Patents

Literature

67 results about "Standing height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

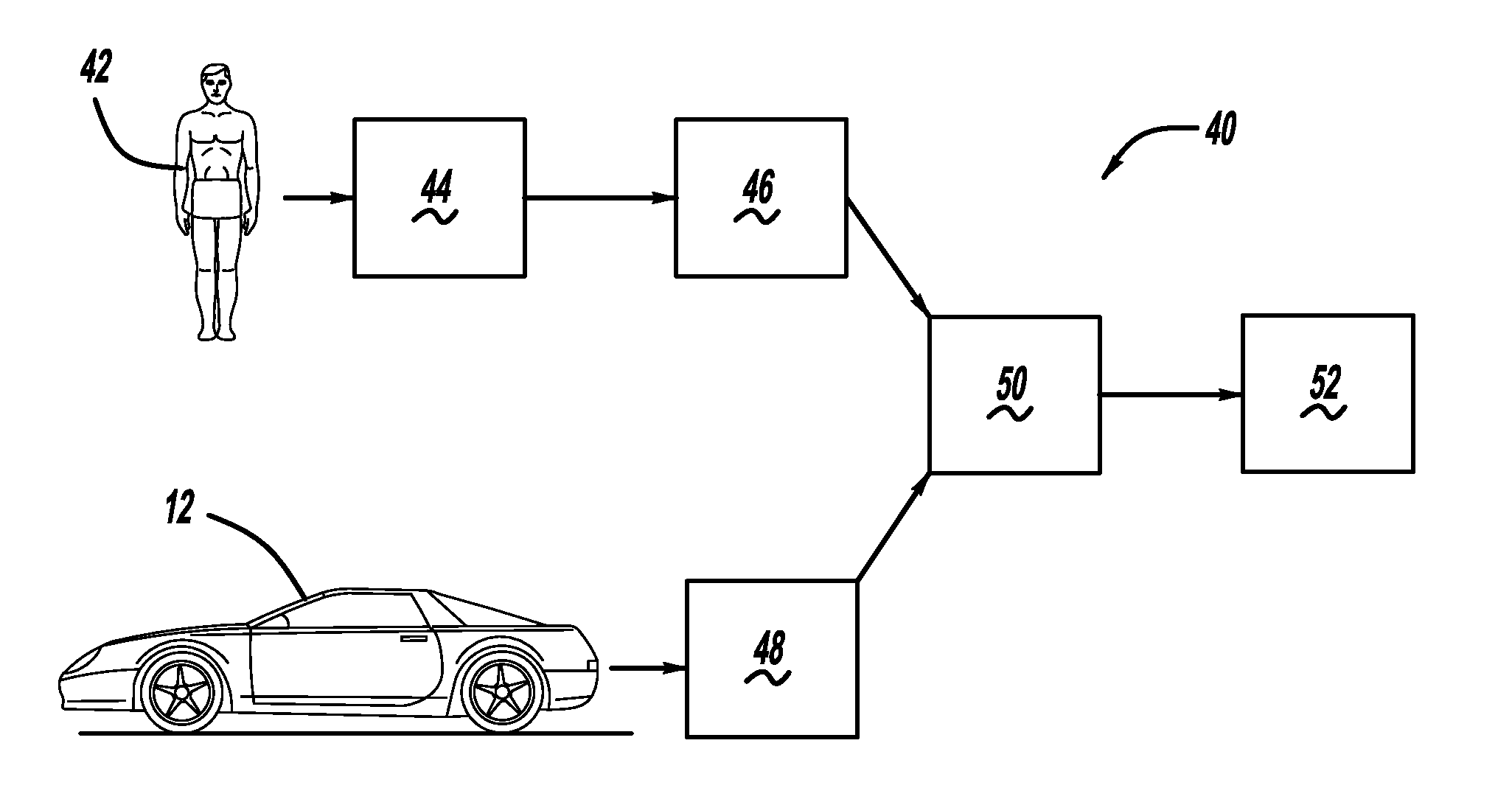

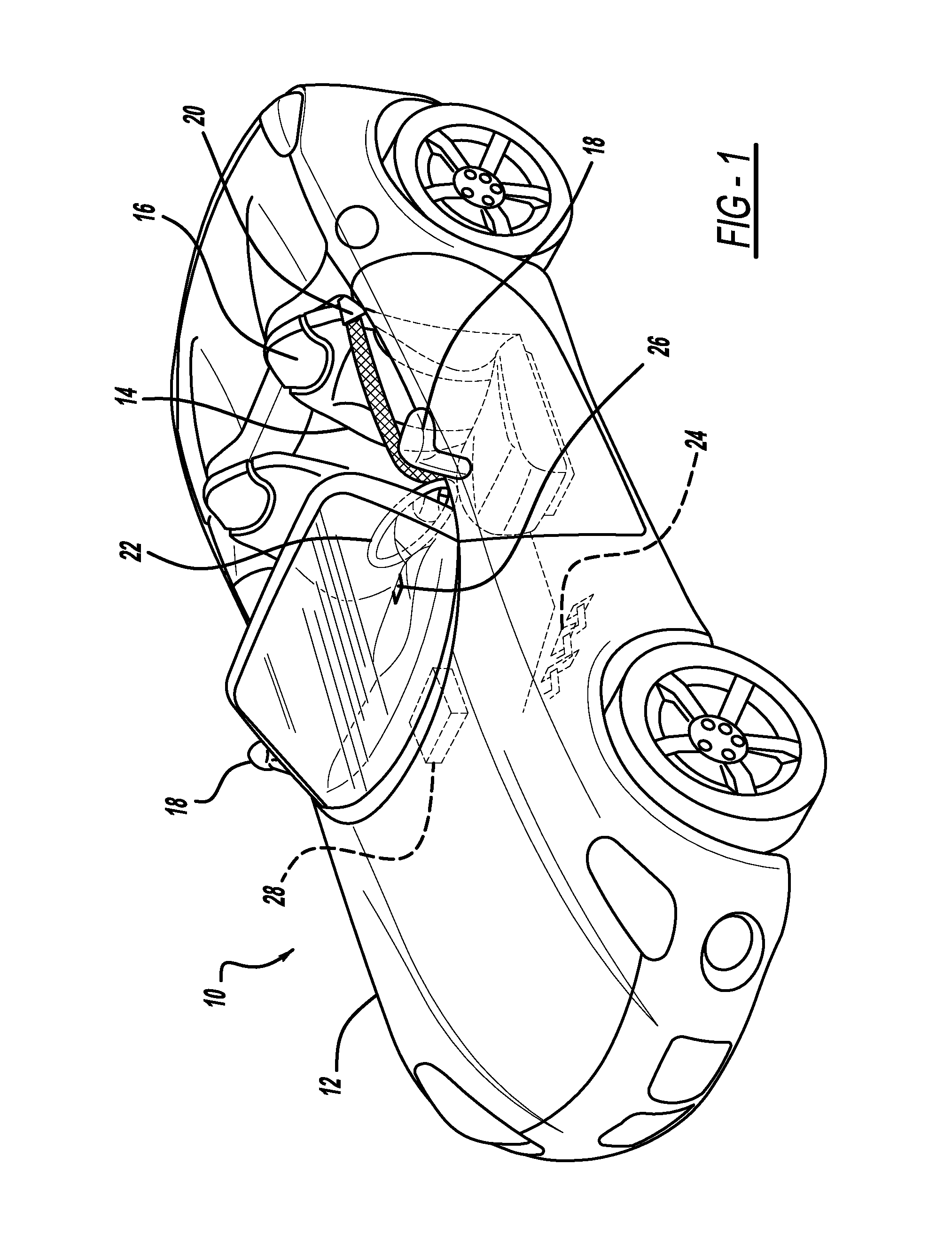

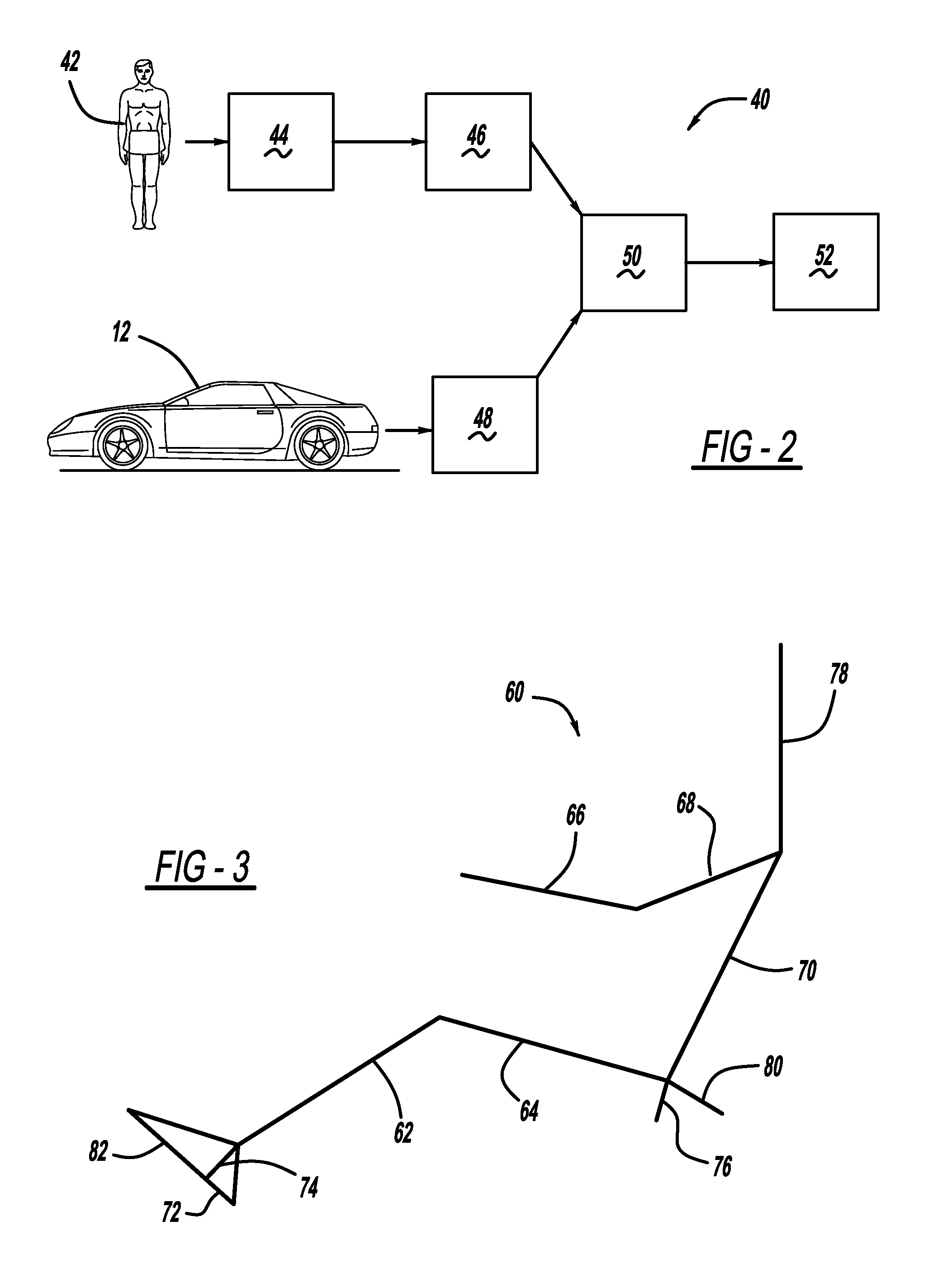

Individualizable convenience system for drivers

A method and system for automatically adjusting a driver seat, steering wheel, pedals, mirrors, and other components of a vehicle, based on information about the size of the driver. The method uses basic information about the driver's size—including standing height, sitting height, and gender—in a model which estimates all anthropometric data for the driver. The anthropometric data for the driver—including upper and lower arm and leg lengths, torso length, and other dimensions—is used in inverse kinematic calculations to determine optimal positions and orientations for the adjustable components of the vehicle's cockpit. The method then pre-adjusts the components before the driver enters the vehicle, and makes compatible adjustments to the mirrors and other components if the driver adjusts the driver seat.

Owner:GM GLOBAL TECH OPERATIONS LLC

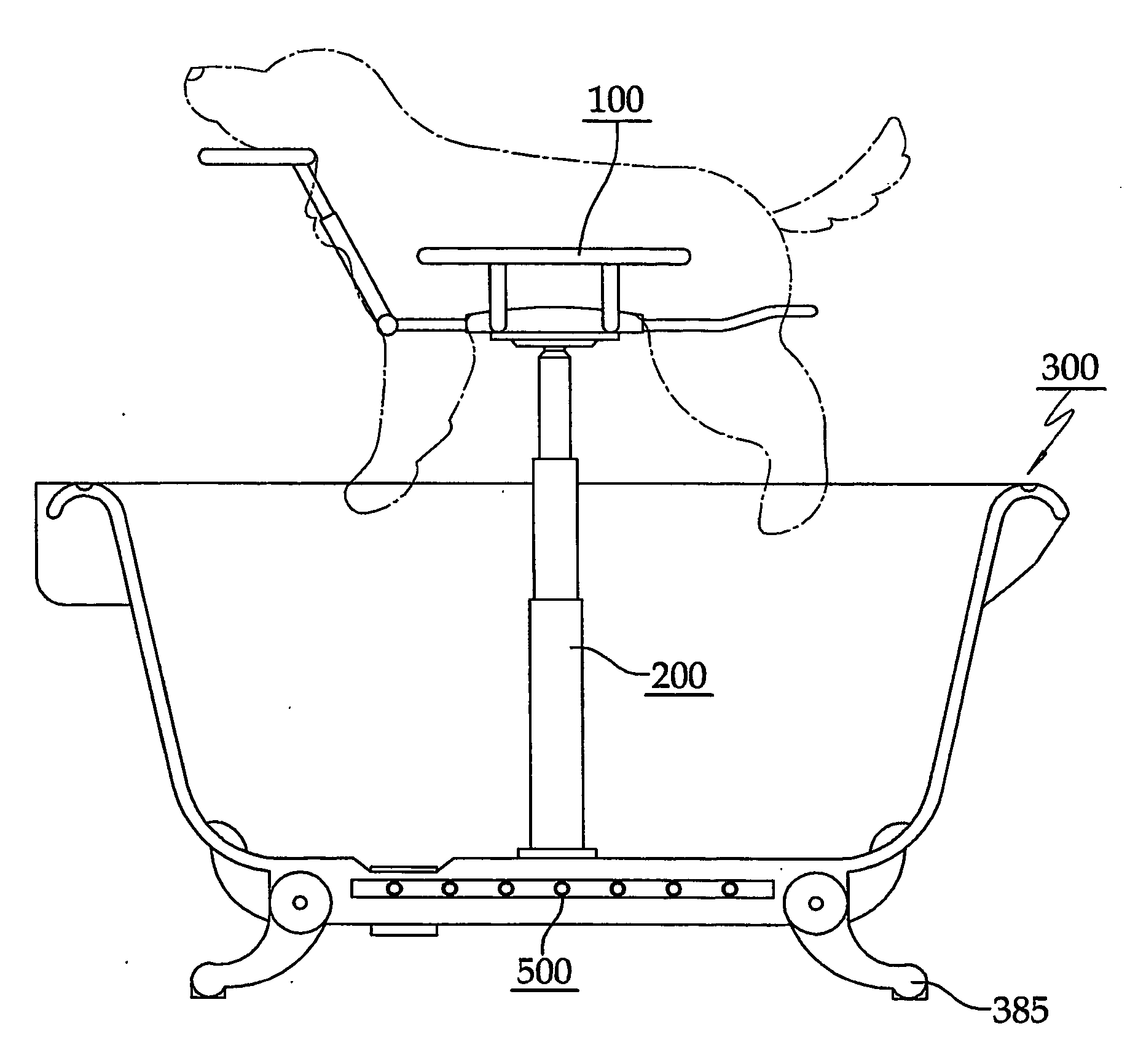

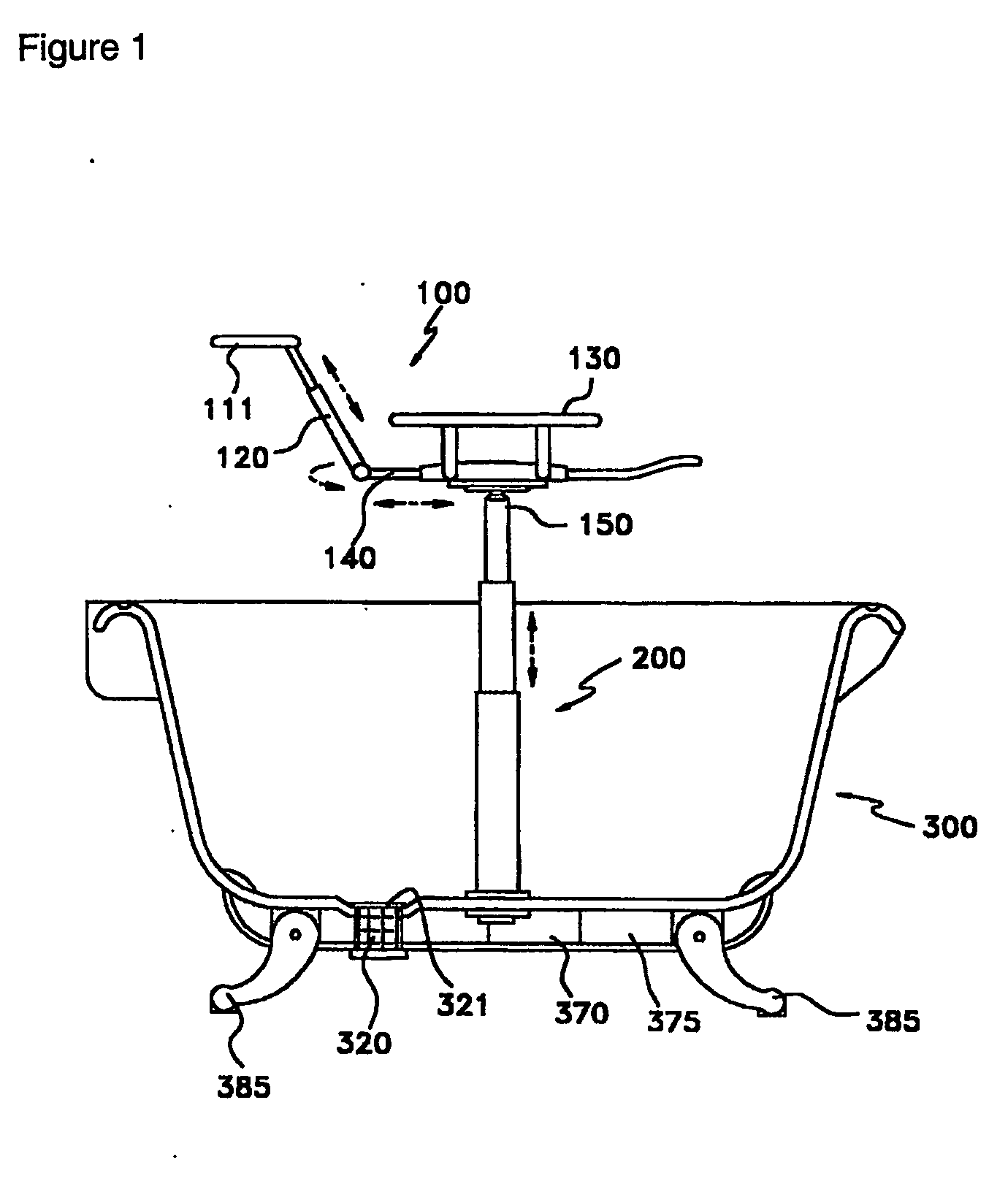

Beauty, medical treatment, and bath system for pet animal

InactiveUS20070079766A1Easy to adaptInhibit inputVeterinary washing devicesAnimal fetteringEngineeringCompanion animal

A system having beauty, medical and bath functions for pets capable of easily achieving beauty, medical and bath functions for pets at home, pets hospital and pets shop is disclosed. The system having beauty, medical and bath functions for pets, comprising a bathtub stand for fixing a pet's head and body; a bathtub stand height adjusting unit for supporting the bathtub and adjusting the height of the bathtub stand; and a bathtub for storing water therein, wherein said bathtub stand height adjusting unit is installed at a bottom of the bathtub.

Owner:PARK SANG HEE

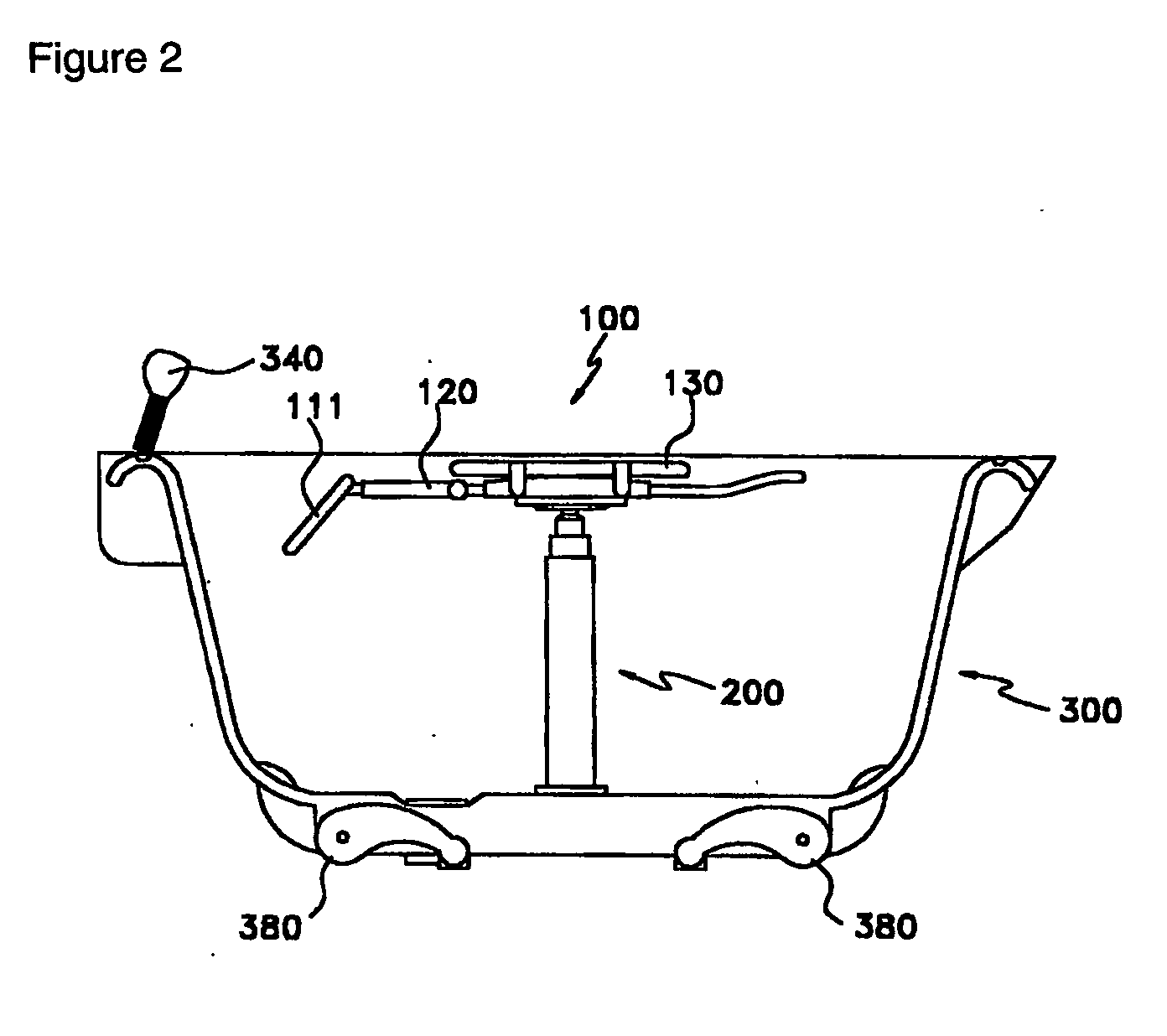

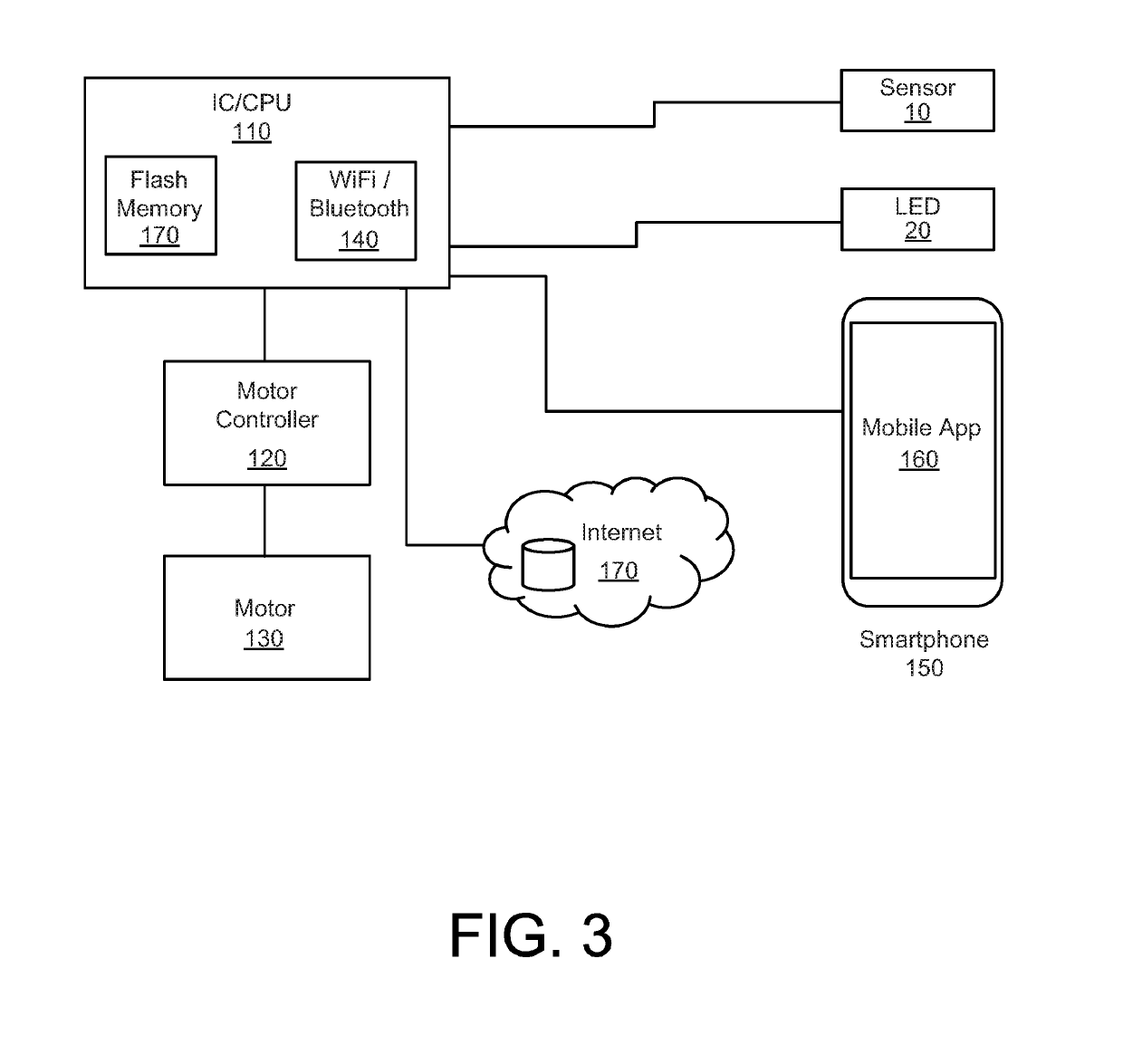

Automatically adjustable desk and tabletop desk with presence detection, usage tracking and methods thereof

InactiveUS20190328129A1Maximize useEasy to adjustOffice tablesFurniture partsEngineeringStanding height

An apparatus and method for automatically adjusting and monitoring use of an adjustable standing desk are disclosed. The invention provides an electric adjustable standing desk with memory to store a user's preferred sitting and standing heights for the desk. A setup mode allows the user to store and adjust the preferred sitting and standing heights. A sensor allows the user to quickly adjust from the sitting to standing heights or vice versa. The invention also provides for presence detection to detect and ensure that a user optimizes the standing functionality.

Owner:QUALGEAR LLC

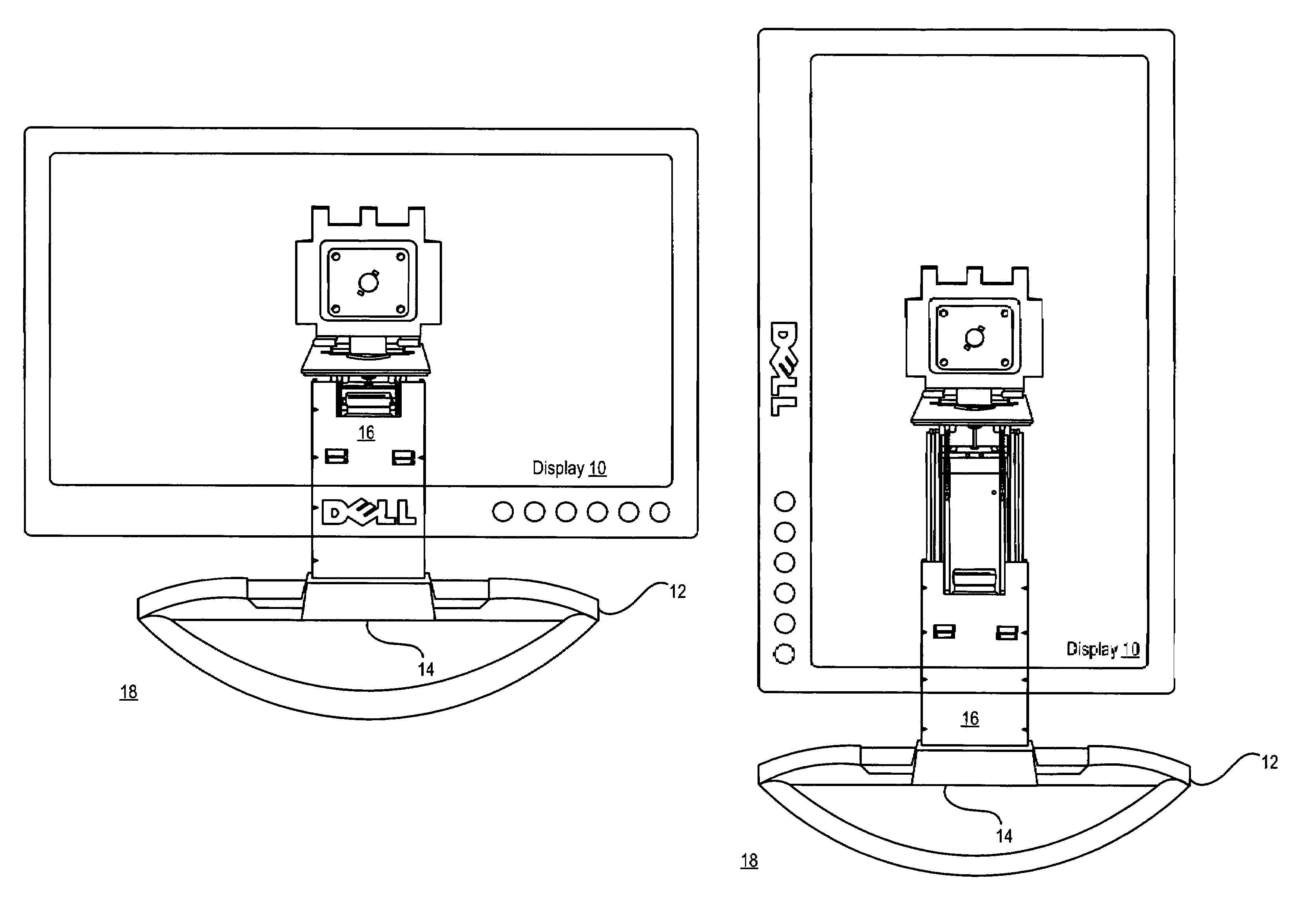

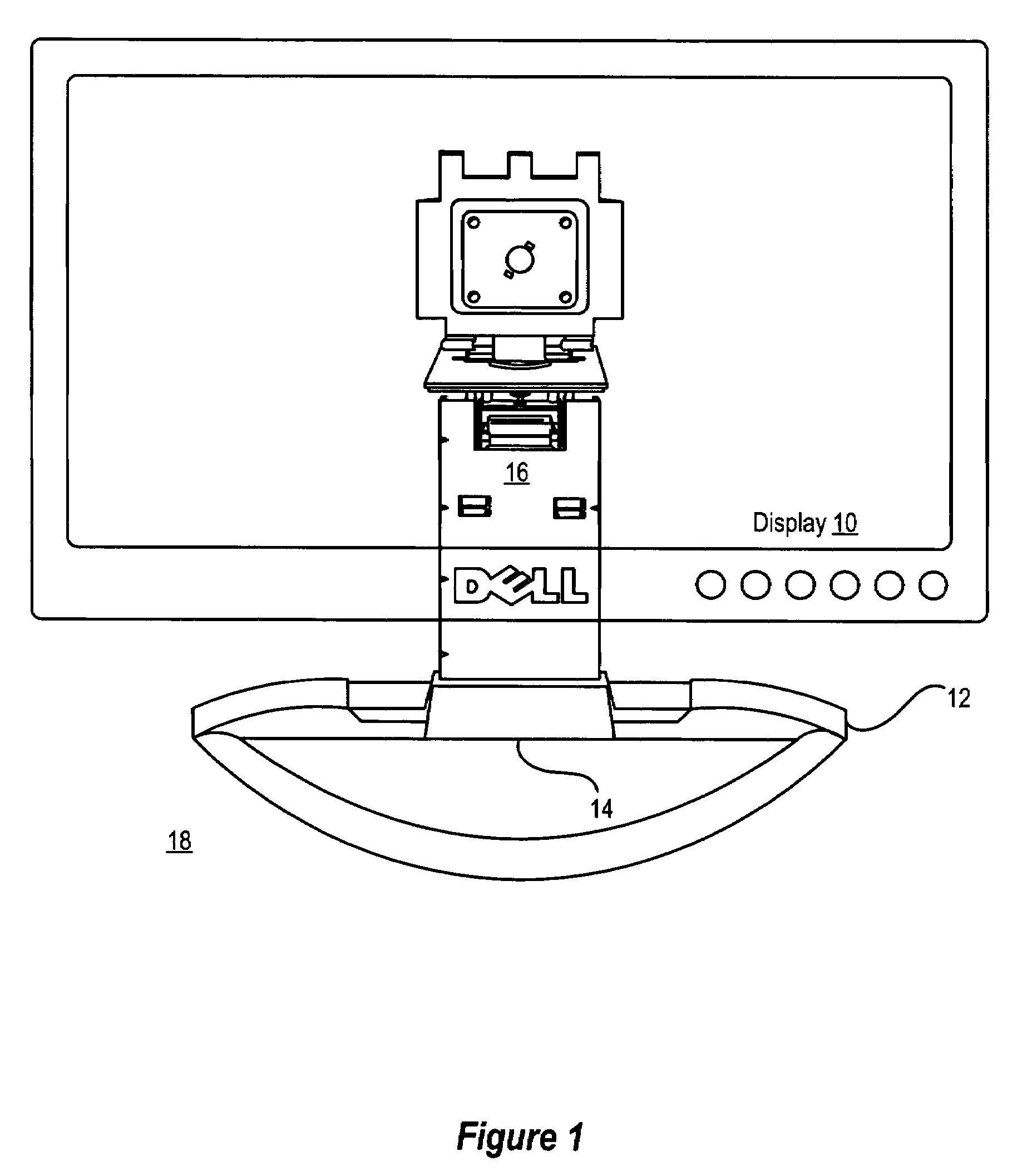

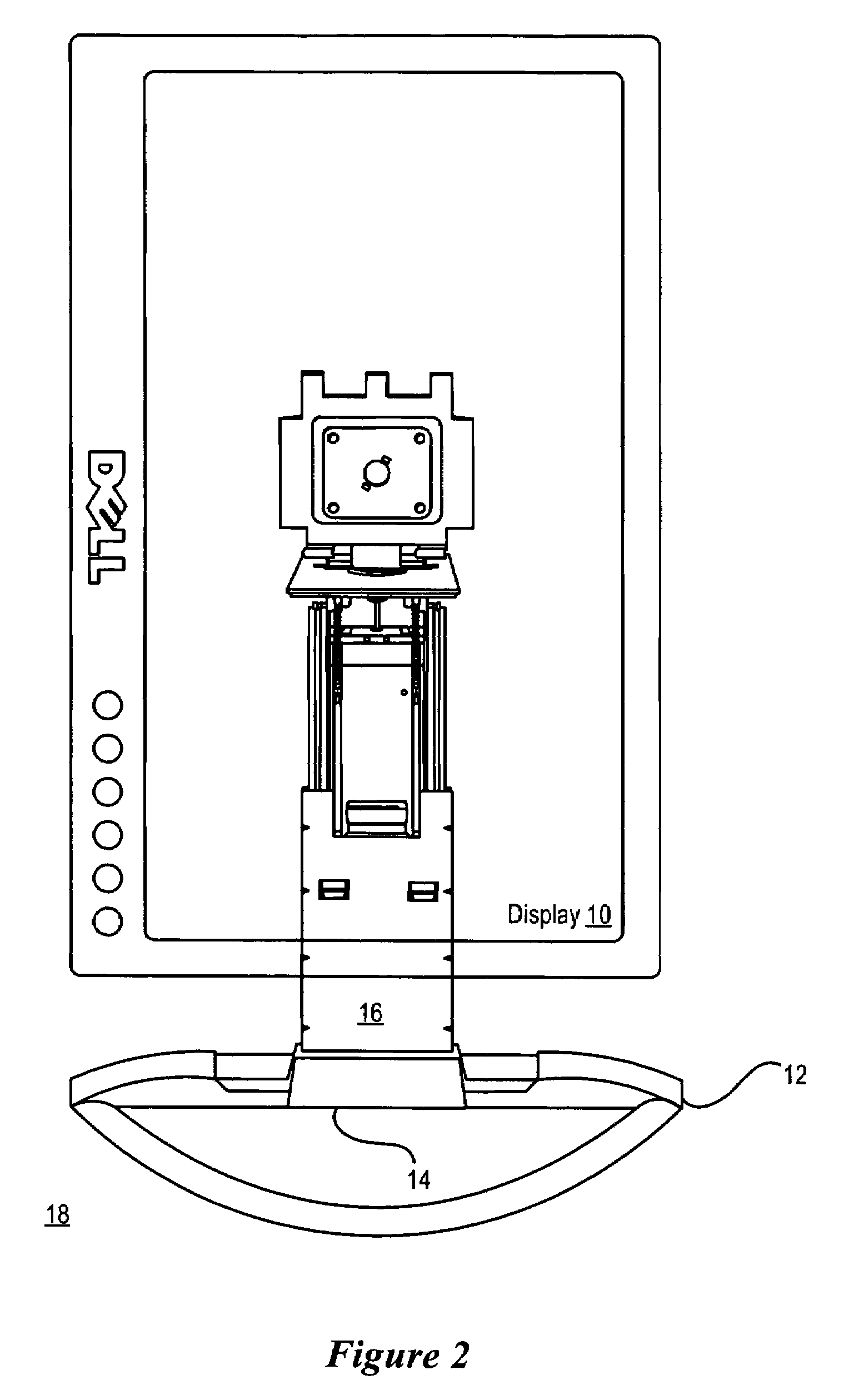

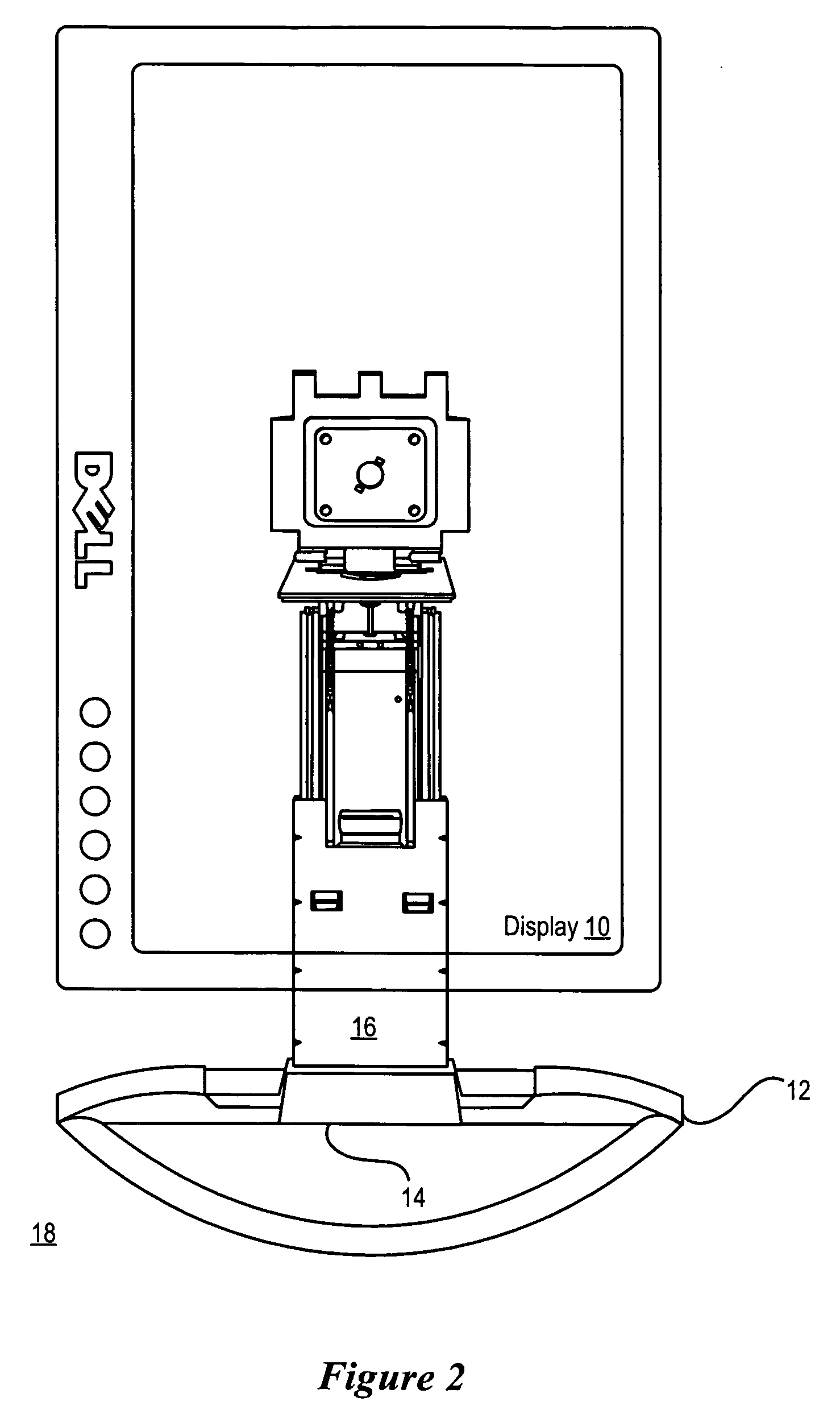

System and method for display stand height adjustment

ActiveUS7430113B2Reduce disadvantagesReduce problemsDigital data processing detailsCathode-ray tube indicatorsDisplay deviceEngineering

Owner:DELL PROD LP

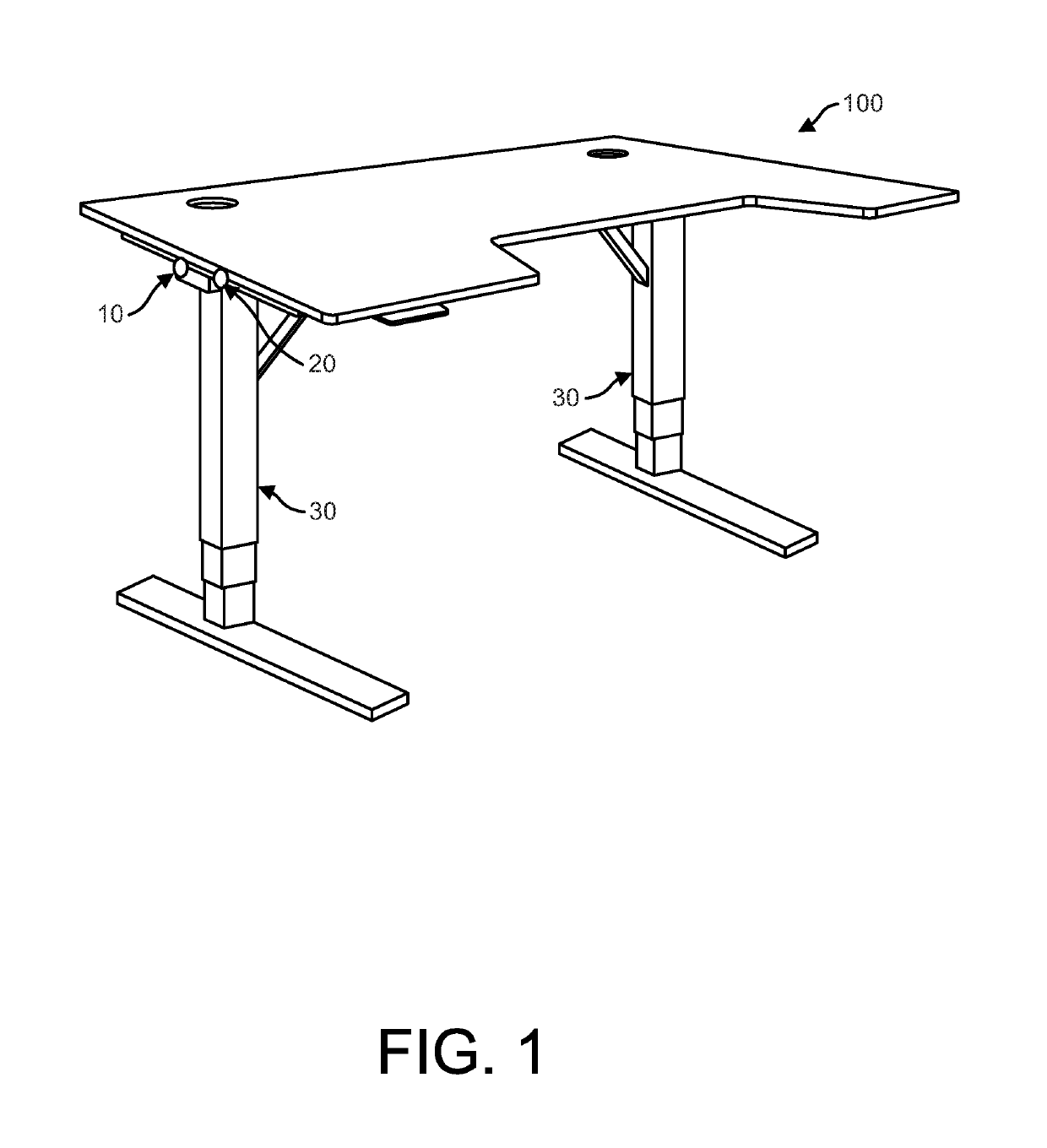

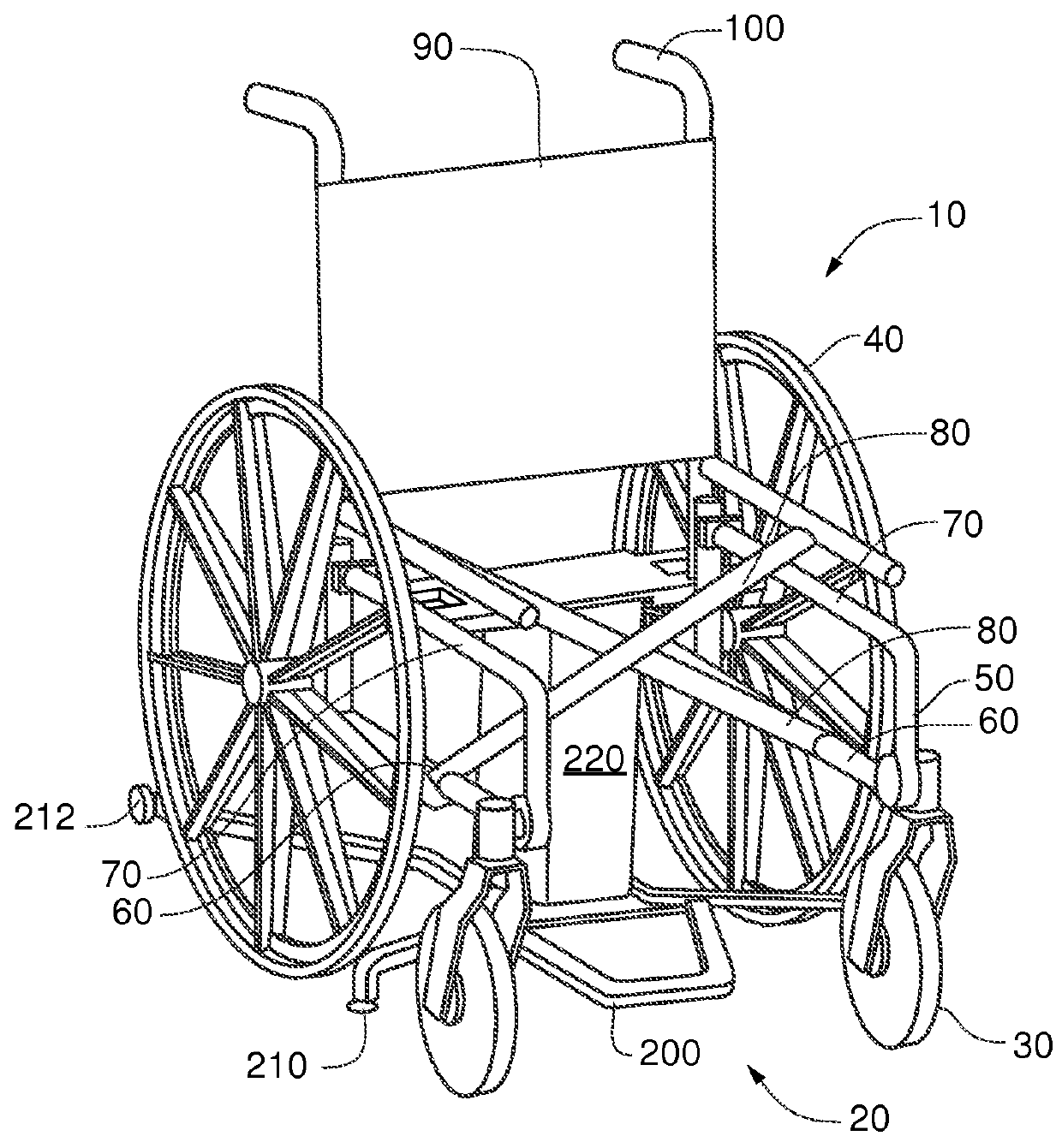

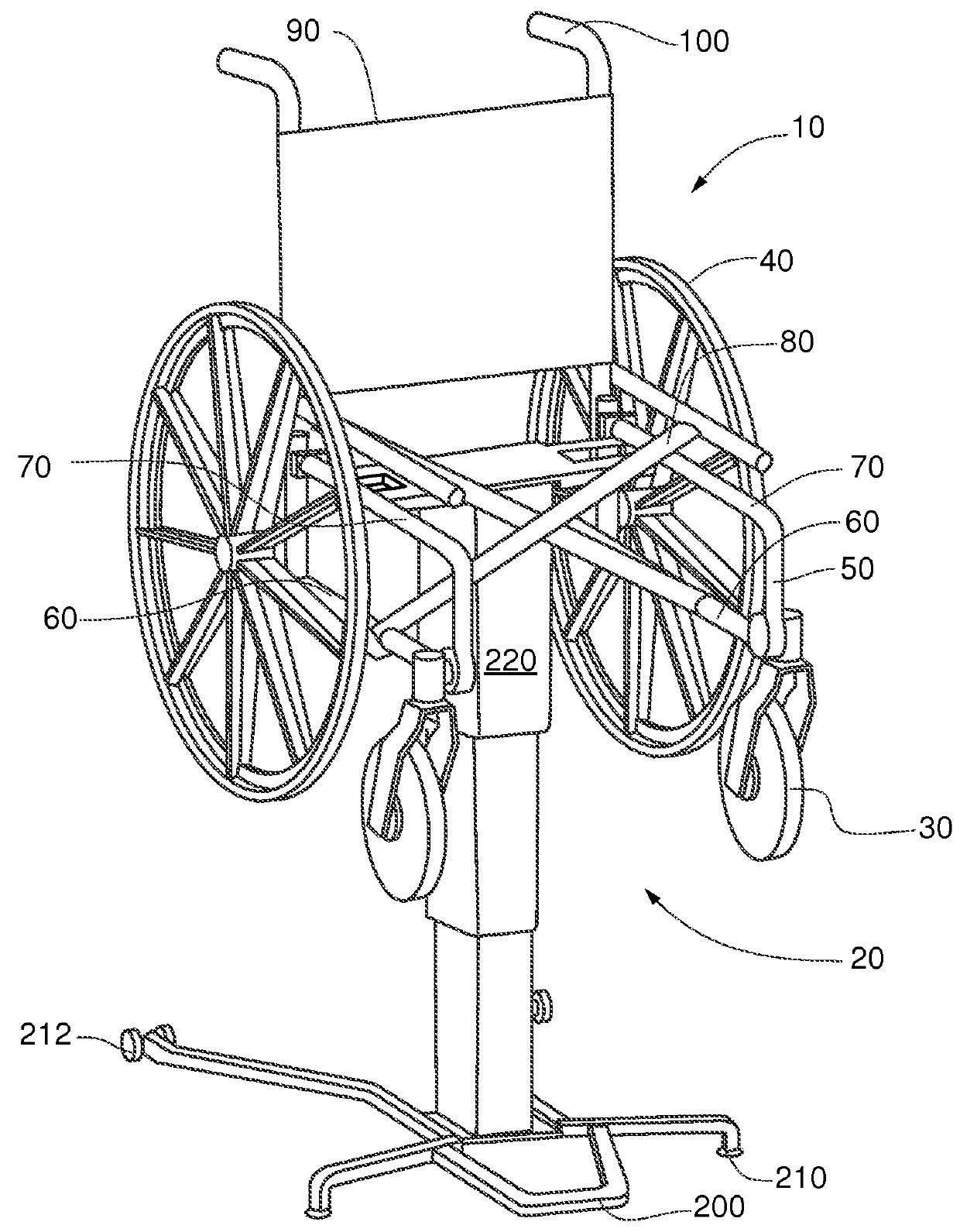

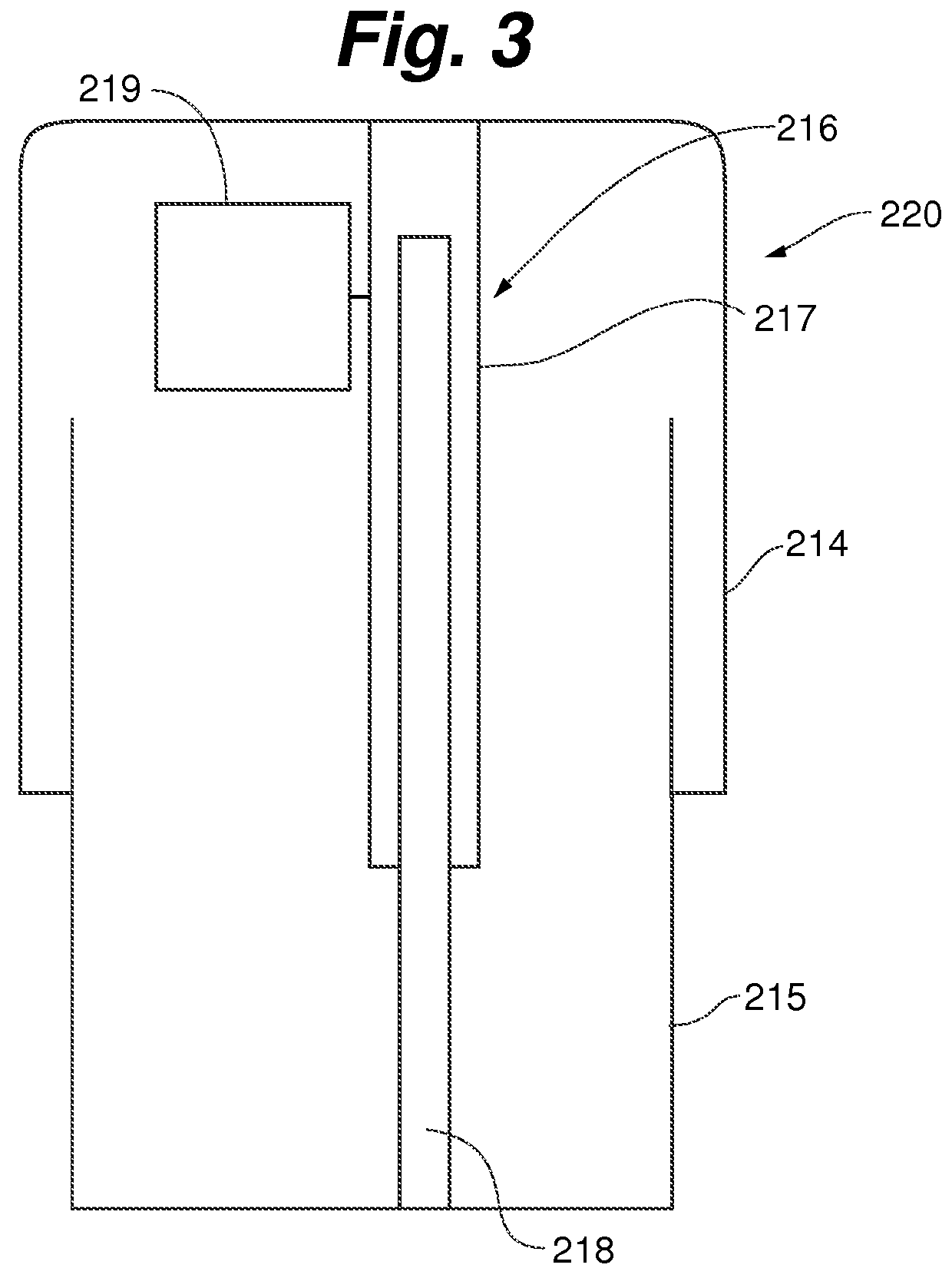

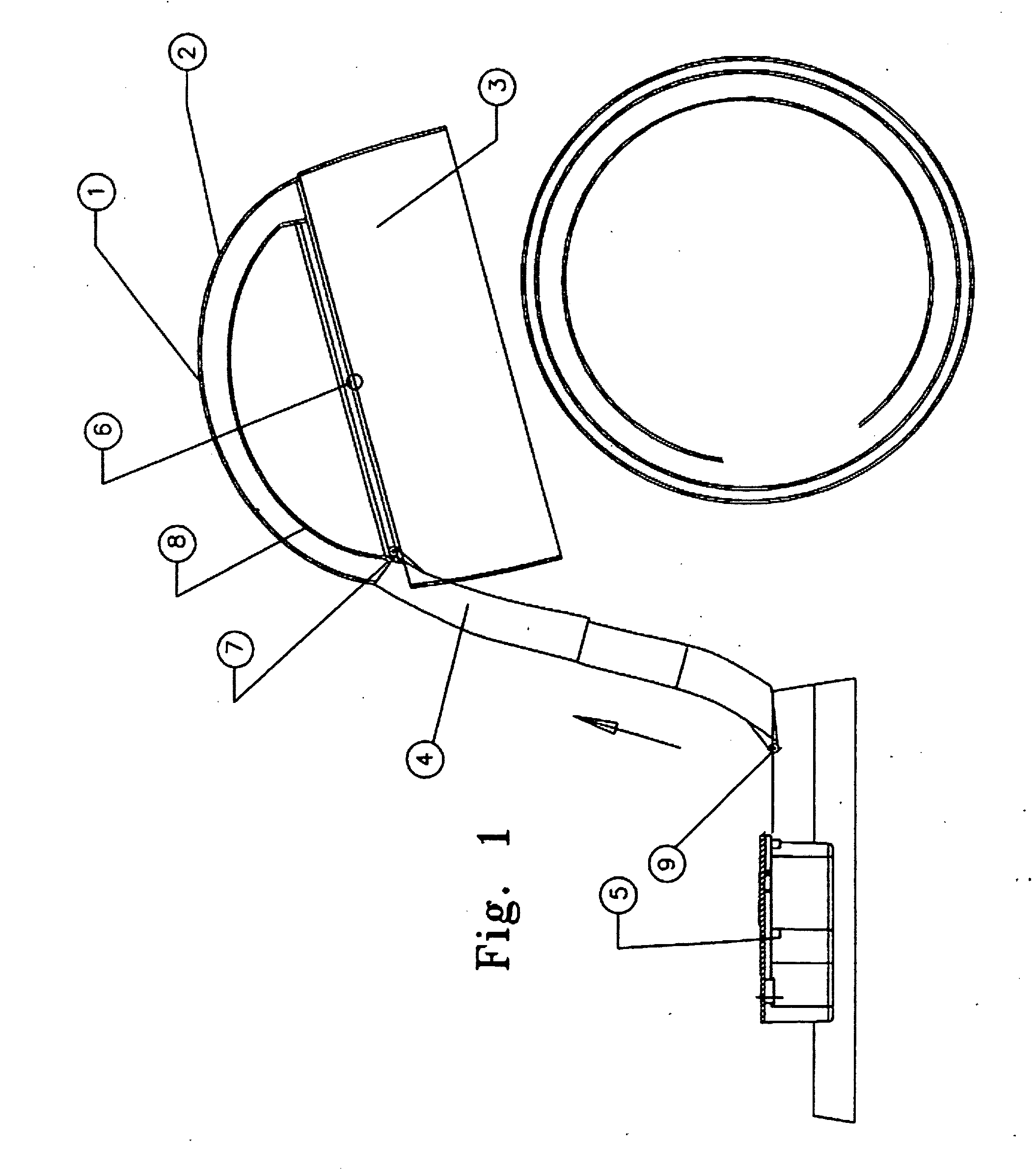

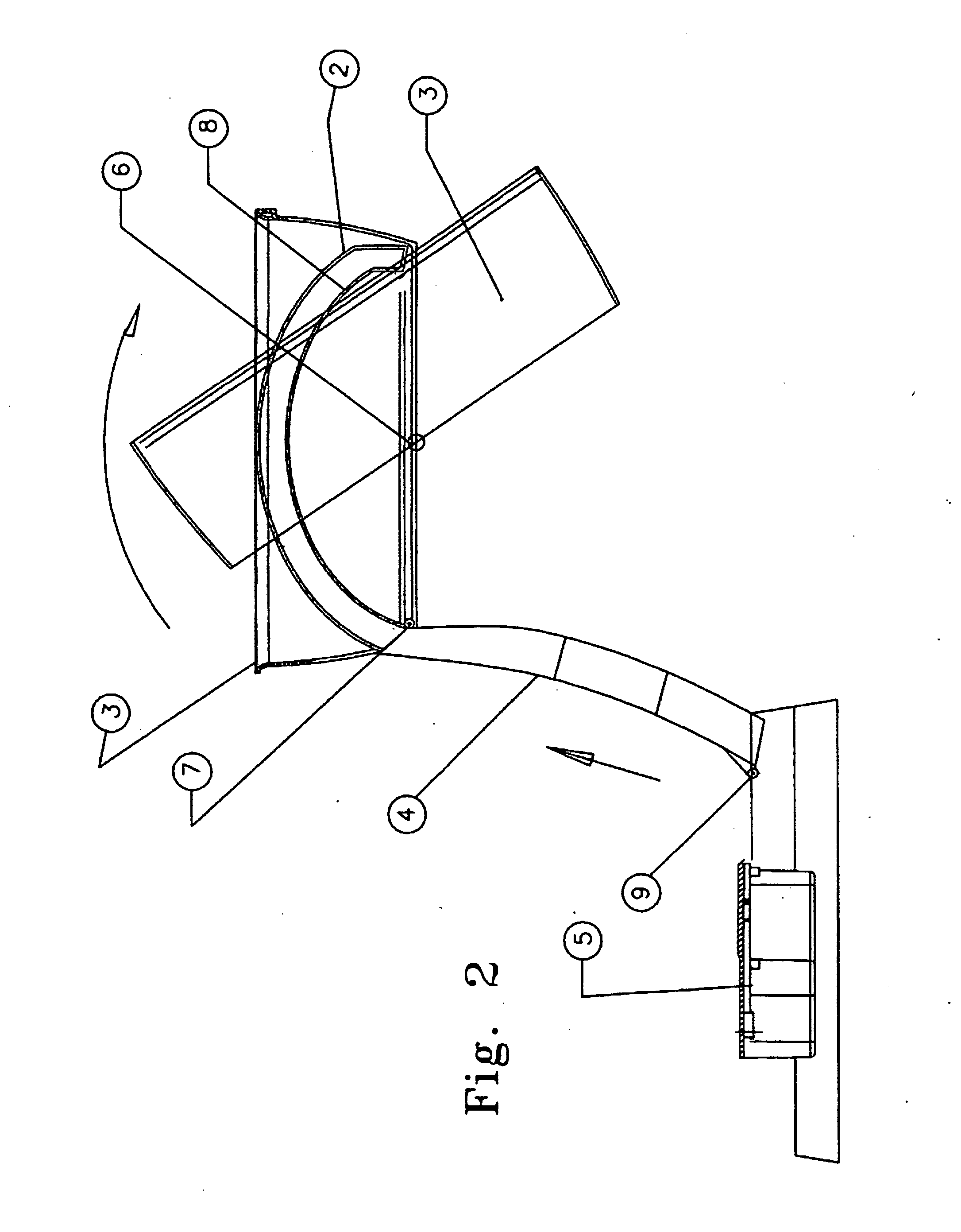

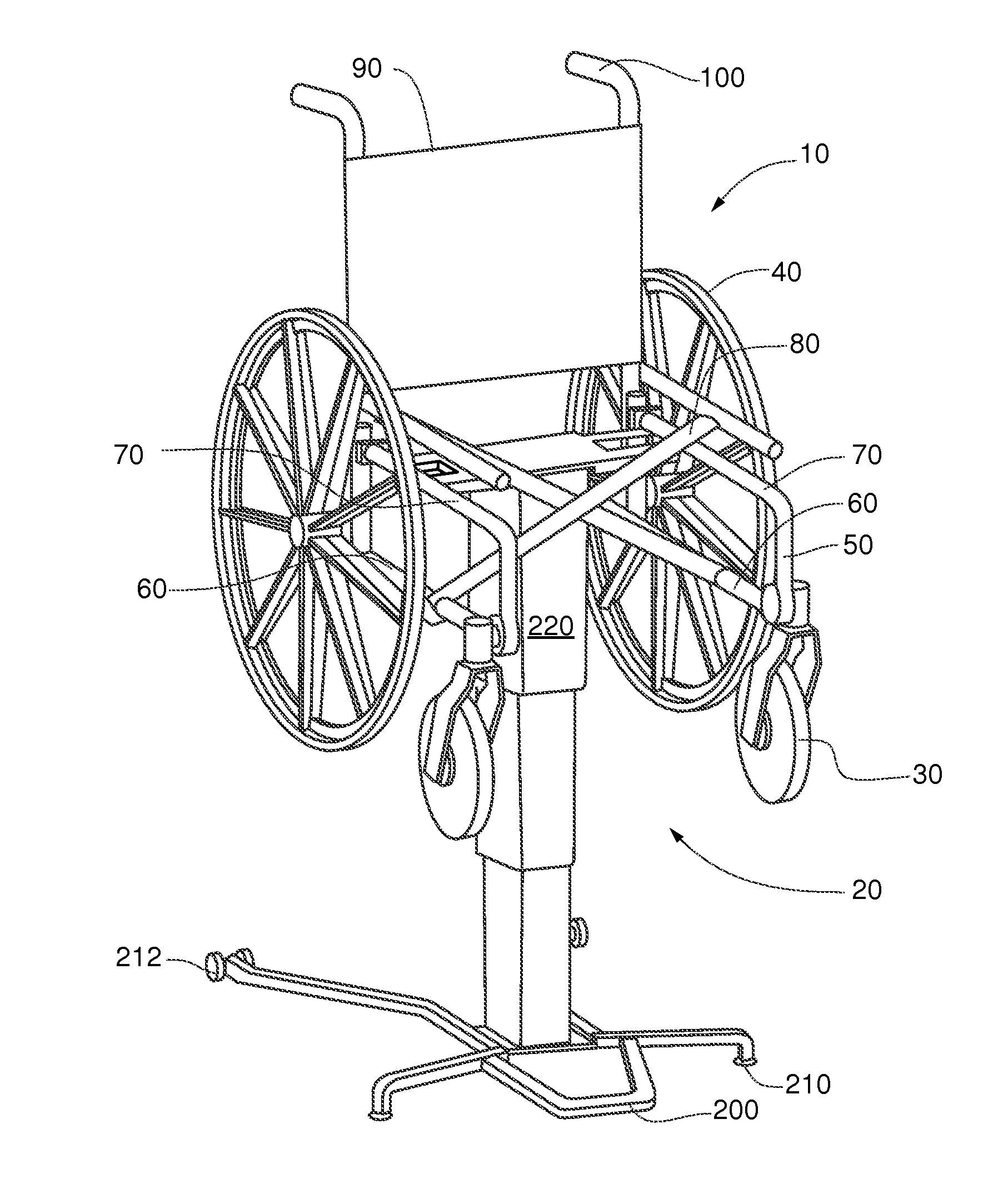

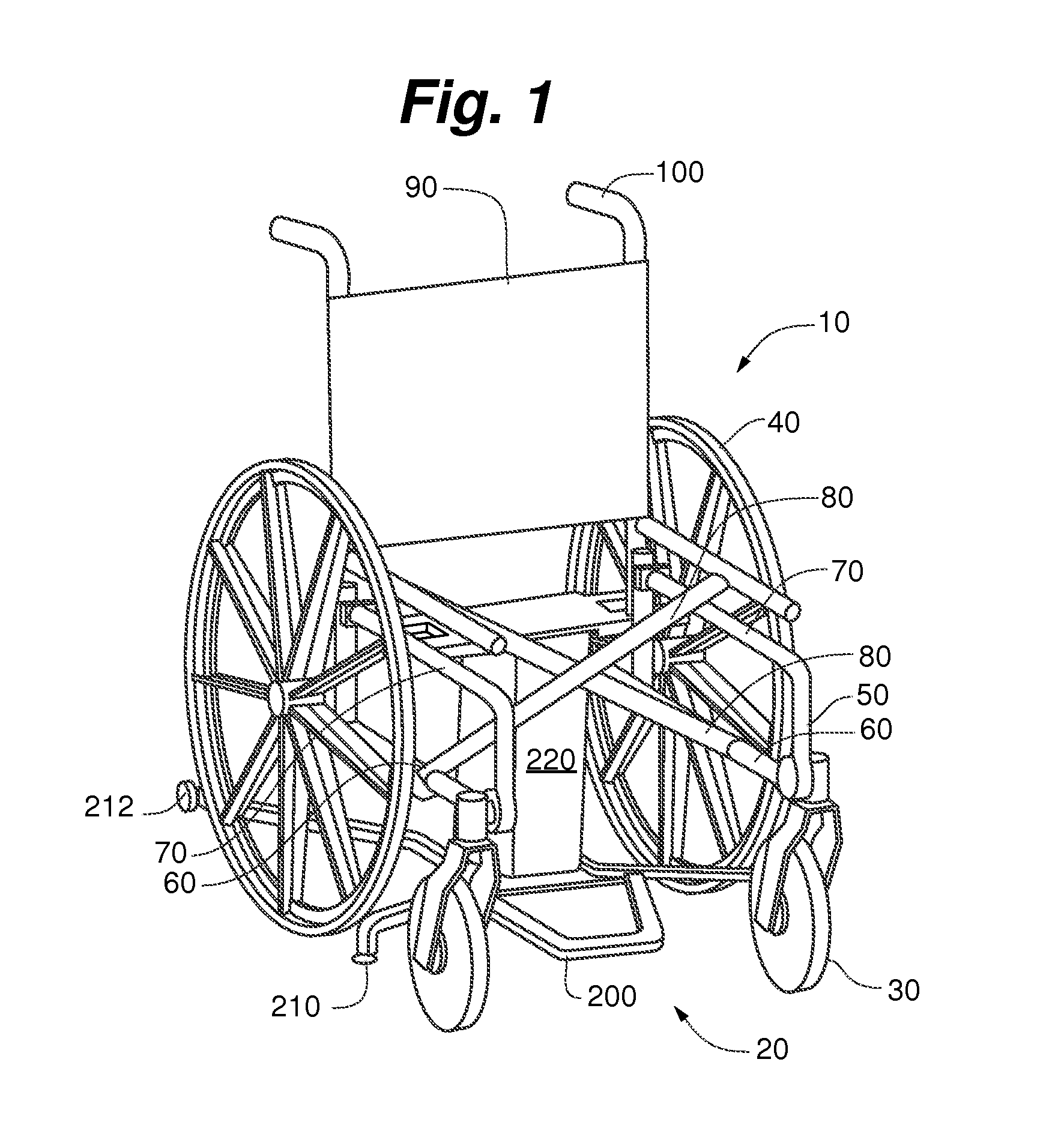

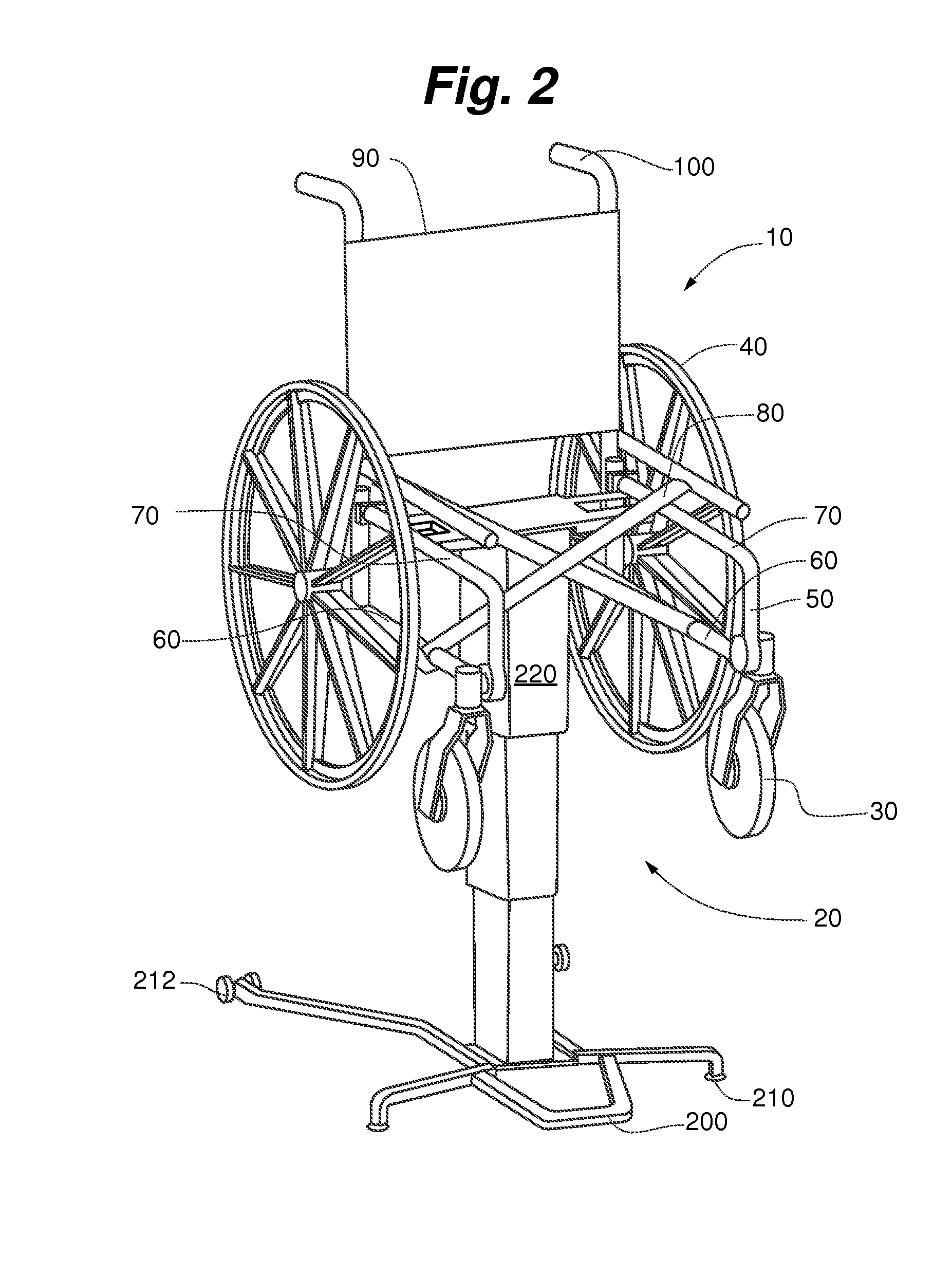

Wheelchair lift system and method

ActiveUS9333132B2Precise positioningWheelchairs/patient conveyanceSeating furnitureWheelchairSitting height

A wheelchair lift system that allows a wheelchair and a person sitting in the wheelchair to be selectively positioned at a standing height or a sitting height. A lift system that is attachable to wide variety of existing wheelchairs.

Owner:KATEZELEVATOR

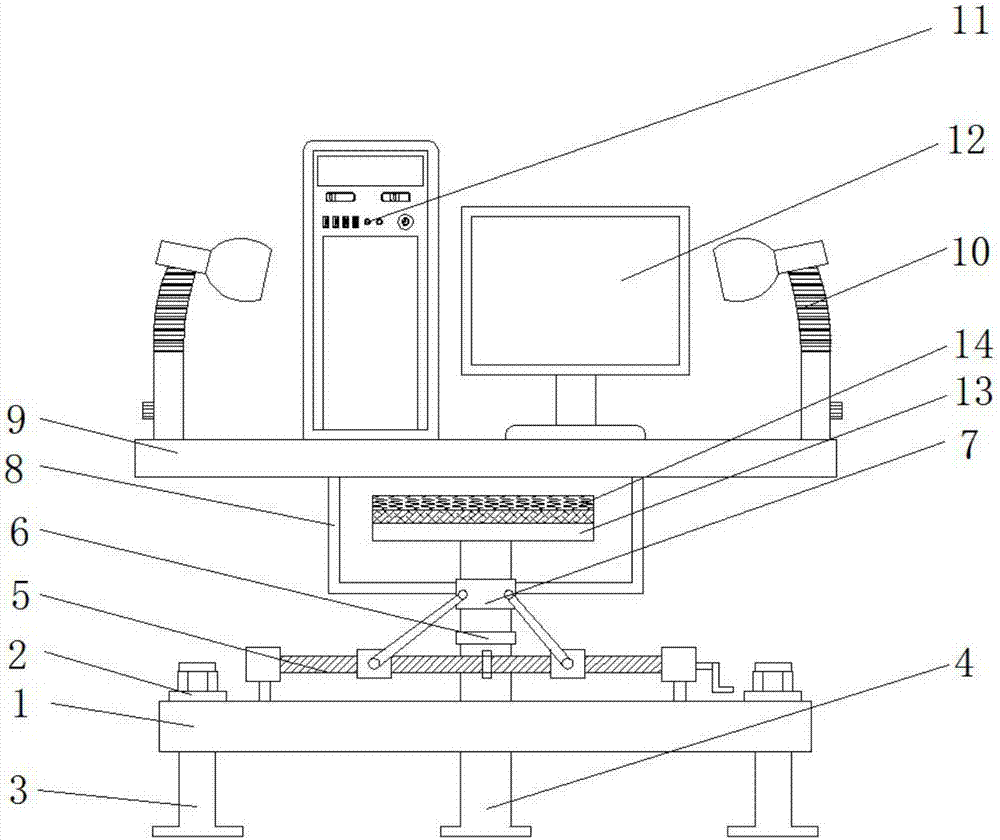

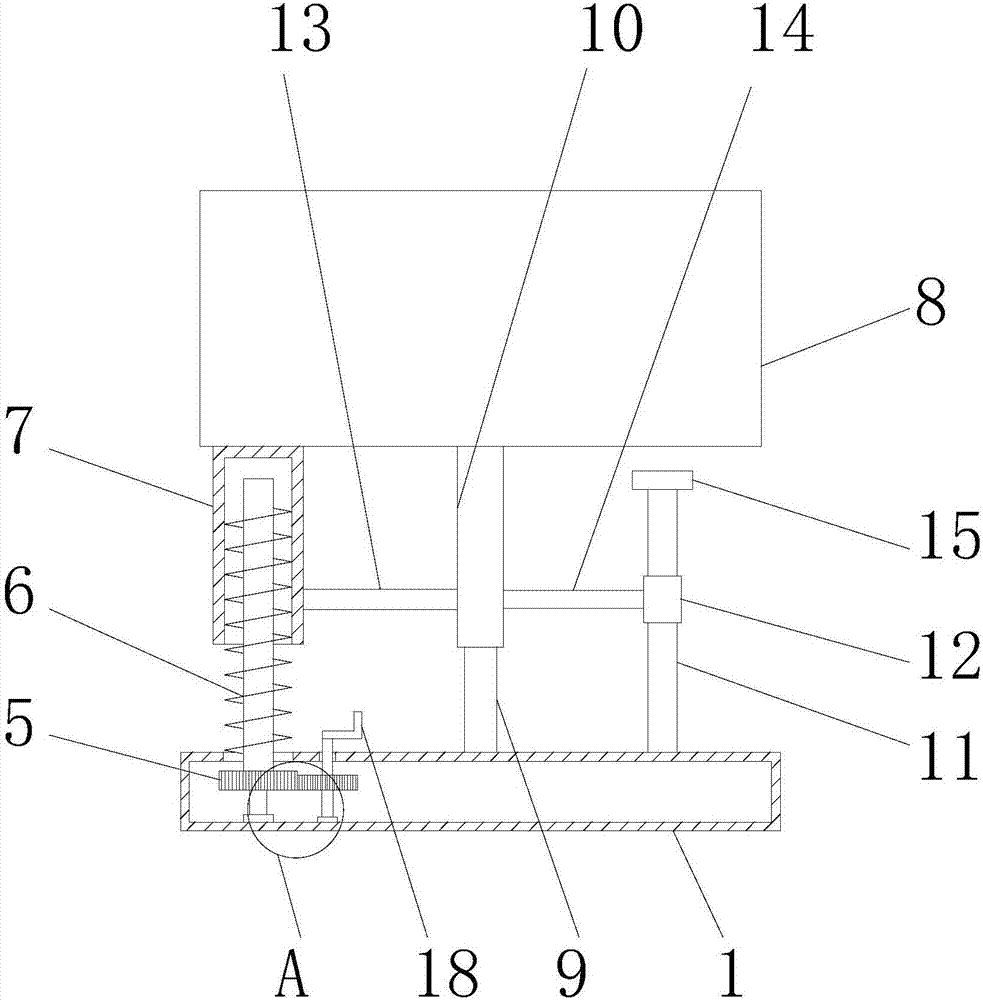

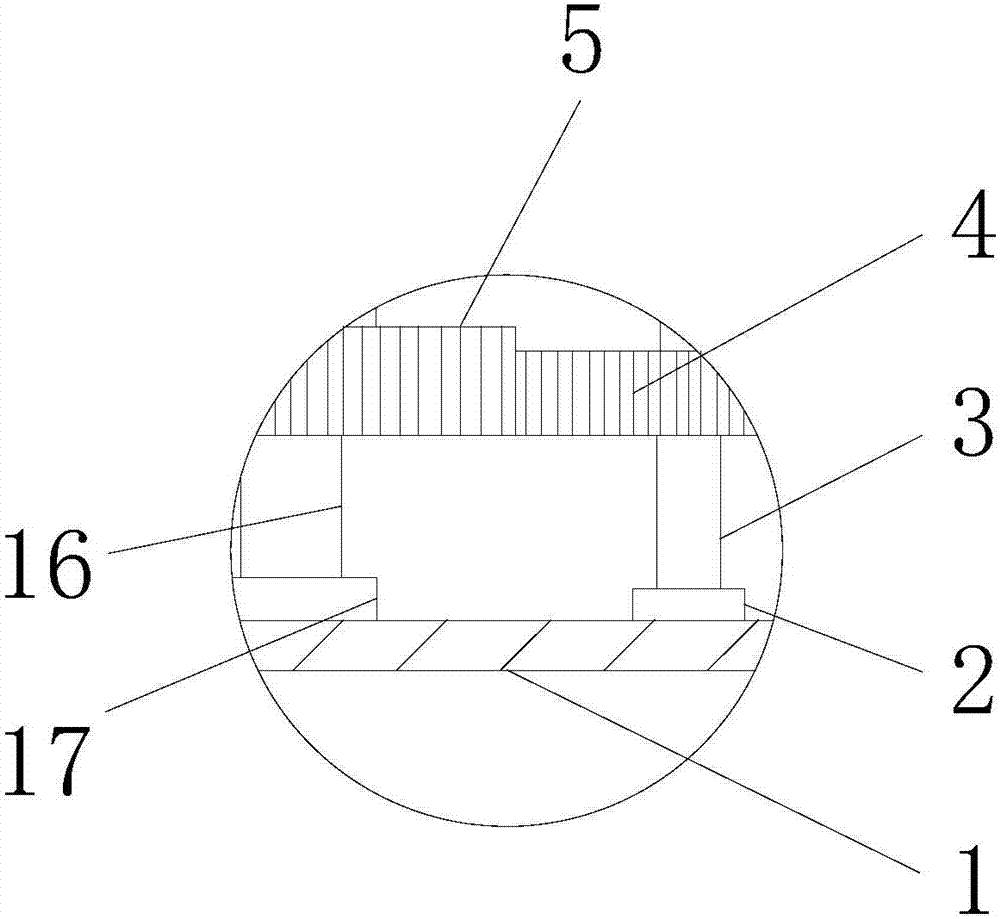

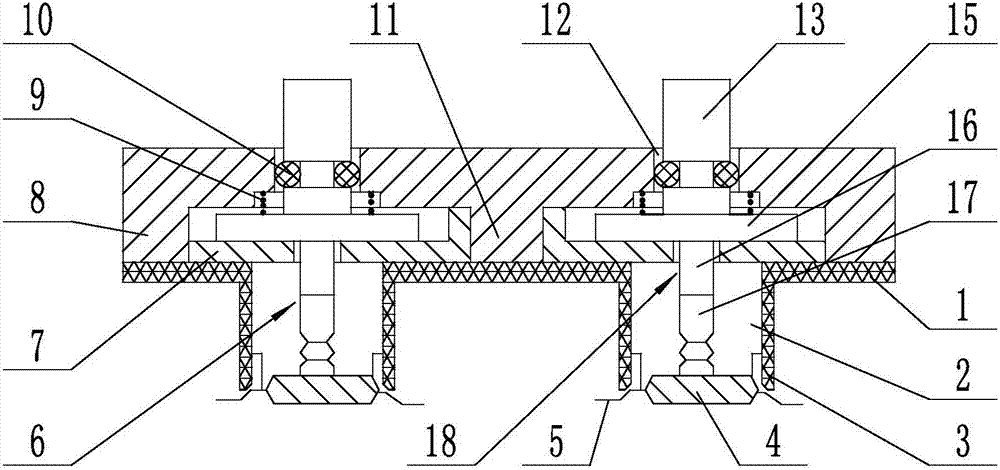

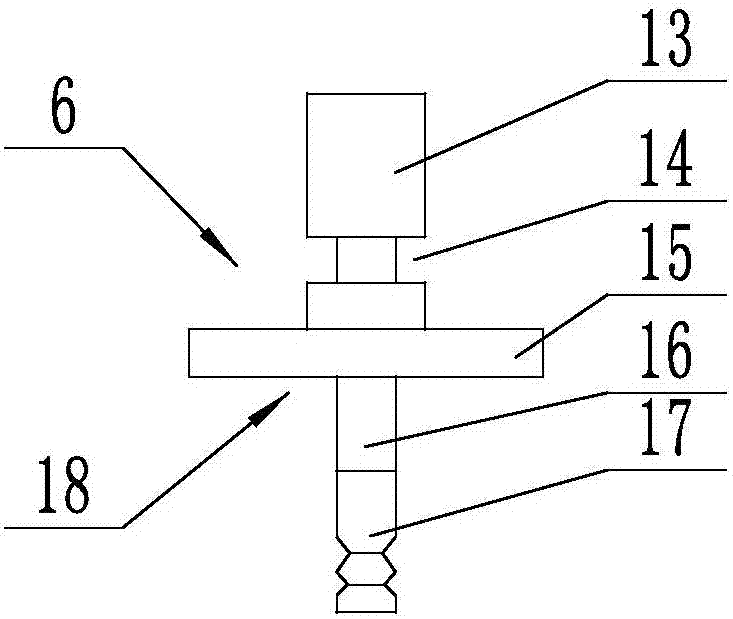

Lifting-type computer device display stand

InactiveCN107374186AAchieve the purpose of liftingTo achieve the purpose of bufferingShow cabinetsNon-rotating vibration suppressionComputer deviceStanding height

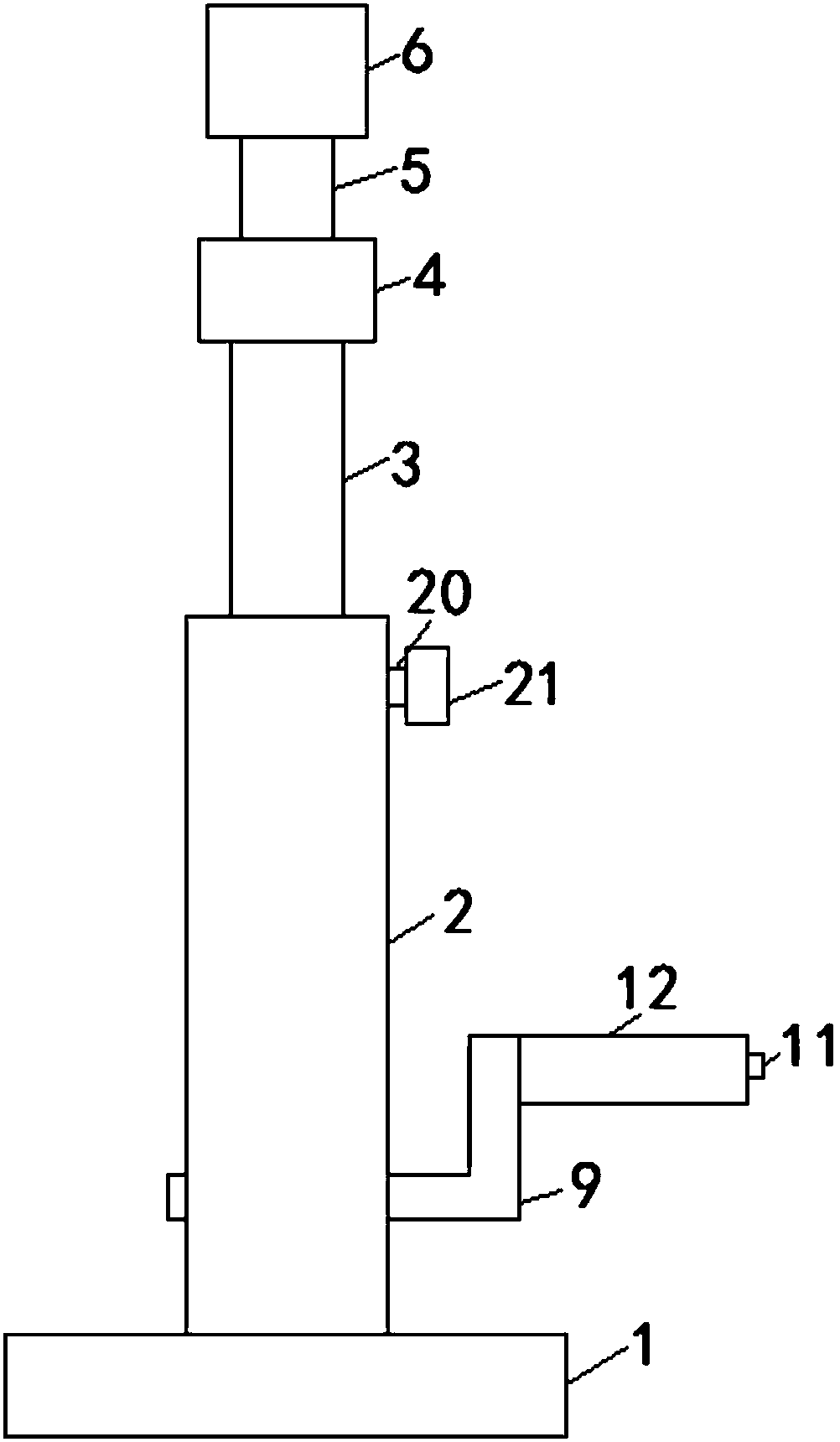

The invention discloses a lifting-type computer device display stand, and relates to the technical field of computers. The lifting-type computer device display stand comprises a base, supporting legs are fixedly connected to the bottom of the base through nuts, a middle supporting column is arranged in the middle of the base, a lifting device is fixedly connected to the upper end of the base, a first baffle and a first sliding block are arranged at the portion, located at the upper end of the base, on the surface of a supporting column, the lifting device is rotationally connected with the first sliding block, supporting rods are fixedly connected to the two sides of the first sliding block, a display stand is fixedly connected to the top end of the supporting rod, spot lamps are fixedly connected to the two ends of the top of the display stand, a host and a display are arranged in the middle of the top end of the display stand, a supporting stand is fixedly connected to the top end of the middle supporting column, and a buffering device is arranged at the top of the supporting stand. According to the lifting-type compute display stand, the lifting device is installed at the bottom end of the display stand, the computer is more roundly displayed in front of persons, and the person-adjustment display-stand height is also conveniently displayed.

Owner:合肥壹佰度信息科技有限公司

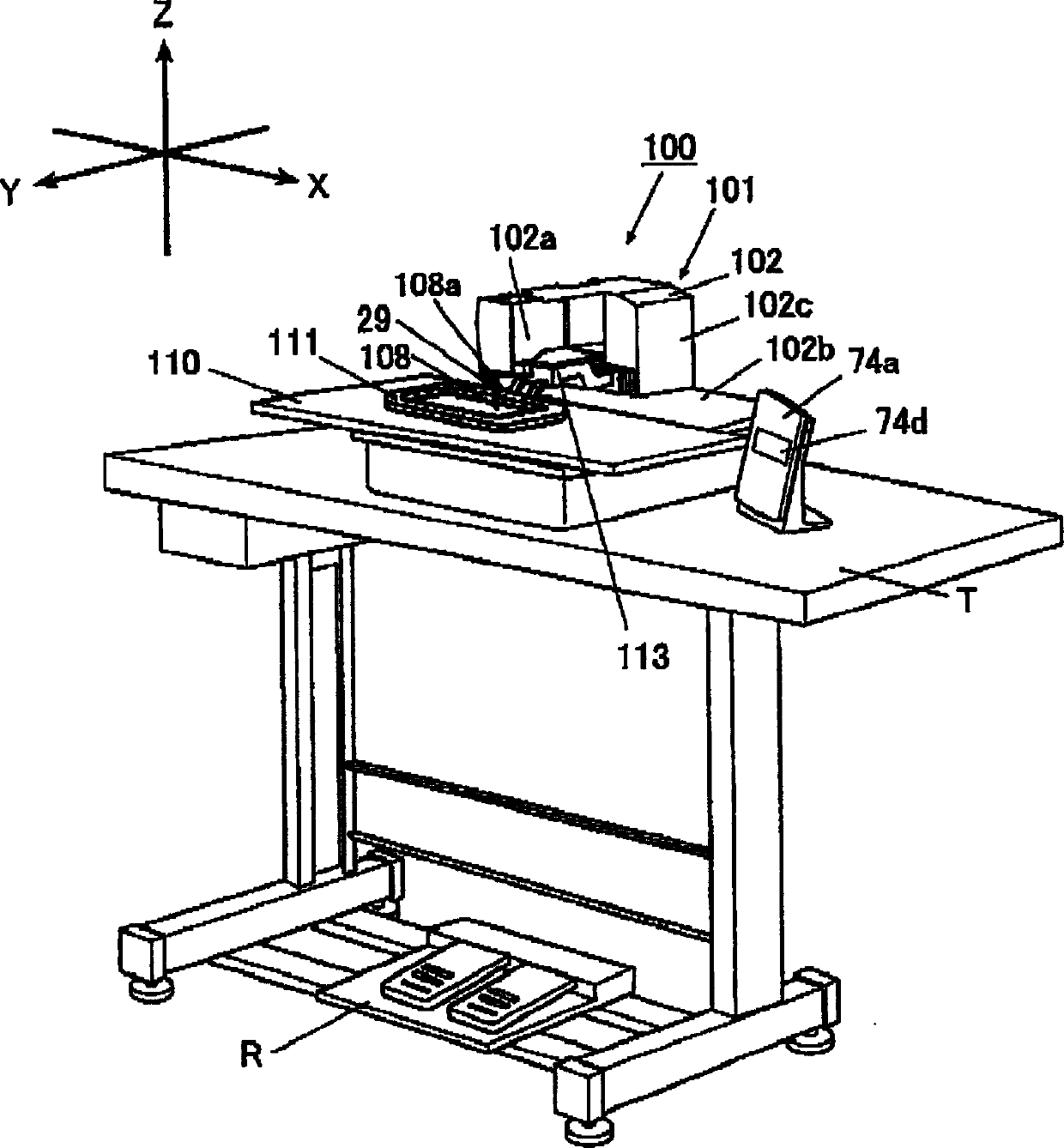

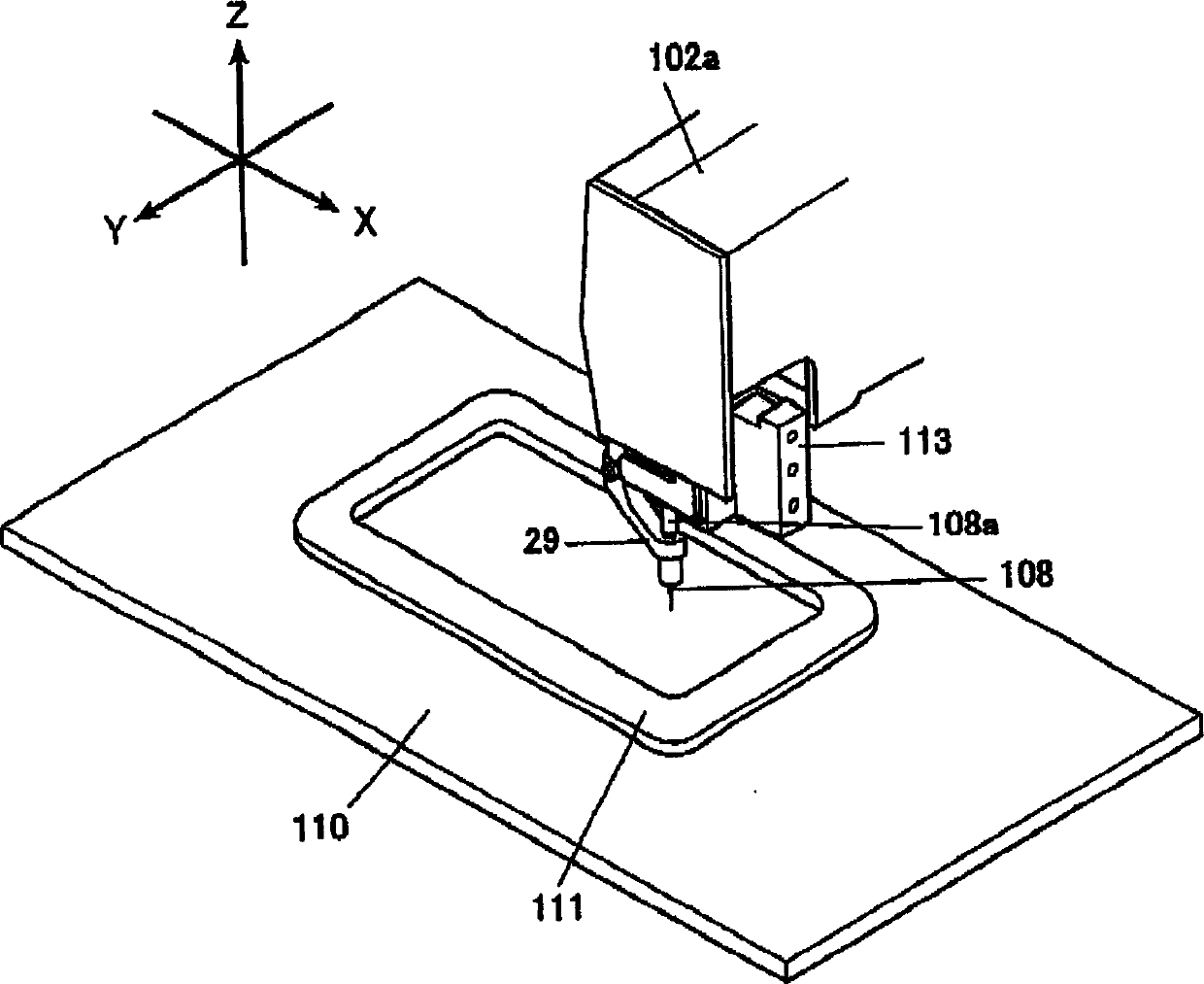

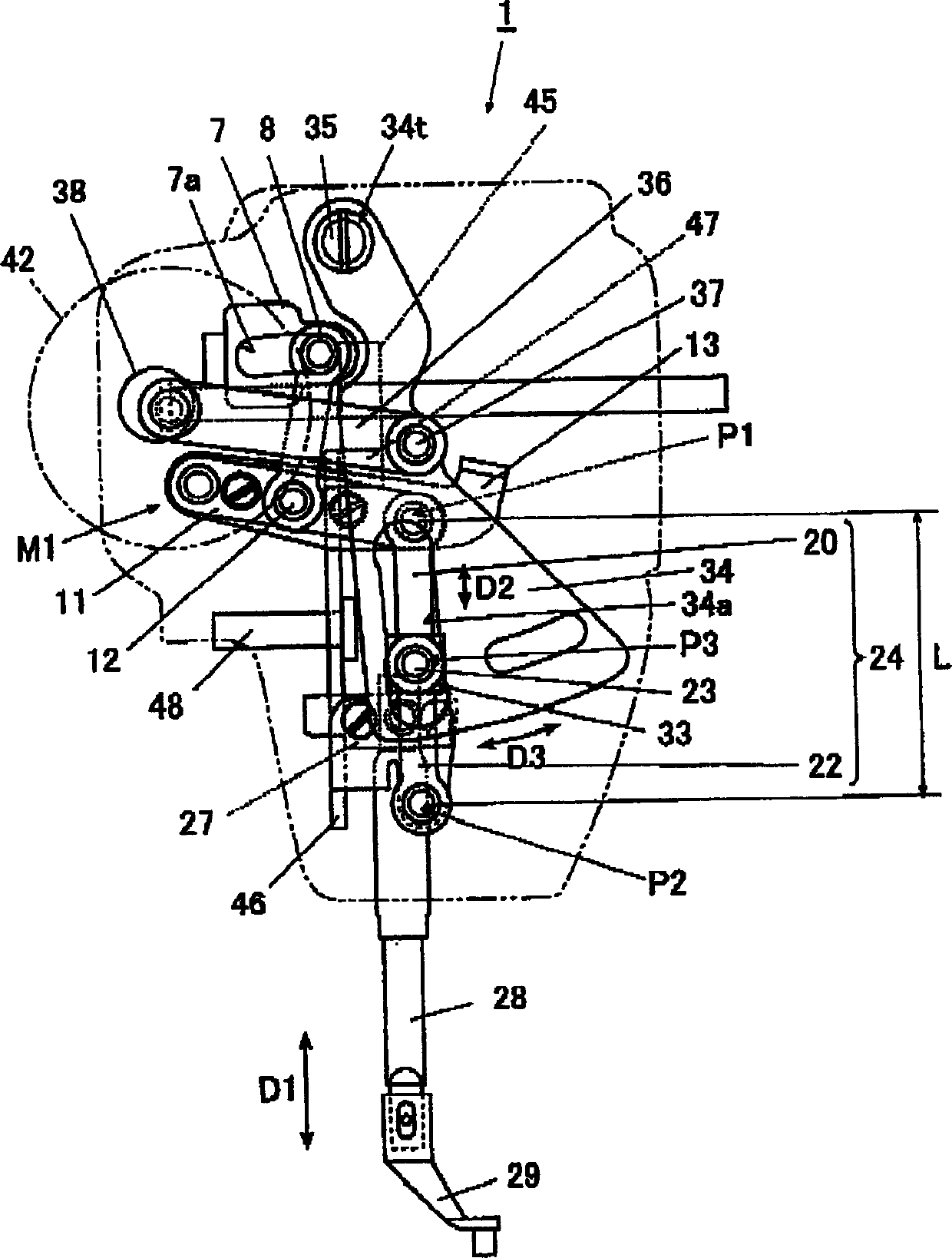

Sewing machine

InactiveCN1757810AHeight adjustableChange altitudeProgramme-controlled sewing machinesPressersEngineeringStanding height

A seaming machine (100) can operate a needle (108) and a holding frame (111) according to a plurality of seaming pattern data composed of stitch data and stored in an EEPROM (72) and form the stitch relative to the stitch data. The seaming machine (100) comprises a middle press stand height adjuster (as controller (1000)) for adjusting the height of a middle press stand (29) of a cloth press (1) according to the middle press stand height stored with the stitch data of seaming pattern data. The invention can change the height of middle press stand at any time to realize effective seaming.

Owner:JUKI CORP

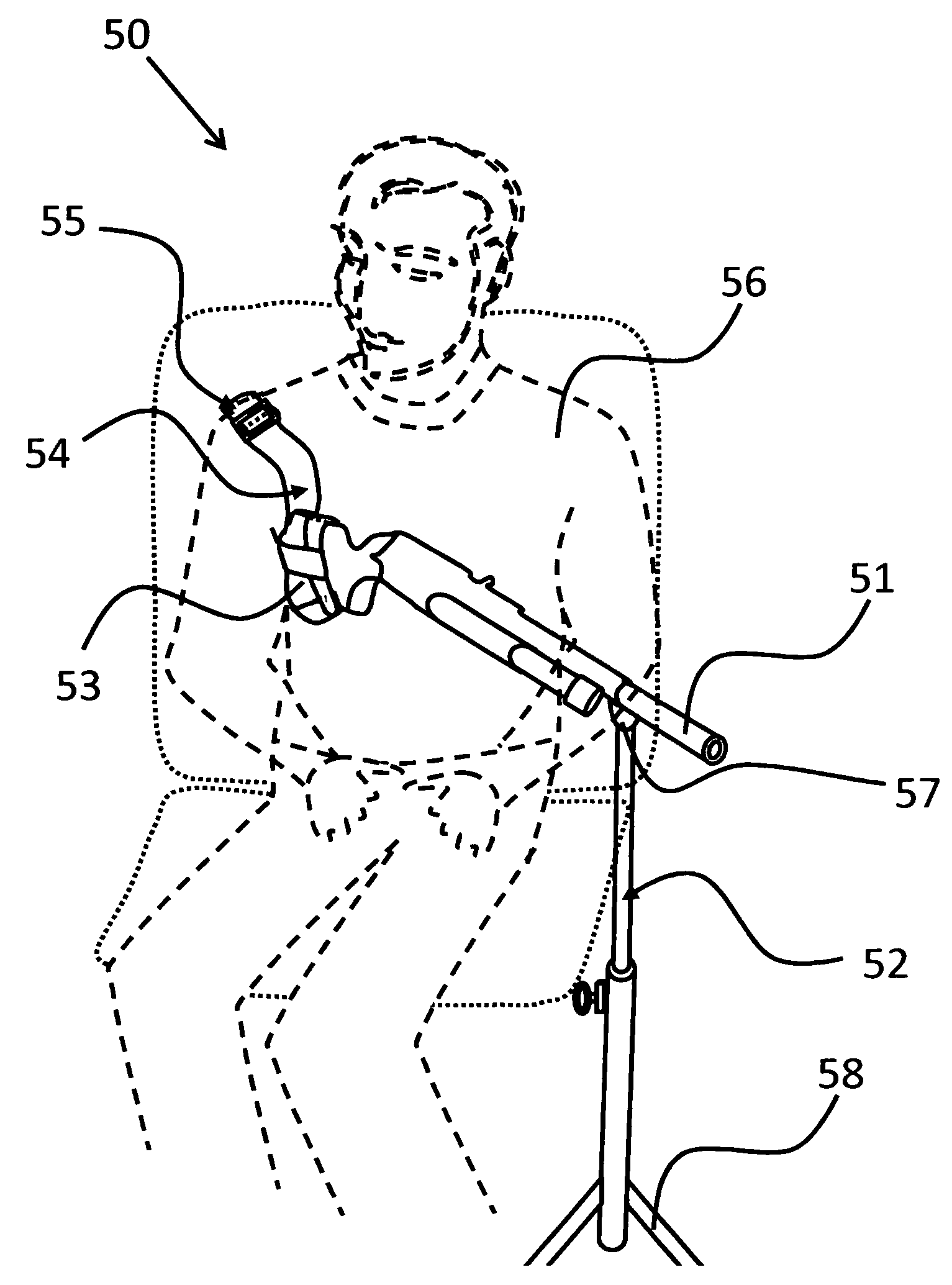

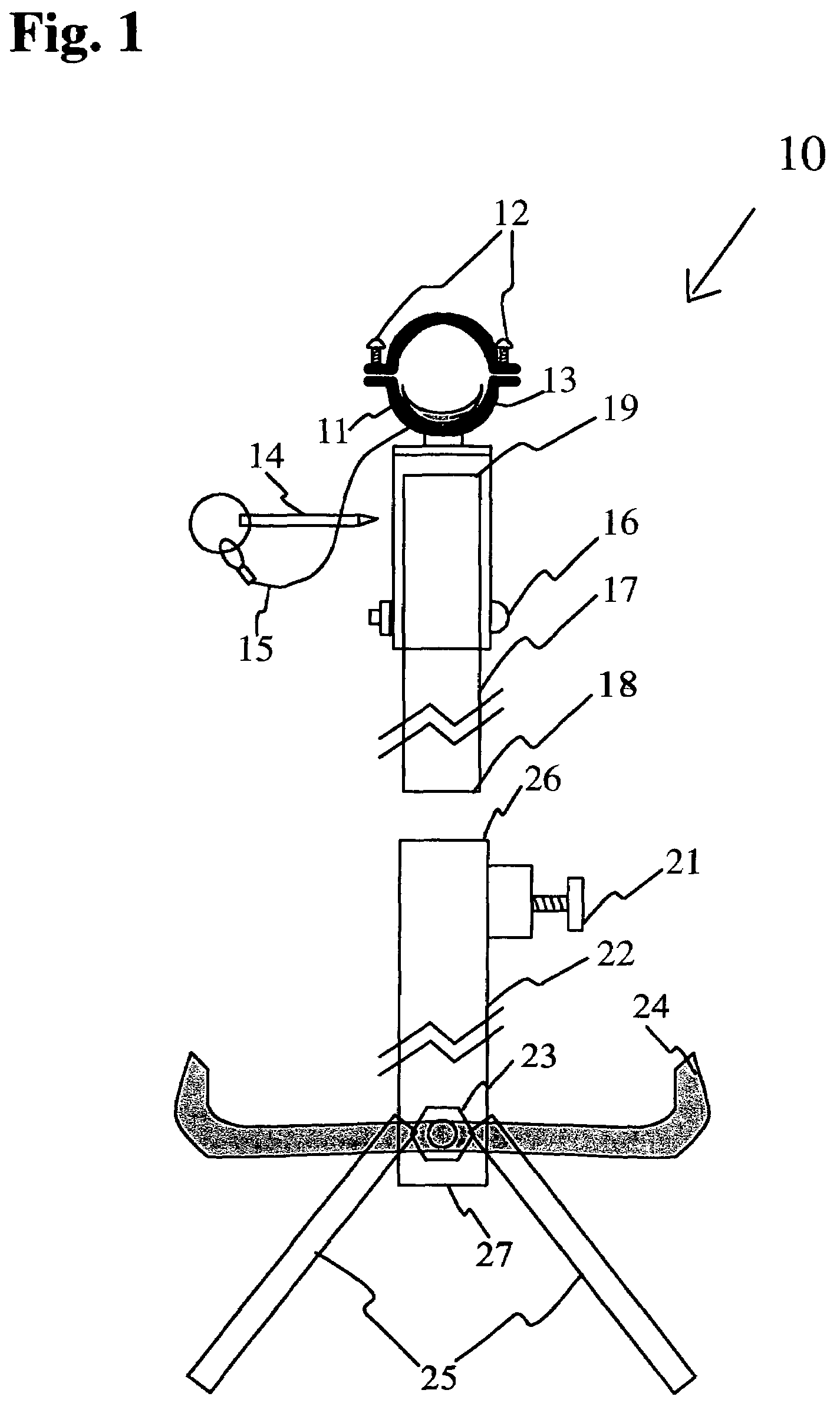

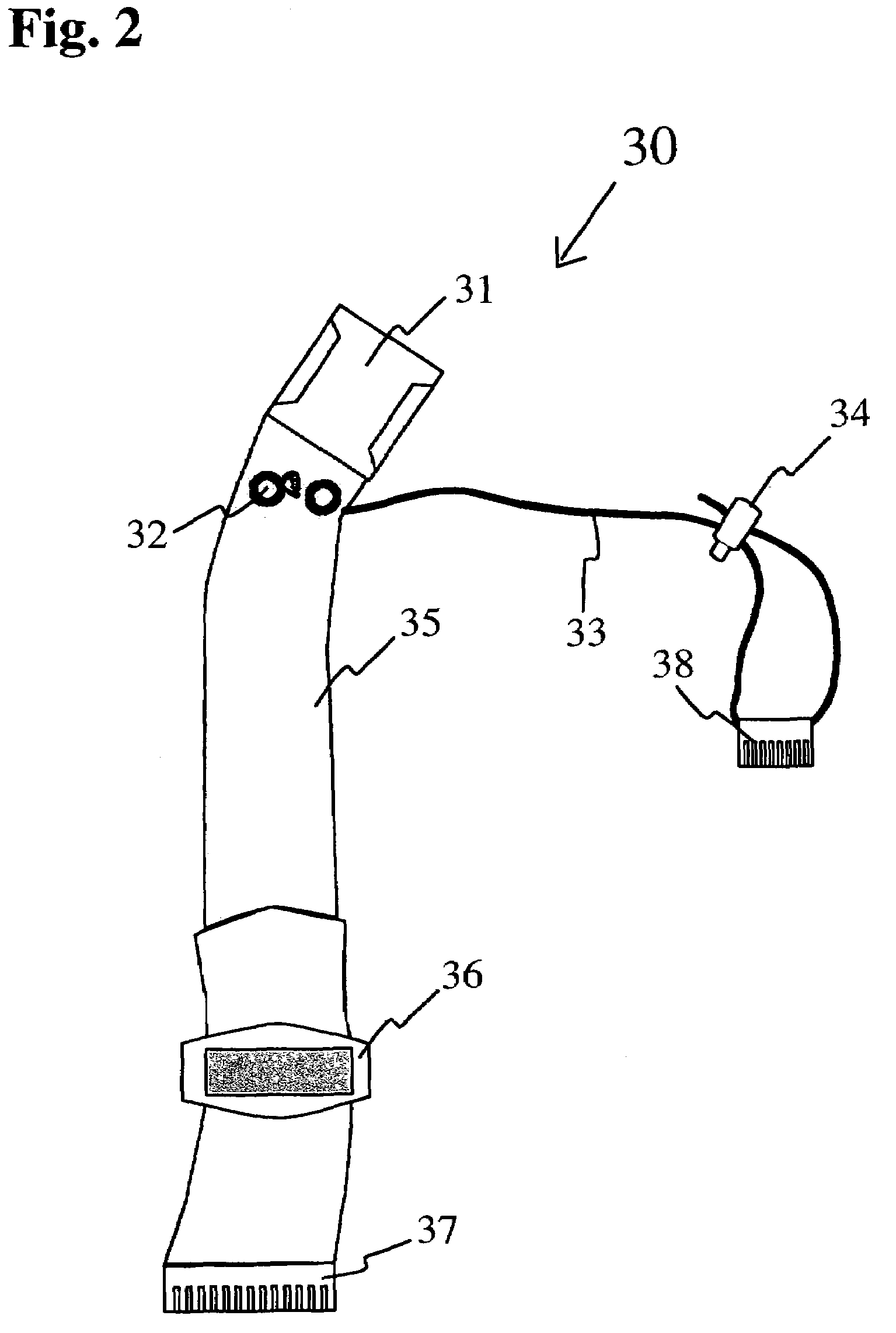

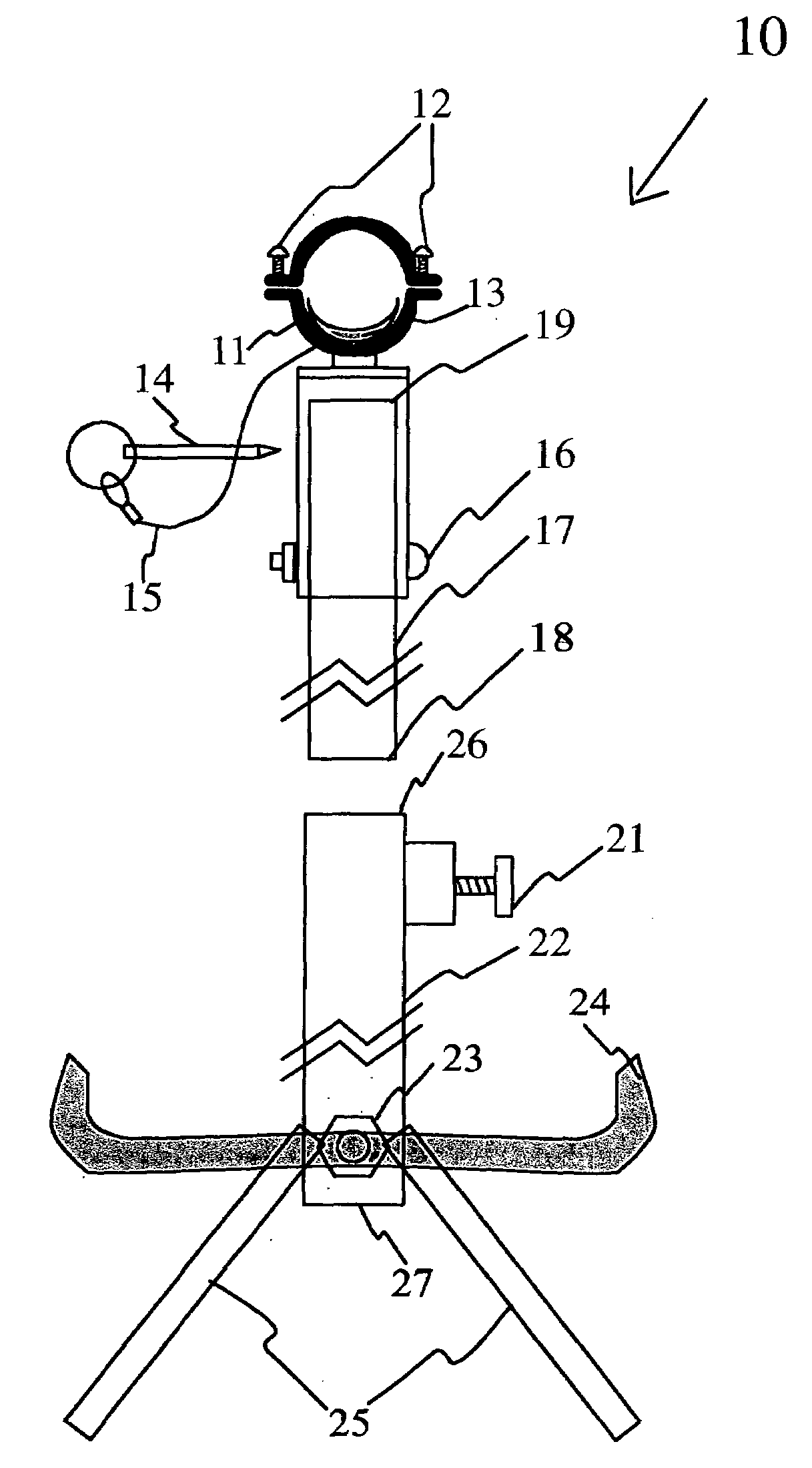

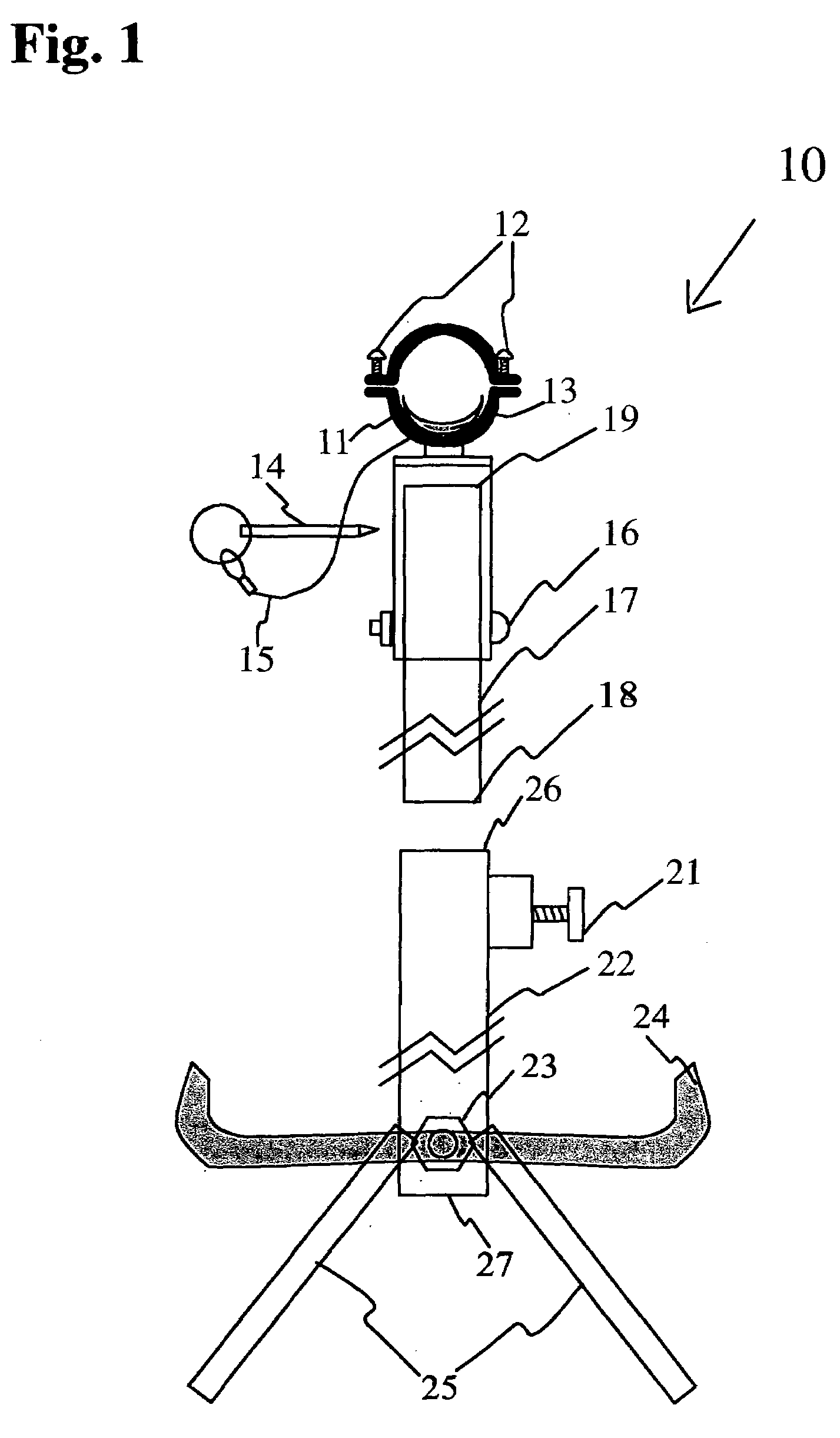

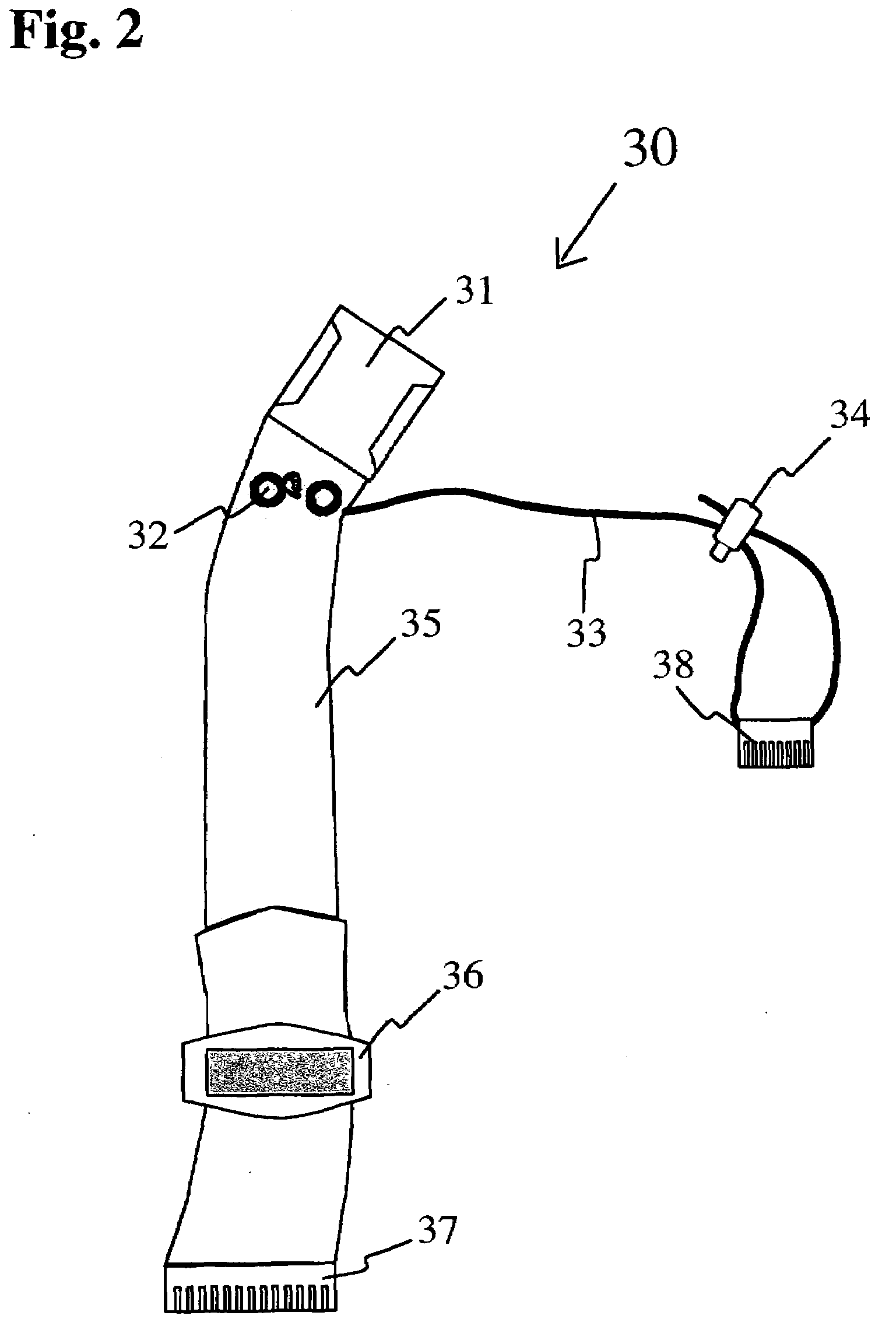

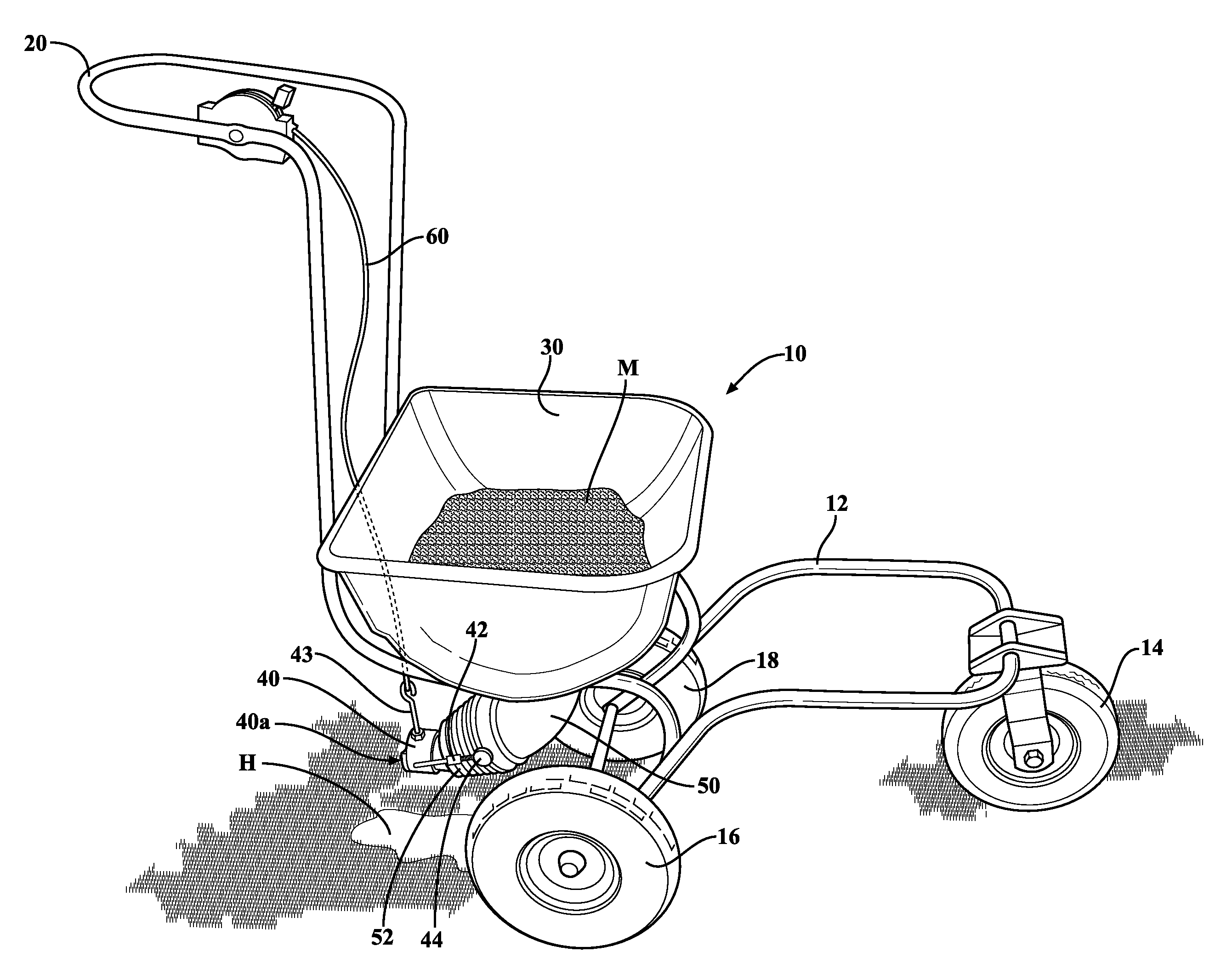

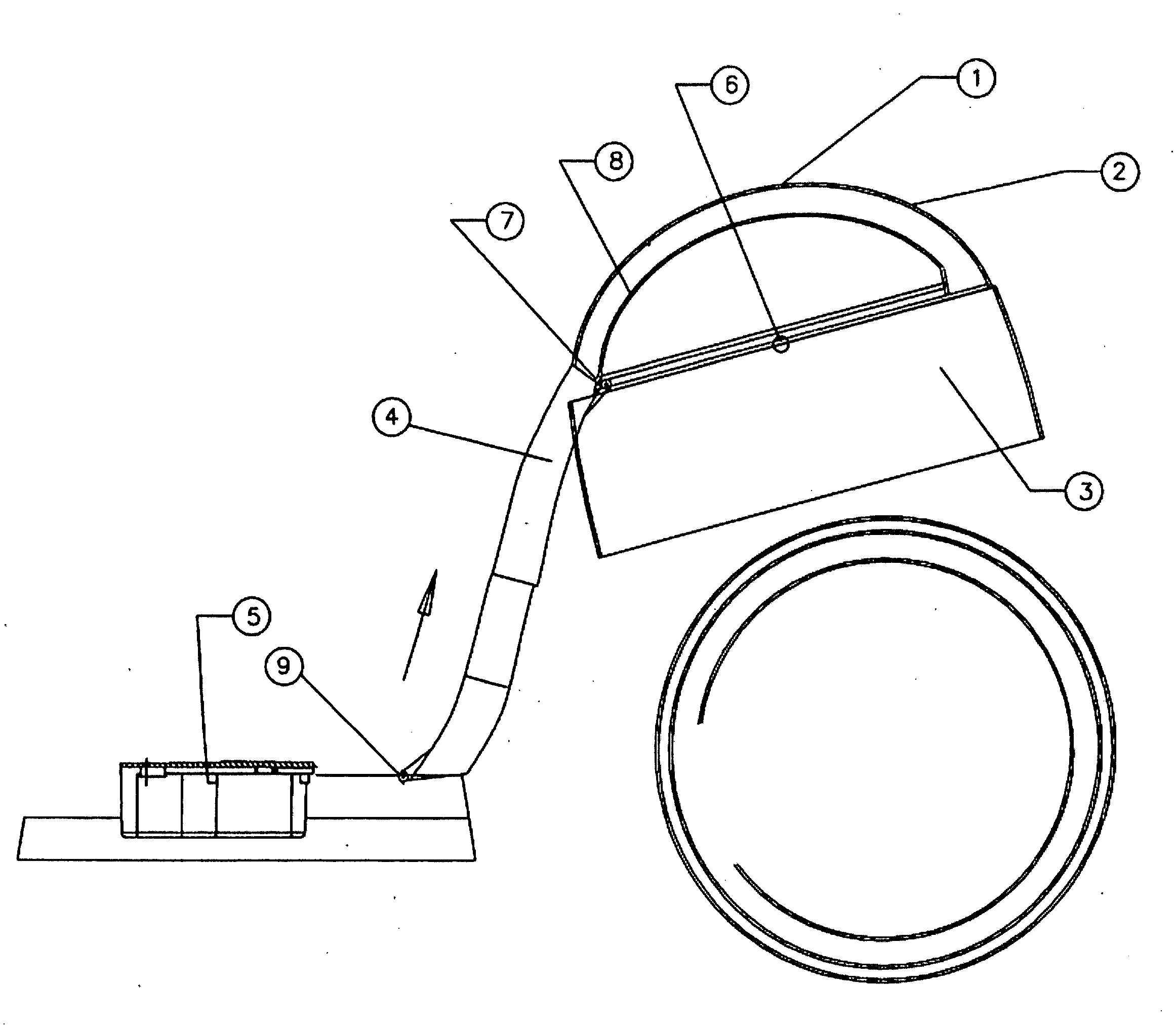

Gun support for hunters

InactiveUS7506470B2Easy to transportStable positionArms wearablesAmmunition loadingHands freeEngineering

A hands-free gun support has an adjustable telescoping barrel stand that supports the front end of a gun in a cradle. The gun butt is attached to a gun butt harness, which is removably attached to a shoulder harness worn by the hunter. The gun is aimed at the firing position and both the telescoping barrel stand and the butt harness support are adjusted so that the gun is completely supported in the firing position and the user's hands are free. The barrel stand height, as well as the horizontal and vertical orientation of the gun mounting cradle can be adjusted and locked. Adjustment of the gun butt harness is accomplished by a standard adjustable clip and a push-button clip in the shoulder harness. The gun support is especially suited for hunting turkey hunting or other game animals that are extremely sensitive to the slightest movement of the gun or the person holding the gun. Hunters engaged in such pursuits must spend long hours holding the gun steady without motion. This otherwise painful task is ameliorated by the hands-free gun support. In use of the present invention, the hunter's hands are not required to hold, steady or aim the gun. All the hunter needs to do is to wait without movement until the time for a firing event.

Owner:PEREKSTA MICHAEL E

Device for ultrasonic inspection

InactiveCN106236135AAutomatically adjust standing heightReduce labor intensityPatient positioningInfrasonic diagnosticsControl switchControl theory

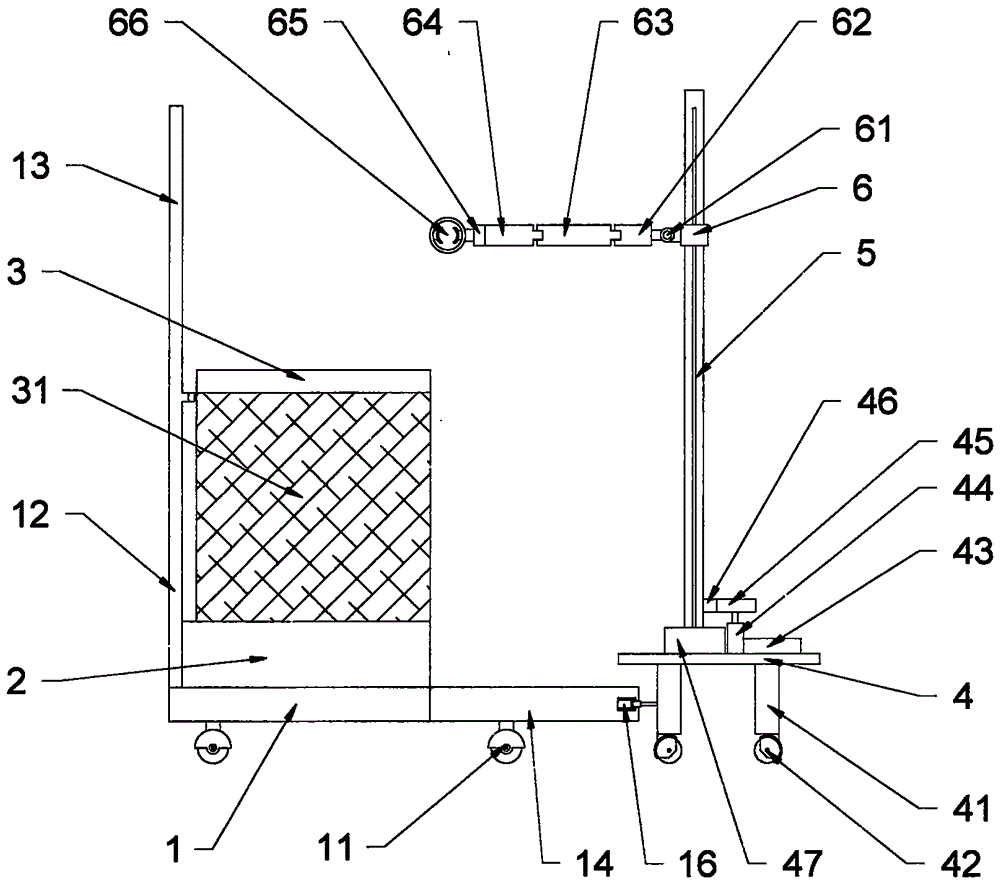

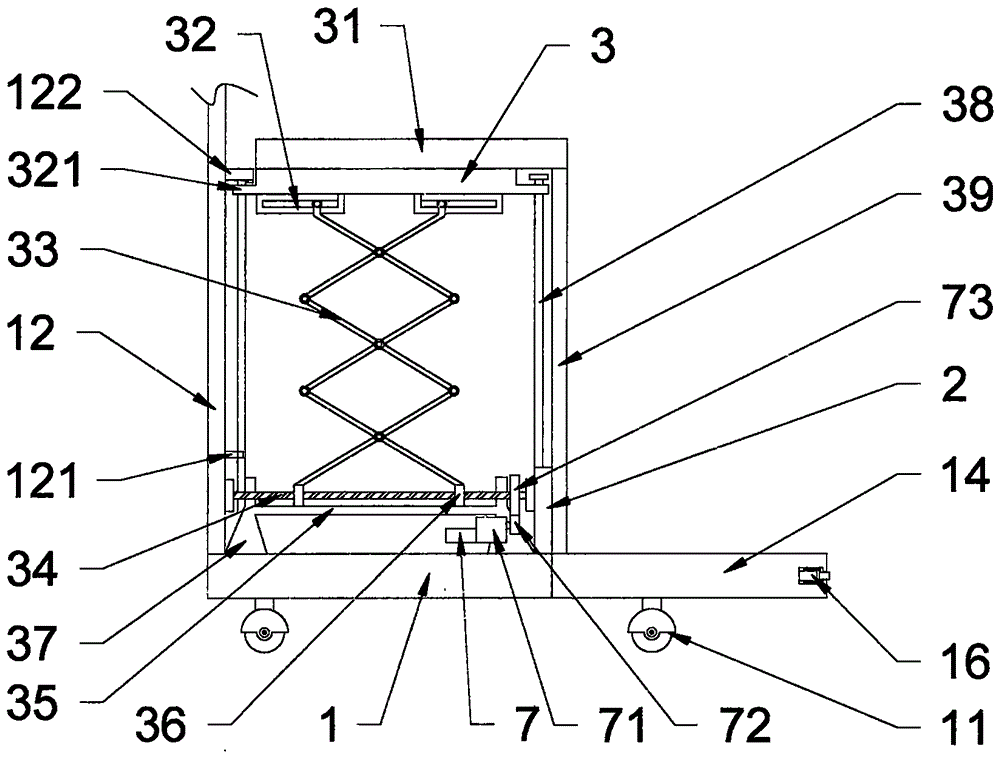

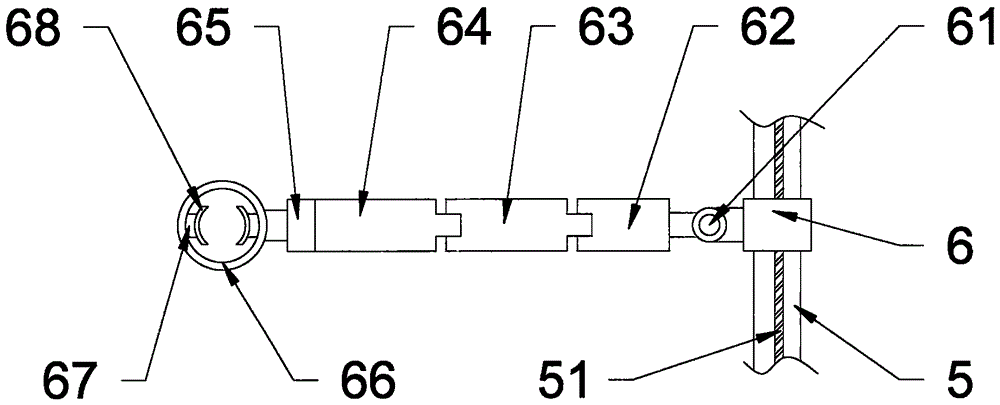

The invention relates to a device for ultrasonic inspection. The device comprises a lifting chair, a lifting rod, a mechanical arm and a controller. The lifting chair comprises a base, a fixing-side supporting frame, a driving mechanism, a lifting frame and a supporting plate. Guiding grooves are formed in the lower surface of the supporting plate, and guiding sliding blocks are arranged at the top ends of supporting rods on most-top layers of two shearing assemblies, and are assembled in the guiding grooves; the lifting rod comprises a second supporting base, a second lead screw and a second servo motor, a guiding sleeve is arranged outside the second lead screw, a lifting sleeve is arranged outside the guiding sleeve, and the mechanical arm is arranged on the lifting sleeve; the mechanical arm comprises a first joint, a second joint, a third joint, a supporting ring and a clamping piece, a first servo motor and the second servo motor are electrically connected with the controller, and a lifting-chair control switch and a lifting-rod control switch are arranged on the controller. The device has the advantages that the structure is simple, the standing height of patients is automatically adjusted, a probe can be supported, and the labor intensity of medical workers can be effectively reduced.

Owner:刘浩

Double-way video networking monitoring locator suitable for engineering field

ActiveCN107676601AImprove accuracyHigh speedClosed circuit television systemsStands/trestlesArchitectural engineeringStanding height

The invention relates to a double-way video networking monitoring locator suitable for an engineering field. The double-way video networking monitoring locator comprises a bottom plate. An outer support pipe is installed at the top of the bottom plate fixedly. An upwards extending lifting rotary support pipe is arranged in the outer support pipe. An anti-falling stable installing block is installed at the top of the lifting rotary support pipe. A connecting pipe is movably connected to the top of the anti-falling stable installing block. A double-way video monitor is fixedly installed at the top of the connecting pipe. According to the double-way video networking monitoring locator, double adjustment of the camera stand height and orientation angle can be conducted through operation of a single L-shaped hand-cranking rod, vibration conducted in a construction site environment can be isolated effectively, and the monitoring locator does not fall under large action of external force. Thedouble-way video networking monitoring locator is simple in structure, low in cost, various in function, high in reliability and especially suitable for application to construction sites.

Owner:ZHEJIANG DEPART ELECTRONICS TECH

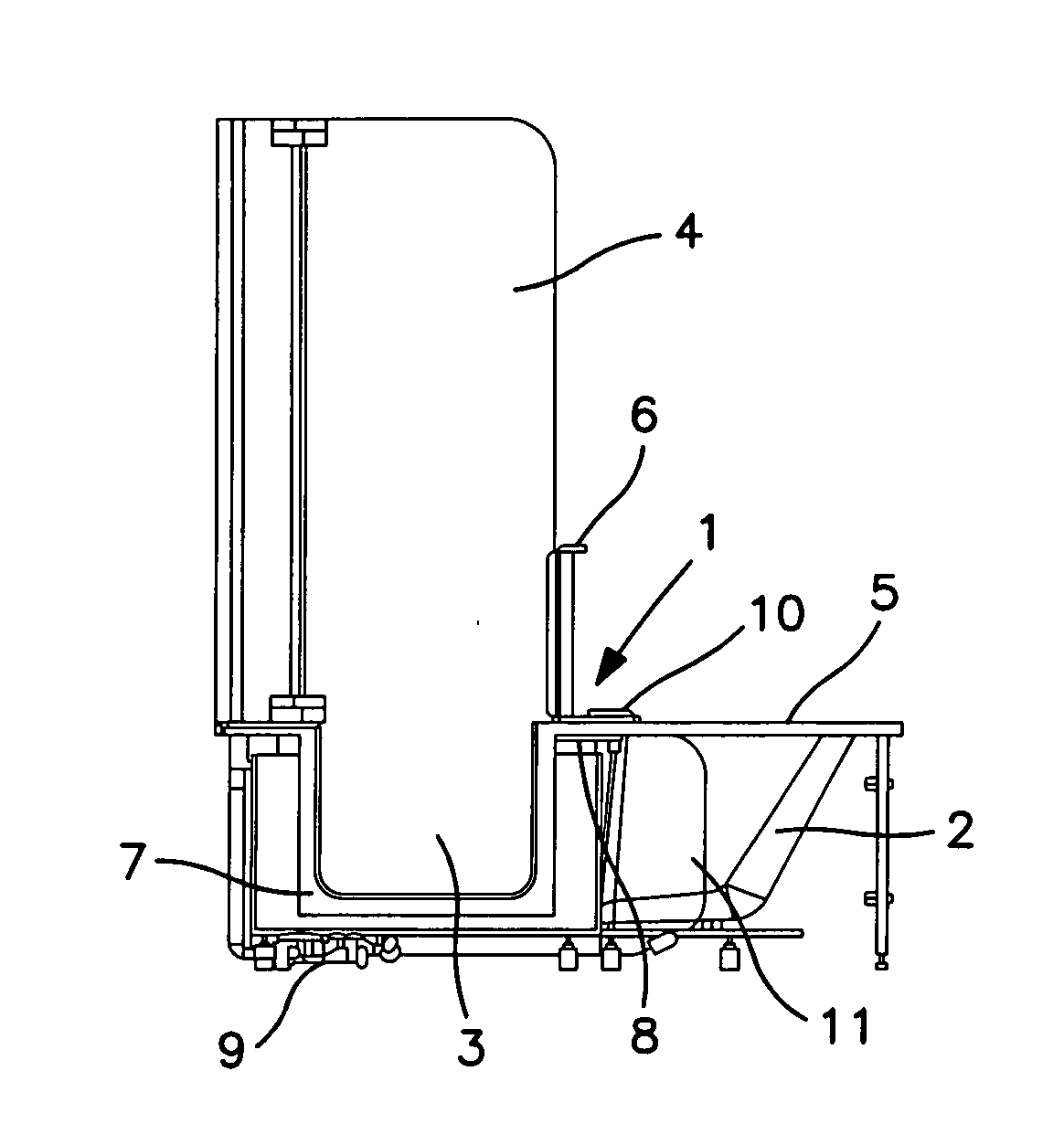

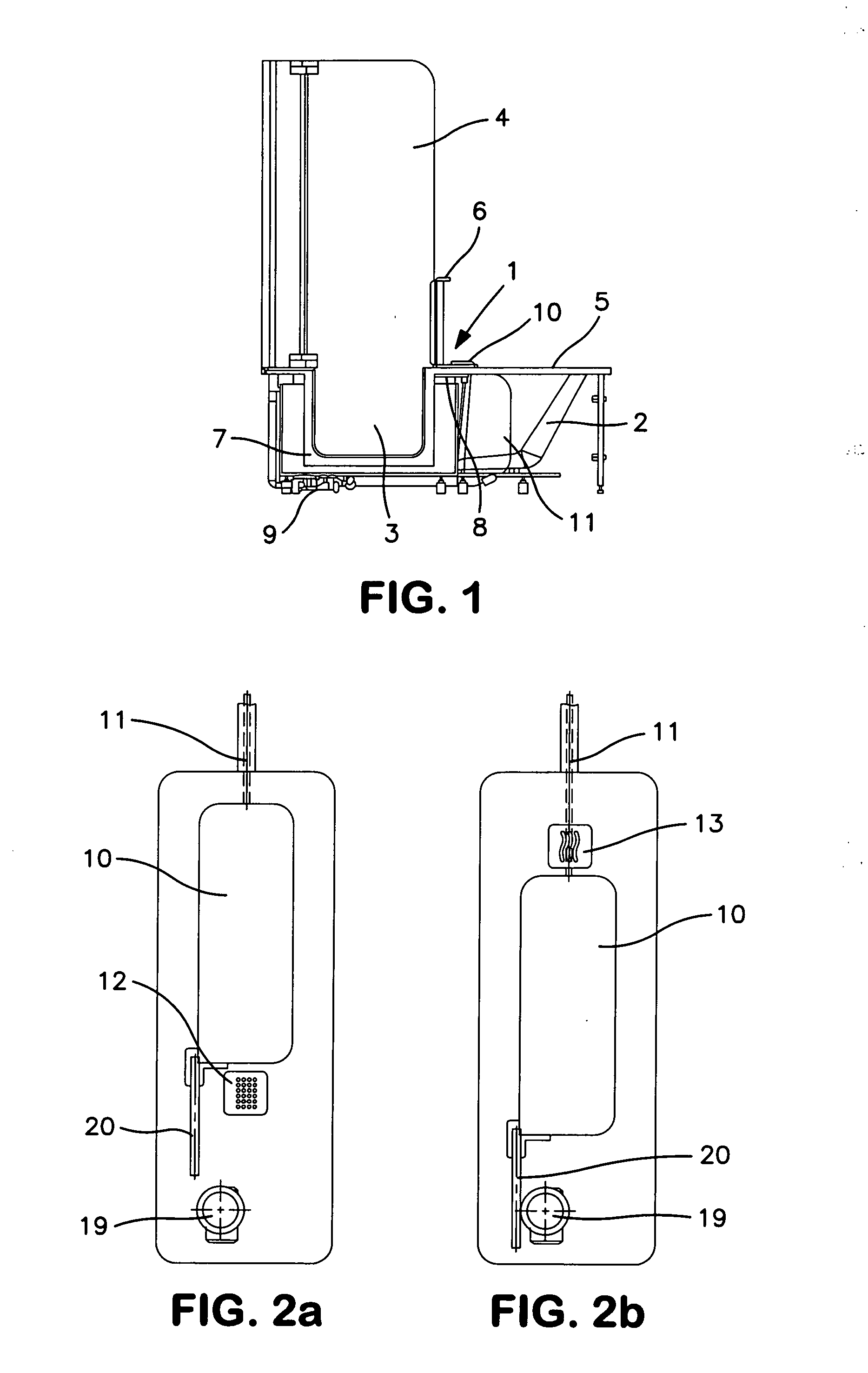

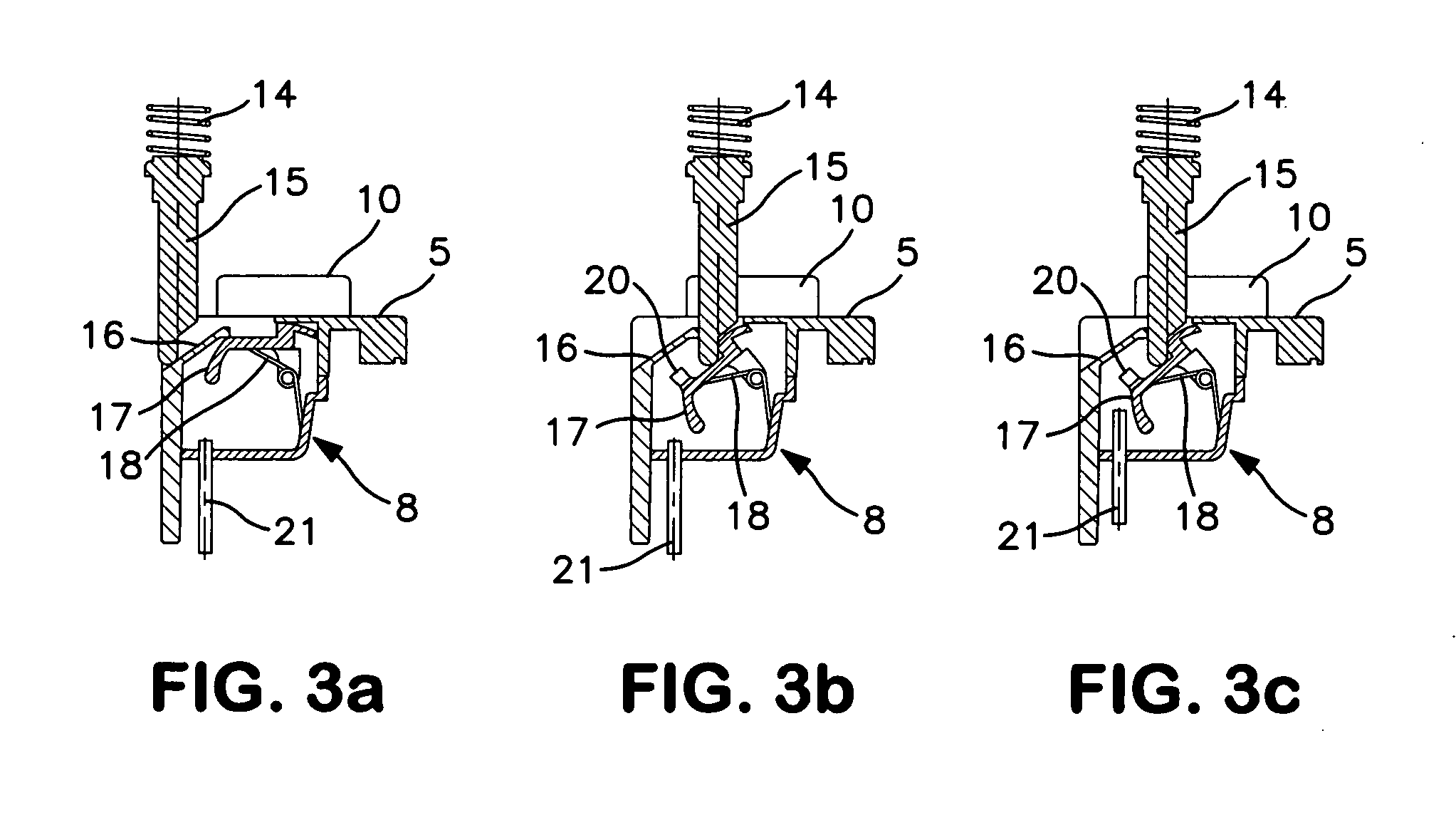

Closing and securing assembly for a bathtub and/or shower basin

The invention relates to a closing and securing assembly for a bathtub and / or shower basin (2), having an entry region (3) which may be closed in a water-tight manner using a door (4) which optionally extends at least to standing height and which may be locked using a locking device (8), and having a discharge drain (9) having a closing mechanism which may be closed only in the locked state of the locking device (8).To provide the greatest possible safety while essentially completely avoiding electrical or electronic components, and which prevents bath water from escaping via the entry region (3) of the basin (2) when the door (4) is open or unlocked, and which allows the door (4) to be opened when the basin (2) is filled above the height of the entry region (3), a mechanical transfer arrangement (11) is provided for connecting a locking device (8) which operates in a strictly mechanical fashion to the closing mechanism, using a control system.

Owner:ARTWEGER

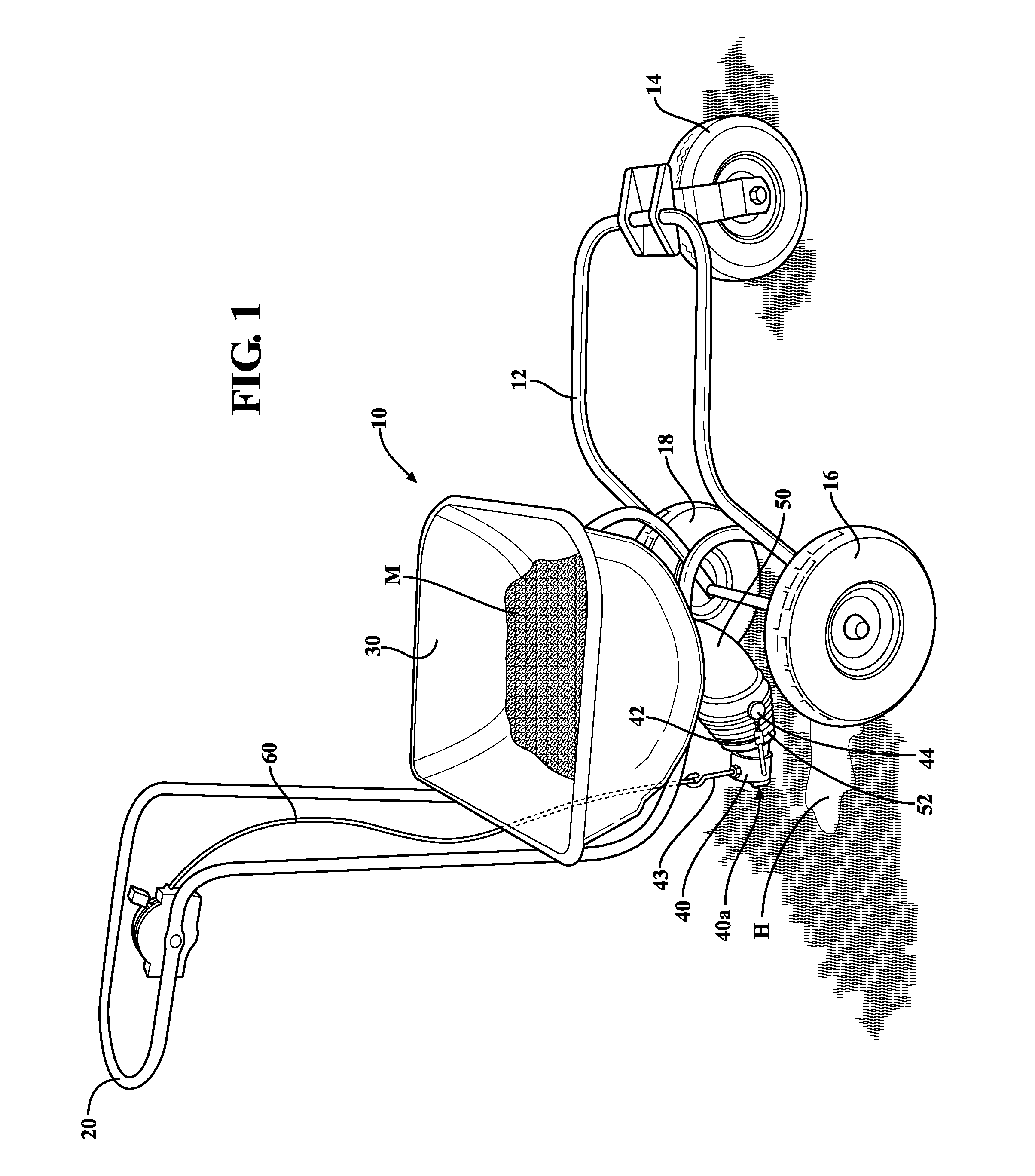

Gun support for hunters

InactiveUS20080086928A1Easy to transportStable positionArms wearablesAmmunition loadingHands freeEngineering

A hands-free gun support has an adjustable telescoping barrel stand that supports the front end of a gun in a cradle. The gun butt is attached to a gun butt harness, which is removably attached to a shoulder harness worn by the hunter. The gun is aimed at the firing position and both the telescoping barrel stand and the butt harness support are adjusted so that the gun is completely supported in the firing position and the user's hands are free. The barrel stand height, as well as the horizontal and vertical orientation of the gun mounting cradle can be adjusted and locked. Adjustment of the gun butt harness is accomplished by a standard adjustable clip and a push-button clip in the shoulder harness. The gun support is especially suited for hunting turkey hunting or other game animals that are extremely sensitive to the slightest movement of the gun or the person holding the gun. Hunters engaged in such pursuits must spend long hours holding the gun steady without motion. This otherwise painful task is ameliorated by the hands-free gun support. In use of the present invention, the hunter's hands are not required to hold, steady or aim the gun. All the hunter needs to do is to wait without movement until the time for a firing event.

Owner:PEREKSTA MICHAEL E

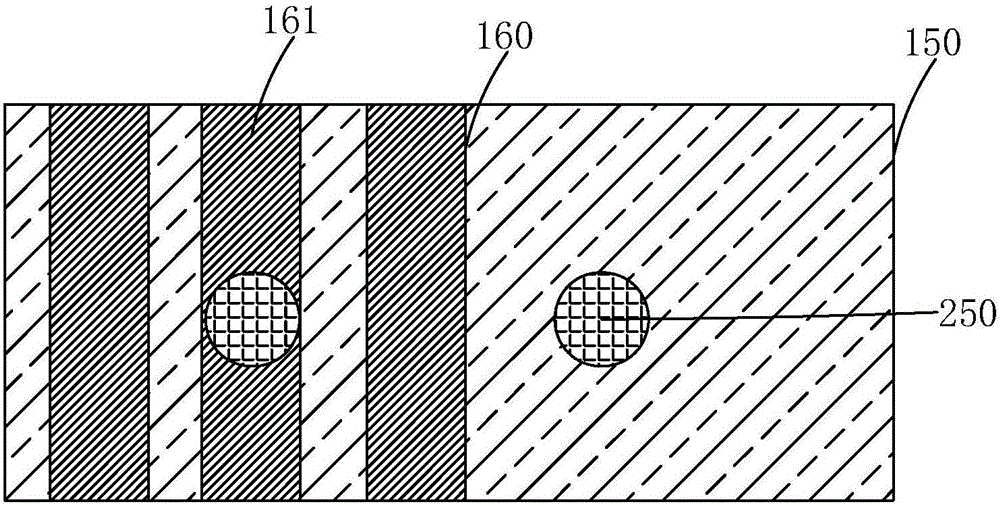

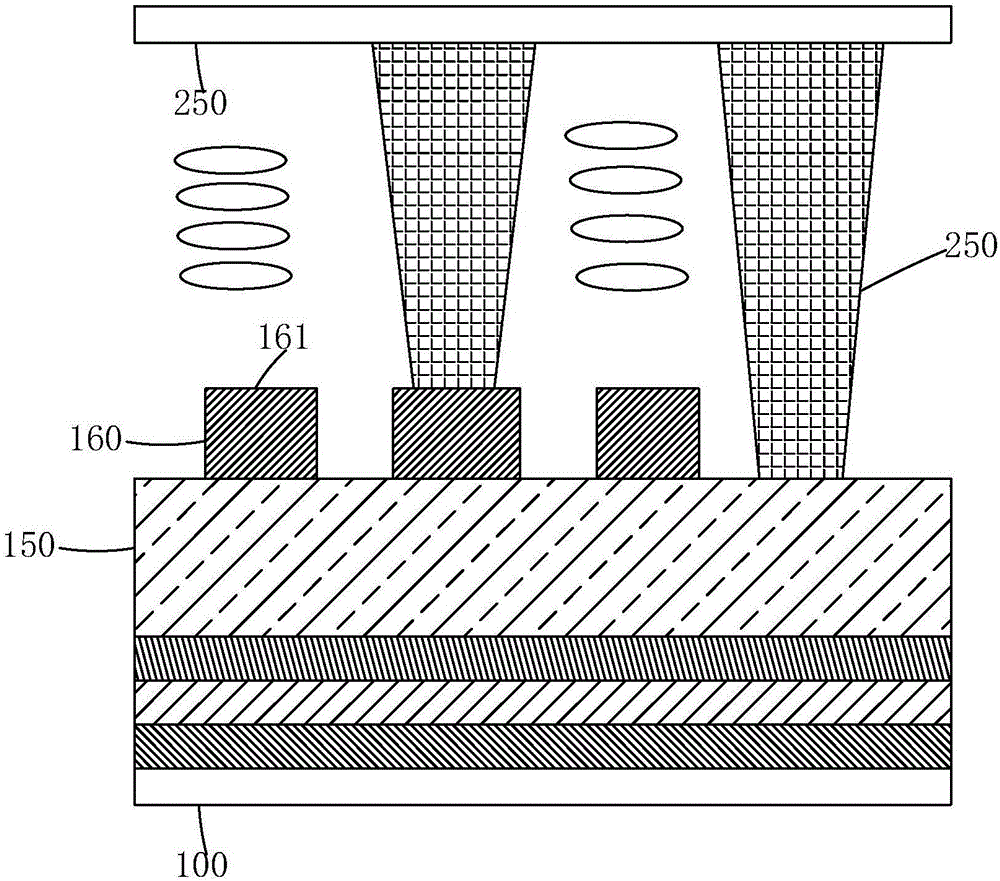

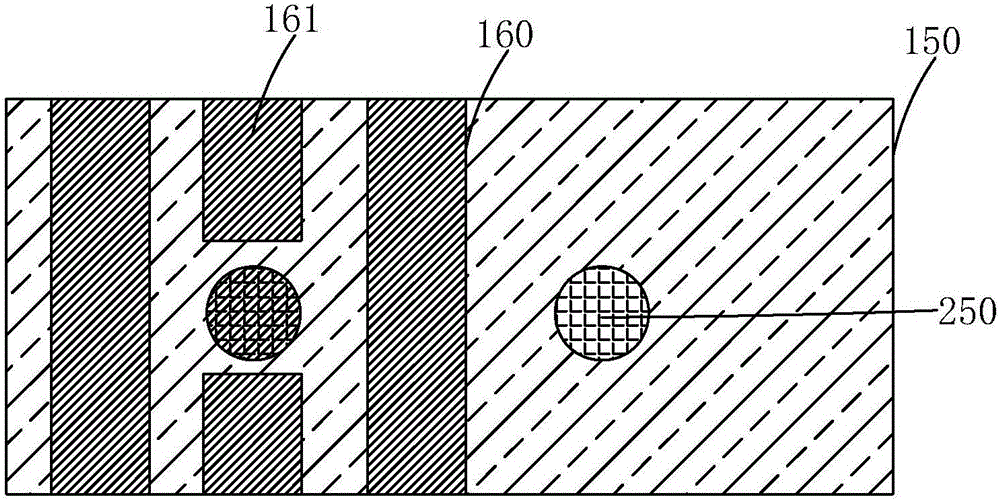

Embedded touch panel

InactiveCN106773222AUniform box thicknessReduce the numberNon-linear opticsInput/output processes for data processingEngineeringStanding height

The invention provides an embedded touch panel. Multiple touch electrode lines are arranged in a third metal layer of an array substrate. The touch electrode lines on which columnar spacers stand correspondingly are overlapped touch electrode lines, grooves are formed in the regions, corresponding to the overlapped touch electrode lines, of a flat layer of the array substrate, the overlapped touch electrode lines are correspondingly arranged in the grooves, the standing height of the column spacers standing on the third metal layer correspondingly is reduced, and therefore the overall box thickness of the panel is uniform. Compared with an existing improvement method, it is not needed to disconnect the touch electrode lines in the third metal layer or reduce the number of the touch electrode lines, therefore, touch performance and pixel electric fields are not affected, only the exposure manufacturing procedure of the flat layer needs to be slightly improved on the aspect of the manufacturing procedures, the manufacturing procedures are simple, and the production cost is low.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

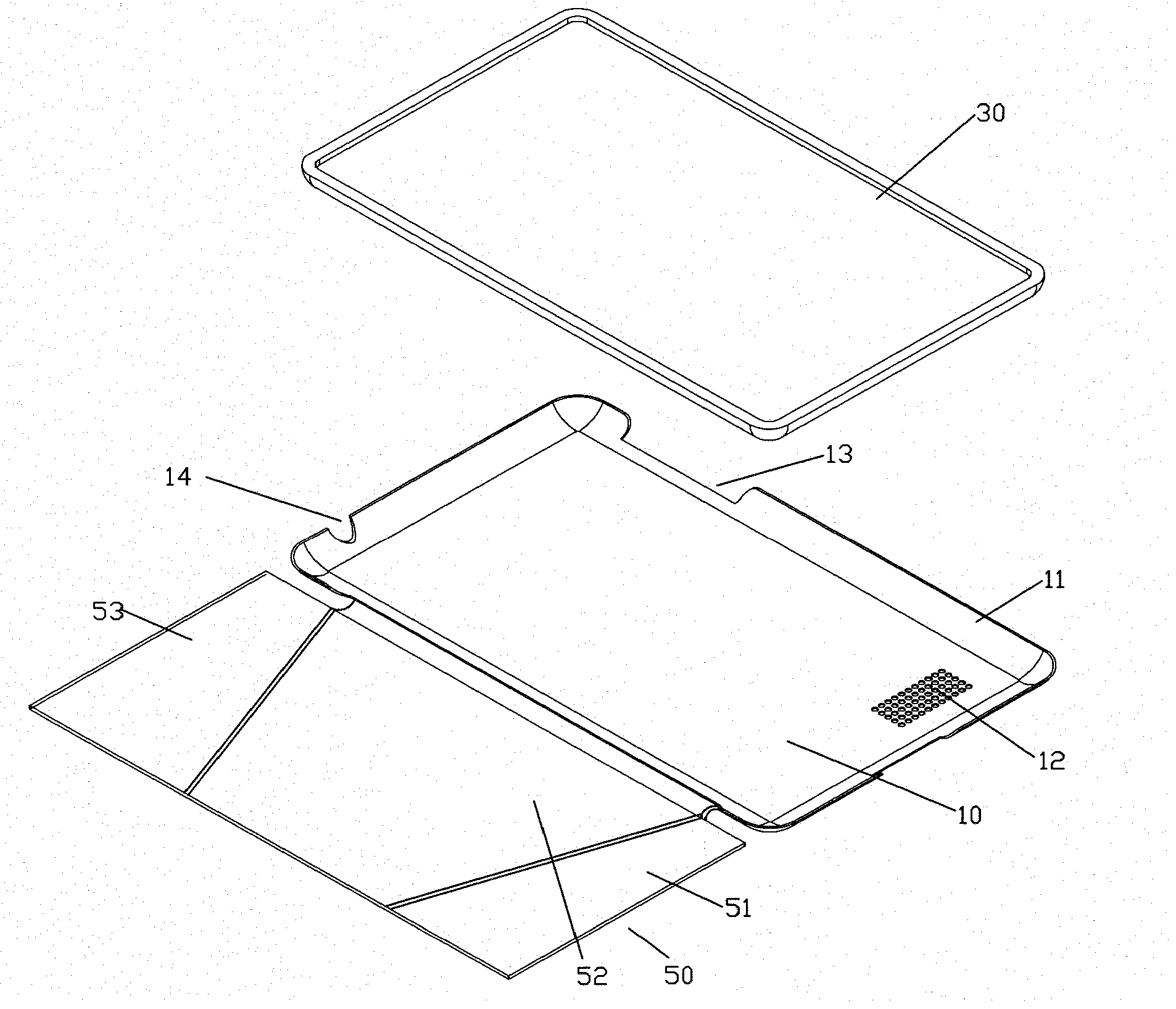

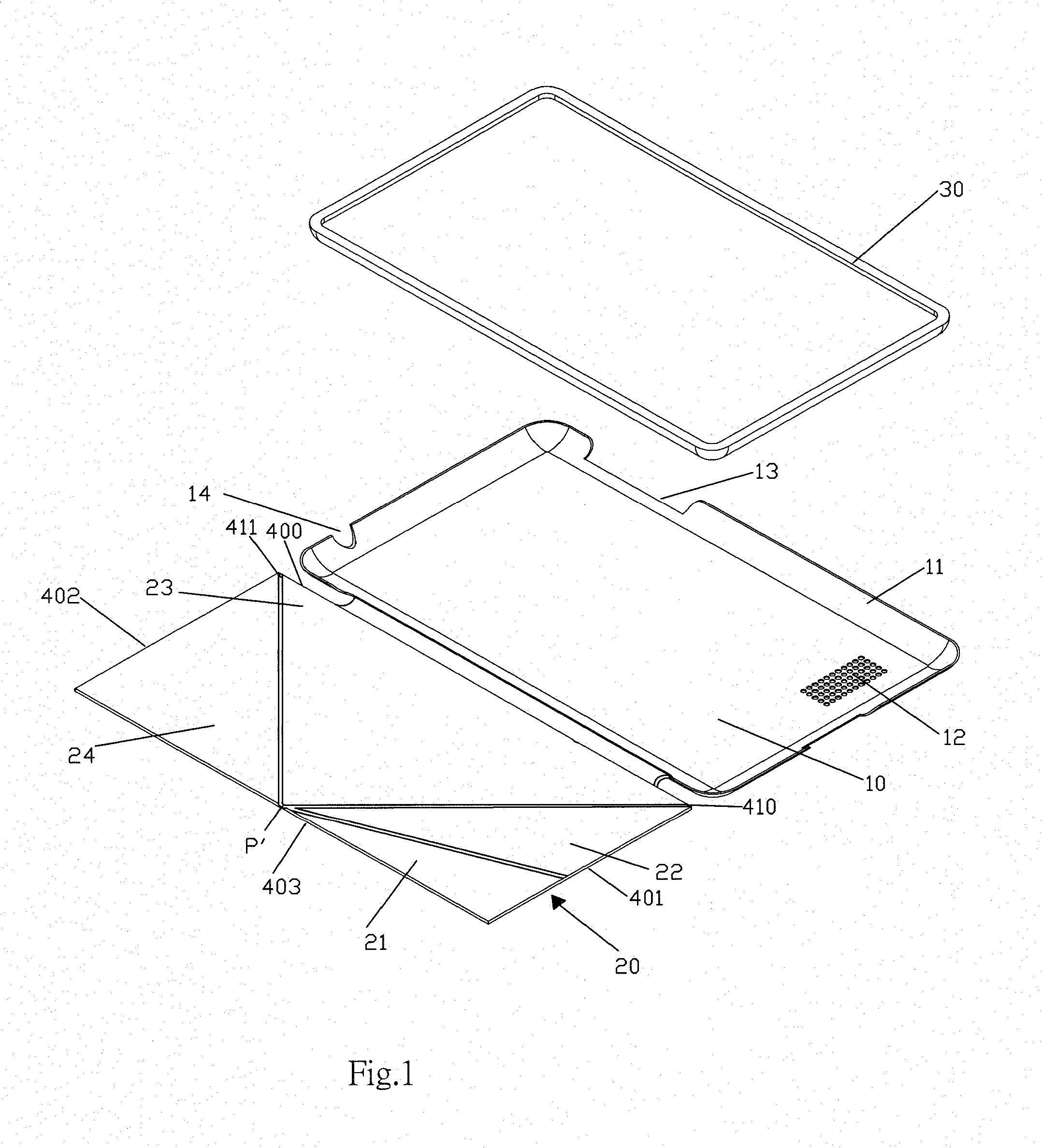

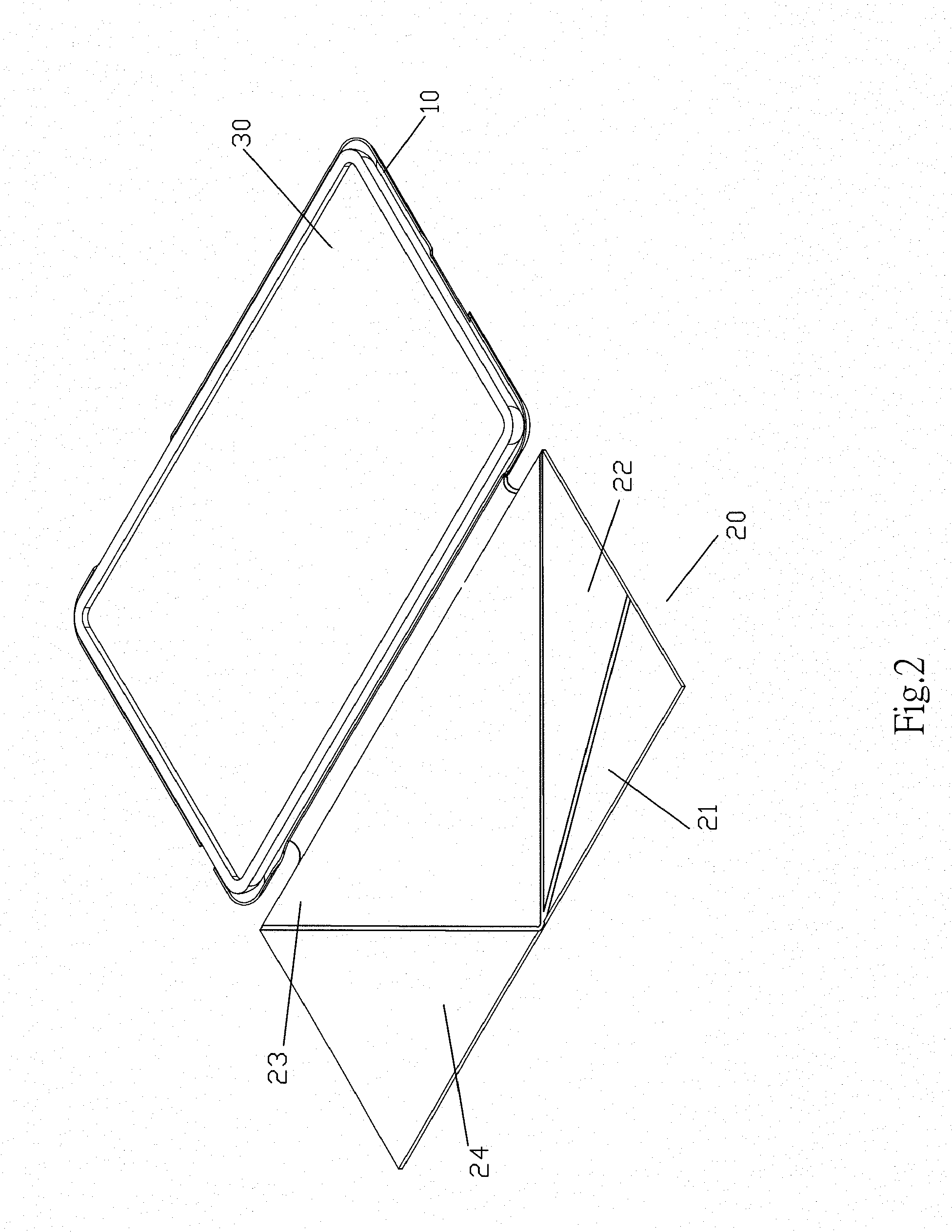

Cover for packaging and supporting tablet computer

A cover for packaging and supporting a tablet computer has a lower casing for protecting a tablet computer; an upper cover rotatably connected to the lower casing for protecting the screen of the tablet computer from damage; the upper cover being formed with at least one foldable line area for folding the upper cover along the foldable line area; wherein the upper cover is used as a cover and a supporter; the upper cover rotates along the lower casing with an angle greater than 180 degrees; the lower casing is folded along the foldable line areas so as to be formed as a supporter of the lower casing for supporting the tablet computer therein. Thus the computer can stand; and the angle between the upper cover and the lower casing is adjustable so as to control the standing height of the tablet computer.

Owner:TRIANGUS +1

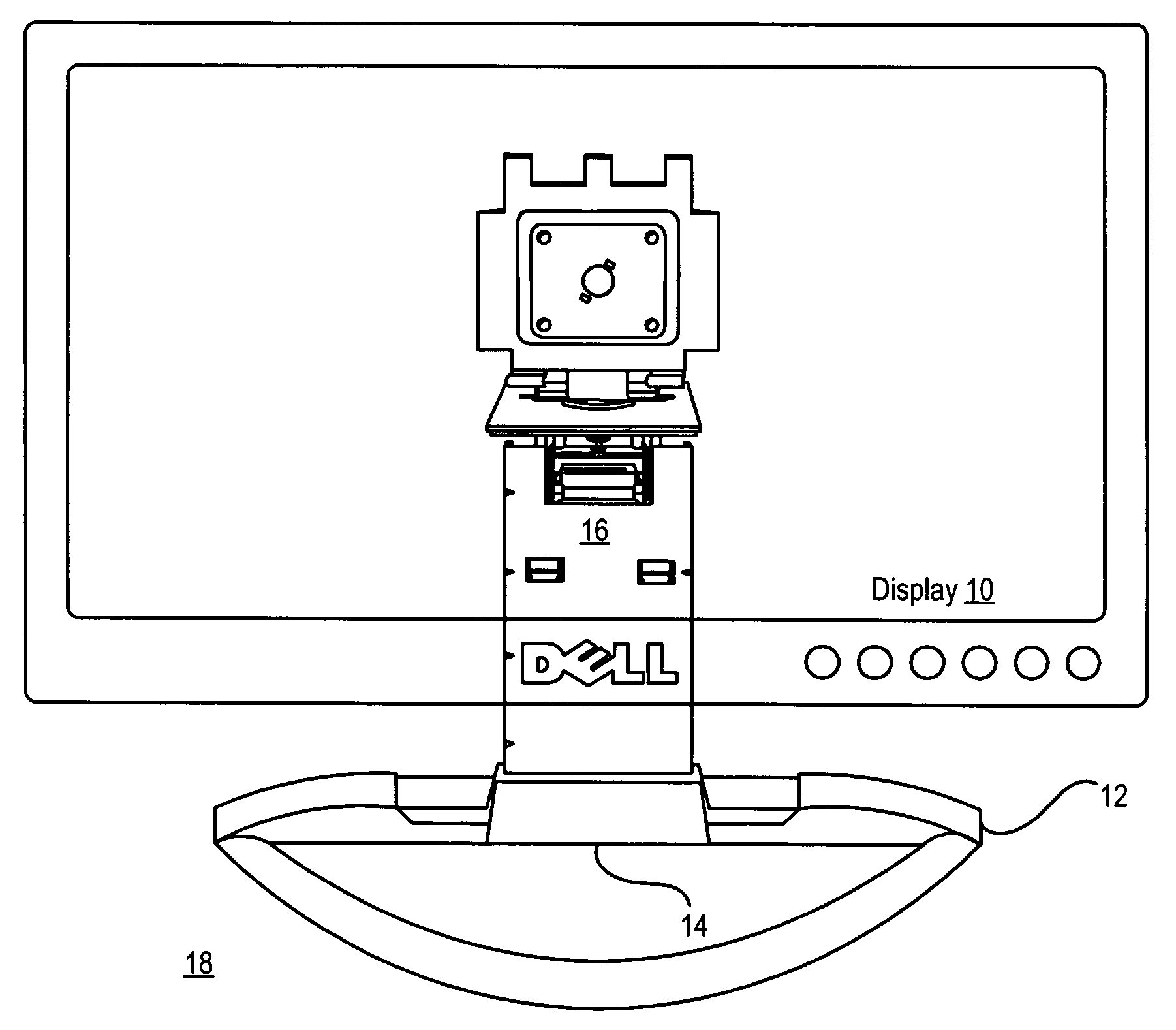

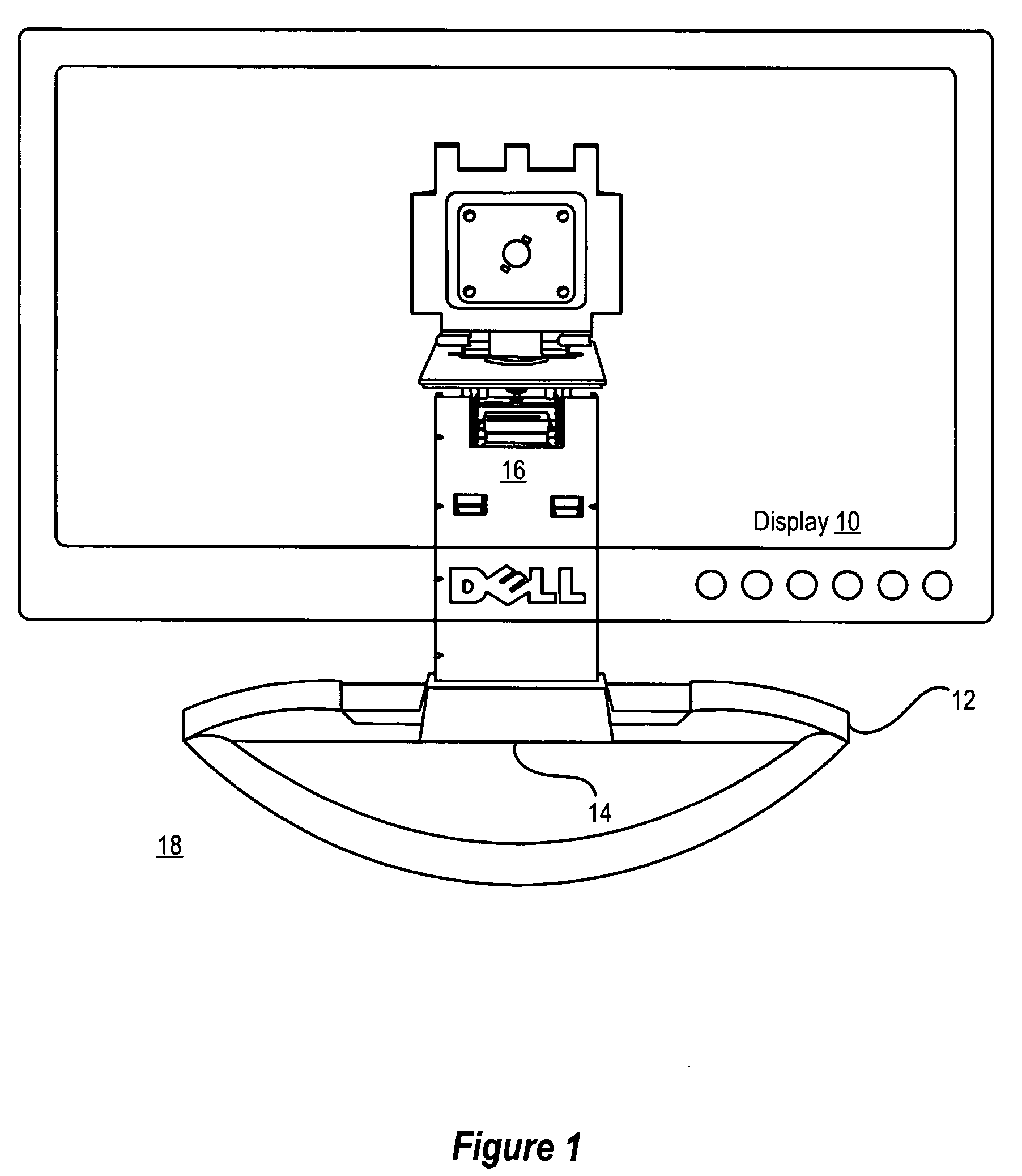

System and method for display stand height adjustment

ActiveUS20070013720A1Reduce disadvantagesReduce problemsDigital data processing detailsCathode-ray tube indicatorsDisplay deviceFlat panel display

Information handling system flat panel displays, such as liquid crystal and plasma displays, are supported on an adjustable stand having a rotation limiter that restricts adjustments of display positions to prevent damage to the display. A display bracket allows rotation of a display between landscape and portrait orientations and a support member allows adjustment of the vertical height of the display bracket relative to a base. The rotation limiter is disposed between the display bracket and support member to restrict rotation of the display bracket from the landscape to the portrait orientation when the support member adjusts the display bracket below a predetermined height at which the display extends beyond the support member. The rotation limiter allows rotation of the display bracket above the predetermined height but restricts height adjustment below the predetermined height unless the display bracket is in the landscape orientation.

Owner:DELL PROD LP

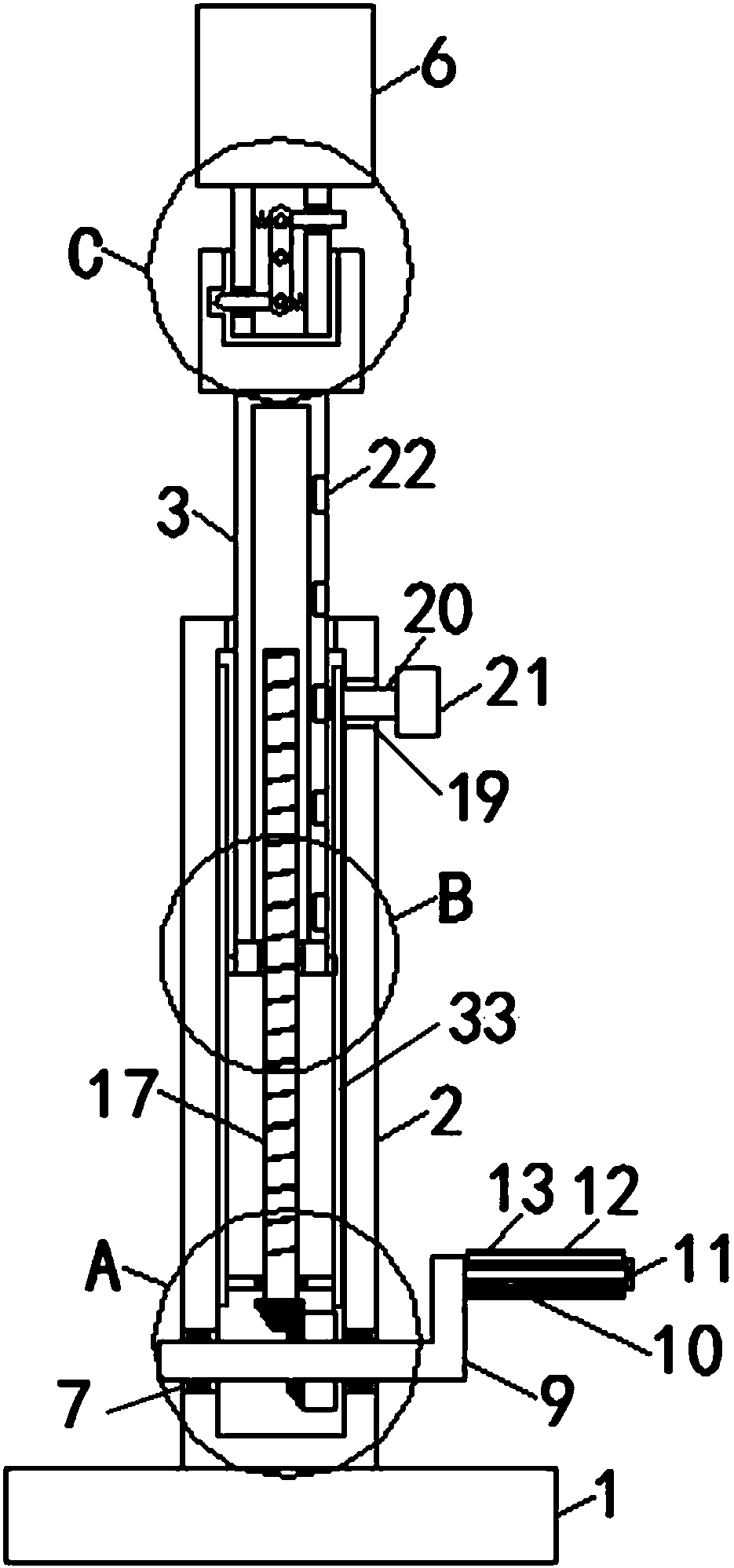

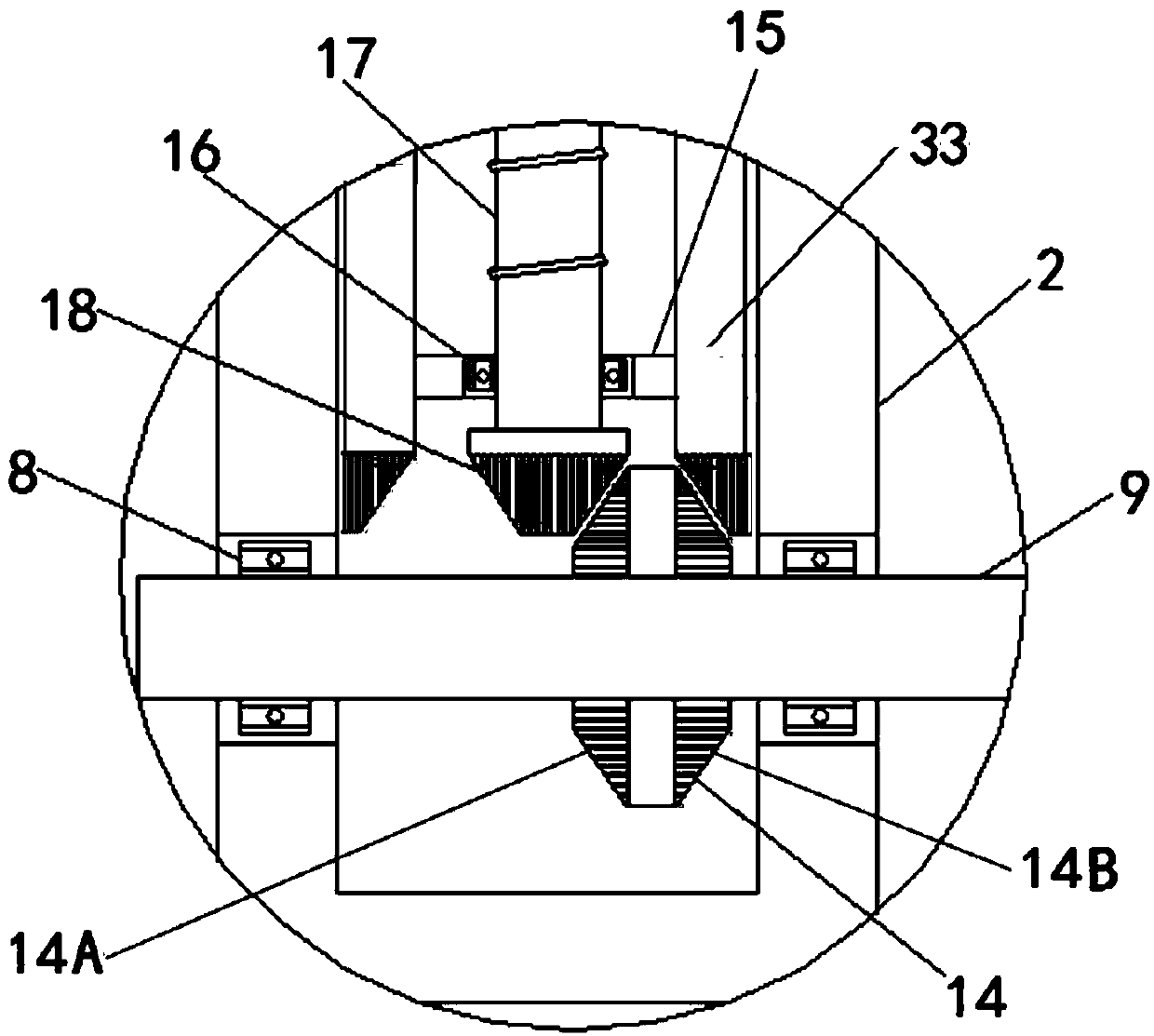

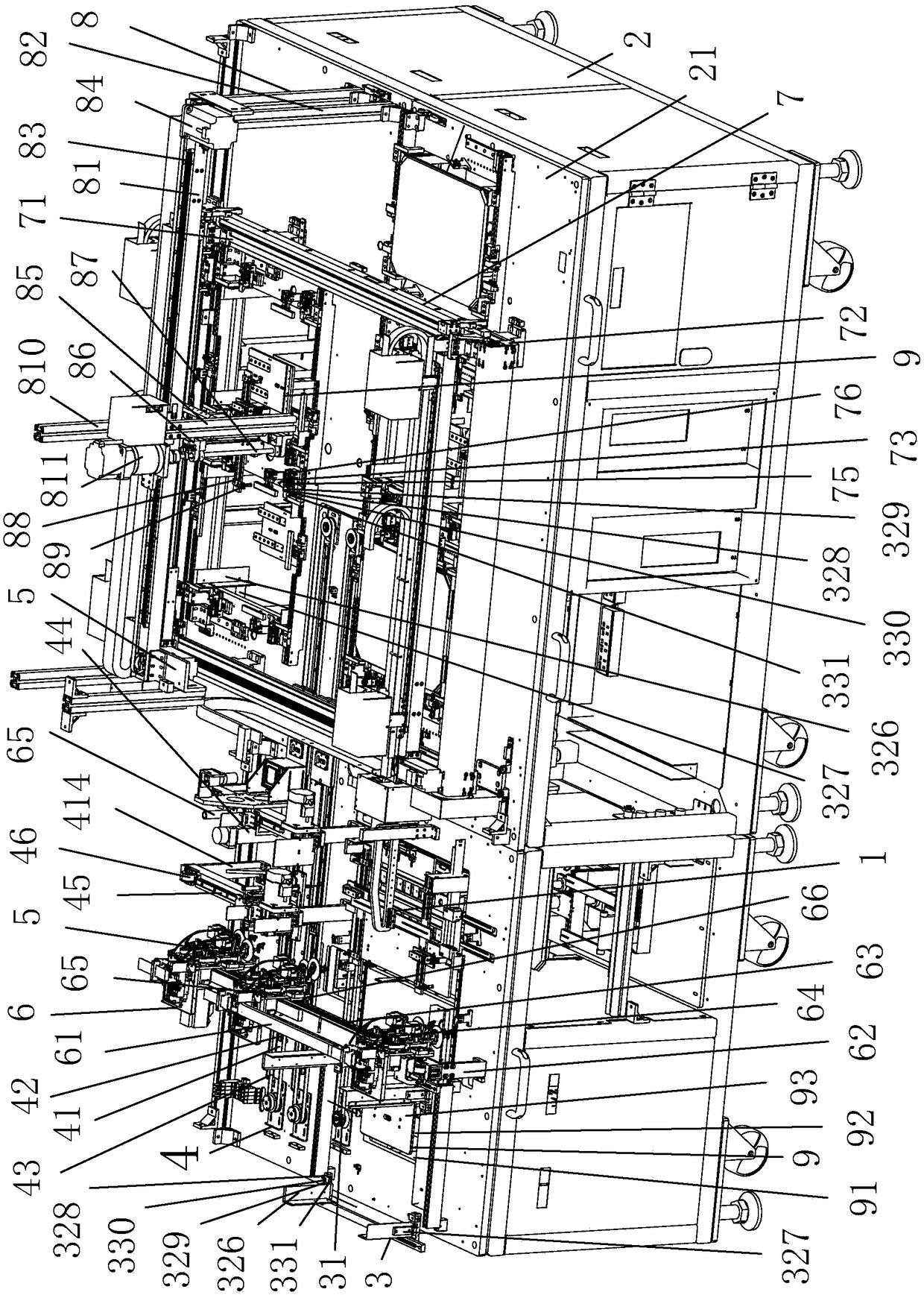

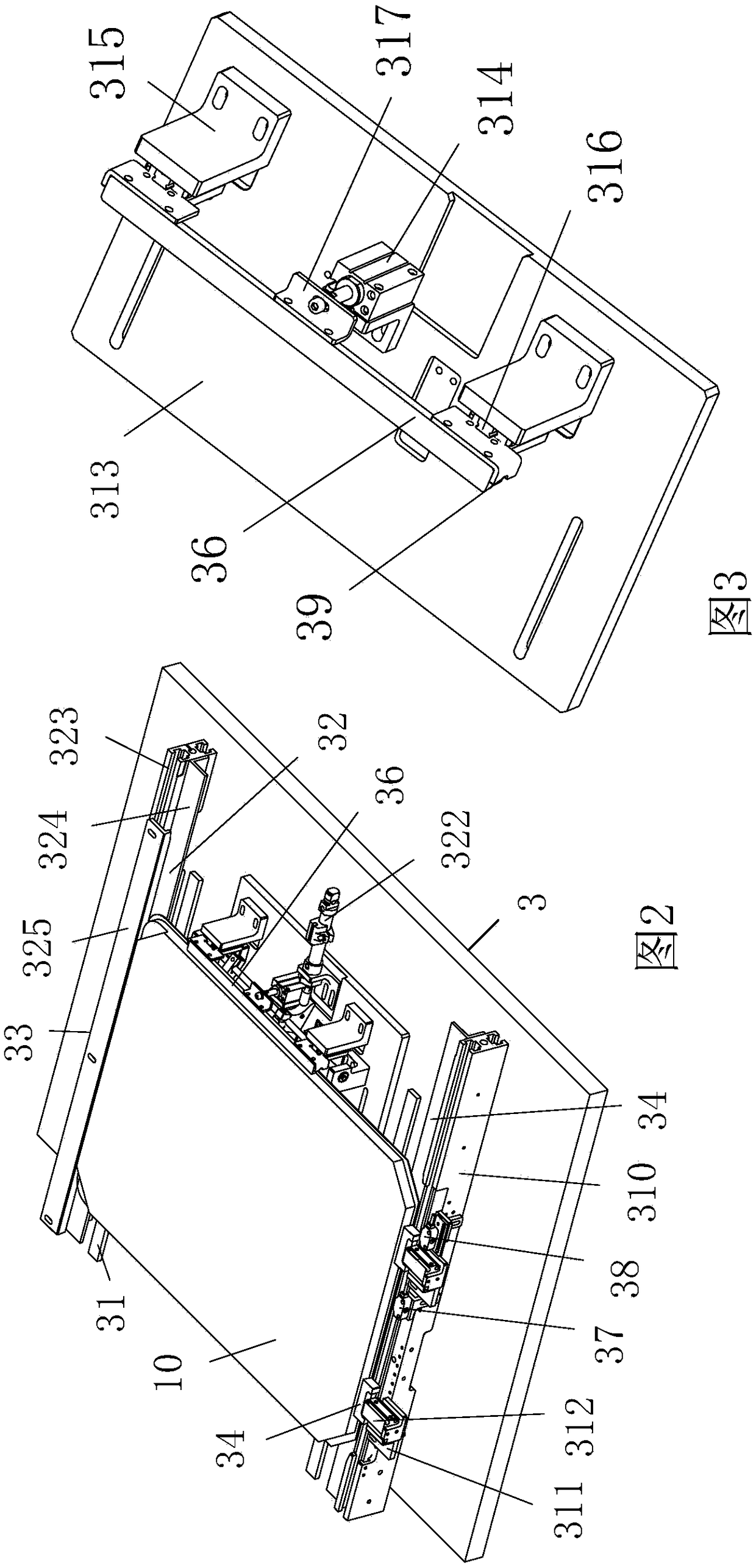

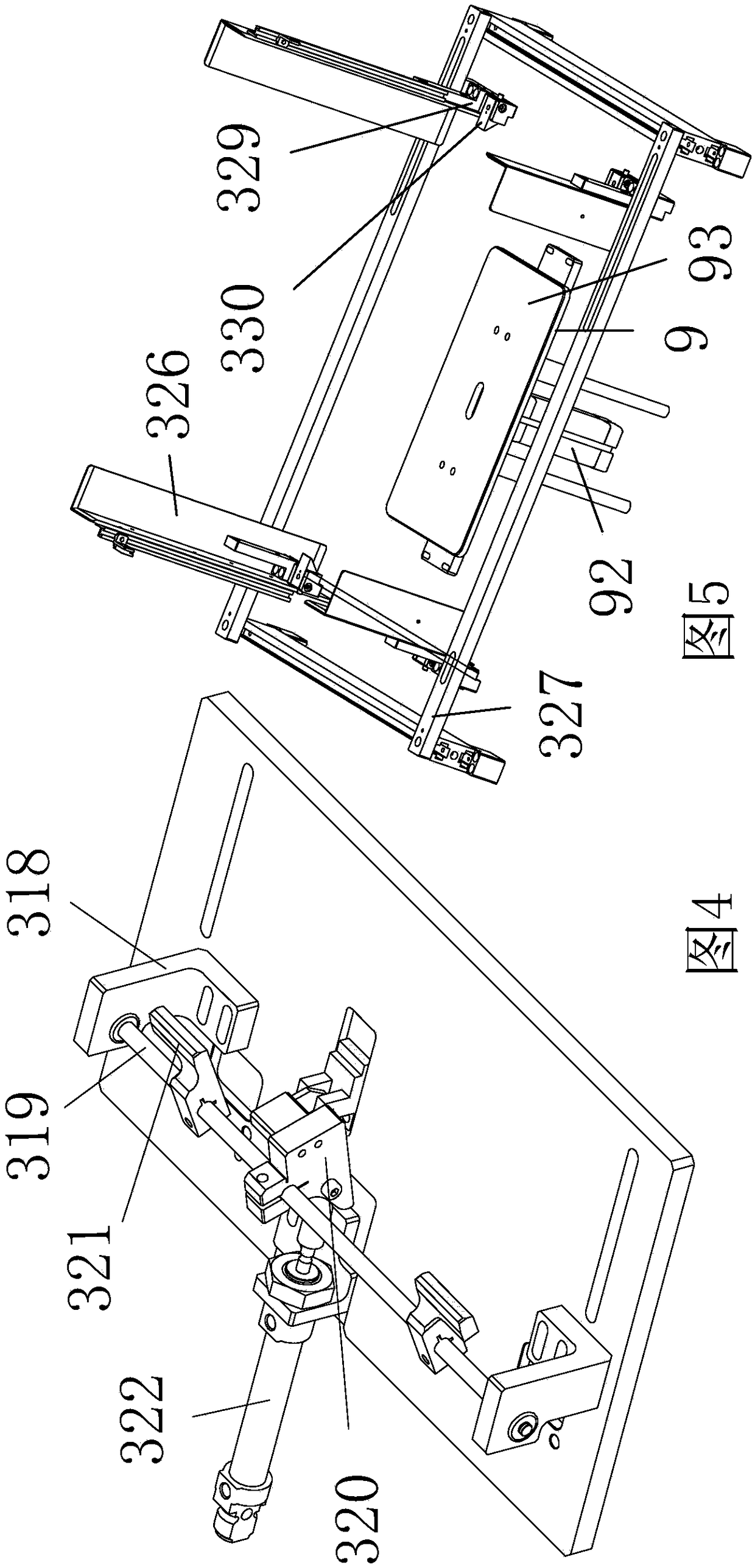

Fingerprint module height measuring code spraying system and height measuring code spraying method

ActiveCN108162594ASimple structureSmooth and accurate liftingTypewritersOther printing apparatusEngineeringStanding height

The invention aims at providing a fingerprint module height measuring code spraying system and a height measuring code spraying method. The fingerprint module height measuring code spraying system comprises a machine base provided with a base plate and an automatic material disc separation device, a material disc positioning and storing device arranged on the base plate and located on the front side of the automatic material disc separation device, a height measuring code spraying device arranged on one side of the automatic material disc separation device, a fingerprint module transferring device with a plurality of adsorption mechanisms located above the material disc positioning and storing device and the height measuring code spraying device, a material receiving device arranged on therear side of the height measuring code spraying device, and an empty disc running device. The fingerprint module height measuring code spraying system is high in fingerprint module standing height testing and code spraying marking efficiency, and organization of automatic production is facilitated.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

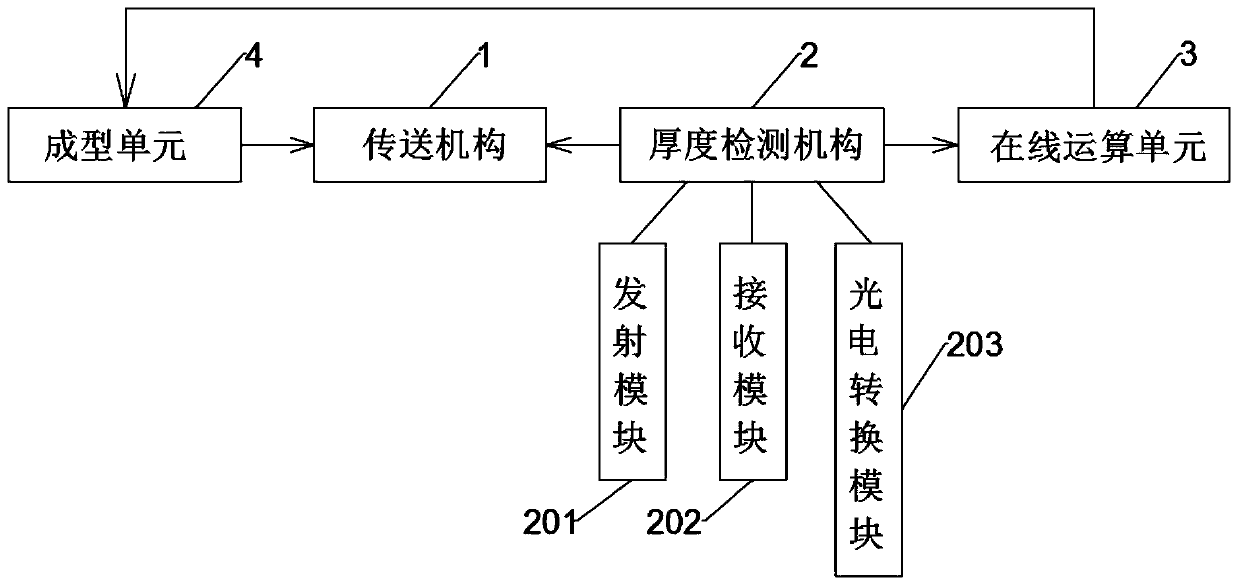

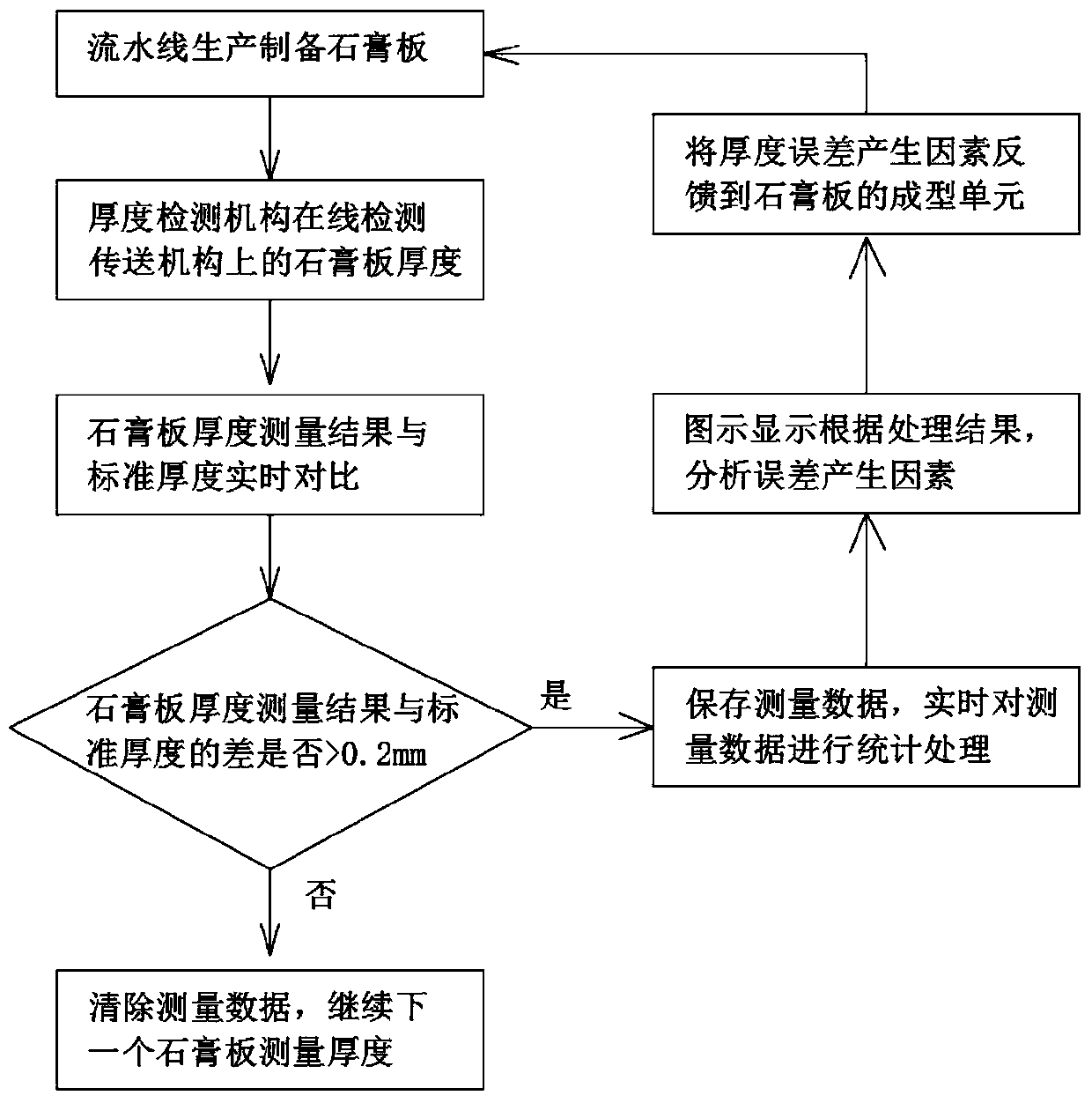

Gypsum board thickness measuring system

ActiveCN110561610AHigh precisionRealize highly automatic calculationAuxillary shaping apparatusUsing optical meansSlice thicknessEngineering

The embodiment of the invention discloses a gypsum board thickness measuring system. The gypsum board thickness measuring system comprises a conveying mechanism and a plurality of thickness measuringmechanisms, wherein the thickness detecting mechanisms are used for measuring the thickness of a gypsum board in a conveying state on line in real time; the plurality of the thickness measuring mechanisms are uniformly distributed from top to bottom along the same vertical line; the total distributed height of the thickness measuring mechanisms is the same as the standing height of the gypsum board; the thickness measuring mechanisms are connected with an online calculation unit; the online calculation unit is used for calculating the thickness of the gypsum board and the difference between the real-time thickness of the gypsum board and the standard thickness in real time; and the online calculation unit and a forming unit of the gypsum board form a feedback system. According to the scheme of the gypsum board thickness measuring system, the forming processing mode of the gypsum board is adjusted while the gypsum board is detected, and the error data is fed back to the forming unit intime, therefore, the rejection rate is reduced, and the production benefit is improved; and the thickness measuring area of the gypsum board is large, and the measuring density is relatively centralized, so that the measuring accuracy is improved.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

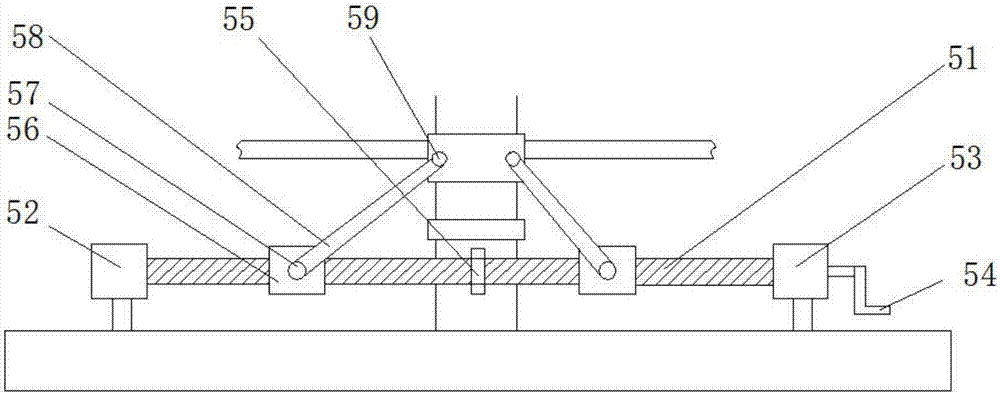

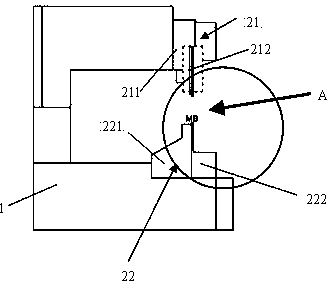

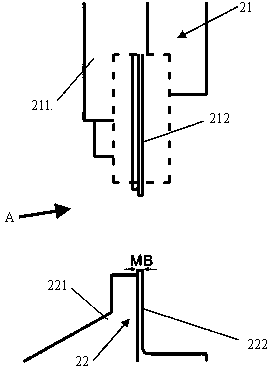

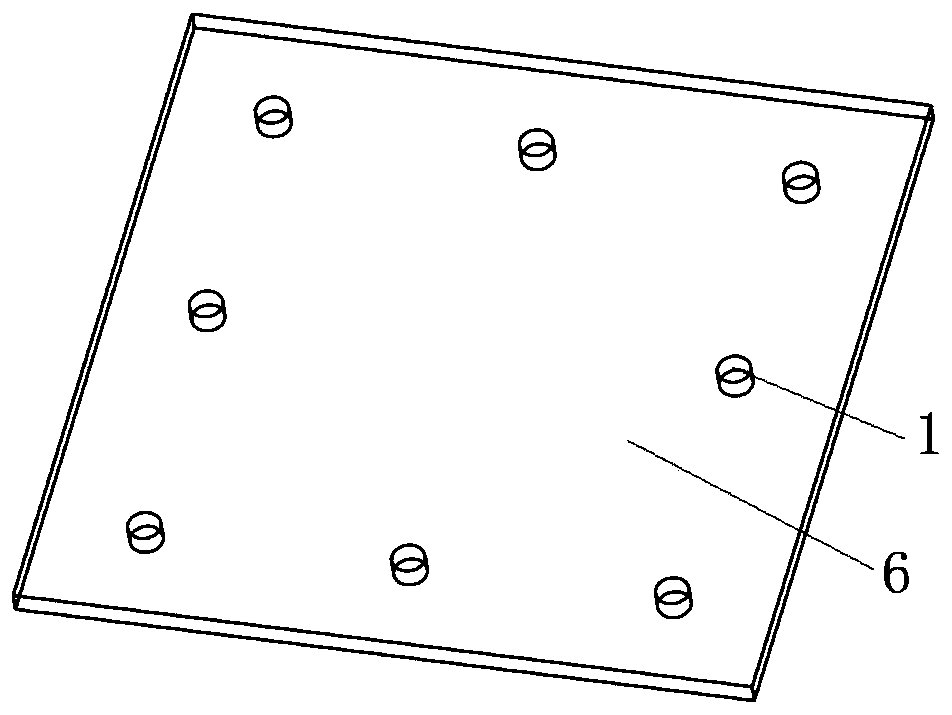

Semi-automatic forming technology and device of multi-pin surface mount device

ActiveCN103658320AHigh precisionGood molding consistencyMetal working apparatusShoulder widthSurface mounting

The invention discloses a semi-automatic forming technology of a multi-pin surface mount device. The technology includes the steps that the shoulder width B is acquired, the thickness MB of an adjustment module, the thicknesses F of pins, the distance H between the lower surfaces of the pins and the bottom plane of a multi-pin surface mount device body, parameters D of the pins, the length C of a single-edge forming cut foot and the bending radius R are acquired; a shoulder width adjustment parameter X(E), a standing height adjustment parameter X(G) and a welding face length adjustment parameter X(C) are acquired according to the following equations: X(E)=B-MB, X(G)=D-H and X(C)=C-MC+R+F; the multi-pin surface mount device is placed on a device fixture to be located on the same plane with the face of the fixture, and the machining lateral side of the multi-pin surface mount device abuts against a forming station lower module; after X(E), X(G) and X(C) are set on a digital micrometer of a die, pin forming is carried out. Good forming uniformity, good coplanarity and high forming precision of the multi-pin surface mount device are achieved by controlling X(E), X(G) and X(C).

Owner:上海航天控制工程研究所

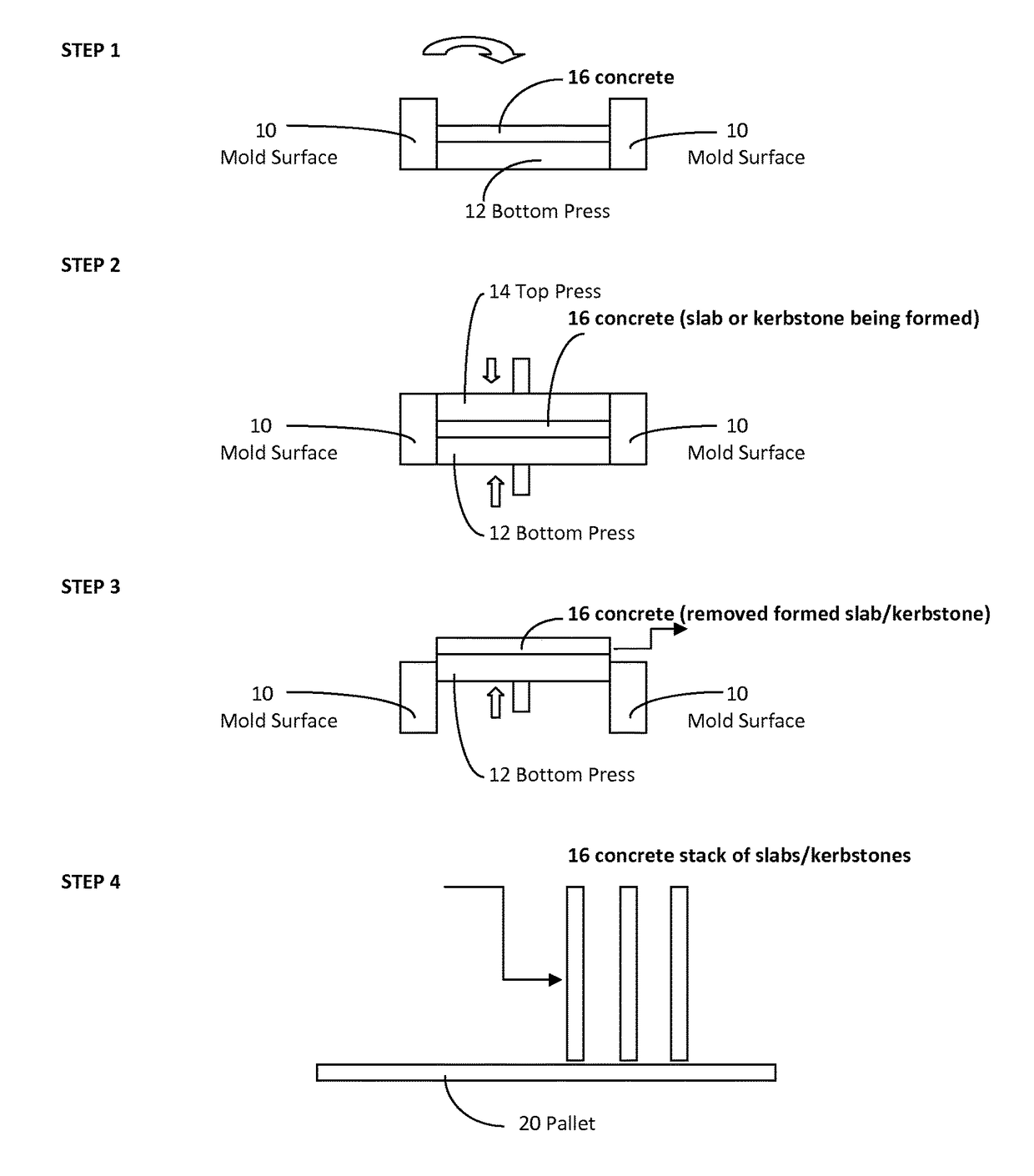

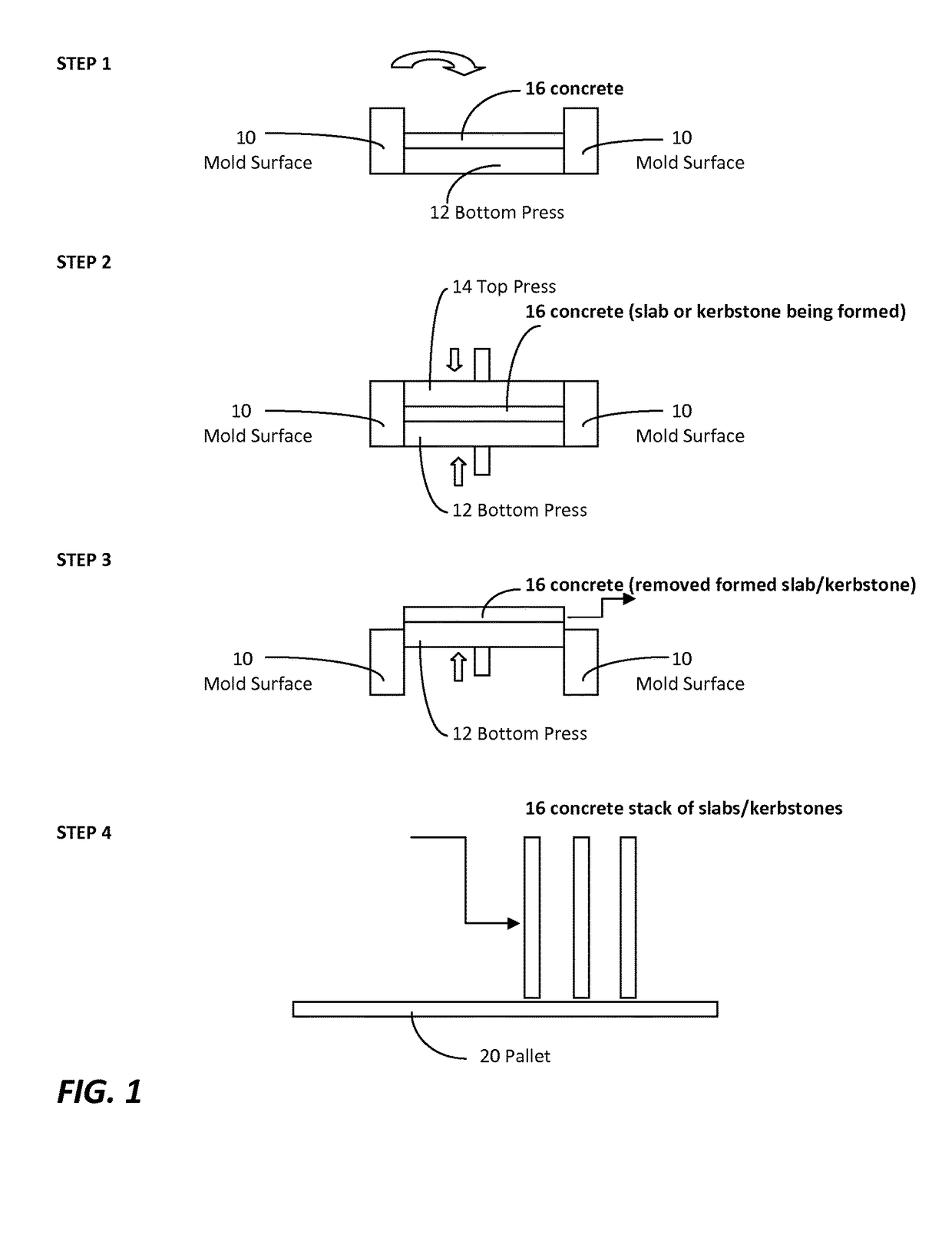

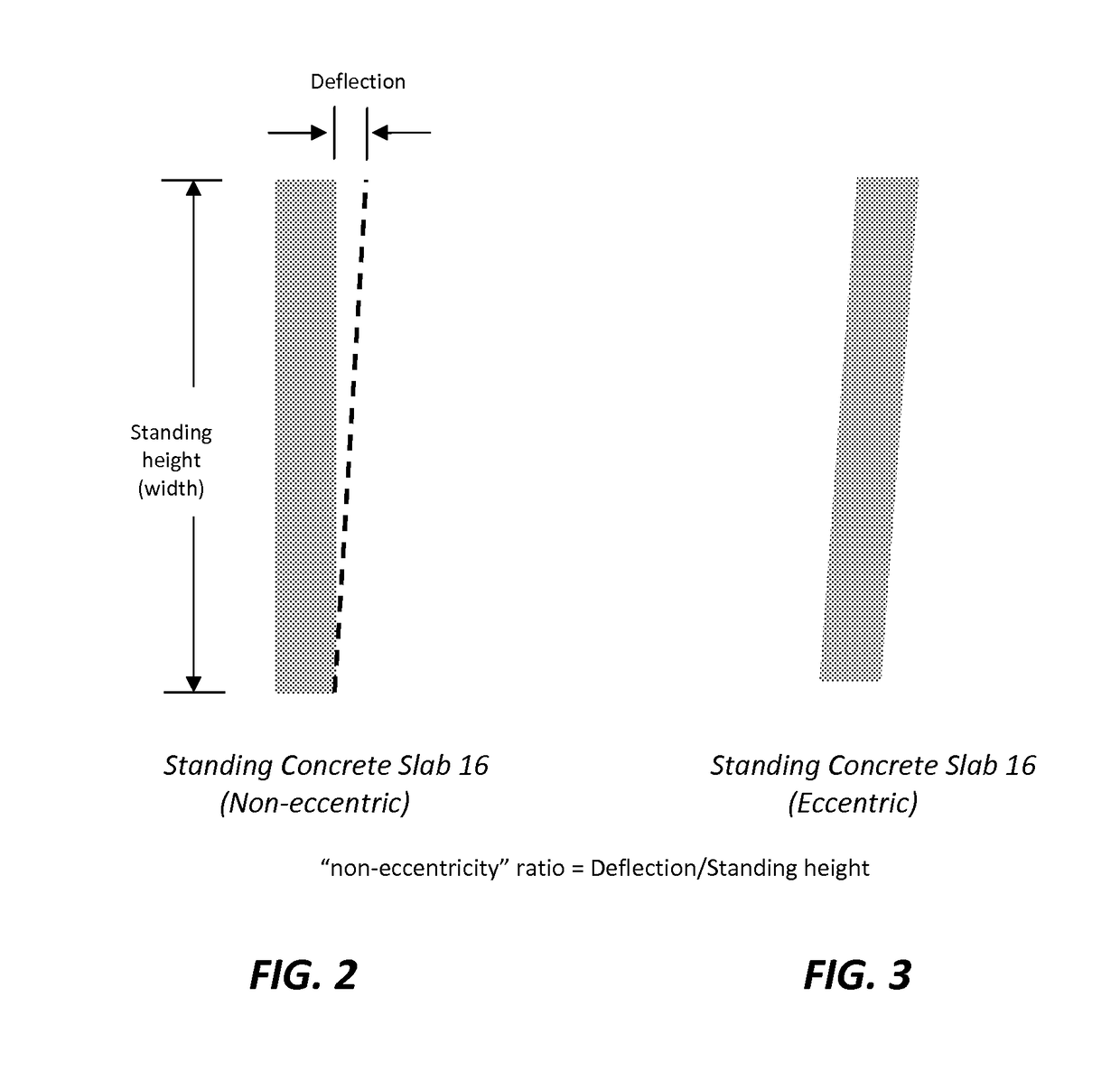

Wet Press Concrete Slab Manufacturing

ActiveUS20170334089A1Excellent non-eccentricityReduce penetrationDischarging arrangementSolid waste managementColloidal silicaColloid

The present invention provides a wet press process and admixture components for making concrete slabs (flags) (16), curb (kerb) units, panels, boards, and other flat shapes, whereby colloidal silica and at least one alkanolamine and optional rheology control components are employed to provide an ideal combination of pressing time, green strength, surface definition, stack-ability, final concrete strength, and permeability. Stack-ability can be expressed in terms of minimum deflection or non-eccentricity of the units while standing on thickness edges at distances apart less than width or standing height. A wet press process typically involves introducing a highly fluid concrete mix into a mold (10,12), applying hydraulic pressure to consolidate the concrete (e.g., 1000-3000 PSI) and to extract excess water, removing the pressed concrete (16) while in a green state from the mold (10,12), and then standing the slab (16) units immediately upon removal from the mold (10,12) while in a green state, on an edge adjacent to but spaced apart from other edge-standing units. In further embodiments, rounded aggregates such as naturally occurring sand and / or gravel obtained from local sources can be incorporated into the concrete slabs without defeating (vertical) stack-ability in the green state.

Owner:GCP APPL TECH INC

Height-adjustable computer rack

InactiveCN107339580AHeight adjustableImprove stabilityLifting devicesStands/trestlesGear driveEngineering

The invention discloses a height-adjustable computer stand, which includes a base, a first fixed shaft is fixedly connected to the bottom of the inner chamber of the base, and a first rotating shaft is movably connected to the shaft center at the top of the first fixed shaft. A first gear is fixedly connected to the top of the first rotating shaft, a second gear meshing with the first gear is arranged on the left side of the inner cavity of the base, and a threaded rod is fixedly connected to the shaft center of the top of the second gear. The present invention can drive the first gear to rotate through the setting of the handle. Through the setting of the first gear and the second gear, the second gear can be driven to rotate through the first gear. At the same time, the second gear drives the threaded rod to rotate. The setting of the sleeve can drive the threaded sleeve to go up and down to adjust the height of the computer, and at the same time solve the problem that the height of the computer support cannot be adjusted, which is inconvenient to use and reduces the use effect of the computer.

Owner:马志明

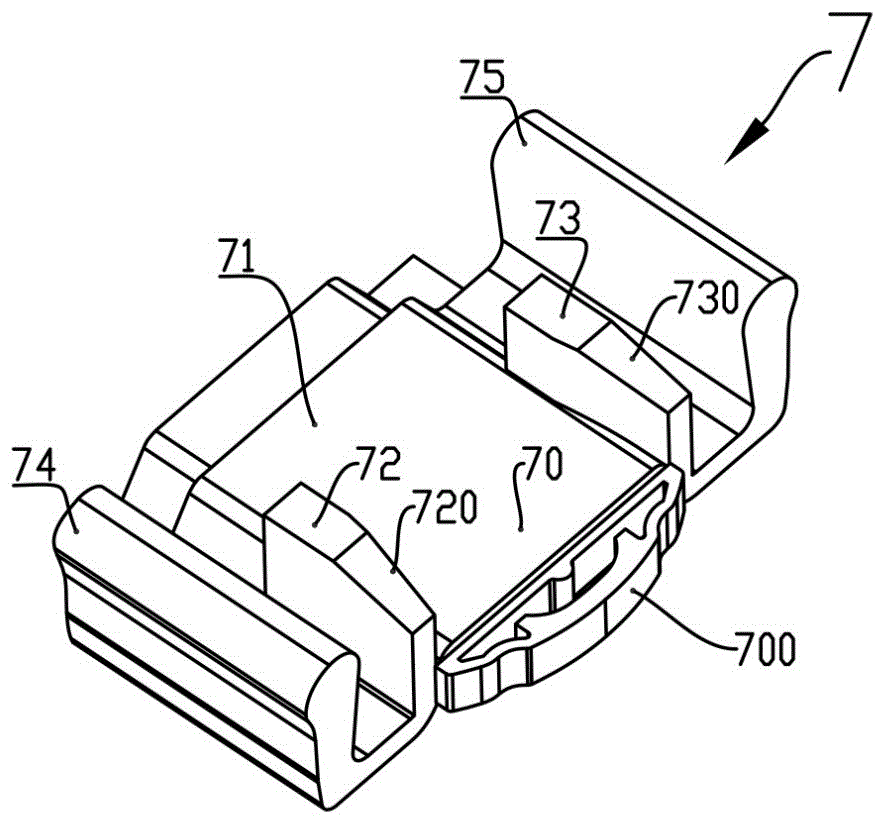

Vacuum absorbing device used for chip testing device

The invention relates to a vacuum absorbing device used for a chip testing device. The vacuum absorbing device comprises a seat body and a cover plate; chip pin support walls projecting out are arranged on the outer surface of the cover plate; chip containing cavities are formed between the chip pin support walls; through holes corresponding to the positions of the chip containing cavities are formed in the seat body; suction nozzle partss are installed between the through holes of the seat body and the chip containing cavities of the cover plate; the suction nozzle part comprises a suction nozzle column body and a rubber suction nozzle; an axial-through air hole is formed in the suction nozzle column body; one end of the suction nozzle column body is projected out of the through hole of the seat body; the other end of the suction nozzle column body is fixed with the rubber suction nozzle; the rubber suction nozzle is communicated with the air hole; the rubber suction nozzle is arranged inside the chip containing cavity; and a spring sleeves the columnar surface of the suction nozzle column body. The telescopic rubber suction nozzle is arranged on the suction nozzlepart, which can effectively avoid the change of a standing height due to a fact that the pin of the chip is under pressure.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

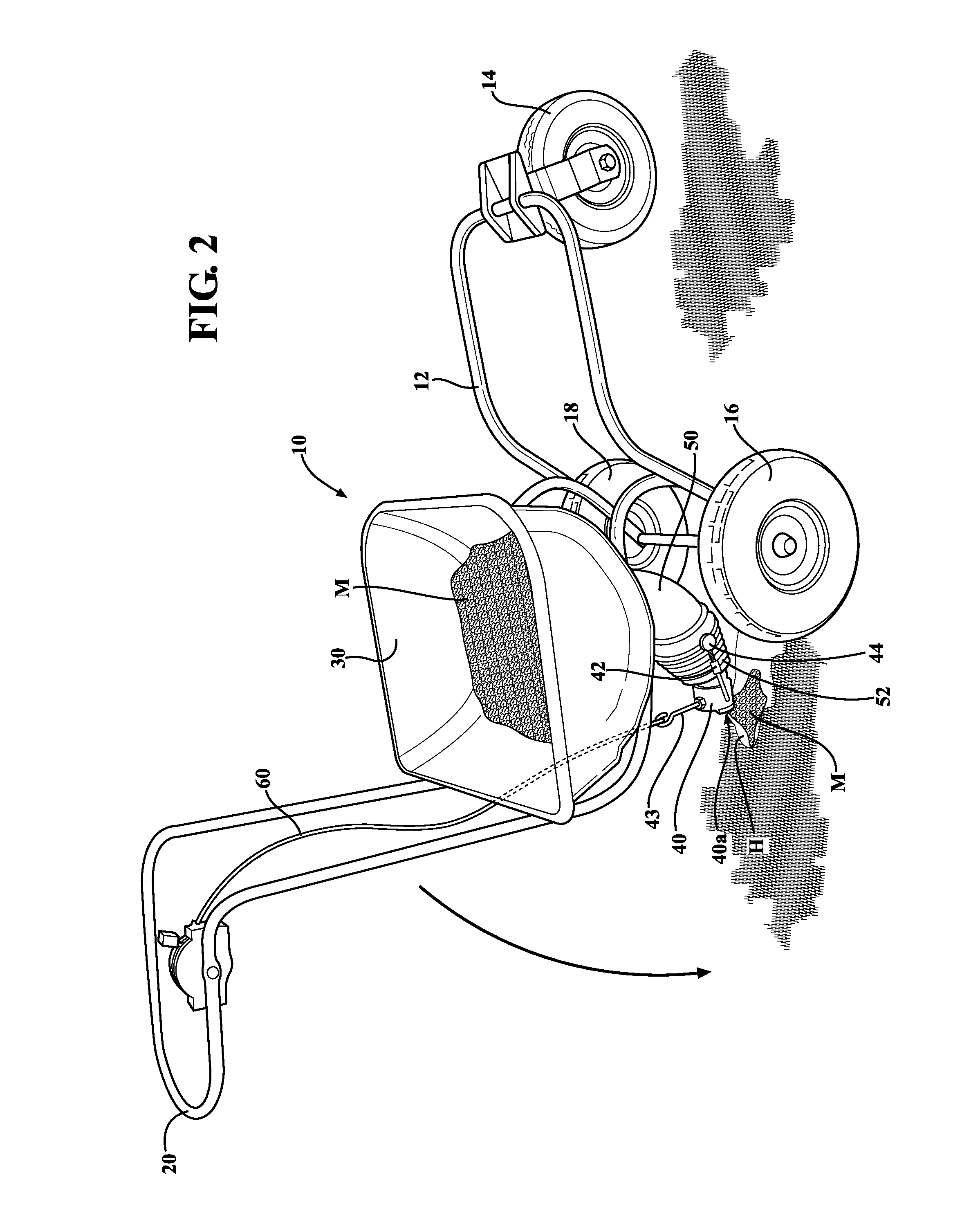

Wheeled divot hole filler for golf courses

InactiveUS8651341B1Shorten the timeSave energyManure treatmentPlantingGolf course turfRemote control

A divot repair cart for filling divot holes with a repair mixture. The cart has a self-supporting wheeled frame, a push handle for use at a standing height, a repair mix reservoir at a first height above the ground, and a rear-facing dispensing spout having a divot alignment position adjacent the ground in which the spout is visible from the push handle for aligning it with a divot hole. Repair mix is dispensed by tilting the cart. The spout may be movable relative to the cart, and further operable with a remote control such as a cable, to move the spout from the divot alignment position to a raised transport position.

Owner:LUTHER RICK

Hardhat dryer that folds efficiently

An efficiently folding hard-bonnet dryer, which can be folded down to only six inches in standing height. This improved design is effected in part by rotating the lower half of the hard bonnet on an axis through the center of the bonnet, and also by telescoping the neck and arranging a pair of motors and a heater in an efficient geometry to span the folded neck.

Owner:CONAIR CORP

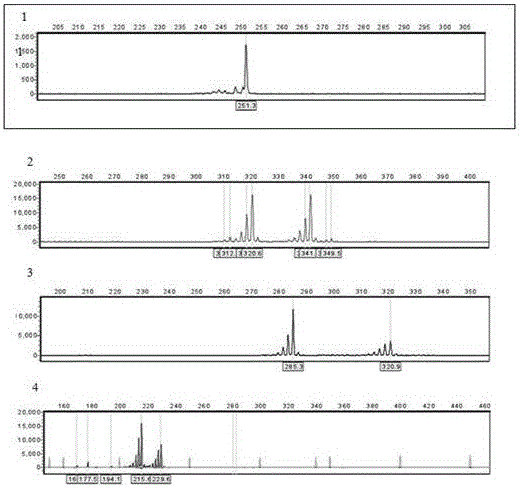

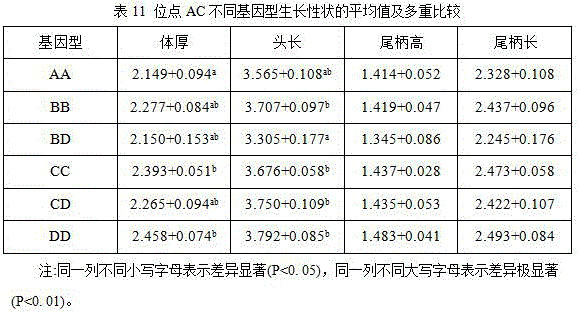

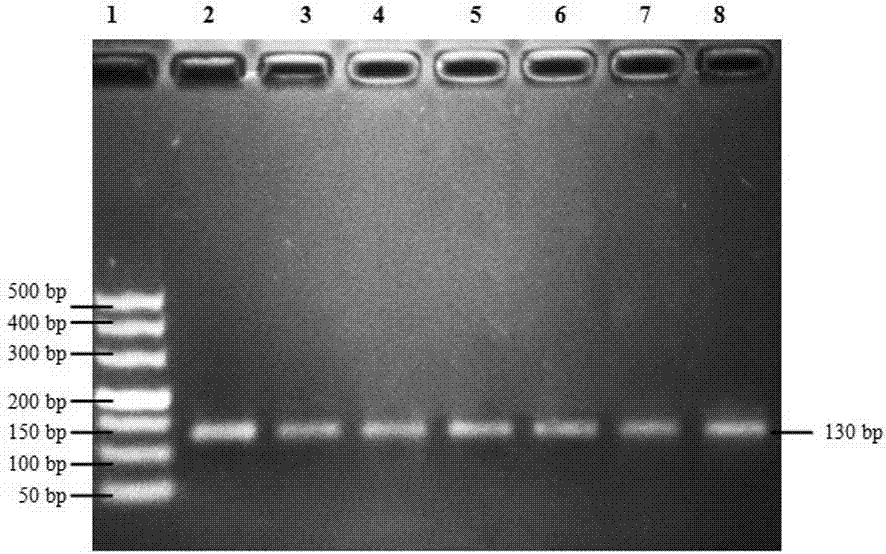

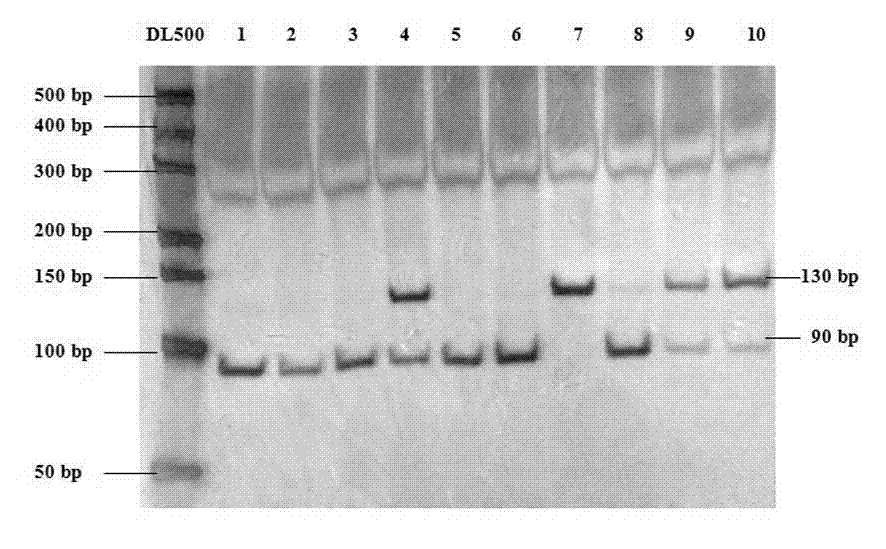

Microsatellite marker relevant with tachysurus fulvidraco growth characteristics and detection and application thereof

ActiveCN106167825AIncrease genetic diversityMicrobiological testing/measurementDNA/RNA fragmentationGenetic diversityMolecular breeding

The invention discloses a microsatellite marker relevant with tachysurus fulvidraco growth characteristics and detection and application thereof. That is, four microsatellite loci are found on a tachysurus fulvidraco GH sequence, the microsatellite loci are amplified by screening specific primers, relevance between the microsatellite loci and growth traits is analyzed, and dominant genotypes favorable for the growth traits are found. Results indicate that three loci are remarkably or extremely remarkably relevant with the growth traits, a locus GA is remarkably relevant with body weight, body length, standing height and body thickness and is extremely remarkably relevant with total length and depth of caudal peduncle, wherein CD is a dominant genotype; a locus TCTT is remarkably relevant with head length and depth of caudal peduncle, wherein BD is a dominant genotype; and a locus AC is remarkably relevant with body thickness and head length, wherein DD is a dominant genotype. The four microsatellite loci obtained by primer amplification have high genetic diversity and are remarkably or extremely remarkably relevant with the growth traits. The microsatellite marker is of great significance for molecular breeding practice.

Owner:SOUTH CHINA AGRI UNIV

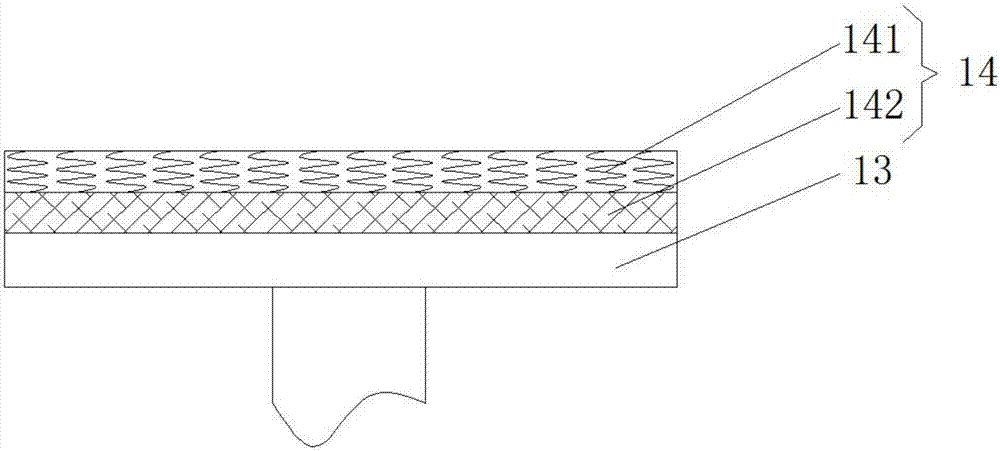

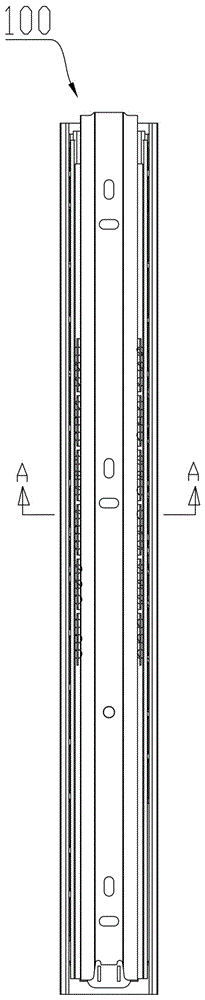

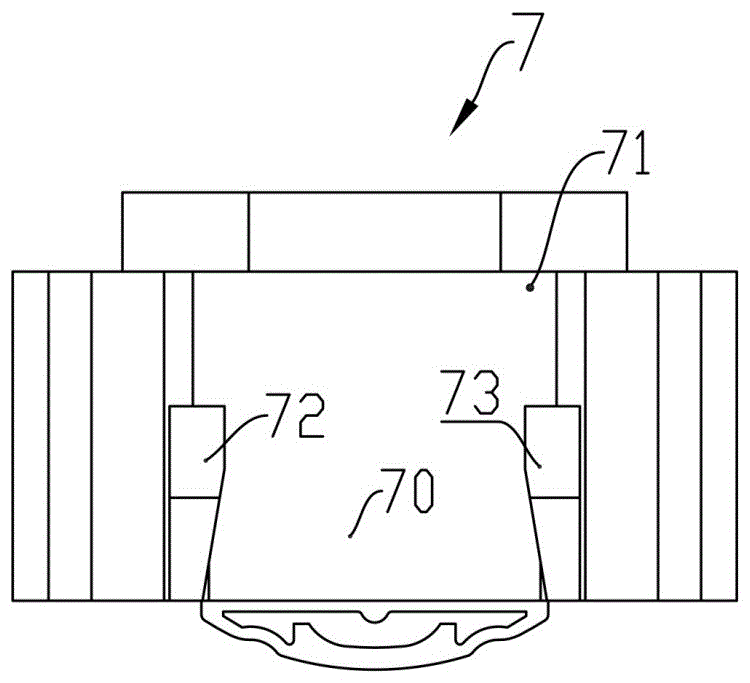

Furniture sliding rail

ActiveCN105962664AImproved ability to withstand impact forcesReduce impact forceDrawersStanding heightCushion

The invention relates to a furniture sliding rail. The furniture sliding rail comprises an outer rail body approximately in a U-type groove shape, a middle rail body approximately in a U-type groove shape and an inner rail body approximately in a U-type groove shape. The middle rail body is axially arranged in a U-type groove of the outer rail body in a sliding mode, the directions of groove openings of the middle rail body and the outer rail body are the same, the inner rail body is axially arranged in a U-type groove of the middle rail body in a sliding mode, and the directions of the groove opening of the middle rail body and a groove opening of the inner rail body are opposite; a limiting stopper capable for stopping the middle rail body and the inner rail body from sliding is arranged at the inner side end of the U-type groove of the outer rail body, and therefore the sliding strokes of the middle rail body and the inner rail body in the direction of the inner side end can be limited. The furniture sliding rail is characterized in that the limiting stopper comprises at least one axial standing piece extending in the axial direction; the limiting stopper comprises a buffering soft cushion block, the buffering soft cushion block is inserted into the axial standing piece, and the height of the buffering soft cushion block is larger than or equal to the standing height of the axial standing piece and smaller than the height of the groove bottom wall of the inner rail body. In this way, due to the layout mode that the axial standing piece extends in the axial direction, the impact force bearing capacity of the limiting stopper is improved.

Owner:林旭文

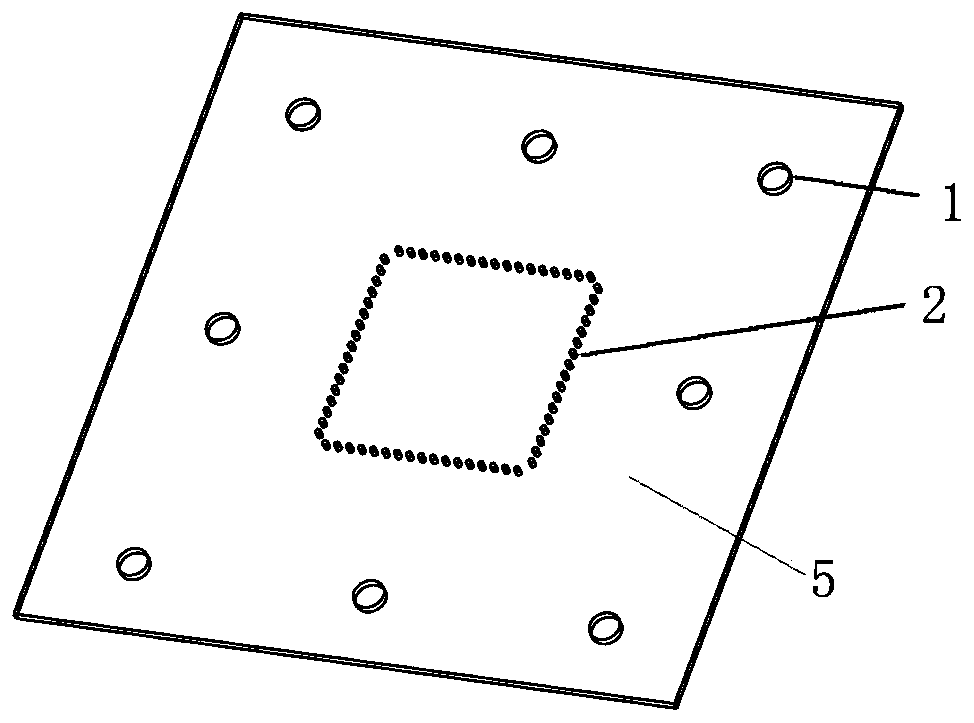

Column planting welding tool for LCCC apparatus and method of planting columns to LCCC apparatus

InactiveCN110116252ARaised standing heightImprove reliabilitySoldering auxillary devicesStructural engineeringStanding height

The invention discloses a column planting welding tool for an LCCC apparatus. The column planting welding tool comprises an upper mold and a lower mold assembled together. A plurality of column planting holes for mounting welding columns are distributed on the upper mold. During use, the welding columns are placed in the column planting holes, a bonding pad of the LCCC apparatus body is welded tothe welding columns, the standing height of the apparatus is lifted up, the stress releasing space of welding points of the apparatus is increased, and the reliability of the apparatus is improved. The tool is simple in structure and easy to manufacture, can weld the welding columns simultaneously, has relatively high universality and can weld the planting columns of the bonding pad. The inventionalso discloses a method of planting the columns to the LCCC apparatus by adopting the column planting welding tool for the LCCC apparatus. By placing the welding columns in the column planting holesand carrying out reflow welding on the bonding pad of the LCCC apparatus body and the welding columns for planting the columns to form the welding points, the assembling reliability of the apparatus is improved greatly, the integral service life is prolonged greatly, the potential quality hazard is eliminated, and the problem of assembling failure of military electronic products caused by reliability of the LCCC apparatus is solved from the origin.

Owner:XIAN MICROELECTRONICS TECH INST

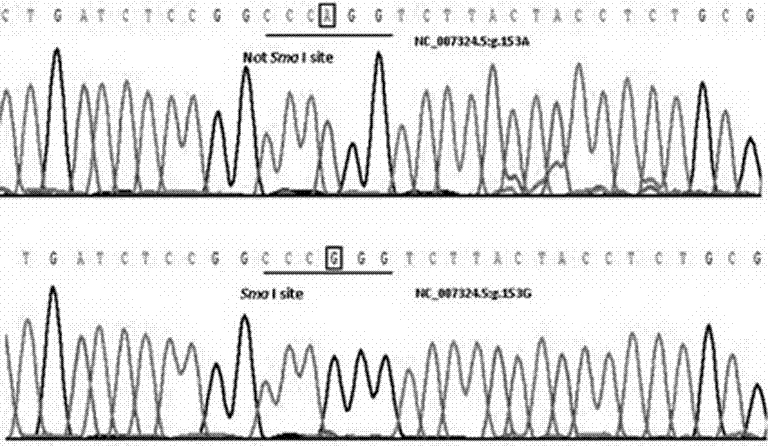

Method for detecting single nucleotide polymorphisms of cattle 17HSDB8 gene

InactiveCN104278083AUnique technical effectImprove molecular markersMicrobiological testing/measurementNucleotideWeight gain

The invention discloses a method for detecting the single nucleotide polymorphisms of a cattle 17HSDB8 gene. The method comprises the following steps: by taking a 17HSDB8 gene-containing cattle genome DNA to be detected as a template and P as a primer, amplifying the cattle 17HSDB8 gene by using a PCR method, then digesting a PCR amplification product by using restriction endonuclease Sma I, then performing polyacrylamide gel electrophoresis to the enzyme-digested segments, and identifying the single nucleotide polymorphisms at 153th locus of the cattle 17HSDB8 gene according to the electrophoresis result. The 17HSDB8 gene has important biological functions on the growth and development characters, and a basis is established for association of the SNP of the gene with the growth character. The single nucleotide polymorphisms of the cattle 17HSDB8 gene has remarkable effect on the early-stage body weight, standing height, body length, chest girth and daily weight gain of a cattle, and can be used as the molecular marker-assisted selection of cattle beef and growth characters so as to further fast establish a cattle population with excellent genetic resources.

Owner:XINYANG NORMAL UNIVERSITY

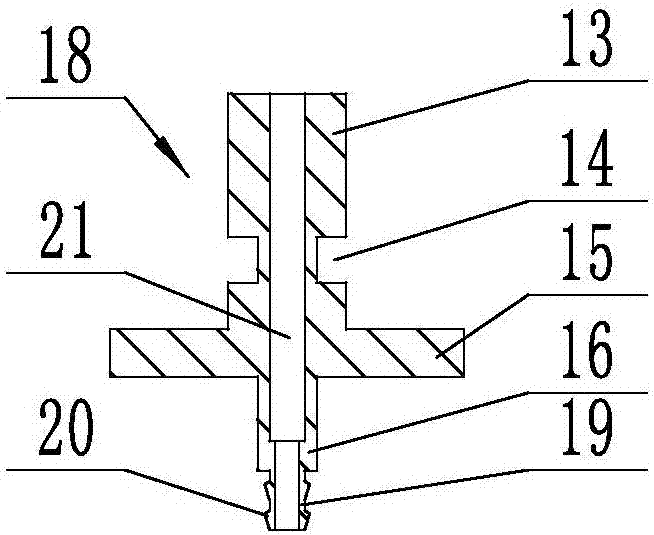

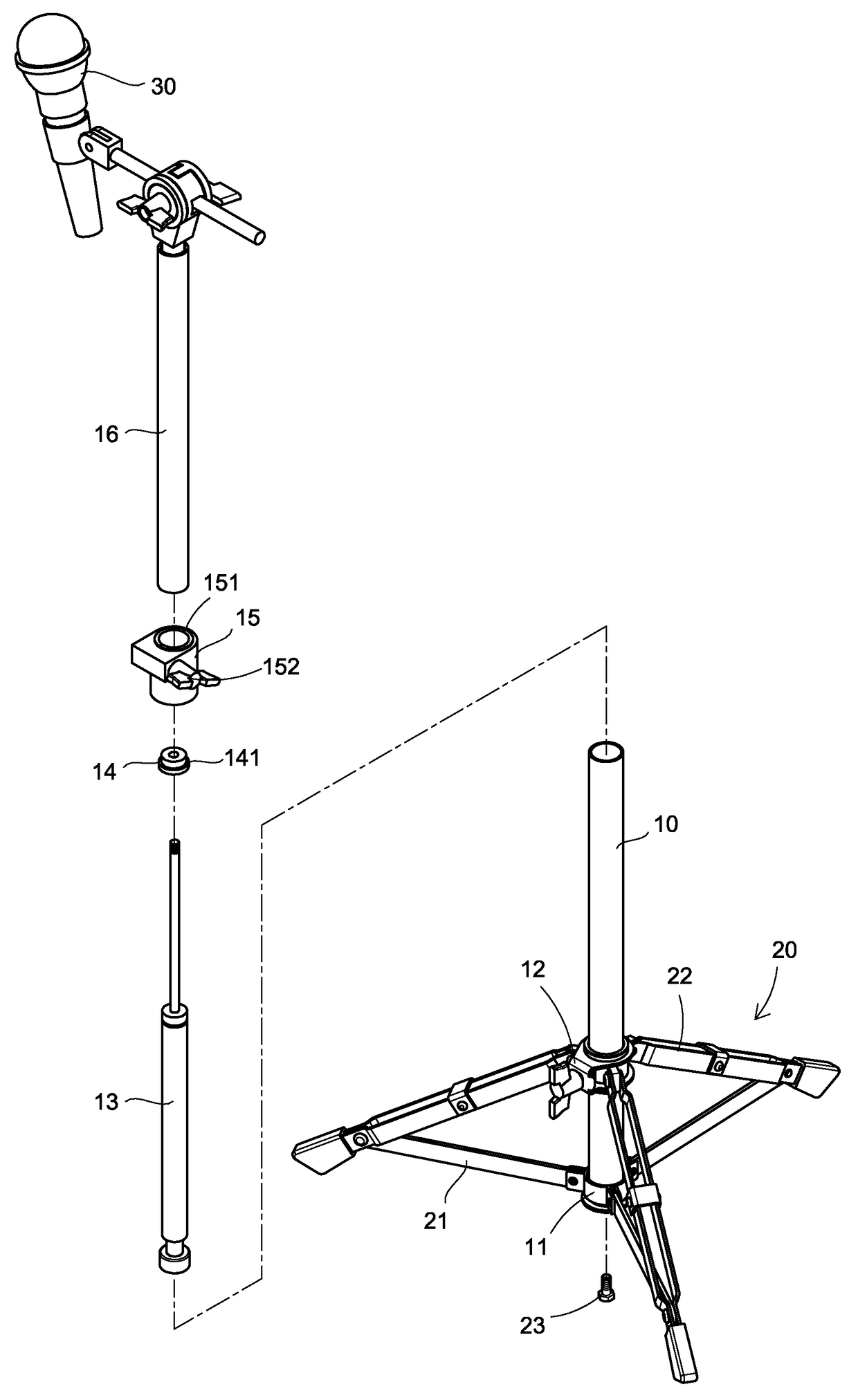

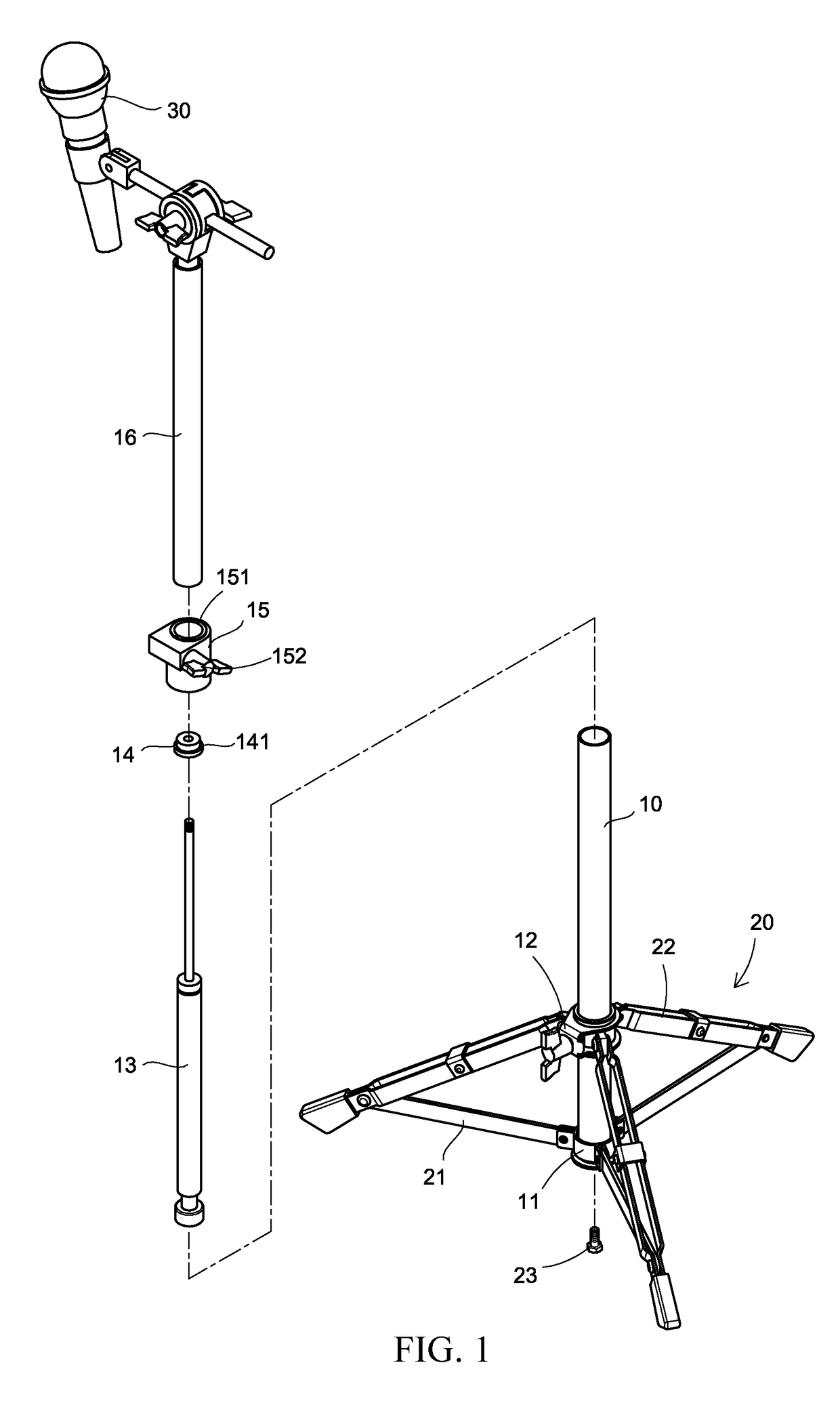

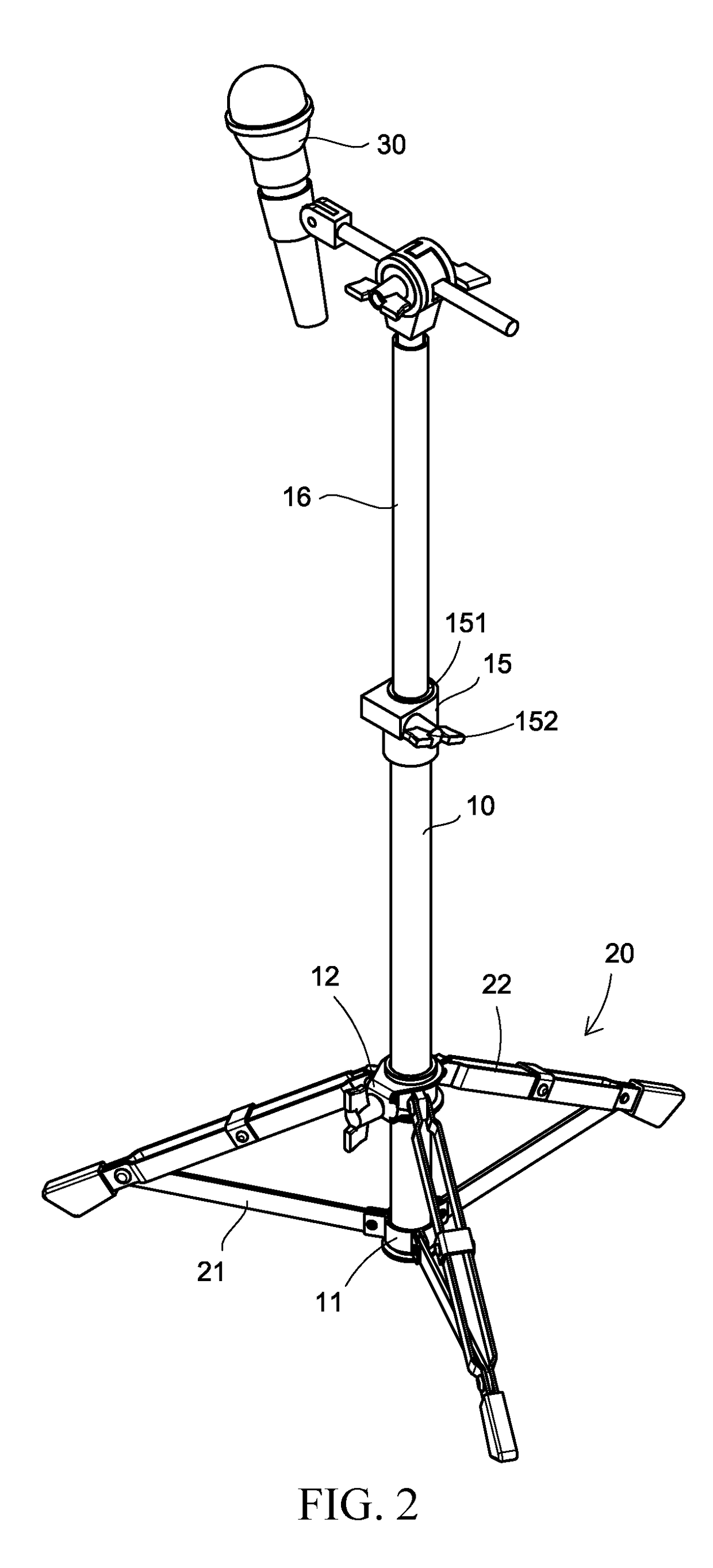

Microphone stand adjusting structure

ActiveUS9961421B2Convenience and securityPracticality securityMicrophonesLoudspeakersEngineeringMechanical engineering

A microphone stand structure allows an upper frame rod to be elevated automatically for adjustment to a proper elevation after a locking seat is released. A pressure rod is received and mounted in a hollow main frame rod and includes an extensible member having a top end supporting a bottom end of the upper frame rod movably inserted into the hollow main frame rod such that the whole stand height can be selectively fixed simply locking the locking seat.

Owner:GAO FONG IND

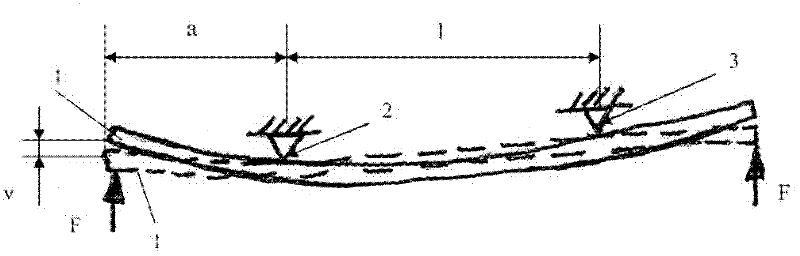

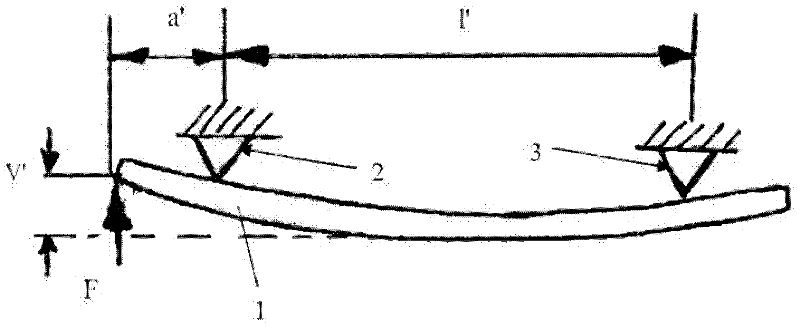

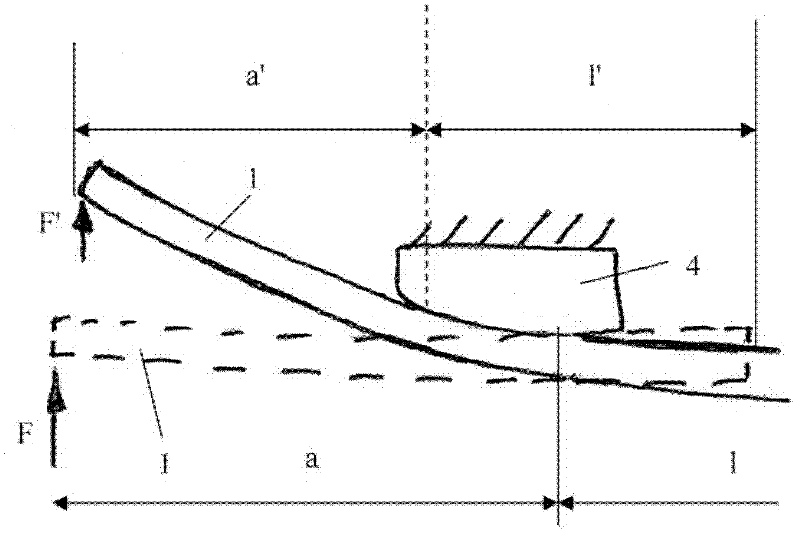

Vehicle with a leaf spring element for the spring suspension of the vehicle

InactiveCN102555721AChange the spring rateChange heightInterconnection systemsLubricating systemVehicle frameStanding height

The invention relates to a vehicle, in particular a passenger car is provided with a vehicle frame having a leaf spring element for the spring suspension of the vehicle, which is mounted on the vehicle frame with two bearing points, which are designed in a manner to adjustably set a spring rate and / or a standing height of the leaf spring element. The leaf spring element is mounted on a frame of the vehicle with the two bearing points and the bearing points are designed adjustable for setting a spring rate and / or a standing height of the leaf spring element.

Owner:GM GLOBAL TECH OPERATIONS LLC

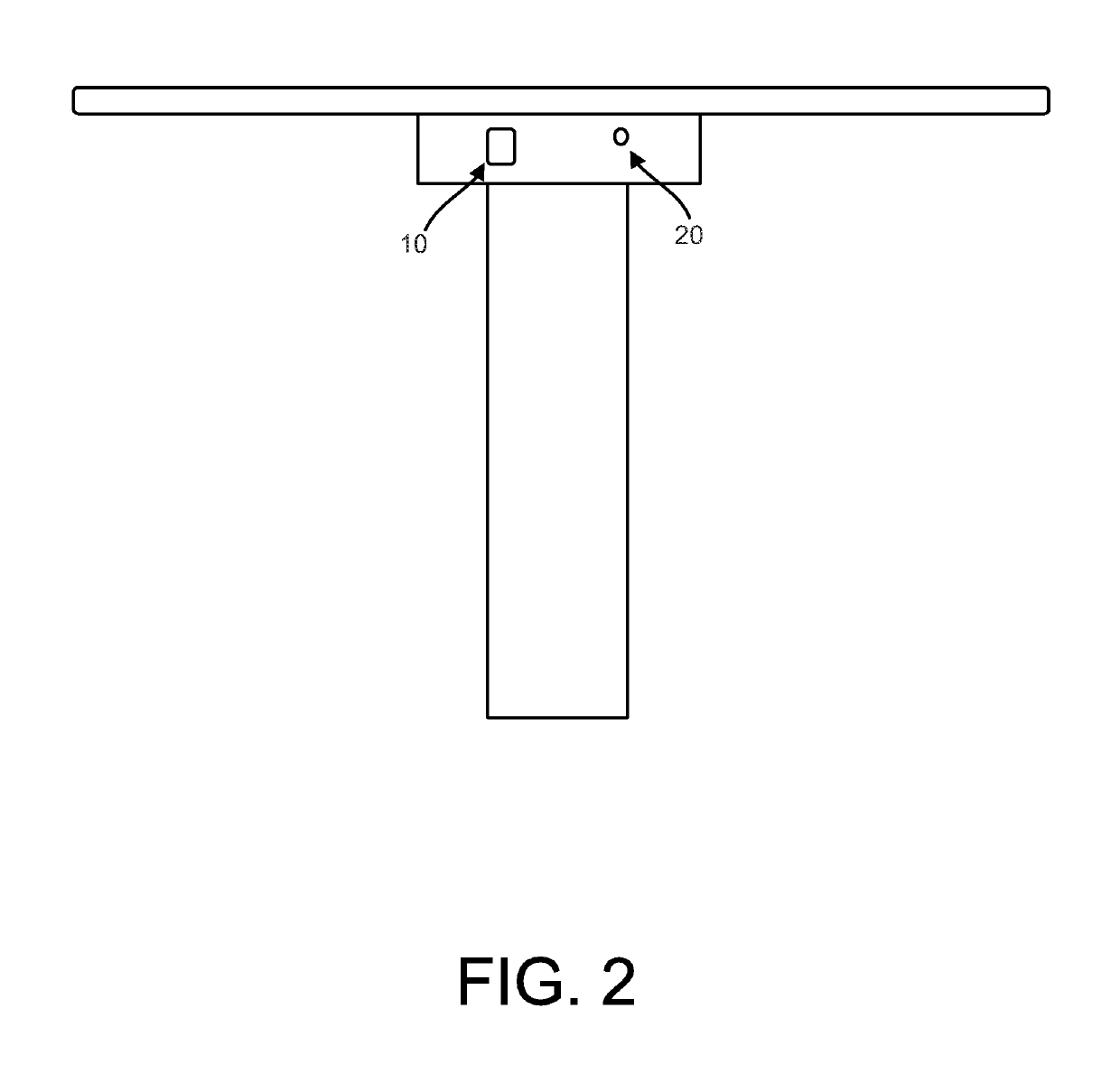

Wheelchair lift system and method

ActiveUS20120205953A1Precise positioningWheelchairs/patient conveyanceAdjustable chairsSitting heightWheelchair

A wheelchair lift system that allows a wheelchair and a person sitting in the wheelchair to be selectively positioned at a standing height or a sitting height. A lift system that is attachable to wide variety of existing wheelchairs.

Owner:KATEZELEVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com