A high-pressure automatic variable control method with hydraulic overload and control valve device

An automatic variable and control method technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as the inability to ensure effective control of external pilot hydraulic controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0020] Example. A high-pressure automatic variable control method with hydraulic overload, which uses a control spool with a differential area to sense the inlet pressure of the motor to realize automatic high-pressure variable inlet pressure and displacement; and introduces a pilot at the tail end of the spool Hydraulic control pressure to realize hydraulic overload function.

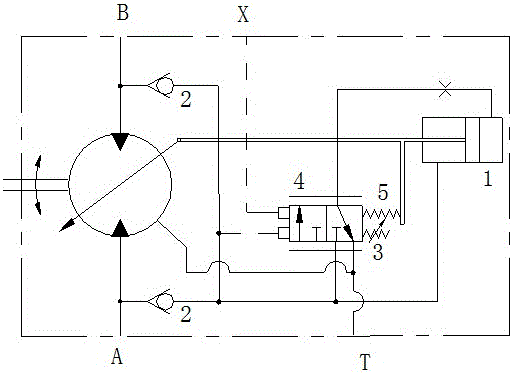

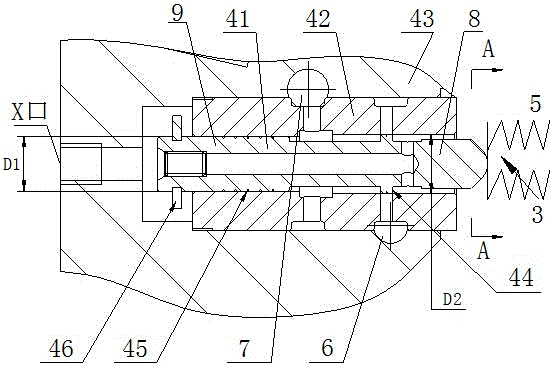

[0021] The control valve device for realizing the above-mentioned high-pressure automatic variable control method with hydraulic overload is constituted as follows: Figure 1-3 As shown, it includes a motor, the inlet and outlet of the motor are respectively connected to the control spool valve 4 through the check valve 2, the control spool valve 4 is provided with a pressure regulating spring 3 and a feedback spring 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com