Calibration method for clearance between rolls of hot-rolling vertical rolls

A calibration method and vertical roll technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of strip quality defects without considering verticality, improve equipment management level, and reduce the amount of repairs , The effect of safety equipment management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

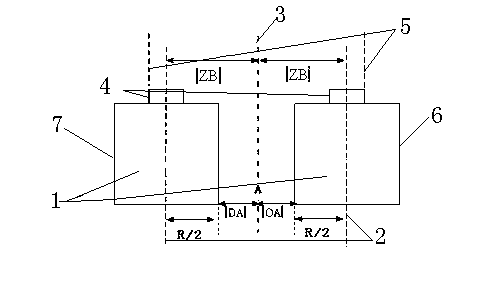

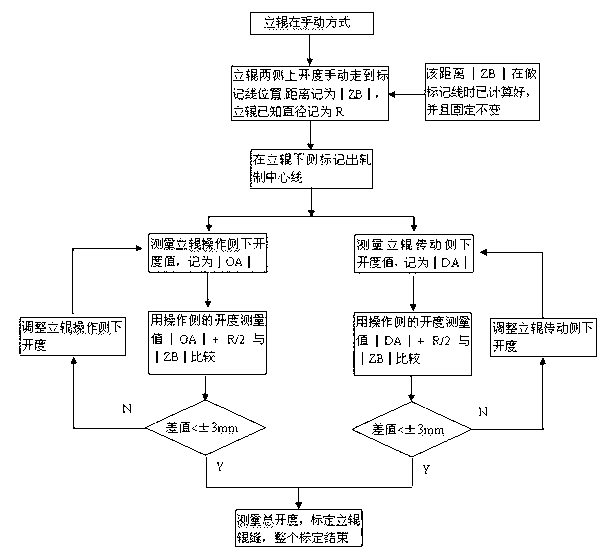

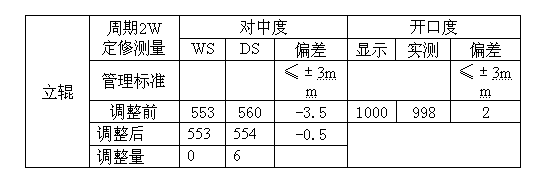

[0020] According to the characteristics and needs of the hot rolling production line, refer to figure 1 , 2 , a method for calibrating the roll gap of hot-rolled vertical rolls, comprising the following steps:

[0021] 1. Firstly, prepare the calibration conditions. Find out the rolling center line 3 at the upper and lower ends of the vertical roll 1 and mark it well. Make two marking lines 5 on both sides of the transmission and operation on the slideway at the upper end of the vertical roll, and the The distance from the marking line 5 to the rolling center line 3 on the vertical roll is equal and known;

[0022] 2. For the calibration of the verticality of the vertical roll 1, align the roll block 4 at the upper end of the vertical roll 1 with the inner side of the marking line 5, so that the opening of the vertical roll can be made as small as possible to facilitate the measurement of the opening of the lower end of the vertical roll. When the two sides of the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com