FP type chip pin forming device and forming method

A technology of chip tubes and pins, which is applied in the field of FP-type chip pin forming devices, can solve the problems of chip damage, static electricity, sparking, etc., and achieve the effect of ensuring physical damage and electrostatic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

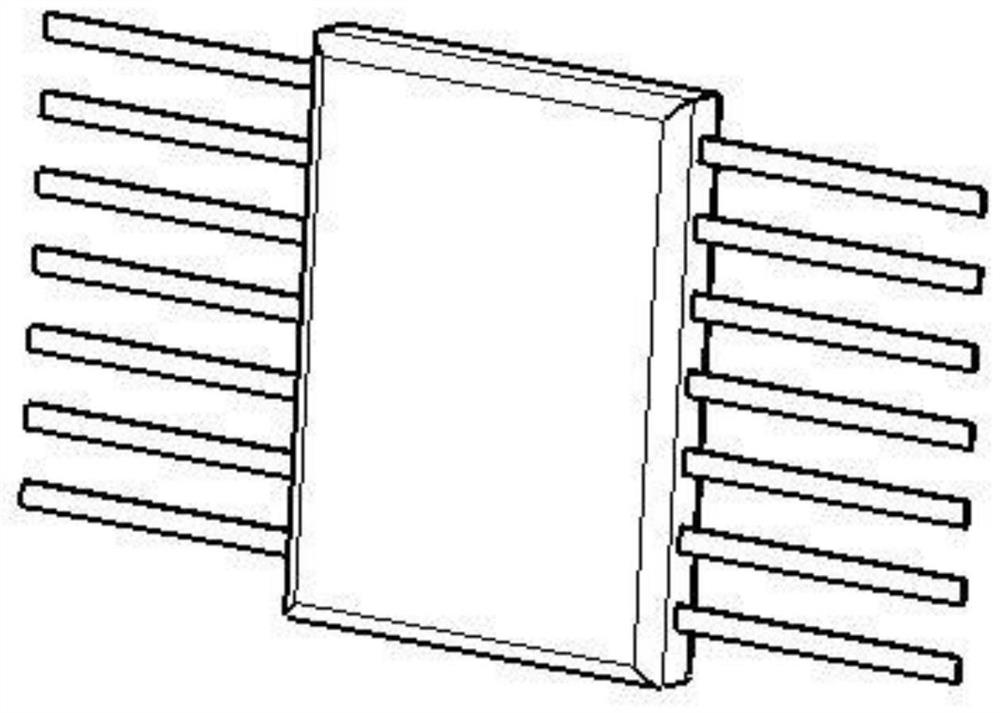

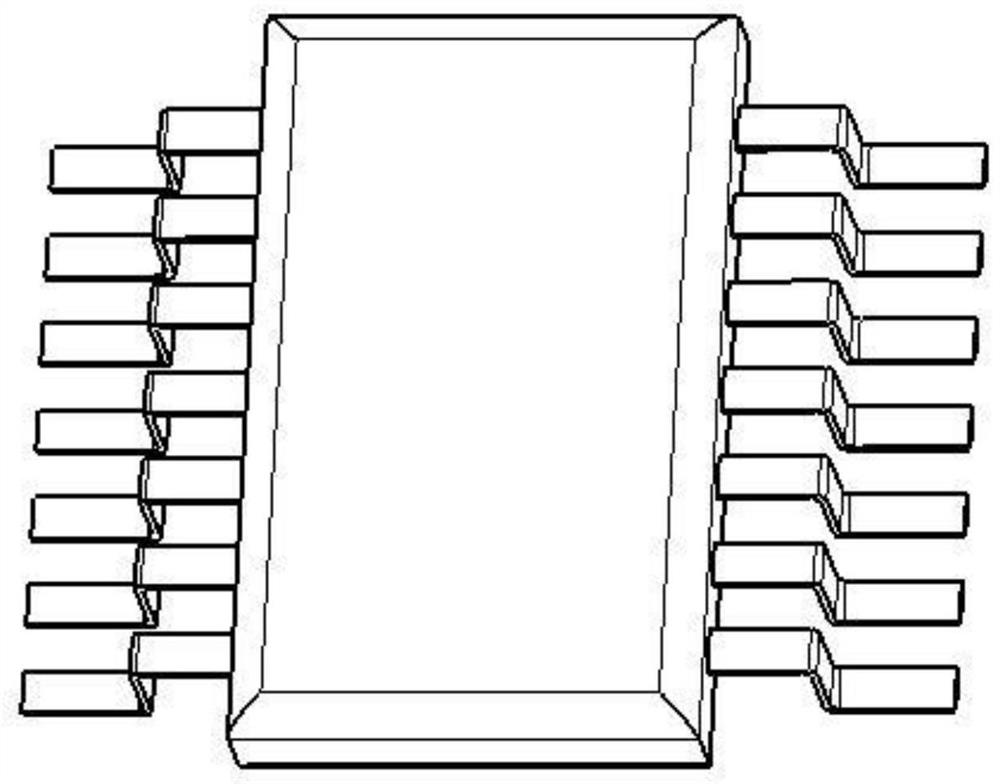

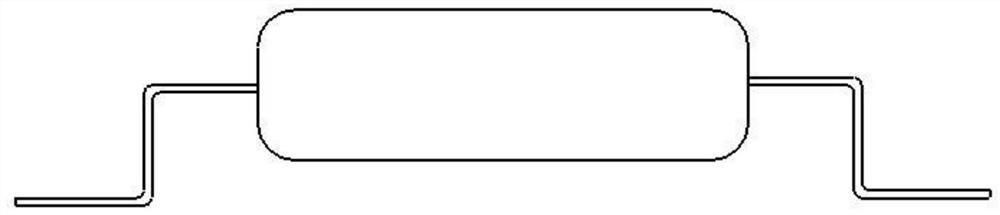

[0029] According to the attached Figure 1-5 The forming device of the present invention is introduced in detail. The forming device includes a clamping device, an upper mold 4 and a lower mold 1, wherein the lower mold 1 includes a bottom plate, two first raised ribs 2 and a raised line 3, and the raised line 3 is located in the center of the bottom plate. Two first convex ribs 2 are symmetrically distributed on both sides of the convex strip 3, wherein the heights of the first convex rib 2, the convex strip 3 and the bottom plate are successively reduced; correspondingly, the upper mold 4 includes a top plate, two first flanges 5 and two The second flange 6, the height of the top plate, the two first flanges 5 and the two second flanges 6 are raised successively, wherein the two first flanges 5 and the two second flanges 6 are about the central axis of the top plate Symmetrical distribution.

[0030] The first flange 5 of the upper mold 4 corresponds to the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com