InactiveUS10150580B1Minimizes spalling of the refractoryRisk minimizationCosmonautic ground equipmentsPretreated surfacesRefractoryRocket

Flame deflectors for rocket launchpads have historically been constructed on-site by spraying on a layer of refractory cement material, resulting in large monolithic structures which lack durability and are vulnerable to degradation by ambient weather. By assembling together a plurality of metal modules and refractory material modules, one obtains a flame deflector structure whose set of modules is matched to an expected heat distribution pattern of the exhaust from the rocket to be launched. Further, modules can be prefabricated at another location, under controlled conditions, and subsequently installed. In case of damage during a launch, any damaged modules can be swapped out and replaced by new modules, thereby minimizing cost and downtime before a subsequent launch event. The modules can be made more weather-resistant by applying an epoxy sealant to their rocket-facing surfaces.

Owner:RENZI FAMILY TRUST

Kiln tool plate for firing ceramic material

ActiveUS9279618B2Improve thermal shock resistanceHigh strengthCharge supportsCeramic shaping apparatusUltimate tensile strengthHeat capacity

A kiln tool plate for firing a ceramic material used during the firing of an article to be fired, where at least uneven conformations are imparted to a front surface side on which the article to be fired is mounted and a back surface side, and opening areas are formed. In the ceramic material firing kiln tool plate, the decrease of heat capacity and the reduction of costs can be achieved, a contact area with the article to be fired is decreased to improve outgassing, and the atmosphere can be made uniform to uniformly manufacture the fired article. Above all, the kiln tool plate for firing the ceramic material has excellent thermal shock resistance, creep resistance, high strength at high temperature and oxidation resistance, and enables weight saving.

Owner:NGK INSULATORS LTD

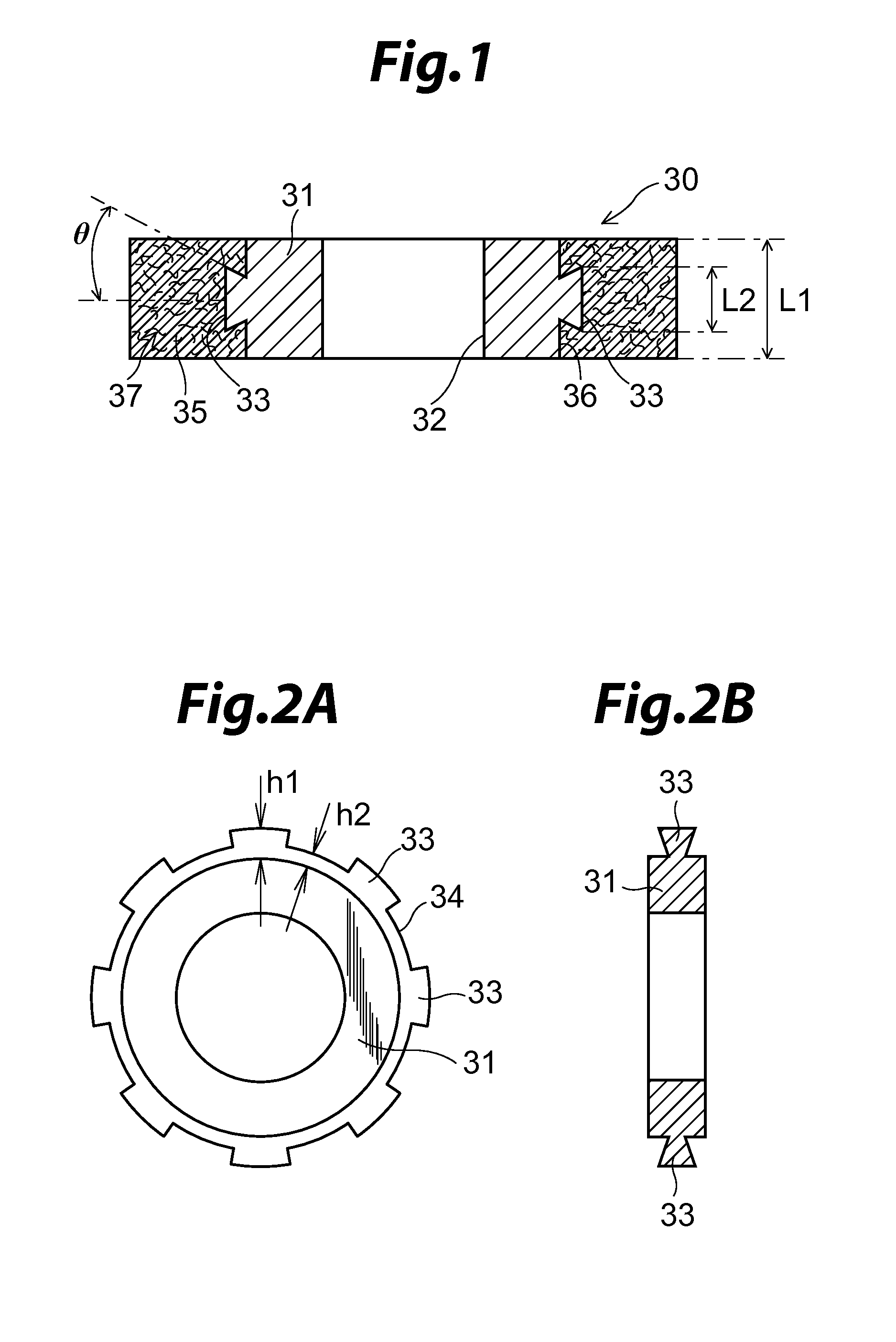

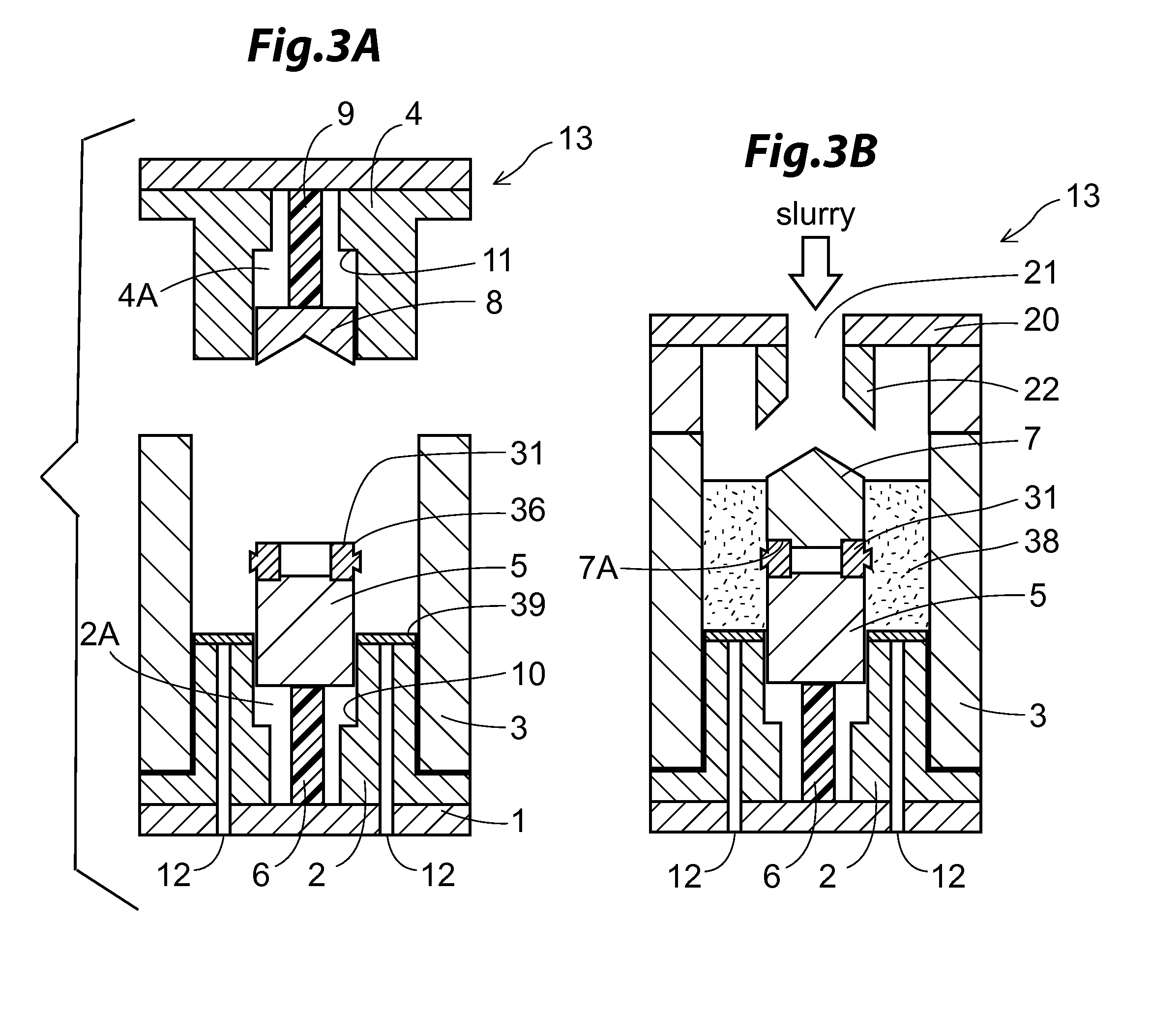

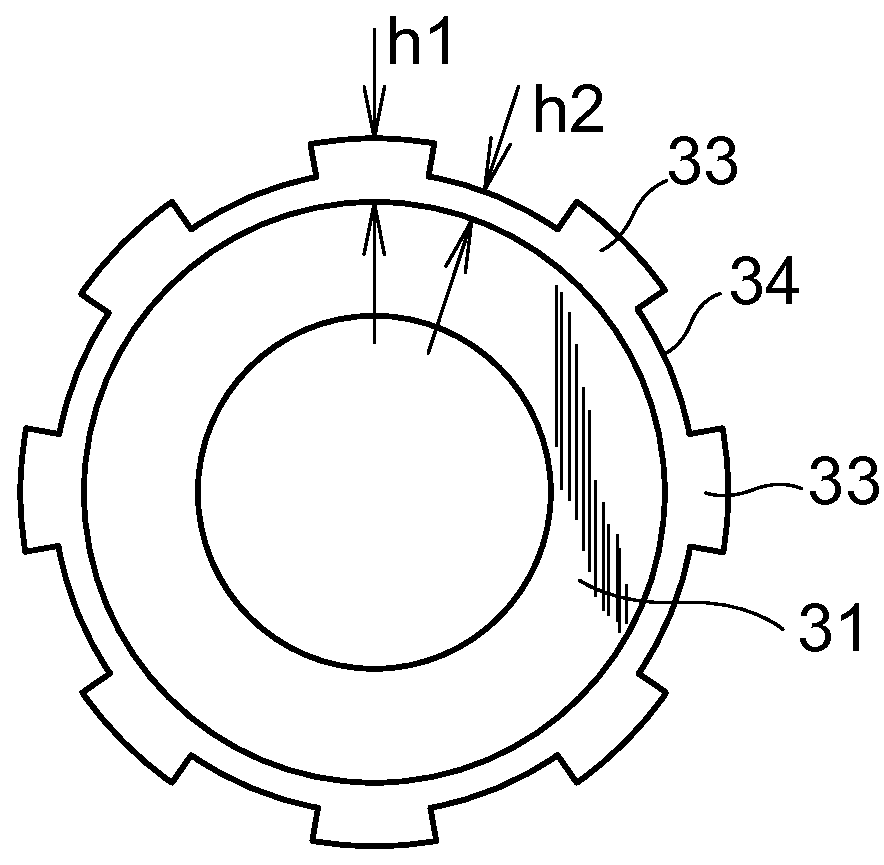

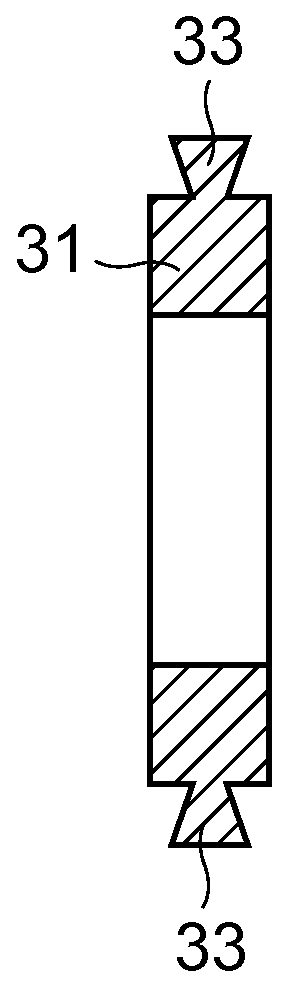

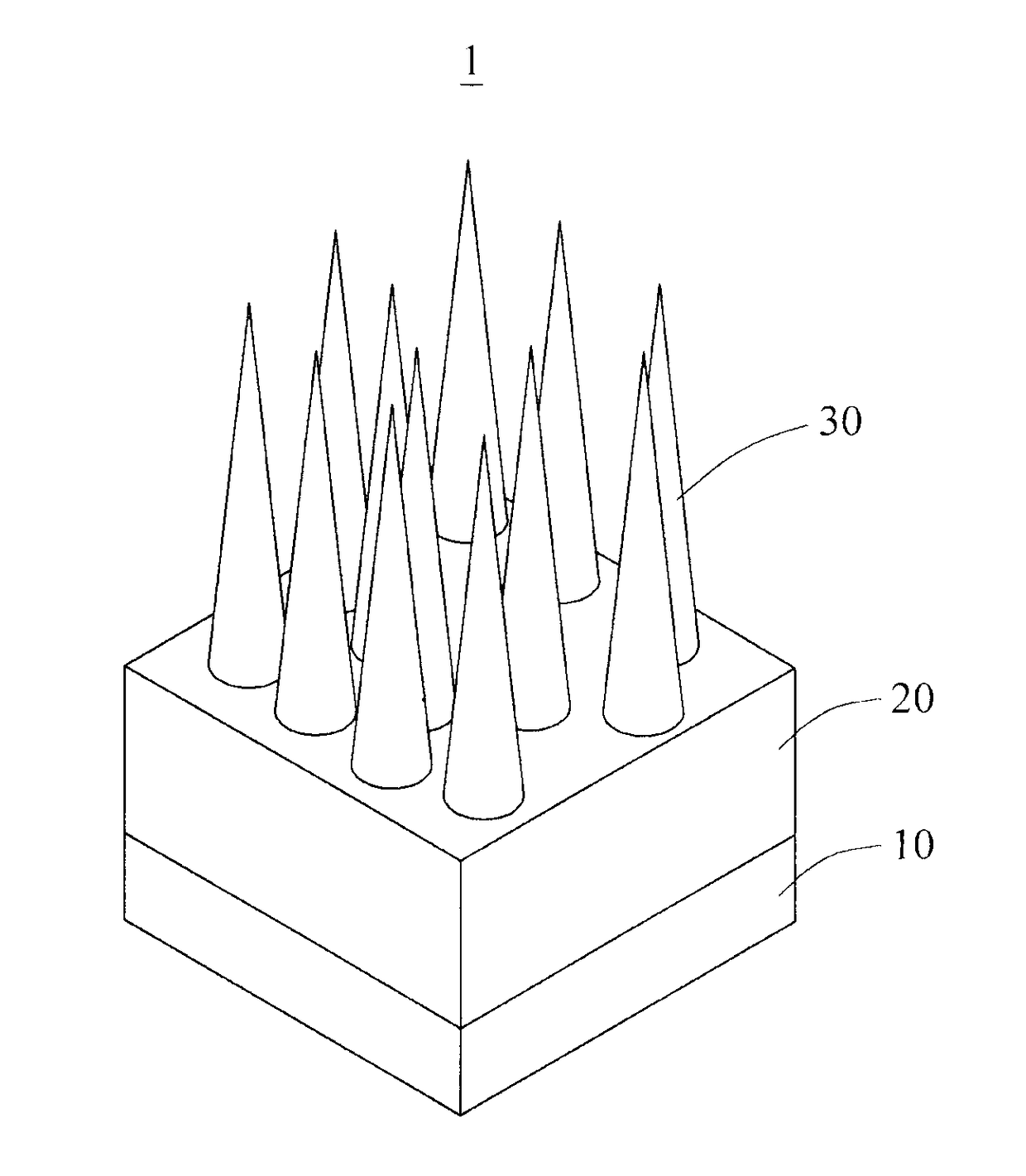

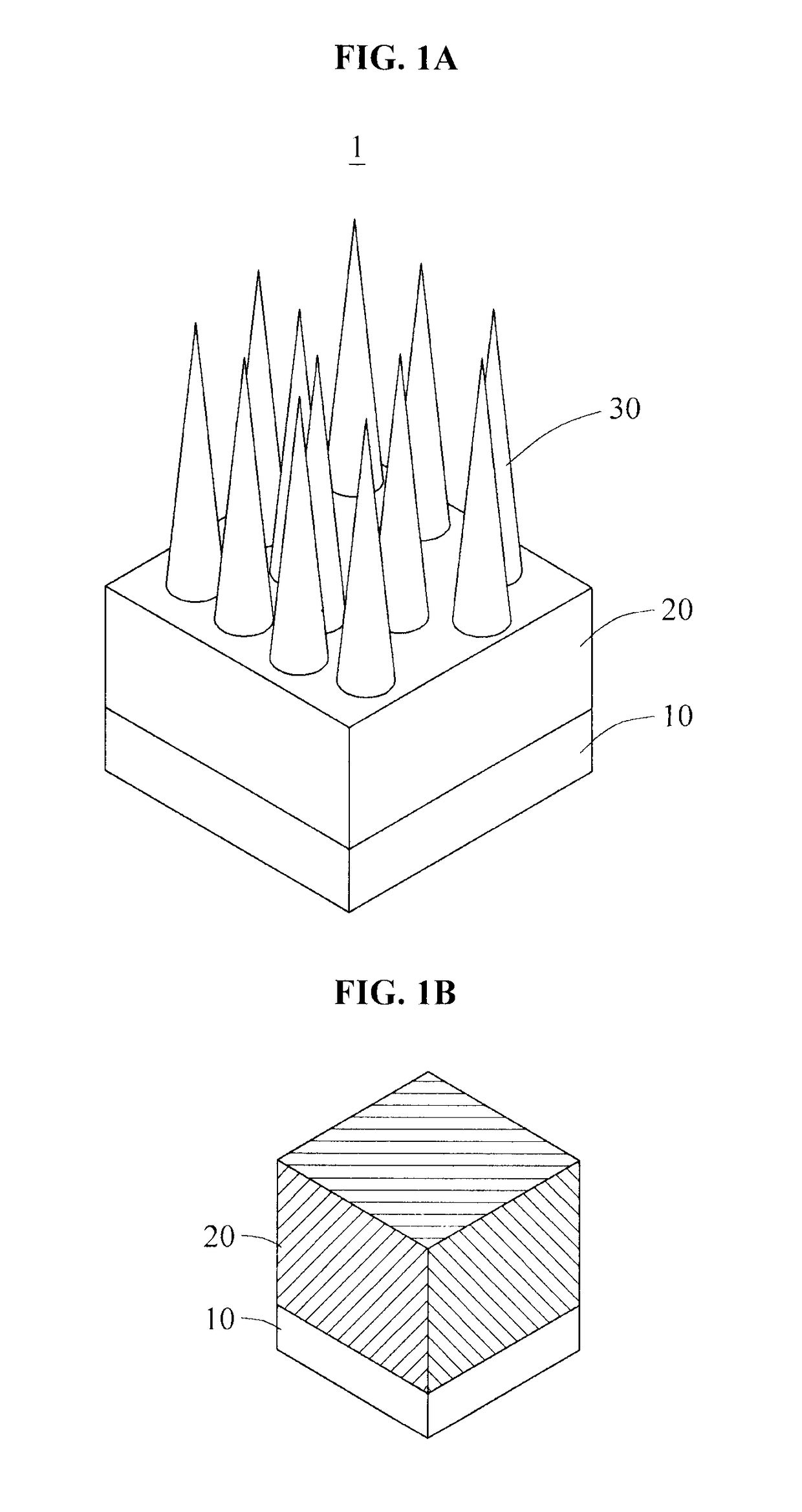

Method of manufacturing fiber substrate and method of manufacturing resin rotator

ActiveUS20160016367A1Uniformly manufacturedImprove mold lifeCeramic shaping apparatusGear wheelsFiberOptoelectronics

There is little fluctuation in amount of short fibers among individual products of fiber substrate. No damage is caused to a mold for the fiber substrate. Continuous production of the fiber substrates is possible. A method of manufacturing a fiber substrate includes the steps of: preparing slurry by dispersing short fibers in a dispersion medium; pouring the slurry into a cylindrical mold from above the cylindrical mold, the slurry being directed to a slurry diffusion member disposed in the center of the cylindrical mold and having an upward pointing conical or pyramidal shape; pouring the dispersion medium or water onto the slurry diffusion member from above the slurry diffusion member to cause the short fibers adhering to the slurry diffusion member to fall down, after the step of pouring the slurry; and discharging the dispersion medium from the cylindrical mold to accumulate the short fibers in the cylindrical mold to obtain a fiber aggregate.

Owner:RESONAC CORP

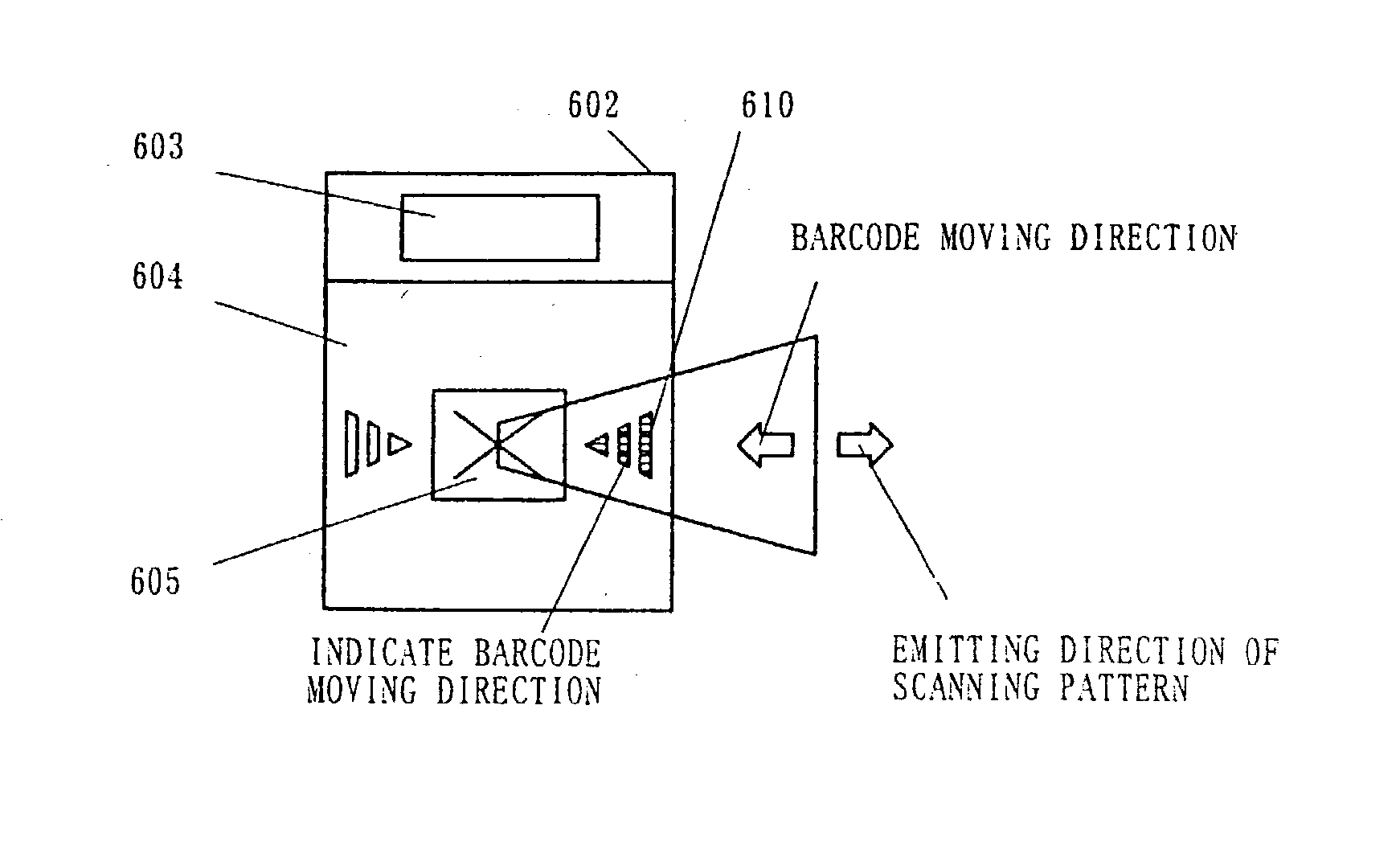

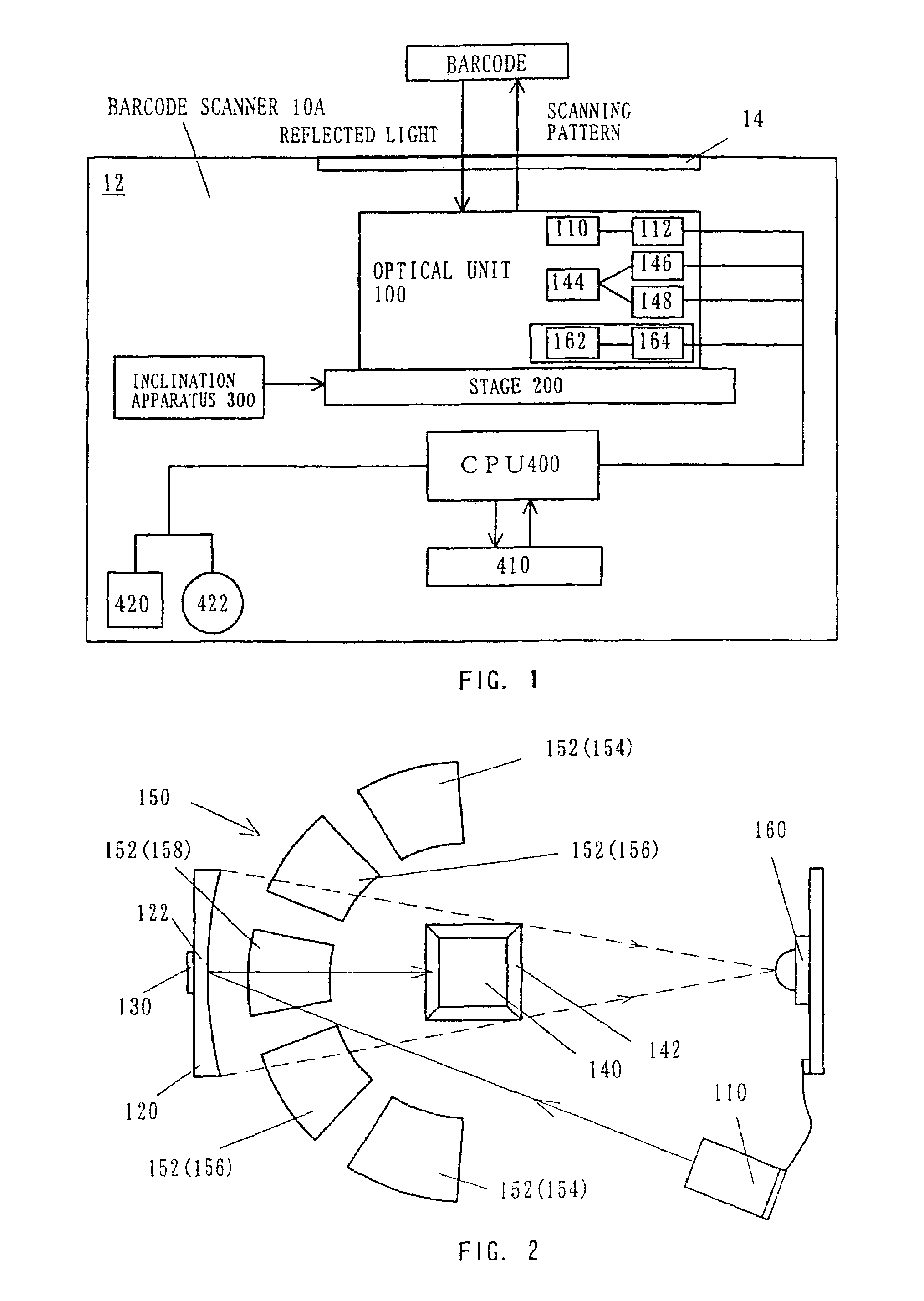

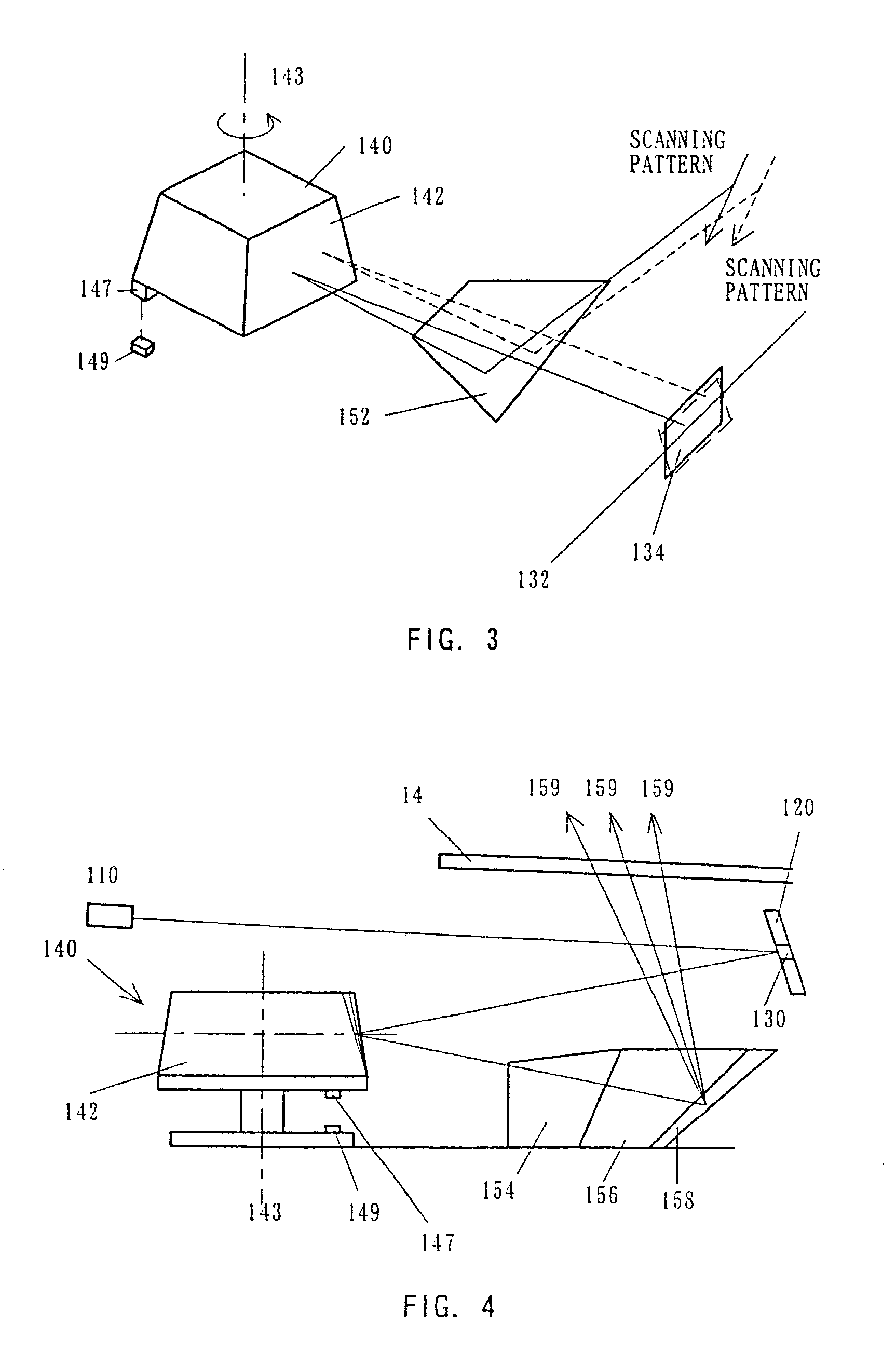

Optical reader having inclinable stage which mounts optical unit thereon

InactiveUS7070109B2High reading relianceSafely securedSensing by electromagnetic radiationOptical elementsEngineeringUser friendliness

An optical reader which is compatible with every environment irrespective of installation and usage environments, thereby enabling uniform manufacturing, satisfactory reading reliance, and operative safety and user-friendliness. The optical unit is mounted on the stage, and there is provided an inclination apparatus which inclines the stage at a desired angle. Thereby, without changing a preset optimal scanning pattern, only its emitting direction becomes changeable freely.

Owner:FUJITSU LTD

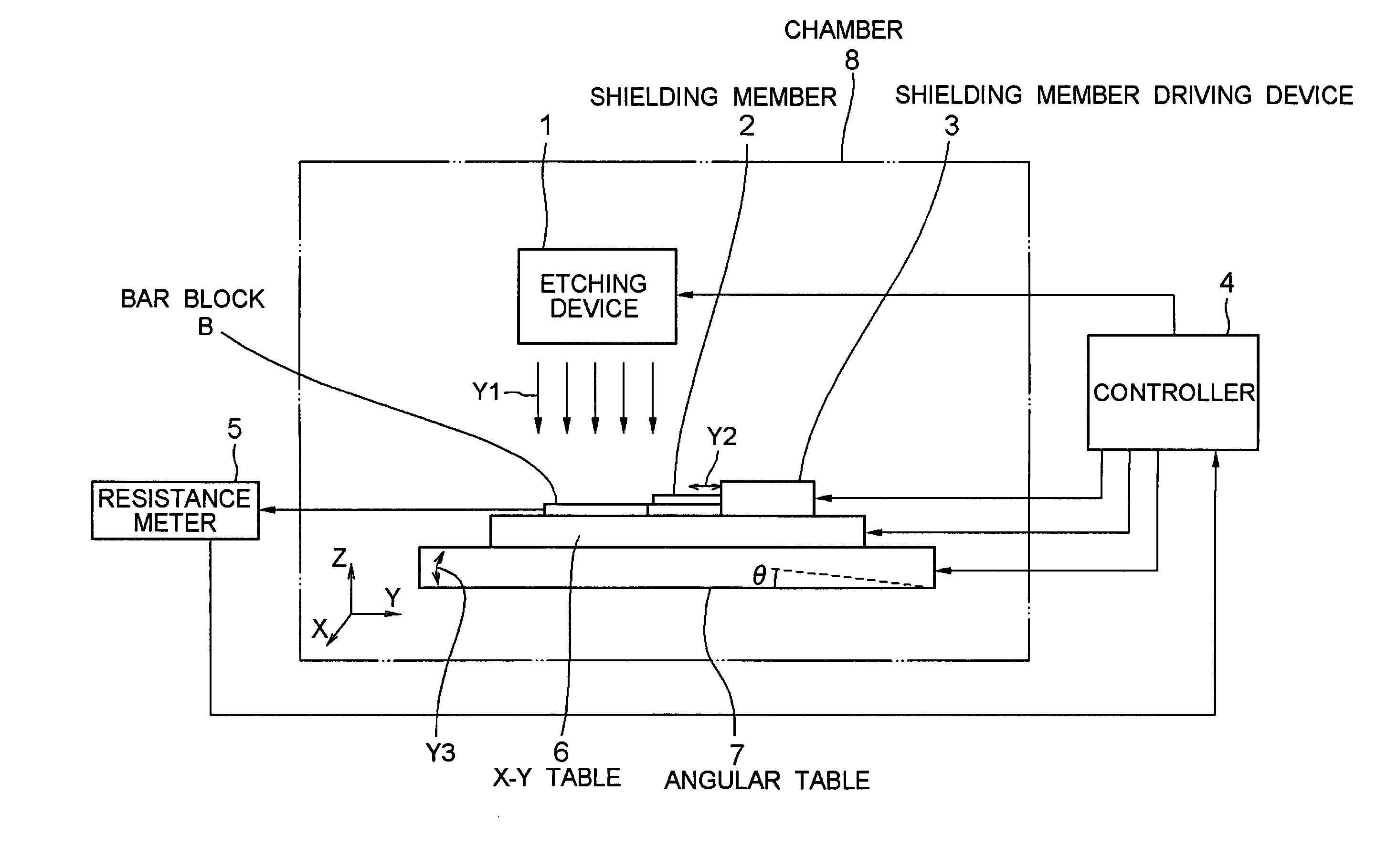

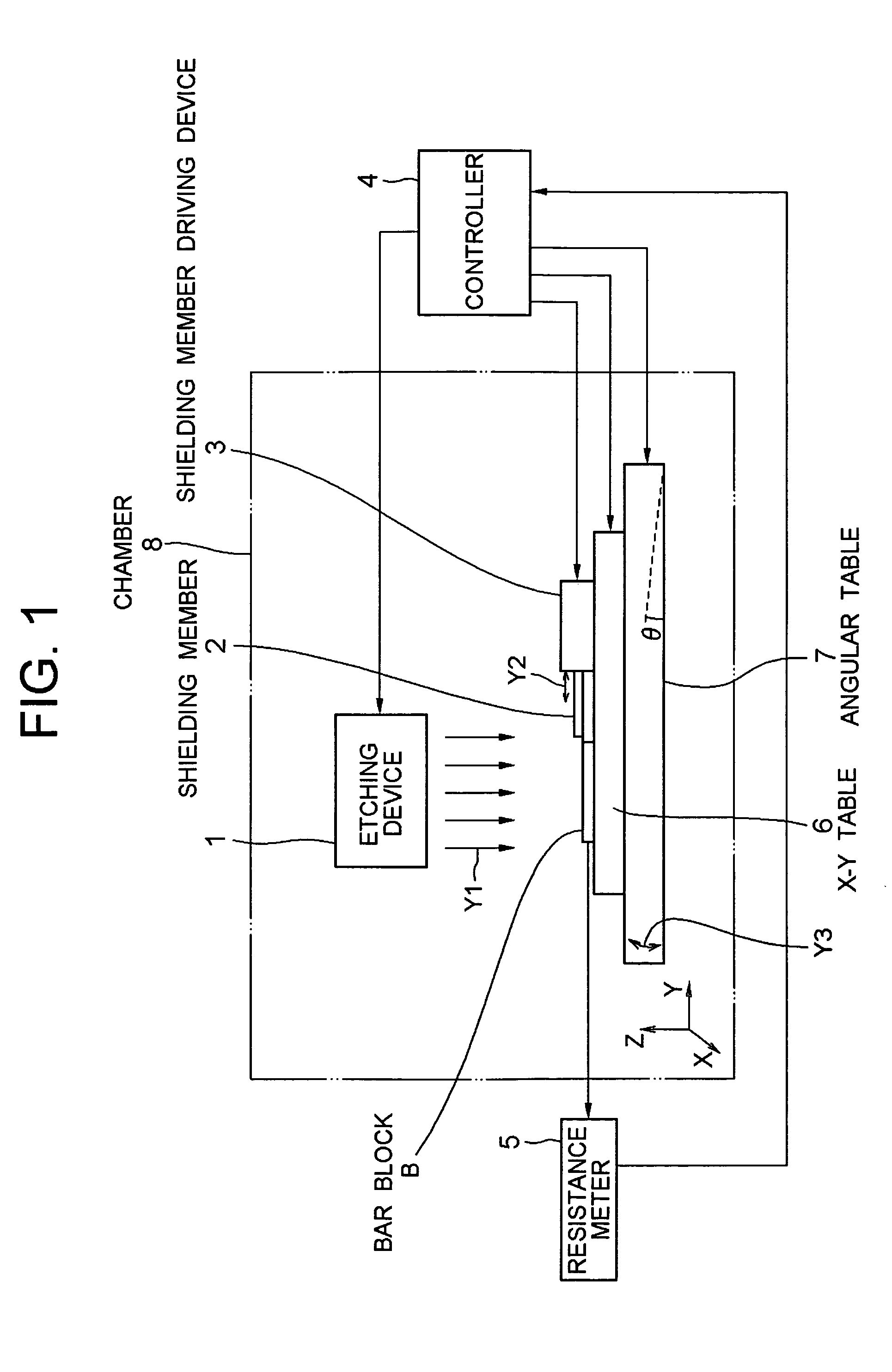

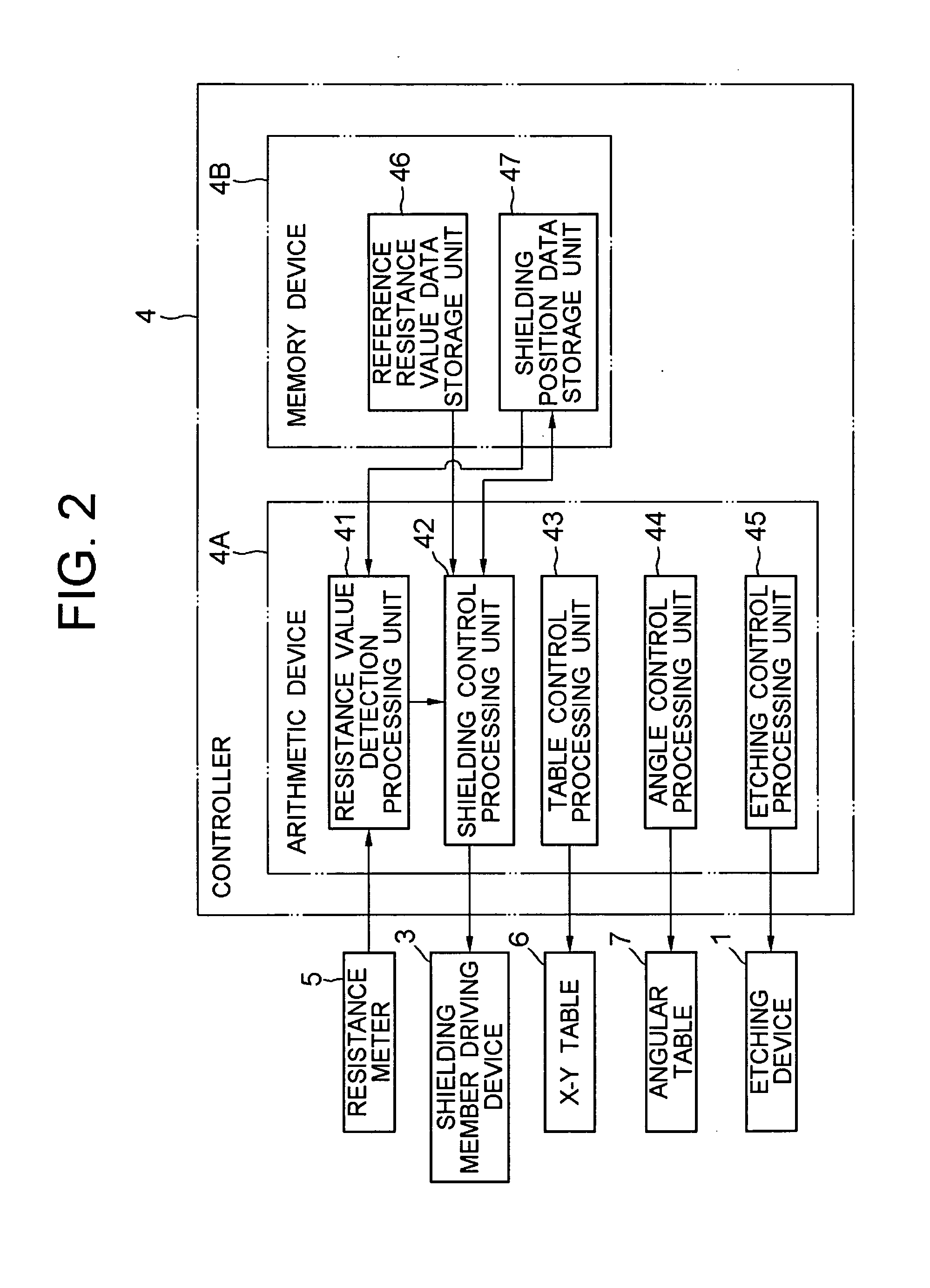

Method and apparatus for forming surface, magnetic head and method of manufacturing the same

InactiveUS20060157447A1Good effectPolished evenlyDecorative surface effectsSemiconductor/solid-state device manufacturingIrradiationBiomedical engineering

It is to manufacture uniform and high-quality structural bodies which face no quality changes due to mechanical process. There is provided a surface forming apparatus that comprises a surface forming device for performing surface forming process to a prescribed structural body, wherein the surface forming device is an irradiation device that irradiates, to the structural body, an energy beam with a prescribed irradiation energy, which can be irradiated in a specific direction.

Owner:SAE MAGNETICS (HK) LTD

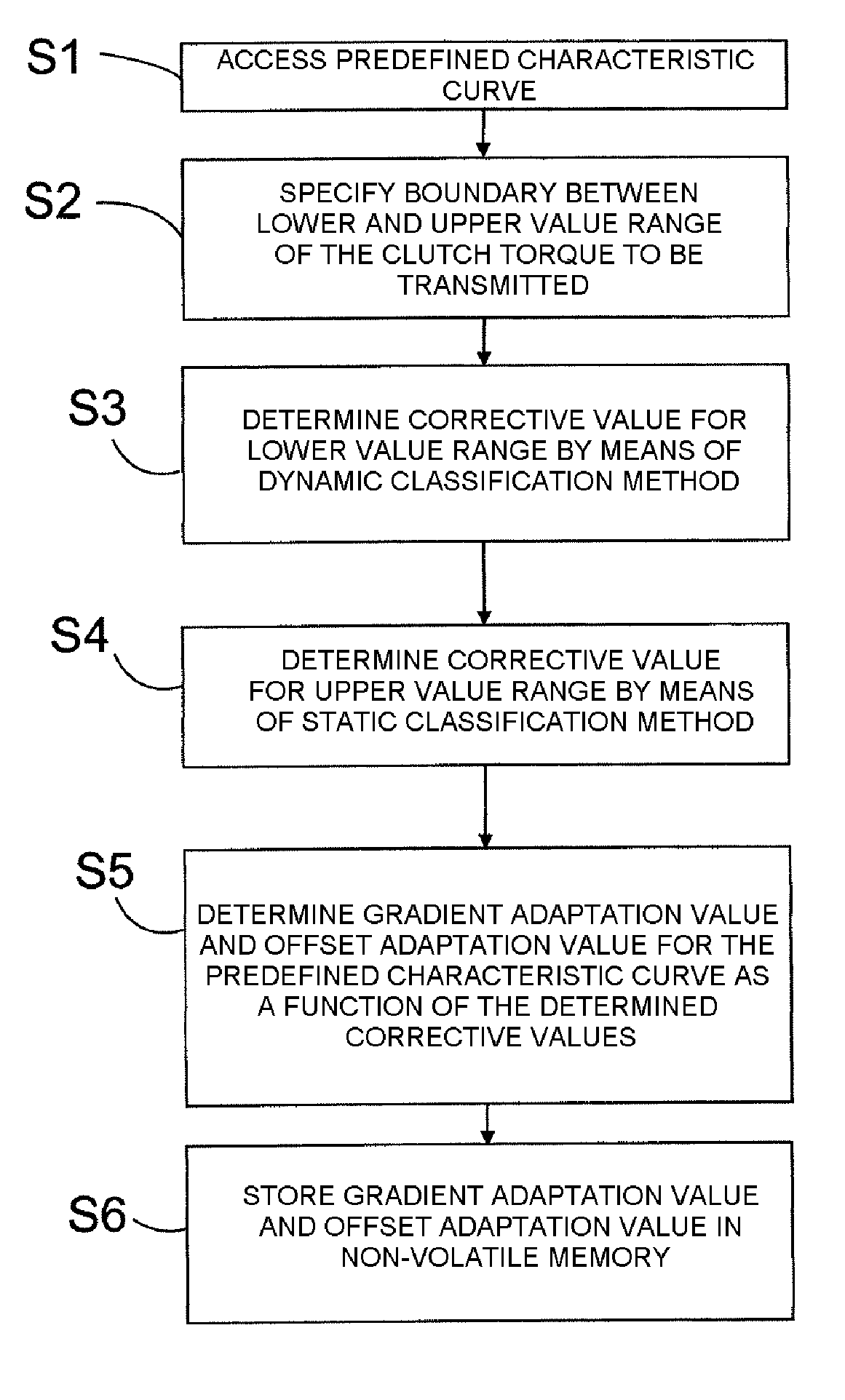

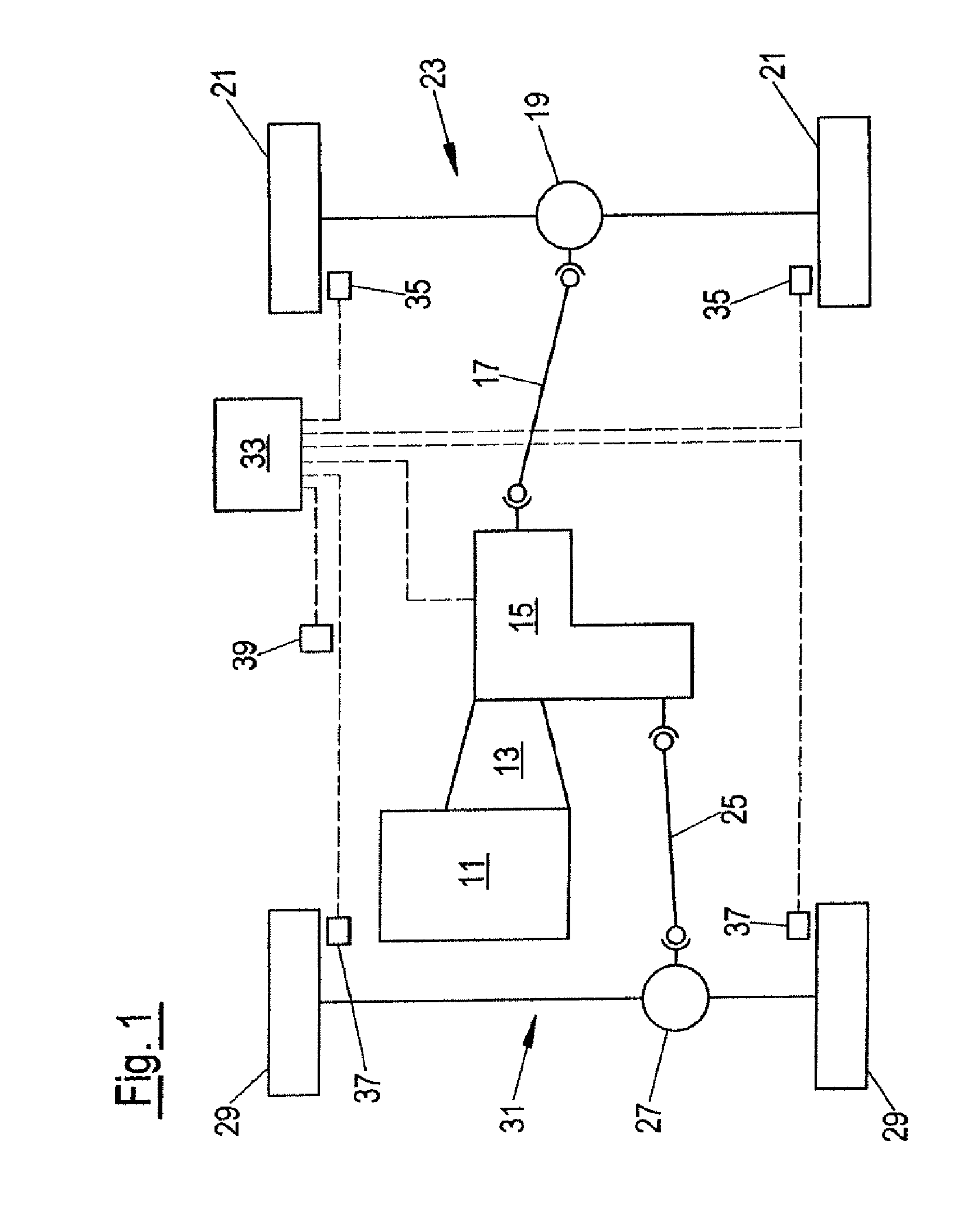

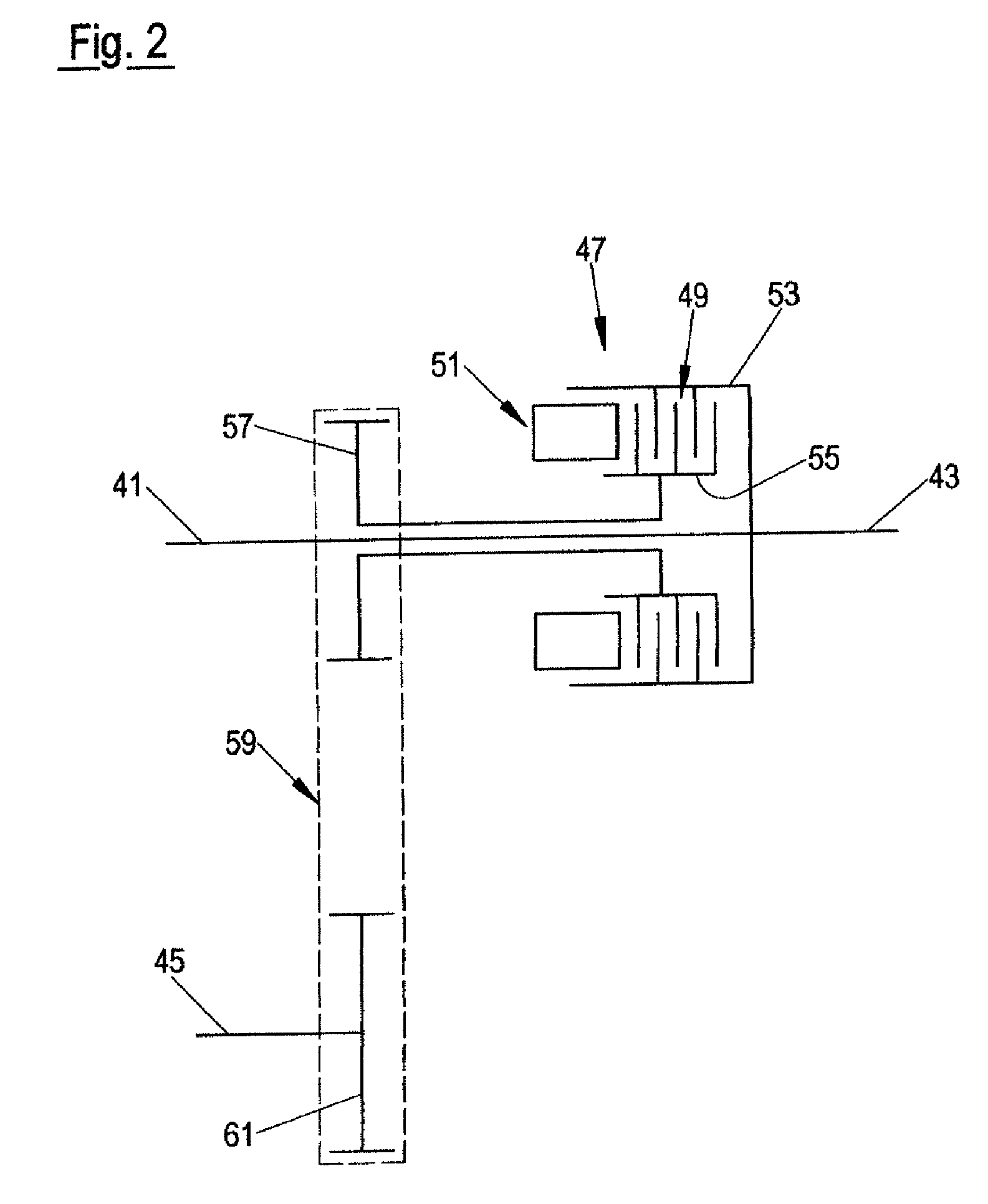

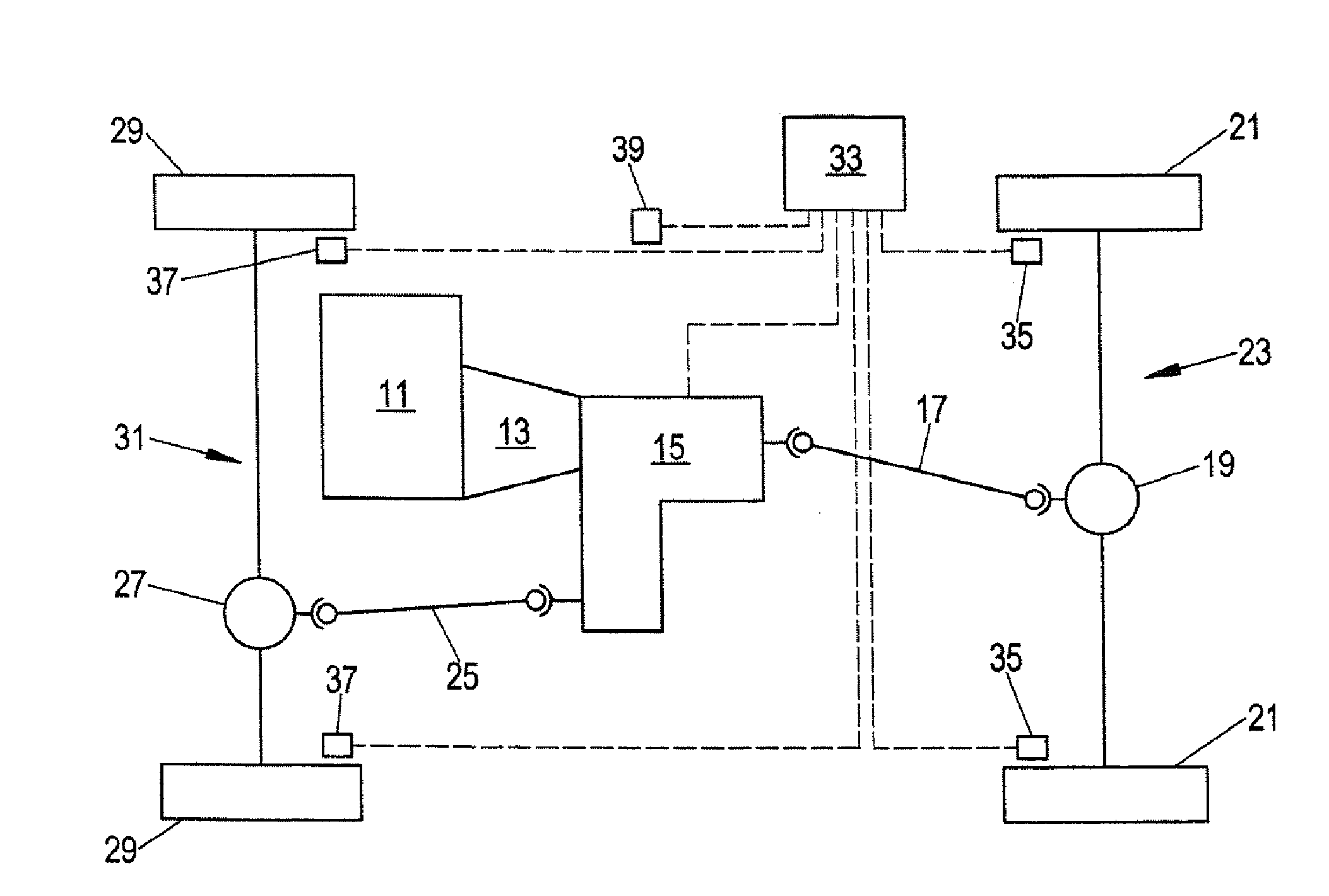

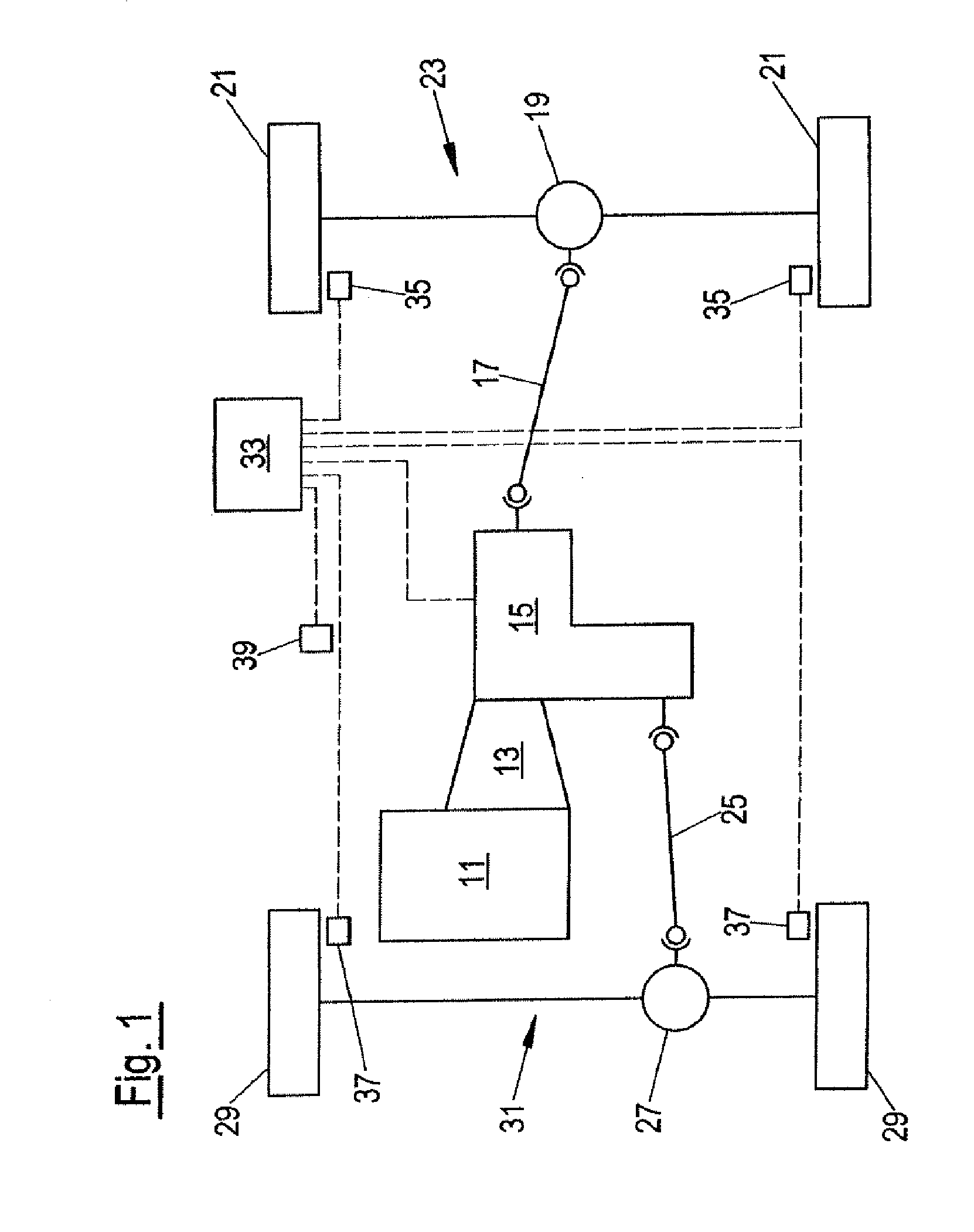

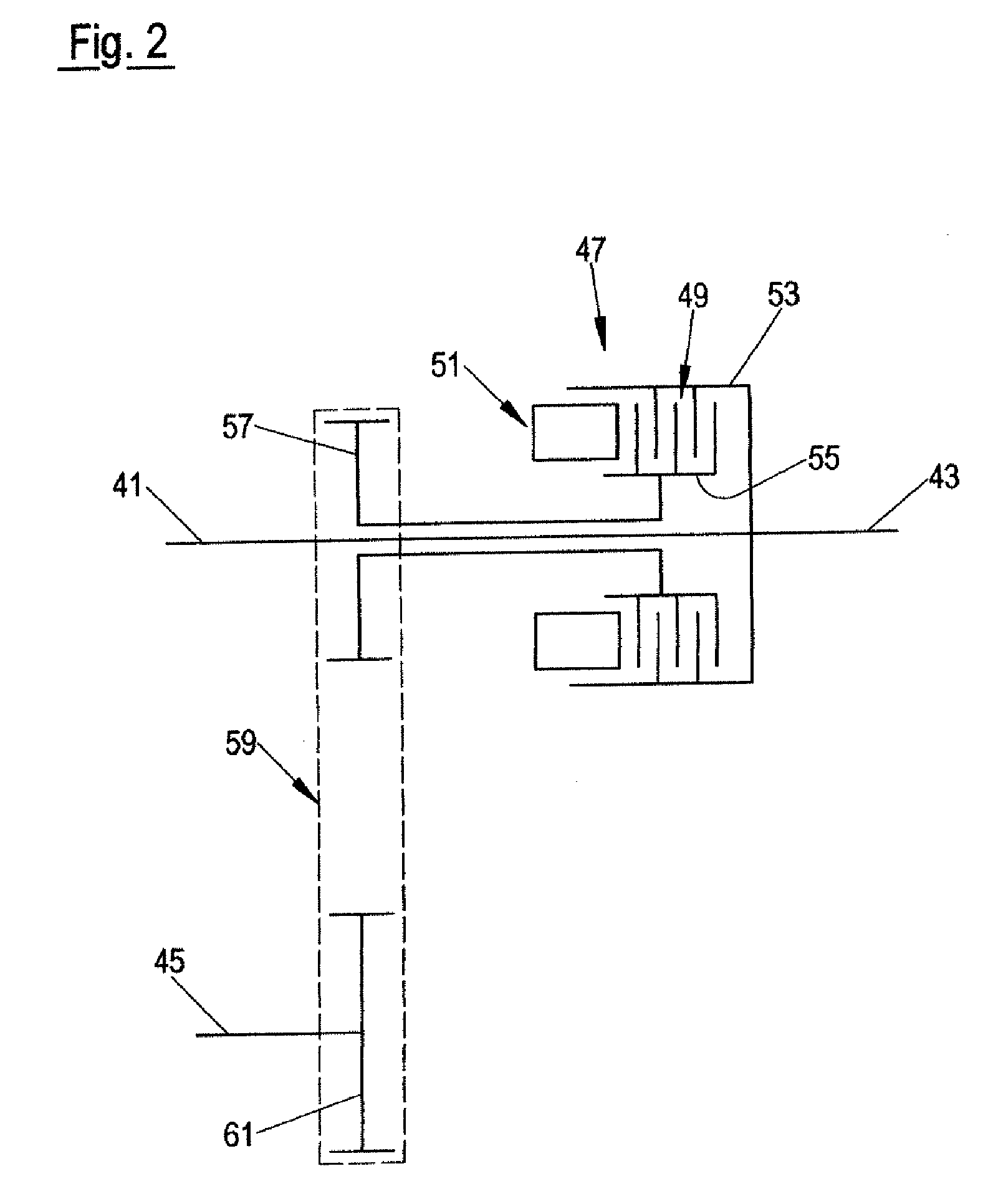

Method for classifying a clutch unit

ActiveUS8229638B2Improve setting accuracyAccurate representationClutchesDigital data processing detailsDrivetrainClassification methods

A method is described for classifying a clutch unit for a drivetrain of a motor vehicle, wherein the clutch unit has at least one friction clutch for the controllable transmission of a torque from an input element to an output element and has an actuator for actuating the friction clutch. Here, the clutch unit is controlled on the basis of a predefined characteristic curve which describes a predefined dependency of the clutch torque to be transmitted on an actuator control variable.

Owner:MAGNA POWERTRAIN AG & CO KG

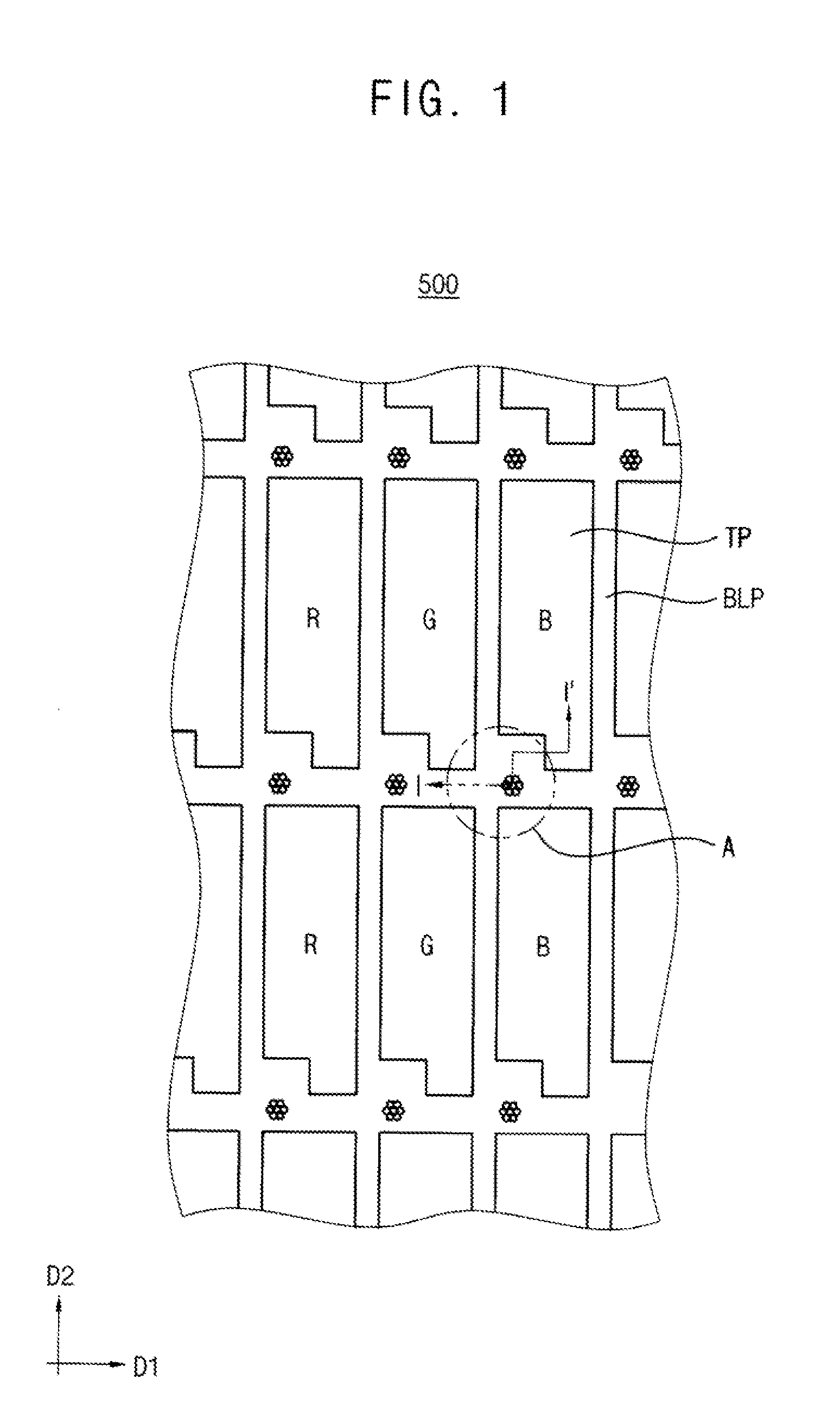

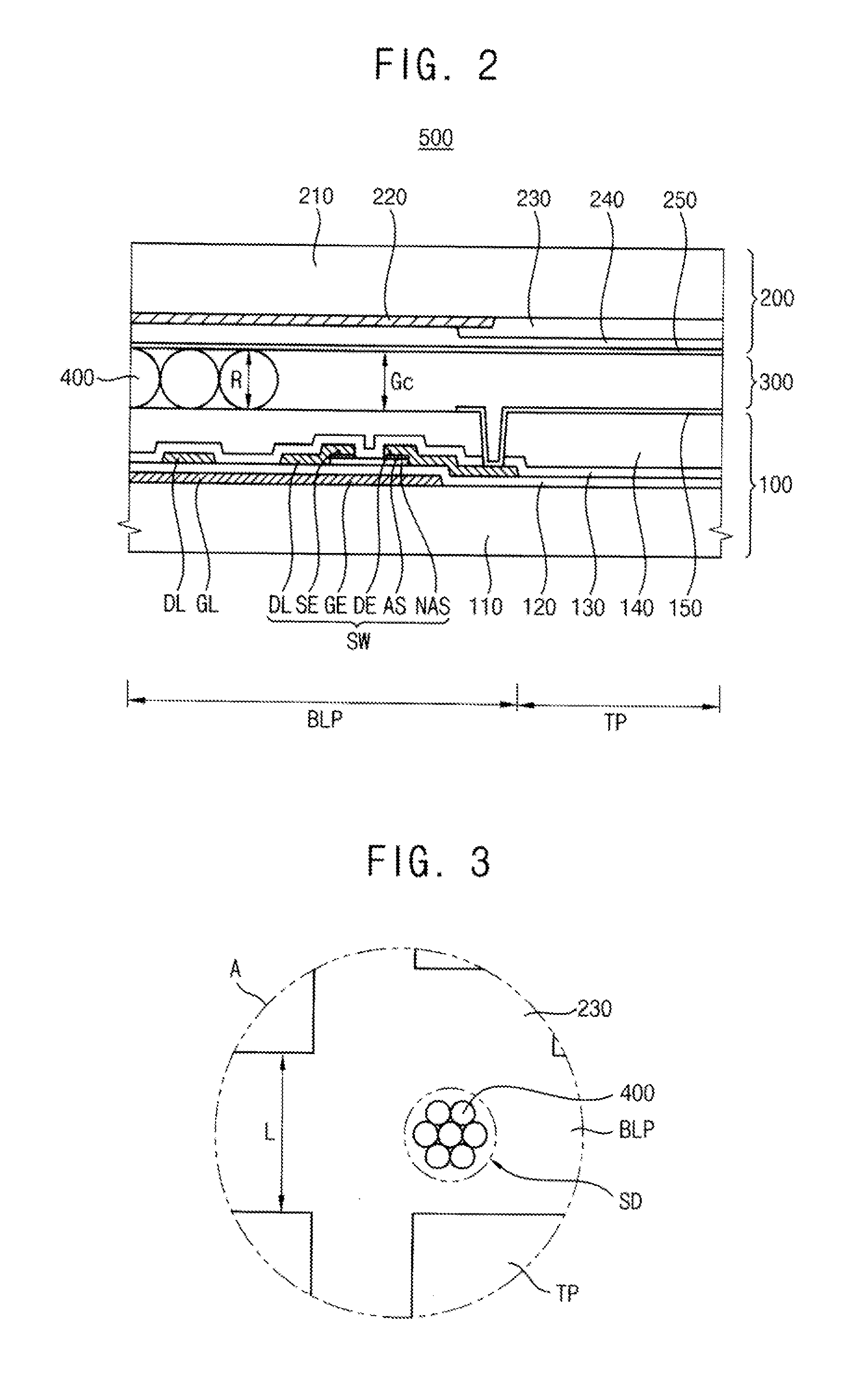

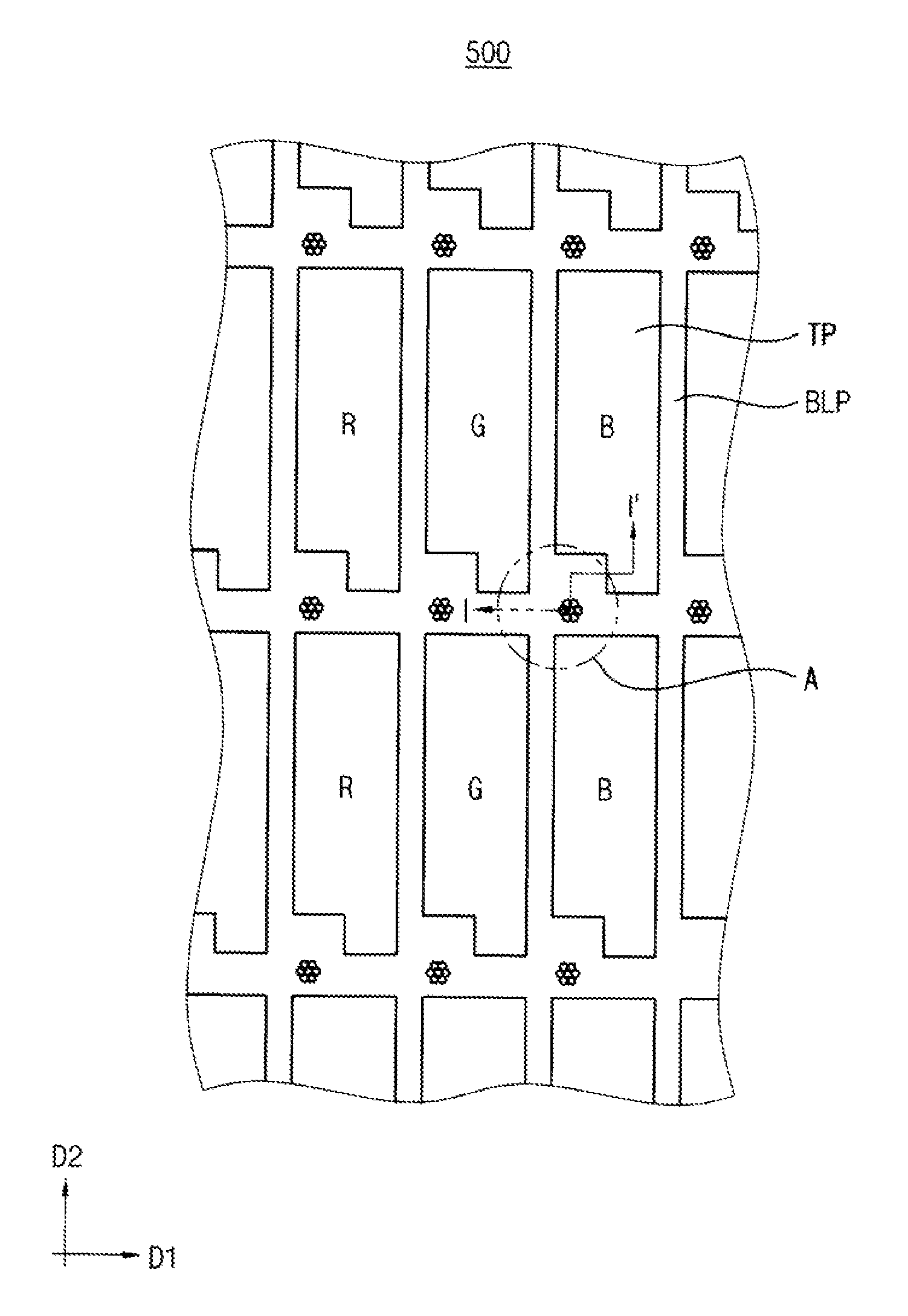

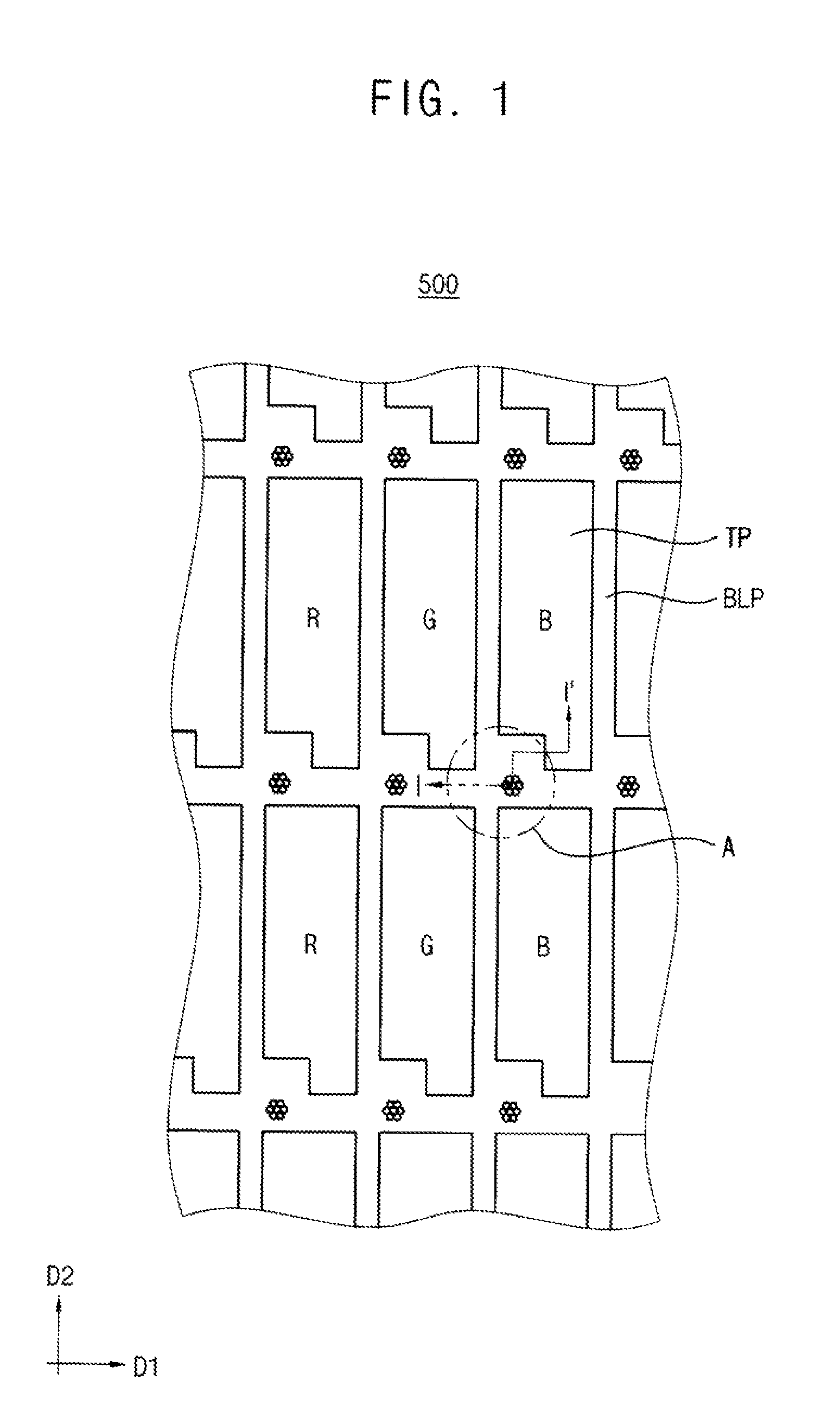

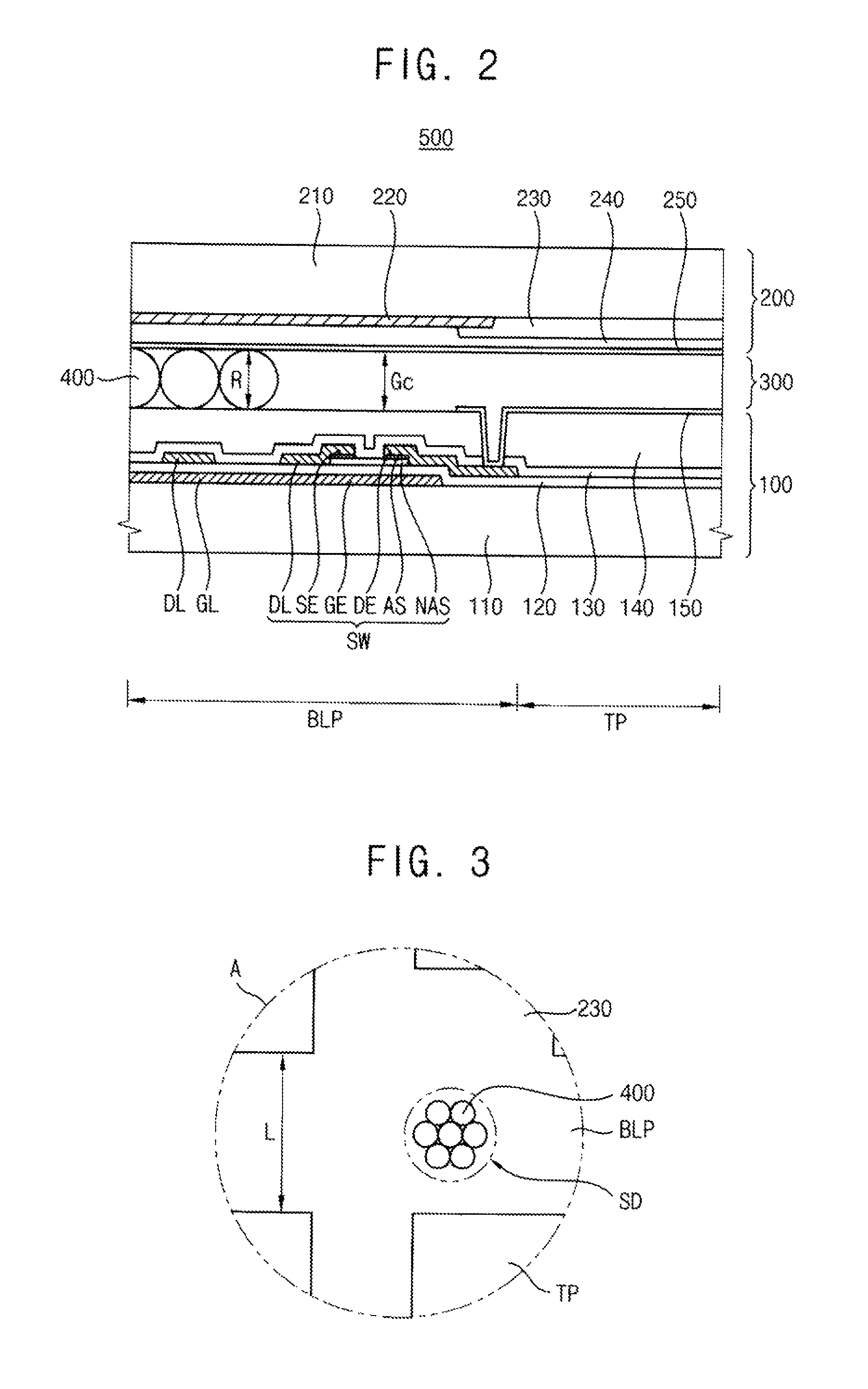

Printing apparatus for manufacturing a spacer and method of manufacturing a display panel

ActiveUS20120133880A1Improve featuresBlock display panelLiquid surface applicatorsLamination ancillary operationsSurface plateEngineering

Owner:SAMSUNG DISPLAY CO LTD

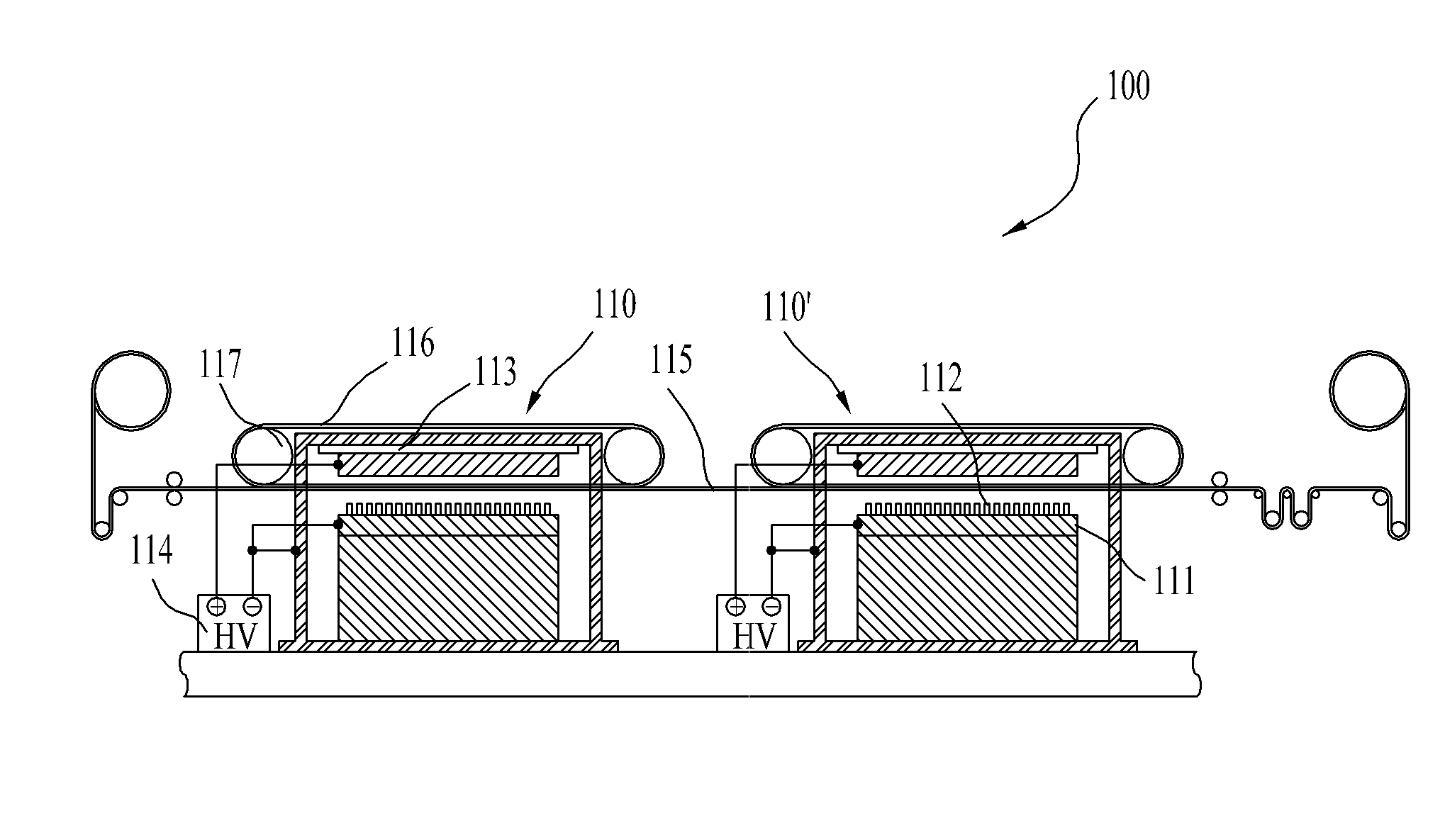

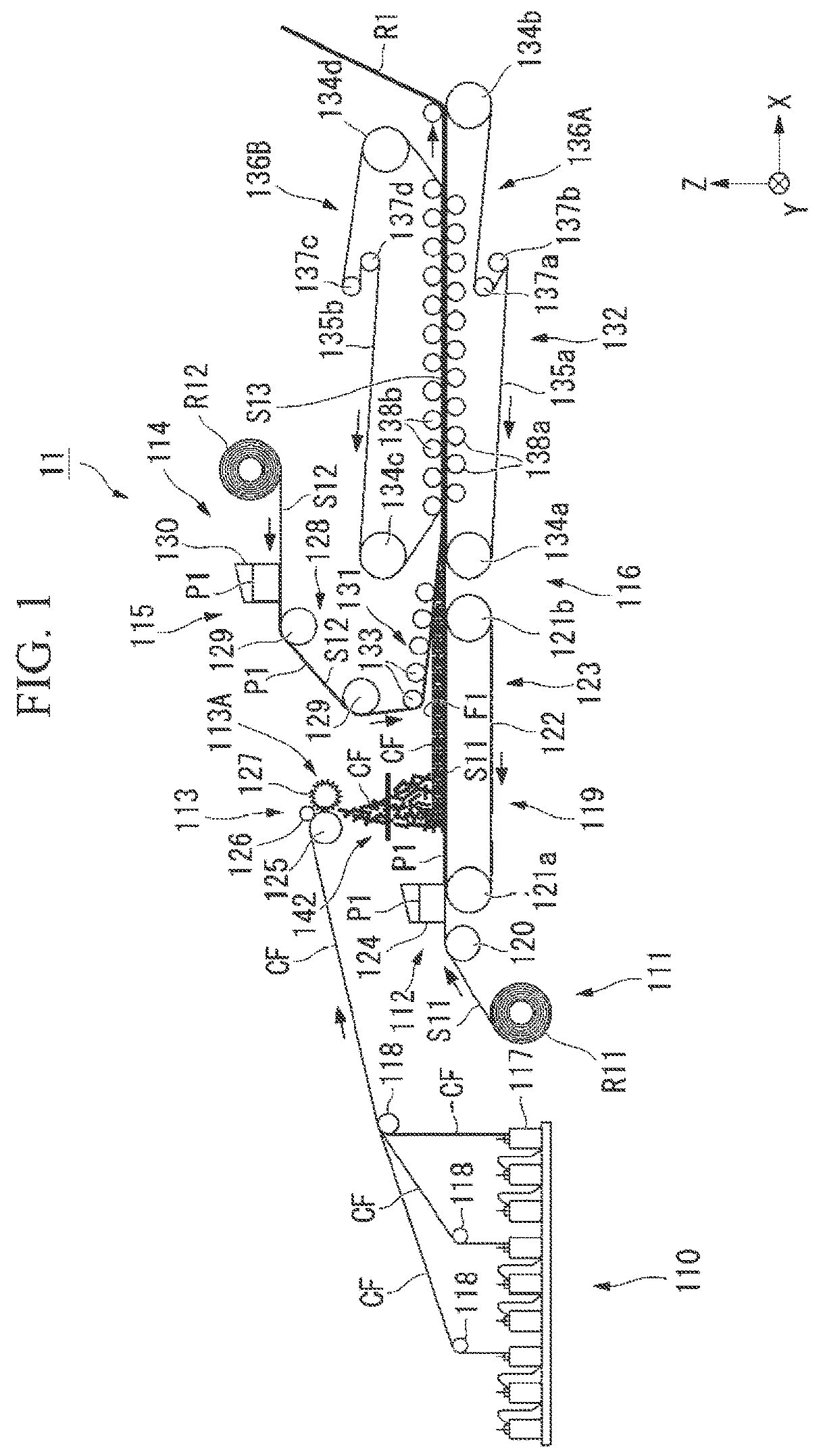

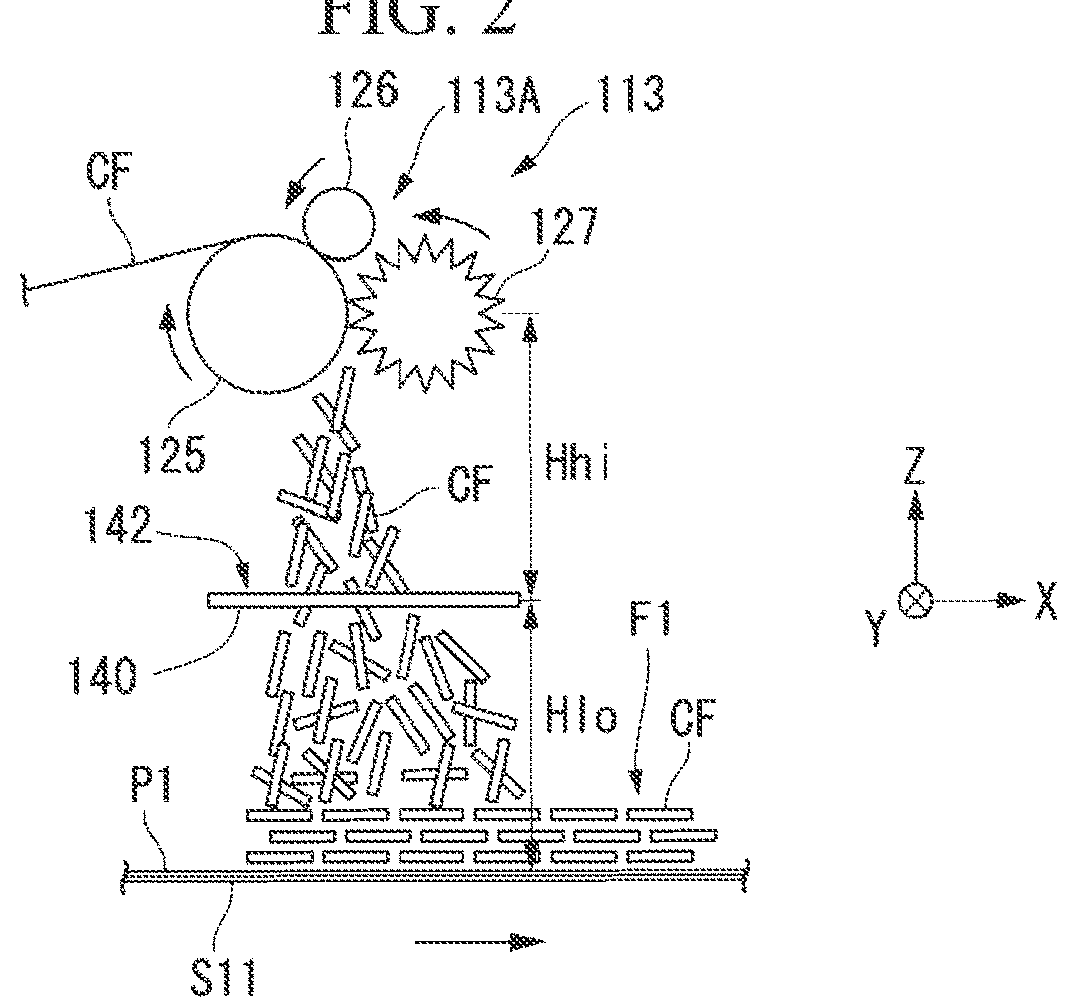

Fiber-reinforced resin material, molded article, method and device for manufacturing fiber-reinforced resin material, and fiber bundle group inspection device

ActiveUS10343352B2Small directionalityIncrease production capacityMaterial analysis using wave/particle radiationInvestigating composite materialsProduction rateFiber bundle

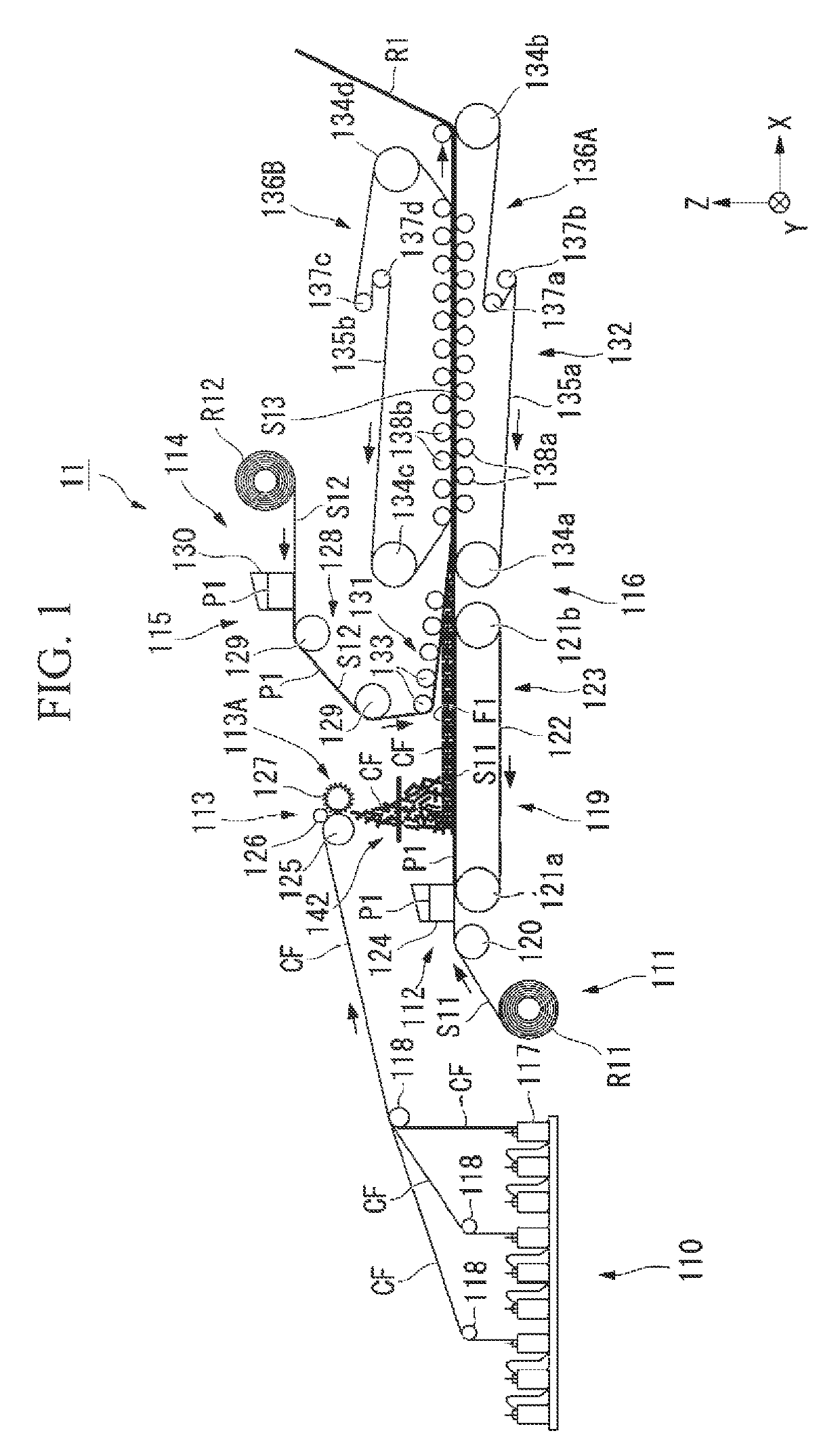

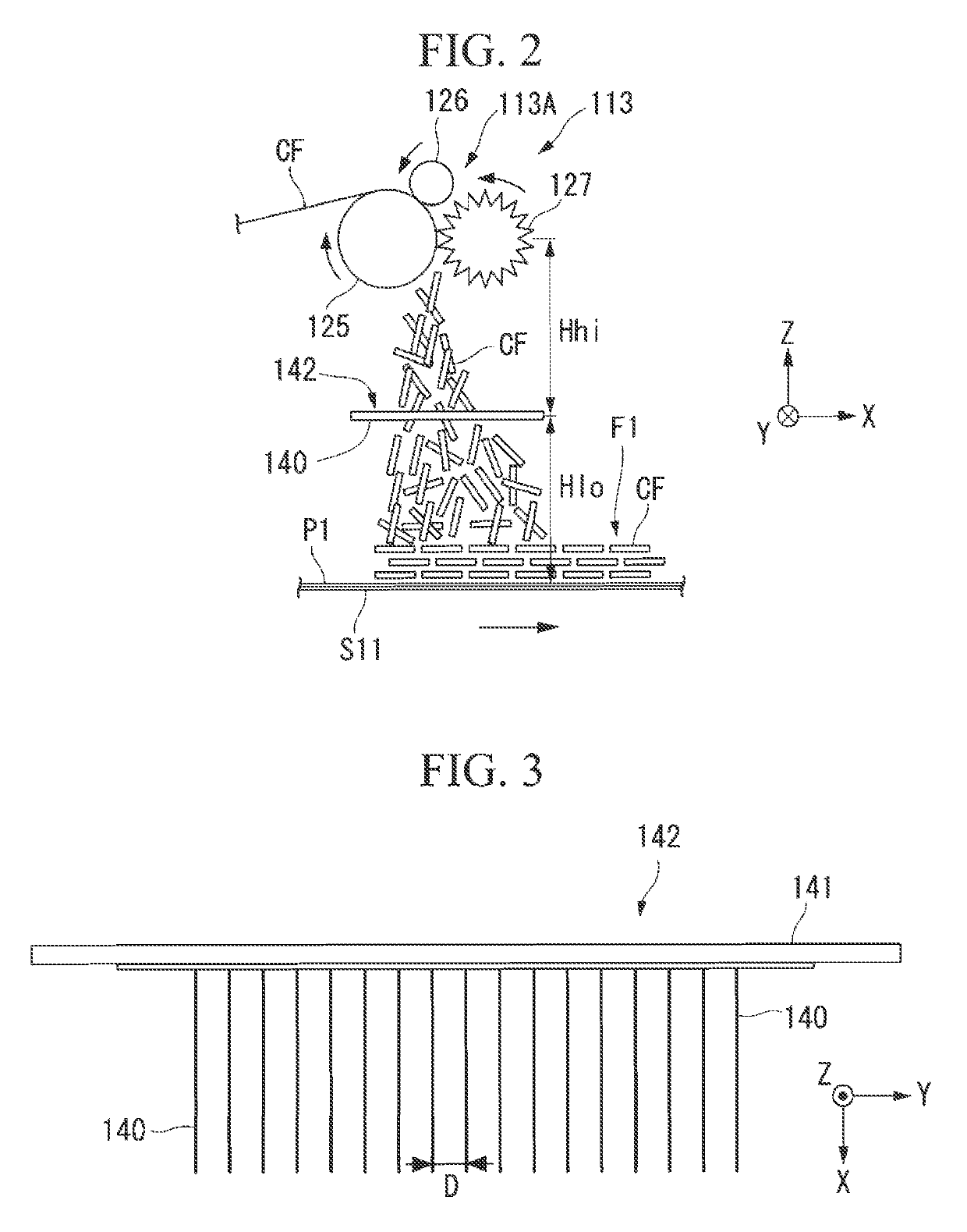

The purpose of the present invention is to provide a fiber-reinforced resin material having minimal directionality of strength as well as excellent productivity, a method and device for manufacturing a fiber-reinforced resin material whereby a molded article is obtained, and a device for inspecting a fiber bundle group. A method for manufacturing a sheet-shaped fiber-reinforced resin material in which a paste (P1) is impregnated between cut fiber bundles (CF), the method for manufacturing a fiber-reinforced resin material including a coating step applying a coating of a paste (P1) on a first sheet (S11) conveyed in a predetermined direction, a cutting step for cutting a long fiber bundle (CF) using a cutter (113A), a scattering step for dispersing the cut fiber bundles (CF) and scattering the cut fiber bundles (CF) on the paste (P1), and an impregnation step for pressing a fiber bundle group (F1) and the paste (P1) on the first sheet (S11) and impregnating the paste (P1) between the fiber bundles (CF).

Owner:MITSUBISHI CHEM CORP

Method for classifying a clutch unit

ActiveUS20110015843A1Reduce memory requirementsEasy to handleClutchesDigital data processing detailsDrivetrainClassification methods

A method is described for classifying a clutch unit for a drivetrain of a motor vehicle, wherein the clutch unit has at least one friction clutch for the controllable transmission of a torque from an input element to an output element and has an actuator for actuating the friction clutch. Here, the clutch unit is controlled on the basis of a predefined characteristic curve which describes a predefined dependency of the clutch torque to be transmitted on an actuator control variable.

Owner:MAGNA POWERTRAIN AG & CO KG

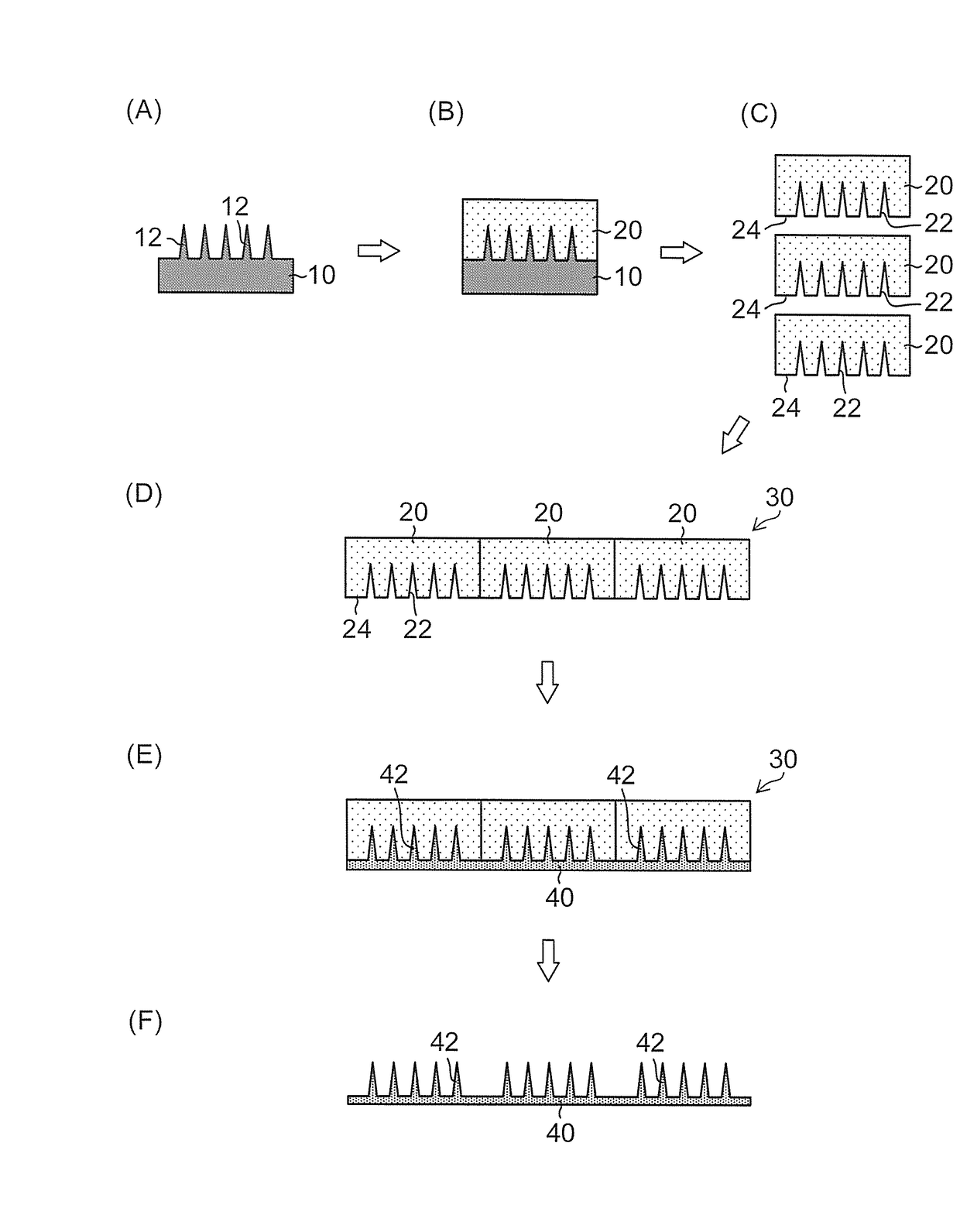

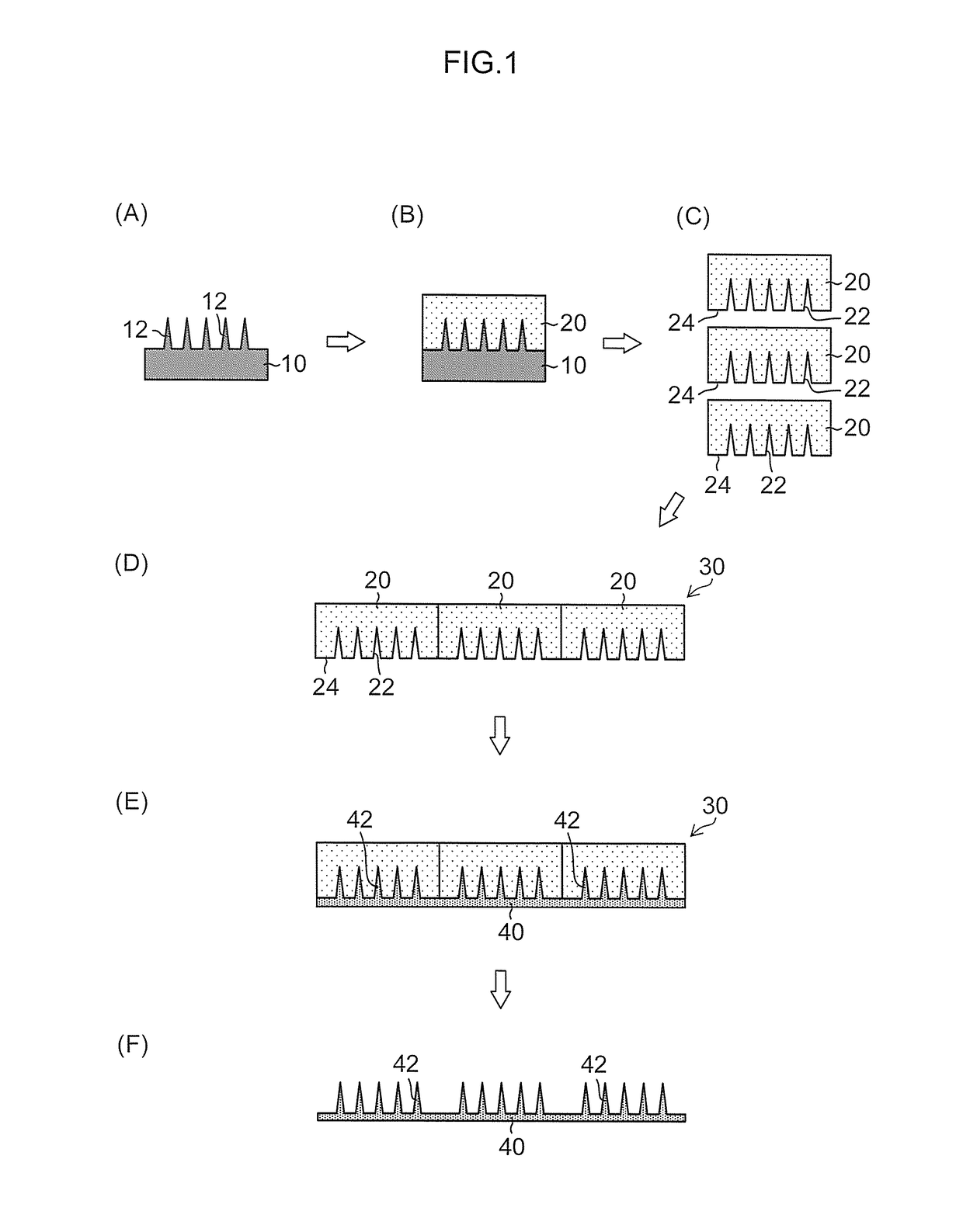

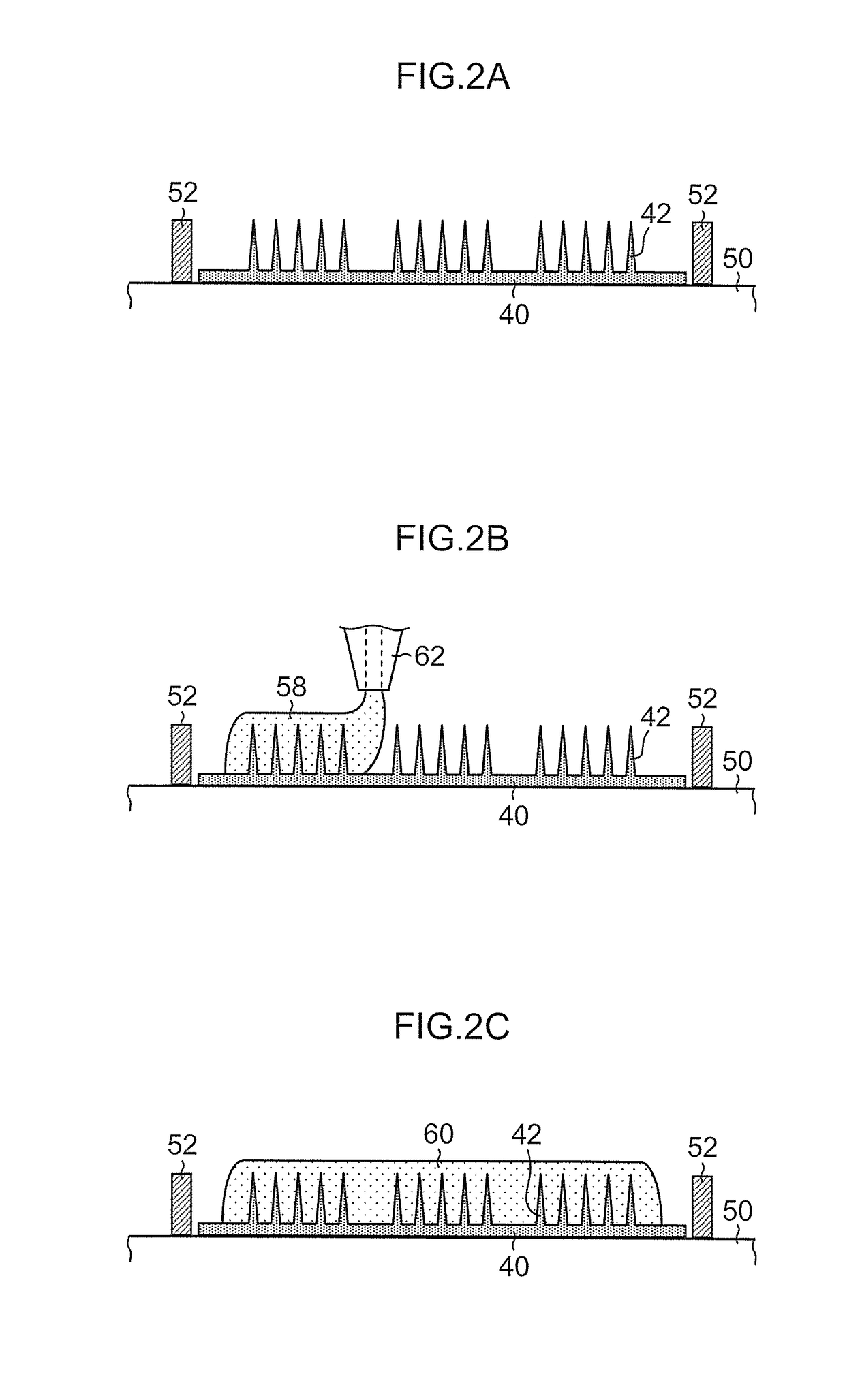

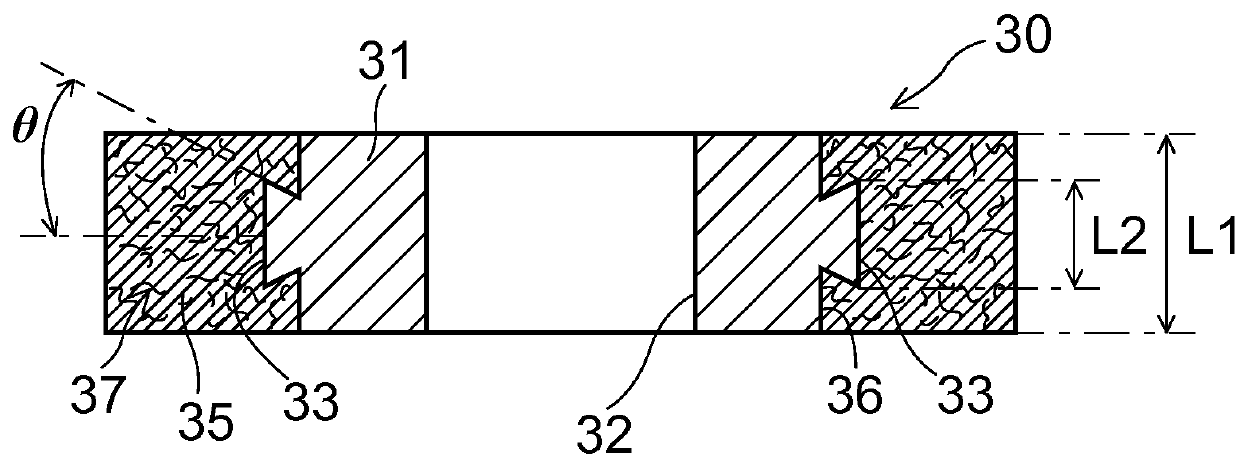

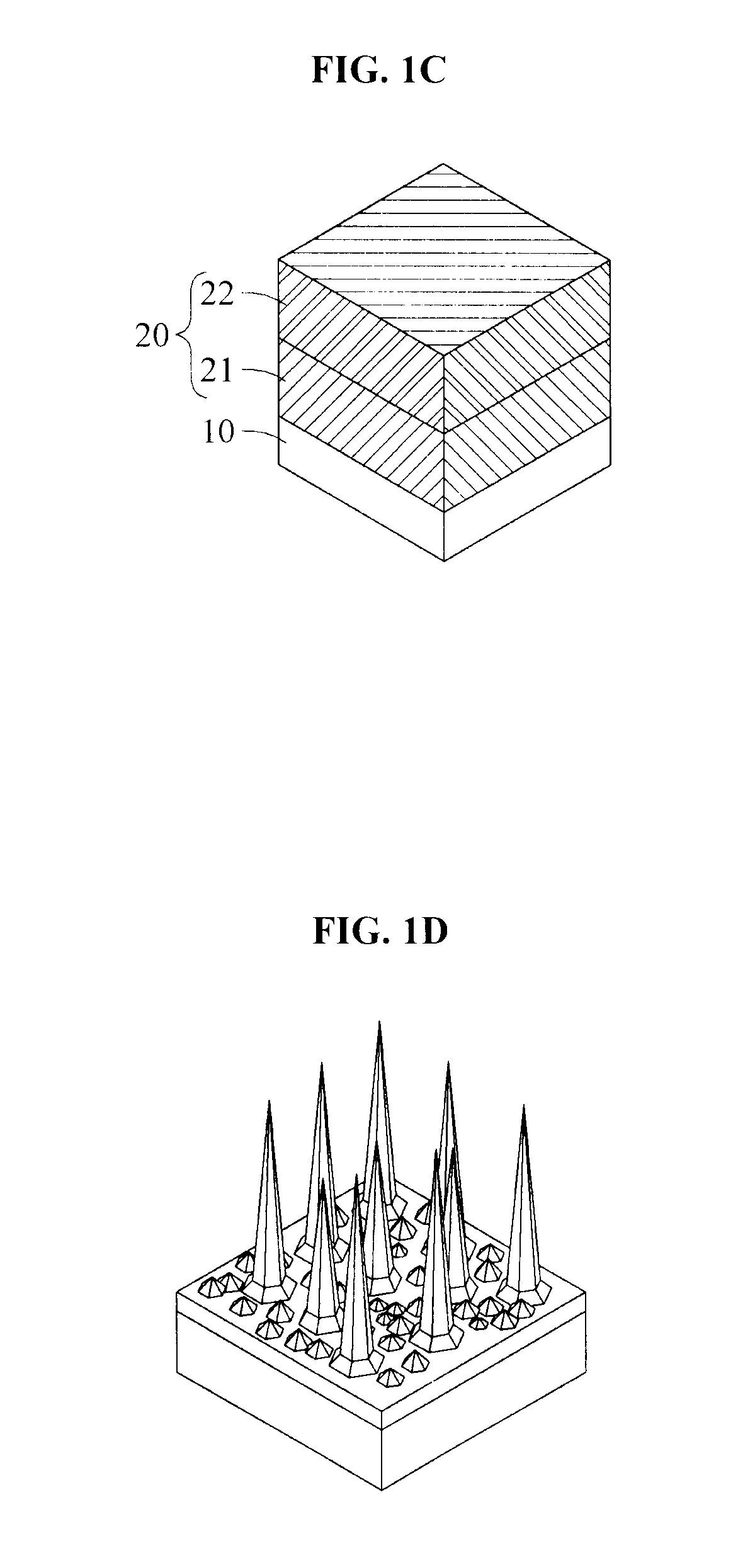

Method of manufacturing mold and method of manufacturing pattern sheet

InactiveUS20170095946A1Increase the areaImprove productivityMicroneedlesDomestic articlesEngineeringMechanical engineering

The method of manufacturing a mold includes the steps of: forming a silicone resin film on a surface of a model having a protrusion pattern; pressing a side of a base plate with which a separation sheet is in close contacts on a gap adjustment mechanism and the silicone resin film; heating and curing the silicone resin film to form the mold; releasing the base plate; and releasing the separation sheet from the mold, after releasing the mold from the model, wherein the gap adjustment mechanism has a height at which a tip of the protrusion pattern sticks into the separation sheet when the base plate is pressed on the gap adjustment mechanism. The method of manufacturing a pattern sheet uses the mold.

Owner:FUJIFILM CORP

Method of manufacturing fiber substrate and method of manufacturing resin rotator

There is little fluctuation in amount of short fibers among individual products of fiber substrate. No damage is caused to a mold for the fiber substrate. Continuous production of the fiber substrates is possible. A method of manufacturing a fiber substrate includes the steps of: preparing slurry by dispersing short fibers in a dispersion medium; pouring the slurry into a cylindrical mold from above the cylindrical mold, the slurry being directed to a slurry diffusion member disposed in the center of the cylindrical mold and having an upward pointing conical or pyramidal shape; pouring the dispersion medium or water onto the slurry diffusion member from above the slurry diffusion member to cause the short fibers adhering to the slurry diffusion member to fall down, after the step of pouring the slurry; and discharging the dispersion medium from the cylindrical mold to accumulate the short fibers in the cylindrical mold to obtain a fiber aggregate.

Owner:RESONAC CORPORATION

Fiber-reinforced resin material, molded article, method and device for manufacturing fiber-reinforced resin material, and fiber bundle group inspection device

ActiveUS20180162070A1Small directionalityIncrease production capacityMaterial analysis using wave/particle radiationInvestigating composite materialsProduction rateFiber bundle

The purpose of the present invention is to provide a fiber-reinforced resin material having minimal directionality of strength as well as excellent productivity, a method and device for manufacturing a fiber-reinforced resin material whereby a molded article is obtained, and a device for inspecting a fiber bundle group. A method for manufacturing a sheet-shaped fiber-reinforced resin material in which a paste (P1) is impregnated between cut fiber bundles (CF), the method for manufacturing a fiber-reinforced resin material including a coating step applying a coating of a paste (P1) on a first sheet (S11) conveyed in a predetermined direction, a cutting step for cutting a long fiber bundle (CF) using a cutter (113A), a scattering step for dispersing the cut fiber bundles (CF) and scattering the cut fiber bundles (CF) on the paste (P1), and an impregnation step for pressing a fiber bundle group (F1) and the paste (P1) on the first sheet (S11) and impregnating the paste (P1) between the fiber bundles (CF).

Owner:MITSUBISHI CHEM CORP

Metal paste manufacturing method for internal electrode of multi layer ceramic capacitor

InactiveUS8980139B2Minimizing reactionImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricRare-earth elementCeramic capacitor

A method of manufacturing a metal paste for an internal electrode according to the present invention includes preparing each of a metal powder and an organic vehicle; preparing a ceramic inhibitor powder in which a nano glass added with a rare-earth element is mixed; manufacturing a primary mixture by mixing the metal powder of 70 to 95 wt % and the ceramic inhibitor powder of 5 to 30 wt % when each of the metal powder, the organic vehicle, and the ceramic inhibitor powder in which the nano glass added with the rare-earth element is mixed is prepared; manufacturing a secondary mixture by mixing the primary mixture of 50 to 70 wt % and the organic vehicle of 30 to 50 wt % when the primary mixture is manufactured; and manufacturing the metal paste for the internal electrode by filtering the secondary mixture when the secondary mixture is manufactured.

Owner:SAMHWA CAPACITOR

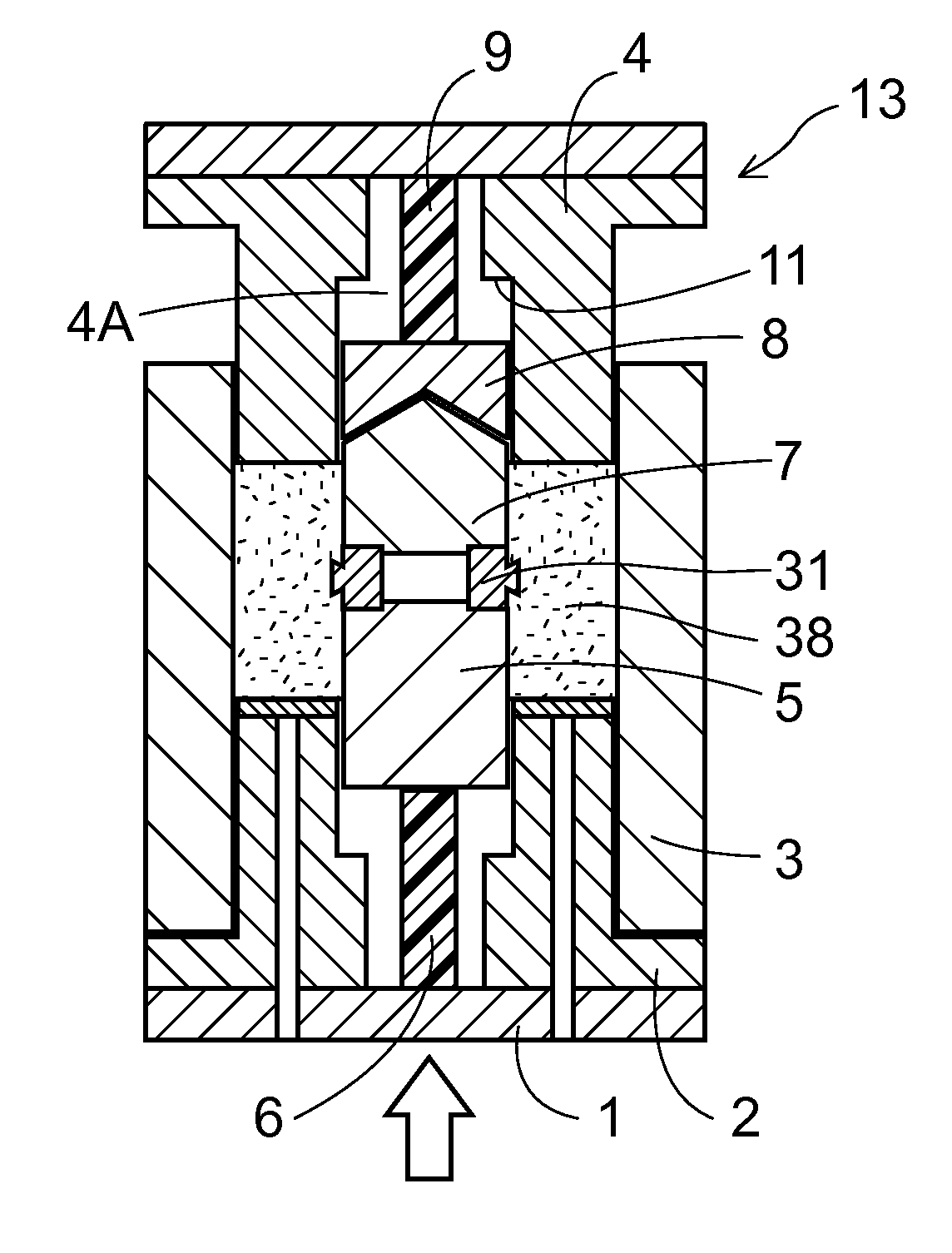

Partitioned reaction container for manufacturing capacitor element including openable and closable passage

InactiveUS8792225B2Constant rangeUniformly manufacturedCapacitor electrolytes/absorbentsCapacitor electrodesMechanical engineeringCapacitor

A reaction container for manufacturing a capacitor element includes a container which accommodates electrolytic solution therein, a partitioning frame which can partition the inside of the container into a plurality of individual chambers, negative electrode members individually arranged in each of the individual chambers, and a constant-current source electrically connected to the cathode members. A passage, which enables movement of the electrolytic solution between each individual chamber and at least one individual chamber of the individual chambers adjacent to each individual chamber, is provided in a manner such that the passage can be opened and closed.

Owner:SHOWA DENKO KK

Control device with blockable attachment places

ActiveUS20050001119A1Avoid disadvantagesAvoid installationCandle holdersLighting support devicesEngineeringElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

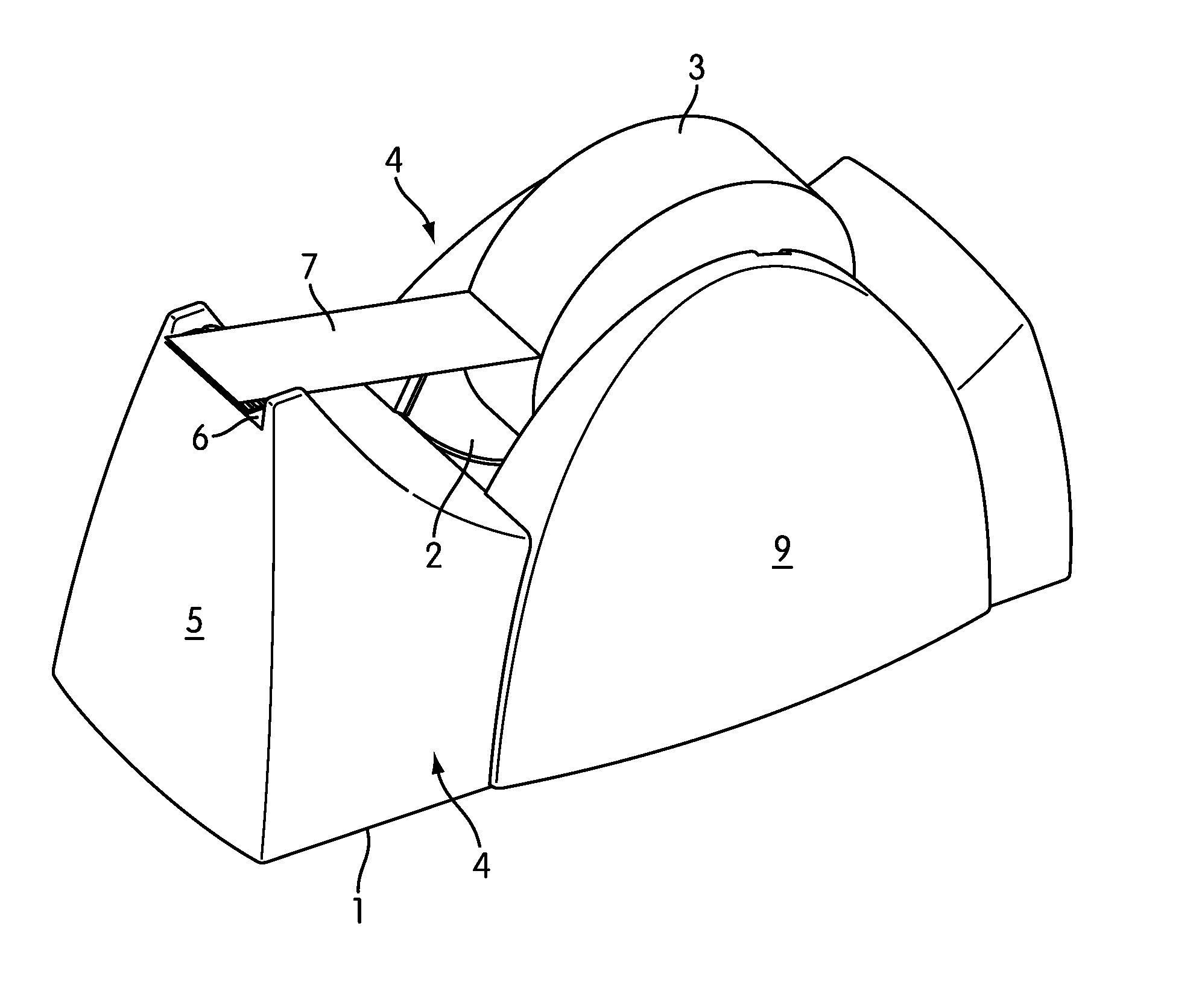

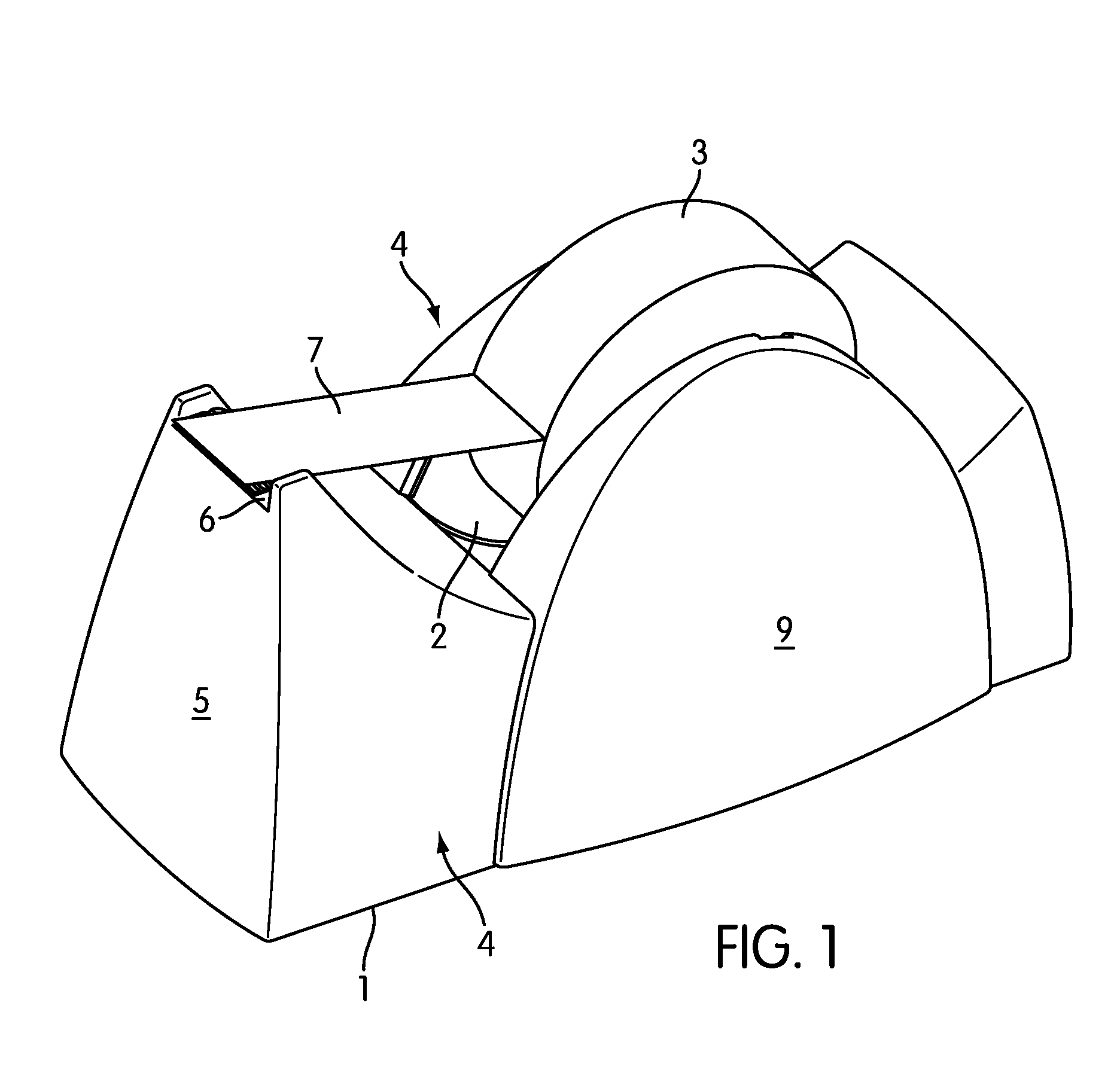

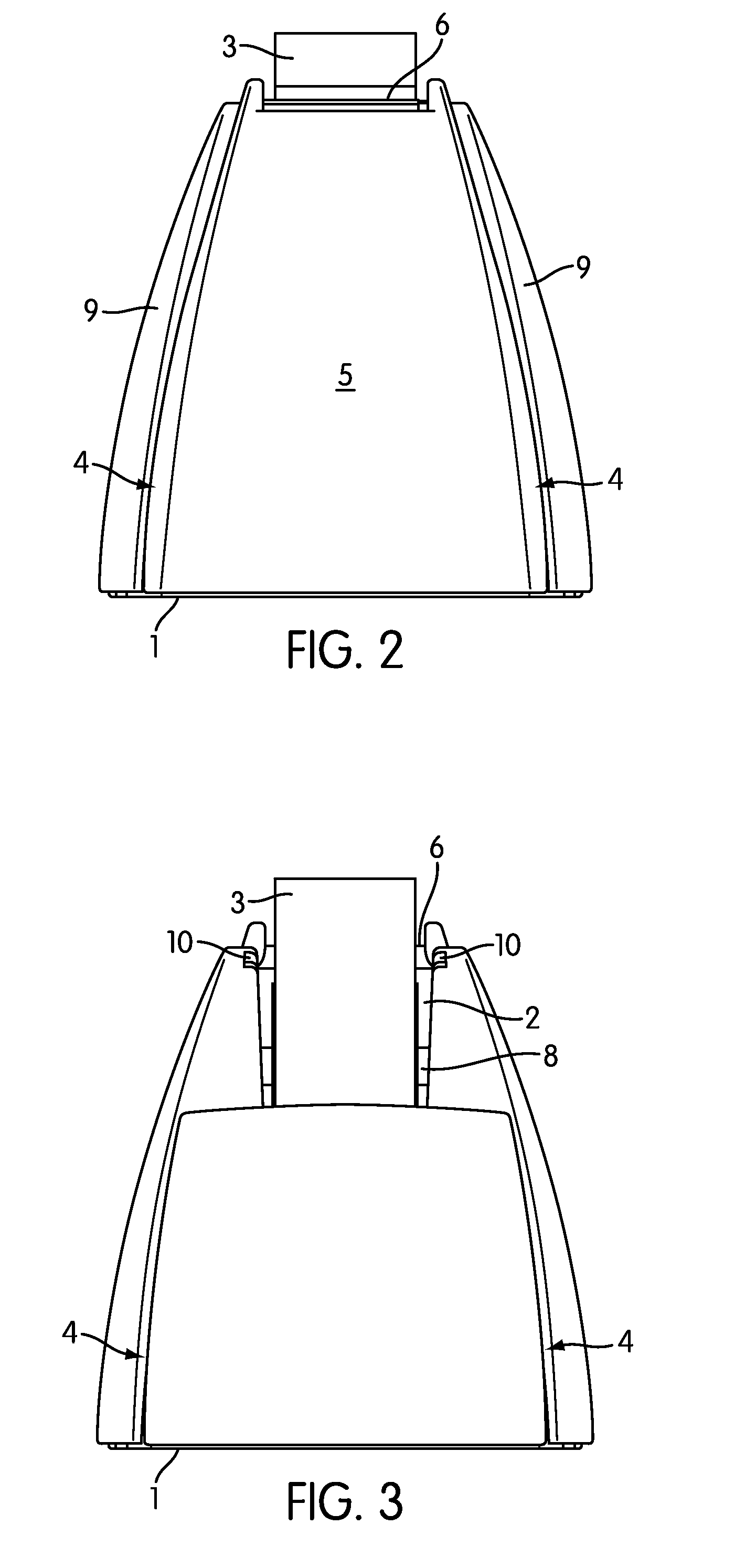

Device for dispensing adhesive tape

InactiveUS20070170303A1Low production costUniformly manufacturedContainers for annular articlesFilament handlingEngineeringMechanical engineering

A table-top tape dispenser, wherein a removable receptacle holding the tape roll is housed in a casing formed by an interchangeable plate that covers the receptacle. The plate element can be customized to display any selected mark or logo, or to add a functional element to the dispenser.

Owner:HENKEL KGAA

Launch pad flame deflector structure and method of making the sam

InactiveUS20190112079A1Minimizes spalling of the refractoryRisk minimizationCosmonautic ground equipmentsPretreated surfacesRefractoryRocket

Flame deflectors for rocket launchpads have historically been constructed on-site by spraying on a layer of refractory cement material, resulting in large monolithic structures which lack durability and are vulnerable to degradation by ambient weather. By assembling together a plurality of metal modules and refractory material modules, one obtains a flame deflector structure whose set of modules is matched to an expected heat distribution pattern of the exhaust from the rocket to be launched. Further, modules can be prefabricated at another location, under controlled conditions, and subsequently installed. In case of damage during a launch, any damaged modules can be swapped out and replaced by new modules, thereby minimizing cost and downtime before a subsequent launch event. The modules can be made more weather-resistant by applying an epoxy sealant to their rocket-facing surfaces.

Owner:RENZI FAMILY TRUST

Control device with blockable attachment places

ActiveUS8747010B2Avoid disadvantagesAvoid installationFurniture partsStands/trestlesElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

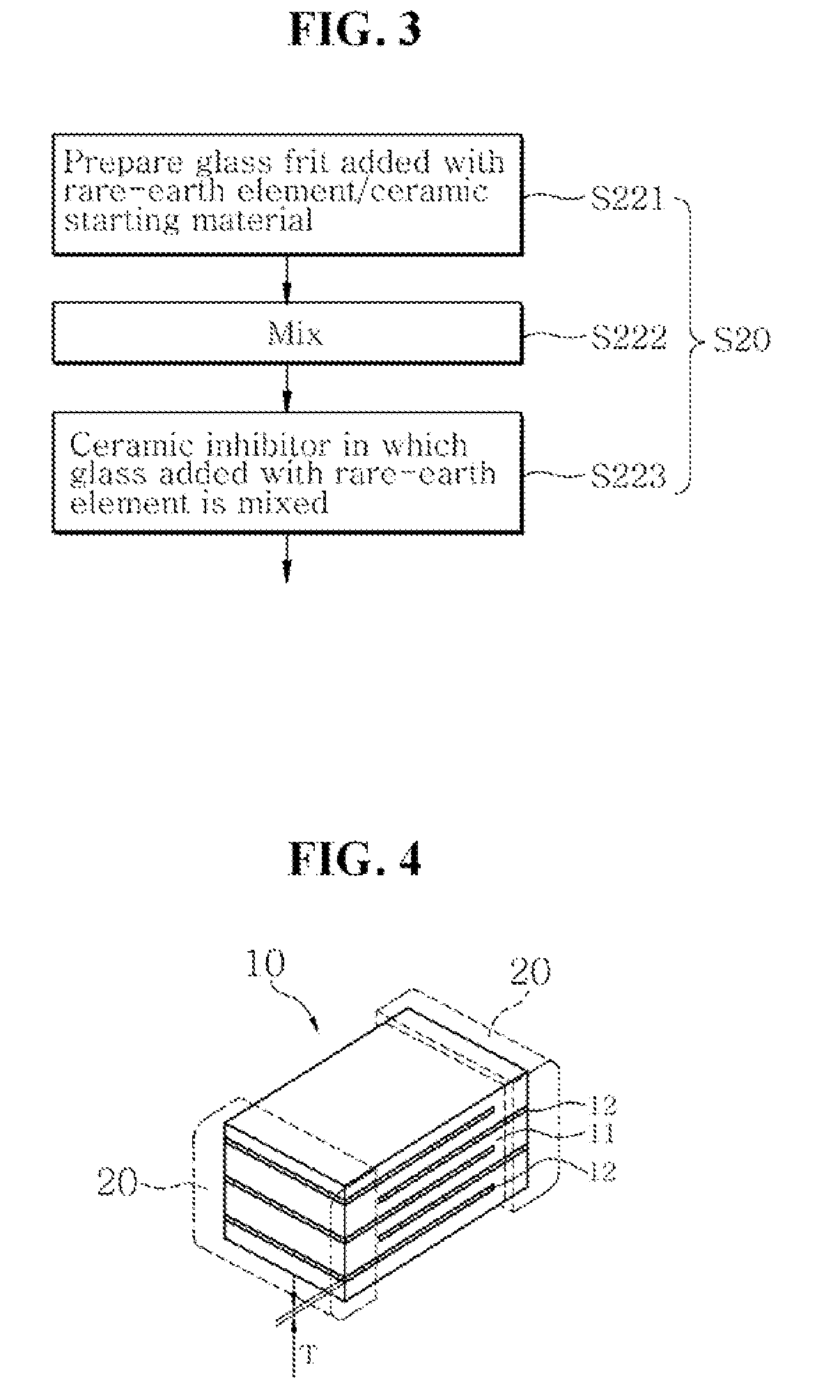

Electron emitter and light emitting apparatus comprising same

InactiveUS20180198027A1Improve performanceUniformly manufacturedNanoinformaticsNanoopticsElectron injectionNanostructure

The present invention relates to an electron emitter, a method for manufacturing the same, and a light emitting apparatus comprising the same, and, more particularly, to an electron emitter comprising a semiconductor wafer having a nanostructure formed in at least a portion thereof. The present invention is capable of providing a large-area electron emitter, and also capable of providing a light emitting apparatus which has improved light emission efficiency and can be operated by an electron injection method.

Owner:KOREA ADVANCED INST OF SCI & TECH

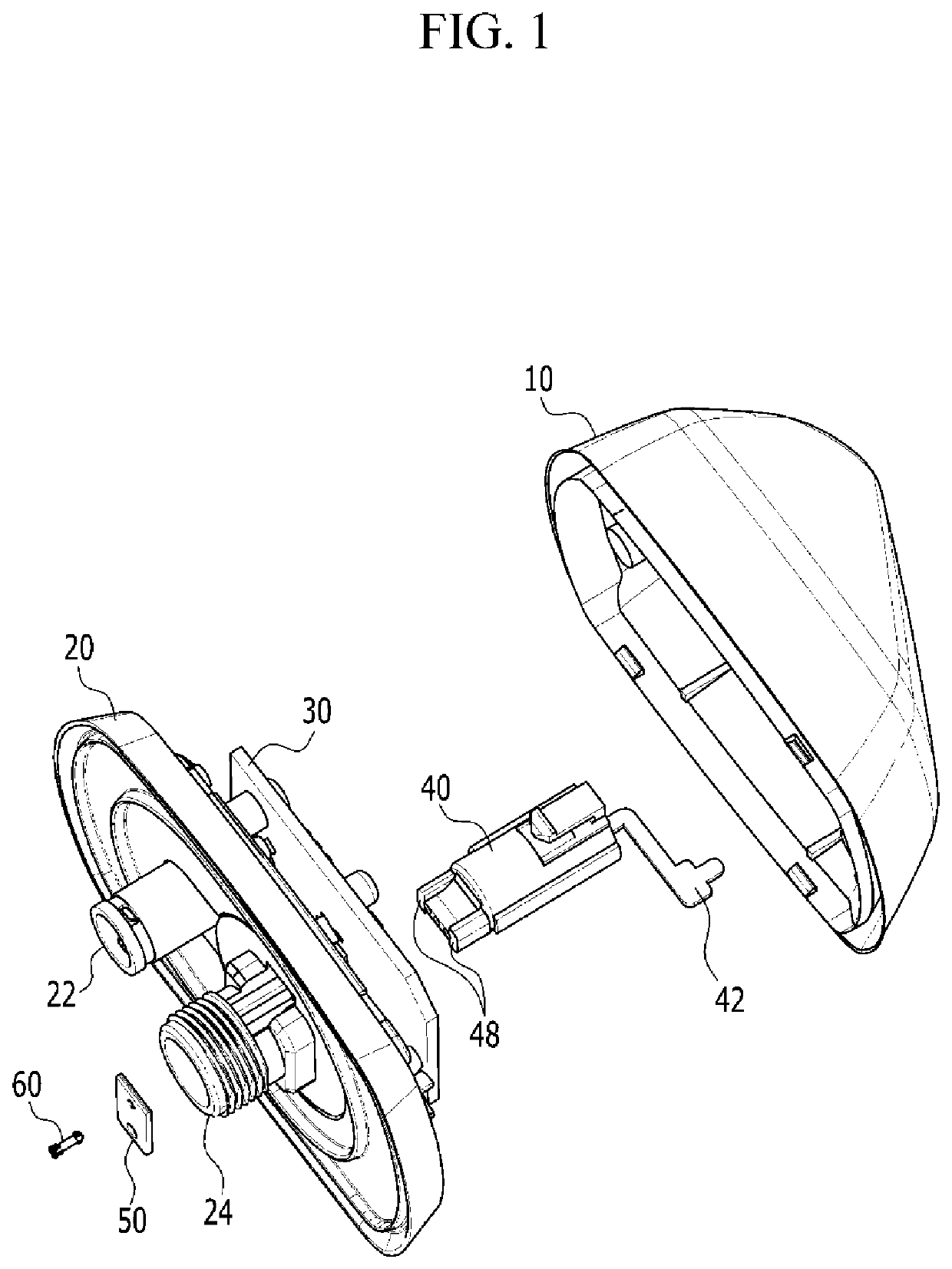

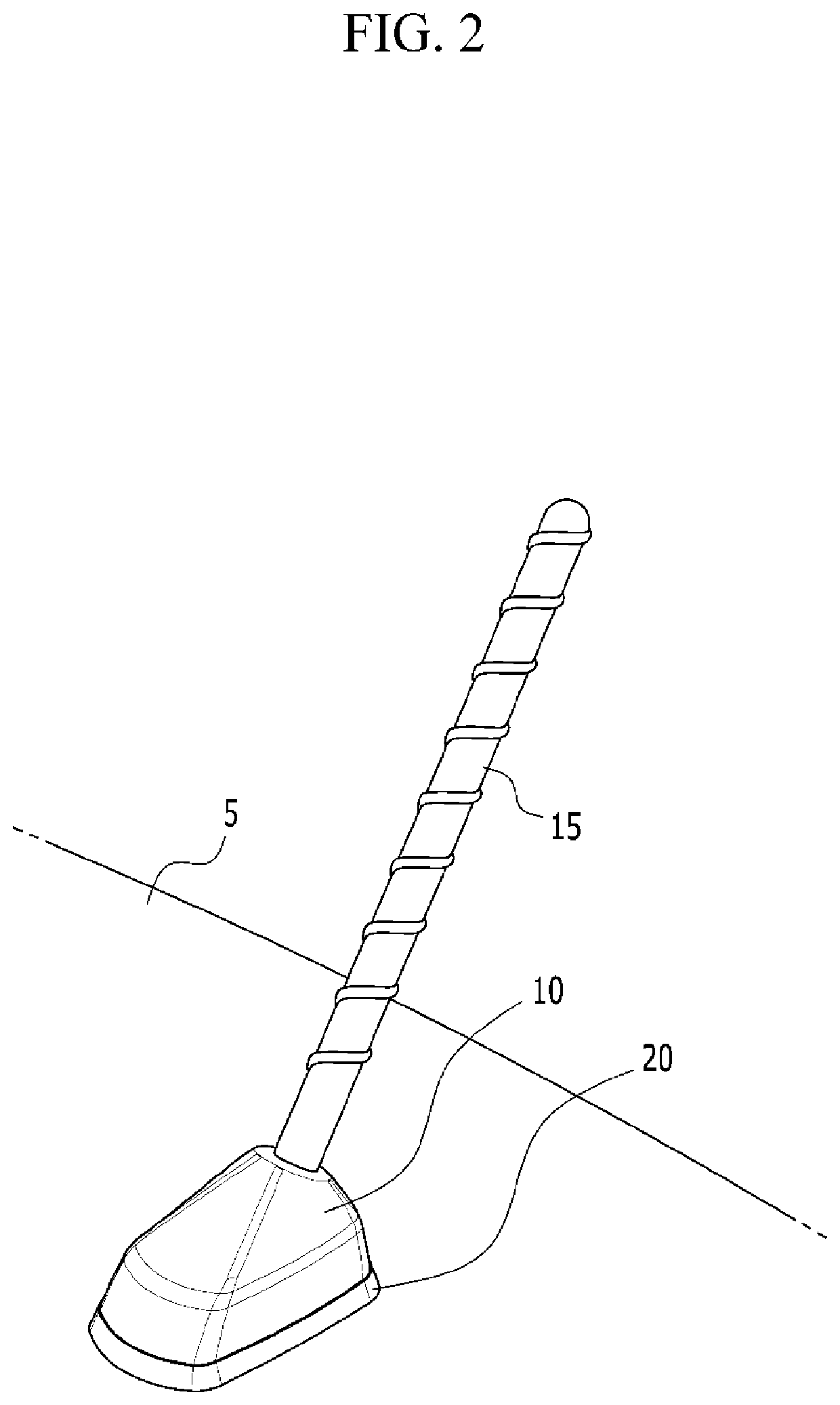

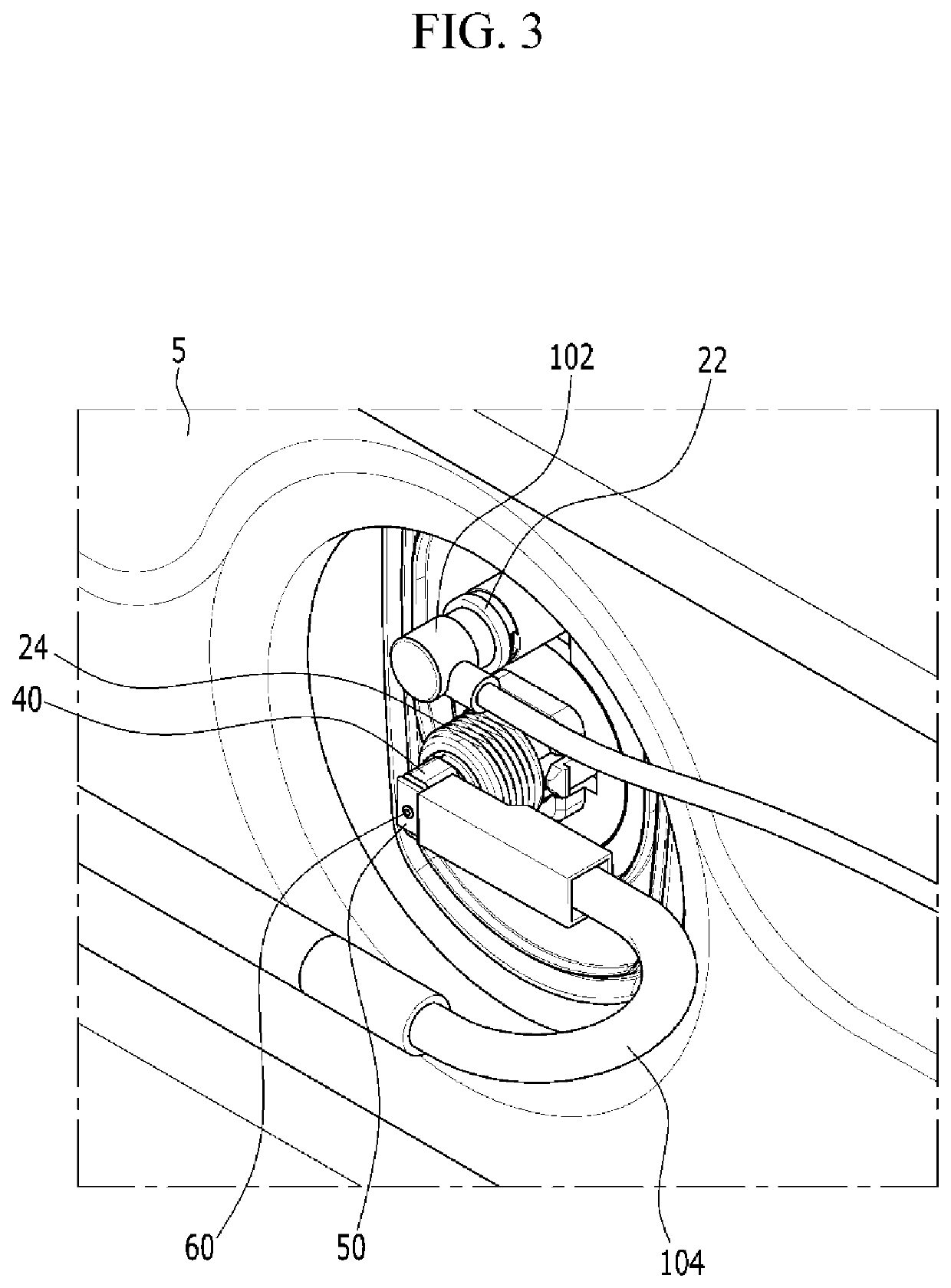

Antenna assembly for vehicle

ActiveUS10658728B2Avoid interferenceImprove productivityVehicle connectorsCollapsable antennas meansStructural engineeringElectric wire

An antenna assembly for a vehicle may include: a cover into which a lower end portion of an antenna is inserted; a base coupled to a lower side of the cover to form an internal compartment; a circuit board mounted on an upper surface of the base to be connected to the lower end portion of the antenna; a terminal mounted to the base wherein an upper end portion thereof is connected to the circuit board and a lower end portion thereof penetrates into the base; a wire connector disposed at the lower end portion of the terminal to be connected to a power wire; and a rotating pin coupling the wire connector with the terminal, wherein the wire connector may be rotatable about the rotating pin.

Owner:HYUNDAI MOTOR CO LTD +1

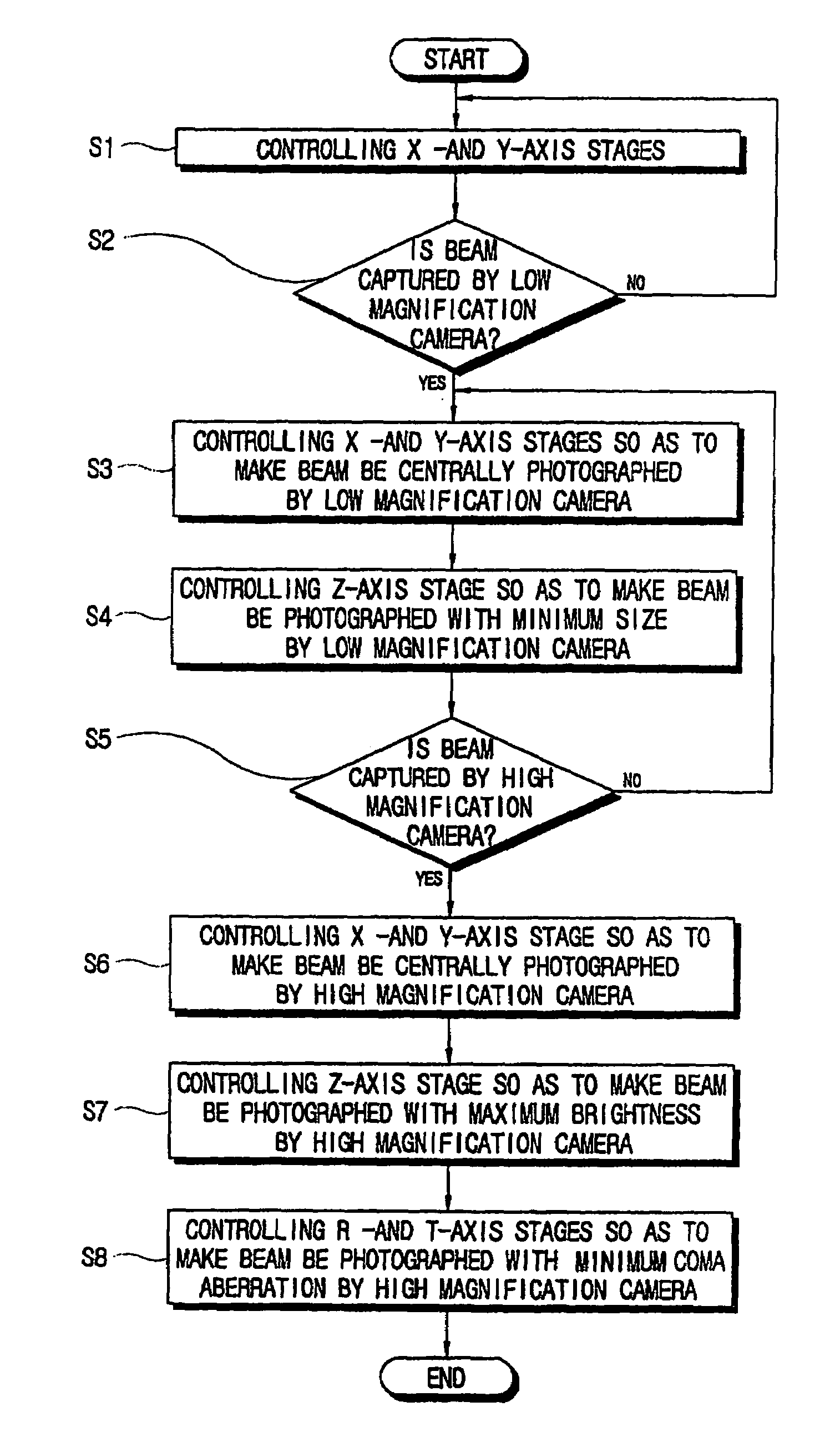

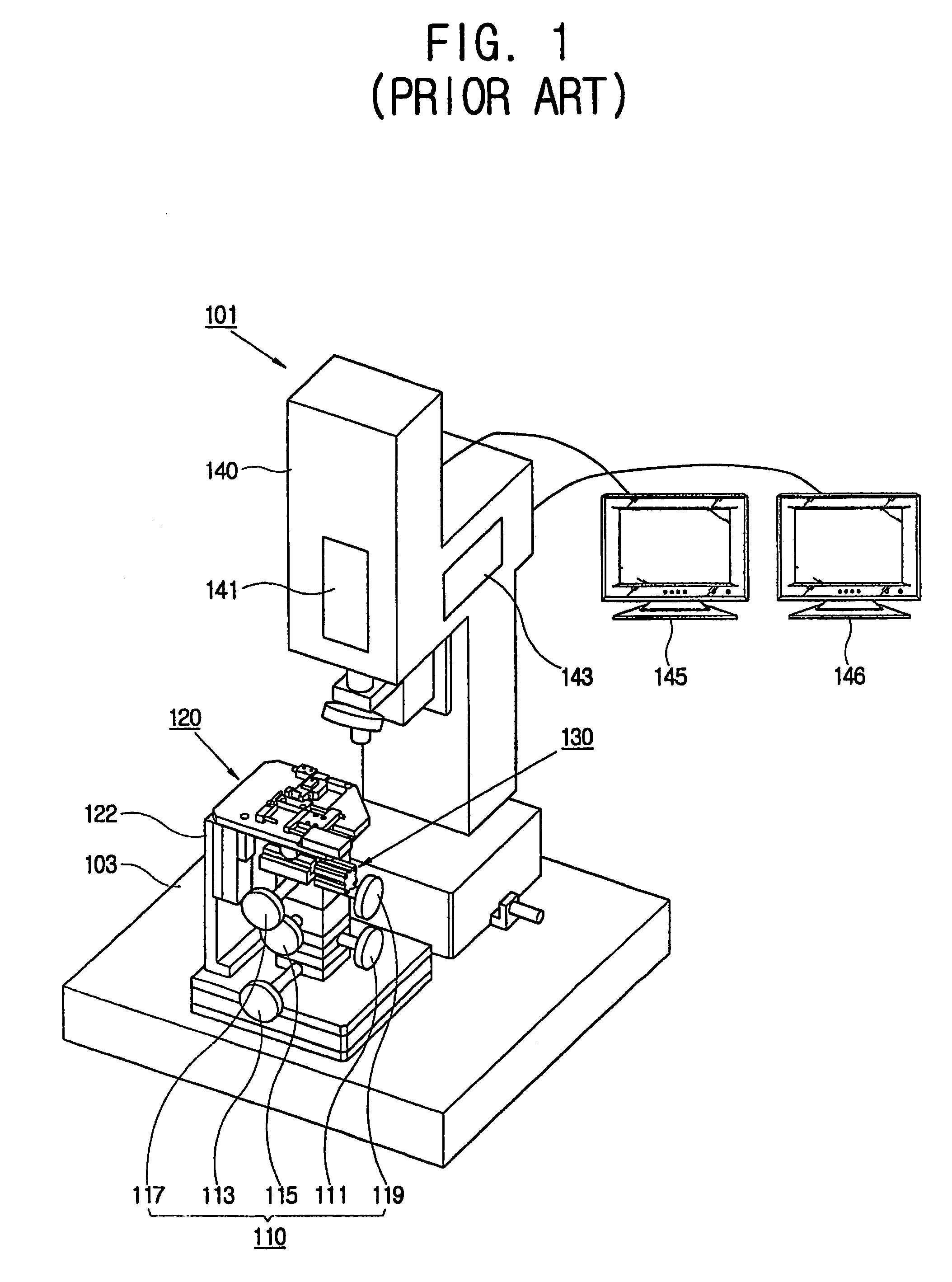

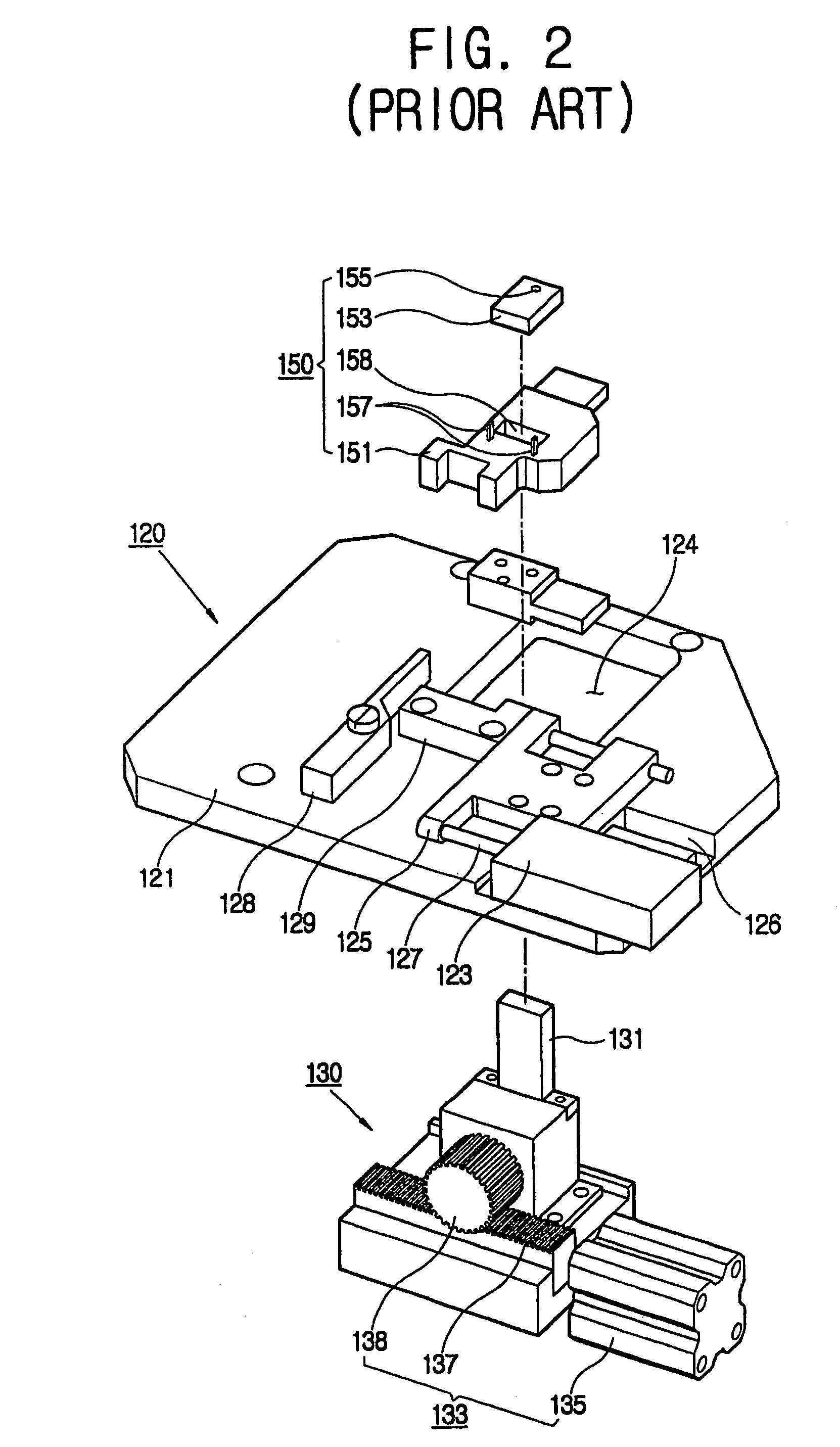

Coma aberration correcting apparatus for optical pickup

InactiveUS7301861B2Increase productivityUniformly manufacturedCombination recordingDisposition/mounting of recording headsOptical pickupEngineering

A coma aberration correcting apparatus of an optical pickup includes an optical pickup main body having a photo diode, and an actuator mounted on an objective lens focusing a beam emitted from the photo diode onto a recording medium. The coma aberration correcting apparatus includes a main supporting unit, a holding unit, an optical system, a driving part, and a controller. The main supporting unit detachably supports the optical pickup main body. The holding unit holds and releases the actuator on the optical pickup main body supported by the main supporting unit. The optical system magnifies and photographs the beam emitted from the photo diode through the objective lens of the actuator held by the holding unit. The driving part adjusts a position of the actuator relative to the optical pickup main body. The controller controls the driving part to correct the coma aberration of the objective lens.

Owner:INTELLECTUAL DISCOVERY CO LTD

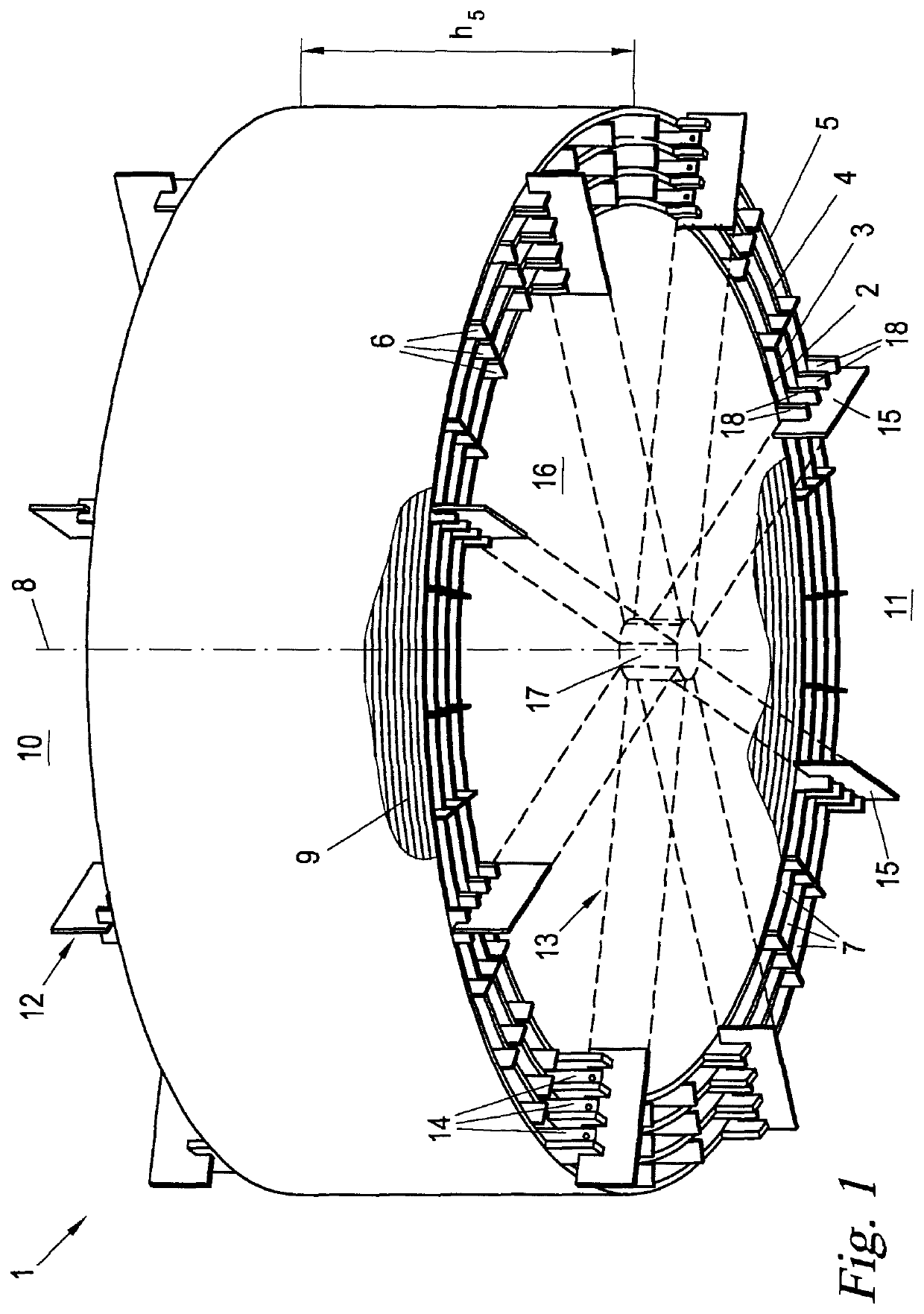

Winding layer pitch compensation for an air-core reactor

ActiveUS10777348B2Easy to produceSimple stepsTransformers/inductances coils/windings/connectionsFixed inductances without magnetic coreEngineeringMechanical engineering

A winding layer pitch compensation for an air-core reactor which has at least two radially spaced apart concentric winding layers, includes a first set of strip-shaped star sheets, each of which is configured to be arranged radially below or above the winding layers and which are provided with at least one receiving slot along an edge extending from that edge, a second set of strip-shaped compensation sheets, each of which is provided with at least one insert slot along an extending from another edge, where a compensation sheet can be inserted into each receiving slot of a star sheet in a formfitting manner, where the star sheet engages into the insert slot of the compensation sheet in a formfitting manner, and where the slot depths of at least two receiving slots of the set of star sheets are different.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com