Electrospinning apparatus

a technology of electropinning apparatus and elongated sheet, which is applied in the direction of filament/thread forming, other domestic articles, manufacturing tools, etc., can solve the problems of elongated sheet being cut, or slacked, and elongated sheet being wrinkled, so as to improve device operation convenience and nanofiber web product reliability, and preventing the effect of sagging, snapping, and damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

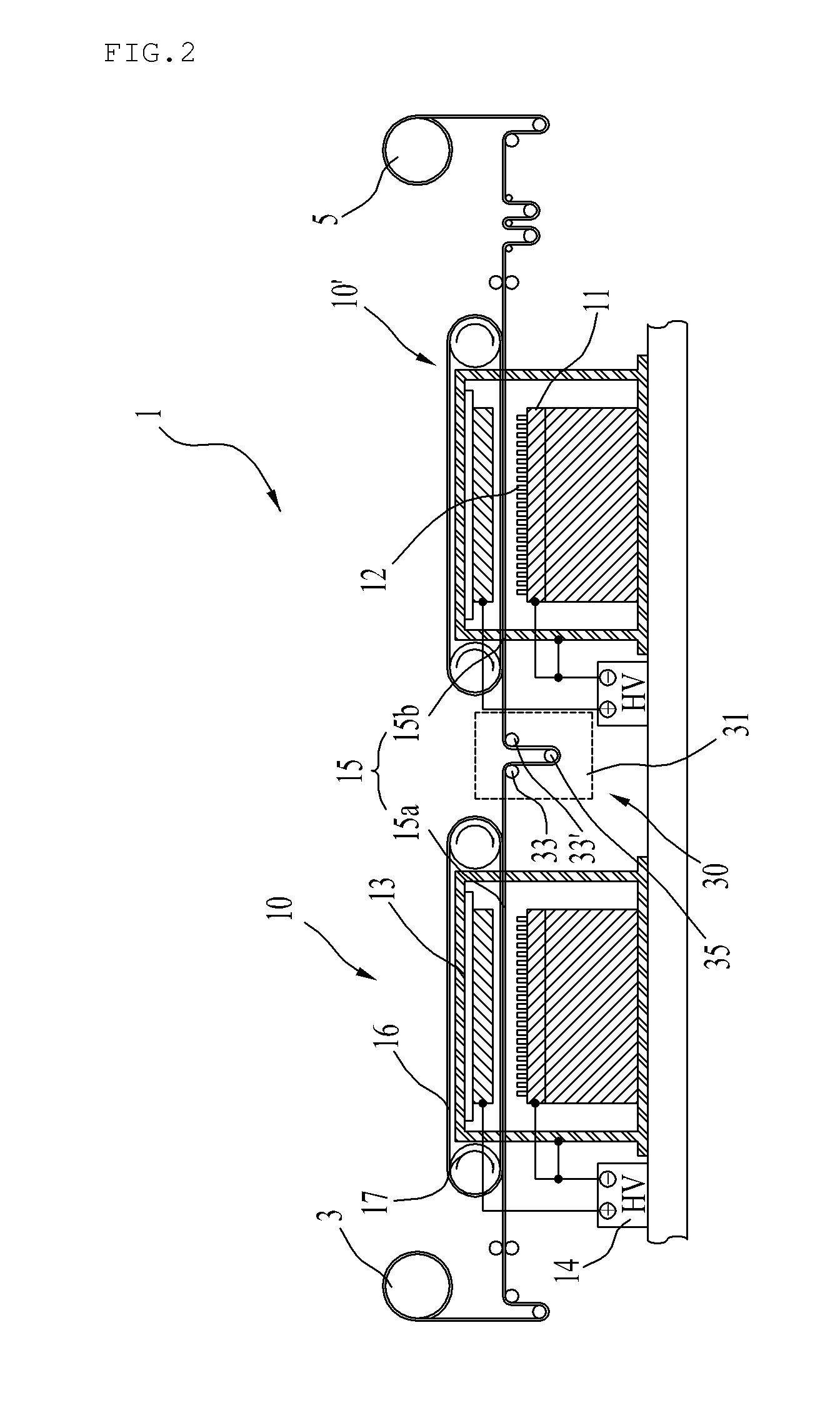

[0173]Installing five units, the elongated sheet (15) is carried in desired carrying speed from the supply roller (3) toward the winding roller (5), laminating nanofiber in order.

[0174]In this case, measuring air permeability of the elongated sheet (15) laminating formed nanofiber from the unit (10, 10′, 10″) of front-end according to the electrospinning apparatus, simultaneously based on measured air permeability by the air permeability measuring device (19b), carrying speed is controlled, after laminating nanofiber on the elongated sheet (15) consecutively in the unit (10′, 10″, 10′″) of rear-end, air permeability is measured, repeatedly carrying speed is controlled, and nanofiber is laminated.

embodiment 2

[0175]Installing five units, the elongated sheet (15) is carried in desired carrying speed from the supply roller (3) toward the winding roller (5), laminating nanofiber in order.

[0176]In this case, measuring air permeability of the elongated sheet (15) laminating formed nanofiber from each of the unit (10, 10′, 10″, 10′″), simultaneously based on measured air permeability according to the air permeability measuring device (19b), the nozzle block (11) discharging amount and the voltage generating device (14) voltage intensity are controlled, after laminating nanofiber on the elongated sheet (15) consecutively in the unit of rear-end (10′, 10″, 10′″), air permeability is measured, repeatedly the nozzle block (11) discharging amount and the voltage generating device (14) voltage intensity are controlled, and nanofiber is laminated.

embodiment 3

[0205]Installing five units, the elongated sheet (15) is carried in desired carrying speed (V) from the supply roller (3) toward the winding roller (5), laminating nanofiber in order.

[0206]In this case, measuring thickness of the elongated sheet (15) on which nanofiber is laminated and formed from the unit of front-end (10, 10′, 10″) according to the electrospinning apparatus, simultaneously based on measured thickness according to the thickness measurement device (19c), carrying speed is controlled, after laminating nanofiber on the elongated sheet (15) consecutively from the unit of rear-end (10, 10′, 10″), thickness is measured, repeatedly carrying speed is controlled, and nanofiber is laminated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com