Intelligent high-speed rolled sheet type blister packing machine

A technology of blister packaging machine and high-speed roller, which is applied in the direction of packaging machine, packaging, transportation packaging, etc., which can solve the problems of wasting materials, difficulty of cartoning machine, difficulty of aluminum foil inspection, etc., and achieve the effect of eliminating errors and eliminating slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

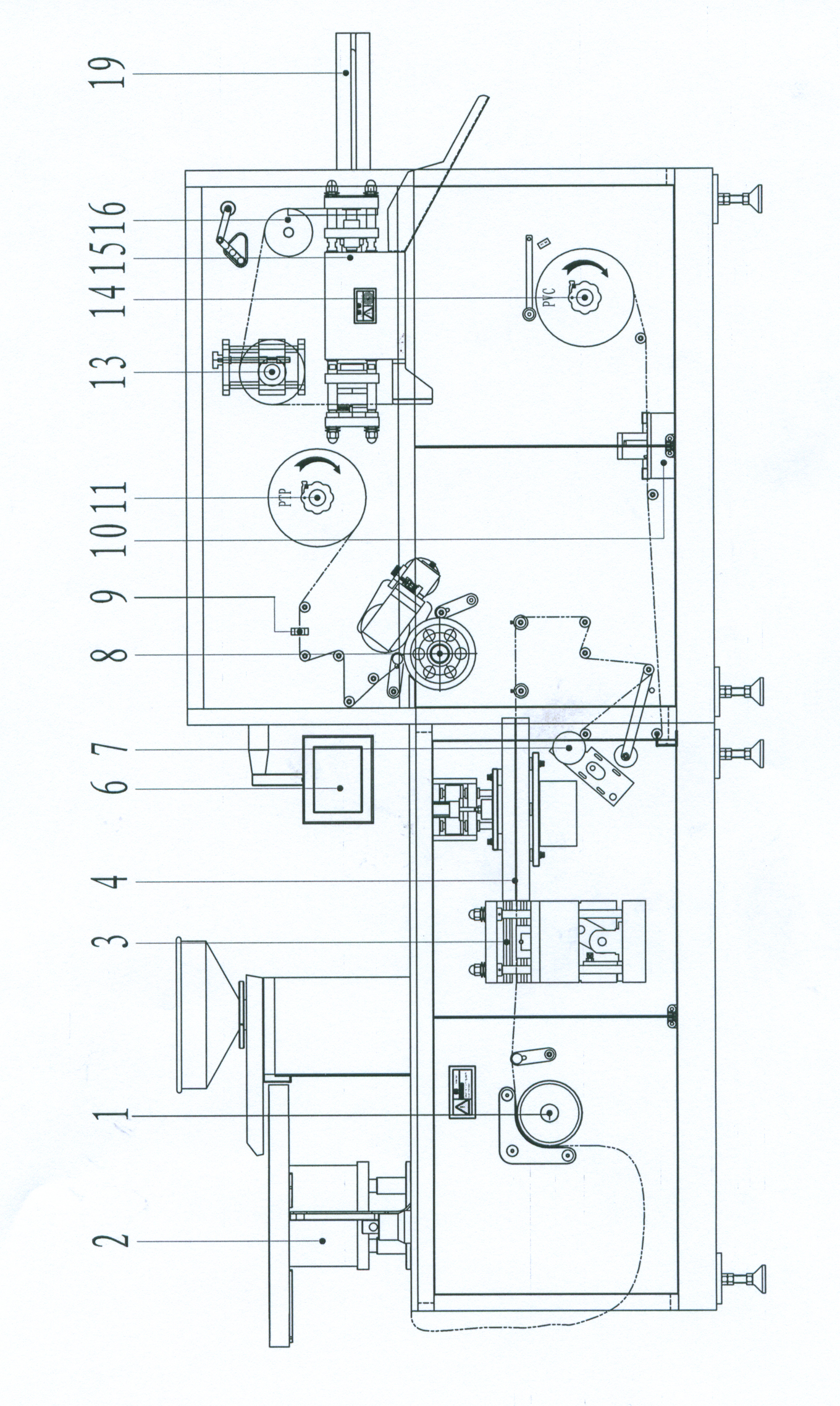

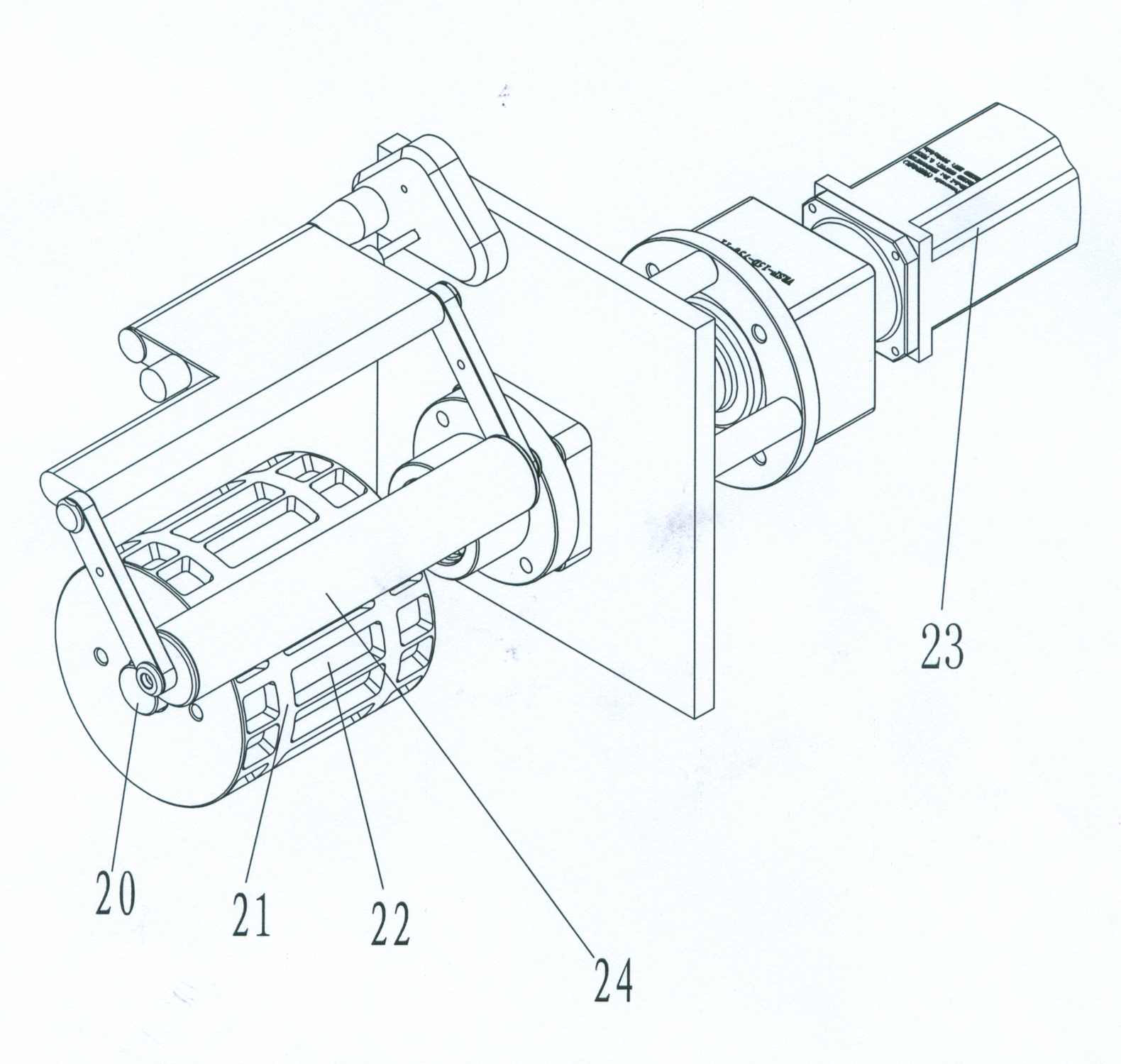

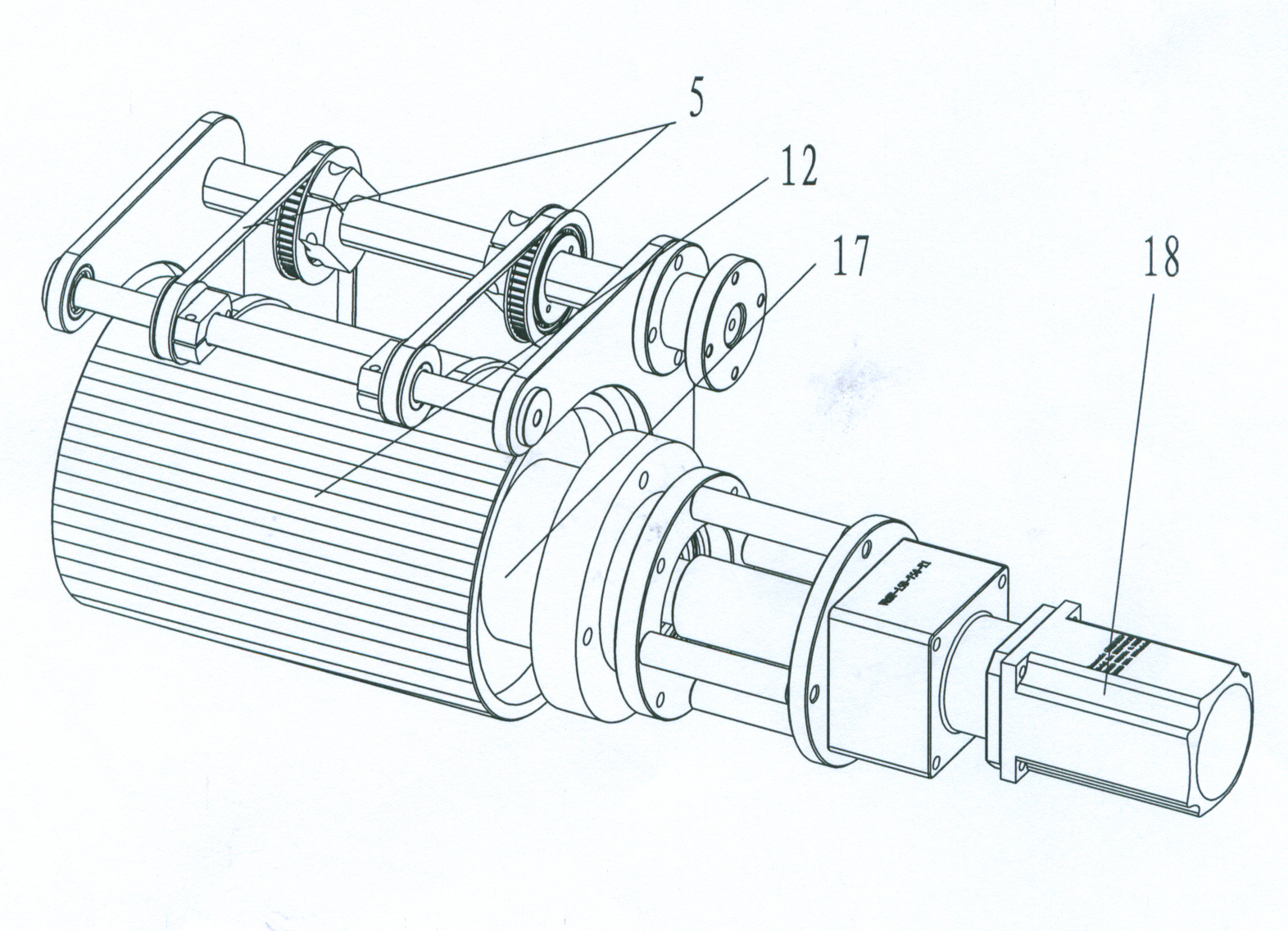

[0020] Accompanying drawing has shown the structure of the present invention and its embodiment, further describe the relevant details of its embodiment below again in conjunction with accompanying drawing, in order to realize above-mentioned purpose, a kind of intelligent high-speed roller plate type blister packaging machine, this machine includes electric control Part 6, PVC discharging mechanism 14, PVC first traction mechanism 7, material feeding mechanism 2, aluminum foil discharging mechanism 11 and PVC and aluminum foil heat sealing mechanism 8, PVC heating mechanism 4 and Compression molding mechanism 3, the PVC heating mechanism 4 has a heating plate, the surface of the heating plate is coated with PTFE coating, the machine also includes a blister traction 16 and a PVC forming traction mechanism 1, the PVC forming traction The mechanism includes a transmission motor 18, the transmission motor 18 is in transmission connection with the traction shaft 17, the traction sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com