Ink ribbon cassette

A technology for ink ribbon cassettes and ink ribbons, applied in the field of ink ribbon cassettes, can solve the problems of inability to detect with high precision, poor printing, and bending of recording paper 37, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

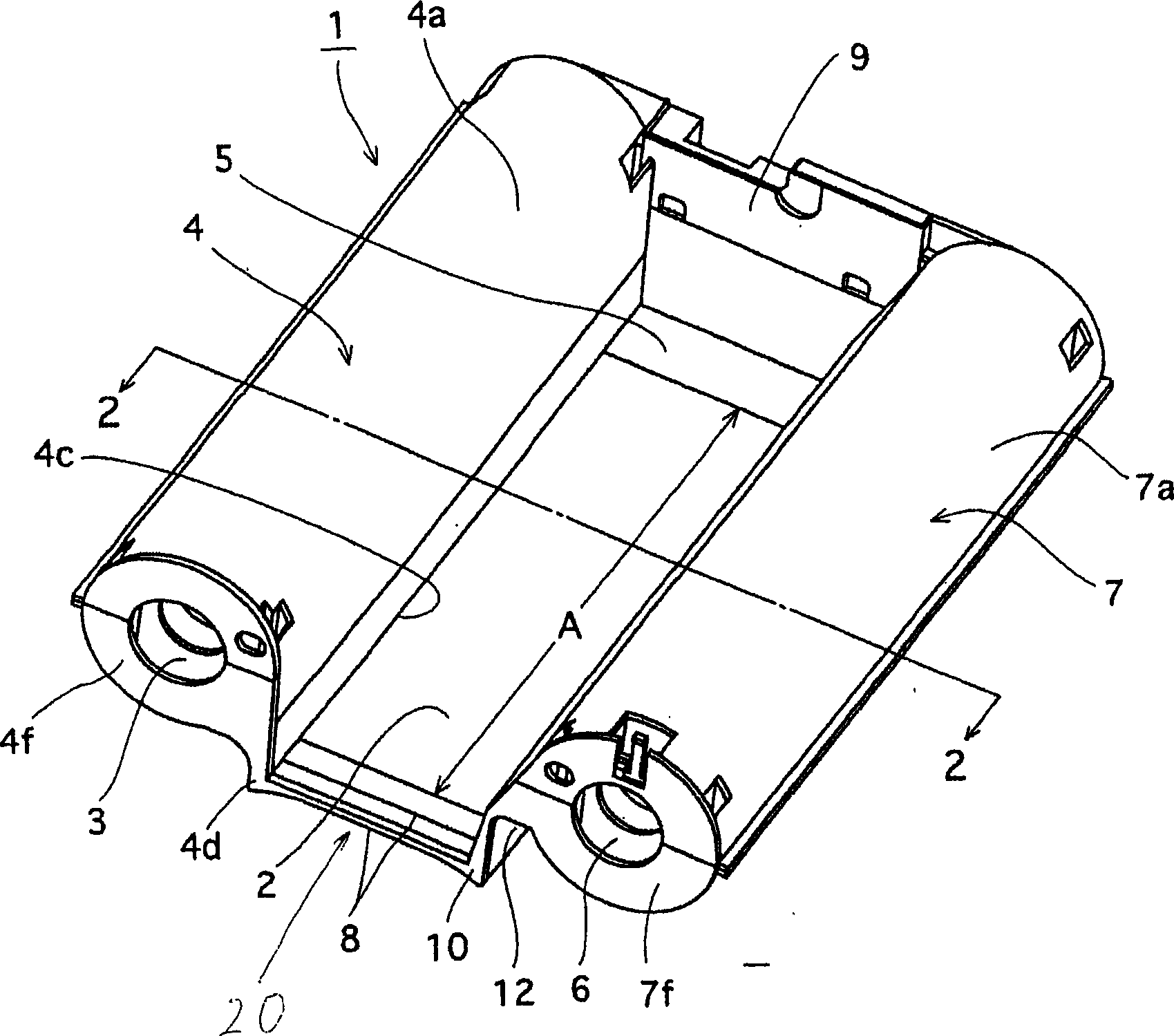

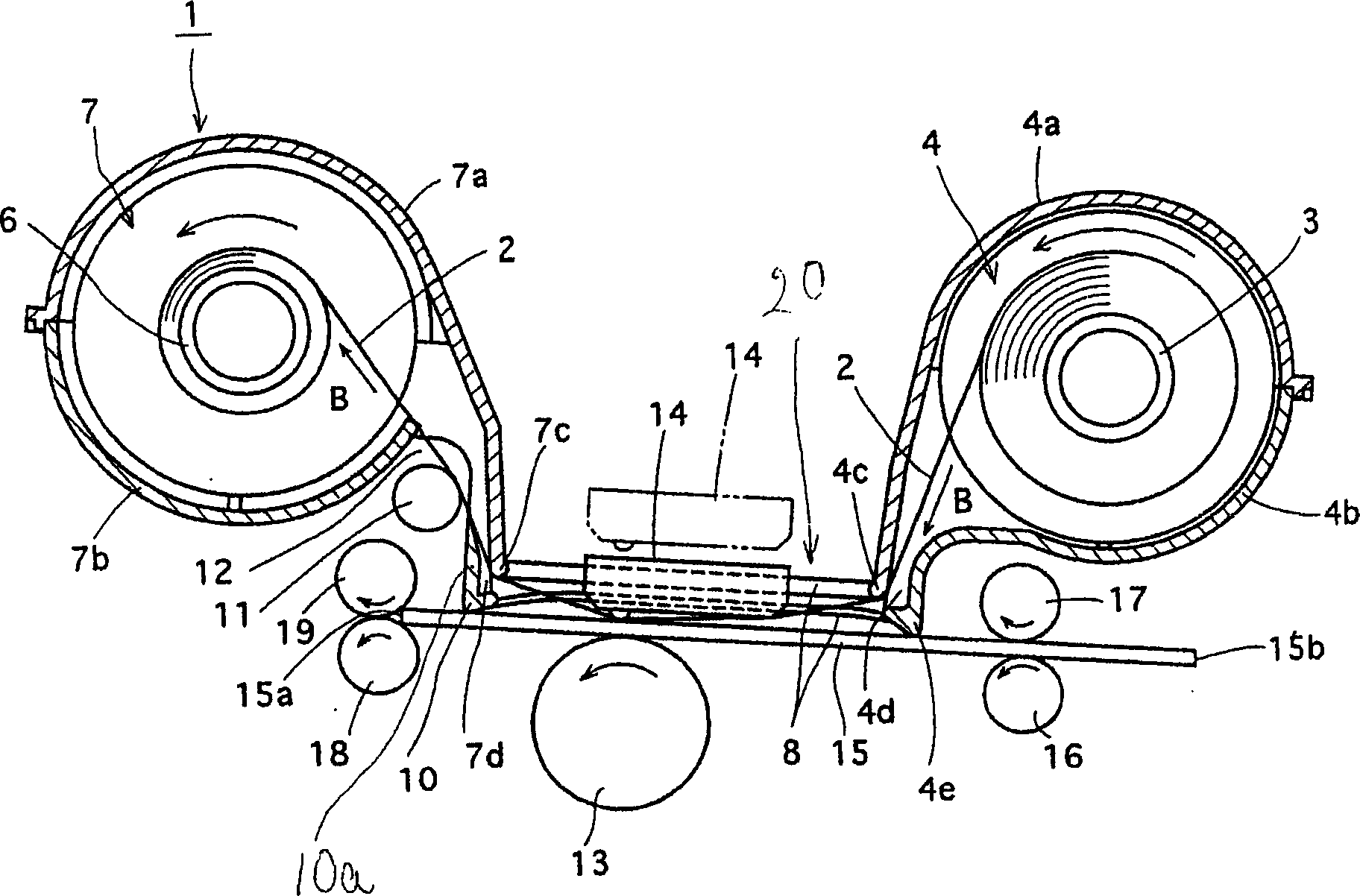

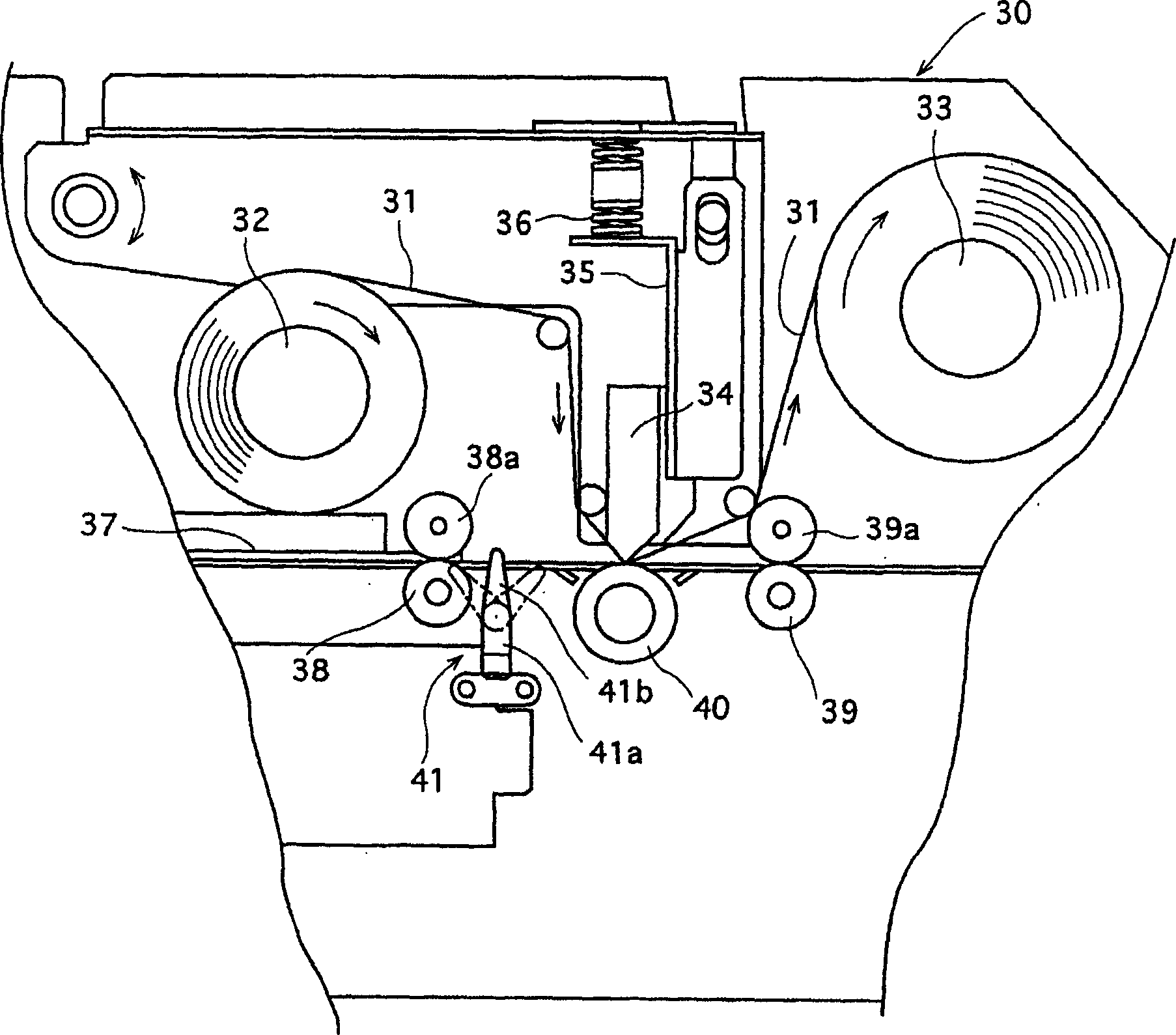

[0040] Hereinafter, the ink ribbon cassette of the present invention will be described based on the drawings. figure 1 is a perspective view of the ink ribbon cassette 1 of the present invention, figure 2 When the ink ribbon cassette of the present invention is mounted on the main body of the printer figure 1 2-2 Sectional Drawing.

[0041] First, the ink ribbon cassette 1 of the present invention is made of a resin material such as figure 1 , figure 2 As shown, a first tape housing portion 4 is formed, and the first tape housing portion 4 accommodates a supply reel 3 on which an unused ink ribbon 2 of width A is wound.

[0042] The inside of the first belt housing portion 4 is formed in a hollow shape by the first wall portion 4a and the second wall portion 4b formed in a substantially circular arc shape and vertically elongated. In addition, a first tape sliding contact portion 4c is formed at the lower end portion of the first wall portion 4a, with which the ink ribbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com