Process for controlling temperature of strip steel

A technology for controlling strips and strips, applied in heat treatment process control, manufacturing tools, coatings, etc., can solve the problems of low control accuracy and slow response speed, and achieve the effects of high control accuracy, fast response speed and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

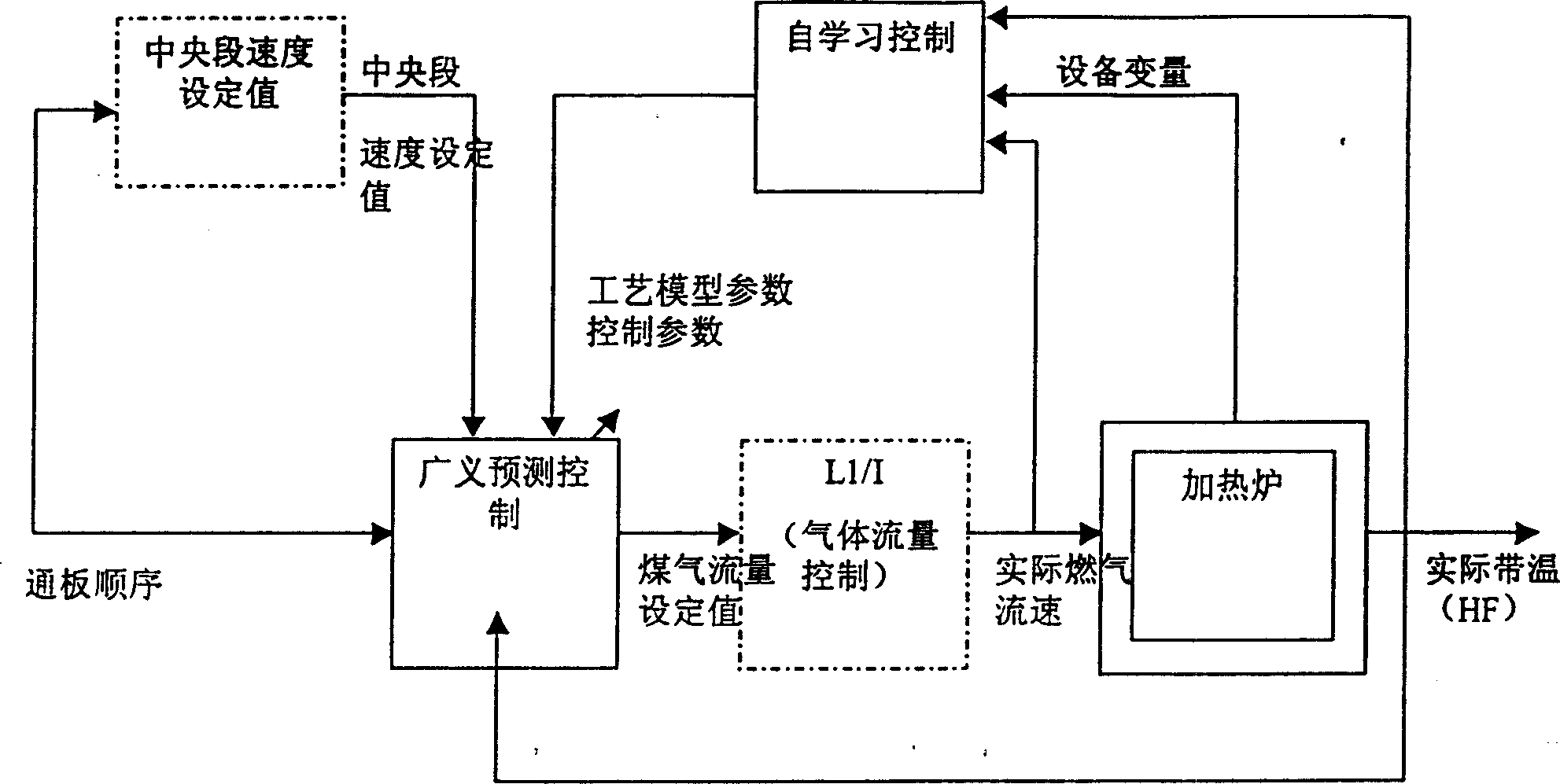

[0017] Such as figure 1 Shown: the method for controlling strip steel temperature of the present invention comprises the steps:

[0018] 1. According to the sequence of plate passing, the basic data of the steel plate, the speed setting value of the central section, the actual temperature of the strip steel, the target temperature of the strip steel, and the self-learning parameters of the process digital model, using the principle of generalized predictive control (GPC), according to The zone temperature dynamic model predicts the zone temperature at a certain time in the future;

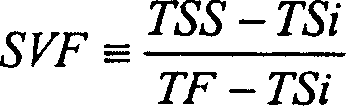

[0019] 2. Make the difference between the target strip temperature and the predicted strip temperature reach the minimum value, and calculate the required gas flow deviation;

[0020] 3. Then calculate the gas flow set value according to the actual gas flow combined with the gas flow deviation;

[0021] 4. Send the gas flow setting value to the instrument control equipment;

[0022] 5. Carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com